Page 1

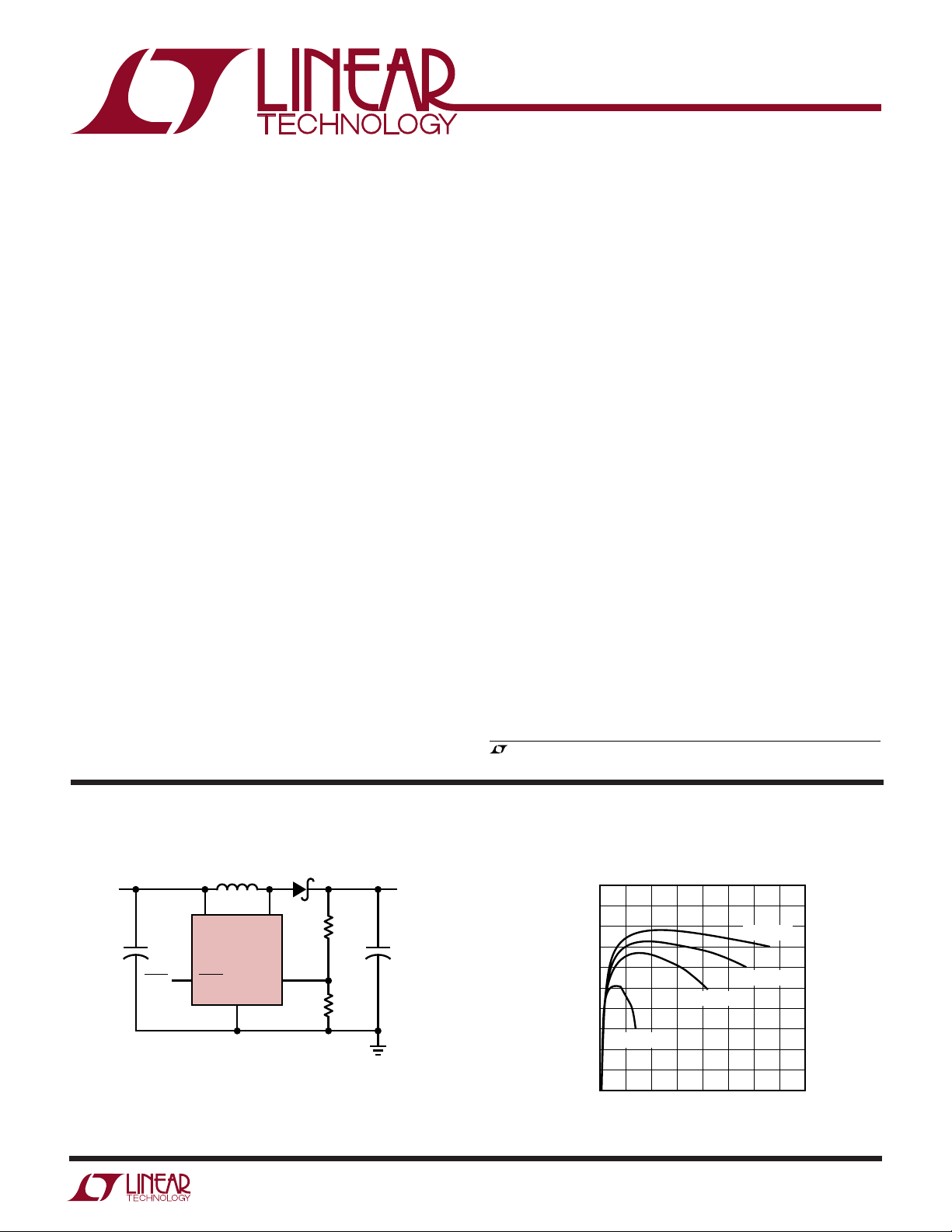

LOAD CURRENT (mA)

0 50 100 150 200 250 300 350 400

EFFICIENCY (%)

1613 TA01a

100

95

90

85

80

75

70

65

60

55

50

VIN = 4.2V

VIN = 3.5V

VIN = 2.8V

VIN = 1.5V

FEATURES

■

Uses Tiny Capacitors and Inductor

■

Internally Compensated

■

Fixed Frequency 1.4MHz Operation

■

Operates with VIN as Low as 1.1V

■

3V at 30mA from a Single Cell

■

5V at 200mA from 3.3V Input

■

15V at 60mA from Four Alkaline Cells

■

High Output Voltage: Up to 34V

■

Low Shutdown Current: <1µA

■

Low V

■

Tiny 5-Lead SOT-23 Package

Switch: 300mV at 300mA

CESAT

U

APPLICATIO S

■

Digital Cameras

■

Pagers

■

Cordless Phones

■

Battery Backup

■

LCD Bias

■

Medical Diagnostic Equipment

■

Local 5V or 12V Supply

■

External Modems

■

PC Cards

LT1613

1.4MHz, Single Cell DC/DC

Converter in 5-Lead SOT-23

U

DESCRIPTIO

The LT®1613 is the industry’s first 5-lead SOT-23 current

mode DC/DC converter. Intended for small, low power

applications, it operates from an input voltage as low as

1.1V and switches at 1.4MHz, allowing the use of tiny, low

cost capacitors and inductors 2mm or less in height. Its

small size and high switching frequency enables the

complete DC/DC converter function to take up less than

0.2 square inches of PC board area. Multiple output power

supplies can now use a separate regulator for each output

voltage, replacing cumbersome quasi-regulated approaches using a single regulator and a custom transformer.

