Page 1

LTC1292/LTC1297

f

SAMPLE

(Hz)

10

AVERAGE I

CC

(µA)

100

1000

10000

1 100 10k

LTC1297• TA02

1

10

1k 100k

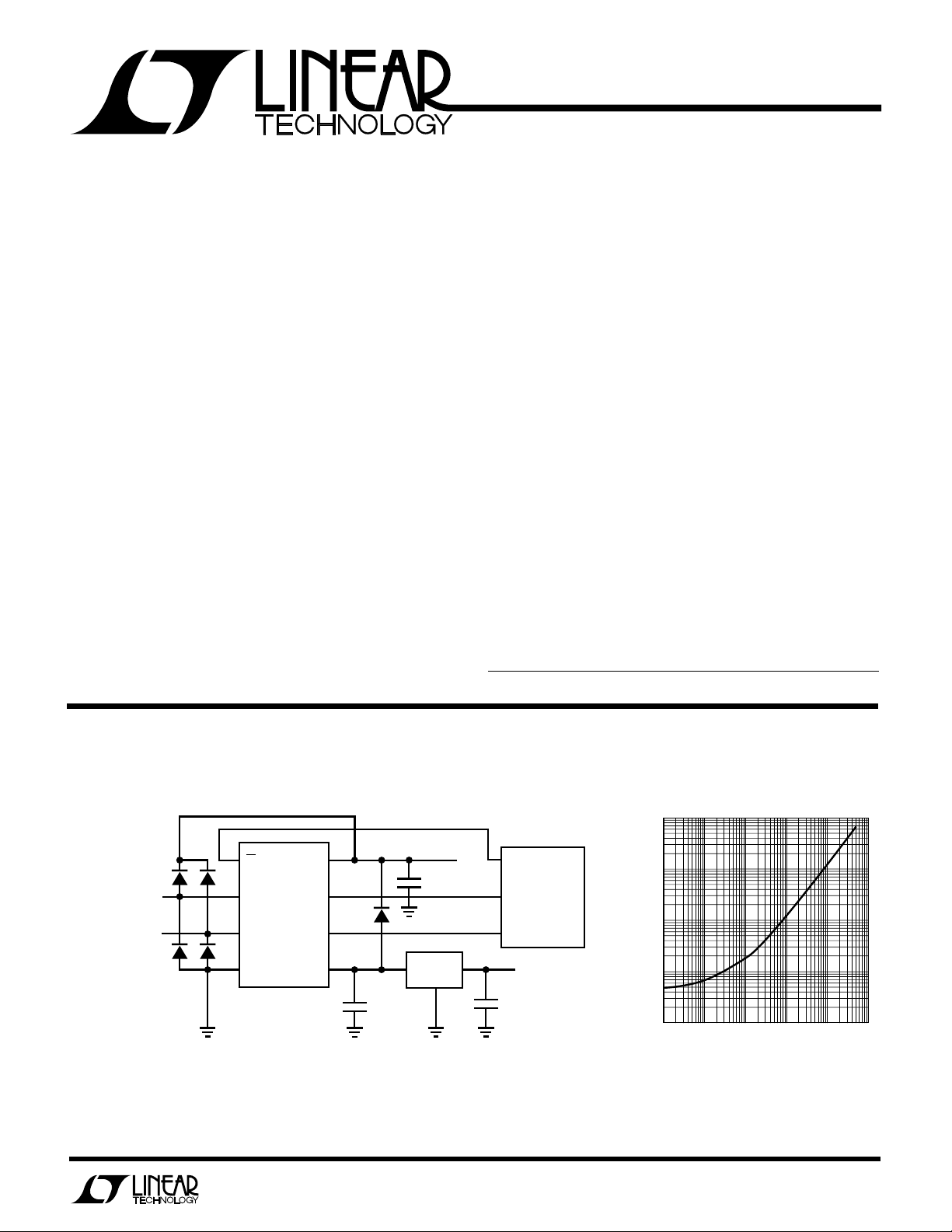

Single Chip 12-Bit

Data Acquisition Systems

EATU

F

■

Built-In Sample-and-Hold

■

Single Supply 5V Operation

■

60kHz Maximum Throughput Rate (LTC1292)

■

Power Shutdown After Each Conversion (LTC1297)

■

Direct 3-Wire Interface to Most MPU Serial Ports and

RE

S

All MPU Parallel Ports

■

Analog Inputs Common Mode to Supply Rails

U

KEY SPECIFICATIO S

■

Resolution: 12 Bits

■

Fast Conversion Time: 12µs Max Over Temp

■

Low Supply Current: 6.0mA

■

Shutdown Supply Current: 5µA (LTC1297)

DUESCRIPTIO

The LTC1292/LTC1297 are data acquisition systems that

contain a 12-bit, switched-capacitor successive approximation A/D, a differential input, sample-and-hold on the

(+) input, and serial I/O. When the LTC1297 is idle between

conversions it automatically powers down reducing the

supply current to 5µA, typically. The LTC1292 is capable

of digitizing signals at a 60kHz rate and with the device’s

excellent AC characteristics, it can be used for DSP applications. All these features are packaged in an 8-pin DIP

and are made possible using LTCMOSTM switched-capacitor technology.

The serial I/O is designed to communicate without external

hardware to most MPU serial ports and all MPU parallel

I/O ports allowing data to be transmitted over three wires.

Because of their accuracy, ease of use and small package

size these devices are well suited for digitizing analog

signals in remote applications where minimum number of

interconnects and power consumption are important.

LTCMOS is trademark of Linear Technology Corporation

DIFFERENTIAL

INPUTS

COMMON MODE

RANGE

0V TO 5V

U

O

A

PPLICATITYPICAL

12-Bit Differential Input Data Acquisition System

LTC1297

V

CC

CLK

1N4148

D

OUT

V

REF

+

AND GND WITH 1N4148 DIODES.

CC

+

4.7µF

TANTALUM

22µF

TANTALUM

LT1027

CS

+

–

*

*FOR OVERVOLTAGE PROTECTION LIMIT THE INPUT CURRENT TO 15mA

PER PIN OR CLAMP THE INPUTS TO V

CONVERSION RESULTS ARE NOT VALID WHEN ANY INPUT IS OVERVOLTAGED

< GND OR V

(V

IN

THE APPLICATIONS INFORMATION.

+IN

–IN

GND

> VCC). SEE SECTION ON OVERVOLTAGE PROTECTION IN

IN

Power Supply Current

vs Sampling Frequency

DO

5V

MC68HC11

SCK

MISO

8V TO 40V

1µF

LTC1292/7 TA01

1

Page 2

LTC1292/LTC1297

O

A

(Notes 1 and 2)

LUTEXI T

S

W

A

WUW

ARB

U

G

I

S

Supply Voltage (VCC) to GND.................................. 12V

Voltage

Analog and Reference

Inputs..................................... –0.3V to V

CC

+ 0.3V

Digital Inputs........................................ –0.3V to 12V

Digital Outputs .......................... –0.3V to V

CC

+ 0.3V

Power Dissipation.............................................. 500mW

Operating Temperature Range

LTC1292/LTC1297BC, LTC1292/LTC1297CC,

LTC1292/LTC1297DC ............................ 0°C to 70°C

LTC1292/LTC1297BI, LTC1292/LTC1297CI,

LTC1292/LTC1297DI ........................ –40°C to 85°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec.)................ 300°C

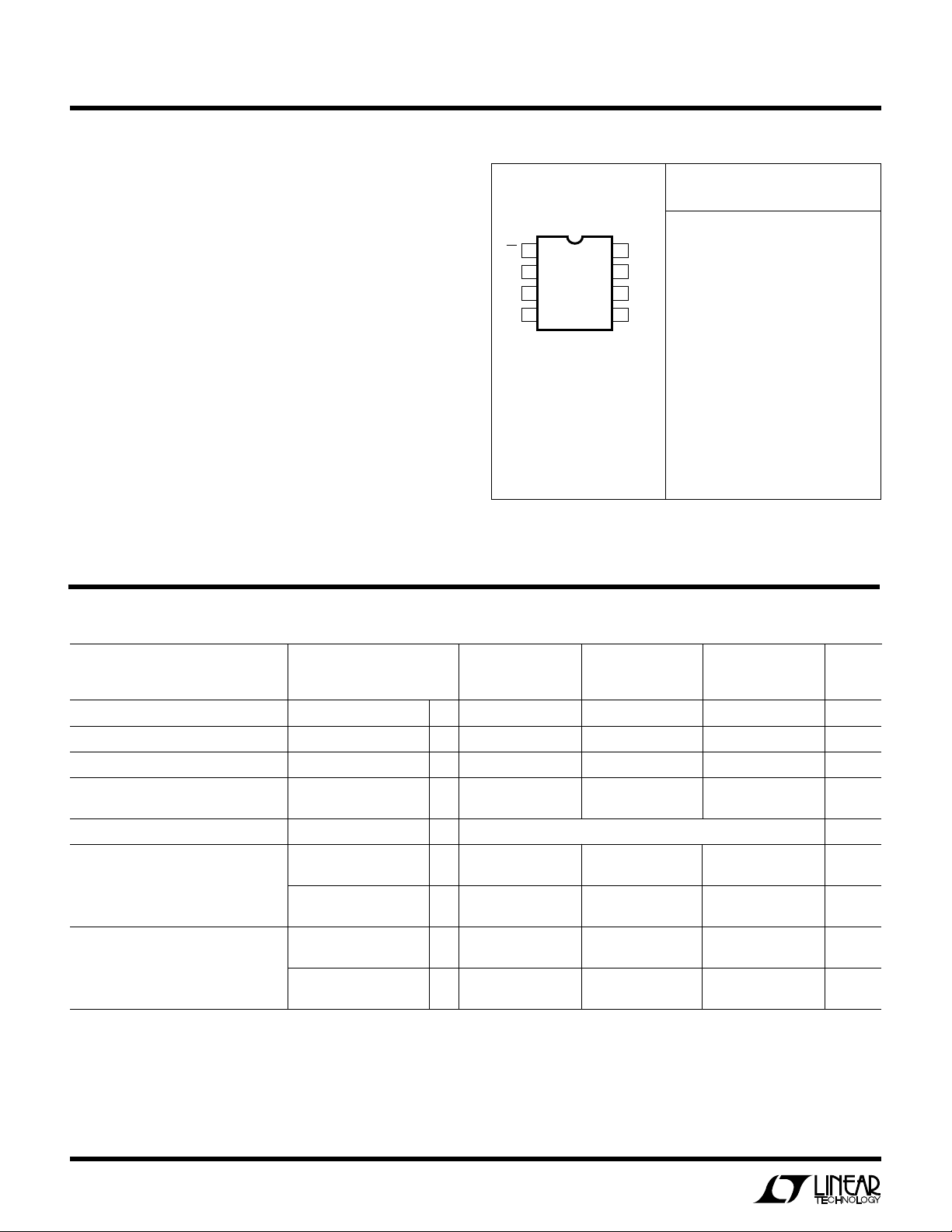

/

PACKAGE

O

RDER I FOR ATIO

ORDER PART NUMBER

TOP VIEW

LTC1292BIN8 LTC1297BIN8

V

CC

LTC1292CIN8 LTC1297CIN8

CLK

LTC1292DIN8 LTC1297DIN8

D

OUT

LTC1292BCJ8 LTC1297BCJ8

V

REF

LTC1292CCJ8 LTC1297CCJ8

LTC1292DCJ8 LTC1297DCJ8

LTC1292BCN8 LTC1297BCN8

LTC1292CCN8 LTC1297CCN8

LTC1292DCN8 LTC1297DCN8

=100°C/W (J8)

JA

=130°C/W (N8)

JA

8

7

6

5

1

CS

2

+IN

3

–IN

4

GND

J8 PACKAGE

8-LEAD CERAMIC DIP

N8 PACKAGE

8-LEAD PLASTIC DIP

T

= 150°C, θ

JMAX

= 100°C, θ

T

JMAX

For Military Temperature Ranges please contact factory.

