Page 1

FEATURES

LT1507

500kHz Monolithic

Buck Mode Switching Regulator

■

Constant 500kHz Switching Frequency

■

Uses All Surface Mount Components

■

Operates with Inputs as Low as 4V

■

Saturated Switch Design (0.3Ω)

■

Cycle-by-Cycle Current Limiting

■

Easily Synchronizable

■

Inductor Size as Low as 2µH

■

Shutdown Current: 20µA

U

APPLICATIONS

■

Portable Computers

■

Battery-Powered Systems

■

Battery Charger

■

Distributed Power

U

DESCRIPTION

The LT®1507 is a 500kHz monolithic buck mode switching

regulator, functionally identical to the LT1375 but optimized for lower input voltage applications. It will operate

over a 4V to 15V input range, compared with 5.5V to 25V

for the LT1375. A 1.5A switch is included on the die along

with all the necessary oscillator, control and logic circuitry. High switching frequency allows a considerable

reduction in the size of external components. The topology

is current mode for fast transient response and good loop

stability. Both fixed output voltage (3.3V) and adjustable

parts are available.

A special high speed bipolar process and new design

techniques allow this regulator to achieve high efficiency

at a high switching frequency. Efficiency is maintained

over a wide output current range by keeping quiescent

supply current to 4mA and by utilizing a supply boost

capacitor to allow the NPN power switch to saturate. A

shutdown signal will reduce supply current to 20µA. The

LT1507 can be externally synchronized from 570kHz to

1MHz with logic level inputs.

The LT1507 fits into standard 8-pin SO and PDIP packages. Temperature rise is kept to a minimum by the high

efficiency design. Full cycle-by-cycle short-circuit protection and thermal shutdown are provided. Standard surface

mount external parts are used including the inductor and

capacitors.

, LTC and LT are registered trademarks of Linear Technology Corporation.

U

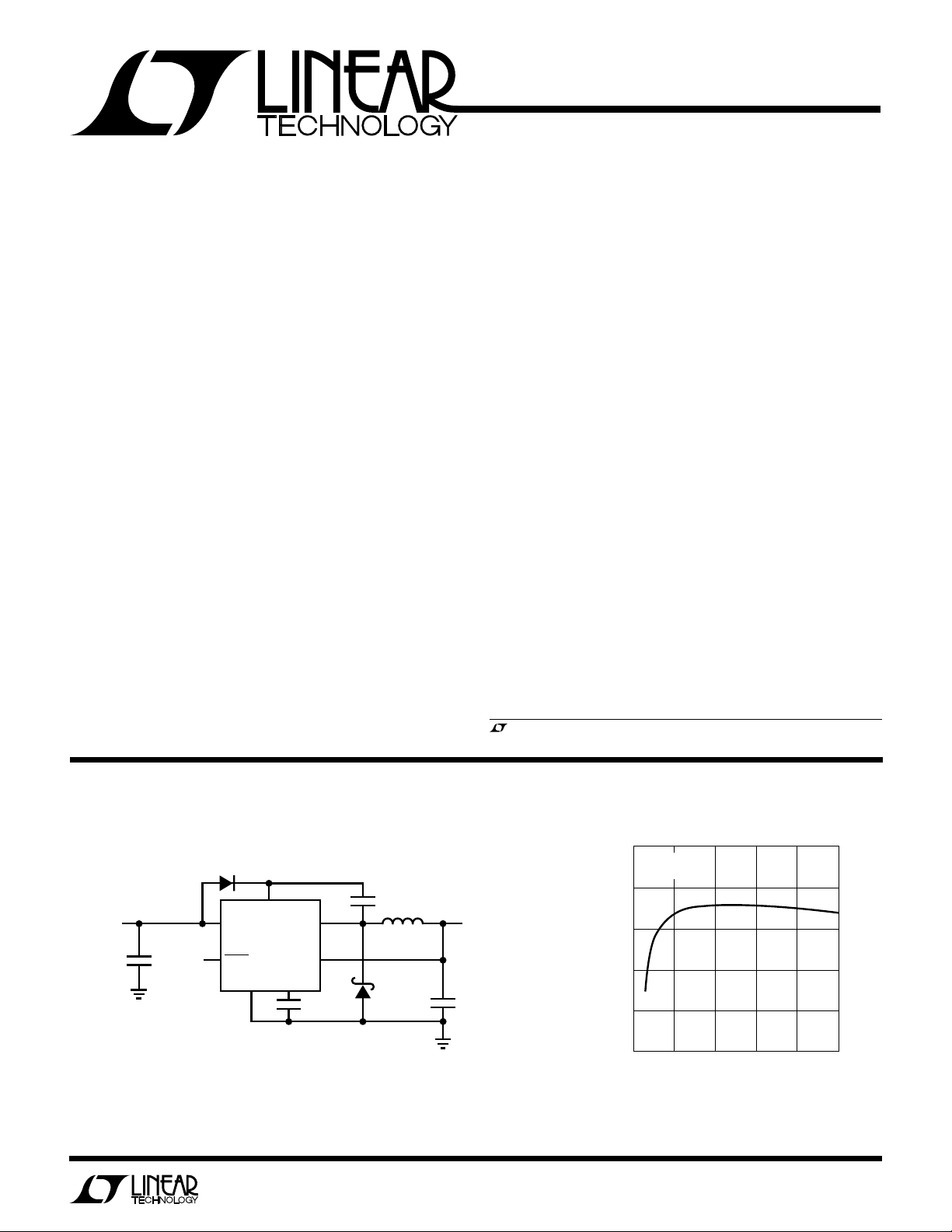

TYPICAL APPLICATION

5V to 3.3V Volt Down Converter

D2†

1N914

BOOST

= ON

V

IN

SHDN

GND V

LT1507-3.3

V

SW

SENSE

C

CC

3.3nF

5V

C3*

47µF

16V

TANTALUM

AVX TPSD477M016R0150 OR SPRAGUE 593D EQUIVALENT.

*

RIPPLE CURRENT RATING ≥ 0.6A

AVX TPSD108M010R0100 OR SPRAGUE 593D EQUIVALENT

**

COILTRONICS CTX5-1. SUBSTITUTION UNITS SHOULD BE RATED

***

AT ≥ 1.25A, USING LOW LOSS CORE MATERIAL

†

SEE BOOST PIN CONSIDERATIONS IN APPLICATIONS INFORMATION

SECTION FOR ALTERNATIVE D2 CONNECTION

+

DEFAULT

(OPEN)

C2

0.1µF

L1***

5µH

D1

1N5818

OUTPUT

3.3V

1.25A

C1**

+

100µF

10V

TANTALUM

100

VIN = 5V

V

OUT

90

80

70

EFFICIENCY (%)

60

50

0

5V to 3.3V Efficiency

= 3.3V

0.25

LOAD CURRENT (A)

0.50

0.75

1.00

1.25

LT1507 • TA02

1

Page 2

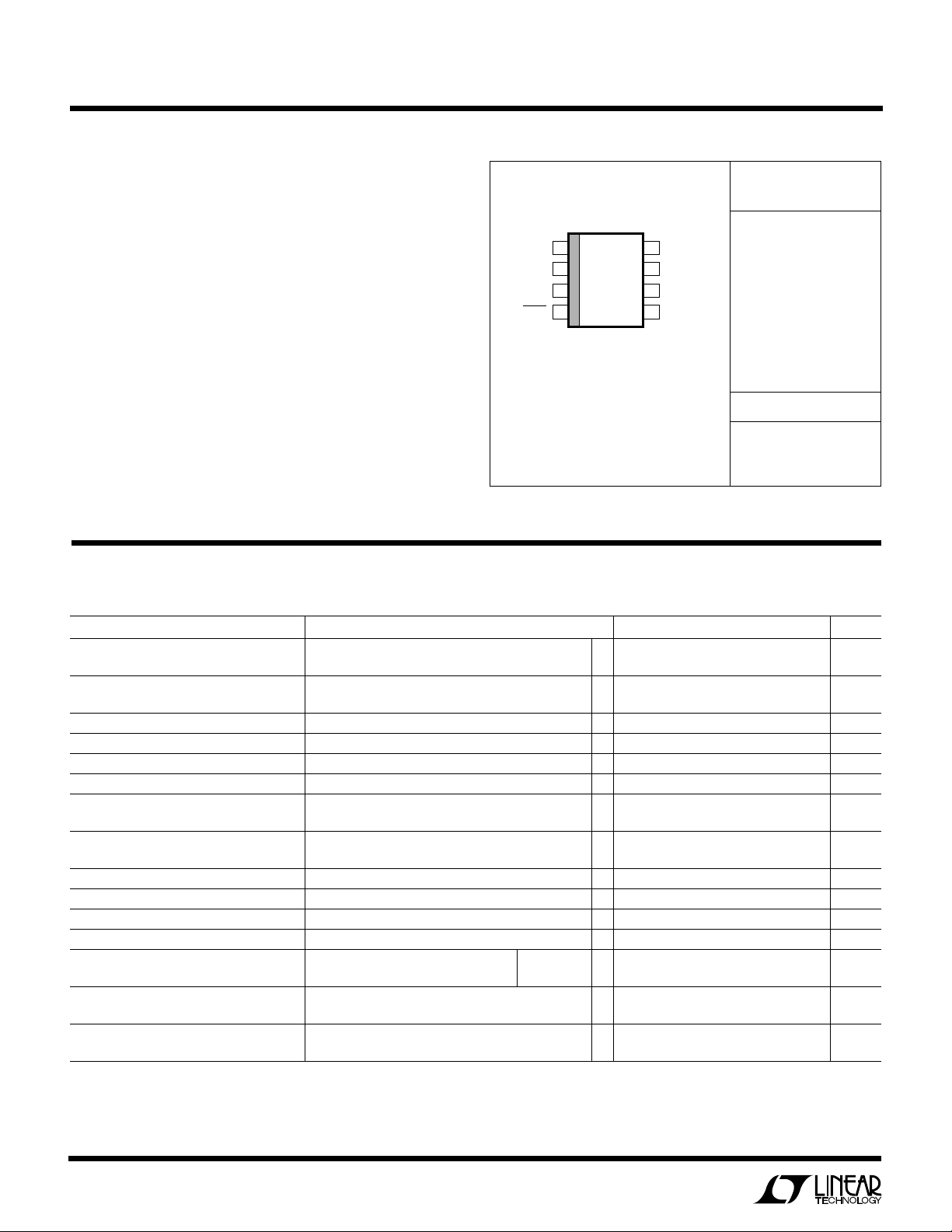

LT1507

1

2

3

4

8

7

6

5

TOP VIEW

V

C

FB/SENSE

GND

SYNC

BOOST

V

IN

V

SW

SHDN

N8 PACKAGE

8-LEAD PDIP

S8 PACKAGE

8-LEAD PLASTIC SO

WW

W

U

ABSOLUTE MAXIMUM RATINGS

Input Voltage ........................................................... 16V

Boost Pin Voltage .................................................... 25V

Shutdown Pin Voltage ............................................... 7V

FB Pin Voltage (Adjustable Part)............................. 3.5V

FB Pin Current (Adjustable Part)............................. 1mA

Sense Voltage (Fixed 3.3V Part) ................................ 5V

Sync Pin Voltage ....................................................... 7V

Operating Ambient Temperature Range

LT1507C.................................................. 0°C to 70°C

LT1507I .............................................. –40°C to 85°C

Max Operating Junction Temperature................... 125°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

