Page 1

1

LTC1503-1.8/LTC1503-2

High Efficiency Inductorless

Step-Down DC/DC Converters

■

Input Voltage Range: 2.4V to 6V

■

Fixed Output Voltages: 1.8V ±4%, 2V ±4%

■

Output Current: Up to 100mA

■

No Inductors

■

Typical Efficiency 25% Higher than LDOs

■

Low Operating Current: 25µA

■

Low Shutdown Current: 5µA

■

600kHz Switching Frequency

■

Shutdown Disconnects Load from V

IN

■

Soft-Start Limits Inrush Current at Turn-On

■

Short-Circuit and Overtemperature Protected

■

Available in 8-Pin MSOP and SO Packages

The LTC®1503-1.8/LTC1503-2 are switched capacitor

step-down DC/DC converters that produce a regulated

output from a 2.4V to 6V input. The parts use switched

capacitor fractional conversion to achieve high efficiency

over the entire input range. No inductors are required.

Internal circuitry controls the step-down conversion ratio

to optimize efficiency as the input voltage and load conditions vary. Typical efficiency is 25% higher than that of a

low dropout (LDO) linear regulator.

Regulation is achieved by sensing the output voltage and

enabling the internal switching network as needed to

maintain a fixed output voltage. This method of regulation

enables the parts to achieve high efficiency at extremely

light loads. Low operating current (25µA with no load, 5µA

in shutdown) and low external parts count (two 1µF flying

capacitors and two 10µF bypass capacitors) make the

LTC1503-1.8/LTC1503-2

ideally suited for space constrained battery-powered applications. The parts are fully

short-circuit and overtemperature protected.

The

LTC1503-1.8/

LTC1503-2 are available in 8-pin MSOP

and SO packages.

, LTC and LT are registered trademarks of Linear Technology Corporation.

■

Cellular Phones

■

Handheld Computers

■

Smart Card Readers

■

Low Power DSP Supplies

■

Portable Electronic Equipment

■

Handheld Medical Instruments

Efficiency vs Input Voltage

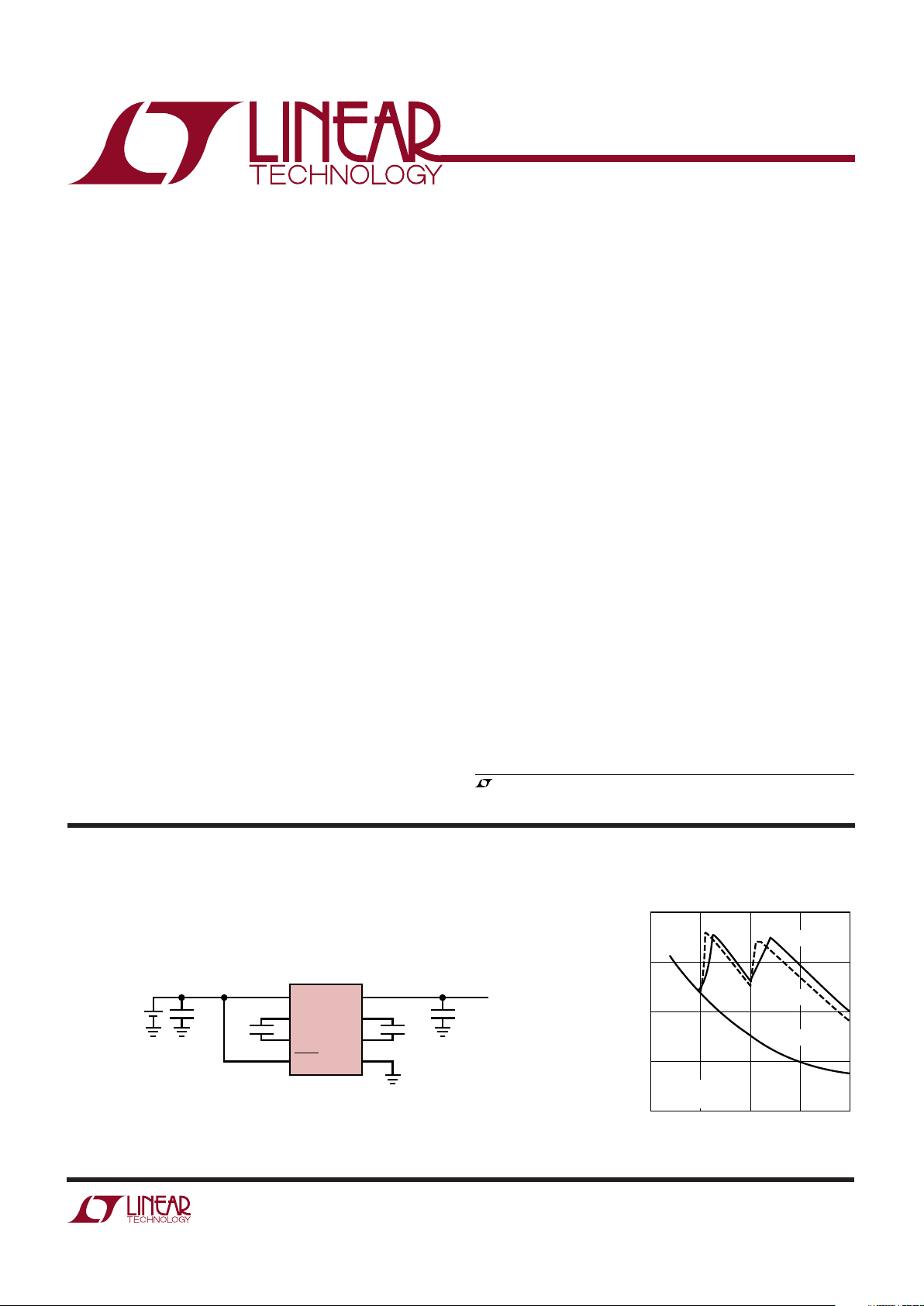

Single Li-Ion to 2V DC/DC Converter

FEATURES

DESCRIPTIO

U

APPLICATIO S

U

TYPICAL APPLICATIO

U

4

2

3

5

1

8

6

7

V

IN

C1

–

C1

+

SHDN/SS

V

OUT

C2

–

C2

+

GND

LTC1503-2

1µF

1503-1.8/2 TA01

1µF

10µF

1-CELL Li-Ion OR

3-CELL NiMH

10µF

V

OUT

= 2V

I

OUT

= 100mA

INPUT VOLTAGE (V)

