Datasheet LTC1159IS-5, LTC1159IS-3.3, LTC1159IS, LTC1159CS-5, LTC1159CS-3.3 Datasheet (Linear Technology)

...Page 1

FEATURES

■

Operation from 4V to 40V Input Voltage

■

Ultrahigh Efficiency: Up to 95%

■

20µA Supply Current in Shutdown

■

High Efficiency Maintained Over Wide Current Range

■

Current Mode Operation for Excellent Line and Load

Transient Response

■

Very Low Dropout Operation: 100% Duty Cycle

■

Short-Circuit Protection

■

Synchronous FET Switching for High Efficiency

■

Adaptive Non-Overlap Gate Drives

■

Available in SSOP and SO Packages

U

APPLICATIO S

■

Step-Down and Inverting Regulators

■

Notebook and Palmtop Computers

■

Portable Instruments

■

Battery-Operated Digital Devices

■

Industrial Power Distribution

■

Avionics Systems

■

Telecom Power Supplies

LTC1159

LTC1159-3.3/LTC1159- 5

High Efficiency Synchronous

Step-Down Switching Regulators

U

DESCRIPTIO

The LTC®1159 series is a family of synchronous step-down

switching regulator controllers featuring automatic Burst

ModeTM operation to maintain high efficiencies at low

output currents. These devices drive external complementary power MOSFETs at switching frequencies up to 250kHz

using a constant off-time current-mode architecture.

A separate pin and on-board switch allow the MOSFET

driver power to be derived from the regulated output

voltage providing significant efficiency improvement when

operating at high input voltages. The constant off-time

current-mode architecture maintains constant ripple current in the inductor and provides excellent line and load

transient response. The output current level is user programmable via an external current sense resistor.

The LTC1159 automatically switches to power saving

Burst Mode operation when load current drops below

approximately 15% of maximum current. Standby current

is only 300µA while still regulating the output and shut-

down current is a low 20µA.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a trademark of Linear Technology Corporation.

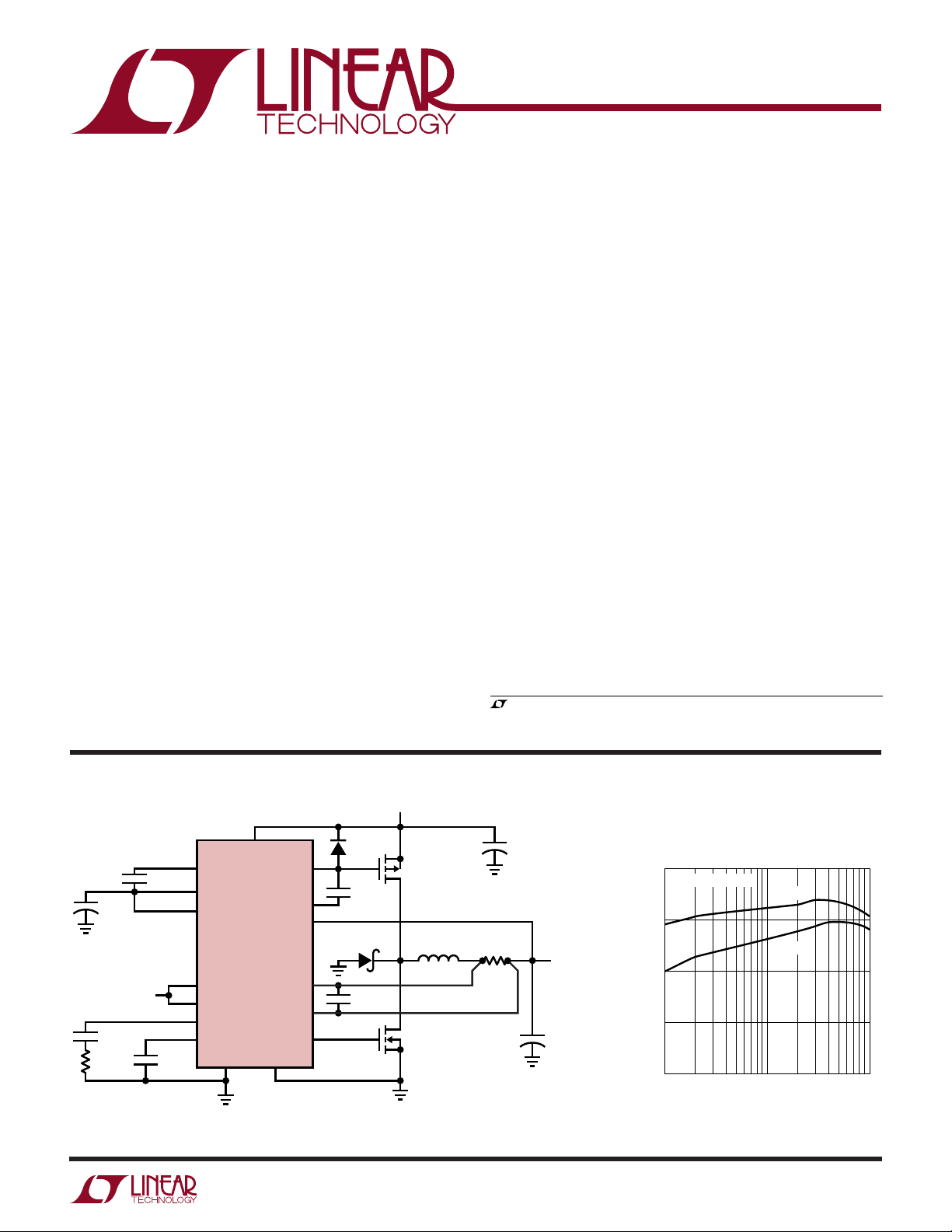

TYPICAL APPLICATIO

V

IN

+

3.3µF

0V = NORMAL

>2V = SHUTDOWN

3300pF

1k

C

T

300pF

CAP

V

CC

V

CC

SHDN1

SHDN2

I

TH

C

T

S-GND

0.15µF

Figure 1. High Efficiency Step-Down Regulator

P-GATE

P-DRIVE

EXTV

LTC1159-5

SENSE

SENSE

N-GATE

P-GND

U

V

IN

+

C

R

SENSE

0.05Ω

IN

100µF

100V

21

4

+

V

OUT

5V/2A

C

OUT

220µF

100

FIGURE 1 CIRCUIT

90

80

EFFICIENCY (%)

70

60

0.02

LTC1159-5 Efficiency

VIN = 10V

VIN = 20V

0.2 2

LOAD CURRENT (A)

LTC1159 • TA01

1N4148

Si9435DY

0.1µF

CC

+

–

D1

MBRS140T3

0.01µF

LTC1159 • F01

L*

33µH

3

Si9410DY

*COILTRONICS CTX33-4-MP

1

Page 2

LTC1159

LTC1159-3.3/LTC1159-5

A

W

O

LUTEXI TIS

S

A

WUW

U

ARB

G

(Note 1)

