Page 1

LT3591

1

3591f

■

Cellular Phones

■

PDAs, Handheld Computers

■

Digital Cameras

■

MP3 Players

■

GPS Receivers

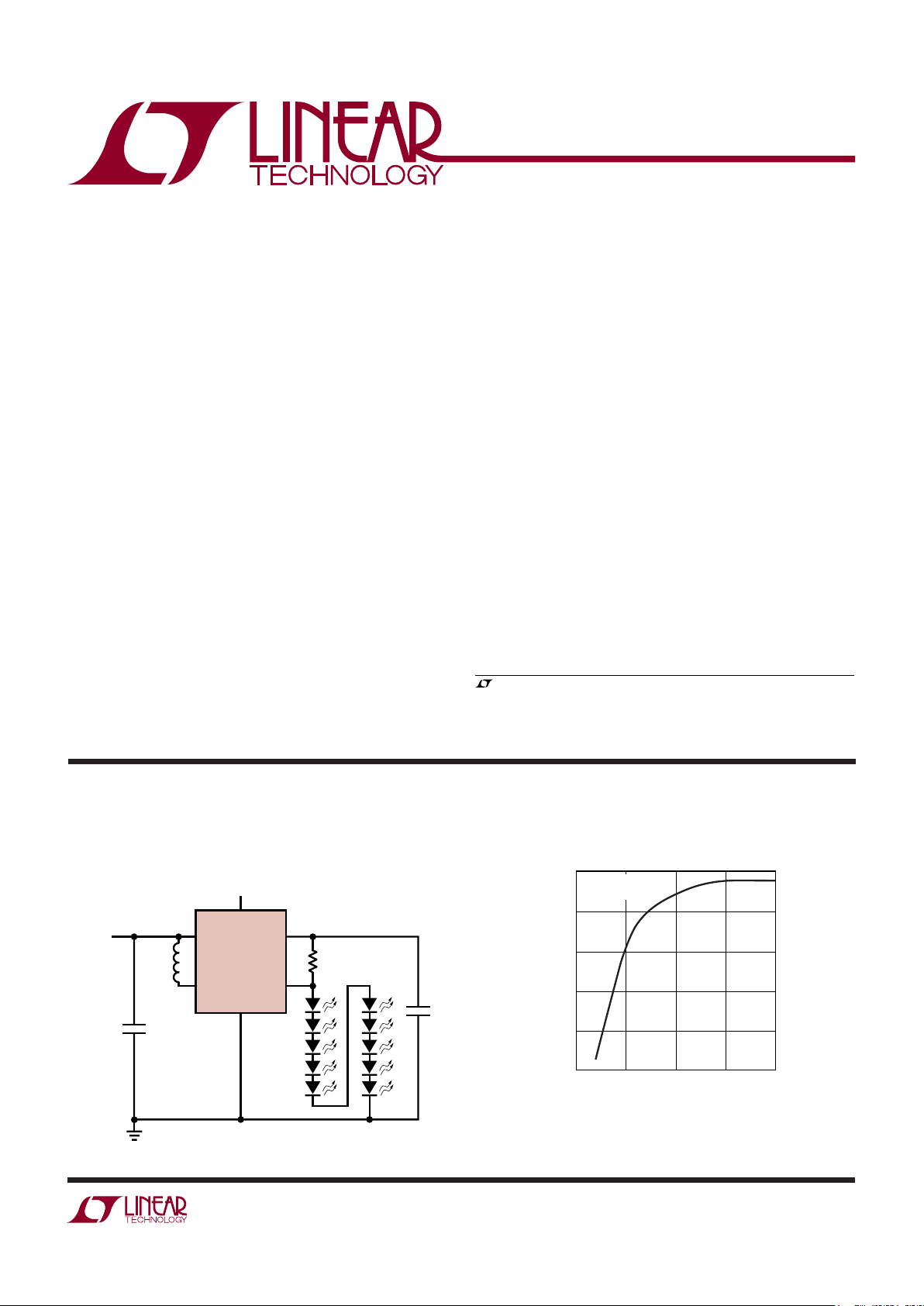

TYPICAL APPLICATION

FEATURES

APPLICATIONS

DESCRIPTION

White LED Driver with

Integrated Schottky in

3mm × 2mm DFN

The LT®3591 is a fi xed frequency step-up DC/DC converter

specifi cally designed to drive up to ten white LEDs in series

from a Li-Ion cell. Series connection of the LEDs provides

identical LED currents resulting in uniform brightness

and eliminating the need for ballast resistors. The device

features a unique high side LED current sense that enables

the part to function as a “one wire current source;” one

side of the LED string can be returned to ground anywhere,

allowing a simpler one wire LED connection. Traditional

LED drivers use a grounded resistor to sense LED current,

requiring a 2-wire connection to the LED string.

The high switching frequency allows the use of tiny inductors and capacitors. A single pin performs both shutdown

and accurate LED dimming control. Few external components are needed: open-LED protection and the Schottky

diode are all contained inside a low profi le 3mm × 2mm

DFN package.

Li-Ion Driver for Ten White LEDs

■

Drives Up to Ten White LEDs from a 3V Supply

■

High Side Sense Allows “One Wire Current Source”

■

Internal Schottky Diode

■

One Pin Dimming and Shutdown

■

80:1 True Color PWMTM Dimming Range

■

42V Open LED Protection

■

1MHz Switching Frequency

■

±5% Reference Accuracy

■

VIN Range: 2.5V to 12V

■

Requires Only 2.2µF Output Capacitor

■

Low Profi le 8-Lead DFN Package

(3mm × 2mm × 0.75mm)

Conversion Effi ciency

CTRL

V

IN

22µH

V

IN

3V TO 5V

R

SENSE

10Ω

3591 TA01a

LT3591

SHUTDOWN AND

DIMMING CONTROL

SW

CAP

LED

GND

2.2µF

1µF

LED CURRENT (mA)

0

EFFICIENCY (%)

60

20

3591 TA01b

5

10

15

80

70

55

65

75

VIN = 3.6V

10 LEDs

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

True Color PWM is a trademark of Linear Technology Corporation. All other trademarks are

the property of their respective owners.

