Page 1

LT1394

7ns, Low Power,

Single Supply, Ground-Sensing

FEATURES

■

UltraFastTM: 7ns

■

Low Power: 6mA

■

Low Offset Voltage: 0.8mV

■

Operates Off Single 5V or Dual ±5V Supplies

■

Input Common Mode Extends to Negative Supply

■

No Minimum Input Slew Rate Requirement

■

Complementary TTL Outputs

■

Inputs Can Exceed Supplies without Phase Reversal

■

Pin Compatible with LT1016, LT1116 and LT1671

■

Output Latch Capability

■

Available in 8-Lead MSOP and SO Packages

U

APPLICATIO S

■

High Speed A/D Converters

■

Zero-Crossing Detectors

■

Current Sense for Switching Regulators

■

Extended Range V/F Coverters

■

Fast Pulse Height/Width Discriminators

■

High Speed Triggers

■

Line Receivers

■

High Speed Sampling Circuits

, LTC and LT are registered trademarks of Linear Technology Corporation.

UltraFast is a trademark of Linear Technology Corporation.

U

Comparator

DESCRIPTIO

The LT®1394 is an UltraFast (7ns) comparator with complementary outputs and latch. The input common mode range

extends from 1.5V below the positive supply down to the

negative supply rail. Like the LT1016, LT1116 and LT1671,

this comparator has complementary outputs designed to

interface directly to TTL or CMOS logic. The LT1394 may

operate from either a single 5V supply or dual ±5V supplies.

Low offset voltage specifications and high gain allow the

LT1394 to be used in precision applications.

The LT1394 is designed for improved speed and stability for

a wide range of operating conditions. The output stage

provides active drive in both directions for maximum speed

into TTL, CMOS or passive loads with minimal cross-conduction current. Unlike other fast comparators, the LT1394

remains stable even for slow transitions through the active

region, which eliminates the need to specify a minimum input

slew rate.

The LT1394 has an internal, TTL/CMOS compatible latch for

retaining data at the outputs. The latch holds data as long as

the LATCH pin is held high. Device parameters such as gain,

offset and negative power supply current are not significantly

affected by variations in negative supply voltage.

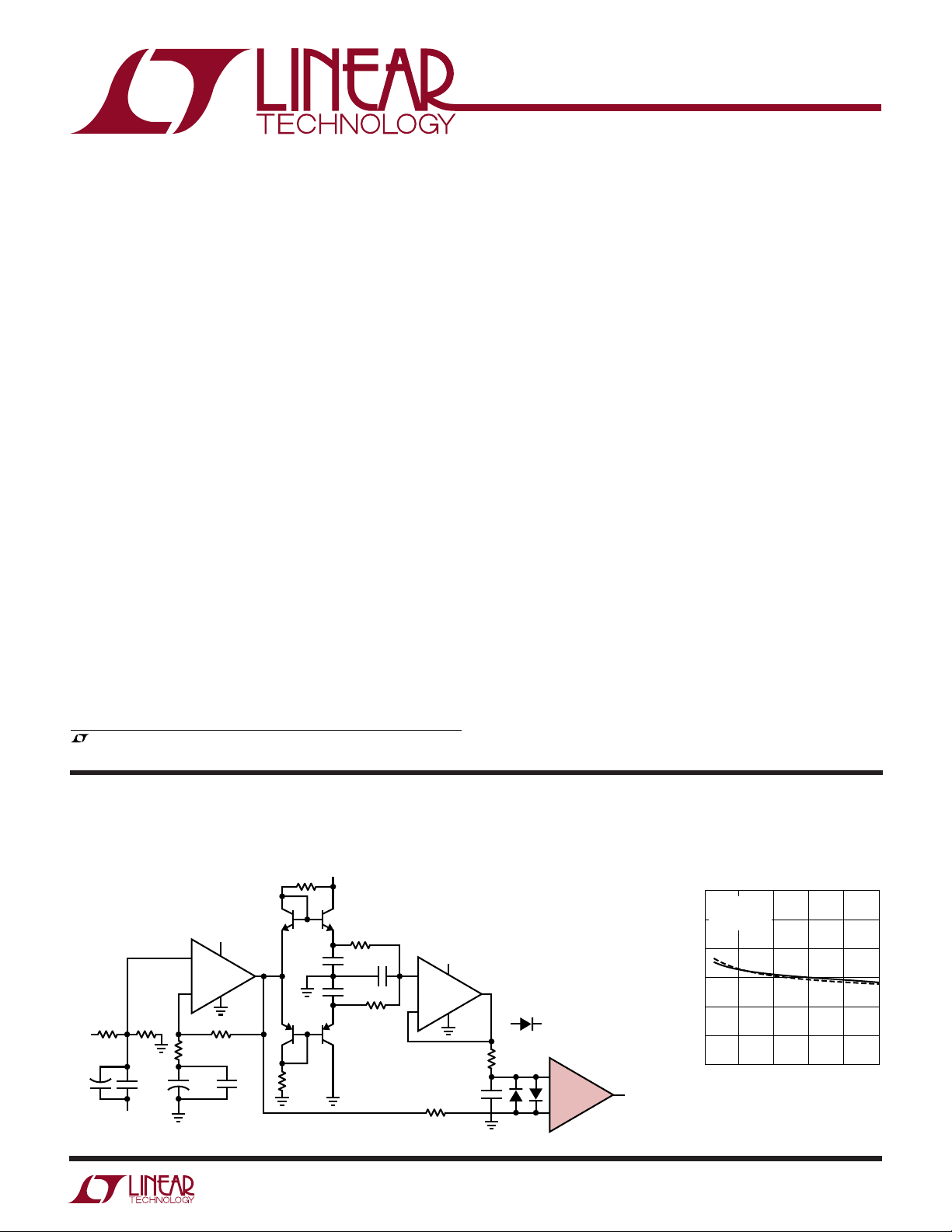

TYPICAL APPLICATIO

45MHz Single Supply Adaptive Trigger

3

Q1 Q2

10µF

5V

+

A1

LT1227

–

750Ω

2k

5V

+

0.1µF

INPUT

510Ω

36Ω

+

100µF

0.1µF

2

13

Q3

15

2k

2k

1

0.005µF

14

U

Propagation Delay vs

5V

6

5

3M

4

500pF

0.005µF

10

12

11

3M

Q4

+

LT1006

–

470Ω

5V

A2

0.1µF

Q1, Q2, Q3, Q4 = CA3096 ARRAY:

TIE SUBSTRATE (PIN 16) TO GROUND

470Ω

= 1N4148

+

LT1394

–

TRIGGER

OUT

1394 F18

12

10

8

6

TIME (ns)

