Page 1

FEATURES

■

Allows Dynamic Control of Output Frequency,

Cadence, Amplitude and DC Offset

■

Active Tracking Supply Configuration Allows Linear

Generation of Ring Tone Signal

■

No High Voltage Post-Filtering Required

■

Capacitive Isolation Eliminates Optocouplers

■

Low Distortion Output Meets International

PTT Requirements

■

Differential Input Signal for Noise Immunity

■

User Adjustable Active Output Current Limit

■

Powered Directly From High Voltage Ringer

Supply—No Additional Supplies Necessary

■

Supply Current: <1mA

■

2% Signal Amplitude Reference

■

Available in 14-Pin SO and DIP Packages

U

APPLICATIO S

■

Wireless Local Loop Telephones

■

Key System/PBX Equipment

■

Fiber to the Curb Telecom Equipment

LT1684

Micropower

Ring Tone Generator

U

DESCRIPTIO

The LT®1684 is a telecommunication ring tone generator.

The IC takes a user-generated pulse width modulated

(PWM) input and converts it to a high voltage sine wave

suitable for telephone ringing applications.

The LT1684 receives capacitor-isolated differential PWM

input signals encoded with desired ring output cadence,

frequency, and amplitude information. The LT1684 normalizes the pulse amplitude to ±1.25V for an accurate

signal voltage reference. The cadence, frequency and

amplitude information is extracted using a multiplepole active filter/amplifier, producing the output ring tone

signal.

The LT1684 uses its own ring tone output as a reference

for generating local supply rails using complementary

high voltage external MOSFETs as dynamic level-shifting

devices. This “active tracking” supply mode of operation

allows linear generation of the high voltage ring tone

signal, reducing the need for large high voltage filtering

elements.

, LTC and LT are registered trademarks of Linear Technology Corporation.

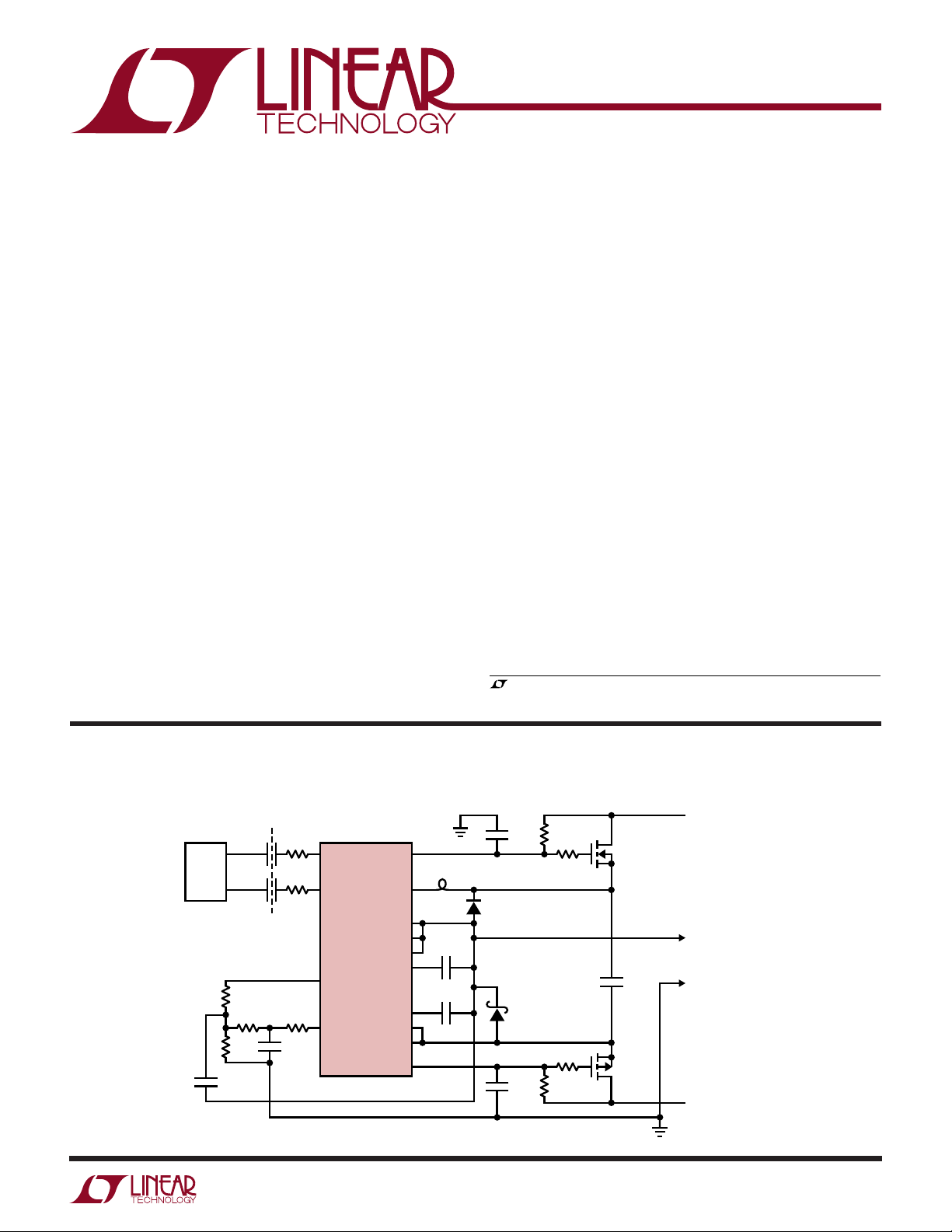

TYPICAL APPLICATIO

1µF

ISOLATION

100pF

100pF

3k

2k

300k

DC

10k

10k

4700pF

PWM

CONTROLLER

P1

µC

P2

FB1: FERRONICS FMB1601 (716) 388-1020

U

5k

Electrically Isolated Ring Tone Generator

6.8nF

1N4001

1N5817

6.8nF

IN A GATE

IN B

LT1684

LIM

OUT

OUT

AT

COMP1

COMP2

GATE

BG

AMPIN LIM

REF

+

FB1

+

V

+

100pF

20pF

–

–

V

–

100k

100Ω

100Ω

100k

IRF610

0.1µF

IRF9610

100V

+

RING TONE

OUTPUT

–

–100V

1684 TA01

±100mA

()

CAPABILITY

1

Page 2

LT1684

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Voltages:

Active Tracking Differential Voltage

(GATE+ – GATE–)..................................–0.3V to 42V

Local Supply Differential Voltage

(V+ – V–)...............................................–0.3V to 36V

Local Supply

Voltage V

+

..............

