Page 1

FEATURES

■

Uses Tiny Capacitors and Inductor

■

Internally Compensated

■

Low Quiescent Current: 30µA

■

Operates with VIN as Low as 1V

■

3V at 30mA from a Single Cell

■

5V at 200mA from 3.3V

■

High Output Voltage Capability: Up to 28V

■

Low Shutdown Current: <1µA

■

Automatic Burst ModeTM Switching at Light Load

■

Low V

■

8-Lead MSOP and SO Packages

Switch: 300mV at 300mA

CESAT

U

APPLICATIO S

LT1610

1.7MHz, Single Cell

Micropower

DC/DC Converter

U

DESCRIPTIO

The LT®1610 is a micropower fixed frequency DC/DC

converter that operates from an input voltage as low as 1V.

Intended for small, low power applications, it switches at

1.7MHz, allowing the use of tiny capacitors and inductors.

The device can generate 3V at 30mA from a single cell

(1V) supply. An internal compensation network can be

connected to the LT1610’s VC pin, eliminating two external components. No-load quiescent current of the LT1610

is 30µA, and the internal NPN power switch handles a

300mA current with a voltage drop of 300mV.

The LT1610 is available in 8-lead MSOP and SO packages.

■

Pagers

■

Cordless Phones

■

Battery Backup

■

LCD Bias

■

Portable Electronic Equipment

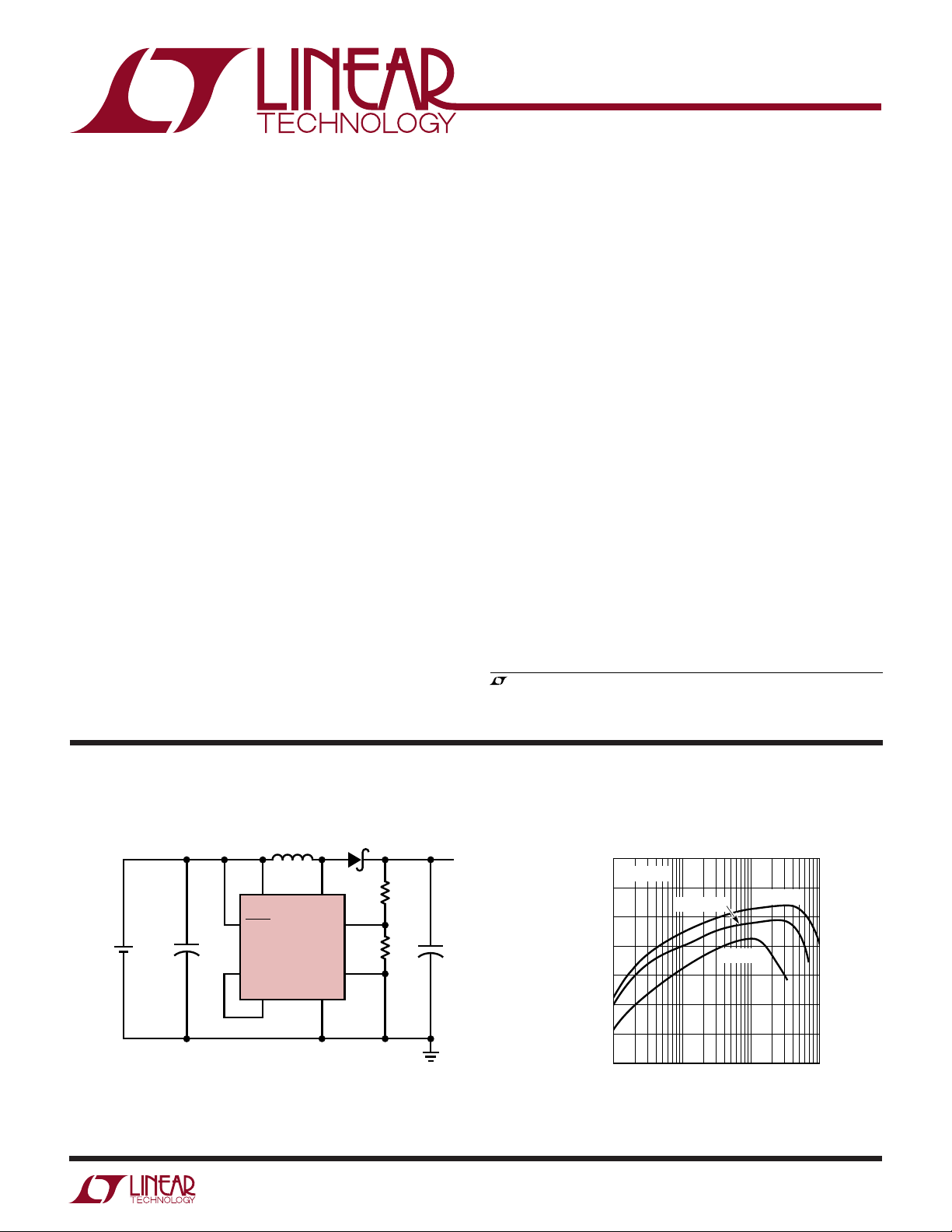

TYPICAL APPLICATIO

L1

4.7µH

65

V

IN

3

C1

22µF

SHDN

LT1610

8

V

C

1

+

1 CELL

C1, C2: AVX TAJA226M006R

D1: MOTOROLA MBR0520

L1: MURATA LQH1C4R7

Figure 1. 1-Cell to 3V Step-Up Converter

U

SW

GNDCOMP

PGND

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a trademark of Linear Technology Corporation.