Page 2

LT3591

2

3591f

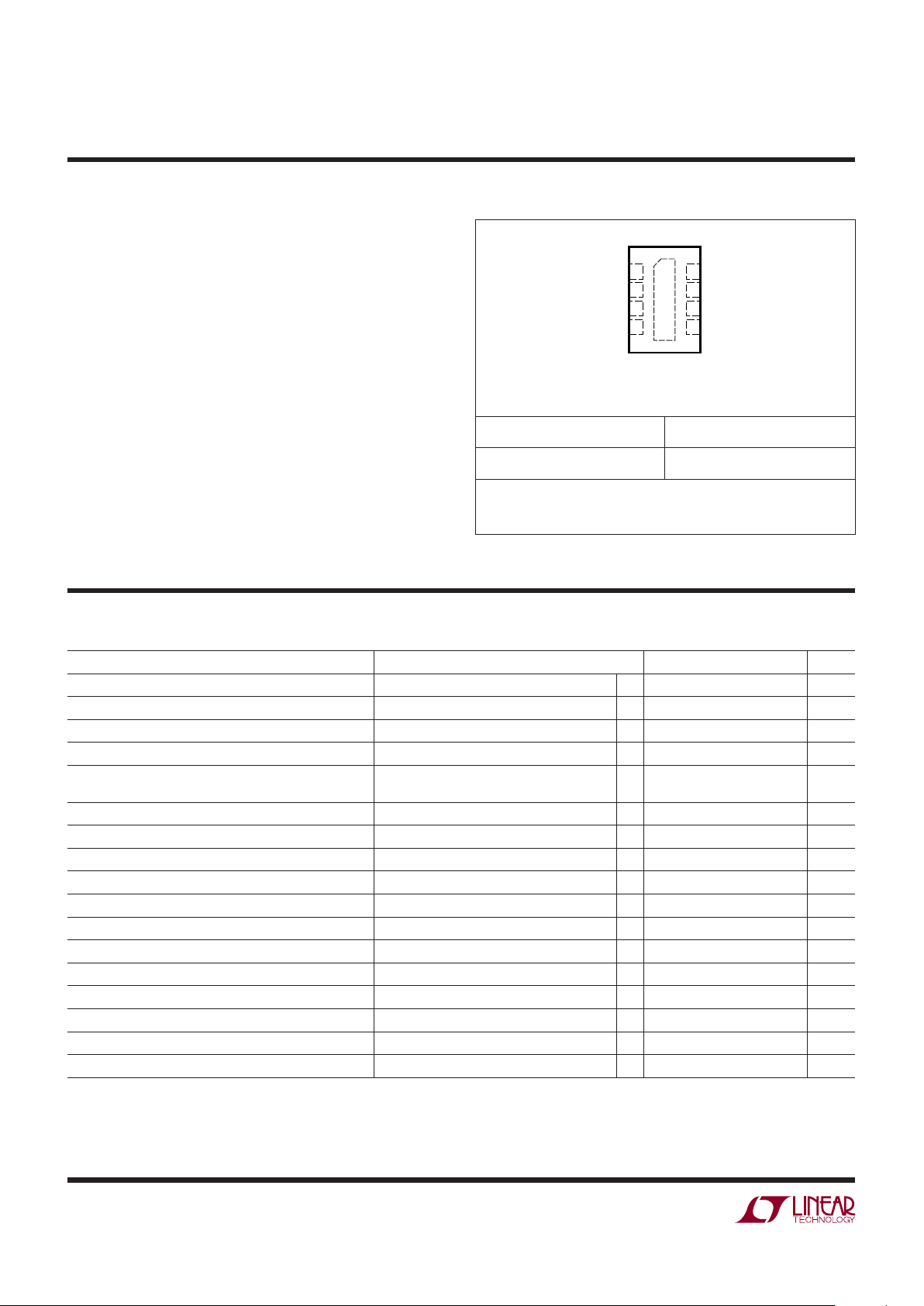

PACKAGE/ORDER INFORMATION

ELECTRICAL CHARACTERISTICS

ABSOLUTE MAXIMUM RATINGS

Input Voltage (VIN) ................................................... 12V

CTRL Voltage ........................................................... 12V

SW Voltage .............................................................. 45V

CAP Voltage ............................................................. 45V

LED Voltage ............................................................. 45V

Operating Junction Temperature Range

(Note 2) ...............................................–40°C to 85°C

Maximum Junction Temperature ........................ 125°C

Storage Temperature Range ...................–65°C to 150°C

(Note 1)

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage

2.5 V

LED Current Sense Voltage (V

CAP

– V

LED

)V

CAP

= 24V, ISW = 300mA

●

190 200 210 mV

CAP Pin Bias Current V

CAP

= 36V, V

LED

= 35.8V

40 80 µA

LED Pin Bias Current V

CAP

= 36V, V

LED

= 35.8V 20 40 µA

Supply Current V

CAP

= 24V, V

LED

= 23V

CTRL = 0V

4

9

5

11

mA

µA

Switching Frequency 0.75 1 1.2 MHz

Maximum Duty Cycle 92 94 %

Switch Current Limit

●

500 800 mA

Switch V

CESAT

ISW = 300mA 200 mV

Switch Leakage Current V

SW

= 24V 0.1 5 µA

V

CTRL

for Full LED Current V

CAP

= 44V

●

1.5 V

V

CTRL

to Shut Down IC 50 mV

V

CTRL

to Turn On IC

●

100 mV

CTRL Pin Bias Current 100 nA

CAP Pin Overvoltage Protection

●

40 42 44 V

Schottky Forward Drop I

SCHOTTKY

= 200mA 0.8 V

Schottky Leakage Current V

R

= 30V 4 µA

TOP VIEW

9

DDB PACKAGE

8-LEAD (3mm × 2mm) PLASTIC DFN

5

6

7

8

4

3

2

1V

IN

GND

NC

SW

CTRL

LED

NC

CAP

T

JMAX

= 125°C, θJA = 76°C/W

EXPOSED PAD (PIN 9) SHOULD BE CONNECTED TO PCB GROUND

ORDER PART NUMBER DDB PART MARKING

LT3591EDDB LCPG

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

The

●

denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

A

= 25°C. VIN = 3V, V

CTRL

= 3V, unless otherwise specifi ed.

Note 2: The LT3591E is guaranteed to meet performance specifi cations

from 0°C to 85°C operating junction temperature range. Specifi cations

over the –40°C to 85°C operating junction temperature range are assured

by design, characterization and correlation with statistical process controls.

