Page 1

FEATURES

LT1513/LT1513-2

SEPIC Constant- or

Programmable-Current/

Constant-Voltage Battery Charger

U

DESCRIPTION

■

Charger Input Voltage May Be Higher, Equal to or

Lower Than Battery Voltage

■

Charges Any Number of Cells Up to 20V

■

1% Voltage Accuracy for Rechargeable Lithium

Batteries

■

100mV Current Sense Voltage for High Efficiency

(LT1513)

■

0mV Current Sense Voltage for Easy Current

Programming (LT1513-2)

■

Battery Can Be Directly Grounded

■

500kHz Switching Frequency Minimizes

Inductor Size

■

Charging Current Easily Programmable or Shut Down

U

APPLICATIONS

■

Charging of NiCd, NiMH, Lead-Acid or Lithium

Rechargeable Cells

■

Precision Current Limited Power Supply

■

Constant-Voltage/Constant-Current Supply

■

Transducer Excitation

■

Universal Input CCFL Driver

The LT®1513 is a 500kHz current mode switching regulator specially configured to create a constant- or programmable-current/constant-voltage battery charger. In addition

to the usual voltage feedback node, it has a current sense

feedback circuit for accurately controlling output current

of a flyback or SEPIC (Single-Ended Primary Inductance

Converter) topology charger. These topologies allow the

current sense circuit to be ground referred and completely

separated from the battery itself, simplifying battery switching and system grounding problems. In addition, these

topologies allow charging even when the input voltage is

lower than the battery voltage. The LT1513 can also drive

a CCFL Royer converter with high efficiency in floating or

grounded mode.

Maximum switch current on the LT1513 is 3A. This allows

battery charging currents up to 2A for a single lithium-ion

cell. Accuracy of 1% in constant-voltage mode is perfect

for lithium battery applications. Charging current can be

easily programmed for all battery types.

, LTC and LT are registered trademarks of Linear Technology Corporation.

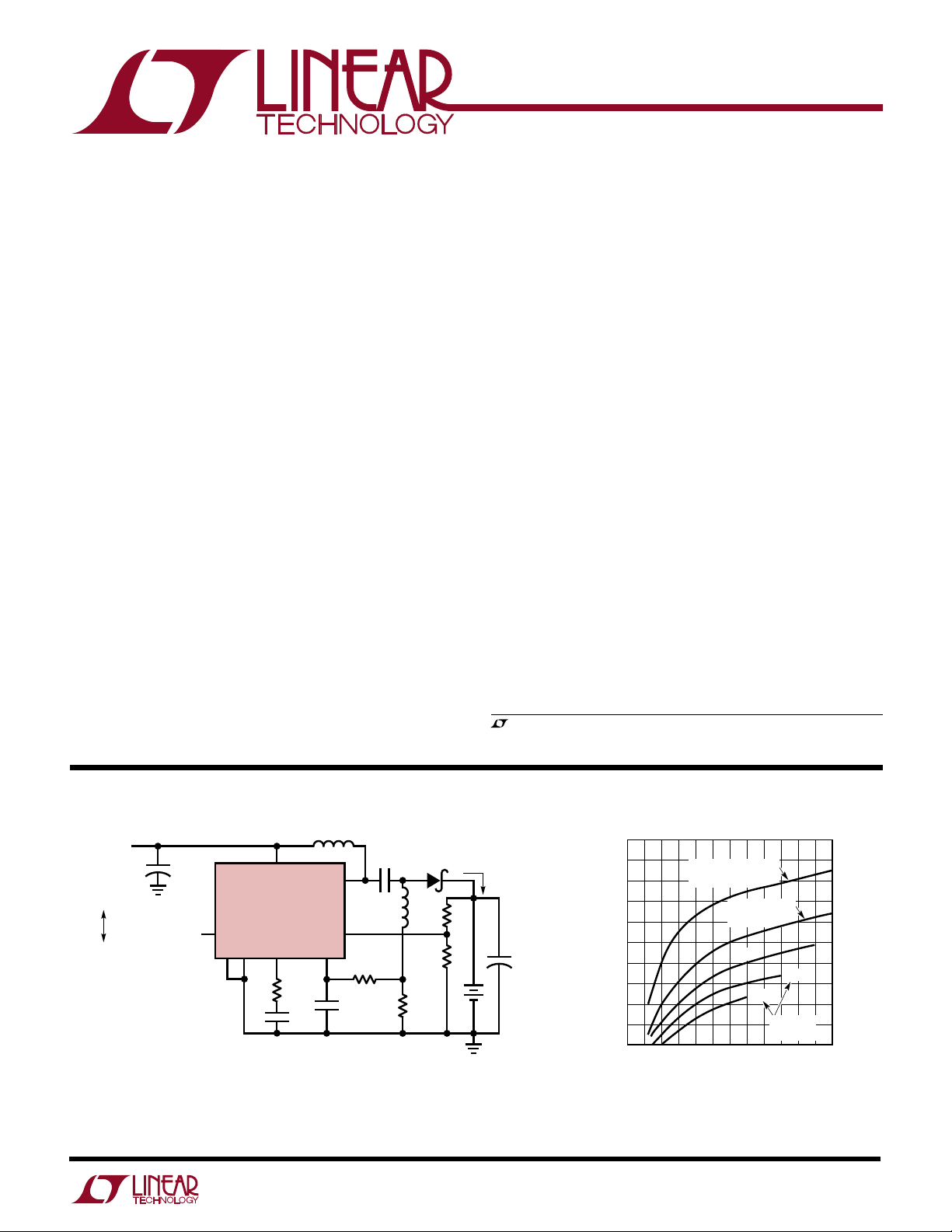

TYPICAL APPLICATION

WALL

ADAPTER

INPUT

CHARGE

SHUTDOWN

C3

+

22µF

25V

SYNC

AND/OR

SHUTDOWN

6

**

LT1513

S/S

GND

TAB4

*

L1A, L1B ARE TWO 10µH WINDINGS ON A

COMMON CORE: COILTRONICS CTX10-4

CERAMIC MARCON THCR40EIE475Z OR TOKIN 1E475ZY5U-C304

†

MBRD340 OR MBRS340T3. MBRD340 HAS 5µA TYPICAL

LEAKAGE, MBRS340T3 50µA TYPICAL

Figure 1. SEPIC Charger with 1.25A Output Current

•

7

V

IN

V

C

13

R5

270Ω

C5

0.1µF

U

L1A*

V

V

I

FB

SW

5

2

FB

C4

0.22µF

R4

39Ω

C2**

4.7µF

†

D1

L1B*

•

R3

0.08Ω

Maximum Charging Current

2.4

2.2

1.25A

R1

C1

+

R2

LT1513 • TA01

22µF

25V

× 2

2.0

1.8

1.6

1.4

1.2

CURRENT (A)

1.0

0.8

0.6

0.4

05

INDUCTOR = 10µH

ACTUAL PROGRAMMED CHARGING CURRENT WILL BE

INDEPENDENT OF INPUT VOLTAGE IF IT DOES NOT

EXCEED VALUES SHOWN

SINGLE Li-Ion CELL

(4.1V)