U

W

PACKAGE/ORDER INFORMATION

ORDER PART

NUMBER

LT1507CN8

LT1507CN8-3.3

LT1507CS8

LT1507CS8-3.3

LT1507IN8

LT1507IN8-3.3

LT1507IS8

LT1507IS8-3.3

T

= 125°C, θJA = 80°C/W TO 120°C/ W (N)

JMAX

= 125°C, θJA = 120°C/W TO 170°C/ W (S)

T

JMAX

DEPENDING ON PC BOARD LAYOUT

Consult factory for Military grade parts.

S8 PART MARKING

1507

15073

1507I

1507I3

U

ELECTRICAL CHARACTERISTICS

TJ = 25°C, VIN = 5V, VC = 1.5V, boost open, switch open unless otherwise specified.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Reference Voltage (Adjustable) 2.39 2.42 2.45 V

All Conditions ● 2.36 2.48 V

Sense Voltage (3.3V) 3.25 3.3 3.35 V

All Conditions ● 3.23 3.37 V

Sense Pin Resistance ● 4.0 6.6 9.5 kΩ

Reference Voltage Line Regulation 4.3V ≤ VIN ≤ 15V ● 0.01 0.03 %/V

FB Input Bias Current ● 0.5 2 µA

Error Amplifier Voltage Gain (Note 8) (Note 1) 150 400

Error Amplifier Transconductance (Note 8) ∆I(V

Pin to Switch Current

V

C

Transconductance 2 A/V

Error Amplifier Source Current VFB = 2.1V or V

Error Amplifier Sink Current VFB = 2.7V or V

VC Pin Switching Threshold Duty Cycle = 0 0.9 V

VC Pin High Clamp VFB = 2.1V or V

Switch Current Limit VC Open, VFB = 2.1V or V

Switch On Resistance (Note 6) ISW = 1.5A, V

Maximum Switch Duty Cycle VFB = 2.1V or V

) = ±10µA 1500 2000 2700 µmho

C

VIN ≥ 5V, V

= 2.9V ● 150 225 320 µA

SENSE

= 3.7V 2 mA

SENSE

= 2.9V 2.1 V

SENSE

= 2.9V DC ≤ 50% ● 1.50 2 3 A

SENSE

= VIN + 5V DC = 80% ● 1.35 3 A

BOOST

= VIN + 5V 0.3 0.4 Ω

BOOST

= 2.9V 90 93 %

SENSE

● 1100 3000 µmho

● 0.5 Ω

● 86 93 %

2

Page 3

LT1507

JUNCTION TEMPERATURE (°C)

–50

2.44

2.43

2.42

2.41

2.40

100

LT1507 • TPC03

–25 0 25 50 75 125

FEEDBACK VOLTAGE (V)

CURRENT (µA)

2.0

1.5

1.0

0.5

0

VOLTAGE

CURRENT

ELECTRICAL CHARACTERISTICS

TJ = 25°C, VIN = 5V, VC = 1.5V, boost open, switch open unless otherwise specified.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Switch Frequency VC Set to Give 50% Duty Cycle 460 500 540 kHz

–25°C ≤ T

TJ ≤ –25°C 440 570 kHz

Switch Frequency Line Regulation 4.3V ≤ VIN ≤ 15V ● 0.05 0.15 %/V

Frequency Shifting Threshold on FB Pin ∆f = 10kHz ● 0.8 1.0 1.3 V

Minimum Input Voltage (Note 2) ● 4 4.3 V

Minimum Boost Voltage (Note 3) ISW ≤ 1.5A ● 3 3.5 V

Boost Current (Note 4) V

BOOST

Input Supply Current (Note 5) ● 3.8 5.4 mA

Shutdown Supply Current V

SHDN

VSW = 0V, VC Open ● 75 µA

Lockout Threshold VC Open ● 2.3 2.38 2.46 V

Shutdown Threshold V

C

Minimum Synchronizing Amplitude ● 1.5 2.2 V

Synchronizing Frequency Range (Note 7) 580 1000 kHz

≤ 125°C 440 560 kHz

J

= VIN + 5V ISW = 500mA, –25°C ≤ TJ ≤ 125°C1222mA

T

≤ –25°C25mA

I

= 1.5A, –25°C ≤ TJ ≤ 125°C2535mA

SW

J

T

≤ –25°C40mA

J

= 0V, VIN ≤ 12V 15 50 µA

Open Device Shutting Down ● 0.15 0.37 0.70 V

Device Starting Up ● 0.25 0.45 0.70 V

● denotes specifications which apply over the operating temperature

The

range.

Note 1: Gain is measured with a V

clamp level to 200mV below the upper clamp level.

Note 2: Minimum input voltage is not measured directly, but is guaranteed

by other tests. It is defined as the voltage where internal bias lines are still

regulated, so that the reference voltage and oscillator frequency remain

constant. Actual minimum input voltage to maintain a regulated output will

depend on output voltage and load current. See Applications Information.

Note 3: This is the minimum voltage across the boost capacitor needed to

guarantee full saturation of the internal power switch.

Note 4: Boost current is the current flowing into the BOOST pin with the

pin held 5V above input voltage. It flows only during switch ON time.

