Page 1

FEATURES

■

UltraFast: 4.5ns at 20mV Overdrive

7ns at 5mV Overdrive

■

Low Power: 4mA per Comparator

■

Optimized for 3V and 5V Operation

■

Pinout Optimized for High Speed Ease of Use

■

Input Voltage Range Extends 100mV

Below Negative Rail

■

TTL/CMOS Compatible Rail-to-Rail Outputs

■

Internal Hysteresis with Specified Limits

■

Low Dynamic Current Drain; 15µA/(V-MHz),

Dominated by Load In Most Circuits

U

APPLICATIO S

■

High Speed Differential Line Receiver

■

Crystal Oscillator Circuits

■

Window Comparators

■

Threshold Detectors/Discriminators

■

Pulse Stretchers

■

Zero-Crossing Detectors

■

High Speed Sampling Circuits

LT1720/LT1721

Dual/Quad,

4.5ns, Single Supply

3V/5V Comparators

with Rail-to-Rail Outputs

U

DESCRIPTIO

The LT®1720/LT1721 are UltraFastTM dual/quad comparators optimized for single supply operation, with a supply

voltage range of 2.7V to 6V. The input voltage range extends

from 100mV below ground to 1.2V below the supply voltage.

Internal hysteresis makes the LT1720/LT1721 easy to use

even with slow moving input signals. The rail-to-rail outputs

directly interface to TTL and CMOS. Alternatively, the symmetric output drive can be harnessed for analog applications

or for easy translation to other single supply logic levels.

The LT1720 is available in the 8-pin MSOP and SO packages;

three pins per comparator plus power and ground. The

LT1721 is available in the 16-pin SSOP and S packages.

The pinouts of the LT1720/LT1721 minimize parasitic effects

by placing the most sensitive inputs (inverting) away from the

outputs, shielded by the power rails. The LT1720/LT1721 are

ideal for systems where small size and low power are

paramount.

, LTC and LT are registered trademarks of Linear Technology Corporation.

UltraFast is a trademark of Linear Technology Corporation.

U

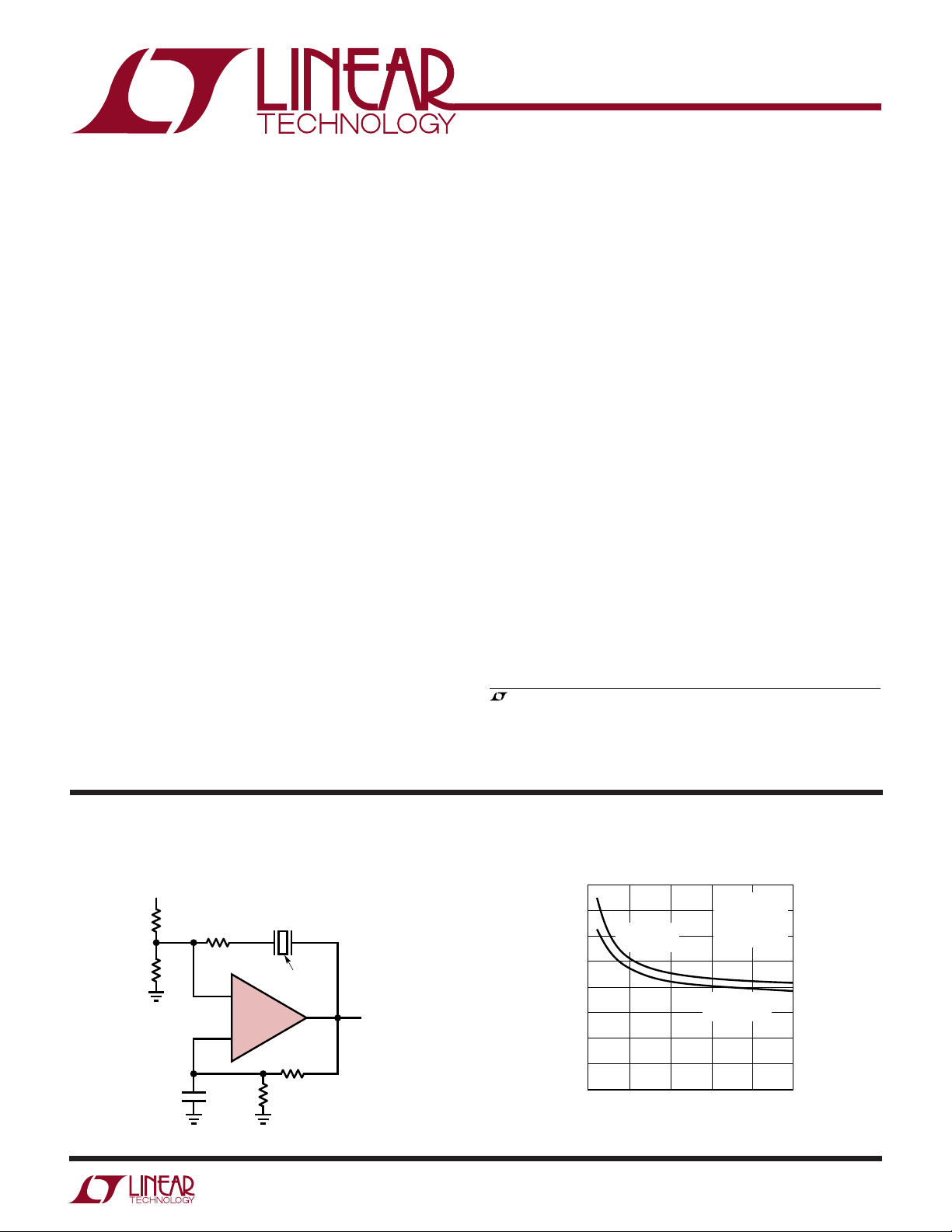

TYPICAL APPLICATIO

2.7V to 6V Crystal Oscillator with TTL/CMOS Output

2.7V TO 6V

2k

620Ω

1MHz TO 10MHz

CRYSTAL (AT-CUT)

220Ω

+

C1

1/2 LT1720

–

0.01µF 1.8k

GROUND

CASE

2k

1720/21 TA01

OUTPUT

Propagation Delay vs Overdrive

8

7

RISING EDGE

6

5

4

DELAY (ns)

3

2

1

0

0

)

(t

PDLH

FALLING EDGE

10 20 40

OVERDRIVE (mV)

30

25°C

V

STEP

V

CC

C

LOAD

(t

= 100mV

= 5V

PDHL

= 10pF

)

50

1720/21 TA02

1

Page 2

LT1720/LT1721

WW

W

ABSOLUTE MAXIMUM RATINGS

U

(Note 1)

Supply Voltage, VCC to GND ...................................... 7V

Input Current ...................................................... ±10mA

Output Current (Continuous) ............................. ±20mA

Junction Temperature........................................... 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

U

W

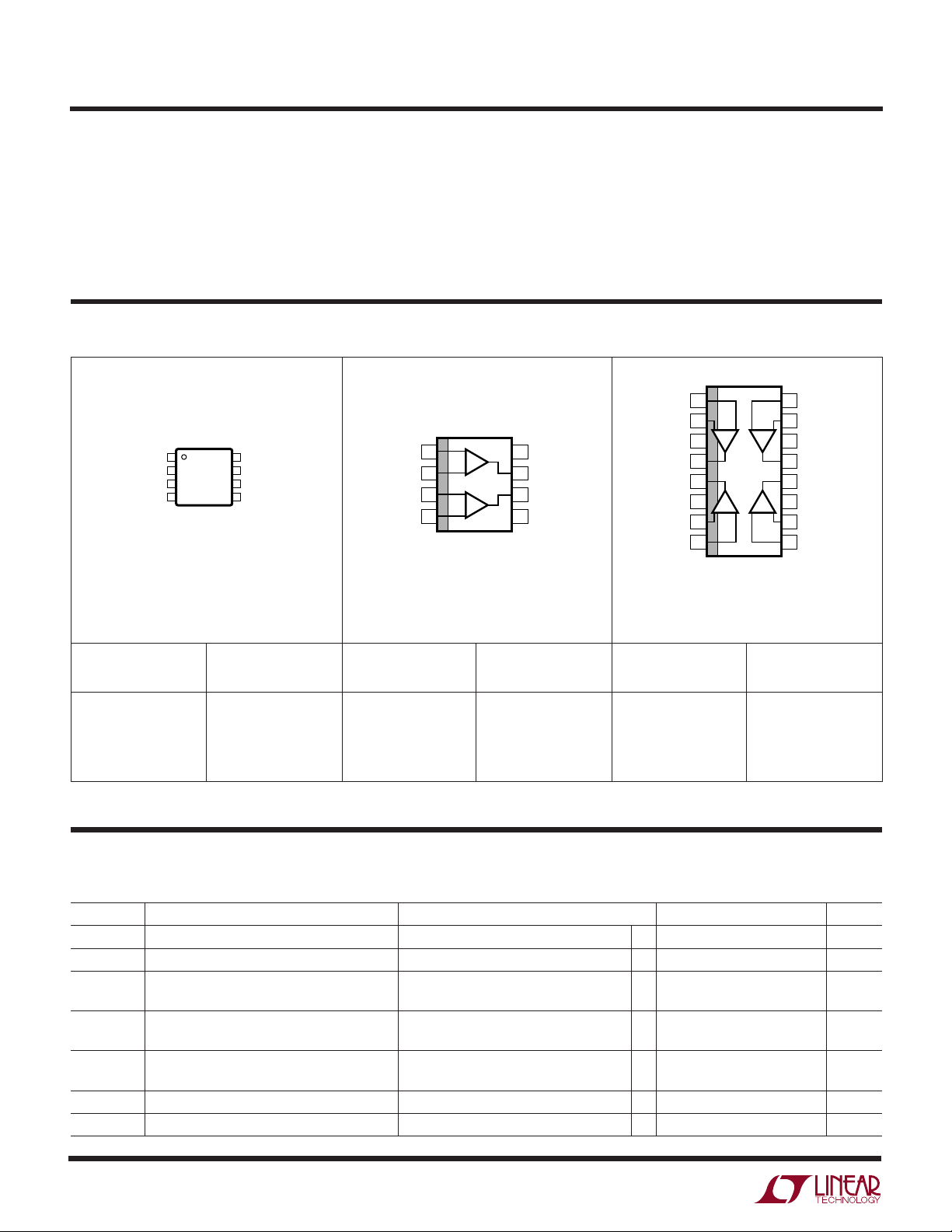

PACKAGE/ORDER INFORMATION

TOP VIEW

+IN A

1

–IN A

2

–IN B

3

+IN B

4

MS8 PACKAGE

8-LEAD PLASTIC MSOP

T

= 150°C, θJA = 230°C/W

JMAX

8

7

6

5

V

CC

OUT A

OUT B

GND

+IN A

1

–IN A

2

–IN B

3

+IN B

4

8-LEAD PLASTIC SO

T

= 150°C, θJA = 200°C/W

JMAX

S8 PACKAGE

Storage Temperature Range ................. –65°C to 150°C

Operating Temperature Range

C Grade .................................................. 0°C to 70°C

I Grade .............................................. – 40°C to 85°C

U

TOP VIEW

–IN A

TOP VIEW

1

+IN A

2

GND

8

V

CC

OUT A

7

OUT B

6

GND

5

3

OUT A

4

OUT B

5

GND

6

+IN B

7

–IN B

8

GN PACKAGE

16-LEAD NARROW

PLASTIC SSOP

T

= 150°C, θJA = 135°C/ W (GN)

JMAX

= 150°C, θJA = 115°C/ W (S)

T

JMAX

16

15

14

13

12

11

10

9

S PACKAGE

16-LEAD PLASTIC SO

–IN D

+IN D

V

CC

OUT D

OUT C

V

CC

+IN C

–IN C

ORDER PART

NUMBER

LT1720CMS8

MS8

PART MARKING

LTDS

ORDER PART

NUMBER

LT1720CS8

LT1720IS8

S8

PART MARKING

1720

1720I

ORDER PART

NUMBER

LT1721CGN

LT1721CS

GN

PART MARKING

1721

1721I

LT1721IGN

LT1721IS

Consult factory for Military grade parts.