D1

R1

1M

2

FB

R2

681k

7

4

V

OUT

3V

30mA

+

C2

22µF

1610 F01

85

V

OUT

80

75

70

65

EFFICIENCY (%)

60

55

50

0.1

Efficiency

= 3V

VIN = 1.25V

VIN = 1V

1 10 100

LOAD CURRENT (mA)

VIN = 1.5V

1610 TA01

1

Page 2

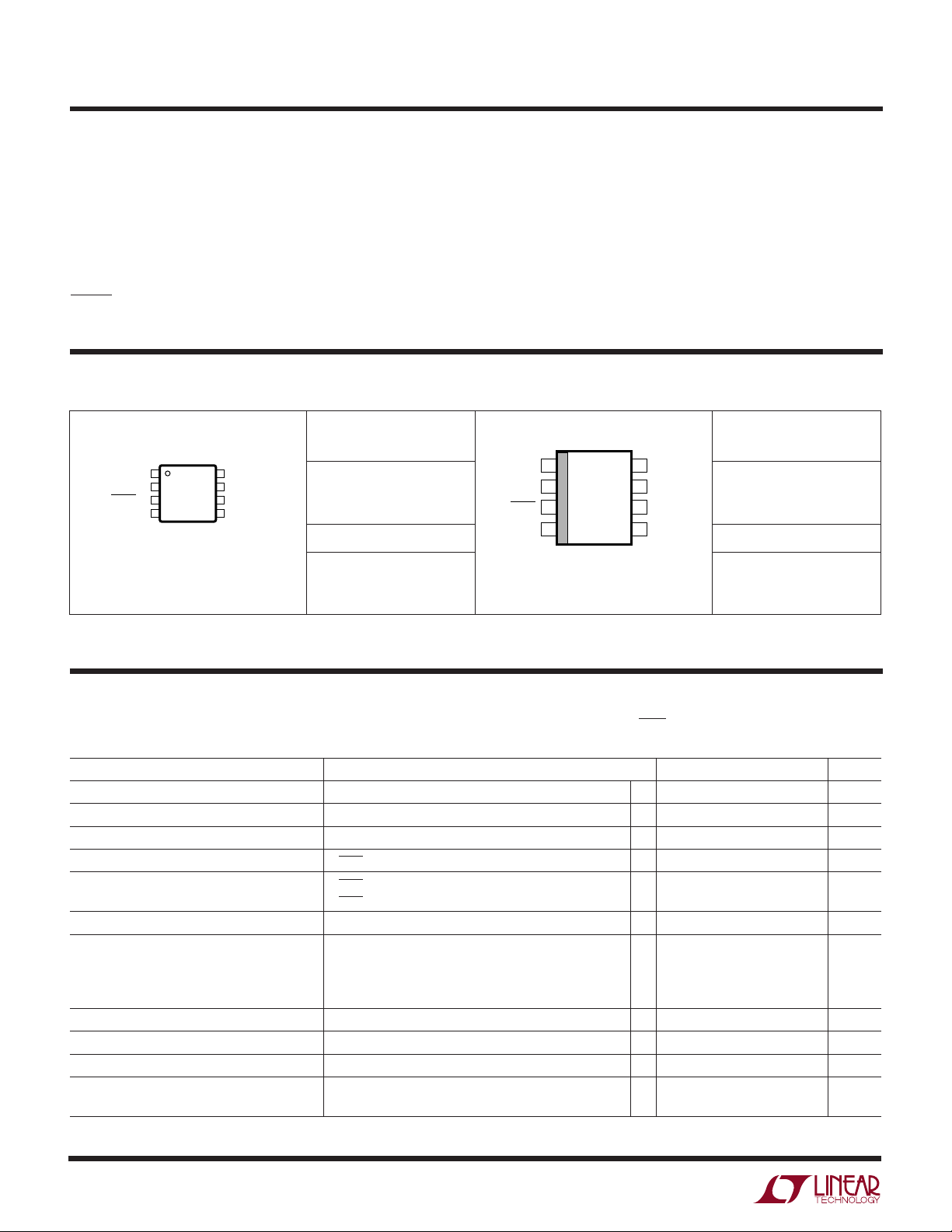

LT1610

1

2

3

4

8

7

6

5

TOP VIEW

V

C

FB

SHDN

PGND

COMP

GND

V

IN

SW

S8 PACKAGE

8-LEAD PLASTIC SO

WW

W

U

ABSOLUTE MAXIMUM RATINGS

(Note 1)

VIN Voltage ................................................................ 8V

SW Voltage ............................................... –0.4V to 30V

FB Voltage ..................................................... VIN + 0.3V

VC Voltage ................................................................ 2V

COMP Voltage .......................................................... 2V

Current into FB Pin .............................................. ±1mA

SHDN Voltage ............................................................ 8V

U

W

U

PACKAGE/ORDER INFORMATION

ORDER PART

TOP VIEW

V

1

C

2

FB

3

SHDN

4

PGND

MS8 PACKAGE

8-LEAD PLASTIC MSOP

T

= 125°C, θJA = 160°C/W

JMAX

8

7

6

5

COMP

GND

V

IN

SW

NUMBER

LT1610CMS8

MS8 PART MARKING

LTDT

Maximum Junction Temperature ......................... 125°C

Operating Temperature Range (Note 1)

Commercial .............................................0°C to 70°C

Extended Commercial (Note 2).......... –40°C to 85°C

Industrial ........................................... –40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ORDER PART

NUMBER

LT1610CS8

LT1610IS8

S8 PART MARKING

1610

T

= 125°C, θJA = 120°C/W

JMAX

1610I

Consult factory for Military grade parts.

