Page 1

FEATURES

■

5-Bit Digitally Programmable 1.8V to 3.5V Fixed

Output Voltage

■

Provides All Features Required by the

Intel

Pentium® II Processor VRM 8.2 DC/DC

Converter Specification

■

Flags for Power Good, Over-Temperature and

Overvoltage Fault

■

19A Output Current Capability from a 5V or 12V Supply

■

Dual N-Channel MOSFET Synchronous Driver

■

Initial Output Accuracy: ±1.5%

■

Excellent Output Accuracy: ±2% Typ Over Line,

Load and Temperature Variations

■

High Efficiency: Over 95% Possible

■

Adjustable Current Limit Without External Sense

Resistors

■

Fast Transient Response

■

Available in 20-Lead SSOP and SW Packages

U

APPLICATIONS

■

Power Supply for Pentium II, SPARC, ALPHA and

PA-RISC Microprocessors

■

High Power 5V or 12V to 1.8V-3.5V Regulators

LTC1553

5-Bit Programmable

Synchronous Switching

Regulator Controller for

Pentium

®

II Processor

U

DESCRIPTION

The LTC®1553 is a high power, high efficiency switching

regulator controller optimized for 5V or 12V input to 1.8V-

3.5V output applications. It features a digitally programmable

output voltage, a precision internal reference and an internal

feedback system that provides output accuracy of ±1.5% at

room temperature and typically ±2% over-temperature, load

current and line voltage shifts. The LTC1553 uses a synchronous switching architecture with two external N-channel

output devices, providing high efficiency and eliminating the

need for a high power, high cost P-channel device. Additionally, it senses the output current across the on-resistance of

the upper N-channel FET, providing an adjustable current

limit without an external low value sense resistor.

The LTC1553 free-runs at 300kHz and can be synchronized

to a faster external clock if desired. It includes all the inputs

and outputs required to implement a power supply conforming to the

Converter Specification

, LTC and LT are registered trademarks of Linear Technology Corporation.

Pentium is a registered trademark of Intel Corporation.

Intel Pentium® II Processor VRM 8.2 DC/DC

.

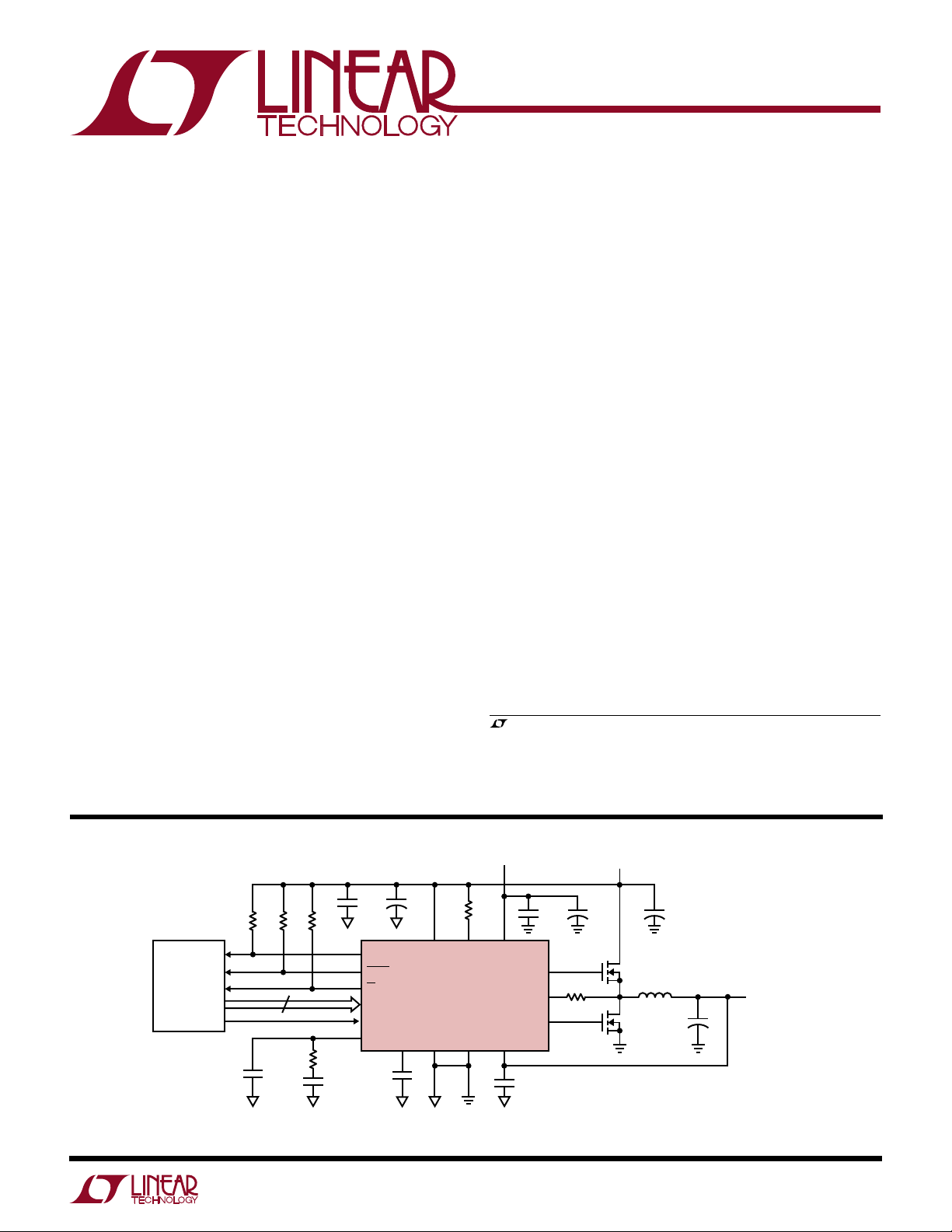

TYPICAL APPLICATION

5.6k

5.6k

PENTIUM® II

SYSTEM

C1

150pF

5

5.6k

R

8.2k

U

C

CC

0.01µF

+

0.1µF

10µF CIN**

PWRGD

FAULT

OT

VID0 TO VID4

OUTEN

COMP

C

SS

0.1µF

V

SS SGND GND SENSE

CC

LTC1553

PV

CC

12V

2.7k

I

MAX

0.1µF

PV

CC

G1

I

FB

G2

0.1µF

Figure 1. 5V to 1.8V-3.5V Supply Application

V

IN

5V

+

10µF

Q1*

20Ω

Q2*

*SILICONIX SUD50N03-10

**SANYO 10MV1200GX

†

COILTRONICS CTX02-13198 OR

PANASONIC 12TS-2R5SP

††

AVX TPSE337M006R0100

+

L

2µH

18A

O†

1200µF

× 4

C

OUT

330µF

× 7

V

OUT

1.8V TO

††

+

3.5V

14A

1553 F01

1

Page 2

LTC1553

WW

W

U

ABSOLUTE MAXIMUM RATINGS

(Note 1)

Supply Voltage

VCC........................................................................ 9V

PVCC................................................................... 20V

Input Voltage

IFB (Note 2)............................................ PVCC + 0.3V

I

...................................................... –0.3V to 13V

MAX

All Other Inputs ......................... –0.3V to VCC + 0.3V

Digital Output Voltage............................... – 0.3V to 13V

IFB Input Current (Notes 2, 3) .......................... – 100mA

Operating Temperature Range ..................... 0°C to 70°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec.)................. 300°C

ELECTRICAL CHARACTERISTICS

VCC = 5V, PVCC = 12V, TA = 25°C, unless otherwise noted. (Note 3)

U

W

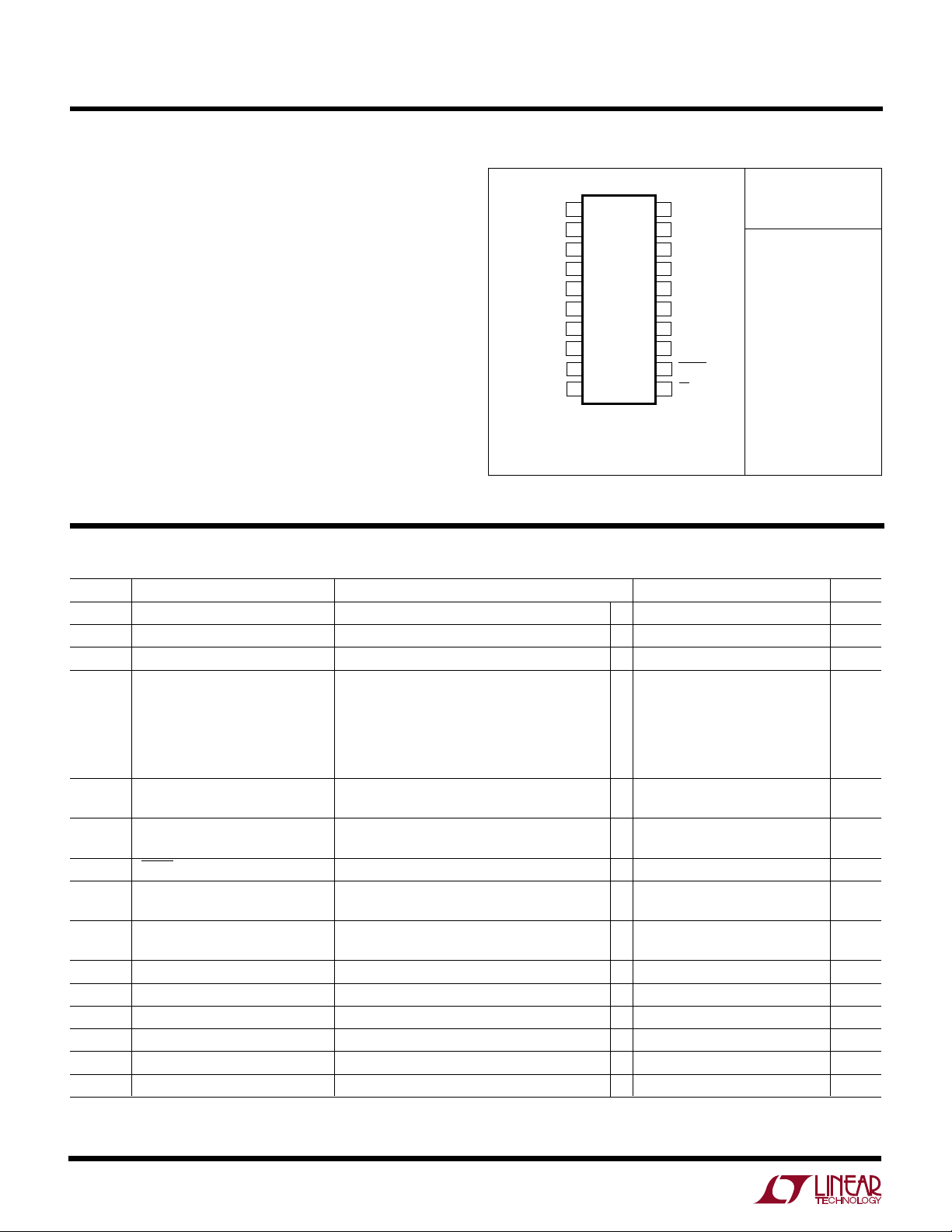

PACKAGE/ORDER INFORMATION

TOP VIEW

1

G2

2

PV

CC

3

GND

4

SGND

5

V

CC

6

SENSE

7

I

MAX

8

I

FB

9

SS

10

COMP

G PACKAGE

20-LEAD PLASTIC SSOP

T

= 125°C, θJA = 100°C/ W (G)

JMAX

= 125°C, θJA = 100°C/ W (SW)

T

JMAX

20-LEAD PLASTIC SO

G1

20

OUTEN

19

VID0

18

VID1

17

VID2

16

VID3

15

VID4

14

PWRGD

13

FAULT

12

OT

11

SW PACKAGE

Consult factory for Industrial and Military grade parts.

