Page 1

OUTPUT VOLTAGE (V)

1

0

OUTPUT VOLTAGE ERROR (%)

3

5

7

10

10 100

138A/338A TA02

1

4

6

9

12

11

8

2

2% RESISTORS

2% RESISTORS

1% RESISTORS

1% RESISTORS

LM338

LM338

LT338A

LT338A

FEATURES

■

Guaranteed

■

Guaranteed

■

Guaranteed

■

100% Thermal Limit Burn-In

■

12A Transient Output Current

1% Initial Tolerance

0.3% Load Regulation

5A Output Current

U

APPLICATIO S

■

High Power Linear Regulator

■

Battery Chargers

■

Power Driver

■

Constant-Current Regulator

LT138A/LT338A

LM138/LM338

5A Positive Adjustable

Voltage Regulator

U

DESCRIPTIO

The LT®138A series of adjustable regulators provide 5A

output current over an output voltage range of 1.2V to 32V.

The internal voltage reference is trimmed to less than 1%,

enabling a very tight output voltage. In addition to excellent line and load regulation, with full overload protection,

the LT138A incorporates new current limiting circuitry

allowing large transient load currents to be handled for

short periods. Transient load currents of up to 12A can be

supplied without limiting, eliminating the need for a large

output capacitor.

The LT138A is an improved version of the popular LM138

with improved circuit design and advanced process techniques to provide superior performance and reliability.

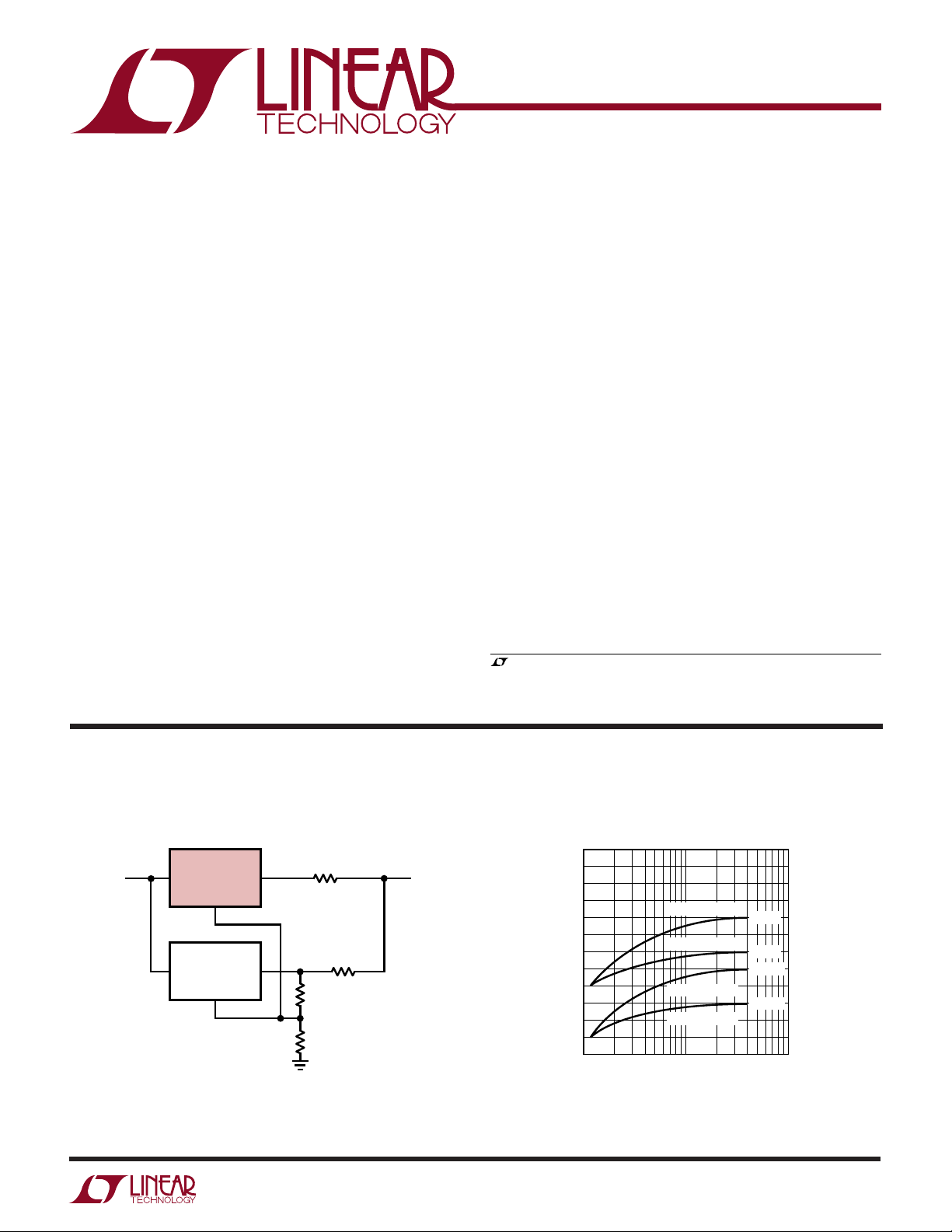

TYPICAL APPLICATIO

V

IN

THIS CIRCUIT WILL NOT WORK WITH LM VERSION DEVICES

*

CURRENT SHARING RESISTORS DEGRADE REGULATION TO 1%

**

U

Parallel Regulators for Higher Current*

LT338A

V

IN

V

IN

V

ADJ

LT350A

V

ADJ

OUT

OUT

0.01Ω**

0.016Ω**

121Ω

1%

365Ω

1%

138/338 TA01

The graph below shows the significant improvement in

output voltage tolerance achieved by using the LT138A or

LT338A.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Output Voltage Error

5V

8A

1

Page 2

LT138A/LT338A

LM138/LM338

A

W

O

LUTEXI TIS

S

A

WUW

U

(Note 1)

