Page 1

LTC1250

Very Low Noise

Zero-Drift Bridge Amplifier

EATU

F

■

Very Low Noise: 0.75µV

■

DC to 1Hz Noise Lower Than OP-07

■

Full Output Swing into 1k Load

■

Offset Voltage: 10µV Max

■

Offset Voltage Drift: 50nV/°C Max

■

Common-Mode Rejection Ratio: 110dB Min

■

Power Supply Rejection Ratio: 115dB Min

■

No External Components Required

■

Pin-Compatible with Standard 8-Pin Op Amps

PPLICATI

A

■

Electronic Scales

■

Strain Gauge Amplifiers

■

Thermocouple Amplifiers

■

High Resolution Data Acquisition

■

Low Noise Transducers

■

Instrumentation Amplifiers

RE

S

O

U

S

Typ, 0.1Hz to 10Hz

P-P

DUESCRIPTIO

The LTC®1250 is a high performance, very low noise zerodrift operational amplifier. The LTC1250’s combination of

low front-end noise and DC precision makes it ideal for use

with low impedance bridge transducers. The LTC1250

features typical input noise of 0.75µV

10Hz, and 0.2µ V

DC to 1Hz noise of 0.35µ V

from 0.1Hz to 1Hz. The LTC1250 has

P-P

, surpassing that of low noise

P-P

bipolar parts including the OP-07, OP-77, and LT1012.

The LTC1250 uses the industry-standard single op amp

pinout, and requires no external components or nulling

signals, allowing it to be a plug-in replacement for bipolar

op amps.

The LTC1250 incorporates an improved output stage

capable of driving 4.3V into a 1k load with a single 5V

supply; it will swing ±4.9V into 5k with ±5V supplies. The

input common mode range includes ground with single

power supply voltages above 12V. Supply current is 3mA

with a ±5V supply, and overload recovery times from

positive and negative saturation are 0.5ms and 1.5ms,

respectively. The internal nulling clock is set at 5kHz for

optimum low frequency noise and offset drift; no external

connections are necessary.

from 0.1Hz to

P-P

and LTC are registered trademarks and LT is a trademark of Linear Technology Corporation.