Input Supply Voltage (Pin 2) ..................... –15V to 60V

VCC Output Current (Pin 3) .................................. 50mA

Continuous Pin Currents (Any Pin)...................... 50mA

Sense Voltages ......................................... –0.3V to 13V

Shutdown Voltages................................................... 7V

EXTVCC Input Voltage ............................................. 15V

Junction Temperature (Note 2)............................ 125°C

WU

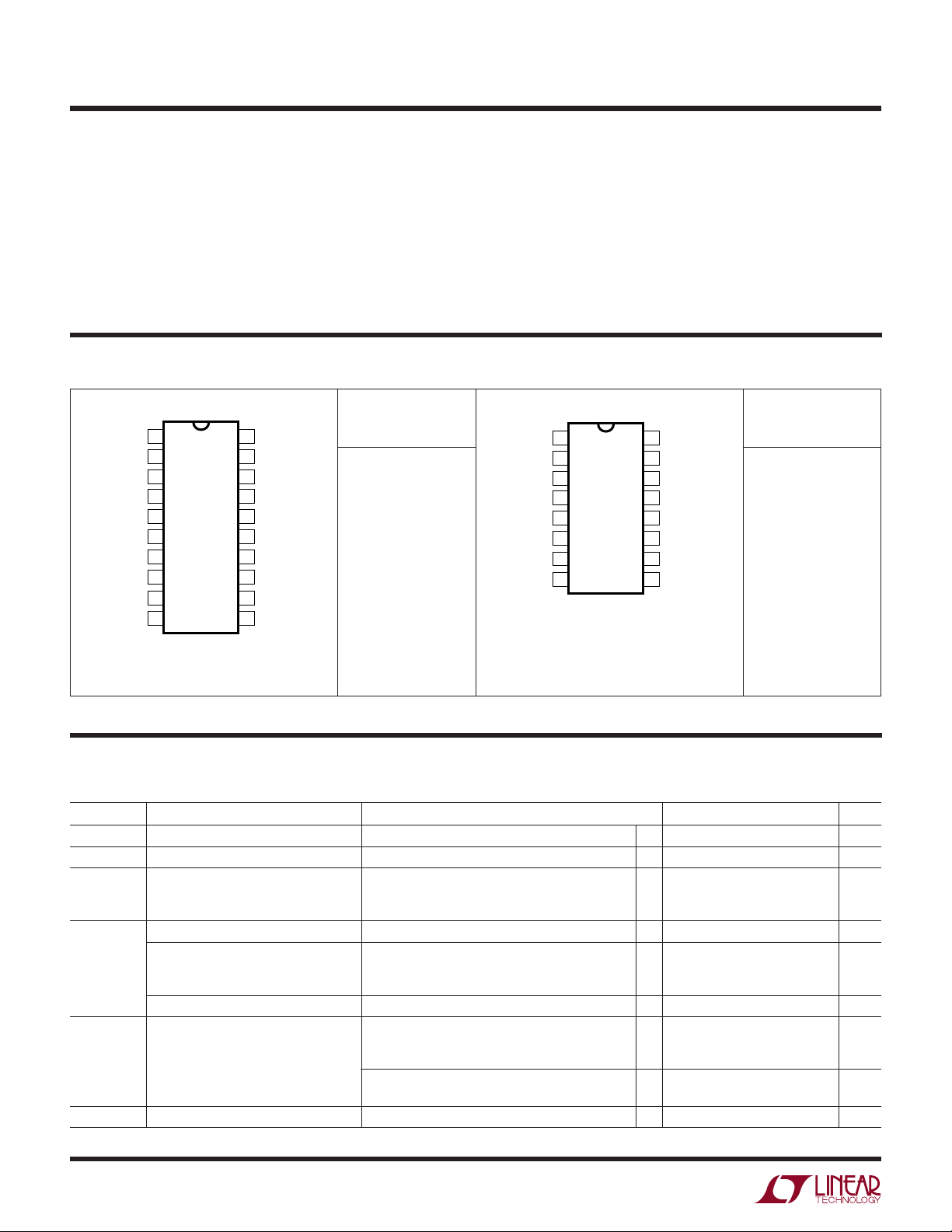

/

PACKAGE

P-GATE

V

IN

V

CC

P-DRIVE

P-DRIVE

V

CC

V

CC

C

T

I

TH

–

SENSE

T

O

RDER I FOR ATIO

TOP VIEW

1

2

3

4

5

6

7

8

9

10

G PACKAGE

20-LEAD PLASTIC SSOP

JMAX

= 125°C, θ

= 135°C/W

JA

20

19

18

17

16

15

14

13

12

11

CAP

SHDN2

EXTV

PGND

N-GATE

PGND

SGND

SHDN1

V

FB

SENSE

ORDER PART

NUMBER

CC

LTC1159CG

LTC1159CG-3.3

LTC1159CG-5

+

Operating Temperature Range

LTC1159C .............................................. 0°C to 70°C

LTC1159I........................................... –40°C to 85°C

Extended Commercial

Temperature Range ............................... – 40°C to 85°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

U

ORDER PART

NUMBER

LTC1159CN

LTC1159CN-3.3

LTC1159CN-5

LTC1159CS

LTC1159CS-3.3

LTC1159CS-5

LTC1159IS

LTC1159IS-3.3

LTC1159IS-5

1

P-GATE

2

V

IN

3

V

CC

P-DRIVE

SENSE

4

5

V

CC

6

C

T

7

I

TH

–

8

N PACKAGE

16-LEAD PDIP

*FIXED OUTPUT VERSIONS

T

= 125°C, θ

JMAX

T

= 125°C, θ

JMAX

TOP VIEW

S PACKAGE

16-LEAD PLASTIC SO

= 80°C/ W (N)

JA

= 110°C/ W (S)

JA

16

15

14

13

12

11

10

9

CAP

SHDN2

EXTV

N-GATE

PGND

SGND

V

(SHDN1)*

FB

SENSE

CC

+

Consult LTC Marketing for parts specified with wider operating temperature ranges.

LECTRICAL C CHARA TERIST

E

ICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 12V, V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

FB

I

FB

V

OUT

∆V

OUT

I

IN

I

EXTVCC

Feedback Voltage (LTC1159 Only) ● 1.21 1.25 1.29 V

Feedback Current (LTC1159 Only) ● 0.2 µA

Regulated Output Voltage VIN = 9V

LTC1159-3.3 I

LTC1159-5 I

Output Voltage Line Regulation VIN = 9V to 40V –40 0 40 mV

Output Voltage Load Regulation

LTC1159-3.3 5mA < I

LTC1159-5 5mA < I

Burst Mode Output Ripple I

VIN Pin Current (Note 4)

Normal Mode V

Shutdown VIN = 12V, V

EXTVCC Pin Current (Note 4) EXTVCC = 5V, Sleep Mode 250 µA

LOAD

LOAD

LOAD

IN

V

IN

V

IN

The ● denotes specifications which apply over the full operating

= 0V (Note 3), unless otherwise noted.

SHDN1

= 700mA ● 3.23 3.33 3.43 V

= 700mA ● 4.90 5.05 5.20 V

< 2A ● 40 65 mV

LOAD

< 2A ● 60 100 mV

LOAD

= 0A 50 mV

= 12V, EXTVCC = 5V 200 µA

= 40V, EXTVCC = 5V 300 µA

= 2V 15 µA

= 40V, V

SHDN2

= 2V 25 µA

SHDN2

P-P

2

Page 3

LTC1159

LTC1159-3.3/LTC1159- 5

LECTRICAL C CHARA TERIST

E

ICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 12V, V

The ● denotes specifications which apply over the full operating

= 0V (Note 3), unless otherwise noted.

SHDN1

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

VIN – V

V

– V

EXT

V

P-GATE

Internal Regulator Voltage VIN = 12V to 40V, EXTVCC = 0V, ICC = 10mA ● 4.25 4.5 4.75 V

VCC Dropout Voltage VIN = 4V, EXTVCC = Open, ICC = 10mA 300 400 mV

CC

EXTVCC Switch Drop VIN = 12V, EXTVCC = 5V, I

CC

= 10mA 250 350 mV

SWITCH

– VINP-Gate to Source Voltage (Off) VIN = 12V –0.2 0 V

VIN = 40V –0.2 0 V

+

V

– Current Sense Threshold Voltage

SENSE

V

SENSE

V

SNDN1

–

LTC1159 V

LTC1159-3.3 V

LTC1159-5 V

SHDN1 Threshold

–

= 5V, VFB = 1.32V (Forced) 25 mV

SENSE

–

V

= 5V, VFB = 1.15V (Forced) ● 130 150 170 mV

SENSE

–

= 3.4V (Forced) 25 mV

SENSE

–

= 3.1V (Forced) ● 130 150 170 mV

V

SENSE

–

= 5.2V (Forced) 25 mV

SENSE

–

= 4.7V (Forced) ● 130 150 170 mV

V

SENSE

LTC1159CG, LTC1159-3.3, LTC1159-5 0.5 0.8 2 V

V

SHDN2

I

SHDN2

I

CT

t

OFF

tr, t

f

SHDN2 Threshold 0.8 1.4 2 V

Shutdown 2 Input Current V

CT Pin Discharge Current V

Off-Time (Note 5) CT = 390pF, I

= 5V 12 20 µA

SHDN2

in Regulation 50 70 90 µA

OUT

= 0V 2 10 µA

V

OUT

= 700mA, VIN = 10V 4 5 6 µs

LOAD

Driver Output Transition Times CL = 3000pF (Pins P-Drive and N-Gate), VIN = 6V 100 200 ns

–40°C ≤ TA ≤ 85°C (Note 6)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

FB

V

OUT

I

IN

I

EXTVCC

V

CC

+

V

SENSE

–

V

SENSE

V

SHDN2

t

OFF

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: T

dissipation P

LTC1159CG, LTC1159CG-3.3, LTC1159CG-5: T

LTC1159CN, LTC1159CN-3.3, LTC1159CN-5: T

LTC1159CS, LTC1159CS-3.3, LTC1159CS-5: T

Feedback Voltage (LTC1159 Only) 1.2 1.25 1.3 V

Regulated Output Voltage VIN = 9V

LTC1159-3.3 I

LTC1159-5 I

= 700mA 3.17 3.30 3.43 V

LOAD

= 700mA 4.85 5.05 5.25 V

LOAD

VIN Pin Current (Note 4)

Normal V

= 12V, EXTVCC = 5V 200 µA

IN

VIN = 40V, EXTVCC = 5V 300 µA

Shutdown VIN = 12V, V

VIN = 40V, V

= 2V 15 µA

SHDN2

= 2V 25 µA

SHDN2

EXTVCC Pin Current (Note 4) EXTVCC = 5V, Sleep Mode 250 µA

Internal Regulator Voltage VIN = 12V to 40V, EXTVCC = 0V, ICC = 10mA 4.5 V

– Current Sense Threshold Voltage Low Threshold (Forced) 25 mV

High Threshold (Forced) 125 150 175 mV

SHDN2 Threshold 0.8 1.4 2 V

Off-Time (Note 5) CT = 390pF, I

= 700mA, VIN = 10V 3.5 5 6.5 µs

LOAD

Note 3: On LTC1159 versions which have a SHDN1 pin, it must be at

ground potential for testing.

is calculated from the ambient temperature TA and power

J

according to the following formulas:

D

= TA + (PD • 135°C/W)

J

= TA + (PD • 80°C/W)

J

= TA + (PD • 110°C/W)

J

Note 4: The LTC1159 V

MOSFET driver currents. When V

, the input current increases by (I

EXTV

CC

and EXTVCC current measurements exclude

IN

power is derived from the output via

CC

• Duty Cycle)/(Efficiency).

GATECHG

See Typical Performance Characteristics and Applications Information.

Note 5: In applications where R

is placed at ground potential, the off-

SENSE

time increases approximately 40%.

3

Page 4

LTC1159

LOAD CURRENT (A)

0

–100

∆V

OUT

(mV)

–80

–60

–40

–20

0

20

0.5 1.0 1.5 2.0

LTC1159 • TPC03

2.5

FIGURE 1 CIRCUIT

V

IN

= 24V

LTC1159-3.3/LTC1159-5

LECTRICAL C CHARA TERIST

E

ICS

Note 6: The LTC1159C, LTC1159C-3.3, and LTC1159C-5 are not tested

and not quality assurance sampled at –40°C and 85°C. These

specifications are guaranteed by design and/or correlation. The LTC1159I,

LTC1159I-3.3 and LTC1159I-5 are guaranteed and tested over the –40°C

Note 7: The logic-level power MOSFETs shown in Figure 1 are rated for

V

= 30V. For operation at VIN > 30V, use standard threshold

DS(MAX)

MOSFETs with EXTV

Information.

to 85°C operating temperature range.

