Page 1

PREPARED BY:

APPROVED BY:

SHAR!FW$~~~~~;~.,

DG-001019

Jan/19/00

‘.

.:

.

13 pages

ELECTRONIC COMPONENTS GROUP

SHARP CORPORATION

‘-*+E’~SE~~T~ DMSION:

.\.\” ;r y ,o’:.>.r.b

\,

SPECIFICATION

optbE~~~~~c~e\i~ion

-...,b? :;” !,f&%\

\

DEVICE SPECIFICATION FOR

Light Emitting Diode

MODEL No.

LTlE9OA

/

1. These specification sheets include materials protected under the copyright of Sharp Corporation (“Sharp”).

Please do not reproduce or cause anyone to reproduce them without Sharp’s consent.

2. When using this product, please observe the absolute maximum ratings and the instructions for use outlined

in these specification sheets, as well as the precautions mentioned below. Sharp assumes no responsibility

for any damage resulting kom use of the product which does not comply with the absolute maximum ratings

and the instructions included in these specification sheets, and the precautions mentioned below.

(Precautions)

(1) This products is designed for use in the following application areas;

[

* OA equipment * Audio visual equipment

* Home appliance

* Telecommunication equipment (Terminal) * Measuring equipment

* Tooling machines * Computers

I

If the use of the product in the above application areas is for equipment listed in paragraphs

(2) or (3), please be sure to observe the precautions given in those respective paragraphs.

(2) Appropriate measures, such as fail-safe design and redundant design considering

the safety design of the overall system and equipment, should be taken to ensure reliability

and safety when this product is used for equipment which demands high reliability and

safety in fimction and precision, such as ;

[

* Transportation control and safety equipment (aircraft, train automobile etc.)

* Traffic signals * Gas leakage sensor breakers * Rescue and security equipment

l

Other safety equipment

I

(3) Please do not use this product for equipment which require extremely high reliability

and safety in function and precision, such as ;

I

* Space equipment * Telecommunication equipment (for trunk lines)

* Nuclear power control equipment * Medical equipment

1

(4) Please contact and consult with a Sharp sales representative if there are any questions

regarding interpretation of the above three paragraphs.

3. Please contact and consult with a Sharp sales representative for any questions about this product.

CUSTOMERS APPROVAL

-

DATE:

BY:

Department General Manager of

Engineering Dept.,IB

Opto-Electronic Devices Division

Electronic Components Group

SHARP CORPORATION

Page 2

1. Application

This specification applies to the light emitting diode device Model No. LTlESOA.

[GaP(Yellow-green)cbip LED device]

2. Outline dimensions and terminal

cormecti~n~

. ..-..............-....Refer to the attached sheet Page 2.

3. Ratings and characteristics

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refer to the attached sheet Page 3-5.

3- 1. Absolute maximum ratings

3-2. Electra-optical characteristics

3-3. Derating Curve

3-4. Characteristics Diagram

4. Reliability

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refer to the attached sheet Page 6.

4- 1. Test items and test conditions

4-2. Failure judgement criteria

5. Incoming inspection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...*

Refer to the attached sheet Page 7.

5-I. hrspection method

5-2. Description of inspection and criteria

6. Taping specification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*.......*.....*

Refer to the attached sheet Page 8-10.

6-1. Taping

6-2. Packing specification

6-3. Label

6-4. Luminous intensity rank

7. Soldering

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refer to the attached sheet Page Il.

7- 1. Reflow soldering

8

Precautionsforuse...............................................

Refer to the attached sheet Page 12.

8-1. Precautions matters for designing circuit

8-2. Cleaning method

9 Environment.....................................................

Refer to the attached sheet Page 12.

9-l. Ozonosphere destructive chemicals.

