Page 1

FEATURES

Final Electrical Specifications

LTC1504

500mA Low Voltage

Step-Down Synchronous

Switching Regulator

U

DESCRIPTION

■

500mA Output Current at 3.3V Output

■

Up to 92% Peak Efficiency

■

Internal Reference Trimmed to 1%

■

Output Can Source or Sink Current

■

Requires as Few as Four External Components

■

Input Voltage Range: 4V to 10V

■

Adjustable Current Limit

■

Small SO-8 Package

■

200kHz Switching Frequency Can be

Synchronized Up to 500kHz

U

APPLICATIONS

■

Small Portable Digital Systems

■

Active Termination

■

Auxiliary Output Voltage Supplies

■

Minimum Part Count/Size Switchers

Daisy-Chained Control Outputs

U

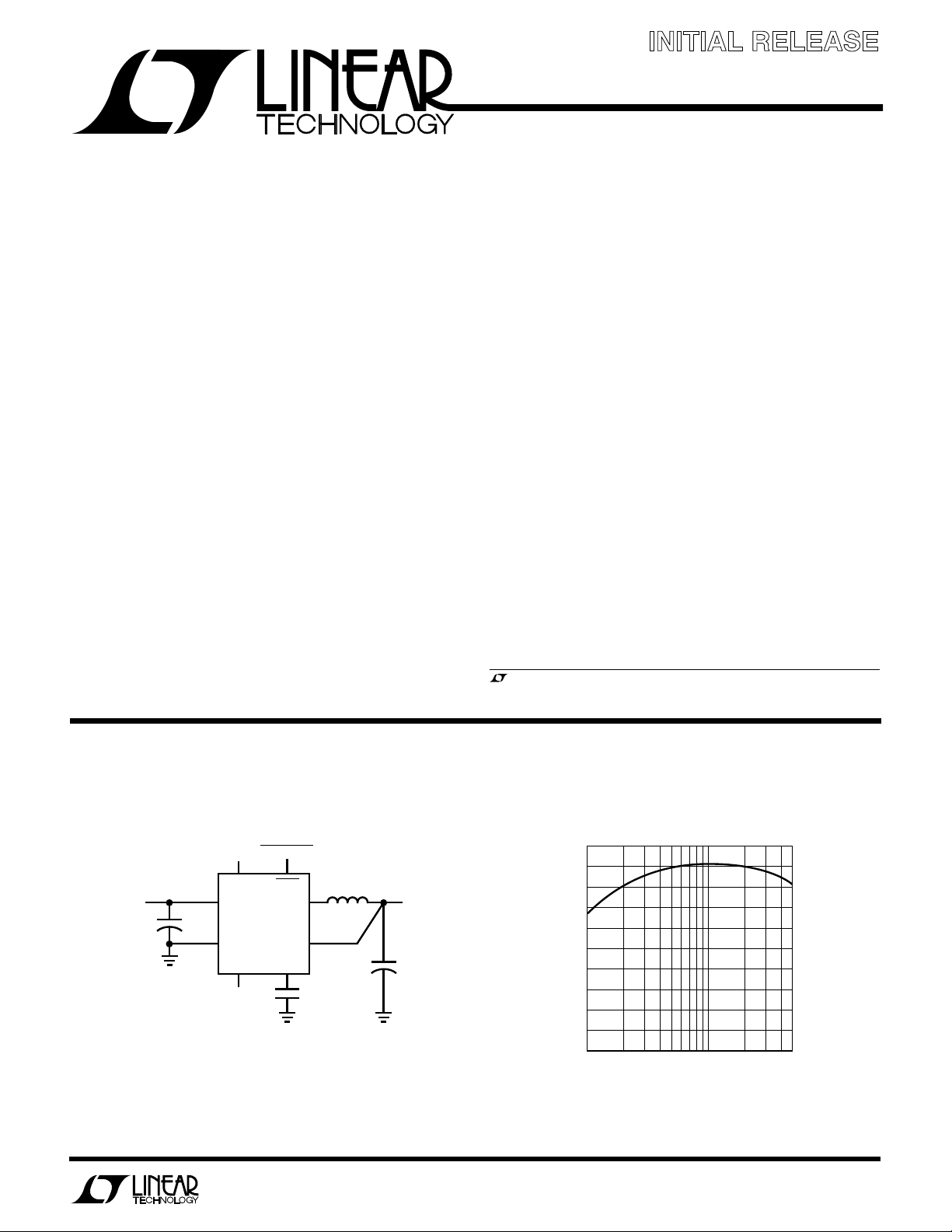

TYPICAL APPLICATION

The LTC®1504 is a self-contained, high efficiency synchronous buck switching regulator. It includes a pair of

on-chip 1.5Ω power switches, enabling it to supply up to

500mA of load current. Efficiency peaks at 92%, minimizing heat and wasted power. The synchronous buck architecture allows the output to source or sink current as

required to keep the output voltage in regulation.

The LTC1504 is available in adjustable and fixed 3.3V

output versions. An adjustable current limit circuit provides protection from overloads. The internal 1% reference combined with a sophisticated voltage feedback loop

provides optimum output voltage accuracy and fast load

transient response. The LTC1504 is specified to operate

with input voltages between 4V and 10V. Contact the LTC

factory for guaranteed specifications at 2.7V supply.

The LTC1504 is available in a plastic SO-8 package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Minimum Part Count 5V to 3.3V Regulator 5V to 3.3V Efficiency

5V

+

C

CIN: AVX TPSC226M016R0375

: AVX TAJC476M010

C

OUT

: COILTRONICS CTX50-1P

L

EXT

IN

SHUTDOWNNC

I

MAX

V

CC

LTC1504-3.3

GND

SS COMP

NC

100

90

SHDN

SENSE

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

SW

1000pF

L

EXT

3.3V AT 500mA

+

C

OUT

1504 • TA01

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

10

LOAD CURRENT (mA)

100 500

1504 • TA02

1

Page 2

LTC1504

WU

U

PACKAGE

/

O

RDER I FOR ATIO

WW

W

U

ABSOLUTE MAXIMUM RATINGS

(Note 1)

Supply Voltage (VCC to GND)................................... 10V

Peak Output Current (SW) .......................................±1A

Input Voltage (All Other Pins) ......... –0.3V to VCC + 0.3V

Operating Temperature Range ..................... 0°C to 70°C

Storage Temperature Range ................. –65°C to 150°C

I

MAX

V

SW

GND

Lead Temperature (Soldering, 10 sec).................. 300°C

*FB FOR LTC1504CS8, SENSE FOR LTC1504CS8-3.3

Consult factory for Industrial and Military grade parts.

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

V

FB

∆V

FB

V

SENSE

∆V

SENSE

I

CC

f

OSC

R

SW

V

IH

V

IL

I

IN

V

OH

V

OL

IOH, I

g

mV

A

V

g

mI

I

MAX

ISSSoft Start Source Current VSS = 0V ● –8 –12 –16 µA

tr, t

f

DC

MAX

Minimum Supply Voltage (Note 7) ● 4V

Feedback Voltage LTC1504CS8 ● 1.25 1.265 1.28 V

Feedback Voltage PSRR Figure 1, 4V ≤ VCC ≤ 10V, LTC1504CS8 ● 1.1 1.6 %

Sense Pin Voltage LTC1504CS8-3.3 ● 3.20 3.30 3.40 V

Sense Voltage PSRR Figure 1, 4V ≤ VCC ≤ 10V, LTC1504CS8-3.3 ● 1.2 1.8 %

Supply Current Figure 1, V

Figure 1, V

= 0V ● 1.0 20 µA

V

SHDN

Internal Oscillator Frequency ● 150 200 250 kHz

Internal Switch Resistance ● 1.3 2.0 Ω

SHDN Input High Voltage ● 2.4 V

SHDN Input Low Voltage ● 0.8 V

SHDN Input Current ● ±0.1 ±1 µA

Error Amplifier Positive Swing Figure 2 ● 4.5 4.95 V

Error Amplifier Negative Swing Figure 2 ● 0.05 0.5 V

Error Amplifier Output Current Figure 2 ● ±50 ±100 ±200 µA

OL

Error Amplifier Transconductance (Note 5) ● 350 600 1100 µmho

Error Amplifier DC Gain (Note 5) ● 40 48 dB

I

Amplifier Transconductance (Note 6) 1000 2000 3000 µmho

LIM

I

Sink Current V

MAX

Output Switch Rise/Fall Time ● 550 ns

Maximum Duty Cycle V

IMAX

COMP

= V

= V

VCC = 5V, TA = 25°C unless otherwise specified. (Note 2)

