Datasheet LTC1265, LTC1265IS, LTC1265CS, LTC1265-5, LTC1265CS-5 Datasheet (Linear Technology)

...Page 1

FEATURES

LTC1265/LTC1265-3.3/LTC1265-5

1.2A, High Efficiency

Step-Down DC/DC Converter

U

DESCRIPTIO

■

High Efficiency: Up to 95%

■

Current Mode Operation for Excellent Line and Load

Transient Response

■

Internal 0.3Ω Power Switch (VIN = 10V)

■

Short-Circuit Protection

■

Low Dropout Operation: 100% Duty Cycle

■

Low-Battery Detector

■

Low 160µA Standby Current at Light Loads

■

Active-High Micropower Shutdown: IQ < 15µA

■

Peak Inductor Current Independent of Inductor Value

■

Available in 14-pin SO Package

U

APPLICATIO S

■

5V to 3.3V Conversion

■

Distributed Power Systems

■

Step-Down Converters

■

Inverting Converters

■

Memory Backup Supply

■

Portable Instruments

■

Battery-Powered Equipment

■

Cellular Telephones

The LTC®1265 is a monolithic step-down current mode

DC/DC converter featuring Burst Mode TM operation at low

output current. The LTC1265 incorporates a 0.3Ω switch

(VIN =10V) allowing up to 1.2A of output current.

Under no load condition, the converter draws only 160µA.

In shutdown it typically draws a mere 5µA making this

converter ideal for current sensitive applications. In dropout the internal P-channel MOSFET switch is turned on

continuously maximizing the life of the battery source. The

LTC1265 incorporates automatic power saving Burst Mode

operation to reduce gate charge losses when the load

currents drop below the level required for continuous

operation.

The inductor current is user-programmable via an external

current sense resistor. Operation up to 700kHz permits

the use of small surface mount inductors and capacitors.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a trademark of Linear Technology Corporation.

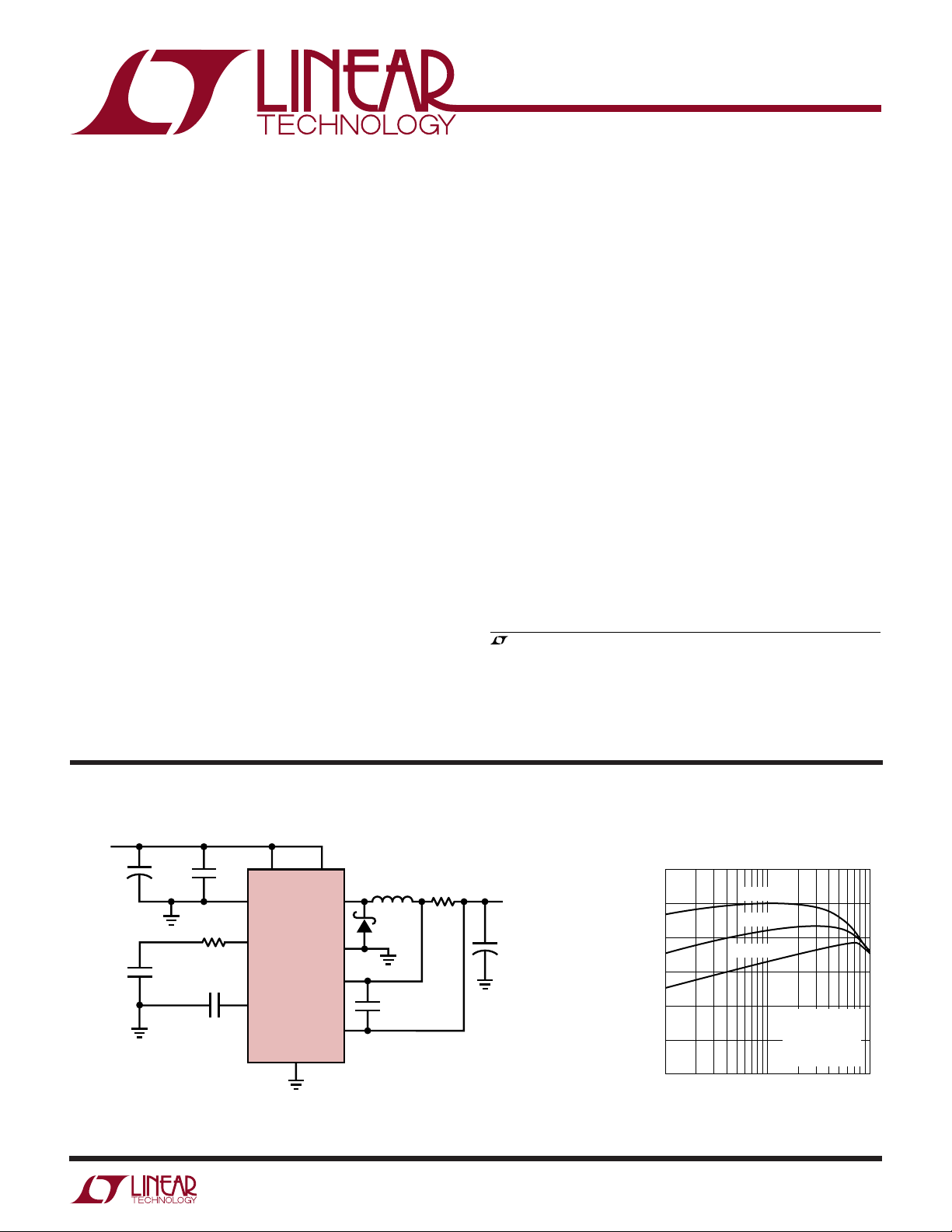

TYPICAL APPLICATIO

V

IN

5.4V TO

12V

†††

+

C

IN

68µF

20V

3900pF

1k

130pF

0.1µF

PWR V

SHDN

I

TH

C

T

IN

LTC1265-5

SGND

Figure 1. High Efficiency Step-Down Converter

U

V

PGND

SENSE

SENSE

IN

SW

LTC1265-5 Efficiency

L1*

33µH

†

D1

+

1000pF

–

COILTRONICS CTX33-4

*

IRC LRC2010-01-R100-J

**

†

MBRS130LT3

††

AVX TPSE227K010

†††

AVX TPSE686K020

R

SENSE

0.1Ω

**

V

OUT

5V

1A

††

C

+

OUT

220µF

10V

LTC1265-FO1

100

95

90

85

EFFICIENCY (%)

80

75

70

0.01

VIN = 6V

VIN = 9V

VIN = 12V

L = 33µH

V

OUT

R

SENSE

C

T

0.10 1.00

LOAD CURRENT (A)