9-2. Bromic non-burning materials

Page 3

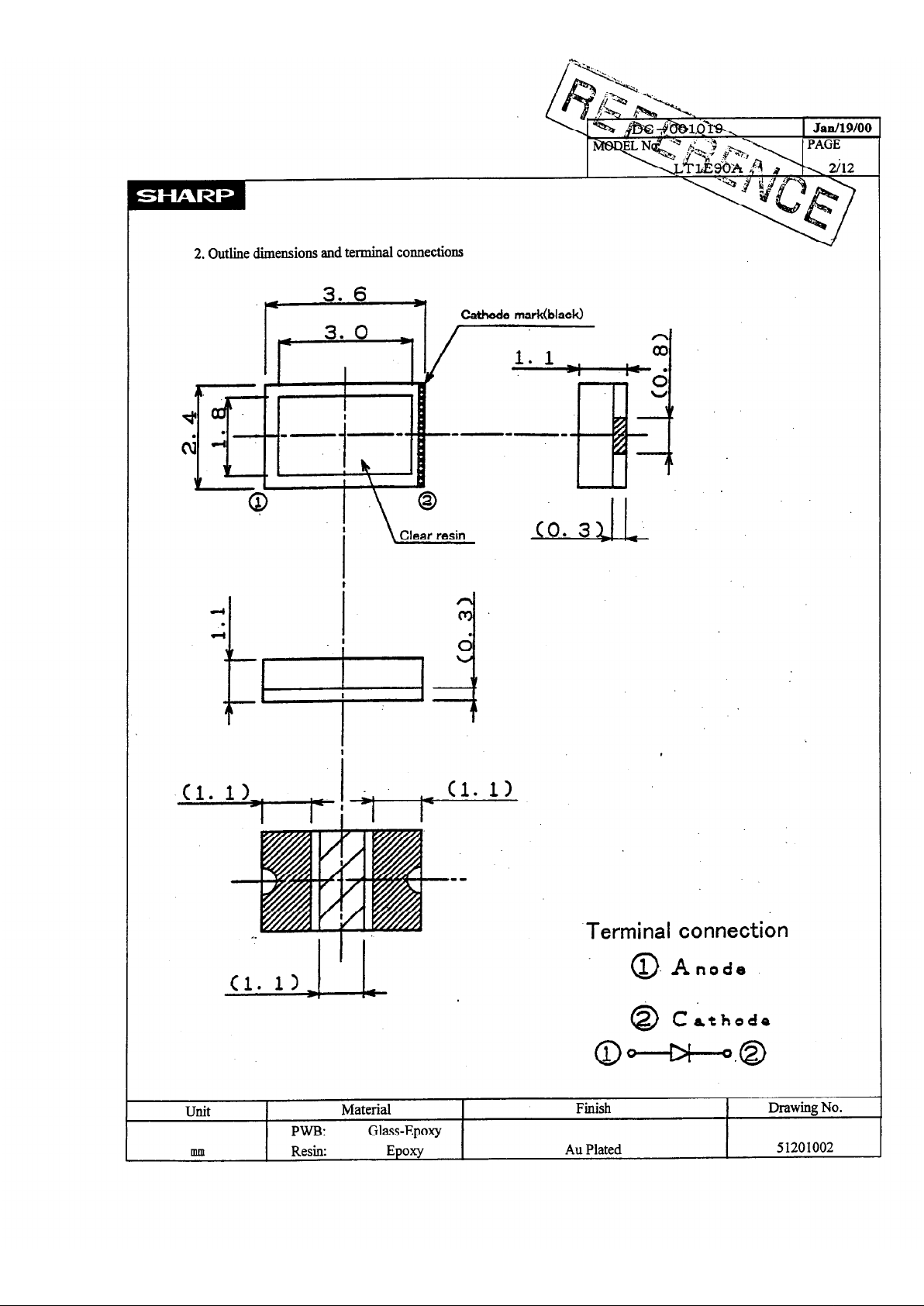

2. Outline dimensions and terminal connections

3. 6

Cathcde mark(blacti

n

cc

-6

.

t

Terminal connection

,I;x

O-Anode

oc

athode

0-Q

unit

mm

Material

Finish

Drawing No.