WU

U

UU W

CO VERTER A D ULTIPLEXER CHARACTERISTICS

LTC1292B

LTC1297B

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX MIN TYP MAX UNITS

Offset Error (Note 4) ● ±3.0 ±3.0 ±3.0 LSB

Linearity Error (INL) (Note 4 & 5) ● ±0.5 ±0.5 ±0.75 LSB

Gain Error (Note 4) ● ±0.5 ±1.0 ±4.0 LSB

Minimum Resolution for Which No 12 12 12 Bits

Missing Codes are Guaranteed

Analog and REF Input Range (Note 7) ● –0.05V to VCC + 0.05V V

On Channel Leakage Current On Channel = 5V ● ±1 ±1 ±1 µA

(Note 8) Off Channel = 0V

On Channel = 0V ● ±1 ±1 ±1 µA

Off Channel = 5V

Off Channel Lekage Current On Channel = 5V ● ±1 ±1 ±1 µA

(Note 8) Off Channel = 0V

On Channel = 0V ● ±1 ±1 ±1 µA

Off Channel = 5V

(Note 3)

LTC1292C

LTC1297C

LTC1292D

LTC1297D

2

Page 3

LTC1292/LTC1297

AC CHARACTERISTICS

(Note 3)

LTC1292B/LTC1297B

LTC1292C/LTC1297C

LTC1292D/LTC1297D

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

CLK

t

SMPL

Clock Frequency VCC = 5V (Note 6) (Note 9) 1.0 MHz

Analog Input Sample Time See Operating Sequence LTC1292 1.5CLK

LTC1297 0.5CLK+5.5µs

t

CONV

Conversion Time See Operating Sequence 12 CLK

Cycles

t

CYC

Total Cycle Time See Operating Sequence (Note 6)

LTC1292 14CLK+2.5µs

LTC1297 14CLK+6µs

t

dDO

t

dis

t

en

t

hDO

t

f

t

r

t

WHCLK

t

WLCLK

t

suCS

Delay Time, CLK↓ to D

Delay Time, CS↑ to D

Delay Time, CLK↓ to D

Data Valid See Test Circuits ● 160 300 ns

OUT

Hi-Z See Test Circuits ● 80 150 ns

OUT

Enabled See Test Circuits ● 80 200 ns

OUT

Time Output Data Remains Valid After CLK↓ 130 ns

D

Fall Time See Test Circuits ● 65 130 ns

OUT

D

Rise Time See Test Circuits ● 25 50 ns

OUT

CLK High Time VCC = 5V (Note 6) 300 ns

CLK Low Time VCC = 5V (Note 6) 400 ns

Setup Time, CS↓ Before CLK↑ VCC = 5V (Note 6) LTC1292 50 ns

(LTC1297 Wakeup Time) LTC1297 5.5 µs

t

WHCS

CS High Time Between Data Transfer Cycles VCC = 5V (Note 6) LTC1292 2.5 µs

LTC1297 0.5 µs

t

WLCS

CS Low Time During Data Transfer VCC = 5V (Note 6) LTC1292 14CLK

LTC1297 14CLK+5.5µs

C

IN

Input Capacitance Analog Inputs On Channel 100 pF

Analog Inputs Off Channel 5 pF

Digital Inputs 5 pF

U

DIGITAL A D DC ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

I

IH

I

IL

V

OH

V

OL

I

OZ

I

SOURCE

I

SINK

High Level Input Voltage VCC = 5.25V ● 2.0 V

Low Level Input Voltage VCC = 4.75V ● 0.8 V

High Level Input Current VIN = V

CC

Low Level Input Current VIN = 0V ● –2.5 µA

High Level Output Voltage VCC = 4.75V, IO = –10µA 4.7 V

IO = 360µA ● 2.4 4.0 V

Low Level Output Voltage VCC = 4.75V, IO = 1.6mA ● 0.4 V

High Z Output Leakage V

Output Source Current V

Output Sink Current V

= VCC, CS High ● 3 µA

OUT

V

= 0V, CS High ● –3 µA

OUT

= 0V –20 mA

OUT

= V

OUT

CC

(Note 3)

LTC1292B/LTC1297B

LTC1292C/LTC1297C

LTC1292D/LTC1297D

● 2.5 µA

20 mA

3

Page 4

LTC1292/LTC1297

U

DIGITAL A D DC ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

CC

I

REF

The ● denotes specifications which apply over the operating temperature

range; all other limits and typicals T

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: All voltage values are with respect to ground (unless otherwise

noted).

Note 3: V

Note 4: One LSB is equal to V

= 5V, 1LSB = 5V/4096 = 1.22mV.

Note 5: Linearity error is specified between the actual end points of the

A/D transfer curve. The deviation is measured from the center of the

quantization band.

Note 6: Recommended operating conditions.

Note 7: Two on-chip diodes are tied to each reference and analog input

which will conduct for reference or analog input voltages one diode drop

Positive Supply Current CS High LTC1292 ● 612 mA

CS Low LTC1297 ● 612 mA

CS High

LTC1297BC, LTC1297CC, LTC1297DC ● 510 µA

Power

Shutdown

CLK Off

LTC1297BI, LTC1297CI, LTC1297DI ● 515 µA

LTC1297BM, LTC1297CM, LTC1297DM

Reference Current CS High ● 10 50 µA

below GND or one diode drop above VCC. Be careful during testing at low

= 25°C.

A

levels (4.5V), as high level reference or analog inputs (5V) can cause

V

CC

this input diode to conduct, especially at elevated temperatures, and cause

errors for inputs near full scale. This spec allows 50mV forward bias of

either diode. This means that as long as the reference or analog input does

not exceed the supply voltage by more than 50mV, the output code will be

= 5V, V

CC

= 5V, CLK = 1.0MHz unless otherwise specified.

REF

divided by 4096. For example, when V

REF

correct. To achieve an absolute 0V to 5V input voltage range will therefore

require a minimum supply voltage of 4.950V over initial tolerance,

REF

temperature variations and loading.

Note 8: Channel leakage current is measured after the channel selection.

Note 9: Increased leakage currents at elevated temperatures cause the S/

H to droop, therefore it is recommended that f

≥ 31kHz at 85°C, and f

(Note 3)

≥ 3kHz at 25°C.

CLK

LTC1292B/LTC1297B

LTC1292C/LTC1297C

LTC1292D/LTC1297D

≥125kHz at 125°C, f

CLK

CLK

LPER

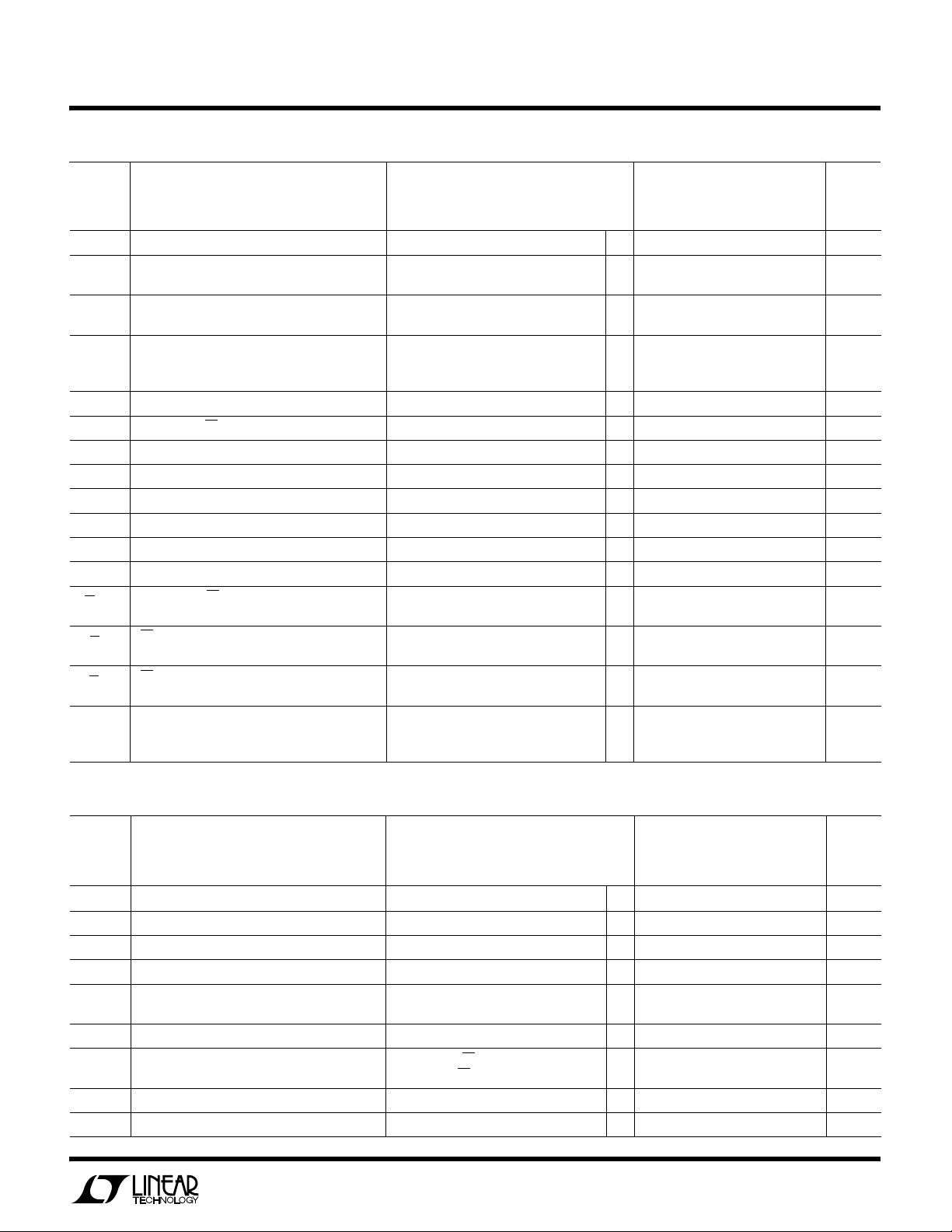

10

CLK = 1MHz

= 25°C

T

A

8

6

4

SUPPLY CURRENT (mA)

2

0

4

SUPPLY VOLTAGE (V)