UW

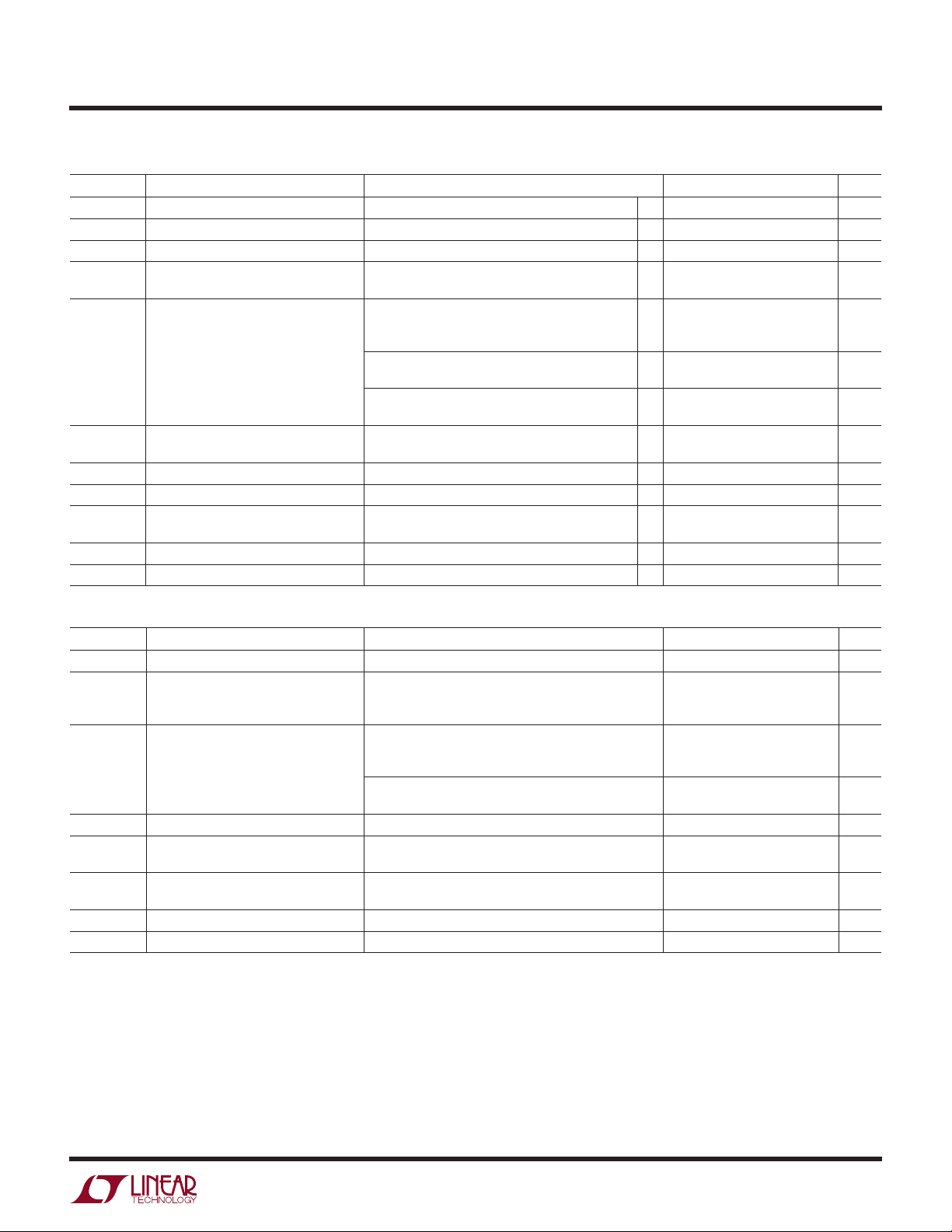

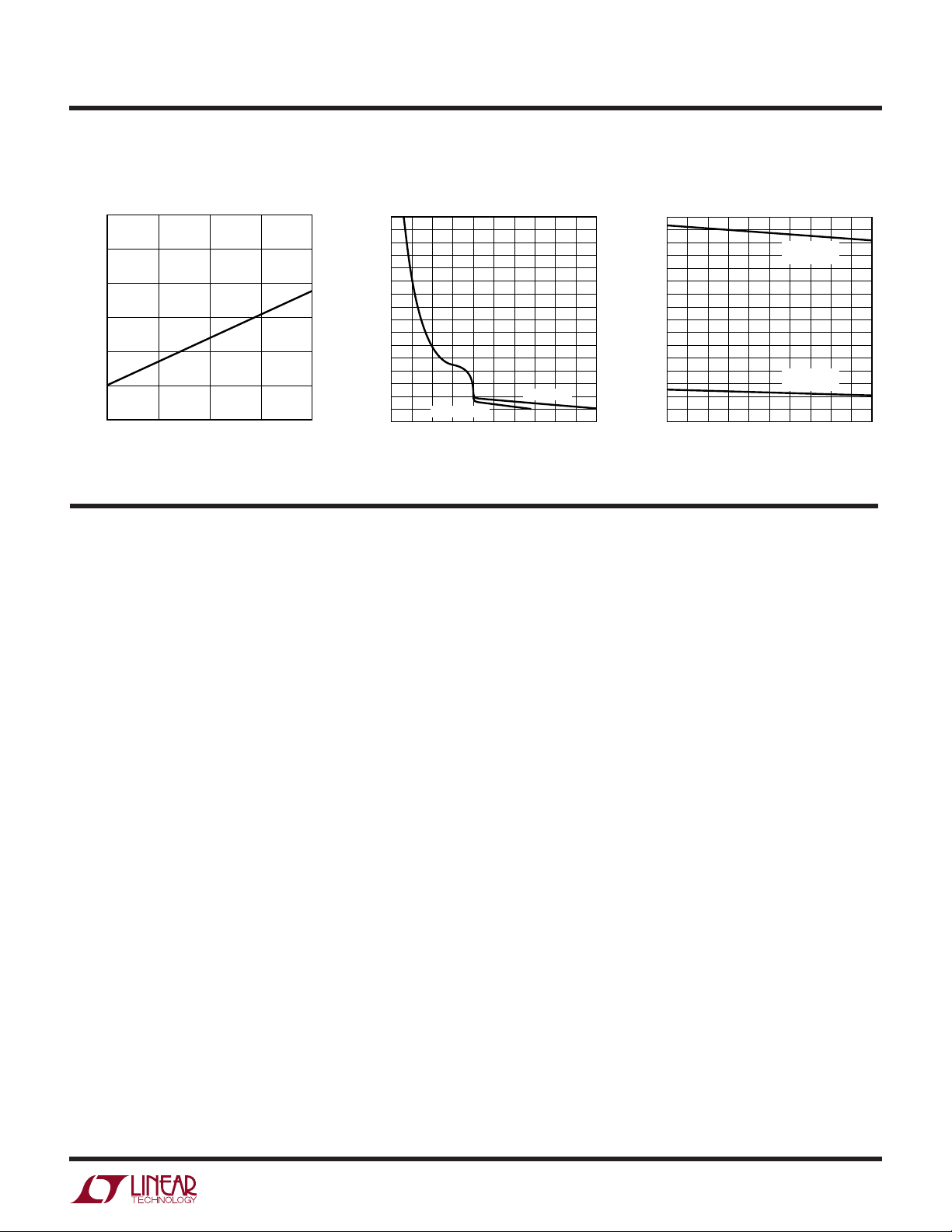

TYPICAL PERFOR A CE CHARACTERISTICS

Efficiency vs Input Voltage

100

FIGURE 1 CIRCUIT

I

= 1A

LOAD

95

90

EFFICIENCY (%)

85

80

0

5101520

INPUT VOLTAGE (V)

NOTE 6

25 30 35 40

LTC1159 • TPC01

Line Regulation

60

FIGURE 1 CIRCUIT

= 1A

I

LOAD

40

20

(mV)

0

OUT

∆V

–20

–40

–60

0

515

10 20

INPUT VOLTAGE (V)

30

25

NOTE 6

35

LT1159 • TPC02

powered from a 12V supply. See Applications

CC

Load Regulation

40

Operating Frequency

EXTVCC Pin Current

10

FIGURE 1 CIRCUIT

8

I

= 1A

LOAD

6

CURRENT (mA)

4

CC

I

= 100mA

EXTV

2

0

0

510

LOAD

I

= 0

LOAD

20

15 25 40

INPUT VOLTAGE (V)

NOTE 6

30 35

LTC1159 • TPC04

VIN Pin Current

500

FIGURE 1 CIRCUIT

400

300

200

SUPPLY CURRENT (µA)

100

0

0

510

INPUT VOLTAGE (V)

NORMAL

V

= 2V

SHDN2

20

15 25 40

NOTE 6

30 35

LTC1159 • TPC05

vs (VIN – V

2.0

V

= 5V

OUT

1.5

1.0

0.5

NORMALIZED FREQUENCY

0

0

5

(VIN – V

OUT

10

OUT

)

T = 0°C

T = 70°C

15

) VOLTAGE (V)

T = 25°C

20

25

LTC1159 • TPC06

4

Page 5

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC1159

LTC1159-3.3/LTC1159- 5

EXTVCC Switch Drop Current Sense Threshold Voltage

600

500

400

(mV)

CC

300

– V

CC

200

EXTV

100

0

0

5101520

SWITCH CURRENT (mA)

LTC1159 • TPC07

U

UU

Off-Time vs V

80

70

60

50

40

30

OFF-TIME (µs)

20

10

0

0

OUT

LTC1159-3.3

1

2

OUTPUT VOLTAGE (V)

LTC1159-5

34

LTC1159 • TPC08

5

160

140

120

100

80

60

SENSE VOLTAGE (mV)

40

20

0

0

20

MAXIMUM

THRESHOLD

THRESHOLD

60 80

40

TEMPERATURE (°C)

PI FU CTIO S

VIN: Main Supply Input Pin.

SGND: Small-Signal Ground. Must be routed separately

from other grounds to the (–) terminal of C

OUT

.

PGND: Driver Power Grounds. Connect to source of Nchannel MOSFET and the (–) terminal of CIN.

VCC: Outputs of internal 4.5V linear regulator, EXTV

switch, and supply inputs for driver and control circuits.

The driver and control circuits are powered from the higher

of the 4.5V regulator or EXTVCC voltage. Must be closely

decoupled to power ground.

SENSE+: The (+) Input for the Current Comparator. A builtin offset between the SENSE+ and SENSE– pins, in conjunction with R

, sets the current trip threshold.

SENSE

N-Gate: High Current Drive for the Bottom N-Channel

MOSFET. The N-Gate pin swings from ground to VCC.

P-Gate: Level-Shifted Gate Drive Signal for the Top

CC

P-Channel MOSFET. The voltage swing at the P-gate pin is

from VIN to VIN – VCC.

P-Drive: High Current Gate Drive for the Top P-Channel

MOSFET. The P-drive pin(s) swing(s) from VCC to ground.

MINIMUM

100

LTC1159 • TPC09

CT: External capacitor CT from this pin to ground sets the

operating frequency. (The frequency is also dependent on

the ratio V

OUT/VIN

.)