= 5V

= 0.1Ω

= 130pF

LTC1265 TA01

1

Page 2

LTC1265/LTC1265-3.3/LTC1265-5

WW

W

ABSOLUTE MAXIMUM RATINGS

U

U

W

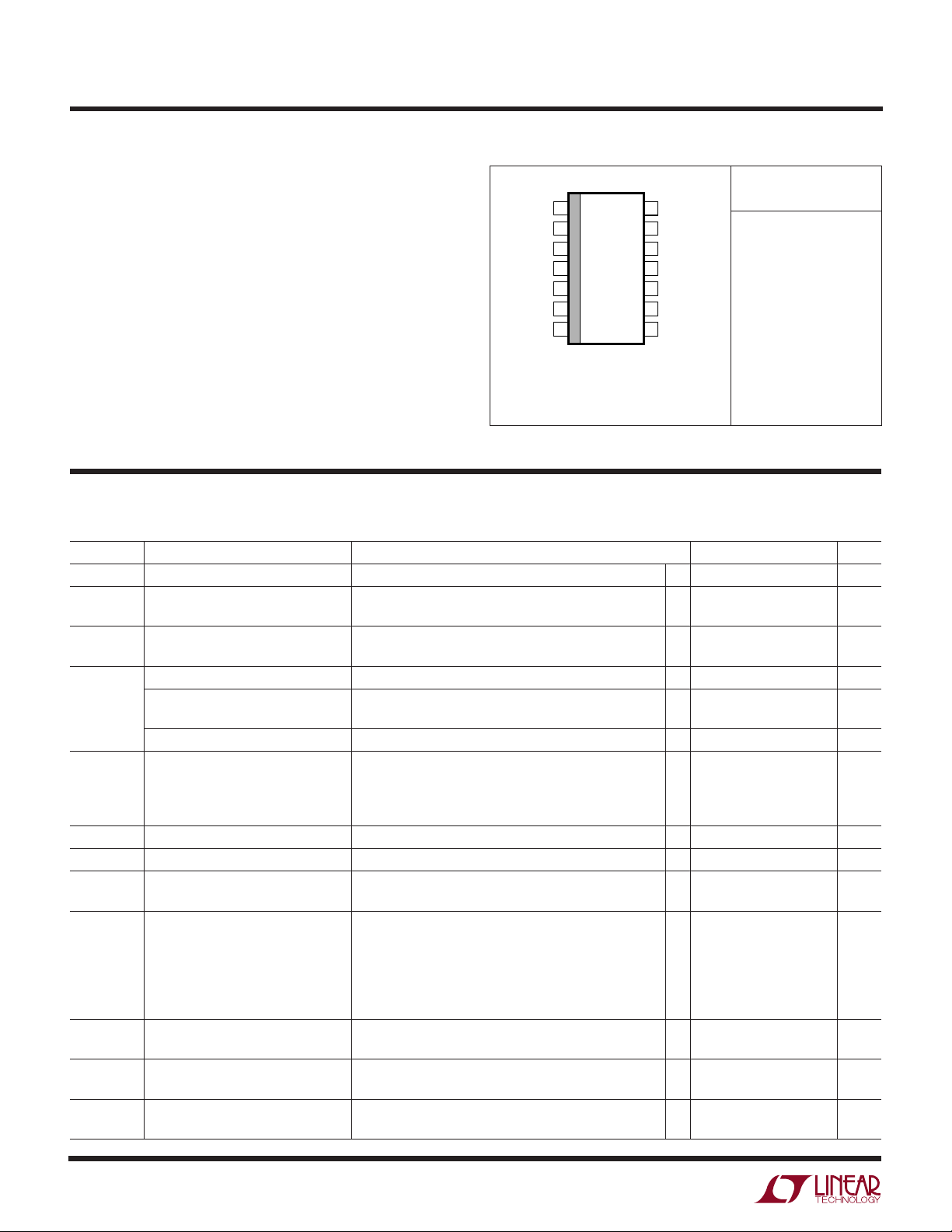

PACKAGE/ORDER INFORMATION

U

(Voltages Refer to GND Pin) (Note 1)

Input Supply Voltage (Pins 1, 2, 13)..........–0.3V to 13V

DC Switch Current (Pin 14) .................................... 1.2A

Peak Switch Current (Pin 14) ................................. 1.6A

Switch Voltage (Pin 14) ..................................V

– 13.0

IN

Operating Temperature Range

LTC1265C ............................................... 0° to 70°C

LTC1265I ........................................ – 40°C to 85°C

Junction Temperature (Note 2)............................. 125°C

Storage Temperature Range ....................– 65° to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

PWR V

LB

SENSE

OUT

LB

TOP VIEW

1

IN

2

V

IN

3

4

IN

5

C

T

6

I

TH

–

7

S PACKAGE

14-LEAD PLASTIC SO

*ADJUSTABLE OUTPUT VERSION

T

= 125°C, θJA = 110°C/W

JMAX

14

SW

13

PWR V

12

PGND

11

SGND

10

SHDN

9

N/C (V

8

SENSE

IN

*)

FB

+

Consult factory for Military grade parts.

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 10V, V

The ● denotes the specifications which apply over the full operating

= 0V, unless otherwise specified.

SHDN

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

FB

V

FB

V

OUT

∆V

OUT

I

Q

V

LBTRIP

I

LBIN

I

LBOUT

V8 – V

R

ON

7

Feedback Current into Pin 9 LTC1265 0.2 1 µA

Feedback Voltage LTC1265C ● 1.22 1.25 1.28 V

= 9V, LTC1265I ● 1.20 1.25 1.30 V

V

IN

Regulator Output Voltage LTC1265-3.3: I

LTC1265-5: I

Output Voltage Line Regulation VIN = 6.5V to 10V, I

Output Voltage Load Regulation LTC1265-3.3: 10mA < I

LTC1265-5: 10mA < I

Burst Mode Operation Output Ripple I

= 0mA 50 mV

LOAD

= 800mA ● 3.22 3.3 3.40 V

LOAD

= 800mA ● 4.9 5 5.2 V

LOAD

= 800mA –40 0 40 mV

LOAD

< 800mA 40 65 mV

LOAD

< 800mA 60 100 mV

LOAD

Input DC Supply Current (Note 3) Active Mode: 3.5V < VIN < 10V 1.8 2.4 mA

Sleep Mode: 3.5V < V

Sleep Mode: 5V < V

Shutdown: V

SHDN

< 10V 160 230 µA

IN

< 10V (LTC1265-5) 160 230 µA

IN

= VIN, 3.5V < VIN < 10V 5 15 µA

Low-Battery Trip Point 1.15 1.25 1.35 V

Current into Pin 4 0.5 µA

Current Sunk by Pin 3 V

Current Sense Threshold Voltage LTC1265: V

= 0.4V, V

LBOUT

= 5V, V

V

LBOUT

V

SENSE

SENSE

LTC1265-3.3: V

V

LTC1265-5: V

V

SENSE

SENSE

= 0V 0.5 1.0 1.5 mA

LBIN

= 10V 1.0 µA

LBIN

–

= 5V, V9 = V

–

= 5V, V9 = V

–

= V

SENSE

–

= V

SENSE

–

= V

–

= V

OUT

OUT

/4 + 25mV (Forced) 25 mV

OUT

/4 – 25mV (Forced) 130 150 180 mV

OUT

+ 100mV (Forced) 25 mV

OUT

– 100mV (Forced) 130 150 180 mV

OUT

+ 100mV (Forced) 25 mV

– 100mV (Forced) 130 150 180 mV

ON Resistance of Switch LTC1265C ● 0.3 0.60 Ω

LTC1265I 0.3 0.70 Ω

I

t

5

OFF

CT Pin Discharge Current V

in Regulation, V

OUT

= 0V 2 10 µA

V

OUT

Switch Off Time (Note 4) CT = 390pF, I

C

= 390pF, I

T

= 800mA (LTC1265C) ● 456 µs

LOAD

= 800mA (LTC1265I) ● 3.5 5 7 µs

LOAD

SENSE

–

= V

OUT

40 60 100 µA

ORDER

PART NUMBER

LTC1265CS

LTC1265CS-5

LTC1265CS-3.3

LTC1265IS

P-P

2

Page 3

LTC1265/LTC1265-3.3/LTC1265-5

INPUT VOLTAGE (V)

4

80

EFFICIENCY (%)

82

86

88

90

100

94

6

8

913

LTC1265 G03

84

96

98

92

57

10

11

12

I

LOAD

= 250mA

I

LOAD

= 800mA

LTC1265-3.3

R

SENSE

= 0.1Ω

C

T

= 130pF

COIL = CTX33-4

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 10V, V

The ● denotes the specifications which apply over the full operating

= 0V, unless otherwise specified.