U

O

A

PPLICATITYPICAL

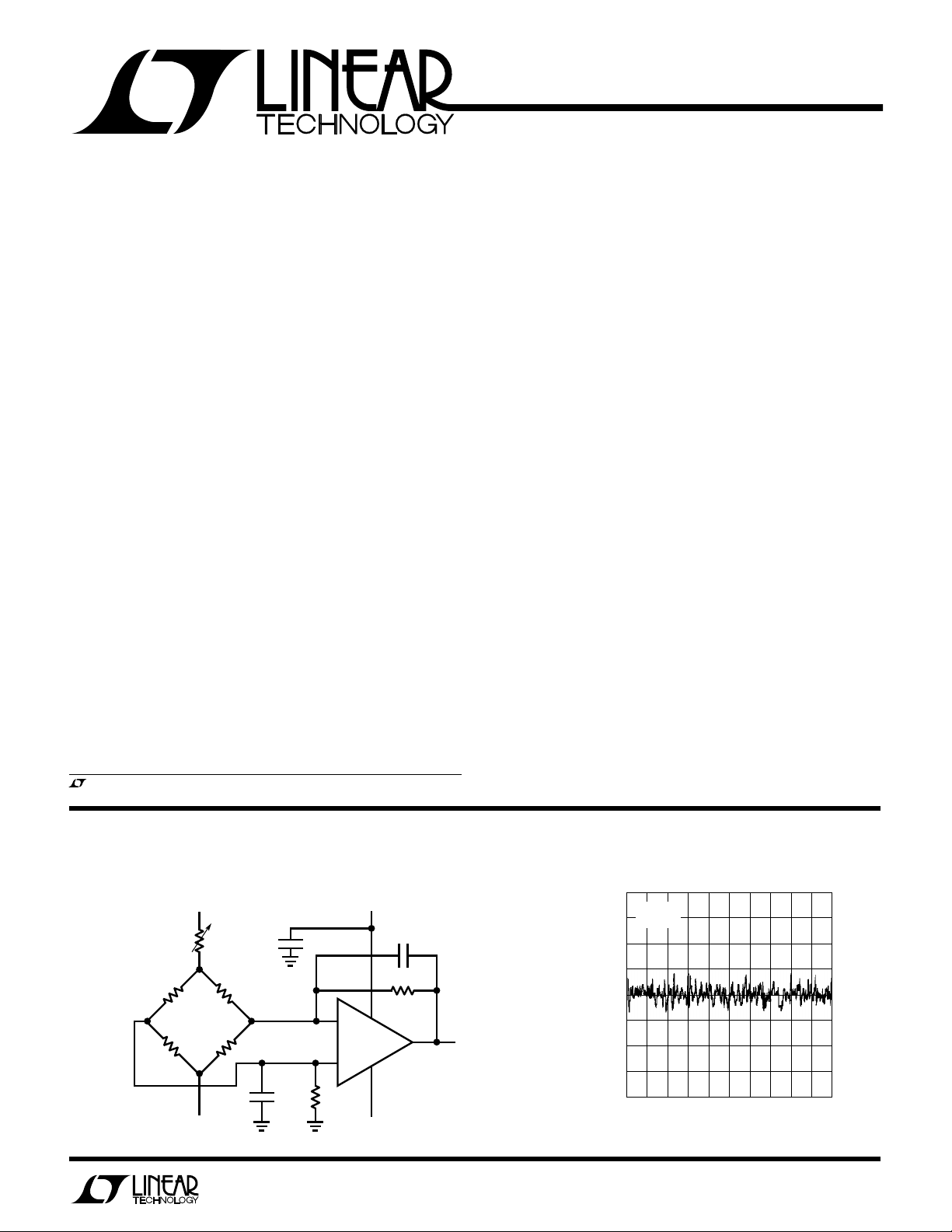

Differential Bridge Amplifier

2

3

18.2k

–

LTC1250

+

5V

1000pF

18.2k

7

6

4

–5V

5V

350Ω

STRAIN

GAUGE

–5V

50Ω

GAIN

TRIM

0.1µF

1000pF

The LTC1250 is available in standard 8-pin ceramic and

plastic DIPs, as well as an 8-pin SOIC package.

Input Referred Noise 0.1Hz to 10Hz

2

VS = ±5V

= 10k

A

V

1

0

µV

A

= 100

V

1250 TA01

–2

–1

2

0

4

TIME (s)

6

8

10

LT1250 TA02

1

Page 2

LTC1250

W

O

A

LUTEXI T

S

Total Supply Voltage (V+ to V–) ............................. 18V

Input Voltage ........................ (V+ + 0.3V) to (V– – 0.3V)

Output Short Circuit Duration ......................... Indefinite

Operating Temperature Range

LTC1250M..................................... – 55°C to 125°C

LTC1250C .......................................... 0°C TO 70°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec.)................ 300°C

LECTRICAL C CHARA TERIST

E

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

OS

∆V

e

n

i

n

I

B

I

OS

CMRR Common-Mode Rejection Ratio VCM = –4V to 3V ● 110 130 110 130 dB

PSRR Power Supply Rejection Ratio VS = ±2.375V to ±8V ● 115 130 115 130 dB

A

VOL

SR Slew Rate RL = 10k, CL = 50pF 10 10 V/µs

GBW Gain-Bandwidth Product 1.5 1.5 MHz

I

S

f

S

Input Offset Voltage TA = 25°C (Note 1) ±5 ±10 ±5 ±10 µV

Average Input Offset Drift (Note 1) ● ±0.01 ±0.05 ±0.01 ±0.05 µV/°C

OS

Long Term Offset Drift 50 50 nV/√Mo

Input Noise Voltage (Note 2) TA = 25°C, 0.1Hz to 10Hz 0.75 1.0 0.75 1.0 µV

Input Noise Current f = 10Hz 4.0 4.0 fA/√Hz

Input Bias Current TA = 25°C (Note 3) ±50 ±150 ±50 ±200 pA

Input Offset Current TA = 25°C (Note 3) ±100 ±300 ±100 ±400 pA

Large-Signal Voltage Gain RL = 10k, V

Maximum Output Voltage Swing R

Supply Current No Load, TA = 25°C 3.0 4.0 3.0 4.0 mA

Internal Sampling Frequency TA = 25°C 4.75 4.75 kHz

A

WUW

ARB

TA = 25°C, 0.1Hz to 1Hz 0.2 0.2 µV

= 1k ● ±4.0 4.3/–4.7 ±4.0 4.3/–4.7 V

L

RL = 100k ±4.92 ±4.95 V

U

/

G

S

I

ICS

VIN = ±5V, TA = Operating Temperature Range, unless otherwise noted.

