Page 1

FEATURES

■

Input Voltage Range: 0.9V to 1.8V

■

0.9V Guaranteed Start-Up Voltage

■

Regulated Output Voltage: 3.3V ±4%

■

Output Current: 10mA (VIN ≥ 1V)

■

No Inductors

■

Shutdown Disconnects Load from V

■

Low Operating Current: 40µA

■

Low Shutdown Current: 5µA

■

Short-Circuit and Overtemperature Protected

■

Application Circuit Fits in <0.125in2 PCB Area

■

Available in 8-Pin MSOP and SO Packages

IN

U

APPLICATIO S

■

Pagers

■

Battery Backup Supplies

■

Portable Electronic Equipment

■

Handheld Medical Instruments

■

Glucose Meters

LTC1502-3.3

Single Cell to 3.3V

Regulated Charge Pump

DC/DC Converter

U

DESCRIPTIO

The LTC®1502-3.3 is a quadrupler charge pump DC/DC

converter that produces a regulated 3.3V output from a

single alkaline cell input. It requires only five small external

capacitors—no inductors are required. Low supply current (40µA typical, 5µA in shutdown) and minimal external

components make the LTC1502-3.3 ideal for space and

power conscious single-cell applications. The total printed

circuit board area of the circuit shown below is less than

0.125in2.

Forcing the C1–/SHDN pin low through an external resis-

tive pull-down puts the part into shutdown mode. During

shutdown, the internal oscillator is stopped and the load is

disconnected from VIN. An internal pull-up current on the

C1–/SHDN pin forces the part back into normal operation

once the pull-down resistance is removed.

The LTC1502-3.3 is short-circuit protected and survives

an indefinite V

available in 8-pin MSOP and SO packages.

, LTC and LT are registered trademarks of Linear Technology Corporation.

