Page 1

FEATURES

■

Greatly Reduced Conducted and Radiated EMI

■

Low Switching Harmonic Content

■

Independent Control of Switch Voltage and

Current Slew Rates

■

2A Current Limited Power Switch

■

Regulates Positive and Negative Voltages

■

20kHz to 250kHz Oscillator Frequency

■

Easily Synchronized to External Clock

■

Wide Input Voltage Range: 2.7V to 23V

■

Low Shutdown Current: 12µA Typical

■

Easier Layout than with Conventional Switchers

U

APPLICATIO S

■

Precision Instrumentation Systems

■

Isolated Supplies for Industrial Automation

■

Medical Instruments

■

Wireless Communications

■

Single Board Data Acquisition Systems

LT1534/LT1534-1

Ultralow Noise

2A Switching Regulators

U

DESCRIPTIO

The LT®1534/LT1534-1 are a new class of switching regulator designed to reduce conducted and radiated electromagnetic interference (EMI). Ultralow noise and EMI are achieved

by providing user control of the output switch slew rates.

Voltage and current slew rates can be independently programmed to optimize switcher harmonic content versus

efficiency. The LT1534/LT1534-1 can reduce high frequency

harmonic power by as much as 40dB with only minor losses

in efficiency.

The LT1534/LT1534-1 utilize a current mode architecture

optimized for low noise boost topologies. The ICs include a

2A power switch along with all necessary oscillator, control

and protection circuitry. Unique error amp circuitry can

regulate both positive and negative voltages. The internal

oscillator may be synchronized to an external clock for more

accurate placement of switching harmonics. Protection features include cycle-by-cycle current limit protection, undervoltage lockout and thermal shutdown.

Low minimum supply voltage and low supply current during

shutdown make the LT1534/LT1534-1 well suited for portable applications. The LT1534/LT1534-1 are available in the

16-pin narrow SO package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

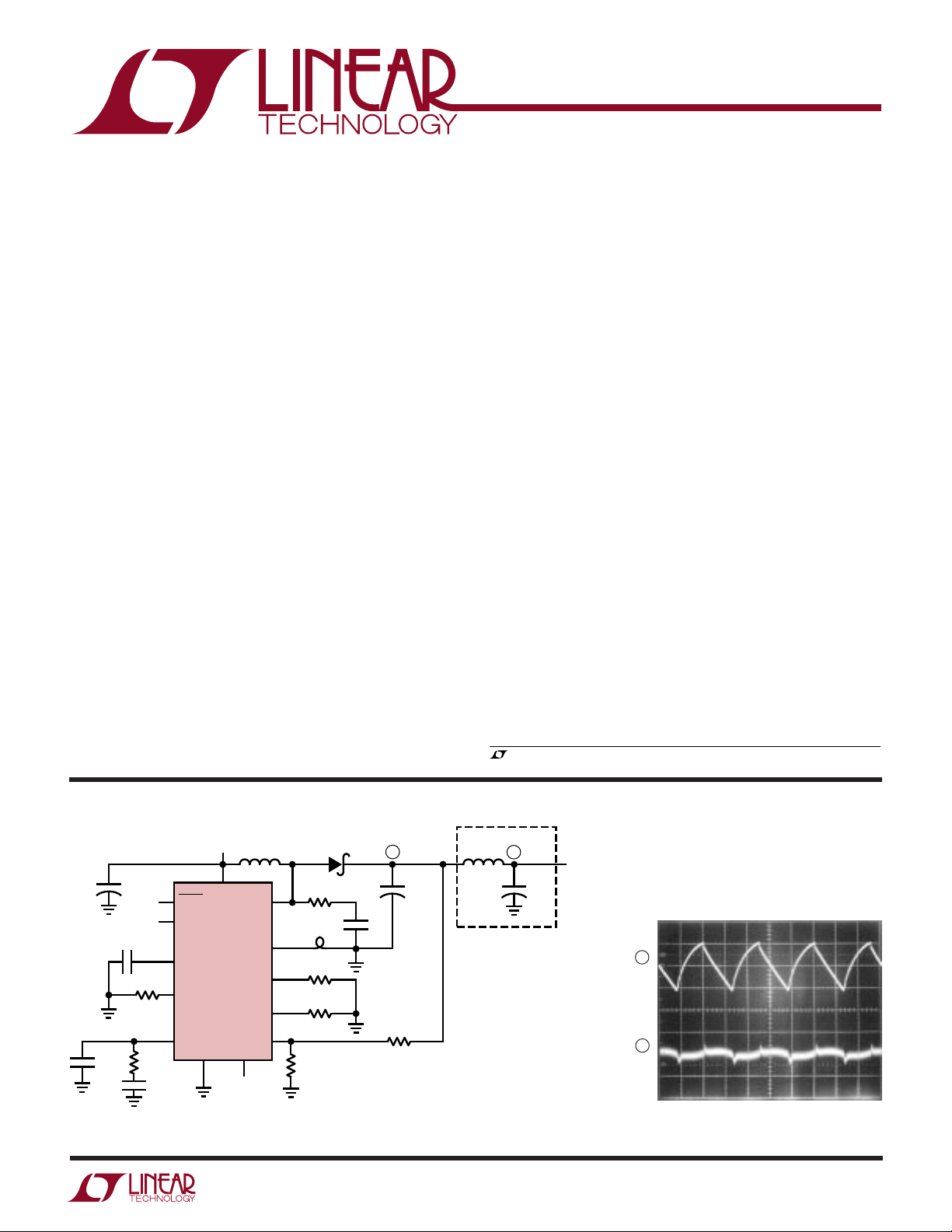

TYPICAL APPLICATION

L1

3.3V

50µH

+

220pF

C

33µF

6.3V

3300pF

IN

16.9k

6.8k

15nF

12

SHDN

4

SYNC

5

C

6

R

11

V

15

V

T

T

C

GND

IN

LT1534-1

9,16

PGND

NFB

R

R

101,8,

COL

VSL

CSL

2

3

14

13

7

FB

2.49k

Figure 1. Low Noise 3.3V to 5V Boost Converter

U

1N5817

10Ω

L2

24k

24k

A

C1

+

47µF

6.3V

×2

1nF

7.5k

CIN: MATSUSHITA ECGCOJB330

C1, C2: MATSUSHITA ECGCOJB47O

L1, L3: COILTRONICS CTX50-4

L2: COILCRAFT B08T (28nH) OR PC TRACE

1534 TA01

L3

50µH

OPTIONAL

B

+

C2

47µF

5V

650mA

50mV/DIV

2mV/DIV

5V Output Noise (BW = 100MHz)

A

B

10µs/DIV

1534 TA02

1

Page 2

LT1534/LT1534-1

WW

W

ABSOLUTE MAXIMUM RATINGS

U

(Note 1)

Input Voltage (VIN) .................................................. 30V

Switch Voltage (COL) .............................................. 35V

SHDN Pin Voltage.................................................... 30V

Feedback Pin Current (FB) .................................... 10mA

Negative Feedback Pin Current (NFB) .................. ±10mA

U

W

U

PACKAGE/ORDER INFORMATION

ORDER PART

NUMBER

LT1534CS

LT1534IS

1

NC

2

COL

3

*NC

4

SYNC

5

C

T

6

R

T

7

FB

8

NFB

16-LEAD PLASTIC SO

*DO NOT CONNECT

T

JMAX

TOP VIEW

16

15

14

13

12

11

10

9

S PACKAGE

= 125°C, θJA = 100°C/W

PGND

COL

V

IN

R

VSL

R

CSL

SHDN

V

C

GND

Operating Junction Temperature Range

LT1534C................................................ 0°C to 125°C

LT1534I ............................................ –40°C to 125°C

Maximum Junction Temperature .......................... 125°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec.)................. 300°C

TOP VIEW

1

GND

2

COL

3

PGND

4

SYNC

5

C

T

6

R

T

7

FB

8

GND

S PACKAGE

**FOUR CORNER PINS ARE FUSED TO INTERNAL

CONNECT THESE FOUR PINS TO EXPANDED

16-LEAD PLASTIC SO

DIE ATTACH PADDLE FOR HEAT SINKING.