Page 3

LT3591

3

3591f

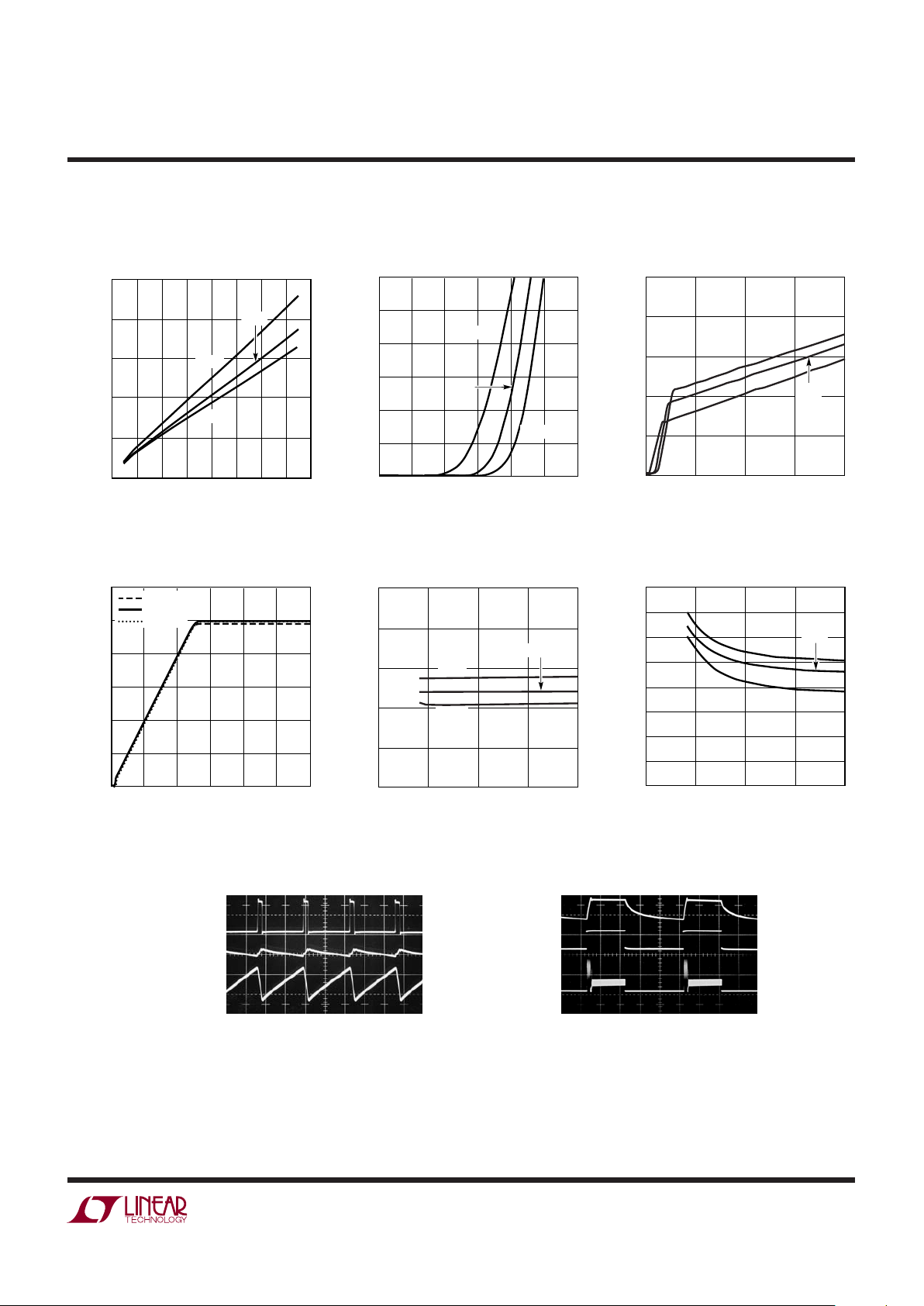

TYPICAL PERFORMANCE CHARACTERISTICS

Switch Saturation Voltage

(V

CESAT

)

Schottky Forward Voltage Drop

Shutdown Current (V

CTRL

= 0V)

Sense Voltage (V

CAP

– V

LED

)

vs V

CTRL

Open-Circuit Output

Clamp Voltage

Input Current in Output

Open Circuit

Switching Waveform

Transient Response

SWITCH CURRENT (mA)

0

500

400

300

200

100

0

300 600

3591 G01

100 200

400 800700

500

SWITCH SATURATION VOLTAGE (mV)

–50°C

125°C

25°C

SCHOTTKY FORWARD DROP (mV)

SCHOTTKY FORWARD CURRENT (mA)

200

300

3591 G02

100

0

600

500

400

0 200 400 600 800

1000 1200

–50°C

125°C

25°C

VIN (V)

0

SHUTDOWN CURRENT (µA)

9

12

15

12

3591 G03

6

3

0

3

6

9

–50°C

125°C

25°C

V

CTRL

(mV)

SENSE VOLTAGE (mV)

80

120

3591 G04

40

0

240

200

160

0 500 1000 1500 2000 2500 3000

–50°C

25°C

125°C

VIN (V)

0

OUTPUT CLAMP VOLTAGE (V)

42

43

12

3591 G05

41

40

3

6

9

45

44

–50°C

125°C

25°C

VIN (V)

0

INPUT CURRENT (mA)

36 912

3591 G06

–50°C

125°C

4

5

6

3

2

0

1

8

7

25°C

V

SW

20V/DIV

V

CAP

50mV/DIV

I

L

200mA/DIV

V

IN

= 3.6V

FRONT PAGE

APPLICATION CIRCUIT

500ms/DIV

3591 G07

V

CTRL

5V/DIV

V

CAP

5V/DIV

I

L

500mA/DIV

V

IN

= 3.6V

FRONT PAGE

APPLICATION CIRCUIT

1ms/DIV

3591 G08

TA = 25°C, unless otherwise specifi ed.