= ±4V ● 125 170 125 170 dB

OUT

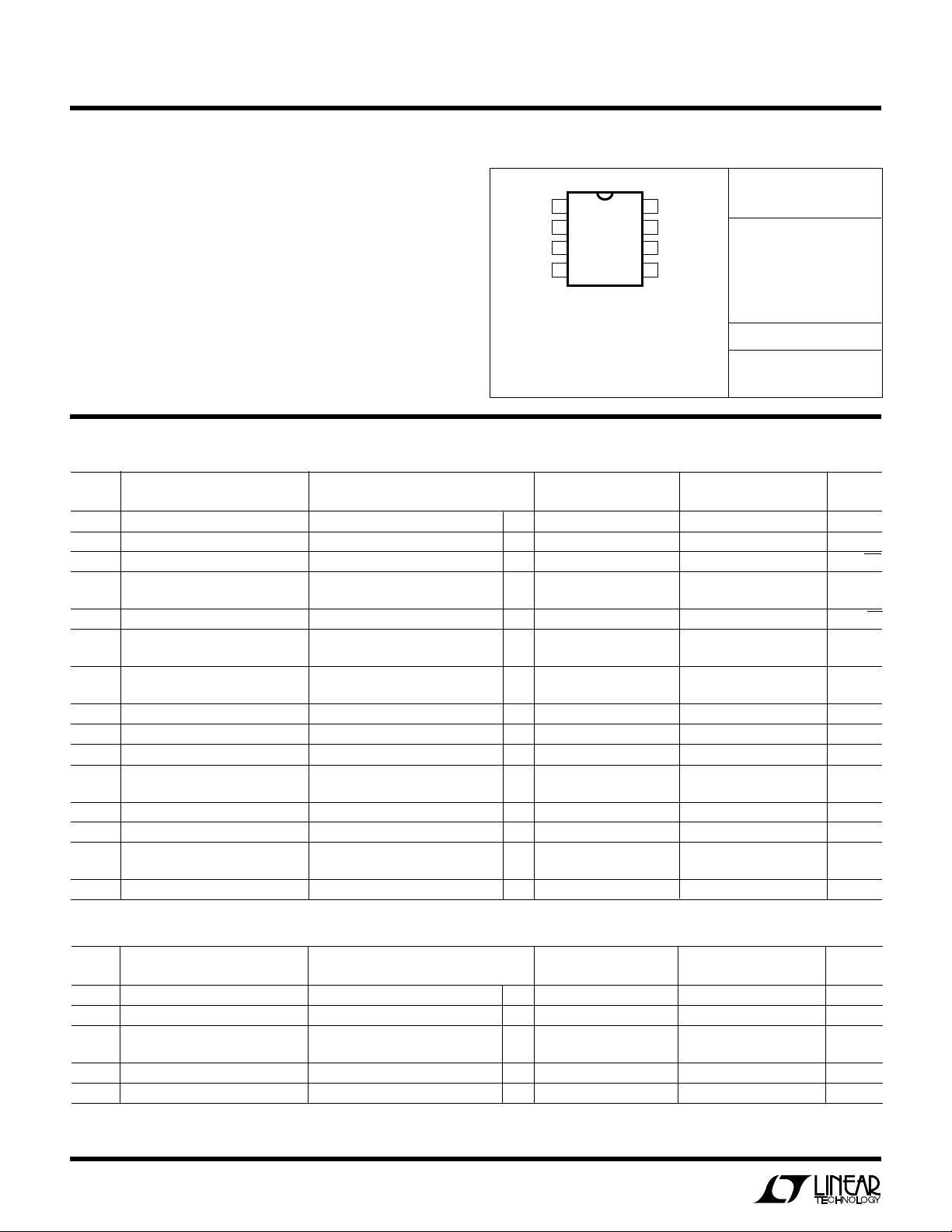

PACKAGE

NC

1

–IN

2

+IN

3

–

V

4

J8 PACKAGE

8-LEAD CERAMIC DIP

8-LEAD PLASTIC SOIC

T

JMAX

T

JMAX

T

JMAX

● ±950 ±450 pA

● ±500 ±500 pA

● 7.0 5.0 mA

O

RDER I FOR ATIO

TOP VIEW

NC

8

+

V

7

OUT

6

NC

5

N8 PACKAGE

8-LEAD PLASTIC DIP

S8 PACKAGE

= 150°C, θJA = 100°CW (J8)

= 110°C, θJA = 130°CW (N8)

= 110°C, θJA = 200°CW (S8)

LTC1250M LTC1250C

S8 PART MARKING

WU

ORDER PART

NUMBER

LTC1250MJ8

LTC1250CJ8

LTC1250CN8

LTC1250CS8

1250

U

P-P

P-P

VIN = 5V, TA = Operating Temperature Range, unless otherwise noted.