PC LANDS FOR PROPER HEAT SINKING.

T

= 125°C, θJA = 50°C/W

JMAX

16

GND

15

V

IN

14

R

VSL

13

R

CSL

12

SHDN

11

V

C

10

NFB

9

GND

ORDER PART

NUMBER

LT1534CS-1

LT1534IS-1

Consult factory for Military grade parts.

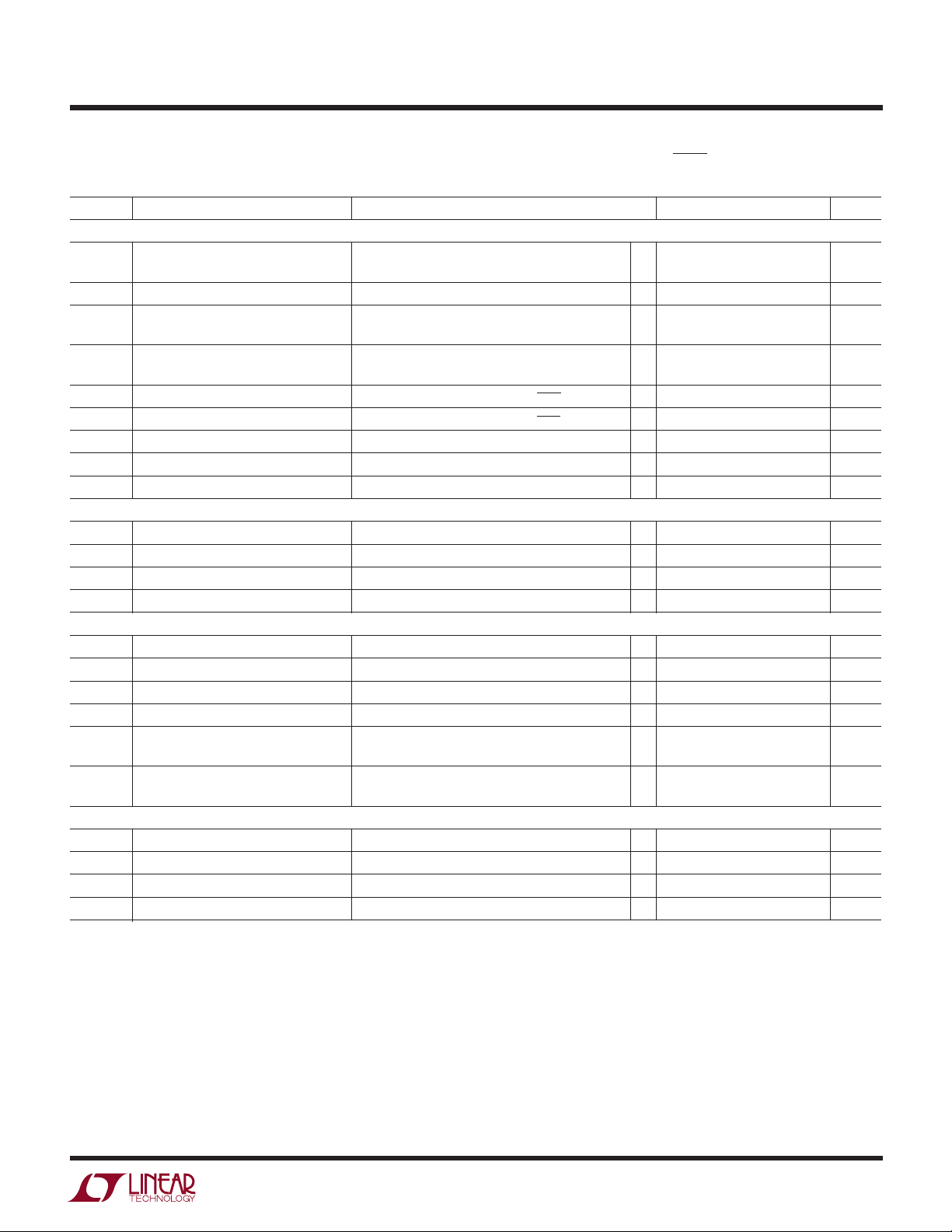

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C, VIN = 5V, VC = 0.9V, VFB = V

The ● denotes the specifications which apply over the full operating

. COL, SHDN, NFB, all other pins open

REF

unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Supply and Protection

V

IN

V

IN(MIN)

I

VIN

I

VIN(OFF)

V

SHDN

I

SHDN

Error Amplifiers

V

REF

I

FB

FB

REG

Recommended Operating Range ● 2.7 23 V

Minimum Input Voltage ● 2.55 2.7 V

Operating Supply Current 2.7V ≤ VIN ≤ 23V, R

Shutdown Supply Current 2.7V ≤ VIN ≤ 23V, V

2.7V ≤ V

≤ 23V, V

IN

, R

VSL

SHDN

SHDN

, RT = 17k ● 12 30 mA

CSL

= 0V ● 12 50 µA

= 0V 12 30 µA

Shutdown Threshold 2.7V ≤ VIN ≤ 23V ● 0.4 0.8 1.2 V

Shutdown Input Current –2 µA

Reference Voltage Measured at Feedback Pin 1.235 1.250 1.265 V

● 1.215 1.250 1.275 V

Feedback Input Current VFB = V

REF

● 250 900 nA

Reference Voltage Line Regulation 2.7V ≤ VIN ≤ 23V ● 0.003 0.03 %/V

2

Page 3

LT1534/LT1534-1

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C, VIN = 5V, VC = 0.9V, VFB = V

The ● denotes the specifications which apply over the full operating

. COL, SHDN, NFB, all other pins open

REF

unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Error Amplifiers

V

NFR

I

NFR

NFB

REG

g

m

I

ESK

I

ESRC

V

CLH

V

CLL

A

V

Oscillator and Sync

f

MAX

f

SYNC

R

SYNC

V

FBfs

Output Switches

DC

MAX

t

IBL

BV

COL

R

ON

I

LIM

∆IIN/∆I

Slew Control

V

SLEWR

V

SLEWF

I

SLEWR

I

SLEWF

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Negative Feedback Reference Voltage Measured at Negative Feedback Pin with ● –2.550 –2.500 –2.420 V