PW:

Glass-Epoxy

Resin:

Epoxy

Au Plated

51201002

Page 4

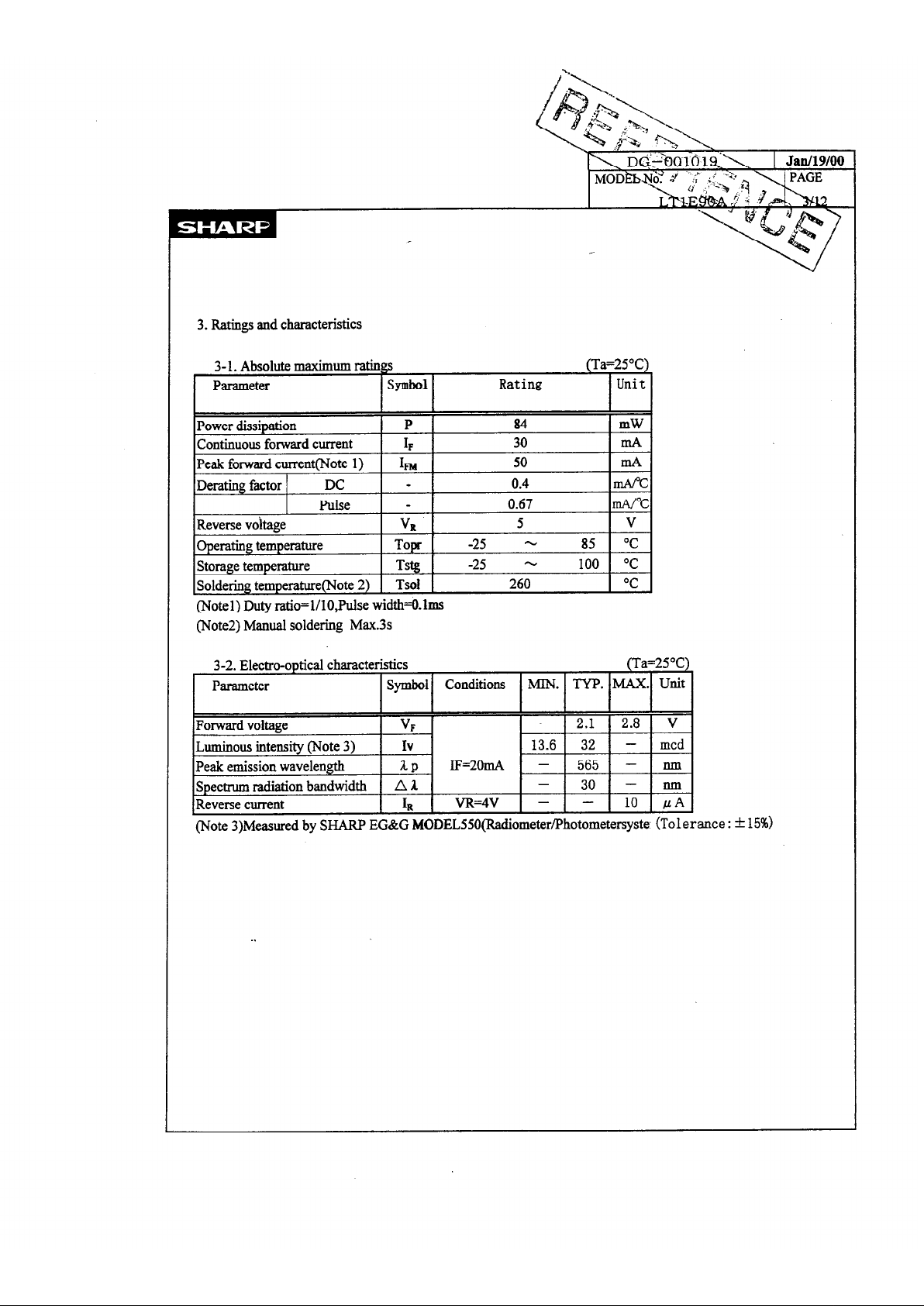

3. Ratings and characteristics

(Notel) Duty ratio=l/lO,Pulse width=O.lms

(Note2) Manual soldering Max3s

(Note 3)Measured by SHARP EG&G MODEL550(Radiometer/Photometersyste- (Tolerance : f 15%)