ELECTRICAL CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. VCC = 5V, VCM = 1V, C

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

V

CMR

+

V

TRIP

–

V

TRIP

V

OS

V

HYST

∆VOS/∆T Input Offset Voltage Drift ● 10 µV/°C

Supply Voltage ● 2.7 6 V

Common Mode Voltage Range (Note 2) ● –0.1 VCC – 1.2 V

Input Trip Points (Note 3) –2.0 5.5 mV

Input Trip Points (Note 3) –5.5 2.0 mV

Input Offset Voltage (Note 3) 1.0 3.0 mV

Input Hysteresis Voltage (Note 3) ● 2.0 3.5 5.0 mV

The ● denotes specifications that apply over the full operating temperature

= 10pF, V

OUT

OVERDRIVE

= 20mV, unless otherwise specified.

● –3.0 6.5 mV

● –6.5 3.0 mV

● 4.5 mV

2

Page 3

LT1720/LT1721

ELECTRICAL CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. VCC = 5V, VCM = 1V, C

The ● denotes specifications that apply over the full operating temperature

= 10pF, V

OUT

OVERDRIVE

= 20mV, unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

B

I

OS

Input Bias Current ● –6 0 µA

Input Offset Current ● 0.6 µA

CMRR Common Mode Rejection Ratio (Note 4) ● 55 70 dB

PSRR Power Supply Rejection Ratio (Note 5) ● 65 80 dB

A

V

V

OH

V

OL

I

CC

t

PD20

t

PD5

∆t

PD

t

SKEW

t

r

t

f

t

JITTER

f

MAX

Voltage Gain (Note 6) ∞

Output High Voltage I

Output Low Voltage I

= 4mA, VIN = V

SOURCE

= 10mA, VIN = V

SINK

+

+ 10mV ● VCC – 0.4 V

TRIP

–

– 10mV ● 0.4 V

TRIP

Supply Current (Per Comparator) VCC = 5V ● 47 mA

= 3V ● 3.5 6 mA

V

CC

Propagation Delay V

Propagation Delay V

OVERDRIVE

OVERDRIVE

= 20mV (Note 7) 4.5 6.5 ns

● 8.0 ns

= 5mV (Notes 7, 8) 7 10 ns

● 13 ns

Differential Propagation Delay (Note 9) Between Channels 0.3 1.0 ns

+

Propagation Delay Skew (Note 10) Between t

PD

–

/t

PD

0.5 1.5 ns

Output Rise Time 10% to 90% 2.5 ns

Output Fall Time 90% to 10% 2.2 ns

Output Timing Jitter VIN = 1.2V

VCM = 2V, f = 20MHz t

Maximum Toggle Frequency V

OVERDRIVE

V

OVERDRIVE

(6dBm), ZIN = 50Ω t

P-P

= 50mV, VCC = 3V 70.0 MHz

= 50mV, VCC = 5V 62.5 MHz

PD

PD

+

–

15 ps

11 ps

RMS

RMS

Note 1: Absolute Maximum Ratings are those values beyond which the

life of a device may be impaired.

Note 2: If one input is within these common mode limits, the other

input can go outside the common mode limits and the output will be

valid.

Note 3: The LT1720/LT1721 comparators include internal hysteresis.

The trip points are the input voltage needed to change the output state

in each direction. The offset voltage is defined as the average of V

and V

–

, while the hysteresis voltage is the difference of these two.

TRIP

TRIP

Note 4: The common mode rejection ratio is measured with VCC = 5V

and is defined as the change in offset voltage measured from V

–0.1V to V

= 3.8V, divided by 3.9V.

CM

CM

=

Note 5: The power supply rejection ratio is measured with VCM = 1V

and is defined as the change in offset voltage measured from V

2.7V to V

= 6V, divided by 3.3V.

CC

CC

=

Note 6: Because of internal hysteresis, there is no small-signal region

in which to measure gain. Proper operation of internal circuity is

ensured by measuring V

and VOL with only 10mV of overdrive.

OH

Note 7: Propagation delay measurements made with 100mV steps.

Overdrive is measured relative to V

TRIP

±

.

Note 8: tPD cannot be measured in automatic handling equipment with

low values of overdrive. The LT1720/LT1721 are 100% tested with a

100mV step and 20mV overdrive. Correlation tests have shown that

limits can be guaranteed with this test, if additional DC tests are

t

PD

performed to guarantee that all internal bias conditions are correct.

+

Note 9: Differential propagation delay is defined as the larger of the

two:

∆t

∆t

PDLH

PDHL

= t

PDLH(MAX)

= t

PDHL(MAX)

– t

PDLH(MIN)

– t

PDHL(MIN)

where (MAX) and (MIN) denote the maximum and minimum values of

a given measurement across the different comparator channels.

Note 10: Propagation Delay Skew is defined as:

t

= |t

– t

SKEW

PDLH

PDHL

|

3

Page 4

LT1720/LT1721

TEMPERATURE (°C)

–50

3.6

3.8

4.2

25 75

1720/21 G03

0.2

0

–25 0

50 100 125

–0.2

–0.4

4.0

COMMON MODE INPUT VOLTAGE (V)

VCC = 5V

SUPPLY VOLTAGE (V)

0

0

SUPPLY CURRENT PER COMPARATOR (mA)

4

7

2

4

5

1720/21 G06

3

2

1

6

5

1

3

6

7

25°C

125°C

–55°C

SUPPLY VOLTAGE (V)

2.5

4.5

DELAY (ns)

5.0

4.0

4.0 5.0

1720/21 G09

3.0 3.5

4.5 5.5 6.0

RISING EDGE

(t

PDLH

)

FALLING EDGE

(t

PDHL

)