Feedback Pin Open

Negative Feedback Input Current V

NFB

= V

NFR

● –37 –25 µA

Negative Feedback Reference Voltage 2.7V ≤ VIN ≤ 23V ● 0.002 0.05 %/V

Line Regulation

Error Amplifier Transconductance ∆IC = ±25µA 1100 1500 1900 µmho

● 700 2300 µmho

Error Amplifier Sink Current VFB = V

Error Amplifier Source Current VFB = V

+ 150mV, VC = 0.9V, V

REF

– 150mV, VC = 0.9V, V

REF

= 1V ● 120 200 350 µA

SHDN

= 1V ● 120 200 350 µA

SHDN

Error Amplifier Clamp Voltage High Clamp, VFB = 1V 1.33 V

Error Amplifier Clamp Voltage Low Clamp, VFB = 1.5V 0.1 V

Error Amplifier Voltage Gain 180 250 V/V

Maximum Switch Frequency 250 kHz

Synchronization Frequency Range f

= 250kHz ● 375 kHz

OSC

SYNC Pin Input Resistance 40 kΩ

FB Pin Threshold for Frequency Shift 5% Reduction from Nominal 0.4 V

Maximum Switch Duty Cycle R

VSL

= R

CSL

= 4.9k, f

= 25kHz ● 88 91 %

OSC

Switch Current Limit Blanking Time 200 ns

Output Switch Breakdown Voltage 2.7V ≤ VIN ≤ 23V ● 35 V

Output Switch-On Resistance I

= 1.5A, Both COL Pins Tied Together ● 0.25 0.43 Ω

COL

Switch Current Limit Duty Cycle = 30% 2 A

Duty Cycle = 80% 1.6 A

Supply Current Increase During 16 mA/A

SW

Switch-On Time

Output Voltage Slew Rising Edge R

Output Voltage Slew Falling Edge R

Output Current Slew Rising Edge R

Output Current Slew Falling Edge R

VSL

VSL

VSL

VSL

, R

= 17k 11 V/µs

CSL

, R

= 17k 14.5 V/µs

CSL

, R

= 17k 1.3 A/µs

CSL

, R

= 17k 1.3 A/µs

CSL

3

Page 4

LT1534/LT1534-1

UW

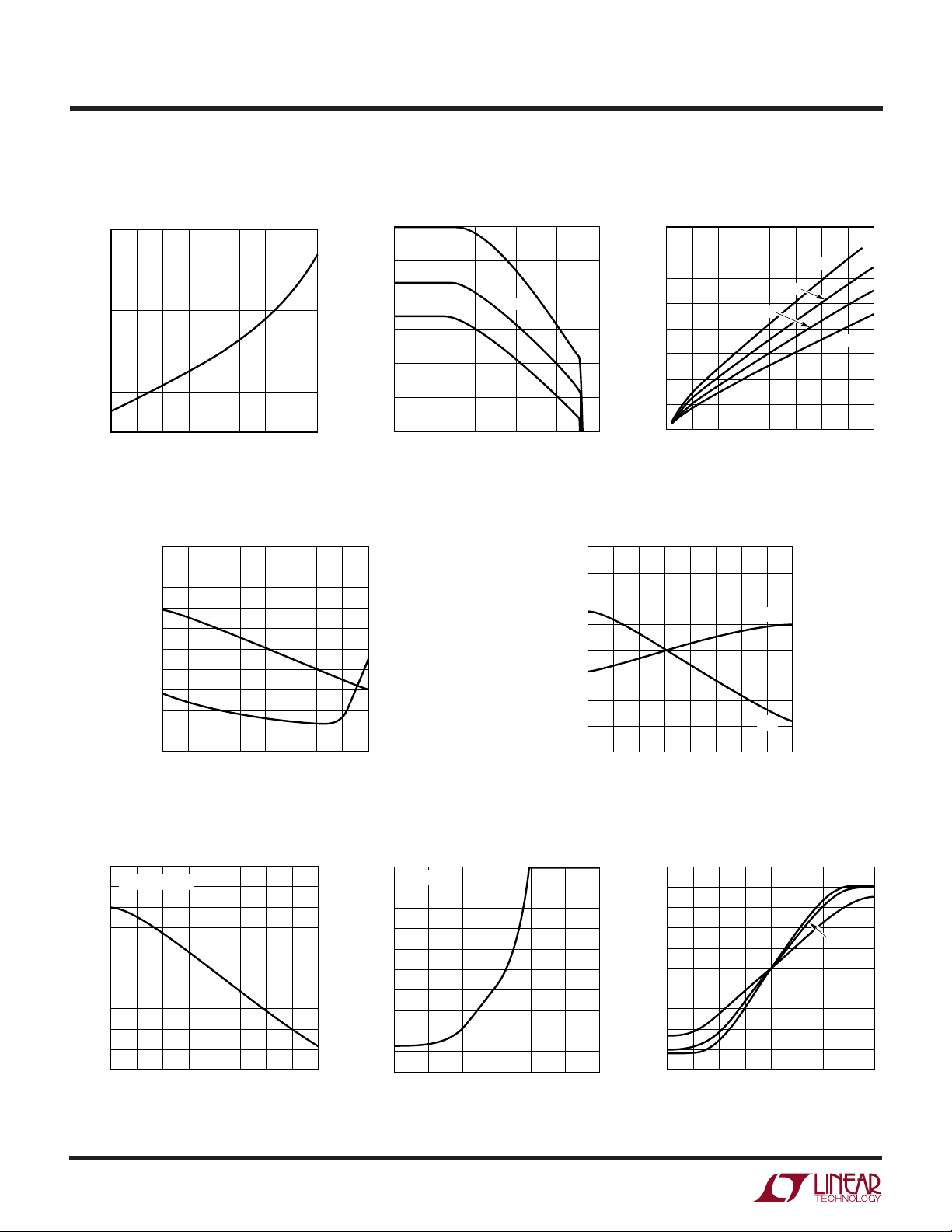

TYPICAL PERFORMANCE CHARACTERISTICS

Minimum Input Voltage (VIN)

vs Temperature

2.70

2.65

2.60

2.55

INPUT VOLTAGE (V)

2.50

2.45

–50

–25 25

0

JUNCTION TEMPERATURE (°C)

50

Feedback Voltage and

Input Current vs Temperature

1.30

1.29

1.28

1.27

1.26

1.25

1.24

1.23

FEEDBACK VOLTAGE (V)

1.22

1.21

1.20

–50

0

–25 25

125

100

75

1534 G01

V

FB

I

FB

50

TEMPERATURE (°C)

75

150

100

125

1533 G04

Change in Maximum Switch

–100

–200

(mA)

–300

LIM

∆I

–400

–500

–600

150

Current (I

0

0

2.0

1.8

FEEDBACK INPUT CURRENT (µA)

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

) vs Duty Cycle

LIM

125°C

20 40 60

DUTY CYCLE (%)

85°C

25°C

80

100

1533 G02

Negative Feedback Voltage and

Input Current vs Temperature

–2.30

–2.35

–2.40

–2.45

–2.50

–2.55

–2.60

NEGATIVE FB VOLTAGE (V)

–2.65

–2.70

–25 25 75

–50

Output Switch Saturation Voltage

vs Switch Current

0.8

0.7

0.6

0.5

0.4

0.3

SWITCH VOLTAGE (V)

0.2

0.1

0

0

0

TEMPERATURE (°C)

0.5

SWITCH CURRENT (A)