SHDN

SHDN

CC

CC

= VCC, I

= VCC, I

= 0 (Note 4) 3 mA

OUT

= 0, VFB/V

OUT

SENSE

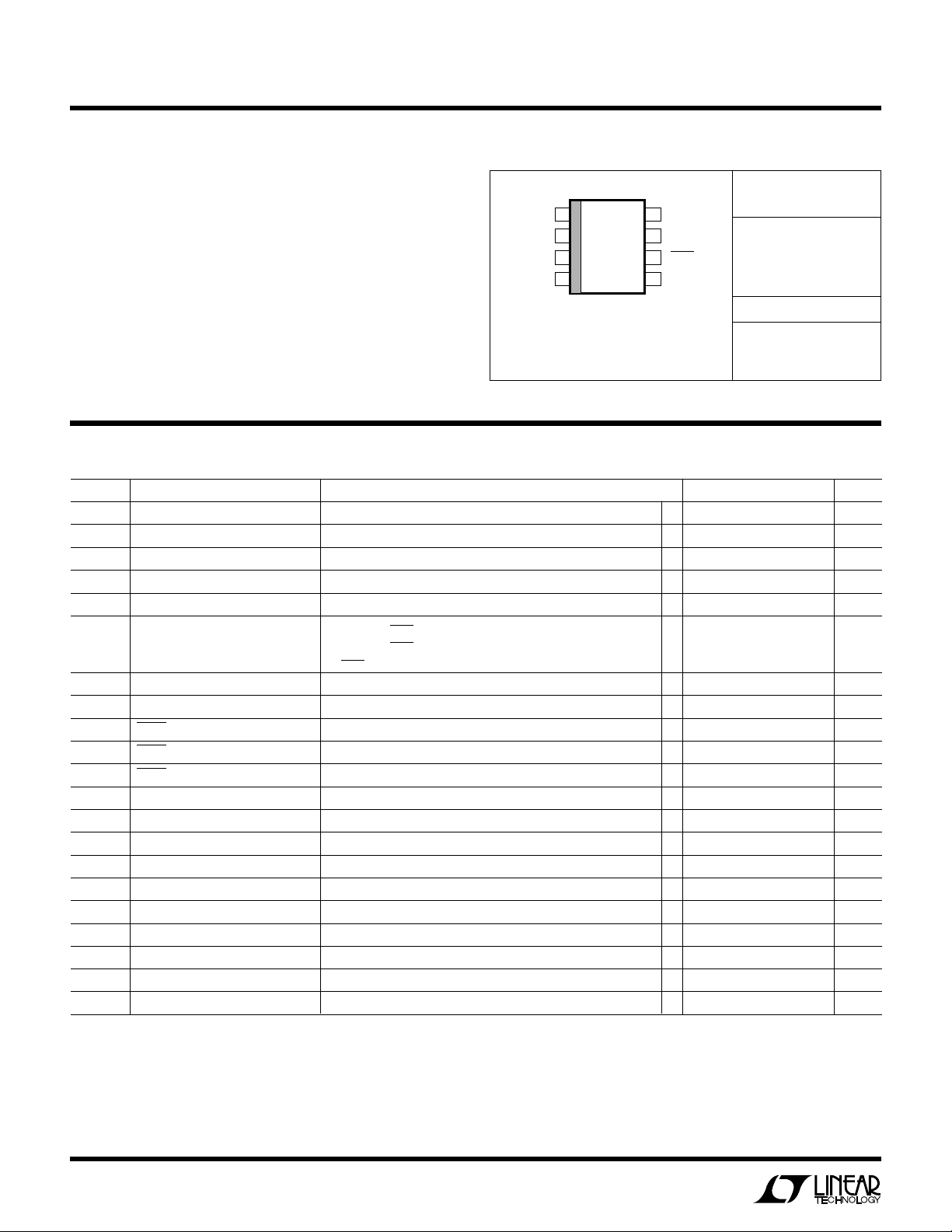

TOP VIEW

1

2

CC

3

4

S8 PACKAGE

8-LEAD PLASTIC SO

T

= 115°C, θJA = 90°C/W

JMAX

= VCC (Note 4) ● 0.3 0.6 mA

COMP

8

SS

7

SHDN

6

FB/SENSE*

5

● 81216 µA

● 84 90 %

ORDER PART

NUMBER

LTC1504CS8

LTC1504CS8-3.3

S8 PART MARKING

1504

15043

2

Page 3

ELECTRICAL CHARACTERISTICS

R

IMAX

(Ω)

10k

CURRENT LIMIT THRESHOLD (mA)

700

600

500

400

300

200

100

0

100k

1504 • TPC04

TA = 25°C

V

CC

= 5V

TEMPERATURE (°C)

–50 –25 0 25 50 75 100 125

SUPPLY CURRENT (mA)

10

1

0.1

1504 • TPC02

VFB = V

OUT

VFB = V

CC

VCC = 5V

I

OUT

= 0

LTC1504

The ● denotes specifications which apply over the full operating

temperature range.

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: All currents into device pins are positive; all currents out of device

pins are negative. All voltages are referenced to ground unless otherwise

specified.

Note 3: This parameter is guaranteed by correlation and is not tested

the output stage will stop switching and the static quiescent current can be

observed. With FB or SENSE hooked up normally, the output stage will be

switching and total dynamic supply current can be measured.

Note 5: Fixed output parts will appear to have g

lower than the specified values, due to the internal divider resistors.

Note 6: The I

(not current limited) operation, the I

Note 7: Contact factory for guaranteed specifications at 2.7V supply.

directly.