ITH: Gain Amplifier Decoupling Point. The current comparator threshold increases with the I

pin voltage.

TH

VFB: For the LTC1159 adjustable version, the VFB pin

receives the feedback voltage from an external resistive

divider used to set the output voltage.

SENSE–: Connects to internal resistive divider which sets

the output voltage in fixed output versions. The SENSE– pin

is also the (–) input of the current comparator.

CAP: Charge Compensation Pin. A capacitor to VCC pro-

vides charge required by the P-gate level-shift capacitor

during supply transitions.

pacitor must be larger than the gate drive capacitor

SHDN1: This pin shuts down the control circuitry only (V

The charge compensation ca-

.

CC

is not affected). Taking SHDN1 pin high turns off the

control circuitry and holds both MOSFETs off. This pin

must be at ground potential for normal operation.

SHDN2: Master Shutdown Pin. Taking SHDN2 high shuts

down VCC and all control circuitry.

5

Page 6

LTC1159

LTC1159-3.3/LTC1159-5

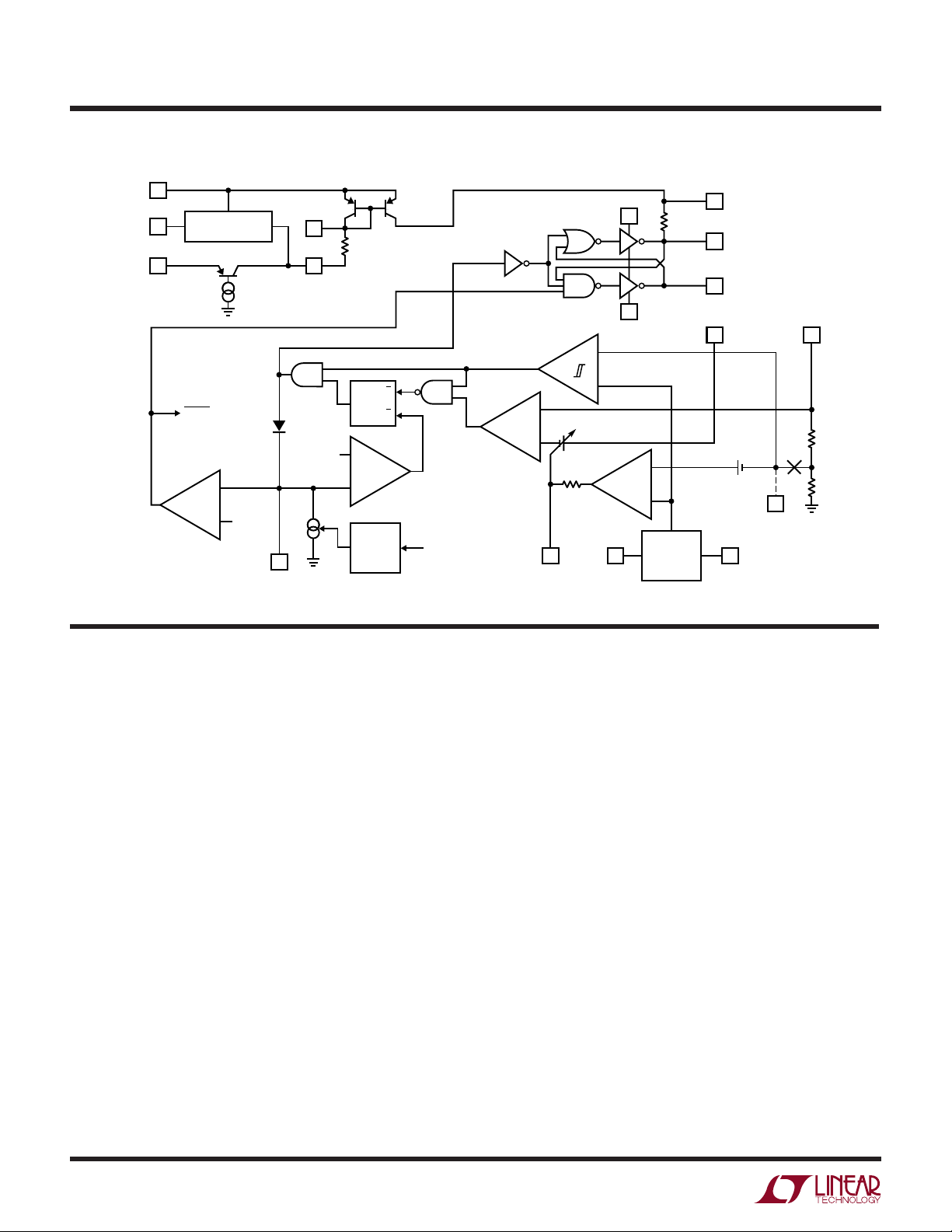

U

U

W

FU CTIO AL DIAGRA

V

IN

SHDN2

EXTV

LOW DROPOUT

4.5V REGULATOR

CC

LOW DROP SWITCH

SLEEP

+

S

V

–

TH2

CAP

V

CC

V

C

T

Internal divider broken at VFB for adjustable versions.

550k

PGND

–

V

+

25mV TO 150mV

13k

SGND

TH

TH1

Q

–

T

+

OFF-TIME

CONTROL

R

S

–

SENSE

–

C

+

I

V

CC

G

550k

–

+

1.25V

REFERENCE

SENSE

P-GATE

P-DRIVE

N-GATE

+

V

OS

SHDN1

–

SENSE

100k

LTC1159 • FD

V

FB

U

OPERATIO

The LTC1159 uses a current mode, constant off-time

architecture to synchronously switch an external pair of

complementary power MOSFETs. Operating frequency is

set by an external capacitor at the CT pin.

The output voltage is sensed either by an internal voltage

divider connected to the SENSE– pin (LTC1159-3.3 and

LTC1159-5) or an external divider returned to the VFB pin

(LTC1159). A voltage comparator V, and a gain block G,

compare the divided output voltage with a reference voltage of 1.25V. To optimize efficiency, the LTC1159 automatically switches between two modes of operation, burst

and continuous.

A low dropout 4.5V regulator provides the operating voltage VCC for the MOSFET drivers and control circuitry during

start-up. During normal operation, the LTC1159 family

powers the drivers and control from the output via the

EXTVCC pin to improve efficiency. The N-GATE pin is

referenced to ground and drives the N-channel MOSFET

gate directly. The P-channel gate drive must be referenced

to the main supply input VIN, which is accomplished by

(Refer to Functional Diagram)

level-shifting the P-drive signal via an internal 550k resistor

and external capacitor.

During the switch “ON” cycle in continuous mode, current

comparator C monitors the voltage between the SENSE

+

and SENSE– pins connected across an external shunt in

series with the inductor. When the voltage across the shunt

reaches its threshold value, the P-gate output is switched

to VIN, turning off the P-channel MOSFET. The timing

capacitor CT is now allowed to discharge at a rate determined by the off-time controller. The discharge current is

made proportional to the output voltage to model the

inductor current, which decays at a rate which is also

proportional to the output voltage. While the timing

capacitor is discharging, the N-gate output is high, turning

on the N-channel MOSFET.

When the voltage on CT has discharged past V

, compara-

TH1

tor T trips, setting the flip-flop. This causes the N-gate output

to go low (turning off the N-channel MOSFET) and the Pgate output to also go low (turning the P-channel MOSFET

back on). The cycle then repeats. As the load current

6

Page 7

OPERATIO

LTC1159

LTC1159-3.3/LTC1159- 5

U

(Refer to Functional Diagram)

increases, the output voltage decreases slightly. This causes

the output of the gain stage to increase the current comparator threshold, thus tracking the load current.

The sequence of events for Burst Mode operation is very

similar to continuous operation with the cycle interrupted

by the voltage comparator. When the output voltage is at or

above the desired regulated value, the P-channel MOSFET

is held off by comparator V and the timing capacitor continues to discharge below V

discharges past V

the internal SLEEP line to go low and the N-channel MOSFET

to turn off.

The circuit now enters sleep mode with both power

MOSFETs turned off. In sleep mode, much of the circuitry

, voltage comparator S trips, causing

TH2

. When the timing capacitor

TH1

WUUU

APPLICATIO S I FOR ATIO

The LTC1159 Compared to the LTC1148/LTC1149

Families

The LTC1159 family is closest in operation to the LTC1149

and shares much of the applications information. In addition to reduced quiescent and shutdown currents, the

LTC1159 adds an internal switch which allows the driver

and control sections to be powered from an external

source for higher efficiency. This change affects Power

MOSFET Selection, EXTVCC Pin Connection, Important

Information About LTC1159 Adjustable Applications, and

Efficiency Considerations found in this section.

The basic LTC1159 application circuit shown in Figure 1

is limited to a maximum input voltage of 30V due to

MOSFET breakdown. If the application does not require

greater than 18V operation, then the LTC1148 or

LTC1148HV should be used. For higher input voltages

where quiescent and shutdown current are not critical, the

LTC1149 may be a better choice since it is set up to drive

standard threshold MOSFETs.

R

R

LTC1159 current comparator has a threshold range that

extends from a minimum of 0.025V/R

Selection for Output Current

SENSE

is chosen based on the required output current. The

SENSE

to a maximum

SENSE

is turned off, dropping the supply current from several

milliamps (with the MOSFETs switching) to 300µA. When

the output capacitor has discharged by the amount of

hysteresis in comparator V, the P-channel MOSFET is

again turned on and this process repeats. To avoid the

operation of the current loop interfering with Burst Mode

operation, a built-in offset is incorporated in the gain stage.

To prevent both the external MOSFETs from being turned

on at the same time, feedback is incorporated to sense the

state of the driver output pins. Before the N-gate output can

go high, the P-drive output must also be high. Likewise, the

P-drive output is prevented from going low when the

N-gate output is high.

of 0.15V/R

the peak of the inductor ripple current, yielding a maximum

output current I

peak-to-peak ripple current.

tion, I

RIPPLE(P-P)

. The current comparator threshold sets

SENSE

equal to the peak value less half the

MAX

For proper Burst Mode opera-

must be less than or equal to the minimum

current comparator threshold.