LTC1250M LTC1250C

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

∆V

e

I

I

OS

n

B

OS

Input Offset Voltage TA = 25°C (Note 1) ±2 ±5 ±2 ±5 µV

Average Input Offset Drift (Note 1) ● ±0.01 ±0.05 ±0.01 ±0.05 µV/°C

OS

Input Noise Voltage (Note 2) TA = 25°C, 0.1Hz to 10Hz 1.0 1.0 µV

TA = 25°C, 0.1Hz to 1Hz 0.3 0.3 µV

Input Bias Current TA = 25°C (Note 3) ±20 ±100 ±20 ±100 pA

Input Offset Current TA = 25°C (Note 3) ±40 ±200 ±40 ±200 pA

P-P

P-P

2

Page 3

LTC1250

TEMPERATURE (°C)

–50

SAMPLING FREQUENCY (kHz)

4

5

6

25

LTC1250 G06

3

2

–25 0 50

1

0

8

7

75 100 150

VS = ±5V

TOTAL SUPPLY VOLTAGE, V+ TO V– (V)

4

2

SAMPLING FREQUENCY (kHz)

3

4

681012

LTC1250 G03

5

6

14

16

TA = 25°C

LECTRICAL C CHARA TERIST

E

ICS

VIN = 5V, TA = Operating Temperature Range, unless otherwise noted.

LTC1250M LTC1250C

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

Maximum Output Voltage Swing R

= 1k 4.0 4.3 4.0 4.3 V

L

RL = 100k 4.95 4.95 V

I

S

f

S

The ● denotes specifications which apply over the full operating

temperature range.

Note 1: These parametes are guaranteed by design. Thermocouple effects

preclude measurement of these voltage levels during automated testing.

Supply Current TA = 25°C 1.8 2.5 1.8 2.5 mA

Sampling Frequency TA = 25°C 3 3 kHz

filter at 0.1Hz. The LTC1250 is sample tested for noise; for 100% tested

parts contact LTC Marketing Dept.

Note 3: At T ≤ 0°C these parameters are guaranteed by design and not

tested.

Note 2: 0.1Hz to 10Hz noise is specified DC coupled in a 10s window;