Page 4

LT3591

4

3591f

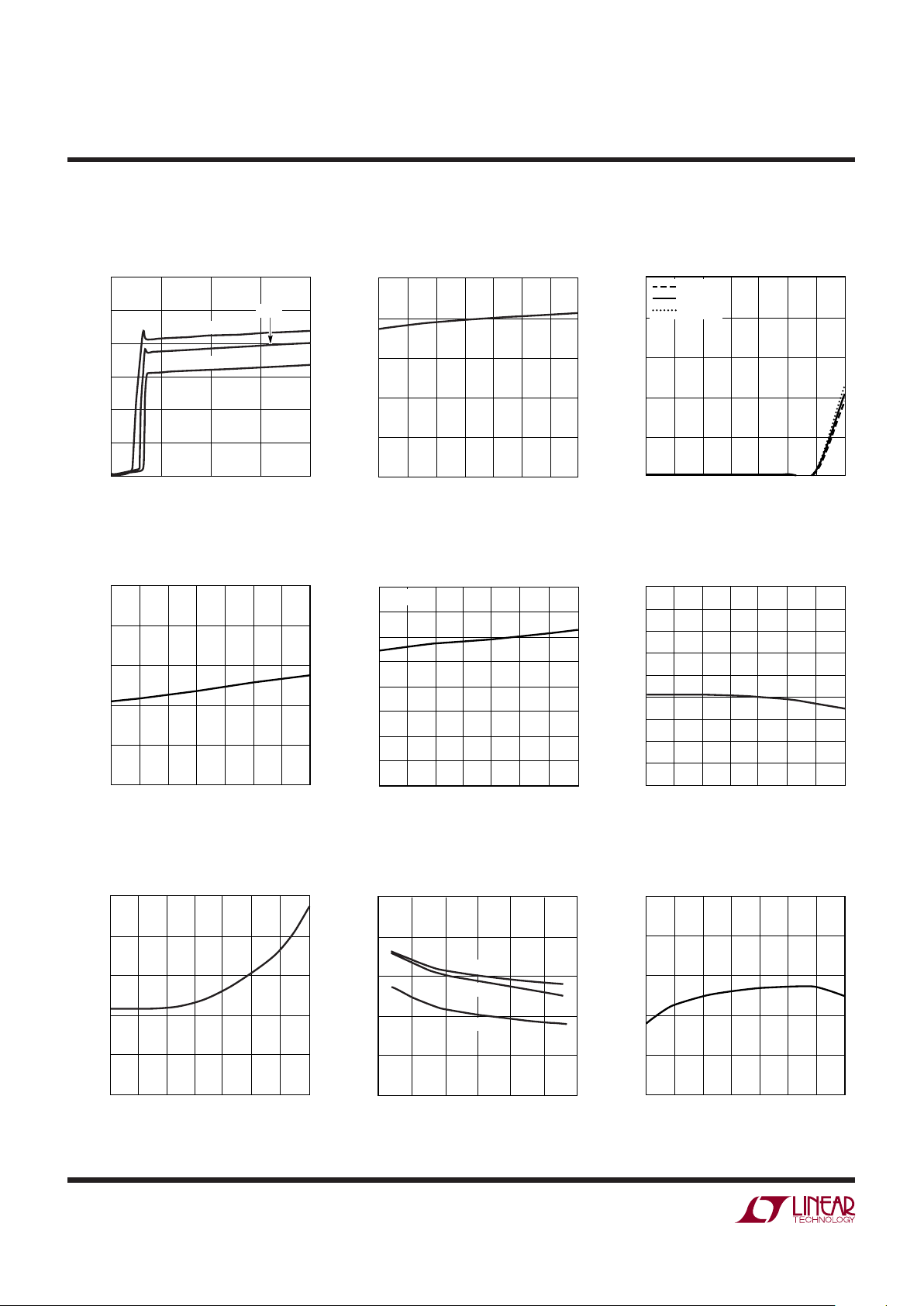

VIN (V)

0

0

QUIESCENT CURRENT (mA)

1

2

3

4

5

6

36 912

3591 G09

–50°C

125°C

25°C

TEMPERATURE (°C)

0

CURRENT LIMIT (mA)

400

1000

3591 G10

200

600

800

–50 –25 0 25 50 75 100 125

–50 25 75

–25 0

50 100 125

TEMPERATURE (°C)

0

SCHOTTKY LEAKAGE CURRENT (µA)

3

6

9

12

15

3591 G11

VR = 10V

V

R

= 16V

V

R

= 20V

TEMPERATURE (°C)

–50 –25

40

OUTPUT CLAMP VOLTAGE (V)

42

45

0

50

75

3591 G12

41

44

43

25

100

125

TEMPERATURE (°C)

–50

INPUT CURRENT (mA)

25 75

3591 G13

–25 0

50 100 125

VIN = 3V

4

5

6

3

2

0

1

8

7

TEMPERATURE (°C)

–50

SWITCHING FREQUENCY (kHz)

25 75

3591 G14

–25 0

50 100 125

1000

1050

1100

950

900

750

800

850

1200

1150

TEMPERATURE (°C)

–50

MAXIMUM DUTY CYCLE (%)

25 75

3591 G15

–25 0

50 100 125

98

96

94

90

92

100

V

CAP

(V)

5

SENSE VOLTAGE (mV)

20 30

3591 G16

10 15

25 35

204

200

196

188

192

208

–50°C

125°C

25°C

TEMPERATURE (°C)

–50 –25

188

SENSE VOLTAGE (mV)

196

208

0

50

75

3591 G17

192

204

200

25

100

125

TYPICAL PERFORMANCE CHARACTERISTICS

Quiescent Current

(V

CTRL

= 3V) Current Limit vs Temperature

Schottky Leakage Current

vs Temperature

Open-Circuit Output Clamp

Voltage vs Temperature

Input Current in Output Open

Circuit vs Temperature

Switching Frequency

vs Temperature

Maximum Duty Cycle

vs Temperature

Sense Voltage (V

CAP

– V

LED

)

vs V

CAP

Sense Voltage (V

CAP

– V

LED

)

vs Temperature

T

A

= 25°C, unless otherwise specifi ed.