5

F

O

R

ATYPICA

LTC1292/7 G01

UW

CCHARA TERIST

E

C

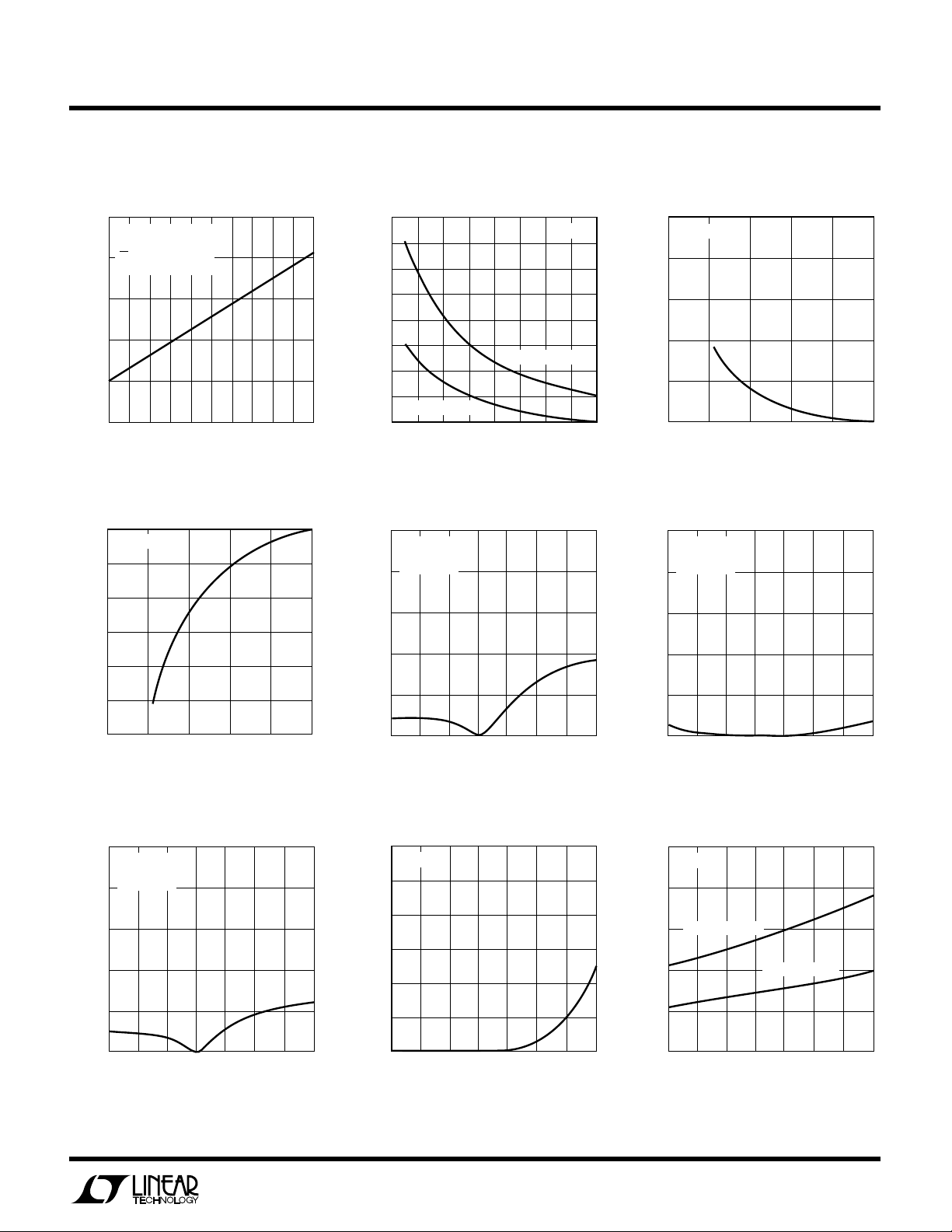

Supply Current vs TemperatureSupply Current vs Supply Voltage

10

9

8

7

6

5

SUPPLY CURRENT (mA)

4

6

3

–50

–30 –10

ICS

CLK = 1MHz

V

CC

10

AMBIENT TEMPERATURE (°C)

50 90

30 70

= 5V

110

LTC1292/7 G02

130

LTC1297 Supply Current (Power

Shutdown) vs Temperature

10

VCC = 5V

9

= 5V

V

REF

CS HIGH

8

CLK OFF

7

6

5

4

3

SUPPLY CURRENT (µA)

2

1

0

–50

0

–25

AMBIENT TEMPERATURE (°C)

50

25

75

100

LTC1292/7 G03

125

4

Page 5

LPER

REFERENCE VOLTAGE (V)

0

LINEARITY (LSB = 1/4096 × V

REF

)

0.75

1.00

1.25

4

LTC1292/7 G06

0.50

0.25

0

1

2

3

5

VCC = 5V

AMBIENT TEMPERATURE (°C)

–50

MAGNITUDE OF LINEARITY CHANGE (LSB)

0.3

0.4

0.5

50

LTC1292/7 G09

0.2

0.1

0

–25

0

25

75

125100

VCC = 5V

V

REF

= 5V

CLK = 1MHz

F

O

R

ATYPICA

UW

CCHARA TERIST

E

C

LTC1292/LTC1297

ICS

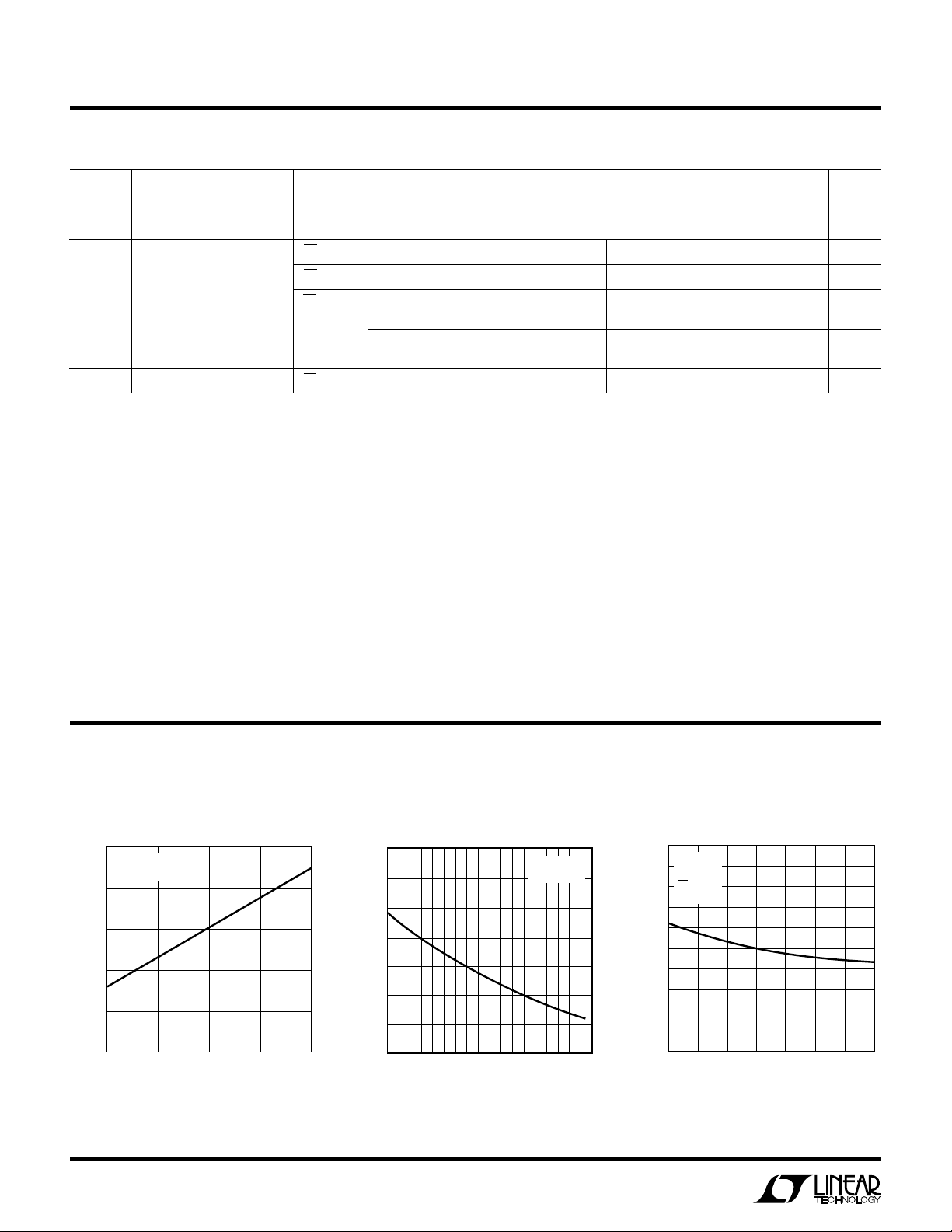

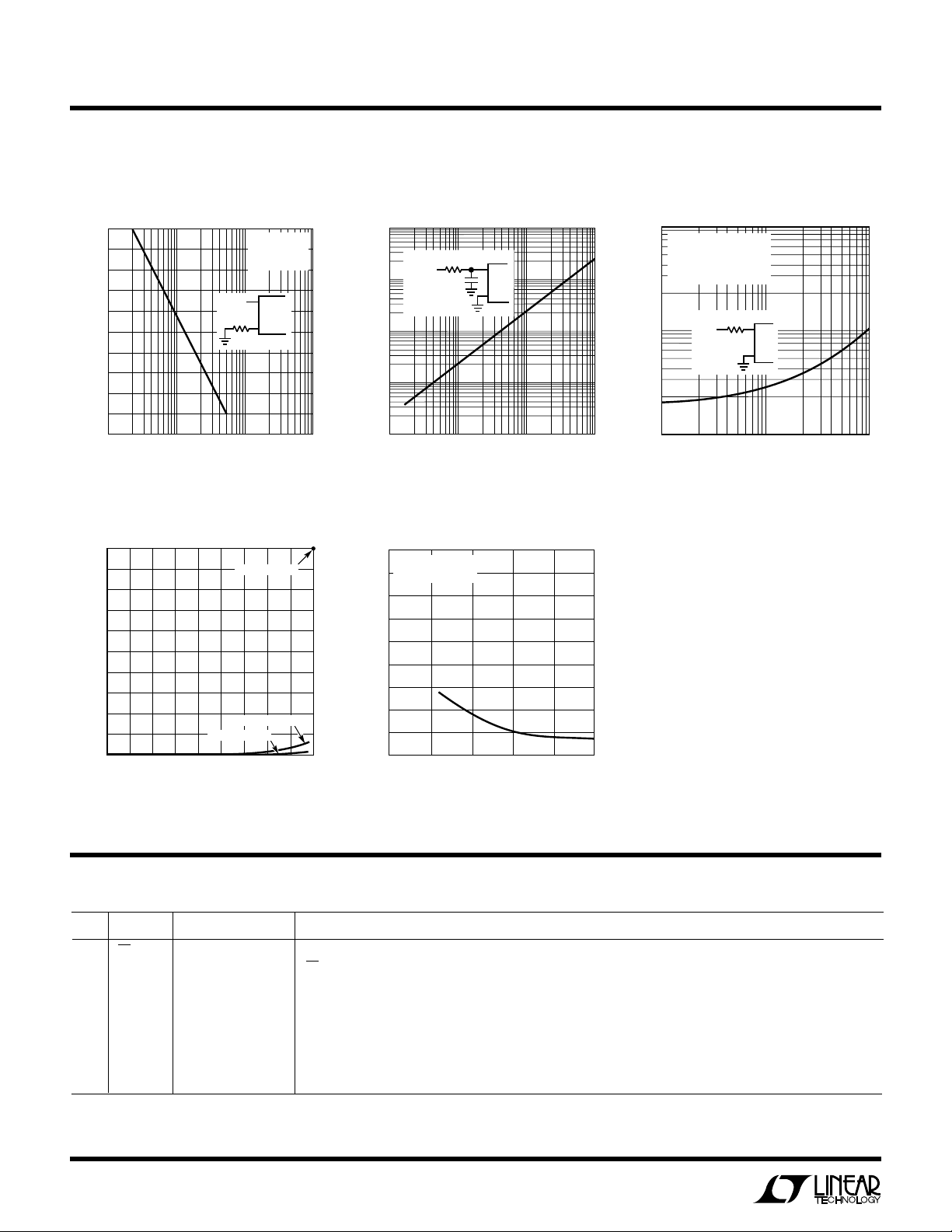

LTC1297 Supply Current (Power

Shutdown) vs CLK Frequency

25

VCC = 5V

= 5V

V

REF

CS HIGH

20

CMOS LOGIC LEVELS

15

10

SUPPLY CURRENT (µA)

5

0

200

0

CLK FREQUENCY (kHz)

400

600

800

LTC1292/7 G04

1000

Unadjusted Offset Voltage vs

Reference Voltage

0.9

0.8

)

REF

0.7

0.6

0.5

0.4

0.3

OFFSET (LSB = 1/4096 × V

0.2

V

= 0.125mV

OS

0.1

1

2

REFERENCE VOLTAGE (V)

3

V

OS

Change in Gain vs

Reference Voltage Change in Offset vs Temperature

)

REF

–0.2

–0.4

–0.6

–0.8

0

V

= 5V

CC

0.5

0.4

0.3

0.2

VCC = 5V

= 5V

V

REF

CLK = 1MHz

VCC = 5V

= 0.250mV

4

LTC1292/7 G05

Change in Linearity vs

Reference Voltage

5

Change in Linearity vs

Temperature

–1.0

CHANGE IN GAIN (LSB = 1/4096 × V

–1.2

0

1234

REFERENCE VOLTAGE (V)

Change in Gain vs Temperature

0.5

VCC = 5V

= 5V

V

REF

CLK = 1MHz

0.4

0.3

0.2

0.1

MAGNITUDE OF GAIN CHANGE (LSB)

0

–50

* AS THE CLK FREQUENCY IS DECREASED FROM 1MHz, MINIMUM CLK FREQUENCY (∆ERROR ≤ 0.1LSB) REPRESENTS THE

FREQUENCY AT WHICH A 0.1LSB SHIFT IN ANY CODE TRANSITION FROM ITS 1MHz VALUE IS FIRST DETECTED (NOTE 9).