2

EFFICIENCY (%)

60

80

6

1503-1.8/2 TA02

40

20

3

4

5

100

LTC1503-2

V

OUT

= 2V

I

OUT

= 100mA

I

OUT

= 1mA

“IDEAL” LDO

Page 2

2

LTC1503-1.8/LTC1503-2

Industrial Temperature Range ............... –40°C to 85°C

Specified Temperature Range (Note 2)... – 40°C to 85°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

(Note 1)

PARAMETER CONDITIONS MIN TYP MAX UNITS

VIN Operating Voltage ● 2.4 6 V

V

OUT

LTC1503-1.8, 0mA < I

OUT

< 100mA ● 1.728 1.8 1.872 V

LTC1503-2, 0mA < I

OUT

< 100mA ● 1.920 2.0 2.080 V

VIN Operating Current I

OUT

= 0mA ● 25 50 µA

VIN Shutdown Current SHDN/SS = 0V ● 510 µA

Output Ripple Voltage LTC1503-X, VIN = 3.6V, I

OUT

= 100mA 25 mV

P-P

Efficiency LTC1503-2, VIN = 3.6V, I

OUT

= 100mA 82.9 %

Switching Frequency Oscillator Free Running 600 kHz

SHDN/SS Input Threshold ● 0.2 0.35 0.5 V

SHDN/SS Input Current V

SHDN/SS

= 0V (Note 3) ● –3.5 –2 –1 µA

V

SHDN/SS

= V

IN

● –1 1 µA

V

OUT

Short-Circuit Current V

OUT

= 0V (Note 4) ● 82250 mA

V

OUT

Turn-On Time CSS = 0nF, VIN = 3.6V, C

OUT

= 10µF 0.1 ms

C

SS

= 10nF 8 ms

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1503C is guaranteed to meet specified performance from

0°C to 70°C and is designed, characterized and expected to meet these

extended temperature limits, but are not tested at –40°C and 85°C. The

LTC1503I is guaranteed to meet the extended temperature limits.

Note 3: Currents flowing into the device are positive polarity. Currents

flowing out of the device are negative polarity.

Note 4: When V

OUT

is less than 150mV, I

OUT

is limited to much less than

the maximum rated output current to prevent damage to the output

devices.