Page 5

LT3591

5

3591f

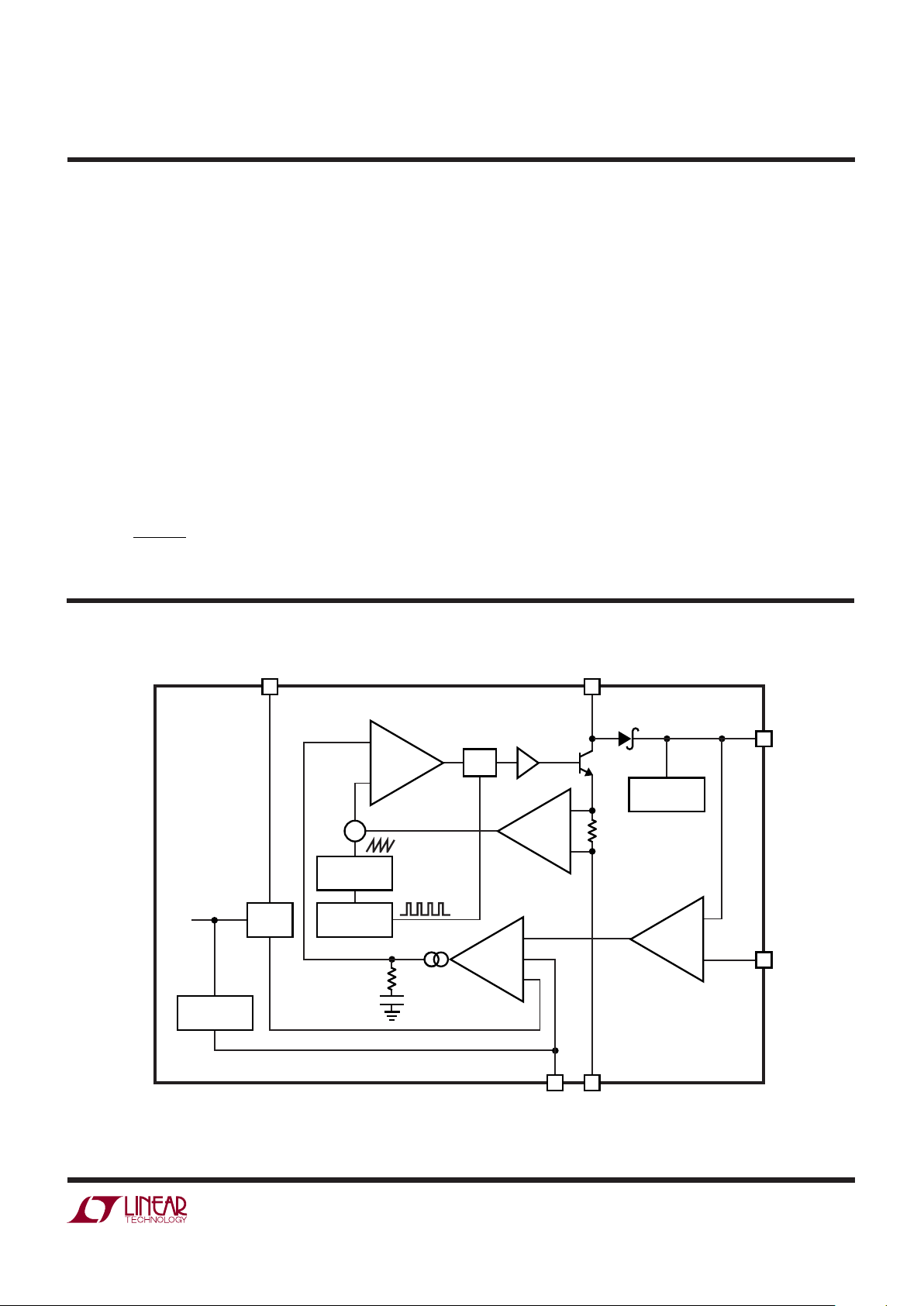

BLOCK DIAGRAM

PIN FUNCTIONS

VIN (Pin 1): Input Supply Pin. Must be locally bypassed.

GND (Pin 2): Ground Pin. Should be tied directly to local

ground plane.

SW (Pin 4): Switch Pin. Minimize trace area at this pin to

minimize EMI. Connect the inductor at this pin.

CAP (Pin 5): Output of the Driver. This pin is connected

to the cathode of internal Schottky. Connect the output

capacitor to this pin and the sense resistor from this pin

to the LED pin.

LED (Pin 7): Connection Point for the Anode of the First

LED and the Sense Resistor. The LED current can be

programmed by :

I

mV

R

LED

SENSE

=

200

CTRL (Pin 8): Dimming and Shutdown Pin. Connect this

pin below 50mV to disable the driver. As the pin voltage

is ramped from 0V to 1.5V, the LED current ramps from

0 to I

LED

( = 200mV/R

SENSE

). The CTRL pin must not be

left fl oating.

Exposed Pad (Pin 9): Ground. The Exposed Pad must

be soldered to PCB ground to achieve the rated thermal

performance.

4

–

+

–

+

R

SW

CAP

1

V

IN

Q

S

DRIVER

Σ

OVERVOLTAGE

PROTECTION

RAMP

GENERATOR

OSCILLATOR

V

REF

1.25V

START-UP

CONTROL

SHDN

Q1

R

–

+

+

5

LED

3591 F01

CTRL GND

7

82

–

+

A = 6.25

A1

R

C

C

C

A2

A3

PWM

COMP

Figure 1. Block Diagram

Page 6

LT3591

6

3591f

Figure 2. Switching Waveforms

OPERATION

The LT3591 uses a constant frequency, current mode

control scheme to provide excellent line and load regulation. Operation can be best understood by referring to the

Block Diagram in Figure 1.

At power-up, the capacitor at the CAP pin is charged up

to V

IN

(input supply voltage) through the inductor and

the internal Schottky diode. If CTRL is pulled higher than

100mV, the bandgap reference, the start-up bias and the

oscillator are turned on. At the start of each oscillator cycle,

the power switch Q1 is turned on. A voltage proportional

to the switch current is added to a stabilizing ramp and the

resulting sum is fed into the positive terminal of the PWM

comparator, A2. When this voltage exceeds the level at the

negative input of A2, the PWM logic turns off the power

switch. The level at the negative input of A2 is set by the

error amplifi er A1, and is simply an amplifi ed version of

the difference between the V

CAP

and V

LED

voltage and the

bandgap reference. In this manner the error amplifi er, A1,

sets the correct peak current level in inductor L1 to keep

the output in regulation. The CTRL pin is used to adjust

the LED current. The LT3591 enters into shutdown when

CTRL is pulled lower than 50mV.

Minimum Output Current

The LT3591 can drive a 2-LED string at 2mA LED current

without pulse skipping using the same external components shown in the application circuit on the front page of

this data sheet. As current is further reduced, the device

will begin skipping pulses. This will result in some low

frequency ripple, although the average LED current remains

regulated down to zero. The photo in Figure 2 details circuit

operation driving two white LEDs at 2mA load. Peak inductor current is less than 40mA and the regulator operates

in discontinuous mode, meaning the inductor current

reaches zero during the discharge phase. After the inductor

current reaches zero, the SW pin exhibits ringing due to

the LC tank circuit formed by the inductor in combination

with the switch and the diode capacitance. This ringing is

not harmful; far less spectral energy is contained in the

ringing than in the switch transitions.

V

SW

5V/DIV

I

L

20mA/DIV

V

IN

= 4.2V

I

LED

= 2mA

2 LEDs

500ns/DIV

3591 F02

Page 7

LT3591

7

3591f

INDUCTOR SELECTION

A 22µH inductor is recommended for most LT3591 applications. Although small size and high effi ciency are

major concerns, the inductor should have low core losses

at 1MHz and low DCR (copper wire resistance). Some

small inductors in this category are listed in Table 1. The

effi ciency comparison of different inductors is shown in

Figure 3.

Table 1. Recommended Inductors

PART

L

(µH)

CURRENT

RATING

(mA)

MAX

DIMENSION

L × W × H

(mm) VENDOR

VLF4012AT220MR51

22 510

4

× 3.8 × 1.2

TDK

www.tdk.com

VLCF4018T220MR49-2

22 490

4.1

× 4.1 × 1.8

VLCF4020T220MR56

22 560

4.1

× 4.1 × 2

LQH43CN220K03 22 420

4.8

× 3.4 × 2.8

Murata

www.murata.com

NR4018T220M 22 590

4.2

× 4.2 × 1.8

Taiyo Yuden

www.t-yuden.com

NR4012T220M 22 510

4.2

× 4.2 × 1.2

CDRH3D18220NC

22 600

4 × 4

× 2

Sumida

www.sumida.com

B82470-A1223-M 22 480

4.8

× 4.8 × 1.2

Epcos

www.epcos.com

APPLICATIONS INFORMATION

CAPACITOR SELECTION

The small size of ceramic capacitors make them ideal for

LT3591 applications. Use only X5R and X7R types because

they retain their capacitance over wider temperature

ranges than other types such as Y5V or Z5U. A 1µF input

capacitor and a 50V, 2.2µF output capacitor are suffi cient

for most applications.

A limited number of manufacturers produce small 50V

capacitors. Table 2 shows a list of several recommended

50V capacitors. Consult the manufacturer for detailed

information on their entire selection of ceramic parts.

Table 2. Recommended Output Capacitors

PART

C

(µF)

VOLTAGE CASE SIZE

VENDORTEMP.