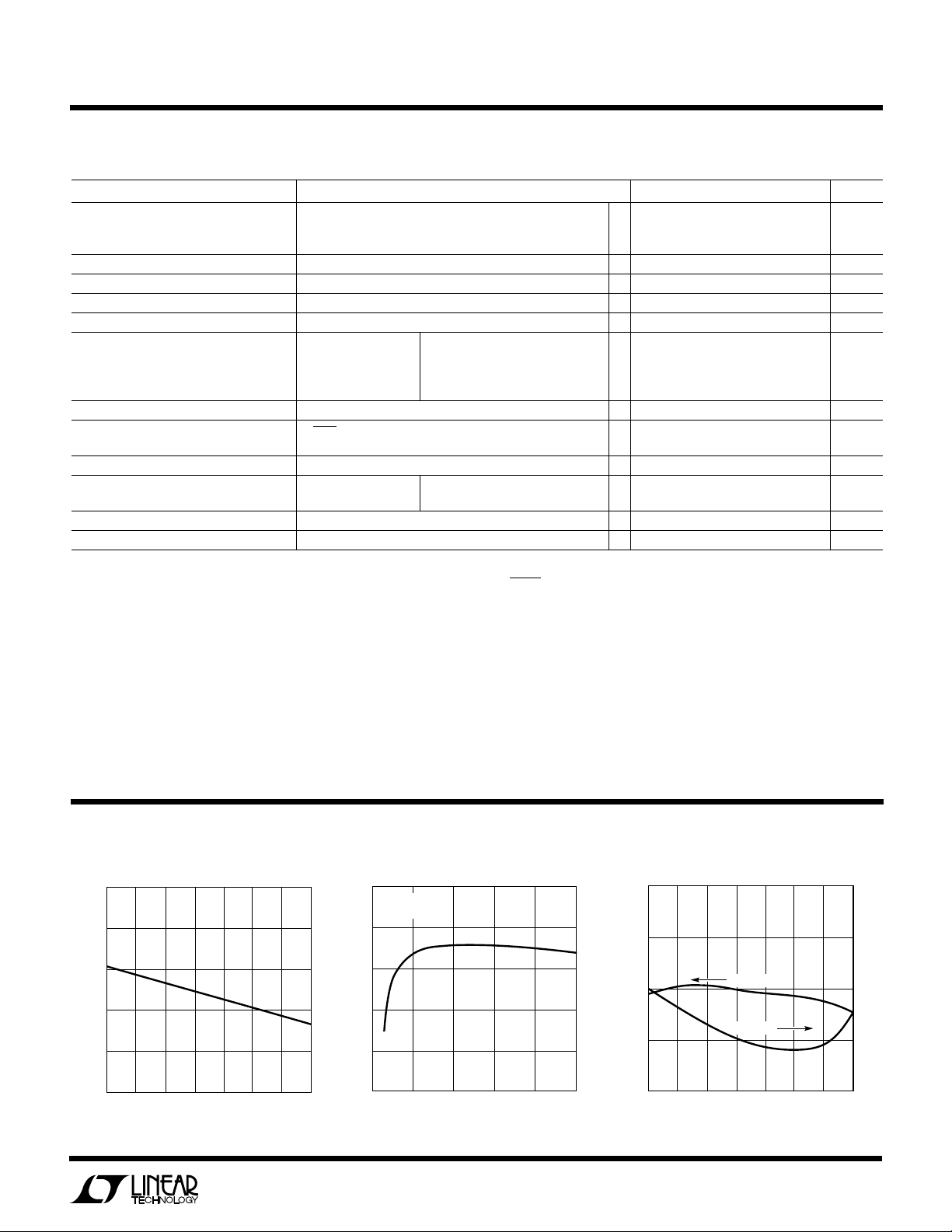

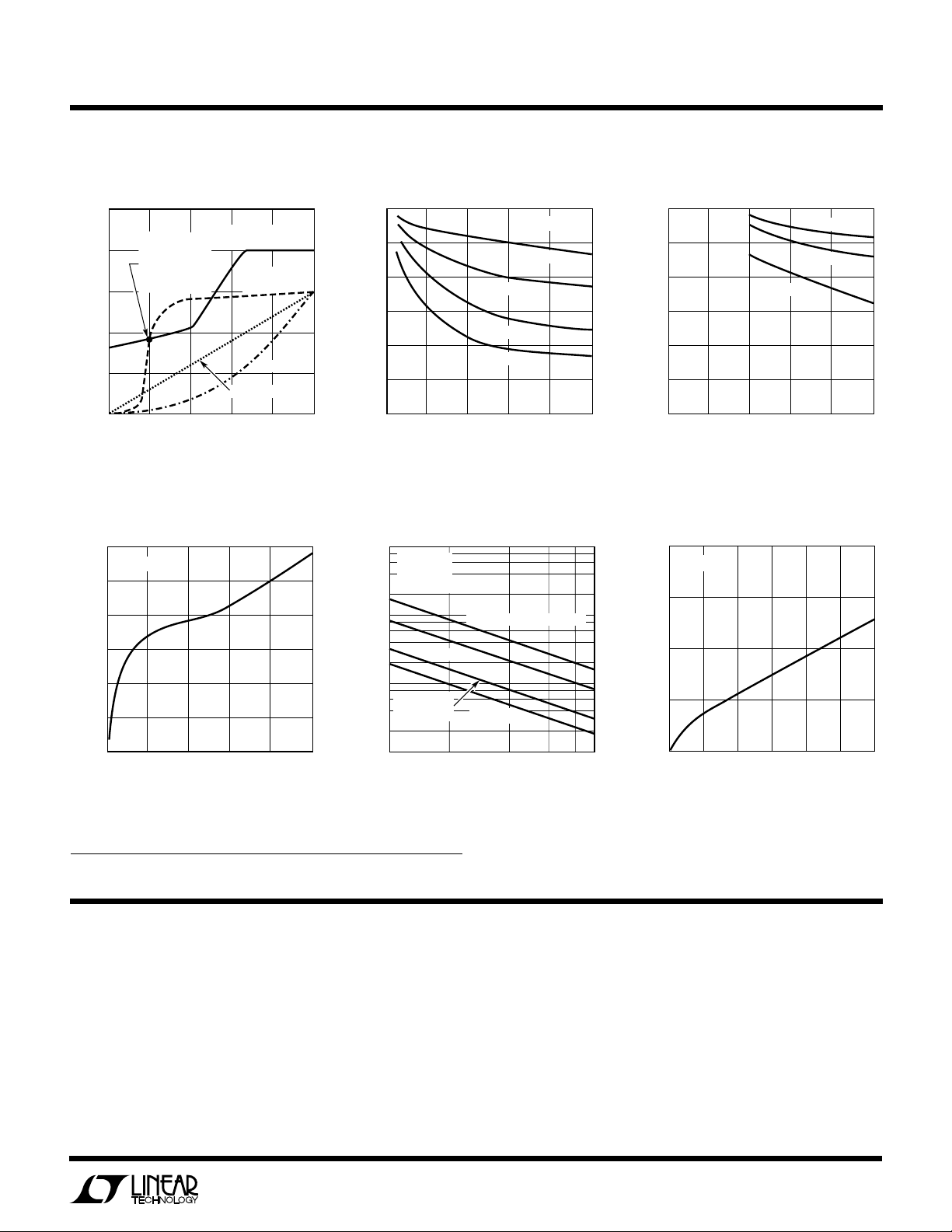

TYPICAL PERFORMANCE CHARACTERISTICS

1.4

1.2

1.0

0.8

THRESHOLD VOLTAGE (V)

0.6

0.4

C

VC Pin Shutdown Threshold

–25 0 25 50 75 125

–50

JUNCTION TEMPERATURE (°C)

swing equal to 200mV above the low

W

U

Switch Peak Current Limit Feedback Pin Voltage and Current

100

VIN = 5V

= 3.3V

V

OUT

90

100

LT1507 • TPC01

80

70

EFFICIENCY (%)

60

50

0

0.25

0.50

LOAD CURRENT (A)

Note 5: Input supply current is the bias current drawn by the V

pin when

IN

the SHDN pin is held at 1V (switching disabled).

Note 6: Switch ON resistance is calculated by dividing V

to VSW voltage

IN

by the forced current (1.5A). See Typical Performance Characteristics for

the graph of switch voltage at other currents.

Note 7: For synchronizing frequency above 700kHz, with duty cycles

above 50%, external slope compensation may be needed. See Applications

Information.

Note 8: Transconductance and voltage gain refer to the internal amplifier

exclusive of the voltage divider. To calculate gain and transconductance

refer to SENSE pin on fixed voltage parts. Divide values shown by the ratio

/2.42.

V

OUT

0.75

1.00

1.25

LT1507 • TA02

3

Page 4

LT1507

INPUT VOLTAGE (V)

0

0

INPUT SUPPLY CURRENT (µA)

5

10

15

20

25

30

36912

LT1507 • TPC06

15

V

SHDN

= 0V

FREQUENCY (Hz)

GAIN (µmho)

PHASE (DEG)

3000

2500

2000

1500

1000

500

200

150

100

50

0

–50

100 10k 100k 10M

LT1507 • TPC09

1k 1M

GAIN

PHASE

R

OUT

200k

C

OUT

12pF

V

C

V

FB

× 2e

–3

ERROR AMPLIFIER EQUIVALENT CIRCUIT

R

LOAD

= 50Ω

LOAD CURRENT (mA)

1

5.0

INPUT VOLTAGE (V)

5.5

6.0

6.5

10 100 1000

LT1507 • TPC12

4.5

4.0

3.5

3.0

MINIMUM VOLTAGE

TO START WITH

STANDARD CIRCUIT

MINIMUM VOLTAGE

TO RUN WITH

STANDARD CIRCUIT

MINIMUM INPUT VOLTAGE CAN BE REDUCED

BY ADDING A SMALL EXTERNAL PNP. SEE

APPLICATIONS INFORMATION

W

U

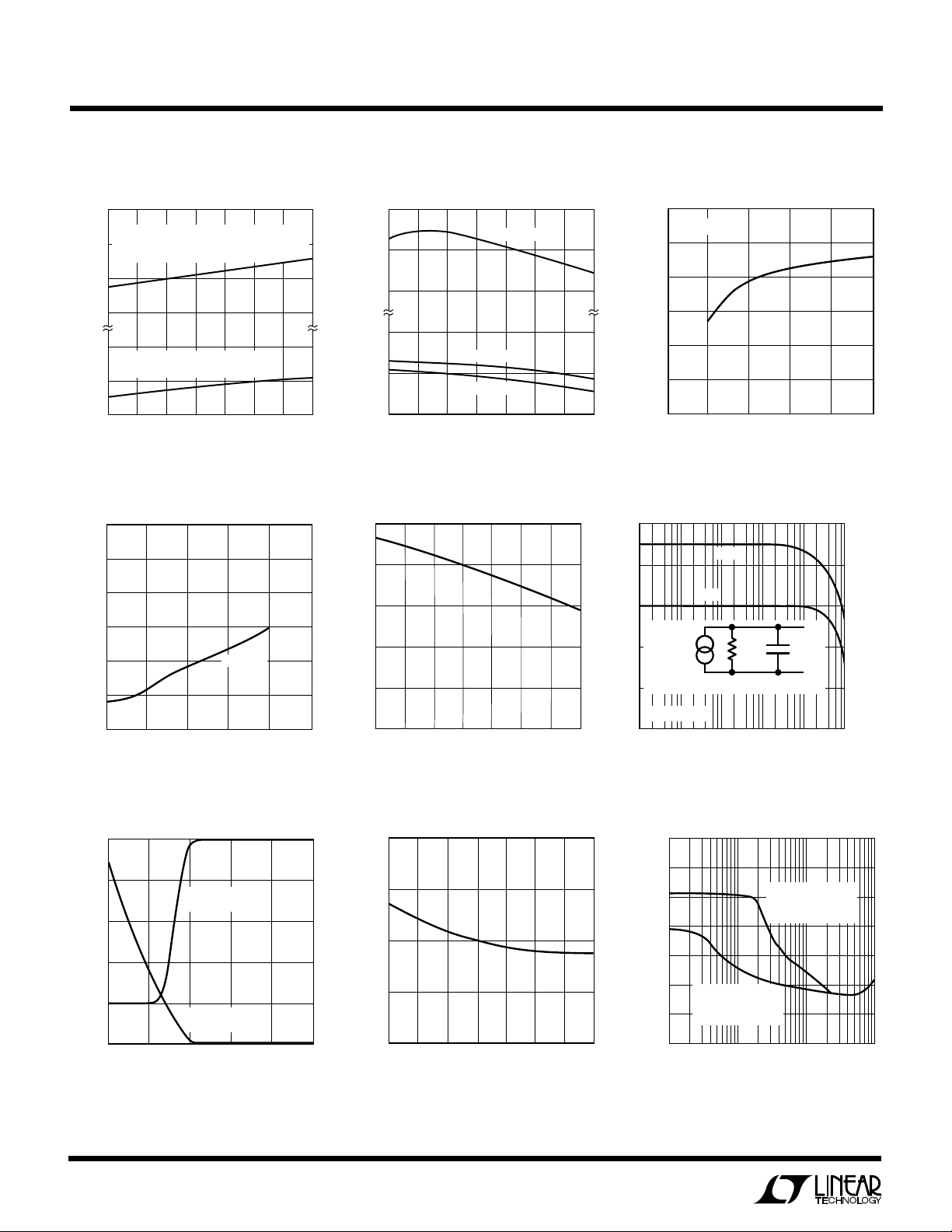

TYPICAL PERFORMANCE CHARACTERISTICS

Shutdown Pin Bias Current

500

CURRENT REQUIRED TO FORCE SHUTDOWN

(FLOWS OUT OF PIN). AFTER SHUTDOWN,

400

CURRENT DROPS TO A FEW µA

300

200

CURRENT (µA)

8

AT 2.38V STANDBY THRESHOLD

(CURRENT FLOWS OUT OF PIN)

4

0

–50

–25 0

25 75

TEMPERATURE (°C)

50 100 125

L11507 • TPC04

Standby and Shutdown Thresholds

2.40

STANDBY

2.36

2.32

0.8

STARTUP

0.4

SHUTDOWN PIN VOLTAGE (V)