(GATE+ – 7.0V) to (GATE+ + 0.3V)

Local Supply

Voltage V

–

..............

(GATE– – 0.3V) to (GATE– + 7.0V)

PWM Input Differential Voltage

(IN A – IN B).........................................–7.0V to 7.0V

PWM Input Voltage

Common Mode................. (V– – 0.3V) to (V+ + 0.3V)

LIM+ Current Limit

Pin Voltage ..................... (OUT – 0.3V) to (V+ + 0.3V)

LIM– Current Limit

Pin Voltage .................... (V– – 0.3V) to (OUT + 0.3V)

All Other Pin Voltages ........... (V– – 0.3V) to (V+ + 0.3V)

UU

W

PACKAGE/ORDER I FOR ATIO

Currents:

LIM+, LIM– Current.......................................... –350mA

OUT Current ....................................................... 350mA

BG

Current .................................................... ±10mA

OUT

PWM (IN A, IN B) Current .................................... ±5mA

GATE+, GATE– Current .......................................±20mA

COMP1 Current .................................................... ±1mA

COMP2 Current .................................................... ±1mA

AT

Current ..................................................... ±20mA

REF

Temperatures:

Operating Junction Temperature Range

Commercial Grade................................. 0°C to 125°C

Industrial Grade................................ –40°C to 125°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

TOP VIEW

1

IN B

2

COMP1

3

COMP2

–

4

LIM

–

5

V

–

6

GATE

7

AT

REF

N PACKAGE

14-LEAD PDIP

T

= 125°C, θ

JMAX

= 125°C, θ

T

JMAX

Consult factory for Military grade parts.

JA

JA

IN A

14

BG

13

OUT

AMPIN

12

+

GATE

11

+

V

10

+

LIM

9

OUT

8

S PACKAGE

14-LEAD PLASTIC SO

= 75°C/W (N)

= 115°C/W (S)

ORDER PART

NUMBER

LT1684CN

LT1684CS

LT1684IN

LT1684IS

2

Page 3

LT1684

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

V+ – V– = 20V, Voltages referenced to pin OUT, V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Supply and Protection

I

S

|V+| Local Supply Voltages V

|V–|V

V

GATE

V

GATE

PWM Receiver

f

PWM

V

IN

R

IN

R

INA,INB

BG Buffer

V

BGOUT

V

BGOUTOS

I

BGOUTSC

R

BGOUT

t

r

t

f

∆t

r-f

t

pr

t

pf

∆t

p

Output Amplifier

V

OUTOS

R

OUT

I

OUTSC

DC Supply Current (Note 2) IN A – IN B ≥ 1.6V ● 680 950 µA

+ Active Tracking Supply FET I

Bias Voltage AT

– Active Tracking Supply FET I

Bias Voltage AT

Input Carrier Frequency 10 kHz

Minimum Valid Differential Input IN A – IN B or IN B – IN A ● 1.6 V

Differential Input Threshold ● 0.50 0.70 1.00 V

| IN A – IN B |

Differential Input Overdrive Impedance VIN > VTH + 100mV ● 710 kΩ

(Note 3, 5)

Single-Ended Input Impedance To Pin OUT ● 50 kΩ

(Note 5)

BG

Normalized Voltage Magnitude |V

OUT

Output Offset Voltage –7 7 mV

[(V

+) + (V

BGOUT

BG

Short-Circuit Current ● ±2 ±4.5 mA

OUT

BG

Output Impedance –2mA ≤ I

OUT

BG

Rise Time (10% to 90%) R

OUT

BG

Fall Time (10% to 90%) R

OUT

BG

RiseTime – Fall Time ● –200 –100 0 ns

OUT

BG

Propagation Delay PWM Input R

OUT

–)]/2 ● –10 10 mV

BGOUT

Transition to 10% Output (Rising Edge)

BG

Propagation Delay PWM Input R

OUT

Transition to 90% Output (Falling Edge)

BG

Propagation Delay ● – 200 –100 100 ns

OUT

Rising Edge – Falling Edge

OUT Offset Voltage V

OUT Output Impedance –10mA ≥ I

OUT Short-Circuit Current LIM+ Shorted to OUT ● ±100 ±190 mA

= V

OUT

GATE

GATE

+ = –100µA, ● 13.2 14.0 14.8 V

GATE

REF

– = 100µA, ● –14.8 –14.0 –13.2 V

GATE

REF

= 5k, C

OUT

= 5k, C

OUT

= 5k, C

OUT

= 5k, C

OUT

AMPIN

R

AMPIN

10mA ≤ I

LIM– Shorted to V

unless otherwise noted.

ATREF

+

+ ≥ V

– ≤ V

–

● 6.5 10 V

= 0V

= 0V

| 1.235 1.250 1.265 V

BGOUT

≤ 2mA 0.2 Ω

BGOUT

= 10pF ● 160 300 ns

OUT

= 10pF ● 260 400 ns

OUT

= 10pF ● 340 500 ns

OUT

= 10pF ● 440 600 ns

OUT

= 0v, I

= 0A – 6 6 mV

OUT

● 1.225 1.250 1.275 V

= 10k (Note 4) ● –8 8 mV

+ ≥ –100mA, LIM+ Shorted to OUT 0.01 Ω

LIM

≤ 100mA, LIM– Shorted to V

OUT

–

–

0.15 Ω

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: IC Supply current specification represents unloaded condition and

does not include external FET gate pull up/down currents (GATE

+

, GATE

–

pins). Actual total IC bias currents will be higher and vary with operating

conditions. See Applications Information.

