Page 1

LT3595

1

3595f

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

True Color PWM is a trademark of Linear Technology Corporation. All other trademarks are

the property of their respective owners.

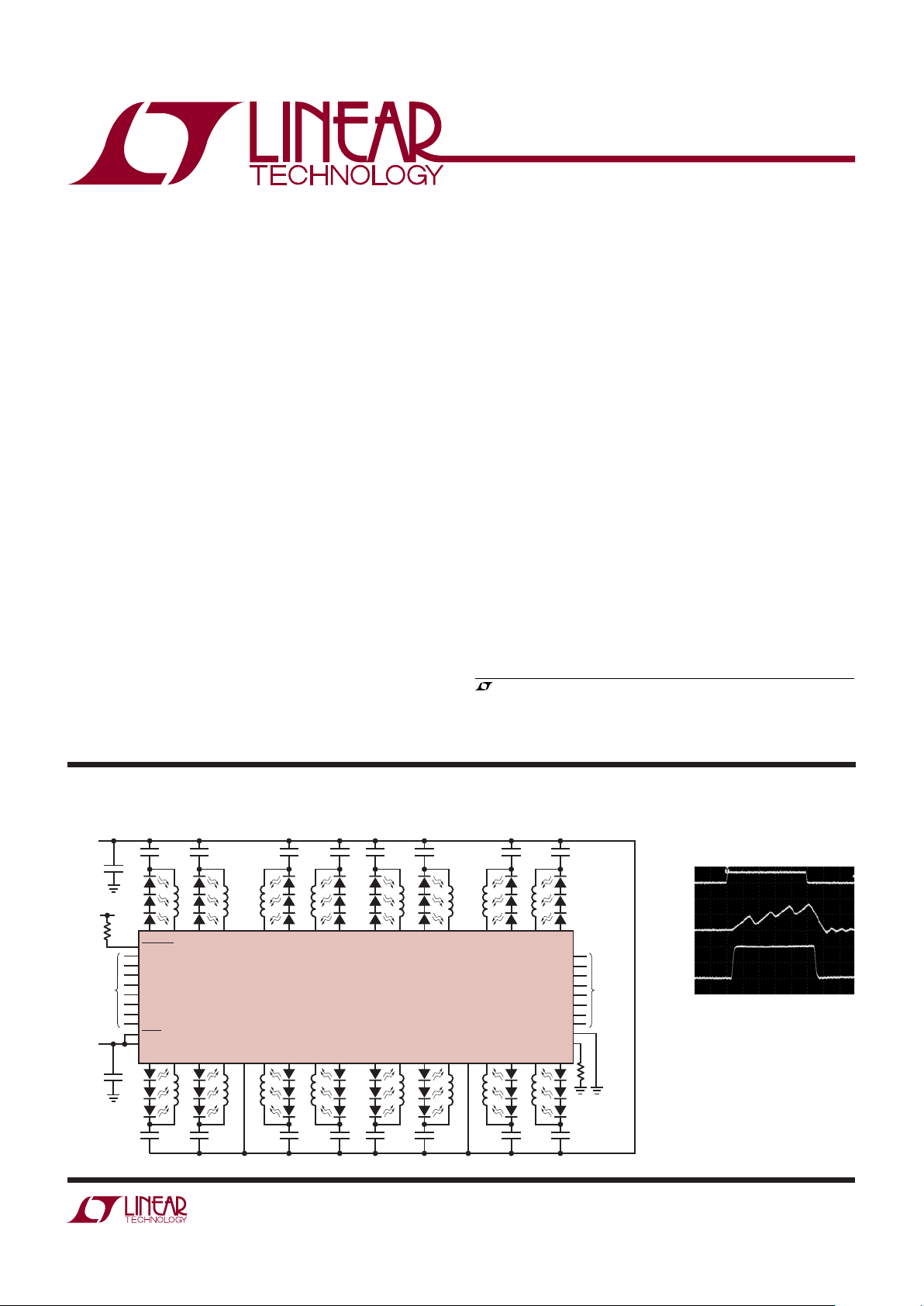

TYPICAL APPLICATION

FEATURES

APPLICATIONS

DESCRIPTION

16 Channel

Buck Mode LED Driver

The LT®3595 is a high performance LED Driver designed

to drive sixteen independent channels of up to 10 LEDs

at currents up to 50mA. Series connection of the LEDs

provides identical LED currents resulting in uniform brightness. Power switches, Schottky diodes, and compensation

components are all internal, providing a small converter

footprint and lower component cost. The high 2MHz

switching frequency permits the use of tiny, low profi le

inductors and capacitors. A fi xed frequency, current mode

architecture results in stable operation over a wide range

of supply and output voltage.

A single external resistor sets the LED current for all sixteen

channels, and dimming is then controlled for each channel

by pulse width modulating the individual PWM pins. Relative current matching among the sixteen drivers is 8% and

the PWM dimming range is 5000:1. The part is available

in a 5mm × 9mm × 0.75mm 56-pin QFN package.