4

2

0

Input Overdrive

TA = 25°C

= 100mV

V

STEP

= ±5V

V

S

0

10 20 30 40

OVERDRIVE (mV)

t

PDLH

t

PDHL

50

1394 TA02

1

Page 2

LT1394

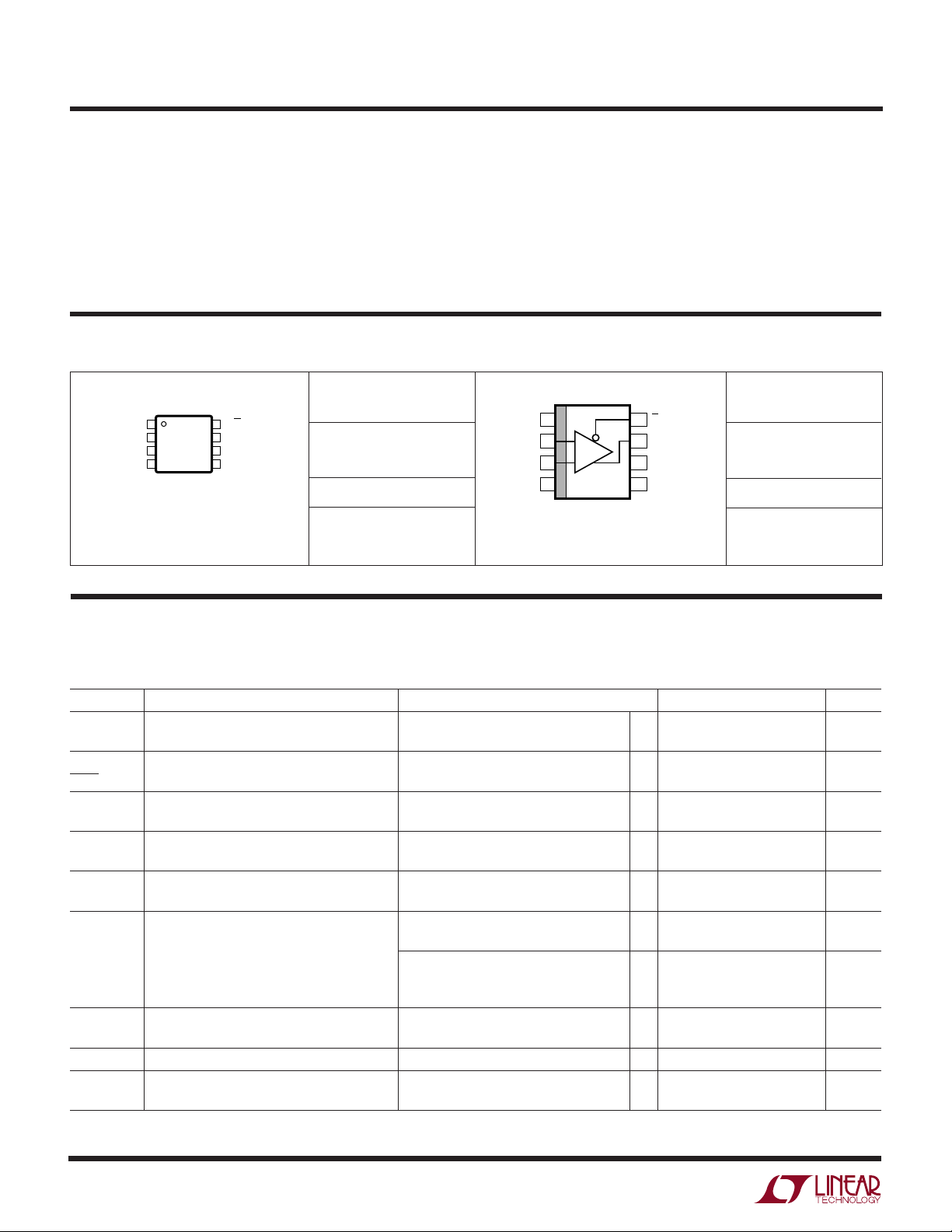

TOP VIEW

Q OUT

Q OUT

GND

V

+

+IN

–IN

V

–

S8 PACKAGE

8-LEAD PLASTIC SO

1

2

3

4

8

7

6

5

+

–

LATCH

ENABLE

WW

W

ABSOLUTE MAXIMUM RATINGS

U

(Note 1)

Total Supply Voltage (V+ to V–) ............................... 12V

Positive Supply Voltage ............................................. 7V

Negative Supply Voltage .......................................... –7V

Differential Input Voltage ....................................... ±12V

Input and Latch Current (Note 2)........................±10mA

Output Current (Continuous)(Note 2) .................±20mA

U

W

PACKAGE/ORDER INFORMATION

TOP VIEW

+

V

1

2

+IN

3

–IN

–

4

V

MS8 PACKAGE

8-LEAD PLASTIC MSOP

T

= 150°C, θJA = 250°C/W

JMAX

8

Q OUT

7

Q OUT

6

GND

5

LATCH

ENABLE

ORDER PART

NUMBER

LT1394CMS8

MS8 PART MARKING

LTBH

Operating Temperature Range ................ –40°C to 85°C

Specified Temperature Range (Note 3)... –40°C to 85°C

Junction Temperature........................................... 150°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

U

ORDER PART

NUMBER

LT1394CS8

LT1394IS8

S8 PART MARKING

T

= 150°C, θJA = 190°C/W

JMAX

1394

1394I

Consult factory for Military grade parts.