Note 3: PWM inputs are high impedance through ±100mV beyond the

input thresholds.

Note 4: 10k resistor from pin AMPIN to ground.

Note 5: Guaranteed but not tested.

3

Page 4

LT1684

I

GATE

(mA)

0.1 0.3 1.0 3.0 10.0

V

GATE

– V

ATREF

(V)

1684 G03

14.3

14.2

14.1

14.0

13.9

13.8

TJ = 25°C

TEMPERATURE (°C)

–50 –25 0 25 50 75 100 125

V

BGOUT

(V)

1684 G06

1.253

1.252

1.251

1.250

1.249

1.248

1.247

1.246

1.245

R

LIM

(Ω)

0 21 4 6 83 5 7 910

OUTPUT CURRENT LIMIT (mA)

1684 G09

200

150

100

50

0

TYPICAL (TJ = 25°C)

MINIMUM (TJ = 125°C)

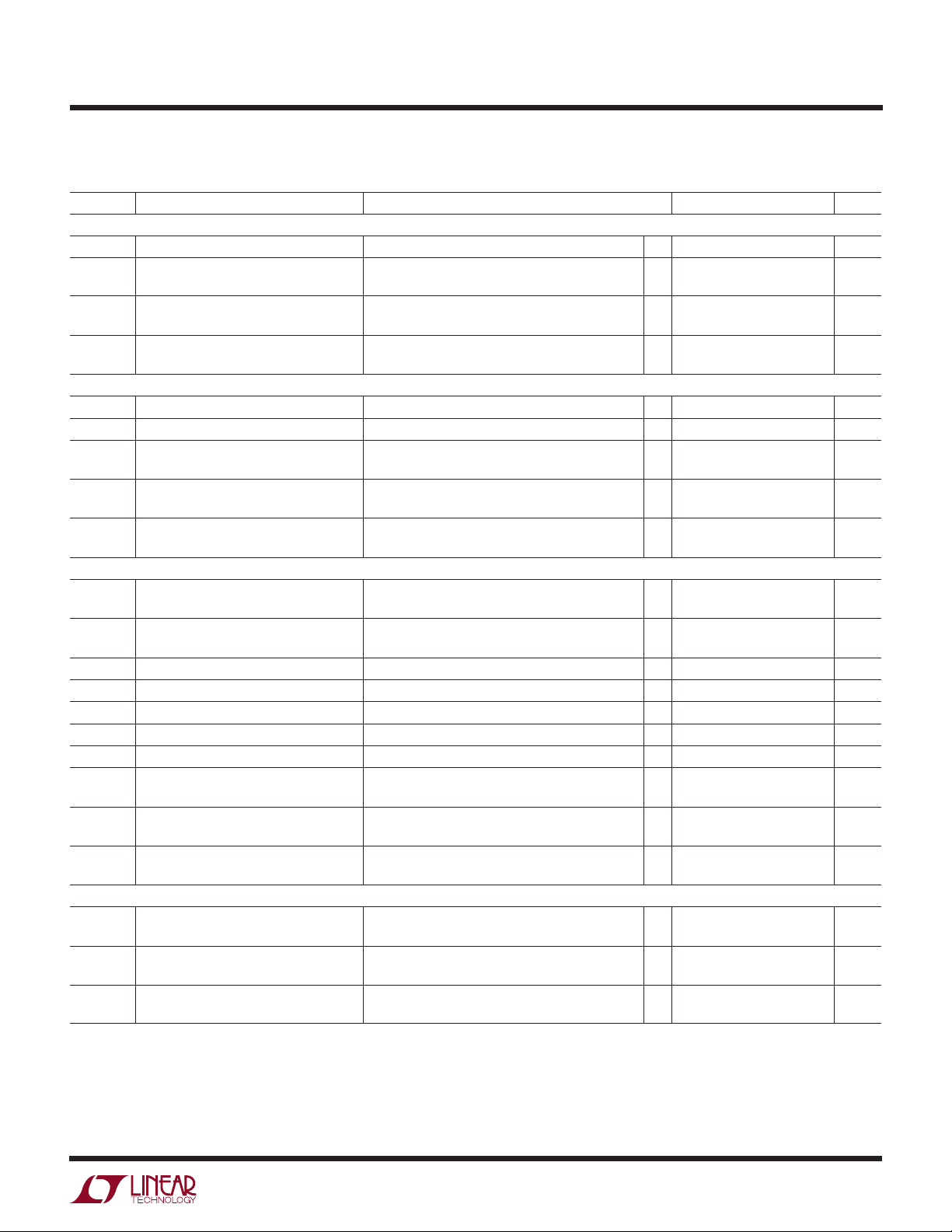

UW

TYPICAL PERFOR A CE CHARACTERISTICS

DC Supply Current vs V+ – V

740

TJ = 25°C

720

700

680

660

640

DC SUPPLY CURRENT (µA)

620

600

14 16 18 20 22 24

V

GATE

IN A – IN B ≥ 1.6V

IN A – IN B ≤ –1.6V

– V

ATREF

V+ – V– (V)

Voltage

Magnitudes vs Temperature

14.5

I

= 1mA

GATE

14.4

14.3

14.2

(V)

14.1

ATREF

14.0

– V

13.9

GATE

13.8

V

13.7

13.6

13.5

–50 –25 0 25 50 75 100 125

TEMPERATURE (°C)

–

1684 G01

DC Supply Current vs Temperature

710

690

670

650

630

IN A – IN B ≤ –1.6V

610

590

DC SUPPLY CURRENT (µA)

570

550

–50 –25 0 25 50 75 100 125

TEMPERATURE (°C)