16-Channel LED Driver (Three LEDs per Channel), 20mA Current

■

4.5V to 45V Input Supply Range

■

Up to 50mA LED Current per Channel

■

100mA, 45V Internal Switches

■

8% Relative LED Current Match at 20mA

■

16 Independent LED Channels

■

5000:1 True Color PWMTM Dimming Range

■

LEDs Disconnected in Shutdown

■

Internal Schottky Diodes

■

Low Quiescent Current

■

2MHz Switching Frequency

■

R

SET

Pin Sets Master LED Current

■

Typical Effi ciency: 92%

■

Open LED Detection and Thermal Protection

■

56-Pin 5mm × 9mm × 0.75mm QFN Package

■

LED Video Billboards

■

LCD Televisions

■

Stadium and Advertising Displays

5000:1 PWM

Dimming at 100Hz

V

IN

15V TO

45V

LED

BRIGHTNESS

CONTROL

V

CC

3V TO

5.5V

V

CC

0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF

0.47

μF

10

μF

10

μF

100k

75.0k

0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF

3595 TA01

OPENLED

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

PWM7

PWM8

V

CC

PWM9

PWM10

PWM11

PWM12

PWM13

PWM14

PWM15

PWM16

GND

R

SET

L1 SW1 SW2 L4SW3 SW7L3 SW4 L5 L6SW5 SW6L2 L7 SW8 L8

L16 SW16 SW15 V

IN

L13SW14 VINSW10L14 SW13 L12 L11SW12 SW11L15 L10 SW9 L9

100μH

100

μH

100

μH

100μH100

μH

100μH

100

μH

100μH

100

μH

100

μH

100

μH

100μH100

μH

100μH

100

μH

100μH

SHDN

LT3595

LED

BRIGHTNESS

CONTROL

400ns/DIV

I

LED

10mA/DIV

I

SW

20mA/DIV

V

PWM

5V/DIV

3595 TA01

b

V

IN

= 15V

3 LEDS AT 20mA

T = 10ms

T

ON

= 2μs

Page 2

LT3595

2

3595f

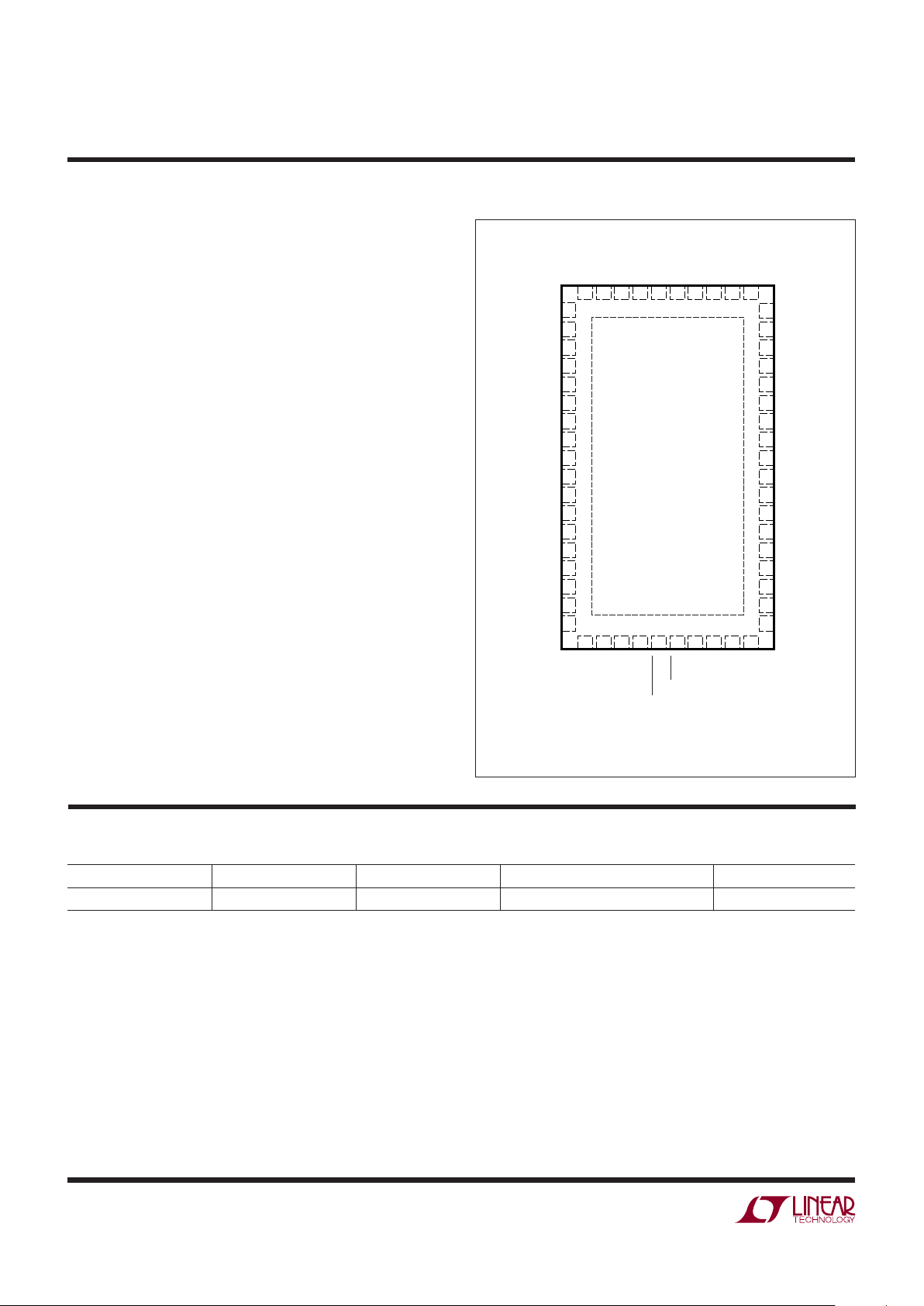

PIN CONFIGURATIONABSOLUTE MAXIMUM RATINGS

Input Voltage (VIN) ....................................................45V

L1-16 Voltage ...........................................................45V

Supply Voltage (V

CC

) ..................................................6V

R

SET

, ⎯O⎯P⎯E⎯N⎯L⎯E⎯D , PWM1-16, ⎯S⎯H⎯D⎯N Voltage ...............6V

Operating Junction Temperature Range

(Note 2) ...............................................–40°C to 85°C

Maximum Junction Temperature .......................... 125°C

Storage Temperature Range ...................–65°C to 125°C

(Note 1)

19 20 21 22

TOP VIEW

57

UHH PACKAGE

56-LEAD (5mm × 9mm) PLASTIC QFN

23 24 25 26 27 28

56 55 54 53 52 51 50 49 48 47

39

40

41

42

43

44

45

46

8

7

6

5

4

3

2

1L16

SW16

L15

SW15

V

IN

SW14

L14

SW13

L13

L12

SW12

L11

SW11

V

IN

SW10

L10

SW9

L9

L1

SW1

L2

SW2

NC

SW3

L3

SW4

L4

L5

SW5

L6

SW6

NC

SW7

L7

SW8

L8

PWM16

PWM15

PWM14

PWM13

VCCR

SET

PWM4

PWM3

PWM2

PWM1

38

37

36

35

34

33

32

31

30

29

9

10

11

12

13

14

15

16

17

18

PWM9

PWM10

PWM11

PWM12

OPENLED

SHDN

PWM5

PWM6

PWM7

PWM8

T

JMAX

= 125°C, θJA = 31°C/W, θJC = 0.5°C/W

EXPOSED PAD (PIN 57) IS GND, MUST BE SOLDERED TO PCB

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3595EUHH#PBF LT3595EUHH#TRPBF 3595 56-Lead (5mm × 9mm) Plastic QFN –40°C to 85°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

Consult LTC Marketing for information on non-standard lead based fi nish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