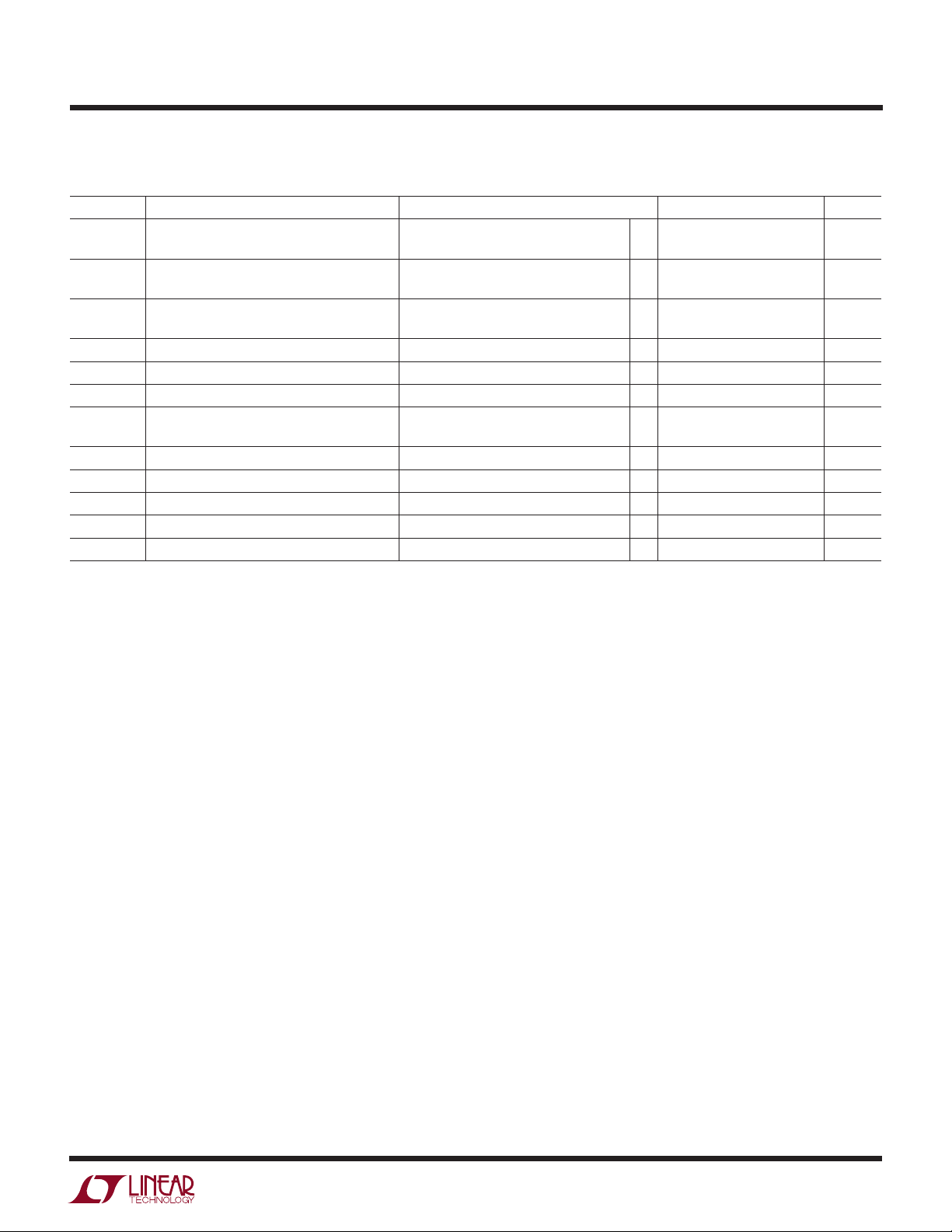

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

V+ = 5V, V– = –5V, V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

OS

∆V

OS

∆T

I

OS

I

B

V

CMR

CMRR Common Mode Rejection Ratio –5V ≤ VCM ≤ 3.5V, TA > 0°C 55 100 dB

PSRR Power Supply Rejection Ratio 4.6V ≤ V+ ≤ 5.4V ● 50 65 dB

A

V

V

OH

2

Input Offset Voltage RS ≤ 100Ω (Note 4) 0.8 2.5 mV

Input Offset Voltage Drift ● 4 µV/°C

Input Offset Current 0.1 0.5 µA

Input Bias Current (Note 5) 2 4.5 µA

Input Voltage Range (Note 6) ● –5 3.5 V

Small Signal Voltage Gain 1V ≤ V

Output Voltage Swing High V+ ≥ 4.6V, I

(Q) = 1.4V, V

OUT

= VCM = 0V unless otherwise noted.

LATCH

Single 5V Supply

–5V ≤ V

Single 5V Supply

0V ≤ V

0V ≤ V

–7V ≤ V

+

V

≤ 3.3V, TA ≤ 0°C55 dB

CM

≤ 3.5V, TA > 0°C 55 100 dB

CM

≤ 3.3V, TA ≤ 0°C55 dB

CM

–

≤ –2V ● 65 100 dB

≤ 2V 750 1600 V/V

OUT

≥ 4.6V, I

OUT

OUT

● 4.0 mV

● 0.8 µA

● 7.0 µA

● 0 3.5 V

= 1mA ● 2.7 3.1 V

= 4mA ● 2.4 3.0 V

Page 3

LT1394

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

V+ = 5V, V– = –5V, V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

OL

+

I

–

I

V

IH

V

IL

I

IL

t

PD

∆t

PD

t

LPD

t

SU

t

H

t

PW(D)

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: This parameter is guaranteed to meet specified perforamnce

through design and characterization. It has not been tested.

Note 3: The LT1394CMS8 and LT1394CS8 are guaranteed to meet

specified performance from 0°C to 70°C and are designed, characterized

and expected to meet these extended temperature limits, but are not tested

at –40°C and 85°C. The LT1394IS8 is guaranteed to meet the extended

temperature limits.

Note 4: Input offset voltage (V

voltages measured by forcing first one output, then the other to 1.4V.

Note 5: Input bias current (I

currents.

Note 6: Input voltage range is guaranteed in part by CMRR testing and in

part by design and characterization.

Output Voltage Swing Low I

Positive Supply Current 6 8.5 mA

Negative Supply Current 1.2 2.2 mA

LATCH Pin High Input Voltage ● 2V

LATCH Pin Low Input Voltage ● 0.8 V

LATCH Pin Current V

Propagation Delay (Note 7) ∆VIN = 100mV, VOD = 5mV 7 9 ns

Differential Propagation Delay (Note 7) ∆VIN = 100mV, VOD = 5mV 0.5 2.2 ns

Latch Propagation Delay (Note 8) 6 ns

Latch Setup Time (Note 8) –0.4 ns

Latch Hold Time (Note 8) 2ns

Minimum Disable Pulse Width 3ns

(Q) = 1.4V, V

OUT

) is defined as the average of the two

OS

) is defined as the average of the two input

B

= VCM = 0V unless otherwise noted.

LATCH

= –4mA ● 0.3 0.5 V

OUT

I

= –10mA 0.4 V

OUT

● 10.0 mA

● 2.5 mA

= 0V ● –4 –10 µA

LATCH

● 14 ns

Note 7: t

and ∆tPD cannot be measured in automatic handling

PD

equipment with low values of overdrive. The LT1394 is 100% tested with a

100mV step and 20mV overdrive. Correlation tests have shown that t

and ∆tPD limits can be guaranteed with this test, if additional DC tests are

performed to guarantee that all internal bias conditions are correct.