0

–50

–25 0

SHUTDOWN

50 100 125

25 75

JUNCTION TEMPERATURE (°C)

Shutdown Supply Current Error Amplifier Transconductance

150

125

100

75

50

INPUT SUPPLY CURRENT (µA)

25

VIN = 10V

2500

2000

1500

1000

500

TRANSCONDUCTANCE (µmho)

Shutdown Supply Current

LT1507 • TPC05

Error Amplifier Transconductance

0

0.1 0.2 0.3 0.4

0

SHUTDOWN VOLTAGE (V)

Frequency Foldback

500

400

300

200

100

0

SWITCHING FREQUENCY (kHz) OR CURRENT (µA)

0

4

SWITCHING

FREQUENCY

FEEDBACK PIN

CURRENT

0.5

1.0

FEEDBACK PIN VOLTAGE (V)

LT1507 • TPC07

0.5

0

–50

0

–25

JUNCTION TEMPERATURE (°C)

50

25

75

100

LT1507 • TPC08

125

Minimum Input Voltage

with 3.3V OutputSwitching Frequency

600

550

500

2.0

LT1507 • TPC10

2.5

1.5

FREQUENCY (kHz)

450

400

–25 0 25 50 75 125

–50

JUNCTION TEMPERATURE (°C)

100

LT1507 • TPC11

Page 5

W

INPUT VOLTAGE (V)

0

0

CURRENT (A)

0.25

0.50

0.75

1.00

1.25

1.50

36912

LT1507 • TPC15

15

L = 10µH

L = 5µH

L = 20µH

U

TYPICAL PERFORMANCE CHARACTERISTICS

LT1507

Current Limit Foldback

2.5

2.0

1.5

1.0

OUTPUT CURRENT (A)

0.5

*POSSIBLE

UNDESIRED

STABLE POINT

FOR CURRENT

SOURCE LOAD

0

20

0

OUTPUT VOLTAGE (%)

*SEE "MORE THAN JUST VOLTAGE FEEDBACK"

IN APPLICATIONS INFORMATION SECTION

FOLDBACK

CHARACTERISTICS

60

40

RESISTOR LOAD

Boost Pin Current

12

TJ = 25°C

10

8

CURRENT

SOURCE LOAD

MOS LOAD

80

LT1507 • TPC13

100

Maximum Load Current

at V

= 3.3V

1.50

1.25

1.00

0.75

CURRENT (A)

0.50

0.25

OUT

V

L = 10µH

L = 5µH

L = 3µH

L = 2µH

0

4

6 8 10 12

INPUT VOLTAGE (V)

Inductor Core Loss for 3.3V Output

1.0

V

= 3.3V

OUT

= 5V

V

IN

= 1A

I

OUT

0.1

TYPE 52 POWDERED IRON

OUT

= 3.3V

LT1507 • TPC14

Maximum Load Current

at V

= 5V

OUT

14

Switch Voltage Drop

0.8

TJ = 25°C

0.6

6

4

BOOST PIN CURRENT (mA)

2

0

0.25 0.50 0.75 1.00

0

Kool Mµ is a registered trademark of Magnetics, Incorporated.

Metglas is a registered trademark of AlliedSignal Incorporated.

SWITCH CURRENT (A)

1.25

LT1507 • TPC16

CORE LOSS (W)

0.01

PERMALLOY

0.001

1

CORE LOSS IS INDEPENDENT OF LOAD CURRENT

UNTIL LOAD CURRENT FALLS LOW ENOUGH

FOR CIRCUIT TO GO INTO DISCONTINUOUS MODE

®

Kool Mµ

µ = 125

246810

INDUCTANCE (µH)

UUU

PIN FUNCTIONS

BOOST (Pin 1): The BOOST pin is used to provide a drive

voltage, higher than the input voltage, to the internal

bipolar NPN power switch. Without this added voltage the

typical switch voltage loss would be about 1.5V. The

additional boost voltage allows the switch to saturate and

voltage loss approximates that of a 0.3Ω FET structure,

but with a much smaller die area. Efficiency improves from

0.4

SWITCH VOLTAGE (V)

0.2

0

0.25 0.50 0.75 1.00

0

SWITCH CURRENT (A)

1.25 1.50

LT1507 • TPC18

Metglas

®

LT1507 • TPC17

70% for conventional bipolar designs to greater than 85%

for these new parts.

VIN (Pin 2): Input Pin. The LT1507 is designed to operate

with an input voltage between 4.5V and 15V. Under certain

conditions, input voltage may be reduced down to 4V.

Actual minimum operating voltage will always be higher

than the output voltage. It may be limited by switch

5

Page 6

LT1507

PIN FUNCTIONS

UUU

saturation voltage and maximum duty cycle. A typical

value for minimum input voltage is 1V above output

voltage. Start-up conditions may require more voltage at

light loads. See Minimum Input Voltage for details.

VSW (Pin 3): The switch pin is driven up to the input voltage

in the ON state and is an open circuit in the OFF state. At

higher load currents, pin voltage during the off condition

will be one diode drop below ground as set by the external

catch diode. At lighter loads the pin will assume an

intermediate state equal to output voltage during part of

the switch OFF time. Maximum

switch pin is 1V with respect to the GND pin, so it must

always be clamped with a catch diode to the GND pin.

SHDN (Pin 4): The shutdown pin is used to turn off the

regulator and to reduce input drain current to a few

microamperes. Actually this pin has two separate thresholds, one at 2.38V to disable switching and a second at

0.4V to force complete micropower shutdown. The 2.38V

threshold functions as an accurate undervoltage lockout

(UVLO). This is sometimes used to prevent the regulator

from delivering power until the input voltage has reached

a predetermined level.

negative

voltage on the

SYNC (Pin 5): The SYNC pin is used to synchronize the

internal oscillator to an external signal. It is directly logic

compatible and can be driven with any signal between

10% and 90% duty cycle. The synchronizing range is

equal to

Sychronizing section for details.

FB/SENSE (Pin 7): The feedback pin is used to set output

voltage using an external voltage divider that generates

2.42V at the pin with the desired output voltage. The fixed

voltage (– 3 .3V) parts have the divider included on the chip

and the feedback pin is used as a sense pin connected

directly to the 5V output. Two additional functions are

performed by the feedback pin. When the pin voltage

drops below 1.7V, switch current limit is reduced. Below

1V, switching frequency is also reduced. See More Than

Just Voltage Feedback.

VC (Pin 8): The VC pin is the output of the error amplifier

and the input of the peak switch current comparator. It is

normally used for frequency compensation but can do

double duty as a current clamp or control loop override.

This pin sets at about 1V for very light loads and 2V at

maximum load. It can be driven to ground to shut off the

regulator, but if driven high, current must be limited to 4mA.

initial

operating frequency up to 1MHz. See

W

BLOCK DIAGRAM

The LT1507 is a constant frequency, current mode buck

converter. This means that there is an internal clock and

two feedback loops that control the duty cycle of the power

switch. In addition to the normal error amplifier, there is

a current sense amplifier that monitors switch current on

a cycle-by-cycle basis. A switch cycle starts with an

oscillator pulse which sets the RS flip-flop to turn the

switch on. When switch current reaches a level set by the

inverting input of the comparator, the flip-flop is reset and

the switch turns off. Output voltage control is obtained by

using the output of the error amplifier to set the switch

current trip point. This technique means that the error

amplifier commands current to be delivered to the output

rather than voltage. A voltage fed system will have low

phase shift up to the resonant frequency of the inductor

and output capacitor, then an abrupt 180° shift will occur.

The current fed system will have 90° phase shift at a much

lower frequency, but will not have the additional 90° shift

until well beyond the LC resonant frequency. This makes

it much easier to frequency compensate the feedback loop

and also gives much quicker transient response.

High switch efficiency is attained by using the BOOST pin

to provide a voltage to the switch driver which is higher

than the input voltage, allowing the switch to be saturated.

This boosted voltage is generated with an external capacitor and diode.

Two comparators are connected to the shutdown pin. One

has a 2.38V threshold for undervoltage lockout and the

second has a 0.4V threshold for complete shutdown.

6

Page 7

BLOCK DIAGRAM

LT1507

W

V

BIAS

SYNC

SHDN

IN

2

5

SHUTDOWN

COMPARATOR

4

2.9V BIAS

REGULATOR

+

0.4V

3.5µA

+

–

2.38V

–

LOCKOUT

COMPARATOR

INTERNAL

V

CC

SLOPE COMP

500kHz

OSCILLATOR

0.1Ω

+

–

CURRENT

SENSE

AMPLIFIER

VOLTAGE GAIN = 5

BOOST

Σ

8

0.9V

+

–

FOLDBACK

CURRENT

LIMIT

CLAMP

V

C

CURRENT

COMPARATOR

Q2

S

R

S

FLIP-FLOP

R

FREQUENCY

SHIFT CIRCUIT

ERROR

AMPLIFIER

g

= 2000µmho

m

DRIVER

CIRCUITRY

–

+

2.42V

1

Q1

POWER

SWITCH

V

3

SW

7

FB/SENSE

Figure 1. Block Diagram

U

WUU

APPLICATIONS INFORMATION

Note: This application section is adapted from the more

complete version found in the LT1375/LT1376 data sheet.

If more details are desired consult the LT1375/LT1376

Applications Information section, but please acquaint

yourself thoroughly with this LT1507 information first so

that differences between the LT1375 and the LT1507 do

not cause confusion.

6

GND

LT1507 • BD

FEEDBACK PIN FUNCTIONS

The feedback pin (FB or SENSE) on the LT1507 is used to

set output voltage and also to provide several overload

protection features. The first part of this section deals with

selecting resistors to set output voltage and the remaining

part talks about foldback frequency and current limiting

created by the FB pin. Please read both parts before

7

Page 8

LT1507

U

WUU

APPLICATIONS INFORMATION

committing to a final design. The fixed 3.3V LT1507-3.3

has internal divider resistors and the FB pin is renamed

SENSE, connected directly to the output.

The suggested value for the output divider resistor from FB

to ground (R2) is 5k or less and the formula for R1 is

shown below. The output voltage error caused by ignoring

the input bias current on the FB pin is less than 0.25% with

R2 = 5k. Please read below if R2 is increased above the

suggested value.