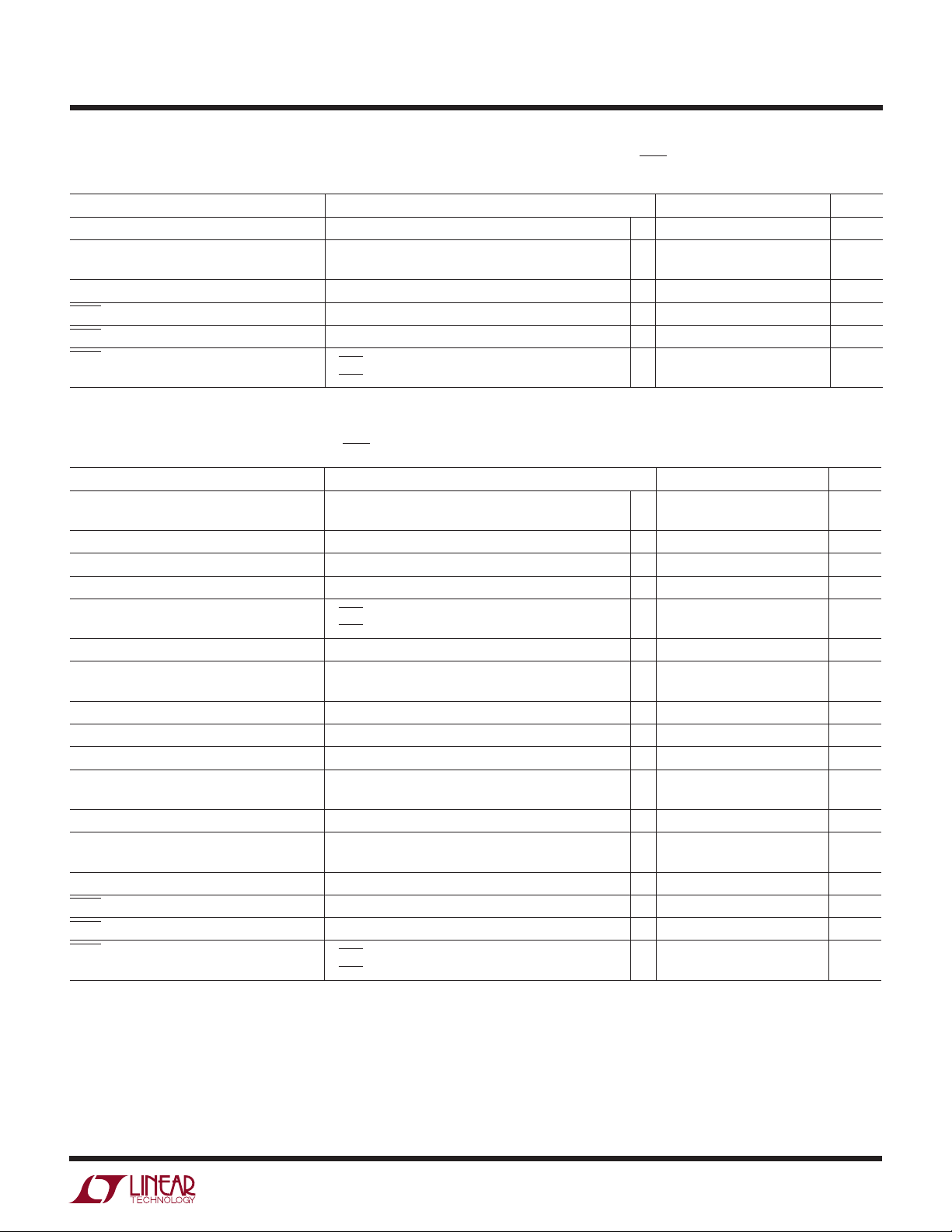

LECTRICAL C CHARA TERIST

E

range, otherwise specifications are at T

= 25°C. Commercial grade 0°C to 70°C, V

A

ICS

The ● denotes specifications which apply over the specified temperature

= 1.5V, V

IN

= VIN, unless otherwise noted.

SHDN

(Note 2)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage 0.9 1 V

Maximum Operating Voltage 8V

Feedback Voltage ● 1.20 1.23 1.26 V

Quiescent Current V

Quiescent Current in Shutdown V

FB Pin Bias Current ● 27 80 nA

Reference Line Regulation 1V ≤ VIN ≤ 2V (25°C, 0°C) 0.6 1 %/V

Error Amp Transconductance ∆I = 2µA25µmhos

Error Amp Voltage Gain 100 V/V

Switching Frequency ● 1.4 1.7 2 MHz

Maximum Duty Cycle 77 80 95 %

= 1.5V, Not Switching 30 60 µA

SHDN

= 0V, VIN = 2V 0.01 0.5 µA

SHDN

= 0V, VIN = 5V 0.01 1.0 µA

V

SHDN

≤ 2V (70°C) 2 %/V

1V ≤ V

IN

2V ≤ V

≤ 8V (25°C, 0°C) 0.03 0.15 %/V

IN

≤ 8V (70°C) 0.2 %/V

2V ≤ V

IN

● 75 95 %

2

Page 3

LT1610

LECTRICAL C CHARA TERIST

E

range, otherwise specifications are at T

= 25°C. Commercial grade 0°C to 70°C, V

A

ICS

The ● denotes specifications which apply over the specified temperature

= 1.5V, V

IN

= VIN, unless otherwise noted.

SHDN

(Note 2)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Switch Current Limit (Note 3) 450 600 900 mA

Switch V

CESAT

Switch Leakage Current VSW = 5V 0.01 1 µA

SHDN Input Voltage High 1V

SHDN Input Voltage Low 0.3 V

SHDN Pin Bias Current V

ISW = 300mA 300 350 mV

● 400 mV

= 3V 10 µA

SHDN

= 0V 0.01 0.1 µA

V

SHDN

The ● denotes specifications which apply over the specified temperature range, otherwise specifications are at TA = 25°C.

Industrial grade –40°C to 85°C, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage TA = 85°C 0.9 1 V

Maximum Operating Voltage 8V

Feedback Voltage ● 1.20 1.23 1.26 V

Quiescent Current 30 60 µA

Quiescent Current in Shutdown V

FB Pin Bias Current ● 27 80 nA

Reference Line Regulation 2V ≤ VIN ≤ 8V (–40°C) 0.03 0.15 %/V

Error Amp Transconductance ∆I = 2µA25µmhos

Error Amp Voltage Gain 100 V/V

Switching Frequency (Note 4) ● 1.4 1.7 2 MHz

Maximum Duty Cycle (Note 4) 77 80 95 %

Switch Current Limit 450 600 900 mA

Switch V

CESAT

Switch Leakage Current VSW = 5V 0.01 1 µA

SHDN Input Voltage High 1V

SHDN Input Voltage Low 0.3 V

SHDN Pin Bias Current V

= 1.5V, V

IN

= VIN, unless otherwise noted.

SHDN

= –40°C 1.25 V

T

A

= 0V, VIN = 2V 0.01 0.5 µA

SHDN

= 0V, VIN = 5V 0.01 1.0 µA

V

SHDN

≤ 8V (85°C) 0.2 %/V

2V ≤ V

IN

● 75 95 %

ISW = 300mA 300 350 mV

● 400 mV

= 3V 10 µA

SHDN

V

= 0V 0.01 0.1 µA

SHDN

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LT1610C is guaranteed to meet specified performance from

0°C to 70°C and is designed, characterized and expected to meet these

extended temperature limits, but is not tested at –40°C and 85°C. The

LT1610I is guaranteed to meet the extended temperature limits.

Note 3: Current limit guaranteed by design and/or correlation to static test.