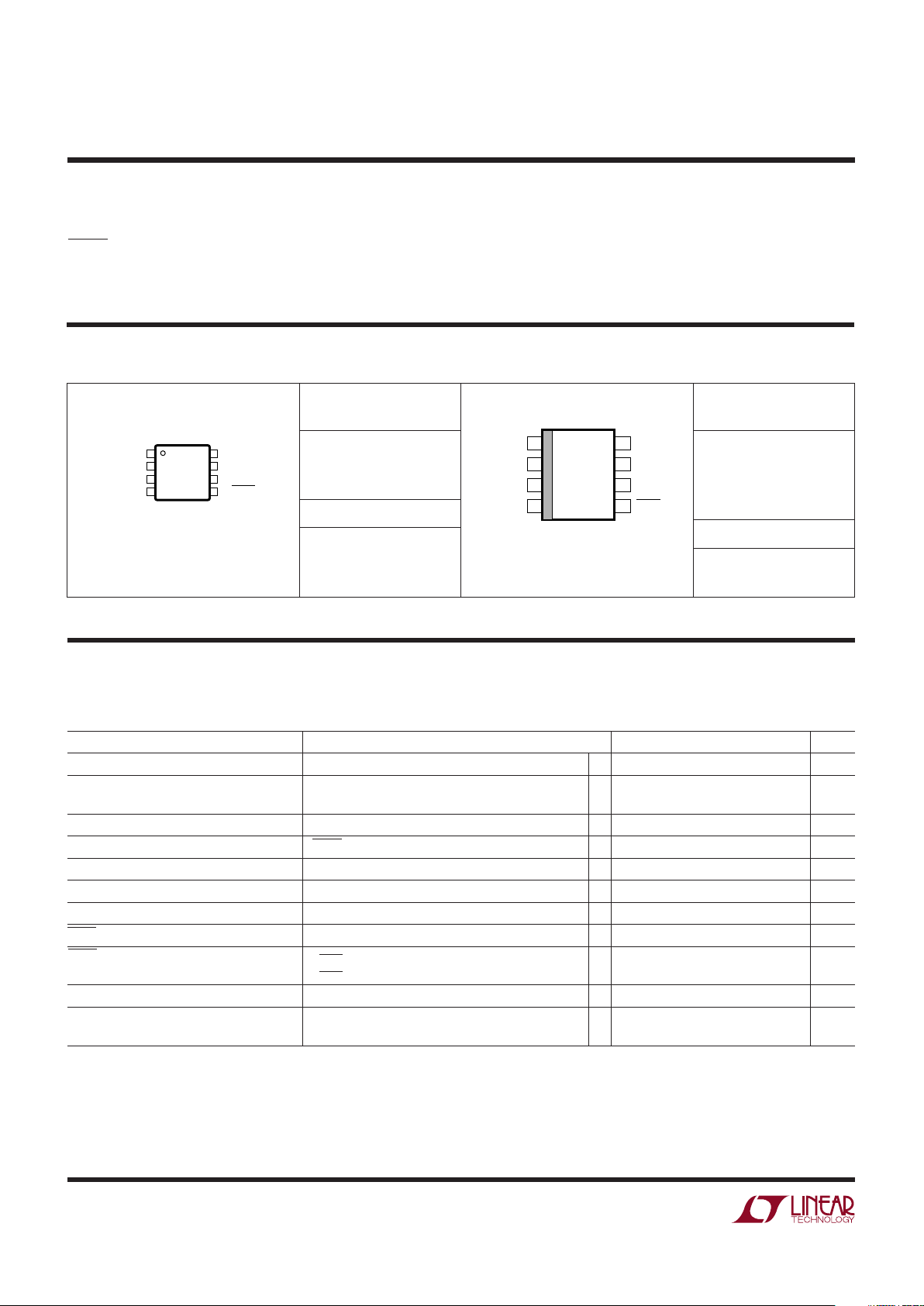

ORDER PART

NUMBER

LTC1503CMS8-1.8

LTC1503CMS8-2

MS8 PART MARKING

LTFX

LTHN

ORDER PART

NUMBER

LTC1503CS8-1.8

LTC1503CS8-2

LTC1503IS8-1.8

LTC1503IS8-2

S8 PART MARKING

150318

15032

Consult factory for Military grade parts.

T

JMAX

= 125°C, θJA = 200°C/W

1

2

3

4

V

OUT

C1

–

C1

+

V

IN

8

7

6

5

C2

–

GND

C2

+

SHDN/SS

TOP VIEW

MS8 PACKAGE

8-LEAD PLASTIC MSOP

T

JMAX

= 125°C, θJA = 150°C/W

1

2

3

4

8

7

6

5

TOP VIEW

S8 PACKAGE

8-LEAD PLASTIC SO

V

OUT

C1

–

C1

+

V

IN

C2

–

GND

C2

+

SHDN/SS

VIN, C1+, C1–, C2+, C2– to GND............... –0.3V to 6.5V

SHDN/SS to GND......................... –0.3V to (VIN + 0.3V)

V

OUT

Short-Circuit Duration............................. Indefinite

Commercial Temperature Range ............ –40°C to 85°C

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

VIN = V

IN(MIN)

to V

IN(MAX)

, C1 = C2 = 1µF, CIN = C

OUT

= 10µF unless otherwise noted.