0.1Hz to 1Hz noise is specified in a 100s window with an RC high-pass

UW

LPER

F

O

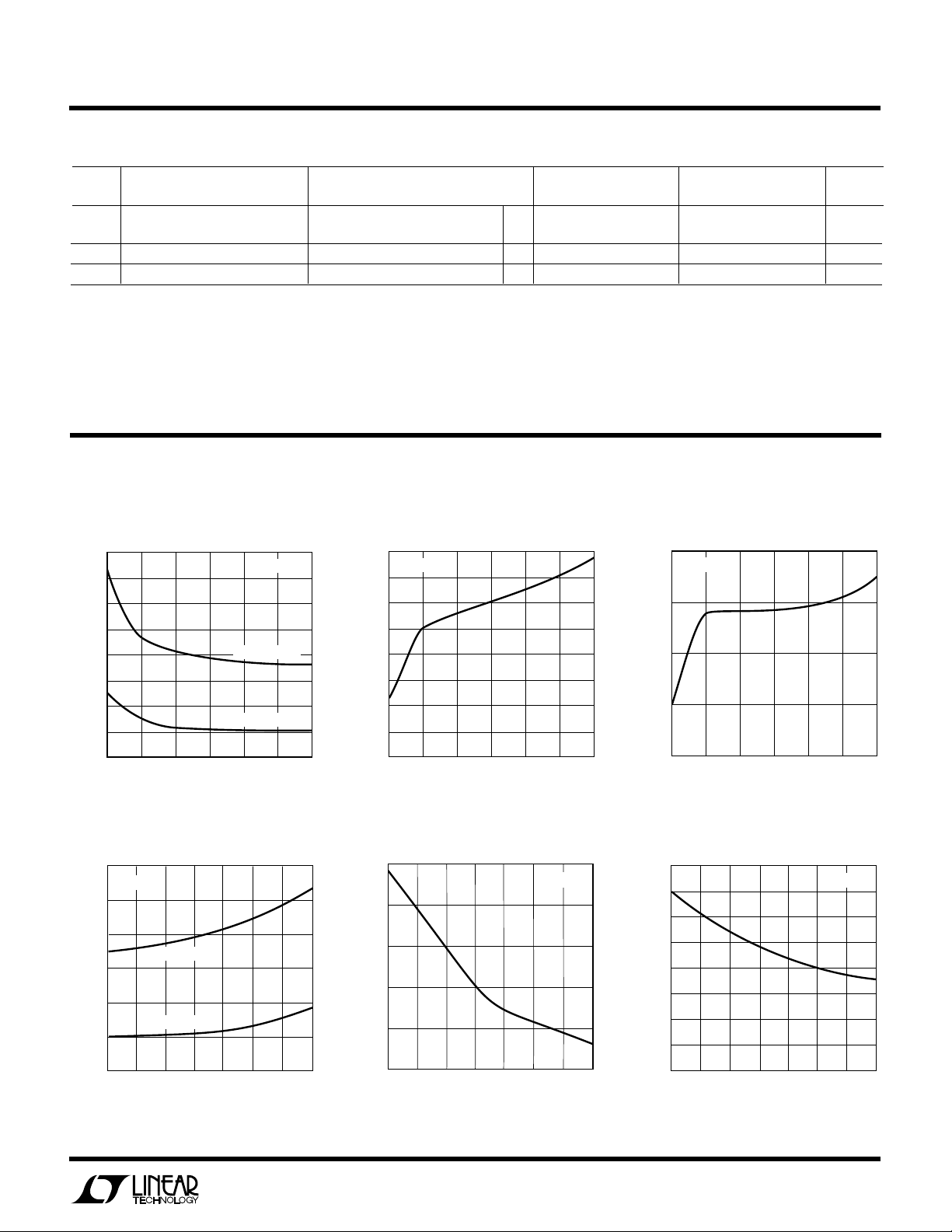

Input Noise vs Supply Voltage

1.6

1.4

1.2

)

P-P

1.0

0.8

0.6

INPUT NOISE (µV

0.4

0.2

0

681012

4

TOTAL SUPPLY VOLTAGE, V+ TO V– (V)

R

TA = 25°C

0.1Hz TO 10Hz

0.1Hz TO 1Hz

14

LTC1250 G01

ATYPICA

CCHARA TERIST

E

C

Supply Current vs Supply Voltage

4.0

TA = 25°C

3.5

3.0

2.5

2.0

1.5

SUPPLY CURRENT (mA)

1.0

0.5

0

16

4

TOTAL SUPPLY VOLTAGE, V+ TO V– (V)

681012

ICS

14

LTC1250 G02

Sampling Frequency vs Supply

Voltage

16

1.2

VS = ±5V

1.0

)

P-P

0.8

0.6

0.4

INPUT NOISE (µV

0.2

0

–50

–25 0

0.1Hz TO 10Hz

0.1Hz TO 1Hz

25 75

TEMPERATURE (°C)

50 100 125

LTC1250 G04

Supply Current vs TemperatureInput Noise vs Temperature

4.5

4.0

3.5

3.0

SUPPLY CURRENT (mA)

2.5

2.0

–50

–25

0

TEMPERATURE (°C)

Sampling Frequency vs

Temperature

VS = ±5V

50

25

75

100

LTC1250 G05

125

3

Page 4

LTC1250

TEMPERATURE (°C)

–25

10

100

1000

10075

LTC1250 G14

–50

125

BIAS CURRENT (

|

pA

|

)

50

025

VS = ±5V

FREQUENCY (Hz)

20

CMRR (dB)

40

80

120

140

1 100 1k 100k

LTC1250 G12

0

10 10k

60

100

VS = ±5V

V

CM

= 1V

RMS

LOAD RESISTANCE (kΩ)

0

0

OUTPUT SWING (V)

4

6

8

18

12

2

4

59

LTC1250 G09

2

14

16

10

13

6

7

8

V

S

= 16V

VS = 10V

VS = 5V

10

V– = GND

R

L

TO GND

LPER

Voltage Noise vs Frequency

80

VS = ±5V

70

= 10Ω

R

S

60

50

40

30

20

VOLTAGE NOISE (nV/√Hz)

10

0

1 100 1k 10k

10

F

O

FREQUENCY (Hz)

R

ATYPICA

LTC1250 G11

UW

CCHARA TERIST

E

C

Gain/Phase vs Frequency

100

80

60

40

GAIN (dB)

20

VS = ±5V OR

SINGLE 5V

0

= 25°C

T

A

= 100pF

C

L

–20

1k 100k 1M 10M

10k

GAIN

FREQUENCY (Hz)

ICS

PHASE:

R

L

= 100k

PHASE:

= 1k

R

L

LTC1250 G10

Bias Current (Magnitude) vs

Temperature

100

80

PHASE MARGIN (DEG)

60

40

20

0

–20

Overload Recovery

0.2

INPUT (V)

0

0

OUTPUT (V)

–5

500µs/DIV

A

= 100, RL = 100k, CL = 50pF, VS = ±5V

V

Transient Response

2V/DIV

4

A

V

1µs/DIV

= 1, RL = 100k, CL = 50pF, VS = ±5V

Common-Mode Input Range

vs Supply Voltage

8

TA = 25°C

6

4

2

0

–2

–4

INPUT COMMON MODE RANGE (V)