SHDN

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

I

10

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: T

dissipation P

Shutdown Pin High Min Voltage at Pin 10 for Device to be in Shutdown 1.2 V

Shutdown Pin Low Max Voltage at Pin 10 for Device to be Active 0.6 V

Shutdown Pin Input Current V

= 8V 0.5 µA

SHDN

Note 3: Dynamic supply current is higher due to the gate charge being

delivered at the switching frequency.

is calculated from the ambient temperature TA and power

J

according to the following formulas:

D

Note 4: In applications where R

off time increases by approximately 40%.

is placed at ground potential, the

SENSE

LTC1265CS, LTC1265CS-3.3, LTC1265CS-5:

TJ = TA + (PD • 110°C/W)

W

U

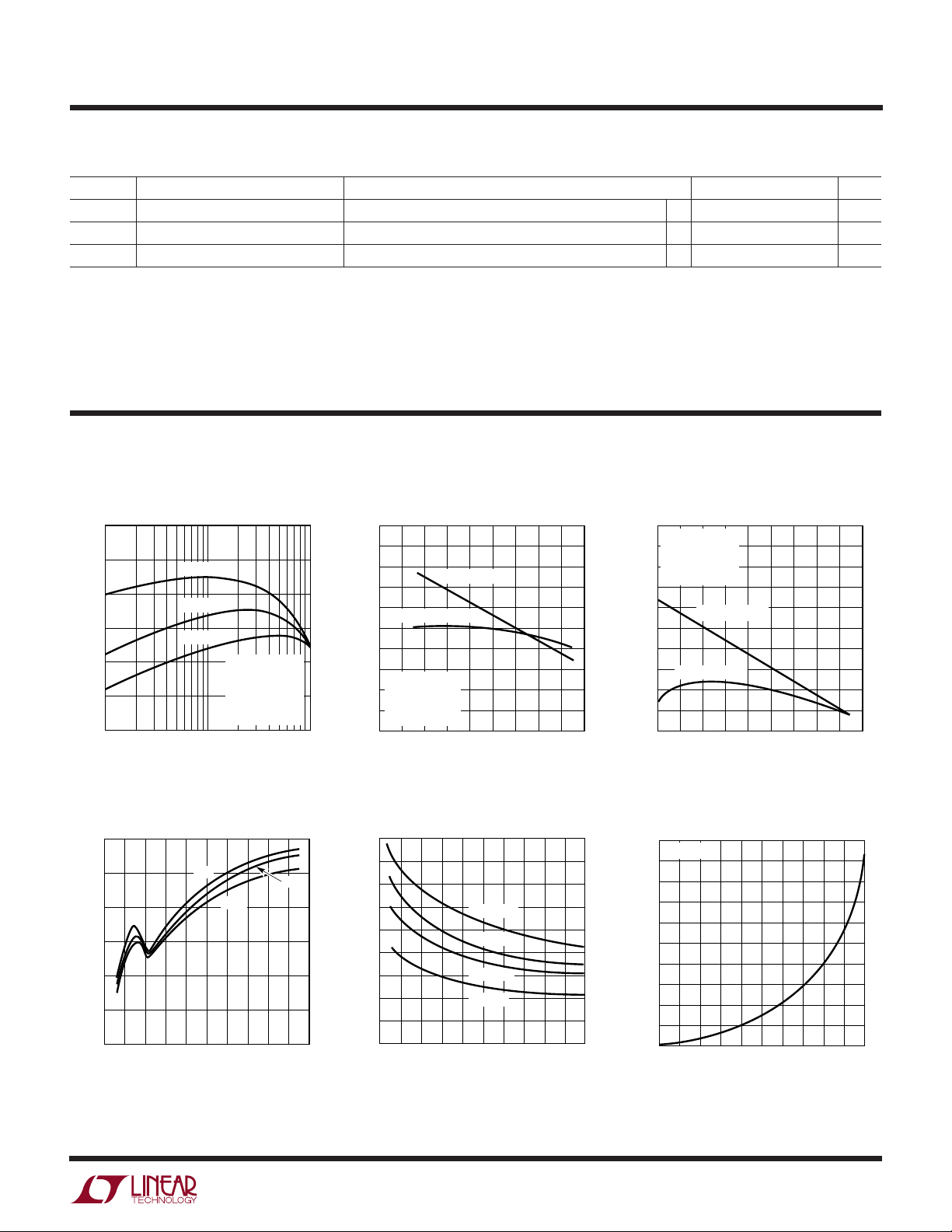

TYPICAL PERFORMANCE CHARACTERISTICS

Efficiency vs Load Current

100

95

90

85

EFFICIENCY (%)

80

75

70

0.01

VIN = 5V

VIN = 9V

VIN = 12V

0.10 1.00

LOAD CURRENT (A)

LTC1265-3.3

= 3.3V

V

OUT

= 0.1Ω

R

SENSE

= 130pF

C

T

COIL = CTX33-4

1265 G01

Efficiency vs Input Voltage

(V

= 5V)

OUT

100

98

96

94

92

90

88

EFFICIENCY (%)

86

LTC1265-5

84

R

SENSE

C

T

82

COIL = CTX33-4

80

4

I

= 250mA

LOAD

I

= 800mA

LOAD

= 0.1Ω

= 130pF

57

6

8

INPUT VOLTAGE (V)

11

913

12

10

1265 G02

Efficiency vs Input Voltage

(V

= 3.3V)

OUT

Operating Frequency

vs (V

– V

IN

1.2

1.0

0.8

0.6

0.4

NORMALIZED FREQUENCY

0.2

0

OUT

21468

(V

IN – VOUT

)

0°C

70°C

) VOLTAGE (V)

25°C

1265 G04

1003579

Switch Resistance

0.9

0.8

0.7

0.6

(Ω)

0.5

(ON)

0.4

RDS

0.3

0.2

0.1

0

3

48

59

= 125°C

T

J

T

= 70°C

J

T

= 25°C

J

T

= 0°C

J

6

7

INPUT VOLTAGE (V)

Switch Leakage Current

300

VIN = 12V

270

240

210

180

150

120

90

LEAKAGE CURRENT (nA)

60

30

12

10

13

11

1265 G05

0

20

0

TEMPERATURE (°C)

