Page 1

ELEC-XROMC COMI’ONEXTS GROUP

SW CORPORATION

f

DEVICE SPECIFICATION FOR

\

Light Emitting Diode

MODEL No.

LTlF67AF

1

1. These specification sheets include materials protected under the copyrjght of Sharp Corporation (“Sharp”).

Please do not reproduce or cause anyone to reproduce them without S* consent

2. When using this product, please 0bsen.e the absolute maximum ratin&!q.nd the instructions for use outlined

in these specification sheets, as well as the precautions mentioned bei@%. Sharp assumes no responsibility

for any damage resulting from use of the product which does not

and the instructions inchrded in these specification sheets, and the precautions mentioned below.

(Precautions)

(1) This products is designed for use in the foUowtig application areas;

* OA equipment * Audio visual equipment * Home tippliance

* Telecommunication equipment (Terminal)

* Tooling machines * Computers

[

If the use of the product in the above application areas is for equipment listed in paragraphs .

(2) or (3), please be sure to observe the precautions given ixi those respective paragraphs.

(2) Appropriate measures, such as fail-safe design and redundant design considering

the safec design of the overall system and equipment, should be taken to ensure reliability

and safety when this product is used for equipment which d&$nds high reliability and

safety in function and precision, such as ;

* Transportation control and safety equipment (aircraft, t@n, automobile etc.)

* Traffic signals * Gas leakage sensor breakers

* Other safety equipment

L

(3) Please do not use this product for equipment which require extremely high reliability

and safety in fnnction and precision, such as ;

* Space equipment * Tekcommunication equipment (for trunk lines)

+ Nuclear power control equipment

C

(4) Please contact and consult with a Sharp sales representative if there are any questions

regarding interpretation of the above three paragraphs.

* Medical equipment

* Measur@g.equipment

. . .

c&r+&

tith the absolute maximum ratings

Ii:. )

.

3

* R@ue and security equipment

/

I

I

1 .

3. Please contact and consult with a Sharp sales representative for any questions about this product.

CUSTOMER’S APPROVAL

DATE:

BY:

DATE:

PRESENTED BY:

Department General Manager of

Enginewing Dept.,BI

Opto-Electronic Devices Division

Electronic Components Group

SHARP CORPORATION

hp. & I t?b

:

Page 2

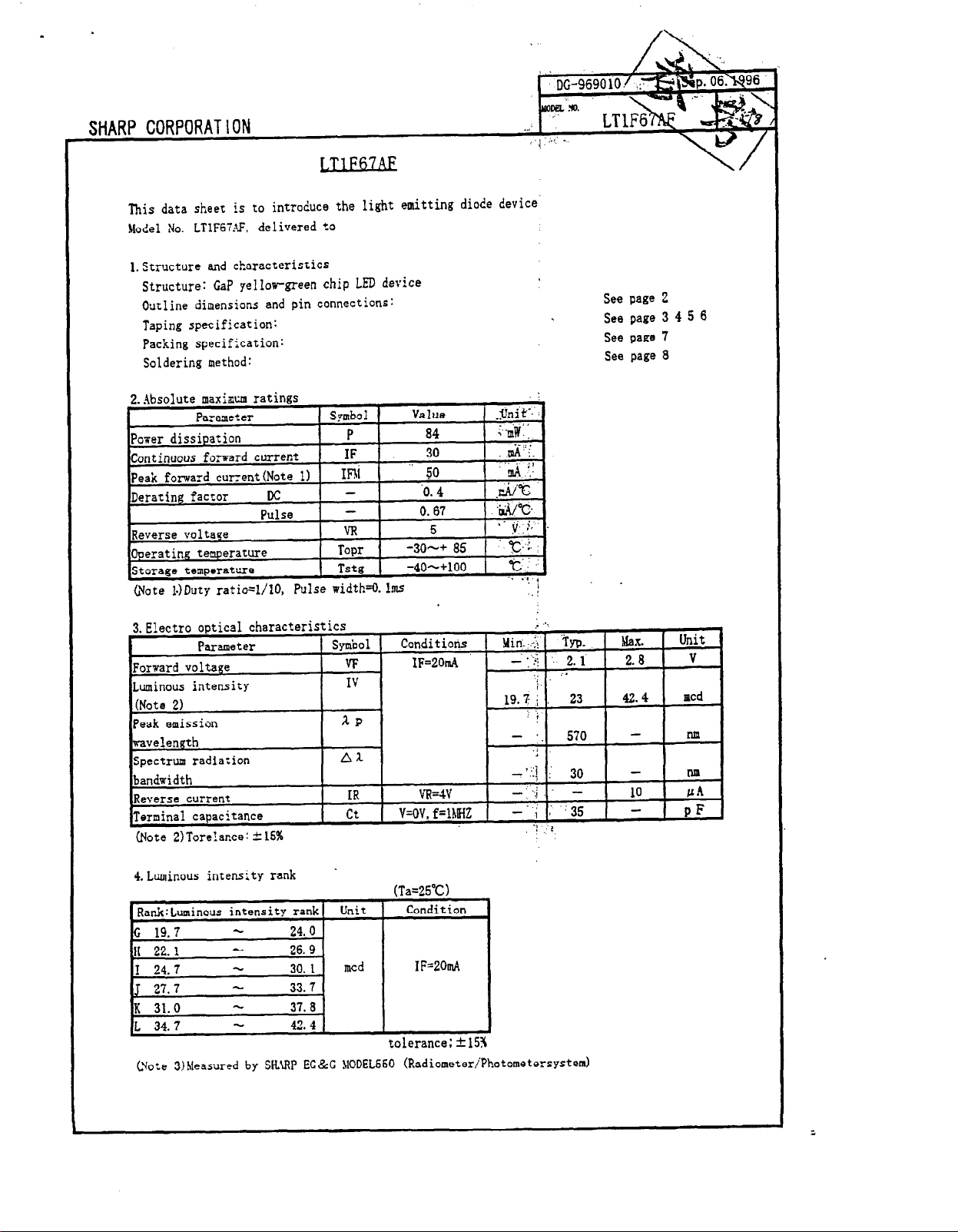

This data sheet is to introduce the light emitting diode device’

Model No. LTlF61.G. delivered

to

l.Structure and characteristics

Structure: CaP gellorgreen chip LED device

Outline dimensions and pin connections:

Taping specification:

Packing specification:

Soldering method:

@ate l.)Duty ratio=l/lO, Pulse width*. lm~

See page 2

See page 3

See page 7

See page 8

4 5 6

(Note 2)Tore!ance: 415%

4. Luminous intensity rank .

(Ta=25”C)

Condition

c 19.7 -

24. 0

H 22.1 - 26. 9

I 24.7 - 30. I mcd

J 27.7 -

K 31.0

L 34.7 -

- 37. 0

33.7 .

42. 4

IF=201n4

t

.olerance; f 15?

Cvote 3)Measured by SH.UP EC&C ~lODEL660 (RadiometeriPhotometersystem)

