Page 1

1

LTC1559-3.3/LTC1559-5

Backup Battery Controller

with Fixed Output

■

Complete Battery Backup System in an SO-8,

16-Pin GN or SO Package

■

Generates Fixed Backup Voltage (3.07V/4.63V) from

a Single 1.2V NiCd Button Cell

■

Automatic Main Supply to Backup Switching

■

Minimum 100mW Output Power

■

Automatic Fast Recharge of NiCd Battery

■

Programmable NiCd Trickle Charge Current

■

Smart NiCd Charger Minimizes Recharge Time and

Maximizes System Efficiency After Backup

■

Onboard Power-Up and Push-Button Reset

Generator

■

Performs VCC Supervisory Functions

■

Reset Assertion Guaranteed at VCC = 1V

■

Short-Circuit Protection

■

Thermal Limiting

FEATURES

DESCRIPTION

U

The LTC®1559 is a backup battery controller that provides

all the functions necessary to implement a backup 3.3V or

5V power supply using a single NiCd cell. It includes a 1.2V

to 3.07V/4.63V boost converter, an intelligent 2-stage

battery charger, automatic backup switching and a microprocessor reset generator. The boost converter uses a

synchronous switching architecture to achieve a typical

efficiency of 70%, ensuring maximum backup lifetime

from a small NiCd cell.

The on-chip NiCd charger uses an internal gas gauge to

minimize fast recharge time and prevent overcharging of

the backup cell, thereby improving system efficiency and

extending the life of the backup cell. The LTC1559 also

provides a user programmable trickle charge current to

compensate for self-discharge losses in the backup cell.

The LTC1559’s automatic backup switching scheme

requires minimum intervention from the host system and

provides feedback to the host to minimize system loading

in the backup state. Its internal VCC fault detector and reset

generator eliminate the need for a separate microprocessor supervisory chip in most applications.

The LTC1559 is available in an SO-8, 16-pin GN or SO

package.

APPLICATIONS

U

■

Notebook Computers

■

Palmtop Computers/PDAs

■

Portable Instruments

■

Battery-Powered Systems

, LTC and LT are registered trademarks of Linear Technology Corporation.

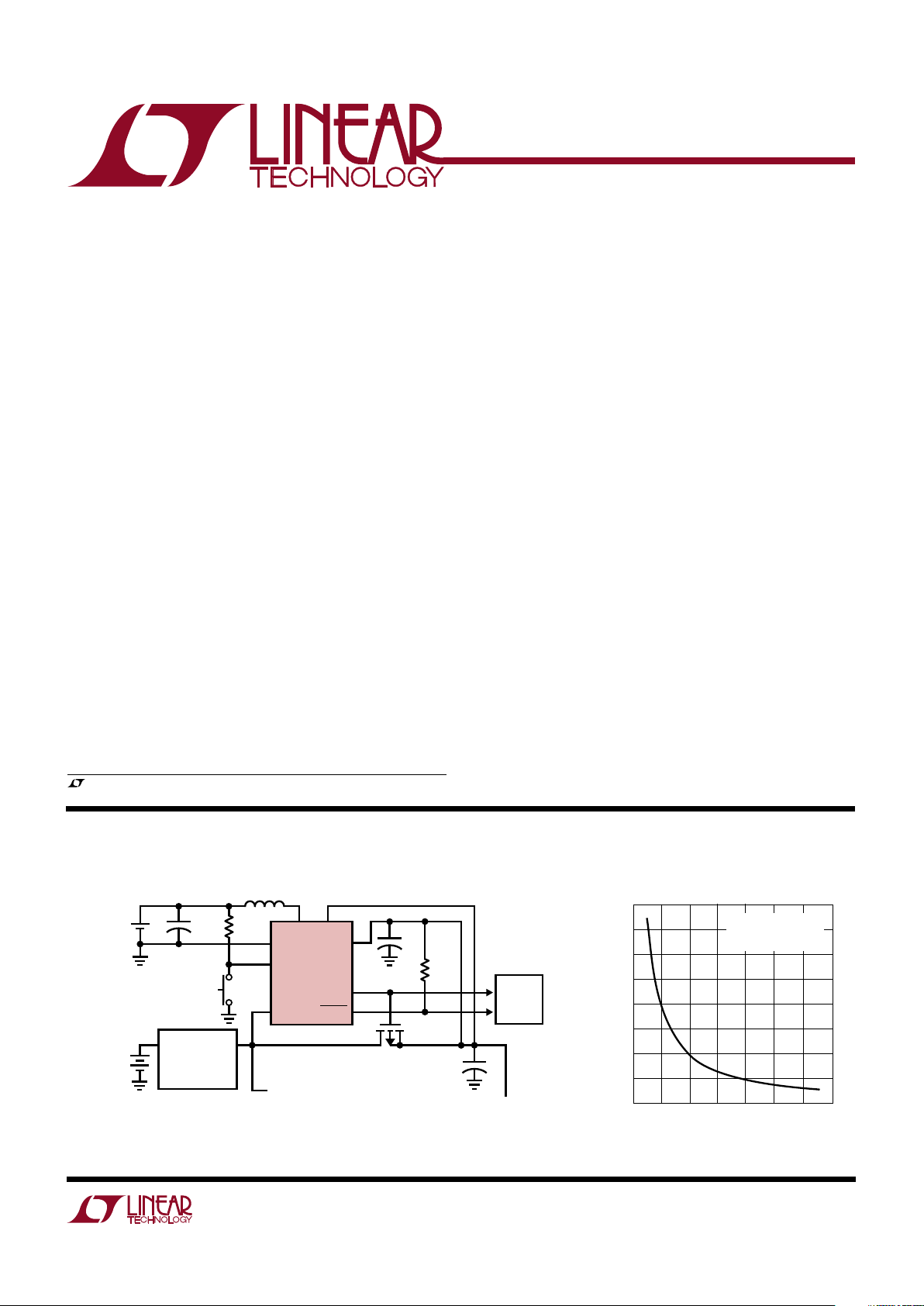

TYPICAL APPLICATION

U

CTL

C1

1µF

**BACKUP

BATTERY

1.2V

NiCd

MAIN

BATTERY

4.5V TO 28V

R1

68k

SW

LTC1559-3.3

*L1

22µH

GND

PS

7

1

8

5

6

3

S1

RESET

1559 TA01

2

4

V

BAK

V

CC

RESET

BACKUP

+

C3

100µF

10V

V

OUT

3.3V AT NORMAL MODE

3A

V

BAK

33mA (3.07V) AT BACKUP MODE

>33mA (3.3V) AT NORMAL MODE

C2

1µF

SYSTEM

µP

R2

100k

Q1

P-MOSFET

Si9424DY

* SUMIDA CD54-22µH

** PANASONIC P-11AAH

† CONSULT LTC1435 DATA SHEET FOR

APPLICATION CIRCUIT INFORMATION

†

LTC1435

SYNCHRONOUS

BUCK

REGULATOR

+

+

Backup Time vs

V

BAK

Output Load Current

V

BAK

LOAD CURRENT (mA)

0

BACKUP TIME (MINUTES)

800

700

600

500

400

300

200

100

0

15 25

1559 TA02

510

20 30 35

V

BAK

= 3.07V

NiCd CELL = P-11AAH

(110mA Hrs)

Page 2

2

LTC1559-3.3/LTC1559-5

ABSOLUTE MAXIMUM RATINGS

W

WW

U

(Note 1)

Terminal Voltages

VCC........................................................................ 6V

V

BAK

.................................................................... 12V

SW ...................................................................... 14V

All Other Pins .............................. – 0.3V to VCC + 0.3V

SW Input Currents ............................................. 500mA

V

BAK

Output Current ................... Short-Circuit Protected

Operating Ambient Temperature Range ....... 0°C to 70°C

Junction Temperature .......................................... 125°C

Storage Temperature Range .................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)...................300°C