60

80

40

100

1265 G06

3

Page 4

LTC1265/LTC1265-3.3/LTC1265-5

W

U

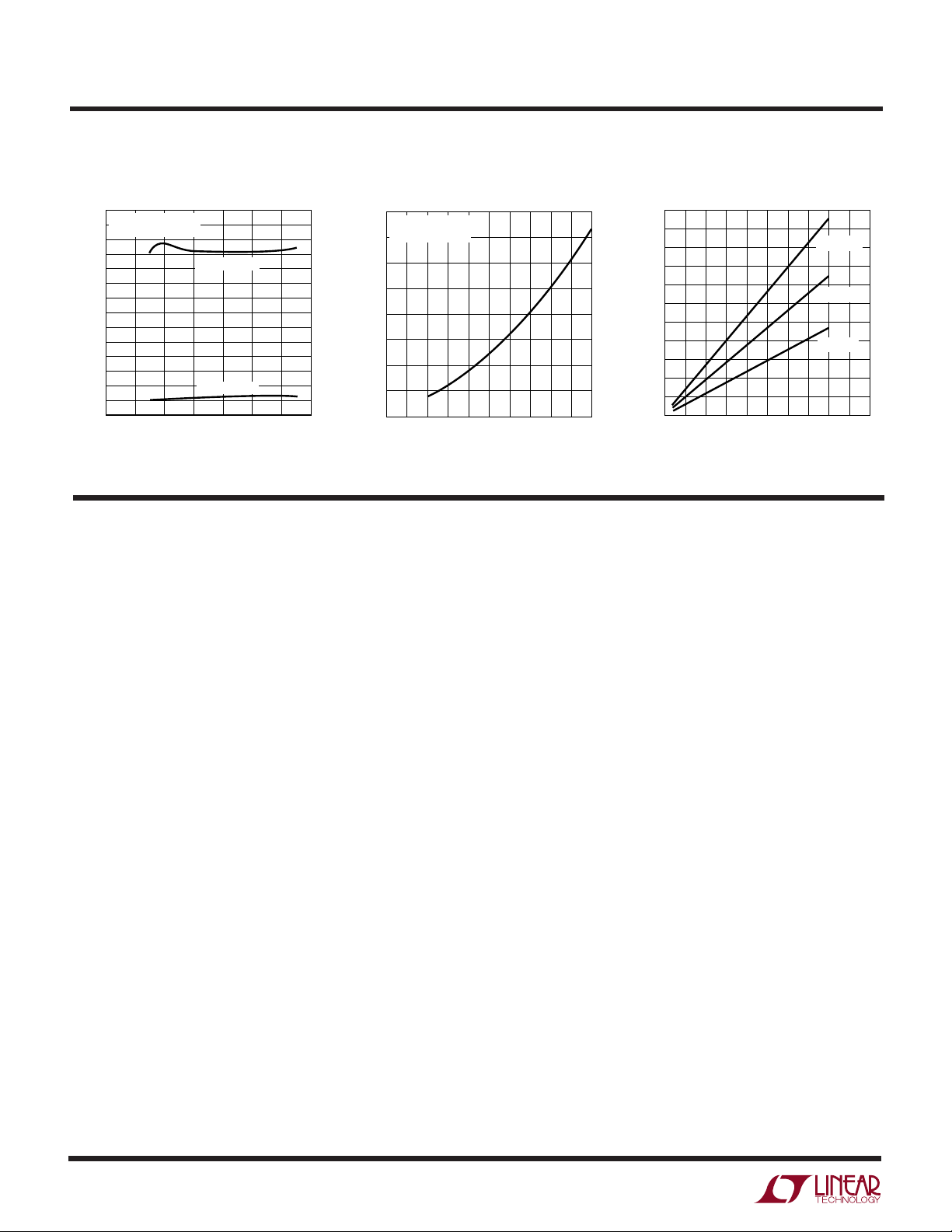

TYPICAL PERFORMANCE CHARACTERISTICS

DC Supply Current

2.1

DOES NOT INCLUDE

GATE CHARGE

1.8

1.5

1.2

0.9

0.6

SUPPLY CURRENT (mA)

0.3

0

0

4

2

INPUT VOLTAGE (V)

ACTIVE MODE

SLEEP MODE

10

814

6

12

1265 G07

Supply Current in Shutdown Gate Charge Losses

8

SHUTDOWN = 3V

T

= 25C

A

7

6

5

4

3

SUPPLY CURRENT (µA)

2

1

0

4

5

3

6

7

INPUT VOLTAGE (V)

UUU

PIN FUNCTIONS

PWR V

its Driver. Must decouple this pin properly to ground. Must

always tie Pins 1 and 13 together.

V

IN

LTC1265.

LB

Comparator. This pin will sink current when Pin 4 (LBIN)

goes below 1.25V. During shutdown, this pin is high

impedance.

LB

The (+) input is connected to a reference voltage of 1.25V.

CT (Pin 5): External capacitor CT from Pin 5 to ground sets

the switch off time. The operating frequency is dependent

on the input voltage and CT.

I

TH

current comparator threshold is proportional to Pin 6

voltage.

SENSE– (Pin 7): Connect to the (–) input of the current

comparator. For LTC1265-3.3 and LTC1265-5, it also

connects to an internal resistive divider which sets the

output voltage.

(Pins 1, 13): Supply for the Power MOSFET and

IN

(Pin 2): Main Supply for All the Control Circuitry in the

(Pin 3): Open-Drain Output of the Low-Battery

OUT

(Pin 4): The (–) Input of the Low-Battery Comparator.

IN

(Pin 6): Feedback Amplifier Decoupling Point. The

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

SWITCHING CURRENT (mA)

1.0

0.5

0

200 400

8

9

11

10

12

13

1265 G08

0

FREQUENCY (kHz)

600

VIN = 12V

VIN = 9V

VIN = 6V

800 1000

1265 G09

SENSE+ (Pin 8): The (+) Pin to the Current Comparator. A

built-in offset between Pins 7 and 8 in conjunction with

R

N/C,V

sets the current trip threshold.

SENSE

(Pin 9): For the LTC1265 adjustable version, this

FB

pin serves as the feedback pin from an external resistive

divider used to set the output voltage. On the LTC1265-3.3

and LTC1265-5 versions, this pin is not used.

SHDN (Pin 10): Pulling this pin HIGH keeps the internal

switch off and puts the LTC1265 in micropower shutdown. Do not float this pin.

SGND (Pin 11): Small-Signal Ground. Must be routed

separately from other grounds to the (–) terminal of C

OUT

.

PGND (Pin 12): Switch Driver Ground. Connects to the

(–) terminal of CIN. Anode of the Schottky diode must be

connected close to this pin.

SW (Pin 14): Drain of the P-Channel MOSFET Switch.

Cathode of the Schottky diode must be connected close to

this pin.

4

Page 5

LTC1265/LTC1265-3.3/LTC1265-5

UU

W

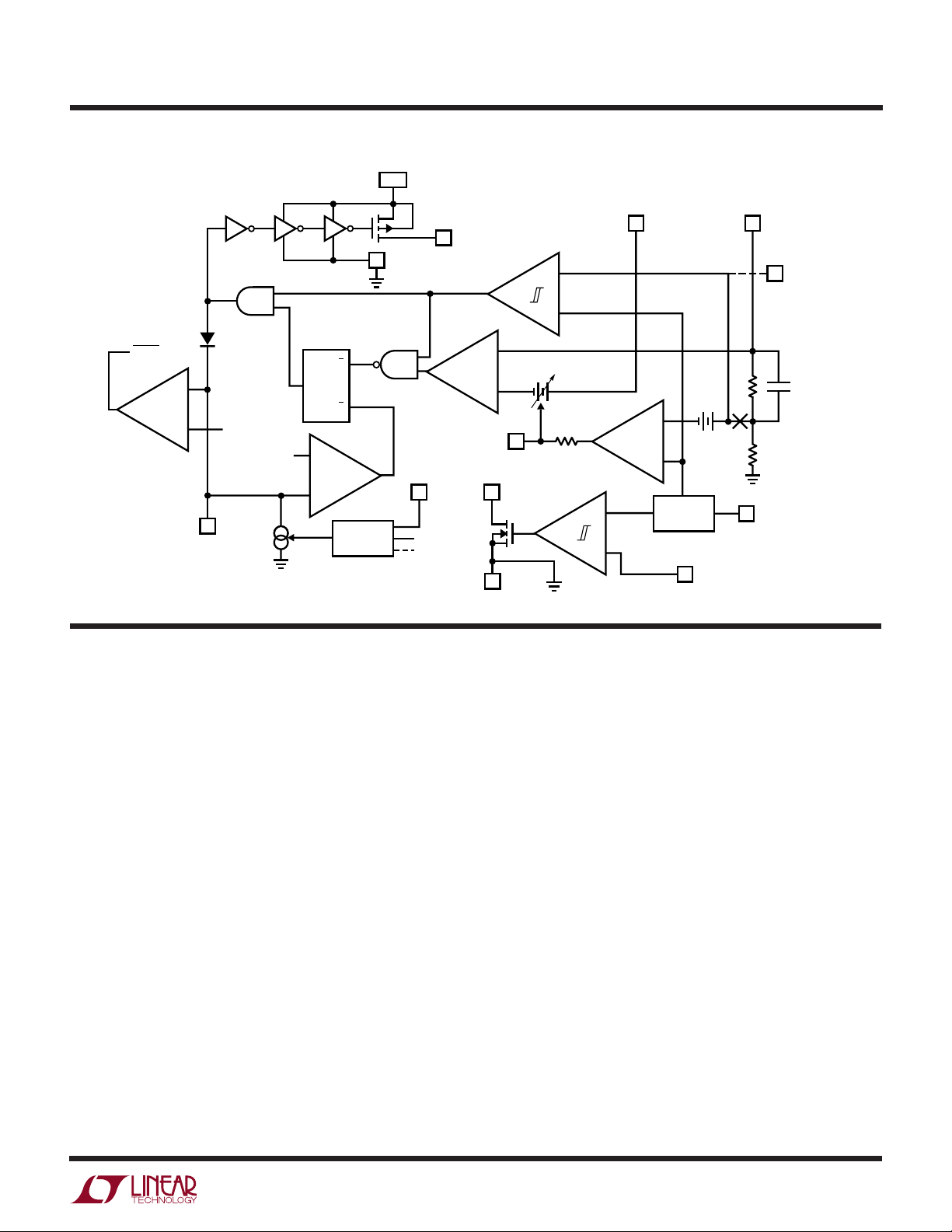

FUNCTIONAL DIAGRA

SLEEP

+

S

–

V

TH2

5

C

T

Q

V

–

TH1

+

(Pin 9 connection shown for LTC1265-3.3 and LTC1265-5; change create LTC1265)