ORDER PART

NUMBER

LTC1553CG

LTC1553CSW

U

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

PV

V

V

CC

CC

FB

OUT

Supply Voltage ● 4.5 8 V

Supply Voltage for G1, G2 ● 18 V

Internal Feedback Voltage (Note 4) 1.265 V

1.8V Initial Output Voltage With Respect to Rated Output Voltage (Figure 2) – 27 (–1.5%) 27 (+1.5%) mV

2.8V Initial Output Voltage – 42 (–1.5%) 42 (+ 1.5%) mV

3.5V Initial Output Voltage – 52 (–1.5%) 52 (+1.5%) mV

1.8V Initial Output Voltage

2.8V Initial Output Voltage

3.5V Initial Output Voltage

∆V

OUT

Output Load Regulation I

Output Line Regulation V

V

PWRGD

Positive Power Good Trip Point % Above Output Voltage (Figure 2) ● 57 %

Negative Power Good Trip Point % Below Output Voltage (Figure 2)

V

FAULT

I

CC

FAULT Trip Point % Above Output Voltage (Figure 2) ● 12 15 20 %

Operating Supply Current OUTEN = VCC = 5V (Note 5) (Figure 3) ● 800 1200 µA

Shutdown Supply Current OUTEN = 0, VID0 to VID4 Floating (Figure 3)

I

PVCC

f

OSC

V

V

G

g

BW

SAWL

SAWH

ERR

mERR

ERR

Supply Current PVCC = 12V, OUTEN = VCC (Note 6) (Figure 3) 15 mA

Internal Oscillator Frequency (Figure 4) ● 250 300 350 kHz

V

at Minimum Duty Cycle (Note 4) 1.8 V

COMP

V

at Maximum Duty Cycle (Note 4) 2.8 V

COMP

Error Amplifier Open-Loop DC Gain (Note 7) ● 40 53 dB

Error Amplifier Transconductance (Note 7) ● 0.9 1.6 2.3 millimho

Error Amplifier –3dB Bandwidth COMP = Open (Note 4) 400 kHz

= 0 to 14A (Note 4) (Figure 2) –5 mV

OUT

= 4.75V to 5.25V, I

IN

= 12V, OUTEN = 0, VID0 to VID4 Floating 1 µA

PV

CC

= 0 (Note 4)(Figure 2) ±1mV

OUT

● – 36 (–2%) 36 (+2%) mV

● – 56 (–2%) 56 (+2%) mV

● – 70 (–2%) 70 (+2%) mV

● –7 –5 %

● 130 250 µA

2

Page 3

LTC1553

ELECTRICAL CHARACTERISTICS

VCC = 5V, PVCC = 12V, TA = 25°C, unless otherwise noted. (Note 3)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

IMAX

I

SS

I

SSIL

I

SSHIL

I

Sink Current V

MAX

Soft Start Source Current VSS = 0V, V

Maximum Soft Start Sink Current V

IMAX

SENSE

= V

= V

CC

IMAX

OUT

Under Current Limit (Notes 8, 9), V

Soft Start Sink Current Under Hard V

SENSE

= 0V, V

= 0V, V

, V

IMAX

= V

SS

IMAX

IFB

= VCC, V

CC

= VCC, V

● 150 180 220 µA

= V

CC

= 0V ● 30 60 150 µA

IFB

= 0V ● 20 45 mA

IFB

● –13 –10 –7 µA

Current Limit

t

SSHIL

t

PWRGD

t

PWRBAD

t

FAULT

t

OT

V

OT

V

OTDD

V

SHDN

tr, t

f

t

NOL

DC

MAX

V

IH

V

IL

R

IN

Hard Current Limit Hold Time V

Power Good Response Time↑ V

Power Good Response Time↓ V

FAULT Response Time V

= 0V, V

SENSE

SENSE

SENSE

SENSE

IMAX

↑ from 0V to Rated V

↓ from Rated V

↑ from Rated V

= 4V, V

↓ from 5V (Note 4) 500 µs

IFB

OUT

to 0V ● 200 500 1000 µs

OUT

to V

OUT

CC

● 0.5 1 2 ms

● 200 500 1000 µs

OT Response Time OUTEN↓, VID0 to VID4 = 0 (Note 10) (Figure 3) ● 15 40 60 µs

Over-Temperature Trip Point OUTEN↓, VID0 to VID4 = 0 (Note 10) (Figure 3) ● 1.9 2 2.12 V

Over-Temperature Driver Disable OUTEN↓, VID0 to VID4 = 0 (Note 10) (Figure 3) ● 1.6 1.7 1.8 V

Shutdown OUTEN↓, VID0 to VID4 = 0 (Note 10) (Figure 3) ● 0.8 V

Driver Rise and Fall Time (Figure 4) ● 90 150 ns

Driver Nonoverlap Time (Figure 4) ● 30 100 ns

Maximum G1 Duty Cycle (Figure 4) ● 77 84 88 %

VID0 to VID4 Input High Voltage ● 2V

VID0 to VID4 Input Low Voltage ● 0.8 V

VID0 to VID4 Internal Pull-Up ● 10 20 kΩ

Resistance

I

SINK

Digital Output Sink Current ● 10 mA

The ● denotes specifications which apply over the full operating

temperature range.

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: When I

is taken below GND, it will be clamped by an internal

FB

diode. This pin can handle input currents greater than 100mA below GND

without latchup. In the positive direction, it is not clamped to V

or PVCC.

CC

Note 3: All currents into device pins are positive; all currents out of the

device pins are negative. All voltages are referenced to ground unless

otherwise specified.

Note 4: This parameter is guaranteed by correlation and is not tested

directly.

Note 5: The LTC1553 goes into the shutdown mode if VID0 to VID4 are

floating. Due to the internal pull-up resistors, there will be an additional

0.25mA/pin if any of the VID0 to VID4 pins are pulled low.

Note 6: Supply current in normal operation is dominated by the current

needed to charge and discharge the external FET gates. This will vary with

the LTC1553 operating frequency, supply voltage and the external FETs

used.

Note 7: The open-loop DC gain and transconductance from the SENSE pin to

COMP pin will be (G

)(1.265/3.3) and (g

ERR

)(1.265/3.3) respectively.

mERR

Note 8: The current limiting amplifier can sink but cannot source current.

Under normal (not current limited) operation, the output current will be zero.

Note 9: Under typical soft current limit, the net soft start discharge current

will be 60µA (I

) + [–10µA(ISS)] = 50µ A. The soft start sink-to-source

SSIL

current ratio is designed to be 6:1.

Note 10: When VID0 to VID4 are all HIGH, the LTC1553 will be forced to

shut down internally. The OUTEN trip voltages are guaranteed by design for

all other input codes.

3

Page 4

LTC1553

OUTPUT CURRENT (A)

0

OUTPUT VOLTAGE (V)

2.825

4

1533 G03

2.820

2.815

2.810

2.805

2.800

2.795

2.790

2.785

2.780

2.775

123

5

67891011121314

REFER TO TYPICAL APPLICATION

CIRCUIT FIGURE 1

V

IN

= 5V, PVCC = 12V, TA = 25°C

TEMPERATURE (°C)

–50

OVER-TEMPERATURE TRIP POINT (V)

