Page 1

FEATURES

Final Electrical Specifications

■

Sample Rate: 2.2Msps

■

72dB S/(N + D) and –89dB THD at Nyquist

■

No Missing Codes over Temperature

■

Available in 16-Pin Narrow SSOP Package

■

Single Supply 5V or ±5V Operation

■

Power Dissipation: 90mW (Typ)

■

Nap Mode with Instant Wake-Up: 15mW

■

Sleep Mode: 10µW

■

True Differential Inputs Reject Common Mode Noise

■

80MHz Full Power Bandwidth Sampling

■

Input Range (1mV/LSB): 0V to 4.096V or ±2.048V

■

Internal Reference Can Be Overdriven Externally

■

3-Wire Interface to DSPs and Processors (SPI and

MICROWIRETM Compatible)

U

APPLICATIONS

■

Telecommunications

■

High Speed Data and Signal Acquisition

■

Digitally Multiplexed Data Acquisition Systems

■

Digital Radio Receivers

■

Spectrum Analysis

■

Low Power and Battery-Operated Systems

■

Handheld or Portable Instruments

■

Imaging Systems

, LTC and LT are registered trademarks of Linear Technology Corporation.

MICROWIRE is a trademark of National Semiconductor Corp.

LTC1402

Serial 12-Bit, 2.2Msps

Sampling ADC with Shutdown

U

DESCRIPTION

The LTC®1402 is a 12-bit, 2.2Msps sampling A/D converter. This high performance device includes a high dynamic range sample-and-hold and a precision reference.

It operates from a single 5V supply or dual ±5V supplies

and draws only 90mW from 5V.

The versatile differential input offers a unipolar range of

4.096V and a bipolar range of ±2.048V for dual supply

systems where high performance op amps perform best,

eliminating the need for special translation circuitry.

The high common mode rejection allows users to eliminate ground loops and common mode noise by measuring

signals differentially from the source.

Outstanding AC performance includes 72dB S/(N + D) and

–93dB SFDR at the Nyquist input frequency of 1.1MHz

with dual ±5V supplies and –84dB SFDR with a single 5V

supply.

The LTC1402 has two power saving modes: Nap and

Sleep. Nap mode consumes only 15mW of power and

Sleep can wake up and convert immediately. In Sleep

mode, it typically consumes 10µW of power. Upon power-

up from Sleep mode, a reference ready (REFRDY) signal

is available in the serial data word to indicate that the

reference has settled and the chip is ready to convert.

The 3-wire serial port allows compact and efficient data

transfer to a wide range of microprocessors, microcontrollers and DSPs. A digital output driver power supply pin

allows direct connection to 3V or lower logic.

October 1999

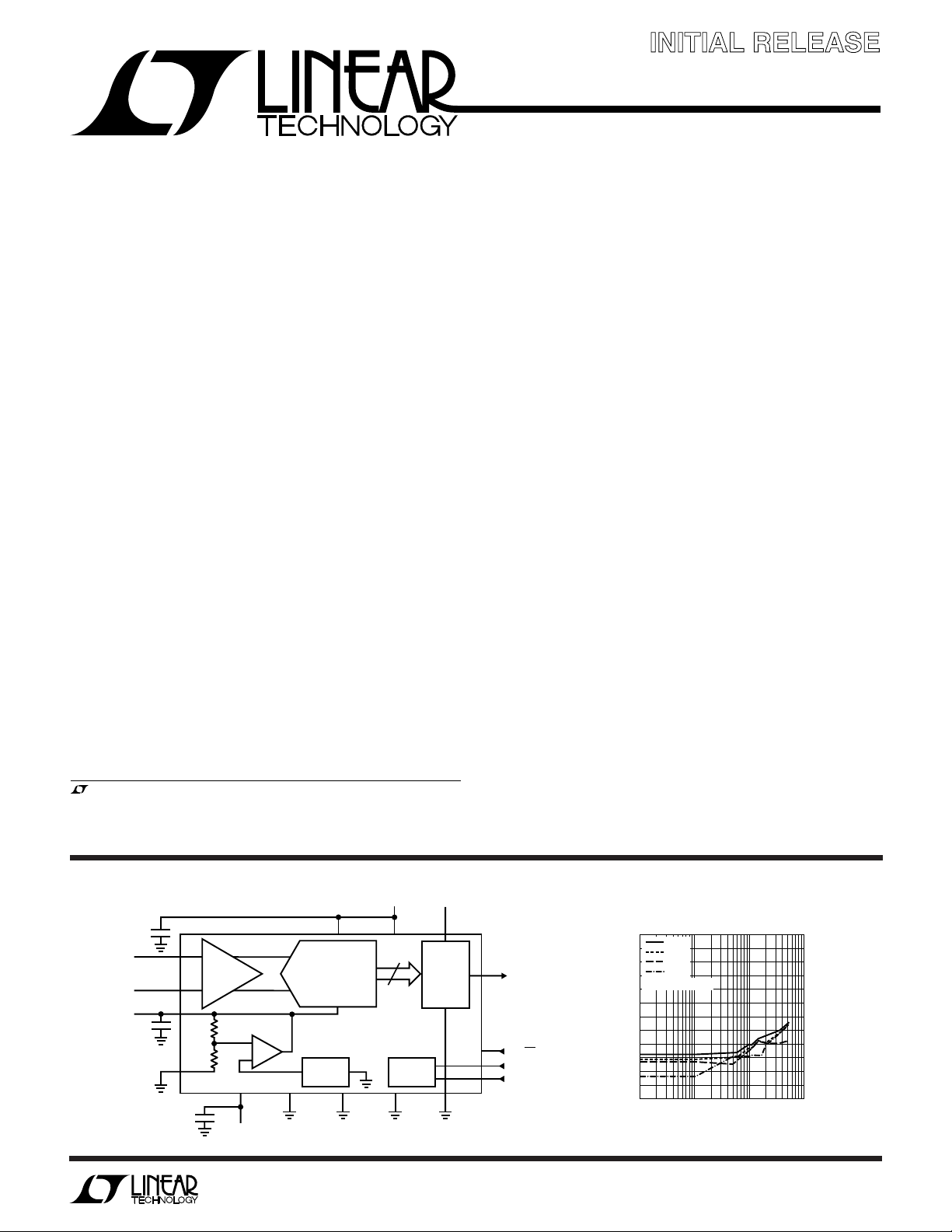

BLOCK DIAGRA

10µF

10µF

GAIN

3

SAMPLE-

AND-HOLD

4

5

7

LTC1402

10µF

+A

IN

–A

IN

V

REF

4.096V

64k

64k

–5V OR 0V

W

5V 3V OR 5V

AVDD11211

12-BIT ADC

–

+

2.048

REFERENCE

AGND1VSS14 13AGND2

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

DV

TIMING

LOGIC

OV

OUTPUT

BUFFER

DD

10

D

OUT

8

BIP/UNI

16

CONV

15

SCK

1402 TA01

OGND962 DGND

DD

5 Harmonic THD, 2nd, 3rd and SFDR

vs Input Frequency (Unipolar)

0

–10

–20

–30

f

SAMPLE

–40

–50

–60

–70

–80

–90

THD, SFDR, 2ND 3RD (dB)

–100

–110

–120

4

10

THD

SFDR

2ND

3RD

= 2.22MHz

5

10

INPUT FREQUENCY (Hz)

6

10

1401 G05

7

10

1

Page 2

LTC1402

T

WW

W

U

ABSOLUTE MAXIMUM RATINGS

AVDD = DVDD = OVDD = V

Supply Voltage (VDD)................................................. 6V

Negative Supply Voltage (VSS) ............................... – 6V

Total Supply Voltage (VDD to VSS) .......................... 12V

Analog Input Voltage

(Note 3) ..........................(VSS – 0.3V) to (VDD + 0.3V)

Digital Input Voltage

(Note 4) ..........................(VSS – 0.3V) to (VDD + 0.3V)

Digital Output Voltage......... (VSS – 0.3V) to (VDD + 0.3V)

Power Dissipation.............................................. 250mW

Operation Temperature Range

LTC1402C ............................................... 0°C to 70°C

LTC1402I............................................ –40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

(Notes 1, 2)