A constant frequency, internally compensated current

mode PWM architecture results in low, predictable output

noise that is easy to filter. The high voltage switch on the

LT1613 is rated at 36V, making the device ideal for boost

converters up to 34V as well as for Single-Ended Primary

Inductance Converter (SEPIC) and flyback designs. The

device can generate 5V at up to 200mA from a 3.3V supply

or 5V at 175mA from four alkaline cells in a SEPIC design.

The LT1613 is available in the 5-lead SOT-23 package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

TYPICAL APPLICATIO

V

IN

3.3V

+ +

C1

15µF

L1: MURATA LQH3C4R7M24 OR SUMIDA CD43-4R7

C1: AVX TAJA156M010

C2: AVX TAJB226M006

D1: MBR0520

Figure 1. 3.3V to 5V 200mA DC/DC Converter

4.7µH

V

IN

LT1613

SHDN

L1

GND

SW

U

D1

V

OUT

5V

R1

37.4k

FBSHDN

R2

12.1k

200mA

C2

22µF

1613 TA01

Efficiency Curve

1

Page 2

LT1613

WW

W

ABSOLUTE MAXIMUM RA TIN GS

(Note 1)

VIN Voltage .............................................................. 10V

SW Voltage................................................–0.4V to 36V

FB Voltage ..................................................... VIN + 0.3V

Current into FB Pin ............................................... ±1mA

SHDN Voltage.......................................................... 10V

Maximum Junction Temperature..........................125°C

Operating Temperature Range

Commercial .............................................0°C to 70°C

U

U

W

PACKAGE/ORDER INFORMATION

ORDER PART NUMBER

TOP VIEW

SW 1

GND 2

FB 3

S5 PACKAGE

5-LEAD PLASTIC SOT-23

5 V

IN

4 SHDN

LT1613CS5

S5 PART MARKING

LTED

U

Extended Commercial (Note 2)........... –40°C to 85°C

Storage Temperature Range................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

Consult factory for Industrial and Military grade parts.

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. Commercial grade 0°C to 70°C, VIN = 1.5V, V

otherwise noted. (Note 2)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage 0.9 1.1 V

Maximum Operating Voltage 10 V

Feedback Voltage ● 1.205 1.23 1.255 V

FB Pin Bias Current ● 27 80 nA

Quiescent Current V

Quiescent Current in Shutdown V

Reference Line Regulation 1.5V ≤ VIN ≤ 10V 0.02 0.2 %/V

Switching Frequency ● 1.0 1.4 1.8 MHz

Maximum Duty Cycle ● 82 86 %

Switch Current Limit (Note 3) 550 800 mA

Switch V

CESAT

Switch Leakage Current VSW = 5V 0.01 1 µA

SHDN Input Voltage High 1V

SHDN Input Voltage Low 0.3 V

SHDN Pin Bias Current V

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

= 1.5V 3 4.5 mA

SHDN

= 0V, VIN = 2V 0.01 0.5 µA

SHDN

= 0V, VIN = 5V 0.01 1.0 µA

V

SHDN

ISW = 300mA 300 350 mV

= 3V 25 50 µA

SHDN

V

= 0V 0.01 0.1 µA

SHDN

The ● denotes the specifications which apply over the full operating

= VIN unless

SHDN

Note 2: The LT1613C is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: Current limit guaranteed by design and/or correlation to static test.