1.96

2.08

2.10

2.12

0

50

75

1553 G06

1.92

2.04

2.00

1.94

2.06

1.90

2.02

1.98

–25

25

100

125

UW

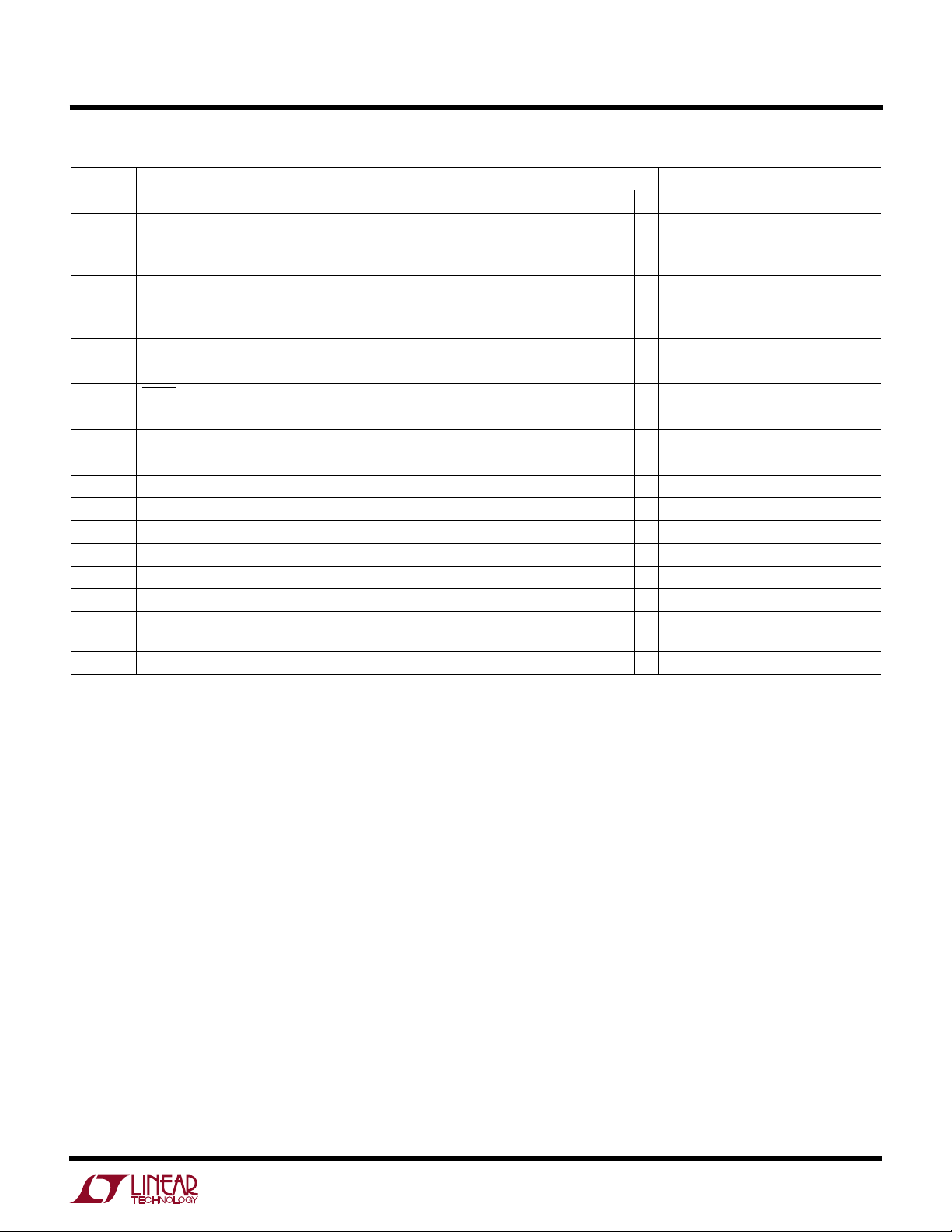

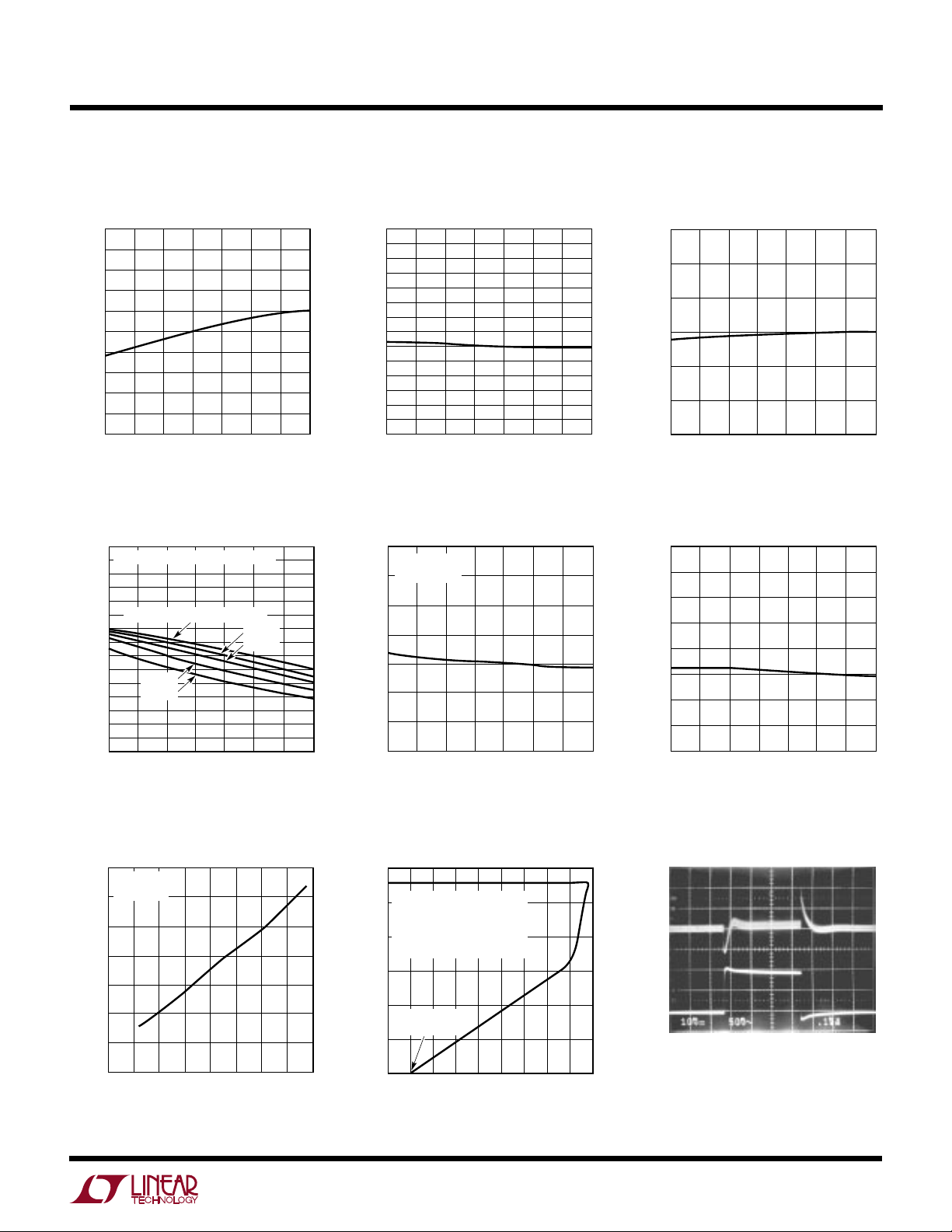

TYPICAL PERFORMANCE CHARACTERISTICS

Typical 2.8V V

140

TOTAL SAMPLE SIZE = 1500

120

100

80

60

NUMBER OF UNITS

40

20

0

2.775

2.785

25°C 100°C

OUTPUT VOLTAGE (V)

OUT

2.795

Distribution

2.805 2.815

1553 G01

2.825

Efficiency vs Load Current

100

90

A

B

80

70

REFER TO TYPICAL APPLICATION

60

CIRCUIT FIGURE 1

= 5V, PVCC = 12V, V

V

50

IN

= 330µF ×7, LO = 2µH

C

OUT

40

EFFICIENCY (%)

A: Q1 = 1 × SUD50N03-10

Q2 = 1 × SUD50N03-10

30

B: Q1 = 2 × SUD50N03-10

20

Q2 = 1 × SUD50N03-10

NO FAN

10

Q1 IS MOUNTED ON 1IN

0

0

2

0.3

4

LOAD CURRENT (A)

Line Regulation Output Temperature Drift

2.825

REFER TO TYPICAL APPLICATION

2.820

CIRCUIT FIGURE 1

OUTPUT = NO LOAD

2.815

2.810

2.805

2.800

2.795

2.790

OUTPUT VOLTAGE (V)

2.785

2.780

2.775

4.75

T

A

= 25°C

4.85

5.05

4.95

INPUT VOLTAGE (V)

5.15

5.25

1553 G04

2.860

2.850

2.840

2.830

2.820

2.810

2.800

2.790

2.780

OUTPUT VOLTAGE (V)

2.770

2.660

2.750

2.740

–50

–25

0

TEMPERATURE (°C)

= 2.8V,

OUT

2

COPPER AREA

6 8 10 12 14

1533 G02

50

25

75

100

1553 G05

Load Regulation

Over-Temperature Trip Point

vs Temperature

125

Over-Temperature Driver Disable

vs Temperature

1.80

1.78

1.76

1.74

1.72

1.70

1.68

1.66

1.64

1.62

OVER-TEMPERATURE DRIVER DISABLE (V)

1.60

–50

4

0

–25

TEMPERATURE (°C)

Error Amplifier Transconductance

vs Temperature

2.3

2.1

1.9

1.7

1.5

1.3

1.1

50

25

75

100

125

1553 G07

0.9

ERROR AMPLIFIER TRANSCONDUCTANCE (millimho)

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

1553 G08

Error Amplifier Open-Loop

DC Gain vs Temperature

60

55

50

45

ERROR AMPLIFIER OPEN-LOOP DC GAIN (dB)

40

–50

–25 0 25 50

TEMPERATURE (°C)

75 100 125

1553 G09

Page 5

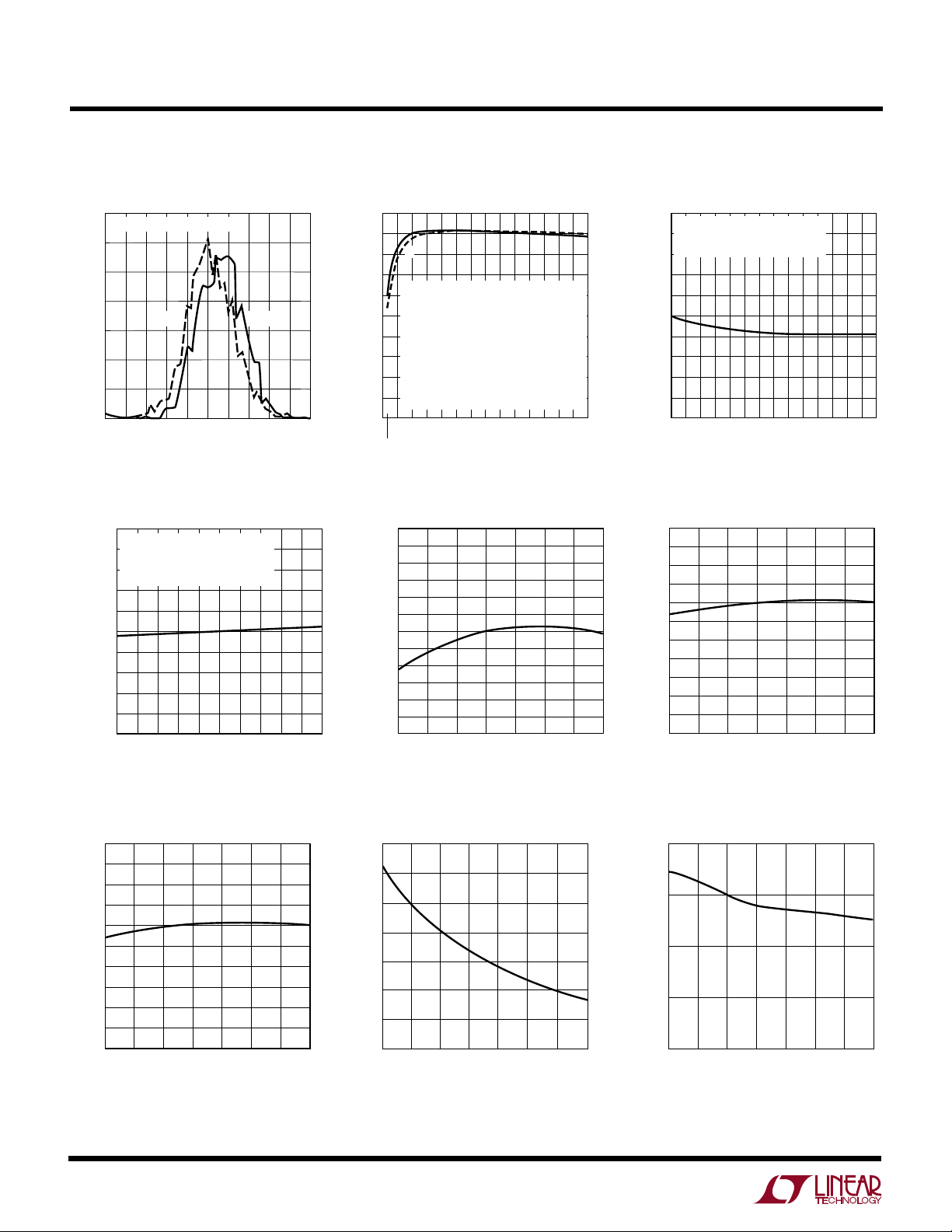

UW

TYPICAL PERFORMANCE CHARACTERISTICS

LTC1553

Oscillator Frequency

vs Temperature

350

340

330

320

310

300

290

280

270

OSCILLATOR FREQUENCY (kHz)

260

250

–50

–25

25

0

TEMPERATURE (°C)

Maximum G1 Duty Cycle

vs Temperature

92

OSCILLATOR FREQUENCY = 300kHz

90

88

G1, G2 CAPACITANCE = 1100pF

86

84

–50

5500pF

7700pF

–25 0

25 75

TEMPERATURE (°C)

82

80

MAXIMUM G1 DUTY CYCLE (%)

78

50

75

2200pF

3300pF

50 100 125

100

125

1553 G10

1553 G13

I

Sink Current

MAX

vs Temperature

220

210

200

190

180

SINK CURRENT (µA)

170

MAX

I

160

150

–50

0

–25

TEMPERATURE (°C)

25

VCC Operating Supply Current

vs Temperature

1.2

VCC = 5V

= 300kHz

f

OSC

1.1

1.0

0.9

0.8

0.7

OPERATING SUPPLY CURRENT (mA)