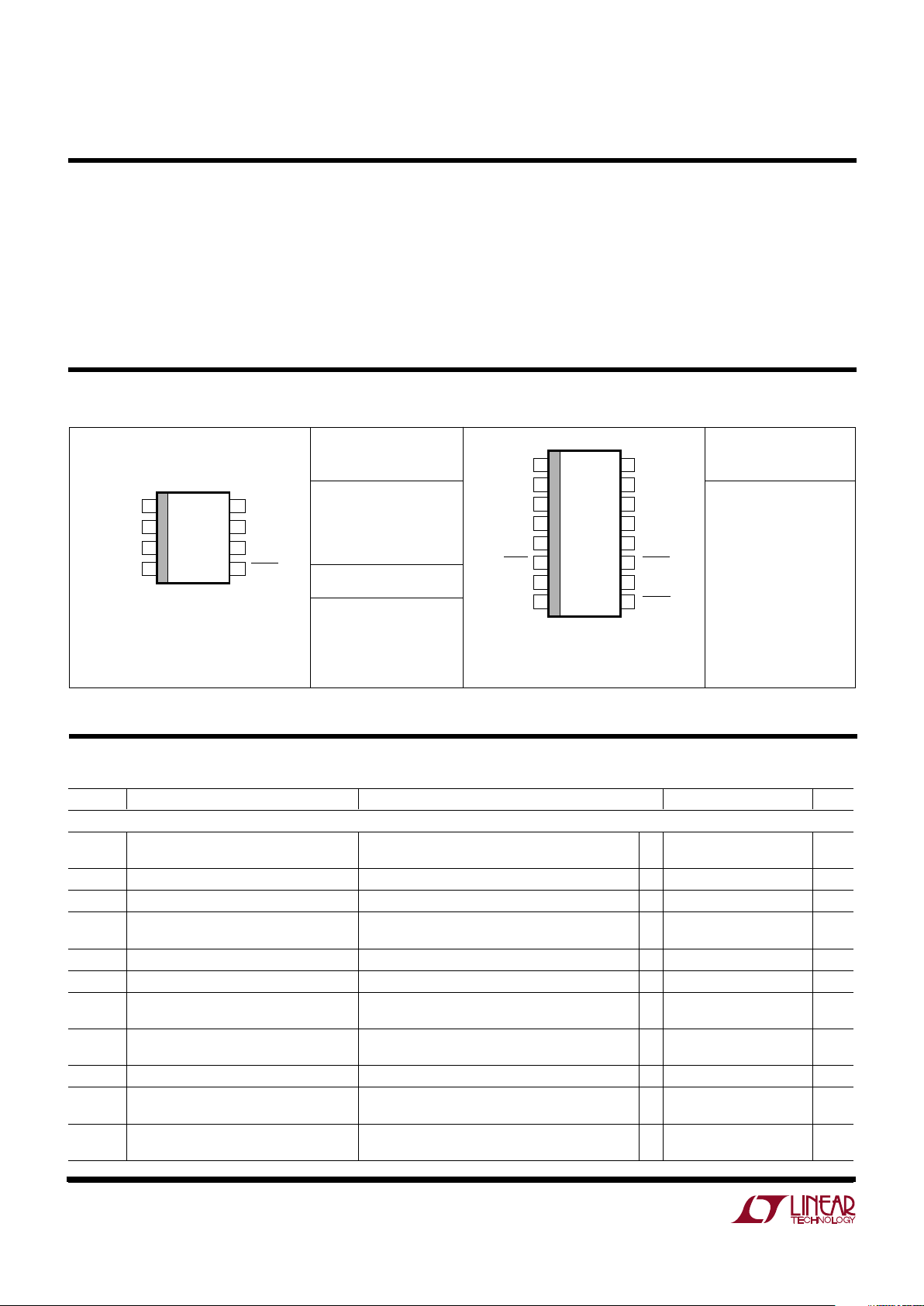

ORDER PART

NUMBER

ORDER PART

NUMBER

S8 PART MARKING

LTC1559CS8-3.3

LTC1559CS8-5

ELECTRICAL CHARACTERISTICS

V

BAT

= 1.2V, TA = 0°C to 70°C unless otherwise noted.

LTC1559CGN-3.3

LTC1559CGN-5

LTC1559CS-3.3

LTC1559CS-5

Consult factory for Industrial and Military grade parts.

T

JMAX

= 125°C, θJA = 130°C/ W

1

2

3

4

8

7

6

5

TOP VIEW

S8 PACKAGE

8-LEAD PLASTIC SO

SW

GND

CTL

PS

V

BAK

V

CC

BACKUP

RESET

T

JMAX

= 125°C, θJA = 110°C/ W (GN)

T

JMAX

= 125°C, θJA = 110°C/ W (S)

TOP VIEW

S PACKAGE

16-LEAD PLASTIC SO

GN PACKAGE

16-LEAD PLASTIC SSOP

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

SW

SW

PGND

GND

CTL

SHDN

PS

NC

V

BAK

V

BAK

V

CC

BACKUP

RESET

RESET

NC

LOBAT

PACKAGE/ORDER INFORMATION

W

U

U

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Battery Backup Switching

V

CC

Operating Voltage Range LTC1559-3.3 ● 2.900 3.5 V

LTC1559-5 ● 4.400 5.5 V

V

BAT

Backup Battery Cell Voltage ● 1.0 1.2 1.5 V

I

VCC

Quiescent Supply Current (Note 2) ● 155 250 µA

I

BAT

Peak Inductor Current (Backup) Boost Converter in Low Current Mode (Note 7) ● 80 165 225 mA

Boost Converter in High Current Mode (Note 7) ● 225 330 445 mA

I

BAT(SHDN)

Battery Standby Current VCC = 0V ● 0.1 15 µA

I

VCC(SHDN)

Supply Current During Shutdown (Note 3) ● 50 µA

V

BAK(ON)VCC

Backup Request/Booster Assertion LTC1559-3.3 ● 3.011 3.070 3.127 V

Trip Point (Note 4) LTC1559-5 ● 4.475 4.625 4.775 V

V

BAK(OFF)VCC

Backup Deassertion Trip Point LTC1559-3.3 ● 3.061 3.119 3.176 V

(Note 4) LTC1559-5 ● 4.550 4.700 4.850 V

V

LOBAT1

Low V

BAT

Detect (Note 3) ● 0.95 1.00 1.05 V

V

UVLO(ON)VCC

UVLO Trip Voltage (Note 4) LTC1559-3.3 ● 2.904 3.003 3.102 V

LTC1559-5 ● 4.400 4.550 4.700 V

V

UVLO(OFF)VCC

UVLO Trip Voltage (Note 4) LTC1559-3.3 ● 3.061 3.119 3.176 V

LTC1559-5

● 4.550 4.700 4.850 V

155933

15595

Page 3

3

LTC1559-3.3/LTC1559-5

ELECTRICAL CHARACTERISTICS

V

BAT

= 1.2V, TA = 0°C to 70°C unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

UVLO Reset Monitor

V

LOBAT2VBAT

UVLO Trip Voltage (Note 5) ● 0.85 0.9 0.95 V

Backup Battery Charger

I

CHGF

Battery Charge Current During Fast Recharge ● 11 16 21 mA

I

CHGT

User-Programmable Trickle Charge ● 0.05 2 mA

Current Range

Q

RECH

Fast Recharge Factor (Note 6) 1.35 1.6 1.85 C/C

Q

TRK

Nominal Trickle Charge Multiplier Factor I

CHGT

= 1mA ● 8 10 12 A/A

V

CTL(CLAMP)

CTL Clamp Voltage in Trickle Mode I

CHGT

= 1mA ● 0.45 0.5 0.55 V

Push-Button Reset

V

CTL

CTL Input Threshold 250 mV

t

CTL

CTL Input Low Time (Debounce Time) 20 26 ms

Reset Timer

t

HRESET

Push-Button Duration for Hard Reset 1.10 1.8 3.4 sec

t

RST

RESET Pulse Width V

CTL

Low for <t

HRESET

(Soft Reset) ● 50 80 150 µs

V

CTL

Low for >t

HRESET

(Hard Reset) ● 115 185 345 ms

V

RST1

RESET Output Voltage VCC = 1V, I

SINK

= 10µA ● 5 200 mV

V

RST

RESET Output Voltage VCC = 4.25V, I

SINK

= 1.6mA ● 0.1 0.4 V

I

SC

RESET Output Current Output Source Current VCC = 3.3V 10 mA

Output Source Current VCC = 5V 20 mA

Short-Circuit Current Output Sink Current VCC = 3.3V 20 mA

Output Sink Current V

CC

= 5V 40 mA

PS Comparator

V

HYST

Comparator Threshold Hysteresis TA = 25°C90mV

Internal VCC Monitor Comparator

tr UVLO, Comparator Propagation Delay (Rising) 7.5 µs

Shutdown Pin (Note 3)

V

SHDN

SHDN Input Threshold Logic Low, V

IL

● 0.8 V

Logic High, V

IH

● 2V

I

SHDN

SHDN Pin Bias Current VCC = 5V, V

SHDN

= 0V ● 815 µA

The ● denotes specifications which apply over the full operating

temperature range.

Note 1: Absolute Maximum Ratings are those values beyond which the life of

a device may be impaired.

Note 2: Quiescent current is measured during push-button reset.

Note 3: Only applies to 16-pin version.

Note 4: Although the V

BAK(ON)

, V

BAK(OFF)

, V

UVLO(ON)

and V

UVLO(OFF)

threshold voltages have a specification tolerance, they are guaranteed by

design and tested in production never to overlap.

Note 5: Low cell voltage reset is only triggered when 0.25V < V

CTL

< 0.9V

for at least 20µs while in backup mode.

Note 6: Fast recharge factor is defined as the ratio of charge replenished to

the NiCd battery during fast recharge to the charge withdrawn from the

NiCd battery during backup.

Note 7: The LTC1559 switches automatically between the low and high

operating current levels. See Applications Information for more details.