Current limit is affected by duty cycle due to ramp generator. See Block

Diagram.

Note 4: Not 100% tested at 85°C.

3

Page 4

LT1610

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Current Limit (DC = 30%)

600

500

400

(mV)

CESAT

300

V

200

100

CESAT

0

vs Current

TA = 25°C

200 300 400

100

SWITCH CURRENT (mA)

TA = 85°C

= –40°C

T

A

500 600

1610 G01

vs Temperature

800

700

600

500

400

SWITCH CURRENT LIMIT (mA)

300

200

–50

02550

–25

TEMPERATURE (°C)

75 100

1610 G02

Current Limit vs Duty CycleV

800

700

600

500

400

300

CURRENT LIMIT (mA)

200

100

0

20 40 60 1007010 30 50 90

0

TA = 25°C

80

DUTY CYCLE (%)

1610 G03

Oscillator Frequency

vs Input Voltage Feedback Voltage

2.50

TA = 25°C

2.25

2.00

1.75

1.50

1.25

1.00

0.75

0.50

SWITCHING FREQUENCY (MHz)

0.25

0

0

13

2

INPUT VOLTAGE (V)

SHDN Pin Current

vs SHDN Pin Voltage

50

40

30

20

SHDN CURRENT (µA)

10

7

4

6

5

1610 G04

1.240

1.235

1.230

1.225

1.220

FEEDBACK VOLTAGE (V)

1.215

1.210

8

V

OUT

50mV/DIV

AC COUPLED

100mA/DIV

31mA

I

LOAD

1mA

–50

–25

Transient Response,

Circuit of Figure 1

I

L1

VIN = 1.25V 500µs/DIV

V

= 3V

OUT

02550

TEMPERATURE (°C)

75 100

1610 G05

1610 TA08

40

35

30

25

20

15

10

QUIESCENT CURRENT (µA)

V

OUT

20mV/DIV

AC COUPLED

SWITCH

VOLTAGE

2V/DIV

SWITCH

CURRENT

50mA/DIV

Quiescent Current

vs Temperature

5

0

–25 0 50

–50

25

TEMPERATURE (°C)

Burst Mode Operation,

Circuit of Figure 1

= 1.25V 20µs/DIV

V

IN

= 3V

V

OUT

= 3mA

I

LOAD

75

100

1610 G06

1610 TA08

4

0

0

12

SHDN VOLTAGE (V)

4

35 8

67

1610 G07

Page 5

UUU

PIN FUNCTIONS

LT1610

VC (Pin 1): Error Amplifier Output. Frequency compensation network must be connected to this pin, either internal

(COMP pin) or external series RC to ground. 220kΩ/

220pF typical value.

FB (Pin 2): Feedback Pin. Reference voltage is 1.23V.

Connect resistive divider tap here. Minimize trace area at

FB. Set V

according to V

OUT

= 1.23V (1 + R1/R2).

OUT

SHDN (Pin 3): Shutdown. Ground this pin to turn off

device. Tie to 1V or more to enable.

PGND (Pin 4): Power Ground. Tie directly to local ground

plane.

W

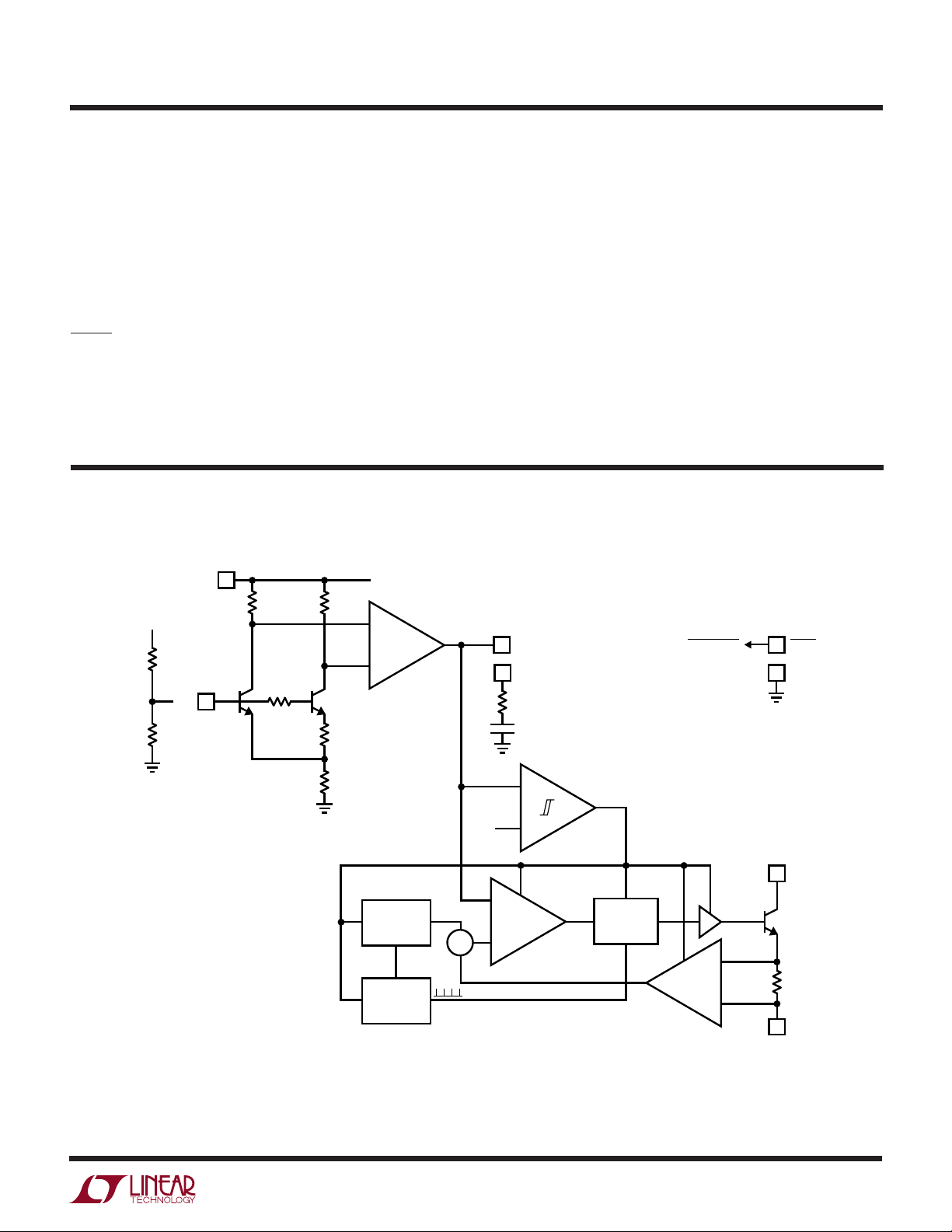

BLOCK DIAGRA

V

IN

V

OUT

R1

(EXTERNAL)

R2

(EXTERNAL)

6

R5

40k

Q1

FB

2

FB

Q2

× 10

R6

40k

R3

30k

V

IN

+

A1

g

m

–

SW (Pin 5): Switch Pin. Connect inductor/diode here.