ARB

G

Power Dissipation.............................. Internally Limited

Input-to-Output Voltage Differential........................ 35V

Operating Junction Temperature Range

LT138A/LM138 ............................... –55°C to 150°C

LT338A/LM338 ................................... 0°C to 125°C

WU

/

PACKAGE

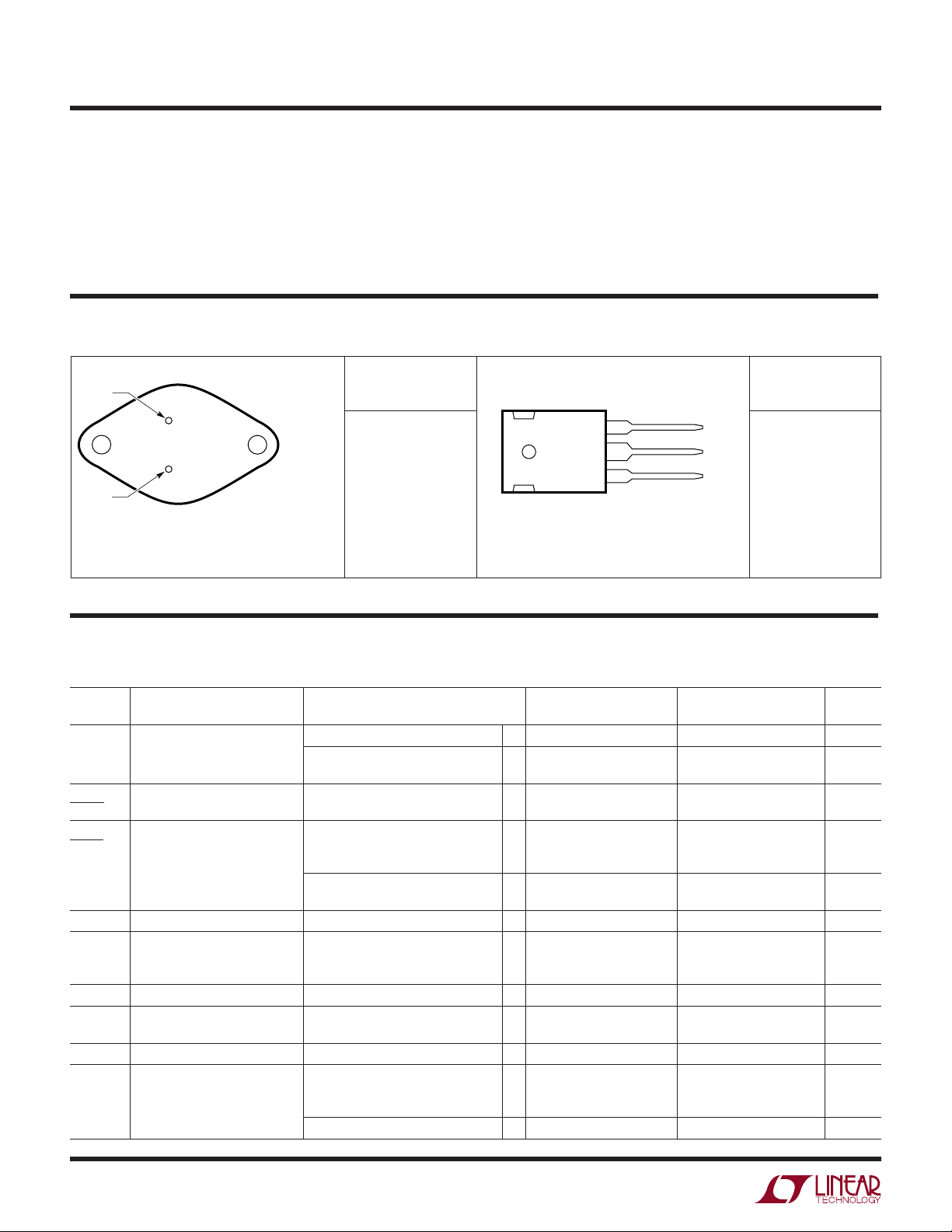

V

IN

ADJ

2-LEAD TO-3 METAL CAN

T

= 150°C, θ

JMAX

= 125°C, θ

T

JMAX

O

BOTTOM VIEW

2

1

K PACKAGE

= 35°C/ W, θ

JA

= 35°C/ W, θ

JA

RDER I FOR ATIO

ORDER

PART NUMBER

CASE

IS OUTPUT

= 1°C/ W (LT138A/LT138)

JC

= 1°C/ W (LT338A/LT338)

JC

LT138AK

LT338AK

LM138K

LM338K

Storage Temperature Range ................ – 65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

UUU

PRECONDITIONI G

100% Thermal Limit Burn-In

U

ORDER

FRONT VIEW

3

2

1

P PACKAGE

3-LEAD PLASTIC TO-3P

T

JMAX

= 125°C, θ

= 45°C/W

JA

V

V

ADJ

PART NUMBER

OUT

IN

LM338P

Consult factory for Industrial grade parts.