R2(V – 2.42)

R1

=

More Than Just Voltage Feedback

The feedback pin is used for more than just output voltage

sensing. It also reduces switching frequency and current

limit when output voltage is very low (see graph in Typical

Performance Characteristics). This is done to control

power dissipation in both the IC and in the external diode

and inductor during short-circuit conditions. A shorted

output requires the switching regulator to operate at very

low duty cycles and the average current through the diode

and inductor is equal to the short-circuit current limit of the

switch (typically 2A of the LT1507, folding back to less

than 1A). Minimum switch ON time limitations would

prevent the switcher from attaining a sufficiently low duty

cycle if switching frequency were maintained at 500kHz,

so frequency is reduced by about 5:1 when the feedback

OUT

2.42

pin voltage drops below 1V (see Frequency Foldback

graph). This does not affect operation with normal load

conditions; one simply sees a gear shift in switching

frequency during start-up as the output voltage rises.

In addition to lower switching frequency, the LT1507 also

operates at lower switch current limit when the feedback

pin voltage drops below 1.5V. This

foldback current limit

greatly reduces power dissipation in the IC, diode and

inductor during short-circuit conditions. Again, it is nearly

transparent to the user under normal load conditions. The

only loads which may be affected are current source loads

which maintain full-load current with output voltage less

than 50% of final value. In these rare situations, the

feedback pin can be clamped above 1.5V with an external

diode to defeat foldback current limit.

Caution

: clamping

the feedback pin means that frequency shifting will also be

defeated, so a combination of high input voltage and dead

shorted output may cause the LT1507 to lose control of

current limit.

The internal circuitry which forces reduced switching

frequency also causes current to flow out of the feedback

pin when output voltage is low. If the FB pin falls below 1V,

current begins to flow out of the pin and reduces frequency

at the rate of approximately 5kHz/µ A. To ensure adequate

frequency foldback (under worst-case short-circuit conditions) the external divider Thevinin resistance must be

low enough to pull 150µ A out of the FB pin with 0.6V on the

8

BOOST

= ON

V

IN

SHDN

GND V

V

IN

C3*

33µF

20V

TANTALUM

AVX TPSD337M020R0200 OR SPRAGUE 593 EQUIVALENT.

*

RIPPLE CURRENT RATING ≥ 0.6A

AVX TPSD108M010R0100 OR SPRAGUE 593 EQUIVALENT

**

COILTRONICS CTX5-1. SUBSTITUTION UNITS SHOULD BE RATED

***

AT ≥ 1.25A, USING LOW LOSS CORE MATERIAL. LOAD CURRENTS

ABOVE 0.85A MAY NEED A 10µH OR 20µH INDUCTOR

+

DEFAULT

(OPEN)

Figure 2. Typical Schematic for LT1507 Adjustable Application

LT1507

V

SW

FB

C

CC

3.3nF

D2

1N914

C2

0.1µF

L1***

5µH

D1

1N5818

R1

5.36k

R2

4.99k

OUTPUT

5V

C1**

+

100µF

10V

TANTALUM

LT1507 • F01

Page 9

LT1507

U

WUU

APPLICATIONS INFORMATION

pin (R

in frequency and current limit are affected by output

voltage divider impedance. Although divider impedance is

not critical, caution should be used if resistors are

increased beyond the suggested values and short-circuit

conditions will occur with high input voltage.

frequency pickup will also increase and the protection

accorded by frequency and current foldback will decrease.

CHOOSING THE INDUCTOR AND OUTPUT CAPACITOR

For most applications the value of the inductor will fall in

the range of 2µH to 10µH. Lower values are chosen to

reduce physical size of the inductor. Higher values allow

more output current because they reduce peak current

seen by the LT1507 switch, which has a 1.5A limit. Higher

values also reduce output ripple voltage and reduce core

loss. Graphs in the Typical Performance Characteristics

section show maximum output load current versus inductor size and input voltage. A second graph shows core loss

versus inductor size for various core materials.

When choosing an inductor you might have to consider

maximum load current, core and copper losses, allowable

component height, output voltage ripple, EMI, fault current in the inductor, saturation and, of course, cost. The

following procedure is suggested as a way of handling

these somewhat complicated and conflicting requirements.

1. Choose a value in microhenries from the graphs of

= R1/R2 ≤ 4k).

DIV

Maximum Load Current and Inductor Core Loss for

3.3V Output. If you want to double check that the

chosen inductor

go to the next section, Maximum Output Load Current.

Choosing a small inductor with lighter loads may result

in discontinuous mode of operation, but the LT1507 is

designed to work well in either mode. Keep in mind that

lower core loss means higher cost, at least for closedcore geometries like toroids. Type 52 powdered iron,

Kool Mµ and Molypermalloy are old standbys for tor-

oids in ascending order of price. A newcomer, Metglas,

gives very low core loss with high saturation current.

Assume that the average inductor current is equal to

load current and decide whether or not the inductor

must withstand continuous fault conditions. If maximum load current is 0.5A, for instance, a 0.5A inductor

The net result is that reductions

value

will allow sufficient load current,

High

may not survive a continuous 1.5A overload condition.

Dead shorts (V

the inductor because the LT1507 has foldback current

limiting (see graph in Typical Performance Characteristics).

2. Calculate peak inductor current at full load current to

ensure that the inductor will not saturate. Peak current

can be significantly higher than output current, especially with smaller inductors and lighter loads, so don’t

omit this step. Powdered iron cores are forgiving

because they saturate softly, whereas ferrite cores

saturate abruptly. Other core materials fall in between

somewhere. The following formula assumes a continuous mode of operation, but it errs only slightly on

the high side for discontinuous mode, so it can be used

for all conditions.

II

=+

PEAK OUT

VIN = Maximum input voltage

f = Switching frequency = 500kHz

3. Decide if the design can tolerate an “open” core geom-

etry like ferrite rods or barrels, which have high magnetic field radiation or whether it needs a closed core

like a toroid to prevent EMI problems. One would not

want an open core next to a magnetic storage media for

instance! This is a tough decision because the rods or

barrels are temptingly cheap and small and there are no

helpful guidelines to calculate when the magnetic field

radiation will be a problem. The following is an example

of just how subtle the “B” field problems can be with

open geometry cores.

We had selected an open drum shaped ferrite core for

the LTC1376 demonstration board because the inductor was extremely small and inexpensive. It met all the

requirements for current and the ferrite core gave low

core loss. When the boards came back from assembly,

many of them had somewhat higher than expected

output ripple voltage. We removed the inductors and

output capacitors and found them to be no different

than the good boards. After much head scratching and

hours of delicate low level ripple measurements on the

good and bad boards, I realized that the problem must

≤ 1V) will actually be more gentle on

OUT

VVV

(– )

OUT IN OUT

fLV

()()( )2

IN

9

Page 10

LT1507

U

WUU

APPLICATIONS INFORMATION

be due to a radiated magnetic field coupling into PC

board traces. But why were some boards bad and

others good? In a moment of desperation (or divine

inspiration) I unsoldered a “bad” inductor, rotated it

180° and resoldered it. Problem fixed!!

It turns out that the inductor was symmetrical in all

regards except that the polarity of the magnetic field

reversed when the unit was rotated 180° because

current flowed in the opposite direction in the coil. In

one direction, the magnetically induced ripple in the

board traces

tor caused the induced field to

Unfortunately the inductor had no physical package

assymmetry to indicate rotation, including part marking, so we had to visually examine the winding in each

unit before soldering it to the boards. This little horror

story should not preclude the use of open core inductors, but it emphasizes the need to carefully check the

effect these seductively small, low cost inductors may

have on regulator or system performances.

added

to output ripple. Rotating the induc-

reduce

output ripple.

Table 1. Representative Surface Mount Units

VALUE DC CORE SERIES HEIGHT

MANUFACTURER (µH) (A) TYPE (Ω) CORE (mm)

Coiltronics

CTX5-1 5 2.3 Tor 0.027 KMµ 4.2

CTX10-1 10 1.9 Tor 0.039 KMµ 4.2

CTX5-1P 5 1.8 Tor 0.021 52 4.2

CTX10-1P 10 1.6 Tor 0.030 52 4.2

Sumida

CDRH64 10 1.7 SC 0.084 Fer 4.5

CDRH73 10 1.7 SC 0.055 Fer 3.4

CD73 10 1.4 Open 0.062 Fer 3.5

CD104 10 2.4 Open 0.041 Fer 4.0

Gowanda

SM20-102K 10 1.3 Open 0.038 Fer 7

Dale

IHSM-4825 10 3.1 Open 0.071 Fer 5.6

IHSM-5832 10 4.3 Open 0.053 Fer 7.1

SC = Semi-closed geometry

Fer = Ferrite core material

52 = Type 52 powdered iron core material

KMµ = Kool Mµ

OUTPUT CAPACITOR

4. Look for an inductor (see Table 1) which meets the

requirements of core shape, peak current (to avoid

saturation), average current (to limit heat) and fault

current (if the inductor gets too hot, wire insulation will

melt and cause turn-to-turn shorts). Keep in mind that

all good things like high efficiency, surface mounting,

low profile and high temperature operation will increase

cost, sometimes dramatically.

5. After making an initial choice, consider secondary things

like output voltage ripple, second sourcing, etc. Use the

experts in the Linear Technology Applications Department if you feel uncertain about the final choice. They

have experience with a wide range of inductor types and

can tell you about the latest developments in low profile,

surface mounting, etc.

The output capacitor is normally chosen by its effective

series resistance (ESR), because that is what determines

output ripple voltage. At 500kHz any polarized capacitor is

essentially resistive. To get low ESR takes

volume

; physi-

cally larger capacitors have lower ESR. The ESR range

needed for typical LT1507 applications is 0.05Ω to 0.5Ω.

A typical output capacitor is an AVX type TPS, 100µF at

10V, with a guaranteed ESR less than 0.1Ω. This is a “D”

size surface mount solid tantalum capacitor. TPS capacitors are specially constructed and tested for low ESR so

they give the lowest ESR for a given volume. The value in

microfarads is not particularly critical and values from

22µF to greater than 500µF work well, but you cannot

cheat mother nature on ESR. If you find a tiny 22µ F solid

tantalum capacitor, it will have high ESR and output ripple

voltage will be terrible. The chart in Table 2 shows some

typical solid tantalum surface mount capacitors.