Minimize trace area at this pin to keep EMI down.

VIN (Pin 6): Input Supply Pin. Must be locally bypassed.

GND (Pin 7): Signal Ground. Carries all device ground

current except switch current. Tie to local ground plane.

COMP (Pin 8): Internal Compensation Network. Tie to V

C

pin, or let float if external compensation is used. Output

capacitor must be tantalum if COMP pin is used for compensation.

1

V

C

COMP

8

R

C

C

C

3

SHDNSHUTDOWN

GND

7

R4

140k

+

BIAS

RAMP

GENERATOR

Σ

1.7MHz

OSCILLATOR

–

A2

+

–

COMPARATOR

Figure 2. LT1610 Block Diagram

ENABLE

FF

RQ

S

A = 3

DRIVER

+

–

5

Q3

4

SW

0.15Ω

PGND

1610 F02

5

Page 6

LT1610

U

WUU

APPLICATIONS INFORMATION

OPERATION

The LT1610 combines a current mode, fixed frequency

PWM architecture with Burst Mode micropower operation

to maintain high efficiency at light loads. Operation can be

best understood by referring to the block diagram in

Figure 2. Q1 and Q2 form a bandgap reference core whose

loop is closed around the output of the converter. When

VIN is 1V, the feedback voltage of 1.23V, along with an

70mV drop across R5 and R6, forward biases Q1 and Q2’s

base collector junctions to 300mV. Because this is not

enough to saturate either transistor, FB can be at a higher

voltage than VIN. When there is no load, FB rises slightly

above 1.23V, causing VC (the error amplifier’s output) to

decrease. When VC reaches the bias voltage on hysteretic

comparator A1, A1’s output goes low, turning off all

circuitry except the input stage, error amplifier and lowbattery detector. Total current consumption in this state is

30µA. As output loading causes the FB voltage to de-

crease, A1’s output goes high, enabling the rest of the IC.

Switch current is limited to approximately 100mA initially

after A1’s output goes high. If the load is light, the output

voltage (and FB voltage) will increase until A1’s output

goes low, turning off the rest of the LT1610. Low frequency ripple voltage appears at the output. The ripple

frequency is dependent on load current and output capacitance. This Burst Mode operation keeps the output regulated and reduces average current into the IC, resulting in

high efficiency even at load currents of 1mA or less.

If the output load increases sufficiently, A1’s output remains

high, resulting in continuous operation. When the LT1610

is running continuously, peak switch current is controlled

by VC to regulate the output voltage. The switch is turned

on at the beginning of each switch cycle. When the summation of a signal representing switch current and a ramp

generator (introduced to avoid subharmonic oscillations at

duty factors greater than 50%) exceeds the VC signal,

comparator A2 changes state, resetting the flip-flop and

turning off the switch. Output voltage increases as switch

current is increased. The output, attenuated by a resistor

divider, appears at the FB pin, closing the overall loop.

Frequency compensation is provided by either an external

series RC network connected between the VC pin and

ground or the internal RC network on the COMP pin (Pin

8). The typical values for the internal RC are 50k and 50pF.

LAYOUT

Although the LT1610 is a relatively low current device, its

high switching speed mandates careful attention to layout

for optimum performance. For boost converters, follow

the component placement indicated in Figure 3 for the best

results. C2’s negative terminal should be placed close to

Pin 4 of the LT1610. Doing this reduces switching currents

in the ground copper which keeps high frequency “spike”

noise to a minimum. Tie the local ground into the system

ground plane at one point only, using a few vias, to avoid

introducing dI/dt induced noise into the ground plane.

6

GROUND PLANE

R1

SHUTDOWN

MULTIPLE

VIAs

Figure 3. Recommended Component Placement for Boost Converter. Note Direct High Current Paths Using

Wide PC Traces. Minimize Trace Area at Pin 1 (VC) and Pin 2 (FB). Use Multiple Vias to Tie Pin 4 Copper to

Ground Plane. Use Vias at One Location Only to Avoid Introducing Switching Currents into the Ground Plane

R2

GND

1

2

LT1610

3

4

+

C2

8

C1

7

6

5

D1

V

OUT

V

IN

+

L1

1610 F03

Page 7

LT1610

U

WUU

APPLICATIONS INFORMATION

A SEPIC (Single-Ended Primary Inductance Converter)

schematic is shown in Figure 4. This converter topology

produces a regulated output over an input voltage range

L1

INPUT

Li-ION

3V to 4.2V

+

C1

22µF

6.3V

C1, C2: AVX TAJA226M006

C3: AVX 1206YC105 (X7R)

D1: MOTOROLA MBR0520

L1, L2: MURATA LQH3C220 (UNCOUPLED)

OR SUMIDA CLS62-220 (COUPLED)

1

8

22µH

65

V

IN

V

C

LT1610

COMP

GND

7

that spans (i.e., can be higher or lower than) the output.

Recommended component placement for a SEPIC is

shown in Figure 5.

C3

1µF

•

SW

SHDN

PGND

CERAMIC

2

FB

3

4

SHUTDOWN

1M

604k

•

L2

22µH

D1

V

OUT

3.3V

120mA

+

C2

22µF

6.3V

1610 F04

GROUND PLANE

R1

R2

SHUTDOWN

MULTIPLE

VIAs

Figure 4. Li-Ion to 3.3V SEPIC DC/DC Converter

V

IN

1

2

LT1610

3

4

C2

8

C1

7

6

5

+

L1 L2

C3

+

GND

D1

V

OUT

1610 F05

Figure 5. Recommended Component Placement for SEPIC

7

Page 8

LT1610

U

WUU

APPLICATIONS INFORMATION

COMPONENT SELECTION

Inductors

Inductors used with the LT1610 should have a saturation

current rating (–30% of zero current inductance) of approximately 0.5A or greater. DCR should be 0.5Ω or less.