503I18

1503I2

ABSOLUTE AXI U RATI GS

WWWU

PACKAGE/ORDER I FOR ATIO

UU

W

ELECTRICAL CHARACTERISTICS

Page 3

3

LTC1503-1.8/LTC1503-2

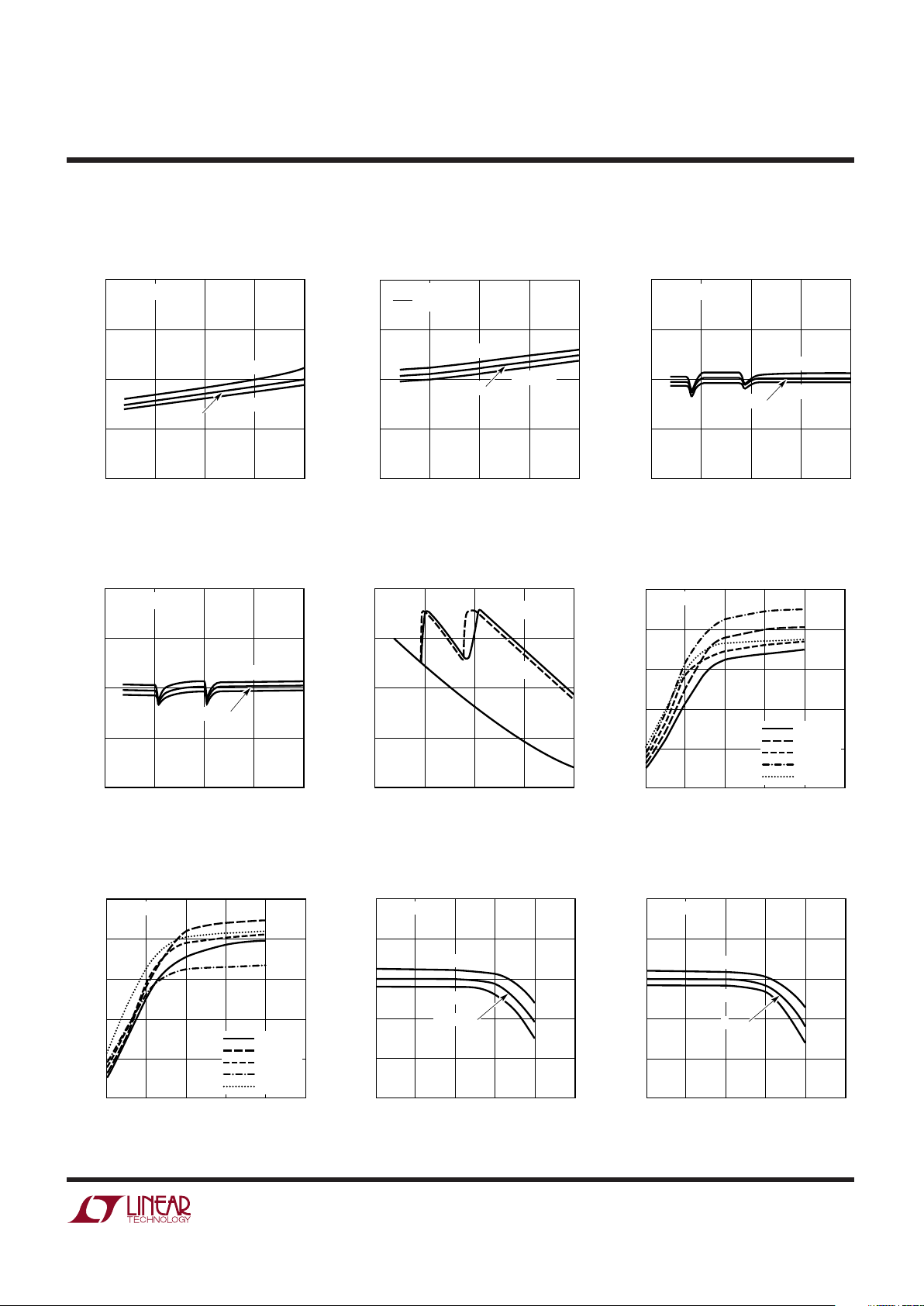

LTC1503-X Input Operating

Current vs Input Voltage

INPUT VOLTAGE (V)

2

INPUT CURRENT (µA)

30

T

A

= 25°C

40

6

1503 G01

20

10

3

4

5

50

I

OUT

= 0mA

TA = –40°C

T

A

= 85°C

LTC1503-1.8

Output Voltage vs Input Voltage

LTC1503-2

Output Voltage vs Input Voltage

LTC1503-1.8

Efficiency vs Input Voltage

INPUT VOLTAGE (V)

2

OUTPUT VOLTAGE (V)

2.00

2.05

6

1503 G03

1.95

1.90

3

4

5

2.10

I

OUT

= 50mA

TA = –40°C

T

A

= 85°C

T

A

= 25°C

INPUT VOLTAGE (V)

2

EFFICIENCY (%)

60

80

6

1503-1.8/2 G05

40

20

3

4

5

100

“IDEAL”

LDO

TA = 25°C

I

OUT

= 100mA

I

OUT

= 1mA

LTC1503-1.8

Efficiency vs Output Current

LTC1503-X Input Shutdown

Current vs Input Voltage

INPUT VOLTAGE (V)

2

INPUT SHUTDOWN CURRENT (µA)

5

7.5

6

1503-1.8/2 TA02

2.5

0

3

4

5

10

V

OUT

= 0V

V

SHDN

/SS = 0V

TA = –40°C

T

A

= 85°C

T

A

= 25°C

INPUT VOLTAGE (V)

2

OUTPUT VOLTAGE (V)

1.80

1.85

6

1503-1.8/2 G03

1.75

1.70

3

4

5

1.90

I

OUT

= 50mA

TA = –40°C

T

A

= 85°C

TA = 25°C

OUTPUT CURRENT (mA)

0.01

EFFICIENCY (%)

60

80

100

100

1503-1.8/2 G06

40

20

0

0.1

1

10

1000

VIN = 5V

V

IN

= 4.4V

V

IN

= 3.6V

V

IN

= 3V

V

IN

= 2.4V

TA = 25°C

LTC1503-2

Efficiency vs Output Current

OUTPUT CURRENT (mA)

0.01

EFFICIENCY (%)

60

80

100

100

1503-1.8/2 G07

40

20

0

0.1

1

10

1000

VIN = 5V

V

IN

= 4.4V

V

IN

= 3.6V

V

IN

= 3V

V

IN

= 2.4V

TA = 25°C

LTC1503-1.8

Output Voltage vs Output Current

OUTPUT CURRENT (mA)

0.01

OUTPUT VOLTAGE (V)

1.80

1.82

1.84

100

1503-1.8/2 G08

1.78

1.76

1.74

0.1

1

10

1000

VIN = 3.3V

TA = –40°C

TA = 85°C

T

A

= 25°C

LTC1503-2

Output Voltage vs Output Current

OUTPUT CURRENT (mA)

0.01

OUTPUT VOLTAGE (V)