Page 5

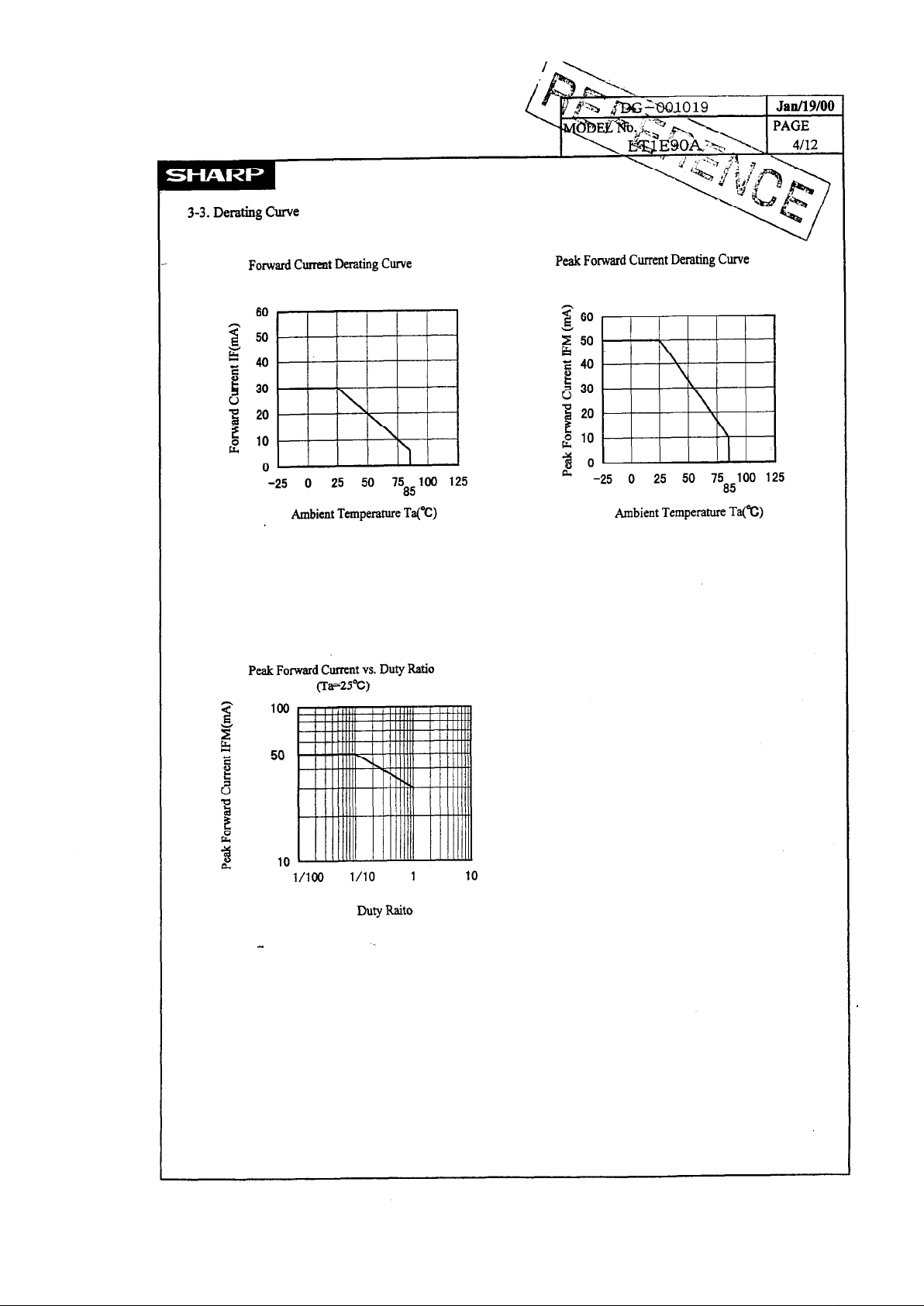

3-3. Derating Curve

Forward Cm-rent Derating Curve

Peak Forward Current Derating Curve

60

0

-25 0 25 50 7565100 125

Ambient Temperature Ta(“C)

Peak Forward Current vs. Duty Ratio

(Ta=259c)

$

60

j 50

E

40

E

6 30

-$j

20

2

g

10

+i k

0

-25 0 25 50 7565100 125

Ambient Temperature Ta(%)