The value of the inductor should be matched to the power

requirements and operating voltages of the application. In

most cases a value of 4.7µH or 10µH is suitable. The Murata

LQH3C inductors specified throughout the data sheet are

small and inexpensive, and are a good fit for the LT1610.

Alternatives are the CD43 series from Sumida and the

DO1608 series from Coilcraft. These inductors are slightly

larger but will result in slightly higher circuit efficiency.

Chip inductors, although tempting to use because of their

small size and low cost, generally do not have enough

energy storage capacity or low enough DCR to be used

successfully with the LT1610.

Diodes

The Motorola MBR0520 is a 0.5 amp, 20V Schottky diode.

This is a good choice for nearly any LT1610 application,

unless the output voltage or the circuit topology require a

diode rated for higher reverse voltages. Motorola also

offers the MBR0530 (30V) and MBR0540 (40V) versions.

Most one-half amp and one amp Schottky diodes are

suitable; these are available from many manufacturers. If

you use a silicon diode, it must be an ultrafast recovery

type. Efficiency will be lower due to the silicon diode’s

higher forward voltage drop.

Capacitors

impedance of the output capacitor. The capacitor should

have low impedance at the 1.7MHz switching frequency of

the LT1610. At this frequency, the impedance is usually

dominated by the capacitor’s equivalent series resistance

(ESR). Choosing a capacitor with lower ESR will result in

lower output ripple.

Perhaps the best way to decrease ripple is to add a 1µF

ceramic capacitor in parallel with the bulk output capacitor. Ceramic capacitors have very low ESR and 1µF is

enough capacitance to result in low impedance at the

switching frequency. The low impedance can have a

dramatic effect on output ripple voltage. To illustrate,

examine Figure 6’s circuit, a 4-cell to 5V/100mA SEPIC

DC/DC converter. This design uses inexpensive aluminum

electrolytic capacitors at input and output to keep cost

down. Figure 7 details converter operation at a 100mA

load, without ceramic capacitor C5. Note the 400mV

spikes on V

After C5 is installed, output ripple decreases by a factor of

8 to about 50mV

efficiency by 1 to 2 percent.

Low ESR and the required bulk output capacitance can be

obtained using a single larger output capacitor. Larger

tantalum capacitors, newer capacitor technologies (for

example the POSCAP from Sanyo and SPCAP from

Panasonic) or large value ceramic capacitors will reduce

the output ripple. Note, however, that the stability of the

circuit depends on both the value of the output capacitor

and its ESR. When using low value capacitors or capacitors with very low ESR, circuit stability should be evaluated carefully, as described below.

OUT

.

. The addition of C5 also improves

P-P

The input capacitor must be placed physically close to the

LT1610. ESR is not critical for the input. In most cases

inexpensive tantalum can be used.

The choice of output capacitor is far more important. The

quality of this capacitor is the greatest determinant of the

output voltage ripple. The output capacitor performs two

major functions. It must have enough capacitance to

satisfy the load under transient conditions and it must

shunt the AC component of the current coming through

the diode from the inductor. The ripple on the output

results when this AC current passes through the finite

8

Loop Compensation

The LT1610 is a current mode PWM switching regulator

that achieves regulation with a linear control loop. The

LT1610 provides the designer with two methods of compensating this loop. First, you can use an internal compensation network by tying the COMP pin to the VC pin. This

results in a very small solution and reduces the circuit’s

total part count. The second option is to tie a resistor R

and a capacitor CC in series from the VC pin to ground. This

allows optimization of the transient response for a wide

variety of operating conditions and power components.

C

Page 9

LT1610

U

WUU

APPLICATIONS INFORMATION

+

V

OUT

200mV/DIV

I

DIODE

500mA/DIV

4 CELLS

C1

22µF

6.3V

C1, C2: ALUMINUM ELECTROLYTIC

C3 TO C5: CERAMIC X7R OR X5R

D1: MBR0520

L1, L2: MURATA LQH3C220 OR SUMIDA CLS62-220

Figure 6. 4-Cell Alkaline to 5V/120mA SEPIC DC/DC Converter

C4

1µF

CERAMIC

L1

22µH

65

V

IN

1

V

C

LT1610

8

COMP

GND

7

C3

1µF

•

SW

SHDN

PGND

CERAMIC

2

FB

3

4

SHUTDOWN

1M

324k

•

D1

L2

22µH

V

OUT

5V

120mA

+

C2

22µF

6.3V

1610 F06

C5

1µF

CERAMIC

sation network is modified to achieve stable operation.

Linear Technology’s Application Note 19 contains a detailed description of the method. A good starting point for

the LT1610 is CC ~ 220pF and RC ~ 220k.

SWITCH

VOLTAGE

10V/DIV

100ns/DIV

1610 F07

Figure 7. Switching Waveforms Without Ceramic Capacitor C5

V

OUT

50mV/DIV

I

DIODE

500mA/DIV

SWITCH

VOLTAGE

10V/DIV

= 4.1V 100ns/DIV 1610 F08

V

IN

LOAD = 100mA

Figure 8. Switching Waveforms with Ceramic Capacitor C5.

Note the 50mV/DIV Scale for V

OUT

It is best to choose the compensation components empirically. Once the power components have been chosen

(based on size, efficiency, cost and space requirements),

a working circuit is built using conservative (or merely

guessed) values of RC and CC. Then the response of the

circuit is observed under a transient load, and the compen-

All Ceramic, Low Profile Design

Large value ceramic capacitors that are suitable for use as

the main output capacitor of an LT1610 regulator are now

available. These capacitors have very low ESR and therefore offer very low output ripple in a small package.

However, you should approach their use with some

caution.

Ceramic capacitors are manufactured using a number of

dielectrics, each with different behavior across temperature and applied voltage. Y5V is a common dielectric used

for high value capacitors, but it can lose more than 80% of

the original capacitance with applied voltage and extreme

temperatures. The transient behavior and loop stability of

the switching regulator depend on the value of the output

capacitor, so you may not be able to afford this loss. Other

dielectrics (X7R and X5R) result in more stable characteristics and are suitable for use as the output capacitor. The

X7R type has better stability across temperature, whereas

the X5R is less expensive and is available in higher values.