DD

U

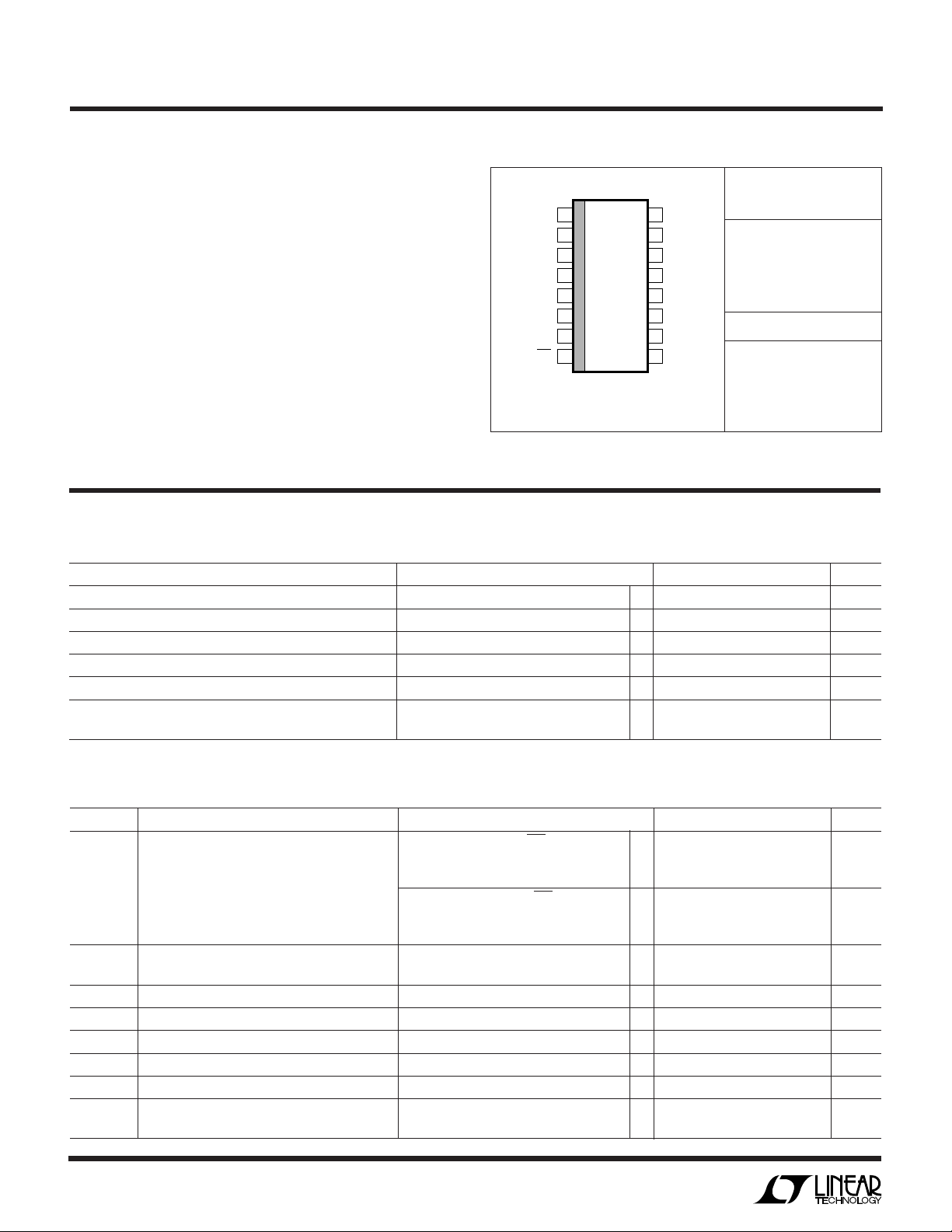

PACKAGE/ORDER INFORMATION

TOP VIEW

AV

1

DD

2

AGND1

+

3

A

IN

–

4

A

IN

5

V

REF

6

AGND2

7

GAIN

8

BIP/UNI

16-LEAD NARROW PLASTIC SSOP

Consult factory for Military grade parts.

GN PACKAGE

T

= 125°C, θJA = 150°C/W

JMAX

CONV

16

15

SCK

14

V

SS

13

DGND

12

DV

DD

11

0V

DD

10

D

OUT

9

OGND

GN PART MARKING

W

ORDER PART

NUMBER

LTC1402CGN

LTC1402IGN

1402

1402I

U

Lead Temperature (Soldering, 10 sec).................. 300°C

U

CONVERTER CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. With internal reference (Note 5).

PARAMETER CONDITIONS MIN TYP MAX UNITS

Resolution (No Missing Codes) ● 12 Bits

Integral Linearity Error (Note 6) ● ±0.35 ±1LSB

Differential Linearity (Note 6) ● ±0.25 ±1LSB

Offset Error (Note 6) ● ±2 ±10 LSB

Full-Scale Error (Note 6) ● ±10 ±15 LSB

Full-Scale Tempco Internal Reference (Note 6) ±15 ppm/°C

The ● denotes the specifications which apply over the full operating

External Reference ±1 ppm/°C

UU

A ALOG I PU

otherwise specifications are at TA = 25°C. (Note 5)

The ● denotes the specifications which apply over the full operating temperature range,

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN

V

CM

I

IN

C

IN

t

ACQ

t

AP

t

JITTER

CMRR Analog Input Common Mode Rejection Ratio fIN = 1MHz, VIN = 2V to –2V –62 dB

Analog Differential Input Range (Notes 3, 11) Bipolar Mode with BIP/UNI High ● ±2.048 V

4.75V ≤ V

–5.25V ≤ V

Unipolar Mode with BIP/UNI Low ● 0 to 4.096 V

4.75V ≤ V

–5.25V ≤ V

Analog Common Mode + Differential Dual ±5V Supply –2.5 to 5 V

Input Range (Note 12) Single 5V Supply 0 to 5 V

Analog Input Leakage Current ● 1 µA

Analog Input Capacitance 10 pF

Sample-and-Hold Acquisition Time ● 60 ns

Sample-and-Hold Aperture Delay Time 2.6 ns

Sample-and-Hold Aperture Delay Time Jitter 1 ps

f

= 100MHz, VIN = 2V to –2V –24 dB

IN

≤ 5.25V V

DD

≤ –4.75V V

SS

≤ 5.25V V

DD

≤ 0V V

SS

2

Page 3

LTC1402

UW

DYNAMIC ACCURACY

otherwise specifications are at TA = 25°C. Bipolar mode with ± 5V supplies and unipolar mode with 5V supply. (Note 5)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

S/(N + D) Signal-to-Noise Plus 100kHz Input Signal 72.5 dB

Distortion Ratio 1.1MHz Input Signal

THD Total Harmonic 100kHz First 5 Harmonics, Bipolar Mode –89 dB

Distortion 1.1MHz First 5 Harmonics, Bipolar Mode

100kHz First 5 Harmonics, Unipolar Mode –87 dB

1.1MHz First 5 Harmonics, Unipolar Mode –82 dB

SFDR Spurious Free 1.1MHz Input Signal in Bipolar Mode –93 dB

Dynamic Range 1.1MHz Input Signal in Unipolar Mode –84 dB

IMD Intermodulation ±1V 1.25MHz into A

Distortion 1.5V to 3.5V 1.25MHz into A

Code-to-Code V

Transition Noise

Full Power Bandwidth VIN = 4V

Full Linear Bandwidth S/(N + D) ≥ 68dB Bipolar Mode 5.0 MHz

Unipolar Mode 3.5 MHz

The ● denotes the specifications which apply over the full operating temperature range,

● 69 72.0 dB

● –89 –74.5 dB

+

, 1.2MHz into A

IN

= 4.096V, 1LSB = 1mV 0.18 LSB

REF

, D

OUT

= 2828

P-P

+

IN

(Note 18) 82 MHz

P-P

–

Bipolar Mode –84 dB

IN

, 1.2MHz into A

–

Unipolar Mode –84 dB

IN

RMS

UU U

INTERNAL REFERENCE CHARACTERISTICS

full operating temperature range, otherwise specifications are at TA = 25°C. (Note 5)

The ● denotes the specifications which apply over the

PARAMETER CONDITIONS MIN TYP MAX UNITS

V

Output Voltage I

REF

V

Output Tempco 15 ppm/°C

REF

V

Line Regulation AVDD = 4.75V to 5.25V, V

REF

V

Output Resistance Load Current = 0.5mA 2 Ω

REF

V

Settling Time 2ms

REF

= 0 4.096 V

OUT

= 4.096V 1 LSB/V

REF

UU

DIGITAL I PUTS A D DIGITAL OUTPUTS

full operating temperature range, otherwise specifications are at TA = 25°C. (Note 5)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

I

IN

C

IN

V

OH

V

OL

I

OZ

C

OZ

I

SOURCE

I

SINK

High Level Input Voltage VDD = 5.25V ● 2.4 V

Low Level Input Voltage VDD = 4.75V ● 0.8 V

Digital Input Current VIN = 0V to V

Digital Input Capacitance 5pF

High Level Output Voltage OVDD = 4.75V, I

OV

DD

OV

DD

Low Level Output Voltage VDD = 4.75V, I

V

= 4.75V, I

DD

Hi-Z Output Leakage D

Hi-Z Output Capacitance D

Output Short-Circuit Source Current V

Output Short-Circuit Sink Current V

OUT

OUT

V

OUT

OUT

V

OUT

OUT

DD

= 4.75V, I

= 3V, I

= 0V to V

= 0V, OVDD = 5V –40 mA

= 0V, OVDD = 3V –15 mA

= OVDD = 5V 40 mA

OUT

OUT

OUT

OUT

OUT

DD

The ● denotes the specifications which apply over the

● ±10 µA

= –10µA 4.7 V

= –200µA ● 4V

= –200µA ● 2.5 2.9 V

= 160µA 0.05 V

= 1.6mA ● 0.10 0.4 V

● ±10 µA

15 pF

3

Page 4

LTC1402

WU

POWER REQUIRE E TS

range, otherwise specifications are at TA = 25°C. (Note 5)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

DD

V

SS

I

DD

I

SS

PD Power Dissipation Active Mode with SCK in Fixed State (Hi or Lo) 90 150 mW

Positive Supply Voltage 4.75 5.00 5.25 V

Negative Supply Voltage –5.25 –5.00 0 V

Positive Supply Current Active Mode ● 18 30 mA

Negative Supply Current Active, Sleep or Nap Modes with SCK Off ● 2 µA

The ● denotes the specifications which apply over the full operating temperature

Nap Mode

Sleep Mode 2 10 µA

● 35 mA

UW

TI I G CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. (Note 5)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

SAMPLE(MAX)

t

THROUGHPUT

t

SCK

t

CONV

t

ACQ

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

8a

t

9

t

10

t

11

t

12

Maximum Sampling Frequency (Conversion Rate) ● 2.2 MHz

Minimum Sampling Period (Conversion + Acquisiton Period) ● 455 ns

Minimum Clock Period ● 28 10000 ns

Conversion Time Greater Than 13 Clocks + 6ns (Note 9) ● 375 ns

Acquisition Time Greater Than 2 Clocks – 6ns (Notes 9, 16) ● 51 ns

Minimum Positive or Negative SCK Pulse Width (Note 9) ● 3.8 6 ns

CONV to SCK Setup Time (Notes 9, 13) ● 7.3 12 ns

SCK After CONV (Note 9) ● 0ns

Minimum Positive or Negative CONV Pulse Width (Note 9) ● 3.5 5 ns

SCK to Sample Mode (Notes 9, 14) ● 914 ns

CONV to Hold Mode (Note 9) ● 3.4 5 ns

Minimum Delay Between Conversions (Note 9) ● 48 ns

Minimum Delay from SCK to Valid Bits 0 Through 11 (Notes 9, 15) ● 912 ns

Minimum Delay from SCK to Valid REFREADY (Notes 9, 15) ● 15 20 ns

SCK to Hi-Z at D

Previous D

REFREADY Bit Delay After Sleep-to-Wake Transition (Notes 9, 17) ● 10 ms

V

Settling Time After Sleep-to-Wake Transition (Notes 9, 17) ● 2ms

REF

OUT

Bit Remains Valid After SCK (Notes 9, 15) ● 47 ns

OUT

The ● denotes the specifications which apply over the full operating temperature

(Notes 9, 15) ● 11.4 16 ns

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: All voltage values are with respect to ground with DGND, AGND1

and AGND2 wired together.