short to ground. The LTC1502-3.3 is

OUT

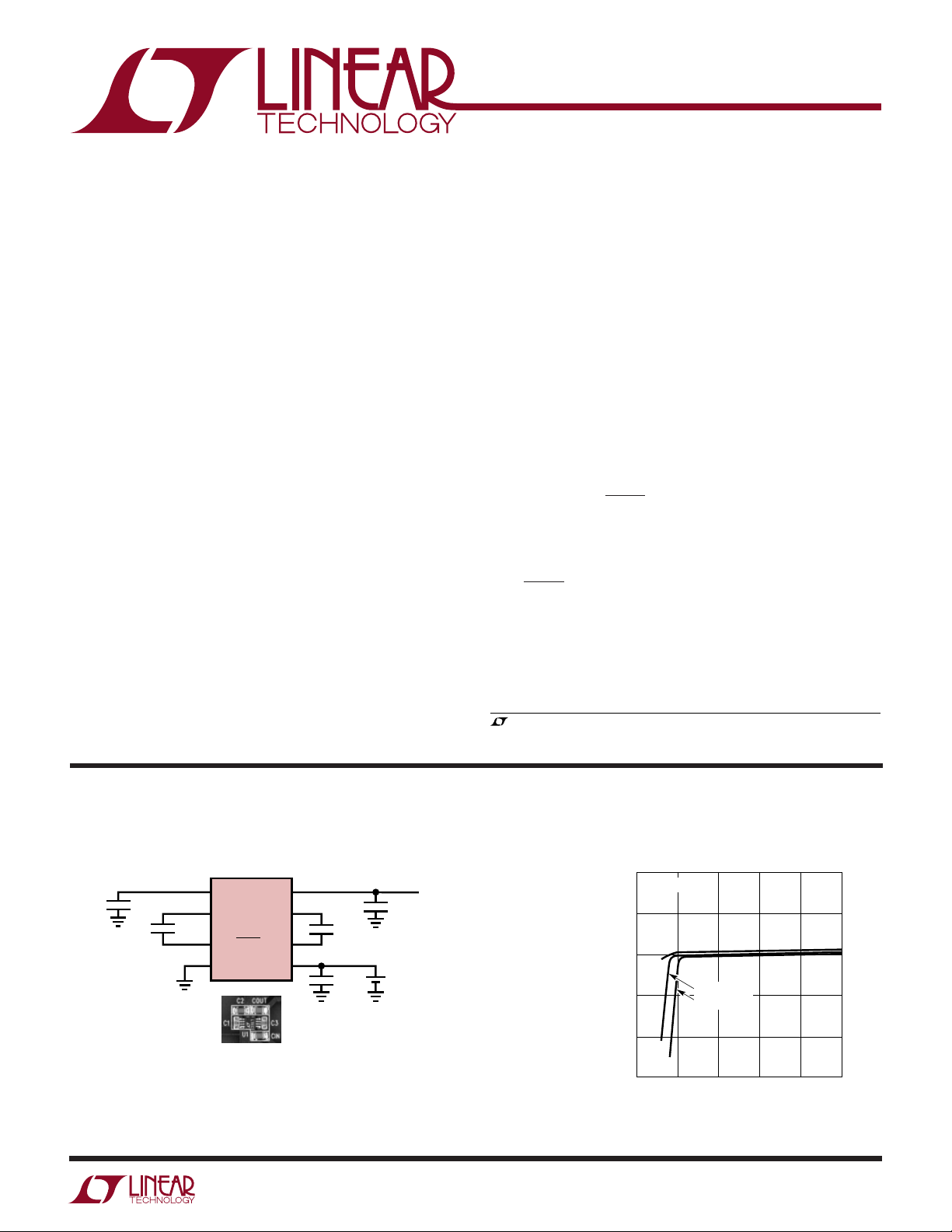

TYPICAL APPLICATIO

Single Cell to 3.3V DC/DC Converter

10µF

1

C2

2

C1

1µF

3

C1–/SHDN

4

GND

PCB LAYOUT FITS IN <0.125IN

V

+

LTC1502-3.3

OUT

C3

C3

+

–

V

IN

U

Output Voltage vs Input Voltage

3.5

8

7

1µF

6

5

10µF

2

V

OUT

I

OUT

10µF

V

IN

SINGLE CELL

NiCd or

ALKALINE

= 3.3V

= 10mA

1502-3.3 TA01

TA = 25°C

3.4

3.3

3.2

OUTPUT VOLTAGE (V)

3.1

3.0

0.8

1.0

I

= 10mA

OUT

= 15mA

I

OUT

1.4

1.2

INPUT VOLTAGE (V)

1.6

1502-3.3 TA02

1.8

1

Page 2

LTC1502-3.3

1

2

3

4

8

7

6

5

TOP VIEW

V

OUT

C3

+

C3

–

V

IN

C2

C1

+

C1–/SHDN

GND

S8 PACKAGE

8-LEAD PLASTIC SO

WW

W

ABSOLUTE MAXIMUM RATINGS

U

(Note 1)