IN A – IN B ≥ 1.6V

PWM Input Thresholds vs

Temperature V

0.85

0.80

0.75

0.70

0.65

0.60

IN A – IN B (V)

0.55

0.50

0.45

–50 –25 0 25 50 75 100 125

1684 G04

TEMPERATURE (°C)

1684 G02

1684 G05

V

– V

GATE

Magnitudes vs I

BGOUT

Voltage

ATREF

GATE

Magnitude vs Temperature

PWM Buffer (Pin BG

Limit vs Temperature

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

PWM BUFFER CURRENT LIMIT (mA)

2.0

–50 –25 0 25 50 75 100 125

TEMPERATURE (°C)

4

OUT

) Current

1684 G07

Output Amplifier Current Limit vs

Temperature (R

250

225

200

175

150

OUTPUT CURRENT LIMIT (mA)

125

100

–50 –25 0 25 50 75 100 125

TEMPERATURE (°C)

LIM

= 0Ω)

Output Amplifier Current Limit vs

External Limiting Resistor Values

1684 G08

Page 5

LT1684

U

UU

PI FU CTIO S

IN B (Pin 1): PWM Negative Input. Input is isolated from

digital source by ~100pF series capacitor. A 10k resistor

can be connected to the IN B pin in series with the isolation

capacitor for transient protection. The PWM receiver implements a diode forward drop of input hysteresis (relative to

IN A). This hysteresis and internal signal limiting assure

common mode glitch rejection with isolation capacitor

mismatches up to 2:1. For maximum performance, however, effort should be made to match the two PWM input

isolation capacitors. Pin IN B is differentially clamped to

pin IN A through back-to-back diodes. This results in a

high impedance differential input through ±100mV beyond the input thresholds. 5k internal input resistors yield

a 10k (nominal) differential overdrive impedance.

COMP1 (Pin 2): Output Amplifier Primary Compensation.

Connect a 100pF capacitor from pin COMP1 to pin OUT.

COMP2 (Pin 3): Output Amplifier Secondary Compensation. Connect a 20pF capacitor from pin COMP2 to pin

OUT.

LIM– (Pin 4): Output Amplifier Current Sink Limit. Pin

implements I

resistor has a typical value of 3.5Ω. For maximum current

drive capability (190mA typical) short pin to pin V–.

Reduction of current sink capability is achieved by placing

additional resistance from pin LIM– to pin V–. (i.e. An

external 3.5Ω resistance from pin LIM– to pin V– will

reduce the current sinking capability of the output amplifier by approximately 50%.)

V– (Pin 5): Local Negative Supply. Typically connected to

the source of the active tracking supply P-channel MOSFET.

V– rail voltage is GATE– self-bias voltage less the MOSFET

VGS. Typical P-channel MOSFET characteristics provide

AT

– V– ≈ 10V.

REF

GATE– (Pin 6): Negative Power Supply FET Gate Drive. Pin

sources current from pull-down resistor to bias gate of

active tracking supply P-channel MOSFET. Self-biases to

a typical value of –14V, referenced to pin AT

resistor value is determined such that current sourced

from the GATE– pin remains greater than 50µA at mini-

mum output signal voltage and less than 10mA at maximum output signal voltage.

• R = VBE current clamp. Internal clamp

OUT

. Pull-down

REF

AT

(Pin 7): Active Tracking Supply Reference. Typi-

REF

cally connected to pin OUT. Pin bias current is the difference between the magnitudes of GATE+ pin bias and

GATE– pin bias (I

OUT (Pin 8): Ring Tone Output Pin. Output of active filter

amplifier/buffer. Used as reference voltage for internal

functions of IC. Usually shorted to pin AT

reference for active tracking supply circuitry. Connect a 1A

(1N4001-type) diode between V+ and OUT and a

1A Schottky diode from V– to OUT for line transient

protection.

LIM+ (Pin 9): Output Amplifier Current Source Limit. Pin

implements I

resistor has a typical value of 3.5Ω. For maximum current

drive capability (190mA typical) short pin LIM+ to pin

OUT. Reduction of current source capability is achieved by

placing additional resistance from pin LIM+ to pin OUT.

(i.e. An external 3.5Ω resistance from pin LIM+ to pin OUT

will reduce the current sourcing capability of the output

amplifier by approximately 50%.)

V+ (Pin 10): Local Positive Supply. Typically connected to

the source of the active tracking supply N-channel MOSFET.

This condition should be made using a ferrite bead.

Operating V+ rail voltage is GATE+ self-bias voltage less

the MOSFET VGS. Typical N-channel MOSFET characteristics provide V+ – AT

GATE+ (Pin 11): Positive Power Supply FET Gate Drive.

Pin sinks current from pull-up resistor to bias gate of

active tracking supply N-channel MOSFET. Self-biases to

a typical value of 14V, referenced to pin AT

resistor value is determined such that sink current into

GATE+ pin remains greater than 50µA at maximum output

signal voltage and less than 10mA at minimum output

signal voltage.

AMPIN (Pin 12): Output Amplifier Input. Connected to

external filter components through series protection resistor (usually 5k). Thevenin DC resistance of external

filter and protection components should be 10k for optimum amplifier offset performance. See Applications Information section.

OUT

= I

ATREF

• R = VBE current clamp. Internal clamp

≈ 10V.

REF

GATE

+ – I

–).

GATE

to generate

REF

REF

. Pull-up

5

Page 6

LT1684

U

UU

PI FU CTIO S

BG

(Pin 13): Normalized PWM Buffered Output. PWM

OUT

differential input is amplitude normalized to ±1.25V (refer-

enced to the OUT pin). This signal is used to drive the

active filter/amplifier. Filter resistor values must be chosen

to limit the maximum current load on this pin to less than

2mA. The output is current limit protected to a typical value

of ±4.5mA.