2.00

2.02

2.04

100

1503-1.8/2 G09

1.98

1.96

1.94

0.1

1

10

1000

VIN = 3.3V

TA = –40°C

TA = 85°C

T

A

= 25°C

TYPICAL PERFOR A CE CHARACTERISTICS

UW

Page 4

4

LTC1503-1.8/LTC1503-2

TYPICAL PERFOR A CE CHARACTERISTICS

UW

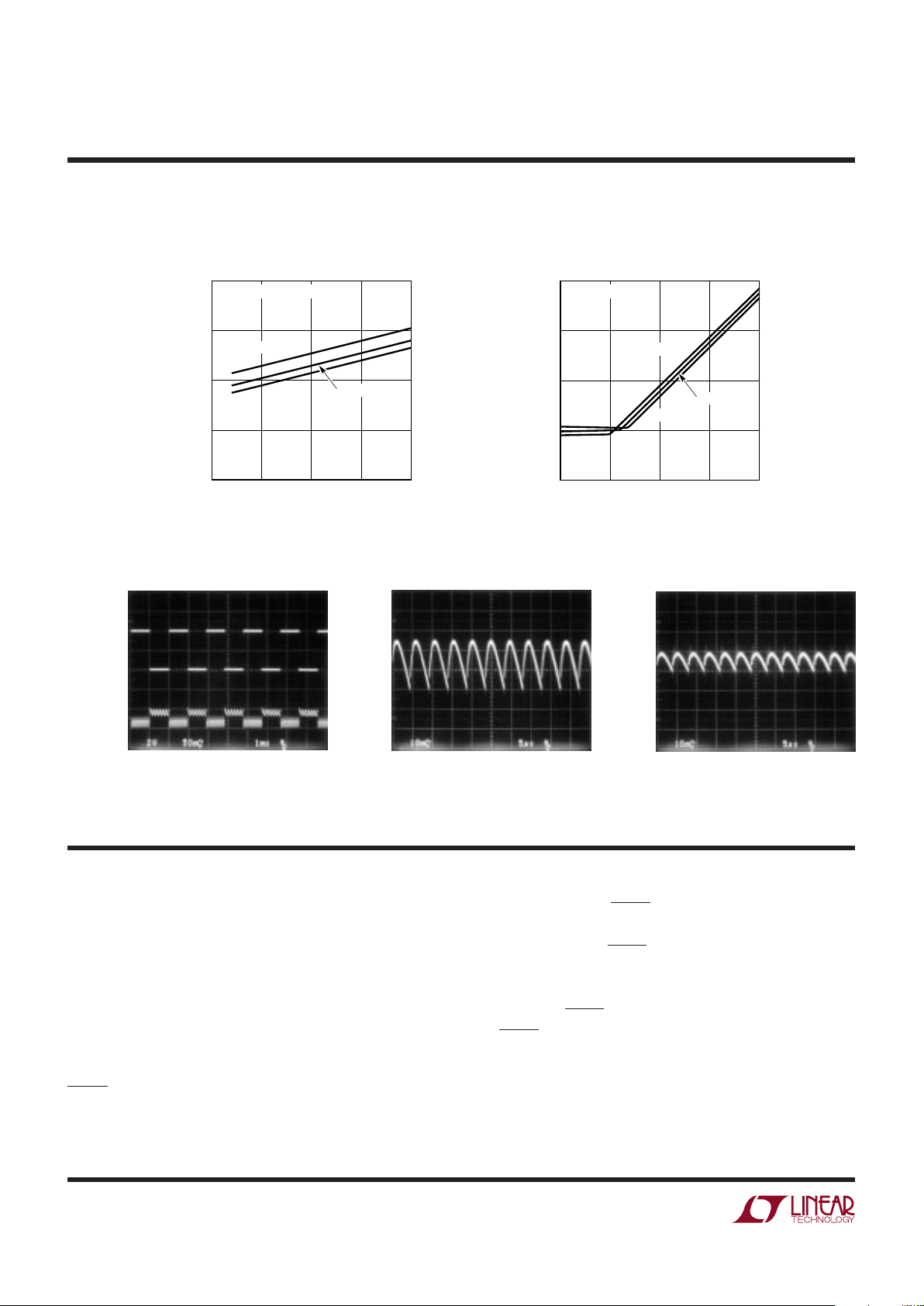

LTC1503-X Output Short-Circuit

Current vs Input Voltage

LTC1503-X Start-Up Time

vs Soft-Start Capacitor

INPUT VOLTAGE (V)

2

OUTPUT CURRENT (mA)

20

30

6

1503-1.8/2 G10

10

0

3

4

5

40

V

OUT

SHORTED TO GND

TA = –40°C

TA = 85°C

T

A

= 25°C

SOFT-START CAPACITOR (nF)

0.01

START-UP TIME (ms)

1

10

100

1503-1.8/2 G10

0.1

0.01

0.1

1

10

100

VIN = 3.6V

TA = –40°C

TA = 25°C

TA = 85°C

Output Load Transient Response

(LTC1503-1.8,1mA to 100mA Step)

I

OUT

50mA/DIV

V

OUT

50mV/DIV

AC COUPLED

100mA

1mA

1ms/DIV

1503-1.8/2 G12

Output Ripple, C

OUT

= 10µF

V

OUT

10mV/DIV

AC COUPLED

5µs/DIV

1503-1.8/2 G13

VIN = 3.6V

V

OUT

= 2V

I

OUT

= 100mA

C

OUT

= 10µF CERAMIC

Output Ripple, C

OUT

= 22µF

V

OUT

10mV/DIV

AC COUPLED

5µs/DIV

1503-1.8/2 G14

VIN = 3.6V

V

OUT

= 2V

I

OUT

= 100mA

C

OUT

= 22µF CERAMIC

V

OUT

(Pin 1): Regulated Output Voltage. V

OUT

is discon-

nected from VIN during shutdown. Bypass V

OUT

to ground

with a ≥10µF low ESR capacitor.

C1– (Pin 2): Flying Capacitor One Negative Terminal.

C1+ (Pin 3): Flying Capacitor One Positive Terminal.

VIN (Pin 4): Input Voltage. VIN may be between 2.4V and

6V. Bypass VIN to ground with a ≥10µF low ESR capacitor.

SHDN/SS (Pin 5): Shutdown/Soft-Start Control. The pin

is designed to be driven with an external open-drain

output. Holding the SHDN/SS pin below 0.25V will force

the part into shutdown mode. An internal pull-up current

of 2µA will force the SHDN/SS voltage to climb to VIN once

the device driving the pin is forced into a Hi-Z state. To

limit inrush current on start-up, connect a capacitor

between the SHDN/SS pin and ground. Capacitance on

the SHDN/SS pin will limit the dV/dt of the pin during turnon which, in turn, will limit the dV/dt of V

OUT

. By selecting

an appropriate soft-start capacitor for a known output

capacitor, the user can control the inrush current during

UU

U

PI FU CTIO S

Page 5

5

LTC1503-1.8/LTC1503-2

C1

+

V

IN

C1

–

C2

+

C2

–

150mV

800k

680k

330k

990k

1.2M

1.2V

V

REF

C

OUT

C

IN

V

OUT

GND

1503-1.8/2 BD

SHDN/SS

–

+

–

+

–

+

+

350mV

+

+

10mVCOMP2

MODE SKIP

REG ENABLE

SOFT-START

LTC1503-2

SHORT CIRCUIT

V

OUT

–

+

COMP1

350mV

V

IN

SHDN

2µA

+

V

REF

RAMP

–

+

–

+

STEP-DOWN

CHARGE

PUMP

MODE

CONTROL

600kHz

OSCILLATOR

–

+

turn-on (see Applications Information). If neither of the

two functions are desired, the pin may be floated or tied

to VIN.