–6

–8

2

34

SUPPLY VOLTAGE (±V)

5

Output Swing vs Load

Resistance, Dual Supplies

10

9

VS = ±8V

8

7

6

VS = ±5V

5

4

VS = ±2.5V

3

OUTPUT SWING (±V)

2

1

0

1357

2

0

4

LOAD RESISTANCE (kΩ)

6

7

LTC1250 G07

R

TO GND

L

NEGATIVE SWING

POSITIVE SWING

6

8

9

LTC1250 G08

Common-Mode Rejection Ratio

vs Frequency

8

Output Voltage Swing vs Load

Resistance, Single Supply

10

Page 5

LPER

F

O

R

ATYPICA

UW

CCHARA TERIST

E

C

LTC1250

ICS

Output Swing vs Output Current,

±5V Supply

5

VS = ±5V

4

3

2

1

0

–1

–2

OUTPUT VOLTAGE (V)

–3

–4

–5

0.01

0.1 1 10

OUTPUT CURRENT (mA)

TEST CIRCUITS

Offset Test Circuit

100pF

100k

5V

–

LTC1250

+

–5V

7

6

OUTPUT

4

2

10Ω

3

1250 TC01

LTC1250 G16

10Ω

Output Swing vs Output Current,

Single 5V Supply

6

5

4

3

2

OUTPUT VOLTAGE (V)

1

0

0.01

100pF

100k

5V

–

LTC1250

+

7

4

–5V

2

3

VS = SINGLE 5V

0.1 1 10

OUTPUT CURRENT (mA)

6

800k

0.02µF

Short-Circuit Current

vs Temperature

40

VS = ±15V

30

20

10

0

–10

–20

SHORT-CIRCUIT CURRENT (mA)

–30

–40

LTC1250 G17

–25 0 50

–50

25

TEMPERATURE (°C)

DC to 10Hz Noise Test Circuit

(for DC to 1Hz Multiply All Capacitor Values by 10)

5V

–

1/2

LT1057

+

–5V

8

1

800k 800k

4

0.04µF

0.01µF

2

3

6

–

1/2

LT1057

5

+

–

V

= V

OUT

+

V

= V

OUT

75 100 125

7

LTC1250 G18

OUTPUT

1250 TC02

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

Input Noise

The LTC1250, like all CMOS amplifiers, exhibits two types

of low frequency noise: thermal noise and 1/f noise. The

LTC1250 uses several design modifications to minimize

these noise sources. Thermal noise is minimized by raising the gM of the front-end transistors by running them at

high bias levels and using large transistor geometries. 1/f

noise is combated by optimizing the zero-drift nulling loop

to run at twice the 1/f corner frequency, allowing it to

reduce the inherently high CMOS 1/f noise to near thermal

levels at low frequencies. The resultant noise spectrum is

quite low at frequencies below the internal 5kHz clock

80

70

60

50

40

30

20

VOLTAGE NOISE (nV/√Hz)

10

0

0.01 1

OP-27

LTC1250

OP-07

0.1

FREQUENCY (Hz)

VS = ±5V

= 10Ω

R

S

LTC1250 F01

Figure 1. Voltage Noise vs Frequency

5

Page 6

LTC1250

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

frequency, approaching the best bipolar op amps at 10Hz

and surpassing them below 1Hz (Figure 1). All this is

accomplished in an industry-standard pinout; the LTC1250

requires no external capacitors, no nulling or clock signals, and conforms to industry-standard 8-pin DIP and 8pin SOIC packages.

Input Capacitance and Compensation

The large input transistors create a parasitic 55pF capacitance from each input to V+. This input capacitance will

react with the external feedback resistors to form a pole

which can affect amplifier stability. In low gain, high

impedance configurations, the pole can land below the

unity-gain frequency of the feedback network and degrade

phase margin, causing ringing, oscillation, and other

unpleasantness. This is true of any op amp, however, the

55pF capacitance at the LTC1250’s inputs can affect

stability with a feedback network impedance as low as

1.9k. This effect can be eliminated by adding a capacitor

across the feedback resistor, adding a zero which cancels

the input pole (Figure 2). The value of this capacitor should

be:

C

F

pF

55

≥

A

V

where AV = closed-loop gain. Note that CF is not dependent

on the value of RF. Circuits with higher gain (AV > 50) or

low loop impedance should not require CF for stability.