Propagation delay (tPD) is measured with the overdrive added to the actual

. Differential propagation delay is defined as:

V

OS

∆tPD = t

Note 8: Latch propagation delay (t

respond when the LATCH pin is deasserted. Latch setup time (t

PDLH

– t

PDHL

) is the delay time for the output to

LPD

SU

interval in which the input signal must remain stable prior to asserting the

latch signal. Latch hold time (tH) is the interval after the latch is asserted in

which the input signal must remain stable.

PD

) is the

3

Page 4

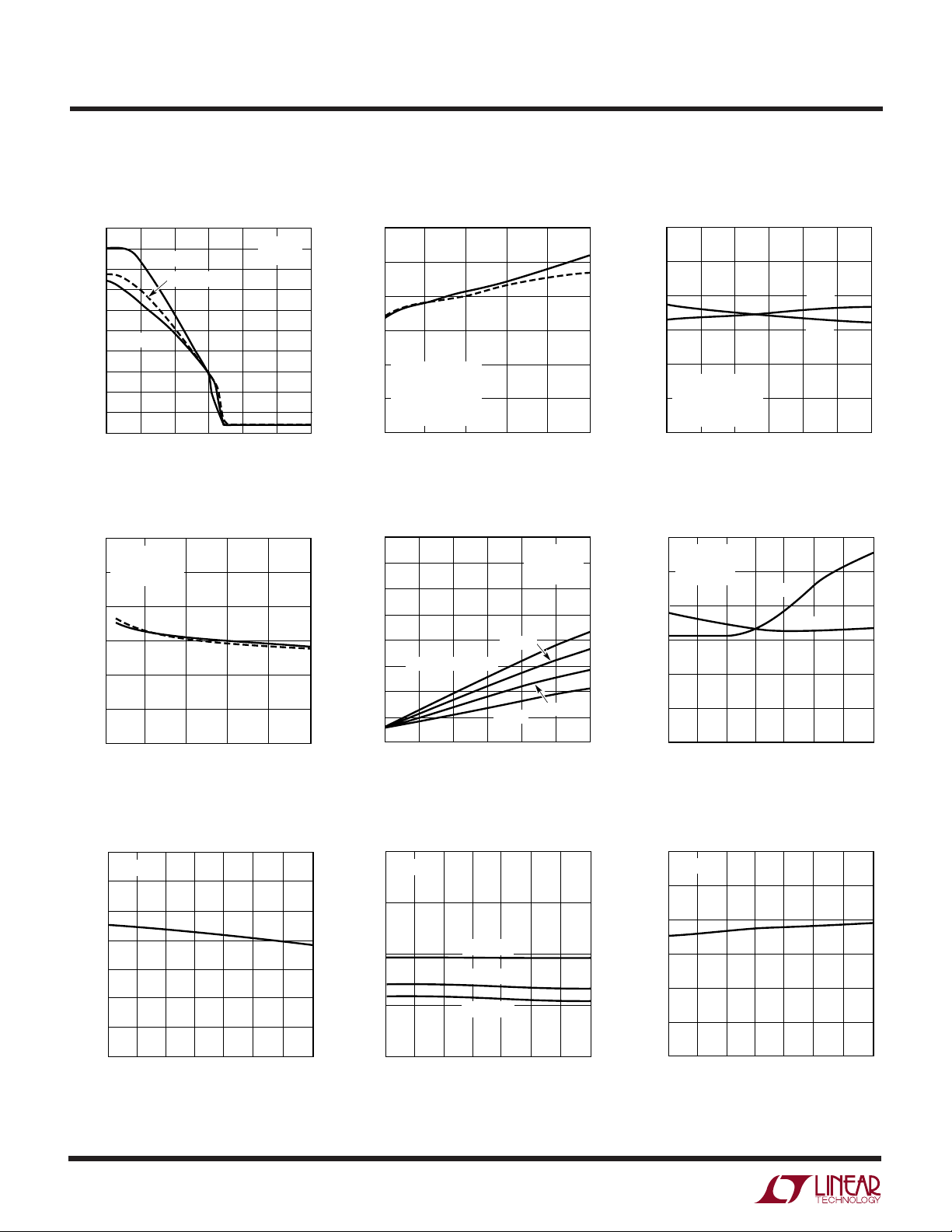

LT1394

POSITIVE SUPPLY VOLTAGE (V)

4.4

TIME (ns)