Page 3

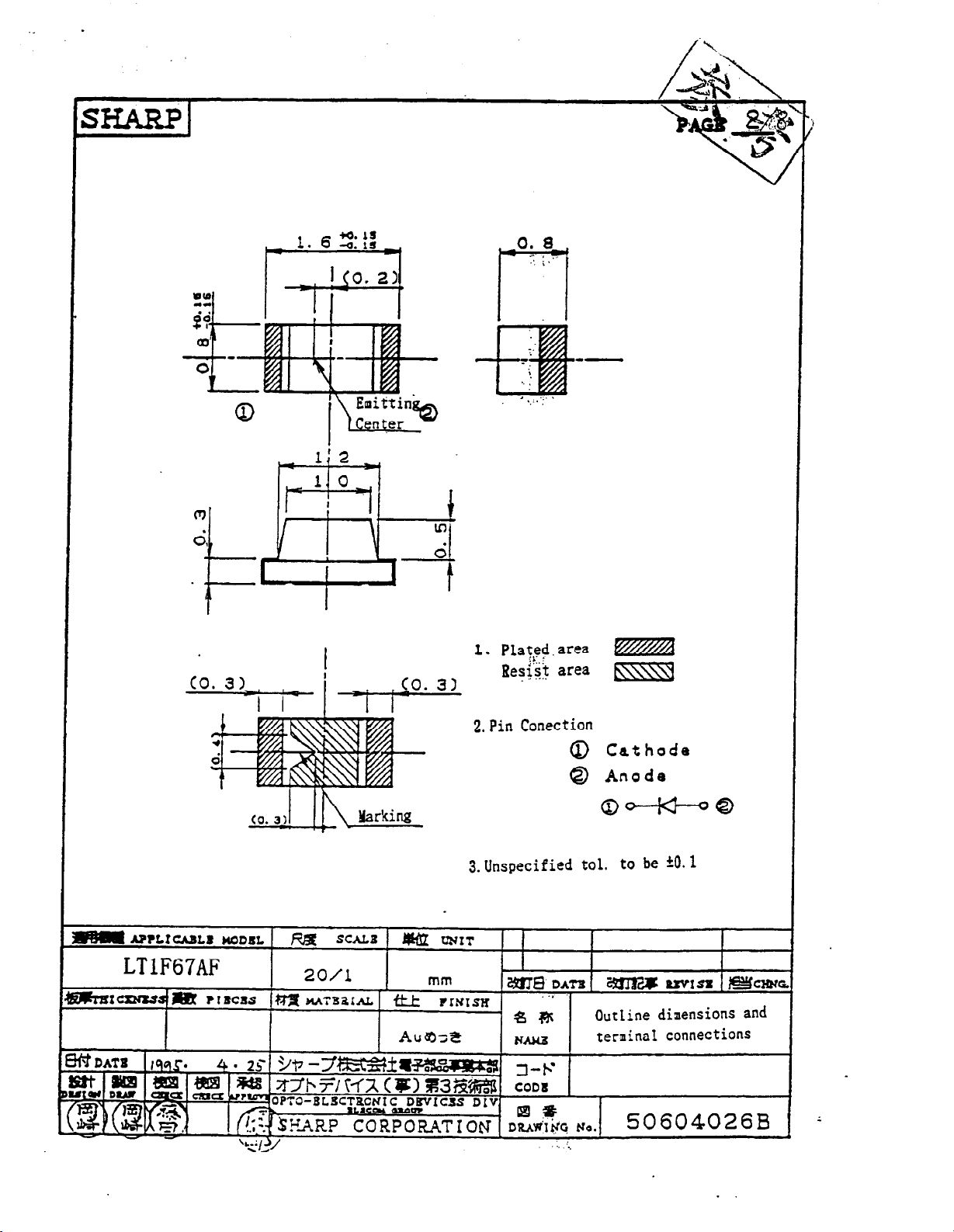

1. Plated.

j!:.;

ReqJ area

2.

Pin Conection

area

M

bxq

0 Cathode

@ Anode

0-0

3. Unspecified tel. to be

Outline dimensions and

terminal connections

iO.1

Page 4

1. This &tO 0h~t 10 to i*troduor thr lapin* sodi,i,fi~mlioO .Of LJ!U

* dcrlcc. lode1 Ho. LmwAF

2 taping

2. I tapiag rptciflc2tioo

2.2 Shipment table

spcciflcatlaa

.

‘SHIPMENT TABLE /-Hodel number

PA-IT NO.

QUANTITY

-Quantity of

- Lot amber* :

prodqcts

noi3[1oaaa

-m --v

LOT No. @ 0 ‘0 @ 8

SHARP

UADC IN JAI.4.Y

- Luminous intensity rank

. *:Lo e indication

0 Production plant code(to be indicated alphabetically)

$3 Production Lot(singie or double figures)

3 Year of producrion(che last tuo figures of

the year)

8 Konch of production

(to be indicated alphabetically with January corresponding to A)

d Date of production(Ol-31)

Page 5

2.3 Rcl+tcd l ttcrs

2.3.1. Packing

There should not be missing’rbova

2.3.2. true strength

1)Cover’trpe strength against peel iag: F=

continuous tbrte products.