0.6

CC

V

0.5

–50

–25 0

25 75

TEMPERATURE (°C)

75

50 125

50 100 125

100

1553 G11

1553 G14

Soft Start Source Current

vs Temperature

–7

–8

–9

–10

–11

–12

SOFT START SOURCE CURRENT (µA)

–13

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

VCC Shutdown Supply Current

vs Temperature

250

225

200

175

150

125

100

SHUTDOWN SUPPLY CURRENT (mA)

75

CC

V

50

–25 0 50

–50

25

TEMPERATURE (°C)

1553 G12

75 100 125

1553 G15

PVCC Supply Current

vs Gate Capacitance

70

PVCC = 12V

= 25°C

T

A

60

50

40

30

SUPPLY CURRENT (mA)

20

CC

PV

10

0

2000 4000 8000

0

GATE CAPACITANCE (pF)

6000

1553 G16

Output Over Current Protection

3.0

Q1 CASE = 90°C, V

2.5

Q1 = 2 × MTD20N03HDL

Q2 = 1 × MTD20N03HDL

2.0

1.5

1.0

OUTPUT VOLTAGE (V)

0.5

= 2.7k, R

R

IMAX

SS CAP = 0.01µF

SHORT-CIRCUIT

CURRENT

0

26

0

4

OUTPUT CURRENT (A)

= 2.8V

OUT

= 20Ω,

IFB

10 18

8

Transient Response

50mV/DIV

5A/DIV

100µs/DIV

14

16

12

1553 G17

1553 G18

5

Page 6

LTC1553

PIN FUNCTIONS

UUU

G2 (Pin 1): Gate Drive for the Lower N-Channel MOSFET,

Q2. This output will swing from PVCC to GND. It will always

be low when G1 is high or when the output is disabled. To

prevent undershoot during a soft start cycle, G2 is held low

until G1 first goes high.

PVCC (Pin 2): Power Supply for G1 and G2. PVCC must be

connected to a potential of at least VIN + V

VIN = 5V, PVCC can be generated using a simple charge

pump connected to the switching node between Q1 and

Q2 (see Figure 7), or it can be connected to an auxiliary 12V

supply if one exists. For applications where VIN = 12V,

PVCC can be generated using a 17V charge pump (see

Figure 9).

GND (Pin 3): Power Ground. GND should be connected to

a low impedance ground plane in close proximity to the

source of Q2.

SGND (Pin 4): Signal Ground. SGND is connected to the

low power internal circuitry and should be connected to

the negative terminal of the output capacitor where it

returns to the ground plane. GND and SGND should be

shorted right at the LTC1553.

VCC (Pin 5): Power Supply. Power for the internal low

power circuity. VCC should be wired separately from the

drain of Q1 if they share the same supply. A 10µ F bypass

capacitor is recommended from this pin to SGND.

SENSE (Pin 6): Output Voltage Pin. Connect to the positive

terminal of the output capacitor. There is an internal 120k

resistor connected from this pin to SGND. SENSE is a very

sensitive pin; for optimum performance, connect an external 0.1µ F capacitor from this pin to SGND. By connecting

a small external resistor between the output capacitor and

the SENSE pin, the initial output voltage can be raised

slightly. Since the internal divider has a nominal impedance of 120kΩ, a 1200Ω series resistor will raise the

nominal output voltage by 1%. If an external resistor is

used, the value of the 0.1µF capacitor on the SENSE pin

must be greatly reduced or loop phase margin will suffer.

Set a time constant for the RC combination of approximately 0.1µ s. So, for example, with a 1200Ω resistor, set

C = 83pF. Use a standard 100pF capacitor.

GS(ON)Q1

. If

I

(Pin 7): Current Limit Threshold. Current limit is set

MAX

by the voltage drop across an external resistor connected

between the drain of Q1 and I

pull-down at I

IFB (Pin 8): Current Limit Sense Pin. Connect to the

switching node between the source of Q1 and the drain of

Q2. If IFB drops below I

will go into current limit. The current limit circuit can be

disabled by floating I

an external 10k resistor. For VIN = 12V, a 15V Zener diode

from IFB to GND is recommended to prevent the voltage

spike at IFB from exceeding the maximum voltage rating.

SS (Pin 9): Soft Start. Connect to an external capacitor to

implement a soft start function. During moderate overload

conditions, the soft start capacitor will be discharged

slowly in order to reduce the duty cycle. In hard current

limit, the soft start capacitor will be forced low immediately and the LTC1553 will rerun a complete soft start

cycle. CSS must be selected such that during power-up the

current through Q1 will not exceed the current limit value.

COMP (Pin 10): External Compensation. The COMP pin is

connected directly to the output of the error amplifier and

the input of the PWM comparator. An RC+ C network is

used at this node to compensate the feedback loop to

provide optimum transient response.

OT (Pin 11): Over-Temperature Fault. OT is an open-drain

output and will be pulled low if OUTEN is less than 2V. If

OUTEN = 0, OT pulls low.

FAULT (Pin 12): Overvoltage Fault. FAULT is an opendrain output. If V

output voltage, FAULT will go low and G1 and G2 will be

disabled. Once triggered, the LTC1553 will remain in this

state until the power supply is recycled or the OUTEN pin

is toggled. If OUTEN = 0, FAULT floats or is pulled high by

an external resistor.

PWRGD (Pin 13): Power Good. This is an open-drain

signal to indicate validity of output voltage. A high indicates that the output has settled to within ±5% of the rated

output for more than 1ms. PWRGD will go low if the output

is out of regulation for more than 500µs. If OUTEN = 0,

PWRGD pulls low.

MAX

.

MAX

and shorting IFB to VCC through

MAX

reaches 15% above the nominal

OUT

. There is a 180µ A internal

MAX

when G1 is on, the LTC1553

6

Page 7

UUU

PIN FUNCTIONS

LTC1553

VID0, VID1, VID2, VID3, VID4 (Pins 18, 17, 16, 15, 14):

Digital Voltage Select. TTL inputs used to set the regulated

output voltage required by the processor (Table 3). There

is an internal 20kΩ pull-up at each pin. When all five VID

n

pins are high or floating, the chip will shut down.

OUTEN (Pin 19): Output Enable. TTL input which enables

the output voltage. The external MOSFET temperature can

be monitored with an external thermistor as shown in

Figure 13. When the OUTEN input voltage drops below 2V,

W

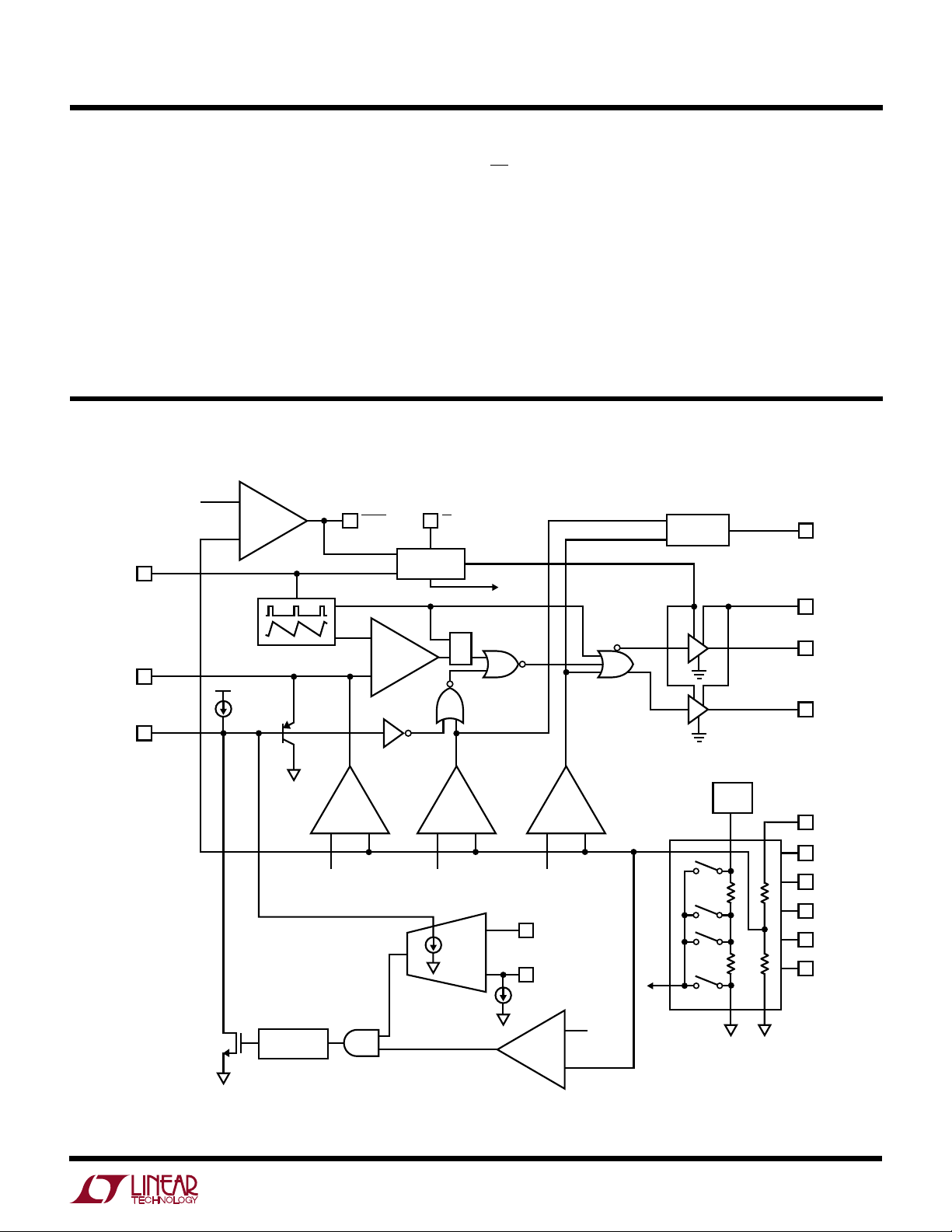

BLOCK DIAGRAM

OUTEN

COMP

19

10

115% V

REF

+

FC

FAULT

12

OT

11

–

LOGIC

–

PWM

+

R

S

OT trips. As OUTEN drops below 1.7V, the drivers are

internally disabled to prevent the MOSFETs from heating

further. If OUTEN is less than 1.2V for longer than 30µs,

the LTC1553 will enter shutdown mode. The internal

oscillator can be synchronized to a faster external clock by

applying the external clocking signal to the OUTEN pin.

G1 (Pin 20): Gate Drive for the Upper N-Channel MOSFET,

Q1. This output will swing from PVCC to GND. It will always

be low when G2 is high or the output is disabled.