C2+ (Pin 6): Flying Capacitor Two Positive Terminal.

GND (Pin 7): Ground. Connect to a ground plane for best

performance.

C2– (Pin 8): Flying Capacitor Two Negative Terminal.

UU

U

PI FU CTIO S

BLOCK DIAGRA

W

Page 6

6

LTC1503-1.8/LTC1503-2

General Operation

The two most common methods for providing regulated

step-down DC/DC conversion are linear DC/DC conversion

(used by LDOs) and inductor-based DC/DC conversion.

Linear regulation provides low cost and low complexity, but

the conversion efficiency is poor since all of the load current must come directly from VIN. Inductor-based stepdown conversion provides the highest efficiency, but the

solution cost and circuit complexity are much higher. The

LTC1503-X provides the efficiency advantages associated

with inductor-based circuits as well as the cost and simplicity advantages of an inductorless converter.

The LTC1503-X is a switched capacitor step-down DC/DC

converter. The part uses an internal switch network and

fractional conversion ratios to achieve high efficiency over

widely varying VIN and output load conditions. Internal

control circuitry selects the appropriate step-down conversion ratio based on VIN, V

OUT

and load conditions to

optimize efficiency. The part has three possible step-down

modes: 2-to-1, 3-to-2 or 1-to-1 (gated switch) step-down

mode. Only two external flying caps are needed to operate

in all three modes. 2-to-1 mode is chosen when VIN is

greater than two times the desired V

OUT

. 3-to-2 mode is

chosen when VIN is greater than 1.5 times V

OUT

but less

than 2 times V

OUT

. 1-to-1 mode is chosen when VIN falls

below 1.5 times V

OUT

. An internal mode skip function will

switch the step-down ratio as needed to maintain output

regulation under heavy load conditions.

Regulation is achieved by sensing the divided down output

voltage and enabling the charge pump as needed to boost

the output back into regulation. This method of regulation

allows the LTC1503-X to achieve high efficiency at very

light loads. The part has shutdown capability as well as

user controlled inrush current limiting. In addition, the

part can withstand an indefinite short-circuit condition on

V

OUT

and is also overtemperature protected.

Step-Down Charge Pump Operation

Figure 1a shows the charge pump switch configuration

that is used for 2-to-1 step down. When the charge pump

is enabled in this mode, a two phase nonoverlapping clock

generates the switch control signals. On phase one of the

clock, flying capacitor C1 is connected through switches

Figure 1a. Step-Down Charge Pump in 2-to-1 Mode

S1 and S2 across V

OUT

. If the voltage on C1 is greater than

the voltage on C

OUT

, charge is transferred from C1 onto

C

OUT

. On phase two, the top plate of C1 is connected to V

IN

and the bottom plate is connected to V

OUT

. If the voltage

across C1 is less than VIN/2 during phase two, charge will

be transferred from C1 onto C

OUT

thereby boosting the

voltage on C

OUT

and raising the voltage across C1. Thus,

in 2-to-1 mode, charge transfer from C1 onto C

OUT

occurs

on both phases of the clock, and the voltage on C

OUT

is

driven towards 1/2VIN until the output is back in regulation. Since charge current is sourced from ground on

phase one of the clock, current multiplication is realized

with respect to VIN, i.e., I

VOUT

equals approximately 2 •

I

VIN

. This results in significant efficiency improvement

relative to a linear regulator.

The 3-to-2 conversion mode also uses a nonoverlapping

clock for switch control but requires two flying capacitors

and a total of seven switches (see Figure 1b). On phase

one, C1 and C2 are connected in series across V

OUT

. If the

sum of the voltages across C1 and C2 is greater than V

OUT

,

charge is transferred from the flying caps onto C

OUT

thereby reducing the average voltage on the flying caps

and raising the voltage on the output capacitor. On phase

two, the two flying capacitors are connected on parallel

between VIN and V

OUT

. Since the average voltage across

the two capacitors during phase one is V

OUT

/2, charge will

be transferred from VIN to V

OUT

through the two flying

caps if VIN minus V

OUT

/2 is greater than V

OUT

. In this

manner, charge is again transferred from the flying caps

to the output on both phases of the clock, and the voltage

on C

OUT

is driven towards (2/3)VIN until the part is back in

regulation. As in 2-to-1 mode, charge current is sourced

from ground on phase one of the clock which results in

increased power efficiency. I

VOUT

in 3-to-2 mode equals

approximately (3/2)I

VIN

.

S4

φ2

S1

φ1

S3

φ2

S2

φ1

C1

(EXTERNAL)

C1

+

C1

–

1503-1.8/2 F01a

V

IN

V

OUT

APPLICATIO S I FOR ATIO

WUUU

Page 7

7

LTC1503-1.8/LTC1503-2

maintain regulation. This will only occur as VIN/V

OUT

nears

a 3-to-2 or 1-to-1 transition point. For example, under light

load conditions, the LTC1503-X can operate in 2-to-1

mode when VIN equals 4.1V with greater than 90% efficiency. However, when the load is increased, the part can

no longer supply enough output current in 2-to-1 mode to

maintain regulation. This causes V

OUT

to droop below the

regulation point until COMP2 trips and forces the part to

skip from 2-to-1 mode to 3-to-2 mode. The COMP2

threshold is about 17mV (V

OUT

referred) below the main

comparator regulation point. Hysteresis in COMP2 will

force the part to transition in and out of mode skipping.