Note 3: When these pins are taken below V

clamped by internal diodes. This product can handle input currents greater

than 100mA below V

Note 4: When these pins are taken below VSS, they will be clamped by

internal diodes. This product can handle input currents greater than

100mA below VSS or greater than VDD. These pins are not clamped to VDD.

Note 5: V

specifications and V

= 5V, f

DD

or greater than VDD without latchup.

SS

= 2.2MHz, VSS = 0V for unipolar mode

SAMPLE

= –5V for bipolar specifications.

SS

or above VDD, they will be

SS

4

Note 6: Linearity, offset and full-scale specifications apply for a singleended A

bipolar mode with ±5V supplies.

Note 7: Integral linearity is defined as the deviation of a code from the

straight line passing through the actual endpoints of a transfer curve. The

deviation is measured from the center of quantization band.

Note 8: Bipolar offset is the offset measured from –0.5LSB when the input

flickers between 1000 0000 0000 and 0111 1111 1111.

Note 9: Guaranteed by design, not subject to test.

Note 10: Recommended operating conditions.

Note 11: The analog input range is defined as the voltage difference

between A

with a single 5V supply if the absolute voltages of the inputs remain within

the single 5V supply voltage.

+

input with A

IN

+

and A

IN

–

grounded and using the internal reference in

IN

–

. The bipolar ±2.048V input range could be used

IN

Page 5

LTC1402

ELECTRICAL CHARACTERISTICS

Note 12: The absolute voltage at A

+

IN

Note 13: If less than 7.3ns is allowed, the output data will appear one

clock cycle later. It is best for CONV to rise half a clock before SCK, when

running the clock at rated speed.

Note 14: Not the same as aperture delay. Aperture delay is smaller (2.6ns)

because the 0.8ns delay through the sample-and-hold is subtracted from

the CONV to Hold mode delay.

Note 15: The rising edge of SCK is guaranteed to catch the data coming

out into a storage latch.

Note 16: The Sample mode is started by the 14th rising clock and it is

ended by the rising edge of convert. Because the start of Sample mode is

and A

–

must be within this range.

IN

slower than the end of Sample mode, the sample time is 6ns less than the

delay between the 14th SCK and CONV.

Note 17: The internal reference settles in 2ms after it wakes up from Sleep

mode with one or more cycles at SCK and a 10µF capacitive load. The

Sleep mode resets the REFREADY bit in the D

REFREADY bit goes high again 10ms after the V

sequence. The

OUT

has stopped slewing in

REF

wake up. This ensures valid REFREADY bit operation even with higher load

capacitances at V

REF

.

Note 18: The full power bandwidth is the frequency where the output code

swing drops to 2828LSBs with a 4V

input sine wave.

P-P

UW

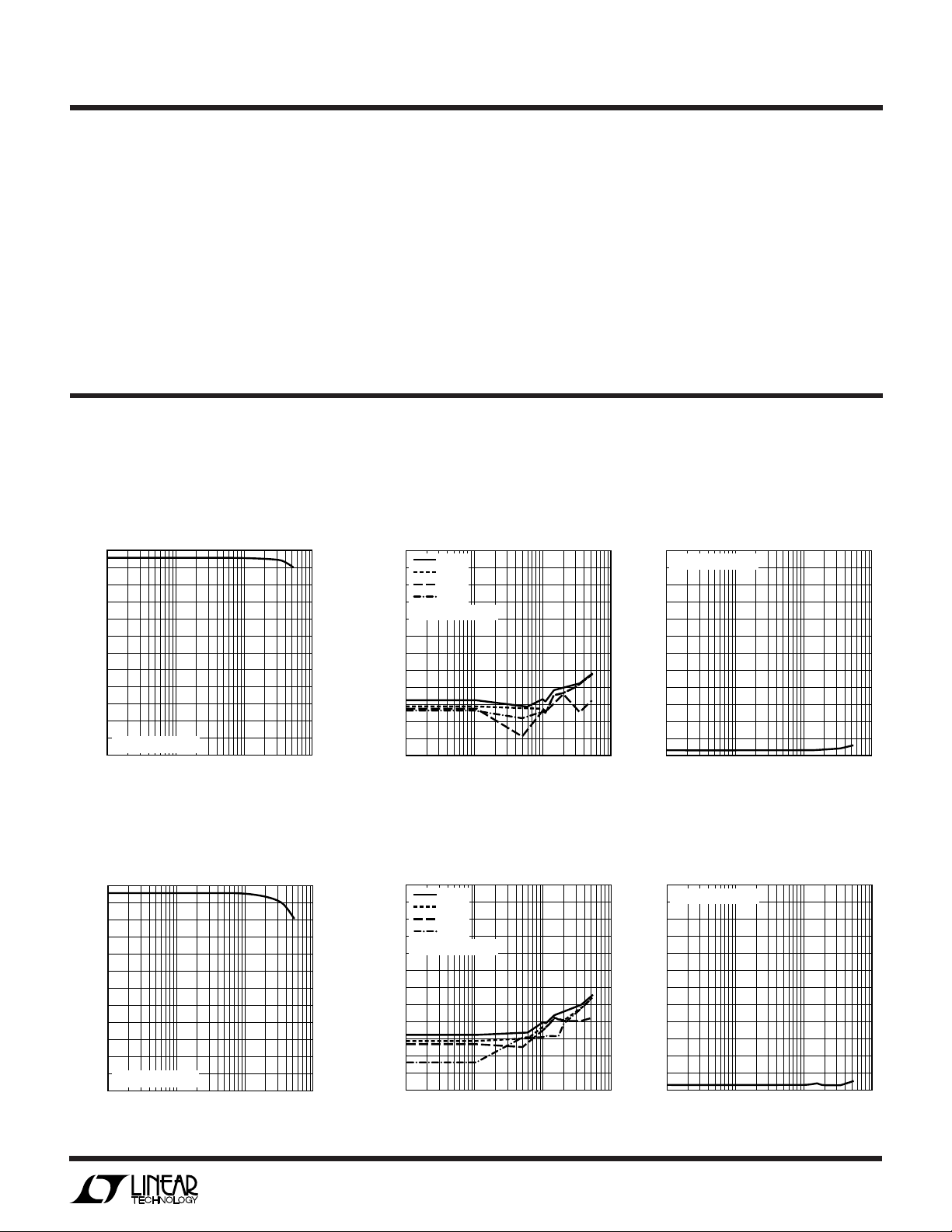

TYPICAL PERFOR A CE CHARACTERISTICS

Unipolar Mode Plots Run with a Single 5V Supply. VDD = 5V, VSS = –5V for Bipolar, VDD = 5V, VSS = 0V for Unipolar), TA = 25°C.

5 Harmonic THD, 2nd, 3rd and

ENOBs and SINAD

vs Input Frequency (Bipolar)

12

11

10

9

8

7

6

5

4

3

EFFECTIVE NUMBER OF BITS

2

1

f

= 2.22MHz

SAMPLE

0

4

10

5

10

INPUT FREQUENCY (Hz)

74

SIGNAL-TO-NOISE + DISTORTION (dB)

68

62

56

50

44

38

32

26

20

14

8

1401 G01

2

7

10

6

10

SFDR vs Input Frequency

(Bipolar)

0

10

f

SAMPLE

4

THD

SFDR

2ND

3RD

= 2.22MHz

5

10

INPUT FREQUENCY (Hz)

–10

–20

–30

–40

–50

–60

–70

–80

–90

THD, SFDR, 2ND 3RD (dB)

–100

–110

–120

(Bipolar Mode Plots Run with Dual ±5V Supplies.

SNR vs Input Frequency (Bipolar)

–2

f

= 2.22MHz

SAMPLE

–8

–14

–20

–26

–32

–38

SNR (dB)

–44

–50

–56

–62

–68

6

10

1401 G02

–74

7

10

4

10

5

10

INPUT FREQUENCY (Hz)

6

10

1401 G03

7

10

ENOBs and SINAD

vs Input Frequency (Unipolar)

12

11

10

9

8

7

6

5

4

3

EFFECTIVE NUMBER OF BITS

2

1

f

= 2.22MHz

SAMPLE

0

4

10

5

10

INPUT FREQUENCY (Hz)

5 Harmonic THD, 2nd, 3rd and

SFDR vs Input Frequency

(Unipolar)

74

SIGNAL-TO-NOISE + DISTORTION (dB)

68

62

56

50

44

38

32

26

20

14

8

1401 G04

2

7

10

6

10

0

10

f

SAMPLE

4

THD

SFDR

2ND

3RD

= 2.22MHz

5

10

INPUT FREQUENCY (Hz)

–10

–20

–30

–40

–50

–60

–70

–80

–90

THD, SFDR, 2ND 3RD (dB)

–100

–110

–120

6

10

1401 G05

7

10

SNR vs Input Frequency (Unipolar)

–2

f

= 2.22MHz

SAMPLE

–8

–14

–20

–26

–32

–38

SNR (dB)

–44

–50

–56

–62

–68

–74

4

10

5

10

INPUT FREQUENCY (Hz)

6

10

1401 G06

7

10

5

Page 6

LTC1402

LOAD CURRENT (mA)

0

4.040

INTERNAL REFERENCE VOLTAGE (V)