50

25°C

100

V

I

NFB

125

1.0

NFB

1533 G05

85°C

150

150°C

35

30

25

20

15

NFB IINPUT CURRENT (µA)

1.5

–40°C

2.0

1534 G03

Error Amplifier Transconductance

vs Temperature

2000

gm = ∆IVC/∆V

1900

1800

1700

1600

1500

1400

1300

1200

TRANSCONDUCTANCE (mho)

1100

1000

–50 25 75 150

–25 0

FB

50

TEMPERATURE (°C)

4

100 125

1534 G08

Switching Frequency vs

Feedback Pin Voltage

100

TA = 25°C

90

80

70

60

50

40

30

20

SWITCHING FREQUENCY (% TYPICAL)

10

0

0

0.1

FEEDBACK PIN VOLTAGE (V)

0.2

0.3 0.4

0.5

1533 G06

0.6

Error Amplifier Output Current (VC)

500

400

300

200

100

0

–100

–200

–300

ERROR AMPLIFIER OUTPUT (µA)

–400

–500

–400 –300 –200 –100

FEEDBACK PIN VOLTAGE FROM NOMINAL (mV)

–40°C

0 100 300

200

125°C

25°C

400

1534 G07

Page 5

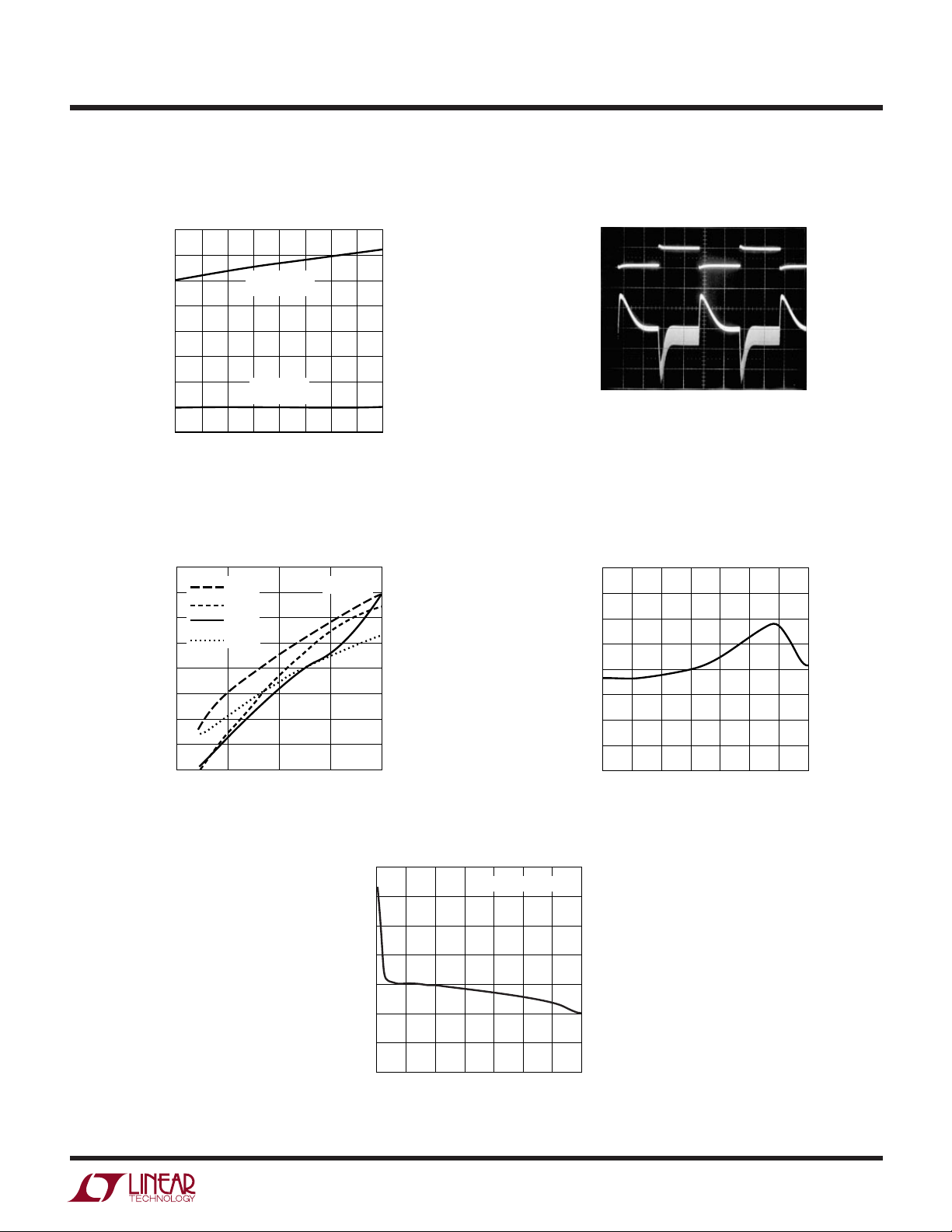

UW

TYPICAL PERFORMANCE CHARACTERISTICS

VC Pin Threshold and Clamp

Voltage vs Temperature

1.6

1.4

1.2

1.0

0.8

0.6

PIN VOLTAGE (V)

C

V

0.4

0.2

0

–50 25 75

–25 0

VC PIN CLAMP

THRESHOLD

TEMPERATURE (°C)

VOLTAGE

VC PIN

50

100 125

1534 G09

0.5A/DIV

100mV/DIV

LT1534/LT1534-1

Load Transient Response

I

LOAD

V

OUT

VIN = 3.3V 500µs/DIV 1534 G10

V

= 5V (NODE A)

OUT

= 0.1A TO 0.5A

I

LOAD

FIGURE 1 CIRCUIT

Typical Output Switch Voltage

and Current Slew Rates vs Slew

Setting Resistance (R

40

I

35

30

25

20

15

VOLTAGE SLEW (V/µs)

10

5

0

0 1/20k 1/10k 1/6.7k 1/5k

I

V

V

RISE

FALL

RISE

FALL

1/R (mmho)

VSL

= R

CSL

TA = 25°C

(%)

OUT

∆V

–0.5

)

4

CURRENT SLEW (A/µs)

3

2

1

0

1534 G11

Load Regulation

2.0

1.5

1.0

0.5

0

FIGURE 1 CIRCUIT

Percent Change in Oscillator

Frequency vs Temperature (NPO

Cap and Metal Film R)

2.0

1.5

1.0

0.5

0

–0.5

–1.0

CHANGE IN FREQUENCY (%)

–1.5

–2.0

–50

–25 25

0

TEMPERATURE (°C)

50

125

100

75

1534 G12

–1.0

–1.5

0

100 300

200

LOAD CURRENT (mA)

400

500

600

700

1534-1 G13

5

Page 6

LT1534/LT1534-1

UUU

PIN FUNCTIONS

(LT1534/LT1534-1)

COL (Pins 2, 15/Pin 2): These two pins should be con-

nected together externally to create the collector of the

power switch. The emitter returns to PGND through a

sense resistor. Large currents flow into these pins so it is

desirable to keep external trace lengths short to minimize

radiation.

SYNC (Pin 4): The SYNC pin can be used to synchronize

the oscillator to an external clock (see Oscillator Sync in

Applications Information section for more details). The

SYNC pin may either be floated or tied to ground if not

used.