PWR V

1, 13

PGND

12

IN

+

SENSE

SW

14

–

V

+

SENSE

78

–

9

V

FB

ADJUSTABLE

VERSION

–

R

S

T

OFF-TIME

CONTROL

V

2 3

IN

–

SENSE

V

FB

C

+

I

TH

LB

11

SGND

25mV TO 150mV

13k

6

0UT

A3

V

OS

–

G

+

+

–

REFERENCE

4

10

SHDN

LB

IN

5pF

100k

1265 FD

U

OPERATION

The LTC1265 uses a constant off-time architecture to

switch its internal P-channel power MOSFET. The off time

is set by an external timing capacitor at CT (Pin 5). The

operating frequency is then determined by the off time and

the difference between VIN and V

The output voltage is set by an internal resistive divider

(LTC1265-3.3 and LTC1265-5) connected to SENSE

(Pin 7) or an external divider returned to VFB (Pin 9 for

LTC1265). A voltage comparator V, and a gain block G,

compare the divided output voltage with a reference

voltage of 1.25V.

To optimize efficiency, the LTC1265 automatically switches

between continuous and Burst Mode operation. The voltage comparator is the primary control element when the

device is in Burst Mode operation, while the gain block

controls the output voltage in continuous mode.

When the load is heavy, the LTC1265 is in continuous

operation. During the switch ON time, current comparator

C monitors the voltage between Pins 7 and 8 connected

across an external shunt in series with the inductor. When

(Refer to Functional Diagram)

.

OUT

–

the voltage across the shunt reaches the comparator’s

threshold value, its output signal will change state, setting

the flip flop and turning the internal P-channel MOSFET off.

The timing capacitor connected to Pin 5 is now allowed to

discharge at a rate determined by the off-time controller.

When the voltage on the timing capacitor has discharged

past V

, comparator T trips, sets the flip flop and causes

TH1

the switch to turn on. Also, the timing capacitor is recharged. The inductor current will again ramp up until the

current comparator C trips. The cycle then repeats.

When the load current increases, the output voltage decreases slightly. This causes the output of the gain stage

(Pin 6) to increase the current comparator threshold, thus

tracking the load current.

When the load is relatively light, the LTC1265 automatically goes into Burst Mode operation. The current loop is

interrupted when the output voltage exceeds the desired

regulated value. The hysteretic voltage comparator V trips

when V

is above the desired output voltage, shutting

OUT

off the switch and causing the capacitor to discharge. This

5

Page 6

LTC1265/LTC1265-3.3/LTC1265-5

U

OPERATION

(Refer to Functional Diagram)

capacitor discharges past V

below V

. Comparator S then trips and a sleep signal is

TH2

until its voltage drops

TH1

generated. The circuit now enters into sleep mode with the

power MOSFET turned off. In sleep mode, the LTC1265 is

in standby and the load current is supplied by the output

capacitor. All unused circuitry is shut off, reducing quiescent current from 2mA to 160µA. When the output capaci-

tor discharges by the amount of the hysteresis of the

comparator V, the P-channel switch turns on again and the

process repeats itself. During Burst Mode operation the

peak inductor current is set at 25mV/R

U

.

SENSE

WUU

APPLICATIONS INFORMATION

The basic LTC1265 application circuit is shown in

Figure 1. External component selection is driven by the

load requirement, and begins with the selection of R

Once R

is known, CT and L can be chosen. Next, the

SENSE

Schottky diode D1 is selected followed by CIN and C

SENSE

OUT

.

.

To avoid the operation of the current loop interfering with

Burst Mode operation, a built-in offset VOS is incorporated

in the gain stage. This prevents the current from increasing until the output voltage has dropped below a minimum

threshold.

Using constant off-time architecture, the operating frequency is a function of the voltage. To minimize the

frequency variation as dropout is approached, the off-time

controller increases the discharge current as VIN drops

below V

+ 2V. In dropout the P-channel MOSFET is

OUT

turned on continuously (100% duty cycle) providing low

dropout operation with V

I

OUT(MAX)

137.5mV

=

R

SENSE

150mV

=

R

(Amps)

SENSE

OUT

–

≅ VIN.

25mV

2 • R

(Amps)

SENSE

R

R

Selection for Output Current

SENSE

is chosen based on the required output current.

SENSE

With the current comparator monitoring the voltage developed across R

, the threshold of the comparator

SENSE

determines the peak inductor current. Depending on the

load current condition, the threshold of the comparator

lies between 25mV/R

and 150mV/R

SENSE

SENSE

. The maxi-

mum output current of the LTC1265 is:

I

OUT(MAX)

where I

150mV

=

R

SENSE

is the peak-to-peak inductor ripple current.

RIPPLE

–

I

RIPPLE

2

(Amps)

At a relatively light load, the LTC1265 is in Burst Mode

operation. In this mode the peak inductor current is set at

25mV/R

. To fully benefit from Burst Mode operation,

SENSE

the inductor current should be continuous during burst

periods. Hence, the peak-to-peak inductor ripple current

must not exceed 25mV/R

To account for light and heavy load conditions, the I

SENSE

.

OUT(MAX)

is then given by:

Solving for R

and allowing a margin of variations in

SENSE

the LTC1265 and extended component values yields:

R

SENSE

=

I

OUT(MAX)

100mV

(Ω)

The LTC1265 is rated with a capability to supply a maximum

of 1.2A of output current.

R

R

that can be used is 0.083Ω.

SENSE

versus maximum output is given in Figure 2.

SENSE

0.5

0.4

0.3

(Ω)

SENSE

R

0.2

0.1

0

0

MAXIMUM OUTPUT CURRENT (A)

Figure 2. Selecting R

Therefore, the minimum value of

A graph for selecting

0.2

0.4

0.6

0.8

SENSE

1

1265 G10

6

Page 7

LTC1265/LTC1265-3.3/LTC1265-5

U

WUU

APPLICATIONS INFORMATION

Under short-circuit condition, the peak inductor current is

determined by:

I

SC(PK)

In this condition, the LTC1265 automatically extends the

off time of the P-channel MOSFET to allow the inductor

current to decay far enough to prevent any current buildup. The resulting ripple current causes the average shortcircuit current to be approximately I

CT and L Selection for Operating Frequency

The LTC1265 uses a constant off-time architecture with

t

determined by an external capacitor CT. Each time the

OFF

P-channel MOSFET turns on, the voltage on CT is reset to

approximately 3.3V. During the off time, CT is discharged

by a current that is proportional to V

is analogous to the current in inductor L, which likewise,

decays at a rate proportional to V

value must track the timing capacitor value.

The value of CT is calculated from the desired continuous

mode operating frequency:

CT =

where VD is the drop across the Schottky diode.

As the operating frequency is increased, the gate charge

losses will reduce efficiency. The complete expression for

operating frequency is given by:

f ≈

where:

=

1.3(10

1

t

OFF

150mV

R

SENSE

1

4

)f

VIN – V

)

V

IN

VIN – V

)

OUT

+ V

(Amps)

V

+ V

IN

(Hz)

)

D

OUT

D

OUT(MAX)

OUT

. Thus the inductor

OUT

(Farads)

)

.

. The voltage on C

T

2V, the LTC1265 reduces t

current in CT.

dropout. (See shelving effect shown in the Operating

Frequency curve under Typical Performance Characteristics.)

To maintain continuous inductor current at light load, the

inductor must be chosen to provide no more than 25mV/

R

following expression for L:

Using an inductance smaller than the above value will

result in the inductor current being discontinuous. A

consequence of this is that the LTC1265 will delay entering

Burst Mode operation and efficiency will be degraded at

low currents.

Inductor Core Selection

With the value of L selected, the type of inductor must be

chosen. Basically, there are two kinds of losses in an

inductor; core and copper losses.