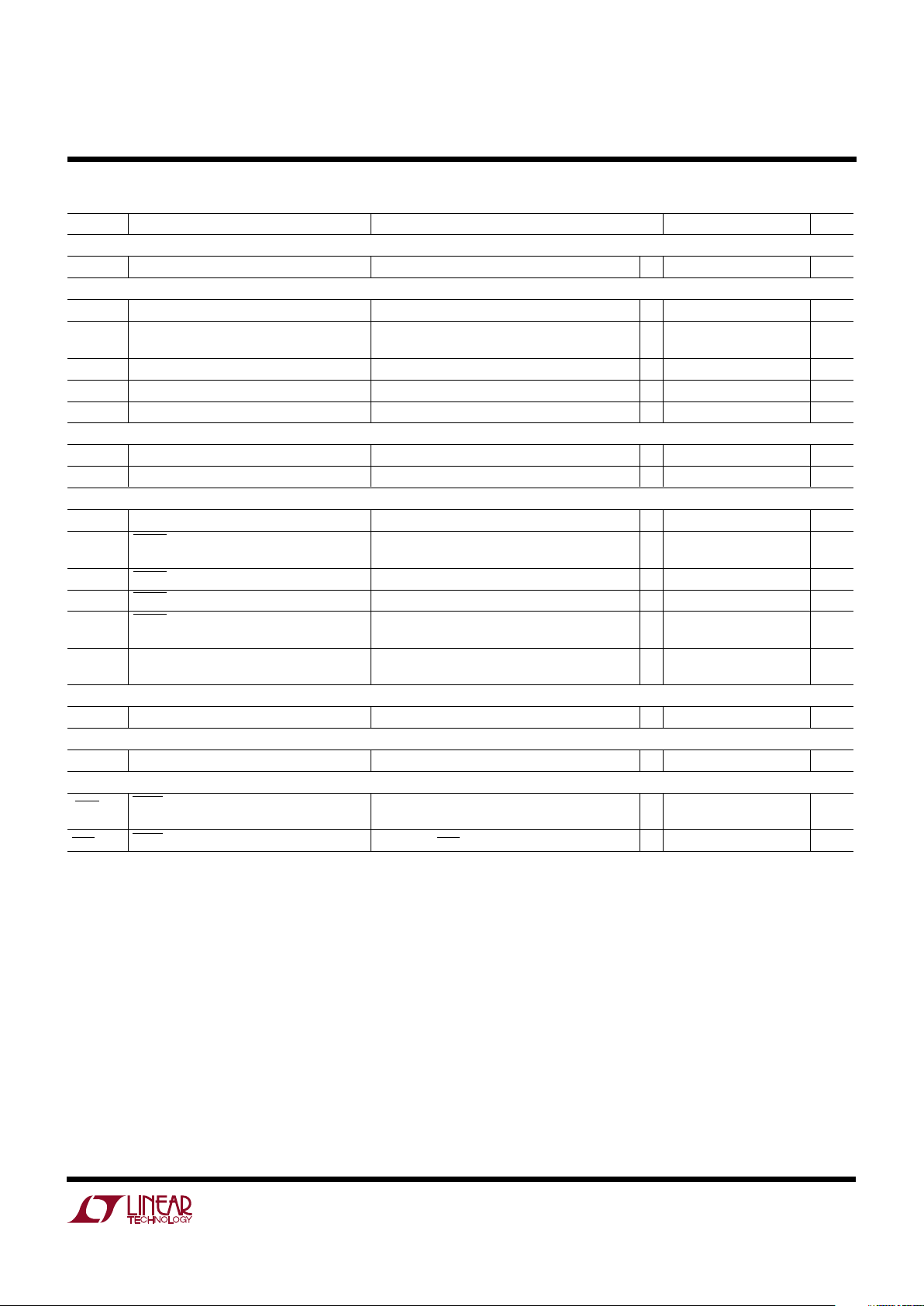

Page 4

4

LTC1559-3.3/LTC1559-5

TYPICAL PERFORMANCE CHARACTERISTICS

UW

NiCd TERMINAL VOLTAGE (V)

1.0

OUTPUT POWER (mW)

140

120

100

80

60

40

20

0

1.1 1.2 1.3 1.4

1559 G01

IPK = 330mA

C

L

= 200µF

Output Power vs Battery Voltage

Boost Converter Switching

FrequencyBackup Time vs Battery Capacity

Normalized Fast Recharge

Current vs Temperature

Trickle Charge Multiplier Factor

Boost Converter Switching

Duty Cycle

TEMPERATURE (°C)

0

0.950

CURRENT RATIO (mA/mA)

0.960

0.970

0.980

0.990

25 50

1559 G06

75

1.000

0.955

0.965

0.975

0.985

0.995

1.005

Fast Recharge Time (Assume

NiCd Battery Fully Exhausted)

BATTERY CAPACITY (mA Hr)

64

0

TIME (HOURS)

10

20

30

40

60

128 256

1559 G07

512

50

RESET Output Voltage

vs Supply Voltage

SUPPLY VOLTAGE (V)

0

0

RESET VOLTAGE (V)

1

2

3

4

6

1

234

4.55V

1559 G08

56

5

4.7V

LTC1559-5

RESET Output Voltage

vs Supply Voltage

OUTPUT VOLTAGE, V

BAK

(V)

2

DUTY CYCLE (%)

40

60

10

1559 G04

20

0

4

6

8

100

80

LTC1559-3.3

V

BAT

= 1.2V

I

PK

= 330mA

NiCd CELL CAPACITY (mA Hr)

50

BACKUP TIME (HOURS)

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

125 250 375 500

1559 G02

V

BAT

= 1.2V

P

OUT

= 100mW

OUTPUT VOLTAGE, V

BAK

(V)

2

SWITCHING FREQUENCY (kHz)

50

75

10

1559 G03

25

0

4

6

8

125

100

LTC1559-3.3

V

BAT

= 1.2V

I

PK

= 330mA

NiCd BATTERY TRICKLE CURRENT (mA)

10.5

10.4

10.3

10.2

10.1

10.0

9.9

9.8

9.7

9.6

9.5

TRICKLE CHARGE FACTOR (mA/mA)

1559 G05

0 0.2 0.4 0.6

0.8

1.0

1.2 1.4 1.6 1.8 2.0

SUPPLY VOLTAGE (V)

0

RESET VOLTAGE (V)

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

1

234

3V

1559 G09

LTC1559-3.3

3.12V

Page 5

5

LTC1559-3.3/LTC1559-5

PIN FUNCTIONS

UUU

Pin Numbers Are Shown First for the SO-8 Package

Then the GN16 and S16 Packages

SW (Pins 1/1, 2): Boost Converter Switching Node. Con-

nect a 22µ H inductor from SW to the positive terminal of

the backup cell. In backup mode, this node is alternately

switched between ground and V

BAK

, generating the backup

output voltage. In fast or trickle charge mode, an internal

regulator outputs a constant DC current from this pin

through the 22µH inductor and into the NiCd battery.

During power-up or undervoltage lockout (UVLO), the SW

pin enters a high impedance state.

GND (Pins 2/4): System Ground. The low power internal

circuitry returns to this pin in the 16-pin packages. GND

and PGND are bonded together to this pin in the 8-pin

package.

CTL (Pins 3/5): Control. This pin provides three functions.

In backup mode this pin is a high impedance input and

monitors the backup battery cell voltage (V

BAT

). If V

BAT

drops below 0.9V, the LTC1559 enters UVLO. During

trickle charge mode, an external resistor R

EXT

sets the

trickle charge current. In all modes, pulling the CTL pin

below 250mV generates either a “soft” or “hard” reset

pulse. See the Applications Information section for more

information.

PS (Pins 4/7): Power Supply Sense. This pin senses the

presence of the main supply and triggers the LTC1559 to

terminate backup mode. During backup, VCC is driven

externally by the LTC1559’s boost convert’s output (V

BAK

).

When PS > VCC during backup, the LTC1559 pulls down

the BACKUP pin, reconnecting the system regulator output to the system VCC. The PS pin is needed in applications

that use a P-channel MOSFET (driven by the BACKUP

signal) to isolate the system regulator during backup. If

not needed, PS can be disabled by tying it to ground.

RESET (Pins 5/11): System Reset, Active Low. This is an

open-drain output. This pin provides a low going reset

signal to the system processor. A 200ms pulse is generated if the CTL pin is pulled low for more than two seconds

(“hard” reset) or if the LTC1559 comes out of UVLO. This

“hard reset” stops the internal boost converter if it is

running. This pin is held low if the LTC1559 is in UVLO and

is guaranteed to be valid when VCC is greater than or equal

to 1V.

RESET also provides a low going 100µ s signal whenever

the CTL pin is pulled low for less than two seconds (“soft”

reset). Unlike hard reset, soft reset does not affect the

LTC1559’s current operating mode.

BACKUP (Pins 6/13): System Backup Signal. This is a

TTL-compatible output driver that pulls low unless the

LTC1559 is in backup mode. BACKUP signals the system

controller that the system is in backup mode so that it can

reduce system loading. BACKUP can also be used to drive

the gate of a P-channel MOSFET in series with the main

system regulator’s output. See the Applications Information section for more details.

VCC (Pins 7/14): Power Supply Input. All internal circuits

except the boost converter are powered from this pin. A

0.1µF bypass capacitor is required from VCC to ground.

The UVLO detector inside the LTC1559 monitors VCC. If

VCC drops below the rated output voltage by 9%, the

LTC1559 enters UVLO mode and RESET is asserted. The

LTC1559-3.3 exits UVLO if VCC rises to greater than

–5.5% of the rated output voltage. The LTC1559-5 exits

UVLO if VCC rises to greater than –6% of the rated output

voltage. See the Applications Information section for more

details.

V

BAK

(Pins 8/15, 16): Backup Supply Output. The LTC1559’s

boost converter provides the regulated output voltage to

the system through V

BAK

during backup mode.

16-Pin GN and SO Packages

PGND (Pin 3): Power Ground. The internal driver circuitry

returns to this pin. PGND should be connected to a low

impedance ground plane in close proximity to the NiCd

battery cell.

SHDN (Pin 6): Chip Shutdown. A TTL-compatible active

low voltage at SHDN puts the LTC1559 into low power

shutdown mode. In shutdown, all internal circuits power

down and are held in a reset state. The SW, CTL and V

BAK

pins enter into high impedance states. In shutdown mode,

supply current drops to below 50µA and current drawn

from the backup cell drops to below 15µA.

Page 6

6

LTC1559-3.3/LTC1559-5

LOBAT (Pin 9): Low Backup Battery Detector Output. This

is an open-drain output with an internal weak pull-up. It is

asserted if the NiCd cell terminal voltage drops below

1.0V. This pin is pulled high if the LTC1559 is in trickle

charge mode.