4.050

.4.060

4070

4.080

4.090

4.100

0.4 0.8 1.2 1.6

1402 G20

2.0

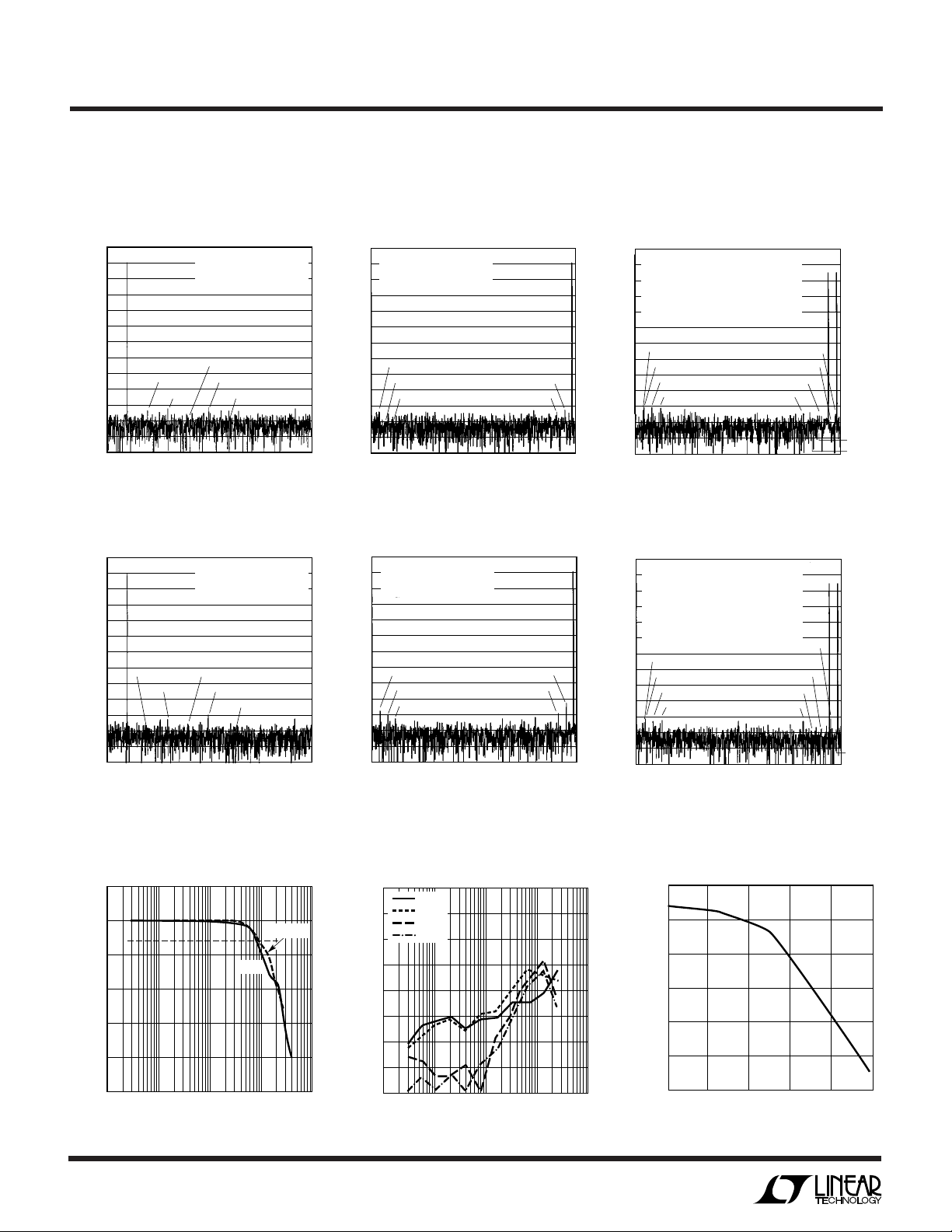

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Unipolar Mode Plots Run with a Single 5V Supply. VDD = 5V, VSS = –5V for Bipolar, VDD = 5V, VSS = 0V for Unipolar), TA = 25°C.

(Bipolar Mode Plots Run with Dual ±5V Supplies.

Sine Wave Spectrum Plot

(Bipolar) ±5V Supply

10

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

Sine Wave Spectrum Plot

(Unipolar) 5V Supply

10

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

2ND

0

4V

Power Bandwidth and

P-P

100mV

P-P

Bandwidth

5

0

–5

–10

AMPLITUDE (dB)

–15

–20

–25

0.1 10 100 1000

6

1

f

SAMPLE

f

= 109592.01Hz

SINE

2048 SAMPLES

4TH

2ND

FREQUENCY (MHz)

3RD

FREQUENCY (MHz)

5TH

3RD

0.55 1.11

f

SAMPLE

= 109592.01Hz

f

SINE

2048 SAMPLES

4TH

5TH

0.55 1.11

Small-Signal

FREQUENCY (MHz)

= 2222222.22Hz

6TH

1402 G09

= 2222222.22Hz

6TH

1402 G12

100mV

P-P

4V

P-P

1402 F07

Sine Wave Spectrum Plot

(Bipolar) Dual ±5V Supply

10

f

= 2222222.22Hz

SAMPLE

0

= 1131727.43Hz

f

SINE

–10

2048 SAMPLES

–20

–30

–40

–50

–60

2ND

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

4TH

6TH

0

0.55 1.11

FREQUENCY (MHz)

Sine Wave Spectrum Plot

(Unipolar) 5V Supply

10

f

= 2222222.22Hz

SAMPLE

0

= 1131727.43Hz

f

SINE

–10

2048 SAMPLES

–20

–30

–40

–50

–60

2ND 3RD

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

4TH

6TH

0

0.55 1.11

FREQUENCY (MHz)

PSRR vs Frequency

0

–10

–20

–30

–40

–50

REJECTION (dB)

–60

–70

–80

V

CC

V

SS

V

DD

DGND

0.1 10 100 1000

1

FREQUENCY (MHz)

5TH

5TH

3RD

1402 G11

1402 G08

1402 G18

IMD Spectrum Plot (Bipolar)

10

f

= 2352941.18Hz

SAMPLE

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

= 1250000Hz ±1V INTO A

f

SINEA

f

= 1199449Hz ±1V INTO A

SINEB

IMD = 83.9dB

2048 SAMPLES

– f

f

A

B

2f

B

fA – f

B

2f

A

0

FREQUENCY (MHz)

0.59 1.18

IMD Spectrum Plot (Unipolar)

10

f

= 2352941.18Hz

SAMPLE

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

= 1250000Hz INTO A

f

SINEA

1.5V TO 3.5V

= 1199449Hz INTO A

f

SINEB

1.5V TO 3.5V

IMD = –84.1dB

2048 SAMPLES

– f

f

A

B

2f

B

fA + f

B

2f

A

0

FREQUENCY (MHz)

2fA – fB, fA + 2f

0.59 1.18

Load Regulation for V

fA + 2f

+

IN

–

IN

2fA + f

3f

,

,

+

IN

–

IN

fA – 2f

A

3f

A

B

B

REF

B

3f

B

2fA – f

B

2fA + f

B

1402 G10

3f

B

B

fA – 2f

B

1402 G13

Page 7

LTC1402

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Unipolar Mode Plots Run with a Single 5V Supply. VDD = 5V, VSS = –5V for Bipolar, VDD = 5V, VSS = 0V for Unipolar), TA = 25°C.

(Bipolar Mode Plots Run with Dual ±5V Supplies.

Positive Power Supply Rejection

for V

4.095

4.090

4.085

4.080

4.075

4.070

INTERNAL REFERENCE VOLTAGE (mV)

4.065

REF

4.5

4.75 5.0 5.25 5.5 5.75

VDD (V)

Negative Power Supply Rejection

for V

4.095

4.090

4.085

4.080

4.075

4.070

INTERNAL REFERENCE VOLTAGE (mV)

4.065

REF

–5

–4 –3 –2 –1

VSS (V)

1402 G21

1402 G19

6.0

Differential Nonlinearity

vs Output Code (Bipolar)

1.00

f

= 2.2MHz

SAMPLE

0.75

0.50

0.25

0

DNL (LSB)

–0.25

–0.50

–0.75

–1.00

0

512

1024

1536

2048

CODE

2560

3072

3584

4096

1402 G15

Differential Nonlinearity

vs Output Code (Unipolar)

1.00

f

= 2.2MHz

SAMPLE

0.75

0.50

0.25

0

DNL (LSB)

–0.25

–0.50

–0.75

–1.00

0

512

0

1024

1536

2048

CODE

2560

3072

3584

4096

1402 G17

Integral Nonlinearity

vs Output Code (Bipolar)

1.00

f

= 2.2MHz

SAMPLE

0.75

0.50

0.25

0

INL (LSB)

–0.25

–0.50

–0.75

–1.00

512

0

1024

1536

Integral Nonlinearity

vs Output Code (Unipolar)

1.00

f

= 2.2MHz

SAMPLE

0.75

0.50

0.25

0

INL (LSB)

–0.25

–0.50

–0.75

–1.00

512

0

1024

1536

2048

CODE

2048

CODE

2560

2560

3072

3072

3584

3584

4096

1402 G14

4096

1402 G16

UUU

PIN FUNCTIONS

AVDD (Pin 1): 5V Analog Power Supply. Bypass to AGND1

and solid analog ground plane with 10µF ceramic (or 10µF

tantalum in parallel with 0.1µF ceramic).

AGND1 (Pin 2): Analog Ground. Tie to solid analog ground

plane. The analog ground plane should be solid and have

no cuts near the LTC1402.

+

A

(Pin 3): Positive Analog Signal Input. 0V to 4.096V in

IN

unipolar mode and ±2.048V in bipolar mode when A

grounded. Both of these ranges operate fully differentially

with respect to A

–

. (Note 3)

IN

IN

–

is

–

A

(Pin 4): Negative Analog Signal Input. Can be grounded

IN

or driven differentially with A

+

. Identical to A

IN

+

, except

IN

that it inverts the input signal. (Note 3)

V

(Pin 5): 4.096V Reference Voltage Output. Bypass to

REF

AGND1 and solid analog ground plane with 10µF ceramic

(or 10µF tantalum in parallel with 0.1µF ceramic).

AGND2 (Pin 6): Analog Ground Return for the Reference

and Internal CDAC. AGND2 could be overdriven externally

above ground. Tie to solid analog ground plane.

7

Page 8

LTC1402

UUU

PIN FUNCTIONS

GAIN (Pin 7): Tie to AGND2 to set the reference voltage to

4.096V or tie to V

to set the reference voltage to 2.048V.

REF

(Note 4)

BIP/UNI (Pin 8): Tie to logic low to set the input range to

unipolar mode or tie to logic high to set the input range to

bipolar mode. (Note 4)

OGND (Pin 9): Output Ground for the Output Driver. This

pin can be tied to the digital ground of the system. All other

ground pins should be tied to the analog ground plane.