10

Page 11

LT1507

I

VVV

VLf

OUT IN OUT

IN

P-P

=

−()( )

()()()

U

WUU

APPLICATIONS INFORMATION

Table 2. Surface Mount Solid Tantalum Capacitor ESR

and Ripple Current

E CASE SIZE ESR (MAX Ω) RIPPLE CURRENT (A)

AVX TPS, Sprague 593D 0.1 to 0.3 0.7 to 1.1

AVX TAJ 0.7 to 0.9 0.4

D CASE SIZE

AVX TPS, Sprague 593D 0.1 to 0.3 0.7 to 1.1

AVX TAJ 0.9 to 2.0 0.36 to 0.24

C CASE SIZE

AVX TPS 0.2 (Typ) 0.5 (Typ)

AVX TAJ 1.8 to 3.0 0.22 to 0.17

Many engineers have heard that solid tantalum capacitors

are prone to failure if they undergo high surge currents.

This is historically true, and type TPS capacitors are

specially tested for surge capability, but surge ruggedness is not a critical issue with the

tantalum capacitors fail during very high

which do not occur at the output of regulators. High

discharge

surges, such as when the regulator output is

dead shorted, do not harm the capacitors.

Unlike the input capacitor, RMS ripple current in the

output capacitor is normally low enough that ripple current rating is not an issue. The current waveform is

triangular with a typical value of 200mA RMS. The formula

to calculate this is:

Output Capacitor Ripple Current (RMS)

VVV

.( )( – )

029

I RMS

RIPPLE

()

=

OUT IN OUT

Ceramic Capacitors

Higher value, lower cost ceramic capacitors are now

becoming available in smaller case sizes. These are tempting for switching regulator use because of their very low

ESR. Unfortunately, the ESR is so low that it can cause

loop stability problems when ceramic is used for the

output capacitor. Solid tantalum capacitor ESR generates

a loop “zero” at 5kHz to 50kHz that is instrumental in

giving acceptable loop phase margin. Ceramic capacitors

remain capacitive to beyond 300kHz and usually resonate

with their ESL before ESR becomes effective. They are

output

LfV

()()( )

IN

capacitor. Solid

turn-on

surges

appropriate for input bypassing because of their high

ripple current ratings and tolerance of turn-on surges.

OUTPUT RIPPLE VOLTAGE

Ripple voltage is determined by the high frequency impedance of the output capacitor and ripple current through the

inductor. Ripple current is triangular (continuous mode)

with a peak-to-peak value of:

Output ripple voltage is also triangular with peak-to-peak

amplitude of:

V

Example: with VIN = 5V, V

I

P-P P-P

VAmV

= (I

RIPPLE

=

5 5 10 500 10

RIPPLE

)(ESR) (peak-to-peak)

P–P

(.)( .)

33 5 33

−

63

(. )(. )

045 01 45

=Ω=

= 3.3V, L = 5µ H, ESR = 0.1Ω;

OUT

−

.

045

=

P-P

MAXIMUM OUTPUT LOAD CURRENT

Maximum load current will be less than the 1.5A rating of

the LT1507, especially with lower inductor values. Inductor ripple current must be taken into account as well as

reduced switch current at high duty cycles. Maximum

switch current

rating (IP) of the LT1507 is 1.5A up to 50%

duty cycle (DC), decreasing to 1.35A at 80% duty cycle,

shown graphically in Typical Performance Characteristics

and as a formula below. Current rating decreases with

duty cycle because the LT1507 has internal slope compensation to prevent current mode subharmonic switching. For more details on subharmonic oscillation read

Application Note 19. Peak guaranteed switch current (IP)

is found from:

V

IA

=≤

15 05

..

P

IA

=− ≥

175

.

P

for

OUT

V

IN

V

05

.( )

OUT

V

IN

for

V

OUT

V

IN

05

.

11

Page 12

LT1507

U

WUU

APPLICATIONS INFORMATION

Example: with V

V

OUT/VIN

IP = 1.75 – (0.5)(0.66) = 1.42A

Maximum load current would be equal to maximum

switch current

finite inductor size, maximum load current is reduced by

one half peak-to-peak inductor current. The following

formula assumes continuous mode operation; the term on

the right must be less than one half of IP.

Continuous mode:

II

OUT MAX P

For the conditions above, with L = 5µH and f = 500kHz;

I

OUT MAX()

At VIN = 8V, V

I

OUT(MAX)

15

.–

==A

Note that there is less load current available at the higher

input voltage because inductor ripple current increases.

This is not always the case. Certain combinations of

inductor value and input voltage range may yield lower

available load current at the lowest input voltage due to

reduced peak switch current at high duty cycles. If load

current is close to the maximum available, please check

maximum available current at both input voltage

extremes. To calculate actual peak switch current with a

given set of conditions, use:

II

SWITCH PEAK OUT

For lighter loads where discontinuous mode operation can

be used, maximum load current is equal to:

= 3.3/5 = 0.67

()

is equal to;

2 5 10 500 10 8

.–. .

15 039 111

()

= 3.3V, VIN = 5V;

OUT

for an infinitely large inductor,

VVV

()(– )

OUT IN OUT

–

=

=

.–

142

==

.–. .

142 022 12

OUT/VIN

33 8 33

( . )( – . )

63

−

()

=+

LfV

()()( )

2

2 5 10 500 10 5

= 0.41, so IP is equal to 1.5A and

()

IN

( . )( – . )

33 5 33

−

63

()

VVV

A

(– )

OUT IN OUT

LfV

()()( )

2

()

IN

but with

Discontinuous mode:

2

IfLV

()()()( )

I

OUT MAX

Example: with L = 2µH, V

I

OUT MAX()

The main reason for using such a tiny inductor is that it is

physically very small, but keep in mind that peak-to-peak

inductor current will be very high. This will increase output

ripple voltage. If the output capacitor has to be made larger

to reduce ripple voltage, the overall circuit could actually

be larger.

CATCH DIODE

The suggested catch diode (D1) is a 1N5818 Schottky or

its Motorola equivalent, MBR130. It is rated at 1A average

forward current and 30V reverse voltage. Typical forward

voltage is 0.42V at 1A. The diode conducts current only

during switch OFF time. Peak reverse voltage is equal to

regulator input voltage. Average forward current in normal

operation can be calculated from:

I

D AVG

()

This formula will not yield values higher than 1A with

maximum load current of 1.25A unless the ratio of input to

output voltage exceeds 5:1. The only reason to consider a

larger diode is the worst-case condition of a high input

voltage and

circuit conditions, foldback current limit will reduce diode

current to less than 1A, but if the output is overloaded and

does not fall to less than 1/3 of nominal output voltage,

foldback will not take effect. With the overloaded condition, output current will increase to a typical value of 1.8A,

determined by peak switch current limit of 2A. With VIN =

10V, V

OUT

IA

D AVG()

=

()

=

=

IVV

OUT IN OUT

=

overloaded

= 2V (3.3V overloaded) and I

1 8 10 2

PIN

VVV

2

()(–)

OUT IN OUT

= 5V and V

OUT

23 6

(.)

1 5 500 10 2 10 15

2 5 15 5

338

m

A

(– )

V

IN

(not shorted) output. Under short-

.( –)

10

()

()( – )

.==

144

IN(MAX)

−

()

OUT

= 15V;

= 1.8A:

12

Page 13

LT1507

U

WUU

APPLICATIONS INFORMATION

This is safe for short periods of time, but it would be

prudent to check with the diode manufacturer if continuous operation under these conditions must be tolerated.

BOOST PIN CONSIDERATIONS

For most applications, the boost components are a 0.22µ F

capacitor and an MBR0520 or BAT85 Schottky diode. This

capacitor value is twice that suggested for the LT1376

because the lower voltages commonly found in LT1507

applications may require lower ripple voltage across the

capacitor to ensure adequate boost voltage under worstcase conditions. Efficiency is not affected by the capacitor

value, but the capacitor should have an ESR of less than

2Ω to ensure that it can be recharged fully under the worstcase condition of minimum input voltage. Almost any type

of film or ceramic capacitor will work fine.

The anode of the diode can be connected to the regulated

output voltage or the unregulated input voltage. The

“boost voltage” generated across the boost capacitor is

then nearly identical to the anode voltage. The input

connection minimizes start-up problems and gives plenty

of boost voltage, but efficiency is slightly lower, especially

with input voltages above 10V. For 5V to 3.3V operation,

or any output voltage less than 3.3V, the diode should be

connected to the input. With input voltage more than 3V

above the output and an output voltage of at least 3.3V the

output connection will give better efficiency. Use the

BAT85 Schottky diode for 3.3V applications where the

anode is connected to the output.

LAYOUT CONSIDERATIONS

Suggested layout for the LT1507 is shown in Figure 3. The

main concern for layout is to minimize the length of the

MINIMIZE AREA OF

CONNECTIONS TO THE

SWITCH NODE AND

BOOST NODE, BUT OBSERVE

CURRENT DENSITY LIMITATIONS

AND CATCH DIODE CLOSE

IN PATH TO L1

KEEP INPUT CAPACITOR

TO REGULATOR AND

TERMINATE THEM

TO SAME POINT

GROUND RING NEED

NOT BE AS SHOWN.

(NORMALLY EXISTS AS

INTERNAL PLANE)

C2

C3

D1

L1

CONNECT OUTPUT CAPACITOR

DIRECTLY TO HEAVY GROUND

INPUT

BOOST

IN

SW

SHDN

C1

C

D2

V

C

FB

GND

SYNC

OUTPUT

TAKE OUTPUT DIRECTLY FROM END OF OUTPUT

CAPACITOR TO AVOID PARASITIC RESISTANCE

AND INDUCTANCE (KELVIN CONNECTION)

F

C

C

R2

R1

SYNC

C

AND RC ARE OPTIONAL.

F

SEE FREQUENCY

R

C

COMPENSATION

TERMINATE GND PIN

DIRECTLY TO GROUND

PLANE WITH VIA TO

MINIMIZE EMI. (MINIMIZE

DISTANCE TO INPUT

CAPACITOR C3). CONNECT

FEEDBACK RESISTORS AND

COMPENSATION

COMPONENTS DIRECTLY

TO GROUND PLANE OR TO

SWITCHER GND PIN.

LT1507 • F03

Figure 3. Suggested Layout

13

Page 14

LT1507

U

WUU

APPLICATIONS INFORMATION

high speed circulating current path shown in Figure 4 and

to make connections to the output capacitor in a manner

that minimizes output ripple and noise. For more details,

see Applications Information section in the LT1376 data

sheet.