PIN FUNCTIONS

UUU

1559 SW01

V

BAT

MAIN

BATTERY

C

OUT

BACKUP

SYSTEM

V

CC

1.2V

NiCd

SW

22µH

LTC1559

RESET

PS

Q

EXT

V

BAK

V

CC

BACKUP

TO

SYSTEM

CONTROL

V

IN

FOR MORE DETAILED CIRCUIT APPLICATION SCHEMATICS,

PLEASE REFER TO THE TYPICAL APPLICATIONS SECTION

MAIN SYSTEM

REGULATOR

V

OUT

V

BAT

BACKUP

RESET

V

CC

PS

1559 SW02

200ms

RATED BATTERY TERMINAL VOLTAGE

RATED V

CC

VOLTAGE

–5.5% (LTC1559-3.3)

–6% (LTC1559-5)

1

2

3

4

Cold Power Boot-Up (Main Battery Replaced/Turned On)

Simplified LTC1559 Connections in a Battery Backup System

SWITCHING WAVEFORMS

UW

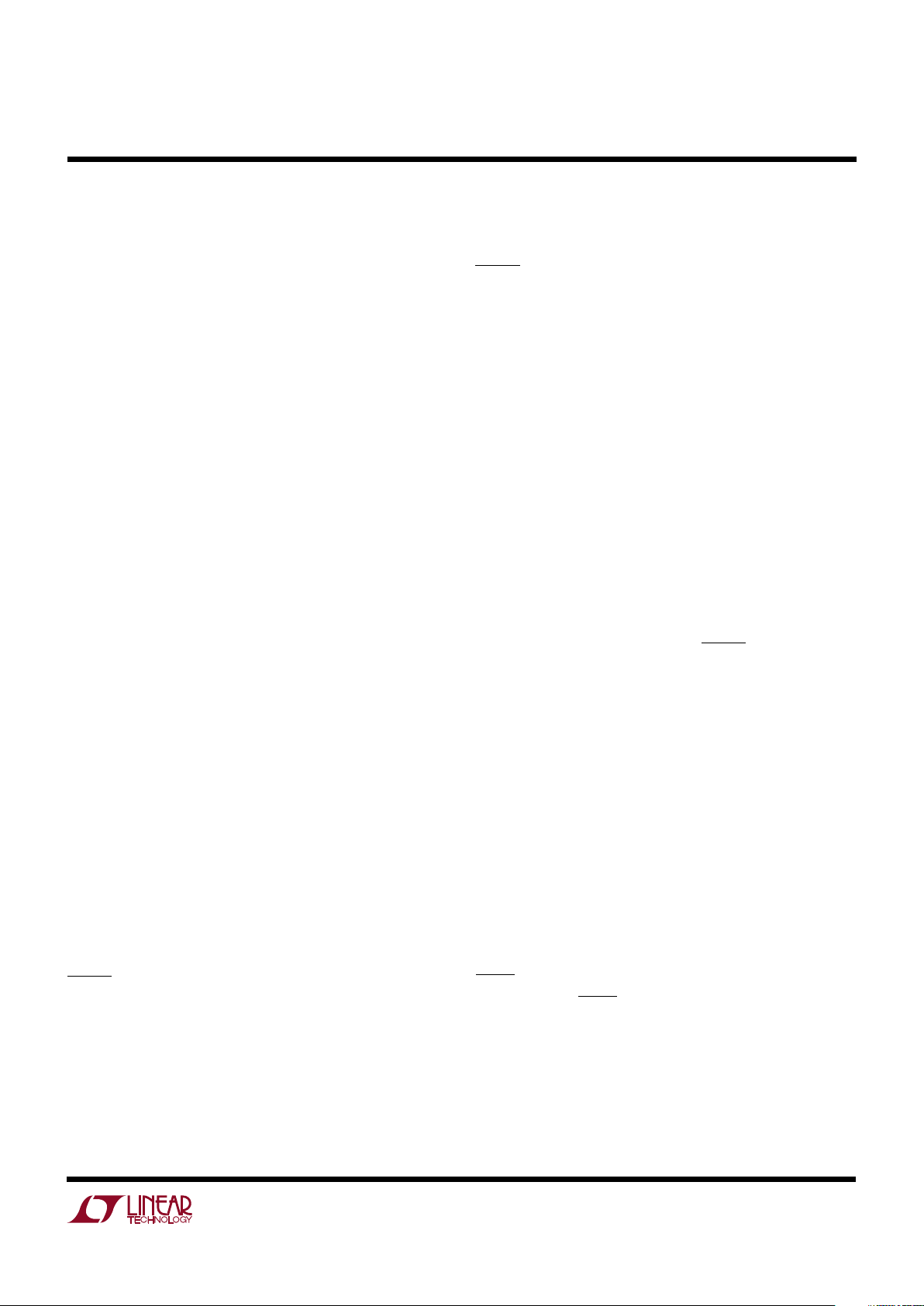

–

+

LEVEL SENSE

AND DEBOUNCE

THERMAL

LIMIT

SHUTDOWN

LOGIC

BANDGAP

V

REF

= 1.272V

CHARGER

RESET

GENERATOR

BOOST/BACKUP

LOGIC

GAS GAUGE

V

REF

V

REF

V

CC

SHDN

PS

RESET

N1

P1

V

BAK

VCC/V

BAK

CTL

SW

–

+

–

+

UVLO

DETECTOR

RESET

BACKUP

LOBAT

1559 BD

BLOCK DIAGRAM

W

RESET (Pin 12): System Reset, Active High. This is a TTLcompatible output driver. It can connect to systems that

require active high logic. The RESET output will go high if

RESET is pulled low.

Page 7

7

LTC1559-3.3/LTC1559-5

SWITCHING WAVEFORMS

UW

Cold Power Boot-Up Description

1. System regulator starts to ramp up the output (PS)

once the V

BAT

voltage increases beyond the minimum

input value.

2. VCC starts to increase once PS is high enough to turn on

Q

EXT

’s body diode. RESET is asserted when VCC is less

than or equal to 1V.

3. The LTC1559’s internal bandgap wakes up. Q

EXT

turns

on and VCC = PS. The LTC1559’s internal boost converter does not turn on as RESET remains asserted.

4. RESET is asserted for a further 200ms after VCC reaches

–5.5% of its rated VCC value for the LTC1559-3.3 and

–6% of its rated VCC value for the LTC1559-5.

Backup Mode (Main Battery Discharged)—

LTC1559-3.3

INDUCTOR

CURRENT

RESET

BACKUP

V

CC

V

NiCd

LOBAT

1559 SW03

t

r

t

r

–7%

1.2V

–7%

–7%

1V

0.9V

–5.5%

BOOST CONVERTER OUTPUT

t

f

t

r

t

r

(4)(3)(2)(1)

“1”

“1”

Backup Mode Description

1. Trigger into Backup Mode. Main battery fails and V

CC

drops 7% below the rated value. The backup pin is

asserted after a tr delay time and the boost converter is

turned on.

2. Backup Mode. The LTC1559’s boost converter charges

and discharges the inductor with 165mA peak current.

If VCC doesn’t increase above VCC(rated value) – 7%

(due to a heavy load), the boost converter increases

peak charging current to 330mA. If VCC rises above

VCC(rated value) – 7%, the boost converter stops and

the backup pin remains asserted.

3. Recovery from Backup Mode. While the boost converter is running, the main battery is restored. This

causes the system regulator to increase PS above VCC.

When PS > VCC or VCC > VCC(rated value) –5.5%, the

BACKUP pin deasserts and the boost converter finishes

its last cycle.

4. Trigger into UVLO. During backup, the 1.2V NiCd cell is

discharged and its terminal voltage falls. The LOBAT pin

is asserted to give an early warning if the cell voltage

drops below 1V. RESET is asserted when the cell

voltage drops below 0.9V and the LTC1559 enters

UVLO mode.

Page 8

8

LTC1559-3.3/LTC1559-5

APPLICATIONS INFORMATION

WUU

U

Overview

The LTC1559 is a versatile backup battery control system

designed to provide all the functions necessary to implement a complete, highly integrated backup system within

a single chip. It allows the system to maintain its rated

supply voltage during backup, offering maximum system design flexibility. The LTC1559 allows the use of a

low cost rechargeable NiCd cell for backup, eliminating

the need for expensive, replaceable 4.5V lithium backup

cells.

The LTC1559 includes an onboard boost converter

designed to generate a fixed voltage (3.07V for 3.3V parts

and 4.625V for 5V parts) from a single 1.2V NiCd cell.

When connected to the system DC/DC converter’s output,

the LTC1559 enables the system connected to the VCC rail

to continue operation when the main power supply fails. A

“smart” recharging circuit uses an accumulating gas

gauge to measure the charge extracted from the backup

battery during a backup cycle. This measured charge is

then replaced in a fast recharge cycle, without wasting

excess power or overcharging the backup cell. An externally adjustable trickle charge circuit maintains the cell

charge after the fast charge cycle has completed, minimizing drain from the main battery during standby.

Included in the LTC1559 is a complete backup circuit that

monitors the main system power and automatically

switches in the backup circuit as the primary power supply

falls away (due to a weak or disconnected main battery).

The LTC1559 also performs VCC supervisory functions

during normal system operations. An LTC1559-3.3

monitors a 3.3V supply voltage at its VCC pin while an

LTC1559-5 monitors a 5V supply at its VCC pin. In both

cases, the LTC1559 derives power for the majority of the

internal circuitry (except for the boost converter) from its

VCC pin. Table 1 shows the signal conditions for the

various operating modes of the LTC1559-3.3. Table 2

shows the signal conditions for the various operating

modes of the LTC1559-5.

Table 1. LTC1559-3.3 Operating Modes

OPERATING MODES CONDITIONS

UVLO Reset 1V < VCC < VCC(rated value) – 9% or

V

BAT

< 0.9V

Push-Button Reset V

CTL

< 250mV

UVLO Reset Recovery VCC > VCC(rated value) – 5.5%

Backup Mode Activation VCC < VCC(rated value) – 7%

Backup Mode Exit VCC > VCC(rated value) – 5.5%

or PS > V

CC

Boost Converter Activation VCC < VCC(rated value) – 7%

Boost Converter Deactivation VCC > VCC(rated value) – 7%

Table 2. LTC1559-5 Operating Modes

OPERATING MODES CONDITIONS

UVLO Reset 1V < VCC < VCC(rated value) – 9%

or V

BAT

< 0.9V

Push-Button Reset V

CTL

< 250mV

UVLO Reset Recovery VCC > VCC(rated value) – 6%

Backup Mode Activation VCC < VCC(rated value) – 7.5%

Backup Mode Exit VCC > VCC(rated value) – 6%

or PS > V

CC

Boost Converter Activation VCC < VCC(rated value) – 7.5%

Boost Converter Deactivation VCC > VCC(rated value) – 7.5%

Boost Converter Operation

The LTC1559 uses an onboard boost converter with a

fixed peak current architecture that provides a simple and

flexible system solution while eliminating the need for

conventional frequency compensation. The boost

converter’s output, set to 93% (LTC1559-3.3) or 92.5%

(LTC1559-5) of the rated VCC, supports the system V

CC

during backup. It supplies a minimum backup power of

100mW. The boost converter operates in a modified

pulse-skipping mode; each switch cycle transfers a known

amount of charge from the backup cell to the regulated

output. This prevents uncontrolled discharge of the backup

cell and allows the LTC1559 to accurately measure the

charge removed from the backup cell by counting the

charge pulses.