0

–25

AMBIENT TEMPERATURE (°C)

25

0.1

MAGNITUDE OF OFFSET CHANGE (LSB)

5

LTC1292/7 G07

0

–50

0

–25

AMBIENT TEMPERATURE (°C)

25

50

75

125100

LTC1292/7 G08

Minimum Clock Rate for

D

0.1 LSB Error*

DELAY TIME FROM CLK↓ (ns)

OUT

D

250

200

150

100

VCC = 5V

0.25

0.20

0.15

0.10

0.05

MINIMUM CLK FREQUENCY (MHz)

–50

50

75

125100

LTC1292/7 G10

–25

25

50

0

AMBIENT TEMPERATURE (°C)

75

125100

LTC1292/7 G11

Delay Time vs Temperature

OUT

VCC = 5V

MSB FIRST DATA

LSB FIRST DATA

50

0

–50

–25

25

0

AMBIENT TEMPERATURE (°C)

50

75

125100

LTC1292/7 G12

5

Page 6

LTC1292/LTC1297

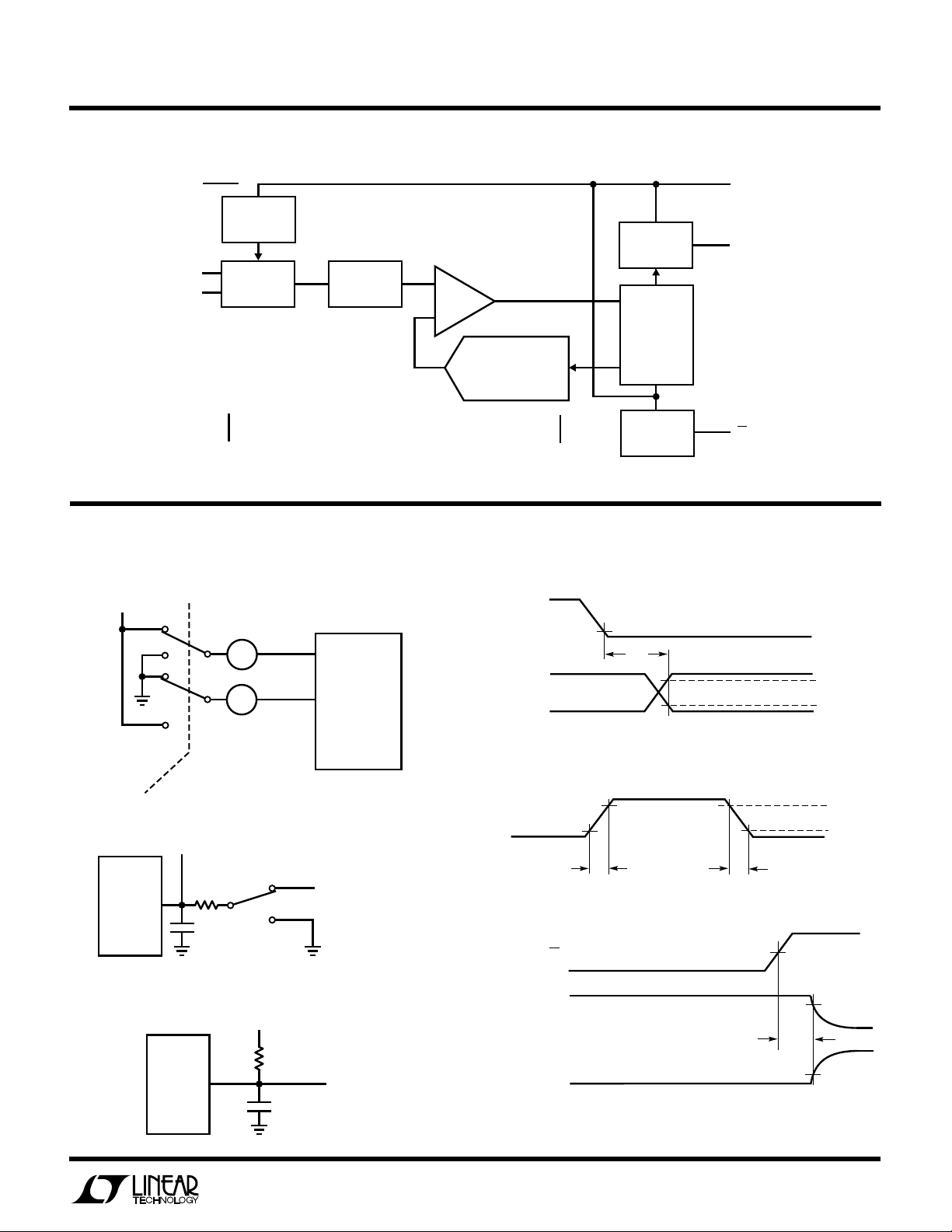

R

SOURCE

+ (Ω)

100

1

S & H AQUISITION TIME TO 0.02% (µs)

10

100

1000 10000

LTC1292/7 G15

+

–

+V

IN

R

SOURCE

V

REF

= 5V

V

CC

= 5V

T

A

= 25°C

0V TO 5V INPUT STEP

LPER

F

O

R

ATYPICA

UW

CCHARA TERIST

E

C

ICS

Maximum Clock Rate vs

Source Resistance

1.0

0.8

+V

0.6

0.4

0.2

MAXIMUM CLK FREQUENCY* (MHz)

0

100

1k 10k 100k

R

SOURCE

R

SOURCE

– (Ω)

IN

Input Channel Leakage Current vs

Temperature

1000

900

800

700

600

500

400

300

200

100

INPUT CHANNEL LEAKAGE CURRENT (nA)

0

–30 10

–10

–50

AMBIENT TEMPERATURE (°C)

GUARANTEED

ON CHANNEL

OFF CHANNEL

70 90

50 130

30

VCC = 5V

= 5V

V

REF

CLK = 1MHz

+

+IN

–IN

–

LTC1292/7G13

110

LTC1292/7 G16

Maximum Filter Resistor vs

Cycle Time

10k

R

FILTER

1k

** (Ω)

FILTER

100

10

MAXIMUM R

1

10

+V

C

FILTER

IN

≥1µF

+

–

100

CYCLE TIME (µs)

1k

Noise Error vs Reference Voltage

2.25

LTC1292/LTC1297

2.00

NOISE = 200µV

1.75

1.50

1.25

1.00

0.75

0.50

PEAK-TO-PEAK NOISE ERROR (LSB)

0.25

0

0

P-P

13

2

REFERENCE VOLTAGE (V)

LTC1292/7 G14

4

LTC1292/7 G17

10k

Sample-and-Hold Acquisition

Time vs Source Resistance

* MAXIMUM CLK FREQUENCY REPRESENTS THE

CLK FREQUENCY AT WHICH A 0.1LSB SHIFT IN

THE ERROR AT ANY CODE TRANSITION FROM ITS

1MHz VALUE IS FIRST DETECTED.

** MAXIMUM R

RESISTOR VALUE AT WHICH A 0.1LSB CHANGE IN

FULL SCALE ERROR FROM ITS VALUE AT

R

= 0Ω IS FIRST DETECTED.

FILTER

5

REPRESENTS THE FILTER

FILTER

U

PI FU CTIO S

# PIN FUNCTION DESCRIPTION

1 CS Chip Select Input A logic low on this input enables the LTC1292/LTC1297. Power shutdown is activated on the LTC1297 when

2, 3 +IN, –IN Analog Inputs These inputs must be free of noise with respect to GND.

4 GND Analog Ground GND should be tied directly to an analog ground plane.

5V

6D

7 CLK Shift Clock This clock synchronizes the serial data transfer.

8V

6

REF

OUT

CC

UU

CS is brought high.

Reference Input The reference input defines the span of the A/D converter and must be kept free of noise with respect to GND.

Digital Data Output The A/D conversion result is shifted out of this output.

Positive Supply This supply must be kept free of noise and ripple by bypassing directly to the analog ground plane.