2

Page 3

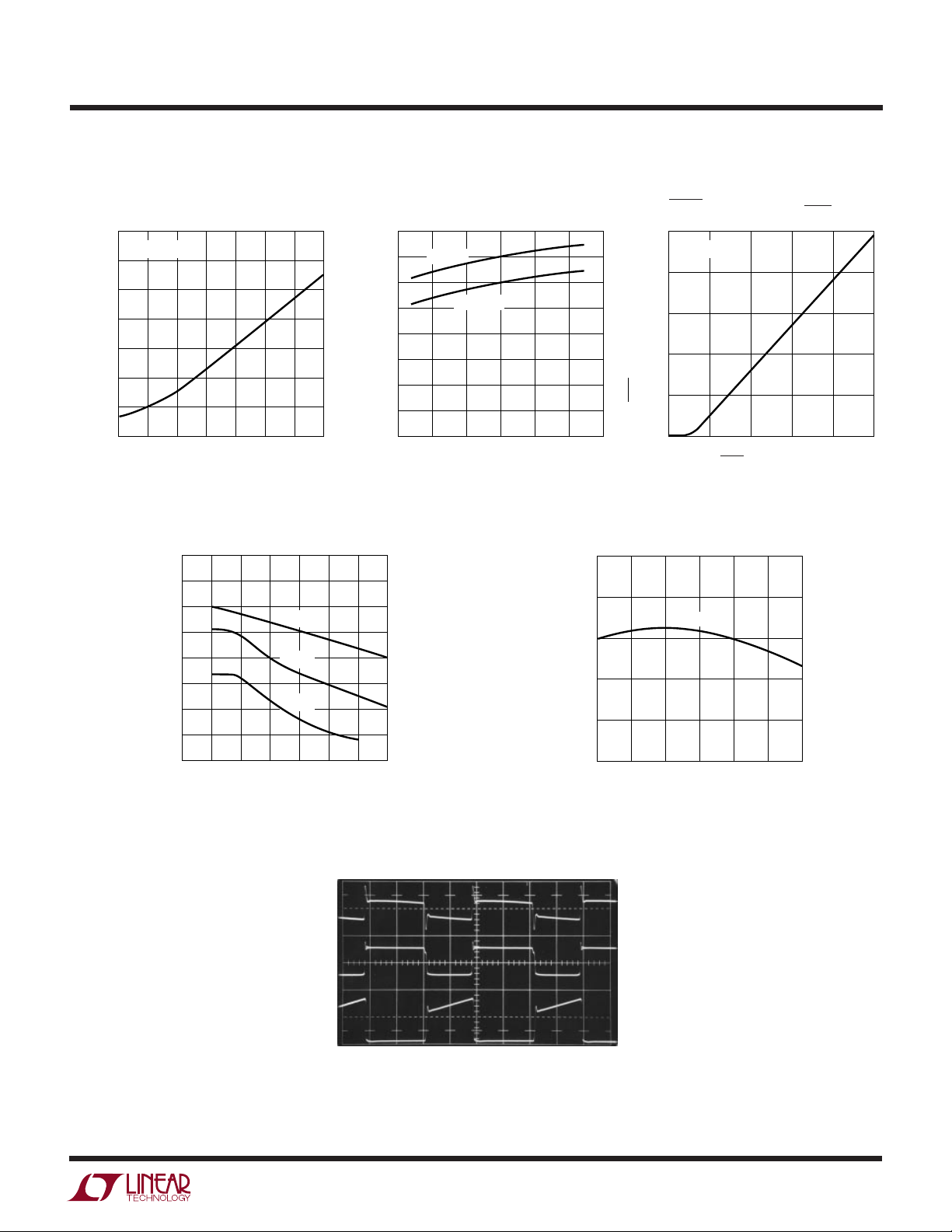

UW

TEMPERATURE (°C)

–50

FEEDBACK PIN VOLTAGE (V)

1613 G05

1.25

1.24

1.23

1.22

1.21

1.20

VOLTAGE

–25 0 25 50 75 100

TYPICAL PERFOR A CE CHARACTERISTICS

Oscillator Frequency vs

Switch V

700

TA = 25°C

600

500

400

(mV)

300

CESAT

V

200

100

0

0 100 200 300 400 500 600 700

vs Switch Current SHDN Pin Current vs V

CESAT

SWITCH CURRENT (mA)

1613 G01

Temperature

2.00

1.75

1.50

1.25

1.00

0.75

0.50

SWITCHING FREQUENCY (MHz)

0.25

VIN = 5V

VIN = 1.5V

0

–50 –25 0 25 50 75 100

TEMPERATURE (°C)

1613 G02

LT1613

SHDN

50

TA = 25°C

40

30

20

10

SHDN PIN BIAS CURRENT (µA)

0

012345

SHDN PIN VOLTAGE (V)

1613 G03

Current Limit vs Duty Cycle

1000

900

800

700

600

500

CURRENT LIMIT (mA)

400

300

200

10 20 30 40 50 60 70 80

70°C

25°C

–40°C

DUTY CYCLE (%)