Core losses are dependent on the peak-to-peak ripple

current and core material. However it is independent of

the physical size of the core. By increasing the inductance, the peak-to-peak inductor ripple current will decrease, therefore reducing core loss. Utilizing low core

loss material, such as molypermalloy or Kool Mµ® will

allow user to concentrate on reducing copper loss and

preventing saturation.

Although higher inductance reduces core loss, it increases copper loss as it requires more windings. When

space is not at a premium, larger wire can be used to

reduce the wire resistance. This also prevents excessive

heat dissipation.

of peak-to-peak ripple current. This results in the

SENSE

L ≥ 5.2(105)R

This prevents audible operation prior to

SENSE(CT)VREG

by increasing the discharge

OFF

V

REG

t

= 1.3(104)C

OFF

V

is the desired output voltage (i.e. 5V, 3.3V). V

REG

the measured output voltage. Thus V

in regulation.

Note that as VIN decreases, the frequency decreases.

When the input-to-output voltage differential drops below

T

)

V

OUT

(sec)

)

REG/VOUT

OUT

= 1

is

CATCH DIODE SELECTION

Losses in the catch diode depend on forward drop and

switching times. Therefore Schottky diodes are a good

choice for low drop and fast switching times.

The catch diode carries load current during the off time.

The average diode current is therefore dependent on the

Kool Mµ is a registered trademark of Magnetics, Inc.

7

Page 8

LTC1265/LTC1265-3.3/LTC1265-5

V

LB_TRIP

= 1.25

1 +

R4

R3

)

)

U

WUU

APPLICATIONS INFORMATION

P-channel switch duty cycle. At high input voltages, the

diode conducts most of the time. As VIN approaches V

the diode conducts only a small fraction of the time. The

most stressful condition for the diode is when the output

is short circuited. Under this condition, the diode must

safely handle I

LTC1265 circuits will be well served by either a 1N5818 or

a MBRS130LT3 Schottky diode. An MBRS0520 is a good

choice for I

C

IN

In continuous mode, the input current of the converter is

a square wave of duty cycle V

voltage transients, a low ESR input capacitor must be

used. In addition, the capacitor must handle a high RMS

current. The CIN RMS current is given by:

I

RMS

This formula has a maximum at VIN = 2V

= I

OUT

design because even significant deviations do not offer

much relief. Note that capacitor manufacturer’s ripple

current ratings are often based on only 2000 hours lifetime. This makes it advisable to further derate the capacitor, or to choose a capacitor rated at a higher temperature

than required. Do not underspecify this component. An

additional 0.1µF ceramic capacitor is also required on

PWR VIN for high frequency decoupling.

C

OUT

The selection of C

resistance (ESR) for proper operation of the LTC1265. The

required ESR of C

ESR

where I

case where the I

of C

OUT

ESR

To avoid overheating, the output capacitor must be sized

to handle the ripple current generated by the inductor. The

OUT(MAX)

I

OUT [VOUT (VIN – VOUT

≈

/2. This simple worst case is commonly used for

< 50mV/I

COUT

is the ripple current of the inductor. For the

RIPPLE

is:

< 2(R

COUT

at close to 100% duty cycle. Most

SC(PK)

≤ 500mA.

OUT/VIN

V

IN

is based upon the effective series

OUT

is:

OUT

RIPPLE

is 25mV/R

RIPPLE

)

SENSE

. To prevent large

1

/

2

)]

(A

RMS

, where I

OUT

, the required ESR

SENSE

)

OUT

RMS

,

worst-case RMS ripple current in the output capacitor is

given by:

≈

150mV

2(R

SENSE

(A

)

)

RMS

OUT

is made too small, the

OUT

and can be improved at

SENSE

has been

RIPPLE(P-P)

I

RMS

Generally, once the ESR requirement for C

met, the RMS current rating far exceeds the I

requirement.

ESR is a direct function of the volume of the capacitor.

Manufacturers such as Nichicon, AVX and Sprague should

be considered for high performance capacitors. The

OS-CON semiconductor dielectric capacitor available

from Sanyo has the lowest ESR for its size at a somewhat

higher price.

In surface mount applications, multiple capacitors may

have to be paralleled to meet the capacitance, ESR or RMS

current handling requirement of the application. Aluminum electrolyte and dry tantalum capacitors are both

available in surface mount configurations. In the case of

tantalum, it is critical that the capacitors are both available

in surface mount configuration and are surge tested for

use in switching power supplies. An excellent choice is the

AVX TPS series of surface mount tantalums, available in

case heights ranging from 2mm to 4mm. Consult the

manufacturer for other specific recommendations.

When the capacitance of C

output ripple at low frequencies will be large enough to trip

the voltage comparator. This causes Burst Mode operation to be activated when the LTC1265 would normally be

in continuous operation. The effect will be most pronounced with low value of R

higher frequencies with lower values of L.

Low-Battery Detection

The low-battery comparator senses the input voltage

through an external resistive divider. This divided voltage

connects to the (–) input of a voltage comparator (Pin 4)

which is compared with a 1.25V reference voltage. Neglecting Pin 4 bias current, the following expression is

used for setting the trip limit:

8

Page 9

LTC1265/LTC1265-3.3/LTC1265-5

U

WUU

APPLICATIONS INFORMATION

The output, Pin 3, is an N-channel open drain that goes low

when the battery voltage is below the threshold set by R3

and R4. In shutdown, the comparator is disabled and Pin

3 is in a high impedance state.

V

IN

R4

4

R3

Figure 3. Low-Battery Comparator

–

+

1.25V REFERENCE

LTC1265

LTC1265 F03

3

THERMAL CONSIDERATIONS

In a majority of applications, the LTC1265 does not

dissipate much heat due to its high efficiency. However, in

applications where the switching regulator is running at

high duty cycles or the part is in dropout with the switch

turned on continuously (DC), the user will need to do some

thermal analysis. The goal of the thermal analysis is to

determine whether the power dissipated by the regulator

exceeds the maximum junction temperature of the part.

The temperature rise is given by:

TR = P(θJA)

where P is the power dissipated by the regulator and θ

JA

is the thermal resistance from the junction of the die to the

ambient temperature.

The junction temperature is simply given by:

TJ = TR + T

A

LTC1265 ADJUSTABLE APPLICATIONS

The LTC1265 develops a 1.25V reference voltage between

the feedback (Pin 9) terminal and signal ground (see

Figure 4). By selecting resistor R1, a constant current is

caused to flow through R1 and R2 to set overall output

voltage. The regulated output voltage is determined by:

R2

V

OUT

= 1.25

1 +

)

R1

)

For most applications a 30k resistor is suggested for R1.

To prevent stray pickup, a 100pF capacitor is suggested

across R1 located close to the LTC1265.

V

OUT

R2

LTC1265

SGND

11

Figure 4. LTC1265 Adjustable Configuration

9

V

FB

100pF

R1

LTC1265 F04

As an example, consider the LTC1265 is in dropout at an

input voltage of 4V with a load current of 0.5A. From the

Typical Performance Characteristics graph of Switch Resistance, the ON resistance of the P-channel is 0.55Ω.

Therefore power dissipated by the part is:

P = I2(R

For the SO package, the θ

) = 0.1375W

DSON

is 110°C/W.

JA

Therefore the junction temperature of the regulator when

it is operating in ambient temperature of 25°C is:

TJ = 0.1375(110) + 25 = 40.1°C

Remembering that the above junction temperature is

obtained from a R

junction temperature based on a higher R

at 25°C, we need to recalculate the

DSON

DSON

since it

increases with temperature. However, we can safely assume that the actual junction temperature will not exceed

the absolute maximum junction temperature of 125°C.

Now consider the case of a 1A regulator with VIN = 4V and

TA = 65°C. Starting with the same 0.55Ω assumption for

R

, the TJ calculation will yield 125°C. But from the

DSON

graph, this will increase the R

to 0.76Ω, which when

DSON

used in the above calculation yields an actual TJ > 148°C.