DOUBLE Li-Ion

CELL (8.2V)

12V

20V

10

INPUT VOLTAGE (V)

20

15

16V

BATTERY

VOLTAGE

25

LT1513 • TA02

30

1

Page 2

LT1513/LT1513-2

A

W

O

LUTEXI T

S

A

WUW

ARB

U

G

I

S

Supply Voltage ....................................................... 30V

Switch Voltage........................................................ 40V

S/S Pin Voltage....................................................... 30V

FB Pin Voltage (Transient, 10ms) ......................... ±10V

VFB Pin Current .................................................... 10mA

IFB Pin Voltage (Transient, 10ms)......................... ±10V

/

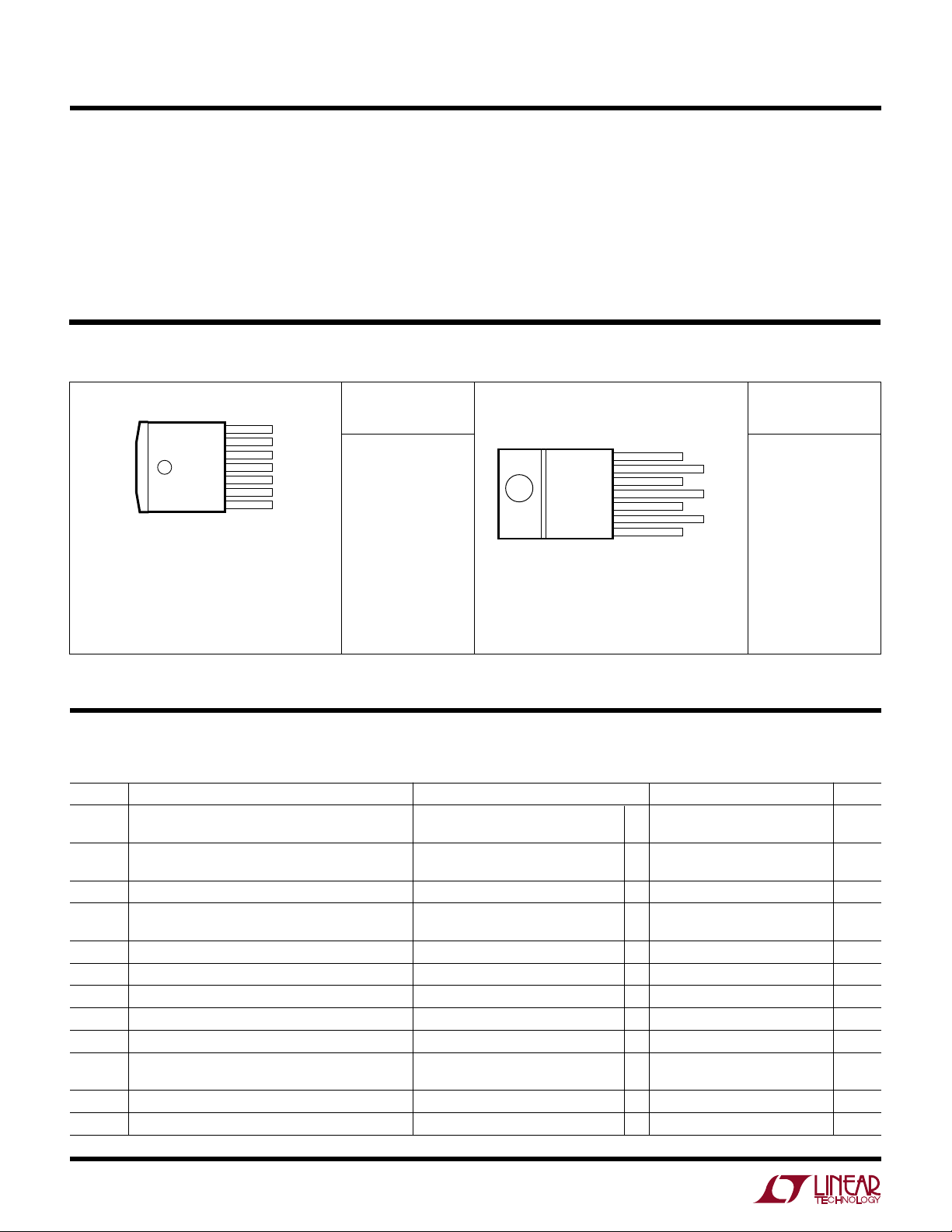

PACKAGE

TAB

IS

GND

7-LEAD PLASTIC DD

WITH PACKAGE SOLDERED TO 0.5INCH

AREA OVER BACKSIDE GROUND PLANE OR INTERNAL

POWER PLANE, θ

> 40°C/W DEPENDING ON MOUNTING TECHNIQUE

O

RDER I FOR ATIO

FRONT VIEW

7

6

5

4

3

2

1

R PACKAGE

T

= 125°C, θ

JMAX

JA

JA

CAN VARY FROM 20°C/W TO

= 30°C/W

2

COPPER

VIN

S/S

V

SW

GND

I

FB

FB

V

C

WU

ORDER PART

NUMBER

LT1513CR

LT1513CR-2

LT1513IR

LT1513IR-2

U

Operating Junction Temperature Range

LT1513C............................................... 0°C to 125°C

LT1513I ............................................ –40°C to 125°C

Short Circuit ......................................... 0°C to 150°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

ORDER PART

NUMBER

FRONT VIEW

V

IN

S/S

V

SW

GND

I

FB

FB

V

C

LT1513CT7-2

LT1513IT7-2

T

JMAX

T7 PACKAGE

7-LEAD TO-220

= 125°C, θ

7

6

5

4

3

2

1

= 50°C/ W, θJC = 4°C/W

JA

Consult factory for Military grade parts.

LECTRICAL C CHARA TERIST

E

VIN = 5V, VC = 0.6V, VFB = V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

REF

V

IREF

I

FBVOS

g

m

FB Reference Voltage Measured at FB Pin 1.233 1.245 1.257 V

FB Input Current VFB = V

FB Reference Voltage Line Regulation 2.7V ≤ VIN ≤ 25V, VC = 0.8V ● 0.01 0.03 %/V

IFB Reference Voltage (LT1513) Measured at IFB Pin –107 –100 – 93 mV

IFB Input Current V

IFB Reference Voltage Line Regulation 2.7V ≤ VIN ≤ 25V, VC = 0.8V ● 0.01 0.05 %/V

IFB Voltage Offset (LT1513-2) (Note 3) I

IFB Input Current V

VFB Source Current V

Error Amplifier Transconductance ∆IC = ±25µA 1100 1500 1900 µmho

Error Amplifier Source Current VFB = V

Error Amplifier Sink Current VFB = V

, IFB = 0V, VSW and S/S pins open, unless otherwise noted.