V

100mV/DIV

AC COUPLED

V

5V/DIV

Feedback Pin Voltage

1613 G04

Switching Waveforms, Circuit of Figure 1

OUT

SW

I

SW

200mA/DIV

= 150mA 200ns/DIV 1613 G06

I

LOAD

3

Page 4

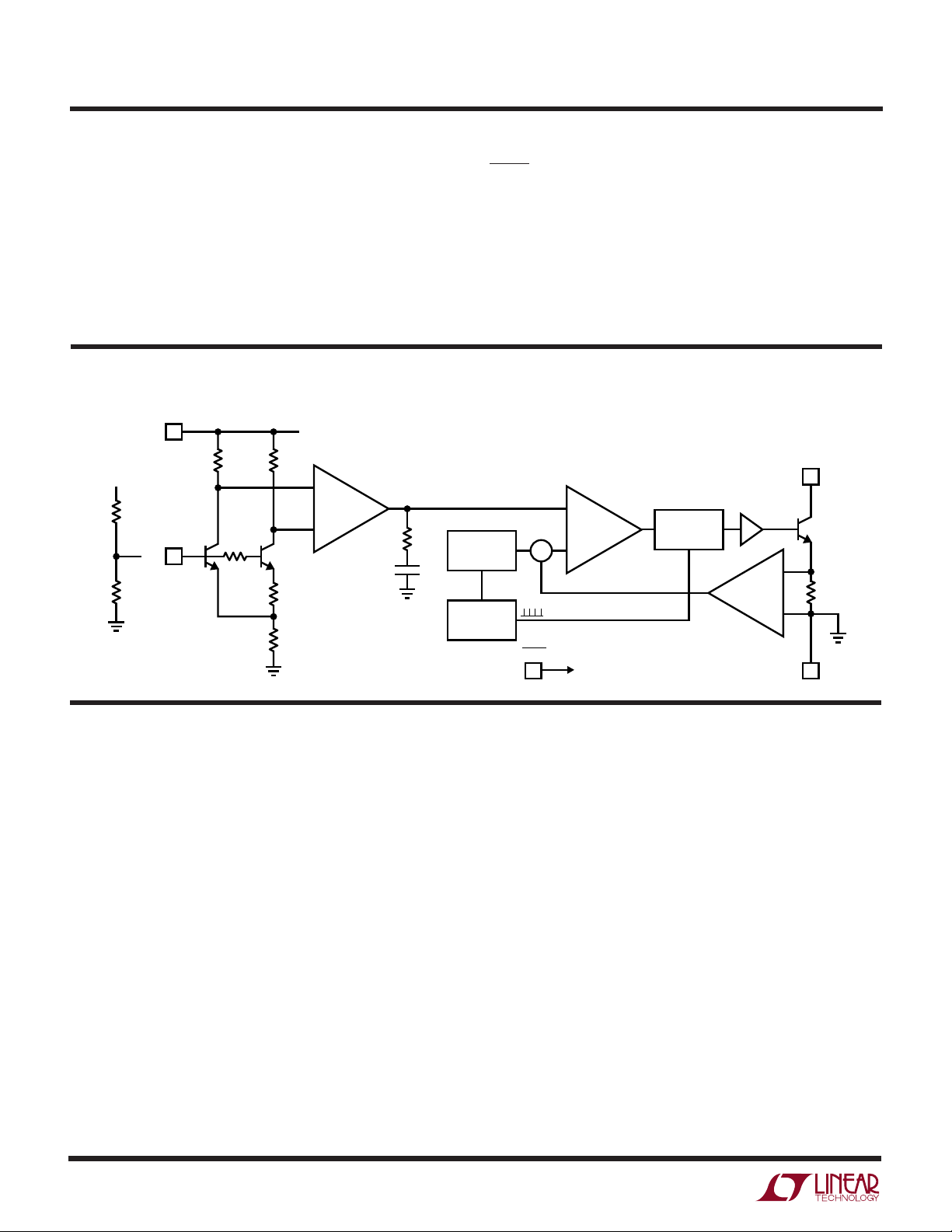

LT1613

UUU

PIN FUNCTIONS

SW (Pin 1): Switch Pin. Connect inductor/diode here.

Minimize trace area at this pin to keep EMI down.

GND (Pin 2): Ground. Tie directly to local ground plane.

FB (Pin 3): Feedback Pin. Reference voltage is 1.23V.

Connect resistive divider tap here. Minimize trace area at

FB. Set V

according to V

OUT

= 1.23V(1 + R1/R2).

OUT

W

BLOCK DIAGRAM

Q2

x10

R6

40k

R3

30k

R4

140k

V

IN

+

A1

g

m

–

R

C

C

C

GENERATOR

1.4MHz

OSCILLATOR

V

OUT

R1

(EXTERNAL)

R2

(EXTERNAL)

V

5

IN

R5

40k

FB

Q1

3

FB

SHDN (Pin 4): Shutdown Pin. Tie to 1V or more to enable

device. Ground to shut down.

VIN (Pin 5): Input Supply Pin. Must be locally bypassed.

SW

1

Q3

+

0.15Ω

–

2

GND

1613 • BD

RAMP

SHDN

4

Σ

COMPARATOR

–

A2

+

SHUTDOWN

FF

RQ

S

DRIVER

U

OPERATIO

The LT1613 is a current mode, internally compensated,

fixed frequency step-up switching regulator. Operation

can be best understood by referring to the Block Diagram.

Q1 and Q2 form a bandgap reference core whose loop is

closed around the output of the regulator. The voltage

drop across R5 and R6 is low enough such that Q1 and Q2

do not saturate, even when VIN is 1V. When there is no

load, FB rises slightly above 1.23V, causing VC (the error

amplifier’s output) to decrease. Comparator A2’s output

stays high, keeping switch Q3 in the off state. As increased

output loading causes the FB voltage to decrease, A1’s

output increases. Switch current is regulated directly on a

cycle-by-cycle basis by the VC node. The flip flop is set at

the beginning of each switch cycle, turning on the switch.

When the summation of a signal representing switch

current and a ramp generator (introduced to avoid

subharmonic oscillations at duty factors greater than

50%) exceeds the VC signal, comparator A2 changes

state, resetting the flip flop and turning off the switch.

More power is delivered to the output as switch current is

increased. The output voltage, attenuated by external

resistor divider R1 and R2, appears at the FB pin, closing

the overall loop. Frequency compensation is provided

internally by RC and CC. Transient response can be optimized by the addition of a phase lead capacitor CPL in

parallel with R1 in applications where large value or low

ESR output capacitors are used.

As the load current is decreased, the switch turns on for a

shorter period each cycle. If the load current is further

decreased, the converter will skip cycles to maintain

output voltage regulation. If the FB pin voltage is increased

significantly above 1.23V, the LT1613 will enter a low

power state where quiescent current falls to approximately 100µA.

4

Page 5

OPERATIO

LT1613

U

LAYOUT

The LT1613 switches current at high speed, mandating

careful attention to layout for proper performance.

You

will not get advertised performance with careless layouts.

Figure 2 shows recommended component placement for

a boost (step-up) converter. Follow this closely in your

PCB layout. Note the direct path of the switching loops.