Note 4: LTC1504 quiescent current is dominated by the gate drive current

drawn by the onboard power switches. With FB or SENSE pulled to V

W

U

CC

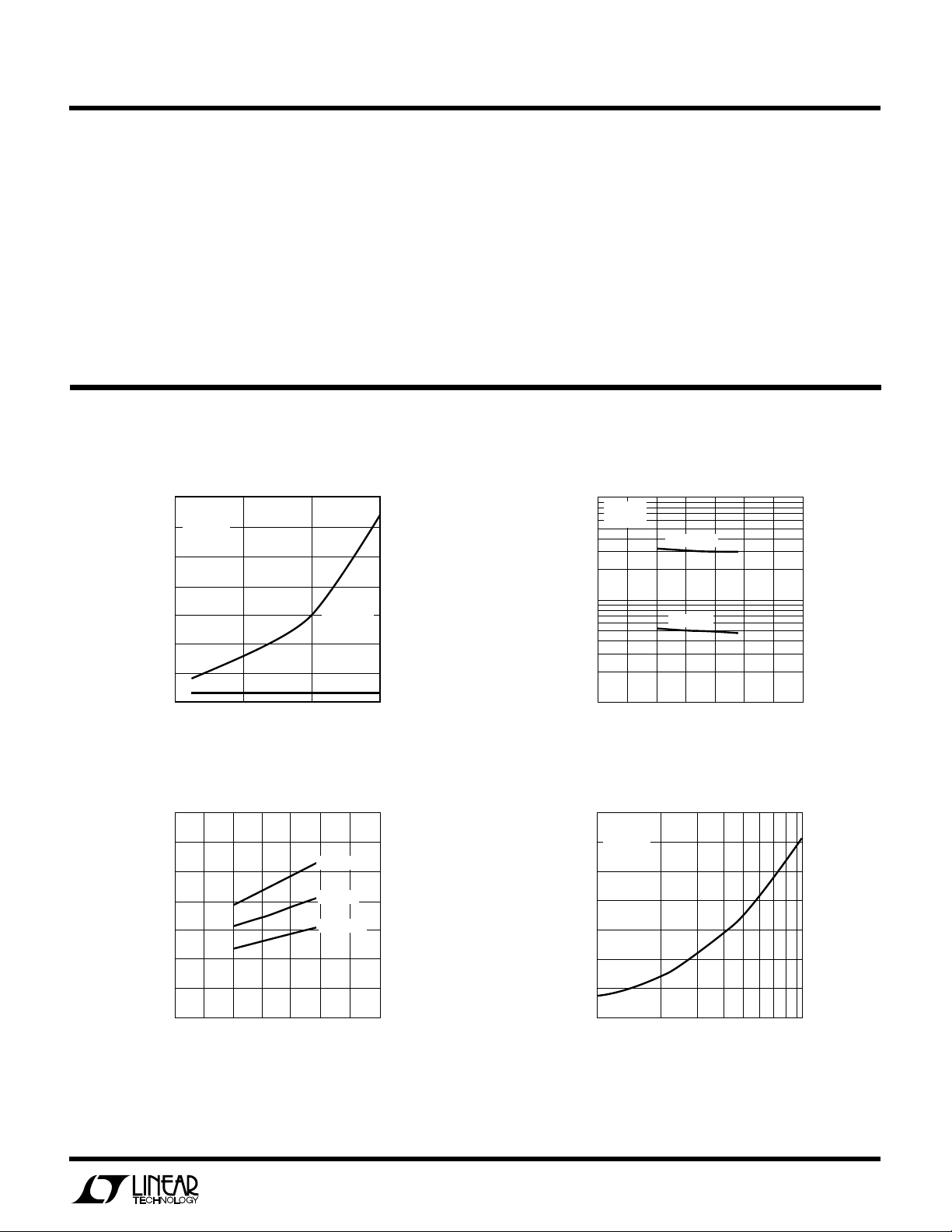

TYPICAL PERFORMANCE CHARACTERISTICS

Supply Current vs Supply Voltage

14

TA = 25°C

= 0

I

OUT

12

10

8

6

VFB = V

OUT

and AV values 2.6 times

mV

amplifier can sink but not source current. Under normal

LIM

output current will be zero.

LIM

Supply Current vs Temperature

SUPPLY CURRENT (mA)

3.5

3.0

2.5

2.0

1.5

1.0

SWITCH ON-RESISTANCE (Ω)

0.5

4

2

0

2.5

VFB = V

CC

5

SUPPLY VOLTAGE (V)

Switch On-Resistance vs

Temperature

0

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

7.5 10

1504 • TPC01

VCC = 3.3V

VCC = 5V

VCC = 10V

1504 • TPC03

Current Limit Threshold vs R

IMAX

3

Page 4

LTC1504

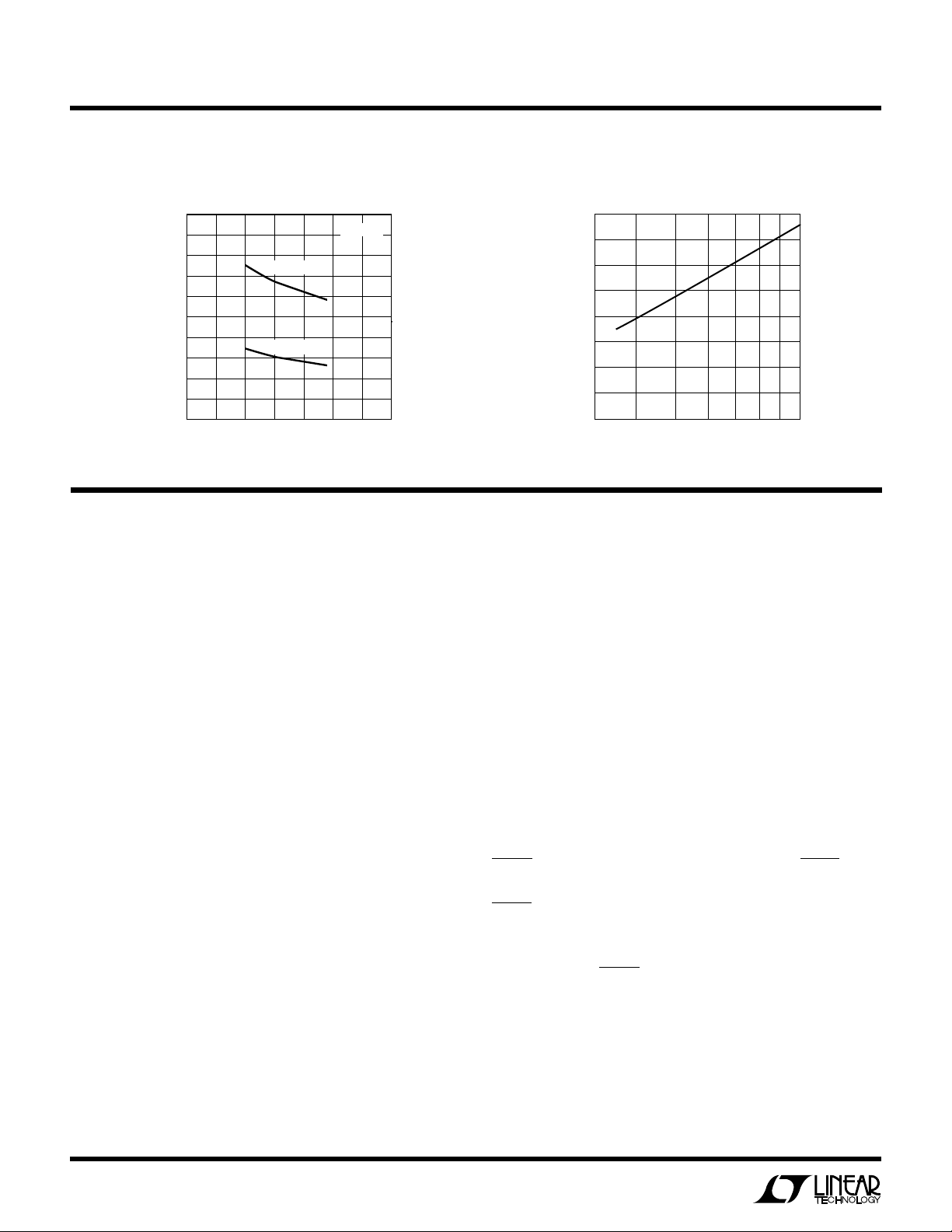

SUPPLY VOLTAGE (V)

357

SHUTDOWN PIN THRESHOLD (V)

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

10

1504 • TPC07

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

Current Limit Threshold vs

Temperature

500

450

400

350

300

250

200

150

100

CURRENT LIMIT THRESHOLD (mA)

50

0

–50

PIN FUNCTIONS

I

(Pin 1): Current Limit Set. Connect a resistor from

MAX

VCC to I

12µA current source from I

drop across this resistor. This voltage is compared to the

voltage drop across the internal high-side switch (Q1)

while it is turned on. See the Applications Information

section for more information. To disable current limit,

leave I

VCC (Pin 2): Power Supply Input. Connect to a power

supply voltage between 4V and 10V. VCC requires a low

impedance bypass capacitor to ground, located as close

as possible to the LTC1504. See the Applications Information section for details on capacitor selection and

placement.

SW (Pin 3): Power Switch Output. This is the switched

node of the buck circuit. Connect SW to one end of the

external inductor. The other end of the inductor should be

connected to C

voltage. Avoid shorting SW to GND or VCC.

GND (Pin 4): Ground. Connect to a low impedance ground.

The input and output bypass capacitors and the feedback

resistor divider (adjustable parts only) should be grounded

as close to this pin as possible. Pin 4 acts as a heat sink

in the LTC1504 S0-8 package and should be connected to

4

to set the current limit threshold. An internal

MAX

floating.

MAX

OUT

VCC = 5V

R

= 47k

IMAX

R

= 22k

IMAX

–25 0 25 50 75

TEMPERATURE (°C)

100

1504 • TPC05

125

UUU

to GND sets the voltage

MAX

and becomes the regulated output

Shutdown Threshold vs

Supply Voltage

as large a copper area as possible to improve thermal

dissipation. See the Thermal Considerations section for

more information.