Since efficiency generally increases with ripple current,

the maximum allowable ripple current is assumed, i.e.,

I

RIPPLE(P-P)

Operating Frequency). Solving for R

a margin for variations in the LTC1159 and external

component values yields:

R

SENSE

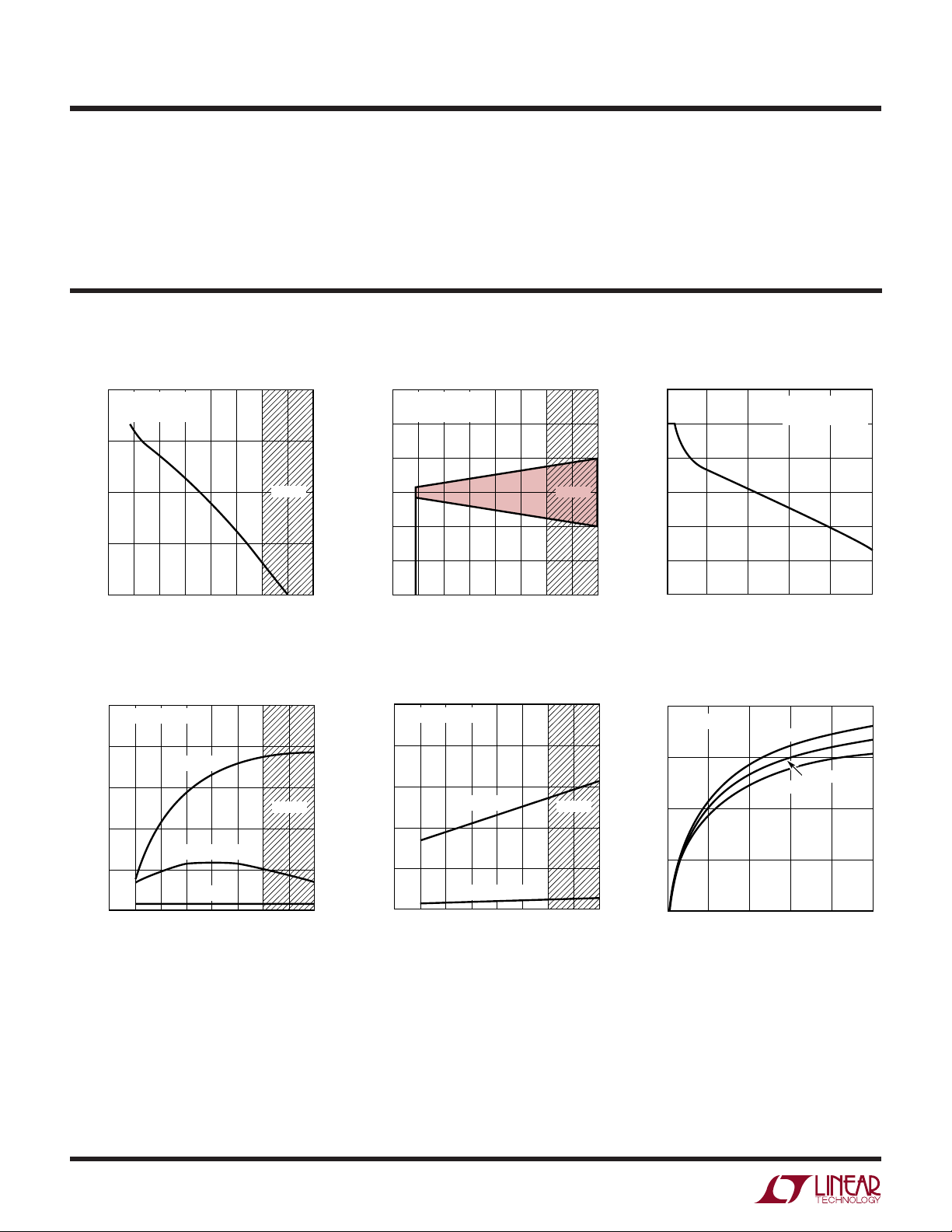

A graph for selecting R

current is given in Figure 2. The LTC1159 series works well

with values of R

The load current below which Burst Mode operation commences, I

both track I

I

SC(PK)

= 0.025V/R

100

= mΩ

I

MAX

from 0.02Ω to 0.2Ω.

SENSE

, and the peak short-circuit current, I

BURST

. Once R

MAX

can be predicted from the following equations:

(see CT and L Selection for

SENSE

SENSE

versus maximum output

SENSE

has been chosen, I

SENSE

and allowing

SC(PK)

and

BURST

,

7

Page 8

LTC1159

LTC1159-3.3/LTC1159-5

WUUU

APPLICATIO S I FOR ATIO

0.20

0.18

0.16

0.14

0.12

(Ω)

0.10

SENSE

R

0.08

0.06

0.04

0.02

0

1

0

MAXIMUM OUTPUT CURRENT (A)

2

3

4

5

LTC1159 • F02

1400

1200

1000

800

600

CAPACITANCE (pF)

T

400

C

200

0

50

0

VIN = 48V

150

100

FREQUENCY (kHz)

V

OUT

= 24V

V

IN

VIN = 12V

200

= 5V

250

LTC1159 • F03

Figure 2. R

I

BURST

I

SC(PK)

≈

=

15mV

R

SENSE

150mV

R

SENSE

The LTC1159 automatically extends t

vs Maximum Output Current

SENSE

during a short

OFF

circuit to allow sufficient time for the inductor current to

decay between switch cycles. The resulting ripple current

causes the average short-circuit current I

reduced to approximately I

MAX

.

SC(AVG)

to be

L and CT Selection for Operating Frequency

The LTC1159 uses a constant off-time architecture with

t

determined by an external timing capacitor CT. The

OFF

value of CT is calculated from the desired continuous mode

operating frequency, f:

CT =

7.8 • 10

f

–5

1 –

)

V

OUT

V

IN

)

A graph for selecting CT versus frequency including the

effects of input voltage is given in Figure 3.

As the operating frequency is increased the gate charge

losses will be higher, reducing efficiency (see Efficiency

Considerations). The complete expression for operating

frequency is given by:

f =

t

OFF

1

1 –

)

V

OUT

V

IN

)

Figure 3. Timing Capacitor Selection

where t

= 1.3 • 104 • C

OFF

T

Once the frequency has been set by CT, the inductor L

must be chosen to provide no more than 0.025V/R

SENSE

of peak-to-peak inductor ripple current. This results in a

minimum required inductor value of:

L

= 5.1 • 105 • R

MIN

SENSE

• CT • V

REG

As the inductor value is increased from the minimum value,

the ESR requirements for the output capacitor are eased at

the expense of efficiency. If too small an inductor is used,

the LTC1159 may not enter Burst Mode operation and

efficiency will be severely degraded at low currents.

Inductor Core Selection

Once the minimum value for L is known, the type of

inductor must be selected. High efficiency converters

generally cannot afford the core loss found in low cost

powdered iron cores, forcing the use of more expensive

ferrite, molypermalloy or Kool Mµ® cores. Actual core loss

is independent of core size for a fixed inductor value, but

it is very dependent on the inductance selected. As induc

tance increases, core losses go down but copper (I2R)

losses will increase.

Ferrite designs have very low core loss, so design goals can

concentrate on copper loss and preventing saturation.

Ferrite core material saturates “hard,” which means that

inductance collapses abruptly when the peak design current is exceeded. This results in an abrupt increase in

Kool Mµ is a registered trademark of Magnetics, Inc.

8

Page 9

V

V

WUUU

APPLICATIO S I FOR ATIO

LTC1159

LTC1159-3.3/LTC1159- 5

inductor ripple current and consequent output voltage

ripple which can cause Burst Mode operation to be falsely

triggered in the LTC1159. Do not allow the core to saturate!

Molypermalloy (from Magnetics, Inc.) is a low loss core

material for toroids, but it is more expensive than ferrite.

A reasonable compromise from the same manufacturer is

Kool Mµ. Toroids are very space efficient, especially when

you can use several layers of wire. Because they generally

lack a bobbin, mounting is more difficult. However, new

surface mount designs available from Coiltronics do not

increase the height significantly.

Power MOSFET Selection

Two external power MOSFETs must be selected for use

with the LTC1159: a P-channel MOSFET for the main

switch and an N-channel MOSFET for the synchronous

switch.

The peak-to-peak drive levels are set by the VCC voltage on

the LTC1159. This voltage is typically 4.5V during start-up

and 5V to 7V during normal operation (see EXTVCC Pin

Connection). Consequently,

logic-level threshold

MOSFETs must be used in most LTC1159 family applications

. The only exception is applications in which EXTV

CC

is powered from an external supply greater than 8V, in

which standard threshold MOSFETs (V

used. Pay close attention to the BV

DSS

< 4V) may be

GS(TH)

specification for the

MOSFETs as well; many of the logic-level MOSFETs are

limited to 30V.

Selection criteria for the power MOSFETs include the “ON”

resistance R

, reverse transfer capacitance C

DS(ON)

RSS

,

input voltage and maximum output current. When the

LTC1159 is operating in continuous mode, the duty cycle

for the P-channel MOSFET is given by:

P-Ch Duty Cycle =

N-Ch Duty Cycle =

OUT

V

IN

V

IN – VOUT

V

IN

The MOSFET dissipations at maximum output current are

given by:

P-Ch PD =

N-Ch PD =

where ∂ is the temperature dependency of R

OUT

V

IN

k(V

)2 (I

IN

V

IN – VOUT

V

IN

(I

MAX

MAX

(I

)2 (1 + ∂P) R

) (C

MAX

) (f)

RSS

)2 (1 + ∂N) R

DS(ON)

DS(ON)

+

DS(ON)

and k

is a constant inversely related to the gate drive current.

Both MOSFETs have I2R losses while the P-channel

equation includes an additional term for transition losses,

which are highest at high input voltages. For VIN < 20V the

high current efficiency generally improves with larger

MOSFETs, while for VIN > 20V the transition losses rapidly

increase to the point that the use of a higher R

device with lower C

actually provides higher effi-

RSS

DS(ON)

ciency. The N-channel MOSFET losses are the greatest at

high input voltage or during a short circuit when the

N-channel duty cycle is nearly 100%.