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. (Note 2)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

∆V

∆V

∆V

∆I

I

ADJ

∆I

I

SC

REF

OUT

IN

OUT

OUT

ADJ

Reference Voltage I

Line Regulation 3V ≤ (VIN – V

Load Regulation 10mA ≤ I

Thermal Regulation 20ms Pulse 0.002 0.01 0.002 0.01 %/W

Ripple Rejection V

Adjust Pin Current ● 45 100 45 100 µA

Adjust Pin Current Change 10mA ≤ I

Minimum Load Current (VIN – V

Current Limit (VIN – V

= 10mA, TJ = 25°C 1.238 1.250 1.262 V

OUT

3V ≤ (VIN – V

10mA ≤ I

V

≤ 5V 5 15 5 15 mV

OUT

≥ 5V 0.1 0.3 0.1 0.3 %

V

OUT

V

≤ 5V ● 20 30 20 30 mV

OUT

≥ 5V ● 0.3 0.6 0.3 0.6 %

V

OUT

= 10V, f = 120Hz

OUT

= 0µF ● 60 60 dB

C

ADJ

= 10µF ● 60 75 60 75 dB

C

ADJ

3V ≤ (VIN – V

DC ● 58 58 A

0.5ms Peak

(VIN – V

) ≤ 35V, ● 1.225 1.250 1.270 1.19 1.24 1.29 V

OUT

≤ 5A, P ≤ 50W

OUT

) ≤ 35V, (Note 3) 0.005 0.01 0.005 0.01 %/V

OUT

≤ 5A, (Note 3)

OUT

≤ 5A, ● 0.2 5 0.2 5 µA

OUT

) ≤ 35V

OUT

) = 35V ● 3.5 5 3.5 5 mA

OUT

) ≤ 10V

OUT

) = 30V, TJ = 25°C121A

OUT

● 0.02 0.04 0.02 0.04 %/V

● 612 612 A

LT138A LM138

2

Page 3

LT138A/LT338A

LM138/LM338

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. (Note 2)

LT138A LM138

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

∆V

OUT

Temperature Stability ● 12 1 %

∆Temp

∆V

OUT

Long-Term Stability TA = 125°C, 1000 Hours 0.3 1 0.3 1 %

∆Time

e

n

θ

JC

RMS Output Noise (% of V

) 10Hz ≤ f ≤ 10kHz 0.001 0.003 %

OUT

Thermal Resistance K Package 1 1 °C/W

Junction-to-Case

The ● denotes specifications which apply over the full operating temperature range,

otherwise specifications are at TA = 25°C. (Note 2)

LT338A LM338

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

REF

∆V

OUT

∆V

IN

∆V

OUT

∆I

OUT

I

ADJ

∆I

ADJ

I

SC

∆V

OUT

∆Temp

∆V

OUT

∆Time

e

n

θ

JC

Reference Voltage I

Line Regulation 3V ≤ (VIN – V

Load Regulation 10mA ≤ I

= 10mA 1.238 1.250 1.262 V

OUT

3V ≤ (VIN – V

10mA ≤ I

V

≤ 5V 5 15 5 25 mV

OUT

V

≥ 5V 0.1 0.3 0.1 0.5 %

OUT

V

≤ 5V ● 20 30 20 50 mV

OUT

≥ 5V ● 0.3 0.6 0.3 1 %

V

OUT

) ≤ 35V, ● 1.225 1.250 1.270 1.19 1.24 1.29 V

OUT

≤ 5A, P ≤ 50W

OUT

) ≤ 35V, (Note 3) 0.005 0.01 0.005 0.03 %/V

OUT

≤ 5A, (Note 3)

OUT

● 0.02 0.04 0.02 0.06 %/V

Thermal Regulation 20ms Pulse 0.002 0.02 0.002 0.02 %/W

Ripple Rejection V

= 10V, f = 120Hz

OUT

C

= 0µF ● 60 60 dB

ADJ

= 10µF ● 60 75 60 75 dB

C

ADJ

Adjust Pin Current ● 45 100 45 100 µA

Adjust Pin Current Change 10mA ≤ I

3V ≤ (V

Minimum Load Current (VIN – V

Current Limit (VIN – V

DC

≤ 5A, ● 0.2 5 0.2 5 µA

OUT

– V

IN

) ≤ 35V

OUT

) = 35V ● 3.5 10 3.5 10 mA

OUT

) ≤ 10V

OUT

● 58 58 A

0.5ms Peak ● 612 612 A

(VIN – V

) = 30V, TJ = 25°C121A

OUT

Temperature Stability ● 12 1 %

Long-Term Stability TA = 125°C, 1000 Hours 0.3 1 0.3 1 %

RMS Output Noise (% of V

) 10Hz ≤ f ≤ 10kHz 0.001 0.003 %

OUT

Thermal Resistance K Package 1 1 °C/W

Junction-to-Case

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: Unless otherwise specified, these specifications apply:

V

– V

IN

= 5V and I

OUT

= 2.5A. These specifications are applicable for

OUT

power dissipations up to 50W.