The LTC1559 enters backup mode when the main battery

voltage drops and causes VCC, the system regulator’s

output, to fall. As shown in Figure 1, VCC is scaled down

by an internal resistor divider and fed to the LTC1559’s

backup comparators. These compare the scaled voltage

Page 9

9

LTC1559-3.3/LTC1559-5

APPLICATIONS INFORMATION

WUU

U

ferred for the first two consecutive switch cycles. If V

CC

falls below

V

CC

(rated value) –7% (LTC1559-3.3)

, the

boost operation starts by connecting the SW pin internally

to ground through an internal 0.5Ω N-channel MOSFET

(N1 in the Block Diagram). The current through the external 22µH inductor rises linearly through this switch.

When the switch current reaches an internally preset level

of 165mA, the boost converter connects the SW pin to the

V

BAK

pin through an internal 2Ω P-channel MOSFET. The

inductor current discharges through the P-channel (P1 in

the Block Diagram) and charges up the system’s V

CC

capacitor (C

OUT

of the system regulator, Figure 1). The

inductor current falls at a rate proportional to the difference between the backup cell voltage and the output

voltage V

BAK

. When the inductor current reaches zero,

indicating all of its energy has been transferred to the

output capacitor, the LTC1559 monitors the VCC voltage.

If VCC has increased above the

V

CC

(rated value) –7%

(LTC1559-3.3)

threshold, the boost converter shuts off

both switches and waits for VCC to drop below

V

CC

(rated

value) –7% (LTC1559-3.3)

again.

with an internal trimmed V

REF

(1.272V), switching the

LTC1559 into backup mode if VCC drops 7%

(LTC1559-3.3) or 7.5% (LTC1559-5) below its rated

value. Upon entering backup mode, the BACKUP pin is

asserted and the internal boost converter turns on. The

BACKUP signal turns off the external P-channel MOSFET

(if used), isolating the system regulator from the LTC1559.

The boost converter charges the VCC capacitor, C

OUT

, of

the system regulator until VCC rises above V

CC

(rated

value) – 7% (LTC1559-3.3) or VCC (rated value) – 7.5%

(LTC1559-5).

Once VCC rises above

V

CC

(rated value) – 7% (LTC1559-

3.3)

, the boost converter deactivates and the freshly

charged VCC capacitor C

OUT

supplies power to the system.

The cycle repeats again when the VCC capacitor’s charge

is drained away and VCC again drops below

V

CC

(rated

value) – 7% (LTC1559-3.3)

. The BACKUP pin remains

asserted until the main battery is restored. This ensures

that the LTC1559 does not switch in and out of backup

mode unnecessarily.

The LTC1559’s boost converter minimizes output ripple

under light load conditions by reducing the charge trans-

Figure 1. Typical LTC1559 Connection

+

BOOST

CONVERTER

SYSTEM

REGULATOR

LTC1559

R1

PS

V

CC

R2

1559 F01

BACKUP

LOGIC

V

REF

BACKUP

SYSTEM

V

CC

V

BAK

C

OUT

LIGHT CURRENT MODE

165mA

(PEAK)

330mA

(PEAK)

HEAVY CURRENT MODE

1559 F02

Figure 2. Inductor Current During Switching

Figure 3. V

BAK

Ripple

1

BOOST

CYCLE

V

BAK

ESR RIPPLE

DISCHARGE

PERIOD

t

DISCH

CHARGE

PERIOD

t

CH

1559 F03

Page 10

10

LTC1559-3.3/LTC1559-5

If VCC is still less than

V

CC

(rated value) –7% (LTC1559-

3.3)

after the first boost cycle, the LTC1559 immediately

reconnects SW to ground, repeating the boost cycle. If

after two consecutive pulses, VCC is still not above the

boost threshold

V

CC

(rated value) –7% (LTC1559-3.3)

,

the LTC1559 decides that the load is not so light after all,

and doubles the internal inductor charging current limit to

330mA for subsequent cycles. This is high current mode.

By doubling the peak inductor current, each boost cycle

effectively carries four times more energy compared to

low current mode (E = 1/2 • LI2), doubling the available

output power. When VCC exceeds the

V

CC

(rated value)

–7% (LTC1559-3.3)

boost threshold, the LTC1559 stops

the boost converter and resets the internal 2-pulse counter.

The next time VCC falls below

V

CC

(rated value) –7%

(LTC1559-3.3)

, the boost converter restarts in low current

mode for at least two boost cycles. Moderate or changing

loads cause the LTC1559 to shift between the two peak

inductor current limits, keeping the output in tight regulation. Near its maximum load capability, the LTC1559 will

stay in 330mA high current mode and the output voltage

V

BAK

will hover around

V

CC

(rated value) –7%

(LTC1559-3.3)

.

VCC Capacitor ESR

The type of output capacitor and the rated VCC value will

affect the LTC1559’s output ripple and efficiency. In most

applications, the VCC capacitor is primarily determined by

the requirements of the main power supply. Such a

capacitor will generally meet the requirements of the

LTC1559. In unusual circumstances or circuits where

the main system VCC capacitor is located some distance

away from the LTC1559, a local output capacitor may be

necessary.

The ripple on the VCC pin is equal to the capacitor ESR

voltage drop due to the boost converter’s output current

pulses. The ripple frequency and output duty cycle is

proportional to the inductor discharge time. Given a fixed

inductor value (22µ H) and a known peak current limit, the

booster’s discharge time in each boost cycle is proportional to the difference between V

BAK

(93% of the rated V

CC

for the LTC1559-3.3 and 92.5% of the rated VCC for the

LTC1559-5) and the battery cell voltage, V

BAT

(1.2V).

APPLICATIONS INFORMATION

WUU

U

Assuming ESR = 0.2Ω, I

IND(PEAK)

= 330mA, VCC = 5V,

V

RIPPLE(P-P)

= (I

IND(PEAK)

)(R

ESR(CAP)

)

= (330mA)(0.2Ω)

= 66mV

Since VCC must be scaled down internally, the external

resistor ratio:

= 5V/1.272V

= 3.931

Therefore the ripple seen by the VCC comparators is:

= 66mV/3.931

= 16.79mV

The discharge time period,

t

DISCH

= (L • I

IND(PEAK)

)/(V

BAK

– V

BAT

)

= (22µH • 330mA)/(4.625 – 1.2V)

= 2.12µs

For VCC = 3.3V and I

IND(PEAK)

= 330mA,

V

RIPPLE(P-P)

= 66mV

RB resistor ratio = 3.3/1.272 = 2.594

Ripple voltage = 25.4mV

t

DISCH

= 3.9µs

The internal VCC comparators are designed to have a slow

response time to filter away this ripple. The V

CC

(rated

value) – 5.5% (LTC1559-3.3) and VCC(rated value) – 9%

comparators have a 6µs rising edge delay and 2µs falling

edge delay. The V

CC

(rated value) – 7% (LTC1559-3.3)

comparator has a similar 6µ s rising time delay but a much

longer falling time delay of 20µs. This enables the com-

parator to control the boost converter properly, and avoids

turning off the boost converter prematurely due to false

triggering by the ESR ripple.

Exit from Backup

When a main battery is inserted into the system, the

LTC1559 follows a specific sequence to exit backup mode

and return control to the main supply. The sequence

depends on the type of main power supply used. In

systems where the main supply’s output impedance is

Page 11

11

LTC1559-3.3/LTC1559-5

APPLICATIONS INFORMATION

WUU

U

to the load while charge on the V

CC

capacitor drains away.

If VCC drops below VCC (rated voltage) – 9% for more than

7.5µ s, the LTC1559’s VCC supervisory circuit activates

UVLO mode, shutting off the boost converter and asserting the Reset pins. The 7.5µ s delay prevents the LTC1559

from being fooled by brief transients or noise spikes on its

VCC pin. Upon receipt of the reset signal, the host system

should shut down in an orderly manner. The LTC1559’s

VCC supervisory circuit will remain alive until VCC is less

than 1V to ensure a valid RESET pin signal.

Backup Cell Voltage Monitoring

As the boost converter removes charge from the backup

NiCd cell, the cell’s terminal voltage falls. Permanent

damage to the NiCd cell can occur if it is discharged to

below 0.9V. To prevent this, the LTC1559 monitors the

cell’s terminal voltage through the CTL pin during backup.

If the CTL pin drops below 0.9V for more than 20µs, the

UVLO circuit shuts down the boost converter and asserts

the RESET and RESET pins. Since the CTL pin can also be

connected to an external push-button reset, the LTC1559

includes internal logic to ensure that the low cell voltage

reset is triggered only if the CTL pin is between 0.9V and

0.25V. This will prevent a push-button reset (which pulls

CTL below 250mV) from being mistaken as a low cell

voltage condition. Unusual situations where the NiCd cell

voltage drops drastically below 0.25V will also trigger

UVLO, since the LTC1559 will treat this as a “hard” reset

after two seconds.

An optional LOBAT output, available in the 16-pin GN or SO

package, can be used to signal the system if the cell

voltage falls below 1V, giving an early warning that the

backup cell is heavily discharged. The LOBAT pin is

disabled if the LTC1559 is in trickle charge mode,

because the CTL pin is regulated to 0.5V by the LTC1559.

Fault Protection and Thermal Limit

The LTC1559’s boost converter incorporates two internal

timers that turn off the switch transistors if the inductor

charge or discharge time gets abnormally long.

The inductor charge time may get abnormally long if the

NiCd cell voltage drops below 0.25V without triggering the

0.25V < V

BAT

< 0.9V low cell voltage comparator. In this

high when inactive (typically a boost regulator with an

output catch diode), the LTC1559 detects the return of the

main supply by watching for VCC to exceed V

CC

(rated

value) – 5.5% (LTC1559-3.3). The LTC1559 then shuts

down its internal boost converter and begins to recharge

the NiCd cell. In such applications, the PS pin is not used

and can be tied to ground. No external P-channel MOSFET

is required to isolate the main supply from the system V

CC

during backup.