REF

ICS

VC = 0.8V ● 1.228 1.245 1.262 V

REF

VFB = 0V, VC = 0.8V ● –110 –100 –90 mV

= V

IFB

VFB

IFB

IREF

(Note 2) ● 10 25 35 µA

IREF

= 60µA (Note 4) ● –7.5 2.5 12.5 mV

= V

IREF

= –10mV, VFB = 1.2V ● – 700 –300 – 100 µA

– 150mV, VC = 1.5V ● 120 200 350 µA

REF

+ 150mV, VC = 1.5V ● 1400 2400 µA

REF

● 600 nA

● – 200 – 10 0 nA

● 700 2300 µmho

300 550 nA

2

Page 3

LT1513/LT1513-2

LECTRICAL C CHARA TERIST

E

VIN = 5V, VC = 0.6V, VFB = V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Error Amplifier Clamp Voltage High Clamp, VFB = 1V 1.70 1.95 2.30 V

A

V

f Switching Frequency 2.7V ≤ VIN ≤ 25V 450 500 550 kHz

BV Output Switch Breakdown Voltage 0°C ≤ TJ ≤ 125°C4047V

Error Amplifier Voltage Gain 500 V/V

VC Pin Threshold Duty Cycle = 0% 0.8 1 1.25 V

Maximum Switch Duty Cycle ● 85 95 %

Switch Current Limit Blanking Time 130 260 ns

, IFB = 0V, VSW and S/S pins open, unless otherwise noted.

REF

ICS

Low Clamp, VFB = 1.5V 0.25 0.40 0.52 V

0°C ≤ TJ ≤ 125°C 430 500 580 kHz

T

< 0°C 400 580 kHz

J

T

< 0°C35V

J

V

SAT

I

LIM

∆IIN/∆ISWSupply Current Increase During Switch ON Time 15 25 mA/A

I

Q

The ● denotes specifications which apply over the full operating

temperature range.

Note 1: For duty cycles (DC) between 50% and 85%, minimum

guaranteed switch current is given by I

Output Switch ON Resistance ISW = 2A ● 0.25 0.45 Ω

Switch Current Limit Duty Cycle = 50% ● 3.0 3.8 5.4 A

Control Voltage to Switch Current 4A/V

Transconductance

Minimum Input Voltage ● 2.4 2.7 V

Supply Current 2.7V ≤ VIN ≤ 25V ● 4 5.5 mA

Shutdown Supply Current 2.7V ≤ VIN ≤ 25V, V

Shutdown Threshold 2.7V ≤ VIN ≤ 25V ● 0.6 1.3 2 V

Shutdown Delay ● 51225µs

S/S Pin Input Current 0V ≤ V

Synchronization Frequency Range ● 600 800 kHz

= 1.33 (2.75 – DC).

LIM

Duty Cycle = 80% (Note 1)

≤ 0.6V, TJ ≥ 0°C ● 12 30 µA

TJ < 0°C50µA

≤ 5V ● –10 15 µA

S/S

S/S

Note 2: The I

Note 3: Consult factory for grade selected parts.

Note 4: The I

pin is servoed to its regulating state with VC = 0.8V.

FB

pin is sevoed to regulate FB to 1.245V

FB

● 2.6 3.4 5.0 A

3

Page 4

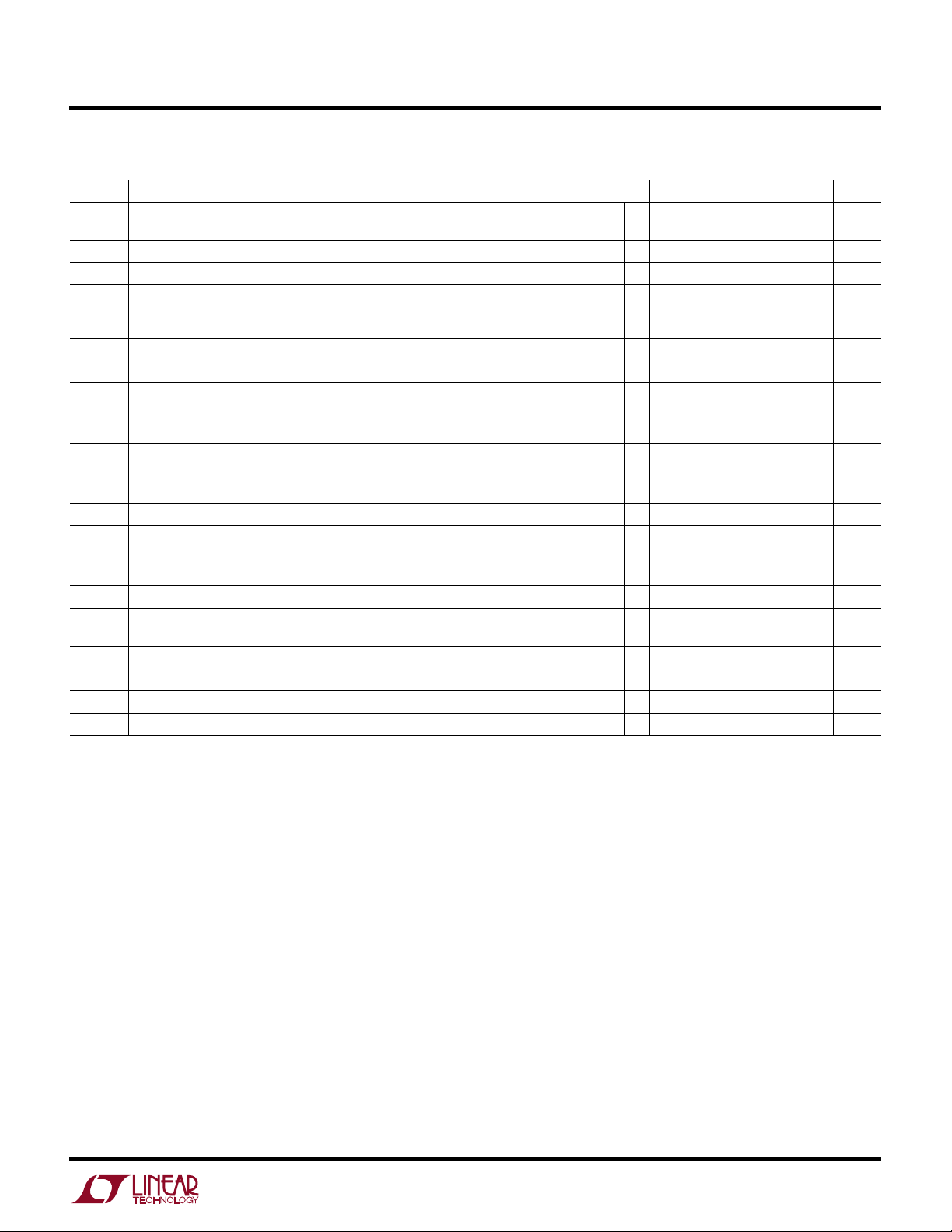

LT1513/LT1513-2

TEMPERATURE (°C)

–50

1.8

INPUT VOLTAGE (V)

2.0

2.2

2.4

2.6

050

100

150

LT1513 • G03

2.8

3.0

–25 25

75

125

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

Switch Saturation Voltage

vs Switch Current

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

SWITCH SATURATION VOLTAGE (V)