VIN to GND.................................................. –0.3V to 2V

V

to GND ............................................... – 0.3V to 5V

OUT

All Other Pins to GND ................................. –0.3V to 5V

V

Short-Circuit Duration............................ Indefinite

OUT

Storage Temperature Range ................ –65°C to 150°C

U

W

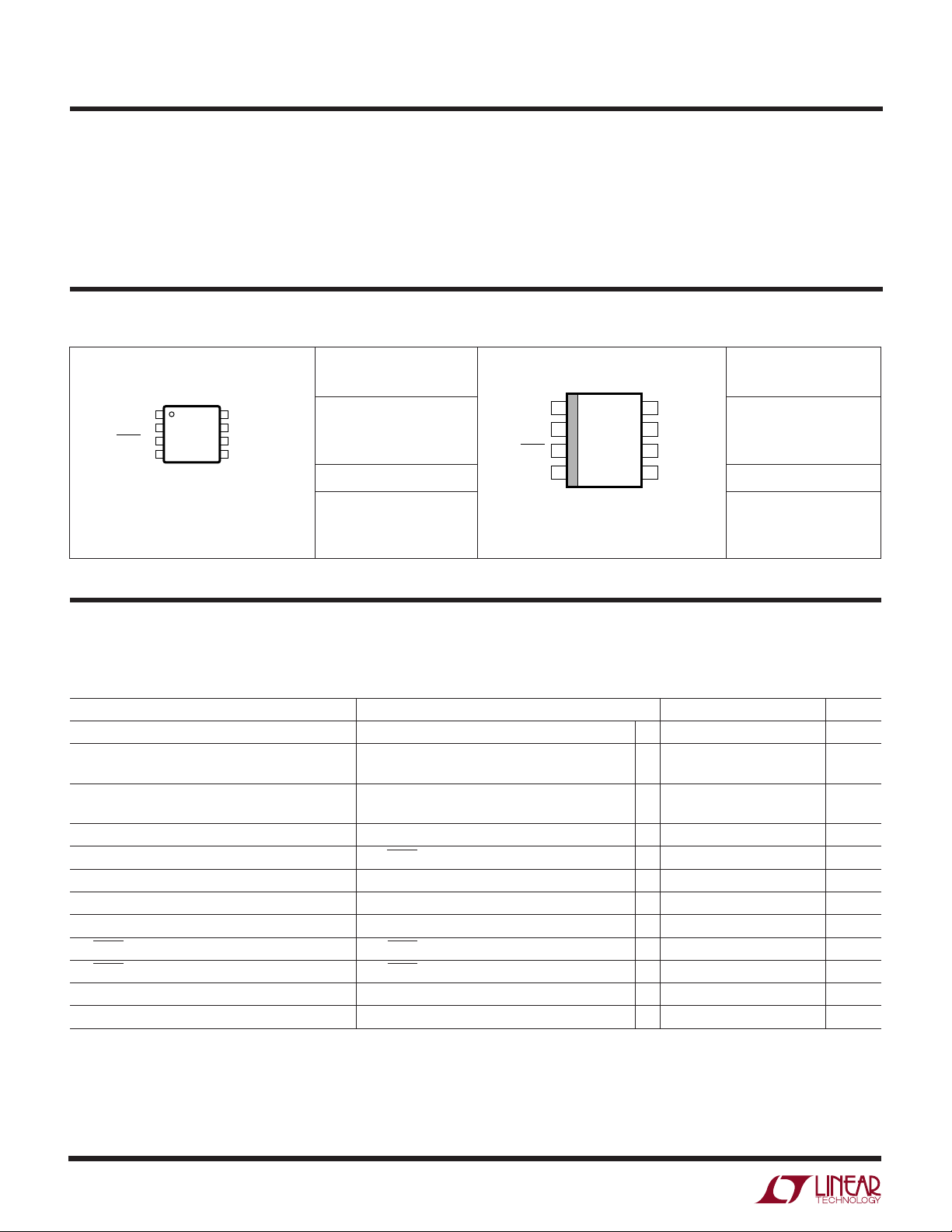

PACKAGE/ORDER INFORMATION

ORDER PART

TOP VIEW

C2

+

C1

C1–/SHDN

GND

8-LEAD PLASTIC MSOP

T

JMAX

1

2

3

4

MS8 PACKAGE

= 125°C, θJA = 250°C/ W

8

V

OUT

+

7

C3

–

6

C3

5

V

IN

Consult factory for Military grade parts.

NUMBER

LTC1502CMS8-3.3

MS8 PART MARKING

LTEC

Operating Temperature Range

Commercial ............................................ 0°C to 70°C

Extended Commercial (Note 4).......... –40°C to 85°C

Industrial ........................................... –40°C to 85°C

Lead Temperature (Soldering, 10 sec)................. 300°C

U

ORDER PART

NUMBER

LTC1502CS8-3.3

LTC1502IS8-3.3

S8 PART MARKING

150233

T

= 125°C, θJA = 150°C/ W

JMAX

502I33

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

VIN = 0.9V to 1.8V, C1 = C3 = 1µF, CIN = C2 = C

PARAMETER CONDITIONS MIN TYP MAX UNITS

VIN Operating Voltage ● 0.9 1.8 V

Minimum VIN Start-Up Voltage TA = 0°C to 70°C (Note 2) ● 0.75 0.9 V

V

Voltage I

OUT

VIN Operating Current I

VIN Shutdown Current C1–/SHDN = 0V ● 515 µA

Output Ripple I

Efficiency VIN = 1V, I

Switching Frequency Oscillator Free-Running 500 kHz

C1–/SHDN Shutdown Input Threshold C1–/SHDN in Hi-Z Sampling State ● 0.20 0.55 0.85 V

C1–/SHDN Shutdown Input Current C1–/SHDN = 0V (Note 3) ● –0.5 –2.5 – 8 µA

V

Turn-On Time VIN = 1V, I

OUT

V

Short-Circuit Current VIN = 1.5V, V

OUT

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: Start-up testing is done with a 100kΩ equivalent load on V

Note 3: Currents flowing into the device are positive polarity. Currents

flowing out of the device are negative polarity.

2

= 10µF unless otherwise specified.