In systems where the main supply’s output impedance is

low when inactive (typically buck regulators), the main

supply must be disconnected from the system VCC during

backup to prevent the inactive supply from loading the

LTC1559. This is typically accomplished using an external

P-channel MOSFET as shown in Figure 1. When the main

supply is restored, the P-channel MOSFET’s body diode

forward-biases. This allows current to flow into the system VCC, but the forward drop across this diode may

prevent VCC from reaching the V

CC

(rated value)

– 5.5% (LTC1559-3.3) threshold that deactivates the

LTC1559’s backup mode. In such systems, the PS pin

should connect directly to the output of the main system

supply. When the system regulator’s voltage rises about

2.5% above the backup VCC, the PS comparator triggers

and causes the LTC1559 to deassert the BACKUP pin

signal. This signals the system controller to restore system loading and resume normal operation. At the same

time, the external P-MOSFET is driven by the BACKUP

signal. The P-channel MOSFET turns on and allows the

main regulator to bypass its body diode and drive the

system VCC directly.

Since the user can replace the main battery anytime during

the LTC1559’s backup operation, the BACKUP signal may

be deasserted while the boost converter is switching. To

prevent the potential problem of residual energy in the

inductor, the LTC1559 will only stop the boost converter

after it completes the current boost converter cycle.

UVLO Under Excessive Backup Load

Very heavy loads (above the LTC1559’s maximum power

output) will pull the boost converter’s output below the

boost threshold. Under these conditions, the LTC1559’s

boost converter continues to supply 330mA current pulses

Page 12

12

LTC1559-3.3/LTC1559-5

case, the NiCd cell is assumed to be damaged and the

LTC1559’s priority is shutting down the system gracefully. In this case, the timer will shut off the N-channel

switch transistor after a maximum charging time (14µs).

The boost converter continues switching but delivers

reduced output power, causing VCC to drop. The LTC1559

enters UVLO if VCC drops below VCC(rated value)

– 9% or if the LTC1559 detects that CTL is lower than

0.25V for two seconds, in which case “hard” reset occurs.

The discharge time can also get abnormally long if a

serious overload condition occurs during switching. The

timer shuts off the P-channel pass transistor after 10µs,

protecting the boost converter. The LTC1559 enters UVLO

as VCC drops below VCC(rated value) – 9%.

In addition, the LTC1559 has safe area operation protection with an internal thermal shutdown circuit. If the device

is overloaded for a long period of time, the thermal

shutdown circuit forces the LTC1559 into UVLO. The

threshold temperature for thermal shutdown is typically

155°C.

The LTC1559’s boost converter is designed so that no

current drains from the battery to the load during output

short circuit or VCC = 0V conditions. This assures that the

system can be powered down for a long period of time.

This eliminates the risk of finding a nonfunctioning backup

system upon power-up.

Backup Cell Fast Recharge

The LTC1559 includes an onboard gas gauge circuit,

consisting of a 23-bit divider and a 9-bit up/down counter.

The gas gauge logic assumes that the boost converter

uses a 22µH inductor, allowing it to accurately measure

battery charge by counting pulses. The gas gauge counts

up from zero as charge is removed from the backup cell in

backup mode. It takes 8.4 million 165mA boost pulses

(low current mode) to increment the up/down counter by

one count. In high current mode, the 330mA pulses skip

the first two bits of the divider because each 330mA pulse

carries four times as much energy as a 165mA pulse. At

maximum load and VCC = 4.625V (LTC1559-5), the gas

gauge counter will increment by one count every 7.5µs

while the boost converter is running. Full count is reached

APPLICATIONS INFORMATION

WUU

U

after approximately 2.2 hours, equivalent to about

512mAhr of charge.

Upon entering recharge mode (after the main battery is

restored) the LTC1559 connects a 16mA fast recharge

current source from VCC to the SW pin. At the same time,

an internal free running oscillator counts down the gas

gauge counter at a rate designed to typically replace 160%

of the charge previously removed from the backup cell.

When the gas gauge counter reaches zero, the LTC1559

reduces the charging current at the SW pin to the userprogrammed trickle charge current level.

Under some circumstances, the LTC1559 can exit backup

mode with invalid gas gauge contents. This occurs under

three possible conditions:

1. The backup cell was completely exhausted during a

backup cycle and the LTC1559 entered UVLO.

2. The backup cell was replaced while the main supply was

disabled.

3. A backup cycle was terminated prematurely by a “hard”

reset or an output overload.

In these cases, the LTC1559 assumes that the backup cell

is exhausted and presets the gas gauge counter to a

default capacity of 128mAhr. It then initiates a recharge

cycle.

Setting the gas gauge to this default value results in a fast

recharge cycle long enough to replenish 1.6 times

128mAhr into the backup cell (13.9 hours). If the backup

cell is actually exhausted, it will be fully recharged. If the

battery is partially or fully charged, or is significantly

smaller than 128mAhr capacity, the extra charging time is

wasted. However, the LTC1559’s 16mA fast charge current is not high enough to damage the cell. Once the fullcount recharge has been completed, the backup cell is

assumed to be fully charged and subsequent backup/

recharge cycles resume normally.

Although the LTC1559 will not fully recharge backup cells

larger than 128mAhr capacity upon power-up, it can still

be used with such cells. Such a cell will be fully replenished

by the subsequent trickle charge cycle. Under most conditions, even a partially charged large cell will still be

capable of supporting several hours of backup. For

Page 13

13

LTC1559-3.3/LTC1559-5

APPLICATIONS INFORMATION

WUU

U

example, a small 60mAhr SAFT cell can back up the

system for 20 minutes at an output power of 100mW. Note

that at VCC = 3.07V (LTC1559-3.3), the boost converter

efficiency improves and allows more backup time from the

same cell compared to VCC = 4.625V (LTC1559-5).

Once it reaches full recharge, a cell bigger than 512mAhr

will overrun the gas gauge counter before it runs out of

charge during an extended backup cycle. The LTC1559

gas gauge counter will not roll over if this occurs; it will

stay at full count until the backup cycle ends and then

partially recharge the cell with a full count cycle as above.

Very short backup cycles (<32s) may not extract enough

charge from the backup cell to increment the gas gauge

counter at all. To ensure that the backup cell is not slowly

“nibbled” away, the gas gauge counter is always

incremented by 1mAhr each time the controller exits

backup. This ensures that the backup cell is replenished

with at least a 1mAhr charge every time the LTC1559

enters backup mode.

Battery Backup Cell Trickle Charge

When the gas gauge counter reaches zero, the LTC1559

terminates fast recharge and reduces the recharge current

to the user-programmed trickle current level. The LTC1559

provides a trickle current that the user can program from

50µ A to 2mA. The trickle current is set by an external

resistor from the positive terminal of the backup cell to the

Figure 4. Trickle Current Charger

R

EXT

V

CC

1µF

I

10I

1.2V

NiCd

CELL

SW

CTL

0.5V

1559 F04

11×1×

LTC1559

+

–

+

+

–

CTL pin. In trickle charge mode, CTL is regulated to 0.5V,

resulting in a CTL pin current of (V

BAT

– 0.5)/R

EXT

. This

current is internally multiplied to feed back ten times the

R

EXT

current into the backup battery. Since the LTC1559

trickle charges only after the completion of the fast

recharge cycle, the backup cell voltage should be very

close to 1.2V. This simplifies the calculation of the R

EXT

resistor value. For example, a 47k resistor from V

BAT

to

CTL sets the trickle charge current to 150µA.

Undervoltage Lockout

The LTC1559 includes an undervoltage lockout (UVLO)

circuit that shuts the system down gracefully if the backup

cell is exhausted or overloaded. As described in the

previous section, the LTC1559 terminates backup operation and remains off until the main power supply returns.

It then runs a fast recharge cycle to recharge the backup

cell. An onboard low-battery comparator in the 16-pin GN

or SO package provides an early warning signal if the

backup cell drops below 1V.

The UVLO circuit trips if the LTC1559’s VCC supervisory

circuit detects that VCC drops below –9% of the rated V

CC

voltage due to overload or output short-circuit conditions.

Once the UVLO circuit trips, the LTC1559 asserts the

RESET and RESET pins until the VCC voltage drops below

1V. It then remains off until VCC rises to within –5.5% of

the rated output voltage (LTC1559-3.3). During power-up

from UVLO, the LTC1559 asserts the RESET and RESET

pins until the VCC(rated value)–5.5%(LTC1559-3.3)

threshold. Once VCC exceeds VCC(rated value) – 5.5%

(LTC1559-3.3), the RESET and RESET pins remain

asserted for another 200ms (“hard” reset) before being

released to inform the system to start operating.

Reset Operation

The LTC1559 includes an onboard push-button reset

switch controller. If the CTL pin is pulled to ground

(<250mV) by a push-button or an open-drain output, the

LTC1559 generates a pulse at the RESET and RESET pins

after the trailing edge of the CTL signal. A short (less than

two seconds) low going signal at CTL generates a “soft”

reset (100µ s) pulse at the reset pins. A low CTL signal for

more than two seconds generates a “hard” reset pulse at

the RESET and RESET pins. During “hard” reset, the

Page 14

14

LTC1559-3.3/LTC1559-5

APPLICATIONS INFORMATION

WUU

U

shut off completely. Note that the backup cell slowly

discharges through R

EXT

in this mode.

Inductor Selection

The LTC1559 is designed to operate with a recommended

inductor value of 22µ H (±20%) with < 0.2Ω DC resistance.

Using inductor values above 22µ H will deliver more output

power but will cause the gas gauge counter to count

inaccurately and under-recharge the backup cell. At the

same time, the N-channel transistor timer will limit the

peak current if the charging time becomes overextended

due to the higher inductor value. Using inductor values

lower than 22µ H will degrade the boost converter’s maximum output power and cause the gas gauge counter to

overcharge the backup cell. Table 3 lists a few recommended surface mount inductor part numbers.