12

10

8

6

4

2

0

4.6 4.8 5.0 5.2 5.4

1394 G03

5.6

t

PDHL

t

PDLH

V– = –5V

T

A

= 25°C

V

STEP

= 100mV

OVERDRIVE = 5mV

W

U

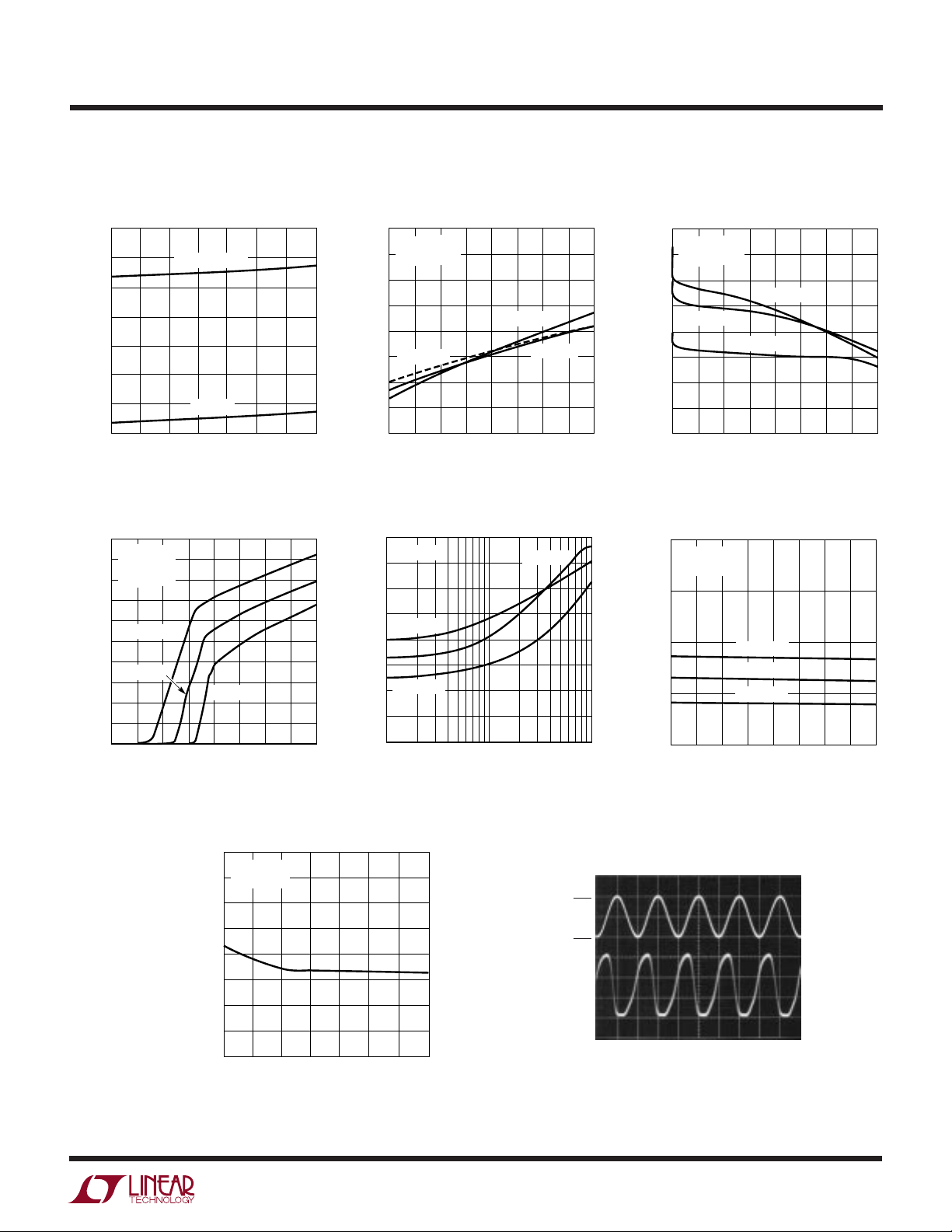

TYPICAL PERFORMANCE CHARACTERISTICS

Gain Characteristics

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

OUTPUT VOLTAGE (V)

1.0

0.5

0

TA = 125°C

TA = 25°C

TA = –55°C

–3

–2

–1

DIFFERENTIAL INPUT VOLTAGE (mV)

Propagation Delay vs

Input Overdrive

12

TA = 25°C

= 100mV

V

STEP

10

= ±5V

V

S

8

6

TIME (ns)

4

2

0

10 20 30 40

0

OVERDRIVE (mV)

01

t

PDLH

t

PDHL

VS = ±5V

= 0

I

OUT

2

1394 G01

1394 TA02

Propagation Delay vs

Load Capacitance

12

10

8

6

TIME (ns)

4

I

= 0

OUT

V

= ±5V

S

= 25°C

T

A

2

= 100mV

V

STEP

OVERDRIVE = 5mV

0

10 20 30 40

3

0

OUTPUT LOAD CAPACITANCE (pF)

t

PDLH

t

PDHL

50

1394 G02

Propagation Delay vs

Source Resistance

80

70

60

50

40

TIME (ns)

50

30

20

10

0

0 0.5

STEP SIZE = 800mV

1.0 2.01.5

SOURCE RESISTANCE (kΩ)

400mV

100mV

VS = ±5V

= 20mV

V

OD

= 25°C

T

A

200mV

2.5

3.0

1394 G04

Propagation Delay vs

Positive Supply Voltage

Propagation Delay vs

Temperature

12

VS = ±5V

= 100mV

V

STEP

10

= 5mV

V

OD

8

6

TIME (ns)

4

2

0

–50

–25 0

TEMPERATURE (°C)

t

PDLH

t

PDHL

50 100 125

25 75

1394 G05

Input Offset Voltage vs

Temperature

2

VS = ±5V

1

0

–1

–2

VOLTAGE (mV)

–3

–4

–5

–50 25 75

–25 0

TEMPERATURE (°C)

4

50 100 125

LT1394 G06

Input Bias Current vs

Temperature

4

VS = ±5V

3

2

1

INPUT BIAS CURRENT (µA)

0

–50 25 75

–25 0

VCM = –5V

VCM = 0V

VCM = 3.5V

TEMPERATURE (°C)

50 100 125

LT1394 G07

Positive Common Mode Limit vs

Temperature

6

VS = ±5V

5

4

3

VOLTAGE (V)

2

1

0

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

1394 G08

Page 5

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

LT1394

Negative Common Mode Limit vs

Temperature

1

0

–1

–2

–3

INPUT VOLTAGE (V)

–4

–5

–6

–50 25 75

–25 0

VS = SINGLE 5V

VS = ±5V

50 100 125

TEMPERATURE (°C)

Positive Supply Current vs

V+ Supply Voltage

10

V– = 0V

9

= –60mV

V

IN

= 0

I

8

OUT

7

6

TA = 125°C

5

4

TA = 25°C

CURRENT (mA)

3

2

1

0

0

13

2

TA = –55°C

4

SUPPLY VOLTAGE (V)

5

Output Low Voltage (VOL) vs

Output Sink Current

0.8

VS = ±5V

LT1394 G09

0.7

0.6

0.5

0.4

VOLTAGE (V)

0.3

0.2

0.1

= 30mV

∆V

IN

TA = 125°C

TA = –55°C

0

02 6 10 14

4

OUTPUT SINK CURRENT (mA)

TA = 25°C

8

12

16

1394 G10

Positive Supply Current vs

Switching Frequency

16

VS = ±5V

14

12

10

TA = 125°C

8

6

CURRENT (mA)

TA = –55°C

4

2

0

7

6

8

1394 G12

1

SWITCHING FREQUENCY (MHz)

TA = 25°C

10 100

1394 G13

Output High Voltage (VOH) vs

Output Source Current

5.0

VS = ±5V

4.5

4.0

3.5

3.0

2.5

OUTPUT VOLTAGE (V)

2.0

1.5

1.0

= –30mV

∆V

IN

TA = 125°C

TA = 25°C

TA = –55°C

02 6 10 14

4

OUTPUT SOURCE CURRENT (mA)

8

Negative Supply Current vs

V– Supply Voltage

4

+

V

= 5V

∆V

= –60mV

IN

3

2

CURRENT (mA)

1

0

–7 –5 –3

–8

TA = 125°C

TA = 25°C

TA = –55°C

–6

NEGATIVE SUPPLY VOLTAGE (V)

–4

–1

16

1394 G11

0

1394 G14

12

–2

Latch Pin Current vs Temperature

8

VS = ±5V

7

6

5

4

3

CURRENT (µA)

2

1

0

= 0V

V

LATCH

–50 25 75

–25 0

TEMPERATURE (°C)

50 100 125

LT1394 G15

Response to 100MHz ±10mV

Sine Wave

+IN

20mV

P-P

3V

Q

OUT

0V

FET PROBES 5ns/DIV

10mV/DIV

1V/DIV

1394 G16

5

Page 6

LT1394

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

+

t

Response Time to

PD

5mV Overdrive

1.4V

+IN

5mV

–95mV

V

= ±5V 2ns/DIV

S

= 2MHz

f

IN

V

= 5mV 1394 G17

OD

Q OUT

0V

UUU

PIN FUNCTIONS

V+ (Pin 1): Positive Supply Voltage. Normally 5V.