OUT

T

= –40°C to 85°C (Note 2) ● 1.1 V

A

≤ 3.5mA, 0.9V ≤ VIN ≤ 1.8V ● 3.17 3.3 3.43 V

OUT

≤ 10mA, 1V ≤ VIN ≤ 1.8V ● 3.17 3.3 3.43 V

I

OUT

= 0mA ● 40 90 µA

OUT

= 10mA, VIN = 1.25V 50 mV

OUT

= 10mA 77 %

OUT

= 0mA 5 ms

OUT

Forced to 0V 20 mA

OUT

Note 4: Commercial grade specifications are guaranteed over the 0°C to

70°C operating temperature range. In addition, commercial grade

OUT

.

specifications are assured over the –40°C to 85°C operating temperature

range by design, characterization and correlation with statistical process

controls. Industrial grade specifications are guaranteed and tested over the

–40°C to 85°C operating temperature range.

P-P

Page 3

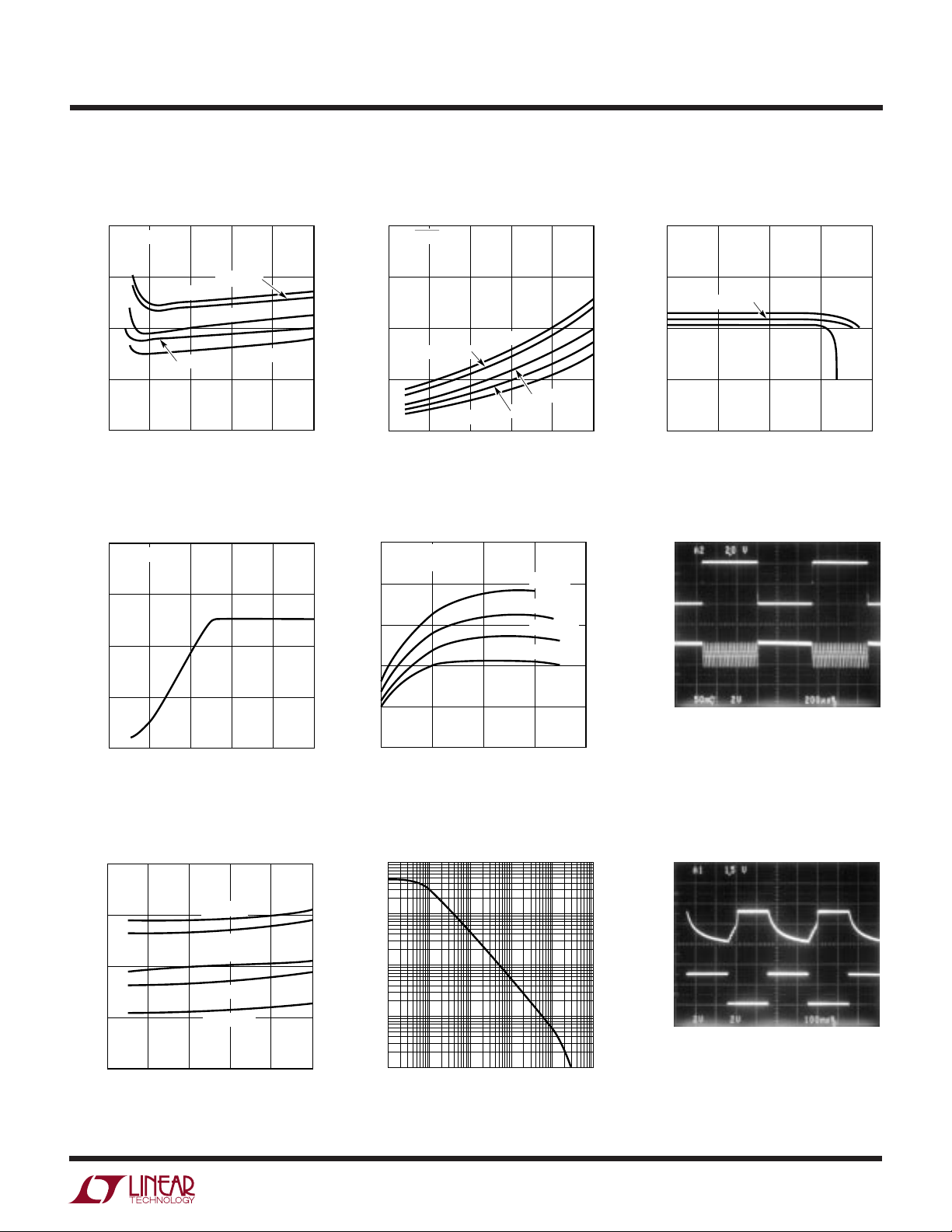

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC1502-3.3

No Load Input Current

vs Input Voltage

80

I

= 0mA

OUT

60

40

INPUT CURRENT (µA)