Page 3

LT3595

3

3595f

ELECTRICAL CHARACTERISTICS

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

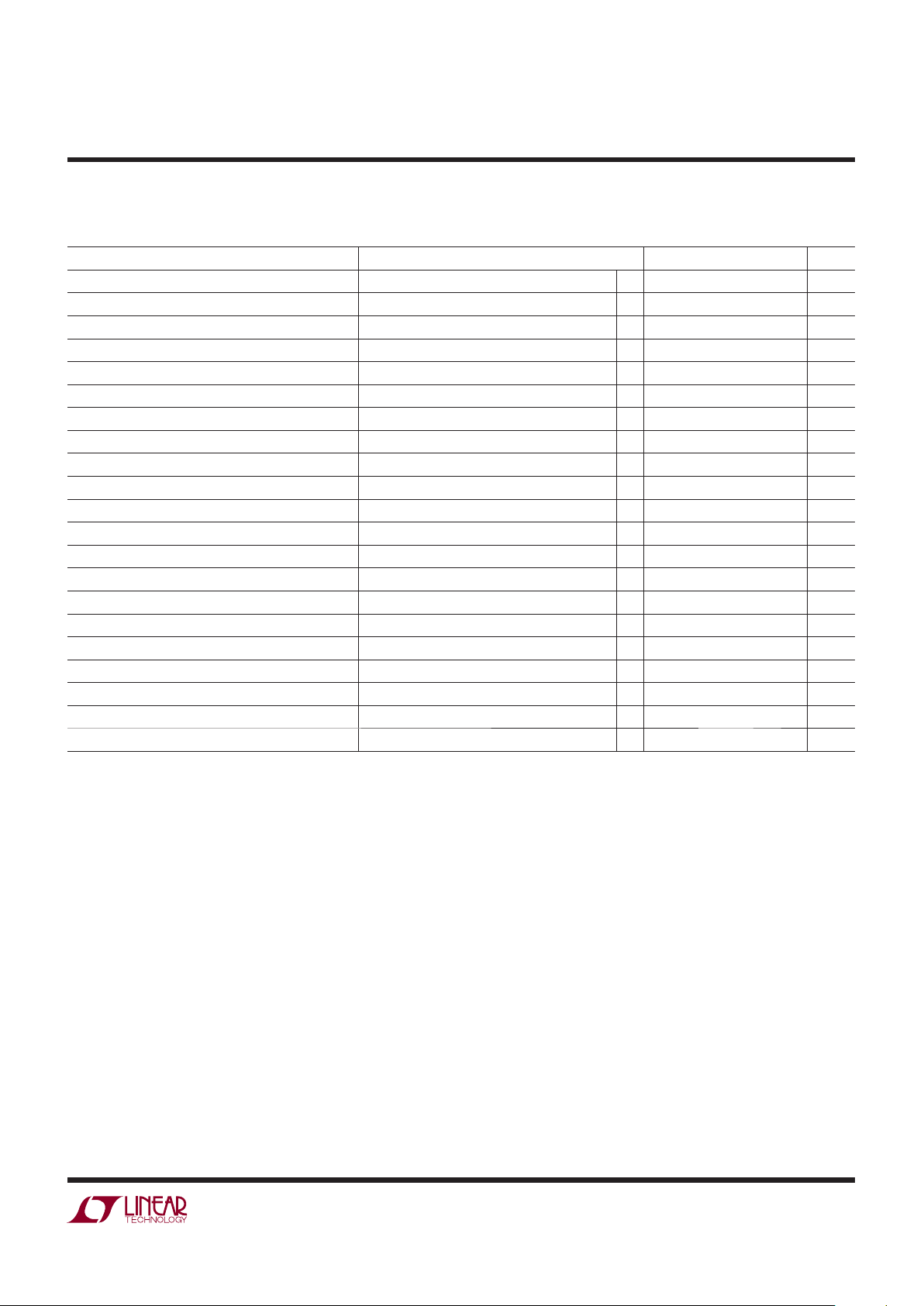

PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN

Operating Voltage

4.5 V

V

CC

Operating Voltage

3 5.5 V

V

CC

Input Under Voltage Lockout

2.6 2.9 V

I

VIN

Quiescent Current ON, No Switching VIN = 45V 0.25 mA

I

VIN

Quiescent Current in Shutdown VIN = 45V, ⎯S⎯H⎯D⎯N = 0V 15 40 μA

I

VCC

Quiescent Current ON, No Switching VCC = 3.3V 17 mA

I

VCC

Quiescent Current in Shutdown VCC = 3.3V, ⎯S⎯H⎯D⎯N = 0V 3 10 μA

I

L1-16

Output Current Accuracy R

SET

= 75.0kΩ 18.4 20 21.6 mA

Switching Frequency 1.622.4MHz

Maximum Duty Cycle

●

78 83 %

Switch Current Limit

●

90 120 150 mA

Switch V

CESAT

ISW1-16 = 50mA 450 mV

Switch Leakage Current VSW1-16 = 45V 0.1 6 μA

Schottky Forward Drop I

SCHOTTKY

= 50mA 0.8 V

Schottky Leakage Current V

IN

= 45V, V

SW1-16

= 0.7V, ⎯S⎯H⎯D⎯N = 0V 0.1 4 μA

⎯S⎯H⎯D⎯

N, PWM1-16 Input Low Voltage 0.4 V

⎯S⎯H⎯D⎯

N, PWM1-16 Input High Voltage 1.6 V

⎯S⎯H⎯D⎯

N Pin Bias Current

⎯S⎯H⎯D⎯

N = 3.3V 35 μA

PWM1-16 Pin Bias Current PWM1-16 = 3.3V 0.1 1 μA

⎯O⎯P⎯E⎯N⎯L⎯E⎯

D Pin Voltage VCC = 3.3V, I

⎯O⎯P⎯E⎯N⎯L⎯E⎯

D

= 200μA 0.12 V

⎯O⎯P⎯E⎯N⎯L⎯E⎯

D Pin Input Leakage Current

⎯O⎯P⎯E⎯N⎯L⎯E⎯

D = 3.3V 0.1 1 μA

The ● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

A

= 25°C, VIN = 45V, VCC = 3.3V, PWM = ⎯S⎯H⎯D⎯N = ⎯O⎯P⎯E⎯N⎯L⎯E⎯D = 3.3V, R

SET

= 75kΩ,

GND = 0V, unless otherwise noted.

Note 2: The LT3595 is guaranteed to meet performance specifi cations

from 0°C to 85°C junction temperature. Specifi cations over the – 40°C

to 85°C operating junction temperature range are assured by design,

characterization and correlation with statistical process controls.