CT (Pin 5): The oscillator capacitor pin is used in

conjunction with RT to set the oscillator frequency.

For RT = 16.9k,

C

= 129/f

T(NF)

RT (Pin 6): The oscillator resistor pin is used to set the

charge and discharge currents of the oscillator capacitor.

The nominal value is 16.9k. It is possible to adjust this

resistance ±25% to get a more accurate oscillator frequency.

FB (Pin 7): The feedback pin is used for positive voltage

sensing and oscillator frequency shifting during start-up

and short-circuit conditions. It is the inverting input to the

error amplifier. The noninverting input of this amplifier

connects internally to a 1.25V reference. This pin should

be left open if not used.

NFB (Pin 8/Pin 10): The negative voltage feedback pin is

used for sensing a negative output voltage. The pin is

connected to the inverting input of the negative feedback

amplifier through a 100k source resistor. The negative

feedback amplifier provides a gain of – 0.5 to the feedback

amplifier; therefore, the nominal regulation point is –2.5V

on NFB. This pin should be left open if not used.

GND (Pin 9/Pins 1, 8, 9, 16): Signal Ground. The internal

error amplifier, negative feedback amplifier, oscillator,

slew control circuitry and the bandgap reference are

OSC(kHz)

referred to this ground. Keep the connection to the feedback divider and VC compensation network free of large

ground currents.

VC (Pin 10/Pin 11): The compensation pin is used for

frequency compensation and current limiting. It is the

output of the error amplifier and the input of the current

comparator. Loop frequency compensation can be performed with an RC network connected from the VC pin to

ground.

SHDN (Pin 11/Pin 12): The shutdown pin is used for

disabling the switcher. Grounding this pin will disable all

internal circuitry. Normally this output can be tied high (to

VIN) or may be left floating.

R

(Pin 12/Pin 13): A resistor to ground sets the current

CSL

slew rate for the power switch. The minimum resistor

value is 3.9k and the maximum value is 68k. Current slew

will be approximately:

I

SLEW(A/µs)

R

(Pin 13/Pin 14): A resistor to ground sets the voltage

VSL

slew rate for the power switch collector. The minimum

resistor value is 3.9k and the maximum value is 68k.

Voltage slew will be approximately:

V

SLEW(V/µs)

VIN (Pin 14/Pin 15): Input Supply Pin. Bypass this pin with

a ≥ 4.7µF low ESR capacitor. When VIN is below 2.55V the

part will go into undervoltage lockout where it will stop

output switching and pull the VC pin low.

PGND (Pin 16/Pin 3): Power Switch Ground. This ground

comes from the emitters of the power switches. In normal

operation this pin should have approximately 25nH inductance to ground. This can be done by trace inductance

(approximately 1") or with wire or a specific inductive

component (e.g., small ferrite bead). This inductance

ensures stability in the current slew control loop during

turn-off. Too much inductance (>50nH) may produce

oscillation on the output voltage slew edges.

= 33/R

= 220/R

CSL(kΩ)

VSL(kΩ)

6

Page 7

BLOCK DIAGRA

V

C

+

NEGATIVE

FEEDBACK

AMP

–

NFB

SYNC

FB

R

T

C

T

100k 50k

W

1.25V

LT1534/LT1534-1

SHDN V

LDO REGULATOR

–

g

m

ERROR

AMP

+

+

OSCILLATOR

INTERNAL V

–

COMP

+

GND

IN

CC

PGND COL COL

+

–

SQ

FF

R

OUTPUT

DRIVER

SLEW CONTROL

1534 BD

R

VSL

R

CSL

U

OPERATIO

In noise sensitive applications, switching regulators tend

to be ruled out as a power supply option due to their

propensity for generating unwanted noise. When switching supplies are required due to efficiency or input/output

voltage constraints, great pains must be taken to work

around the noise generated by a typical supply. These

steps may include precise synchronization of the power

supply oscillator to an external clock, synchronizing the

rest of the circuit to the power supply oscillator, or halting

power supply switching during noise sensitive operations.

The LT1534 greatly simplifies the task of eliminating

supply noise by enabling the design of an inherently low

noise switching regulator power supply.

The LT1534 is a fixed frequency, current mode switching

regulator with unique circuitry to control the voltage and

current slew rates of the output switch. Slew control

capability provides much greater control over power supply components that can create conducted and radiated

electromagnetic interference. The current mode control

provides excellent AC and DC line regulation and simplifies

loop compensation.

Current Mode Control

A switching cycle begins with an oscillator discharge pulse

which resets the RS flip-flop, turning on the output driver

(refer to Block Diagram). The switch current is sensed

across an internal resistor and the resulting voltage is

amplified and compared to the output of the error amplifier

(VC pin). The driver is turned off once the output of the

current sense amplifier exceeds the voltage on the VC pin.

Internal slope compensation is provided to ensure stability under high duty cycle conditions.

Output regulation is obtained using the error amp to set

the switch current trip point. The error amp is a transconductance amplifier that integrates the difference between

the feedback output voltage and an internal 1.25V reference. The output of the error amp adjusts the switch

current trip point to provide the required load current at

the desired regulated output voltage. This method of

controlling current rather than voltage provides faster

input transient response, cycle by cycle current limiting

for better output switch protection and greater ease in

compensating the feedback loop.

The VC pin serves three different purposes. It is used for

loop compensation, current limit adjustment and soft

starting. During normal operation the VC voltage will be

between 0.2V and 1.33V. An external clamp may be used

for lowering the current limit. A capacitor coupled to an

external clamp can be used for soft starting.

7

Page 8

LT1534/LT1534-1

U

OPERATIO

The negative feedback amplifier allows for direct regulation of negative output voltages. The voltage on the NFB

pin gets amplified by a gain of – 0.5 and driven onto the FB

input, i.e., the NFB pin regulates to –2.5V while the

amplifier output internally drives the FB pin to 1.25V as in

normal operation. The negative feedback amplifier input

impedance is 100k (typ) referred to ground.

Slew Control

Control of output voltage and current slew rates is done via

two feedback loops. One loop controls the output switch

collector voltage dV/dt and the other loop controls the

emitter current dI/dt. Output slew control is achieved by

comparing the currents generated by these two slewing

events to currents created by external resistors R

R

. The two control loops are combined internally to

CSL

provide a smooth transition from current slew control to

voltage slew control.

U

WUU

VSL

and

APPLICATIONS INFORMATION

Internal Regulator

Most of the control circuitry operates from an internal 2.4V

low dropout regulator that is powered from VIN. The

internal low dropout design allows VIN to vary from 2.7V

to 23V with virtually no change in device performance.

When the part is put into shutdown, the internal regulator

is turned off, leaving only a small (12µA typ) current drain

from VIN.

Protection Features

There are three modes of protection in the LT1534. The

first is overcurrent limit. This is achieved via the clamping

action of the VC pin. The second is thermal shutdown that

disables both output drivers and pulls the VC pin low in the

event of excessive chip temperature. The third is undervoltage lockout that also disables both outputs

and pulls the VC pin low whenever VIN drops below 2.5V.

Reducing EMI from switching power supplies has traditionally invoked fear in designers. Many switchers are

designed solely on efficiency and as such produce waveforms filled with high frequency harmonics that then

propagate through the rest of the power supply.