HEIGHT

(mm)

GRM21BR71H105KA12L 1 50V 0805 Murata

www.murata.com

X7R 1.25 ± 0.15

GRM31MR71H105KA88 1 50V 1206

X7R 1.15 ± 0.1

GRM31CR71H225KA88 2.2 50V 1206

X7R 1.6 ± 0.2

GRM31CR71H475KA12L 4.7 50V 1206

X7R 1.6 ± 0.2

UMK316BJ475KL-T 4.7 50V 1206 Taiyo Yuden

www.t-yuden.com

X7R 1.6 ± 0.2

Figure 3. Effi ciency Comparison of Different Inductors

LED CURRENT (mA)

0

50

EFFICIENCY (%)

55

85

80

65

5

10

3591 F03

70

75

60

15

20

TAIYO YUDEN NR4018T220M

TDK VLCF4018T-220MR49-2

TAIYO YUDEN NR4012T220M

TDKVLCF4012AT-220MR51

MURATA LQH43CN220K03

TDK VLCF4020T-220MR56

SUMIDA CDRH3D18-220NC

EPCOS B82470-A1223-M

VIN = 3.6V

10 LEDs

Page 8

LT3591

8

3591f

APPLICATIONS INFORMATION

SCHOTTKY DIODE

The LT3591 has a built-in Schottky diode. The internal

schottky saves board space in space constrained applications. In less space sensitive applications, an external

schottky diode connected between the SW node and the

CAP node increases effi ciency one to two percent. It is

important to use a properly rated schottky diode that can

handle the peak switch current of the LT3591. In addition,

the schottky diode must have a breakdown voltage of at least

40V along with a low forward voltage in order to achieve

higher effi ciency. One recommended external schottky

diode for the LT3591 is the Phillips PMEG4005AEA.

OVERVOLTAGE PROTECTION

The LT3591 has an internal open-circuit protection circuit.

In the cases of output open circuit, when the LEDs are

disconnected from the circuit or the LEDs fail open circuit,

V

CAP

is clamped at 42V (typ). The LT3591 will then switch

at a very low frequency to minimize input current. The V

CAP

and input current during output open circuit are shown in

the Typical Performance Characteristics. Figure 4 shows

the transient response when the LEDs are disconnected.

For low DCR inductors, which is usually the case for this

application, the peak inrush current can be simplifi ed as

follows:

I

V

L

r

L

LC

PK

IN

=

⎛

⎝

⎜

⎞

⎠

⎟

=

=

–.

•

• exp – •

•

•

–

06

2

2

1

ω

αωπ

α

ω

rr

L

2

2

4•

where L is the inductance, r is the DCR of the inductor

and C is the output capacitance.

Table 3 gives inrush peak currents for some component

selections.

Table 3. Inrush Peak Currents

VIN (V) r (Ω)L (µH) C

OUT

(µF) IP (A)

4.2 0.3 22 2.2 1.06

4.2 0.71 22 2.2 0.96

4.2 0.58 15 1 0.83

4.2 1.6 15 1 0.68

PROGRAMMING LED CURRENT

The feedback resistor (R

SENSE

) and the sense voltage

(V

CAP

– V

LED

) control the LED current.

The CTRL pin controls the sense reference voltage as

shown in the Typical Performance Characteristics. For

CTRL higher than 1.5V, the sense reference is 200mV,

which results in full LED current. In order to have accurate

LED current, precision resistors are preferred (1% is recommended). The formula and table for R

SENSE

selection

are shown below.

R

mV

I

SENSE

LED

=

200

V

CAP

20V/DIV

I

L

500mA/DIV

V

IN

= 3.6V

CIRCUIT OF

FRONT PAGE

APPLICATION

LEDs DISCONNECTED

AT THIS INSTANT

500µs/DIV

3591 F04

Figure 4. Output Open-Circuit Waveform

INRUSH CURRENT

The LT3591 has a built-in Schottky diode. When supply

voltage is applied to the V

IN

pin, an inrush current fl ows

through the inductor and the Schottky diode and charges

up the CAP voltage. The Schottky diode inside the LT3591

can sustain a maximum current of 1A.

Page 9

LT3591

9

3591f

APPLICATIONS INFORMATION

Table 4. R

SENSE

Value Selection for 200mV Sense

I

LED

(mA) R

SENSE

(Ω)

540

10 20

15 13.3

20 10

DIMMING CONTROL

There are three different types of dimming control circuits.

The LED current can be set by modulating the CTRL pin

with a DC voltage, a fi ltered PWM signal or directly with

a PWM signal.

Using a DC Voltage

For some applications, the preferred method of brightness

control is a variable DC voltage to adjust the LED current.

The CTRL pin voltage can be modulated to set the dimming of the LED string. As the voltage on the CTRL pin

increases from 0V to 1.5V, the LED current increases from

0 to I

LED

. As the CTRL pin voltage increases beyond 1.5V,

it has no effect on the LED current.

The LED current can be set by:

I

mV

R

when V V

I

V

LED

SENSE

CTRL

LED

CTRL

≈>

≈

200

15

6

,.

.

225

125

•

,.

R

when V V

SENSE

CTRL

<

Feedback voltage variation versus control voltage is given

in the Typical Performance Characteristics.

Using a Filtered PWM Signal

A fi ltered PWM signal can be used to control the

brightness of the LED string. The PWM signal is fi ltered

(Figure 5) by a RC network and fed to the CTRL pin.

The corner frequency of R1, C1 should be much lower

than the frequency of the PWM signal. R1 needs to be

much smaller than the internal impedance of the CTRL

pin which is 10MΩ (typ).

Direct PWM Dimming

Changing the forward current fl owing in the LEDs not only

changes the intensity of the LEDs, it also changes the color.

The chromaticity of the LEDs changes with the change in

forward current. Many applications cannot tolerate any

shift in the color of the LEDs. Controlling the intensity of

the LEDs with a direct PWM signal allows dimming of the

LEDs without changing the color. In addition, direct PWM

dimming offers a wider dimming range to the user.

Dimming the LEDs via a PWM signal essentially involves

turning the LEDs on and off at the PWM frequency. The

typical human eye has a limit of ~60 frames per second.

By increasing the PWM frequency to ~80Hz or higher,

the eye will interpret that the pulsed light source is continuously on. Additionally, by modulating the duty cycle

(amount of “on-time”), the intensity of the LEDs can be

controlled. The color of the LEDs remains unchanged in

this scheme since the LED current value is either zero or

a constant value.

Figure 6 shows a Li-Ion powered driver for ten white LEDs.

Direct PWM dimming method requires an external NMOS

tied between the cathode of the lowest LED in the string

LT3591

CTRL

C1

0.1µF

PWM

10kHz TYP

3591 F05

R1

100k

Figure 5. Dimming Control Using a Filtered PWM Signal

CTRL

PWM

FREQ

V

IN

L1

22µH

V

IN

3V TO

5V

R

SENSE

10Ω

3591 F06

LT3591

SW

CAP

LED

100k

GND

0V

5V

C2

2.2µF

Q1

Si2308

C1

1µF

Figure 6. Li-Ion to Ten White LEDs with Direct PWM Dimming

Page 10

LT3591

10

3591f

and ground as shown in Figure 6. A Si2308 MOSFET can

be used since its source is connected to ground. The PWM

signal is applied to the CTRL pin of the LT3591 and the gate

of the MOSFET. The PWM signal should traverse between

0V to 5V, to ensure proper turn on and off of the driver

and the NMOS transistor Q1. When the PWM signal goes

high, the LEDs are connected to ground and a current of

I

LED

= 200mV/R

SENSE

fl ows through the LEDs. When the

PWM signal goes low, the LEDs are disconnected and

turn off. The MOSFET ensures that the LEDs quickly turn

off without discharging the output capacitor which in turn

allows the LEDs to turn on faster. Figure 7 shows the PWM

dimming waveforms for the circuit in Figure 6.