The term (1 + ∂) is generally given for a MOSFET in the form

of a normalized R

vs Temperature curve, but

DS(ON)

∂ = 0.007/°C can be used as an approximation for low

voltage MOSFETs. C

is usually specified in the MOSFET

RSS

electrical characteristics. The constant k = 5 can be used for

the LTC1159 to estimate the relative contributions of the

two terms in the P-channel dissipation equation.

The Schottky diode D1 shown in Figure 1 only conducts

during the dead time between the conduction of the two

power MOSFETs. D1 prevents the body diode of the

N-channel MOSFET from turning on and storing charge

during the dead time, which could cost as much as 1% in

efficiency (although there are no other harmful effects if

D1 is omitted). Therefore, D1 should be selected for a

forward voltage of less than 0.6V when conducting I

MAX

.

9

Page 10

LTC1159

LTC1159-3.3/LTC1159-5

WUUU

APPLICATIO S I FOR ATIO

CIN and C

Selection

OUT

In continuous mode, the source current of the P-channel

MOSFET is a square wave of duty cycle V

OUT/VIN

.

To prevent large voltage transients, a low ESR input

capacitor sized for the

maximum RMS current must be

used. The maximum RMS capacitor current is given by:

OUT

1/2

)]

, where

CIN Required I

RMS

≈

MAX

OUT(VIN – VOUT

V

IN

[V

I

This formula has a maximum at VIN = 2V

I

RMS

= I

/2. This simple worst-case condition is com-

MAX

monly used for design because even significant deviations

do not offer much relief. Note that capacitor manufacturer’s

ripple current ratings are often based on only 2000 hours

of life. This makes it advisable to further derate the

capacitor, or to choose a capacitor rated at a higher

temperature than required. Several capacitors may be

paralleled to meet size or height requirements in the

design. An additional 0.1µF ceramic capacitor may also be

required on VIN for high frequency decoupling.

The selection of C

series resistance (ESR). The ESR of C

twice the value of R

is driven by the required effective

OUT

must be less than

OUT

for proper operation of the

SENSE

LTC1159:

C

Required ESR < 2R

OUT

SENSE

Optimum efficiency is obtained by making the ESR equal to

R

. Manufacturers such as Nichicon, Chemicon, and

SENSE

Sprague should be considered for high performance capacitors. The OS-CON semiconductor dielectric capacitor

available from Sanyo has the lowest ESR for its size at a

somewhat higher price. Once the ESR requirement for

C

has been met, the RMS current rating generally far

OUT

exceeds the I

RIPPLE(P-P)

requirement.

In surface mount applications, multiple capacitors may

have to be paralleled to meet the capacitance, ESR or RMS

current handling requirements of the application. Aluminum electrolytic and dry tantalum capacitors are both

available in surface mount configurations. In the case of

tantalum, it is critical that the capacitors are surge tested

for use in switching power supplies. An excellent choice is

the AVX TPS series of surface mount tantalums, available

in case heights ranging from 2mm to 4mm. For example,

if 200µF/10V is called for in an application requiring 3mm

height, two AVX 100µF/10V (P/N TPSD107K010) could be

used. Consult the manufacturer for other specific recommendations.

At low supply voltages, a minimum value of C

OUT

is

suggested to prevent an abnormal low frequency operating

mode (see Figure 4). When C

is too small, the output

OUT

ripple at low frequencies will be large enough to trip the

voltage comparator. This causes the Burst Mode operation

to be activated when the LTC1159 would normally be in

continuous operation. The effect is most pronounced with

low values of R

and can be improved by operating at

SENSE

higher frequencies with lower values of L. The output

remains in regulation at all times.

1000

800

600

(µF)

OUT

C

400

R

SENSE

200

0

0

Figure 4. Minimum Suggested C

L = 50µH

= 0.05Ω

1

(VIN – V

L = 50µH

R

SENSE

L = 25µH

R

SENSE

2

) VOLTAGE (V)

OUT

= 0.02Ω

= 0.02Ω

3

4

LTC1159 • TPC04

OUT

5

Load Transient Response

Switching regulators take several cycles to respond to a

step in DC (resistive) load current. When a load step

occurs, V

where ESR is the effective series resistance of C

also begins to charge or discharge C

loop adapts to the current change and returns V

steady-state value. During this recovery time V

shifts by an amount equal to ∆I

OUT

OUT

• ESR,

LOAD

. ∆I

OUT

LOAD

until the regulator

to its

OUT

can be

OUT

monitored for overshoot or ringing which would indicate a

stability problem. The ITH external components shown in

the Figure 1 circuit will provide adequate compensation for

most applications.

A second, more severe transient is caused by switching in

loads with large (>1µF) supply bypass capacitors. The

10

Page 11

WUUU

APPLICATIO S I FOR ATIO

LTC1159

LTC1159-3.3/LTC1159- 5

discharged bypass capacitors are effectively put in parallel

with C

, causing a rapid drop in V

OUT

. No regulator can

OUT

deliver enough current to prevent this problem if the load

switch resistance is low and it is driven quickly. The only

solution is to limit the rise time of the switch drive so that

the load rise time is limited to approximately 25 • C

LOAD

.

Thus a 10µF capacitor would require a 250µs rise time,

limiting the charging current to about 200mA.

Line Transient Response

The LTC1159 has better than 60dB line rejection and is

generally impervious to large positive or negative line

voltage transients. However, one rarely occurring condition can cause the output voltage to overshoot if the proper

precautions are not observed. This condition is a negative

VIN transition of several volts followed within 100µs by a

positive transition of greater than 0.5V/µs slew rate.

The reason this condition rarely occurs is because it takes

tens of amps to slew the regulator input capacitor at this

rate! The solution is to add a diode between the cap and V

IN

pins of the LTC1159 as shown in several of the typical

application circuits. If you think your system could have

this problem, add the diode. Note that in surface mount

applications it can be combined with the P-gate diode by

using a low cost common cathode dual diode.

EXTVCC Pin Connection

The LTC1159 contains an internal PNP switch connected

between the EXTVCC and VCC pins. The switch closes and

supplies the VCC power whenever the EXTVCC pin is higher

in voltage than the 4.5V internal regulator. This allows the

V

IN

V

IN

P-DRIVE

LTC1159-3.3

P-GATE

N-GATE

P-GND

EXTV

+

C

P-CH

N-CH

CC

BAT85

IN

R

SENSE

C

1µF

OUT

+

21

4

+

LTC1159 • F05a

V

OUT

L

1:1

•

•

3

MOSFET driver and control power to be derived from the

output during normal operation and from the internal

regulator when the output is out of regulation (start-up,

short circuit).

Significant efficiency gains can be realized by powering V

CC

from the output, since the VIN current resulting from the

driver and control currents will be scaled by a factor of

(Duty Cycle)/(Efficiency). For 5V regulators this simply

means connecting the EXTVCC pin directly to V

OUT

. However, for 3.3V and other low voltage regulators, additional

circuitry is required to derive VCC power from the output.

The following list summarizes the four possible connections for EXTVCC:

1. EXTVCC Left Open. This will cause VCC to be powered

only from the internal 4.5V regulator resulting in reduced

MOSFET gate drive levels and an efficiency penalty of up to

10% at high input voltages.

2. EXTVCC Connected Directly to V

. This is the normal

OUT

connection for a 5V regulator and provides the highest

efficiency.

3. EXTVCC Connected to an Output-Derived Boost Network. For 3.3V and other low voltage regulators, efficiency

gains can still be realized by connecting EXTVCC to an

output-derived voltage which has been boosted to greater

than 4.5V. This can be done either with the inductive boost

winding shown in Figure 5a or the capacitive charge pump

shown in Figure 5b. The charge pump has the advantage of

simple magnetics and generally provides the highest efficiency at the expense of a slightly higher parts count.

V

IN

+

C

BAT85

IN

VN2222LL

L

0.22µF

LTC1159 • F05b

R

SENSE

BAT85

BAT85

V

OUT

+

C

OUT

V

IN

P-DRIVE

LTC1159-3.3

P-GATE

N-GATE

P-GND

EXTV

P-CH

N-CH

CC

+

1µF

Figure 5a. Inductive Boost Circuit for EXTV

CC

Figure 5b. Capacitive Charge Pump for EXTV

CC

11

Page 12

LTC1159

LTC1159-3.3/LTC1159-5

WUUU

APPLICATIO S I FOR ATIO

4. EXTVCC Connected to an External Supply. If an external

supply is available in the 5V to 12V range, it may be used

to power EXTVCC providing it is compatible with the

MOSFET gate drive requirements. There are no restrictions

on the EXTVCC voltage relative to VIN. EXTVCC may be

higher than VIN providing EXTV

does not exceed the 15V

CC

absolute maximum rating.

When driving standard threshold MOSFETs, the external supply must always be present during operation to

prevent MOSFET failure due to insufficient gate drive

. The

LTC1149 family should also be considered for applications

which require the use of standard threshold MOSFETs.

Important Information About LTC1159 Adjustable

Applications

When an output voltage other than 3.3V or 5V is required,

the LTC1159 adjustable version is used with an external

resistive divider from V

to the VFB pin (Figure 6). The

OUT

regulated voltage is determined by:

V

= 1.25V

OUT

1 +

)

R2

R1

)

The VFB pin is extremely sensitive to pickup from the

inductor switching node

. Care should be taken to isolate

the feedback network from the inductor, and the 100pF

capacitor should be connected between the VFB and SGND

pins next to the package.

In LTC1159N and LTC1159S applications with V

OUT

>

5.5V, the VCC pin may self-power through the SENSE pins

when SHDN2 is taken high, preventing shutdown. In these

applications, a pull-down must be added to the SENSE– pin

as shown in Figure 6. This pull-down effectively takes the

place of the SHDN1 pin, ensuring complete shutdown.

Note: For versions in which both the SHDN1 and SHDN2

pins are available (LTC1159G and all fixed output versions), the two pins are simply connected to each other and

driven together to guarantee complete shutdown.

The Figure 6 circuit cannot be used to regulate a V

OUT

which

is greater than the maximum voltage allowed on the

LTC1159 SENSE pins (13V). In applications with V

13V, R

must be moved to the ground side of the

SENSE

OUT

>

output capacitor and load. This operates the current sense

comparator at 0V common mode, increasing the off-time

approximately 40% and requiring the use of a smaller

timing capacitor CT.