D

(Pin 10): Three-State Data Output. (Note 3) Each

OUT

output data word represents the analog input at the start

of the previous conversion.

OVDD (Pin 11): Output Data Driver Power. Tie to VDD when

driving 5V logic. Tie to 3V when driving 3V logic.

DVDD (Pin 12): Digital Power for Internal Logic. Bypass to

DGND with 10µF ceramic (or 10µF tantalum in parallel

with 0.1µF ceramic).

DGND (Pin 13): Digital Ground for Internal Logic. Tie to

solid analog ground plane.

VSS (Pin 14): Negative Supply Voltage. Bypass to solid

analog ground plane with 10µF ceramic (or 10µF tantalum

in parallel with 0.1µF ceramic) or tie directly to the solid

analog ground plane for single supply use. Must be set

more negative than either A

IN

+

or A

–

. Set to 0V or –5V.

IN

SCK (Pin 15): External Clock. Advances the conversion

process and sequences the output data at D

OUT

on the

rising edge. Responds to 5V or 3V CMOS and to TTL levels.

(Note 4). One or more pulses wake from Nap or Sleep.

CONV (Pin 16): Holds the input analog signal and starts

the conversion on the rising edge. Responds to 5V or 3V

CMOS and to TTL levels. (Note 4). Two pulses with SCK in

fixed high or fixed low state start Nap Mode. Four pulses

with SCK in fixed high or fixed low state start Sleep mode.

BLOCK DIAGRA

3

+

A

IN

4

–

A

IN

2.048V REF

64k

7

GAIN

5

V

REF

DGND

6

2

13

AGND2

AGND1

W

+

–

64k

INTERNAL

CLOCK

C

SAMPLE

C

SAMPLE

12-BIT CAPACITIVE DAC

SUCCESSIVE APPROXIMATION

REGISTER

CONTROL LOGIC

16 15

SCKCONV

ZEROING SWITCHES

+

COMPREF AMP

–

OUTPUT

DRIVER

1402 BD

1

AV

DD

12

DV

DD

14

V

SS

8

BIP/UNI

10

D

OUT

11

OV

DD

9

OGND

8

Page 9

LTC1402

UW

W

TI I G DIAGRA S

t

2

t

3

SCK

CONV

INTERNAL

S/H STATUS

D

OUT

t

t

SAMPLE SAMPLEHOLD HOLD

123456789101112131415 16 1 2

4

6

t

8a

Hi-Z Hi-Z

REPRESENTS THE ANALOG INPUT FROM THE PREVIOUS CONVERSION

D

OUT

REF D11 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0D10

REFRDY BIT + 12-BIT DATA WORD

t

CONV

t

THROUGHPUT

Nap Mode and Sleep Mode Waveforms

t

7

t

5

t

ACQ

t

8

REF

1402 TD01

SCK

CONV

NAP

SLEEP

V

REF

REFRDY

t

1

NOTE: NAP AND SLEEP ARE INTERNAL SIGNALS. REFRDY APPEARS AS A BIT IN THE D

D

SCK

OUT

SCK to D

V

IH

t

8

t

10

V

OH

V

OL

OUT

Delay

SCK

D

OUT

t

1

t

12

t

11

WORD.

OUT

V

IH

t

9

1402 TD03

90%

10%

1402 TD02

9

Page 10

LTC1402

U

WUU

APPLICATIONS INFORMATION

DRIVING THE ANALOG INPUT

The differential analog inputs of the LTC1402 are easy to

drive. The inputs may be driven differentially or as a singleended input (i.e., the A

–

A

inputs are sampled at the same instant. Any unwanted

IN

signal that is common to both inputs will be reduced by the

common mode rejection of the sample-and-hold circuit.

The inputs draw only one small current spike while charging the sample-and-hold capacitors at the end of conversion. During conversion, the analog inputs draw only a

small leakage current. If the source impedance of the

driving circuit is low, then the LTC1402 inputs can be

driven directly. As source impedance increases, so will

acquisition time (see Figure 1). For minimum acquisition

time with high source impedance, a buffer amplifier must

be used. The only requirement is that the amplifier driving

the analog input(s) must settle after the small current

spike before the next conversion starts (settling time must

be 50ns for full throughput rate).

1500

1400

1300

1200

1100

1000

900

800

700

600

500

400

ACQUISITION TIME (ns)

300

200

100

0

10 1k 10k

Figure 1. Acquisition Time vs Source Resistance

in Bipolar and Unipolar Modes

CHOOSING AN INPUT AMPLIFIER

Choosing an input amplifier is easy if a few requirements

are taken into consideration. First, to limit the magnitude

of the voltage spike seen by the amplifier from charging

the sampling capacitor, choose an amplifier that has a low

output impedance (< 100Ω) at the closed-loop bandwidth

frequency. For example, if an amplifier is used in a gain of

1 and has a unity-gain bandwidth of 50MHz, then the

output impedance at 50MHz must be less than 100Ω. The

–

input is grounded). The A

IN

±5V

5V

100

SOURCE RESISTANCE (Ω)

1402 F01

100k

IN

+

and

second requirement is that the closed-loop bandwidth

must be greater than 40MHz to ensure adequate smallsignal settling for full throughput rate. If slower op amps

are used, more time for settling can be provided by

increasing the time between conversions. The best choice

for an op amp to drive the LTC1402 will depend on the

application. Generally, applications fall into two categories: AC applications where dynamic specifications are

most critical, and time domain applications where DC

accuracy and settling time are most critical. The following

list is a summary of the op amps that are suitable for

driving the LTC1402. More detailed information is available in the Linear Technology Databooks and on the

LinearViewTM CD-ROM.

LT®1206: 60MHz Current Feedback Amplifier with Shutdown Pin (Amplifier Draws 200µA While in Shutdown).

±5V to ±15V supplies. Distortion is –80dB to 1MHz

(2V

into 30Ω). Good for AC applications. Dual avail-

P-P

able with shutdown as LT1207. Output swings to within

2VBE of the supply rails.

LT1223: 100MHz Video Current Feedback Amplifier. 6mA

supply current. ±5V to ±15V supplies. Low distortion at

frequencies above 400kHz. Low noise. Good for AC applications.

LT1227: 140MHz Video Current Feedback Amplifier. 10mA

supply current; has shutdown pin (draws 120µA while in

shutdown). ±5V to ±15V supplies. Lowest distortion

(– 92dB) at frequencies above 400kHz. Low noise. Best for

AC applications.

LT1229/LT1230: Dual and Quad 100MHz Current Feedback Amplifiers. ±2V to ±15V supplies. Low noise. Good

AC specifications, 6mA supply current each amplifier.

LT1360: 50MHz Voltage Feedback Amplifier. 3.8mA supply current. ±5V to ±15V supplies. Good AC and DC

specifications. 70ns settling to 0.5LSB.

LT1363: 70MHz, 1000V/µs Op Amps. 6.3mA supply cur-

rent. Good AC and DC specifications. 60ns settling to

0.5LSB.

LT1364/LT1365: Dual and Quad 70MHz, 1000V/µs Op

Amps. 6.3mA supply current per amplifier. 60ns settling

to 0.5LSB.

LinearView is a trademark of Linear Technology Corporation.

10

Page 11

LTC1402

U

WUU

APPLICATIONS INFORMATION

LT1630: Dual 30MHz Rail-to-Rail Voltage FB Amplifier.

2.7V to ±15V supplies. Very high A

520ns settling to 0.5LSB for a 4V swing. THD and noise

are –93dB to 40kHz and below 1LSB to 320kHz (AV = 1,

2V

into 1kΩ, VS = 5V), making the part excellent for AC

P-P

applications (to 1/3 Nyquist) where rail-to-rail performance is desired. Quad version is available as LT1631.

LT1632: Dual 45MHz Rail-to-Rail Voltage FB Amplifier.

2.7V to ±15V supplies. Very high A

400ns settling to 0.5LSB for a 4V swing. It is suitable for

applications with a single 5V supply. THD and noise are

–93dB to 40kHz and below 1LSB to 800kHz (AV = 1,

2V

into 1kΩ, VS = 5V), making the part excellent for AC

P-P

applications where rail-to-rail performance is desired.

Quad version is available as LT1633.

LT1813: Dual 100MHz 750V/µs 3mA Voltage Feedback

Amplifier. 5V to ±5V supplies. Distortion is –86dB to

100kHz and – 77dB to 1MHz with ±5V supplies (2V

500Ω). Excellent part for fast AC applications with ±5V

supplies.

INPUT FILTERING AND SOURCE IMPEDANCE

The noise and the distortion of the input amplifier and

other circuitry must be considered since they will add to

the LTC1402 noise and distortion. The small-signal bandwidth of the sample-and-hold circuit is 80MHz. Any noise

or distortion products that are present at the analog inputs

will be summed over this entire bandwidth. Noisy input

circuitry should be filtered prior to the analog inputs to

minimize noise. A simple 1-pole RC filter is sufficient for

many applications. For example, Figure 2 shows a 68pF

capacitor from A

+

to ground and a 51Ω source resistor

IN

to limit the input bandwidth to 47MHz. The 68pF capacitor

also acts as a charge reservoir for the input sample-andhold and isolates the ADC input from sampling glitchsensitive circuitry.

High quality capacitors and resistors should be used since

these components can add distortion. NPO and silver mica

type dielectric capacitors have excellent linearity.

Carbon surface mount resistors can generate distortion

from self heating and from damage that may occur during

soldering. Metal film surface mount resistors are much

, 500µV offset and

VOL

, 1.5mV offset and

VOL

P-P

into

ANALOG

INPUT

51Ω

68pF

10µF

3

4

2

5

6

7

+

A

IN

–

A

IN

AGND1

LTC1402

V

REF

AGND2

GAIN

1402 F02

Figure 2. RC Input Filter

less susceptible to both problems. When high amplitude

unwanted signals are close in frequency to the desired signal

frequency, a multiple pole filter is required. Figure 3 shows

a simple implementation using an LTC1560-1 fifth order

elliptic continuous-time 1MHz filter.