Page 7

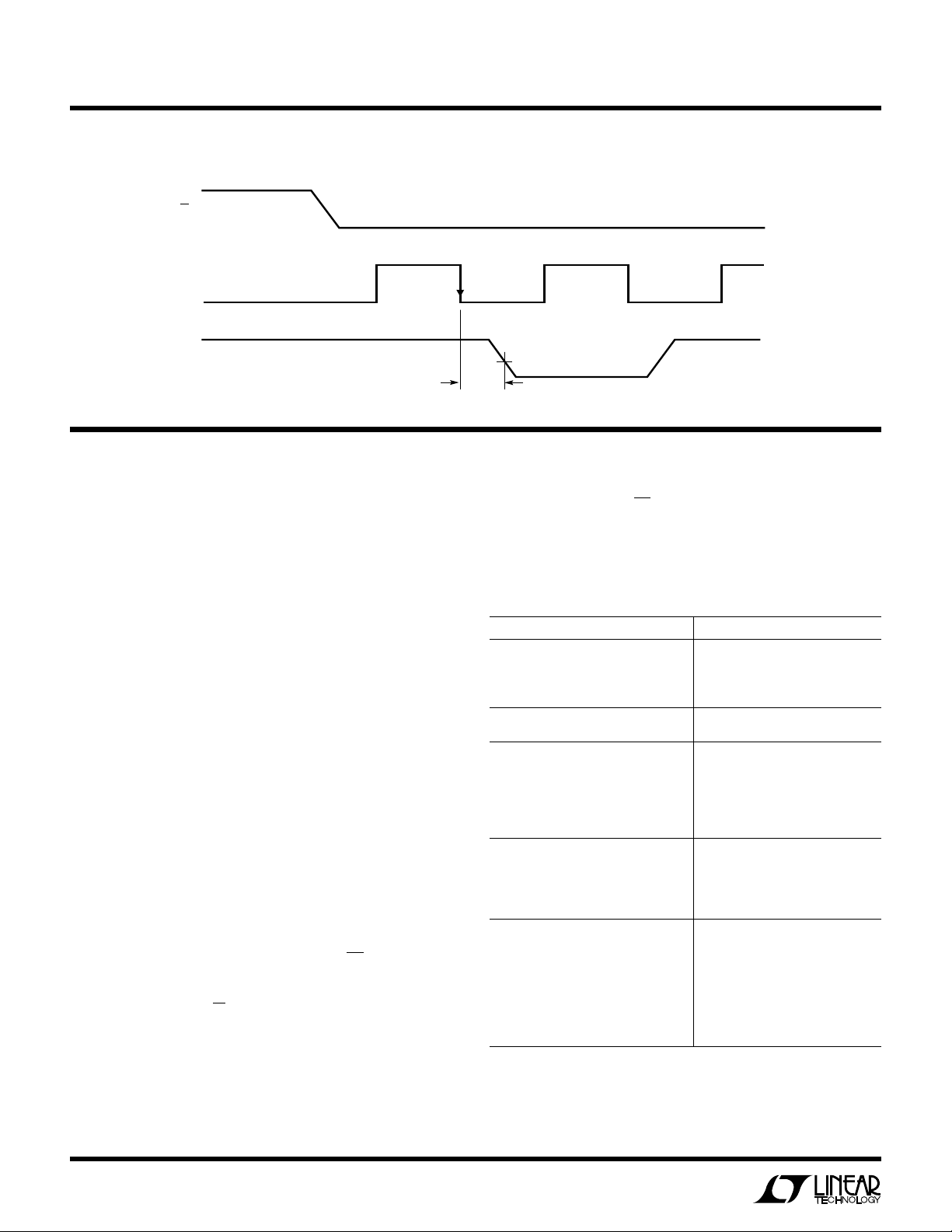

BLOCK

LTC1292/LTC1297

W

IDAGRA

8

V

CC

2

+IN

3

–IN

GND

TEST CIRCUITS

On and Off Channel Leakage Current

5V

INPUT

SHIFT

REGISTER

ANALOG

INPUT MUX

4

I

ON

A

I

OFF

A

SAMPLE

AND

HOLD

ON CHANNEL

OFF CHANNEL

COMP

12-BIT

CAPACITIVE

DAC

CLK

D

OUTPUT

SHIFT

REGISTER

12-BIT

SAR

5

V

REF

CONTROL

AND

TIMING

Voltage Waveforms for D

0.8V

t

dDO

OUT

7

CLK

6

D

OUT

1

CS

LTC1292/7 BD

Delay Time, t

OUT

dDO

2.4V

0.4V

LTC1292/7 TC04

POLARITY

Load Circuit for t

TEST POINT

D

OUT

Load Circuit for t

D

OUT

3k

100pF

1.4V

3kΩ

100pF

dis

dDO

and t

en

5V t

dis

t

WAVEFORM 1

dis

, tr and t

TEST POINT

LTC1292/7 TC01

WAVEFORM 2, t

LTC1292/7 TC02

f

LTC1292/7 TC03

Voltage Waveforms for D

D

OUT

t

r

en

Voltage Waveforms for t

CS

D

OUT

WAVEFORM 1

(SEE NOTE 1)

D

OUT

WAVEFORM 2

(SEE NOTE 2)

NOTE 1: WAVEFORM 1 IS FOR AN OUTPUT WITH INTERNAL CONDITIONS SUCH

THAT THE OUTPUT IS HIGH UNLESS DISABLED BY THE OUTPUT CONTROL.

LTC1292/7 TC06

NOTE 2: WAVEFORM 2 IS FOR AN OUTPUT WITH INTERNAL CONDITIONS SUCH

THAT THE OUTPUT IS LOW UNLESS DISABLED BY THE OUTPUT CONTROL.

Rise and Fall Times, tr, t

OUT

t

f

dis

2.0V

t

dis

f

2.4V

0.4V

LTC1292/7 TC05

90%

10%

7

Page 8

LTC1292/LTC1297

TEST CIRCUITS

Voltage Waveforms for t

CS

CLK

D

OUT

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

The LTC1292/LTC1297 are data acquisition components

which contain the following functional blocks:

1. 12-Bit Succesive Approximation Capacitive A/D

Converter

2. Differential Input

3. Sample-and-Hold (S/H)

4. Synchronous, Half-Duplex Serial Interface

5. Control and Timing Logic

DIGITAL CONSIDERATIONS

Serial Interface

The LTC1292/LTC1297 communicate with microprocessors and other external circuitry via a synchronous, halfduplex, three-wire serial interface (see Operating Sequence). The clock (CLK) synchronizes the data transfer

with each bit being transmitted on the falling CLK edge.

The LTC1292/LTC1297 do not require a configuration

input word and have no DIN pin. They are permanently

configured to have a single differential input and to perform a unipolar conversion. A falling CS initiates data

transfer. To allow the LTC1297 to recover from the power

shutdown mode, t

pulse enables D

OUT

result is output on the D

has to be met. Then the first CLK

suCS

. After one null bit, the A/D conversion

line with a MSB-first sequence

OUT

followed by a LSB-first sequence. With the half-duplex

serial interface the D

data is from the current conver-

OUT

sion. This provides easy interface to MSB-first or LSB-first

en

0.8V

t

en

B11

LTC1292/7 TC07

serial ports. Bringing CS high resets the LTC1292/LTC1297

for the next data exchange and puts the LTC1297 into its

power shutdown mode.

Table 1. Microprocessor with Hardware Serial Interfaces

Compatible with the LTC1292/LTC1297**

PART NUMBER TYPE OF INTERFACE

Motorola

MC6805S2, S3 SPI

MC68HC11 SPI

MC68HC05 SPI

RCA

CDP68HC05 SPI

Hitachi

HD6305 SCI Synchronous

HD6301 SCI Synchronous

HD63701 SCI Synchronous

HD6303 SCI Synchronous

HD64180 SCI Synchronous

National Semiconductor

COP400 Family MICROWIRE

COP800 Family MCROWIRE/PLUS

NS8050U MICROWIRE/PLUS

HPC16000 Family MICROWIRE/PLUS

Texas Instruments

TMS7002 Serial Port

TMS7042 Serial Port

TMS70C02 Serial Port

TMS70C42 Serial Port

TMS32011* Serial Port

TMS32020* Serial Port

TMS370C050 SPI

* Requires external hardware

** Contact factory for interface information for processors not on this list

†

MICROWIRE and MICROWIRE/PLUS are trademarks of National

Semiconductor Corp.

†

†

8

Page 9

LTC1292/LTC1297

PPLICATI

A

CS

CLK

D

OUT

t

SMPL

CS

t

CLK

D

OUT

suCS

t

SMPL

Hi-Z

Hi-Z

B11

U

O

S

I FOR ATIO

B9B10

B11

B7

B8

t

CONV

B9B10

B8

WU

LTC1292 Operating Sequence

B4

B7

t

CONV

B5B6

B3

LTC1297 Operating Sequence

B4

B5B6

U

t

CYC

B3

B0B1B2

B1

t

CYC

B0B1B2

B3

B2

B1

B2

B5B4

B6

B7

B3

B5B4

B6

B7

B10B9B8

B11

POWER SHUTDOWN MODE

B10B9B8

B11

t

SMPL

LTC1292/7 AI01

LTC1292/7 AI02

Microprocessor Interfaces

The LTC1292/LTC1297 can interface directly (without

external hardware) to most popular microprocessors’

(MPU) synchronous serial formats (see Table 1). If an

MPU without a dedicated serial port is used, then three of

the MPU’s parallel port lines can be programmed to form

the serial link to the LTC1292/LTC1297. Included here are

one serial interface example and one example showing a

parallel port programmed to form the serial interface.

CS

CLK

D

OUT

RECEIVED WORD

MPU

B11

BYTE 1

?

?

?

O

1ST TRANSFER

Figure 1. Data Exchange Between LTC1292 and MC68HC11

B10

B10 B9

B9

B8

B8B11

B7

Motorola SPI (MC68HC11)

The MC68HC11 has been chosen as an example of an MPU

with a dedicated serial port. This MPU transfers data MSB

first and in 8-bit increments. A dummy DIN word sent to the

data register starts the SPI process. With two 8-bit transfers,

the A/D result is read into the MPU (Figure 1). For the

LTC1292 the first 8-bit transfer clocks B11 through B8 of

the A/D conversion result into the processor. The second

8-bit transfer clocks the remaining bits B7 through B0 into

B5 B4

B6

B5

B6

B7

B3 B2

BYTE 2

B3B4

2ND TRANSFER

B1

B2 B1

B0

B1

B0

LTC1292/7 F01

9

Page 10

LTC1292/LTC1297

PPLICATI

A

ANALOG

INPUTS

U

O

S

I FOR ATIO

LTC1292

CS

CLK

D

OUT

WU

DO

SCK

MISO

U

MC68HC11

Figure 2. Hardware and Software Interface to Motorola MC68HC11 Microcontroller

MC68HC11 CODE for LTC1292 Interface

LABEL MNEMONIC OPERAND COMMENTS

LDAA #$50 CONFIGURATION DATA FOR SPCR

STAA $1028 LOAD DATA INTO SPCR ($1028)

LDAA #$1B CONFIG. DATA FOR PORT D DDR

STAA $1009 LOAD DATA INTO PORT D DDR

LDAA #$00 LOAD DUMMY DIN WORD INTO

ACC A

STAA $50 LOAD DUMMY DIN DATA INTO $50

LOOP LDX #$1000 LOAD INDEX REGISTER X WITH

$1000

LDAB #$00 LOAD ACC B WITH $00

LDAA $50 LOAD DUMMY DIN INTO ACC A

FROM $50

STAA $102A LOAD DUMMY DIN INTO SPI,

START SCK

NOP DELAY CS FALL TIME TO RIGHT

JUSTIFY DATA

D

FROM LTC1292 STORED ON MC68HC11 RAM

OUT

LOCATION #61

LOCATION #62

LABEL MNEMONIC OPERAND COMMENTS

OO

B5

B6

STAB $08, X D0 GOES LOW (CS GOES LOW)

NOP 6 NOPS FOR TIMING

LDAA $1029 CHECK SPI STATUS REG

LDAA $102A LOAD LTC1292 MSBs INTO ACC A

STAA $61 STORE MSBs IN $61

STAA $102A LOAD DUMMY DIN INTO SPI,

NOPS 6 NOPS FOR TIMING

BSET $08,X,$01 D0 GOES HIGH (CS GOES HIGH)

LDAA $1029 CHECK SPI STATUS REGISTER

LDAA $102A LOAD LTC1292 LSBs IN ACC

STAA $62 STORE LSBs IN $62

JMP LOOP START NEXT CONVERSION

MSB

OO

B4 B2

B10 B9 B8B11

B3B7

B1

B0

START SCK

BYTE 1

BYTE 2

LTC1292/7 F02

the MPU. The data is right-justified in the two memory

locations (Figure 2). This was made possible by delaying

the falling edge of CS till after the second CLK. ANDing the

first byte with 0F

clears the four most significant bits.

HEX

This operation was not included in the code. It can be

inserted in the data gathering loop or outside the loop

when the data is processed.

CS

CLK

D

OUT

RECEIVED WORD

MPU

B11

B11

0

?

B9

B10

BYTE 1

B10

1ST TRANSFER

B8

B8 B7

B6

B7

B6B9

Figure 3. Data Exchange Between LTC1297 and MC68HC11

B5 B4

For the LTC1297 (Figure 3) a delay must be introduced to

accommodate the setup time, t

, before the dummy

suCS

DIN word is sent to the data register. The first 8-bit transfer

clocks B11 through B6 of the A/D conversion result into

the processor. The second 8-bit transfer clocks the remaining bits B5 through B0 into the MPU. Note B1 and B2

from the LSB-first data word have also been clocked in.