20

0

0.8

TA = 85°C

TA = 0°C

1.0

INPUT VOLTAGE (V)

1.2

= 70°C

T

A

TA = 25°C

T

1.4

Maximum Start-Up Load Current

vs Input Voltage

16

TA = 25°C

12

8

LOAD CURRENT (mA)

4

0

0.8

1.0

INPUT VOLTAGE (V)

1.2

1.4

= –40°C

A

1.6

1.6

1502-3.3 G01

1502-3.3 G04

1.8

1.8

Shutdown Input Current

vs Input Voltage

16

–

/SHDN = 0V

C1

12

8

TA = 70°C

INPUT CURRENT (µA)

4

0

1.0

0.8

T

T

= – 40°C

A

1.2

INPUT VOLTAGE (V)

Efficiency vs Output Current

100

TA = 25°C

= 3.3V

V

OUT

80

60

40

EFFICIENCY (%)

20

0

0.01

0.1

OUTPUT CURRENT (mA)

1

= 85°C

A

1.4

T

A

TA = 25°C

= 0°C

1.6

= 1V

V

IN

VIN = 1.25V

VIN = 1.5V

VIN = 1.8V

10

1502-3.3 G05

1502-3.3 G02

100

1.8

Output Voltage vs Output Current

3.40

3.35

3.30

OUTPUT VOLTAGE (V)

3.25

3.20

0.01

I

OUT

0mA to 10mA

5mA/DIV

V

OUT

AC COUPLED

50mV/DIV

= 25°C

T

A

VIN = 1.5V

V

= 1V

IN

0.1

OUTPUT CURRENT (mA)

= 1.8V

V

IN

1

10

Load Transient Response

VIN = 1.25V

T

= 25°C

A

200µs/DIV

100

1502-3.3 G03

1502-3.3 G06

Oscillator Frequency

vs Input Voltage

700

600

500

400

OSCILLATOR FREQUENCY (kHz)

300

0.8

1.0

TA = 85°C

TA = – 40°C

1.2

INPUT VOLTAGE (V)

TA = 70°C

TA = 25°C

TA = 0°C

1.4

1.6

1502-3.3 G07

1.8

Calculated Battery Life,

Battery = 2400mA • Hr AA Cell

100k

10k

1k

BATTERY LIFE (HOURS)

100

10

0.001

0.1 1 100.01 100

AVERAGE LOAD CURRENT (mA)

1502-3.3 G08

Shutdown Waveforms

(See Figure 1)

V

OUT

2V/DIV

OFF

V

CTRL

ON

V

= 1.25V

IN

R

= 10k

LOAD

= 25°C

T

A

100µs/DIV

1502-3.3 G09

3

Page 4

LTC1502-3.3

UUU

PIN FUNCTIONS

C2 (Pin 1): Charge Pump 1 (CP1) Output. This pin also

serves as the input supply for charge pump 2 (CP2). To

ensure proper start-up, the C2 pin must not be externally

loaded. Bypass the C2 pin with a ≥10µF low ESR capacitor

to ground.

C1+ (Pin 2): Charge Pump 1 Flying Capacitor Positive

Terminal.

C1–/SHDN (Pin 3): Charge Pump 1 Flying Capacitor Negative Terminal and Shutdown Input. Pulling this pin to

ground through a ≈100Ω resistor will put the part into

shutdown mode. With a high resistance pull-down FET,

the series resistor may be eliminated. The external pulldown device must be high impedance for normal operation (see Applications Information). Peak voltage present

on this pin is approximately equal to VIN.

W

BLOCK DIAGRAM

GND (Pin 4): Ground. Connect to a ground plane for best

performance.

VIN (Pin 5): Input Supply Voltage. Bypass VIN with a ≥10µF

low ESR capacitor to ground.

C3– (Pin 6): Charge Pump 2 (CP2) Flying Capacitor

Negative Terminal.

C3+ (Pin 7): Charge Pump 2 Flying Capacitor Positive

Terminal.