FB (LTC1504CS8) (Pin 5): Feedback. Connect FB to a

resistor divider from V

to GND to set the regulated

OUT

output voltage. The LTC1504CS8 feedback loop will servo

the FB pin to 1.265V.

SENSE (LTC1504CS8-3.3) (Pin 5): Output Voltage Sense.

Connect directly to the output voltage node. The

LTC1504CS8-3.3 feedback loop will servo SENSE to 3.3V.

SENSE is connected to an internal resistor divider which

will load any external dividers. For output voltages other

than 3.3V, use the LTC1504CS8.

SHDN (Pin 6): Shutdown, Active Low. When SHDN is at a

logic High, the LTC1504 will operate normally. When

SHDN is Low, the LTC1504 ceases all internal operation

and supply current drops below 1µ A. In shutdown, the SW

pin is pulled low. This ensures that the output is actively

shut off when SHDN is asserted, but it prevents other

supplies from providing power to the output when the

LTC1504 is inactive. See the Applications Information

section for more details.

SS (Pin 7): Soft Start. Connect an external capacitor

(usually 0.1µ F) from SS to GND to limit the output rise time

Page 5

UUU

PIN FUNCTIONS

LTC1504

during power-up. CSS also compensates the current limit

loop, allowing the LTC1504 to enter and exit current limit

cleanly. See the Applications Information section for more

details.

W

BLOCK DIAGRAM

SHDN

COMP

SAW

12V

SS

I

LIM

–+

TO INTERNAL BLOCKS

–

+

FB

+–

PWM

MIN

+–

COMP (Pin 8): External Compensation. An external RC

network should be connected to COMP to compensate the

feedback loop. COMP is connected to the output of the

internal error amplifier.

V

CC

Q1

SW

Q2

MAX

+–

I

MAX

TEST CIRCUITS

V

CC

+

C

IN

CIN: AVX TPSE107M016R0125

: SANYO 16CV220GX

C

OUT

: COILCRAFT D03316-473

L

EXT

1µF

12V

NC

I

SHDN

MAX

V

CC

LTC1504

GNDSWFB/SENSE

SS COMP

0.1µF

Figure 1

7.5k

0.01µF

FB

20.4k

12.6k

(ADJ ONLY)

SENSE

(–3.3V ONLY)

1504 • BD

–

+

40mV

V

REF

+

–

1.265V

+

40mV

–

Figure 3. Block Diagram

V

REF

A: TEST V

B: TEST V

LTC1504

–

+

, IOL

OL

, I

OH

OH

COMP

1504 • TC02

L

EXT

+

220pF

V

OUT

C

OUT

1504 • TC01

A

FB/SENSE

B

Figure 2

5

Page 6

LTC1504

U

WUU

APPLICATIONS INFORMATION

OVERVIEW

The LTC1504 is a complete synchronous switching regulator controller (see Block Diagram). It includes two

on-chip 1.5Ω power MOSFETs, eliminating the need for

external power devices and minimizing external parts

count. The internal switches are set up as a synchronous

buck converter with a P-channel device (Q1) from the

input supply to the switching node and an N-channel

device (Q2) as the synchronous rectifier device from the

switching node to ground. An external inductor, input and

output bypass capacitors and the compensation network

complete the control loop. The LTC1504 adjustable output

parts require an additional pair of resistors to set the

output voltage. The LTC1504-3.3 parts include an onboard

resistor divider preset to a 3.3V output voltage. A functional 3.3V output regulator can be constructed with an

LTC1504-3.3 and as few as four external components.

The LTC1504 feedback loop includes a precision reference

trimmed to 1% (V

feedback amplifier (FB) and an onboard PWM generator

(SAW and PWM). Two additional feedback comparators

(MIN and MAX) monitor the feedback voltage and override

the primary feedback amplifier when the regulated out falls

outside a ±3% window, improving transient response.

The internal sawtooth oscillator typically runs at 200kHz.

Q1 and Q2 are capable of carrying peak currents in excess

of 500mA, with the continuous output power level limited

primarily by the thermal dissipation of the SO-8 package.

With a 5V input and a 3.3V output, the LTC1504 can supply

500mA of continuous output current with an appropriate

layout. An on-chip current limit circuit, set with a single

external resistor, can be used to help limit power dissipation. See the Thermal Considerations section for more

information.

Theory of Operation

The LTC1504 primary feedback loop consists of the main

error amplifier FB, the PWM generator, the output drive

logic and the power switches. The loop is closed with the

external inductor and the output bypass capacitor. The

feedback amplifier senses the output voltage directly at the

SENSE pin for fixed output versions or through an external

), a wide bandwidth transconductance

REF

resistor divider in the adjustable output version. This

feedback voltage is compared to the 1.265V internal

reference voltage by FB and an error signal is generated at

the COMP pin. COMP is a high impedance node that is

brought out to an external pin for optimizing the loop

compensation.

COMP is compared to a 200kHz sawtooth wave by comparator PWM. This raw pulse-width modulated signal is

logically combined with the outputs of the transient comparators MIN and MAX before reaching the output stage.

The output stage generates nonoverlapping drive for the

onboard P- and N-channel power MOSFETs, which drive

the SW pin with a low impedance image of the PWM

waveform. Typical open-loop output impedance at SW is

between 1Ω and 3Ω, depending on supply voltage. This

high power pulse train is filtered by the external inductor

and capacitor, providing a steady DC value at the output

node. This node returns to FB or SENSE, closing the loop.

The MIN and MAX comparators in the feedback loop

provide high speed fault correction in situations where the

FB amplifier may not respond quickly enough. MIN compares the feedback signal to a voltage 40mV (3%) below

the internal reference. At this point, MIN overrides the FB

amplifier and forces the loop to full duty cycle. Similarly,

MAX monitors the output voltage at 3% above the internal

reference and forces the output to 0% duty cycle when

tripped. These two comparators prevent extreme output

perturbations with fast output transients, while allowing

the main feedback loop to be optimally compensated for

stability.

The LTC1504 includes yet another feedback loop that

controls operation in current limit. The I

monitors the voltage at the SW pin while Q1 is on. It

compares this voltage to the voltage at the I

peak current through Q1 rises, the voltage drop across it

due to its RON increases proportionally. When SW drops

below I

creased beyond the desired value, I

controlled amount of current out of SS, the external soft

start pin. As SS falls, it pulls COMP down with it, limiting

the duty cycle and reducing the output voltage to control

the current. The speed at which the current limit circuit

reacts is set by the value of the external soft start capacitor.

, indicating the current through Q1 has in-

MAX

LIM

amplifier

LIM

pin. As the

MAX

starts pulling a

6

Page 7

LTC1504

U

WUU

APPLICATIONS INFORMATION

EXTERNAL COMPONENT SELECTION

External components required by the LTC1504 fall into

three categories: input bypass, output filtering and compensation. Additional components to set up soft start and

current limit are usually included as well. A minimum

LTC1504 circuit can be constructed with as few as four

external components; a circuit that utilizes all of the

LTC1504s functionality usually includes eight or nine

external components, with two additional feedback resistors required for adjustable parts. See the Typical Applications section for examples of external component hookup.

Input Bypass

The input bypass capacitor is critical to proper LTC1504

operation. The LTC1504 includes a precision reference

and a pair of high power switches feeding from the same

VCC pin. If VCC does not have adequate bypassing, the

switch pulses introduce enough ripple at VCC to corrupt

the reference voltage and the LTC1504 will not regulate

accurately. Symptoms of inadequate bypassing include

poor load regulation and/or erratic waveforms at the SW

pin. If an oscilloscope won’t trigger cleanly when looking

at the SW pin, there isn’t adequate input bypass.