Therefore the LTC1265 would be unsuitable for a 4V input,

1A output regulator operating at TA = 65°C.

9

Page 10

LTC1265/LTC1265-3.3/LTC1265-5

U

WUU

APPLICATIONS INFORMATION

Board Layout Checklist

When laying out the printed circuit board, the following

checklist should be used to ensure proper operation of the

LTC1265. These items are also illustrated graphically in

the layout diagram of Figure 5. Check the following in your

layout:

1. Are the signal and power grounds segregated? The

LTC1265 signal ground (Pin 11) must return to the (–)

plate of C

anode of the Schottky diode, and the (–) plate of CIN,

whose leads should be as short as possible.

2. Does the (+) plate of the CIN connect to the power V

(Pins 1,13) as close as possible? This capacitor provides the AC current to the internal P-channel MOSFET

and its driver.

3. Is the input decoupling capacitor (0.1µF) connected

closely between power VIN (Pins 1,13) and power

ground (Pin 12)? This capacitor carries the high frequency peak currents.

. The power ground (Pin 12) returns to the

OUT

IN

4. Is the Schottky diode closely connected between the

power ground (Pin 12) and switch (Pin 14)?

5. Does the LTC1265 SENSE– (Pin 7) connect to a point

close to R

and the (+) plate of C

SENSE

? In adjustable

OUT

applications, the resistive divider, R1 and R2, must be

connected between the (+) plate of C

and signal

OUT

ground.

6. Are the SENSE– and SENSE+ leads routed together with

minimum PC trace spacing? The 1000pF capacitor

between Pins 7 and 8 should be as close as possible to

the LTC1265.

7. Is SHDN (Pin 10) actively pulled to ground during

normal operation? The SHDN pin is high impedance

and must not be allowed to float.

1k

3900pF

PWR V

1000pF

1

2

3

4

5

6

7

V

IN

LB

OUT

LB

IN

C

T

I

TH

SENSE

IN

LTC1265

–

1000pF

SW

PWR V

PGND

SGND

SHDN

N/C (VFB)

SENSE

V

IN

14

13

IN

D1

+

12

11

10

SHDN

9

8

+

OUTPUT DIVIDER REQUIRED

WITH ADJUSTABLE VERSION ONLY

C

IN

R1

R2

0.1µF

C

+

OUT

LTC1265 F05

Figure 5. LTC1265 Layout Diagram (See Board Layout Checklist)

L

R

SENSE

V

OUT

BOLD LINES INDICATE

HIGH PATH CURRENTS

10

Page 11

LTC1265/LTC1265-3.3/LTC1265-5

U

WUU

APPLICATIONS INFORMATION

Troubleshooting Hints

Since efficiency is critical to LTC1265 applications, it is

very important to verify that the circuit is functioning

correctly in both continuous and Burst Mode operation. As

the LTC1265 is highly tolerant of poor layout, the output

voltage will still be regulated. Therefore, monitoring the

output voltage will not tell you whether you have a good or

bad layout. The waveform to monitor is the voltage on the

timing capacitor Pin 5.

In continuous mode the voltage on the CT pin is a sawtooth

with approximately 0.9V

never dip below 2V as shown in Figure 6a.

3.3V

(PIN 5)

T

2.4V

swing. This voltage should

P-P

When the load currents are low (I

LOAD

< I

BURST

) Burst

Mode operation occurs. The voltage on CT pin now falls to

ground for periods of time as shown in Figure 6b. During

this time the LTC1265 is in sleep mode with quiescent

current reduced to 160µA.

The inductor current should also be monitored. If the

circuit is poorly decoupled, the peak inductor current will

be haphazard as in Figure 7a. A well decoupled LTC1265

has a clean inductor current as in Figure 7b.

SLEEP MODE

3.3V

(PIN 5)

T

2.4V

VOLTAGE AT C

0V

TIME

(a) CONTINUOUS MODE OPERATION

(a) POORLY DECOUPLED LTC1265

VOLTAGE AT C

0V

LTC1265 F06a

Figure 6. CT Waveforms

Figure 7. Inductor Waveforms

TIME

(b) Burst Mode OPERATION

(b) WELL DECOUPLED LTC1265

LTC1265 F06b

11

Page 12

LTC1265/LTC1265-3.3/LTC1265-5

LOAD CURRENT (mA)

0.01

70

EFFICIENCY (% )

75

80

85

90

100

0.1 1.0

1265 G11

95

L = DALE LPT4545-220 (22µH)

V

OUT

= 3.3V

C

T

= 100pF

U

WUU

APPLICATIONS INFORMATION

Design Example

As a design example, assume VIN = 5V, V

= 0.8A and f = 250kHz. With this information we can easily

calculate all the important components.

From (1),

R

= 100mV/0.8 = 0.125Ω

SENSE

From (2) and assuming VD = 0.4V,

CT ≅ 100pF

Using (3), the value of the inductor is:

L ≥ 5.2(105)(0.125)(100pF)3.3V = 22µH

For the catch diode, a MBRS130LT3 or 1N5818 will be

sufficient in this application.

CIN will require an RMS current rating of at least 0.4A at

temperature, and C

will require an ESR of (from 5):

OUT

OUT

= 3.3V, I

MAX

V

IN

5V

+

C

IN

V

IN

LTC1265-3.3

PGND

SENSE

SENSE

SGND

IN

SW

22µH

0.125Ω

D1

+

1000pF

–

+

LTC1265 F08

V

3.3V

0.8A

C

OUT

OUT

3900pF

0.1µF

1k

100pF

PWR V

SHDN

I

TH

C

T

Figure 8. Design Example Circuit

ESR

The inductor ripple current is given by:

I

RIPPLE

At light loads the peak inductor current is at:

I

PEAK

Therefore, at load current less than 0.1A the LTC1265 will

be in Burst Mode operation. Figure 8 shows the complete

circuit and Figure 9 shows the efficiency curve with the

above calculated component values.

< 0.25Ω

COUT

V

+ V

=

OUT

)

D

t

OFF

)

L

= 25mV/0.125 = 0.2A

= 0.22A

Figure 9. Design Example Efficiency Curve

12

Page 13

U

TYPICAL APPLICATIONS

V

IN

5V

4

3

270pF

3900pF

AVX TPSD107K010

*

AVX TPSE227K010

**

†

COILCRAFT D03316-473

††

DALE WSL2010-0.1-1%

5

1k

6

7

LTC1265/LTC1265-3.3/LTC1265-5

High Efficiency 5V to 3.3V Converter

2 1, 13

V

IN

LB

IN

LTC1265-3.3

LB

OUT

C

T

I

THR

–

SENSE

1000pF

PWR V

IN

14

SW

12

PGND

11

SGND

10

SHDN SHDN

9

NC

8

+

SENSE

+

0.1µF

C

*

IN

100µF

10V

†

L1

47µH

MBRS130LT1

R

SENSE

0.1Ω

††

LTC1265 TA02

V

OUT

C

OUT

220µF

10V

3.3V

**

1A

+

AVX TPSD226K025

*

AVX TPSD107K010

**

†

L1 SELECTION

MANUFACTURER

COILCRAFT

COILTRONICS

DALE

SUMIDA

††

IRC LRC2010-01-R100-J

D1

= MBRS130LT3

VIN (V)

I

3.5

4.0

5.0

6.0

7.0

7.5

OUT(MAX)

360

430

540

630

720

740

PART NO.