IN A (Pin 14): PWM Positive Input. Input is isolated from

digital source by ~100pF series capacitor. A 10k resistor

should be connected to the IN A pin in series with the

isolation capacitor for transient protection. The PWM

UU

W

FUNCTIONAL BLOCK DIAGRA

PWM

INPUT

100pF

+

100pF

–

IN A

IN B

BG

5k10k

5k10k

OUT

receiver implements a diode forward drop of input hysteresis (relative to IN B). This hysteresis and internal signal

limiting assure common mode glitch rejection with isolation capacitor mismatches up to 2:1. For maximum performance, however, effort should be made to match the two

PWM input isolation capacitors. Pin IN A is differentially

clamped to pin IN B through back-to back isolation-base

diodes. This results in a high impedance differential input

±100mV beyond the input thresholds. 5k internal input

resistors yield a 10k (nominal) differential overdrive impedance.

1.25V

+

V

–1.25V

+

V

+

GATE

FILTER

ELEMENTS

RING

OUTPUT

(RING RETURN)

100pF

20pF

AMPIN

COMP1

COMP2

–

5k

+

LT1684 Block Diagram

15k

CURRENT

LIMIT

14V

14V

AT

LIM

OUT

GATE

LIM

REF

+

–

–

–

V

–

V

1684 BD

6

Page 7

OPERATIO

LT1684

U

(Refer to Functional Block Diagram)

BASIC THEORY OF OPERATION

The LT1684 operates using a user-provided pulse-widthmodulated (PWM) digital signal as input*. The low frequency modulation component of this signal represents

the desired output waveform. Changing the PWM input

can thus dynamically control the frequency, cadence,

amplitude and DC offset of the desired output. This method

of sine wave generation can accomodate all popular ring

tone frequencies including 17Hz, 20Hz, 25Hz and 50Hz.

The LT1684 receives the PWM input by a capacitorisolated differential input at pins IN A and IN B. This signal

is amplitude normalized by a bandgap reference and

output single-ended on the BG

carrier is ±1.25V about the voltage on the OUT pin.

The low frequency component of the normalized PWM

signal is recovered using an active filter circuit constructed using an onboard driver amplifier. This amplifier

also provides current drive for the final ring tone output.

The ring tone output is used as the reference for a floating

active biasing scheme by pin AT

output rises and falls through its typical range of hundreds

of volts, the LT1684 “tracks” the output signal, maintaining local supply voltages across the IC of approximately

±10V.

Input Receiver/Reference Buffer

The differential receiver for the PWM input signal requires

minimum differential input levels of 1.6V to assure valid

change-of-state. The receiver inputs are capacitor coupled,

isolating the LT1684 from the PWM generator. The receiver is leading edge triggered.

The input receiver controls a switched-state output that

forces an amplitude normalized voltage (referenced to the

OUT pin) of ±1.25V that follows the PWM input. This

switched voltage is driven off-chip on pin BG

the IN A input is driven higher than IN B (by the required

pin such that the PWM

OUT

. As the ring tone

REF

OUT

. When

1.6V), the reference drives BG

When IN B input is driven higher than IN A, BG

to –1.25V relative to OUT.

The amplitude normalized representation of the input

PWM signal is used as the input for the active filter element

and output driver.

Output Amplifier/Driver

The normalized PWM signal output on the BG

converted to the final ring tone signal by an active filter.

This filter consists of an onboard amplifier and a few

external components. Although many different types of

filters can be constructed, a 2-pole Multiple Feedback

(MFB) configuration generally provides adequate performance and is desirable due to its simplicity and effectiveness.

The low frequency component of the ±1.25V PWM signal

contains the desired ring tone frequency and cadence

information. The MFB active filter strips this information

from the PWM signal and amplifies this low frequency

component to generate the final desired output.

Active Tracking Supplies

Implementation of the active tracking supply technique

enables linear generation of the ring tone output, and takes

advantage of the intrinsic supply noise immunity of a

linear amplifier, reducing the need for large high voltage

filtering elements.

Two external power MOSFETs act as voltage level-shifting

devices and generate the power supply voltages for the

LT1684. The LT1684 uses its own output as a voltage

reference for the FET level shifters, “suspending” itself (by

these generated supply voltages) about the signal output.

In this manner, the LT1684 can linearly generate a signal

hundreds of volts in amplitude at its output, while maintaining ±10V local supply rails across the IC itself.

to +1.25V above OUT.

OUT

is forced

OUT

OUT

pin is

* Contact Linear Technology for code.

7

Page 8

LT1684

WUUU

APPLICATIO S I FOR ATIO

Encoded PWM Signal Input Basics

The LT1684 accepts a user-supplied PWM carrier that

represents the desired output ring tone signal. This PWM

input is normalized by the LT1684 such that ring tone

output amplitudes can be accurately encoded into the

PWM input.

The LT1684 accepts a differential input to maximize rejection of system transients and ground noise. If no differential signal is readily available from the PWM controller, a

simple inverter/buffer block can be used to create the

differential signal required.

Each differential input is internally connected through a 5k

series resistor to back-to-back isolation-base diodes. These

devices internally clamp the differential input signal to

±100mV greater than the input comparator hysteresis

range. The input comparator toggles with a differential

hysteresis equal to that of a standard diode forward

voltage (0.7V nominal). As such, the differential impedance of the input remains high throughout the input

hysteresis region, then reduces to a nominal value of 10k

(7k minimum) as the input is overdriven beyond the

comparator input threshold. A minimum differential input

of 1.6V is specified to assure valid switching.

The PWM signal can be visualized in terms of instantaneous ring tone amplitude, normalized to the LT1684

amplitude reference. For a given desired output voltage

V

, the input pulse train required follows the relation:

OUTN

V

= 2 • V

OUTN

DC = [V

V

DC = PWM input duty cycle

OUTN

= 1.25V normalized peak voltage

REF

• (DC – 0.5), or

REF

/ (2 • V

)] + 0.5, where:

REF

A 10% to 90% duty cycle range is a practical limit for a

10kHz input carrier. This corresponds to normalized signal amplitude of ±1V. Duty cycles exceeding this range can

cause increased output signal distortion as signal energy

is lost due to finite rise and fall times becoming a significant percentage of the signal pulses. The associated

reduction in the pulse energy manifests itself as a “soft

clipping” of the output signal resulting in an increase in

harmonic distortion.