Ideally, the LTC1504 requires a low impedance bypass

right at the chip and a larger reservoir capacitor that can be

located somewhat farther away. This requirement usually

can be met with a ceramic capacitor right next to the

LTC1504 and an electrolytic capacitor (usually 10µF to

100µF, depending on expected load current) located some-

where nearby. In certain cases, the bulk capacitance

requirement can be met by the output bypass of the input

supply. Applications running at very high load currents or

at input supply voltages greater than 6V may require the

local ceramic capacitor to be 1µF or greater. In some

cases, both the low impedance and bulk capacitance

requirements can be met by a single capacitor, mounted

very close to the LTC1504. Low ESR organic semiconductor (OS-CON) electrolytic capacitors or surge tested surface mount tantalum capacitors can have low enough

impedance to keep the LTC1504 happy in some circuits.

Often the RMS current capacity of the input bypass capacitors is more important to capacitor selection than value.

Buck converters like the LTC1504 are hard on input

capacitors, since the current flow alternates between the

full load current and near zero during every clock cycle. In

the worst case (50% duty cycle or V

= 0.5VIN) the RMS

OUT

current flow in the input capacitor is half of the total load

current plus half the ripple current in the inductor—

perhaps 300mA in a typical 500mA load current application. This current flows through the ESR of the input

bypass capacitor, heating it up and shortening its life,

sometimes dramatically. Many ordinary electrolytic capacitors that look OK at fist glance are not rated to

withstand such currents—check the RMS current rating

before you specify a device! If the RMS current rating isn’t

specified, it should not be used as an input bypass

capacitor. Again, low ESR electrolytic and surge tested

tantalums usually do well in LTC1504 applications and

have high RMS current ratings. The local ceramic bypass

capacitor usually has negligible ESR allowing it to withstand large RMS currents without trouble. Table 1 shows

typical surface mount capacitors that make acceptable

input bypass capacitors in LTC1504 applications.

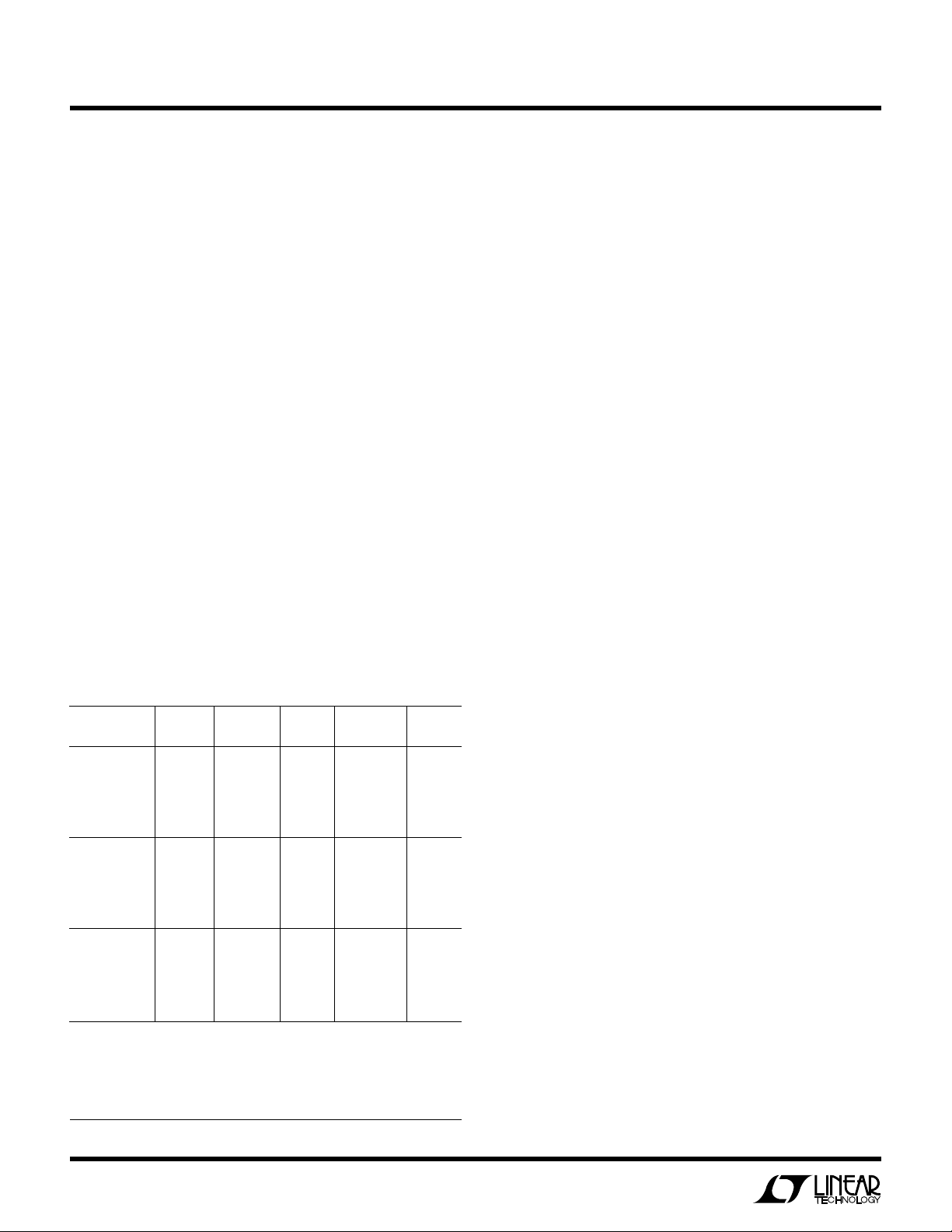

Table 1. Representative Surface Mount Input Bypass Capacitors

PART VALUE ESR MAX RMS TYPE HEIGHT

AVX

TPSC226M016R0375 22µF 0.38Ω 0.54A Tantalum 2.6mm

TPSD476M016R0150 47µF 0.15Ω 0.86A Tantalum 2.9mm

TPSE107M016R0125 100µF 0.13Ω 1.15A Tantalum 4.1mm

1206YC105M 1µF Low >1A X7R Ceramic 1.5mm

1210YG106Z 10µF Low >1A Y5V Ceramic 1.7mm

Sanyo

16SN33M 33µF 0.15Ω 1.24A OS-CON 7mm

16SN68M 68µF 0.1Ω 1.65A OS-CON 7mm

16CV100GX 100µF 0.44Ω 0.23A* Electrolytic 6mm

16CV220GX 220µF 0.34Ω 0.28A* Electrolytic 7.7mm

Sprague

593D476X0016D2W 47µF 0.17Ω 0.93A Tantalum 2.8mm

593D107X0016E2W 100µ 0.15Ω 1.05A Tantalum 4mm

*Note: Use multiple devices in parallel or limit output current to prevent capacitor overload.

Inductor

The LTC1504 requires an external inductor to be connected from the switching node SW to the output node

where the load is connected. Inductor requirements are

fairly straightforward; it must be rated to handle continuous DC current equal to the maximum load current plus

7

Page 8

LTC1504

U

WUU

APPLICATIONS INFORMATION

half the ripple current and its value should be chosen

based on the desired ripple current and/or the output

current transient requirements. Large value inductors

lower ripple current and decrease the required output

capacitance, but limit the speed that the LTC1504 can

change the output current, limiting output transient response. Small value inductors result in higher ripple

currents and increase the demands on the output capacitor, but allow faster output current slew rates and are often

smaller and cheaper for the same DC current rating. A

typical inductor used in an LTC1504 application might

have a maximum current rating between 500mA and 1A

and an inductance between 33µH and 220µH.

Different core materials and shapes will change the size/

current and price/current relationship of an inductor. Toroid

or shielded pot cores in ferrite or permalloy materials are

small and don’t radiate much energy, but generally cost more

than powdered iron rod core inductors with similar electrical

characteristics. The choice of which style inductor to use

often depends more on the price vs size requirements and any

radiated field/EMI requirements than on what the LTC1504

requires to operate. Table 2 shows some typical surface

mount inductors that work well in LTC1504 applications.