Note 3: See thermal regulation specifications for changes in output voltage

due to heating effects. Load and line regulation are measured at a constant

junction temperature by low duty cycle pulse testing.

3

Page 4

LT138A/LT338A

TEMPERATURE (°C)

–75

ADJUSTMENT CURRENT (µA)

35

40

45

75

65

138A/338A G03

30

–25 25 125

50

55

60

LM138/LM338

UW

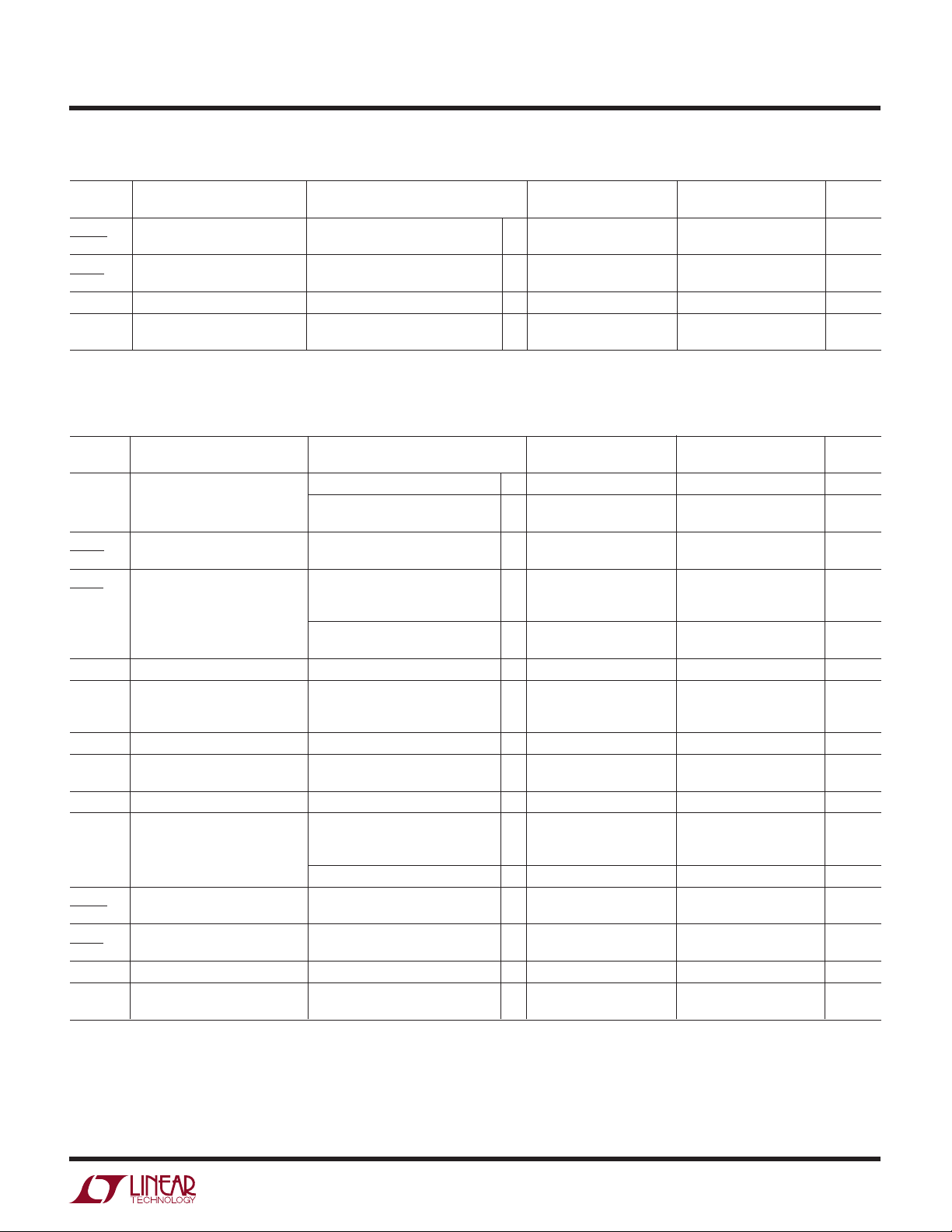

TYPICAL PERFOR A CE CHARACTERISTICS

Load RegulationLoad Regulation

0.2

= 15V

V

IN

V

= 10V

OUT

0.1

PRELOAD = 50mA

I

0

–0.1

–0.2

–0.3

OUTPUT VOLTAGE DEVIATION (%)

–0.4

–75

= 3A

OUT

I

= 5A

OUT

–50 0

–25

TEMPERATURE (°C)

50 150

25

Temperature Stability

1.270

1.260

1.250

1.240

REFERENCE VOLTAGE (V)