The normalized PWM signal is amplified to the desired

output signal level by the active filter/amplifier stage.

Thus, dividing the desired peak output amplitude by the

peak normalized encoded amplitude (V

the required DC gain of the active filter.

System Considerations

Assuming use of a 10% to 90% maximum PWM range, the

peak normalized signal will be:

V

(pk) = ± 0.8 • V

PWM

V

(pk) = V

OUT

Thus, the DC gain of the output filter equals the desired

peak voltage of the output ring tone signal.

The frequency characteristics of the lowpass output filter

must reflect the allowable carrier ripple on the output

signal. For example, a 10kHz carrier system could use a

2-pole Butterworth lowpass with a cutoff frequency of

100Hz. This filter provides 40dB of input signal rejection

at 10kHz yielding 25mV

the output filter/amplifier was 100, the output ripple voltage would be riding on a ±100V sine wave, and therefore

be about –78dB relative to the output ring signal.

(pk) • Filter DC Gain

PWM

= ±1.0V, and:

REF

output ripple. If the DC gain of

P-P

OUT/VOUTN

) yields

8

Page 9

WUUU

APPLICATIO S I FOR ATIO

LT1684

For applications that are extremely output ripple sensitive,

additional carrier rejection can be accomplished by modifying the output filter/amplifier characteristics such as

implementing elliptical filter characteristics with a lower

cutoff frequency or implementation of additional poles.

Filter Design and Component Selection

The ring tone information represented in the low frequency component of the input PWM signal is retrieved

using an active filter. This filter also generates the appropriate low frequency gain required to produce the high

voltage output signal and references the output to ground

(or other system reference). The frequency and gain

characteristics of this circuit element are both configurable

by the appropriate choice of external passive filter elements. Because of the active tracking supply mode of

operation, conventional active filter topologies cannot be

used. Most amplifier/filter topologies can, however, be

“transformed” into active tracking supply topologies.

A conventional amplifier circuit topology can be “transformed” into an active tracking supply amplifier circuit by:

a) Inverting the amplifier signal polarity (swap amplifier +

and – connections) and input source polarity.

b) Referencing all signals to the output except the feedback elements, which are referenced to ground (swap

output and ground).

A variety of amplifier/filter configurations can be realized

using the transformation technique. A 2-pole filter is

generally adequate for most ringer applications. Due to the

relative simplicity of infinite-gain Multiple Feedback (MFB)

configurations, these filters are good candidates for ringer

applications. Component selection and active tracking

supply transformation will be described for the following

2-pole MFB infinite-gain lowpass filter.

Conventional Amplifier Configuration Active Tracking Supply Amplifier

R1 R2

+

V

IN

–

Lowpass Mulitple Feedback Active Filter Active Tracking Supply Lowpass

R1 R3

+

V

IN

–

–

+

LOAD

C2R2

–

C1

+

TRANSFORMATION

TRANSFORMATION

LOAD

+

V

IN

–

R1

Multiple Feedback Filter

+

V

IN

–

R2

–

+

R2

C1

R3R1

C2

–

+

LOAD

LOAD

1684 F01

9

Page 10

LT1684

HERTZ (Hz)

1 10 100 1K 10K 100K

FILTER GAIN (dB)

1684 F02

–50

0

50

WUUU

APPLICATIO S I FOR ATIO

The component selections for the active tracking supply

lowpass MFB filter configuration follow the relations:

C2 = mC

R2 = 1± [1–4mQ2(1+|HO|)]

m ≤ 1 / [4Q2(1+|HO|)]

1

1/2

2ωnC1mQ

R1 = R2 / |HO|

R3 =1

2

2

ω

C

R2m

n

1

Example:

Conditions: Output ring tone peak voltage = 100V

Ring frequency = 20Hz

Input duty cycle range = 10% to 90%

Filter Q = 0.707

Set: fn = ωn / 2π = 100Hz

Choose: C1 = 1.0µF (a convenient value)

Then: m ≤ [4(0.7)2(1+100)]–1 ≈ .005

Active Tracking Supply Lowpass Multiple

Feedback Filter Transfer Characteristic (AV vs fn)

However, bootstrapping an amplifier system about its

own output creates a complex myriad of inherent stability

and response issues. Attempting such a configuration

with generic “jelly-bean” components is not recommended

for the faint of heart or type-A personalities. The LT1684,

however, makes for a simplistic approach to active tracking component selection.

This filter configuration yields a DC Gain of 100, a corner

frequency of just under 100Hz with gain reduction of only

0.1% at 20Hz, and a 10kHz carrier rejection of greater than

40dB at the output.

Active Tracking Supply Components

Given the previous discussion, implementation of an

active tracking supply system may seem almost trivial.

C2 = mC1 C2 = 4700pF

(sets m = 0.0047)

R2 = 1± [1–4(0.0047)(0.707)2(101)]

1/2

(4π100)(1e–6)(.0047)(0.707)

R2 = 300k

R1 = 300k/100

R1 = 3.0k

R3 = [(2π100)2(1e–6)2(300k)(0.0047)]

R3 = 2k

–1

The high voltage MOSFET transistors used in the circuit

must have an operating VDS specified at greater than the

corresponding high voltage supply rail plus the opposite

maximum excursion of the output signal. For example, if

a system is designed with a 240V supply (+120V,

–120V) and outputs a ring signal that has a 100V peak

amplitude, the MOSFET VDS ratings must be greater than

240/2 + 100 = 220V.