25°C

V

STEP

= 100mV

OVERDRIVE = 20mV

C

LOAD

= 10pF

W

U

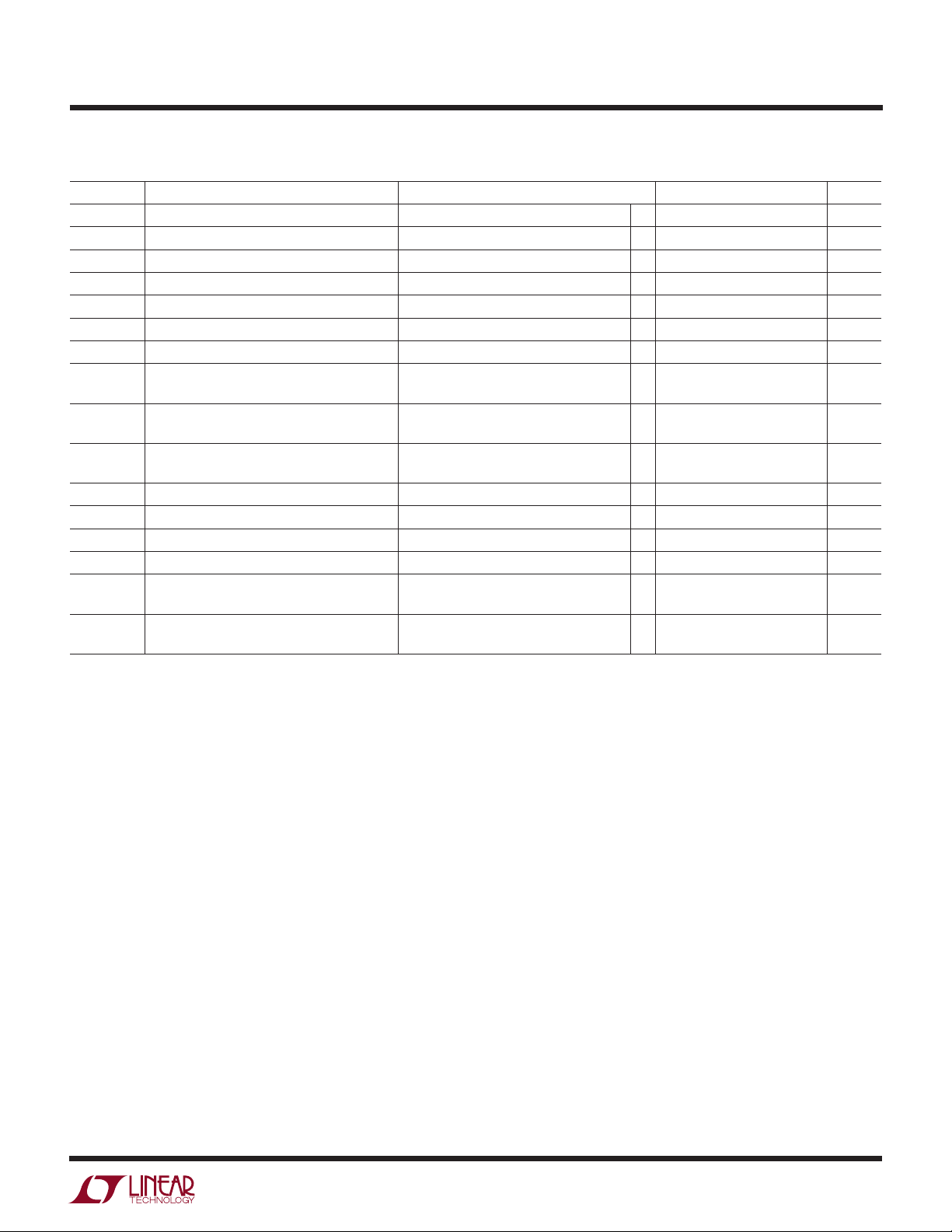

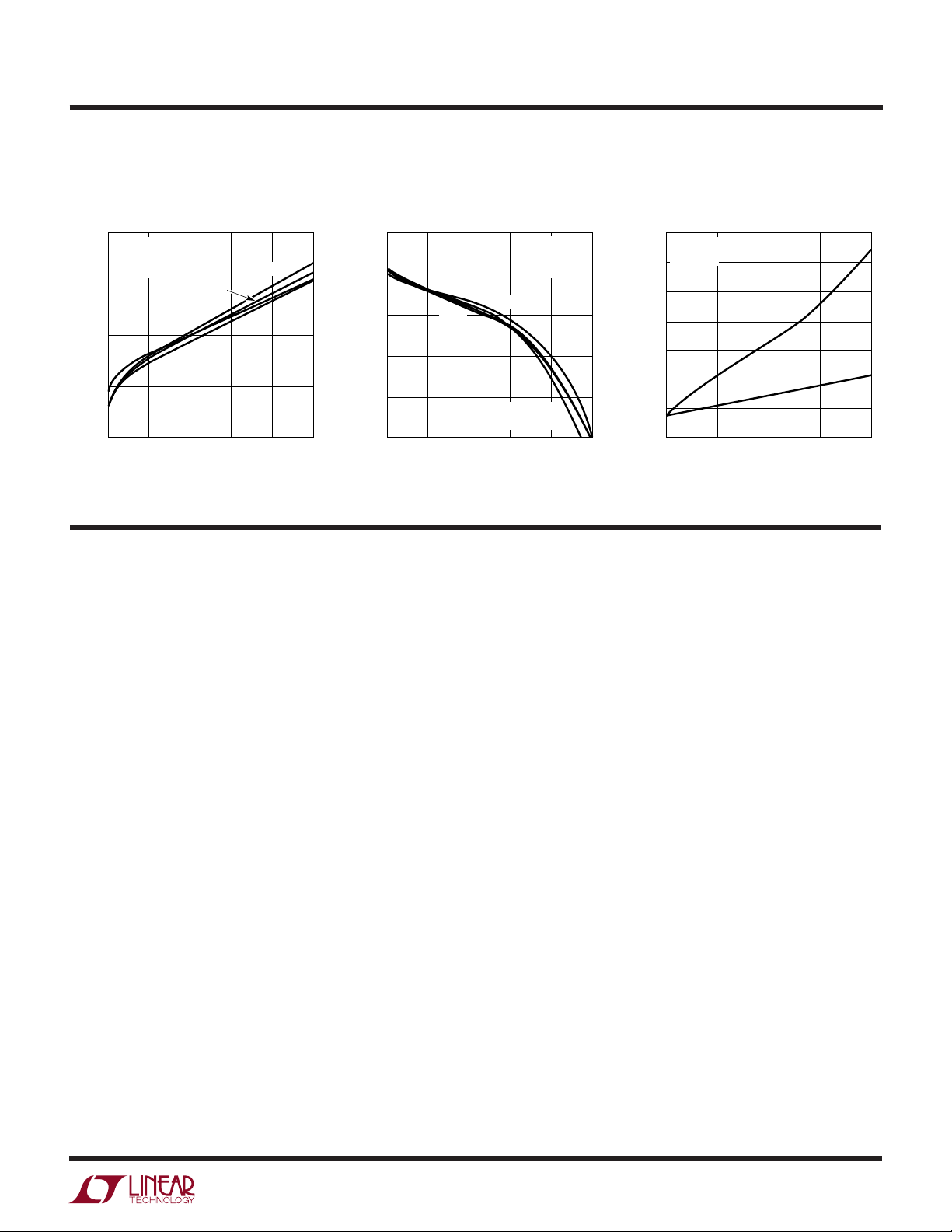

TYPICAL PERFORMANCE CHARACTERISTICS

Input Offset and Trip Voltages

vs Supply Voltage

3

V

2

1

0

–1

AND TRIP POINT VOLTAGE (mV)

–2

OS

V

25°C

V

= 1V

CM

–3

2.5

3.0 3.5

SUPPLY VOLTAGE (V)

TRIP

V

V

TRIP

4.5 5.5 6.0

4.0 5.0

Input Current

vs Differential Input Voltage

2

25°C

1

V

= 5V

CC

0

–1

–2

–3

–4

INPUT CURRENT (µA)

–5

–6

–7

–4 –3 –2 –1 0 5

–5

DIFFERENTIAL INPUT VOLTAGE (V)

+

OS

–

1720/21 G01

1234

1720/21 G04

Input Offset and Trip Voltages

vs Temperature

3

+

V

2

1

0

–1

AND TRIP POINT VOLTAGE (mV)

–2

OS

V

–3

–50 0 50 75 125

–25 25 100

TRIP

V

OS

–

V

TRIP

TEMPERATURE (°C)

1720/21 G02

Quiescent Supply Current

vs Temperature

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

–50

QUIESCENT SUPPLY CURRENT PER COMPARATOR (mA)

VCC = 5V

–25 0 50

25

TEMPERATURE (˚C)

= 3V

V

CC

75 100 125

1720/21 G05

Input Common Mode Limits

vs Temperature

Quiescent Supply Current

vs Supply Voltage

Propagation Delay

vs Load Capacitance

9

25°C

= 100mV

V

8

STEP

OVERDRIVE = 20mV

7

V

= 5V

CC

6

5

4

DELAY (ns)

3

2

1

0

0

4

10 20 40

OUTPUT LOAD CAPACITANCE (pF)

30

RISING EDGE

)

(t

PDLH

FALLING EDGE

)

(t

PDHL

1720/21 G07

Propagation Delay

vs Temperature

8.0

7.5

7.0

6.5

6.0

5.5

5.0

PROPAGATION DELAY (ns)

4.5

50

4.0

–50

VCC = 3V

VCC = 5V

VCC = 5V

VCC = 3V

–25 0 50

25

TEMPERATURE (°C)

t

PDLH

VCM = 1V

V

= 100mV

STEP

C

= 10pF

LOAD

OVERDRIVE = 5mV

OVERDRIVE = 20mV

75 100 125

1720/21 G08

Propagation Delay

vs Supply Voltage

Page 5

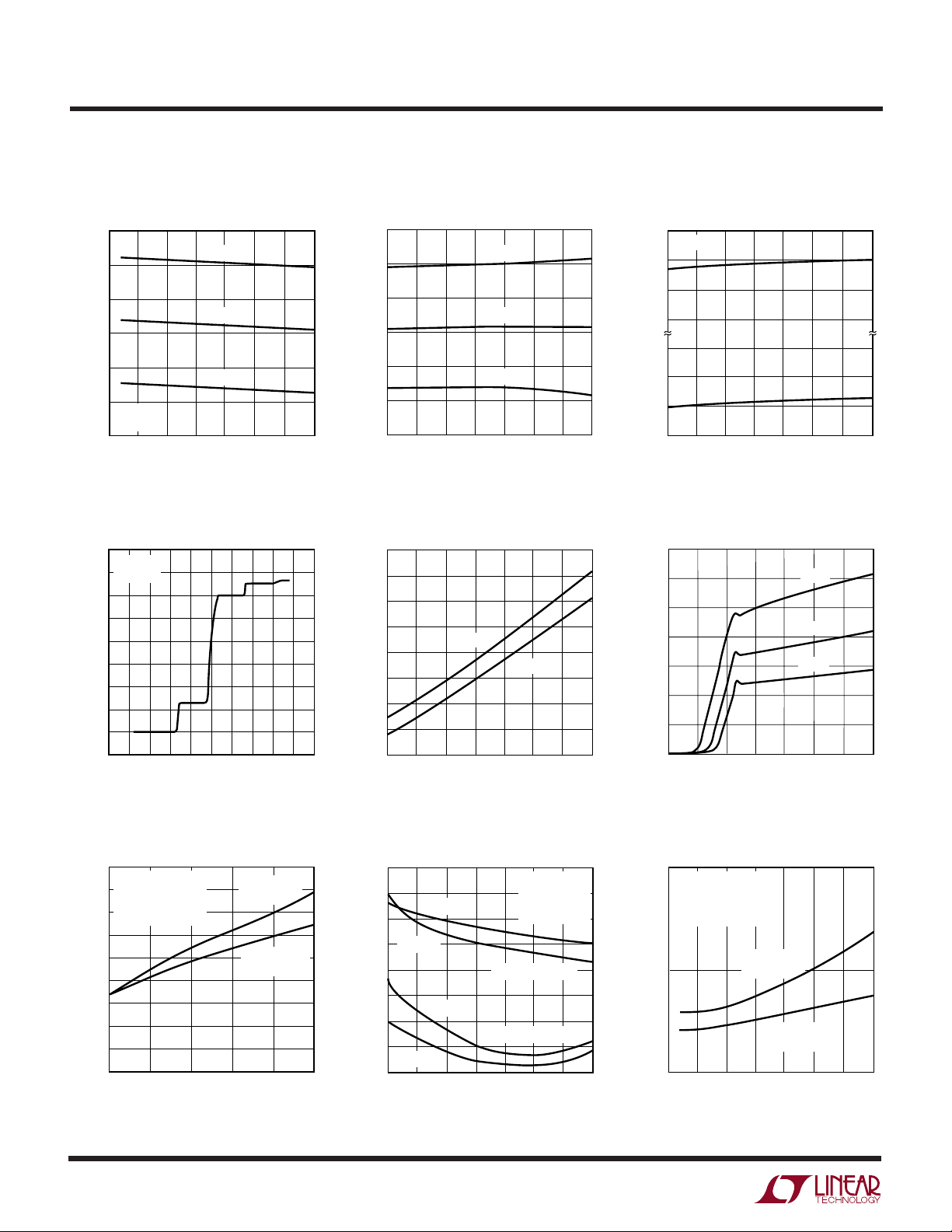

W

FREQUENCY (MHz)

0

7

8

10

30

NO LOAD

1720/21 G12

6

5

10 20 40

4

3

9

SUPPLY CURRENT PER COMPARATOR (mA)

25°C

V

CC

= 5V

C

LOAD

= 20pF

U

TYPICAL PERFORMANCE CHARACTERISTICS

LT1720/LT1721

Output Low Voltage

vs Load Current

0.5

VCC = 5V

= 1V

V

CM

= –15mV

V

IN

0.4

0.3

–55°C

OUTPUT VOLTAGE (V)

0.2

0.1

4

0

OUTPUT SINK CURRENT (mA)

V

CC

8

125°C

= 2.7V

125°C

25°C

12

16

20

1720/21 G10

Output High Voltage

vs Load Current

0.0

(V)

125°C

CC

–0.2

–0.4

–0.6

–0.8

OUTPUT VOLTAGE RELATIVE TO V

–1.0

0

OUTPUT SOURCE CURRENT (mA)

UUU

PIN FUNCTIONS

LT1720

+IN A (Pin 1): Noninverting Input of Comparator A.

Supply Current vs Frequency

VCC = 5V

= 1V

V

CM

= 15mV

V

IN

–55°C

25°C

25°C

V

= 2.7V

CC

4

12

16

8

20

1720/21 G11

LT1721

–IN A (Pin 1): Inverting Input of Comparator A.

–IN A (Pin 2): Inverting Input of Comparator A.

–IN B (Pin 3): Inverting Input of Comparator B.

+IN B (Pin 4): Noninverting Input of Comparator B.

GND (Pin 5): Ground.

OUT B (Pin 6): Output of Comparator B.

OUT A (Pin 7): Output of Comparator A.

VCC (Pin 8): Positive Supply Voltage.

+IN A (Pin 2): Noninverting Input of Comparator A.

GND (Pins 3, 6): Ground.

OUT A (Pin 4): Output of Comparator A.

OUT B (Pin 5): Output of Comparator B.

+IN B (Pin 7): Noninverting Input of Comparator B.

–IN B (Pin 8): Inverting Input of Comparator B.

–IN C (Pin 9): Inverting Input of Comparator C.

+IN C (Pin 10): Noninverting Input of Comparator C.

VCC (Pins 11, 14): Positive Supply Voltage.

OUT C (Pin 12): Output of Comparator C.

OUT D (Pin 13): Output of Comparator D.

+IN D (Pin 15): Noninverting Input of Comparator D.

–IN D (Pin 16): Inverting Input of Comparator D.

5

Page 6

LT1720/LT1721

TEST CIRCUITS

15V

P-P

BANDWIDTH-LIMITED

TRIANGLE WAVE

~

1kHz

V

CC

50k

50Ω

50Ω

DUT

V

1/2 LT1720 OR

CM

NOTES: LT1638, LT1112, LTC203s ARE POWERED FROM ±15V.