Page 4

LT3595

4

3595f

R

SET

RESISTANCE (kΩ)

25

LED CURRENT (mA)

30

50

40

60

50 150

20

10

0

75 100 125

3595 G05

DUTY CYCLE (%)

0.01

LED CURRENT (mA)

1

10

100

0.1

0.01

0.001

0.1

1

10

100

3595 G04

VIN = 45V

10 LEDS AT 20mA

PWM FREQUENCY = 100Hz

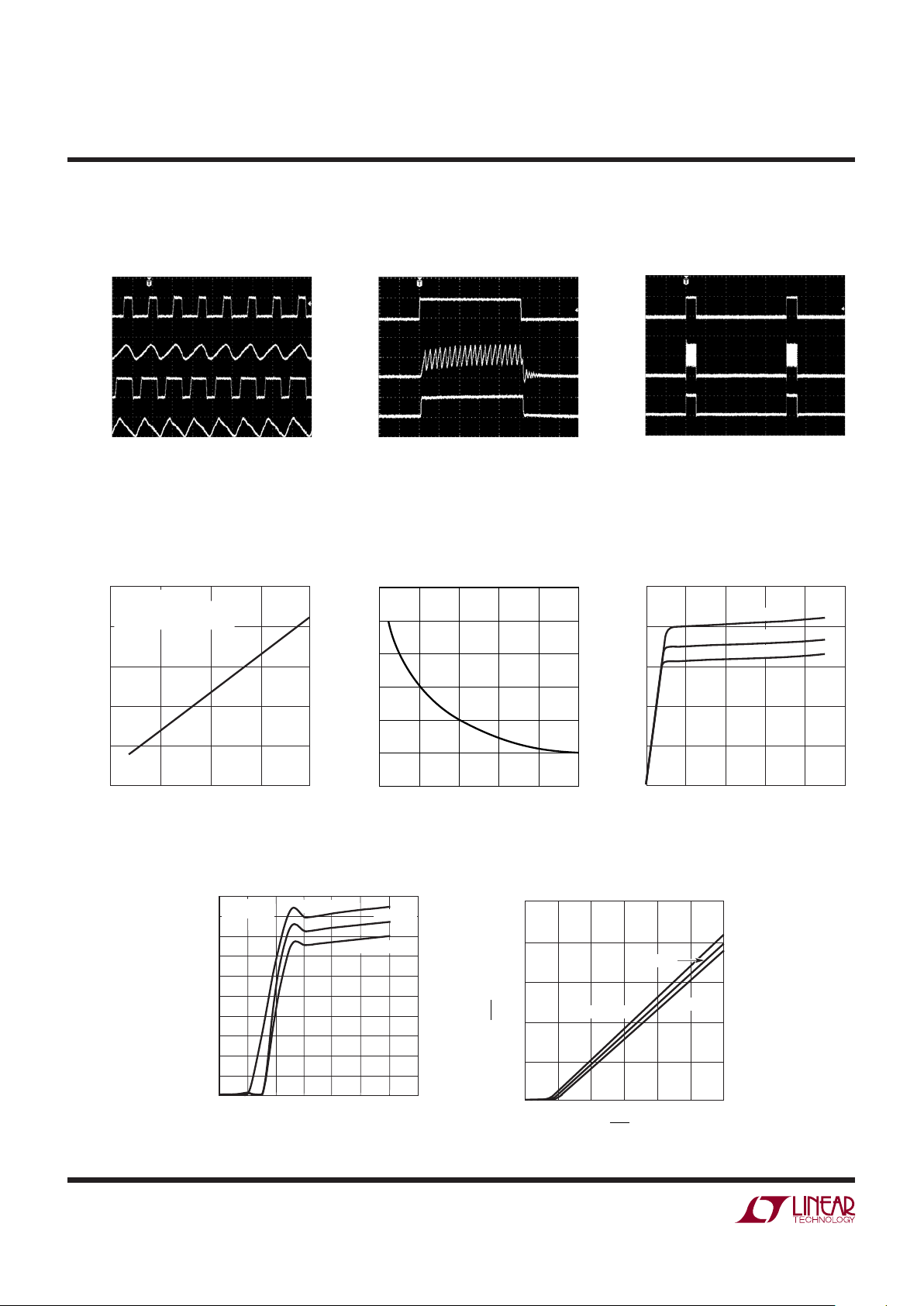

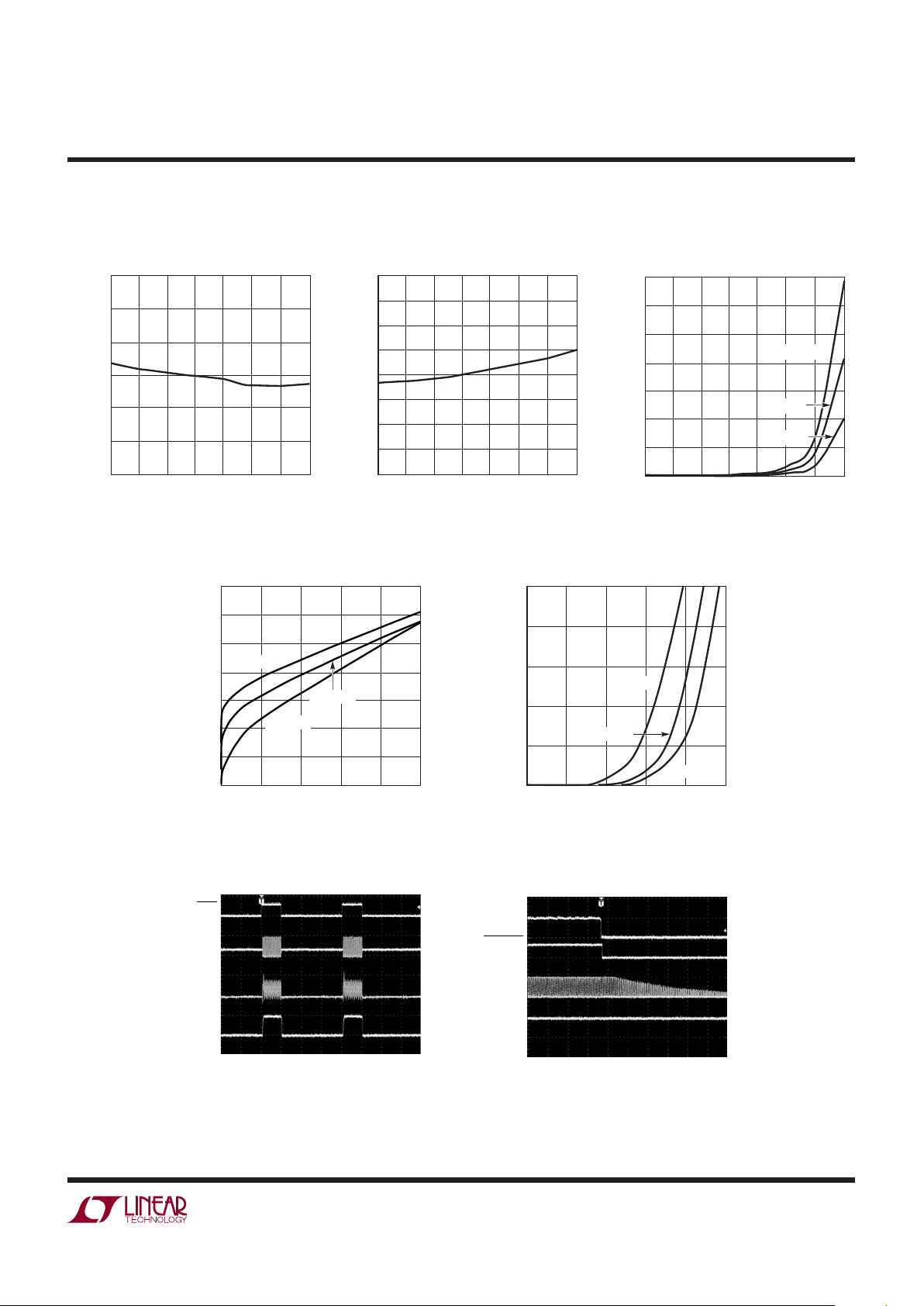

TYPICAL PERFORMANCE CHARACTERISTICS

Switching Waveforms

PWM Dimming Waveforms

(1000:1)

LED Current vs PWM Duty Cycle

Wide Dimming Range (5000:1)

LED Current vs R

SET

Resistance

VIN Quiescent Current

VCC Quiescent Current

⎯S⎯H⎯D⎯

N Pin Bias Current

PWM Dimming Waveforms

(10:1)

VIN (V)

0

V

IN

CURRENT (mA)

1.2

1.6

2.0

40

0.8

0.4

0

10

20

30

50

3595 G06

T = 25°C

T = 125°C

T = – 40°C

400ns/DIV

10 LEDS

V

SW1

50V/DIV

10 LEDS

I

L1

50mA/DIV

5 LEDS

V

SW2

50V/DIV

5 LEDS

I

L2

50mA/DIV

3595 G01

V

IN

= 45V

I

LED

= 20mA

2μs/DIV

I

LED

20mA/DIV

I

L

20mA/DIV

PWM

5V/DIV

3595 G02

V

IN

= 40V

10 LEDS AT 20mA

PWM FREQUENCY = 100H

z

TON = 10μs

2ms/DIV

I

LED

20mA/DIV

I

L

20mA/DIV

PWM

5V/DIV

3595 G03

V

IN

= 40V

10 LEDS AT 20mA

PWM FREQUENCY = 100H

z

TON = 1ms

V

CC

(V)

0

0

V

CC

CURRENT (mA)

2

6

8

10

20

14

2

4

5

4

16

18

12

1

3

6

7

3595 F07

T = 125°C

T = –40°C

T = 25°C

VCC = 3.3V

0

0

20

40

60

80

100

1

234

56

3595 F08

T = 125°C

T = –40°C

I

SHDN

(μA)

T = 25°C

V

SHDN

(V)

Page 5

LT3595

5

3595f

Current Limit vs Temperature

TYPICAL PERFORMANCE CHARACTERISTICS

Switching Frequency

vs Temperature

Schottky Leakage Current

vs Temperature

Switch Saturation Voltage

(V

CESAT

)

Schottky Forward Voltage Drop

Transient Response

⎯O⎯P⎯E⎯N⎯L⎯E⎯

D Waveforms