DO3316-473

CTX50-4

LPT4545-500LA

CD74-470

(mA)

Positive-to-Negative (–5V) Converter

V

220pF

2200pF

IN

2 1, 13

V

PWR V

IN

4

LB

IN

LTC1265-5

3

LB

OUT

5

C

T

1k

6

I

THR

7

SENSE

1000pF

IN

SW

PGND

SGND

SHDN

SENSE

+

–

3.5V TO 7.5V

TP0610L

14

12

11

10

8

100k

SHDN

D1

L1

50µH

C

*

IN

+

†

R

SENSE

0.1Ω

0.1µF

††

22µF

25V

× 2

V

OUT

–5V

C

OUT

100µF

+

10V

LTC1265 TA03

**

13

Page 14

LTC1265/LTC1265-3.3/LTC1265-5

U

TYPICAL APPLICATIONS

5V Buck-Boost Converter

V

75pF

3300pF

IN

1k

4

3

5

6

7

LB

LB

C

I

THR

SENSE

2 1, 13

V

PWR V

IN

IN

LTC1265

OUT

T

–

0.01µF

IN

SW

PGND

SGND

SHDN SHDN

V

FB

+

SENSE

(V)

V

IN

3.5

4.0

5.0

6.0

7.0

7.5

L1B

3

TOP VIEW

4

L1B

SANYO OS-CON CAPACITOR

*

IRC LRC2010-01-R162-J

**

†

L1A, L2A SELECTION

MANUFACTURER

COILTRONICS

DALE

I

OUT(MAX)

240

275

365

490

610

665

(mA)

L1A

2

•

1

L1A

PART NO.

CTX33-4

LPT4545-330LA

3.5V TO 7.5V

*

C

+

IN

4

3

•

33µF

10V*

††

L1B

33µH

R

SENSE

0.162Ω

+

**

0.1µF

14

12

11

10

9

8

100µF

16V

L1A

33µH

1

1N5818

•

100pF

††

V

OUT

2

75k

25k

5V

+

C

*

OUT

100µF

10V

LTC1265 F09

V

(V)

I

IN

OUT(MAX)

4.0

40

5.0

60

6.0

80

7.0

100

8.0

115

9.0

130

10.0

150

11.0

165

12.0

180

L1B

3

TOP VIEW

4

L1B

AVX TPSE686K020

*

AVX TPSE336K025

**

†

IRC LRC2010-01-R162-J

††

L1A,L2A SELECTION

MANUFACTURER

COILTRONICS

DALE

(mA)

L1A

2

•

1

L1A

PART NO.

CTX50-4

LPT4545-500LA

4V TO 12V

75pF

3300pF

9V to 12V and – 12V Outputs

MBRS130LT3

V

IN

+

C

*

2 1, 13

V

PWR V

IN

4

LB

IN

LTC1265

3

LB

OUT

5

C

T

1k

6

I

THR

7

SENSE

0.01µF

SW

PGND

SGND

SHDN SHDN

V

–

SENSE

IN

FB

+

0.1µF

1N914

14

12

11

10

9

8

IN

68µF

20V

SI19430DY

33µF**

4

•

3

25V

††

L1B

50µH

R

SENSE

0.162Ω

+

*

††

L1A

50µH

•

1

MBRS130LT3

100pF

2

301k

+

34k

LTC1265 TA05

+

C

68µF

20V

OUT

*

C

OUT

68µF

20V

V

12V

OUT

*

V

OUT

–12V

14

Page 15

U

TYPICAL APPLICATIONS

V

51pF

3300pF

IN

4

3

5

1k

6

7

3.5V TO 12.5V

LTC1265/LTC1265-3.3/LTC1265-5

2.5mm Max Height 5V-to-3.3V (500mA)

2 1, 13

V

IN

LB

IN

LTC1265-3.3

LB

OUT

C

T

I

THR

–

SENSE

1000pF

PWR V

IN

14

SW

12

PGND

11

SGND

10

SHDN SHDN

9

N/C

8

+

SENSE

0.1µF

*

C

+

IN

15µF

10V × 2

**

MBRS0520LT1

AVX TAJB156K010

*

AVX TAJB226K06

†

IRC LRC2010-01-R200-J

††

SUMIDA CLS62-180

††

L1

18µH

†

R

SENSE

0.20Ω

LTC1265 TA06

C

OUT

22µF

+

6.3V × 2

**

V

OUT

3.3V

500mA

0V: V

5V: V

75pF

3300pF

OUT

OUT

V

= 5V

= 3.3V

3.5V TO 12.5V

Logic Selectable 0V/3.3V/5V 700mA Regulator

DALE 593D68X0020E2W

*

DALE 593D107X0010D2W

**

†

IRC LRC2010-01-R15-J

††

L1 SELECTION

56.2k

PART NO.

DO3316-333

CTX33-4

LPT4545-330LA

CD74-330

= 3.3V/5V

OUT

= 0V

OUT

45.3k

75k

LTC1265 TA07

**

C

OUT

100µF

+

10V

V

OUT

0V/3.3V/5V

700mA

MANUFACTURER

COILCRAFT

IN

1k

21, 13

V

PWR V

IN

4

LB

IN

LTC1265

3

LB

OUT

5

C

T

6

I

THR

7

SENSE

–

1000pF

IN

SW

PGND

SGND

SHDN V

V

FB

+

SENSE

0.1µF

14

12

11

10

†††

SHDN

9

8

C

*

+

IN

68µF

20V

MBRS130LT3

100pF

COILTRONICS

DALE

SUMIDA

†††

V

= 0V: V

SHDN

= 5V: V

††

L1

33µH

†

R

SENSE

0.15Ω

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

15

Page 16

LTC1265/LTC1265-3.3/LTC1265-5

U

TYPICAL APPLICATIONS

4-NiCad Battery Charger

V

IN

FAST CHARGE: = 0V

TRICKLE CHARGE: > 2V

VN2222L

8V TO 12.5V

51Ω

270pF

1k

3300pF

4

3

5

6

7

LB

LB

C

I

THR

SENSE

2 1, 13

V

PWR V

IN

IN

LTC1265

OUT

T

–

SENSE

1000pF

SW

PGND

SGND

SHDN

V

IN

FB

+

0.1µF

14

12

11

10

CHARGER

ON/OFF

9

8

+

C

*

IN

22µF, 25V

MBRS130LT3

100pF

R

SENSE

0.10Ω

DALE 593D226X0025D2W

*

DALE 593D107X0016E2W

**

†

DALE WSL2010-0.10-1%

††

L1 SELECTION

MANUFACTURER

COILCRAFT

COILTRONICS

SUMIDA

††

L1

100µH

†

30k

138k

PART NO.

DO3316-104

CTX100-4P

CD105-101

**

C

OUT

100µF

+

10V

MBRS130LT3

LTC1265 TA08

V

OUT

4 NICAD

1A FAST CHARGE

0.1A TRICKLE CHARGE

U

PACKAGE DESCRIPTION

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

*

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

**

× 45°

0.016 – 0.050

(0.406 – 1.270)

0° – 8° TYP

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

Dimension in inches (millimeters) unless otherwise noted.

0.337 – 0.344*

(8.560 – 8.738)

13

12

11

3

4

0.050

(1.270)

BSC

0.004 – 0.010

(0.101 – 0.254)

(5.791 – 6.197)

0.228 – 0.244

14

1

2

10

5

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1143 Dual Step-Down Switching Regulator Controller Dual Version of LTC1147

LTC1147 Step-Down Switching Regulator Controller Nonsynchronous, 8-Pin, VIN ≤ 16V

LTC1148HV Step-Down Switching Regulator Controller Synchronous, VIN ≤ 20V

LTC1174 Step-Down Switching Regulator with Internal 0.5A Switch VIN ≤ 18.5V, Comparator/Low Battery Detector

LTC1474/LTC1475 Low Quiescent Current Step-Down Regulators Monolithic, IQ = 40µA, 400mA, MS8

LTC1574 Step-Down Switching Regulator with Internal 0.5A Switch VIN ≤ 18.5V, Comparator

and Schottky Diode

LTC1622 Low Input Voltage Step-Down DC/DC Controller Constant Frequency, 2V to 10V VIN, MS8

LTC1627 Monolithic Synchronous Step-Down Switching Regulator Constant Frequency, I

LTC1772 Constant Frequency Step-Down DC/DC Controller SOT-23, 2.2V to 9.8V V

to 500mA, 2.65V to 8.5V V

OUT

IN

9

6

IN

8

0.150 – 0.157**

(3.810 – 3.988)

7

S14 1298

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

126535fa LT/TP 1299 2K REV A • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1995

Loading...

Loading...