1/4 LT1721

1/2 LT1638

+

–

100k

100k

200kΩ PULL-DOWN PROTECTS LTC203 LOGIC INPUTS

WHEN DUT IS NOT POWERED

0.1µF

+

–

100k

100k

+

–

1/2 LT1638

200k

2.4k

0.15µF

±V

LTC203

LTC203

Test Circuit

TRIP

16

9

1

8

15 3 214

1000 × V

TRIP

HYST

OS

TRIP

+

–

1000 × V

10k

1000 × V

10k

1000 × V

1720/21 TC01

1µF

1µF

–

–

1/2 LT1112

+

1/2 LT1112

+

10nF

1

8

10 6 711

2 14 153

10nF

16

9

7 11 106

6

–3V

Response Time Test Circuit

– V

+V

CC

+

–

TRIP

–V

CM

0.01µF

10 × SCOPE PROBE

(C

≈ 10pF)

IN

0.01µF

CM

+

)

1720/21 TC02

0V

–100mV

25Ω

0.1µF

0V

PULSE

IN

1N5711

50Ω

–5V

130Ω

400Ω

2N3866

750Ω

V1*

*V1 = –1000 • (OVERDRIVE + V

NOTE: RISING EDGE TEST SHOWN.

FOR FALLING EDGE, REVERSE LT1720 INPUTS

1/2 LT1720 OR

25Ω

50k

50Ω

DUT

1/4 LT1721

Page 7

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

Input Voltage Considerations

The LT1720/LT1721 are specified for a common mode

range of –100mV to 3.8V when used with a single 5V

supply. In general the common mode range is 100mV

below ground to 1.2V below VCC. The criterion for this

common mode limit is that the output still responds

correctly to a small differential input signal. Also, if one

input is within the common mode limit, the other input

signal can go outside the common mode limits, up to the

absolute maximum limits (a diode drop past either rail at

10mA input current) and the output will retain the correct

polarity.

When either input signal falls below the negative common

mode limit, the internal PN diode formed with the substrate can turn on, resulting in significant current flow

through the die. An external Schottky clamp diode

between the input and the negative rail can speed up

recovery from negative overdrive by preventing the substrate diode from turning on.

When both input signals are below the negative common

mode limit, phase reversal protection circuitry prevents

false output inversion to at least –400mV common mode.

However, the offset and hysteresis in this mode will

increase dramatically, to as much as 15mV each. The input

bias currents will also increase.

When both input signals are above the positive common

mode limit, the input stage will become debiased and the

output polarity will be random. However, the internal

hysteresis will hold the output to a valid logic level, and

because the biasing of each comparator is completely

independent, there will be no impact on any other comparator. When at least one of the inputs returns to within

the common mode limits, recovery from this state will take

as long as 1µs.

The propagation delay does not increase significantly

when driven with large differential voltages. However, with

low levels of overdrive, an apparent increase may be seen

with large source resistances due to an RC delay caused

by the 2pF typical input capacitance.

Input Protection

The input stage is protected against damage from large

differential signals, up to and beyond a differential voltage

equal to the supply voltage, limited only by the absolute

maximum currents noted. External input protection circuitry is only needed if currents would otherwise exceed

these absolute maximums. The internal catch diodes can

conduct current up to these rated maximums without

latchup, even when the supply voltage is at the absolute

maximum rating.

The LT1720/LT1721 input stage has general purpose

internal ESD protection for the human body model. For use

as a line receiver, additional external protection may be

required. As with most integrated circuits, the level of

immunity to ESD is much greater when residing on a

printed circuit board where the power supply decoupling

capacitance will limit the voltage rise caused by an ESD

pulse.

Input Bias Current

Input bias current is measured with both inputs held at 1V.

As with any PNP differential input stage, the LT1720/

LT1721 bias current flows out of the device. With a

differential input voltage of even just 100mV or so, there

will be zero bias current into the higher of the two inputs,

while the current flowing out of the lower input will be

twice the measured bias current. With more than two

diode drops of differential input voltage, the LT1720/

LT1721’s input protection circuitry activates, and current

out of the lower input will increase an additional 30% and

there will be a small bias current into the higher of the two

input pins, of 4µA or less. See the Typical Performance

curve “Input Current vs Differential Input Voltage.”

High Speed Design Considerations

Application of high speed comparators is often plagued

by oscillations. The LT1720/LT1721 have 4mV of internal

hysteresis, which will prevent oscillations as long as

parasitic output to input feedback is kept below 4mV.

7

Page 8

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

However, with the 2V/ns slew rate of the LT1720/LT1721

outputs, a 4mV step can be created at a 100Ω input

source with only 0.02pF of output to input coupling. The

pinouts of the LT1720/LT1721 have been arranged to

minimize problems by placing the most sensitive inputs

(inverting) away from the outputs, shielded by the power

rails. The input and output traces of the circuit board

should also be separated, and the requisite level of

isolation is readily achieved if a topside ground plane runs

between the outputs and the inputs. For multilayer boards

where the ground plane is internal, a topside ground or

supply trace should be run between the inputs and

outputs, as illustrated in Figure 1.

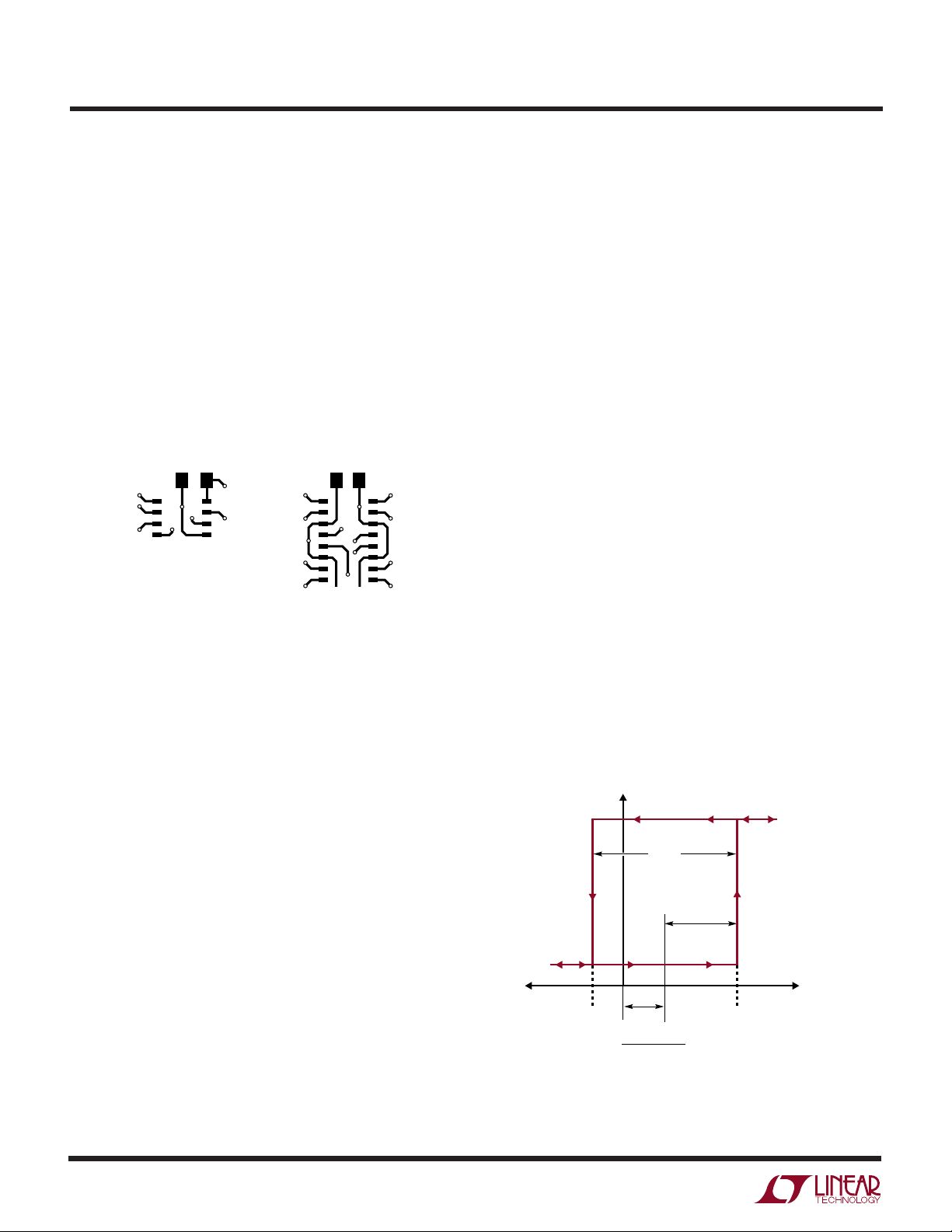

(b)(a)

1720/21 F01

Figure 1. Typical Topside Metal for Multilayer PCB Layouts

Figure 1a shows a typical topside layout of the LT1720 on

such a multilayer board. Shown is the topside metal etch

including traces, pin escape vias, and the land pads for an

SO-8 LT1720 and its adjacent X7R 10nF bypass capacitor

in a 1206 case.

The ground trace from Pin 5 runs under the device up to

the bypass capacitor, shielding the inputs from the

outputs. Note the use of a common via for the LT1720 and

the bypass capacitor, which minimizes interference from

high frequency energy running around the ground plane or

power distribution traces.

The supply bypass should include an adjacent

10nF ceramic capacitor and a 2.2µF tantalum capacitor no

farther than 5cm away; use more capacitance if driving

more than 4mA loads. To prevent oscillations, it is helpful

to balance the impedance at the inverting and noninverting

inputs; source impedances should be kept low, preferably

1kΩ or less.

The outputs of the LT1720/LT1721 are capable of very

high slew rates. To prevent overshoot, ringing and other

problems with transmission line effects, keep the output

traces shorter than 10cm, or be sure to terminate the lines

to maintain signal integrity. The LT1720/LT1721 can drive

DC terminations of 250Ω or more, but lower characteristic

impedance traces can be driven with series termination or

AC termination topologies.

Hysteresis

The LT1720/LT1721 include internal hysteresis, which

makes them easier to use than many other comparable

speed comparators.

The input-output transfer characteristic is illustrated in

Figure 2 showing the definitions of VOS and V

HYST

based

upon the two measurable trip points. The hysteresis band

makes the LT1720/LT1721 well behaved, even with slowly

moving inputs.

OUT

V

V

HYST

+

–

– V

(= V

TRIP

TRIP

V

HYST

)

/2

V

OH

Figure 1b shows a typical topside layout of the LT1721 on

a multilayer board. In this case, the power and ground

traces have been extended to the bottom of the device

solely to act as high frequency shields between input and

output traces.

Although both VCC pins are electrically shorted internal to

the LT1721, they must be shorted together externally as

well in order for both to function as shields. The same is

true for the two GND pins.

8

V

OL

0

–

V

TRIP

V

Figure 2. Hysteresis I/O Characteristics

+

V

+ V

TRIP

=

OS

TRIP

2

V

TRIP

–

+

∆VIN = V

1720/21 F02

+

–

– V

IN

IN

Page 9

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

The exact amount of hysteresis will vary from part to part

as indicated in the specifications table. The hysteresis level

will also vary slightly with changes in supply voltage and

common mode voltage. A key advantage of the LT1720/

LT1721 is the significant reduction in these effects, which

is important whenever an LT1720/LT1721 is used to detect a threshold crossing in one direction only. In such a

case, the relevant trip point will be all that matters, and a

stable offset voltage with an unpredictable level of hysteresis, as seen in competing comparators, is of little value.