TEMPERATURE (°C)

–50

130

140

150

25 75

120

110

–25 0

50 100 125

100

90

CURRENT LIMIT (mA)

3595 G09

TEMPERATURE (°C)

–50

2.0

2.2

2.1

2.3

2.4

25 75

1.9

1.8

–25 0

50 100 125

1.7

1.6

SWITCHING FREQUENCY (MHz)

3595 G10

TEMPERATURE (°C)

–50

0.8

1.0

1.4

25 75

0.6

0.4

–25 0

50 100 125

0.2

0

1.2

SCHOTTKY LEAKAGE CURRENT (μA)

3595 G11

VIN = 45V

VIN = 24V

VIN = 4.5V

SWITCH CURRENT (mA)

0

500

600

700

80

400

300

20 40 60 100

200

100

0

SWITCH SATURATION VOLTAGE (mV)

T = 125°C

T = –40°C

T = 25°C

SCHOTTKY FORWARD DROP (V)

0

SCHOTTKY FORWARD CURRENT (mA)

60

80

100

0.8

40

20

0

0.2

0.4

0.6

1

3595 G13

T = 125°C

T = – 40°C

T = 25°C

100μs/DIV

V

SW

50V/DIV

I

SW

50mA/DIV

I

LED

20mA/DIV

3595 G1

4

V

IN

= 45V

10 LEDS AT 20mA

V

SHDN

5V/DIV

20μs/DIV

V

SW

CH 1

50V/DIV

I

LED

CH 2

20mA/DIV

I

LED

CH 1

20mA/DIV

3595 G1

5

OPENLED

5V/DIV

V

IN

= 45V

10 LEDS AT 20mA

Page 6

LT3595

6

3595f

PIN FUNCTIONS

L1-16 (Pins 1, 3, 7, 9, 10, 12, 16, 18, 29, 31, 35, 37,

38, 40, 44, 46): LED Pins. Connection point for the anode

of the highest LED in each string.

SW1-16 (Pins 2, 4, 6, 8, 11, 13, 15, 17, 30, 32, 34,

36, 39, 41, 43, 45): Switch Pins. Minimize trace area

at these pins to minimize EMI. Connect the inductors to

these pins.

V

IN

(Pins 5, 14): 4.5V to 45V Input Supply Pin.

Must be locally bypassed. Both V

IN

pins must be tied

together.

PWM1-16 (Pins 19-22, 25-28, 47-50, 53-56): Input Pin

for LED Dimming Function. The rising edge of each channel

must be synchronized.

⎯O⎯P⎯E⎯N⎯L⎯E⎯

D (Pin 23): Open Collector Output for Reporting

Faults. If any channel experiences an open LED connection, the

⎯O⎯P⎯E⎯N⎯L⎯E⎯

D pin is pulled low.