Dropout Voltage

4

= 100mV

∆V

OUT

3

I

= 5A

OUT

I

= 3A

2

I

= 1A

INPUT-OUTPUT DIFFERENTIAL (V)

100

125

75

138/338 G01

1

–75

–50 0

OUT

–25

25

TEMPERATURE (°C)

50 150

OUT

100

125

75

138/338 G02

Adjustment Current

Output Impedance Minimum Operating Current

0.1

0.01

OUTPUT IMPEDANCE (Ω)

0.001

10

1

VIN = 15V

= 10V

V

OUT

I

= 500mA

OUT

= C

OUT

= 0µF

C

ADJ

= C

OUT

= 10µF

C

ADJ

5

4

3

2

QUIESCENT CURRENT (mA)

1

TJ = 25°C

= 150°C

T

J

T

= –55°C

J

1.230

–50

–25 0 25 50

TEMPERATURE (°C)

75 100 125 150

138A/338A G04

0.0001

100

10

FREQUENCY (Hz)

10k

100k

1k

1M

138/338 G05

0

0

510

15 25 40

INPUT-OUTPUT DIFFERENTIAL (V)

20

30 35

138A/338A G06

Ripple Rejection Ripple RejectionRipple Rejection

100

C

= 10µF

ADJ

80

C

= 0µF

60

40

RIPPLE REJECTION (dB)

VIN – V

20

0

OUT

I

= 500mA

OUT

f = 120Hz

= 25°C

T

J

05

ADJ

= 5V

20

15

10

OUTPUT VOLTAGE (V)

25

30

138A/338A G07

35

100

80

60

40

RIPPLE REJECTION (dB)

20

VIN = 15V

V

I

0

10

OUT

OUT

= 10V

= 0.2A

100

C

ADJ

C

ADJ

= 0µF

10k

1k

FREQUENCY (Hz)

= 10µF

100k

1M

138A/338A G08

80

70

60

RIPPLE REJECTION (dB)

50

40

V

V

f = 120Hz

T

0.1

C

= 10µF

ADJ

C

ADJ

= 15V

IN

= 10V

OUT

= 25°C

CASE

OUTPUT CURRENT (A)