This will result in a slight V

OUT

decrease of approximately

20mV under mode skipping conditions.

Shutdown/Soft-Start Operation

The SHDN/SS pin is used to implement both low current

shutdown and soft-start. The soft-start feature limits

inrush currents when the regulator is initially powered up

or taken out of shutdown. Forcing a voltage lower than

0.35V (typ) will put the part into shutdown mode. Shutdown mode disables all control circuitry and forces the

charge pump V

OUT

into a high impedance state. A 2µA pull-

up current on the SHDN/SS pin will force the part into

active mode if the pin is left floating or is driven with an

open-drain output that is in a high impedance state. If the

pin is not driven with an open-drain device, it must be

forced to a logic high voltage of 2.2V (min) to ensure

proper V

OUT

regulation. The SHDN/SS pin should not be

driven to a voltage higher than VIN.

To implement soft-start, the SHDN/SS pin must be driven

with an open-drain device and a capacitor must be

connected from the SHDN/SS pin to GND. Once the opendrain device is turned off, a 2µA pull-up current will begin

charging the external SS capacitor and force the voltage

on the pin to ramp towards VIN. As soon as the SHDN

threshold is reached (0.35V typ), the internal reference

voltage which controls the V

OUT

regulation point will

follow the ramp voltage on the SHDN/SS pin (minus a

0.35V offset to account for the SHDN threshold) until the

reference reaches its final band gap voltage. This occurs

when the voltage on the SHDN/SS pin reaches

Figure 1b. Step-Down Charge Pump in 3-to-2 Mode

In 1-to-1 mode, switch S1 and S2 are connected in series

between VIN and V

OUT

as needed to boost V

OUT

back into

regulation (see Figure 1c). The REG ENABLE signal from

the main comparator (COMP1) controls switches S1 and

S2 directly. Since all of the V

OUT

current is sourced from

VIN, the efficiency in 1-to-1 mode is approximately equal

to that of a linear regulator.

Figure 1c. Step-Down Charge Pump in 1-to-1 Mode

Mode Selection and Mode Skipping

The optimal step-down conversion mode is chosen based

on VIN to V

OUT

differential voltage and output load conditions. Two internal comparators are used to select the

default step-down mode based on the VIN and V

OUT

voltage. A separate comparator (COMP2) is used to sense

a droop on V

OUT

due to a heavy output load and force the

charge pump to skip to a higher output current mode to

S1

φ1

S5

φ2

S7

φ2

S4

φ2

S2

φ1

C1

(EXTERNAL)

C2

(EXTERNAL)

C1

+

C1

–

C2

–

GND

C2

+

1503-1.8/2 F01b

V

IN

V

OUT

S3

φ1

S6

φ2

S2 S1

C1

(EXTERNAL)

C1

+

C1

–

1503-1.8/2 F01c

V

IN

V

OUT

APPLICATIO S I FOR ATIO

WUUU

Page 8

8

LTC1503-1.8/LTC1503-2

2ms/DIV 1503-1.8/2 F02bLTC1503-2

C

SS

= 0nF

C

OUT

= 10µF

R

LOAD

= 50Ω

Capacitor Selection

For best performance, it is recommended that low ESR

capacitors be used for CIN and C

OUT

to reduce noise and

ripple. If the ESR of the output capacitor is too high

(>0.5Ω), both efficiency and output load regulation may

be degraded. The CIN and C

OUT

capacitors should be either

ceramic or tantalum and should be 10µF or greater. If the

input source impedance is very low (<0.5Ω), CIN may not

be needed. Ceramic capacitors are recommended for the

flying caps C1 and C2 with values of 0.47µF to 2.2µF.

Smaller values may be used in low output current applications (e.g., I

OUT

< 10mA). For best performance choose

the same capacitance value for both C1 and C2.

Output Ripple

Normal LTC1503-X operation produces voltage ripple on

the V

OUT

pin. Output voltage ripple is required for the parts

to regulate. Low frequency ripple exists due to the hysteresis in the sense comparator and propagation delays in the

charge pump enable/disable circuits. High frequency ripple

is also present mainly from the ESR (equivalent series

resistance) in the output capacitor. Typical output ripple

(VIN = 3.6V) under maximum load is 25mV peak-to-peak

with a low ESR 10µF output capacitor.

The magnitude of ripple voltage depends on several factors. High input voltages increase the output ripple since

more charge is delivered to C

OUT

per charging cycle. Large

output current load and/or a small output capacitor (< 10µF)

results in higher ripple due to higher output voltage dV/dt.

High ESR capacitors (ESR > 0.5Ω) on the output pin cause

high frequency voltage spikes on V

OUT

with every clock

cycle.

There are several ways to reduce the output voltage ripple

(see Figure 3). A larger C

OUT

capacitor (22µF or greater)

will reduce both the low and high frequency ripple due to

the lower C

OUT

charging and discharging dV/dt and the

lower ESR typically found with higher value (larger case

size) capacitors. A low ESR ceramic output capacitor will

minimize the high frequency ripple, but will not reduce the

low frequency ripple unless a high capacitance value is

chosen. A reasonable compromise is to use a 10µF to 22µF

tantalum capacitor in parallel with a 1µF to 3.3µF ceramic

approximately 1.9V. Since the ramp rate on the SHDN/SS

pin controls the ramp rate on V

OUT

, the average inrush

current can be controlled through selection of CSS and

C

OUT

. For example, a 4.7nF capacitor on SHDN/SS results

in a 4ms ramp time from 0.35V to 1.9V on the pin. If C

OUT

is 10µF, the 4ms V

REF

ramp time results in an average

C

OUT

charge current of only 5mA (see Figure 2c).