0.1

0

0.8

0.4

0

1.2

SWITCH CURRENT (A)

1.6

100°C

2.0

Negative Feedback Input Current

vs Temperature

0

–10

–20

–30

–40

NEGATIVE FEEDBACK INPUT CURRENT (µA)

–50

–50

–25 25

0

150°C

25°C

–55°C

2.4

2.8

3.2

3.6

LT1513 • G01

50

TEMPERATURE (°C)

Minimum Input Voltage

vs Temperature

4.0

Switch Current Limit

vs Duty Cycle

6

5

4

3

2

SWITCH CURRENT LIMIT (A)

1

0

20 40 60 80

DUTY CYCLE (%)

–55°C

25°C AND

125°C

LT1513 • G02

10010030 50 70 90

Output Charging Characteristics

Showing Constant-Current and

Constant-Voltage Operation

12

CHARGING CURRENT

10

WITH 12V INPUT

8

6

4

BATTERY VOLTAGE (V)

2

125

100

75

150

LT1513 • G06

0

(A) (B)

0.4 0.8 1.2 1.6

CHARGING CURRENT (A)

V

= 12VMAXIMUM AVAILABLE

IN

(A) 8.4V BATTERY

= 0.5A

I

CHRG

(B) 8.4V BATTERY

I

= 1A

CHRG

(C) 4.2V BATTERY

I

= 1.5A

(C)

1513 G07

CHRG

2.00.200.6 1.0 1.4 1.8

4

Minimum Peak-to-Peak

Synchronization Voltage vs Temperature

)

3.0

P-P

2.5

2.0

1.5

1.0

0.5

MINIMUM SYNCHRONIZATION VOLTAGE (V

0

–50

f

= 700kHz

SYNC

050

–25 25

TEMPERATURE (°C)

75

100

125

LT1513 • G04

150

Feedback Input Current

vs Temperature

800

VFB = V

–25

REF

0

50

25

TEMPERATURE (°C)

700

600

500

400

300

200

FEEDBACK INPUT CURRENT (nA)

100

0

–50

75

100

125

LT1513 • G05

150

Page 5

UUU

PIN FUNCTIONS

V

(Pin 1): The compensation pin is primarily used for

C

frequency compensation, but it can also be used for soft

starting and current limiting. It is the output of the error

amplifier and the input of the current comparator. Peak

switch current increases from 0A to 3.6A as the VC voltage

varies from 1V to 1.9V. Current out of the VC pin is about

200µ A when the pin is externally clamped below the

internal 1.9V clamp level. Loop frequency compensation

is performed with a capacitor or series RC network from

the VC pin

FB (Pin 2): The feedback pin is used for positive output

voltage sensing. The R1/R2 voltage divider connected to

FB defines Li-Ion float voltage at full charge, or acts as a

voltage limiter for NiCd or NiMH applications. FB is the

inverting input to the voltage error amplifier. Input bias

current is typically 300nA, so divider current is normally

set to 100µ A to swamp out any output voltage errors due

to bias current. The noninverting input of this amplifier is

tied internally to a 1.245V reference. The grounded end of

the output voltage divider should be connected directly to

the LT1513 ground pin (avoid ground loops).

I

FB

charging current. It is the input to a current sense amplifier

that controls charging current when the battery voltage is

below a programmed limit. During constant-current

operation, the LT1513 IFB pin regulates at –100mV. Input

resistance of this pin is 5kΩ, so filter resistance (R4,

Figure 1) should be less than 50Ω. The 39Ω, 0.22µ F filter

shown in Figure 1 is used to convert the pulsating current

in the sense resistor to a smooth DC current feedback

signal. The LT1513-2 IFB pin regulates at 0mV to provide

programmable current limit. The current through R5,

Figure 5, is balanced by the current through R4, programming the maximum voltage across R3.

directly to the ground pin

(Pin 3): The current feedback pin is used to sense

(avoid ground loops).

LT1513/LT1513-2

GND (Pin 4): The ground pin is common to both control

circuitry and switch current. VC, FB and S/S signals must

be Kelvin and connected as close as possible to this pin.

The TAB of the R package should also be connected to the

power ground.

V

(Pin 5): The switch pin is the collector of the power

SW

switch, carrying up to 3A of current with fast rise and fall

times. Keep the traces on this pin as short as possible to

minimize radiation and voltage spikes. In particular, the

path in Figure 1 which includes SW to C2, D1, C1 and

around to the LT1513 ground pin should be as short as

possible to minimize voltage spikes at switch turn-off.

S/S (Pin 6): This pin can be used for shutdown and/or

synchronization. It is logic level compatible, but can be

tied to VIN if desired. It defaults to a high ON state when

floated. A logic low state will shut down the charger to a

micropower state. Driving the S/S pin with a continuous

logic signal of 600kHz to 800kHz will synchronize switching frequency to the external signal. Shutdown is avoided

in this mode with an internal timer.

VIN (Pin 7): The input supply pin should be bypassed with

a low ESR capacitor located right next to the IC chip. The

grounded end of the capacitor must be connected directly

to the ground plane to which the TAB is connected.

TAB: The TAB on the surface mount R package is electrically connected to the ground pin, but a low inductance

connection must be made to both the TAB and the pin for

proper circuit operation. See suggested PC layout in

Figure 4.

5

Page 6

LT1513/LT1513-2

BLOCK DIAGRAM

W

V

IN

S/S

4k

I

FB

50k*

V

FB

1.245V

REF

SHUTDOWN

DELAY AND RESET

SYNC

+

–

–

–

+

*REMOVE ON LT1513-2

500kHz

OSC

I

FBA

EA

LOW DROPOUT

2.3V REG

LOGIC DRIVER

COMP

IA

≈ 6

A

V

C

Figure 2

V

ANTISAT

+

–

SW

SWITCH

0.04Ω

LT1513 • BD

U

OPERATION

The LT1513 is a current mode switcher. This means that

switch duty cycle is directly controlled by switch current

rather than by output voltage or current. Referring to the

Block Diagram, the switch is turned “on” at the start of each

oscillator cycle. It is turned “off” when switch current

reaches a predetermined level. Control of output voltage

and current is obtained by using the output of a dual

feedback voltage sensing error amplifier to set switch

current trip level. This technique has the advantage of

simplified loop frequency compensation. A low dropout

internal regulator provides a 2.3V supply for all internal

circuitry on the LT1513. This low dropout design allows

input voltage to vary from 2.7V to 25V. A 500kHz oscillator

is the basic clock for all internal timing. It turns “on” the

output switch via the logic and driver circuitry. Special

adaptive antisat circuitry detects onset of saturation in the

power switch and adjusts driver current instantaneously to

limit switch saturation. This minimizes driver dissipation

and provides very rapid turn-off of the switch.

A unique error amplifier design has two inverting inputs

which allow for sensing both output voltage and current. A

1.245V bandgap reference biases the noninverting input.

The first inverting input of the error amplifier is brought out

for positive output voltage sensing. The second inverting

input is driven by a “current” amplifier which is sensing

output current via an external current sense resistor. The

current amplifier is set to a fixed gain of –12.5 which

provides a –100mV current limit sense voltage.