The LT1720/LT1721 are many times better than prior comparators in these regards. In fact, the CMRR and PSRR

tests are performed by checking for changes in either trip

point to the limits indicated in the specifications table.

Because the offset voltage is the average of the trip points,

the CMRR and PSRR of the offset voltage is therefore

guaranteed to be at least as good as those limits. This

more stringent test also puts a limit on the common mode

and power supply dependence of the hysteresis voltage.

Additional hysteresis may be added externally. The rail-torail outputs of the LT1720/LT1721 make this more predictable than with TTL output comparators due to the

LT1720/LT1721’s small variability of VOH (output high

voltage).

To add additional hysteresis, set up positive feedback by

adding additional external resistor R3 as shown in Figure

3. Resistor R3 adds a portion of the output to the threshold

set by the resistor string. The LT1720/LT1721 pulls the

outputs to the supply rail and ground to within 200mV of

the rails with light loads, and to within 400mV with heavy

loads. For the load of most circuits, a good model for the

voltage on the right side of R3 is 300mV or VCC – 300mV,

for a total voltage swing of (VCC – 300mV) – 300mV =

VCC – 600mV.

With this in mind, calculation of the resistor values needed

is a two-step process. First, calculate the value of R3 based

on the additional hysteresis desired, the output voltage

swing, and the impedance of the primary bias string:

R3 = (R1R2)(VCC – 0.6V)/(additional hysteresis)

Additional hysteresis is the desired overall hysteresis less

the internal 3.5mV hysteresis.

The second step is to recalculate R2 to set the same

average threshold as before. The average threshold before

was set at VTH = (V

)(R1)/(R1 + R2). The new R2 is

REF

calculated based on the average output voltage (VCC/2)

and the simplified circuit model in Figure 4. To assure that

the comparator’s noninverting input is, on average, the

same VTH as before:

R2′ = (V

– VTH)/(VTH/R1 + (VTH – VCC/2)/R3)

REF

For additional hysteresis of 10mV or less, it is not uncommon for R2′ to be the same as R2 within 1% resistor

tolerances.

This method will work for additional hysteresis of up to a

few hundred millivolts. Beyond that, the impedance of R3

is low enough to effect the bias string, and adjustment of

R1 may also be required. Note that the currents through

the R1/R2 bias string should be many times the input

currents of the LT1720/LT1721. For 5% accuracy, the

current must be at least 120µA(6µA IB ÷ 0.05); more for

higher accuracy.

V

REF

R2

R1

INPUT

Figure 3. Additional External Hysteresis

R3

+

1/2 LT1720

–

1720/21 F03

V

REF

R2′

V

TH

R1

Figure 4. Model for Additional Hysteresis Calculations

R3

+

1/2 LT1720

–

V

AVERAGE

V

=

1720/21 F04

CC

2

9

Page 10

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

Interfacing the LT1720/LT1721 to ECL

The LT1720/LT1721 comparators can be used in high

speed applications where Emitter-Coupled Logic (ECL) is

deployed. To interface the outputs of the LT1720/LT1721

to ECL logic inputs, standard TTL/CMOS to ECL level

translators such as the 10H124, 10H424 and 100124 can

be used. These components come at a cost of a few

nanoseconds additional delay as well as supply currents of

50mA or more, and are only available in quads. A faster,

simpler and lower power translator can be constructed

with resistors as shown in Figure 5.

Figure 5a shows the standard TTL to Positive ECL (PECL)

resistive level translator. This translator cannot be used

for the LT1720/LT1721, or with CMOS logic, because it

depends on the 820Ω resistor to limit the output swing

(VOH) of the all-NPN TTL gate with its so-called totem-pole

output. The LT1720/LT1721 are fabricated in a complementary bipolar process and their output stage has a PNP

driver that pulls the output nearly all the way to the supply

rail, even when sourcing 10mA.

Figure 5b shows a three resistor level translator for interfacing the LT1720/LT1721 to ECL running off the same

supply rail. No pull-down on the output of the LT1720/

LT1721 is needed, but pull-down R3 limits the VIH seen by

the PECL gate. This is needed because ECL inputs have

both a minimum and maximum VIH specification for

proper operation. Resistor values are given for both ECL

interface types; in both cases it is assumed that the

LT1720/LT1721 operates from the same supply rail.

Figure 5c shows the case of translating to PECL from an

LT1720/LT1721 powered by a 3V supply rail. Again,

resistor values are given for both ECL interface types. This

time four resistors are needed, although with 10KH/E, R3

is not needed. In that case, the circuit resembles the

standard TTL translator of Figure 5a, but the function of

the new resistor, R4, is much different. R4 loads the

LT1720/LT1721 output when high so that the current

flowing through R1 doesn’t forward bias the LT1720/

LT1721’s internal ESD clamp diode. Although this diode

can handle 20mA without damage, normal operation and

performance of the output stage can be impaired above

100µA of forward current. R4 prevents this with the

minimum additional power dissipation.

Finally, Figure 5d shows the case of driving standard,

negative-rail, ECL with the LT1720/LT1721. Resistor values are given for both ECL interface types and for both a

5V and 3V LT1720/LT1721 supply rail. Again, a fourth

resistor, R4 is needed to prevent the low state current from

flowing out of the LT1720/LT1721, turning on the internal

ESD/substrate diodes. Not only can the output stage functionality and speed suffer, but in this case the substrate is

common to all the comparators in the LT1720/LT1721, so

operation of the other comparator(s) in the same package

could also be affected. Resistor R4 again prevents this

with the minimum additional power dissipation.

For all the dividers shown, the output impedance is about

110Ω. This makes these fast, less than a nanosecond,

with most layouts. Avoid the temptation to use speedup

capacitors. Not only can they foul up the operation of the

ECL gate because of overshoots, they can damage the

ECL inputs, particularly during power-up of separate

supply configurations.

The level translator designs assume one gate load. Multiple gates can have significant IIH loading, and the transmission line routing and termination issues also make this

case difficult.

ECL, and particularly PECL, is valuable technology for high

speed system design, but it must be used with care. With

less than a volt of swing, the noise margins need to be

evaluated carefully. Note that there is some degradation of

noise margin due to the ±5% resistor selections shown.

With 10KH/E, there is no temperature compensation of the

logic levels, whereas the LT1720/LT1721 and the circuits

shown give levels that are stable with temperature. This

will degrade the noise margin over temperature. In some

configurations it is possible to add compensation with

diode or transistor junctions in series with the resistors of

these networks.

For more information on ECL design, refer to the ECLiPS

data book (DL140), the 10KH system design handbook

(HB205) and PECL design (AN1406), all from Motorola.

10

Page 11

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

5V

180Ω

LSTTL

(a) STANDARD TTL TO PECL TRANSLATOR

1/2 LT1720

(b) LT1720/LT1721 OUTPUT TO PECL TRANSLATOR

1/2 LT1720

270Ω

820Ω

R1

3V

5V

10KH/E

V

CC

R2

R3

V

CC

R2

R1

R3R4

DO NOT USE FOR LT1720/LT1721

LEVEL TRANSLATION. SEE TEXT

10KH/E

100K/E

10KH/E

100K/E

V

5V OR 5.2V

4.5V

5V OR 5.2V

CC

V

CC

4.5V

R1

510Ω

620Ω

R1

300Ω

330Ω

R2

180Ω

180Ω

R2

180Ω

180Ω

R3

750Ω

510Ω

R3

OMIT

1500Ω

R4

560Ω

1000Ω

(c) 3V LT1720/LT1721 OUTPUT TO PECL TRANSLATOR

V

CC

R4

1/2 LT1720

(d) LT1720/LT1721 OUTPUT TO STANDARD ECL TRANSLATOR

R1

R3

R2

V

EE

ECL FAMILY

Figure 5

V

EE

10KH/E

100K/E –4.5V

–5.2V

R2

270Ω

510Ω

270Ω

390Ω

R3

330Ω

300Ω

300Ω

270Ω

R4

1200Ω

330Ω

1500Ω

430Ω

1720/21 F05

R1

V

CC

5V

560Ω

3V

270Ω

680Ω

5V

330Ω

3V

11

Page 12

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

Circuit Description

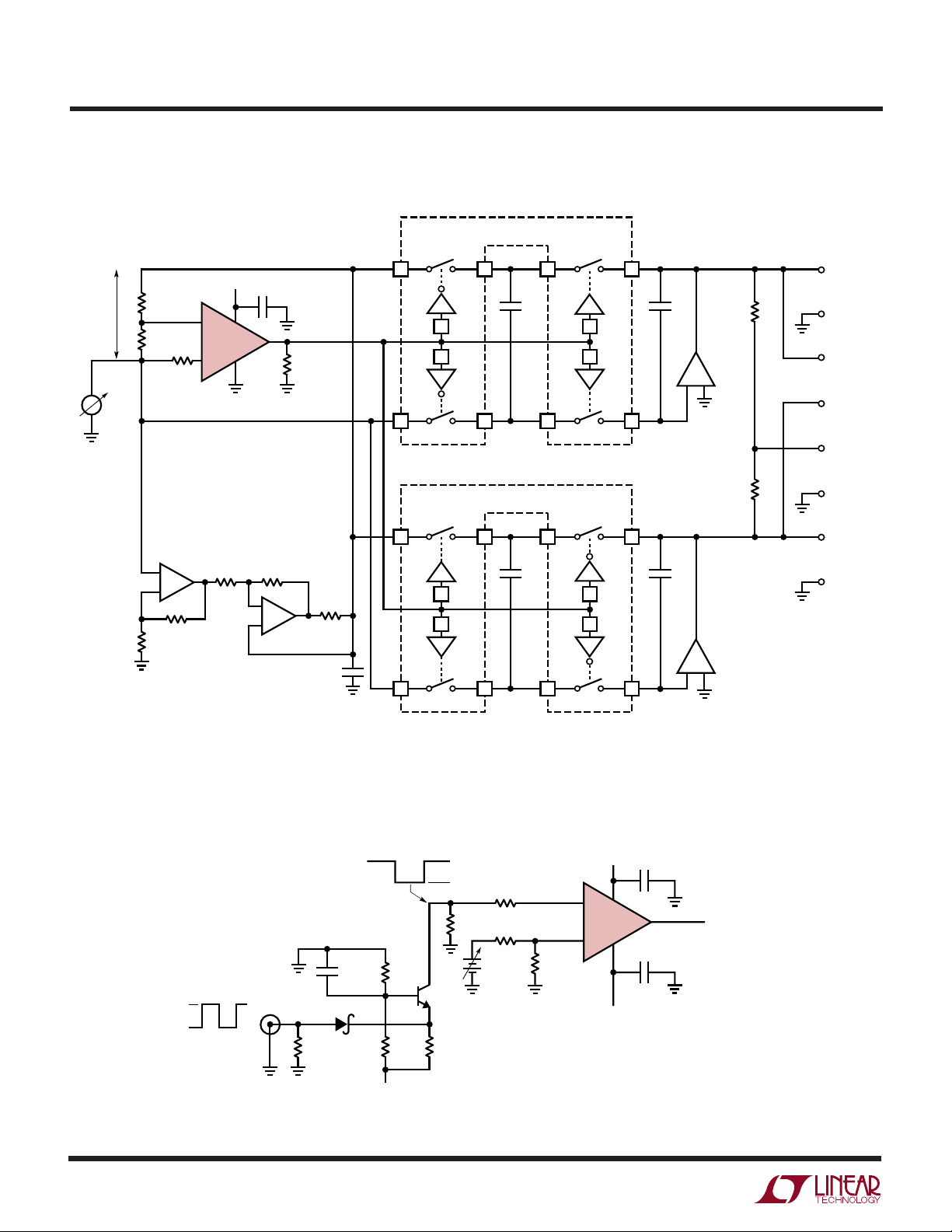

The block diagram of one comparator in the LT1720/LT1721

is shown in Figure 6. There are differential inputs

(+ IN/–IN), an output (OUT), a single positive supply (VCC)

and ground (GND). All comparators are completely independent, sharing only the power and ground pins. The

circuit topology consists of a differential input stage, a

gain stage with hysteresis and a complementary

common-emitter output stage. All of the internal signal

paths utilize low voltage swings for high speed at low power.