Table 3. Recommended Inductors

PART TYP INDUCTOR DCR

MANUFACTURER NUMBER VALUE (Ω)

Sumida CD54-220 22µH ±20% 0.18

Sumida CDRH73/74 22µH ±20% 0.2/0.11

Capacitor Selection

The LTC1559 requires a VCC capacitor of 100µ F to ensure

that boost converter can regulate the output under maximum load conditions. The capacitor’s ESR should be

small (<0.2Ω) to minimize voltage spikes that might

incorrectly trigger the LTC1559’s internal VCC comparators. Note that the LTC1559 can usually share the output

capacitor with the system regulator. However, a 1µF is

recommended directly at the LTC1559’s VCC pin. The V

CC

capacitor’s ratings like V

MAX

, I

RIPPLE(RMS)

all must meet

the system regulator’s specifications as well.

Battery Selection

A primary application for the LTC1559 is a “bridging”

supply, only providing backup current while the main

system battery is being replaced. In these applications,

the LTC1559 works well with NiCd button cells or small

cylindrical cells, reducing system costs and board space.

It is optimized for use with up to 512mAhr battery

capacities.

Figure 5. Push-Button Resets

CTL

RESET

(A)

0V

0V

0V

20ms

DEBOUNCE

(B)

>0.25V

t

CTL

< 20ms

20ms < t

CTL

< 2s

>0.25V

“SOFT” PUSH-BUTTON RESET AT CTL

(A) CTL < 0.25V FOR LESS THAN 20ms

(B) CTL > 0.25V FOR MORE THAN 20ms

“HARD” PUSH-BUTTON RESET AT CTL

CTL < 0.25V FOR MORE THAN 2s

20ms DEBOUNCE AT FALLING AND RISING RESET EDGE

100µs 100µs

CTL

1559 F05

RESET

CTL

RESET

200ms

2s

t

CTL

> 2s

20ms

20ms

LTC1559 disables the boost converter if it is in backup

mode. All signals at the CTL pin are debounced for 20ms

to prevent multiple resets, allowing the CTL pin to be

connected directly to a push-button to ground.

The RESET pin is an open-drain output that requires an

external pull-up resistor. The RESET pin is a TTL compatible CMOS output.

Shutdown

The 16-pin LTC1559 has a TTL compatible input, SHDN

that shuts down the whole chip, asserts the RESET and

RESET pins and places the CTL, V

BAK

and SW pins into

high impedance states. The SHDN pin has an internal pullup of 8µ A that ensures the chip will not shut down if the pin

is left floating. The chip consumes less than 50µA during

shutdown.

Although there is no SHDN pin for the SO-8 package, the

user can shut down the part by pulling CTL to ground. The

chip enters “hard” reset leaving only the bandgap and

comparators alive. The charger and the boost converter

Page 15

15

LTC1559-3.3/LTC1559-5

The LTC1559 works with standard or memory backup

specific NiCd cells. Memory backup cells can operate at

higher temperatures and have lower self-discharge rates.

The LTC1559’s trickle charger is designed to accommodate both memory backup cells (with low self-discharge)

and standard cells (with higher self-discharge). Some

recommended manufacturers and part numbers are listed

in Table 4.

The internal resistance of the backup cell increases power

dissipation as the boost converter draws current from it

during switching, degrading efficiency. Due to the fixed

inductor peak current architecture, the LTC1559’s boost

converter output power drops significantly when the NiCd

cell’s internal resistance increases at the end of its charge.

The inductor charging time increases due to a larger R/L

time constant, decreasing the switching frequency. It is

advisable, especially for batteries with high internal resistance, to include a 1µF or larger bypass capacitor across

the battery to ensure that the boost converter can deliver

the maximum output power regardless of the NiCd internal resistance.

APPLICATIONS INFORMATION

WUU

U

Table 4. Button/Cylindrical NiCd 1.2V Cells

MANUFACTURER PART CAPACITY R

SERIES

(TYPE) NUMBER (mAhr) (Ω)