V

(Pin 8): 3.3V Regulated Output Voltage. V

OUT

disconnected from VIN during shutdown. Bypass V

OUT

is

OUT

with a ≥10µF low ESR capacitor to ground.

C3

HIZ2

C3C1

–

CP2

+

C3

8

2.1M

V

OUT

C

OUT

–

1.2M

C2

SHUTDOWN

–

C1

/SHDN

32

V

IN

5

C

IN

U2

2.5µA

–

+

+

0.55V

HIZ1

CLK1/CLK2

SHDN OSCEN

TIMING

CONTROL

CP1

+

C1

400k

V

IN

C2

1 6 7

–

+

1M

U3

COMP2COMP3

U4

+

C2

V

OUT

BIAS

CONTROL

INTERNAL

V

CC

COMP1

1.2V

REF

4

GND

1502-3.3 BD

4

Page 5

TEST CIRCUIT

LTC1502-3.3

1

1µF

C2

2

C1

LTC1502-3.3

3

C1–/SHDN

4

GND

+

SWITCH

CLOSED FOR

SHUTDOWN

U

10µF

100Ω

100pF

WUU

APPLICATIONS INFORMATION

Regulator Operation

The LTC1502-3.3 uses a quadrupler charge pump DC/DC

converter to produce a boosted output voltage. The

quadrupler charge pump consists of two voltage doubler

charge pumps (CP1 and CP2 on the Block Diagram)

cascaded in series. CP1 doubles the input voltage VIN and

the CP1 output voltage is stored on external capacitor C2.

The C2 pin also serves as the input for doubler CP2 whose

output is stored on the output capacitor C

doubler is controlled by a two-phase clock which is

generated in the Timing Control circuit. On phase one of

the clock, the flying capacitors C1 and C3 are charged to

their respective input voltages. On phase two each charged

flying capacitor is stacked on top of the input voltage and

discharged through an internal switch onto its respective

output. This sequence of charging and discharging the

CP1 and CP2 flying capacitors continues at the free

running oscillator frequency (500kHz typ) until the output

is in regulation.

Regulation is achieved by comparing the divided down

output voltage to a fixed voltage reference. The charge

pump clocks are disabled when the output voltage is

above the desired regulation point set by COMP1. When

the output has dropped below the lower trip point of

COMP1, the charge pump clocks are turned back on until

V

is boosted back into regulation.

OUT

Enhanced Start-Up

Enhanced start-up capability is provided by the COMP2

circuitry. COMP2 compares the divided down C2 voltage

to the input voltage VIN. The COMP2 output disables the

output charge pump CP2 whenever the divided C2 voltage

OUT

. Each

8

V

OUT

7

+

C3

1µF

6

–

C3

5

V

IN

10µF

10µF

V

IN

I

1502-3.3 TC

OUT

is lower than VIN. The CP2 output is thereby forced into a

high impedance state until the voltage on C2 has been

raised above VIN (the C2 pin should not be loaded for

proper start-up). This allows a higher internal gate drive

voltage to be generated (from the C2 pin) before the output

(V

) is connected to a load. Hysteresis in COMP2 forces

OUT

CP2 to be turned ON and OFF while C

is charging up to

OUT

prevent a lockup condition if C2 droops too low during

start-up. By the time the output nears the regulation point,

the C2 voltage is well above the lower trip point of COMP2

and CP2 will remain enabled. This method of disabling the

output charge pump while an internal boosted gate drive

supply is developed allows the part to start up at low

voltages with a larger output current load than would

otherwise be possible.

Shutdown

Shutdown is implemented using an external pull-down

device on the C1–/SHDN pin. The recommended external

pull-down device is an open-drain FET with resistive current limiting (see Figure 1). The pull-down device must sink

up to 300µA and pull down below 0.2V to ensure proper

shutdown operation, however, the actual series resistance

is not critical. The pull-down device must also go into a HiZ state for the LTC1502-3.3 to become active.