APPLICATIONS INFORMATION

The calculations show that for a 100Hz signal the dimming

range is 83 to 1. In addition, the minimum PWM duty cycle

of 1.2% ensures that the LED current has enough time

to settle to its fi nal value. Figure 8 shows the dimming

range achievable for different frequencies with a settling

time of 120µs.

I

L

500mA/DIV

I

LED

20mA/DIV

PWM

5V/DIV

VIN = 3.6V

10 LEDs

2ms/DIV

3591 F07

Figure 7. Direct PWM Dimming Waveforms

The time it takes for the LED current to reach its programmed value sets the achievable dimming range for a

given PWM frequency. For example, the settling time of

the LED current in Figure 7 is approximately 120µs for a

3.6V input voltage. The achievable dimming range for this

application and 100Hz PWM frequency can be determined

using the following method.

Example:

ƒƒ==

== =

100 120

11

100

001

Hz t µs

ts

SETTLE

PERIOD

,

.

DDim Range

t

t

s

µs

Mi

PERIOD

SETTLE

.

:===

001

120

83 1

nn Duty Cycle

t

t

µs

s

SETTLE

PERIOD

•

.

==100

120

001

••.%

%.%

100 1 2

100 1 2 100

=

=→Duty Cycle Range at HHz

PWM DIMMING FREQUENCY (Hz)

10

PWM DIMMING RANGE

100

1000

10000

100 1000 10000

3591 F08

1

10

PULSING MAY BE VISIBLE

Figure 8. Dimming Range vs Frequency

In addition to extending the dimming range, PWM dimming

improves the effi ciency of the converter for LED currents

below 20mA. Figure 9 shows the effi ciency for traditional

analog dimming of the front page application and PWM

dimming of the application in Figure 6.

Figure 9. PWM vs Analog Dimming Effi ciency

LED CURRENT (mA)

0

EFFICIENCY (%)

60

65

70

20

3591 F09

55

5

10

15

80

75

PWM DIMMING

ANALOG DIMMING

VIN = 3.6V

10 LEDs

Page 11

LT3591

11

3591f

APPLICATIONS INFORMATION

LOW INPUT VOLTAGE APPLICATIONS

The LT3591 can be used in low input voltage applications.

The input supply voltage to the LT3591 must be 2.5V or

higher. However, the inductor can be run off a lower battery

voltage. This technique allows the LEDs to be powered off

two alkaline cells. Most portable devices have a 3.3V logic

supply voltage which can be used to power the LT3591.

The LEDs can be driven straight from the battery, resulting

in higher effi ciency.

Figure 10 shows six LEDs powered by two AA cells. The

battery is connected to the inductor and the chip is powered

off a 3.3V logic supply voltage.

CTRL

V

IN

C2

4.7µF

C1: TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31CR71H475KA12L

L1: TAIYO YUDEN NR4018T150M

C1

1µF

L1

15µH

C1

1µF

2 AA CELLS

2V TO 3.2V

3.3V

R

SENSE

10Ω

3591 F10

LT3591

SHUTDOWN AND

DIMMING CONTROL

SW

CAP

LED

GND

Figure 10. 2 AA Cells to Six White LEDs

BOARD LAYOUT CONSIDERATIONS

As with all switching regulators, careful attention must be

paid to the PCB board layout and component placement.

To prevent electromagnetic interference (EMI) problems,

proper layout of high frequency switching paths is essential.

Minimize the length and area of all traces connected to

the switching node pin (SW). Keep the sense voltage pins

(CAP and LED) away from the switching node. Place C

OUT

next to the CAP pin. Always use a ground plane under the

switching regulator to minimize interplane coupling. Recommended component placement is shown in Figure 11.

Figure 11. Recommended Component Placement

L1

C

IN

C

OUT

3591 F11

V

IN

CTRL

LED

CAP

R

SENSE

SW

6

7

GND

9

8

3

2

1

5

4

Page 12

LT3591

12

3591f

TYPICAL APPLICATIONS

LED CURRENT (mA)

EFFICIENCY (%)

60

70

85

80

55

65

75

10

3491 TA02b

2005 15

NO SCHOTTKY

EXTERNAL SCHOTTKY

VIN = 3.6V

10 LEDs

LED CURRENT (mA)

0

EFFICIENCY (%)

65

70

50

3591 TA03b

60

10

20

30 40

80

75

VIN = 3.6V

4 LEDs

Li-Ion Driver for Ten White LEDs Effi ciency

Li-Ion Driver for Four White LEDs at 50mA

Effi ciency

SW

V

IN

L1

22µH

D1

*OPTIONAL

V

IN

3V TO 5V

R

SENSE

10Ω

3591 TA02a

LT3591

SHUTDOWN

AND DIMMING

CONTROL

CTRL

CAP

LED

GND

C2

2.2µF

C1

1µF

C1:TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31CR71H225KA88

L1: TAIYO YUDEN NR4018T220M

D1: PHILLIPS PMEG4005AEA

CTRL

V

IN

L1

10µH

V

IN

3V TO 5V

R

SENSE

3.92Ω

3591 TA03a

LT3591

SHUTDOWN AND

DIMMING CONTROL

SW

CAP

LED

GND

C2

4.7µF

C1

1µF

C1:TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31CR71H475KA12L

L1: MURATA LQH32CN100K53

Page 13

LT3591

13

3591f

TYPICAL APPLICATIONS

CAP LED

V

IN

C2

4.7µF

C1

1µF

L1

22µH

C1: TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31CR71H475KA12L

C3: MURATA GRM21BR71H105KA12L

L1: TAIYO YUDEN NR4018T220M

V

IN

3V

PV

IN

24V

R

SENSE

2Ω

3591 TA05a

LT3591

SHUTDOWN

AND

DIMMING

CONTROL

CTRL SW

GND

C3

1µF

LED CURRENT (mA)

0

70

EFFICIENCY (%)

75

95

3591 TA05b

20 40 60 80 100

80

85

90

CAP LED

V

IN

C2

4.7µF

C1

1µF

L1

22µH

V

IN

3V

PV

IN

24V

R

SENSE

2Ω

3591 TA06a

LT3591

SHUTDOWN

AND

DIMMING

CONTROL

CTRL SW

GND

C3

1µF

C1: TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31CR71H475KA12L

C3: MURATA GRM21BR71H105KA12L

L1: TAIYO YUDEN NR4018T220M

LED CURRENT (mA)