The second concern in using ceramic capacitors is that

many switching regulators benefit from the ESR of the

9

Page 10

LT1610

U

WUU

APPLICATIONS INFORMATION

output capacitor because it introduces a zero in the

regulator’s loop gain. This zero may not be effective

because the ceramic capacitor’s ESR is very low. Most

current mode switching regulators (including the LT1610)

can easily be compensated without this zero. Any design

should be tested for stability at the extremes of operating

temperatures; this is particularly so of circuits that use

ceramic output capacitors.

Figure 9 details a 2.5V to 5V boost converter. Transient

response to a 5mA to 105mA load step is pictured in Figure

10. The “double trace” of V

ESR of C2. This ESR aids stability. In Figure 11, C2 is

replaced by a 10µF ceramic capacitor. Note the low phase

margin; at higher input voltage, the converter may oscillate. After replacing the internal compensation network

with an external 220pF/220k series RC, the transient

response is shown in Figure 12. This is acceptable transient response.

Table 1

FIGURE C2 COMPENSATION

10 AVX TAJA226M006 Tantalum Internal

11 Taiyo Yuden JMK316BJ106 Internal

12 Taiyo Yuden JMK316BJ106 220pF/220k

at 105mA load is due to the

OUT

V

OUT

100mV/DIV

LOAD

CURRENT

105mA

5mA

500µs/DIV

1610 F10

Figure 10. Tantalum Output Capacitor

and Internal RC Compensation

V

OUT

100mV/DIV

LOAD

CURRENT

105mA

5mA

500µs/DIV

1610 F11

Figure 11. 10µF X5R-Type Ceramic Output Capacitor

and Internal RC Compensation has Low Phase Margin

V

IN

2.5V

+

C1

22µF

R

C1: AVX TAJA226M006

C2: SEE TABLE

D1: MOTOROLA MBR0520

L1: MURATA LQH30100

L1

10µH

65

V

IN

3

SHDN

LT1610

1

C

COMP

C

C

C

8

SW

GNDV

PGND

D1

1M

2

FB

R2

324k

7

4

V

5V

100mA

+

C2

22µF

1610 F09

Figure 9. 2.5V to 5V Boost Converter Can Operate with a

Ceramic Output Capacitor as Long as Proper RC and C

C

are Used. Disconnect COMP Pin if External Compensation

Components Are Used

OUT

V

OUT

100mV/DIV

LOAD

CURRENT

105mA

5mA

500µs/DIV

1610 F12

Figure 12. Ceramic Output Capacitor with 220pF/220k

External Compensation has Adequate Phase Margin

10

Page 11

U

LOAD (mA)

60

EFFICIENCY (%)

70

80

90

0.1 10 100 1000

1610 TA05

50

1

3.3V

OUT

3V

IN

1.5V

IN

2V

IN

TYPICAL APPLICATIONS

L1

4.7µH

65

2 CELLS

V

IN

3

C1

15µF

SHDN

8

V

C

1

+

LT1610

SW

GNDCOMP

PGND

2

FB

7

4

LT1610

Efficiency2-Cell to 5V Converter

D1

1M

324k

V

OUT

5V

50mA

+

C2

15µF

90

VIN = 2V

80

70

EFFICIENCY (%)

60

VIN = 3V

VIN = 1.5V

C1, C2: AVX TAJA156M010R

D1: MOTOROLA MBR0520

L1: SUMIDA CD43-4R7

MURATA LQH1C4R7

+

2 CELLS

C1: AVX TAJA106M010R

C2: AVX TAJB336M006R

D1: MBR0520

L1: MURATA LQH3C4R7

C1

10µF

5V to 12V/100mA Boost Converter

V

IN

5V

1

+

C1

15µF

8

C1: AVX TAJA156M010

C2: AVX TAJB156M016

D1: MOTOROLA MBR0520

L1: MURATA LQH3C100M24

L1

4.7µH

65

V

IN

1

V

C

LT1610

8

GND

7

L1

10µH

65

V

IN

V

C

GND

7

SW

LT1610

SHDNCOMP

PGND

4

SW

FB

SHDNCOMP

PGND

4

D1

2

FB

3

SHUTDOWN

D1

2

3

SHUTDOWN

R2

1M

R3

115k

R2

1M

R3

604k

+

+

C2

15µF

C2

33µF

V

OUT

12V

100mA

1610 TA06

1610 TA02

V

OUT

3.3V

70mA

1610 TA04

50

0.1

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

0.1

110

LOAD CURRENT (mA)

100 1000

Efficiency2-Cell to 3.3V Converter

Efficiency

1 10 100

LOAD CURRENT (mA)

1610 TA03

1610 TA07

11

Page 12

LT1610

U

TYPICAL APPLICATIONS

5V to 9V/150mA Boost Converter Efficiency

V

IN

5V

+

C1

15µF

C1: AVX TAJA156M010

C2: AVX TAJB156M016

D1: MOTOROLA MBR0520

L1: MURATA LQH3C100M24

L1

10µH

65

V

IN

1

V

C

LT1610

8

GND

7

LOAD

CURRENT

SW

SHDNCOMP

PGND

D1

2

FB

3

4

SHUTDOWN

R2

1M

R3

158k

V

OUT

9V

150mA

+

C2

15µF

1610 TA08

5V to 9V Boost Converter Transient Response

V

OUT

200mV/DIV

140mA

10mA

INDUCTOR

CURRENT

200mA/DIV

200µs/DIV

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

1610 TA10

1

10 100 300

LOAD CURRENT (mA)

1610 TA09

12

Page 13

U

TYPICAL APPLICATIONS

3.3V TO 8V/70mA, –8V/5mA, 24V/5mA TFT LCD Bias Supply Uses All Ceramic Capacitors