Active Filter Tuned Oscillator—

No PWM Input Required

A simple yet effective method of producing a high quality

sine wave is to place a high-Q bandpass filter and a hard

limited gain element in a positive feedback loop. This

circuit will oscillate at the bandpass frequency, producing

a sine wave at the filter output. The product of the fundamental component of the limiter and the filter gain at the

bandpass frequency determines the output amplitude.

This type of circuit is commonly referred to as an active

filter tuned oscillator.

10

Page 11

WUUU

APPLICATIO S I FOR ATIO

LT1684

Active Filter Tuned Oscillator Block Diagram

1684 F03

The LT1684 can be implemented easily into a telephone

ringer circuit based on the active filter tuned oscillator

topology, eliminating the need for a user-supplied PWM

input signal. The LT1684’s active filter amplifier can be

used as a high-Q bandpass filter element by configuring

it as an active tracking supply bandpass. The LT1684’s

controlled output receiver/buffer is also convenient for

use as the hard limiter. Because the LT1684 receiver/

buffer requires a true differential input for proper operation, a dual comparator IC such as the LT1017 must be

bootstrapped along with the LT1684 to provide differential control signals. The LT1017 and LT1684 receiver/

buffer combine to create a high gain hard limiter whose

output is controlled to ±1.25V. The LT1684 active

bandpass filter is then connected as a positive feedback

element with the limiter component, which completes

the active filter tuned oscillator topology.

The active bandpass filter circuit is easily configured using

a basic MFB bandpass configuration, however, the active

tracking supply technique used by the LT1684 requires

“transformation” of this topology. This “transformation”

swaps the amplifier signal polarity, references all signals

to the output, and references all feedback elements to

ground as described previously in the Filter Design and

Component Selection section.

The design equations for the active tracking bandpass

filter are the same as the pretransformation MFB topology,

such that if CF1 = CF2 = C:

RF1 = Q/(ωO • C •H0)

RF2 = Q/(2Q2 –H0)(ωO • C)

RF3 = 2Q/(ωO • C)

Example:

Conditions: Output peak voltage = 95V

Bandpass MFB Filter

C

F2

R

F3

R

F1

C

F1

+

V

IN

R

–

Active Tracking Bandpass MFB Filter

F2

R

F1

R

F2

C

F1

C

F2

–

+

+

–

V

IN

–

+

R

F3

V

OUT

1684 F5b

V

OUT

1684 F4a

Ring frequency = 20Hz

Bandpass Q = 9.4

A square wave with peak amplitude A has a fundamental

component with amplitude 4A/π, where A = 1.25V. Therefore, the desired filter’s bandpass gain HO = 95/(4 •

1.25/π) ~ 60. Given capacitor values C = 0.22µF (a conve-

nient value) and desired filter characteristics of: Q = 9.4,

HO = 60, ωO = 2π(20Hz), then: RF1 = 5.6k, RF2 = 2.7k,

RF3 = 680k. The amplitude, frequency and envelope response time of the output signal can be adjusted by simply

changing the values of resistors RF1 to RF3 accordingly.

This produces a high voltage, high quality 20Hz sine wave

at the filter output with a peak amplitude of 95V. Differential amplitude and frequency characteristics are achieved

by simply changing a few resistor values. The output of the

LT1684 is internally current limited to a minimum of

±100mA peak, allowing this ring tone generation circuit to

be used with loads up to 7 REN with no degradation of the

output waveform.

11

Page 12

LT1684

WUUU

APPLICATIO S I FOR ATIO

Active Filter Tuned Oscillator Ring Tone Generator

110V

8

5

+

+

V

C2

100pF

D1

1N5817

R10

10k

C1 20pF

1

2

3

4

5

6

7

7

IN B

COMP1

COMP2

LIM

–

V

GATE

AT

REF

1/2 LT1017

–

4

LT1684

–

–

IN A

BG

OUT

AMPIN

GATE

LIM

OUT

–

V

R9

10k

6V

R8

10k

14

13

12

11

+

10

+

9

+

R

F3

8

680k

C

C

F1

F2

0.22µF

0.22µF

1

8

+

V

1/2 LT1017

–

V

4

R

F1

5.6k

R

F2

2.7k

3

+

R6

1k

2

–

R5

100k

R3

100k

R2

100Ω

FB1

C4

6.8nF

C3

6.8nF

M1

IRF610

C5

0.1µF

D2

1N4001

+

OUTPUT

–

±100mA

()

PEAK

–110V

FB1: FERRONICS FMB1601 (716) 388-1020

Ringer Output

R4

100k

R1 100Ω

M2

IRF9610

1684 F05a

12

Page 13

TYPICAL APPLICATIO S

U

M1

IRF610

D1

1N4001

C3

LT1684

+

–

OUTPUT

0.1µF

M2

IRF9610

1684 TA03

C14

+

876

LT1017

123

R2 10k

10µF

160V

CC

V

OUT A

OUT B

–IN A

–IN B

+IN A

C15

+

5

+IN B

EE

V

4

R1

R8

10µF

1k

100k

160V

R3

R4 10k

10k

14

IN A

IN B

1

C6

R7

100pF

100k

13

BG

COMP1

2

R6

12

OUT

3

C5 20pF

FB1

100Ω

11

10

+

+

GATE

AMPIN

LT1684

COMP2

LIM–V–GATE–AT

4

5

DS1

F1

R

V

1N5817

10k

R10

91V

DZ2

F3

R

680k

620k

F2

R

2.7k

3.3k

F1

R

5.6k

6.8k

95V

70V

V (PEAK)

7

10

LOAD (REN)

R

6.8nF

F2

2.7k

DZ4

91V

R5 100Ω

R14

100k

10k

R12

50k

R13

15

2

C2

6.8nF

5.6k

0.22µF

F1

C

9

+

LIM

6

15

R11

C1

0.22µF

F2

C

F3

R

680k

8

OUT

REF

7

50k

2

C11

0.47µF

160V

C12

0.47µF

160V

3

4

OPTO2 H11AG1

6

C10

0.1µF

C13

0.01µF

R15

4

2k

FB1: FERRONICS FMB1601 (716) 388-1020

D4

MURS160

C9

0.47µF

2

•

T1

5V-15V to Ring Tone Fully Isolated Converter Using an Active Filter-Tuned Oscillator Circuit