SAFT GB60 60 1.1

(Memory Backup) GB170 170 0.4

GB280 280 0.4

SAFT VB10E 100 0.038

(Standard) VB22E 220 0.022

VB30E 300 0.017

VB60E 600 0.014

Sanyo N-50AAA 55 0.055

(Standard) N-110AA 120 0.03

N-120TA 130 0.034

N-150N 170 0.027

N-200AAA 220 0.021

N-270AA 305 0.015

N-500A 500 0.09

Panasonic (Standard) P-11AA 110 0.08

Page 16

16

LTC1559-3.3/LTC1559-5

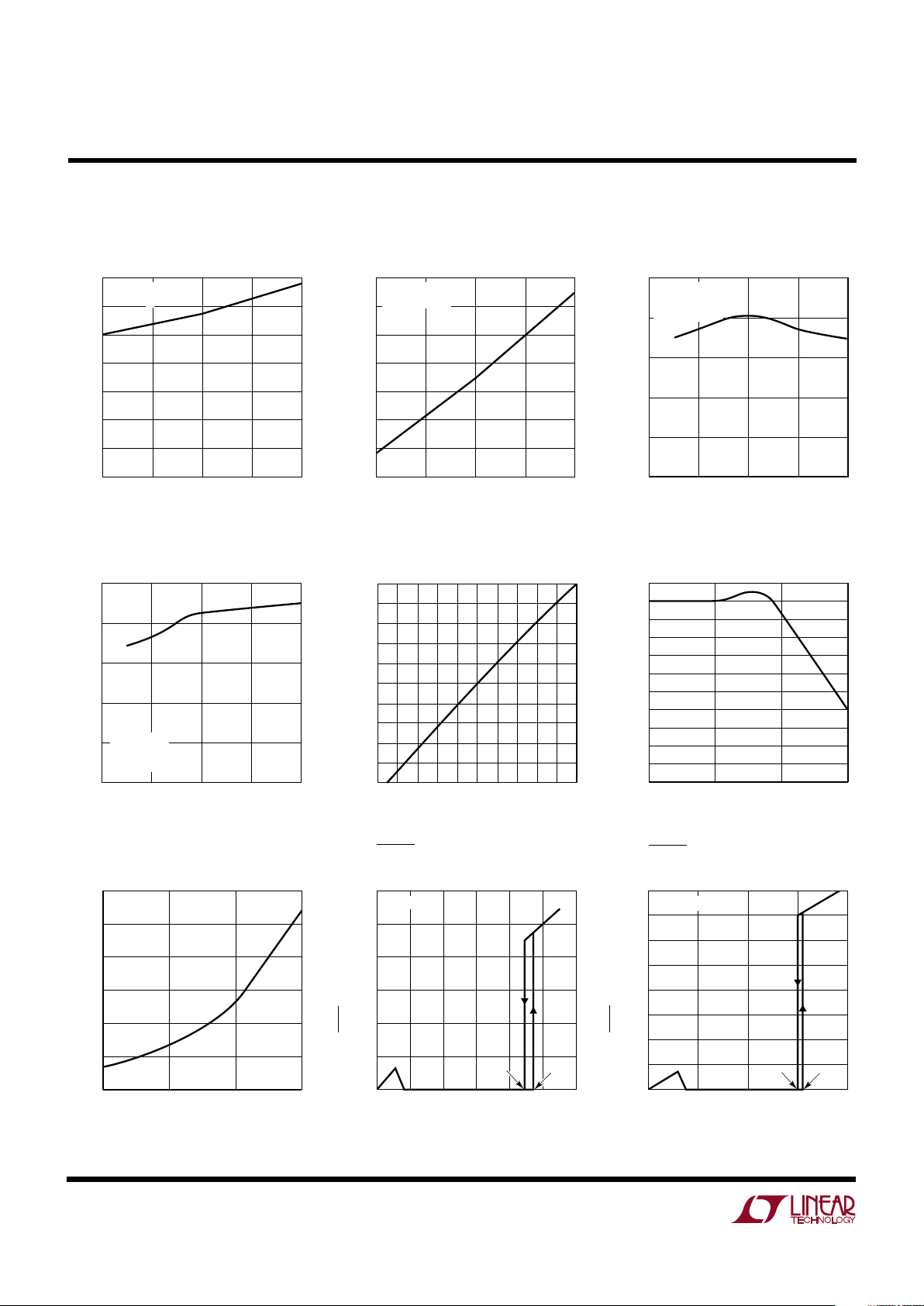

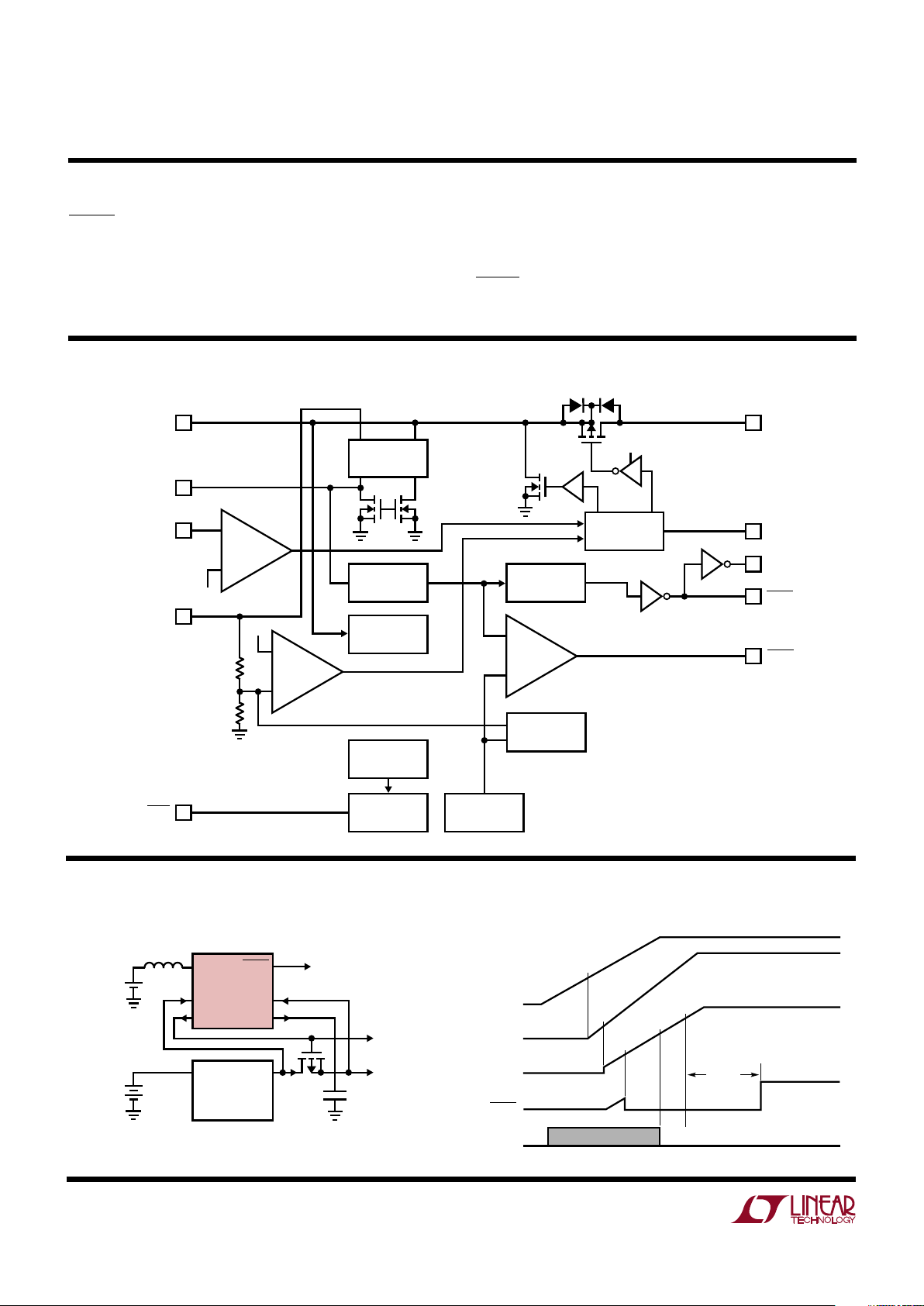

TYPICAL APPLICATION

U

LTC1559-3.3 Backup System with an LTC1435 Main System Regulator (LTC1435 Output Sense at the Drain of Q11)

Description

The PS pin connects to Q11’s drain and allows the LTC1559

to detect the restoration of the main battery during backup

mode. Once the LTC1435’s output is greater than V

OUT

+

BG

SENSE

–

SENSE

+

INTV

CC

BOOST

SW

C

OSC

SGND PGND

RUN/SS

I

TH

V

OSENSE

V

IN

LTC1435

TG

C4

0.1

µ

F

R

SENSE

**

0.033Ω

L1*

10

µ

H

*SUMIDA CDRH125-10

**IRC LR2010-01-R033-F

†

SUMIDA CD54-220

C3

4.7

µ

F

16V

D1

CMDSH-3

1559 TA03

D2

MBRS140T3

R5

20k

1%

R1

35.7k

1%

C5

1000pF

C6

100pF

Q2

N-CHANNEL

Si4412DY

Q1

N-CHANNEL

Si4412DY

SFB

EXTV

CC

11

7

8

12

15

14

13

C

IN

22µF

35V

× 2

16

5

10

1

2

3

6

4

9

C

OSC

68pF

R

C

10k

C

SS

0.1

µ

F

CC

330pF

C1

100pF

CC2

51pF

+

C2

0.1µF

BACKUP

OUTPUT

3.3V

MAIN

OUTPUT

3.3V

CTL

C11

1µF

6.3V

BACKUP

BATTERY

1.2V

NiCd

MAIN

BATTERY

4.5 TO 28V

Q11

P-CHANNEL

Si9424Y

R14

14k

SW

LTC1559-3.3

L11

†

22µH

GND

PS

7

1

8

5

6

3

RESET

PUSH-BUTTON

2

4

V

BAK

V

CC

RESET

BACKUP

+

R15

100k

C12

1µF

RESET

BACKUP

+

+

C

OUT

100µF

10V

×2

+

C15

100µF

10V

during backup mode, the LTC1559 deasserts its BACKUP

pin and returns control back to the LTC1435. Q11 turns on

and allows the LTC1435 to charge C15. Please refer to the

Applications Information section for more details.

Page 17

17

LTC1559-3.3/LTC1559-5

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

1

2

3

4

0.150 – 0.157**

(3.810 – 3.988)

8

7

6

5

0.189 – 0.197*

(4.801 – 5.004)

0.228 – 0.244

(5.791 – 6.197)

0.016 – 0.050

0.406 – 1.270

0.010 – 0.020

(0.254 – 0.508)

× 45°

0°– 8° TYP

0.008 – 0.010

(0.203 – 0.254)

SO8 0996

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

TYP

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

*

**

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

Page 18

18

LTC1559-3.3/LTC1559-5

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

GN Package

16-Lead Plastic SSOP (Narrow 0.150)

(LTC DWG # 05-08-1641)

GN16 (SSOP) 1197

* DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

12

3

4

5

678

0.229 – 0.244

(5.817 – 6.198)

0.150 – 0.157**

(3.810 – 3.988)

16

15

14

13

0.189 – 0.196*

(4.801 – 4.978)

12 11 10

9

0.016 – 0.050

(0.406 – 1.270)

0.015 ± 0.004

(0.38

± 0.10)

× 45°

0° – 8° TYP

0.007 – 0.0098

(0.178 – 0.249)

0.053 – 0.068

(1.351 – 1.727)

0.008 – 0.012

(0.203 – 0.305)

0.004 – 0.0098

(0.102 – 0.249)

0.025

(0.635)

BSC

Page 19

19

LTC1559-3.3/LTC1559-5

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

S Package

16-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.016 – 0.050

0.406 – 1.270

0.010 – 0.020

(0.254 – 0.508)

× 45°

0° – 8° TYP

0.008 – 0.010

(0.203 – 0.254)

1

2

3

4

5

6

7

8

0.150 – 0.157**

(3.810 – 3.988)

16

15

14

13

0.386 – 0.394*

(9.804 – 10.008)

0.228 – 0.244

(5.791 – 6.197)

12

11 10

9

S16 0695

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

TYP

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

*

**

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

Page 20

20

LTC1559-3.3/LTC1559-5

LINEAR TECHNOLOGY CORPORATION 1998

LTC1559-3.3 Backup System with an LTC1435 Main System Regulator

(LTC1435 Output Sense at the Source of Q11, LTC1559’s PS Pin Is Grounded)

1559f LT/TP 1098 4K • PRINTED IN USA

PART NUMBER DESCRIPTION COMMENTS

LTC690/LTC691 Microprocessor Supervisory Circuits Microprocessor Power Supply Monitor and Backup with Power Fail

LTC694/LTC695 Comparator

LTC699 Microprocessor Supervisory Circuits Microprocessor Power Supply Monitor and Backup

LTC1232 Microprocessor Supervisory Circuits Include Push-Button Reset

LTC1235 Microprocessor Supervisory Circuits Include Push-Button Reset and Power Fail Comparator

LTC1149 High Efficiency Synchronous Step-Down VIN up to 48V, Burst ModeTM Operation

Switching Regulator

LTC1435 High Efficiency, Low Noise Synchronous Ultrahigh Efficiency, Burst Mode Operation

Step-Down Switching Regulator

LTC1479 PowerPathTM Controller for Dual Complete Power Management Controller for Battery

Battery Systems Notebook Computers and Other Portable Equipment

LTC1558 Battery Backup Controller with Similar to LTC1559 Except That It Backs up the Main System Regulator’s

Programmable Output Input, Allowing Backup of Multiple Output Voltages

PowerPath and Burst Mode are trademarks of Linear Technology Corporation.

RELATED PARTS

Description

With its SENSE pin at the source of Q11, the LTC1435 can

raise V

OUT

above VCC(rated voltage) – 5.5% once the main

TYPICAL APPLICATION

U

+

BG

SENSE

–

SENSE

+

INTV

CC

BOOST

SW

C

OSC

SGND PGND

RUN/SS

I

TH

V

OSENSE

V

IN

LTC1435

TG

C4

0.1

µ

F

R

SENSE

**

0.033Ω

L1*

10

µ

H

*SUMIDA CDRH125-10

**IRC LR2010-01-R033-F

†

SUMIDA CD54-220

C3

4.7

µ

F

16V

D1

CMDSH-3

1559 TA04

D2

MBRS140T3

R5

20k

1%

R1

35.7k

1%

C5

1000pF

C6

100pF

Q2

N-CH

Si4412DY

Q1

N-CHANNEL

Si4412DY

SFB

EXTV

CC

11

7

8

12

15

14

13

C

IN

22µF

35V

× 2

16

5

10

1

2

3

6

4

9

C

OSC

68pF

R

C

10k

C

SS

0.1

µ

F

CC

330pF

C1

100pF

CC2

51pF

+

C2

0.1µF

V

OUT

3.3V

CTL

C11

1µF

6.3V

BACKUP

BATTERY

1.2V

NiCd

MAIN

BATTERY

4.5 TO 28V

Q11

P-CHANNEL

Si9424DY

R14

14k

SW

LTC1559-3.3

L11

†

22µH

GND

PS

7

1

8

5

6

3

RESET

PUSH-BUTTON

2

4

V

BAK

V

CC

RESET

BACKUP

+

R15

100k

C12

1µF

RESET

BACKUP

+

C

OUT

100µF

10V

×2

+

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

battery is restored. Thus, the LTC1559 does not use the PS

pin to sense the LTC1435’s output during backup mode.

The PS pin is grounded in this case. Please refer to the

Applications Information section for more details.

Loading...

Loading...