B3 B2

BYTE 2

B3

B4

B5

2ND TRANSFER

B0

B1

B1B2

B1

B0 B1

B3

B2

B2

LTC1292/7 F03

10

Page 11

LTC1292/LTC1297

U

O

PPLICATI

A

ANALOG

INPUTS

MC68HC11 CODE for LTC1297 Interface

LABEL MNEMONIC OPERAND COMMENTS

LDAA #$50 CONFIGURATION DATA FOR SPCR

STAA $1028 LOAD DATA INTO SPCR ($1028)

LDAA #$1B CONFIG. DATA FOR PORT D DDR

STAA $1009 LOAD DATA INTO PORT D DDR

LDAA #$00 LOAD DUMMY DIN WORD INTO

STAA $50 LOAD DUMMY DIN DATA INTO $0

LOOP LDX #$1000 LOAD INDEX REGISTER X WITH

LDAB #$00 LOAD ACC B WITH $00

LDAA $50 LOAD DIN INTO ACC FROM $50

BCLR $08,X,$01 D0 GOES LOW (CS GOES LOW)

NOP 3 NOP FOR t

NOP

NOP

STAA $102A LOAD DUMMY DIN INTO SPI,

S

I FOR ATIO

LTC1297

CS

CLK

D

OUT

Figure 4. Hardware and Software Interface to Motorola MC68HC11 Microcontroller

ACC A

$1000

START CLK

WU

DO

SCK

MISO

TIMING

suCS

U

MC68HC11

D

FROM LTC1297 STORED ON MC68HC11 RAM

OUT

LOCATION #61

LOCATION #62

LABEL MNEMONIC OPERAND COMMENTS

LOOP1 LDAA $1029 CHECK SPI STATUS REG

LOOP2 LDAA $1029 CHECK SPI STATUS RES

OO

B5

B6

BPL LOOP1 CHECK IF TRANSFER IS DONE

LDAA $102A LOAD LTC1297 MSBs INTO ACC A

STAA $61 STORE MSBs IN $61

STAA $102A LOAD DUMMY DIN INTO SPI,

BPL LOOP2 CHECK IF TRANSFER IS DONE

BSET $08X,$01 D0 GOES HIGH (CS GOES HIGH)

LDAA $102A LOAD LTC1297 LSBs INTO ACC A

STAA $62 STORE LSBs IN $62

ROR $61 ROTATE RIGHT WITH CARRY

ROR $62 NEEDED TO RIGHT JUSTIFY

ROR $61 THE DATA IN $61 AND $62

ROR $62

JMP LOOP START NEXT CONVERSION

MSB

OO

B4 B2

B10 B9 B8B11

B3B7

B1

B0

START SCK

LTC1292/7 F04

BYTE 1

BYTE 2

The data is right- justified in the two memory locations by

rotating right twice (Figure 4). ANDing the first byte with

0F

clears the four most significant bits. This operation

HEX

was not included in the code. It can be inserted in the data

gathering loop or outside the loop when the data is

processed.

Interfacing to the Parallel Port of the Intel 8051 Family

The Intel 8051 has been chosen to show the interface

between the LTC1292/LTC1297 and parallel port

microprocessors. The signals CS and CLK are generated

on two port lines and the D

signal is read on a third port

OUT

line. After a falling CLK edge each data bit is loaded into the

carry bit and then rotated into the accumulator. Once the

first 8 MSBs have been shifted into the accumulator they

are loaded into register R2. The last four bits are shifted in

the same way and loaded into register R3. The output data

is left-justified in registers R2 and R3 (Figure 5).

For the LTC1297 four NOPs need to be inserted in the 8051

code after CS goes low to allow the LTC1297 to wake up

from power shutdown (t

suCS

).

11

Page 12

LTC1292/LTC1297

PPLICATI

A

O

ANALOG

INPUTS

D

U

S

I FOR ATIO

LTC1292

LTC1297

CS

CLK

OUT

WU

D

CS

CLK

OUT

B11

P1.4

P1.3

P1.1

B10

U

8051

B9

Figure 5. Hardware and Software Interface to Intel 8051 Processor

8051 CODE

LABEL MNEMONIC OPERAND COMMENTS

MOV P1,#02h BIT 1 PORT 1 SET AS INPUT

CLR P1.3 CLK GOES LOW

SETB P1.4 CS GOES HIGH

CONT CLR P1.4 CS GOES LO

NOP 4 NOP FOR LTC1297 t

NOP Time) (Not Needed for LTC1292)

NOP

NOP

SETB P1.3 CLK GOES HIGH

CLR P1.3 CLK GOES LOW

SETB P1.3 CLK GOES HIGH

CLR P1.3 CLK GOES LOW

MOV R4,#08H LOAD COUNTER

LOOP MOV C,P1.1 READ DATA BIT INTO CARRY

RLC A ROTATE DATA BIT INTO ACC

SETB P1.3 CLK GOES HIGH

CLR P1.3 CLK GOES LOW

DJNZ R4,LOOP NEXT BIT

MOV R2,A STORE MSBs IN R2

MOV C,P1.1 READ DATA BIT INTO CARRY

suCS

(Wakeup

D

FROM LTC1292/LTC1297 STORED IN 8051 RAM

OUT

MSB

R2

R3

B8

B7

LABEL MNEMONIC OPERAND COMMENTS

B10 B9 B8B11

B3

B5B6

B1

B2

B3

B4

CLR A CLEAR ACC

RLC A ROTATE DATA BIT (B3) INTO ACC

CLR P1.3 CLK GOES LOW

MOV C,P1.1 READ DATA BIT INTO CARRY

RLC A ROTATE DATA BIT (B2) INTO ACC

SETB P1.3 CLK GOES HIGH

CLR P1.3 CLK GOES LOW

MOV C,P1.1 READ DATA BIT INTO CARRY

RLC A ROTATE DATA BIT (B1) INTO ACC

SETB P1.3 CLK GOES HIGH

CLR P1.3 CLK GOES LOW

MOV C,P1.1 READ DATA BIT INTO CARRY

SETB P1.4 CS GOES HIGH

RRC A ROTATE DATA BIT (B0) INTO ACC

RRC A ROTATE RIGHT INTO ACC

RRC A ROTATE RIGHT INTO ACC

RRC A ROTATE RIGHT INTO ACC

MOV R3,A STORE LSBs IN R3

AJMP CONT START NEXT CONVERSION

B7

B0

OO

B1

B2

SETB P1.3 CLK GOES HIGH

B5

B6

B0

B4

OO

LTC1292/7 F05

Sharing the Serial Interface

The LTC1292/LTC1297 can share the same two-wire

serial interface with other peripheral components or other

LTC1292/LTC1297s (Figure 6). In this case, the CS signals

decide which LTC1292 is being addressed by the MPU.

12

ANALOG CONSIDERATIONS

Grounding

The LTC1292/LTC1297 should be used with an analog

ground plane and single point grounding techniques. Do

not use wire wrapping techniques to breadboard and

evaluate the device. To achieve the optimum performance

Page 13

LTC1292/LTC1297

1

2

3

4

5

6

7

8

22µF

TANTALUM

V

CC

LTC1292/7 F07

LTC1292

LTC1297

0.1µF

U

O

PPLICATI

A

2

10

OUTPUT PORT

SERIAL DATA

MPU

Figure 6. Several LTC1292/LTC1297s Sharing One 2-Wire Serial Interface

2

LTC1292

LTC1297

2 CHANNELS

S

I FOR ATIO

22

CS

LTC1292

LTC1297

2 CHANNELS 2 CHANNELS

use a PC board. The ground pin (Pin 4) should be tied

directly to the ground plane with minimum lead length (a

low profile socket is fine). Figure 7 shows an example of

an ideal LTC1292/LTC1297 ground plane design for a twosided board. Of course this much ground plane will not

always be possible, but users should strive to get as close

to this ideal as possible.

WU

2

LTC1292

LTC1297

CS

CS

U

2-WIRE SERIAL

INTERFACE TO OTHER

PERIPHERALS OR

LTC1292/LTC1297s

LTC1292/7 F06

minimum and the VCC supply should have a low output

impedance such as obtained from a voltage regulator

(e.g., LT323A). For high frequency bypassing a 0.1µF

ceramic disk placed in parallel with the 22µF is

recommended. Again the leads should be kept to a

minimum. Figures 8 and 9 show the effects of good and

poor VCC bypassing.

Figure 7. Example Ground Plane

for the LTC1292/LTC1297

Bypassing

For good performance, V

must be free of noise and

CC

ripple. Any changes in the VCC voltage with respect to

ground during a conversion cycle can induce errors or

noise in the output code. VCC noise and ripple can be kept

below 0.5mV by bypassing the VCC pin directly to the

analog ground plane with a minimum of 22µF tantalum

capacitor and with leads as short as possible. The lead

from the device to the VCC supply also should be kept to a

VERTICAL: 0.5mV/DIV

HORIZONTAL: 10µs/DIV

Analog Inputs

Because of the capacitive redistribution A/D conversion

techniques used, the analog inputs of the LTC1292/

LTC1297 have capacitive switching input current spikes.

These current spikes settle quickly and do not cause a

problem. If large source resistances are used or if slow

settling op amps drive the inputs, take care to insure that

the transients caused by the current spikes settle completely

before the conversion begins.

CS

VERTICAL: 0.5mV/DIV

HORIZONTAL: 10µs/DIV

V

CC

Figure 8. Poor VCC Bypassing. Noise and

Ripple Can Cause A/D Errors

Figure 9. Good VCC Bypassing Keeps

Noise and Ripple on VCC Below 1mV

13

Page 14

LTC1292/LTC1297

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

Source Resistance

The analog inputs of the LTC1292/LTC1297 look like a

100pF capacitor (CIN) in series with a 500Ω resistor (RON)

(Figures 10a and 10b). CIN gets switched between (+) and

(–) inputs once during each conversion cycle. Large

external source resistors and capacitances will slow the

settling of the inputs. It is important that the overall RC

time constant is short enough to allow the analog inputs to

settle completely within the allowed time.

“+” Input Settling

The input capacitor for the LTC1292 is switched onto the

“+” input during the sample phase (t

11b and 11c). The sample period can be as short as t

+ 1/2 CLK cycle or as long as t

WHCS

, see Figures 11a,

SMPL

WHCS

+ 1 1/2 CLK cycles

before a conversion starts. This variability depends on

where CS falls relative to CLK. The voltage on the “+” input

must settle completely within the sample period. Minimizing

R

SOURCE

+ and C1 will improve the settling time. If large “+”

input source resistance must be used, the sample time can

be increased by using a slower CLK frequency. With the

minimum possible sample time of 3.0µ s, R

SOURCE

+ < 2.0k

and C1 < 20pF will provide adequate settling time.

The sample period for the LTC1297 starts on the falling

edge of CS and ends on the falling edge of the first CLK

“+”

INPUT

+

R

VIN +

VIN –

SOURCE

R

SOURCE

CS↑

500Ω

t

WHCS

+ 0.5 CLK

C1

“–”

INPUT

–

C2

LTC1292

RON

CIN

100pF

LTC1292/7 F10a

Figure 10a. Analog Input Equivalent Circuit for the LTC1292

“+”

INPUT

+

R

VIN +

VIN –

SOURCE

R

SOURCE

t

+ 0.5 CLK

CS↓

suCS

500Ω

C1

“–”

INPUT

–

C2

RON

LTC1297

C

IN

100pF

LTC1292/7 F10b

Figure 10b. Analog Input Equivalent Circuit for the LTC1297

(Figure 12). The length of the sample period is t

suCS

+0.5

CLK cycles. Again, the voltage on the “+” input must settle

completely within the sample period. If large “+” input

source resistance must be used, the sample time can be

increased by using a slower CLK frequency or by increasing

14

CLK

D

OUT

(+) INPUT

(–) INPUT

“+” and “–” Input Settling Windows

t

WHCS

CS

t

SUCS

t

(+) INPUT MUST SETTLE DURING THIS TIME

Figure 11a. Setup Time (t

SMPL

HI-Z

1ST BIT TEST (–) INPUT MUST

SETTLE DURING THIS TIME

) Is Met for the LTC1292

suCS

B11

B10

B9

LTC1292/7 F11a

Page 15

LTC1292/LTC1297

PPLICATI

A

CLK

D

OUT

(+) INPUT

(–) INPUT

U

O

S

I FOR ATIO

CS

(+) INPUT MUST SETTLE DURING THIS TIME

WU

t

WHCS

t

SMPL

HI-Z

U

Figure 11b. Setup Time (t

1ST BIT TEST (–) INPUT MUST

SETTLE DURING THIS TIME

) Is Met for the LTC1292

suCS

B11

B10

B9

LTC1292/7 F11b

t

WHCS

CS

CLK

t

(+) INPUT MUST SETTLE DURING THIS TIME

D

OUT

(+) INPUT

(–) INPUT

Figure 11c. Setup Time (t

t

. With the minimum possible sample time of 6µs,

suCS

R

SOURCE

+ < 5k and C1 < 20pF will provide adequate

SMPL

HI-Z

suCS

settling time. In general for both the LTC1292 and LTC1297

keep the product of the total resistance and the total

capacitance less than t

/9. If this condition can not be

SMPL

met, then make C1 > 0.47µF (see RC Input Filtering

section).