COILTRONICS

160V

1

14239-X3

12

•

5, 6

C7

D2

MURS160

220µF

10V

11

7, 8

•

49

D3

DZ1

1N4001

44V

R9

39Ω

C8

1nF

OPTO1 H11AG1

DS2

4

SW

IN

V

5

C4

1µF

6

MBRS1100

1

C

V

LT1270

FB

2

GND

+

INPUT

5V TO 15V

13

Page 14

LT1684

TYPICAL APPLICATIO S

U

5kW PWM-to-Analog Converter

300k

120V

6800pF

1000pF

10k

14

PWM

1000pF

IN

3k

0.1µF

FB1: FERRONICS FMB1601 (716) 388-1020

10k

2k

470pF

IN A

1

IN B

13

BG

5k

12

AMPIN

6800pF

OUT

GATE

LT1684

GATE

–120V

100k

11

+

COMP1

COMP2

–

6

100Ω

LIM

AT

LIM

100k

V

OUT

REF

V

100Ω

1nF

IN

1nF

V

LT1166

V

BOTTOM

47Ω

2N3906

1

TOP

SENSE

SENSE

4

2N3904

47Ω

100Ω

8

+

7

+

I

LIM

3

V

OUT

6

–

I

LIM

5

–

100Ω

TYPICAL POWER SLICE

(1 OF 13 IN PARALLEL)

100V

IRF230

1k

0.22Ω

1µF

1µF

0.22Ω

1k

IRF9240

–100V

0.22Ω

1µH

1684 TA04

5kW

LOAD

3.9k

180µH

100Ω

2

V

100Ω

2N3906

MTP2N50E

FB1

10

+

2

9

+

8

7

3

4

–

5

–

100pF

MTP2N50E

20pF

180µH

2k

2N3904

14

Page 15

PACKAGE DESCRIPTIO

U

Dimensions in inches (millimeters) unless otherwise noted.

N Package

14-Lead PDIP (Narrow 0.300)

(LTC DWG # 05-08-1510)

0.770*

(19.558)

MAX

14

0.255 ± 0.015*

(6.477 ± 0.381)

11

1213

8910

LT1684

0.300 – 0.325

(7.620 – 8.255)

0.009 – 0.015

(0.229 – 0.381)

+0.035

0.325

–0.015

+0.889

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

0.020

(0.508)

MIN

0.130 ± 0.005

(3.302 ± 0.127)

0.125

(3.175)

MIN

0.005

(0.125)

MIN

S Package

14-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

13

14

2

31

0.045 – 0.065

(1.143 – 1.651)

0.100

(2.54)

BSC

0.337 – 0.344*

(8.560 – 8.738)

12

6

9

7

0.065

(1.651)

TYP

0.018 ± 0.003

(0.457 ± 0.076)

N14 1098

8

5

4

11

10

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0° – 8° TYP

0.016 – 0.050

(0.406 – 1.270)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.150 – 0.157**

(3.810 – 3.988)

1

3

2

4

0.050

(1.270)

BSC

5

7

6

0.004 – 0.010

(0.101 – 0.254)

S14 1298

15

Page 16

LT1684

TYPICAL APPLICATIO

V

IN

PWM

INPUT

5V

+

–

C1

100pF

C3 100pF

C4 20pF

C2

100pF

R4

10k

IN B

COMP1

COMP2

–

LIM

–

V

GATE

AT

REF

LT1684

–

IN A

BG

OUT

AMPIN

GATE

LIM

OUT

R2

10k

R3

5k

+

FB1

+

V

D1

1N4001

+

1µF

U

5V Input Nonisolated 5 REN Ring Generator

100V

D2

MURS160T3

C11

IRF610

+

0.47µF

160V

+

C10

0.47µF

160V

D3

MURS160T3

M1

MBRS1100

DZ1

60V

MMSZ5264BT1

R10

100k

R8

100Ω

C8

300k

R1

2k

C5

R5

4700pF

R6

3k

C7

6.8nF

160V

C6

6.8nF

160V

T1

COILTRONICS

CTX 14468-X1

12

•

10

9

•

•

7

DS1

4, 5

1, 2

4

1

R11

470Ω

SW

V

C

C9

0.1µF

+

U1

LT1271

GND

C12

220µF

35V

5

V

IN

R12

5k

2

FB

3

R7

100Ω

DS2

D1N5817

FB1: FERRONICS FMB1601 (716) 388-1020

M2

IRF9610

R9

100k

C13 0.1µF

–100V

R16

1M

R15

12k

RING TONE

OUT

D4

D1N4148

LT1211

1

OUT A

–IN A

V

EE

V

OUT B

–IN B+IN A

+IN B

27

36

4

D5

8

CC

D1N4148

5

1684 TA02

R14

1M

R13

12k

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1082 1A High Voltage Switching Regulator VIN = 3V to 75V, SW Voltage = 100V

LT1166 Power Output Stage Automatic Bias System Sets Class AB Bias Currents, Eliminates Adjustments

and Thermal Runaway

LTC1177-5/LTC1177-12 Isolated MOSFET Drivers 2500V

LT1270 8A Power Switching Regulator VIN = 3.5V to 30V, IQ = 7mA

LT1271 4A Power Switching Regulator VIN = 3.5V to 30V, IQ = 7mA

LT1339 High Power Synchronous DC/DC Controller Operation Up to 60V, Output Current Up to 50A

LT1676 Wide Input Range, High Efficiency, Step-Down Switching Regulator Operation Up to 60V, 100kHz, Up to 500mA Output

Isolation, UL Recognized

RMS

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

1684f LT/TP 0300 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1999

Loading...

Loading...