Inverting Regular Applications

The LTC1159 can also be used to obtain negative output

voltages from positive inputs. In these inverting applications, the current sense resistor connects to ground while

the LTC1159 and N-channel MOSFET connections, which

would normally go to ground, instead ride on the negative

output. This allows the negative output voltage to be set by

V

IN

12

+

1µF

3300pF

1k

0V = NORMAL

>3V = SHUTDOWN

+

Si4401DY

Si4840DY

=

V

OUT

VALUES SHOWN FOR V

0.15µF

C

T

390pF

CAP

V

CC

V

CC

I

TH

C

T

SHDN2

V

IN

LTC1159

P-GATE

P-DRIVE

N-GATE

PGND

EXTV

V

SGND

SENSE

SENSE

1N4148

0.1µF

5M

CC

FB

+

–

100pF

0.01µF

VN2222LL

100Ω

100Ω

Figure 6. High Efficiency Adjustable Regulator with 5.5V < V

100µF

50V

100µH

1N5819

R2

1 +

()

R1

1.25

3

OUT

OUT

R

SENSE

0.039Ω

LTC1159 • F06

= 12V/2.5A

< 13V

21

4

R2

215k

R1

24.9k

V

OUT

+

150µF

16V

OS-CON

Page 13

WUUU

APPLICATIO S I FOR ATIO

LTC1159

LTC1159-3.3/LTC1159- 5

the same process as in conventional applications, using

either the internal divider (LTC1159-3.3, LTC1159-5) or an

external divider with the adjustable version.

Figure 15 in the Typical Applications shows a synchronous

12V to –12V converter that can supply up to 1A with better

than 85% efficiency. By grounding the EXTVCC pin in the

Figure 15 circuit, the entire 12V output voltage is placed

across the driver and control circuits since the LTC1159

ground pins are at –12V. During start-up or short-circuit

conditions, operating power is supplied by the internal

4.5V regulator. The shutdown signal is level-shifted to the

negative output rail by Q3, and Q4 ensures that Q1 and Q2

remain off during the entire shutdown sequence.

Efficiency Considerations

The percent efficiency of a switching regulator is equal to

the output power divided by the input power times 100%.

It is often useful to analyze individual losses to determine

what is limiting the efficiency and which change would

produce the most improvement. Percent efficiency can be

expressed as:

%Efficiency = 100 – (L1 + L2 + L3 + ...)

where L1, L2, etc., are the individual losses as a percentage

of input power.

Although all dissipative elements in the circuit produce

losses, four main sources usually account for most of the

losses in LTC1159 circuits: 1) LTC1159 VIN current, 2)

LTC1159 VCC current, 3) I2R losses and 4) P-channel

transition losses.

1. LTC1159 VIN current is the DC supply current given in

the electrical characteristics which excludes MOSFET driver

and control currents. VIN current results in a small (<1%)

loss which increases with VIN.

2. LTC1159 VCC current is the sum of the MOSFET driver

and control circuit currents. The MOSFET driver current

results from switching the gate capacitance of the power

MOSFETs. Each time a MOSFET gate is switched from low

to high to low again, a packet of charge dQ moves from V

to ground. The resulting dQ/dt is a current out of VCC which

is typically much larger than the control circuit current. In

continuous mode, I

are the gate charges of the two MOSFETs.

GATECHG

≈ f (QP + QN), where QP and Q

CC

N

By powering EXTVCC from an output-derived source, the

additional VIN current resulting from the driver and control

currents will be scaled by a factor of (Duty Cycle)/(Efficiency). For example in a 20V to 5V application, 10mA of

VCC current results in approximately 3mA of VIN current.

This reduces the mid-current loss from 10% or more (if the

driver was powered directly from VIN) to only a few percent.

3. I2R losses are easily predicted from the DC resistances

of the MOSFET, inductor and current shunt. In continuous

mode all of the output current flows through L and

R

N-channel MOSFETs. If the two MOSFETs have approximately the same R

MOSFET can simply be summed with the resistances of L

and R

R

the total resistance is 0.3Ω. This results in losses ranging

from 3% to 12% as the output current increases from

0.5A to 2A. I2R losses cause the efficiency to roll-off at

high output currents.

4. Transition losses apply only to the P-channel MOSFET,

and only when operating at high input voltages (typically

20V or greater). Transition losses can be estimated from:

Other losses including CIN and C

Schottky conduction losses during dead time, and inductor

core losses, generally account for less than 2% total

additional loss.

Auxiliary Windings—Suppressing Burst Mode

Operation

The LTC1159 synchronous switch removes the normal

limitation that power must be drawn from the inductor

primary winding in order to extract power from auxiliary

windings. With synchronous switching, auxiliary outputs may be loaded without regard to the primary output

load, providing that the loop remains in continuous

mode operation.

Burst Mode operation can be suppressed at low output

currents with a simple external network that cancels the

0.025V minimum current comparator threshold. This technique is also useful for eliminating audible noise from

, but is “chopped” between the P-channel and

SENSE

, then the resistance of one

DS(ON)

to obtain I2R losses. For example, if each

SENSE

= 0.1Ω, RL = 0.15Ω, and R

DS(ON)

Transition Loss ≈ 5(VIN)2(I

)(C

MAX

ESR dissipative losses,

OUT

= 0.05Ω, then

SENSE

)(f)

RSS

13

Page 14

LTC1159

LTC1159-3.3/LTC1159-5

WUUU

APPLICATIO S I FOR ATIO

certain types of inductors in high current (I

OUT

> 5A)

applications when they are lightly loaded.

An external offset is put in series with the SENSE– pin to

subtract from the built-in 0.025V offset. An example of this

technique is shown in Figure 7. Two 100Ω resistors are

inserted in series with the leads from the sense resistor.

With the addition of R3, a current is generated through R1

causing an offset of:

V

OFFSET

LTC1159

= V

SENSE

SENSE

OUT

9

+

8

–

R1

)

R1 + R3

1000pF

)

R

3

SENSE

LTC1159 • F07

21

4

+

C

OUT

L

R2

100Ω

R1

100Ω

R3

If V

> 0.025V, the minimum threshold will be

OFFSET

cancelled and Burst Mode operation is prevented from

occurring. Since V

is constant, the maximum load

OFFSET

current is also decreased by the same offset. Thus, to get

back to the same I

, the value of the sense resistor must

MAX

be reduced:

R

SENSE

75

≈ mΩ

I

MAX

To prevent noise spikes from erroneously tripping the

current comparator, a 1000pF capacitor is needed across

the SENSE– and SENSE+ pins.

Board Layout Checklist

When laying out the printed circuit board, the following

checklist should be used to ensure proper operation of the

LTC1159. These items are also illustrated graphically in

the layout diagram of Figure 8. Check the following in your

layout:

Figure 7. Suppressing Burst Mode Operation

BOLD LINES INDICATE HIGH CURRENT PATHS

1N4148

0.15µF

1µF

+

1

P-GATE

2

V

IN

3

4

5

6

7

8

V

CC

P-DRIVE

V

CC

C

T

I

TH

SENSE

–

0.1 µF

3300pFC

T

1k

CAP

SHDN2

EXTV

N-GATE

PGND

SGND

V

(SHDN1)

SENSE

1000pF

CC

FB

+

16

15

14

13

12

11

10

9

SHUTDOWN

100pF

P-CHANNEL

5V EXTV

CONNECTION

R1

R2

+

C

IN

+

D1

N-CHANNEL

V

IN

–

L

CC

OUTPUT DIVIDER

REQUIRED WITH

ADJUSTABLE

VERSION ONLY

–

3

C

OUT

+

1

V

OUT

R

SENSE

2

4

+

14

LTC1159 • F08

Figure 8. LTC1159 Layout Diagram (N and S Packages)

Page 15

WUUU

APPLICATIO S I FOR ATIO

LTC1159

LTC1159-3.3/LTC1159- 5

1) Are the signal and power grounds segregated? The

LTC1159 signal ground must connect separately to the

(–) plate of C

. The other ground pin(s) should return to

OUT

the source of the N-channel MOSFET, anode of the Schottky diode and (–) plate of CIN, which should have as short

lead lengths as possible.

2) Does the LTC1159 SENSE– pin connect to a point close

to R

and the (+) plate of C

SENSE

? In adjustable applica-

OUT

tions, the resistive divider R1, R2 must be connected

between the (+) plate of C

3

) Are the SENSE– and SENSE+ leads routed together

and signal ground.

OUT

with minimum PC trace spacing? The differential

decoupling capacitor between the two SENSE pins should

be as close as possible to the LTC1159. Up to 100Ω may

be placed in series with each sense lead to help decouple

the SENSE pins. However, when these resistors are used,

the capacitor should be no larger than 1000pF.

4) Does the (+) plate of CIN connect to the source of the

P-channel MOSFET as closely as possible? An additional

0.1µF ceramic capacitor between VIN and power ground

may be required in some applications.

5) Is the VCC decoupling capacitor connected closely between the VCC pins of the LTC1159 and power ground?

This capacitor carries the MOSFET driver peak currents.

6) In adjustable versions, the feedback pin is very sensitive

to pickup from the switch node. Care must be taken to

isolate VFB from possible capacitive coupling of the inductor switch signal.

7) Is the SHDN1 pin actively pulled to ground during

normal operation? SHDN1 is a high impedance pin and

must not be allowed to float.

Troubleshooting Hints

Since efficiency is critical to LTC1159 applications it is very

important to verify that the circuit is functioning correctly

in both continuous and Burst Mode operation. The waveform to monitor is the voltage on the CT pin .

In continuous mode (I

a sawtooth with a 0.9V

> I

LOAD

swing. This voltage should never

P-P

) the voltage should be

BURST

dip below 2V as shown in Figure 9a. When the load current

is low (I

LOAD

< I

), Burst Mode operation should occur

BURST

with the CT waveform periodically falling to ground as

shown in Figure 9b.

If the CT pin is observed falling to ground at high output

currents, it indicates poor decoupling or improper grounding. Refer to the Board Layout Checklist.