SWITCH NODE

HIGH

FREQUENCY

V

C

IN

3

CIRCULATING

PATH

Figure 4. High Speed Switching Path

INPUT BYPASSING AND VOLTAGE RANGE

Input Bypass Capacitor

Stepdown converters draw current from the input supply

in pulses. The average height of these pulses is equal to

load current and the duty cycle is equal to V

and fall time of the current is very fast. A local bypass

capacitor across the input supply is necessary to ensure

proper operation of the regulator and minimize the ripple

current fed back into the input supply.

forces switching current to flow in a tight local loop,

minimizing EMI.

Do not cheat on the ripple current rating of the input

bypass capacitor, but also don’t get hung up on the value

in microfarads.

The input capacitor is intended to absorb

all the switching current ripple, which can have an RMS

value as high as one half of load current. Ripple current

ratings on the capacitor must be observed to ensure

reliable operation. The actual value of the capacitor in

microfarads is not particularly important because at

500kHz, any value above 5µ F is essential resistive. Ripple

current rating is the critical parameter. RMS ripple current

can be calculated from:

VVV

I RMS I

RIPPLE OUT

()

=

OUT IN OUT

L1

C

LOAD

1

OUT/VIN

The capacitor also

(– )

2

V

IN

5V

LT1507 • F04

. Rise

The term inside the radical has a maximum value of 0.5

when input voltage is twice output and stays near 0.5 for

a relatively wide range of input voltages. It is common

practice, therefore, to simply use the worst-case value and

assume that RMS ripple current is one half of load current.

At maximum output current of 1.5A for the LT1507, the

input bypass capacitor should be rated at 0.75A ripple

current. Note however, that there are many secondary

considerations in choosing the final ripple current rating.

These include ambient temperature, average versus peak

load current, equipment operating schedule and required

product lifetime. For more details see Application Notes 19

and 46.

Input Capacitor Type

Some caution must be used when selecting the type of

capacitor used at the input of regulators. Aluminum

electrolytics are lowest cost, but are physically large to

achieve adequate ripple current rating, and size constraints (especially height) may preclude their use.

Ceramic capacitors are now available in larger values and

their high ripple current and voltage rating make them

ideal for input bypassing. Cost is slightly higher and

footprint may also be somewhat larger. Solid tantalum

capacitors are a good choice except that they have a

history of occasional spectacular failures when they are

subjected to very large current surges during power-up.

The capacitors can short and then burn with a brilliant

white light and lots of nasty smoke. This phenomenon

occurs in only a small percentage of units, but it has led

some OEM companies to forbid their use in high surge

applications. The input bypass capacitor of regulators can

see such high surges when a battery or high capacitance

source is connected.

Several manufacturers have developed a line of solid

tantalum capacitors specially tested for surge capability

(AVX TPS series for instance, see Table 2). Even these

units may fail if the input current surge exceeds a value

equal to the voltage rating of the capacitor divided by 1Ω

(10A for a 10V capacitor). For this reason, AVX recommends using the highest voltage rating possible for the

input capacitor.

For equal case size

, this means that lower

values of capacitance must be used. As stated above, this

14

Page 15

LT1507

LOAD CURRENT (mA)

1

INPUT VOLTAGE (V)

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

10 100 1000

LT1400 • GXX

VALID ONLY FOR V

OUT

= 3.3V

MINIMUM VOLTAGE

TO START WITH

STANDARD CIRCUITS

MINIMUM VOLTAGE

TO START WITH

PNP ADDED

MINIMUM VOLTAGE

TO RUN WITH

STANDARD CIRCUIT

MINIMUM VOLTAGE

TO RUN WITH

PNP ADDED

MINIMUM VOLTAGE

TO RUN WITH

PNP ADDED

U

WUU

APPLICATIONS INFORMATION

is not a problem, but it should be noted that for

size

, the ripple current rating and ESR of higher voltage

capacitors will be somewhat worse. The lower input

operating voltages of the LT1507 allow considerable

derating of capacitor voltage. If solid tantalum units are

used, it would be wise to use units rated at 25V or more,

as long as ripple current requirements are met. Design

Note 122 discusses the problem of showing typical input

capacitor surges that occur when batteries or adapters are

hot plugged to typical regulator systems.

A new capacitor type known as OS-CON uses a “semiconductor” dielectric to achieve extremely low ESR and high

ripple current rating. These are ideal for input bypassing

because they are not surge sensitive. They are not suggested for output capacitors because the very low ESR

may present loop stability problems. Price and size (height)

are issues to be considered. The original manufacturer is

Sanyo but there are now additional sources.

Larger capacitors may be necessary when the input voltage is very close to the minimum specified on the data

sheet. A 5µ F ceramic input capacitor for instance, moves

at about 0.1V/µ s during switch ON time when load current

is 1A, creating a ripple voltage due to reactance. This is in

addition to the ripple caused by capacitor ESR. Physically

larger input capacitors will have more capacitance (less

reactance)

and

lower ESR. Small voltage dips during

switch ON time are not normally a problem, but at very low

input voltage they may cause erratic operation because the

input voltage drops below the minimum specification.

Problems can also occur if the input to output voltage

differential is near minimum.

equal case

to 1.5V higher than the standard running voltage, especially at light loads. An approximate formula to calculate

minimum

running

voltage at load currents

above 100mA

is:

V

IN MIN

With V

V

IN(MIN)

VI

= 3.3V and I

OUT

= 3.9V. Increasing load current to 1A raises

()(.)

+Ω

OUT OUT

085

03

.

= 0.1A, this formula yields

OUT

ImA

()=

≥

OUT()

100

minimum input to 4.2V. For start-up and operation at light

loads, see the next section.

Minimum Start-Up Voltage and Operation

at Light Loads

The boost capacitor supplies current to the BOOST pin

during switch ON time. This capacitor is recharged only

during switch OFF time. Under certain conditions of light

load and low input voltage, the capacitor may not be fully

recharged during the relatively short OFF time. This causes

the boost voltage to collapse and minimum input voltage

is increased. Start-up voltage at light loads is higher than

normal running voltage for the same reasons. Figure 5

shows minimum input voltage for a 3.3V output, both for

start-up and for normal operation. This graph indicates

that a 5V to 3.3V converter with 4.7V minimum input

voltage, will not start correctly below a 40mA load current

and will not run correctly below a 4mA load current. If

minimum load current is less than 50mA, a preload should

be added or the circuit in Figure 6 can be used.

Minimum Input Voltage (After Start-Up)

Minimum input voltage to make the LT1507 “run” correctly is typically 3.6V, but to regulate the output, a buck

converter input voltage must always be higher than the

output voltage. To calculate minimum operating input

voltage, switch voltage loss and maximum duty cycle

must be taken into account. With the LT1507 there is the

additional consideration of proper operation of the boost

circuit. The boost circuit allows the power switch to

saturate for high efficiency, but it also sometimes results

in a start-up or low current operating voltage that is 0.5V

Figure 5. Minimum Input Voltage for V

OUT

= 3.3V

15

Page 16

LT1507

U

WUU

APPLICATIONS INFORMATION

The circuit in Figure 6 will allow operation at light loads

with low input voltages. It uses a small PNP to charge the

boost capacitor (C2) and an extra diode (D3) to complete

the power path from VSW to the boost capacitor. Note that

the diodes have been changed to Schottky BAT85s to

optimize low voltage operation. Figure 5 shows that with

the added PNP, minimum load current can be reduced to

6mA and still guarantee proper start-up with 4.7V input.

D2

BAT85

C2

INPUT

+

V

IN

GND V

BOOST

LT1507-3.3

0.22µF

V

SENSE

C

C

SW

C

D3

BAT85

Q1

2N3906

L1

D1

1N5818

V

= 3.3V

OUT

+

C1

problems. For low input voltage, high sync frequency

applications, the circuit shown in Figure 7 can be used to

generate an external slope compensation ramp that eliminates subharmonic oscillation. See Frequency Compensation section for a discussion of an entirely different

cause of subharmonic switching before assuming that the

cause is insufficient slope compensation. Application Note

19 has more details on the theory of slope compensation.

V

SW

LT1507

SYNC

GND V

CS

1000pF

RS

5.2k

Figure 7. Adding External Slope Compensation for High

Sync Frequencies

C

RC

470Ω

C

C

2000pF

V

OUT

+

LT1507 • F07

LT1507 • F06

Figure 6. Adding a Small PNP to Reduce Minimum

Start-Up Voltage

SYNCHRONIZING

The LT1507 SYNC pin is used to synchronize the internal

oscillator to an external signal. It is directly logic compatible and can be driven with any signal between 10% and

90% duty cycle. The synchronizing range is equal to

initial

operating frequency up to 1MHz (above 700kHz external

slope compensation may be needed). This means that

minimum practical sync frequency is equal to the worstcase

high

self-oscillating frequency (560kHz) not the

typical operating frequency of 500kHz. Caution should be

used when synchronizing above 700kHz because at higher

sync frequencies, the amplitude of the internal slope

compensation used to prevent subharmonic switching is

reduced. This type of subharmonic switching only occurs

at input voltages less than twice the output voltage and

shows up as alternating pulse widths at the switch node.

It does not cause the regulator to lose regulation, but

switch frequency content down to 100kHz may be objectionable. Higher inductor values will tend to eliminate

External Slope Compensation Ramp

The LT1507 is a current mode switching regulator and

therefore, it requires something called “slope compensation”

when operated above 50% duty cycle in continuous

mode.

This condition occurs when input voltage is less

than twice output voltage. Slope compensation adds a

ramp to the switch current sense signal generated on the

chip during switch ON time. Typically the ramp is generated from a portion of the internal oscillator waveform. In

the LT1507, the ramp is arranged to be zero until the

oscillator waveform reaches about 40% of its final value.

This minimizes the total amount of ramp added to switch

current. The reason for doing it this way is that the ramp

subtracts from switch current limit, so that switch current

limit would be considerably lower at high duty cycle

compared to low duty cycle if the ramp existed at all duty

cycles. By starting the ramp at the 40% point, changes in

current limit are minimized. No ramp is needed when

operating below 50% duty cycle.