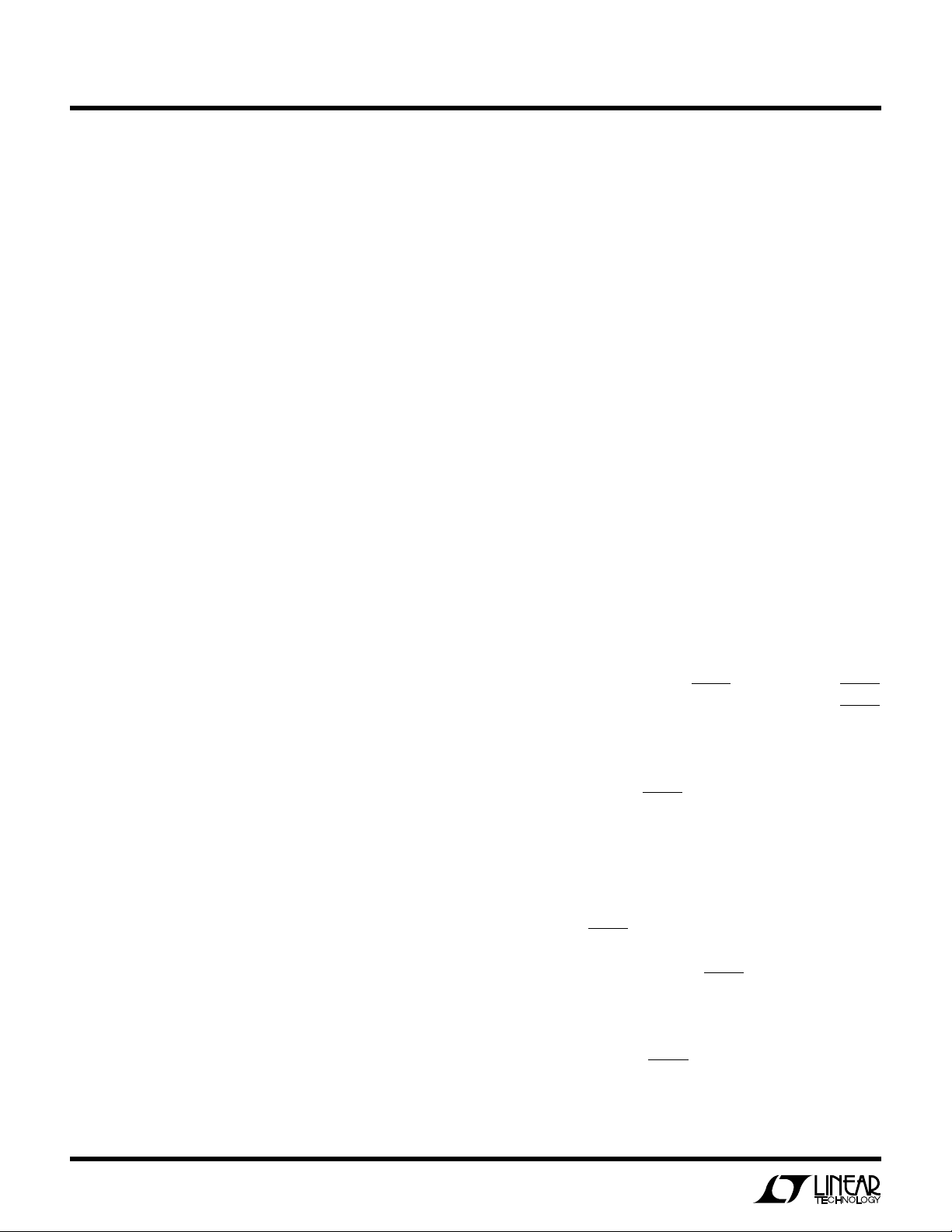

Table 2. Representative Surface Mount Inductors

CORE CORE

PART VALUE MAX DC TYPE MATERIAL HEIGHT

CoilCraft

DT3316-473 47µH 1A Shielded Ferrite 5.1mm

DT3316-104 100µH 0.8A Shielded Ferrite 5.1mm

DO1608-473 47µH 0.5A Open Ferrite 3.2mm

DO3316-224 220µH 0.8A Open Ferrite 5.5mm

Coiltronics

CTX50-1 50µH 0.65A Toroid KoolMµ

CTX100-2 100µH 0.63A Toroid KoolMµ 6mm

CTX50-1P 50µH 0.66A Toroid Type 52 4.2mm

CTX100-2P 100µH 0.55A Toroid Type 52 6mm

Sumida

CDRH62-470 47µH 0.54A Shielded Ferrite 3mm

CDRH73-101 100µH 0.50A Shielded Ferrite 3.4mm

CD43-470 47µH 0.54A Open Ferrite 3.2mm

CD54-101 100µH 0.52A Open Ferrite 4.5mm

Output Capacitor

The output capacitor affects the performance of the

LTC1504 in a couple of ways: it provides the first line of

Kool Mµ is a registered trademark of Magnetics, Inc..

®

4.2mm

defense during a transient load step and it has a large effect

on the compensation required to keep the LTC1504 feedback loop stable. Transient load response of an LTC1504

circuit is controlled almost entirely by the output capacitor

and the inductor. In steady load operation, the average

current in the inductor will match the load current. When

the load current changes suddenly, the inductor is suddenly carrying the wrong current and requires a finite

amount of time to correct itself—at least several switch

cycles with typical LTC1504 inductor values. Even if the

LTC1504 had psychic abilities and could instantly assume

the correct duty cycle, the rate of change of current in the

inductor is still related to its value and will not change

instantaneously.

Until the inductor current adjusts to match the load current, the output capacitor has to make up the difference.

Applications that require exceptional transient response

(2% or better for instantaneous full-load steps) will require relatively large value, low ESR output capacitors.

Applications with more moderate transient load requirements can often get away with traditional standard ESR

electrolytic capacitors at the output and can use larger

valued inductors to minimize the required output capacitor value. Note that the RMS current in the output capacitor

is slightly more than half of the inductor ripple current—

much smaller than the RMS current in the input bypass

capacitor. Output capacitor lifetime is usually not a factor

in typical LTC1504 applications.

Large value ceramic capacitors used as output bypass

capacitors provide excellent ESR characteristics but can

cause loop compensation difficulties. See the Loop Compensation section.

Loop Compensation

Loop compensation is strongly affected by the output

capacitor. From a loop stability point of view, the output

inductor and capacitor form a series RLC resonant circuit,

with the L set by the inductor value, the C by the value of

the output capacitor and the R dominated by the output

capacitor’s ESR. The amplitude response and phase shift

due to these components is compensated by a network of

Rs and Cs at the COMP pin to (hopefully) close the

feedback loop in a stable manner. Qualitatively, the L and

8

Page 9

LTC1504

U

WUU

APPLICATIONS INFORMATION

C of the output stage form a 2nd order roll-off with 180° of

phase shift; the R due to ESR forms a single zero at a

somewhat higher frequency that reduces the roll-off to

first order and reduces the phase shift to 90°.

If the output capacitor has a relatively high ESR, the zero

comes in well before the initial phase shift gets all the way

to 180° and the loop only requires a single small capacitor

from COMP to GND to remain stable (Figure 4a). If, on the

other hand, the output capacitor is a low ESR type to

maximize transient response, the ESR zero can increase in

frequency by a decade or more and the output stage phase

shift can get awfully close to 180° before it turns around

and comes back to 90°. Large value ceramic, OS-CON

electrolytic and low impedance tantalum capacitors fall

into this category. These loops require an additional zero

to be inserted at the COMP pin; a series RC in parallel with

a smaller C to ground will usually ensure stability. Figure

4b shows a typical compensation network which will

optimize transient response with most output capacitors.

Adjustable output parts can add a feedforward capacitor

across the feedback resistor divider to further improve

phase margin. The typical applications in this data sheet

V

OUT

R

*

LTC1504

Figure 4a. Minimum Compensation Network

LTC1504

R

Figure 4b. Optimum Compensation Network

FB

COMP

C

C

*ADJUSTABLE PARTS ONLY

FB

COMP

C

C

C

C

FB1

R

*

FB2

1504 • F04a

V

OUT

R

*

FB1

R

FB2

F

*ADJUSTABLE PARTS ONLY

CFF*

*

1504 • F04b

show compensation values that work with several combinations of external components—use them as a starting

point. For complex cases or stubborn oscillations, contact

the LTC Applications Department.