3.3V

(a) CONTINUOUS MODE OPERATION

(b) Burst Mode OPERATION

Figure 9. CT Pin 6 Waveforms

0V

3.3V

0V

LTC1159 • F09

15

Page 16

LTC1159

LTC1159-3.3/LTC1159-5

U

TYPICAL APPLICATIO S

1N4148

1N4148

V

IN

8V TO 20V5V

+

IRF7205

47µF

25V × 2

OS-CON

1µF

WIMA

1

0.15µF

0.1µF

+

3.3µF

1000pF

0.047µF

2k 10k

2

3

4

5

6

7

8

*MAGNETICS 77120-A7 CORE, 16T 18GA. WIRE

**KRL SL-1-R020J

Figure 10. High Efficiency 8V to 20V Input 2.5/5A Output Regulator

1N4148 1N4148

1

P-GATE

0.15µF

0.1µF

+

1µF

270pF

3300pF

1k

2

V

IN

3

V

CC

4

P-DRIVE

LTC1159-3.3

5

V

CC

6

C

T

7

I

TH

8

–

SENSE

*COILTRONICS CTX20-4

**KRL SL-1/2-R040J

P-GATE

V

IN

V

CC

P-DRIVE

V

CC

C

T

I

TH

SENSE

CAP

SHDN2

EXTV

N-GATE

PGND

SGND

SHDN1

SENSE

LTC1159

–

16

15

14

CC

13

12

11

10

9

+

CAP

SHDN2

EXTV

N-GATE

PGND

SGND

V

SENSE

16

15

14

CC

13

12

11

10

FB

9

+

V

IN

4V TO 20V

SHUTDOWN

100pF

1000pF

+

Si9435DY

Si9410DY MBRS130LT3

SHUTDOWN

0.01µF

47µF

25V

OS-CON

IRF7201IRF7201 MBRS330

10k

1%

100Ω

100Ω

10k

1%

0.1µF

BAT85

L*

15µH

L*

20µH

VN2222LL

0.22µF

**

R

SENSE

0.02Ω

3

BAT85

BAT85

3

R

21

4

LTC1159 • F10

SENSE

0.04Ω

V

OUT

2.5V/5A

+

330µF

6.3V × 3

AVX

**

21

V

OUT

3.3V/2.5A

4

+

330µF

6.3V × 2

AVX

+

1µF

LTC1159 • F11

16

Figure 11. 5:1 Input Range (4V to 20V) High Efficiency 3.3V/2.5A Regulator

Page 17

TYPICAL APPLICATIO S

U

12V

LTC1159

LTC1159-3.3/LTC1159- 5

V

IN

15V TO 40V

+

MPSA06

MPSA56

10µF

0.33µF

0.1µF

750pF

1N4148 1N4148

1

P-GATE

0.15µF

0.047µF

470Ω

2

V

IN

3

V

CC

4

P-DRIVE

LTC1159-5

5

V

CC

6

C

T

7

I

TH

8

–

SENSE

*HURRICANE LAB HL-KK122T/BB

**DALE LVR-3-0.01

CAP

SHDN2

EXTV

N-GATE

PGND

SGND

SHDN1

SENSE

16

15

14

CC

13

12

11

10

9

+

1N4148

MPSA56

SHUTDOWN

1000pF

18k

SMP40P06

HEAT SINK

MTP75N05HD

100Ω

100Ω

L*

22µH

MBR350

Figure 12. High Current, High Efficiency 15V to 40V Input 5V/10A Output Regulator

+

3

R

1200µF

50V × 2

LXF

SENSE

0.01Ω

**

21

4

LTC1159 • F12

1µF

WIMA

V

OUT

5V/10A

220µF

+

10V × 3

OS-CON

1N4148 1N4148

1

P-GATE

0.15µF

0.1µF

+

3.3µF

390pF

3300pF

470Ω

2

3

4

5

6

7

8

V

IN

V

CC

P-DRIVE

V

CC

C

T

I

TH

SENSE

LTC1159

–

CAP

SHDN2

EXTV

N-GATE

PGND

SGND

V

SENSE

CC

FB

+

VN2222LL

Figure 13. High Efficiency 15V to 40V Input 12V/5A Output Regulator

V

IN

15V TO 40V

+

100µF

63V × 2

Si4401DY

5M

16

15

14

13

12

11

10

9

100pF

1000pF

Si4840DY

10.5k

90.9k

1%

0V = NORMAL

>3V = SHUTDOWN

1%

100Ω

100Ω

SXC

L*

50µH

R

0.02Ω

3

MBR350

*COILTRONICS CTX50-5-KM

**IRC LO-3-0.02 ±5%

SENSE

**

21

1µF

WIMA

4

+

LTC1159 • F13

V

OUT

12V/5A

150µF

16V × 2

OS-CON

17

Page 18

LTC1159

LTC1159-3.3/LTC1159-5

U

TYPICAL APPLICATIO S

V

IN

5.5V TO 24V

BAS16 BAS16

0.22µF

+

2.2µF

1000pF

1k

0.33µF

2200pF

1

2

3

4

5

6

7

8

P-GATE

V

IN

V

CC

P-DRIVE

V

CC

C

T

I

TH

SENSE

LTC1159

–

1000pF

CAP

SHDN2

EXTV

N-GATE

PGND

SGND

SENSE

CC

V

FB

+

16

15

0V = NORMAL

>2V = SHUTDOWN

14

Si9410DY

13

12

11

10

9

56pF

BAS16

+

10µF

100Ω

100Ω

24.9k

1%

Si9435DYSi9435DY

MBRS140T3

1µF

124k

1%

47µF

+

25V × 2

OS-CON

T*

•

•

•

BAS16

+

0.01µF

102k

1%

3

1

**

R

SENSE

0.02Ω

2

4

*HURRICANE LAB HL-8700

**KRL SL-1-R020J

100k

1µF

WIMA

5V

OUTPUT

+

Si9410DY

1k

BAS16

LTC1159 • F14

220µF

10V × 4

+

AVX

220µF

10V × 2

AVX

3.3V

OUTPUT

Figure 14. 17W Dual Output High Efficiency 5V and 3.3V Regulator

PACKAGE DESCRIPTIO

5.20 – 5.38**

(.205 – .212)

.13 – .22

(.005 – .009)

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

*

DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED .152mm (.006") PER SIDE

**

DIMENSIONS DO NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED .254mm (.010") PER SIDE

.55 – .95

(.022 – .037)

MILLIMETERS

(INCHES)

° – 8°

0

U

G Package

20-Lead Plastic SSOP (5.3mm)

(Reference LTC DWG # 05-08-1640)

.65

(.0256)

BSC

.25 – .38

(.010 – .015)

1.73 – 1.99

(.068 – .078)

.05 – .21

(.002 – .008)

7.07 – 7.33*

(.278 – .289)

1718 14 13 12 1115161920

12345678910

7.65 – 7.90

(.301 – .311)

G20 SSOP 0501

18

Page 19

PACKAGE DESCRIPTIO

U

N Package

16-Lead PDIP (Narrow .300 Inch)

(Reference LTC DWG # 05-08-1510)

15

16

0.255 ± 0.015*

(6.477 ± 0.381)

2

1

LTC1159

LTC1159-3.3/LTC1159- 5

0.770*

(19.558)

MAX

14

3

12

13

4

11

6

5

910

8

7

0.300 – 0.325

(7.620 – 8.255)

0.009 – 0.015

(0.229 – 0.381)

+0.035

0.325

–0.015

+0.889

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

0.020

(0.508)

MIN

0.130 ± 0.005

(3.302 ± 0.127)

0.125

(3.175)

MIN

S Package

16-Lead Plastic Small Outline (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1610)

16

0.228 – 0.244

(5.791 – 6.197)

0.100

(2.54)

BSC

15

0.045 – 0.065

(1.143 – 1.651)

0.386 – 0.394*

(9.804 – 10.008)

13

14

0.065

(1.651)

TYP

0.018 ± 0.003

(0.457 ± 0.076)

N16 1098

12

11

10

9

0.150 – 0.157**

(3.810 – 3.988)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0° – 8° TYP

0.016 – 0.050

(0.406 – 1.270)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

4

5

0.050

(1.270)

BSC

3

2

1

7

6

8

0.004 – 0.010

(0.101 – 0.254)

S16 1098

19

Page 20

LTC1159

LTC1159-3.3/LTC1159-5

U

TYPICAL APPLICATIO

1N4148

0.15µF

Q1

Si9435

V

IN

= 12V

0.1

+

330

µ

µ

F

F

35V

NICHICON

SHUTDOWN

5V OR 3.3V

Q3

TP0610L

20k

510k

*

DALE TJ4-100-1

IRC LR2512-01-R050-J

**

C

390pF

5.1V

1N5993

µ

10.5k

90.5k

Q2

Si9410

150µF

16V × 2

+

OS-CON

MBRS140

L*

µ

H

100

OUTPUT

–12V/1A

3

1

R

**

SENSE

0.05Ω

2

4

1159 F15

1

P-GATE

2

V

IN

3

4

5

6

7

8

100Ω

V

CC

P-DRIVE

V

CC

C

T

I

TH

SENSE

0.1µF

1N5818

T

6800pF

1k

LTC1159

3.3

µ

+

–

1000pF

EXTV

N-GATE

F

(SHDN1)

SENSE

CAP

SHDN2

PGND

SGND

V

16

15

14

CC

13

12

11

10

FB

9

+

100Ω

200pF

Q4

2N7002

Figure 15. High Efficiency 12V to –12V 1A Converter

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1628 2-Phase, Dual Step-Down Controller VIN ≤ 36V, Minimum CIN, Current Mode

LTC1702 550kHz Dual, 2-Phase Step-Down Controller Minimum CIN, No Sense Resistor Required, VIN ≤ 7V

LTC1735 Synchronous Step-Down Controller 3.5V ≤ VIN ≤ 36V, 0.8V ≤ V

LTC1773 550kHz Synchronous Step-Down Controller 2.65V ≤ VIN ≤ 8.5V, 0.8V ≤ V

LTC1778 No R

TM

Step-Down Controller No Sense Resistor Required, t

SENSE

LTC1876 Triple Output, 2-Phase Controller Two, 2-Phase Step-Down Controllers and Step-Up DC/DC Converter in One IC

No R

is a trademark of Linear Technology Corporation.

SENSE

Linear Technology Corporation

20

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

≤ 6V, Synchronizable

OUT

≤ VIN, Synchronizable to 750kHz, MS10

OUT

≤ 100ns, Current Mode, GN16

ON(MIN)

1159fa LT/TP 0801 2K REV A • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1994

Loading...

Loading...