Input capacitor C1

must

be placed close (<5mm) to the IC

package. As little as 10mm of wire or PC trace from CIN to

VIN will cause problems such as inability to regulate or

oscillation.

The ground terminal of output capacitor C2 should tie

close to Pin 2 of the LT1613. Doing this reduces dI/dt in the

ground copper which keeps high frequency spikes to a

minimum. The DC/DC converter ground should tie to the

PC board ground plane at one place only, to avoid introducing dI/dt in the ground plane.

A SEPIC (single-ended primary inductance converter)

schematic is shown in Figure 3. This converter topology

produces a regulated output voltage that spans (i.e., can

be higher or lower than) the output. Recommended component placement for a SEPIC is shown in Figure 4.

L1A

V

IN

SHDN

22µH

LT1613

GND

V

IN

4V TO

7V

+

C1

15µF

C1, C2: AVX TAJA156M016

C3: TAIYO YUDEN JMK325BJ226MM

D1: MOTOROLA MBR0520

L1, L2: MURATA LQH3C220

C3

1µF

R2

32.4k

R1

100k

L1B

22µH

D1

V

OUT

5V/150mA

+

C2

15µF

1613 F03

SW

FBSHDN

Figure 3. Single-Ended Primary Inductance Converter (SEPIC)

Generates 5V from An Input Voltage Above or Below 5V

L1AL1B

+

V

OUT

D1

C3

+

C2

VIAS TO

GROUND

PLANE

R2

C1

15

2

34

V

IN

SHUTDOWN

L1

+

V

OUT

+

VIAS TO

GROUND

PLANE

D1

C2

R2

GROUND

C1

15

2

34

R1

V

IN

SHUTDOWN

1613 F02

Figure 2. Recommended Component Placement for Boost

Converter. Note Direct High Current Paths Using Wide PCB

Traces. Minimize Area at Pin 3 (FB). Use Vias to Tie Local

Ground Into System Ground Plane. Use Vias at Location Shown

to Avoid Introducing Switching Currents Into Ground Plane

GROUND

R1

1613 F04

Figure 4. Recommended Component Placement for SEPIC

COMPONENT SELECTION

Inductors

Inductors used with the LT1613 should have a saturation

current rating (where inductance is approximately 70% of

zero current inductance) of approximately 0.5A or greater.

DCR of the inductors should be 0.5Ω or less. For boost

converters, inductance should be 4.7µH for input voltage

less than 3.3V and 10µH for inputs above 3.3V. When

using the device as a SEPIC, either a coupled inductor or

two separate inductors can be used. If using separate

inductors, 22µH units are recommended for input voltage

above 3.3V. Coupled inductors have a beneficial mutual

inductance, so a 10µH coupled inductor results in the

same ripple current as two 20µH uncoupled units.

5

Page 6

LT1613

OPERATIO

U

Table 1 lists several inductors that will work with the

LT1613, although this is not an exhaustive list. There are

many magnetics vendors whose components are suitable

for use.

Diodes

A Schottky diode is recommended for use with the LT1613.

The Motorola MBR0520 is a very good choice. Where the

input to output voltage differential exceeds 20V, use the

MBR0530 (a 30V diode). If cost is more important than

efficiency, the 1N4148 can be used, but only at low current

loads.

Capacitors

The input bypass capacitor must be placed physically

close to the input pin. ESR is not critical and in most cases

an inexpensive tantalum is appropriate.

The choice of output capacitor is far more important. The

quality of this capacitor is the greatest determinant of the

output voltage ripple. The output capacitor must have

enough capacitance to satisfy the load under transient

conditions and it must shunt the switched component of

current coming through the diode. Output voltage ripple

results when this switched current passes through the

finite output impedance of the output capacitor. The

capacitor should have low impedance at the 1.4MHz

switching frequency of the LT1613. At this frequency, the

impedance is usually dominated by the capacitor’s equivalent series resistance (ESR). Choosing a capacitor with

lower ESR will result in lower output ripple.

Ceramic capacitors can be used with the LT1613 provided

loop stability is considered. A tantalum capacitor has

some ESR and this causes an “ESR zero” in the regulator

loop. This zero is beneficial to loop stability. The internally

compensated LT1613 does not have an accessible compensation node, but other circuit techniques can be employed to counteract the loss of the ESR zero, as detailed

in the next section.

Some capacitor types appropriate for use with the LT1613

are listed in Table 2.

OPERATION WITH CERAMIC CAPACITORS

Because the LT1613 is internally compensated, loop stability must be carefully considered when choosing an

output capacitor. Small, low cost tantalum capacitors

have some ESR, which aids stability. However, ceramic

capacitors are becoming more popular, having attractive

characteristics such as near-zero ESR, small size and

reasonable cost. Simply replacing a tantalum output capacitor with a ceramic unit will decrease the phase margin,

in some cases to unacceptable levels. With the addition of

a phase lead capacitor (CPL) and isolating resistor (R3),

the LT1613 can be used successfully with ceramic output

capacitors as described in the following figures.