LT1610

0.22µF: TAIYO YUDEN EMK212BJ224MG

1µF: TAIYO YUDEN LMK212BJ105MG

4.7µF: TAIYO YUDEN LMK316BJ475ML

D1: MOTOROLA MBRO520

D2, D3, D4: BAT54S

L1: SUMIDA CDRH5D185R4

V

IN

3.3V

3

C1

4.7µF

1

100k

51pF

D2

0.22µF

0.22µF

L1

5.4µH

65

V

SHDN

V

C

GND

IN

7

SW

COMP

LT1610

FB

PGND

4

V

OFF

–8V

1µF

1µF

C2

4.7µF

1610 TA18

5mA

V

ON

24V

5mA

AV

DD

8V

70mA

1µF

D3

0.22µF

D4

D1

8

274k

2

48.7k

AV

DD

LOAD

AV

DD

200mV/DIV

V

ON

500mV/DIV

V

OFF

200mV/DIV

70mA

25mA

TFT LCD Bias Supply Transient Response

VON LOAD = 5mA

V

LOAD = 5mA

OFF

200µs/DIV

1610 TA19

13

Page 14

LT1610

U

TYPICAL APPLICATIONS

Single Cell Super Cap Charger

CHARGE

SHUTDOWN

+

C1

15µF

1 AA

ALKALINE

C1, C2: AVX TAJA156M010

D1: MOTOROLA MBR0530T1

L1: MURATA LQH1C4R7

Q1: 2N3906

15k

3.3nF

L1

4.7µH

65

V

IN

3

SHDN

LT1610

1

C

GND

7

SW

COMP

PGND

D1

8

+

2

FBV

4

C2

15µF

R4

20Ω

R1

200k

Q1

R2

2M

R3

845k

+

1610 TA11

V

OUT

4.5V

C

BIG

Super Cap Charger Output Current vs Output Voltage Super Cap Charger Output Power vs Output Voltage

25

20

60

50

15

10

OUTPUT CURRENT (mA)

5

0

2.0

3.0 3.5 4.0

2.5

OUTPUT VOLTAGE (V)

4.5 5.0

1610 TA12

40

30

20

OUTPUT POWER (mW)

10

0

2.0

2.5

OUTPUT VOLTAGE (V)

3.0 3.5 4.0

4.5 5.0

1610 TA13

14

Page 15

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

MS8 Package

8-Lead Plastic MSOP

(LTC DWG # 05-08-1660)

0.118 ± 0.004*

(3.00 ± 0.102)

8

7

6

5

LT1610

0.192 ± 0.004

(4.88 ± 0.10)

12

0.040

± 0.006

SEATING

PLANE

(1.02 ± 0.15)

0.012

(0.30)

0.0256

REF

(0.65)

TYP

0.007

(0.18)

0.021

± 0.006

(0.53 ± 0.015)

* DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

° – 6° TYP

0

0.118 ± 0.004**

4

3

0.034 ± 0.004

(0.86 ± 0.102)

(3.00 ± 0.102)

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.189 – 0.197*

(4.801 – 5.004)

7

8

5

6

0.006 ± 0.004

(0.15 ± 0.102)

MSOP (MS8) 1197

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0°– 8° TYP

0.016 – 0.050

(0.406 – 1.270)

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

0.150 – 0.157**

(3.810 – 3.988)

1

3

2

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

TYP

SO8 0996

15

Page 16

LT1610

U

TYPICAL APPLICATIONS N

INPUT

Li-ION

3V to 4.2V

4 CELLS

Li-Ion to 3.3V SEPIC DC/DC Converter

C3

SW

FB

SHDN

4

1µF

CERAMIC

2

3

SHUTDOWN

L1

22µH

•

65

V

IN

+

C1

22µF

6.3V

C1, C2: AVX TAJB226M006

C3: AVX 1206YC105 (X7R)

D1: MOTOROLA MBR0520

L1, L2: MURATA LQH3C220 (UNCOUPLED)

OR SUMIDA CLS62-220 (COUPLED)

1

8

V

C

COMP

GND

LT1610

PGND

7

4-Cell to 5V/120mA SEPIC DC/DC Converter

SW

FB

SHDN

4

1µF

CERAMIC

2

3

SHUTDOWN

L1

22µH

•

65

V

IN

C1

22µF

6.3V

1

8

V

C

COMP

GND

LT1610

PGND

7

+

C1, C2: AVX TAJB226M006

C3: AVX 1206YC105 (X7R)

D1: MOTOROLA MBR0520

L1, L2: MURATA LQH3C220 (UNCOUPLED)

OR SUMIDA CLS62-220 (COUPLED)

Efficiency

80

VIN = 2.7V

= 3.6V

V

0.1

IN

= 4.2V

V

IN

1 10 100

LOAD CURRENT (mA)

1610 TA15

1M

604k

•

L2

22µH

D1

V

OUT

3.3V

120mA

+

C2

22µF

6.3V

1610 TA14

70

60

50

EFFICIENCY (%)

40

30

4-Cell to 5V Efficiency

C3

1M

324k

•

L2

22µH

D1

V

OUT

5V

120mA

+

C2

22µF

6.3V

1610 TA16

80

VIN = 3.6V

V

V

70

V

60

50

EFFICIENCY (%)

40

30

0.1

= 4.2V

IN

= 5V

IN

= 6.5V

IN

1 10 100

LOAD CURRENT (mA)

1610 TA17

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC®1474 Micropower Step-Down DC/DC Converter 94% Efficiency, 10µA IQ, 9V to 5V at 250mA

LT1307 Single Cell Micropower 600kHz PWM DC/DC Converter 3.3V at 75mA from 1 Cell, MSOP Package

LTC1440/1/2 Ultralow Power Single/Dual Comparators with Reference 2.8µA IQ, Adjustable Hysteresis

LTC1502-3.3 Single Cell to 3.3V Regulated Charge Pump 40µA IQ, No Inductors, 3.3V at 10mA from 1V Input

LT1521 Micropower Low Dropout Linear Regulator 500mV Dropout, 300mA Current, 12µA I

LT1611 Inverting 1.4MHz DC/DC Converter 5V to –5V at 150mA, Tiny SOT-23 Package

LT1613 Step-Up 1.4MHz DC/DC Converter 3.3V to 5V at 200mA, Tiny SOT-23 Package

LTC1682 Doubler Charge Pump with Low Noise Linear Regulator Fixed 3.3V and 5V Outputs, 1.8V to 4.4V Input Range, 50mA Output

Linear Technology Corporation

16

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

Q

1610f LT/TP 0699 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1998

Loading...

Loading...