The timing control circuitry forces the CP1 switches into

a high impedance state every 16 clock cycles. The Hi-Z

duration is equal to one clock cycle. At the end of the

Hi-Z time interval, the voltage on the C1–/SHDN pin is

sampled. If the C1–/SHDN pin has been pulled to a logic

low state, the part will go into shutdown mode. When the

pull-down device is disabled, an internal pull-up current

5

Page 6

LTC1502-3.3

U

WUU

APPLICATIONS INFORMATION

1

C2

2

+

C1

LTC1502-3.3

3

C1–/SHDN

4

100Ω

ON OFF

V

CTRL

Figure 1. Pull-Down Circuitry for Shutdown

GND

will force a logic high on the C1–/SHDN pin and put the part

back into active mode. If no external pull-down is present

during the Hi-Z interval, the internal pull-up current will

maintain a logic high on the C1–/SHDN pin thereby keeping the part in active mode.

The shutdown feature can be used to prevent charge pump

switching during noise sensitive intervals. Since the charge

pump oscillator is disabled during shutdown, output switching noise can be eliminated while the external pull-down is

active. The LTC1502-3.3 takes between 20µs and 50µs to

switch from shutdown to active mode once the pull-down

device has been turned off (assuming a 100pF external

capacitance to GND on the C1–/SHDN pin). A 100k pull-up

resistor from VIN to C1–/SHDN will speed up this transition

by a factor of five at the expense of 10µA or so of additional

shutdown current. To maintain regulation, a sufficiently

large output capacitor must be used to prevent excessive

V

droop while the charge pump is in shutdown. Also,

OUT

there must be adequate time for the charge pump to

recharge the output capacitor while the part is active. In

other words, the average load current must be low enough

for the LTC1502-3.3 to maintain a 3.3V output while the

part is active.

Capacitor Selection

For best performance, it is recommended that low ESR

capacitors be used for CIN, C2 and C

and ripple. The CIN, C2 and C

capacitors should be

OUT

either ceramic or tantalum and should be 10µF or greater.

If the input source impedance is very low (<0.5Ω), C

may not be needed. Ceramic capacitors are recommended

for the flying capacitors C1 and C3 with values of 0.47µF

to 2.2µF. Smaller values may be used in low output current

applications (e.g., I

< 1mA).

OUT

8

V

OUT

7

+

C3

6

–

C3

5

V

IN

to reduce noise

OUT

10µF

1502-3.3 F01

IN

Output Ripple

Normal LTC1502-3.3 operation produces voltage ripple

on the V

pin. Output voltage ripple is required for

OUT

regulation. Low frequency ripple exists due to the hysteresis in the sense comparator and propagation

delays in the charge pump enable/disable circuits. High

frequency ripple is also present mainly from the ESR

(equivalent series resistance) in the output capacitor. Typical output ripple (VIN = 1.25V) under maximum load is

50mV peak-to-peak with a low ESR 10µF output capacitor.

The magnitude of the ripple voltage depends on several

factors. High input voltages increase the output ripple

since more charge is delivered to C

per charging cycle.

OUT

Large output current load and/or a small output capacitor

(<10µF) results in higher ripple due to higher output

voltage dV/dt. High ESR capacitors (ESR > 0.5Ω) on the

output pin cause high frequency voltage spikes on V

OUT

with every clock cycle.

There are several ways to reduce the output voltage ripple.

A larger C

the low and high frequency ripple due to the lower C

capacitor (22µF or greater) will reduce both

OUT

OUT

charging and discharging dV/dt and the lower ESR typically found with higher value (larger case size) capacitors.

A low ESR ceramic output capacitor will minimize the high

frequency ripple, but will not reduce the low frequency

ripple unless a high capacitance value is chosen. A reasonable compromise is to use a 10µF to 22µF tantalum

capacitor in parallel with a 1µF to 3.3µF ceramic capacitor

on V

to reduce both the low and high frequency ripple.

OUT

An RC filter may also be used to reduce high frequency

voltage spikes (see Figure 2).

8

V

OUT

+

LTC1502-3.3

V

OUT

LTC1502-3.3

Figure 2. Output Ripple Reduction Techniques

10µF

TANTALUM

8

+ +

2Ω

10µF10µF

1µF

CERAMIC

V

OUT

V

OUT

1502-3.3 F02

6

Page 7

LTC1502-3.3

U

WUU

APPLICATIONS INFORMATION

Short-Circuit Protection

When the output is shorted to ground, the LTC1502-3.3

will continuously charge the C2 capacitor up to approximately 1.4 times VIN, and then discharge C2 into the

shorted output. Since the discharging of C2 into V

OUT

will

bring the C2 voltage below the COMP2 start-up comparator trip voltage, the output charge pump will be forced

Hi-Z while C2 charges up again. Hence, the internal charge

U

PACKAGE DESCRIPTION

0.007

(0.18)

0.021

± 0.006

(0.53 ± 0.015)

* DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

° – 6° TYP

0

Dimensions in inches (millimeters) unless otherwise noted.