The LT1534 provides control over two of the more important variables for controlling EMI with switching inductive

loads: switch voltage slew rate and switch current slew

rate. The use of this part will reduce noise and EMI over

conventional switch mode controllers. Because these

variables are under control, a supply built with this part will

exhibit far less tendency to create EMI and less chance of

wandering into problems during production.

It is beyond the scope of this data sheet to get into EMI

fundamentals. AN70 contains much information concerning noise in switching regulators and should be consulted.

Oscillator Frequency

The oscillator determines the switching frequency and

therefore the fundamental positioning of all harmonics.

The use of good quality external components is important

to ensure oscillator frequency stability. The oscillator is a

sawtooth design. A current defined by external resistor R

is used to charge and discharge the capacitor CT. The

discharge rate is approximately ten times the charge rate.

By allowing the user to have control over both components, trimming of oscillator frequency can be more easily

achieved.

The external capacitance CT is chosen by:

C

= 2180/[f

T(nF)

where f

For RT equal to 16.9k, this simplifies to:

C

T(nF)

(e.g., CT = 1.29nF for f

A good quality temperature stable capacitor should be

chosen.

Nominally RT should be 16.9k. Since it sets up current, its

temperature coefficient should be selected to compliment

the capacitor. Ideally, both should have low temperature

coefficients.

is the desired oscillator frequency in kHz.

OSC

= 129/f

OSC(kHz)

OSC(kHz)

• R

T(kΩ)

= 100kHz)

OSC

]

T

8

Page 9

LT1534/LT1534-1

U

WUU

APPLICATIONS INFORMATION

If the FB pin is below 0.4V the oscillator discharge time will

increase, causing the oscillation frequency to decrease by

approximately 6:1. This feature helps minimize power

dissipation during start-up and short-circuit conditions.

Oscillator frequency is important for noise reduction in

two ways: 1) the lower the oscillator frequency the lower

the harmonics of waveforms are, making it easier to filter

them, 2) the oscillator will control the placement of output

frequency harmonics which can aid in specific problems

where you might be trying to avoid a certain frequency

bandwidth that is used for detection elsewhere.

Oscillator Sync

If a more precise frequency is desired (e.g., to accurately

place harmonics) the oscillator can be synchronized to an

external clock. Set the RC timing components for an

oscillator frequency 10% lower than the desired sync

frequency.

Drive the SYNC pin with a square wave (with greater than

1.4V amplitude). The rising edge of the sync square wave

will initiate clock discharge. The sync pulse should have a

minimum of 0.5µs pulse width.

Be careful in synchronizing to frequencies much different

from the part since the internal oscillator charge slope

determines slope compensation. It would be possible to

get into subharmonic oscillation if the sync doesn’t allow

for the charge cycle of the capacitor to initiate slope

compensation. In general, this will not be a problem until

the sync frequency is greater than 1.5 times the oscillator

free-run frequency.

Slew Rate Setting

Setting the voltage and current slew rates is easy. External

resistors to ground on the R

the slew rates. Determining what slew rate to use is more

difficult. There are several ways to approach the problem.

First start by putting a 50k resistor pot with a 3.9k series

resistance on each pin. In general, the next step will be to

monitor the noise that you are concerned with. Be careful

in measurement technique (consult AN70). Keep probe

ground leads very short.

VSL

and R

pins determine

CSL

Usually it will be desirable to keep the voltage and current

slew resistors approximately the same. There are circumstances where a better optimization can be found by

adjusting each separately, but as these values are separated further, a loss of independence of control will occur.

Starting from the lowest resistor setting adjust the pots

until the noise level meets your guidelines. Note that

slower slewing waveforms will dissipate more power so

that efficiency will drop. You can also monitor this as you

make your slew adjustment.

It is possible to use a single slew setting resistor. In this

case the R

VSL

and R

pins are tied together. A resistor

CSL

with a value of 2k to 34k (one half the individual resistors)

can then be tied from these pins to ground.

Emitter Inductance

A small inductance in the power ground minimizes a

potential dip in the output current falling edge that can

occur under fast slewing, 25nH is usually sufficient. Greater

than 50nH may produce unwanted oscillations in the

voltage output. The inductance can be created by wire or

board trace with the equivalent of one inch of straight

length. A spiral board trace will require less length.

Positive Output Voltage Setting

Sensing of a positive output voltage is usually done using

a resistor divider from the output to the FB pin. The

positive input to the error amp is connected internally to a

1.25V bandgap reference. The FB pin will regulate to this

voltage.

R1

FB PIN

R2

Figure 2

V

OUT

1534 F01

Referring to Figure 2, R1 is determined by:

RR

12

V

OUT

125

.

1=−

The FB bias current represents a small error and can

usually be ignored for values of R1||R2 up to 10k.

9

Page 10

LT1534/LT1534-1

U

WUU

APPLICATIONS INFORMATION

One word of caution. Sometimes a feedback zero is added

to the control loop by placing a capacitor across R1 above.

If the feedback zero capacitively pulls the FB pin above the

internal regulator voltage (2.4V typ), output regulation

may be disrupted. A series resistance with the feedback

pin can eliminate this potential problem.

Negative Output Voltage Setting

Negative output voltage can be sensed using the NFB pin.

In this case regulation will occur when the NFB pin is at

–2.5V. The input bias current for the NFB pin is –25µA

(I

) and must be accounted for when selecting divider

NFB

resistor values.

R1

NFB PIN

I

NFB

R2

Figure 3

Referring to Figure 3, R1 is chosen such that:

–V

1534 F02

OUT

Thermal Considerations

Computing power dissipation for this IC requires careful

attention to detail. Reduced output slewing causes the part

to dissipate more power than would occur with fast edges.

However, much improvement in noise can be produced

with modest decrease in supply efficiency.

Power dissipation is a function of topology, input voltage,

switch current and slew rates. It is impractical to come up

with an all-encompassing formula. It is therefore recommended that package temperature be measured in each

application. The part has an internal thermal shutdown to

prevent device destruction, but this should not replace

careful thermal design.

1. Dissipation due to input current:

PVmA

=+

VIN IN

11

60

I

where I is the average switch current.

2. Dissipation due to the driver saturation:

.

−

=

RR

12

V

OUT

•

.•

+µ

25 2 25

25

RA

A suggested value for R2 is 2.5k. The NFB pin is normally

left open if the FB pin is being used.

Dual Polarity Output Voltage Sensing

Certain applications may benefit from sensing both positive and negative output voltages. When doing this each

output voltage resistor divider is individually set as previously described. When both FB and NFB pins are used, the

LT1534 will act to prevent either output from going

beyond its set output voltage. The highest output (lightest

load) will dominate control of the regulator. This technique

would prevent either output from going unregulated high

at no load. However, this technique will also compromise

output load regulation.

Shutdown

If the shutdown pin is pulled low, the regulator will turn off.

The supply current will be reduced to less than 20µA.

P

= (V

VSAT

where V

approximately 0.1 + (0.2)(I), DC

)(I)(DC

SAT

is the output saturation voltage which is

SAT

MAX

)

is the maximum

MAX

duty cycle.