5

1

R

LOAD

C

SS

1503-1.8/2 F02a

V

CTRL

ON OFF

SHDN/SS

V

OUT

LTC1503-X

(a)

V

CTRL

2V/DIV

V

OUT

1V/DIV

(b)

2ms/DIV 1503-1.8/2 F02bLTC1503-2

C

SS

= 4.7nF

C

OUT

= 10µF

R

LOAD

= 50Ω

V

CTRL

2V/DIV

V

OUT

1V/DIV

(c)

Figure 2. Shutdown/Soft-Start Operation

APPLICATIO S I FOR ATIO

WUUU

Page 9

9

LTC1503-1.8/LTC1503-2

Figure 3. Output Ripple Reduction Techniques

+

V

OUT

LTC1503-X

LTC1503-X

V

OUT

10µF

TANTALUM

0.5Ω

1µF

CERAMIC

+

V

OUT

V

OUT

1503-1.8/2 F03

10µF

TANTALUM

+

10µF

TANTALUM

capacitor on V

OUT

to reduce both the low and high frequency ripple. An RC filter may also be used to reduce high

frequency voltage spikes.

Protection Features

The LTC1503-X contains both thermal shutdown and

short-circuit protection features. The charge pump will

shut down when the junction temperature reaches approximately 150°C and will resume operation once the

junction temperature has dropped back to 125°C. The part

will limit output current to 20mA (typ) when a short-circuit

condition (V

OUT

< 150mV) exists to prevent damage to the

internal switches. During start-up, the 20mA current limit

is disabled once V

OUT

reaches 0.7V (typ). The part can

survive an indefinite short from V

OUT

to GND.

Layout Considerations

For best regulation and noise performance, careful board

layout is required. Improper bypassing and grounding

may lead to poor load regulation and output ripple performance. All capacitors, especially CIN and C

OUT

, must be as

close as possible to the VIN and V

OUT

pins. Connecting the

GND pin and all bypass capacitors to an uninterrupted

ground plane is also advised. See Figure 4 for recommended component placement and grounding.

C2

LTC1503-X

GNDC1

V

IN

C

IN

C

OUT

1503-1.8/2 F04

SHDN/SS

V

OUT

Figure 4. Recommended Component Placement and Grounding

APPLICATIO S I FOR ATIO

WUUU

Page 10

10

LTC1503-1.8/LTC1503-2

Dimensions in inches (millimeters) unless otherwise noted.

MS8 Package

8-Lead Plastic MSOP

(LTC DWG # 05-08-1660)

MSOP (MS8) 1098

* DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

0.021

± 0.006

(0.53 ± 0.015)

0

° – 6° TYP

SEATING

PLANE

0.007

(0.18)

0.040

± 0.006

(1.02 ± 0.15)

0.012

(0.30)

REF

0.006 ± 0.004

(0.15 ± 0.102)

0.034 ± 0.004

(0.86 ± 0.102)

0.0256

(0.65)

BSC

12

3

4

0.193 ± 0.006

(4.90 ± 0.15)

8

7

6

5

0.118 ± 0.004*

(3.00 ± 0.102)

0.118 ± 0.004**

(3.00 ± 0.102)

U

PACKAGE DESCRIPTIO

Page 11

11

LTC1503-1.8/LTC1503-2

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

Dimensions in inches (millimeters) unless otherwise noted.

0.016 – 0.050

(0.406 – 1.270)

0.010 – 0.020

(0.254 – 0.508)

×

45

°

0°– 8° TYP

0.008 – 0.010

(0.203 – 0.254)

SO8 1298

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

1

2

3

4

0.150 – 0.157**

(3.810 – 3.988)

8

7

6

5

0.189 – 0.197*

(4.801 – 5.004)

0.228 – 0.244

(5.791 – 6.197)

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

*

**

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

U

PACKAGE DESCRIPTIO

Page 12

12

LTC1503-1.8/LTC1503-2

LINEAR TECHNOLOGY CORPORATION 1999

150312f LT/TP 0200 4K • PRINTED IN USA

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

PART NUMBER DESCRIPTION COMMENTS

LTC1474/LTC1475 Low Quiescent Current Step-Down DC/DC Converter I

OUT

to 250mA, IQ = 10µA; 8-Lead MSOP

LTC1502-3.3 Single Cell to 3.3V Quadrupler Charge Pump VIN = 0.9V to 1.8V, I

OUT

= 10mA; IQ = 40µA

LTC1514/LTC1515 Micropower, Regulated 5V Step-Up/Step-Down 2V to 10V Input Range; Up to 50mA Output Current: Short-Circuit

Charge Pump DC/DC Converters and Overtemperature Protected

LTC1555/LTC1556 SIM Power Supply and Level Translator Step-Up/Step-Down Charge Pump Generates 5V or 3V

LTC1627 Monolithic Synchronous Buck Step-Down 2.65V to 8.5V Input Range; V

OUT

from 0.8V, I

OUT

to 500mA;

Switching Regulator Low Dropout Operation; 100% Duty Cycle

LTC1754-3.3 3.3V Charge Pump with Shutdown in SOT-23 50mA Output Current, ICC = 13µA

LTC1754-5 5V Charge Pump with Shutdown in SOT-23 50mA Output Current, ICC = 13µA

RELATED PARTS

DC/DC Converter with Shutdown and Soft-Start

4

2

3

5

1

8

6

7

LTC1503-1.8

1µF

10nF2N7002ON OFF

1503-1.8/2 TA03

1µF

10µF

1-CELL Li-Ion OR

3-CELL NiMH

10µF

V

OUT

= 1.8V

I

OUT

= 100mA

V

OUT

C2

–

C2

+

GND

V

IN

C1

–

C1

+

SHDN/SS

TYPICAL APPLICATIO

U

Loading...

Loading...