MS8 Package

8-Lead Plastic MSOP

(LTC DWG # 05-08-1660)

0.040

± 0.006

(1.02 ± 0.15)

SEATING

PLANE

0.012

(0.30)

0.0256

REF

(0.65)

BSC

pump gate drive voltage is limited to (1.4)(V

IN(MAX)

C2 pin, and no continuous current is supplied to V

) on the

. The

OUT

resulting output short-circuit current is limited to under

20mA (typ) thereby allowing the LTC1502-3.3 to endure

an indefinite output short circuit without damage. When

the short is removed, the part will start up, and operate

normally.

0.118 ± 0.004*

0.034 ± 0.004

(0.86 ± 0.102)

0.006 ± 0.004

(0.15 ± 0.102)

(3.00 ± 0.102)

0.193 ± 0.006

(4.90 ± 0.15)

8

7

12

6

5

0.118 ± 0.004**

4

3

(3.00 ± 0.102)

MSOP (MS8) 1098

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0.016 – 0.050

(0.406 – 1.270)

(1.346 – 1.752)

0°– 8° TYP

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.053 – 0.069

0.004 – 0.010

(0.101 – 0.254)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.050

(1.270)

BSC

0.228 – 0.244

(5.791 – 6.197)

0.189 – 0.197*

(4.801 – 5.004)

7

8

1

2

5

6

0.150 – 0.157**

(3.810 – 3.988)

SO8 1298

3

4

7

Page 8

LTC1502-3.3

U

TYPICAL APPLICATIONS

Single Cell to 3.3V DC/DC Converter with Shutdown

SHDN

µCONTROLLER

10µF

100Ω

1µF

1

C2

2

C1

3

C1–/SHDN

4

GND

+

LTC1502-3.3

8

V

OUT

7

+

C3

1µF

6

–

C3

5

V

IN

10µF

V

OUT

I

OUT

10µF

SINGLE CELL

NiCd OR

ALKALINE

= 10mA

1502-3.3 TA03

Single Cell Battery Backup Supply with Autoswitchover and No Reverse Current

MAIN

SUPPLY

5V

TRICKLE

CHARGE

150k

1 CELL

NiCd

10µF

10µF

31

LT1521-3.3

1µF

1µF

1

7

6

5

C2

+

C3

LTC1502-3.3

–

C1–/SHDN

C3

V

IN

2

8

V

OUT

2

+

C1

3

4

GND

1µF

100Ω

= 3.3V

V

= 3.3V

OUT

= 300mA

I

OUT

= 10mA

(I

OUT

IN BACKUP MODE)

10µF

1.1M

470k

*REFERRED TO MAIN SUPPLY

3.9V V

TRIP

*

3

4

5

6

LTC1540

+

–

21

7

8

Q1

2N7002

LOGIC LOW =

BACKUP MODE

1502-3.3 TA04

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1307/LT1307B 750mA Single Cell Micropower 600kHz PWM DC/DC Converter 3.3V at 75mA from 1 Cell, MSOP Package

LT1308A/LT1308B 2A Single Cell Micropower 600kHz PWM DC/DC Converter 3.3V at 300mA from 1 Cell, SO-8 Package

LTC1517-3.3 Micropower Regulated 3.3V Charge Pump DC/DC Converter I

LTC1558/LTC1559 Backup Battery Controller with Programmable Output Uses Single NiCd Cell, 100mW Output (Min)

LT1610 Single Cell Micropower 1.7MHz PWM DC/DC Converter 30µA IQ, MSOP Package

LT1611 1.4MHz Inverting Switching Regulator 5V to – 5V at 150mA, Low Output Noise, SOT-23 package

LT1613 1.4MHz Boost Switching Regulator 5V at 200mA from 3.3V Input, SOT-23 Package

LT1615 Micropower Boost Switching Regulator 30µA IQ, V

LTC1682 Low Noise Doubler Charge Pump 60µV

= 15mA (VIN ≥ 2.5V)

OUT

Up to 34V, SOT-23 Package

OUT

Noise, I

RMS

Up to 50mA, MSOP

OUT

8

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

15023f LT/TP 0899 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1999

Loading...

Loading...