The input stage topology maximizes the input dynamic

range available without requiring the power, complexity

and die area of two complete input stages such as are

found in rail-to-rail input comparators. With a 2.7V supply,

the LT1720/LT1721 still have a respectable 1.6V of input

common mode range. The differential input voltage range

is rail-to-rail, without the large input currents found in

competing devices. The input stage also features phase

reversal protection to prevent false outputs when the

inputs are driven below the –100mV common mode

voltage limit.

Technology’s rail-to-rail amplifiers and other products.

But the output of a comparator is digital, and this output

stage can drive TTL or CMOS directly. It can also drive ECL,

as described earlier, or analog loads as demonstrated in

the applications to follow.

The bias conditions and signal swings in the output stages

are designed to turn their respective output transistors off

faster than on. This nearly eliminates the surge of current

from VCC to ground that occurs at transitions, keeping the

power consumption low even with high output-toggle

frequencies.

The low surge current is what keeps the power consumption low at high output-toggle frequencies. The frequency

dependence of the supply current is shown in the Typical

Performance Characteristics. Just 20pF of capacitive load

on the output more than triples the frequency dependent

rise. The slope of the no-load curve is just 32µA/MHz. With

a 5V supply, this current is the equivalent of charging and

discharging just 6.5pF. The slope of the 20pF load curve is

133µA/MHz, an addition of 101µA/MHz, or 20µA/MHz-V,

units that are equivalent to picoFarads.

The internal hysteresis is implemented by positive, nonlinear feedback around a second gain stage. Until this point,

the signal path has been entirely differential. The signal

path is then split into two drive signals for the upper and

lower output transistors. The output transistors are connected common emitter for rail-to-rail output operation.

The Schottky clamps limit the output voltages at about

300mV from the rail, not quite the 50mV or 15mV of Linear

NONLINEAR STAGE

+

+IN

–IN

+

A

V1

–

Σ

+

A

+

Σ

Figure 6. LT1720/LT1721 Block Diagram

V2

–

The LT1720/LT1721 dynamic current can be estimated by

adding the external capacitive loading to an internal equivalent capacitance of 5pF to 15pF, multiplied by the toggle

frequency and the supply voltage. Because the capacitance of routing traces can easily approach these values,

the dynamic current is dominated by the load in most

circuits.

V

CC

+

–

OUT

+

–

GND

1720/21 F06

12

Page 13

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

Speed Limits

The LT1720/LT1721 comparators are intended for high

speed applications, where it is important to understand a

few limitations. These limitations can roughly be divided

into three categories: input speed limits, output speed

limits, and internal speed limits.

There are no significant input speed limits except the

shunt capacitance of the input nodes. If the 2pF typical

input nodes are driven, the LT1720/LT1721 will respond.

The output speed is constrained by two mechanisms, the

first of which is the slew currents available from the output

transistors. To maintain low power quiescent operation,

the LT1720/LT1721 output transistors are sized to deliver

25mA to 45mA typical slew currents. This is sufficient to

drive small capacitive loads and logic gate inputs at

extremely high speeds. But the slew rate will slow dramatically with heavy capacitive loads. Because the propagation

delay (tPD) definition ends at the time the output voltage is

halfway between the supplies, the fixed slew current

actually makes the LT1720/LT1721 faster at 3V than 5V

with 20mV of input overdrive.

Another manifestation of this output speed limit is skew,

the difference between t

the LT1720/LT1721 vary with the process variations of the

PNP and NPN transistors, for rising edges and falling

edges respectively. The typical 0.5ns skew can have either

polarity, rising edge or falling edge faster. Again, the skew

will increase dramatically with heavy capacitive loads.

The skews of comparators in a single package are correlated, but not identical. Besides some random variability,

there is a small (100ps to 200ps) systematic skew due to

physical parasitics of the packages. For the LT1720 SO-8,

comparator A, whose output is adjacent to the VCC pin, will

have a relatively faster rising edge than comparator B.

Likewise, comparator B, by virtue of an output adjacent to

the ground pin will have a relatively faster falling edge.

Similar dependencies occur in the LT1721 S16, while the

systemic skews in the smaller MSOP and SSOP packages

are half again as small. Of course, if the capacitive loads on

the two comparators of a single package are not identical,

the differential timing will degrade further.

PD

+

and t

–

. The slew currents of

PD

The second output speed limit is the clamp turnaround.

The LT1720/LT1721 output is optimized for fast initial

response, with some loss of turnaround speed, limiting

the toggle frequency. The output transistors are idled in a

low power state once VOH or VOL is reached by detecting

the Schottky clamp action. It is only when the output has

slewed from the old voltage to the new voltage, and the

clamp circuitry has settled, that the idle state is reached

and the output is fully ready to transition again. This clamp

turnaround time is typically 8ns for each direction, resulting in a maximum toggle frequency of 62.5MHz, or a

125MB data rate. With higher frequencies, dropout and

runt pulses can occur. Increases in capacitive load will

increase the time needed for slewing due to the limited

slew currents and the maximum toggle frequency will

decrease further. For higher toggle frequency applications, consider the LT1394, whose linear output stage can

toggle at 100MHz typical.

The internal speed limits manifest themselves as dispersion. All comparators have some degree of dispersion,

defined as a change in propagation delay versus input

overdrive. The propagation delay of the LT1720/LT1721

will vary with overdrive, from a typical of 4.5ns at 20mV

overdrive to 7ns at 5mV overdrive (typical). The LT1720/

LT1721’s primary source of dispersion is the hysteresis

stage. As a change of polarity arrives at the gain stage, the

positive feedback of the hysteresis stage subtracts from

the overdrive available. Only when enough time has

elapsed for a signal to propagate forward through the gain

stage, backwards through the hysteresis stage and forward through the gain stage again, will the output stage

receive the same level of overdrive that it would have

received in the absence of hysteresis.

With 5mV of overdrive, the LT1720/LT1721 are faster with

a 5V supply than with a 3V supply, the opposite of what is

true with 20mV overdrive. This is due to the internal speed

limit, because the gain stage is faster at 5V than 3V due

primarily to the reduced junction capacitances with higher

reverse voltage bias.

In many applications, as shown in the following examples,

there is plenty of input overdrive. Even in applications

providing low levels of overdrive, the LT1720/LT1721 are

13

Page 14

LT1720/LT1721

–

+

–

+

–

+

C1

1/2 LT1720

C2

1/2 LT1720

A1

LT1636

V

CC

2.7V TO 6V

2k

620Ω

220Ω

1MHz TO 10MHz

CRYSTAL (AT-CUT)

100k

100k

1720 F07

1.8k

2k

1k

0.1µF

0.1µF

0.1µF

OUTPUT

OUTPUT

GROUND

CASE

U

WUU

APPLICATIONS INFORMATION

fast enough that the absolute dispersion of 2.5ns

(= 7 – 4.5) is often small enough to ignore.

The gain and hysteresis stage of the LT1720/LT1721 is

simple, short and high speed to help prevent parasitic

oscillations while adding minimum dispersion. This internal “self-latch” can be usefully exploited in many

applications because it occurs early in the signal chain, in

a low power, fully differential stage. It is therefore highly

immune to disturbances from other parts of the circuit,

either in the same comparator, on the supply lines, or

from the other comparator(s) in the same package. Once

a high speed signal trips the hysteresis, the output will

respond, after a fixed propagation delay, without regard

to these external influences that can cause trouble in

nonhysteretic comparators.

±V

The input trip points are tested using the circuit shown in

the Test Circuits section that precedes this Applications

Information section. The test circuit uses a 1kHz triangle

wave to repeatedly trip the comparator being tested. The

LT1720/LT1721 output is used to trigger switched capacitor sampling of the triangle wave, with a sampler for each

direction. Because the triangle wave is attenuated 1000:1

and fed to the LT1720/LT1721’s differential input, the

sampled voltages are therefore 1000 times the input trip

voltages. The hysteresis and offset are computed from the

trip points as shown.

Test Circuit

TRIP

noninverting input. The circuit will operate with any AT-cut

crystal from 1MHz to 10MHz over a 2.7V to 6V supply

range. As the power is applied, the circuit remains off until

the LT1720/LT1721 bias circuits activate, at a typical V

CC

of 2V to 2.2V (25°C), at which point the desired frequency

output is generated.

The output duty cycle for this circuit is roughly 50%, but

it is affected by resistor tolerances and, to a lesser extent,

by comparator offsets and timings. If a 50% duty cycle is

required, the circuit of Figure 7 creates a pair of complementary outputs with a forced 50% duty cycle. Crystals

are narrow-band elements, so the feedback to the noninverting input is a filtered analog version of the square wave

output. Changing the noninverting reference level can therefore vary the duty cycle. C1 operates as in the previous

example, whereas C2 creates a complementary output by

comparing the same two nodes with the opposite input

polarity. A1 compares band-limited versions of the outputs and biases C1’s negative input. C1’s only degree of

freedom to respond is variation of pulse width; hence the

outputs are forced to 50% duty cycle. Again, the circuit

operates from 2.7V to 6V, and the skew between the edges

of the two outputs are shown in Figure 8. There is a slight

duty cycle dependence on comparator loading, so equal

capacitive and resistive loading should be used in critical

Crystal Oscillators

A simple crystal oscillator using one comparator of an

LT1720/LT1721 is shown on the first page of this data

sheet. The 2k-620Ω resistor pair set a bias point at the

comparator’s noninverting input. The 2k-1.8k-0.1µF path

sets the inverting input node at an appropriate DC average

level based on the output. The crystal’s path provides

resonant positive feedback and stable oscillation occurs.

Although the LT1720/LT1721 will give the correct logic

output when one input is outside the common mode

range, additional delays may occur when it is so operated,

opening the possibility of spurious operating modes.

Therefore, the DC bias voltages at the inputs are set near

the center of the LT1720/LT1721’s common mode range

and the 220Ω resistor attenuates the feedback to the

14

Figure 7. Crystal Oscillator with Complementary

Outputs and 50% Duty Cycle

Page 15

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

1000

800

600

400

OUTPUT SKEW (ps)

200

0

2.5

3.5 5.53.0 4.0 5.0

SUPPLY VOLTAGE (V)

Figure 8. Timing Skew of Figure 7’s Circuit

applications. This circuit works well because of the two

matched delays and rail-to-rail style outputs of the LT1720.

The circuit in Figure 9 shows a crystal oscillator circuit that

generates two nonoverlapping clocks by making full use of

the two independent comparators of the LT1720.

C1 oscillates as before, but with a lower reference level,

C2’s output will toggle at different times. The resistors set

the degree of separation between the output’s high pulses.