⎯S⎯H⎯D⎯

N (Pin 24): Shutdown. Tie to 1.6V or greater to enable

the device. Tie below 0.4V to turn off the device.

NC (Pins 33, 42): No Connect. Connect these pins to

ground.

R

SET

(Pin 51): External Resistor to Set the Master LED

Current. The LED current is equal to:

I

V

R

LED

SET

=

121

1240

.

•

where R

SET

is the value of the external resistor. Use a

kelvin for ground metal.

V

CC

(Pin 52): 3.3V Input Supply. Must be locally by-

passed.

Exposed Pad (Pin 57): Ground. The Exposed Pad must

be soldered to PCB. Use wide metal from backtab to the

grounds of the input capacitors on V

CC

and VIN.

Page 7

LT3595

7

3595f

BLOCK DIAGRAM

3595 BD

+

–

57

23

52

24

51

DFC

CONTROL

RAMP

GENERATOR

R

S

V/I

Q

2MHz

OSCILLATOR

Σ

CONTROL

ISNS

1 CHANNEL

16X

VREG

V

REG

V

CC

3.3V

L1-16

SW1-16

OPENLED

GND

V

IN

C1

10

μF

R

SET

V

CC

SHDN

R

SET

L

1-16

100μH

C

OUT1-16

0.47μF

C

IN

10μF

V

IN

PWM1-16

REF

+

–

PWM

Page 8

LT3595

8

3595f

OPERATION

The LT3595 uses a constant-frequency, current mode

control scheme to provide excellent line and load regulation. Operation is best understood by referring to the Block

Diagram. The oscillator, V-I converter and internal regulator

are shared by the sixteen converters. The control circuitry,

power switches, PWM comparators and dimming control

(DFC) are identical for all converters.

The LT3595 enters shutdown mode when the

⎯S⎯H⎯D⎯

N pin

is lower than 400mV. If the

⎯S⎯H⎯D⎯

N pin is above 1.6V,

then the LT3595 turns on. At the start of each oscillator

cycle, the power switch is turned on. Current ramps up

through the output capacitor, the inductor, and the switch

to ground. When the voltage across the output capacitor

is larger than the LEDs’ forward voltage, current fl ows

through the LEDs.

When the switch is on, a voltage proportional to the switch

current is added to a stabilizing ramp and the resulting

sum is fed into the positive terminal of the PWM comparator. When this voltage exceeds the level at the negative

input of the PWM comparator, the PWM logic turns off

the power switch. The level at the negative input of the

PWM comparator is set by the error amplifi er output. This

voltage is set by the LED current and the bandgap reference. In this manner, the error amplifi er sets the correct

peak current level in the inductor to keep the LED output

current in regulation. The external R

SET

resistor is used

to program the LED current from 10mA to 50mA.

Input Voltage Range

The minimum input voltage required to generate a specifi c

output voltage in an LT3595 application is limited by its

4.5V input voltage or by its maximum duty cycle. The duty

cycle is the fraction of time that the internal switch is on

divided by the total period. It is determined by the input

voltage and the voltage across the LEDs:

DC

VV

VV V

LED D

VIN CESAT D

=

+

−+

where V

LED

is the voltage drop across the LEDs, VD is

the Schottky forward drop, and V

CESAT

is the saturation

voltage of the internal switch. This leads to a minimum

input voltage of:

V

VV

DC

VV

IN MIN

LED D

MAX

CESAT D()

=

+

+−

where DC

MAX

is the minimum rating of maximum duty

cycle.

The maximum input voltage is limited by the absolute

maximum rating of 45V.

Pulse-Skipping

At low duty cycles, the LT3595 may enter pulse-skipping

mode. Low duty cycle occurs at higher input voltages and

lower LED count. The LT3595 can drive currents without

pulse-skipping provided the voltage across the LED

string is greater than 15% of the input supply voltage. If

the current decreases to the point that the LED voltage is

less than 15% of the input supply, the device may begin

skipping pulses. This will result in some low frequency

ripple, although the LED current remains regulated on an

average basis down to 10mA.

Page 9

LT3595

9

3595f

TYPICAL APPLICATIONS

Discontinuous Current Mode

The LT3595 can drive a 10-LED string at 15mA LED current operating in continuous conduction mode using the

recommended external components shown in the application circuit on page 1 of this data sheet. As current

is further reduced, the regulator enters discontinuous

conduction mode. The photo in Figure 1 details circuit

operation driving ten LEDs at 10mA load. The inductor

current reaches zero during the discharge phase and the

SW pin exhibits ringing. The ringing is due to the LC tank

circuit formed by the inductor in combination with the

switch and diode capacitance. This ringing is not harmful;

far less spectral energy is contained in the ringing than in

the switch transitions.

OPERATION

Figure 1. Switching Waveforms

Inductor Selection

A 100μH inductor is recommended for most LT3595

applications. Although small size and high effi ciency are

major concerns, the inductor should have low core losses

at 2MHz and low DCR (copper wire resistance). Some

inductors that meet these criteria are listed in Table 1. An

effi ciency comparison of different inductors is shown in

Figure 2.

Table 1. Inductor Manufacturers

VENDOR

PART

SERIES

INDUCTANCE

RANGE (μH)

RELEVANT TO

LT3595

DIMENSIONS

(mm)

Coilcraft

www.coilcraft.com

DO1605

LPS4012

1812FS

MSS5131

100 to 680

100 to 680

100 to 680

100 to 390

5.4 × 4.2 × 1.8

4 × 4 × 1.2

5.8 × 4.9 × 3.8

5.1 × 5.1 × 3.1

Sumida

www.sumida.com

CDC4D20 100 to 680 4.8 × 4.8 × 2

Toko

www.tokoam.com

D53LC 100 to 680 5.2 × 5.4 × 3

TDK

www.component.

tdk.com

VLCF4020T 100 to 330 4 × 4 × 2

Coiltronics

www.cooperet.com

SD3812

SD52

100 to 330

100 to 330

4 × 4 × 1.2

5.6 × 5.2 × 2

Murata

www.murata.com

LQH32M

LQH43M

100 to 560

100 to 680

3.2 × 2.5 × 2

4.5 × 3.2 × 2

Capacitor Selection

The small size of ceramic capacitors make them ideal for

LT3595 applications. Only X5R and X7R types should be

used because they retain their capacitance over wider

voltage and temperature ranges than other types such

as Y5V or Z5U. Typically, 10μF capacitors on V

IN

and

V

CC

are suffi cient. The output capacitor used across the

Figure 2. Effi ciency Comparison of Different Inductors

400ns/DIV

I

L

20mA/DIV

V

SW

20V/DIV

3595 F01

V

IN

= 45V

10 LEDS AT 10mA

I

LED

(mA)

0.01

EFFICIENCY (%)

100

95

90

85

0.1

1

10

100

3595 F02

COILCRAFT 1812FS-104KLB

COILCRAFT LPS4012-104MLB

TOKO A915AY-101M

TDK VLCF4020T-101MR26

COILTRONICS SD3812-101

COILTRONICS SD52-101

VIN = 45V

10 LEDS

L = 100μH

Page 10

LT3595

10

3595f

APPLICATIONS INFORMATION

LED string depends on the number of LEDs and can vary

from 0.47μF to 1μF. Refer to Table 2 for proper output

capacitor selection.