+IN (Pin 2): Noninverting Input.

–IN (Pin 3): Inverting Input.

V– (Pin 4): Negative Supply Voltage. Normally either 0V or

– 5V.

–

t

Response Time to

PD

5mV Overdrive

1.4V

5mV

+IN

–95mV

VS = ±5V 2ns/DIV

= 2MHz

f

IN

V

= 5mV 1394 G18

OD

Q OUT

0V

GND (Pin 6): Ground.

Q OUT (Pin 7): Noninverting Logic Output. This pin is high

when +IN is above –IN and LATCH ENABLE is low.

Q OUT (Pin 8): Inverting Logic Output. This pin is low

when +IN is above –IN and LATCH ENABLE is low.

LATCH ENABLE (Pin 5): Latch Control Pin. When high, the

outputs remain in a latched condition, independent of the

current state of the inputs.

UW

W

TI I G DIAGRA S

V

OD

∆V

V

IN

V

OUT

IN

t

PD

1394 TD01

LATCH

ENABLE

V

V

OUT

t

SU

IN

t

H

t

L

PD

1394 TD02

6

Page 7

LT1394

U

WUU

APPLICATIONS INFORMATION

Common Mode Considerations

The LT1394 is specified for a common mode range of – 5V

to 3.5V on a ±5V supply or a common mode range of 0V

to 3.5V on a single 5V supply. A more general consideration is that the common mode range is 0V below the

negative supply and 1.5V below the positive supply, independent of the actual supply voltage. The criterion for

common mode limit is that the output still responds

correctly to a small differential input signal.

When either input signal falls below the negative common

mode limit, the internal PN diode formed with the substrate can turn on, resulting in significant current flow

through the die. An external Schottky clamp diode

between the input and the negative rail can speed up

recovery from negative overdrive by preventing the substrate diode from turning on. The zero-crossing detector

in Figure 1 demonstrates the use of a fast clamp diode.

The zero-crossing detector terminates the transmission

line at its 50Ω characteristic impedance. Negative inputs

should not fall below – 2V to keep the signal current within

the clamp diode’s maximum forward rating. Positive

inputs should not exceed the device’s absolute maximum

ratings or the power rating on the terminating resistor.

Either input may go above the positive common mode

limit without damaging the comparator. The upper voltage

limit is determined by an internal diode from each input to

the positive supply. The input may go above the positive

supply as long as it does not go far enough above it to

conduct more than 10mA. Functionality will continue if the

remaining input stays within the allowed common mode

range. There will, however, be an increase in propagation

delay as the input signal switches back into the common

mode range.

+

LT1394

–

5V

Q

Q

1394 F01

R

S

50Ω

V

IN

CABLE

R

1N5712

Figure 1. Fast Zero-Crossing Detector

T

50Ω

Input Bias Current

Input bias current is measured with the output held at

1.4V. As with any PNP differential input stage, the LT1394

bias current flows out of the device. It will go to zero on an

input which is high and double on an input which is low.

LATCH Pin Dynamics

The LATCH pin is intended to retain input data (output

latched) when the LATCH pin goes high. The pin will float

to a high state when disconnected, so a flow-through

condition requires that the LATCH pin be grounded. The

LATCH pin is designed to be driven with either a TTL or

CMOS output. It has no built-in hysteresis.

To guarantee data retention, the input signal must remain

valid at least 2ns after the latch goes high (hold time), and

must be valid at least –0.4ns before the latch goes high

(setup time). The negative setup time simply means that

the data arriving 0.4ns after (rather than before) the latch

signal is valid. When the latch signal goes low, new data

will appear at the output in approximately 6ns (latch

propagation delay).

Measuring Response Time

To properly measure the response of the LT1394 requires

an input signal source with very fast rise times and

exceptionally clean settling characteristics. The last

requirement comes about because the standard comparator test calls for an input step size that is large compared

to the overdrive amplitude. Typical test conditions are

100mV step size with 5mV overdrive. This requires an

input signal that settles to within 1% (1mV) of final value

in only a few nanoseconds with no ringing or settling tail.

Ordinary high speed pulse generators are not capable of

generating such a signal, and in any case, no ordinary

oscilloscope is capable of displaying the waveform to

check its fidelity. Some means must be used to inherently

generate a fast, clean edge with known final value. The

circuit shown in Figure 2 is the best electronic means of

generating a fast, clean step to test comparators. It uses

a very fast transistor in a common base configuration. The

transistor is switched off with a fast edge from the generator and the collector voltage settles to exactly 0V in just a

few nanoseconds. The most important feature of this

7

Page 8

LT1394

U

WUU

APPLICATIONS INFORMATION

0V

25Ω

25Ω

10k

V1**

–100mV

–3V

0.1µF

PULSE

IN

0V

50Ω

130Ω

2N3866

750Ω400Ω

–5V

Figure 2. Response Time Test Circuit

circuit is the lack of feedthrough from the generator to the

comparator input. This prevents overshoot on the comparator input, which would give a false fast reading on

comparator response time.

To adjust the circuit for exactly 5mV overdrive, V1 is

adjusted so that the LT1394 output under test settles to

1.4V (in the linear region). Then V1 is changed by –1V to

set overdrive to 5mV.

High Speed Design Techniques

A substantial amount of design effort has made the LT1394

relatively easy to use. It is much less prone to oscillation

than some slower comparators, even with slow input

signals. However, as with any high speed comparator,

there are a number of pitfalls which may arise because of

PC board layout and design. The most common problems

involve power supply bypassing. Bypassing is necessary

to maintain low supply impedance. DC resistance and

inductance in supply wires and PC traces can quickly build

up to unacceptable levels. This allows the supply line to

move with changing internal current levels of the connected devices. This will almost always result in improper

operation. In addition, adjacent devices connected through

an unbypassed supply can interact with each other through

the finite supply impedances. Bypass capacitors furnish a

simple solution to this problem by providing a local

reservoir of energy at the device, keeping supply impedances low.

Bypass capacitors should be as close as possible to the

LT1394. A good high frequency capacitor such as a 0.1µF

0.01µF*

5V

Q

50Ω

+

LT1394

–

–5V

Q

0.01µF

FET PROBE

FET PROBE

* TOTAL LEAD LENGTH INCLUDING DEVICE PIN.