The LT1513-2 option removes the feedback resistors

around the IFB amplifier and connects its output to the FB

signal. This provides a ground referenced current sense

voltage suitable for external current programming and

makes amplifier input and output available for external

loop compensation.

The error signal developed at the amplifier output is

brought out externally and is used for frequency compensation. During normal regulator operation this pin sits at a

voltage between 1V (low output current) and 1.9V (high

output current). Switch duty cycle goes to zero if the VC pin

is pulled below the VC pin threshold, placing the LT1513 in

an idle mode.

6

Page 7

LT1513/LT1513-2

LT1513

V

IN

L1A

L1B

GND

V

FB

1513 F03

V

SW

ADAPTER

INPUT

C2

SCHEMATIC SIMPLIFIED FOR CLARITY

D2 = 1N914, 1N4148 OR EQUIVALENT

C6

470pF

R6

470k

R3

R1

R2

D2

D1

C1

+

U

WUU

APPLICATIONS INFORMATION

The LT1513 is an IC battery charger chip specifically optimized to use the SEPIC converter topology. A complete

charger schematic is shown in Figure 1. The SEPIC topology

has unique advantages for battery charging. It will operate

with input voltages above, equal to or below the battery

voltage, has no path for battery discharge when turned off,

and eliminates the snubber losses of flyback designs. It also

has a current sense point that is ground referred and need

not be connected directly to the battery. The two inductors

shown are actually just two identical windings on one

inductor core, although two separate inductors can be used.

A current sense voltage is generated with respect to ground

across R3 in Figure 1. The average current through R3 is

always identical to the current delivered to the battery. The

LT1513 current limit loop will servo the voltage across R3

to –100mV when the battery voltage is below the voltage

limit set by the output divider R1/R2. Constant-current

charging is therefore set at 100mV/R3. R4 and C4 filter the

current signal to deliver a smooth feedback voltage to the I

pin. R1 and R2 form a divider for battery voltage sensing and

set the battery float voltage. The suggested value for R2 is

12.4k. R1 is calculated from:

RV

2 1 245

(–.)

R

1

=

V

BAT

BAT

1 245 2 0 3

.(.)

RA

+µ

= battery float voltage

0.3µ A = typical FB pin bias current

A value of 12.4k for R2 sets divider current at 100µ A. This is

a constant drain on the battery when power to the charger is

off. If this drain is too high, R2 can be increased to 41.2k,

reducing divider current to 30µA. This introduces an addi-

tional uncorrectable error to the constant voltage float mode

of about ±0.5% as calculated by:

±µ

V Error =

BAT

0.15 A(R1)(R2)

1.245(R1+R2)

FB

Figure 3. D2, C6 and R6 form a peak detector to drive the gate

of the FET to about the same as the battery voltage. If power

is turned off, the gate will drop to 0V and the only drain on the

battery will be the reverse leakage of the catch diode D1. See

Diode Selection for a discussion of diode leakage.

Figure 3. Eliminating Divider Current

Maximum Input Voltage

Maximum input voltage for the LT1513 is partly determined

by battery voltage. A SEPIC converter has a maximum

switch voltage equal to input voltage plus output voltage.

The LT1513 has a maximum input voltage of 30V and a

maximum switch voltage of 40V, so this limits maximum

input voltage to 30V, or 40V – V

, whichever is less.

BAT

Shutdown and Synchronization

The dual function S/S pin provides easy shutdown and

synchronization. It is logic level compatible and can be

pulled high or left floating for normal operation. A logic low

on the S/S pin activates shutdown, reducing input supply

current to 12µ A. To synchronize switching, drive the S/S pin

between 600kHz and 800kHz.

Inductor Selection

±0.15µA = expected variation in FB bias current around the

nominal 0.3µ A typical value.

With R2 = 41.2k and R1 = 228k, (V

to variations in bias current would be ±0.42%.

A second option is to disconnect the divider when charger

power is off. This can be done with a small NFET as shown in

= 8.2V), the error due

BAT

L1A and L1B are normally just two identical windings on one

core, although two separate inductors can be used. A typical

value is 10µ H, which gives about 0.5A peak-to-peak inductor current. Lower values will give higher ripple current,

which reduces maximum charging current. 5µ H can be used

if charging currents are at least 20% lower than the values

7

Page 8

LT1513/LT1513-2

U

WUU

APPLICATIONS INFORMATION

shown in the maximum charging current graph. Higher

inductance values give slightly higher maximum charging

current, but are larger and more expensive. A low loss toroid

core such as Kool Mµ®, Molypermalloy or Metglas® is

recommended. Series resistance should be less than 0.04Ω

for each winding. “Open core” inductors, such as rods or

barrels are not recommended because they generate large

magnetic fields which may interfere with other electronics

close to the charger.

Input Capacitor

The SEPIC topology has relatively low input ripple current

compared to other topologies and higher harmonics are

especially low. RMS ripple current in the input capacitor is

less than 0.25A with L = 10µH and less than 0.5A with

L = 5µ H. A low ESR 22µ F, 25V solid tantalum capacitor (AVX

type TPS or Sprague type 593D) is adequate for most

applications with the following caveat. Solid tantalum

capacitors can be destroyed with a very high turn-on surge

current such as would be generated if a low impedance input

source were “hot switched” to the charger input. If this

condition can occur, the input capacitor should have the

highest possible voltage rating, at least twice the surge input

voltage if possible. Consult with the capacitor manufacturer

before a final choice is made. A 4.7µ F ceramic capacitor such

as the one used for the coupling capacitor can also be used.

These capacitors do not have a turn-on surge limitation. The

input capacitor must be connected directly to the VIN pin and

the ground plane close to the LT1513.

in Figure 1. These are AVX type TPS or Sprague type 593D

surface mount solid tantalum units intended for switching

applications. Do not substitute other types without ensuring

that they have adequate ripple current ratings. See Input

Capacitor section for details of surge limitation on solid

tantalum capacitors if the battery may be “hot switched” to

the output of the charger.

Coupling Capacitor

C2 in Figure 1 is the coupling capacitor that allows a SEPIC

converter topology to work with input voltages either higher

or lower than the battery voltage. DC bias on the capacitor is

equal to input voltage. RMS ripple current in the coupling

capacitor has a maximum value of about 1A at full charging

current. A conservative formula to calculate this is:

IVV

()(.)

I

COUP RMS

()

(1.1 is a fudge factor to account for inductor ripple current

and other losses)

With I

The recommended capacitor is a 4.7µF ceramic type from

Marcon or Tokin. These capacitors have extremely low ESR

and high ripple current ratings in a small package. Solid

tantalum units can be substituted if their ripple current rating

is adequate, but typical values will increase to 22µ F or more

to meet the ripple current requirements.

= 1.2A, VIN = 15V and V

CHRG

CHRG IN BAT

=

+ 11

V

()

2

IN

BAT

= 8.2V, I

COUP

= 1.02A.