Table 2. Recommended Output Capacitor Values (V

LED

= 3.5V)

# LEDs C

OUT

(μF)

3-10 0.47

1-2 1

Table 3. Recommended Ceramic Capacitor Manufacturers

Taiyo Yuden (408) 573-4150

www.t-yuden.com

TDK (847) 803-6100

www.component.tdk.com

Murata (714) 852-2001

www.murata.com

Kemet (408)-986-0424

www.kemet.com

Table 3 shows a list of several ceramic capacitor manufacturers. Consult the manufacturers for detailed information

on their entire selection of ceramic parts.

Open LED Detection

The LT3595 detects an open LED on any channel and

reports it to the

⎯O⎯P⎯E⎯N⎯L⎯E⎯

D pin. The fault also reports during startup until the output voltage and LED current are

in regulation. Therefore, it can also be used as a “power

ok” signal.

Programming LED Current

The set resistor (R

SET

in the Block Diagram) controls

the LED current in all sixteen channels. LED current as

a function of the R

SET

resistance is shown in the Typical

Performance Characteristics. Common values for LED current and their required resistor values are listed in Table 4.

Since resistor error directly translates to LED current error,

precision resistors are preferred (1% is recommended).

The maximum allowed resistor value is 150k.

Table 4. LED Current vs R

SET

Resistance

R

SET

(kΩ)I

LED

(mA)

150 10

75.0 20

49.9 30

37.4 40

30.1 50

Page 11

LT3595

11

3595f

Figure 3. Timing Diagram for Multi-Channel Modulation

Dimming Control

The sixteen PWM1-16 inputs control the dimming function. Each channel is modulated by its corresponding

PWM1-16 input. On a rising edge of any PWM1-16, the

IC’s internal support circuitry is enabled and the specifi c

channel turns on. LED current fl ows in the channel until

the falling edge of the PWM1-16 input. In this way, the

average LED current is modulated. The minimum on time

APPLICATIONS INFORMATION

of a channel is 2μs and the maximum period is 10ms (at

100Hz). Therefore, the maximum dimming ratio is 5000:1.

Since the maximum R

SET

produces 10mA, the minimum

modulated LED current is 2μA.

When multiple channels are modulated, the rising edges

of PWM1-16 must be synchronized. The falling edges may

be asynchronous. A sample timing diagram is shown in

Figure 3.

3595 F03

PWM1-4

PWM5-8

PWM9-16

I

LED1-4

I

LED5-8

I

LED9-16

t

MAX

= 10ms

t

ON(MIN)

= 2μs

SYNCHRONIZED RISING EDGES

Page 12

LT3595

12

3595f

APPLICATIONS INFORMATION

Figure 4. PCB Layer 1

Figure 5. PCB Layer 2

Board Layout Considerations

As with all switching regulators, careful attention must be

paid to the PCB board layout and component placement.

To prevent electromagnetic interference (EMI) problems,

proper layout of high frequency switching paths is essential.

Minimize the length and area of all traces connected to

the SW1-16

and PWM1-16 pins. Keep the sense voltage

pins (VIN and L1-16) away from the switching nodes.

Place C

OUT1-16

and CIN close to the VIN pins. Always use

a ground plane under the switching regulator to minimize

interplane coupling. Recommended component placement

is shown in Figures 4-7.

Page 13

LT3595

13

3595f

APPLICATIONS INFORMATION

Figure 6. PCB Layer 3

Figure 7. PCB Layer 4

Page 14

LT3595

14

3595f

30W LED Driver for 160 LEDs (16 Strings, 10 LEDs per String) at 50mA

Conversion Effi ciency

TYPICAL APPLICATIONS

V

IN

45V

0.47

μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF

0.47

μF

10

μF

0.47

μF 0.47μF

0.47

μF

0.47

μF 0.47μF 0.47μF 0.47μF

3595 TA02

L1 SW1 SW2 L4SW3 SW7L3 SW4 L5 L6SW5 SW6L2 L7 SW8 L8

L16 SW16 SW15 V

IN

L13SW14 VINSW10L14 SW13 L12 L11SW12 SW11L15 L10 SW9 L9

100μH

100

μH

100

μH

100μH100

μH

100μH

100

μH

100

μH

100

μH

100

μH

100

μH

100μH100

μH

100μH

100

μH

100

μH

LT3595

LED

BRIGHTNESS

CONTROL

3V TO

5.5V

V

CC

10μF

100k

30.1k

OPENLED

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

PWM7

PWM8

V

CC

PWM9

PWM10

PWM11

PWM12

PWM13

PWM14

PWM15

PWM16

GND

R

SET

LED

BRIGHTNESS

CONTROL

SHDN

5000:1 PWM Dimming at 100Hz

I

LED

(mA)

10

EFFICIENCY (mA)

100

95

90

85

20

30

40

50

3595 TA02b

400ns/DIV

I

SW

50mA/DIV

I

LED

20mA/DIV

V

PWM

5V/DIV

3595 TA02

c

10 LEDS AT 40mA

Page 15

LT3595

15

3595f

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

PACKAGE DESCRIPTION

UHH Package

56-Lead Plastic QFN (5mm × 9mm)

(Reference LTC DWG # 05-08-1727 Rev A)

5.00 ± 0.10

(2 SIDES)

NOTE:

1. DRAWING IS NOT A JEDEC PACKAGE OUTLINE

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

PIN 1

TOP MARK

(SEE NOTE 6)

55

1

2

BOTTOM VIEW—EXPOSED PAD

3.45 ±0.10

7.13 ±0.10

6.80 REF

9.00 ± 0.10

(2 SIDES)