70

EFFICIENCY (%)

80

95

90

75

85

40 80

3591 TA06b

10020060

24V to Four White LEDs at 100mA Effi ciency

24V to Five White LEDs at 100mA Effi ciency

Page 14

LT3591

14

3591f

TYPICAL APPLICATIONS

CTRL

V

IN

C2

2.2µF

C1

1µF

L1

22µH

V

IN

3V TO 5V

R

SENSE

10Ω

3591 TA07a

LT3591

SHUTDOWN AND

DIMMING CONTROL

SW

CAP

LED

GND

C1: TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31CR71H225KA88

L1: TAIYO YUDEN NR4018T220M

LED CURRENT (mA)

0

EFFICIENCY (%)

50

55

60

15

85

80

3591 TA07b

510 20

65

70

75

VIN = 3.6V

7 LEDs

CTRL

V

IN

C2

2.2µF

C1

1µF

L1

22µH

V

IN

3V TO 5V

R

SENSE

10Ω

3591 TA08a

LT3591

SHUTDOWN AND

DIMMING CONTROL

SW

CAP

LED

GND

C1: TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31CR71H225KA88

L1: TAIYO YUDEN NR4018T220M

LED CURRENT (mA)

0

55

EFFICIENCY (%)

60

85

80

3591 TA08b

20

65

70

75

15

510

VIN = 3.6V

8 LEDs

Li-Ion Driver for Seven White LEDs Conversion Effi ciency

Li-Ion Driver for Eight White LEDs Conversion Effi ciency

Page 15

LT3591

15

3591f

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

PACKAGE DESCRIPTION

DDB Package

8-Lead Plastic DFN (3mm × 2mm)

(Reference LTC DWG # 05-08-1702 Rev B)

2.00 ±0.10

(2 SIDES)

NOTE:

1. DRAWING CONFORMS TO VERSION (WECD-1) IN JEDEC PACKAGE OUTLINE M0-229

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE TOP AND BOTTOM OF PACKAGE

0.40 ± 0.10

BOTTOM VIEW—EXPOSED PAD

0.56 ± 0.05

(2 SIDES)

0.75 ±0.05

R = 0.115

TYP

R = 0.05

TYP

2.15 ±0.05

(2 SIDES)

3.00 ±0.10

(2 SIDES)

14

85

PIN 1 BAR

TOP MARK

(SEE NOTE 6)

0.200 REF

0 – 0.05

(DDB8) DFN 0905 REV B

0.25 ± 0.05

2.20 ±0.05

(2 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

0.61 ±0.05

(2 SIDES)

1.15 ±0.05

0.70 ±0.05

2.55 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

0.50 BSC

PIN 1

R = 0.20 OR

0.25 × 45°

CHAMFER

0.50 BSC

Page 16

LT3591

16

3591f

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

© LINEAR TECHNOLOGY CORPORATION 2007

LT 0207 • PRINTED IN USA

RELATED PARTS

TYPICAL APPLICATION

PART NUMBER DESCRIPTION COMMENTS

LT1618 Constant-Current, Constant Voltage 1.24MHz, High Effi ciency

Boost Regulator

Up to 16 White LEDs, V

IN

: 1.6V to 18V, V

OUT(MAX)

= 34V,

I

Q

= 1.8mA, ISD < 1µA, MS Package

LT1937 Constant-Current, 1.2MHz, High Effi ciency White LED Boost

Regulator

Up to 4 White LEDs, V

IN

: 2.5V to 10V, V

OUT(MAX)

= 34V,

I

Q

= 1.9mA, ISD < 1µA, ThinSOTTM/SC70 Packages

LTC

®

3200

Low Noise, 2MHz Regulated Charge Pump White LED Driver Up to 6 White LEDs, V

IN

: 2.7V to 4.5V, IQ = 8mA, ISD < 1µA,

MS Package

LTC3200-5 Low Noise, 2MHz Regulated Charge Pump White LED Driver Up to 6 White LEDs, VIN: 2.7V to 4.5V, IQ = 8mA, ISD < 1µA,

ThinSOT Package

LTC3201 Low Noise, 1.7MHz Regulated Charge Pump White LED Driver Up to 6 White LEDs, V

IN

: 2.7V to 4.5V, IQ = 6.5mA, ISD < 1µA,

MS Package

LTC3202 Low Noise, 1.5MHz Regulated Charge Pump White LED Driver Up to 8 White LEDs, V

IN

: 2.7V to 4.5V, IQ = 5mA, ISD < 1µA,

MS Package

LTC3205 High Effi ciency, Multidisplay LED Controller Up to 4 (Main), 2 (Sub) and RGB, VIN: 2.8V to 4.5V,

I

Q

= 50µA, ISD < 1µA, 24-Lead QFN Package

LT3465/LT3465A Constant-Current, 1.2MHz/2.7MHz, High Effi ciency White LED

Boost Regulator with Integrated Schottky Diode

Up to 6 White LEDs, V

IN

: 2.7V to 16V, V

OUT(MAX)

= 34V,

I

Q

= 1.9mA, ISD < 1µA, ThinSOT Package

LT3466/LT3466-1 Dual Full Function, 2MHz Diodes White LED Step-Up Converter

with Built-In Schottkys

Up to 20 White LEDs, V

IN

: 2.7V to 24V, V

OUT(MAX)

= 39V,

DFN, TSSOP-16 Packages

LT3486 Dual 1.3A White LED Converter with 1000:1 True Color PWM

Dimming

Drives Up to 16 100mA White LEDs. V

IN

: 2.5V to 24V,

V

OUT(MAX)

= 36V, DFN, TSSOP Packages

LT3491 2.3MHz White LED Driver with Integrated Schottky Diode Drives Up to 6 LEDs. V

IN

: 2.5V to 12V, V

OUT(MAX)

= 27V, SC70 and

DFN Packages

LT3497 Dual Full Function 2.3MHz LED Driver with 250:1 True Color

PWM Dimming with Integrated Schottky Diodes

Up to 12 White LEDs, V

IN

: 2.5V to 10V, V

OUT(MAX)

= 32V,

3mm × 2mm DFN Package

ThinSOT is a trademark of Linear Technology Corporation

CTRL

V

IN

C2

2.2µF

C1

1µF

L1

22µH

V

IN

3V TO 5V

R

SENSE

10Ω

3591 TA09a

LT3591

SHUTDOWN AND

DIMMING CONTROL

SW

CAP

LED

GND

C1: TAIYO YUDEN EMK107BJ105MA

C2: MURATA GRM31CR71H225KA88

L1: TAIYO YUDEN NR4018T220M

LED CURRENT (mA)

0

85

80

75

70

65

60

55

15

3591 TA09b

510

20

EFFICIENCY (%)

VIN = 3.6V

9 LEDs

Li-Ion Driver for Nine White LEDs Conversion Effi ciency

Loading...

Loading...