SOCKET AND CAPACITOR LEADS SHOULD BE

LESS THAN 0.5 IN. USE GROUND PLANE

** (V

+ OVERDRIVE)/200

OS

1394 F02

ceramic is recommended, in parallel with a larger capacitor such as a 4.7µF tantalum.

Poor trace routes and high source impedances are also

common sources of problems. Be sure to keep trace

lengths as short as possible, and avoid running any output

trace adjacent to an input trace to prevent unnecessary

coupling. If output traces are longer than a few inches, be

sure to terminate them with a resistor to eliminate any

reflections that may occur. Resistor values are typically

250Ω to 400Ω. Also, be sure to keep source impedances

as low as possible, preferably 1kΩ or less.

Crystal Oscillators

Figure 3’s circuits are crystal oscillators. In the circuit (a)

the resistors at the LT1394’s positive input set a DC bias

point. The 2k-0.068µF path sets up phase shifted feedback

and the circuit looks like a wideband unity-gain follower at

DC. The crystal’s path provides resonant positive feedback and stable oscillation occurs. The circuit (b) is

similar, but supports oscillation frequencies to 30MHz.

Above 10MHz, AT-cut crystals operate in overtone mode.

Because of this, oscillation can occur at multiples of the

desired frequency. The damper network rolls off gain at

high frequency, ensuring proper operation.

Switchable Output Crystal Oscillator

Figure 4 permits crystals to be electronically switched by

logic commands. This circuit is similar to the previous

examples, except that oscillation is only possible when

one of the logic inputs is biased high.

8

Page 9

LT1394

U

WUU

APPLICATIONS INFORMATION

5V

2k

(a)

(b)

22Ω

820pF

2k

5V

2k

2k

Figure 3. Crystal Oscillators for Outputs to 30MHz. Circuit (b)’s

Damper Network Supresses Overtone Crystal’s Harmonic Modes

XTAL X

XTAL B

5V

1k

XTAL A

+

1k

LT1394

–

75pF

= 1N4148

GROUND XTAL CASES

Figure 4. Switchable Output Crystal Oscillator. Biasing A or B

High Places Associated Crystal in Feedback Path. Additional

Crystal Branches Are Permissible

1MHz TO 10MHz

CRYSTAL (AT-CUT)

+

LT1394

–

0.068µF

10MHz TO 25MHz

CRYSTAL (AT-CUT)

+

LT1394

–

200pF

D2

D1

2k

OUTPUT

2k

OUTPUT

2k

1394 F03

R

LOGIC INPUTS

X

AS MANY STAGES

D

X

AS DESIRED

1k

B

1k

A

OUTPUT

1394 F04

Temperature-Compensated Crystal Oscillator (TXCO)

Figure 5 is a temperature-compensated crystal oscillator

(TXCO). This circuit reduces oscillator temperature drift

by inserting a temperature-dependent compensatory correction into the crystal’s frequency trimming network.

This open-loop correction technique relies on cancellation

of the temperature characteristics of the oscillator, which

are quite repeatable.

The LT1394 and associated components form the crystal

oscillator, operating similarly to Figure 3’s examples. The

LM134, a temperature-dependent current source, biases

A1. A1 takes gain referred to the LM134’s output and the

negative offset supplied via the 470kΩ-LT1004 reference

path. Note that the LT1004’s negative voltage bias is

bootstrapped from the oscillator’s output, maintaining

single supply operation. This arrangement delivers temperature-dependent bias to the varactor diode, causing a

scaled variation in the crystal’s resonance versus ambient

temperature. The varactor’s bias-dependent capacitance

shift pulls crystal frequency to complement the circuit’s

temperature drift. The simple first order fit provided by the

compensation is very effective. Figure 6 shows results.

The –70ppm frequency shift over 0°C to 70°C is corrected

within a few ppm. The “FREQ SET” trim also biases the

varactor, allowing accurate output frequency setting. It is

worth noting that better compensation is possible by

including higher order terms in the temperature-to-voltage conversion.

18ns, 500µV Sensitivity Comparator

The ultimate limitation on comparator sensitivity is available gain. Unfortunately, increasing gain invariably

involves giving up speed. The gain vs. speed trade-off in a

fast comparator is usually a practical compromise

designed to satisfy most applications. Some situations,

however, require more sensitivity (e.g., higher gain) with

minimal impact on speed. Figure 7’s circuit adds a differential preamplifier ahead of the LT1394, increasing gain.

This permits 500µV comparisons in 18ns. A parallel path

DC stabilization approach eliminates preamplifier drift as

an error source. A1 is the differential preamplifier, operating at a gain of 100. Its output is AC-coupled to the LT1394.

9

Page 10

LT1394

U

WUU

APPLICATIONS INFORMATION

0.01µF

+

–

0.068µF

MV-209

VARACTOR

DIODE

LT1394

2k

2M

10MHz

1µF

10M

2k

5V

390Ω

XTAL AT-CUT, 35° 25′ ANGLE

* 1% FILM RESISTOR

2M

0.01µF

4.7k

BAT-85

5.8M*

A1

LT1077

+

1µF

–

+

50k

1M*

1M*

470k*

LT1004-1.2

226Ω*

100k

1M

FREQ SET

5V

LM134

10mV/°C

10k*

10MHz

0.05ppm/°C

1394 F05

Figure 5. Temperature-Compensated 10MHz Crystal Oscillator.

Temperature-Dependent Varactor Bias Reduces Drift by 20:1

0

–10

–20

–30

–40

–50

–60

FREQUENCY DEVIATION (ppm)

–70

0

UNCOMPENSATED

(VARACTOR CORRECTION

DISABLED) –1ppm/°C

10 20

TEMPERATURE (°C)

COMPENSATED

≈ 0.05ppm/°C

40 60 70

30 50

1394 F06

Figure 6. Figure 5’s Compensated vs Uncompensated

Temperature Dependence. First Order Compensation

Reduces Oscillator Drift to 0.05ppm/°C

200pF

+INPUT

–INPUT

5V

+

A2

2k

1/2 LT1126

–

–

A3

1/2 LT1126

10k

200Ω

10k

+

200pF

+

LM733

A = 100

–

–5V

5V

+

A1

1µF

1k

+

LT1394

–

OUTPUT

2k

–

1µF

–5V

1k

1394 F07

10

Figure 7. Parallel Preamplified Paths Allow 18ns Comparator

Response to 500µV Overdrive

Page 11

LT1394

U

WUU

APPLICATIONS INFORMATION

A1 has poorly defined DC characteristics, necessitating

some form of DC correction. A2 and A3, operating at a

differential gain of 100, provide this function. They differentially sense a band limited version of A1’s inputs and feed

DC and low frequency amplified information to the comparator. The low frequency roll-off of A1’s signal path

complements A2-A3’s high frequency roll-off. The summation of these two signal channels at the LT1394 inputs

results in flat response from DC to high frequency.