With the values shown, each output has a 44% high and

4.5 6.0

1720/21 F08

56% low duty cycle, sufficient to allow 2ns between the

high pulses. Figure 10 shows the two outputs.

The optional A1 feedback network shown can be used to

force identical output duty cycles. The steady state duty

cycles of both outputs will be 44%. Note, though, that the

addition of this network only adjusts the percentage of

time each output is high to be the same, which can

be

important in switching circuits requiring identical settling

times. It cannot adjust the relative phases between the two

outputs to be exactly 180° apart, because the signal at the

input node driven by the crystal is not a pure sinusoid.

Q0

2V/DIV

Q1

2V/DIV

20ns/DIV

Figure 10. Nonoverlapping Outputs of Figure 9's Circuit

V

CC

2.7V TO 6V

2k

620Ω

10MHz

CRYSTAL (AT-CUT)

220Ω

GROUND

CASE

+

1.3k

1/2 LT1720

–

2.2k

C1

OPTIONAL—

2k

0.1µF

SEE TEXT

1k

0.1µF

A1

LT1636

+

–

100k

OUTPUT 0

100k

0.1µF

+

C2

1/2 LT1720

OUTPUT 1

–

Figure 9. Crystal-Based Nonoverlapping 10MHz Clock Generator

1720/21 F09

15

Page 16

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

Timing Skews

For a number of reasons, the LT1720/LT1721’s superior

timing specifications make them an excellent choice for

applications requiring accurate differential timing skew.

The comparators in a single package are inherently well

matched, with just 300ps ∆tPD typical. Monolithic construction keeps the delays well matched vs supply voltage

and temperature. Crosstalk between the comparators,

usually a disadvantage in monolithic duals and quads, has

minimal effect on the LT1720/LT1721 timing due to the

internal hysteresis, as described in the Speed Limits

section.

The circuits of Figure 11 show basic building blocks for

differential timing skews. The 2.5k resistance interacts

with the 2pF typical input capacitance to create at least

±4ns delay, controlled by the potentiometer setting.

A differential and a single-ended version are shown. In the

differential configuration, the output edges can be smoothly

scrolled through ∆t = 0 with negligible interaction.

3ns Delay Detector

It is often necessary to measure comparative timing of

pulse edges in order to determine the true synchronicity of

clock and control signals, whether in digital circuitry or in

high speed instrumentation. The circuit in Figure␣ 12 is a

delay detector which will output a pulse when signals X

and Y are out of sync (specifically, when X is high and Y is

low). Note that the addition of an identical circuit to detect

the opposite situation (X low and Y high) allows for full

skew detection.

Comparators U1A and U1B clean up the incoming signals

and render the circuit less sensitive to input levels and

slew rates. The resistive divider network provides level

shifting for the downstream comparator’s common mode

input range, as well as offset to keep the output low except

during a decisive event. When the upstream comparator’s

outputs can overcome the resistively generated offset

(and hysteresis), comparator U1C performs a Boolean

“X*_Y” function and produces an output pulse (see Figure␣ 13). The circuit will give full output response with

input delays down to 3ns and partial output response with

input delays down to 1.8ns. Capacitor C1 helps ensure that

an imbalance of parasitic capacitances in the layout will

not cause common mode excursions to result in differential mode signal and false outputs.

1

Make sure the input levels at X and Y are not too close to the 0.5V threshold set by the R8–R9

divider. If you are still getting false outputs, try increasing C1 to 10pF or more. You can also look

for the problem in the impedance balance (R5 || R6 = R7) at the inputs of U1C. Increasing the offset

by lowering R5 will help reject false outputs, but R7 should also be lowered to maintain impedance

balance. For ease of design and parasitic matching, R7 can be replaced by two parallel resistors

equal to R5 and R6.

1

INPUT

16

LT1720

C

IN

+

–

C

IN

2.5k

C

IN

–

+

C

IN

V

REF

DIFFERENTIAL ±4ns

RELATIVE SKEW

INPUT

2.5k

V

REF

LT1720

C

IN

+

–

C

IN

0ns TO 4ns

SINGLE-ENDED

DELAY

C

IN

–

+

C

IN

1720/21 F11

Figure 11. Building Blocks for Timing Skew Generation with the LT1720

Page 17

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

DELAY DETECTOR

5V

R5

1.82k*

C1

5.6pF

R7

261Ω*

0.1µF

X

51Ω*

+

U1A

1/4 LT1721

301Ω*

–

R8*

R9

487Ω*

4.53k

–

U1B

1/4 LT1721

Y

51Ω*

X

Y

Z

+

1V

0V

1V

0V

5V

0V

301Ω*

5V

301Ω*

R6

301Ω*

–

U1C

1/4 LT1721

+

OPTIONAL LOGARITHMIC PULSE STRETCHER (SEE TEXT)

CAPTURE

1N5711

Z

V

IN

R1

499Ω*

V

C

C2

540pF

**

5V

475Ω*

+

R3

R2

1k*

1Ω*

–

DELAY

* 1% METAL FILM RESISTOR

** 270pF ×2 FOR REDUCED LEAD INDUCTANCE

R4

30Ω*

+

1/4 LT1721

–

V

OFF

5V

U1D

0.33µF

L

1720/21 F12

RESULT OF X AND NOT Y

Figure 12. 3ns Delay Detector with Logarithmic Pulse Stretcher

X

Y

Z

Figure 13. Output Pulse Due to Delay of Y Input Pulse

17

Page 18

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

Optional Logarithmic Pulse Stretcher

The fourth comparator of the quad LT1721 can be put to

work as a logarithmic pulse stretcher. This simple circuit

can help tremendously if you don’t have a fast enough

oscilloscope (or control circuit) to easily capture 3ns pulse

widths (or faster). When an input pulse occurs, C2 is

charged up with a 180ns capture2 time constant. The

hysteresis and 10mV offset across R3 are overcome

within the first nanosecond3, switching the comparator

output high. When the input pulse subsides, C2 discharges with a 540ns time constant, keeping the comparator on until the decay overrides the 10mV offset across R3

minus hysteresis. Because of this exponential decay, the

output pulse width will be proportional to the logarithm of

the input pulse width. It is important to bypass the circuit’s

VCC well to avoid coupling into the resistive divider. R4

keeps the quiescent input voltage in a range where forward

leakage of the diode due to the 0.4V VOL of the driving

comparator is not a problem.

Neglecting some effects4, the output pulse is related to the

input pulse as:

t

= τ2 • ln {VCH • [1 – exp (–tP/τ1)]/(V

OUT

– τ1 • ln [VCH/(VCH – V

+ t

P

– VH/2)]

OFF

where

tP = input pulse width

t

= output pulse width

OUT

τ1 = R1 || R2 • C2 the capture time constant

τ2 = R2 • C2 the decay time constant

V

= 10mV the voltage drop across R1

OFF

VH = 3.5mV LT1721 hysteresis

VC = VIN – V

FDIODE

the input pulse voltage after

the diode drop

VCH = VC • R2/(R1 + R2) the effective source voltage

for the charge

– VH/2)}

OFF

(1)

For simplicity, with tP < τ1, and neglecting the very slight

delay in turn-on due to offset and hysteresis, the equation

can be approximated by:

t

= τ2 • ln [(VCH • tP/τ1)/(V

OUT

– VH/2)] (2)

OFF

For example, an 8ns input pulse gives a 1.67µs output

pulse. Doubling the input pulse to 16ns lengthens the

output pulse by 0.37µs. Doubling the input pulse again to

32ns adds another 0.37µs to the output pulse, and so on.

The rate of 0.37µs per octave falls out of the above

equation as:

∆t

/octave = τ2 • ln(2) (3)

OUT

There is ±0.01µs jitter5 in the output pulse which gives an

uncertainty referred to the input pulse of less than 2%

(60ps resolution on a 3ns pulse with a 60MHz oscilloscope—not bad!). The beauty of this circuit is that it gives

resolution precisely where it’s hardest to get. The jitter is

due to a combination of the slow decay of the last few

millivolts on C2 and the 4nV/√Hz noise and 400MHz

bandwidth of the LT1721 input stage. Increasing the offset

across R3 or decreasing τ2 will decrease this jitter at the

expense of dynamic range.

The circuit topology itself is extremely fast, limited theoretically only by the speed of the diode, the capture time

constant τ1 and the pulse source impedance. Figure 14

shows results achieved with the implementation shown,

compared to a plot of equation (1). The low end is limited

by the delivery time of the upstream comparators. As the

input pulse width is increased, the log function is constrained by the asymptotic RC response but, rather than

becoming clamped, becomes time linear. Thus, for very

long input pulses the third term of equation (1) dominates

and the circuit becomes a 3µs pulse stretcher.

2

So called because the very fast input pulse is “captured,” for later examination, as a charge on the

capacitor.

3

Assuming the input pulse slew rate at the diode is infinite. This effective delay constant, about 0.4%

of τ

or 0.8ns, is the second term of equation 1, below. Driven by the 2.5ns slew-limited LT1721,

1

this effective delay will be 2ns.

4

VC is dependent on the LT1721 output voltage and nonlinear diode characteristics. Also, the

Thevenin equivalent charge voltage seen by C2 is boosted slightly by R2 being terminated above

ground.

5

Output jitter increases with inputs pulse widths below ~3ns.

18

Page 19

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

14

12

10

8

6

STRETCHED (µs)

OUT

4

t

2

0

1 100 1000 10000

Figure 14. Log Pulse Stretcher Output Pulse vs Input Pulse

NANOSECOND

INPUT RANGE

1 FOOT CABLE

2V

0V

SPLITTER

10

MEASURED

t

PULSE

EQUATION 1

(ns)

X

Y

CIRCUIT OF

FIGURE 12

n FOOT CABLE

1720/21 F14

L

MICROSECOND

OUTPUT RANGE

t

OUT

(SEE TEXT)

easily measured 1.70µs output pulses. A 12 foot cable

length difference will result in ~18.4ns delay and 2.07µs

output pulses. The difference in the two output pulse

widths is the per-octave response of your circuit (see

equation (3)). Shorter cable length differences can be

used to get a plot of circuit performance down to 1.5ns (if

any), which can then later be used as a lookup reference

when you have moved from quantifying the circuit to using

the circuit. (Note there is a slight aberration in performance below 10ns. See Figure 14.) As a final check, feed

the circuit with identical cable lengths and check that it is

not producing any output pulses.

10ns Triple Overlap Generator

The circuit of Figure 16 utilizes an LT1721 to generate

three overlapping outputs whose pulse edges are separated by 10ns as shown. The time constant is set by the RC

network on the output of comparator A. Comparator B and

D trip at fixed percentages of the exponential voltage decay

across the capacitor. The 4.22kΩ feed-forward to the C

comparator’s inverting input keeps the delay differences

the same in each direction despite the exponential nature

of the RC network’s voltage.

There is a 15ns delay to the first edge in both directions,

due to the 4.5ns delay of two LT1721 comparators, plus

6ns delay in the RC network. This starting delay is shortened somewhat if the pulse was shorter than 40ns because the RC network will not have fully settled; however,

the 10ns edge separations stay constant.