External Schottky Diode

An external Schottky diode can be included across the

internal N-channel switch (Q2) to improve efficiency at

heavy loads. The diode carries the inductor current during

the nonoverlap time while the LTC1504 turns Q1 off and

Q2 on and prevents current from flowing in the intrinsic

body diode in parallel with Q2. This diode will improve

efficiency by a percentage point or two as output current

approaches 500mA and can help minimize erratic behavior at very high peak current levels caused by excessive

parasitic current flow through Q2. A Motorola MBRS0530L

is usually adequate, with the cathode connected to SW and

the anode connected to GND. Note that this diode is not

required for normal operation and has a negligible effect

on efficiency at low (< 250mA) output currents.

Soft Start and Current Limit

Soft start and current limit are linked in the LTC1504. Soft

start works in a straightforward manner. An internal 12µ A

current source connected to the SS pin will pull up an

external capacitor connected from SS to GND at a rate

determined by the capacitor value. COMP is clamped to a

voltage one diode drop above SS; as SS rises, COMP will

rise at the same rate. When COMP reaches roughly 2V

below VCC, the duty cycle will slowly begin to increase until

the output comes into regulation. As SS continues to rise,

the feedback amplifier takes over at COMP, the clamp

releases and SS rises to VCC. During a soft start cycle, the

MIN feedback comparator is disabled to prevent it from

overriding the COMP pin and forcing the output to maximum duty cycle.

Current limit operates by pulling down on the soft start pin

when it senses an overload condition at the output. The

current limit amplifier (I

) compares the voltage drop

LIM

across the internal P-channel switch (Q1) during its on

time to the voltage at the I

MAX

pin. I

includes an internal

MAX

12µA pull-down, allowing the voltage to be set by a single

resistor between VCC and I

. When the IR drop across

MAX

9

Page 10

LTC1504

U

WUU

APPLICATIONS INFORMATION

Q1 exceeds the drop across the I

current out of the external soft start capacitor, reducing the

voltage at SS. A soft start capacitor should always be used

if current limit is enabled. SS, in turn, pulls down on COMP,

limiting the output duty cycle and controlling the output

current. When the current overload is removed, the I

amplifier lets go of SS and allows it to rise again as if it were

completing a soft start cycle. The size of the external soft

start capacitor controls both how fast the current limit

responds once an overload is detected and how fast the

output recovers once the overload is removed. The soft

start capacitor also compensates the feedback loop created by the I

feedback loop, the additional phase shift due to the output

inductor and capacitor do not come into play and the loop

can be adequately compensated with a single capacitor.

Usually a 0.1µF ceramic capacitor from SS to GND pro-

vides adequate soft start behavior and acceptable current

limit response.

This type of current limit circuit works well with mild

current overloads and eliminates the need for an external

current sensing resistor, making it attractive for LTC1504

applications. These same features also handicap the current limit circuit under severe short circuits when the

output voltage is very close to ground. Under this condition, the LTC1504 must run at extremely narrow duty

cycles (<5%) to keep the current under control. When the

on-time falls below the time required to sense the current

in Q1, the LTC1504 responds by reducing the oscillator

frequency, increasing the off-time to decrease the duty

cycle and allow it to maintain some control of the output

current. The oscillator frequency may drop by as much as

a factor of 10 under severe current overloads.

Under extreme short circuits (e.g., screwdriver to ground)

the on-time will reduce to the point where the LTC1504 will

lose control of the output current. At this point, output

current will rise until the inductor saturates, and the

current will be limited by the parasitic ESL of the inductor

and the RON of Q2 inside the LTC1504. This current is

usually nondestructive and dissipates a limited amount of

power since the output voltage is very low. A typical

LTC1504 circuit can withstand such a short for many

seconds without damage. The test circuit in Figure 1 will

amplifier. Because the I

LIM

resistor, I

MAX

LIM

pulls

LIM

LIM

loop is a current

typically withstand a direct output short for more than 30

seconds without damage to the LTC1504. Eventually,

however, a continuous short may cause the die temperature to rise to destructive levels.

Note that the current limit is primarily designed to protect

the LTC1504 from damage and is not intended to be used

to generate an accurate constant-current output. As the

die temperature varies in a current limited condition, the

RON of the internal switches will change and the current

limit threshold will move around. RON will also vary from

part-to-part due to manufacturing tolerance. The external

I

resistor should be chosen to allow enough room to

MAX

account for these variations without allowing the current

limit to engage at the maximum expected load current. A

current limit setting roughly double the expected load is

often a good compromise, eliminating unintended current

limit operation while preventing circuit destruction under

actual fault conditions. If desired, current limit can be

disabled by floating the I

will pull I

Shutdown

The LTC1504 includes a micropower shutdown mode

controlled by the logic level at SHDN. A logic High at SHDN

allows the part to operate normally. A logic Low at SHDN

stops all internal switching, pulls COMP, SS and SW to

GND and drops quiescent current below 1µA typically.

Note that the internal N-channel power MOSFET from SW

to GND turns on when SHDN is asserted. This ensures that

the output voltage drops to zero when the LTC1504 is shut

down, but prevents other devices from powering the

output when the LTC1504 is disabled.

External Clock Synchronization

The LTC1504 SHDN pin can double as an external clock

input for applications that require a synchronized clock or

a faster switching speed. The SHDN pin terminates the

internal sawtooth wave and resets the oscillator immediately when it goes low, but waits 50µs before shutting

down the rest of the internal circuitry. A clock signal

applied directly to the SHDN pin will force the LTC1504

internal oscillator to lock to its frequency as long as the

external clock runs faster than the internal oscillator

to GND and the I

MAX

pin; the internal current source

MAX

amplifier will be disabled.

LIM

10

Page 11

LTC1504

U

WUU

APPLICATIONS INFORMATION

frequency. Attempting to synchronize to a frequency

lower than the 250kHz maximum internal frequency may

result in inconsistent pulse widths and is not recommended.

Because the sawtooth waveform rises at a fixed rate

internally, terminating it early by synchronizing to a fast

external clock will reduce the amplitude of the sawtooth

wave that the PWM comparator sees, effectively raising

the gain from COMP to SW. 500kHz is the maximum

recommended synchronization frequency; higher frequencies will reduce the sawtooth amplitude to the point that

the LTC1504 may run erratically.

THERMAL CONSIDERATIONS

Each of the LTC1504 internal power switches has approximately 1.5Ω of resistance at room temperature and will

happily carry more than the rated maximum current if the

current limit is set very high or is not connected. Since the

inductor current is always flowing through one or the

other of the internal switches, a typical application supplying 500mA of load current will cause a continuous dissipation of approximately 375mW. The SO-8 package has a

thermal resistance of approximately 90°C/W, meaning

that the die will begin to rise toward 34°C above ambient

at this power level. The RON of the internal power switches

increases as the die temperature rises, increasing the

power dissipation as the feedback loop continues to keep

the output current at 500mA. At high ambient temperatures, this cycle may continue until the chip melts, since

the LTC1504 does not include any form of thermal shutdown. Applications can safely draw peak currents above

the 500mA level, but the average power dissipation should

be carefully calculated so that the maximum 115°C die

temperature is not exceeded.

The LTC1504 dissipates the majority of its heat through its

pins, especially GND (Pin 4). Thermal resistance to ambient can be optimized by connecting GND to a large copper

region on the PCB, which will serve as a heat sink.

Applications which will operate the LTC1504 near maximum power levels or which must withstand short circuits

of extended duration should maximize the copper area at

all pins and ensure that there is some airflow over the part

to carry away excess heat. For layout assistance in situa-

tions where power dissipation may be a concern, contact

the LTC Applications Department.

The current limit circuit can be used to limit the power

under mild overloads to a safe level, but severe overloads

where the output is shorted to ground may still cause the die

temperature to rise dangerously. For more information on

current limit behavior, see the Current Limit section.