= 0µF

110

138/338 G09

4

Page 5

UW

TYPICAL PERFOR A CE CHARACTERISTICS

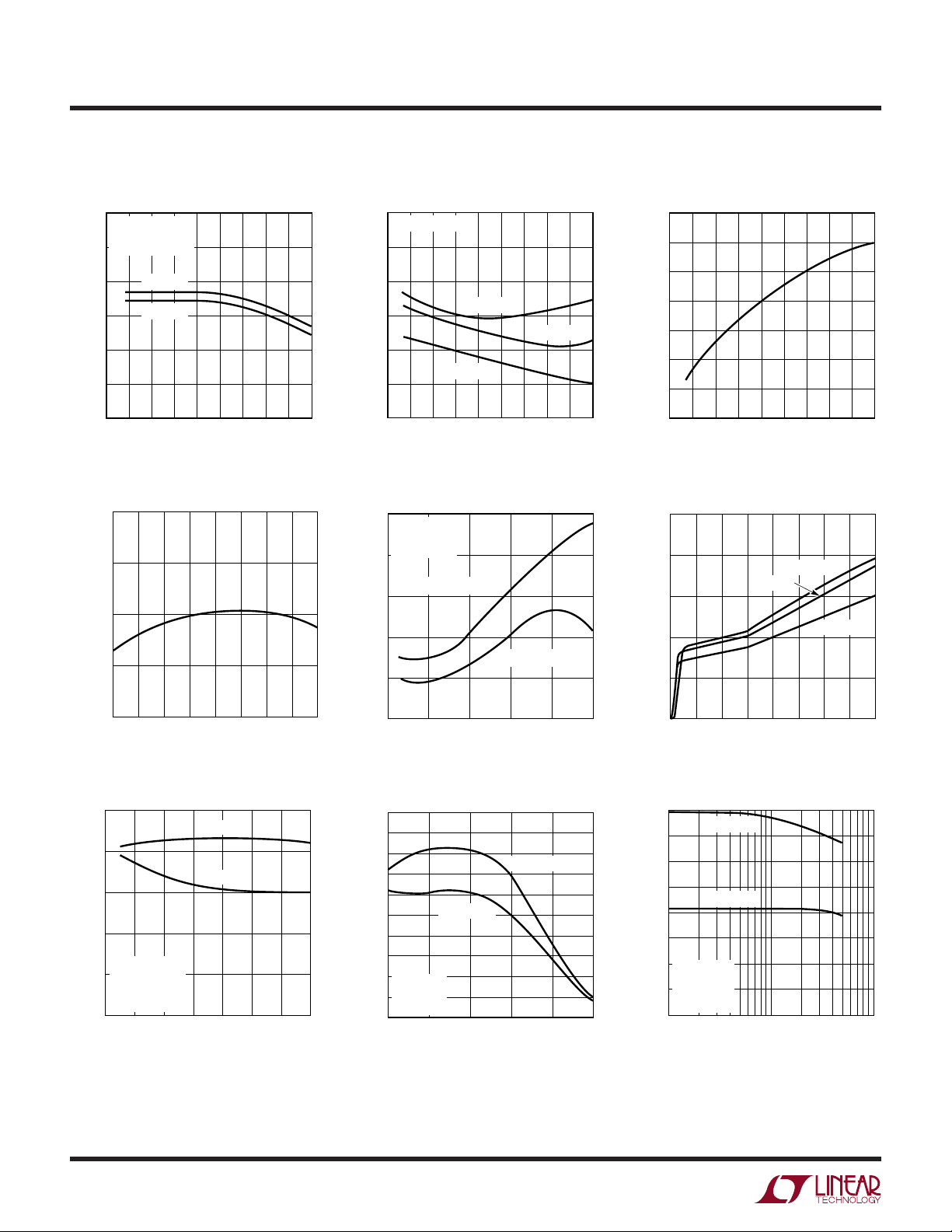

Current Limit Current LimitCurrent Limit

16

12

8

OUTPUT CURRENT (A)

4

0

0

10

INPUT-OUTPUT DIFFERENTIAL (V)

PEAK CURRENT LIMIT

DC CURRENT LIMIT

= 25°C

T

CASE

PRELOAD = 0A

PRELOAD = 5A

PRELOAD = 1A

20

30

138A/338A G10

40

14

12

10

PRELOAD = 5A

8

6

4

OUTPUT CURRENT (A)

VIN = 10V

2

= 5V

V

OUT

= 25°C

T

CASE

0

0.1

PRELOAD = 0A

1 10 100

TIME (ms)

138A/338A G11

LT138A/LT338A

LM138/LM338

14

12

10

8

6

4

OUTPUT CURRENT (A)

2

0

0.1

PRELOAD CURRENT = 0

T

= 25°C

CASE

VIN – V

VIN – V

VIN – V

VIN – V

1 10 100

TIME (ms)

= 10V

OUT

= 15V

OUT

= 20V

OUT

= 30V

OUT

138A/338A G12

Line Transient Response

1.5

V

= 10V

OUT

I

1.0

0.5

–0.5

DEVIATION (V)

OUTPUT VOLTAGE

–1.0

–1.5

1.0

0.5

CHANGE (V)

INPUT VOLTAGE

= 50mA

OUT

T

= 25°C

J

0

0

0

CL = 1µF

C

= 10µF

L

C

C

10 40

U

20 30

TIME (µs)

138A/338A G13

WUU

OUT

ADJ

= 0

= 0

APPLICATIONS INFORMATION

General

The LT138A develops a 1.25V reference voltage between

the output and the adjustable terminal (see Figure 1). By

placing a resistor, R1, between these two terminals, a constant current is caused to flow through R1 and down through

R2 to set the overall output voltage. Normally this current

is the specified minimum load current of 5mA or 10mA.

Because I

with the current through R1, it represents a small error and

can usually be ignored. It is easily seen from the output

voltage equation, that even if the resistors were of exact

value, the accuracy of the output is limited by the accuracy

of V

REF

is very small and constant when compared

ADJ

. Earlier adjustable regulators had a reference

Load Transient Response

3

2

CL = 1µF

= 10µF

C

ADJ

1

0

–1

DEVIATION (V)LOAD CURRENT (A)

OUTPUT VOLTAGE

–2

–3

6

4

2

0

010

CL = 0

= 0

C

ADJ

VIN = 15V

= 10V

V

OUT

= 25°C

T

CASE

PRELOAD = 100mA

20 40

TIME (µs)

30

138A/338A G14

tolerance of ±4% which is dangerously close to the ±5%

supply tolerance required in many logic and analog systems. Further, even 1% resistors can drift 0.01%/°C, adding additional error to the output voltage tolerance.

LT338A

V

IN

V

IN

+

I

ADJ

50µA

V

= V

OUT

Figure 1. Basic Adjustable Regulator

V

OUT

ADJ

1 + + I

REF

()

V

REF

R2

• R2

ADJ

R1

R1

R2

138A/338A F01

V

OUT

5

Page 6

LT138A/LT338A

LM138/LM338

U

WUU

APPLICATIONS INFORMATION

For example, using 2% resistors and ±4% tolerance for

V

, calculations will show that the expected range of a

REF

5V regulator design would be 4.66V ≤ V

approximately ±7%. If the same example were used for a

15V regulator, the expected tolerance would be ±8%. With

these results most applications required some method of

trimming, usually a trim pot. This solution is both expensive and not conductive to volume production.

One of the enhancements of Linear Technology’s adjustable regulators over existing devices is the tightened

initial tolerance of V

. This allows relatively inexpen-

REF

sive 1% or 2% film resistors to be used for R1 and R2 to

set the output voltage within an acceptable tolerance.

With a guaranteed 1% reference, a 5V power supply

design, using ±2% resistors, would have a worst-case

manufacturing tolerance of ±4%. If 1% resistors are used,

the tolerance will drop to ±2.5%. A plot of the worst-case

output voltage tolerance as a function of resistor tolerance

is shown on the front page of this data sheet.

For convenience, a table of standard 1% resistor values is

shown in Table 1.