C

F

R

F

R

IN

C

P

Figure 2. CF Cancels Phase Shift Due to Parasitic C

–

LTC1250

+

1250 F02

P

Larger values of CF, commonly used in band-limited DC

circuits, may actually increase low frequency noise. The

nulling circuitry in the LTC1250 closes a loop that includes

the external feedback network during part of its cycle. This

loop must settle to its final value within 150µ s or it will not

fully cancel the 1/f noise spectrum and the low frequency

noise of the part will rise. If the loop is underdamped (large

RF, no CF) it will ring for more than 150µs and the noise

and offset will suffer.

The solution is to add CF as above but beware! Too large

a value of CF will overdamp the loop, again preventing it

from reaching a final value by the 150µs deadline. This

condition doesn’t affect the LTC1250’s offset or output

stability, but 1/f noise begins to rise. As a rule of thumb,

the RFCF feedback pole should be ≥ 7kHz (1/150µs, the

frequency at which the loop settles) for best 1/f performance; values between 100pF and 500pF work well with

feedback resistors below 100k. This ensures adequate

gain at 7kHz for the LTC1250 to properly null. High value

feedback resistors (above 1M) may require experimentation to find the correct value because parasitics, both in

the LTC1250 and on the PC board, play an increasing role.

Low value resistors (below 5k) may not require a capacitor at all.

Input Bias Current

The inputs of the LTC1250, like all zero-drift op amps,

draw only small switching spikes of AC bias current; DC

leakage current is negligible except at very high temperatures. The large front-end transistors cause switching

spikes 3 to 4 times greater than standard zero-drift op

amps: the ±50pA bias current spec is still many times

better than most bipolar parts. The spikes don’t match

from one input pin to the other, and are sometimes (but

not always) of opposite polarity. As a result, matching the

impedances at the inputs (Figure 3) will not cancel the bias

current, and may cause additional errors. Don’t do it.

R

F

R

IN

Figure 3. Extra Resistor Will

–

LTC1250

+

Not

Cancel Bias Current Errors

1250 F03

6

Page 7

LTC1250

–

+

LTC1250

47k

R

F

C

F

0.01

1250 F04

U

O

PPLICATI

A

Output Drive

The LTC1250 includes an enhanced output stage which

provides nearly symmetrical output source/sink currents.

This output is capable of swinging a minimum of ±4V into a

1k load with ±5V supplies, and can sink or source >20mA

into low impedance loads. Lightly loaded (RL ≥100k), the

LTC1250 will swing to within millivolts of either rail. In single

supply applications, it will typically swing 4.3V into a 1k load

with a 5V supply.

Minimizing External Errors

The input noise, offset voltage, and bias current specs for the

LTC1250 are all well below the levels of circuit board

parasitics. Thermocouples between the copper pins of the

LTC1250 and the tin/lead solder used to connect them can

overwhelm the offset voltage of the LTC1250, especially if a

soldering iron has been around recently. Note also that when

the LTC1250’s output is heavily loaded, the chip may

dissipate substantial power, raising the temperature of the

package and aggravating thermocouples at the inputs.

Although the LTC1250 will maintain its specified accuracy

under these conditions, care must be taken in the layout to

prevent or compensate circuit errors. Be especially careful

of air currents when measuring low frequency noise; nearby

moving objects (like people) can create very large noise

peaks with an unshielded circuit board. For more detailed

explanations and advice on how to avoid these errors, see

the LTC1051/LTC1053 data sheet.

S

I FOR ATIO

WU

U

the previous page). Applications which require spike-free

output in addition to minimum noise will need a low-pass

filter after the LTC1250; a simple RC will usually do the job

(Figure 4). The LTC1051/LTC1053 data sheet includes more

information about zero-drift amplifier sampling behavior.

Figure 4. RC Output Pole Limits Bandwidth to 330Hz

Single Supply Operation

The LTC1250 will operate with single supply voltages as low

as 4.5V, and the output swings to within millivolts of either

supply when lightly loaded. The input stage will common

mode to within 250mV of ground with a single 5V supply,

and will common mode to ground with single supplies

above 11V. Most bridge transducers bias their inputs above

ground when powered from single supplies, allowing them

to interface directly to the LTC1250 in single supply applications. Single-ended, ground-referenced signals will need to

be level shifted slightly to interface to the LTC1250’s inputs.