I

l/loo

l/10 1 10

I

Duty Raito

Page 6

34. Characteristics Diagram(typ) (Note I)

Forward Current vs.Forward Voltage

CTa=250C)

1 1.2 1.4 1.6 1.6 2 2.2 2.4

Forward Voltage VF(V)

R&he, Luminous Iitedy -a!. Forward CmmB

Cla=250C)

1000%

Forward Current IF(mA)

Relative Luminous Intensity

vs. Ambient Temperature

IIF=2omAI

loo0

Q

@

.2

E

Y

2 loo

0

.c

E

3

8

2

3

3 1ol"""""""""

-60 -40 -20 0 20 40 60 80 100 120

Ambient Temprature Ta(“C)

(Note 1) Above characteristic data are typical data and not a guarantteed data.

Page 7

4. Reliability

The reliability of products shall be satisfied with items listed below.

4- 1. Test items and test conditions

I

Test items

I

Test conditions

Confidence level: 90%

temperature cycling I -25”c(3Omin)-+lOO”c(3Omin),3Otimes

High temp. and high

humidity storage

Ta=+60”C, 9O%RH, t-500h

High temperature storage Ta=lOO”C,t=SOOh

Low temperature storage I Ta=-25”C,t-500h

Operating test

Ta=25”C,I,=30mA,t=50Oh

Mechanical shock

15 ooom/s2, o.sms,

3times I *X&Y+Z direction

Variable f?equency I 200m/s2, 100-2 000-IOOHAsweepfor 4min.,

vibration 4times/*X.*Y.*Z direction

Soldering heat

Refer to the attached sheet,

Page 11/12 ltimes

n=22, c=o 10

n=22, c=o 10

n=22, c=o 10

n=22, c=o

10

n=22, C=O

10

n=ll, C=O 20

n=ll, C=O 20

n=ll, c=O 20

4-2. Failure judgement criteria * 1

Parameter Symbol Failure judgement criteria *2

Forward voltage

VF

VF > u&L. x 1.2

Reverse current

IR

IR > U.S.L. x 2.0

Luminous intensity

Iv The Grst stage value X 0.5 > Iv

* 1: Meas+g condition is in accordance with specification.

*2: U.S.L. is shown by Upper Specification Limit.

Page 8

5. Incoming inspection

5- 1. Inspection method

A single sampling plan, normal inspection level S4 based on IS0 2859-l shall be adopted.

5-2. Description of inspection and criteria

JO.

Inspection items

Criteria

Defect

AQL

1 Radiation color

Not correct

2 Taping

Product inserted in reverse direction

Major

defect

0.1%

3 Solderability 1

Plating abnormality observed over 50% or

greater percentage * 1

4

Electra-optical

characteristics

Not conforming to, the specification

5 Outline dimensions

Not conforming to the specification

6 Appearance

Dust : @ 0.8mm or more

Thread dust : 2Smm or more in length and 0.25mm or

more in width

Air bubbles : 4 0.8mm or more

Scratch : 2.5mm or more in length and 0.25mm or more in

width

However&e product is qualified as a good unit if the

scrach does not touch the Auwire.when seen from the front.

Resin barr : Over the unspecified tolerance

Minor

defect

0.4%

Resin ond plated crack :0.3mrn or more

7 Solderability 2

could solder 50% or greater and less than 90% out of

judgement area * 1

. _

Page 9

6-l .Taping

6-I-l.Shape and dimension of tape(TYP.)

ension exe

6-I-2.Shape and dimension of reel(TYP.)

Parameter Symbol ~Dimaasio~/

Remarks

Page 10

6-l-3 .Taping specification

6-2-2.Strage

conditions

Temperature : 5 to 30°C Humidity : less than 6O%RH

*Recommendable conditions:

0 in taping

Temprature:60”C to 65”C,Time:36 to 48 hours

@ in individual (on PWB or metallic tray)

Temprature:100°Cto1200C ,Time:2 to 3 hours

(2) Cover tape strength against peeling:F=O.l-UN( 6 =lOOor less)

Cover tape

t ’ - ‘Tape speed :

5mm/s

<- Forward

Carrier tape

(3) Tape strength against bending:

The radius of bending circle should be 30mm or more.