A boost converter, stepping up 2.5V to 5V, is shown in

Figure 5. Tantalum capacitors are used for the input and

output (the input capacitor is not critical and has little

6

Table 1. Inductor Vendors

VENDOR PHONE URL PART COMMENT

Sumida (847) 956-0666 www.sumida.com CLS62-22022 22µH Coupled

CD43-220 22µH

Murata (404) 436-1300 www.murata.com LQH3C-220 22µH, 2mm Height

LQH3C-100 10µH

LQH3C-4R7 4.7µH

Coiltronics (407) 241-7876 www.coiltronics.com CTX20-1 20µH Coupled, Low DCR

Table 2. Capacitor Vendors

VENDOR PHONE URL PART COMMENT

Taiyo Yuden (408) 573-4150 www.t-yuden.com Ceramic Caps X5R Dielectric

AVX (803) 448-9411 www.avxcorp.com Ceramic Caps

Tantalum Caps

Murata (404) 436-1300 www.murata.com Ceramic Caps

Page 7

OPERATIO

V

IN

V

OUT

5V

C

PL

330pF

1613 F08

SW

L1

10µH

D1

GND

LT1613

C1: AVX TAJA156M010R

C2: TAIYO YUDEN LMK325BJ106MN

D1: MBR0520

L1: MURATA LQH3C100K04

R2

12.1k

R3

10k

R1

37.4k

FBSHUTDOWN

C1

15µF

V

IN

2.5V

C2

10µF

SHDN

+

LT1613

U

effect on loop stability, as long as minimum capacitance

requirements are met). The transient response to a load

step of 50mA to 100mA is pictured in Figure 6. Note the

“double trace,” due to the ESR of C2. The loop is stable and

settles in less than 100µs. In Figure 7, C2 is replaced by a

10µF ceramic unit. Phase margin decreases drastically,

L1

V

IN

SHDN

10µH

LT1613

GND

V

IN

2.5V

+

C1

15µF

C1: AVX TAJA156M010R

C2: AVX TAJA226M006R

D1: MOTOROLA MBR0520

L1: MURATA LQH3C100

Figure 5. 2.5V to 5V Boost Converter with “A”

Case Size Tantalum Input and Output Capacitors

SW

D1

R1

37.4k

FBSHDN

R2

12.1k

V

OUT

5V

+

C2

22µF

1613 F05

resulting in a severely underdamped response. By adding

R3 and CPL as detailed in Figure 8’s schematic, phase

margin is restored, and transient response to the same

load step is pictured in Figure 9. R3 isolates the device FB

pin from fast edges on the V

node due to parasitic PC

OUT

trace inductance.

Figure 10’s circuit details a 5V to 12V boost converter,

delivering up to 130mA. The transient response to a load

step of 10mA to 130mA, without CPL, is pictured in

Figure 11. Although the ringing is less than that of the

previous example, the response is still underdamped and

can be improved. After adding R3 and CPL, the improved

transient response is detailed in Figure 12.

Figure 13 shows a SEPIC design, converting a 3V to 10V

input to a 5V output. The transient response to a load step

of 20mA to 120mA, without CPL and R3, is pictured in

Figure 14. After adding these two components, the improved response is shown in Figure 15.

V

OUT

20mV/DIV

AC COUPLED

LOAD CURRENT

100mA

50mA

200µs/DIV

1613 F06

Figure 6. 2.5V to 5V Boost Converter Transient

Response with 22µF Tantalum Output Capacitor.