Output Capacitor

It is assumed as a worst case that all the switching output

ripple current from the battery charger could flow in the

output capacitor. This is a desirable situation if it is necessary to have very low switching ripple current in the battery

itself. Ferrite beads or line chokes are often inserted in series

with the battery leads to eliminate high frequency currents

that could create EMI problems. This forces all the ripple

current into the output capacitor. Total RMS current into the

capacitor has a maximum value of about 1A, and this is

handled with the two paralleled 22µ F, 25V capacitors shown

Kool Mµ is a registered trademark of Magnetics, Inc.

Metglas is a registered trademark of AlliedSignal Inc.

8

Diode Selection

The switching diode should be a Schottky type to minimize

both forward and reverse recovery losses. Average diode

current is the same as output charging current, so this will be

under 2A. A 3A diode is recommended for most applications,

although smaller devices could be used at reduced charging

current.

Maximum diode reverse voltage will be equal to

input voltage plus battery voltage.

Diode reverse leakage current will be of some concern

during charger shutdown. This leakage current is a direct

drain on the battery when the charger is not powered. High

Page 9

LT1513/LT1513-2

U

WUU

APPLICATIONS INFORMATION

current Schottky diodes have relatively high leakage currents (5µ A to 500µA) even at room temperature. The latest

very-low-forward devices have especially high leakage currents. It has been noted that surface mount versions of some

Schottky diodes have as much as ten times the leakage of

their through-hole counterparts. This may be because a low

forward voltage process is used to reduce power dissipation

in the surface mount package. In any case, check leakage

specifications carefully before making a final choice for the

switching diode. Be aware that diode manufacturers want

to specify a maximum leakage current that is ten times

higher than the typical leakage. It is very difficult to get them

to specify a low leakage current in high volume production.

This is an on going problem for all battery charger circuits

and most customers have to settle for a diode whose typical

leakage is adequate, but theoretically has a worst-case

condition of higher than desired battery drain.

Thermal Considerations

Care should be taken to ensure that worst-case conditions

do not cause excessive die temperatures. Typical thermal

resistance is 30°C/W for the R package but this number will

vary depending on the mounting technique (copper area,

airflow, etc.).

Average supply current (including driver current) is:

ImA

=+4

IN

VI

BAT CHRG

V

IN

0 024()( )(.)

Switch power dissipation is given by:

2

CHRG SW BAT IN BAT

V

()

+()()( )()

2

IN

P

SW

IRVVV

=

RSW = Output switch ON resistance

Total power dissipation of the die is equal to supply current

times supply voltage, plus switch power:

P

D(TOTAL)

For VIN = 10V, V

= (IIN)(VIN) + P

= 8.2V, I

BAT

SW

= 1.2A, RSW = 0.3Ω,

CHRG

IIN = 4mA + 24mA = 28mA

PSW = 0.64W

PD = (10)(0.028) + 0.64 = 0.92W

GROUND PLANE

++

LT1513 TAB AND GROUND

PIN SOLDERED TO

GROUND PLANE

C5

R5

C1,C3,C5 AND R3

R3

TIED DIRECTLY TO

GROUND PLANE

Figure 4. LT1513 Suggested Partial Layout for Critical Thermal and Electrical Paths

C3

C1 C1

L1A L1B

+

V

C2

2 WINDING

INDUCTOR

V

IN

BAT

D1

LT1513 • F04

9

Page 10

LT1513/LT1513-2

U

WUU

APPLICATIONS INFORMATION

Programmed Charging Current

LT1513-2 charging current can be programmed with a DC

voltage source or equivalent PWM signal, as shown in

Figure 5. In constant-current mode, IFB acts as a virtual

ground. The I

voltage across R4 in the ratio R4/R5.

Charging current is given by:

I

CHARGE

IFB input current is small and can normally be ignored, but

IFB offset voltage must be considered if operating over a

wide range of program currents. The voltage across R3 at

maximum charge current can be increased to reduce

offset errors at lower charge currents. In Figure 5, I

from 0V to 5V corresponds to an I

+37/–62mA. C4 and R4 smooth the switch current waveform. During constant-current operation, the voltage feedback network loads the FB pin, which is held at V

IFB amplifier. It is recommended that this load does not

voltage across R5 is balanced by the

SET

VRRI

()(/)–45

ISET FBVOS

=

R

3

CHARGE

of 0A to 1A

REF

SET

by the

exceed 60µA to maintain a sharp constant voltage to

constant current crossover characteristic. I

CHARGE

can

also be controlled by a PWM input. Assuming the signal is

a CMOS rail-to-rail output with a source impedance of less

than a few hundred ohms, effective I

by the PWM ratio. I

CHARGE

has good linearity over the

is VCC multiplied

SET

entire 0% to 100% range.

Voltage Mode Loop Stability

The LT1513 operates in constant-voltage mode during the

final phase of charging lithium-ion and lead-acid batteries.

This feedback loop is stabilized with a series resistor and

capacitor on the VC pin of the chip. Figure 6 shows the

simplified model for the voltage loop. The error amplifier is

modeled as a transconductance stage with gm = 1500µ mho

LT1513-2

I

FB

R5

249k

I

SET

R4

10k

C4

0.1µF

L1B

R3

0.2Ω

1513 F05

MODULATOR SECTION

I

V14(VIN)

V1

**

C

P

3pF

RP**

V

C

R5

330Ω

C5

0.1µF

* FOR 8.4V BATTERY. ADJUST VALUE OF R1 FOR ACTUAL BATTERY VOLTAGE

** R

P

THIS IS A SIMPLIFIED AC MODEL FOR THE LT1513 IN CONSTANTVOLTAGE MODE. RESISTOR AND CAPACITOR NUMBERS

CORRESPOND TO THOSE USED IN FIGURE 1. R

THE PHASE DELAY IN THE MODULATOR. C3 IS 3pF FOR A 10µH

INDUCTOR. IT SHOULD BE SCALED PROPORTIONALLY FOR OTHER

INDUCTOR VALUES (6pF FOR 20µH). THE MODULATOR IS A

TRANSCONDUCTANCE WHOSE GAIN IS A FUNCTION OF INPUT AND

BATTERY VOLTAGE AS SHOWN.

1M

RG

330k

AND CP MODEL PHASE DELAY IN THE MODULATOR

P

g

= =

m

V

= DC INPUT VOLTAGE

IN

V

BAT

+ V

V

IN

= DC BATTERY VOLTAGE

–

EA

+

g

m

1500µmho

BAT

1.245V

AND CP MODEL

P

I

Figure 6. Constant-Voltage Small-Signal Model

Figure 5

P

R1*

71.5k

FB

+

R2

12.5k

AS SHOWN, THIS LOOP HAS A UNITY-GAIN FREQUENCY OF

ABOUT 250Hz. UNITY-GAIN WILL MOVE OUT TO SEVERAL

KILOHERTZ IF BATTERY RESISTANCE INCREASES TO SEVERAL

OHMS. R5 IS NOT USED IN ALL APPLICATIONS, BUT IT GIVES

BETTER PHASE MARGIN IN CONSTANT-VOLTAGE MODE WITH

HIGH BATTERY RESISTANCE.