DISDR

SYSTEM

POWER

DOWN

DELAY

13

2

20

PWRGD

PV

CC

G1

I

SS

SS

9

Q

SS

ERR

+

–

V

REF

HCL MONOMHCL

MIN

+

–

V

– 5% V

REF

–

CC

+

I

MAX

8

7

REF

LVC

I

I

FB

MAX

+ 5%

MAX

–+

+

0.5V

0.7V

REF

REF

FB

V

REF

/

BG

DAC

–

1

6

18

17

16

15

14

G2

SENSE

VID0

VID1

VID2

VID3

VID4

1553 BD

7

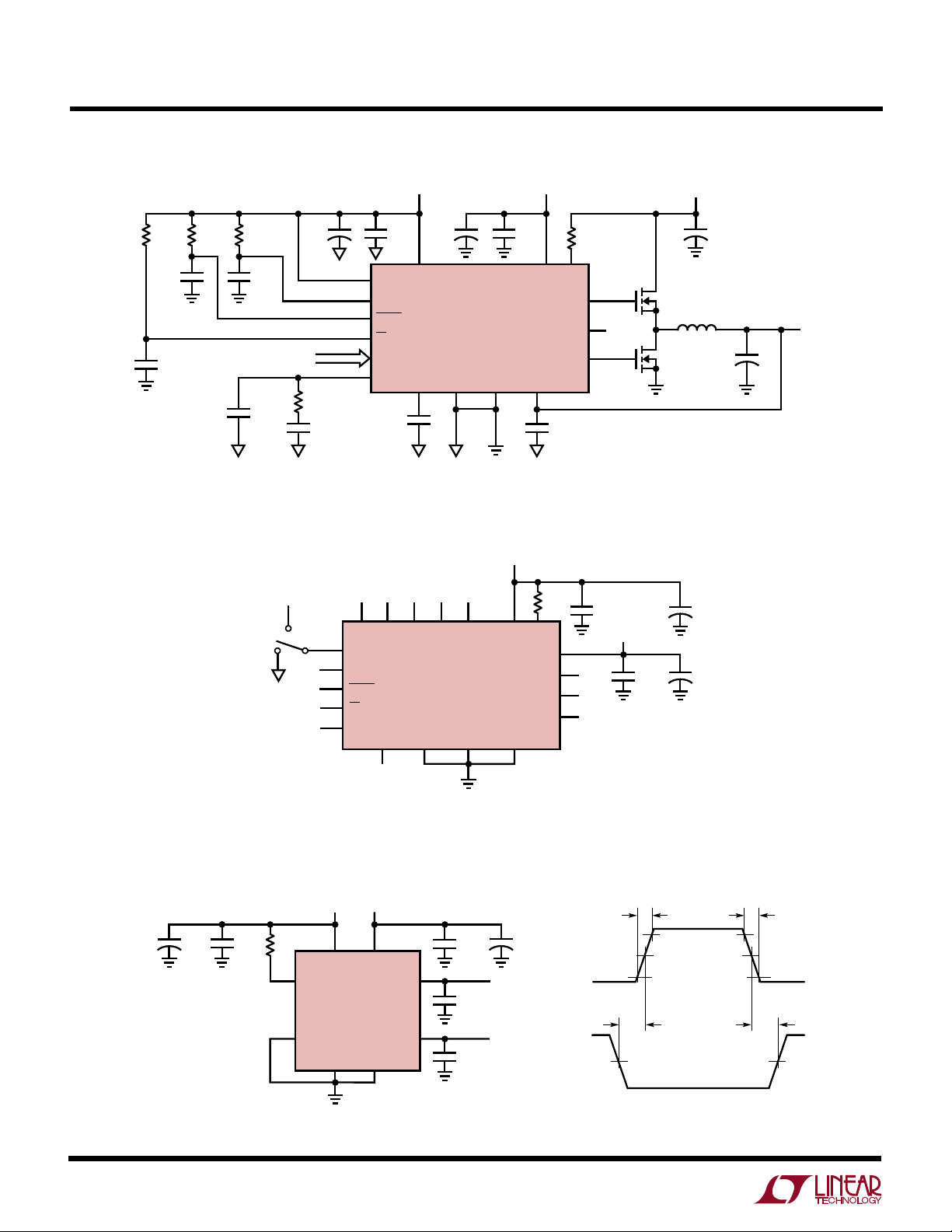

Page 8

LTC1553

TEST CIRCUITS

3k3k

0.1µF

PV

12V

CC

10k

V

IN

5V

CIN**

+

1200µF

× 4

V

CC

5V

3k

10µF

0.1µF

++

10µF

100pF

100pF

100pF

VID0 TO VID4

C1

150pF

V

CC

R

C

8.2k

CC

0.01µF

VID0 VID1 VID2 VID3 VID4

VID0 VID1 VID2 VID3 VID4

OUTEN

PWRGD

NC

FAULT

NC

OT

NC

COMP

NC

V

CC

OUTEN

PWRGD

FAULT

OT

VID0 TO VID4

COMP

SS SGND GND SENSE

0.1µF

LTC1553

Figure 2

V

CC

V

CC

LTC1553

SS SGND GND SENSE

PV

I

PV

I

MAX

I

FB

CC

G1

NC

I

MAX

G2

0.1µF

10k

FB

CC

G1

NC

NC

G2

NC

*SILICONIX SUD50N03-10

**SANYO 10MV1200GX

PANASONIC 12TS-2R5SP

††

0.1µF

PV

CC

0.1µF

L

O†

Q1*

2µH

15A

††

C

+

Q2*

†

COILTRONICS CTX02-13198 OR

AVX TPSE337M006R0100

OUT

330µF

× 7

+

10µF

+

10µF

V

OUT

1553 F02

8

NC

1553 F03

Figure 3

V

PV

CC

CC

5V

12V

+

10µF

0.1µF

10k

I

FB

SENSE

SGND GND

V

CC

LTC1553

PV

CC

G1

G2

0.1µF

5000pF

5000pF

+

10µF

G1 RISE/FALL

G2 RISE/FALL

t

r

90%

50%

10%

t

NOL

50% 50%

90%

50%

10%

t

f

t

NOL

1553 F04

Figure 4

Page 9

U U

FU CTIO TABLES

LTC1553

Table 1. OT Logic

OUTEN (V) OT*

< 2 0

> 2 1

Table 2. PWRGD and FAULT Logic

INPUT OUTPUT*

OUTEN V

0 X 010

1 < 95% 1 1 0

1 > 95% 1 1 1

1 >105% 1 1 0

1 > 115% 1 0 0

** OT FAULT PWRGD

SENSE

< 105%

Table 3. Rated Output Voltage

INPUT PIN

V

V

ID4

01111Disabled† (1.30)

01110Disabled† (1.35)

01101Disabled† (1.40)

01100Disabled† (1.45)

01011Disabled† (1.50)

01010Disabled† (1.55)

01001Disabled† (1.60)

01000Disabled† (1.65)

00111Disabled† (1.70)

00110Disabled† (1.75)

ID3

V

ID2

V

ID1

V

ID0

RATED OUTPUT

VOLTAGE (V)

Table 3. Rated Output Voltage (cont)

INPUT PIN

V

* With external pull-up resistor

** With respect to the output voltage selected in Table 3 as required by

†

X Don’t care

V

ID4

00101 1.80

00100 1.85

00011 1.90

00010 1.95

00001 2.00

00000 2.05

11111 SHDN

11110 2.1

11101 2.2

11100 2.3

11011 2.4

11010 2.5

11001 2.6

11000 2.7

10111 2.8

10110 2.9

10101 3.0

10100 3.1

10011 3.2

10010 3.3

10001 3.4

10000 3.5

Intel Specification VRM 8.2

These code selections are disabled in LTC1553

ID3

V

ID2

V

ID1

V

ID0

RATED OUTPUT

VOLTAGE (V)

9

Page 10

LTC1553

U

WUU

APPLICATIONS INFORMATION

OVERVIEW

The LTC1553 is a voltage feedback, synchronous switching regulator controller (see Block Diagram) designed for

use in high power, low voltage step-down (buck) converters. It is designed to satisfy the requirements of the Intel

Pentium II power supply specification. It includes an

on-chip DAC to control the output voltage, a PWM generator, a precision reference trimmed to ±1%, two high power

MOSFET gate drivers and all the necessary feedback and

control circuitry to form a complete switching regulator

circuit.

The LTC1553 includes a current limit sensing circuit that

uses the upper external power MOSFET as a current

sensing element, eliminating the need for an external

sense resistor. Once the current comparator, CC, detects

an overcurrent condition, the duty cycle is reduced by

discharging the soft start capacitor through a voltagecontrolled current source. Under severe overloads or

output short circuit conditions, the chip will be repeatedly

forced into soft start until the short is removed, preventing

the external components from being damaged. Under

output overvoltage conditions, the MOSFET drivers will be

disabled permanently until the chip power supply is

recycled or the OUTEN pin is toggled.

Output regulation can be monitored with the PWRGD pin

which in turn monitors the internal MIN and MAX comparators. If the output is ±5% beyond the selected value

for more than 500µs, the PWRGD output will be pulled

low. Once the output has settled within ±5% of the

selected value for more than 1ms, PWRGD will return

high.

THEORY OF OPERATION

Primary Feedback Loop

The regulator output voltage at the SENSE pin is divided

down internally by a resistor divider with a total resistance

of approximately 120kΩ. This divided down voltage is

subtracted from a reference voltage supplied by the DAC

output. The resulting error voltage is amplified by the error

amplifier and the output is compared to the oscillator ramp

waveform by the PWM comparator. This PWM signal

controls the external MOSFETs through G1 and G2. The

resulting chopped waveform is filtered by LO and C

closing the loop. Loop frequency compensation is achieved

with an external RC + C network at the COMP pin, which is

connected to the output node of the transconductance

amplifier.

OUT

OUTEN can optionally be connected to an external negative temperature coefficient (NTC) thermistor placed near

the external MOSFETs or the microprocessor. Three threshold levels are provided internally. When OUTEN drops to

2V, OT will trip, issuing a warning to the external CPU. If

the temperature continues to rise and the OUTEN input

drops to 1.7V, the G1 and G2 pins will be forced low. If

OUTEN is pulled below 1.2V, the LTC1553 will go into

shutdown mode, cutting the supply current to a minimum.

If thermal shutdown is not required, OUTEN can be connected to a conventional TTL enable signal. The freerunning 300kHz PWM frequency can be synchronized to

a faster external clock connected to OUTEN. Adjusting the

oscillator frequency can add flexibility in the external

component selection. See the Clock Synchronization

section.

MIN, MAX Feedback Loops

Two additional comparators in the feedback loop provide

high speed fault correction in situations where the ERR

amplifier may not respond quickly enough. MIN compares

the feedback signal FB to a voltage 60mV (5%) below the

internal reference. If FB is lower than the threshold of this

comparator, the MIN comparator overrides the ERR

amplifier and forces the loop to full duty cycle which is set

by the internal oscillator typically to 84%. Similarly, the

MAX comparator forces the output to 0% duty cycle if FB

is more than 5% above the internal reference. To prevent

these two comparators from triggering due to noise, the

MIN and MAX comparators’ response times are deliberately controlled so that they take two to three microseconds to respond. These two comparators help prevent

extreme output perturbations with fast output transients,

while allowing the main feedback loop to be optimally

compensated for stability.

10

Page 11

LTC1553

II

I

LMAX LOAD

RIPPLE

=+

2

Q1

180µA

G1

Q2

C

IN

L

O

V

OUT

1553 F05

C

OUT

R

IMAX

V

IN

–

+

CC

G2

20Ω

LTC1553

I

MAX

I

FB

8

7

+

+

APPLICATIONS INFORMATION

Soft Start and Current Limit

The LTC1553 includes a soft start circuit which is used for

initial start-up and during current limit operation. The SS

pin requires an external capacitor to GND with the value

determined by the required soft start time. An internal

10µA current source is included to charge the external SS

capacitor. During start-up, the COMP pin is clamped to a

diode drop above the voltage at the SS pin. This prevents

the error amplifier, ERR, from forcing the loop to maximum duty cycle. The LTC1553 will begin to operate at low

duty cycle as the SS pin rises above about 1.2V (V

1.8V). As SS continues to rise, QSS turns off and the error

amplifier begins to regulate the output. The MIN comparator is disabled when soft start is active to prevent it from

overriding the soft start function.