3. Dissipation due to output slew using approximations

for slew rates:

Rf

()

()

VSL OSC

P

=

SLEW

Note if V

VI

IN

()

33 10

()

and ∆I are small with respect to VIN and I,

SAT

2

+

2

I

∆

4

R

()

CSL

9

IV

IN

()

+

220 10

()

2

V

−

SAT

4

9

2

then:

R

()

VSL

fVI

()()()

OSC IN

P

SLEW

IR

()( )

CSL

=

33 10 220 10

()

+

99

V

()

IN

()

10

Page 11

LT1534/LT1534-1

VC PIN

1534 F03

R

VC

2k

C

VC

0.01µF

C

VC2

4.7nF

U

WUU

APPLICATIONS INFORMATION

where ∆I is the ripple current in the switch, R

R

are the slew resistors and f

VSL

is the oscillator

OSC

frequency.

Power dissipation PD is the sum of these three terms. Die

junction temperature is then computed as:

TJ = T

where T

+ (PD)(θJA)

AMB

is ambient temperature and θJA is the package

AMB

thermal resistance. For the 16-pin SO with fused leads the

θJA is 50°C/W.

For example, with f

= 40kHz, 0.4A average current and

OSC

0.1A of ripple, the maximum duty cycle is 88%. Assume

slew resistors are both 17k and V

is 0.26V, then:

SAT

PD = 0.176W + 0.094W + 0.158W = 0.429W

In an S16 fused lead package the die junction temperature

would be 21°C above ambient.

Frequency Compensation

Loop frequency compensation is accomplished by way of

a series RC network on the output of the error amplifier (V

pin). Referring to Figure 4, the main pole is formed by

capacitor CVC and the output impedance of the error

amplifier (approximately 400kΩ). The series resistor R

creates a “zero” which improves loop stability and transient response. A second capacitor C

, typically one-

VC2

tenth the size of the main compensation capacitor, is

sometimes used to reduce the switching frequency ripple

on the VC pin. VC pin ripple is caused by output voltage

ripple attenuated by the output divider and multiplied by

the error amplifier. Without the second capacitor, VC pin

ripple is:

VgR

125.

V

CPIN RIPPLE

where V

()( )()()

RIPPLE

=

= Output ripple (V

RIPPLE m VC

V

OUT

)

P-P

gm = Error amplifier transconductance

RVC = Series resistor on VC pin

V

= DC output voltage

OUT

To prevent irregular switching, VC pin ripple should be

kept below 50mV

maximum output load current and will also be increased if

. Worst-case VC pin ripple occurs at

P-P

CSL

and

VC

poor quality (high ESR) output capacitors are used. The

addition of a 0.0047µF capacitor on the VC pin reduces

switching frequency ripple to only a few millivolts. A low

value for RVC will also reduce VC pin ripple, but loop phase

margin may be inadequate.

Figure 4

Capacitors

While the IC reduces the source of switcher noise, it is

essential for the lowest noise, that the filter capacitors

should have low parasitic impedance. Sanyo OS-CON,

Panasonic Specialty Polymer and tantalum capacitors are

the preferred types. Aluminum electrolytics are not suitable for this application. In general, ESR is more critical

than capacitance. At higher frequencies, ESL can also be

C

important. Paralleling capacitors can reduce both ESR and

ESL.

Design Note 95 offers more information about capacitor

selection. The following is a brief summary:

Solid tantalum capacitors have small size and low

impedance. Typically they are available for voltages

below 50V. They may have a problem with surge

currents (AVX TPS line addresses this issue).

OS-CON capacitors have very low impedance but are

only available for 25V or less. Form factor may be a

problem. Sometimes their very low ESR can cause loop

stability problems.

Ceramic capacitors are generally used for high frequency and high voltage bypass. They too can have

such a low ESR as to cause loop stability problems.

Often they can resonate with their ESL before ESR

becomes effective.

Specialty Polymer Aluminum: Panasonic has come out

with their series CD capacitors. While they are only

available for voltages below 16V, they have very low

ESR and good surge capability.

11

Page 12

LT1534/LT1534-1

U

WUU

APPLICATIONS INFORMATION

Input Capacitor

The ESR of this capacitor acts with high frequency current

components to produce much of the conducted noise of

the switcher. Values of 1µF to 47µF are typical with ESR

less than 0.3Ω. Place the capacitor close to the IC and

inductor.

The input capacitor can see a high surge current when a

battery of high capacitance source is connected “live.”

Some solid tantalum capacitors can fail under this condition. Several manufacturers have developed a line of

solid tantalum capacitors specially tested for surge capability (e.g., AVX TPS series). However, even these units

may fail if the input voltage approaches the maximum

voltage rating of the capacitor. AVX recommends derating capacitor voltage by 2:1 for high surge applications.

Output Filter Capacitor

Output capacitors are usually chosen on the basis of ESR

since this will determine output ripple. However, low ESR

is also needed for low output noise and this will typically

be the tougher requirement. Typically required ESR will be

less than 0.2Ω . Typical capacitance values are in the 47µF

to 500µF range. Again keep connection length as short as

possible. Table 1 shows some typical surface mount

capacitors.

Table 1

SIZE CAPACITOR ESR (MAX Ω)

E CASE AVX TPS, Sprague 593D 0.1 to 0.3

AVX TAJ 0.7 to 0.9

D CASE AVX TPS, Sprague 593D 0.1 to 0.3

AVX TAJ 0.9 to 2.0

Panasonic CD 0.05 to 0.18

C CASE AVX TPS 0.2 (Typ)

AVX TAJ 1.8 to 3.0

B CASE AVX TAJ 2.5 to 10

Fast Voltage Slew Edges

A very fast voltage slew under certain operating conditions

may produce ringing on the COL voltage waveform. While

there is small harmonic energy in this, it can be eliminated

by placing an RC network of 10Ω in series with 1000pF

from the COL pin to ground.

Switching Diodes

In general, switching diodes should be Schottky diodes

such as 1N5817-19 or MBR320-330.

Choosing the Inductor

For a boost converter, inductor selection involves tradeoffs of size, maximum output power, transient response

and filtering characteristics. Higher inductor values provide more output power and lower input ripple. However,

they are physically larger and can impede transient response. Low inductor values have high magnetizing current, which can reduce maximum power and increase

input current ripple.

The following procedure can be used to handle these

trade-offs:

1. Assume that the average inductor current for a boost

converter is equal to load current times V

decide whether the inductor must withstand continuous overload conditions. If average inductor current at

maximum load current is 0.5A, for instance, a 0.5A

inductor may not survive a continuous 1.5A overload

condition. Also be aware that boost converters are not

short-circuit protected, and under output short conditions, only the available current of the input supply

limits inductor current.

OUT/VIN

and

12

Page 13

LT1534/LT1534-1

U

WUU

APPLICATIONS INFORMATION

2. Calculate peak inductor current at full load current to

ensure that the inductor will not saturate. Peak current

can be significantly higher than output current, especially with smaller inductors and lighter loads, so don’t

omit this step. Powdered iron cores are forgiving because they saturate softly, whereas ferrite cores saturate abruptly. Other core material falls in between. The

following formula assumes continuous mode operation but it errors only slightly on the high side for discontinuous mode, so it can be used for all conditions.

V

II

=+

PEAK OUT

OUT

V

IN

L = inductance value

VIN = supply voltage

V

= output voltage

OUT

I = output current

f = oscillator frequency

VV V

()

IN OUT IN

•••2

LfV

–

OUT

3. Choose a core geometry. For low EMI problems a

closed structure should be used such as a pot core, ER

core, E core or toroid (see AN70 appendix I).