C1C1

R

CAP

≈0.15Ω

EACH

+

C1

22µF

EACH

R

BAT

0.1Ω

BATTERY

1513 F06

10

Page 11

LT1513/LT1513-2

U

WUU

APPLICATIONS INFORMATION

(from the Electrical Characteristics). Amplifier output resistance is modeled with a 330k resistor. The power stage

(modulator section) of the LT1513 is modeled as a transconductance whose value is 4(VIN)/(VIN + V

simplified model of the actual power stage, but it is sufficient

when the unity-gain frequency of the loop is low compared

to the switching frequency. The output filter capacitor model

includes its ESR (R

). A series resistance (R

CAP

assigned to the battery model.

Analysis of this loop normally shows an extremely stable

system for all conditions, even with 0Ω for R5. The one

condition which can cause reduced phase margin is with a

very large battery resistance (>5Ω), or with the battery

replaced with a resistive load. The addition of R5 gives good

phase margin even under these unusual conditions. R5

should not be increased above 330Ω without checking for

two possible problems. The first is instability in the constant

current region (see Constant-Current Mode Loop Stability),

and the second is subharmonic switching where switch duty

cycle varies from cycle to cycle. This duty cycle instability is

caused by excess switching frequency ripple voltage on the

VC pin. Normally this ripple is very low because of the

filtering effect of C5, but large values of R5 can allow high

ripple on the VC pin. Normal loop analysis does not show this

). This is a very

BAT

) is also

BAT

problem, and indeed small signal loop stability can be

excellent even in the presence of subharmonic switching.

The primary issue with subharmonics is the presence of EMI

at frequencies below 500kHz.

Constant-Current Mode Loop Stability

The LT1513 is normally very stable when operating in constant-current mode (see Figure 7), but there are certain conditions which may create instabilities. The combination of

higher value current sense resistors (low programmed charging current), higher input voltages, and the addition of a loop

compensation resistor (R5) on the VC pin may create an unstable current mode loop. (A resistor is sometimes added in

series with C5 to improve loop phase margin when the loop

is operating in voltage mode.) Instability results

because loop gain is too high in the 50kHz to 150kHz region

where excess phase occurs in the current sensing amplifier

and the modulator. The I

amplifier (gain of –12.5) has a

FBA

pole at approximately 150kHz. The modulator section consisting of the current comparator, the power switch and the

magnetics, has a pole at approximately 50kHz when the

coupled inductor value is 10µH. Higher inductance will reduce

the pole frequency proportionally. The design procedure presented here is to roll off the loop to unity-gain at a frequency

of 25kHz or lower to avoid these excess phase regions.

V1

MODULATOR SECTION

C

RP**

FB

V

C

R5

330Ω

C5

0.1µF

THIS IS A SIMPLIFIED AC MODEL FOR THE LT1513 IN

CONSTANT-CURRENT MODE. RESISTOR AND CAPACITOR

NUMBERS CORRESPOND TO THOSE USED IN FIGURE 1.

AND CP MODEL THE PHASE DELAY IN THE PowerPath.

R

P

C3 IS 3pF FOR A 10µH INDUCTOR. IT SHOULD BE SCALED

PROPORTIONALLY FOR OTHER INDUCTOR VALUES (6pF

FOR 20µH). THE PowerPath IS A TRANSCONDUCTANCE

WHOSE GAIN IS A FUNCTION OF INPUT AND BATTERY

VOLTAGE AS SHOWN.

1M

R

G

330k

P

3pF

EA

g

m

1500µmho

–

+

I

=

P

1.245V

4(V1)(V

V

IN

Figure 7. Constant-Current Small-Signal Model

I

P

)

IN

+ V

BAT

R

A

100k

C

A

10pF

THE CURRENT AMPLIFIER HAS A FIXED VOLTAGE GAIN OF 12.

ITS PHASE DELAY IS MODELED WITH R

THE ERROR AMPLIFIER HAS A TRANSCONDUCTANCE OF

1500µmho AND AN INTERNAL OUTPUT SHUNT RESISTANCE OF

330k.

AS SHOWN, THIS LOOP HAS A UNITY-GAIN FREQUENCY OF

ABOUT 27kHz. R5 IS NOT USED IN ALL APPLICATIONS, BUT IT

GIVES BETTER PHASE MARGIN IN CONSTANT VOLTAGE MODE.

VOLTAGE

GAIN = 12

–

I

FBA

+

I

FB

AND CA.

A

R4

24Ω

C4

0.22µF

R3

0.1Ω

1513 F07

11

Page 12

LT1513/LT1513-2

U

WUU

APPLICATIONS INFORMATION

The suggested way to control unity loop frequency is to

increase the filter time constant on the IFB pin (R4/C4 in

Figures 1 and 7). The filter resistor cannot be arbitrarily

increased because high values will affect charging current

accuracy. Charging current will increase by 1% for each

40Ω increase in R4. There is no inherent limitation on the

value of C4, but if this capacitor is ceramic, it should be an

X7R type to maintain its value over temperature. X7R

dielectric requires a larger footprint.

The formula for calculating the minimum value for the filter

capacitor C4 is:

RV R

3 4 12 1500 5

()()()()( )()

C

4

=

VIN = Highest input voltage

1500µ = Transconductance of error amplifier

(EA)f = Desired unity-gain frequency

V

= Battery voltage

BAT

IN

fR V V

24

()( )( )

π

IN BAT

µ

+

For example, assume V

current set to 0.25A), R4 = 24Ω, R5 = 330Ω and V

0 4 4 15 12 0 0015 330

CF4

The value for C4 could be reduced to a more manageable size

by increasing R4 to 75Ω and reducing R5 to 300Ω, yielding

0.47µ F for C4. The 2% increase in charging current can be

ignored or factored into the value for R3.

More Help

Linear Technology Field Application Engineers have a CAD

spreadsheet program for detailed calculations of circuit

operating conditions. In addition, our Applications Department is always ready to lend a helping hand. The LT1371

data sheet may also be helpful. The LT1513 is identical

except for the current amplifier circuitry.

. ( )( )( )( . )( )

IN(MAX)

= 15V, R3 = 0.4Ω (charging

= 8V,

BAT

=

15 81=+

)6.3(25000)(39)(

µ

12

Page 13

U

TYPICAL APPLICATIONS

LT1513/LT1513-2

Lithium-Ion Battery Charger with

Switchable Charge Current

Many battery chemistries require several constant-current

settings during the charging cycle. The circuit shown in

Figure 8 uses the LT1513-2 to provide switchable 1.35A and

0.13A constant-current modes. The circuit is based on a

standard SEPIC battery charger circuit set to a single

lithium-ion cell charge voltage of 4.1V. The LT1513-2 has I

FB

referenced to ground allowing a simple resistor network to

set the charging current values. In constant-current mode,

the IFB error amplifier drives the FB pin, increasing charging

current, until IR4 is balanced by IR5.