–5V

1

2

V

IN

LTC1560-1

3

4

0.1µF

8

7

6

5

5V

0.1µF

Figure 3. 1MHz Fifth Order Elliptic Lowpass Filter

10µF

3

4

2

5

6

7

+

A

IN

–

A

IN

AGND1

LTC1402

V

REF

AGND2

GAIN

1402 F03

BIPOLAR AND UNIPOLAR INPUT RANGES

The ±2V bipolar input range of the LTC1402 is optimized

for low noise and low distortion. Most op amps also

perform best over this same range, allowing direct coupling to the analog inputs and eliminating the need for

special translation circuitry. The inputs of the LTC1402

may also be driven fully differential in bipolar mode with

a single supply. Each input should not swing more than

2V

individually to get the best performance from single

P-P

supply amplifiers.

The 0V to 4V range is ideal for single ended input use with

single supply applications.

11

Page 12

LTC1402

U

WUU

APPLICATIONS INFORMATION

INTERNAL REFERENCE

The LTC1402 has an on-chip, temperature compensated,

curvature corrected, bandgap reference that is factory

trimmed to 2.048V. It is connected internally to a reference

amplifier, see Figure 4. The reference amplifier amplifies

the voltage at the V

internal reference voltage of 4.096V. This provides buffering for the high speed capacitive DAC. The reference

amplifier output V

capacitor to ground. The reference amplifier is stable with

capacitors of 1µF or greater. For the best noise perfor-

mance, a 10µF ceramic or a 10µF tantalum in parallel with

a 0.1µF ceramic is recommended.

The V

pin can be driven with an external reference as

REF

shown in Figure 5a. The GAIN pin (Pin 7) is tied to the

positive supply to disable the internal reference buffer.

A DAC may also be used to drive V

Figure 6. This is useful in applications where the peak

input signal amplitude may vary. The input span of the

pin by 2 to create the required

REF

, (Pin 5) must be bypassed with a

REF

as shown in

REF

ADC can then be adjusted to match the peak input signal,

maximizing the signal-to-noise ratio. The filtering of the

internal LTC1402 reference amplifier will limit the bandwidth and settling time of this circuit. A settling time of

5ms should be allowed after a reference adjustment.

DIFFERENTIAL INPUTS

The LTC1402 has a unique differential sample-and-hold

circuit that allows inputs from –2.5V to 5V. The ADC will

always convert the difference of A

IN

+

– A

–

independent

IN

of the common mode voltage. The common mode rejection holds up at extremely high frequencies, see Figure 7.

The only requirement is that both inputs not exceed

–2.5V or 5V. Integral nonlinearity errors (INL) and differential nonlinearity errors (DNL) are independent of the

common mode voltage. However, the bipolar zero error

(BZE) will vary. The change in BZE is typically less than

0.1% of the common mode voltage. Figure 5b shows the

use of bipolar mode with single 5V supply.

4.096V

5

LTC1402

V

REF

REFERENCE

AMP

2.048V

+

–

10µF

7

6

GAIN

AGND2

64k

64k

Figure 4. LTC1402 Reference Circuit

5V

V

IN

LT1019-2.5

V

OUT

ANALOG INPUT

10µF

5V

3

4

5

6

7

BANGAP

REFERENCE

+

A

IN

–

A

IN

LTC1402

V

REF

AGND2

GAIN

1402 F04

1402 F04a

5V

V

IN

LT1019-2.5

2.5V ±2.048V

10µF

V

10µF

3

4

5

6

7

+

A

IN

–

A

IN

V

REF

AGND2

GAIN

LTC1402

IN

Figure 5b. Bipolar Mode with Single Supply

3

+

A

IN

ANALOG INPUT

LTC1450

5V

10µF

4

5

6

7

–

A

IN

V

REF

AGND2

GAIN

LTC1402

BIP

V

SS

1402 F04a

1402 F06

14

Figure 5a. Using the LT1019-2.5 as an External Reference

12

Figure 6. Driving V

with a DAC

REF

Page 13

LTC1402

U

WUU

APPLICATIONS INFORMATION

0

–10

–20

–30

–40

AMPLITUDE (dB)

–50

–60

–70

0.1 10 100 1000

Figure 7. CMRR vs Input Frequency

FULL-SCALE AND OFFSET ADJUSTMENT

Figure 8 shows the ideal input/output characteristics for

the LTC1402 in bipolar mode and unipolar mode. Figure 9a

shows the components required for full-scale error adjustment. Figure 9b includes the components for offset

and full-scale adjustment.

Adjustment in Bipolar Mode with Pin 8 Held High

The code transitions occur midway between successive

integer LSB values (i.e., – FS + 0.5LSB, – FS + 1.5LSB, –FS

+ 2.5LSB,...FS – 2.5LSB, FS – 1.5LSB). The output at D

is two’s complement binary with 1LSB = FS – (–FS)/4096

= 4.096V/4096 = 1.0mV. In applications where absolute

accuracy is important, offset and full-scale errors can be

adjusted to zero. Offset error must be adjusted before fullscale error. In Figure 9b, zero offset is achieved by adjusting the offset applied to the A

error, apply – 0.5mV (i.e., –0.5LSB) to A

offset at the A

flickers between 0000 0000 0000 and 1111 1111 1111.

For full-scale adjustment in Figures 9a and 9b, apply an

input voltage of 2.0465V (FS – 1.5LSB) to A

R5 until the output code flickers between 0111 1111 1110

and 0111 1111 1111.

Adjustment in Unipolar Mode with Pin 8 Held Low

1

FREQUENCY (MHz)

–

IN

–

input using R8 until the output code

IN

1402 F07

input. For zero offset

+

and adjust the

IN

+

and adjust

IN

OUT

011...111

011...110

011...101

BIPOLAR OUTPUT CODE

100...010

100...001

100...000

FS – 1LSB–(FS – 1LSB)

INPUT VOLTAGE (V)

111...111

111...110

111...101

000...010

000...001

000...000

1402 F08

Figure 8. LTC1402 Transfer Characteristic

ANALOG INPUT

0V TO 4.096V

OR ±2.048V

500Ω

R1

51Ω

R2

R3

39k

51Ω

R4

470k

R5

10µF

+

A

3

IN

S/H

–

4

A

IN

2.048V

5

V

REF

REFERENCE

AMP

64k

GAIN

7

AGND26

64k

LTC1402

BANGAP

REFERENCE

Figure 9a. Full-Scale Adjustment Circuit with ±10LSB Range

5V

R7

R4

470k

R6

24k

R2

24k

10µF

+

A

3

IN

S/H

–

A

4

IN

2.048V

V

5

REF

REFERENCE

AMP

64k

GAIN

7

AGND26

64k

LTC1402

BANGAP

REFERENCE

ANALOG INPUT

0V TO 4.096V

OR ±2.048V

OFFSET

R8

ADJ

10k

FULL-SCALE

ADJ

R1

51Ω

R3

51Ω

5V

7.5k

R5

500Ω

UNIPOLAR OUTPUT CODE

1402 F09a

The code transitions occur midway between successive

integer LSB values (i.e., –FS + 0.5LSB, – FS + 1.5LSB,

– FS + 2.5LSB,...FS – 2.5LSB, FS – 1.5LSB). The output at

1402 F09b

Figure 9b. Offset and Full-Scale Adjustment

Circuits with ±10LSB Range

13

Page 14

LTC1402

U

WUU

APPLICATIONS INFORMATION

D

is binary with 1LSB = FS/4096 = 4.096V/4096 =

OUT

1.0mV. In applications where absolute accuracy is important, offset and full-scale errors can be adjusted to zero.

Offset error must be adjusted before full-scale error. In

Figure 9b, zero offset is achieved by adjusting the offset

applied to the A

– 0.5mV (i.e., –0.5LSB) to A

–

A

input using R8 until the output code flickers between

IN

0000 0000 0000 and 0000 0000 0001. For full-scale adjustment in Figures 9a and 9b, apply an input voltage of

2.0465V (FS – 1.5LSBs) to A

output code flickers between 1111 1111 1110 and 1111

1111 1111.

BOARD LAYOUT AND BYPASSING

Wire wrap boards are not recommended for high resolution and/or high speed A/D converters. To obtain the best

performance from the LTC1402, a printed circuit board

with ground plane is required. Layout for the printed

circuit board should ensure that digital and analog signal

lines are separated as much as possible. In particular, care

should be taken not to run any digital track alongside an

analog signal track.

An analog ground plane separate from the logic system

ground should be established under and around the ADC.

Pin 2 (AGND1), Pin 6 (AGND2), Pin 13 (DGND) and all

other analog grounds should be connected directly to an

analog ground plane. Pin 9 (OGND) should be connected

near Pin13 (DGND), where the analog ground plane ties to

the logic system ground. The V

the DVDD bypass capacitor should also be connected to

this analog ground plane, see Figure 10. No other digital

grounds should be connected to this analog ground plane.

–

input. For zero offset error apply

IN

+

and adjust the offset at the

IN

+

and adjust R5 until the

IN

bypass capacitor and

REF

Low impedance analog and digital power supply common

returns are essential to low noise operation of the ADC and

the foil width for these tracks should be as wide as

possible. The traces connecting the pins and bypass

capacitors must be kept short and should be made as wide

as possible.

The LTC1402 has differential inputs to minimize noise

coupling. Common mode noise on the A

will be rejected by the input CMRR. The A

used as a ground sense for the A

+

input; the LTC1402 will

IN

IN

IN

+

and A

–

hold and convert the difference voltage between A

–

A

. The leads to A

IN

+

(Pin 3) and A

IN

–

(Pin 4) should be

IN

–

leads

IN

input can be

+

and

IN

kept as short as possible. In applications where this is not

possible, the A

IN

+

and A

–

traces should be run side-by-

IN

side to cancel noise coupling.

SUPPLY BYPASSING

High quality, low series resistance 10µF ceramic bypass

capacitors should be used at the VDD and V

REF

pins.

Surface mount ceramic capacitors such as Murata

GRM235Y5V106Z016 provide excellent bypassing in a

small board space. Alternatively, 10µF tantalum capaci-

tors in parallel with 0.1µF ceramic capacitors can be used.

Bypass capacitors must be located as close to the pins as

possible. The traces connecting the pins and the bypass

capacitors must be kept short and should be made as wide

as possible.