4. Select an inductor that can handle peak current, average current (heating effects) and fault current.

5. Finally, double check output voltage ripple. The experts

in the Linear Technology Applications department have

experience with a wide range of inductor types and can

assist you in making a good choice.

Further Help

AN70 has more information on noise in switching regulators and its measurement. AN19 has general information

on switcher design. The Linear Technology applications

group is always ready to lend a helping hand.

U

TYPICAL APPLICATIO S

Low Noise ±12V Dual Output Flyback Converter with Dual Polarity Output Voltage Sensing

2.7V TO 10V

10µF

P6KE-20A

1N4148

15

V

2700pF

16.9k

10k

0.047µF

IN

SHDN

4

SYNC

5

C

LT1534-1

T

6

R

T

11

V

C

GND

9,16

NFB

COL

PGND

R

VSL

R

CSL

101,8,

2.49k

1%

212

3

14

13

7

FB

MBR330

T1

17

10

4

8

2

9

3

NOTE 1

9.31k

1%

MBR330

10Ω

1nF

NOTE 1: 25nH TRACE INDUCTANCE

OR COILCRAFT B10T

L1, L2: COILTRONICS CTX50-4

L1

50µH

+

C1

47µF

+

C2

47µF

21.5k

1%

2.49k

1%

+

47µF

+

47µF

L2

50µH

OPTIONAL

T1: PHILIPS EFD-15-3F3 CORE

GAP FOR PRIMARY

L = 100µH

12V

50mA

–12V

50mA

PIN 1 TO TO 10, 16 TURNS 24AWG

PIN 3 TO 8, 45 TURNS 38AWG

PIN 4 TO 7, 45 TURNS 36AWG

PIN 2 TO 9, 16 TURNS 24AWG

1534 TA04

13

Page 14

LT1534/LT1534-1

U

TYPICAL APPLICATIO S

Ultralow Noise Regulator for a Thermo-Electric Cooler,

Maintaining Sensitive Electronics at Low Temperatures

12V

110k

10k

D1: MOTOROLA MBR5320T3

L1: MIDCOM 38440

L2: COILCRAFT B07T

L3, L4: SUMIDA CD43-220

U2A, U2B: LT1490

100Ω

0.1µF

U2B

L3

22µH

L4

22µH

+

–

3.3M

0.1µF

+

+

100k

C3

22µF

16V

C4

22µF

16V

499k

R6

25k

10k

1534 TA05

0A TO 1.5A

THERMOELECTRIC

COOLER

499k

R

T

10k

NTC

R1

50mΩ

R2

10k

R3

690k

10k

0.01µF

3.3k

5.6V

C2

+

47µF

16V

1000pF

L2

22nF

PGND

V

IN

FB

LT1534-1

C

T

2200pF

D1

10Ω

COL

U1

R

T

R

R

GND

18k 10k

C1

47µF

16V

L1

100µH

1 TO 5 6 TO 10

1k

V

C

CSL

VSL

2N3904

R4

5.1k

Q5

0.1µF

+

–

U2A

+

2N3904

24k

R5

1.6k

INPUT VOLTAGE

4V TO 12V

1300pF

14

16.9k

2k

11

4

5

6

33nF

SHDN

SYNC

C

T

R

T

V

C

4.7µF

LT1534-1

GND

9,16

Ultralow Noise 5V to –3V Cuk Converter

–3V

A Cuk converter is a natural topology for a low noise

0.7A

4.7µF

1534 TA06

C1

47µF

L1B

20µH

MBR320

15

V

IN

212

COL

3

PGND

14

R

VSL

13

R

CSL

7

FB

NFB

101,8,

4.99k

1%

L1A

20µH

NOTE 1

1k

1%

NOTE 1: 25nH TRACE INDUCTANCE

OR COILCRAFT B10T

L1: COILTRONICS CTX20-4

converter. The Cuk converter is a dual of a buck boost

converter. C1 is the primary means of storing and transferring energy. Like a buck boost, the DC transfer function

is approximately V

OUT/VIN

= DC/(1 – DC). The output

voltage, though negative, can be higher or lower in magnitude from the input. The two inductors can be separate

however, by placing them on the same winding input and

output current ripple can be greatly reduced. The additional slew control provided by the LT1534 will reduce the

high frequency content even further.

Page 15

PACKAGE DESCRIPTION

LT1534/LT1534-1

U

Dimensions in inches (millimeters) unless otherwise noted.

S Package

16-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.386 – 0.394*

(9.804 – 10.008)

13

16

14

15

12

11

10

9

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

×

°

45

0.016 – 0.050

(0.406 – 1.270)

0° – 8° TYP

0.228 – 0.244

(5.791 – 6.197)

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.150 – 0.157**

(3.810 – 3.988)

4

5

0.050

(1.270)

BSC

3

2

1

7

6

8

0.004 – 0.010

(0.101 – 0.254)

S16 1098

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

15

Page 16

LT1534/LT1534-1

TYPICAL APPLICATION

V

IN

3V TO 12V

4

SYNC

12

SHDN

10

NFB

11

V

C

R

T

6.8k

0.01µF

220pF

16.9k

U

Low Noise Wide Input Range ±5V Supply

+

C1

10µF

16V

15

V

IN

LT1534-1

GND

9,16

R

VSL

141,8

4k TO

25k

C

T

5

6

1500pF

COL

PGND

R

CSL

FB

13

2

3

7

4k TO

25k

28nH

2.49k

C2

10µF

16V

+

1

4

2

5

+

10Ω

V

OUT1

1nF

C3

10µF

16V

L2

7.5k

*TOTAL OUTPUT CURRENT ≤ 300mA

C1, C2, C3: MATSUSHITA ECGCICB6R8

C4, C5: MATSUSHITA ECGC0JB470

L2: COILCRAFT B08T OR PC TRACE

T1: COILTRONICS VP2-0216

1N5817

T1

6

3

12

9

11

1N5817

T1

8

10

T1

7

V

OUT1

5V

150mA*

+

C4

47µF

6.3V

+

C5

47µF

6.3V

V

OUT2

–5V

150mA*

1534 TA03

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1129 700mA Micropower Low Dropout Regulator 0.4V Dropout Voltage, Reverse Battery Protection

LT1175 500mA Negative Low Dropout Micropower Regulator Positive or Negative Shutdown Logic

LT1370 500kHz High Efficiency 6A Switching Regulator 90% Efficiency, Constant Frequency, High Power

LT1371 500kHz High Efficiency 3A Switching Regulator 90% Efficiency, Constant Frequency, Synchronizable

LT1377 1MHz High Efficiency 1.5A Switching Regulator High Frequency, Small Inductor

LT1425 Isolated Flyback Switching Regulator Excellent Regulation Without Transformer “Third Winding”

LT1533 Ultralow Noise 1A Switching Regulator Push-Pull Design for Low Noise Isolated Supplies

LT1763 500mA Low Noise Micropower LDO 20µV

LT1777 700mA Low Noise Step-Down Switching Regulator Programmable dI/dt Limit, 48VMax V

(10Hz to 100kHz), 30µA Quiescent Current

RMS

IN

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

1534fa LT/TP 0300 2K REV A • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1998

Loading...

Loading...