The LTC1553 includes yet another feedback loop to control operation in current limit. Just before every falling

edge of G1, the current comparator, CC, samples and

holds the voltage drop measured across the external

MOSFET, Q1, at the IFB pin. Note that when VIN = 12V, the

IFB pin requires an external Zener to GND to prevent

voltage transients at the switching node between Q1 and

Q2 from damaging internal structures. CC compares the

voltage at IFB to the voltage at the I

current rises, the measured voltage across Q1 increases

due to the drop across the R

at IFB drops below I

has exceeded the maximum level, CC starts to pull current

out of the external soft start capacitor, cutting the duty

cycle and controlling the output current level. The CC

comparator pulls current out of the SS pin in proportion to

the voltage difference between IFB and I

overload conditions, the SS pin will fall gradually, creating

a time delay before current limit takes effect. Very short,

mild overloads may not affect the output voltage at all.

More significant overload conditions will allow the SS pin

to reach a steady state, and the output will remain at a

reduced voltage until the overload is removed. Serious

overloads will generate a large overdrive at CC, allowing it

to pull SS down quickly and preventing damage to the

output components.

U

DS(ON)

, indicating that Q1’s drain current

MAX

WUU

pin. As the peak

MAX

of Q1. When the voltage

. Under minor

MAX

COMP

By using the R

of Q1 to measure the output current,

DS(ON)

the current limiting circuit eliminates an expensive discrete sense resistor that would otherwise be required. This

helps minimize the number of components in the high

current path. Due to switching noise and variation of

R

, the actual current limit trip point is not highly

DS(ON)

accurate. The current limiting circuitry is primarily meant

to prevent damage to the power supply circuitry during

fault conditions. The exact current level where the limiting

circuit begins to take effect will vary from unit to unit as the

≈

R

DS(ON)

of Q1 varies.

For a given current limit level, the external resistor from

I

to VIN can be determined by:

MAX

IR

R

IMAX

()( )

LMAX DS ON Q

=

()1

I

IMAX

where,

I

= Maximum load current

LOAD

I

f

= Inductor ripple current

RIPPLE

VV V

−

()()

IN OUT OUT

=

= LTC1553 oscillator frequency = 300kHz

OSC

fLV

()()()

OSC O IN

LO = Inductor value

R

DS(ON)Q1

I

IMAX

= Hot on-resistance of Q1 at I

= Internal 180µA sink current at I

Figure 5. Current Limit Setting

LMAX

MAX

11

Page 12

LTC1553

U

WUU

APPLICATIONS INFORMATION

Table 4. Recommended Minimum R

MAXIMUM OPERATING SUD50N03-10 MTD20N03HDL

LOAD CURRENT (A) SUD50N03-10 (TWO IN PARALLEL) MTD20N03HDL (TWO IN PARALLEL)

12 2.4 1.2 4.3 2.2

14 2.7 1.3 5.1 2.7

16 3.0 1.5 6.2 3.0

18 3.6 1.8 6.8 3.3

20 3.9 2.0 7.5 3.6

OUTEN and Thermistor Input

The LTC1553 includes a low power shutdown mode,

controlled by the logic at the OUTEN pin. A high at OUTEN

allows the part to operate normally. A low level at OUTEN

stops all internal switching, pulls COMP and SS to ground

internally and turns Q1 and Q2 off. OT and PWRGD are

pulled low, and FAULT is left floating. In shutdown, the

LTC1553 quiescent current will drop to about 130µ A. The

remaining current is used to keep the thermistor sensing

circuit at OUTEN alive. Note that the leakage current of

the external MOSFETs may add to the total shutdown

current consumed by the circuit, especially at elevated

temperature.

OUTEN is designed with multiple thresholds to allow it to

also be utilized for over-temperature protection. The power

MOSFET operating temperature can be monitored with an

external negative temperature coefficient (NTC) thermistor

mounted next to the external MOSFET which is expected

to run the hottest–– often the high-side device, Q1. Electrically, the thermistor should form a voltage divider with

another resistor, R1, connected to VCC. Their midpoint

should be connected to OUTEN (see Figure 6). As the

temperature increases, the OUTEN pin voltage is reduced.

Under normal operating conditions, the OUTEN pin should

stay above 2V. All circuits will function normally, and the

OT pin will remain in a high state. If the temperature gets

abnormally high, the OUTEN pin voltage will eventually

drop below 2V. OT will switch to a logic low, providing an

over-temperature warning to the system. As OUTEN drops

below 1.7V, the LTC1553 disables both FET drivers. If

Resistor (kΩ) vs Maximum Operating Load Current and External MOSFET Q1

IMAX

V

CC

5.6k

PENTIUM II

SYSTEM

NTC THERMISTOR

MOUNT IN CLOSE

THERMAL PROXIMITY

TO Q1

Figure 6. OUTEN Pin as a Thermistor Input

OT

V

CC

R1

R2

OUTEN

G1

LTC1553

G2

OUTEN is less than 1.2V, the LTC1553 will enter shutdown

mode. To activate any of these three modes, the OUTEN

voltage must drop below the respective threshold for

longer than 30µs.

Clock Synchronization

The internal oscillator can be synchronized to an external

clock by applying the external clocking signal to the

OUTEN pin. The synchronizing range extends from the

initial operating frequency up to 500kHz. If the external

frequency is much higher than the natural free-running

frequency, the peak-to-peak sawtooth amplitude within

the LTC1553 will decrease. Since the loop gain is inversely

proportional to the amplitude of the sawtooth, the compensation network may need to be adjusted slightly. Note

that the temperature sensing circuitry does not operate

when external synchronization is used.

V

IN

Q1

L

O

Q2

V

OUT

+

C

OUT

1553 F06

12

Page 13

LTC1553

Q1

G1

Q2

0.1µF

L

O

V

OUT

1553 F07

C

OUT

C

IN

V

IN

PV

CC

1N5248B

18V

1N5817

OPTIONAL FOR V

IN

> 5V

G2

LTC1553

20

1

2

+

+

Q1

Q2

0.1µF

0.1µF

10µF

L

O

V

OUT

1553 F08

C

OUT

C

IN

V

IN

1N5248B

18V

1N5817

LTC1553

1N5817 1N5817

+

G1

PV

CC

G2

20

1

2

+

+

U

WUU

APPLICATIONS INFORMATION

MOSFET Gate Drive

Power for the internal MOSFET drivers is supplied by

PVCC. This supply must be above the input supply voltage

by at least one power MOSFET V

tion. This higher voltage can be supplied with a separate

supply, or it can be generated using a simple charge pump

as shown in Figure 7. The 84% typical maximum duty

cycle ensures sufficient off-time to refresh the charge

pump during each cycle. Figure 8 shows a tripling charge

pump, which provides additional VGS overdrive to the

external MOSFETs. This circuit can be useful for standard

threshold MOSFETs which demand a higher turn-on voltage. An 18V Zener diode (1N5248B) is recommended with

tripler charge pump designs to ensure that PVCC never

exceeds the LTC1553’s 20V absolute maximum PV

voltage. This becomes more critical as VIN rises. With V

= 12V, the doubler circuit of Figure 7 will also exceed the

20V limit. Figure 9 shows an alternate 17V charge pump

derived from both the 5V and 12V supplies.

for efficient opera-

GS(ON)

CC

IN

Figure 7. Doubling Charge Pump

If the OUTEN pin is low, G1 and G2 are both held low to

prevent output voltage undershoot. As VCC and PV

CC

power up from a 0V condition, an internal undervoltage

lockup circuit prevents G1 and G2 from going high until

VCC reaches about 3.5V. If VCC powers up while PVCC is at

ground potential, the SS is forced to ground potential

internally. SS clamps the COMP pin low and prevents the

drivers from turning on. On power-up or recovery from

thermal shutdown, the drivers are designed such that G2

is held low until G1 first goes high.

Power MOSFETs

Two N-channel power MOSFETs are required for most

LTC1553 circuits. They should be selected based primarily on threshold and on-resistance considerations. The

required MOSFET threshold should be determined based

on the available power supply voltages and/or the complexity of the gate driver charge pump scheme. In 5V input

designs where a 12V supply is used to power PVCC,

standard MOSFETs with R

6V can be used with good results. However, logic level

devices will improve efficiency. The current drawn from

the 12V supply varies with the MOSFETs used and the

LTC1553 operating frequency, but is generally less than

50mA.

specified at VGS = 5V or

DS(ON)

Figure 8. Tripling Charge Pump

V

IN

0.1µF

12V

+

C

IN

Q1

L

O

Q2

V

OUT

+

C

OUT

1553 F09

1N5817

V

CC

5V

10Ω

PV

V

5

2

CC

C

VCC

LTC1553

1N5248B

18V

CC

G1

20

G2

1

Figure 9. 17V Charge Pump for VIN = 12V

13

Page 14

LTC1553

U

WUU

APPLICATIONS INFORMATION

The LTC1553 designs that use a 5V VIN voltage and a

doubler charge pump to generate PVCC will not provide

enough drive voltage to fully enhance standard power

MOSFETs. Under this condition, the effective MOSFET

R

FETs and reducing efficiency. Logic level FETs are a better

choice for 5V-only systems as shown in Figure 7 or 12V

input systems using the 17V charge pump of Figure 9.

They can be fully enhanced with the generated charge

pump voltage and will operate at maximum efficiency.

Note that doubler charge pump designs running from

supplies higher than 5V, and all tripler charge pump

designs, should include a Zener clamp diode at PVCC to

prevent transients from exceeding the absolute maximum

rating at that pin. See the MOSFET Gate Drive section for

more charge pump information.

Once the threshold voltage has been selected, R

should be chosen based on input and output voltage,

allowable power dissipation and maximum required output current. In a typical LTC1553 buck converter circuit

the average inductor current is equal to the output load

current. This current is always flowing through either Q1

or Q2 with the power dissipation split up according to the

duty cycle:

The R

be calculated by rearranging the relation P = I2R.

may be quite high, raising the dissipation in the

DS(ON)

V

DC Q

()

DC Q

()

DS(ON)

R

DS ON Q

()

OUT

1

=

V

IN

−

VV

()

V

21

=− =

OUT

V

IN

required for a given conduction loss can now

P

=

1

DC Q I

()

[]

IN OUT

V

IN

VP

MAX Q

1

()

1

()

MAX

()

=

2

VI

()()

IN MAX Q

OUT MAX

DS(ON)

1

()

2

P

should be calculated based primarily on required

MAX

efficiency or allowable thermal dissipation. A typical high

efficiency circuit designed for Pentium II with a 5V input

and a 2.8V, 11.2A output might allow no more than 4%

efficiency loss at full load for each MOSFET. Assuming

roughly 90% efficiency at this current level, this gives a

P

value of:

MAX

[(2.8)(11.2A/0.9)(0.04)] = 1.39W per FET

and a required R

R

DS ON Q

=

1

()

()( )

R

DS ON Q

()

Note also that while the required R

large MOSFETs, the dissipation numbers are only 1.39W

per device or less––large TO-220 packages and heat sinks

are not necessarily required in high efficiency applications. Siliconix Si4410DY or International Rectifier IRF7413

(both in SO-8) or Siliconix SUD50N03 or Motorola

MTD20N03HDL (both in D PAK) are small footprint surface mount devices with R

of gate drive that work well in LTC1553 circuits. With

higher output voltages, the R

significantly lower than that for Q2. These conditions can

often be met by paralleling two MOSFETs for Q1 and using

a single device for Q2. Note that using a higher P

in the R

cost and circuit efficiency while increasing MOSFET heat

sink requirements.