POWER-DOWN MODES

Upon power-up, the LTC1402 is initialized to the active

state and is ready for conversion. The Nap and Sleep Mode

waveforms show the power-down modes for the LTC1402.

14

ANALOG

INPUT

CIRCUITRY

12

OV

3

+

A

IN

–

A

IN

REF

4

+

–

AGND2 AGND1V

6145

ANALOG GROUND PLANE

Figure 10. Power Supply Grounding Practice

V

SS

LTC1402

10µF

AVDDDV

2

DGND

DD

11213 9

10µF10µF

DD

D

OUT

OGND

3V TO 5V

10

DIGITAL

SYSTEM

SYSTEM

GROUND

1402 F10

Page 15

LTC1402

U

WUU

APPLICATIONS INFORMATION

The SCK and CONV inputs control the power-down modes

(see Timing Diagrams). Two rising edges at CONV, without any intervening rising edges at SCK, put the LTC1402

in Nap mode and the power drain drops from 90mW to

15mW. The internal reference remains powered in Nap

mode. One or more rising edges at SCK wake up the

LTC1402 for service very quickly, and CONV can start an

accurate conversion within a clock cycle. Four rising edges

at CONV, without any intervening rising edges at SCK, put

the LTC1402 in Sleep mode and the power drain drops

from 90mW to 10µW. One or more rising edges at SCK

wake up the LTC1402 for operation. The internal reference

(V

) takes 2ms to slew and settle with a 10µF load, and

REF

the REFREADY bit in the D

10ms to go high after the reference output Pin 5 (V

finished slewing. Figure 11 shows the power consumption

versus the conversion rate. Note that, for slower conversion rates, the Nap and Sleep modes can be used for substantial reductions in power consumption.

100

SUPPLY CURRENT (mA)

0.01

0.001

Figure 11. Power Consumption vs Sample Rate

in Normal Mode, Nap Mode and Sleep Mode

VDD CURRENT

DUAL ±5V

VDD CURRENT

10

1

0.1

0.01 0.1 1

SINGLE 5V

VDD CURRENT

SLEEP MODE

VSS CURRENT

SINGLE 5V

SAMPLE RATE (MHz)

DIGITAL INTERFACE

The LTC1402 has a 3-wire SPI (Serial Protocol Interface)

interface. The SCK and CONV inputs and D

implement this interface. The SCK and CONV inputs are TTL

compatible and also accept swings from 3V or 5V logic. The

amplitude of D

can easily produce 5V logic or 3V logic

OUT

swings by tying the independent output supply Pin 11

(OVDD) to the same supply as system logic. A detailed

description of the three serial port signals follows.

stream takes an additional

OUT

REF

VDD CURRENT

NAP MODE

VSS CURRENT

DUAL ±5V

10

1402 F11

output

OUT

) has

CONV at Pin 16

The rising edge of CONV starts a conversion but subsequent rising edges at CONV, during the following 14 SCK

cycles of conversion, are ignored by the LTC1402. The

duty cycle of CONV can be arbitrarily chosen to be used as

a frame sync signal for the processor serial port. A simple

approach to generate CONV is to create a pulse that is one

SCK wide to drive the LTC1402 and then buffer this signal

with the appropriate number of inverters to drive the frame

sync input of the processor serial port. It is good practice

to drive the LTC1402 CONV input first to avoid digital noise

interference during the sample-to-hold transition triggered

by CONV at the start of conversion. Another point to consider is the level of jitter in the CONV signal if the input

signals have fast transients or sinewaves. Some processors can be programmed to generate a convenient frame

sync pulse at their serial port, but often this signal is derived from a jittery processor phase locked loop clock

multiplier. This is true even if a low jitter crystal clock is the

reference for the processor clock multiplier.

SCK at Pin 15

The rising edge of SCK advances the conversion process

and also udpates each bit in the D

data stream. After

OUT

CONV rises, the second rising edge of SCK sends out the

REFREADY bit. Subsequent edges send out the 12 data

bits, with the MSB sent first. A simple approach is to

generate SCK to drive the LTC1402 and then buffer this

signal with the appropriate number of inverters to drive the

serial clock input of the processor serial port. The rising

edge of SCK is guaranteed to coincide with stable data at

D

. It is good practice to drive the LTC1402 SCK input

OUT

first to avoid digital noise interference during the internal

bit comparison decision by the internal high speed comparator. Unlike the CONV input, the SCK input is not

sensitive to jitter because the input signal is already

sampled and held constant.

D

at Pin 10

OUT

Upon power-up, the D

the high impedance state. The D

impedance until a new conversion is started. D

output is automatically reset to

OUT

output remains in high

OUT

OUT

sends

out 13 bits in the output data stream after the second rising

edge of SCK after the start of conversion with the rising

15

Page 16

LTC1402

U

WUU

APPLICATIONS INFORMATION

edge of CONV. Please note the delay specification from

SCK to a valid D

by the next rising edge of SCK.

DIGITAL JITTER AT CONV (PIN 16)

In high speed applications, where high amplitude sinewaves

above 100kHz are sampled, the CONV signal must have as

little jitter as possible (10ps or less). The square wave

output of a common crystal clock module usually meets

this requirement easily. The challenge is to generate a CONV

signal from this crystal clock without jitter corruption from

other digital circuits in the system. A clock divider and any

gates in the signal path from the crystal clock to the CONV

input should not share the same integrated circuit with

other parts of the system. As shown in the interface circuit

examples, the LTC1402’s SCK and CONV inputs should be

driven first with digital buffers used to drive the serial port

interface. Also note that the master clock in the DSP may

already be corrupted with jitter, even if it comes directly

from the DSP crystal. Another problem with high speed

processor clocks is that they often use a low cost, low

OUT

. D

is always guaranteed to be valid

OUT

speed crystal (i.e., 10MHz) to generated a fast, but jittery,

phase locked loop system clock (i.e., 40MHz). The jitter, in

these PLL-generated high speed clocks, can be several

nanoseconds. Note that if you choose to use the frame

sync signal generated by the DSP port, this signal will have

the same jitter of the DSP’s master clock.

SERIAL TO PARALLEL CONVERSION

You can take advantage of the serial interface of the LTC1402

in a parallel data system to minimize bus wiring congestion in the PC board layout. Figure 12 shows an example

of this interface. It is best to send the SCK and CONV

signals to the LTC1402, and then bus them together across

the board to avoid excessive time skew among the three

signals. It is usually not necessary to buffer D

, if the PC

OUT

track is not too long. Buffering SCK and CONV prevents

jitter from corrupting these signals. The relative phase

between SCK and CONV affects the position of the parallel

word at the output of the 74HC595. The position of the

output word in Figure 12 assumes 16 clocks between each

CONV rising edge, and the CONV pulse is one clock wide.

LTC1402

OV

CONV

SCK

D

OUT

OGND

5V

11

DD

74ACT04

16

15

10

9

CONV

CLK

3-WIRE SERIAL

INTERFACE LINK

12

11

14

13

12

11

14

13

10

SRCLR

RCK

SRCK

74HC595

SER

G

10

SRCLR

RCK

SRCK

74HC595

SER

G

QH′

QH′

15

QA

1

D0

QB

2

D1

QC

3

D2

QD

4

D3

QE

5

D4

QF

6

D5

QG

7

D6

QH

9

15

QA

D7

1

QB

D8

2

QC

D9

3

QD

D10

4

QE

D11

5

QF

REFRDY

6

QG

7

QH

9

1402 F12

16

Figure 12. Serial to Parallel Interface

Page 17

LTC1402

U

WUU

APPLICATIONS INFORMATION

HARDWARE INTERFACE TO TMS320C54x

The LTC1402 is a serial output ADC whose interface has

been designed for high speed buffered serial ports in fast

digital signal processors (DSPs). Figure 13 shows an

example of this interface using a TMS320C54X.

The buffered serial port in the TMS320C54x has direct

access to a 2kB segment of memory. The ADC’s serial data

can be collected in two alternating 1kB segments, in real

time, at the full 2.2Msps conversion rate of the LTC1402.

The DSP assembly code sets frame sync mode at the BFSR

pin to accept an external positive going pulse, and the

serial clock at the BCLKR pin to accept an external positive

11

OV

DD

16

CONV

LTC1402

SCK

D

OUT

OGND

15

10

9

CONV

CLK

3-WIRE SERIAL

INTERFACE LINK

edge clock. Buffers near the LTC1402 may be added to

drive long tracks to the DSP to prevent corruption of the

signal to LTC1402. This configuration is adequate to

traverse a typical system board, but source resistors at the

buffer outputs, and termination resistors at the DSP may

be needed to match the characteristic impedance of very

long transmission lines. If you need to terminate the D

OUT

transmission line, buffer it first with one or two 74ACxx

gates. The TTL threshold inputs of the DSP port respond

properly to the 2.5V swing of the terminated transmission

lines. The OVDD supply output driver supply voltage can be

driven directly from the DSP.

5V

V

CC

BFSR

TMS320C54x

BCLKR

REF B11 B10

BDR

1402 F13

Figure 13. DSP Serial Interface to TMS320C54x

; ***************************************************************************

; Files: BSP2KB.ASM ->

; 2kbyte collection into DSKPlus TMS320C542 with Serial Port interface to LTC1402

; first element at 1024, last element at 1023, two middle elements at 2047 and 0000

; bipolar mode

; ***************************************************************************

.width 160

.length 110

.title “sineb0 BSP in auto buffer mode”

.mmregs

.setsect “.text”, 0x500,0 ;Set address of executable

.setsect “vectors”, 0x180,0 ;Set address of incoming 1402 data

.setsect “buffer”, 0x800,0 ;Set address of BSP buffer for clearing

.setsect “result”, 0x1800,0 ;Set address of result for clearing

.text ;.text marks start of code

start: ;Make sure /PWRDWN is low at J1-9 to turn off AC01 adc

tim=#0fh

prd=#0fh

tcr = #10h ; stop timer

tspc = #0h ; stop TDM serial port to AC01

pmst = #01a0h ; set up iptr. Processor Mode STatus register

sp = #0700h ; init stack pointer.

dp = #0 ; data page

ar2 = #1800h ; pointer to computed receive buffer.

ar3 = #0800h ; pointer to Buffered Serial Port receive buffer

ar4 = #0h ; reset record counter

call sineinit ; Double clutch the initialization to insure a proper

sinepeek: ; insert debugger break here to view results

call sineinit ; reset. The external frame sync must occur 2.5 clocks

wait goto wait

; or more after the port comes out of reset.