L1A

V

IN

CHARGE

SHUTDOWN

PRECHARGE

CHARGE

3.3V

R6

10k

R7

910Ω

Q1

+

C3

25µF

25V

R3

330Ω

C5

0.1µF

CTX10-4

•

7

V

IN

6

S/S

LT1513-2

1

V

C

GND

V

SW

V

I

4

R5

36k

I

CHARGE

()()–

=

4

5

R FBVOS

R

3

IRI

There are several ways to control IR5 including DAC, PWM or

resistor network as shown here. If the lithium cell requires

precharging, Q1 is turned on, setting a constant current of

0.13A. When charge voltage is reached, Q1 is turned off,

programming the full charge current of 1.35A. As the cell

voltage approaches 4.1V, the voltage sensing network (R1,

R2) starts driving the VFB pin, changing the LT1513-2 to

constant-voltage mode. As charging current falls, the output

remains in constant-voltage mode for the remainder of the

charging cycle. When charging is complete, the LT1513-2

can be shut down with the S/S pin.

C2

4.7µF

5

2

FB

3

FB

R4

4.7k

C4

0.22µF

D1

MBRS330T3

L1B

•

R3

0.25Ω

R1

78.7k

0.5%

R2

34k

0.5%

+

Li-Ion

RECHARGABLE

CELL

C1

22µF

25V

×2

GND

1513 F08

Figure 8. Lithium-Ion Battery Charger

13

Page 14

LT1513/LT1513-2

U

TYPICAL APPLICATIONS

This Cold Cathode Fluorescent Lamp driver uses a Royer

class self-oscillating sine wave converter to driver a high

voltage lamp with an AC waveform. CCFL Royer converters

have significantly degraded efficiency if they must operate at

low input voltages, and this circuit was designed to handle

input voltages as low as 2.7V. Therefore, the LT1513 is

connected to generate a negative current through L2 that

allows the Royer to operate as if it were connected to a

constant higher voltage input.

2.7V

C1

TO 20V

C10

10nF

47µF

ELECT

+

V

6

S/S

2

V

FB

V

7

IN

C

1

D2

15V

C9

1µF

R7

2k

L1

20µH

LT1513-2

V

GND

R4

20k

C5

4.7nF

SW

5

I

FB

4, TAB

R3

3

C6

0.1µF

10k

R5

330k

The Royer output winding and the bulb are allowed to float in

this circuit. This can yield significantly higher efficiency in

situations where the stray bulb capacitance to surrounding

enclosure is high. To regulate bulb current in Figure 9, Royer

input

current is sensed with R2 and filtered with R3 and C6.

This negative feedback signal is applied to the IFB pin of the

LT1513. For more information on this circuit contact the LTC

Applications Department and see Design Note 133. Considerable written application literature on Royer CCFL circuits is

also available from other LTC Application and Design Notes.

R2

0.25Ω

12

•

Q1

5

NEGATIVE VOLTAGE

IS GENERATED HERE

T1

•

10

LAMP CURRENT

6

C4

27pF

3kV

CCFL

5.6mA

C2

4.7µF

CERAMIC

L2

20µH

D1

3A

Q2

C3

0.082µF

WIMA

3

•

4

R1

470Ω

14

PWM DIMMING

(≈1kHz)

C2: TOKIN MULTILAYER CERAMIC

C3: MUST BE A LOW LOSS CAPACITOR, WIMA MKP-20 OR EQUIVALENT

L1, L2: COILTRONICS CTX20-4 (MUST BE SEPARATE INDUCTORS)

Q1, Q2: ZETEX ZTX849 OR FZT849

T1: COILTRONICS CTX110605 (67:1)

Figure 9. CCFL Power Supply for Floaing Lamp Configuration Operates on 2.7V

1513 F09

Page 15

PACKAGE DESCRIPTION

LT1513/LT1513-2

U

Dimensions in inches (millimeters) unless otherwise noted.

R Package

7-Lead Plastic DD Pak

(LTC DWG # 05-08-1462)

0.256

(6.502)

0.060

(1.524)

0.300

(7.620)

BOTTOM VIEW OF DD PAK

HATCHED AREA IS SOLDER PLATED

COPPER HEAT SINK

0.060

(1.524)

0.075

(1.905)

0.183

(4.648)

0.060

(1.524)

TYP

0.330 – 0.370

(8.382 – 9.398)

+0.012

0.143

–0.020

+0.305

3.632

()

–0.508

0.026 – 0.036

(0.660 – 0.914)

0.390 – 0.415

(9.906 – 10.541)

15° TYP

0.040 – 0.060

(1.016 – 1.524)

0.165 – 0.180

(4.191 – 4.572)

T7 Package

7-Lead Plastic TO-220 (Standard)

(LTC DWG # 05-08-1422)

0.059

(1.499)

TYP

0.013 – 0.023

(0.330 – 0.584)

0.045 – 0.055

(1.143 – 1.397)

+0.008

0.004

–0.004

+0.203

0.102

()

–0.102

0.095 – 0.115

(2.413 – 2.921)

0.050 ± 0.012

(1.270 ± 0.305)

R (DD7) 0396

0.390 – 0.415

(9.906 – 10.541)

0.460 – 0.500

(11.684 – 12.700)

0.040 – 0.060

(1.016 – 1.524)

0.147 – 0.155

(3.734 – 3.937)

DIA

0.230 – 0.270

(5.842 – 6.858)

0.570 – 0.620

(14.478 – 15.748)

0.330 – 0.370

(8.382 – 9.398)

0.152 – 0.202

0.260 – 0.320

(6.604 – 8.128)

0.026 – 0.036

(0.660 – 0.914)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

(3.860 – 5.130)

0.165 – 0.180

(4.191 – 4.572)

0.700 – 0.728

(17.780 – 18.491)

0.135 – 0.165

(3.429 – 4.191)

0.620

(15.75)

TYP

0.045 – 0.055

(1.143 – 1.397)

0.095 – 0.115

(2.413 – 2.921)

0.013 – 0.023

(0.330 – 0.584)

0.155 – 0.195

(3.937 – 4.953)

T7 (TO-220) (FORMED) 1197

15

Page 16

LT1513/LT1513-2

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1239 Backup Battery Management System Charges Backup Battery and Regulates Backup Battery Output when

Main Battery Removed

LTC®1325 Microprocessor Controlled Battery Management System Can Charge, Discharge and Gas Gauge NiCd, NiMH and Pb-Acid Batteries

with Software Charging Profiles

LT1510 1.5A Constant-Current/Constant-Voltage Battery Charger Step-Down Charger for Li-Ion, NiCd and NiMH

LT1511 3.0A Constant-Current/Constant-Voltage Battery Charger Step-Down Charger that Allows Charging During Computer Operation and

with Input Current Limiting Prevents Wall-Adapter Overload

LT1512 SEPIC Constant-Current/Constant-Voltage Battery Charger Step-Up/Step-Down Charger for Up to 1A Current

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417 ● (408) 432-1900

FAX: (408) 434-0507

●

TELEX: 499-3977 ● www.linear-tech.com

1513fa LT/TP 0198 REV A 4K • PRINTED IN THE USA

LINEAR TE CHNOLO GY CORPOR ATION 1 996

Loading...

Loading...