Table 1. 0.5% and 1% Standard Resistance Values

1.00 1.47 2.15 3.16 4.64 6.81

1.02 1.50 2.21 3.24 4.75 6.98

1.05 1.54 2.26 3.32 4.87 7.15

1.07 1.58 2.32 3.40 4.99 7.32

1.10 1.62 2.37 3.48 5.11 7.50

1.13 1.65 2.43 3.57 5.23 7.68

1.15 1.69 2.49 3.65 5.36 7.87

1.18 1.74 2.55 3.74 5.49 8.06

1.21 1.78 2.61 3.83 5.62 8.25

1.24 1.82 2.67 3.92 5.76 8.45

1.27 1.87 2.74 4.02 5.90 8.66

1.30 1.91 2.80 4.12 6.04 8.87

1.33 1.96 2.87 4.22 6.19 9.09

1.37 2.00 2.94 4.32 6.34 9.31

1.40 2.05 3.01 4.42 6.49 9.53

1.43 2.10 3.09 4.53 6.65 9.76

Standard resistance values are obtained from the Decade Table by

multiplying by multiples of 10. As an example, 1.21 can represent 1.21Ω,

12.1Ω, 121Ω, 1.21k etc.

Bypass Capacitors

Input bypassing using a 1µF tantalum or 25µf electrolytic

is recommended when the input filter capacitors are more

than 5 inches from the device. Improved ripple rejection

≤ 5.36V or

OUT

(80dB) can be accomplished by adding a 10µF capacitor

from the ADJ pin to ground. Increasing the size of the

capacitor to 20µF will help ripple rejection at low output

voltage since the reactance of this capacitor should be

small compared to the voltage setting resistor, R2. For

improved AC transient response and to prevent the possibility of oscillation due to unknown reactive load, a 1µF

capacitor is also recommended at the output. Because of

their low impedance at high frequencies, the best type of

capacitor to use is solid tantalum.

Protection Diodes

The LT138A/LT338A do not require a protection diode

from the adjustment terminal to the output (see Figure 2).

Improved internal circuitry eliminates the need for this

diode when the adjustment pin is bypassed with a capacitor to improve ripple rejection.

If a very large output capacitor is used, such as a 100µF

shown in Figure 2, the regulator could be damaged or

destroyed if the input is accidentally shorted to ground or

crowbarred, due to the output capacitor discharging into

the output terminal of the regulator. To prevent this, a

diode D1 as shown, is recommended to safely discharge

the capacitor.

D1

1N4002

LT338A

V

IN

V

V

IN

ADJ

OUT

C

ADJ

10µF

Figure 2

NOT

R1

NEEDED

R2

+

V

C

OUT

100µF

138A/338A F02

OUT

Load Regulation

Because the LT138A is a three-terminal device, it is not

possible to provide true remote load sensing. Load regulation will be limited by the resistance of the wire connecting the regulator to the load. The data sheet specification

for load regulation is measured at the bottom of the

package. Negative side sensing is a true Kelvin connection, with the bottom of the output divider returned to the

6

Page 7

LT138A/LT338A

LM138/LM338

U

WUU

APPLICATIONS INFORMATION

negative side of the load. Although it may not be immediately obvious, best load regulation is obtained when the

top of the resistor divider, R1, is connected

case

not to the load

. This is illustrated in

directly

Figure 3

to the

. If R1

were connected to the load, the effective resistance between the regulator and the load would be:

RR

R

PP

21

+

R

1

R ParasiticLine sis ce

=, Re tan

Connected as shown, RP is not multiplied by the divider

ratio. RP is about 0.004Ω per foot using 16 gauge wire.

This translates to 4mV/ft at 1A load current, so it is

important to keep the positive lead between regulator and

load as short as possible, and use large wire or PC board

traces.

U

TYPICAL APPLICATIONS

R

P

LT338A

ADJ

V

OUT

V

IN

V

IN

PARASITIC

LINE RESISTANCE

CONNECT

R1 TO CASE

R1

R

R2

CONNECT

R2 TO LOAD

138A/338A F03

Figure 3. Connections for Best Load Regulation

L

Improving Ripple Rejection

LT338A

V

IN

+

*C1 IMPROVES RIPPLE REJECTION, X

SHOULD BE SMALL COMPARED TO R2

IN

1µF

ADJ

V

OUT

R1

121Ω

1%

R2

365Ω

1%

C

1.2V to 25V Adjustable Regulator

LT338A

V

IN

*

**

†

V

IN

+

C1*

1µF

NEEDED IF DEVICE IS FAR FROM FILTER CAPACITORS

OPTIONAL, IMPROVES TRANSIENT RESPONSE

V

= 1.25V

OUT

V

OUT

ADJ

R2

5k

R2

1 +

()

R1

R1

240Ω

+

138A/338A TA04

+

138A/338A TA03

V

C2**

1µF

C

10µF

OUT

5VV

*

L

†

7

Page 8

LT138A/LT338A

LM138/LM338

U

TYPICAL APPLICATIONS

Temperature Compensated Lead Acid Battery Charger

5V Regulator with Shutdown

LT338A

1µF

V

IN

ADJ

1k

1k

V

TTL

IN

+

V

OUT

2N3904

5V

121Ω

1%

365Ω

1%

138A/338A TA05

V

RETURN

3A

LT338A

V

IN

2N3906

ADJ

50Ω

V

OUT

243Ω

1%

10k

12V

2k

50k

138A/338A TA07

Remote Sensing

R

P

LT338A

ADJ

V

OUT

25Ω

121Ω

365Ω

7

6

LM301A

1

100pF

V

IN

IN

(MAX DROP

300mV)