0.75 ± 0.05

R = 0.115

TYP

0.20 ± 0.05

(UH) QFN 0406 REV A

0.40 BSC

0.200 REF

0.200 REF

0.00 – 0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

APPLY SOLDER MASK TO AREAS THAT ARE NOT SOLDERED

3.60 REF

0.40 ±0.10

0.00 – 0.05

0.75 ± 0.05

0.70 ± 0.05

0.40 BSC

6.80 REF (2 SIDES)

3.60 REF

(2 SIDES)

4.10 ± 0.05

(2 SIDES)

5.50 ± 0.05

(2 SIDES)

7.13 ±0.05

3.45 ±0.05

8.10 ± 0.05 (2 SIDES)

9.50 ± 0.05 (2 SIDES)

0.20 ± 0.05

PACKAGE

OUTLINE

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.20mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON THE TOP AND BOTTOM OF PACKAGE

PIN 1 NOTCH

R = 0.30 TYP OR

0.35 × 45° CHAMFER

56

Page 16

LT3595

16

3595f

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

© LINEAR TECHNOLOGY CORPORATION 2007

LT 0807 • PRINTED IN USA

RELATED PARTS

TYPICAL APPLICATIONS

PART NUMBER DESCRIPTION COMMENTS

LT3463/

LT3463A

Dual Output, Boost/Inverter, 250mA I

SW

, Constant Off-Time, High

Effi ciency Step-Up DC/DC Converter with Integrated Schottky Diodes

VIN: 2.3V to 15V, V

OUT(MAX)

= ±40V, IQ = 40μA, ISD < 1μA,

3mm × 3mm DFN-10 Package

LT3465/

LT3465A

Constant-Current, 1.2MHz/2.7MHz, High Effi ciency White LED Boost

Regulator with Integrated Schottky Diode

VIN: 2.7V to 16V, V

OUT(MAX)

= 34V, IQ = 1.9mA, ISD < 1μA,

ThinSOT

TM

Package

LT3466/

LT3466-1

Dual Constant-Current, 2MHz, High Effi ciency White LED Boost

Regulator with Integrated Schottky Diode

V

IN

: 2.7V to 24V, V

OUT(MAX)

= 40V, IQ = 5mA, ISD < 16μA,

3mm × 3mm DFN-10 Package

LT3474 36V, 1A (I

LED

), 2MHz, Step-Down LED Driver VIN: 4V to 36V, V

OUT(MAX)

= 13.5V, 400:1 True Color PWMTM,

I

SD

< 1μA, TSSOP-16E Package

LT3475 Dual 1.5A (I

LED

), 36V, 2MHz, Step-Down LED Driver VIN: 4V to 36V, V

OUT(MAX)

= 13.5V, 3000:1 True Color PWM,

ISD < 1μA, TSSOP-20E Package

LT3476 Quad Output 1.5A, 2MHz High Current LED Driver with 1000:1

Dimming

V

IN

: 2.8V to 16V, V

OUT(MAX)

= 36V, 1000:1 True Color PWM,

I

SD

< 10μA, 5mm × 7mm QFN-10 Package

LT3486 Dual 1.3A , 2MHz High Current LED Driver V

IN

: 2.5V to 24V, V

OUT(MAX)

= 36V, 1000:1 True Color PWM,

I

SD

< 1μA, 5mm × 3mm DFN and TSSOP-16E Packages

LT3491 Constant-Current, 2.3MHz, High Effi ciency White LED Boost

Regulator with Integrated Schottky Diode

V

IN

: 2.5V to 12V, V

OUT(MAX)

= 27V, IQ = 2.6mA, ISD < 8μA,

2mm × 2mm DFN-6 and SC70 Packages

LT3497 Dual 2.3MHz, Full Function LED Driver with Integrated Schottky

Diodes and 250:1 True Color PWM Dimming

VIN: 2.5V to 10V, V

OUT(MAX)

= 32V, IQ = 6μA, ISD < 12μA,

3mm × 2mm DFN-10 Package

LT3498 2.3MHz, 20mA LED Driver and OLED Driver with Integrated Schottky

Diodes

VIN: 2.5V to 12V, V

OUT(MAX)

= 32V, IQ = 1.65mA, ISD < 9μA,

3mm × 2mm DFN-12 Package

LT3517/LT3518 2.3A/1.3A 45V, 2.5MHz Full Featured LED Driver with True Color

PWM Dimming

VIN: 3V to 30V/40V, V

OUT(MAX)

= 42V, 3000:1 True Color PWM,

I

SD

< 5μA, 4mm × 4mm QFN-16 Package

LT3590 48V Buck Mode LED Driver V

IN

: 4.5V to 55V, V

OUT(MAX)

= 5V, IQ = 700μA, ISD < 15μA,

2mm × 2mm DFN-16 and SC70 Packages

LT3591 Constant-Current, 1MHz, High Effi ciency White LED Boost Regulator

with Integrated Schottky Diode and 80:1 True Color PWM Dimming

VIN: 2.5V to 12V, V

OUT(MAX)

= 40V, IQ = 4mA, ISD < 9μA,

3mm × 2mm DFN-8 Package

True Color PWM and ThinSOT are trademarks of Linear Technology Corporation.

5000:1 PWM Dimming at 100Hz16-Channel LED Driver (Three LEDs per Channel), 20mA Current

V

IN

15V TO

45V

0.47

μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF

0.47

μF

10

μF

0.47

μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF 0.47μF

3595 TA03

L1 SW1 SW2 L4SW3 SW7L3 SW4 L5 L6SW5 SW6L2 L7 SW8 L8

L16 SW16 SW15 V

IN

L13SW14 VINSW10L14 SW13 L12 L11SW12 SW11L15 L10 SW9 L9

100μH

100

μH

100

μH

100μH100

μH

100μH

100

μH

100μH

100

μH

100

μH

100

μH

100μH100

μH

100μH

100

μH

100μH

LT3595

LED

BRIGHTNESS

CONTROL

3V TO

5.5V

V

CC

10μF

100k

75.0k

OPENLED

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

PWM7

PWM8

V

CC

PWM9

PWM10

PWM11

PWM12

PWM13

PWM14

PWM15

PWM16

GND

R

SET

LED

BRIGHTNESS

CONTROL

SHDN

400ns/DIV

I

LED

10mA/DIV

I

SW

20mA/DIV

V

PWM

5V/DIV

3595 TA03

b

V

IN

= 15V

3 LEDS AT 20mA

T = 10ms

T

ON

= 2μs

Loading...

Loading...