1ST BIT TEST (–) INPUT MUST

SETTLE DURING THIS TIME

B11

B10

LTC1292/7 F11c

) Is Not Met for the LTC1292

“–” Input Settling

At the end of the sample phase the input capacitor switches

to the “–” input and the conversion starts (see Figures 11a,

11b, 11c and 12). During the conversion, the “+” input

voltage is effectively “held” by the sample-and-hold and

will not affect the conversion result. It is critical that the

15

Page 16

LTC1292/LTC1297

PPLICATI

A

CS

CLK

D

OUT

(+) INPUT

(–) INPUT

U

O

S

I FOR ATIO

Figure 12. “+” and “–” Input Settling Windows for the LTC1297

WU

t

WHCS

U

(+) INPUT MUST SETTLE

HI-Z

t

suCS

t

SMPL

DURING THIS TIME

1ST BIT TEST (–) INPUT MUST

SETTLE DURING THIS TIME

B11

B10

LTC1292/7 F12

“–” input voltage be free of noise and settle completely

during the first CLK cycle of the conversion. Minimizing

R

SOURCE

– and C2 will improve settling time. If large “–”

input source resistance must be used the time can be

extended by using a slower CLK frequency. At the maximum

CLK frequency of 1MHz, R

SOURCE

– < 250Ω and C2 < 20pF

will provide adequate settling.

Input Op Amps

When driving the analog inputs with an op amp it is

important that the op amp settles within the allowed time

(see Figures 11a, 11b, 11c and 12). Again the “+” and

“–” input sampling times can be extended as described

above to accommodate slower op amps. Most op amps

including the LT1006 and LT1013 single supply op amps

can be made to settle well even with the minimum settling

windows of 3.0µs for the LTC1292 or 6.0µs for the

LTC1297 (“+” input) and 1µ s (“–” input) that occurs at the

maximum clock rate of 1MHz. Figures 13 and 14 show

examples of both adequate and poor op amp settling.

VERTICAL: 5mV/DIV

HORIZONTAL: 500ns/DIV

Figure 13. Adequate Settling of Op Amp Driving Analog Input

VERTICAL: 5mV/DIV

16

HORIZONTAL: 20µs/DIV

Figure 14. Poor Op Amp Settling Can Cause A/D Errors

Page 17

LTC1292/LTC1297

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

RC Input Filtering

It is possible to filter the inputs with an RC network as

shown in Figure 15. For large values of CF (e.g., 1µF) the

capacitive input switching currents are averaged into a net

DC current. A filter should be chosen with a small resistor

and large capacitor to prevent DC drops across the resistor.

The magnitude of the DC current is approximately IDC =

100pF × VIN/t

and is roughly proportional to VIN. When

CYC

running the LTC1292(LTC1297) at the minimum cycle

time of 16.5µs (20µs), the input current equals 30µA

(25µA) at VIN = 5V. Here a filter resistor of 4Ω (5Ω) will

cause 0.1LSB of full scale error. If a large filter resistor

must be used, errors can be reduced by increasing the

cycle time as shown in the typical performance

characteristics curve Maximum Filter Resistor vs Cycle

Time.

I

FILTER

DC

C

FILTER

“+”

LTC1292

LTC1297

“–”

R

V

IN

curve of S&H Acquisition Time vs Source Resistance). The

input voltage is sampled during the t

time as shown

SMPL

in Figure 11. The sampling interval begins at the rising

edge of CS for the LTC1292, and at the falling edge of CS

for the LTC1297, and continues until the falling edge of the

CLK before the conversion begins. On this falling edge the

S&H goes into the hold mode and the conversion begins.

Differential Input

With a differential input the A/D no longer converts a single

voltage but converts the difference between two voltages.

The voltage on the +IN pin is sampled and held and can be

rapidly time-varying as in single-ended mode. The voltage

on the –IN pin must remain constant and be free of noise

and ripple throughout the conversion time. Otherwise the

differencing operation will not be done accurately. The

conversion time is 12 CLK cycles. Therefore a change in

the –IN input voltage during this interval can cause

conversion errors. For a sinusoidal voltage on the –IN

input this error would be:

LTC1292/7 F15

Figure 15. RC Input Filtering

Input Leakage Current

Input leakage currents also can create errors if the source

resistance gets too large. For example, the maximum input

leakage specification of 1µ A (at 125°C) flowing through a

source resistance of 1k will cause a voltage drop of 1mV

or 0.8LSB. This error will be much reduced at lower

temperatures because leakage drops rapidly (see typical

performance characteristics curve Input Channel Leakage

Current vs Temperature).

SAMPLE-AND-HOLD

Single-Ended Input

The LTC1292/LTC1297 provide a built-in sample-andhold (S&H) function on the +IN input for signals acquired

in the single-ended mode (–IN pin grounded). The sampleand-hold allows the LTC1292/LTC1297 to convert rapidly

varying signals (see typical performance characteristics

VfV

ERROR MAX IN PEAK

Where f

V

(–IN)

is its peak amplitude and f

PEAK

CLK. Usually V

=

2

π

( ) (– )

()

is the frequency of the –IN input voltage,

will not be significant. For a 60Hz

ERROR

12

f

CLK

is the frequency of the

CLK

1292/7 E1

signal on the –IN input to generate a 0.25LSB error

(300µV) with the converter running at CLK = 1MHz, its

peak value would have to be 66mV. Rearranging the above

equation the maximum sinusoidal signal that can be

digitized to a given accuracy is given as:

f

IN MAX

(– )

=

ERROR MAX

V

π

2

PEAK

()

f

CLK

12

1292/7 E2

V

For 0.25LSB error (300µV) the maximum input sinusoid

with a 5V peak amplitude that can be digitized is 0.8Hz.

Reference Input

The voltage on the reference input of the LTC1292/

LTC1297 determine the voltage span of the A/D converter. The reference input has transient capacitive

switching currents due to the switched-capacitor con-

17

Page 18

LTC1292/LTC1297

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

version technique (see Figure 16). During each bit test

of the conversion (every CLK cycle) a capacitive current

spike will be generated on the reference pin by the A/D.

These current spikes settle quickly and do not cause a

problem. If slow settling circuitry is used to drive the

reference input, take care to insure that transients

caused by these current spikes settle completely during

each bit test of the conversion.

+

REF

14

V

OUT

REF

–

REF

13

R

Figure 16. Reference Input Equivalent Circuit

EVERY

CLK CYCLE

R

ON

LTC1292

LTC1297

8pF TO 40pF

LTC1292/7 F16

Figures 17 and 18 show examples of both adequate and

poor settling. Using a slower CLK will allow more time

for the reference to settle. Even at the maximum CLK

rate of 1MHz most references and op amps can be

made to settle within the 1µ s bit time. For example the

LT1027 will settle adequately. With a 10µF bypass

capacitor at V

the LT1021 can also be used.

REF

Reduced Reference Operation

The effective resolution of the LTC1292/LTC1297 can

be increased by reducing the input span of the converter. The LTC1292/LTC1297 exhibit good linearity

over a range of reference voltages (see typical performance characteristics curves of Change in Linearity vs

Reference Voltage). Care must be taken when operating at low values of V

because of the reduced LSB

REF

step size and the resulting higher accuracy requirement

placed on the converter. Offset and noise are factors

that must be considered when operating at low V

values. The internal reference for V

has been tied to

REF

REF

the GND pin. Any voltage drop from the GND pin to the

ground plane will cause a gain error.

VERTICAL: 0.5mV/DIV

HORIZONTAL: 1µs/DIV

Figure 17. Adequate Reference Settling (LT1027)

VERTICAL: 0.5mV/DIV

HORIZONTAL: 10µs/DIV

Figure 18. Poor Reference Settling Can Cause A/D Errors

Offset with Reduced V

REF

The offset of the LTC1292/LTC1297 has a larger effect

on the output code when the A/D is operated with a

reduced reference voltage. The offset (which is typically a fixed voltage) becomes a larger fraction of an

LSB as the size of the LSB is reduced. The typical

performance characteristics curve of Unadjusted Offset Error vs Reference Voltage shows how offset in

LSBs is related to reference voltage for a typical value

of VOS. For example a V

of 0.1mV, which is 0.1LSB

OS

with a 5V reference becomes 0.4LSB with a 1.25V

reference. If this offset is unacceptable, it can be

corrected digitally by the receiving system or by offsetting the –IN input to the LTC1292/LTC1297.

Noise with Reduced V

REF

The total input referred noise of the LTC1292/LTC1297

can be reduced to approximately 200µV

using a

P-P

ground plane, good bypassing, good layout techniques

and minimizing noise on the reference inputs. This

noise is insignificant with a 5V reference input but will

18

Page 19

LTC1292/LTC1297

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

become a larger fraction of an LSB as the size of the LSB

is reduced. The typical performance characteristics

curve of Noise Error vs Reference Voltage shows the

LSB contribution of this 200µV of noise.

For operation with a 5V reference, the 200µV noise is

only 0.16LSB peak-to-peak. Here the LTC1292/LTC1297

noise will contribute virtually no uncertainty to the

output code. For reduced references, the noise may

become a significant fraction of an LSB and cause

undesirable jitter in the output code. For example, with

a 1.25V reference, this 200µV noise is 0.64LSB peak-

to-peak. This will reduce the range of input voltages

over which a stable output code can be achieved by

0.64LSB. Now, averaging readings may be necessary.

This noise data was taken in a very clean test fixture.

Any setup induced noise (noise or ripple on VCC, V

REF

or VIN) will add to the internal noise. The lower the

reference voltage used, the more critical it becomes to

have a noise-free setup.

Gain Error Due to Reduced V

REF

The gain error of the LTC1292/LTC1297 is very good

over a wide range of reference voltages. The error

component that is seen in the typical performance

characteristics curve Change in Gain Error vs Reference Voltage is due to the voltage drop on the GND pin

from the device to the ground plane. To minimize this

error the LTC1292/LTC1297 should be soldered directly onto the PC board. The internal reference point

for V

is tied to GND. Any voltage drop in the GND pin

REF

will make the reference voltage, internal to the device,

less than what is applied externally (Figure 19). This

drop is typically 420µV due to the product of the pin

LTC1292

LTC1297

DAC

REF–

REF+

V

GND

ICC

Figure 19. Parasitic Resistance in GND Pin

R

PIN

REF

±

REFERENCE

VOLTAGE

LTC1292/7 F19

resistance (R

current. For example, with V

) and the LTC1292/LTC1297 supply

PIN

= 1.25V this will result

REF

in a gain error change of –1.0LSB from the gain error

measured with V

REF

= 5V.

LTC1292 AC Characteristics

Two commonly used figures of merit for specifying the

dynamic performance of the A/Ds in digital signal

processing applications are the Signal-to-Noise Ratio

(SNR) and the “Effective Number of Bits (ENOB).” SNR

is the ratio of the RMS magnitude of the fundamental to

the RMS magnitude of all the non-fundamental signals

up to the Nyquist frequency (half the sampling frequency). The theoretical maximum SNR for a sine wave

input is given by:

SNR = (6.02N + 1.76dB)

where N is the number of bits. Thus the SNR depends

on the resolution of the A/D. For an ideal 12-bit A/D the

SNR is equal to 74dB. Fast Fourier Transform (FFT)

plots of the output spectrum of the LTC1292 are shown

in Figures 20a and 20b. The input (fIN) frequencies are

1kHz and 28kHz with the sampling frequency (fS) at

58.8 kHz. The SNRs obtained from the plots are 73.0dB

and 61.5dB.