DS(ON)

=

2

calculations will generally decrease MOSFET

of:

DS(ON)

VW

5139

.

()( )

VA

2 8 11 2

..

VW

5139

()( )

VV A

−

528112

()()

..

DS(ON)

=

0 019

.

2

.

values below 0.03Ω at 5V

DS(ON)

Ω

=

0 025

.

2

values suggest

DS(ON)

of Q1 may need to be

Ω

value

MAX

R

DS ON Q

14

=

2

()

DC Q I

[]

P

MAX Q

2

()

2

()

()

MAX

=

2

VP

()

IN MAX Q

VV I

−

()()

IN OUT MAX

2

()

2

Page 15

LTC1553

U

WUU

APPLICATIONS INFORMATION

Table 5. Recommended MOSFETs for LTC1553 Applications

TYPICAL INPUT

R

PARTS AT 25°C (mΩ) RATED CURRENT (A) C

Siliconix SUD50N03-10 19 15 at 25°C 3200 1.8 175

TO-252 10 at 75°C

Siliconix Si4410DY 20 10 at 25°C 2700 — 150

SO-8 8 at 75°C

Motorola MTD20N03HDL 35 20 at 25°C 880 1.67 150

D PAK 16 at 100°C

SGS-Thomson STD20N03L 23 20 at 25°C 2300 2.5 175

D PAK 14 at 100°C

Motorola MTB75N03HDL 7.5 75 at 25°C 4025 1.0 150

DD PAK 59 at 100°C

IRF IRL3103S 14 56 at 25°C 1600 1.8 175

DD PAK 40 at 100°C

IRF IRLZ44 28 50 at 25°C 3300 1.0 175

TO-220 36 at 100°C

Fuji 2SK1388 37 35 at 25°C 1750 2.08 150

TO-220

DS(ON)

CAPACITANCE

(pF) θJC (°C/W) T

ISS

JMAX

(°C)

Note: Please refer to the manufacturer’s data sheet for testing conditions

and detail information.

Inductor Selection

The inductor is often the largest component in the LTC1553

design and should be chosen carefully. Inductor value and

type should be chosen based on output slew rate requirements, output ripple requirements and expected peak

current. Inductor value is primarily controlled by the

required current slew rate. The maximum rate of rise of

current in the inductor is set by its value, the input-tooutput voltage differential and the maximum duty cycle of

the LTC1553. In a typical 5V input, 2.8V output application, the maximum current slew rate will be:

VV

−

()

DC

MAX

IN OUT

183.

=

LL

A

s

µ

where L is the inductor value in µ H. With proper frequency

compensation, the combination of the inductor and output

capacitor will determine the transient recovery time. In

general, a smaller value inductor will improve transient

response at the expense of increased output ripple voltage

and inductor core saturation rating. A 2µ H inductor would

have a 0.9A/µs rise time in this application, resulting in a

5.5µs delay in responding to a 5A load current step. During

this 5.5µ s, the difference between the inductor current and

the output current must be made up by the output capacitor, causing a temporary voltage droop at the output. To

minimize this effect, the inductor value should usually be

in the 1µ H to 5µ H range for most typical 5V input LTC1553

circuits. To optimize performance, different combinations

of input and output voltages and expected loads may

require different inductor values.

Once the required value is known, the inductor core type

can be chosen based on peak current and efficiency

requirements. Peak current in the inductor will be equal to

the maximum output load current plus half of the peak-topeak inductor ripple current. Ripple current is set by the

inductor value, the input and output voltage and the

operating frequency. The ripple current is approximately

equal to:

VV V

−

()()

I

RIPPLE

f

= LTC1553 oscillator frequency = 300kHz

OSC

IN OUT OUT

=

fLV

()()()

OSC O IN

LO = Inductor value

15

Page 16

LTC1553

U

WUU

APPLICATIONS INFORMATION

Solving this equation with our typical 5V to 2.8V application with a 2µH inductor, we get:

22 056

..

()( )

kHz HAµ

300 2

()()

Peak inductor current at 11.2A load:

11 2

The ripple current should generally be between 10% and

40% of the output current. The inductor must be able to

withstand this peak current without saturating, and the

copper resistance in the winding should be kept as low as

possible to minimize resistive power loss. Note that in

circuits not employing the current limit function, the

current in the inductor may rise above this maximum

under short circuit or fault conditions; the inductor should

be sized accordingly to withstand this additional current.

Inductors with gradual saturation characteristics are often

the best choice.

Input and Output Capacitors

A typical LTC1553 design puts significant demands on

both the input and the output capacitors. During constant

load operation, a buck converter like the LTC1553 draws

square waves of current from the input supply at the

switching frequency. The peak current value is equal to the

output load current plus 1/2 peak-to-peak ripple current,

and the minimum value is zero. Most of this current is

supplied by the input bypass capacitor. The resulting RMS

current flow in the input capacitor will heat it up, causing

premature capacitor failure in extreme cases. Maximum

RMS current occurs with 50% PWM duty cycle, giving an

RMS current value equal to I

capacitor with an adequate ripple current rating must be

used to ensure reliable operation.

Note that capacitor manufacturers’ ripple current ratings

are often based on only 2000 hours (three months)

2

=

2

P-P

A

12 2..A

2

A+=

/2. A low ESR input

OUT

lifetime at rated temperature. Further derating of the input

capacitor ripple current beyond the manufacturer’s specification is recommended to extend the useful life of the

circuit. Lower operating temperature will have the largest

effect on capacitor longevity.

The output capacitor in a buck converter sees much less

ripple current under steady-state conditions than the input

capacitor. Peak-to-peak current is equal to that in the

inductor, usually 10% to 40% of the total load current.

Output capacitor duty places a premium not on power

dissipation but on ESR. During an output load transient,

the output capacitor must supply all of the additional load

current demanded by the load until the LTC1553 can

adjust the inductor current to the new value. Output

capacitor ESR results in a step in the output voltage equal

to the ESR value multiplied by the change in load current.

An 11A load step with a 0.05Ω ESR output capacitor will

result in a 550mV output voltage shift; this is 19.6% of the

output voltage for a 2.8V supply! Because of the strong

relationship between output capacitor ESR and output

load transient response, the output capacitor is usually

chosen for ESR, not for capacitance value; a capacitor with

suitable ESR will usually have a larger capacitance value

than is needed for energy storage.

Electrolytic capacitors rated for use in switching power

supplies with specified ripple current ratings and ESR can

be used effectively in LTC1553 applications. OS-CON

electrolytic capacitors from SANYO and other manufacturers give excellent performance and have a very high

performance/size ratio for electrolytic capacitors. Surface

mount applications can use either electrolytic or dry

tantalum capacitors. Tantalum capacitors must be surge

tested and specified for use in switching power supplies.

Low cost, generic tantalums are known to have very short

lives followed by explosive deaths in switching power

supply applications. AVX TPS series surface mount

devices are popular surge tested tantalum capacitors that

work well in LTC1553 applications.

A common way to lower ESR and raise ripple current

capability is to parallel several capacitors. A typical LTC1553

16

Page 17

LTC1553

fLC =

1

2π√(L

O

)(C

OUT

)

U

WUU

APPLICATIONS INFORMATION

application might exhibit 5A input ripple current. SANYO

OS-CON part number 10SA220M (220µ F/10V) capacitors

feature 2.3A allowable ripple current at 85°C; three in

parallel at the input (to withstand the input ripple current)

will meet the above requirements. Similarly, AVX

TPSE337M006R0100 (330µ F/6V) have a rated maximum

ESR of 0.1Ω; seven in parallel will lower the net output

capacitor ESR to 0.014Ω. For low cost application, SANYO

MV-GX series of capacitors can be used with acceptable

performance.

Feedback Loop Compensation

The LTC1553 voltage feedback loop is compensated at the

COMP pin, attached to the output node of the internal g

error amplifier. The feedback loop can generally be compensated properly with an RC + C network from COMP to

GND as shown in Figure 10a.

Loop stability is affected by the values of the inductor,

output capacitor, output capacitor ESR, error amplifier

transconductance and error amplifier compensation network. The inductor and the output capacitor creates a

double pole at the frequency:

m

Figure 10b shows the Bode plot of the overall transfer

function.

The compensation value used in this design is based on

the following criteria: fSW = 12fCO, fZ = fLC and fP = 5fCO. At

the closed-loop frequency fCO, the attenuation due the LC

filter and the input resistor divider is compensated by the

gain of the PWM modulator and the gain of the error

amplifier (g

)(RC). Although a mathematical approach

mERR

to frequency compensation can be used, the added

SENSE

6

LTC1553

COMP

10

R

C

C

C

Figure 10a. Compensation Pin Hook-Up

C1

–

ERR

+

DAC

1553 F10

The ESR of the output capacitor forms a zero at the

frequency:

f

ESR

=

2π(ESR)(C

1

)

OUT

The compensation network at the error amplifier output is

to provide enough phase margin at the 0dB crossover

frequency for the overall closed-loop transfer function.

The zero and pole from the compensation network are:

fZ =

2π(R

1

)(CC)

C

and

fP =

2π(R

1

)(C1)

C

respectively.

fSW = LTC1553 SWITCHING

FREQUENCY

= CLOSED-LOOP CROSSOVER

f

CO

LC

FREQUENCY

f

ESR

f

CO

–20dB/DECADE

f

P

FREQUENCY

1553 F10b

f

Z

LOOP GAIN

f

Figure 10b. Bode Plot of the LTC1553 Overall Transfer Function

17

Page 18

LTC1553

U

WUU

APPLICATIONS INFORMATION

complication of input and/or output filters, unknown

capacitor ESR, and gross operating point changes with

input voltage, load current variations, all suggest a more

practical empirical method. This can be done by injecting

a transient current at the load and using an RC network box

to iterate toward the final compensation values, or by

obtaining the optimum loop response using a network

analyzer to find the actual loop poles and zeros.

Table 6. Suggested Compensation Network for 5V Input

Application Using Multiple Paralleled 330µF AVX TPS Output

Capacitors

LO (µH) CO (µF) RC (kΩ)C

1 990 1.8 0.022 680

1 1980 3.6 0.01 330

1 4950 9.1 0.01 120

2.7 990 5.1 0.01 220

2.7 1980 10 0.01 120

2.7 4950 24 0.0047 47

5.6 990 10 0.01 120

5.6 1980 20 0.0047 56

5.6 4950 51 0.0036 22

(µF) C1 (pF)

C

the suggested values slightly because of board layout and

operating condition differences.

An alternate output capacitor is the Sanyo MV-GX series.

Using multiple parallel 1500µF Sanyo MV-GX capacitors

for the output capacitor, Table 8 shows the suggested

compensation component value for a 5V input application

based on the inductor and output capacitor values.