Fault Conditions

Sampling Behavior

The LTC1250’s zero-drift nulling loop samples the input at

≈ 5kHz, allowing it to process signals below 2kHz with no

aliasing. Signals above this frequency may show aliasing

behavior, although wideband internal circuitry generally

keeps errors to a minimum. The output of the LTC1250 will

have small spikes at the clock frequency and its harmonics;

these will vary in amplitude with different feedback configurations. Low frequency or band-limited systems should not

be affected, but systems with higher bandwidth

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

(oversampling A/Ds, for example) may need to filter out

these clock artifacts. Output spikes can be minimized with a

large feedback capacitor, but this will adversely affect noise

performance (see Input Capacitance and Compensation on

The LTC1250 is designed to withstand most external fault

conditions without latch-up or damage. However, unusually

severe fault conditions can destroy the part. All pins are

protected against faults of ±25mA or 5V beyond either

supply, whichever comes first. If the external circuitry can

exceed these limits, series resistors or voltage clamp diodes

should be included to prevent damage.

The LTC1250 includes internal protection against ESD damage. All data sheet parameters are maintained to 1kV ESD on

any pin; beyond 1kV, the input bias and offset currents will

increase, but the remaining specs are unaffected and the

part remains functional to 5kV at the input pins and 8kV at the

output pin. Extreme ESD conditions should be guarded

against by using standard anti-static precautions.

7

Page 8

LTC1250

PPLICATITYPICAL

Reference Buffer

O

U

SA

Differential Thermocouple Ampliifer

15V

7.5k

7

3

2

+

LTC1250

–

4

31

LM399

4

2

±10ppm ERROR AT ±15mA

OUTPUT NOISE

1µV

P-P

2.5µV/°C DRIFT (DUE TO LM399)

PACKAGE DESCRIPTIO

J8 Package 8-Lead Ceramic DIP N8 Package 8-Lead Plastic DIP

CORNER LEADS OPTION

(4 PLCS)

0.023 – 0.045

(0.584 – 1.143)

HALF LEAD

0.045 – 0.068

(1.143 – 1.727)

FULL LEAD

OPTION

0.300 BSC

(0.762 BSC)

0.008 – 0.018

(0.203 – 0.457)

0.385 ± 0.025

(9.779 ± 0.635)

NOTE: LEAD DIMENSIONS APPLY TO SOLDER DIP/PLATE OR TIN PLATE LEADS.

OPTION

0° – 15°

0.005

(0.127)

MIN

0.025

(0.635)

RAD TYP

0.045 – 0.068

(1.143 – 1.727)

0.014 – 0.026

(0.360 – 0.660)

87

12

R1

6

–

†

TYPE K

V

CM

1250 TA03

10k

0.1%

+

R2

10k

0.1%

R4

1M

0.1%

5V

V

IN

V

OUT

LT1025

GND

–5V

U

Dimensions in inches (millimeters) unless otherwise noted.

0.405

(10.287)

MAX

65

0.255 ± 0.015*

(6.477 ± 0.381)

0.065

(1.651)

TYP

0.045 ± 0.015

(1.143 ± 0.381)

3

4

0.220 – 0.310

(5.588 – 7.874)

0.015 – 0.060

(0.381 – 1.524)

0.100 ± 0.010

(2.540 ± 0.254)

0.200

(5.080)

MAX

0.125

3.175

MIN

J8 0694

0.300 – 0.325

(7.620 – 8.255)

0.009 – 0.015

(0.229 – 0.381)

+0.025

0.325

–0.015

+0.635

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTURSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm).

R3

C1

100pF

1M

0.1%

5V

7

2

3

–

LTC1250

+

6

4

–5V

C2

100pF

R5

3k

10mV/°C

†

R9

FOR BEST ACCURACY, THERMOCOUPLE

33k

RESISTANCE SHOULD BE LESS THAN 100Ω

0.400*

(10.160)

MAX

(1.143 – 1.651)

0.100 ± 0.010

(2.540 ± 0.254)

876

1234

0.045 – 0.065

5

0.018 ± 0.003

(0.457 ± 0.076)

V

OUT

100mV/°C

R6

7.5k

1%

R7

500Ω

FULL-SCALE TRIM

R8

5k

1%

1250 TA04

0.130 ± 0.005

(3.302 ± 0.127)

0.125

0.015

(3.175)

MIN

(0.380)

MIN

N8 0694

8

S8 Package 8-Lead Plastic SOIC

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006 INCH (0.15mm).

× 45°

0.016 – 0.050

0.406 – 1.270

0°– 8° TYP

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7487

(408) 432-1900

●

FAX

: (408) 434-0507

●

TELEX

: 499-3977

0.050

(1.270)

BSC

0.004 – 0.010

(0.101 – 0.254)

0.228 – 0.244

(5.791 – 6.197)

0.189 – 0.197*

(4.801 – 5.004)

8

1

7

2

5

6

0.150 – 0.157*

(3.810 – 3.988)

3

LINEAR TECHNOLOGY CORPORATION 1994

SO8 0294

4

LT/GP 0894 2K REV A • PRINTED IN USA

Loading...

Loading...