Apparent Double Trace on V

Is Due to Switching

OUT

Frequency Ripple Current Across Capacitor ESR

V

OUT

20mV/DIV

AC COUPLED

LOAD CURRENT

100mA

50mA

Figure 7. 2.5V to 5V Boost Converter with

10µF Ceramic Output Capacitor, No C

200µs/DIV

1613 F07

PL

Figure 8. 2.5V to 5V Boost Converter with Ceramic

Output Capacitor. CPL Added to Increase Phase Margin,

R3 Isolates FB Pin from Fast Edges

V

OUT

20mV/DIV

AC COUPLED

LOAD CURRENT

100mA

50mA

200µs/DIV

Figure 9. 2.5V to 5V Boost Converter with 10µF Ceramic

Output Capacitor, 330pF CPL and 10k in Series with FB Pin

1613 F09

7

Page 8

LT1613

OPERATIO

U

V

IN

SHDN

10µH

LT1613

GND

V

IN

5V

+

C1

22µF

C1: AVX TAJB226M010

C2: TAIYO YUDEN EMK325BJ475MN

D1: MOTOROLA MBR0520

L1: MURATA LQH3C100

L1

SW

D1

C

PL

200pF

R1

R3

107k

10k

FBSHUTDOWN

R2

12.3k

Figure 10. 5V to 12V Boost Converter with 4.7µF Ceramic

Output Capacitor, CPL Added to Increase Phase Margin

V

OUT

100mV/DIV

AC COUPLED

V

OUT

12V

130mA

C2

4.7µF

1613 F10

V

IN

3V TO

10V

+

C1

22µF

C1: AVX TAJB226M010

C2: TAIYO YUDEN LMK325BJ106MN

C3: TAIYO YUDEN LMK212BJ105MG

D1: MOTOROLA MBR0520

L1, L2: MURATA LQH3C220

V

IN

SHDN

Figure 13. 5V Output SEPIC with Ceramic

Output Capacitor. CPL Adds Phase Margin

V

OUT

50mV/DIV

AC COUPLED

L1

22µH

LT1613

GND

SW

C3

1µF

L2

C

22µH

R3

10k

FBSHUTDOWN

R2

12.1k

PL

330pF

R1

37.4k

D1

V

5V

C2

10µF

1613 F13

OUT

LOAD CURRENT

AC COUPLED

LOAD CURRENT

Figure 12. 5V to 12V Boost Converter with 4.7µF

Ceramic Output Capacitor and 200pF Phase-Lead

Capacitor CPL and 10k in Series with FB Pin

130mA

10mA

200µs/DIV

Figure 11. 5V to 12V Boost Converter

with 4.7µF Ceramic Output Capacitor

V

OUT

100mV/DIV

130mA

10mA

200µs/DIV

1613 F11

1613 F12

LOAD CURRENT

120mA

20mA

200µs/DIV

Figure 14. 5V Output SEPIC with 10µF

Ceramic Output Capacitor. No CPL. VIN = 4V

V

OUT

50mV/DIV

AC COUPLED

LOAD CURRENT

120mA

20mA

200µs/DIV

Figure 15. 5V Output SEPIC with 10µF Ceramic Output

Capacitor, 330pF CPL and 10k in Series with FB Pin

1613 F14

1613 F15

8

Page 9

OPERATIO

LT1613

U

START-UP/SOFT-START

When the LT1613 SHDN pin voltage goes high, the device

rapidly increases the switch current until internal current

limit is reached. Input current stays at this level until the

output capacitor is charged to final output voltage. Switch

current can exceed 1A. Figure 16’s oscillograph details

start-up waveforms of Figure 17’s SEPIC into a 50Ω load

without any soft-start. The output voltage reaches final

value in approximately 200µs, while input current reaches

400mA. Switch current in a SEPIC is 2x the input current,

so the switch is conducting approximately 800mA peak.

Soft-start reduces the inrush current by taking more time

to reach final output voltage. A soft-start circuit consisting

of Q1, RS1, RS2 and CS1 as shown in Figure 17 can be used

to limit inrush current to a lower value. Figure 18 pictures

V

and input current with RS2 of 33kΩ and CS of 10nF.

OUT

Input current is limited to a peak value of 200mA as the

V

OUT

2V/DIV

time required to reach final value increases to 1.7ms. In

Figure 19, CS is increased to 33nF. Input current does not

exceed the steady-state current the device uses to supply

power to the 50Ω load. Start-up time increases to 4.3ms.

CS can be increased further for an even slower ramp, if

desired.

V

OUT

2V/DIV

I

IN

200mA/DIV

V

S

5V/DIV

500µs/DIV

Figure 18. Soft-Start Components in Figure 17’s SEPIC

Reduces Inrush Current. CSS = 10nF, R

V

OUT

2V/DIV

LOAD

1613 F18

= 50Ω

I

200mA/DIV

V

SHDN

5V/DIV

IN

200µs/DIV

Figure 16. Start-Up Waveforms of

Figure 17’s SEPIC Into 50Ω Load

SOFT-START COMPONENTS

R

S1

33k

S

C

S

R

10nF/

33nF

C1: AVX TAJB226M006

C2: TAIYO YUDEN LMK325BJ106MN

C3: TAIYO YUDEN LMK212BJ105MG

33k

S2

I

IN

200mA/DIV

V

S

1613 F16

5V/DIV

Figure 19. Increasing CS to 33nF Further

Reduces Inrush Current. R

SW

C3

1µF

L2

22µH

R3

10k

FBV

R2

12.1k

C

330pF

37.4k

L1

V

IN

4V

22µF

Q1

2N3904

+

C1

22µH

V

IN

LT1613

SHDN

GND

D1: MOTOROLA MBR0520

L1, L2: MURATA LQH3C220

Figure 17. 5V SEPIC with Soft-Start Components

1ms/DIV

= 50Ω

LOAD

PL

R1

D1

C2

10µF

R

LOAD

1613 F17

V

OUT

5V

1613 F18

9

Page 10

LT1613

U

TYPICAL APPLICATIO S

6.5V TO 4V

4-Cell to 5V SEPIC DC/DC Converter

L1

22µH

+

4-CELL

C1

15µF

V

IN

SHDN

SW

LT1613

FBSHDN

GND

1µF

C3

374k

121k

L2

22µH

D1

V

OUT

5V

175mA

+

C2

22µF

V

IN

3.5V TO

8V

+

C1

22µF

C1: AVX TAJB226M016

C2: AVX TAJA475M025

D1: MOTOROLA MBR0520

L1: MURATA LQH3C100

3.3V to 8V/70mA, –8V/5mA, 24V/5mA TFT LCD Bias Supply Uses All Ceramic Capacitors

V

IN

SHDN

L1, L2: MURATA LQH3C220

C3: AVX 1206YG105 CERAMIC

D1: MBR0520

L1

10µH

LT1613

GND

SW

D1

1nF

10k

FBSHDN

4-Cell to 15V/30mA DC/DC Converter

V

OUT

R1

137k

1%

R2

12.1k

+

0.22µF

15V/30mA

C2

4.7µF

D2

1613 TA04

0.22µF

1µF

85

80

75

70

65

EFFICIENCY (%)

60

55

50

1613 • TA03

Efficiency

VIN = 6.5V

VIN = 3.6V

0 102030405060708090100

D3

LOAD CURRENT (mA)