By rewriting the SNR expression it is possible to obtain

the equivalent resolution based on the SNR measurement.

SNR dB

–..176

N

=

602

1292/7 E3

This is the effective number of bits (ENOB). For the

example shown in Figures 20a and 20b, N = 11.8 bits

and 9.9 bits, respectively. Figure 21 shows a plot of

ENOB as a function of input frequency. The 2nd harmonic distortion term accounts for the degradation of

the ENOB as fIN approaches fS/2.

Figure 22 shows an FFT plot of the output spectrum for

two tones applied to the input of the A/D. Nonlinearities

in the A/D will cause distortion products at the sum and

difference frequencies of the fundamentals and products of the fundamentals. This is classically referred to

as intermodulation distortion (IMD).

19

Page 20

LTC1292/LTC1297

U

O

PPLICATI

A

MAGNITUDE (dB)

–20

–40

–60

–80

–100

–120

–140

0

0

S

I FOR ATIO

510

FREQUENCY (kHz)

20 30

15 25

LTC1292/7 F20a

Figure 20a. fIN = 1kHz, fS = 58.8kHz, SNR = 73.0dB

0

–20

–40

–60

–80

MAGNITUDE (dB)

–100

–120

–140

0

510

FREQUENCY (kHz)

20 30

15 25

LTC1292/7 F20b

Figure 20b. fIN = 28kHz, fS = 58.8kHz, SNR = 61.5dB

12.0

11.5

11.0

10.5

10.0

9.5

9.0

EFFECTIVE NUMBER OF BITS

8.5

8.0

20 40 80

0

FREQUENCY (kHz)

fS = 58.8kHz

60

LT1292/7 F21

Figure 21. LTC1292 ENOB vs Input Frequency

WU

100

U

0

–20

–40

–60

–80

MAGNITUDE (dB)

–100

–120

–140

0

Figure 22. f

510

FREQUENCY (kHz)

= 5.1kHz, f

IN1

20 30

15 25

LTC1292/7 F22

= 5.6kHz, fS = 58.8kHz

IN2

Overvoltage Protection

Applying signals to the LTC1292/LTC1297’s analog

inputs that exceed the positive supply or that go below

ground will degrade the accuracy of the A/D and possibly damage the devices. For example this condition

would occur if a signal is applied to the analog inputs

before power is applied to the LTC1292/LTC1297. Another example is the input source is operating from

different supplies of larger value than the LTC1292/

LTC1297. These conditions should be prevented either

with proper supply sequencing or by use of external

circuitry to clamp or current limit the input source.

There are two ways to protect the inputs. In Figure 23

diode clamps from the inputs to VCC and GND are used.

The second method is to put resistors in series with the

analog inputs for current limiting. Limit the current to

15mA per channel. The +IN input can accept a resistor

value of 1k but the –IN input cannot accept more than

250Ω when clocked at its maximum clock frequency of

1MHz. If the LTC1292/LTC1297 are clocked at the

maximum clock frequency and 250Ω is not enough to

current limit the input source, then the clamp diodes are

recommended (Figures 24a and 24b). The reason for

the limit on the resistor value is that the MSB bit test is

affected by the value of the resistor placed at the –IN

input (see discussion on Analog Inputs and the typical

performance characteristics Maximum CLK Frequency

vs Source Resistance).

20

Page 21

LTC1292/LTC1297

U

O

PPLICATI

A

If VCC and V

REF

be turned on first, then V

S

I FOR ATIO

are not tied together, then VCC should

. If this sequence cannot be

REF

met, connecting a diode from V

WU

to VCC is recom-

REF

mended (see Figure 25).

1N4148 DIODES

CS

+IN

LTC1292

LTC1297

–IN

GND

Figure 23. Overvoltage Protection with Clamp Diodes

CS

1k

250Ω

+IN

–IN

GND

LTC1292

LTC1297

Figure 24a. Overvoltage Protection with

Current Limiting Resistors

D

CLK

V

V

OUT

REF

V

CC

CLK

D

OUT

V

REF

5V

CC

LTC1292/7 F24a

5V

LTC1292/7 F23

U

Because a unique input protection structure is used on

the digital input pins, the signal levels on these pins can

exceed the device V

1N4148 DIODES

1k

Figure 24b. Overvoltage Protection with

Diode Clamps and Current Limiting Resistor

Figure 25. Separate VCC and V

without damaging the device.

CC

CS

+IN

–IN

GND

CS

+IN

–IN

GND

LTC1292

LTC1297

LTC1292

LTC1297

V

CC

CLK

D

OUT

V

REF

V

CC

CLK

D

OUT

V

REF

1N4148

LTC1292/7 F25

Supplies

REF

LTC1292/7 F24

5V

5V

5V

V

CLK

+5V

DD

Q4

Q3

Q2

Q1

EN

0.1µF

LTC1292/7 F26

f/32

22µF

CS

V

IN

+IN

LTC1292

–IN

GND

TO OSCILLOSCOPE

V

CC

CLK

D

OUT

V

REF

CLOCK IN

1MHz

CLK

EN

Q1

Q2

Q3

Q4

RESET

V

SS

RESET

CD4520

Figure 26. “Quick Look” Circuit for the LTC1292

21

Page 22

LTC1292/LTC1297

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

A “Quick Look” Circuit for the LTC1292

Users can get a quick look at the function and timing of

the LTC1292 by using the “Quick Look” circuit in Figure

26. V

is tied to VCC. VIN is applied to the +IN input

REF

and the –IN input is tied to the ground plane. CS is driven

at 1/32 the clock rate by the CD4520 and D

the data. The output data from the D

OUT

outputs

OUT

pin can be

viewed on an oscilloscope that is set up to trigger on the

falling edge of CS (Figure 27). Note the LSB data is

partially clocked out before CS goes high.

CLK

CS

D

OUT

A “Quick Look” Circuit for the LTC1297

A circuit similar to the one used for the LTC1292 can be

used for the LTC1297(Figure 28). A one shot has been

generated with NAND gates, a resistor and capacitor to

satisfy the setup time t

. This can be eliminated if a

suCS

slower clock is used. When CS goes low the one shot is

triggered. This turns off the clock to the LTC1297 for a

fixed time to meet t

. Once the clock starts D

suCS

OUT

is

shifted out one bit at a time. CS is driven at 1/64 the

clock rate by the 74HC393. The output data from the

D

pin can be viewed on an oscilloscope that is set to

OUT

trigger on the falling edge of CS. See Figure 29.

CLK

CS

NULL

BIT

MSB

(B11)

VERTICAL: 5V/DIV

HORIZONTAL: 2µs/DIV

LSB

LSB-FIRST DATA

(B0)

(B1)

Figure 27. Scope Trace of the LTC1292 “Quick Look”

Circuit Showing A/D Output 101010101010 (AAA

22µF

TANTALUM

+

CS

V

IN

+IN

LTC1297

–IN

GND

TO OSCILLOSCOPE

D

V

V

CLK

OUT

REF

CC

HEX

f/64

)

D

OUT

LSB-FIRST DATA

LSB

MSB

NULL

(B11)

BIT

VERTICAL: 5V/DIV

HORIZONTAL: 5µs/DIV

(B0)

(B1)

Figure 29. Scope Trace of the LTC1297 “Quick Look”

Circuit Showing A/D Output 101010101010 (AAA

5V

f

A1

CLR1

1QA

1QB

1QC

1QD

GND

74HC393

V

CLR2

2QA

2QB

2QC

2QD

CC

A2

0.1µF

HEX

)

22

340Ω

0.02µF

CLOCK IN 1MHz

Figure 28. “Quick Look” Circuit for the LTC1297

LTC1292/7 F28

Page 23

LTC1292/LTC1297

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

Opto-Isolated Temperature Monitor

Amplification of sensor outputs is often required to

generate a signal large enough to be properly digitized.

For example, a J-type thermocouple provides only

52µV/°C. The 5µV offset of the LTC1050 chopper op

amp generates less than 0.1°C error (Figure 31). Cold

junction compensation is provided by the LT1025A.

(For more detail see LTC Design Note 5).

In the opto-isolated interface two signals are generated

from one. This allows a two-wire interface to the

LTC1292. A long high signal (>1ms) on the CLK IN input

allows the 0.1µ F capacitor to discharge taking CS high.

This resets the A/D for the next conversion. When CLK

IN starts toggling, CS goes low and stays there until the

next extended CLK IN high time. See Figure 30.

ISOLATED

5V

5V/DIV

CLK IN

A

CS

DATA OUT

20µs/DIV

Figure 30. Opto-Isolated Temperature

Monitor Digital Waveforms

+

22 Fµ

2

V

IN

LT1025A

GND

4

2k

0.1%

H

J

–

R

TYPE J

5

0°C – 500°C TEMPERATURE RANGE

3.4k

0.1%

2

–

3

+

+

+

1 F

µ

0.33 Fµ

LTC1050

178k

0.1%

+

7

6

4

47Ω

1 Fµ

1N4148

+

1

2

3

4

LT1019-2.5

LTC1292

CS

+IN

–IN

GND

8

V

CC

7

CLK

6

D

OUT

5

V

REF

4.7 Fµ

3Ω

1N4148

1N4148

A

10k

+

100k

+

0.1 Fµ

74C14

5k

1k

4N28s

3

4

6

500k

1

2

1

5V

1k

2

3

4

6

500k

5V

CLK IN

5k

DATA

OUT

LTC1292/7 F31

Figure 31. Opto-Isolated Temperature Monitor

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

23

Page 24

LTC1292/LTC1297

PACKAGE DESCRIPTIO

U

Dimensions in inches (millimeters) unless otherwise noted.

J8 Package

8-Lead Ceramic DIP

0.290 – 0.320

(7.366 – 8.128)

0.008 – 0.018

(0.203 – 0.457)

0.385 ± 0.025

(9.779 ± 0.635)

0° – 15°

0.300 – 0.320

(7.620 – 8.128)

0.045 – 0.068

(1.143 – 1.727)

FULL LEAD

OPTION

CORNER LEADS OPTION

(4 PLCS)

0.023 – 0.045

(0.584 – 1.143)

HALF LEAD

OPTION

0.200

(5.080)

MAX

0.015 – 0.060

(0.381 – 1.524)

0.045 – 0.068

(1.143 – 1.727)

0.014 – 0.026

(0.360 – 0.660)

NOTE: LEAD DIMENSIONS APPLY TO SOLDER DIP OR TIN PLATE LEADS.

0.100 ± 0.010

(2.540 ± 0.254)

0.125

3.175

MIN

J8 0293

N8 Package

8-Lead Plastic DIP

0.045 – 0.065

(1.143 – 1.651)

0.130 ± 0.005

(3.302 ± 0.127)

0.005

(0.127)

MIN

0.025

(0.635)

RAD TYP

0.400

(10.160)

MAX

876

0.405

(10.287)

MAX

87

12

5

65

3

4

0.220 – 0.310

(5.588 – 7.874)

24

0.065

(1.651)

0.009 – 0.015

(0.229 – 0.381)

+0.025

0.325

–0.015

+0.635

8.255

()

–0.381

TYP

0.045 ± 0.015

(1.143 ± 0.381)

0.100 ± 0.010

(2.540 ± 0.254)

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7487

(408) 432-1900

●

FAX

: (408) 434-0507

●

TELEX

: 499-3977

0.125

(3.175)

MIN

0.018 ± 0.003

(0.457 ± 0.076)

0.020

(0.508)

MIN

0.250 ± 0.010

(6.350 ± 0.254)

1234

LT/GP 0294 2K REV A • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1994

N8 0392

Loading...

Loading...