Table 8. Suggested Compensation Network for 5V Input

Application Using Multiple Paralleled 1500µF SANYO MV-GX

Output Capacitors

LO (µH) CO (µF) RC (kΩ)C

1 4500 4.3 0.022 270

1 6000 5.6 0.0047 220

1 9000 8.2 0.01 150

2.7 4500 11 0.01 100

2.7 6000 15 0.01 82

2.7 9000 22 0.01 56

5.6 4500 24 0.01 56

5.6 6000 30 0.0047 39

5.6 9000 47 0.0047 27

(µF) C1 (pF)

C

Table 7. Suggested Compensation Network for 12V Input

Application Using Multiple Paralleled 330µF AVX TPS Output

Capacitors

LO (µH) CO (µF) RC (kΩ)C

1 990 0.82 0.047 1500

1 1980 1.5 0.033 820

1 4950 3.9 0.022 330

2.7 990 2.2 0.033 560

2.7 1980 4.3 0.022 270

2.7 4950 10 0.01 120

5.6 990 4.3 0.022 270

5.6 1980 8.2 0.010 150

5.6 4950 22 0.010 56

(µF) C1 (pF)

C

Tables 6 and 7 show the suggested compensation components for 5V and 12V input applications based on the

inductor and output capacitor values. The values were

calculated using multiple paralleled 330µ F AVX TPS series

surface mount tantalum capacitors as the output capacitor. The optimum component values might deviate from

VID0 to VID4, PWRGD and FAULT

The digital inputs (VID0 to VID4) program the internal DAC

which in turn controls the output voltage. These digital

input controls are intended to be static and are not

designed for high speed switching. Forcing V

OUT

to step

from a high to a low voltage by changing the VIDn pins

quickly can cause FAULT to trip.

Figure 11 shows the relationship between the V

OUT

voltage, PWRGD and FAULT. To prevent PWRGD from interrupting the CPU unnecessarily, the LTC1553 has a built-in

t

PWRBAD

delay to prevent noise at the SENSE pin from

toggling PWRGD. The internal time delay is designed to

take about 500µs for PWRGD to go low and 1ms for it to

recover. Once PWRGD goes low, the internal circuitry

watches for the output voltage to exceed 115% of the rated

voltage. If this happens, FAULT will be triggered. Once

FAULT is triggered, G1 and G2 will be forced low immediately and the LTC1553 will remain in this state until V

CC

power supply is recycled or OUTEN is toggled.

18

Page 19

LTC1553

U

WUU

APPLICATIONS INFORMATION

15%

V

OUT

5%

RATED V

OUT

–5%

t

PWRBAD

PWRGD

FAULT

Figure 11. PWRGD and FAULT

t

PWRGD

LAYOUT CONSIDERATIONS

When laying out the printed circuit board, the following

checklist should be used to ensure proper operation of the

LTC1553. These items are also illustrated graphically in

the layout diagram of Figure 12. The thicker lines show the

high current paths. Note that at 10A current levels or

above, current density in the PC board itself is a serious

concern. Traces carrying high current should be as wide

as possible. For example, a PCB fabricated with 2oz copper

requires a minimum trace width of 0.15" to

carry 10A.

1. In general, layout should begin with the location of the

power devices. Be sure to orient the power circuitry so

that a clean power flow path is achieved. Conductor

widths should be maximized and lengths minimized.

After you are satisfied with the power path, the control

circuitry should be laid out. It is much easier to find

routes for the relatively small traces in the control

circuits than it is to find circuitous routes for high

current paths.

2. The GND and SGND pins should be shorted right at the

LTC1553. This helps to minimize internal ground

t

FAULT

1553 F11

disturbances in the LTC1553 and prevents differences

in ground potential from disrupting internal circuit

operation. This connection should then tie into the

ground plane at a single point, preferably at a fairly quiet

point in the circuit such as close to the output capacitors. This is not always practical, however, due to

physical constraints. Another reasonably good point to

make this connection is between the output capacitors

and the source connection of the low side FET Q2. Do

not tie this single point ground in the trace run between

the low side FET source and the input capacitor ground,

as this area of the ground plane will be very noisy.

3. The small signal resistors and capacitors for frequency

compensation and soft start should be located very

close to their respective pins and the ground ends

connected to the signal ground pin through a separate

trace. Do not connect these parts to the ground plane!

4. The VCC and PVCC decoupling capacitors should be as

close to the LTC1553 as possible. The 10µF bypass

capacitors shown at VCC and PVCC will help provide

optimum regulation performance.

5. The (+) plate of CIN should be connected as close as

possible to the drain of the upper MOSFET. An additional 1µF ceramic capacitor between VIN and power

ground is recommended.

6. The SENSE pin is very sensitive to pickup from the

switching node. Care should be taken to isolate SENSE

from possible capacitive coupling to the inductor switching signal. A 0.1µF is required between the SENSE pin

and the SGND pin next to the LTC1553.

7. OUTEN is a high impedance input and should be

externally pulled up to a logic HIGH for normal

operation.

8. Kelvin sense I

and IFB at Q1 drain and source pins.

MAX

19

Page 20

LTC1553

U

WUU

APPLICATIONS INFORMATION

V

IN

+

C

IN

L

V

OUT

O

+

C

OUT

BOLD LINES INDICATE

HIGH CURRENT PATHS

Q1

Q2

+

10µF

10µF

C

SS

R

+

IMAX

1

LTC1553

0.1µF

C

10

2

3

4

5

6

7

8

9

0.1µF

G2

PV

CC

GND

SGND

V

CC

SENSE

I

MAX

IFB

SS

COMP

PV

CC

0.1µF

R

IFB

R

C

C1

C

OUTEN

VID0

VID1

VID2

VID3

VID4

PWRGD

FAULT

20

G1

19

18

VID0

17

VID1

VID2

VID3

VID4

5.6k

5.6k

5.6k

1153 F12

16

15

14

13

12

11

OT

Figure 12. LTC1553 Layout Diagram

20

Page 21

LTC1553

U

WUU

APPLICATIONS INFORMATION

0.1µF

C1

150pF

5.6k5.6k

R

8.2k

C

CC

0.01µF

V

PWRGD

FAULT

OT

VID0 TO VID4

OUTEN

COMP

SS

C

SS

0.1µF

PENTIUM II

SYSTEM

DALE

NTHS-1206N02

MOUNT THERMISTER

IN CLOSE THERMAL

PROXIMITY TO Q1

5.6k

5

5V

1.8k

Figure 13. Single Supply LTC1553 5V to 1.8V-3.5V Application with Thermal Monitor

+

10µF

CC

LTC1553

SGND SENSE

I

MAX

GND

2.7k

V

IN

5V

+

CIN**

1N5817

PV

CC

G1

I

FB

G2

0.1µF

0.1µF

Q1*

20Ω

Q2*

*SILICONIX SUD50N03-10

**SANYO 10MV1200GX

†

COILTRONICS CTX02-13198 OR

PANASONIC 12TS-2R5SP

††

1200µF

× 4

L

O†

2µH

18A

††

C

+

OUT

330µF

× 7

AVX TPSE337M006R0100

v

OUT

1553 F13

21

Page 22

LTC1553

PACKAGE DESCRIPTION

U

Dimension in inches (millimeters) unless otherwise noted.

G Package

20-Lead Plastic SSOP (0.209)

(LTC DWG # 05-08-1640)

0.278 – 0.289*

(7.07 – 7.33)

1718 14 13 12 1115161920

0.301 – 0.311

(7.65 – 7.90)

0.205 – 0.212**

(5.20 – 5.38)

0° – 8°

0.005 – 0.009

(0.13 – 0.22)

*

DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSIONS DO NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

0.022 – 0.037

(0.55 – 0.95)

12345678910

0.0256

(0.65)

BSC

0.010 – 0.015

(0.25 – 0.38)

0.068 – 0.078

(1.73 – 1.99)

0.002 – 0.008

(0.05 – 0.21)

G20 SSOP 0595

22

Page 23

PACKAGE DESCRIPTION

U

Dimension in inches (millimeters) unless otherwise noted.

SW Package

20-Lead Plastic Small Outline (Wide 0.300)

(LTC DWG # 05-08-1620)

0.496 – 0.512*

(12.598 – 13.005)

19 18

20

16

17

14 13

15

LTC1553

1112

NOTE 1

0.291 – 0.299**

(7.391 – 7.595)

0.010 – 0.029

(0.254 – 0.737)

0.009 – 0.013

(0.229 – 0.330)

NOTE:

1. PIN 1 IDENT, NOTCH ON TOP AND CAVITIES ON THE BOTTOM OF PACKAGES ARE THE MANUFACTURING OPTIONS.

THE PART MAY BE SUPPLIED WITH OR WITHOUT ANY OF THE OPTIONS

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

*

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

**

NOTE 1

× 45°

0° – 8° TYP

0.016 – 0.050

(0.406 – 1.270)

0.093 – 0.104

(2.362 – 2.642)

0.050

(1.270)

2345678

1

TYP

0.014 – 0.019

(0.356 – 0.482)

TYP

0.394 – 0.419

(10.007 – 10.643)

910

0.037 – 0.045

(0.940 – 1.143)

0.004 – 0.012

(0.102 – 0.305)

S20 (WIDE) 0396

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

23

Page 24

LTC1553

TYPICAL APPLICATION

+

5.6k

5.6k

PENTIUM II

SYSTEM

5

NC

R

C1

6.2k

180pF

Figure 14. External Clock Synchronized 12V to 1.8V-3.5V Application

U

10µF

C

CC

0.022µF

0.1µF

V

PWRGD

FAULT

OT

VID0 TO VID4

OUTEN

COMP

C

SS

0.1µF

V

CC

5V

1N5817

10Ω

CC

LTC1553

SGND SENSE

SS

PV

GND

V

IN

12V

1N5248B

18V

CC

I

MAX

G1

I

G2

0.1µF

FB

5.1k

0.1µF

20Ω

1N5245B

15V

L

O†

Q1*

4µH

18A

Q2*

* MOTOROLA MTD20N03HDL

** SANYO 16MV1000GX

†

COILTRONICS CTX02-13199

††

AVX TPSE337M006R0100

CIN**

+

1000µF

× 4

v

OUT

††

C

OUT

330µF

× 6

1553 F14

+

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1142 Current Mode Dual Step-Down Switching Regulator Controller Dual Version of LTC1148

LTC1148 Current Mode Step-Down Switching Regulator Controller Synchronous, VIN ≤ 20V

LTC1149 Current Mode Step-Down Switching Regulator Controller Synchronous, VIN ≤ 48V, for Standard Threshold FETs

LTC1159 Current Mode Step-Down Switching Regulator Controller Synchronous, VIN ≤ 40V, for Logic Threshold FETs

LTC1266 Current Mode Step-Up/Down Switching Regulator Controller Synchronous N- or P-Channel FETs, Comparator/Low-Battery Detector

LTC1430 High Power Step-Down Switching Regulator Controller Synchronous N-Channel FETs, Voltage Mode

LTC1435 High Efficiency Low Noise Synchronous Step-Down Drive Synchronous N-Channel, VIN ≤ 36V

Switching Regulator

LTC1438 Dual High Efficiency Low Noise Synchronous Step-Down Dual LTC1435 with Power-On Reset

Switching Regulator

24

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417 ● (408) 432-1900

FAX: (408) 434-0507

●

TELEX: 499-3977 ● www.linear-tech.com

1553f LT/TP 0198 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1997

Loading...

Loading...