Problems can occur with this technique if the regulator is

used with a combination of high external sync frequency

and more than 50% duty cycle. The basic sync function

16

Page 17

LT1507

U

WUU

APPLICATIONS INFORMATION

works by prematurely tripping the oscillator before it

reaches its normal peak value. For instance, if the oscillator is synchronized at twice its nominal frequency, oscillator amplitude will drop by half. A ramp which previously

started at the 40% point now starts at the 80% point! This

effectively blocks slope compensation and the regulator

may respond with fluctuating pulse widths, a “phase

oscillation” if you will. The regulator output stays in

regulation but subharmonic frequencies are generated at

the switch node.

The solution to this problem is to generate an external

ramp that replaces the missing internal ramp. As it turns

out, this is not difficult if the sync signal can be arranged

to have a fairly low duty cycle (< 35%). The ramp is created

by AC coupling a resistor from the sync signal to the

compensation capacitor as shown in Figure 7. This generates a negative ramp on the VC pin during switch ON time

that emulates the missing internally generated ramp.

Amplitude of the ramp should be about 100mV to 200mV

peak-to-peak. The formulas for calculating the values of

RS and CS are shown below. Note that the CS value is

unimportant as long as it exceeds the value given. The

formula assures that the impedance of CS will be small

compared to RS.

VDCDC

()( )

R

C

SYNC S S

=

S

S

>

VCf

P-P

20

π

fR

()( )

2

S

−

1

()()

C

For VIN = 4.7, V

VmV

≥

P-P

2 1 10 5 10 1 8

To avoid small values of RS, the compensation capacitor (CC)

should be made as small as possible. 2000pF will work in

most situations. If we increase VPP to 90mV for a little

cushion, RS will be:

Rk

=

S

.

0 09 2 10 1 10

≥

CpF

π

2 1 10 5200

THERMAL CALCULATIONS

Power dissipation in the LT1507 chip comes from four

sources: switch DC loss, switch AC loss, boost circuit

current and input quiescent current. The formulas below

show how to calculate each of these losses. These formulas assume continuous mode operation, so they should

not be used for calculating efficiency at light load currents.

Switch loss:

P

RI V

=+

SW

= 3.3V, f = 1MHz, L = 5µ H and DCS = 25%:

OUT

(. .)( . )

66 47 1 025

−−

()(. )(. )

()

SW OUT OUT

66

5 0 25 0 75

−

()

20

6

()

()()

V

IN

−

96

()

=

612

2

71

=

.

=

.

52

ns I V f

()()()

16

OUT IN

V

= Peak-to-peak value of sync signal

SYNC

DCS = Duty cycle

V

= Desired amplitude of ramp

P-P

f = Sync frequency

Theoretical minimum amplitude for the ramp, assuming

no internal ramp, is:

V

≥

P-P

g

= Transconductance from VC pin to switch current

mP

(1.8A/V for the LT1507).

of incoming sync signal

VVDC

21

−−()()

OUT IN S

fLg

()()( )

2

mP

Boost current loss:

2

P

BOOST

Quiescent current loss:

PV V

=+(. ) (. )0 003 0 005

Q IN OUT

RSW = Switch resistance (≈ 0.4Ω)

16ns = Equivalent switch current/voltage overlap time

f = Switching frequency

V

=+

OUT

0 008

.

V

IN

I

OUT

75

17

Page 18

LT1507

U

WUU

APPLICATIONS INFORMATION

Example: with VIN = 5V, V

P

PW

PW

(.)()(.)

=+

SW

=+=

026 004 03

BOOST

(. ) .(. ) .

=+ =

5 0 003 3 3 0 005 0 032

Q

2

04 1 33

5

...

2

(.)

33

=

..

0 008

5

= 3.3V, I

OUT

93

−

16 10 1 5 500 10

()

OUT

()()

= 1A;

W

1

75

0 046

=

+

()

Total power dissipation is 0.3 + 0.046 + 0.032 = 0.38W.

Thermal resistance for the LT1507 packages is influenced

by the presence of internal or backside planes. With a full

plane under the SO package, thermal resistance will be

about 120°C/W. No plane will increase resistance to about

150°C/W. To calculate die temperature, use the proper

thermal resistance number for the desired package and

add in worst-case ambient temperature;

TJ = TA + θJA(P

TOT

)

parallel with 12pF. In all practical applications, the compensation network from VC pin to ground has a much

lower impedance than the output impedance of the amplifier at frequencies above 500Hz. This means that the error

amplifier characteristics themselves do not contribute

excess phase shift to the loop and the phase/gain charac-

With the S8 package (θJA = 120°C/W) at an ambient

temperature of 70°C;

TJ = 70 + 120(0.38) = 116°C

teristics of the error amplifier section are completely

controlled by the external compensation network.

The complete small-signal model is shown in Figure 9. R1

and R2 are the divider used to set output voltage. These are

FREQUENCY COMPENSATION

internal on the fixed voltage LT1507-3.3 with R1 = 1.8k

and R2 = 5k. RC, CC and CF are external compensation

The LT1507 uses a “current mode” architecture to help

alleviate phase shift created by the inductor. The basic

connections are shown in Figure 9. Gain of the power stage

can be modeled as 1.8A/V transconductance from the V

C

pin voltage to current delivered to the output. This is

shown in Figure 8 where the transconductance from V

C

pin to inductor current is essentially flat from 50Hz to

50kHz and phase shift is minimal in the important loop

unity-gain band of 1kHz to 50kHz. Inductor variation from

3µ H to 20µH will have very little effect on these curves.

Overall gain from the VC pin to output is then modeled as

the product of 1.8A/V transconductance multiplied by the

complex impedance of the load in parallel with the output

capacitor model.

The error amplifier can be modeled as a transconductance

of 2000µmho, with an output impedance of 200kΩ in

2.0

1.5

1.0

0.5

PIN TO INDUCTOR CURRENT (A/V)

C

GAIN-V

0

10 1k 10k 100k

Figure 8. Phase and Gain from VC Pin Voltage

to Inductor Current

POWER STAGE

= 1.8A/V

g

m

12pF

200k

GND V

Figure 9. Small-Signal Model for Loop Stability Analysis

ERROR AMPLIFIER

g

R

C

C

F

= 2000µho

m

C

C

C

V

= 3.3V

OUT

= 250mA

I

OUT

= 5V

V

IN

L = 10µH

PHASE

100

FREQUENCY (Hz)

LT1507

–

+

GAIN (A/V)

2.42V

80

PHASE-V

C

PIN TO INDUCTOR CURRENT (C°)

40

0

–40

–80

LT1507 • F08

V

SW

L1

R1

F

B

R2

1507 • F09

OUTPUT

ESR

+

C1

18

Page 19

LT1507

FREQUENCY (kHz)

LOOP GAIN (dB)

LOOP PHASE (°C)

80

60

40

20

0

–20

200

150

100

50

0

–50

0.01 10.1 10 100 100

LT1511 • F10

VIN = 10V

V

OUT

= 5V, I

OUT

= 500mA

C

OUT

= 100µF, 10V, AVX TPS

C

C

= 3.3nF, RC = 0

L = 10µH

GAIN

PHASE

U

WUU

APPLICATIONS INFORMATION

components. In many cases only CC is needed. Adding R

will improve phase margin, but this may necessitate the need

for CF to limit switching frequency ripple at the VC pin.

In Figure 10, full loop phase/gain characteristics are shown

with a compensation capacitor (CC) of 0.0033µ F, giving the

error amplifier a pole at 240Hz, with phase rolling off to 90°

and staying there. The overall loop has a gain of 77dB at low

frequency rolling off to unity gain at 20kHz. Phase shows a

2-pole characteristic until the ESR of the output capacitor

brings it back above 10kHz. Phase margin is about 60° at

unity-gain.

Analog experts will note that around 1kHz, phase dips to

within 20° of the zero phase margin line. This is typical of

switching regulators because of the 2-pole rolloff generated

by the output capacitor and the compensation network. This

region of low phase is not a problem as long as it does not

occur near unity-gain. In practice, the variability of output

capacitor ESR tends to dominate all other effects with respect

to loop response. Variations in ESR

will

cause unity-gain to

C

move around, but at the same time phase moves with it so

that adequate phase margin is maintained over a very wide

range of ESR (≥ 5:1)

Figure 10. Overall Loop Phase and Gain

Undervoltage Lockout

See Application Information in LT1376 data sheet.

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

8-Lead PDIP (Narrow 0.300)

0.300 – 0.325

(7.620 – 8.255)

0.065

(1.651)

TYP

(0.127)

0.100 ± 0.010

(2.540 ± 0.254)

0.009 – 0.015

(0.229 – 0.381)

+0.025

0.325

–0.015

+0.635

8.255

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

()

–0.381

0.045 – 0.065

(1.143 – 1.651)

0.005

MIN

N8 Package

(LTC DWG # 05-08-1510)

0.130 ± 0.005

(3.302 ± 0.127)

0.125

(3.175)

MIN

0.018 ± 0.003

(0.457 ± 0.076)

0.015

(0.380)

MIN

0.255 ± 0.015*

(6.477 ± 0.381)

876

12

0.400*

(10.160)

MAX

3

5

4

N8 0695

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

19

Page 20

LT1507

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.189 – 0.197*

(4.801 – 5.004)

7

8

5

6

0.150 – 0.157**

(3.810 – 3.988)

4

0.050

(1.270)

BSC

0.004 – 0.010

(0.101 – 0.254)

SO8 0695

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0°– 8° TYP

0.016 – 0.050

0.406 – 1.270

0.228 – 0.244

(5.791 – 6.197)

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

1

3

2

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1371 3A 500kHz Step-Up Switching Regulator High Current DC/DC Conversion Uses Small Power Components

LT1372 1.5A 500kHz Step-Up Switching Regulator Includes Positive and Negative Output Voltage Regulation

LT1375 1.5A 500kHz Step-Down Switching Regulator Includes Synchronization Capability

LT1376 1.5A 500kHz Step-Down Switching Regulator Output Biasing Yields 90% Efficiency

LT1377 1.5A 1MHz Step-Up Switching Regulator Highest Frequency Monolithic Switching Regulator

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417 ● (408) 432-1900

FAX: (408) 434-0507

●

TELEX: 499-3977 ● www.linear-tech.com

1507f LT/TP 0697 4K • PRINTED IN USA

LINE AR TECHNOLO GY CORP O RATION 1996

Loading...

Loading...