0.1-O. 8N (I=lO*

or

Ied)

+-- Forward

2) Tape strength

The radius

If it .is less than 30aa.‘the

2.3.3. Taking

out of

11 Products should be

2) Products

2.3.4.. Jointing of true

There should not

3:

@anti

tp per reel

Average: 4.000 pcs.

against bending

of bending

products

should not

be

joint of cover tape or csrrier tape.

per reel

Cdneir tape

circ!e should

cover

easily

taken

be 30~ or aore.

tape may psi.

out.

be attached to the eover’taph rt txeling.

Page 6

4-1. Taping

4-1-I. Shape and diwnsion of tape(TYP. >

.

\/I

r3 -

: P2 ’

PI

-I

Parameter ~ysbol~imens iod Benarks

Concave square ‘fere icai

hole lot part

iasertion Pitch

Round

sprocket _

hole Position E

Center

cer dimension

Cover

Carrier

kickness of the entire

unit

3 i-taterial

Co

ten-

cape

tape Uidch

Horitoatal B

Diameter Da

Pitch

Vert.dire P2

Hori .dire F

Wid:h ( W,

Thickness 1 t3

Thickness 1 cl

Carrier

cape

A

1 1.1)am Dimeasioq excludes cocaes R

I 1.9mm

pi 1

PO

4. Omm

1. sala

4.Omn

1.75mm

2.omm

3.5ms

5.5mm 1

at inside

AccumuLa{:ed error

DistaaciI:becueen

Ceacer Line of

round

0. lnm [

1 wo

to

. ..PET. Cover tape...Polyescer

8. Omm ) .

0.2mm 1

1.2IIFA

With cover tape and carrier tape combined

bottom

. .

tape edge and hole center

the concave square hole and

sprocket hole

i0.5mm/lO

pitch

1

X--I

Page 7

a-l-2.Shapc and dimensian of reel (TYP. )

Parameter -

Diameter

Flange Thickness

Inner space direccioa 1 W

Hub

External

Spindle bale

Key

diameter E )6Qmm

diameter C

slit Width 1 E 1 2.0mm

Degch 1 U

Notation for part came etc.

3 Hatcrial: Reel.. .Polystyrene

1 Symbol } Dimension )’ &e@rks

I A

I c

Labeling on one side of f Lange.

I

9178mm

l.Smm

1anlm

+13fUlQ

4.5mm

Diqension of shaft

1 (Part name.quantity,loc No.)

core

Page 8

Packing Specification

In order to avoid the absorption of humidity in transport .a& storage, the~devices are

psdtcd in alusim0 skve.

4

1. Storage Conditions

The storage should lx done under follaaing conditions:

Temperature . 5 to 3oc

Humidity

less than 6OUl-l

2. Treatment after Opening

1)

Please

make a soldering within 2 days after opening under following conditions:

.-

Temperature 5 to 3OC

Humidity

less than 60;YRH

2) In case the devices are not used for a long time after opening, the storage in dq box

is recommendable. Or it is better to repack the devices with a desiccative by the

sealer

and put them in the same storage conditions as 6-I. Then they should be used rithin 2

W?XkS.

3) Please make a soldering after a following baking treatment if unused term should be

over the amditions of 2).

Remmendable Gmdi tions:

(TJ in taping

Tesprature 60t Time 90 to 100 Hours

@ in individual ( on PIB or metallic tray >

Temperature 11OC Time 3 to 4 Nours

Page 9

M aunt ing precautions

1. Soldering

l-1

Xeflow soldering

To be

doae’undet

the following conditiqa.

I

UN. EOse c

Recommendable T hermal M ode1

1-2 Reflow soldering precautions

Second time soldering

(Storage condition:at30C,RH(60%)

2. Soldering iron method

At 3OOC withln r seconds

When using a soldering iran.care must be taken not to damage the package

(Pay attion not to altou any undue stress or heat

shoufd be done witin 8 ham after the first one is l%shcd

ux. 5’5 ec

P3(

on package.)

1

Z

X-l

Page 10

LT1F67AF

Loading...

Loading...