If it is less than 3Omm, the cover may peel.

(4) Jointing of tape:

There should not be joint of cover tape or carrier tape.

(5) Quantity per reel:

Average 3,OOOpcs. per reel

(6) Mass per product:

Average 0.02g I product

(7)Mass per packing:

Average 15Og I packing

(8) Others: @ There should not be missing above continuous three products.

@ Products should be easily taken out.

@ Products should not be attached to the cover tape at peeling.

6-2. Packing specification

6-2-l. Dampproof package

In other to avoid the absorption of humidity in transport and storage,

the products are packed

in aluminum sleeve.

Label

6-2-3.Treatment after opening

(1) Please make a soldering within 15 days after opening under following condition;

Temperature : 5 to 30°C Humidity : less than 6O%RH

(2) In case the devices are not used for a long time after opening ,tbe storage in dry box is recommendable.

Or it is better to repack the devices with a desiccative by tbe sealer and put them in the some storage

conditions as 6-2-2. Then they should be used within 15 days.

(3) Please make a soldering after a following baking treatment if unused term should be over the conditions of (2)

Page 11

PART No.

- Model number

- Quantityofproducts

3T No.IW9819

+ EL4J C-3 Bar code

- Lot m&ber(Notel) and Luminous rank

- Production Cm@’

(Note l)Lot number indication

0 Production plant code(to be indicated alphabetically)

@ Prod&ion lot(smgle or double figures)

@ Year of production(the last two figures of the year)

@ Month of production

(to be indicated alphabetically with January corresponding to A)

L

@ Date of production(0 l-3 1)

64Luminous intensity rank (Note2) (Note3)

A

B

C

D

,!

I

Luminous intensity Unit

13.6 - 22.1

16.3 - 265

19.6

- 31.7

23.5 - 38.2

mcd

Ta=25”C)

Condition

Ir=2OmA

I

I 1 58.5 - 95.0

J

1 70.2 -

(114.0)

(Tolerance : f 15%)

(Note 2) Not ask the delivery ratio of each rank.

(Note 3)

In case of the distribution of the hrminous intensity shift to high, at that point new upper rank is

prescribed and lower rank is delete.

Page 12

7- 1 Jteflow soldering

(1) It is not recommended to exceed the soldering temperature and time shown below.

Caused by substrate- bend or the other mechanical stress during reflow soldering

may happen Au wire disconnection etc. Therefore please check and study your

solder reflow machine’s beat condition.

(2) Reflow soldering temper&u-e profile

to be done under the following condition.

Time(s)

Recommendable Thermal Model

(3) Recommendable Metal Mask pattern for screen print

Recommend OSmm to 0.7mm thickness metal mask

for screen print. Caused by solder reflow condition,

solder paste, substrate and the other material etc.,

may change solderability.

Please check and study actual solderability before

usage.

/ -.

Center of the product

._

J I

w

c\i

* 1.75 - & 2 0 - _ 1.75 ~

I --

-

Recommended soldar pattern (U&mm)

Page 13

Jad19IOO

8. Precautions for use

8- 1. Precautions matters for designing circuit

This product is not designed as electromagnetic and ionized-particle radiation resistant

8-2. Cleaning method

Please use only the following types of solvenL”water”

Recommend conditions:

RT. 4OkHz,3OW/l, time is less than 3 minutes

Please check the effect on the product from ultrasonic bath, ultrasonic output, duration, board size method.

and product mounting

Please test the cleaning method under actual conditions and check for abnormalities before actual use.

9. Enviromnent

9- 1. Ozonosphere destructive chemicals.

(1) The product doesn’t contain following substance.

(2) The product doesn’t have a production line whose process requires following substance.

Restricted part: CFCs,haloneqCCl.+Trichloroethane(Methychloroform)

9-2. Bromic non-burning materials

The product doesn’t contain bromic non-burning materials(PBBOs,PBBs)

Page 14

LT1E90A, surface mount, yellow-green, 3 mm x 3 mm, 670 nm, chip LED

Loading...

Loading...