17

Page 18

LTC1402

U

WUU

APPLICATIONS INFORMATION

; ————————Buffered Receive Interrupt Routine —————————

breceive:

ifr = #10h ; clear interrupt flags

TC = bitf(@BSPCE,#4000h) ; check which half (bspce(bit14)) of buffer

if (NTC) goto bufull ; if this still the first half get next half

bspce = #(2023h + 08000h) ; turn on halt for second half (bspce(bit15))

return_enable

; ———————mask and shift input data after 2k buffer is full——bufull:

b = *ar3+ << -2 ; load acc b with BSP buffer and shift right 2

b = #00FFFh & b ; mask out the REF bit and the 3 other tristate bits

b = #00800h ^ b ; invert BIPOLAR MSB. Comment this line in UNIPOLAR mode

*ar2+ = data(#0bh) ; store B to out buffer and advance AR2 pointer

TC = (@ar2 == #02000h) ; output buffer is 2k starting at 1800h

if (TC) goto start ; restart if out buffer is at 1fffh

goto bufull

; —————————dummy bsend return————————————

bsend return_enable ;this is a dummy return to define bsend

; ——————————— end ISR ——————————————

;initialize buffered serial port

**********************************************************************

* BSP initialization code for the ‘C54x DSKplus *

* for use with 1402 in standard mode *

* BSPC and SPC are the same in the ‘C542 *

**********************************************************************

ON .set 1

OFF .set !ON

YES .set 1

NO .set !YES

BIT_8 .set 2

BIT_10 .set 1

BIT_12 .set 3

BIT_16 .set 0

GO .set 0x80

**********************************************************************

* This is an example of how to initialize the Buffered Serial Port (BSP).

* The BSP is initialized to require an external CLK and FSX for

* operation. The data format is 16-bits, burst mode, with autobuffering

* enabled.

*

*

*****************************************************************************************************

*Timing at BSP pins in DSKPLUS TMS320c542 board with inverters at BCLKR and BFSR. *

*BFSR Pin JP1-20 ~\___/~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~\___/~~~~~~~~~~*

*BCLKR Pin JP1-14 _/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/~\_/ *

*BDR Pin JP1-26 -_—_—<REF-B11-B10-B09-B08-B07-B06-B05-B04-B03-B02-B01-B00>—_—_—<REF-B11- *

*CLKIN Pin JP5-09 ~~~~~\_______/~~~~~~~\_______/~~~~~~~\_______/~~~~~~~\_______/~~~~~~~\_______/~~~~ *

* *

*A 2 place right shift is needed to right justify the input data. *

*The REF bit is also be masked in this example *

*****************************************************************************************************

*

Loopback .set NO ;(digital looback mode?) DLB bit

Format .set BIT_16 ;(Data format? 16,12,10,8) FO bit

IntSync .set NO ;(internal Frame syncs generated?) TXM bit

IntCLK .set NO ;(internal clks generated?) MCM bit

BurstMode .set YES ;(if BurstMode=NO, then Continuous) FSM bit

CLKDIV .set 3 ;(3=default value, 1/4 CLOCKOUT)

PCM_Mode .set NO ;(Turn on PCM mode?)

FS_polarity .set NO ;(change polarity)YES=^^^\_/^^^, NO=___/^\___

CLK_polarity .set YES ;(change polarity)for BCLKR YES=_/^, NO=~\_

Frame_ignore .set !YES ;(inverted !YES -ignores frame)

XMTautobuf .set NO ;(transmit autobuffering)

RCVautobuf .set YES ;(receive autobuffering)

XMThalt .set NO ;(transmit buff halt if XMT buff is full)

RCVhalt .set NO ;(receive buff halt if RCV buff is full)

XMTbufAddr .set 0x800 ;(address of transmit buffer)

XMTbufSize .set 0x000 ;(length of transmit buffer)

;in vector table below

18

Page 19

LTC1402

U

WUU

APPLICATIONS INFORMATION

RCVbufAddr .set 0x800 ;(address of receive buffer)

RCVbufSize .set 0x800 ;(length of receive buffer)works up to 800

*

*

*

**********************************************************************

.eval ((Loopback >> 1)|((Format & 2)<<1)|(BurstMode <<3)|(IntCLK <<4)|(IntSync <<5)) ,SPCval

.eval ((CLKDIV)|(FS_polarity <<5)|(CLK_polarity<<6)|((Format & 1)<<7)|(Frame_ignore<<8)|(PCM_Mode<<9)), SPCEval

.eval (SPCEval|(XMTautobuf<<10)|(XMThalt<<12)|(RCVautobuf<<13)|(RCVhalt<<15)), SPCEval

sineinit:

bspc = #SPCval ; places buffered serial port in reset

ifr = #10h ; clear interrupt flags

imr = #210h ; Enable HPINT,enable BRINT0

intm = 0 ; all unmasked interrupts are enabled.

bspce = #SPCEval ; programs BSPCE and ABU

axr = #XMTbufAddr ; initializes transmit buffer start address

bkx = #XMTbufSize ; initializes transmit buffer size

arr = #RCVbufAddr ; initializes receive buffer start address

bkr = #RCVbufSize ; initializes receive buffer size

bspc = #(SPCval | GO) ; bring buffered serial port out of reset

return ;for transmit and receive because GO=0xC0

.space 16*32 ;clear a chunk at the end to mark the end

;======================================================================

;

; VECTORS

;

;======================================================================

.sect “vectors” ;The vectors start here

;get BSP vectors

; ***************************************************************************

; Vector Table for the ‘C54x DSKplus

; BSP vectors and Debugger vectors

; TDM vectors just return

; ***************************************************************************

; The vectors in this table can be configured for processing external and

; internal software interrupts. The DSKplus debugger uses four interrupt

; vectors. These are RESET, TRAP2, INT2, and HPIINT.

; * DO NOT MODIFY THESE FOUR VECTORS IF YOU PLAN TO USE THE DEBUGGER *

;

; All other vector locations are free to use. When programming always be sure

; the HPIINT bit is unmasked (IMR=200h) to allow the communications kernel and

; host PC interact. INT2 should normally be masked (IMR(bit 2) = 0) so that the

; DSP will not interrupt itself during a HINT. HINT is tied to INT2 externally.

;

;

;

.mmregs

reset goto #80h ;00; RESET * DO NOT MODIFY IF USING DEBUGGER *

nop

nop

nmi return_enable ;04; non-maskable external interrupt

nop

nop

nop

trap2 goto #88h ;08; trap2 * DO NOT MODIFY IF USING DEBUGGER *

nop

nop

.space 52*16 ;0C-3F: vectors for software interrupts 18-30

int0 return_enable ;40; external interrupt int0

nop

nop

nop

int1 return_enable ;44; external interrupt int1

nop

nop

nop

int2 return_enable ;48; external interrupt int2

nop

nop

nop

19

Page 20

LTC1402

U

WUU

APPLICATIONS INFORMATION

tint return_enable ;4C; internal timer interrupt

nop

nop

nop

brint goto breceive ;50; BSP receive interrupt

nop

nop

nop

bxint goto bsend ;54; BSP transmit interrupt

nop

nop

nop

trint return_enable ;58; TDM receive interrupt

nop

nop

nop

U

± 0.004

Dimensions in inches (millimeters) unless otherwise noted.

16-Lead Plastic SSOP (Narrow 0.150)

× 45°

0.053 – 0.068

(1.351 – 1.727)

0.008 – 0.012

(0.203 – 0.305)

PACKAGE DESCRIPTION

0.015

(0.38 ± 0.10)

0.007 – 0.0098

(0.178 – 0.249)

0.016 – 0.050

(0.406 – 1.270)

* DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

0° – 8° TYP

txint return_enable ;5C; TDM transmit interrupt

nop

nop

int3 return_enable ;60; external interrupt int3

nop

nop

nop

hpiint dgoto #0e4h ;64; HPIint * DO NOT MODIFY IF USING

DEBUGGER *

nop

nop

.space 24*16 ;68-7F; reserved area

.sect “buffer” ;Set address of BSP buffer for clearing

.space 16*0x800

.sect “result” ;Set address of result for clearing

.space 16*0x800

.end

GN Package

(LTC DWG # 05-08-1641)

0.0250

(0.635)

BSC

0.004 – 0.0098

(0.102 – 0.249)

0.229 – 0.244

(5.817 – 6.198)

16

15

12

0.189 – 0.196*

(4.801 – 4.978)

14

12 11 10

13

5

4

3

678

9

0.150 – 0.157**

(3.810 – 3.988)

GN16 (SSOP) 1098

0.009

(0.229)

REF

RELATED PARTS

PART NUMBER RESOLUTION SPEED COMMENTS

16-Bit

LTC1604 16 333ksps ±2.5V Input Range, ±5V Supply

LTC1605 16 100ksps ±10V Input Range, Single 5V Supply

14-Bit

LTC1414 14 2.2Msps 175mW, 80dB SINAD and 95dB SFDR

LTC1419 14 800ksps 150mW, 81.5dB SINAD and 95dB SFDR

LTC1416 14 400ksps 75mW, Low Power with Excellent AC Specs

LTC1418 14 200ksps 15mW, Single 5V, Serial/Parallel I/O

12-Bit

LTC1412 12 3Msps 150mW, 72dB SINAD and 82dB SFDR

LTC1410 12 1.25Msps 150mW, 71.5dB SINAD and 84dB THD

LTC1415 12 1.25Msps 55mW, Single 5V Supply

LTC1409 12 800ksps 80mW, 71.5dB SINAD and 84dB THD

LTC1404 12 600ksps High Speed Serial I/O in SO-8 Package

LTC1400 12 400ksps High Speed Serial I/O in SO-8 Package

Linear Technology Corporation

20

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

LINEAR TECHNOLOGY CORPORATION 1999

1402i LT/TP 1099 • PRINTED IN USA

Loading...

Loading...