V

OFF

–8V

5mA

V

ON

24V

5mA

1µF

VIN = 5V

1613 TA04a

10

0.22µF: TAIYO YUDEN EMK212BJ224MG

1µF: TAIYO YUDEN LMK212BJ105MG

4.7µF: TAIYO YUDEN LMK316BJ475ML

D1: MOTOROLA MBRO520

D2, D3, D4: BAT54S

L1: SUMIDA CDRH5D185R4

V

3.3V

IN

C1

4.7µF

5.4µH

V

IN

LT1613

GND

D4

0.22µF

L1

D1

SW

274k

FBSHDN

48.7k

1µF

C2

4.7µF

1613 TA05

AV

8V

70mA

DD

Page 11

U

TYPICAL APPLICATIO S

4-Cell to 5V/50mA, 12V/10mA, 15V/10mA Digital Camera Power Supply

C1: TAIYO YUDEN JMK316BJ106ML

C2, C3, C4: TAIYO YUDEN EMK212BJ105MG

C5: TAIYO YUDEN JMK212BJ475MG

D1: MOTOROLA MBR0520

D2, D3: BAT54

T1: COILCRAFT CCI8245A (847) 639-6400

7V TO 3.6V

V

IN

C1

10µF

LT1613

D3

2

D2

5

T1

6

1

V

IN

SW

D1

3

4

C2

1µF

C3

1µF

C4

1µF

C5

4.7µF

270pF

15V/10mA

12V/10mA

5V/50mA

SHUTDOWN

LT1613

FBSHDN

GND

102k

33.2k

4-Cell to 5V/50mA, 15V/10mA, –7.5V/10mA Digital Camera Power Supply

D2

C1: TAIYO YUDEN JMK316BJ106ML

C2, C3, C4: TAIYO YUDEN EMK212BJ105MG

C5: TAIYO YUDEN JMK212BJ475MG

D1: MOTOROLA MBR0520

D2, D3: BAT54

T1: COILCRAFT CCI8244A (847) 639-6400

V

7V TO 3.6V

IN

C1

10µF

V

IN

2

D1

5

T1

3

6

1

SW

4

C2

1µF

D3

270pF

C3

1µF

C5

4.7µF

C4

1µF

1613 TA07

15V/10mA

5V/50mA

–7.5V/10mA

LT1613

SHUTDOWN

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

FBSHDN

GND

102k

33.2k

1613 TA08

11

Page 12

LT1613

U

TYPICAL APPLICATIONS

V

IN

2.7V

TO 4.5V

+

C1: AVX TAJA4R7M010

C2: TAIYO YUDEN LMK212BJ105MG

D1: BAT54S DUAL DIODE

L1: MURATA LQH3C2R2

PACKAGE DESCRIPTION

2.60 – 3.00

(0.102 – 0.118)

1.50 – 1.75

(0.059 – 0.069)

Li-Ion to 16V/20mA Step-Up DC/DC Converter

C1

4.7µF

V

IN

SHDN

L1

2.2µH

SW

LT1613

FBSHDN

GND

D1

165k

1%

13.7k

1%

C2

1µF

X5R

CERAMIC

1613 TA06

16V

20mA

U

Dimensions in inches (millimeters) unless otherwise noted.

S5 Package

5-Lead Plastic SOT-23

(LTC DWG # 05-08-1633)

2.80 – 3.00

0.00 – 0.15

(0.00 – 0.006)

0.90 – 1.45

(0.035 – 0.057)

(0.110 – 0.118)

(NOTE 3)

0.35 – 0.55

(0.014 – 0.022)

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DIMENSIONS ARE INCLUSIVE OF PLATING

3. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

4. MOLD FLASH SHALL NOT EXCEED 0.254mm

5. PACKAGE EIAJ REFERENCE IS SC-74A (EIAJ)

0.09 – 0.20

(0.004 – 0.008)

(NOTE 2)

0.35 – 0.50

(0.014 – 0.020)

FIVE PLACES (NOTE 2)

0.90 – 1.30

(0.035 – 0.051)

1.90

(0.074)

REF

0.95

(0.037)

REF

S5 SOT-23 0599

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1307 Single Cell Micropower DC/DC 3.3V/75mA From 1V; 600kHz Fixed Frequency

LT1317 2-Cell Micropower DC/DC 3.3V/200mA From Two Cells; 600kHz Fixed Frequency

LTC1474 Low Quiescent Current, High Efficiency Step-Down Converter 94% Efficiency, 10µA IQ, 9V to 5V at 250µA

LT1521 300mA Low Dropout Regulator with Micropower Quiescent 500mV Dropout, 300mA Output Current, 12µA I

Current and Shutdown

LTC1517-5 Micropower, Regulated Charge Pump 3-Cells to 5V at 20mA, SOT-23 Package, 6µA I

LT1610 1.7MHz Single Cell Micropower DC/DC Converter 30µA IQ, MSOP Package, Internal Compensation

LT1611 Inverting 1.4MHz Switching Regulator 5V to –5V at 150mA, Low Output Noise

LT1615/LT1615-1 Micropower DC/DC Converter in 5-Lead SOT-23 20V at 12mA from 2.5V Input, Tiny SOT-23 Package

Q

Q

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

1613f LT/TP 1299 4K • PRINTED IN USA

LINEAR TE CHNOLOGY CORPOR ATION 1997

Loading...

Loading...