1720/21 F15

Figure 15. RG-58 Cable with Velocity of Propogation = 66%;

Delay at Y = (n – 1) • 1.54ns

You don’t need expensive equipment to confirm the actual

overall performance of this circuit. All you need is a

respectable waveform generator (capable of >~100kHz), a

splitter, a variety of cable lengths and a 20MHz or 60MHz

oscilloscope. Split a single pulse source into different

cable lengths and then into the delay detector, feeding the

longer cable into the Y input (see Figure 15). A 6 foot cable

length difference will create a ~9.2ns delay (using 66%

propagation speed RG-58 cable), and should result in

The values shown utilize only the lowest 75% of the supply

voltage span, which allows it to work down to 2.7V supply.

The delay differences grow a couple nanoseconds from 5V

to 2.7V supply due to the fixed VOL/VOH drops which grow

as a percentage at low supply voltage. To keep this effect

to a minimum, the 1kΩ pull-up on comparator A provides

equal loading in either state.

Fast Waveform Sampler

Figure 17 uses a diode-bridge-type switch for clean, fast

waveform sampling. The diode bridge, because of its

inherent symmetry, provides lower AC errors than other

semiconductor-based switching technologies. This circuit features 20dB of gain, 10MHz full power bandwidth

19

Page 20

LT1720/LT1721

V

CC

–

+

U1A

1/4 LT1721

–

+

U1B

1/4 LT1721

–

+

U1D

1/4 LT1721

–

+

U1C

1/4 LT1721

681Ω

681Ω

1.37k

V

CC

909Ω

215Ω

V

CC

INPUT

OUTPUTS

V

REF

100pF

453Ω

1k

750Ω

V

CC

10ns 10ns

10ns

1720/21 F16

10ns

4.22k

U

WUU

APPLICATIONS INFORMATION

Figure 16. 10ns Triple Overlap Generator

5V

2.2k

2.2k

SAMPLE

COMMAND

2k

10pF

±100mV FULL SCALE

= 1N5711

= CA3039 DIODE ARRAY

(SUBSTRATE TO –5V)

3.6k1.5k

0.1µF

+

C

IN

1/2 LT1720

–

SKEW

COMP

2.5k

2k

+

1/2 LT1720

–

C

IN

INPUT

+

LT1227

1k

–

AC BALANCE

3pF

1.1k

1.1k

MRF501 MRF501

820Ω

11

6

9

LM3045

13

10 7

51Ω

–5V

DC BALANCE

500Ω

8

51Ω

680Ω

1720/21 F17

5V

1.1k

1.1k

820Ω

OUTPUT

±1V FULL SCALE

909Ω

100Ω

20

Figure 17. Fast Waveform Sampler Using the LT1720 for Timing-Skew Compensation

Page 21

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

and 100µV/°C baseline uncertainty. Switching delay is

less than 15ns and the minimum sampling window width

for full power response is 30ns.

The input waveform is presented to the diode bridge

switch, the output of which feeds the LT1227 wideband

amplifier. The LT1720 comparators, triggered by the sample

command, generate phase-opposed outputs. These signals are level shifted by the transistors, providing complementary bipolar drive to switch the bridge. A skew

compensation trim ensures bridge-drive signal simultaneity within 1ns. The AC balance corrects for parasitic

capacitive bridge imbalances. A DC balance adjustment

trims bridge offset.

The trim sequence involves grounding the input via 50Ω

and applying a 100kHz sample command. The DC balance

is adjusted for minimal bridge ON vs OFF variation at the

output. The skew compensation and AC balance adjustments are then optimized for minimum AC disturbance in

the output. Finally, unground the input and the circuit is

ready for use.

Voltage-Controlled Clock Skew Generator

It is sometimes necessary to generate pairs of identical

clock signals that are phase skewed in time. Further, it is

desirable to be able to set the amount of time skew via a

tuning voltage. Figure 18’s circuit does this by utilizing

the LT1720 to digitize phase information from a varactortuned time domain bridge. A 0V to 2V control signal

provides ≈±10ns of output skew. This circuit operates

from a 2.7V to 6V supply.

CLOCK

INPUT

= 1N4148

= 74HC04

* 1% FILM RESISTOR

** SUMIDA CD43-100

†

POLYSTYRENE, 5%

10ns

TRIM

“FIXED”

2k

2k*

“SKEWED”

12pF

INPUT

0V TO 2V ≈

±10ns

SKEW

†

MV-209

VARACTOR

DIODE

14k

+

–

0.005µF

A1

LT1077

2.5k*

36pF

V

CC

2.7V TO 6V

+

C1

1/2 LT1720

–

†

+

1/2 LT1720

V

CC

2.5k

2.5k

C2

Q

Q′

FIXED

OUTPUT

SKEWED

OUTPUT

–

1M

0.1µF

1M

6.2M*

1.82M*

V

CC

2.2µF

L1**

+

V

IN

V

C

SW

LT1317

GND

200pF

47µF

+

1.1M

FB

100k

1720/21 F18

Figure 18. Voltage-Controlled Clock Skew

21

Page 22

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

Coincidence Detector

High speed comparators are especially suited for interfacing pulse-output transducers, such as particle detectors,

to logic circuitry. The matched delays of a monolithic dual

are well suited for those cases where the coincidence of

two pulses needs to be detected. The circuit of Figure 19

is a coincidence detector that uses an LT1720 and discrete

components as a fast AND gate.

The reference level is set to 1V, an arbitrary threshold. Only

when both input signals exceed this will a coincidence be

detected. The Schottky diodes from the comparator outputs to the base of the MRF-501 form the AND gate, while

the other two Schottkys provide for fast turn-off. A logic

+

51Ω

3.9k

5V

1k

1/2 LT1720

–

AND gate could instead be used, but would add considerably more delay than the 300ps contributed by this discrete stage.

This circuit can detect coincident pulses as narrow as 3ns.

For narrower pulses, the output will degrade gracefully,

responding, but with narrow pulses that don’t rise all the

way to “high” before starting to fall. The decision delay is

4.5ns with input signals 50mV or more above the reference level. This circuit creates a TTL compatible output but

it can typically drive CMOS as well.

For a more detailed description of the operation of this

circuit, see Application Note 75, pages 10 and 11.

5V 5V

300Ω

GROUND

CASE LEAD

MRF501

OUTPUT

0.1µF

–

1/2 LT1720

+

51Ω

COINCIDENCE COMPARATORS

Figure 19. A 3ns Coincidence Detector

4× 1N5711

300ps AND GATE

300Ω

1720/21 F19

22

Page 23

WW

SI PLIFIED SCHE ATIC

LT1720/LT1721

OUTPUT

1720/21 SS

150Ω

CC

V

–IN

150Ω

+IN

GND

23

Page 24

LT1720/LT1721

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.189 – 0.197*

(4.801 – 5.004)

7

8

5

6

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

×

°

45

0.016 – 0.050

(0.406 – 1.270)

(1.346 – 1.752)

0°– 8° TYP

0.053 – 0.069

0.014 – 0.019

(0.355 – 0.483)

TYP

0.150 – 0.157**

(3.810 – 3.988)

1

3

2

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

SO8 1298

24

Page 25

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

MS8 Package

8-Lead Plastic MSOP

(LTC DWG # 05-08-1660)

0.118 ± 0.004*

(3.00 ± 0.102)

8

7

6

5

LT1720/LT1721

0.193 ± 0.006

(4.90 ± 0.15)

12

0.040

± 0.006

SEATING

PLANE

(1.02 ± 0.15)

0.012

(0.30)

0.0256

REF

(0.65)

BSC

0.007

(0.18)

0.021

± 0.006

(0.53 ± 0.015)

* DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

° – 6° TYP

0

0.118 ± 0.004**

4

3

0.034 ± 0.004

(0.86 ± 0.102)

(3.00 ± 0.102)

0.006 ± 0.004

(0.15 ± 0.102)

MSOP (MS8) 1098

25

Page 26

LT1720/LT1721

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

S Package

16-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.386 – 0.394*

(9.804 – 10.008)

13

16

14

15

12

11

10

9

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

×

°

45

0.016 – 0.050

(0.406 – 1.270)

0° – 8° TYP

0.228 – 0.244

(5.791 – 6.197)

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.150 – 0.157**

(3.810 – 3.988)

4

5

0.050

(1.270)

BSC

3

2

1

7

6

8

0.004 – 0.010

(0.101 – 0.254)

S16 1098

26

Page 27

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

GN Package

16-Lead Plastic SSOP (Narrow 0.150)

(LTC DWG # 05-08-1641)

0.189 – 0.196*

(4.801 – 4.978)

16

15

14

12 11 10

13

LT1720/LT1721

0.009

(0.229)

9

REF

0.015

± 0.004

(0.38 ± 0.10)

0.007 – 0.0098

(0.178 – 0.249)

0.016 – 0.050

(0.406 – 1.270)

* DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

0° – 8° TYP

× 45°

0.229 – 0.244

(5.817 – 6.198)

0.053 – 0.068

(1.351 – 1.727)

0.008 – 0.012

(0.203 – 0.305)

12

0.150 – 0.157**

(3.810 – 3.988)

5

4

3

678

0.0250

(0.635)

BSC

0.004 – 0.0098

(0.102 – 0.249)

GN16 (SSOP) 1098

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

27

Page 28

LT1720/LT1721

TYPICAL APPLICATION

U

Pulse Stretcher

For detecting short pulses from a single sensor, a pulse

stretcher is often required. The circuit of Figure 20 acts as

a one-shot, stretching the width of an incoming pulse to a

consistent 100ns. Unlike a logic one-shot, this LT1720based circuit requires only 100pV-s of stimulus to trigger.

The circuit works as follows: Comparator C1 functions as

a threshold detector, whereas comparator C2 is configured as a one-shot. The first comparator is prebiased with

a threshold of 8mV to overcome comparator and system

offsets and establish a low output in the absence of an

input signal. An input pulse sends the output of C1 high,

which in turn latches C2’s output high. The output of C2

is fed back to the input of the first comparator, causing

regeneration and latching both outputs high. Timing

5V

PULSE SOURCE

50Ω

51Ω

15k

24Ω

6.8k

1N5711

–

C1

1/2 LT1720

+

1/2 LT1720

capacitor C now begins charging through R and, at the

end of 100ns, C2 resets low. The output of C1 also goes

low, latching both outputs low. A new pulse at the input

of C1 can now restart the process. Timing capacitor C can

be increased without limit for longer output pulses.

This circuit has an ultimate sensitivity of better than 14mV

with 5ns to 10ns input pulses. It can even detect an

avalanche generated test pulse of just 1ns duration with

sensitivity better than 100mV.6␣ It can detect short events

better than the coincidence detector of Figure 14 because

the one-shot is configured to catch just 100mV of upward

movement from C1’s VOL, whereas the coincidence

detector’s 3ns specification is based on a full, legitimate

logic high, without the help of a regenerative one-shot.

6

See Linear Technology Application Note 47, Appendix B. This circuit can detect the output of the

pulse generator described after 40dB attenuation.

0.01µF

R

1k

C

–

C2

+

100pF

OUTPUT

100ns

2k

2k

1720/21 F20

2k

Figure 20. A 1ns Pulse Stretcher

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1016 UltraFast Precision Comparator Industry Standard 10ns Comparator

LT1116 12ns Single Supply Ground-Sensing Comparator Single Supply Version of LT1016

LT1394 7ns, UltraFast, Single Supply Comparator 6mA Single Supply Comparator

LT1671 60ns, Low Power, Single Supply Comparator 450µA Single Supply Comparator

LT1719 4.5ns Single Supply 3V/5V Comparator Single Comparator Similar to the LT1720/LT1721

17201f LT/TP 1099 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1998

28

Linear Technolog y Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

Loading...

Loading...