LAYOUT CONSIDERATIONS

Like all precision switching regulators, the LTC1504

requires special care in layout to ensure optimum performance. The large peak currents coupled with significant

DC current flow will conspire to keep the output from

regulating properly if the layout is not carefully planned. A

poorly laid out op amp or data converter circuit will fail to

give the desired performance, but will usually still act like

an op amp or data converter. A poorly laid out LTC1504

circuit may look nothing at all like a regulator.

or plug-in prototyping boards are not useful for breadboarding LTC1504 circuits!

Perhaps most critical to proper LTC1504 performance is

the layout of the ground node and the location of the input

and output capacitors. The negative terminals of both the

input and output bypass capacitors should come together

at the same point, as close as possible to the LTC1504

ground pin. The compensation network and soft start

capacitor can be connected together on their own trace,

which should come directly back to this same common

ground point. The input supply ground and the load return

should also connect to this common point. Each ground

line should come to a star connection with Pin 4 at the

center of the star. This node should be a fairly large copper

region to act as a heat sink if required.

Second in importance is the proximity of the low ESR (usually

ceramic) input bypass capacitor. It should be located as close

to the LTC1504 VCC and GND pins as physically possible.

Ideally, the capacitor should be located right next to the

package, straddling the SW pin. High peak current applications or applications with VCC greater than 6V may require a

1µ F or larger ceramic capacitor in this position.

One node that isn’t quite so critical is SW. Extra lead length

or narrow traces at this pin will only add parasitic induc-

Wire-wrap

11

Page 12

LTC1504

U

WUU

APPLICATIONS INFORMATION

tance in series with the external inductor, slightly raising

its value. The SW trace need only be wide enough to

support the maximum peak current under short circuit

conditions—perhaps 1A. If a trace needs to be compromised to make the layout work, this is the one. Note that

long traces at the SW node may aggravate EMI considerations—don’t get carried away. If a Schottky diode is used

at the SW node, it should be located at the LTC1504 end

of the trace, close to the device pins.

The LTC Applications Department has constructed literally hundreds of layouts for the LTC1504 and related

U

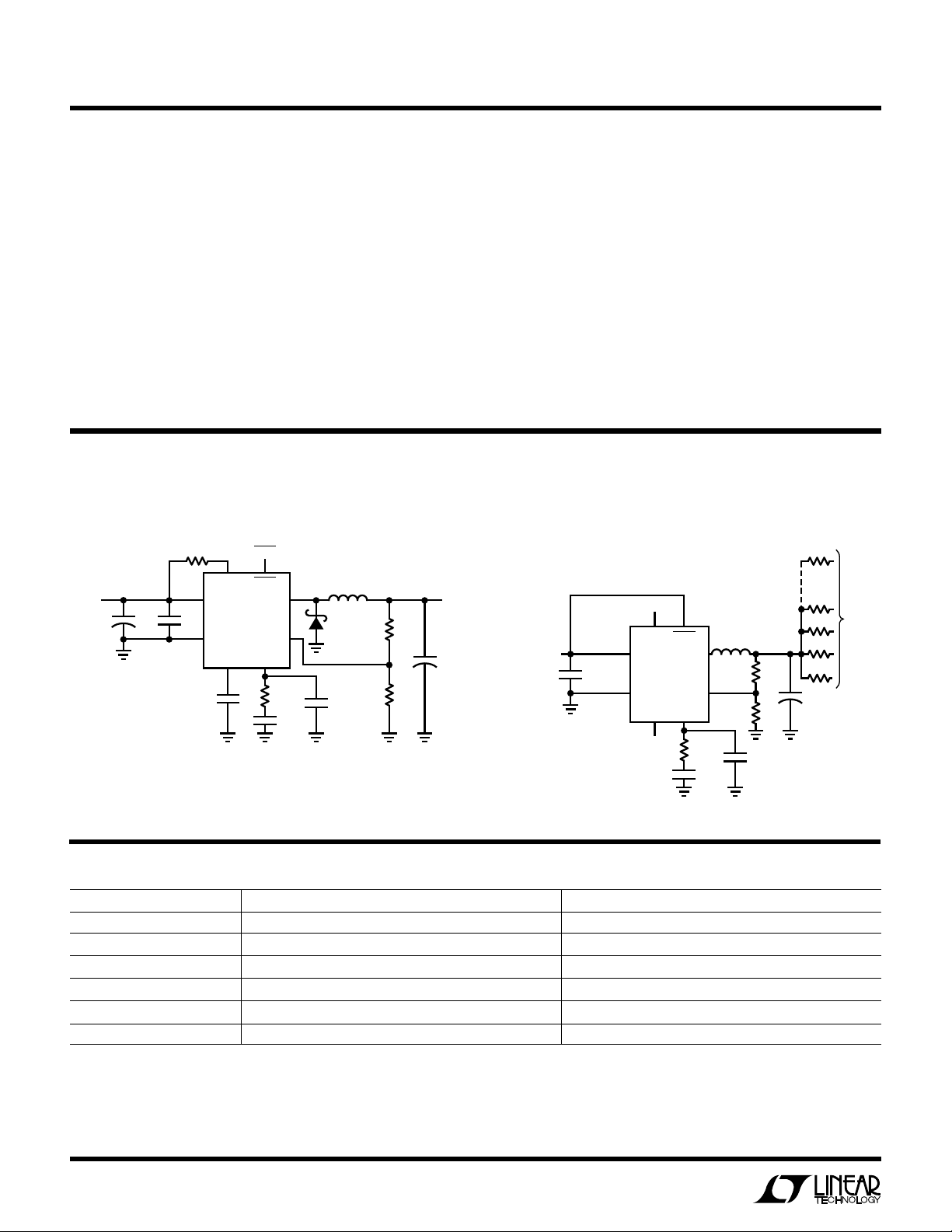

TYPICAL APPLICATIONS

High Efficiency 5V to 2.5V Converter with Current Limit

R

*

IMAX

V

CC

5V

+

CIN: AVX TPSE107M016R0125

: SANYO 16CV220GX

C

OUT

: COILCRAFT DO3316-473

L

EXT

*SELECT R

IMAX

1µF

C

IN

0.1µF

VALUE USING CURRENT LIMIT THRESHOLD GRAPH ON PAGE 3

I

MAX

V

CC

LTC1504

GND

SS COMP

SHDN

SHDN

SW

FB

7.5k

0.01µF

L

EXT

MBRS0530L

220pF

11.8k

12.1k

V

OUT

2.5V

+

C

OUT

1504 • TA03

parts, many of which worked and some of which are now

archived in the Bad Layout Hall of Fame. If you need layout

assistance or you think you have a candidate layout for the

Hall of Fame, give Applications a call at (408) 954-8400.

Demo boards with properly designed layouts are available

and specialized layouts can be designed if required. The

applications team is also experienced in external component selection for a wide variety of applications, and they

have a never-ending selection of tall tales to tell as well.

When in doubt, give them a call.

SCSI-2 Active Terminator

110Ω

•

•

•

110Ω

110Ω

110Ω

110Ω

C

OUT

1504 • TA04

18

TO

27

LINES

TERMPWR

C

: AVX TPSC107M006R0150

OUT

: SUMIDA CD54-470

L

EXT

4.7µF

CERAMIC

NC

I

MAX

V

CC

LTC1504

GND

SS COMP

NC

SHDN

SW

FB

7.5k

0.01µF

L

EXT

15k

+

12k

220pF

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1174 600mA, High Efficiency Step-Down Converter Nonsynchronous, Better Low Load Efficiency

LT®1307 Single Cell 600kHz DC/DC Converter Boost Mode, Micropower

LT1372 1.5A, 500kHz Step-Up Switching Regulator Boost Mode, High Power

LT1376 1.5A, 500kHz Step-Down Switching Regulator Nonsynchronous, 1.5A Max Current

LTC1433/LTC1434 450mA, Low Noise Current Mode Step-Down Converters Nonsynchronous, Better Low Load Efficiency

LT1507 1.5A, 500kHz Monolithic Buck Regulator Nonsynchronous, 1.5A Max Current

1504i LT/TP 0897 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1997

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417 ● (408) 432-1900

FAX: (408) 434-0507

●

TELEX: 499-3977 ● www.linear-tech.com

Loading...

Loading...