V

IN

–

2

1k

+

3

8

5µF

4

V

OUT

5V

R

L

+

25Ω

138A/338A TA06

RETURN

8

Page 9

WW

SCHE ATIC DIAGRA

LT138A/LT338A

LM138/LM338

LT138A/LT338A

IN

V

300Ω

Q24

Q23

200Ω

D1

Q28

Q27

120Ω

Q26

12k

C3

6.7k

Q21

1.6k

Q19

18k

160k

400Ω

5pF

Q22

Q18

16k

D2

Q25

Q20

160Ω

3Ω

2.4k

Q17

12k

OUT

V

138A/338A SS

0.01Ω

ADJ

+

C2

C1

20k5.6k50Ω190Ω310Ω310Ω

30pF

30pF

+

Q14

3k

Q16

5.1k4.1k

Q15

Q13

Q1

Q9

Q6Q4

Q2

12.4k

4k

Q5

30k

Q12

Q10

Q11

Q8

130Ω

Q1

10Ω4.1k180Ω

Q7

Q3

160k

9

Page 10

LT138A/LT338A

LM138/LM338

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

K Package

2-Lead TO-3 Metal Can

(LTC DWG # 05-08-1310)

0.320 – 0.350

(8.13 – 8.89)

0.420 – 0.480

(10.67 – 12.19)

0.210 – 0.220

(5.33 – 5.59)

0.425 – 0.435

(10.80 – 11.05)

0.067 – 0.077

(1.70 – 1.96)

0.760 – 0.775

(19.30 – 19.69)

0.038 – 0.043

(0.965 – 1.09)

1.177 – 1.197

(29.90 – 30.40)

0.060 – 0.135

(1.524 – 3.429)

0.655 – 0.675

(16.64 – 17.15)

0.490 – 0.510

(12.45 – 12.95)

R

0.151 – 0.161

(3.86 – 4.09)

DIA, 2PLCS

0.167 – 0.177

(4.24 – 4.49)

R

K2 (TO-3) 1098

10

Page 11

PACKAGE DESCRIPTION

LT138A/LT338A

LM138/LM338

U

Dimensions in inches (millimeters) unless otherwise noted.

P Package

3-Lead Plastic TO-3P (Similar to TO-247)

(LTC DWG # 05-08-1450)

0.560

(14.224)

0.325

(8.255)

BOTTOM VIEW OF TO-3P

HATCHED AREA IS SOLDER PLATED

COPPER HEAT SINK

0.580

(14.732)

(17.780)

0.124

(3.149)

0.275

(6.985)

0.700

0.098

(2.489)

0.830 – 0.870

(21.08 – 22.10)

0.580 – 0.6OO

0.580 – 0.6OO

(14.73 – 15.24)

(14.73 – 15.24)

0.780 – 0.800

(19.81 – 20.32)

0.042 – 0.052

(1.07 – 1.32)

0.170

(4.32)

MAX

0.074 – 0.084

(1.88 – 2.13)

0.620 – 0.64O

0.620 – 0.64O

(15.75 – 16.26)

(15.75 – 16.26)

0.215

(5.46)

BSC

0.113 – 0.123

(2.87 – 3.12)

MOUNTING HOLE

0.115 – 0.145

(2.92 – 3.68)

DIA

0.170 – 0.2OO

(4.32 – 5.08)

EJECTOR PIN MARKS

0.105 – 0.125

(2.67 – 3.18)

DIA

18° – 22°

3° – 7°

0.187 – 0.207

(4.75 – 5.26)

0.060 – 0.080

(1.52 – 2.03)

0.087 – 0.102

(2.21 – 2.59)

0.020 – 0.040

(0.51 – 1.02)

P3 0996

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

11

Page 12

LT138A/LT338A

LM138/LM338

U

TYPICAL APPLICATIONS

15V

Lamp Flasher

LT338A

V

+

1k

IN

1µF

OFF

2N3904

ADJ

12k

12k

12k

V

OUT

10µF

10µF

10µF

+

+

+

12V

138A/338A TA08

Automatic Light Control

LT338A

V

IN

ADJ

V

OUT

1.2k

138A/338A TA09

Protected High Current Lamp Driver

15V

12V

5A

TTL OR

CMOS

LT338A

ADJ

V

IN

V

OUT

10k

138A/338A TA10

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1084 5A Low Dropout Operates to 30V Input

LT1580 7A Fast Transient Response Regulator with 0.7V Dropout For 3.3V to 2.xxV Applications

LT1581 10A Fast Transient Response Regulator For 3.3V to 2.xxV Applications

LT1585/LT1587 7A/4.6A/3A Low Dropout Fast Transient Response Regulator For 1.2V to 3.3V Outputs from 5V

12

Linear T echnology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

138afa LT/LT 1199 2K REV A • PRINTED IN THE USA

LINEAR TECHNOLOGY CORPORATION 1991

Loading...

Loading...