Figure 8 shows waveforms for the high gain comparator.

Trace A is a 500µV overdrive on a 1mV step applied to the

circuit’s positive input (negative input grounded). Trace B

shows the resulting amplified step at A1’s positive output.

Trace C is A2’s band limited output. A1’s wideband output

combines with A2’s DC corrected information to yield the

A = 1mV/DIV

B = 0.1V/DIV

(AC-COUPLED)

C = 0.1V/DIV

correct, amplified composite signal at the LT1394’s positive input in Trace D. The LT1394’s output is Trace E. Figure

9 details circuit propagation delay. The output responds in

18ns to a 500µV overdrive on a 1mV step. Figure 10 plots

response time versus overdrive. As might be expected,

propagation delay decreases at higher overdrives. A1’s

noise limits usable sensitivity.

1100

1000

900

800

OVERDRIVE (µV)

700

600

500

15

Figure 10. Response Time vs Overdrive for the

Composite Comparator

16 17 18

RESPONSE TIME (ns)

1394 F10

D = 0.1V/DIV

E = 5V/DIV

5µs/DIV 1394 F08

Figure 8. 500µV Input (Trace A) Is Split into Wideband

and Low Frequency Gain Paths (Traces B and C) and

Recombined (Trace D). Comparator Output Is Trace E

A = 1mV/DIV

B = 1V/DIV

10ns/DIV 1394 F09

Figure 9. Parallel Path Comparator Shows 18ns

Response (Trace B) to 500µV Overdrive (Trace A)

Voltage-Controlled Delay

The ability to set a precise, predictable delay has broad

application in pulse circuitry. Figure 11’s configuration

sets a 0 to 300ns delay from a corresponding 0V to 3V

control voltage. It takes advantage of the LT1394’s speed

and the clean dynamics of an emitter switched current

source.

Q1 and Q2 form a current source that charges the 1000pF

capacitor. When the trigger input is high (Trace A, Figure

12) both Q3 and Q4 are on. The current source is off and

Q2’s collector (Trace B) is at ground. The latch input at the

LT1394 prevents it from responding and its output remains

high. When the trigger input goes low, the LT1394’s latch

input is disabled and its output drops low. Q4’s collector

(Trace C) lifts and Q2 comes on, delivering constant

current to the 1000pF capacitor (Trace B). The resulting

linear ramp at the LT1394’s positive input is compared to

the delay programming voltage input. When a crossing

occurs, the comparator goes high (Trace D). The length of

time the comparator was low is directly proportional to the

11

Page 12

LT1394

U

WUU

APPLICATIONS INFORMATION

0.1µF

5V

Q2

100Ω

100Ω

(DELAY

CALIB)

Q4

LT1634

Q1

1000pF

220Ω

PNP = 2N5087

NPN = 2N2369

Figure 11. Fast, Precise, Voltage-Controlled Delay.

Emitter Switched Current Source Has Clean,

Predictable Dynamics

DELAY PROGRAMMING

VOLTAGE INPUT

0V TO 3V = 0 TO 300ns DELAY

51pF

330Ω

Q3

330Ω

TRIGGER INPUT

200ns MINIMUM

1k

0.1µF

–

LT1394

+

Q OUTPUT

Q OUTPUT

1394 F11

A = 5V/DIV

B = 2V/DIV

C = 5V/DIV

D = 5V/DIV

100ns/DIV

1394 F12

Figure 12. Voltage-Controlled Delay’s Waveforms.

Programming Voltage Determines Delay Between Input

(Trace A) Falling Edge and Output (Trace D) Rising Edge.

High Linearity Timing Ramp (Trace B) Permits 1ns

Accuracy and 100ps Repeatability

A = 2V/DIV

B = 0.1V/DIV

C = 2V/DIV

D = 2V/DIV

delay programming voltage. The fast switching and ramp

linearity permits 1ns accuracy and 100ps repeatability.

Figure 13, a high speed expansion of the current source

turn-on, details the clean switching. Q4 goes off within 2ns

of the trigger input (Trace A) dropping low, enabling the

current source (Q2’s emitter is Trace C). Concurrently, the

1000pF capacitor’s ramp (Trace B) begins. The LT1394’s

output (Trace D) drops low about 7ns later, returning high

after crossing (in this case) a relatively low programming

voltage. Figure 14 juxtaposes the waveforms differently,

permitting enhanced study of circuit timing. Switching

begins with the input trigger falling low (Trace A). The ramp

(Trace C) begins 3ns after the current source turns on (Q2

emitter is Trace D). The output pulse (Trace B) begins

about 4ns later.

To calibrate this circuit apply a trigger input and 3V to the

programming input. Adjust the 100Ω trim for a 300ns

width at the LT1394’s output.

10ns/DIV 1394 F13

Figure 13. High Speed Expansion of Figure 12. Ramp

(Trace B) Begins When Trigger (Trace A) Falls and

Current Source Turns On (Trace C). Trace D is Output

A = 1V/DIV

B = 1V/DIV

C = 0.1V/DIV

D = 1V/DIV

10ns/DIV 1394 F14

Figure 14. Delay’s Output Switching Begins with

Trigger Falling Low (Trace A). Ramp (Trace C) Starts

3ns After Current Source Turn-On (Trace D). Output

(Trace B) Begins 4ns Later

12

Page 13

LT1394

U

WUU

APPLICATIONS INFORMATION

Fast, High Impedance, Variable Threshold Trigger

A frequent requirement in instrumentation is a fast trigger

with a variable threshold. Often, a high impedance input is

also required. Figure 15 meets these requirements. Comparator C1 is the basic trigger, with threshold voltage set at

its negative input. Source follower Q1 provides high

impedance with about 2pF input capacitance and 50pA bias

current. Normally, Q1’s source bias point would be uncertain and drifty, but stabilization techniques eliminate this

concern. A1 measures filtered versions of Q1’s gate and

source voltages. A1’s output biases Q2, forcing Q1’s

channel current to whatever value is required to equalize

A1’s inputs, and hence Q1’s gate and source voltages. A1’s

input filtering and roll-off are far slower than input frequencies of interest; its action does not interfere with the

circuit’s main signal path. The 330pF capacitor prevents

fast edges coupled through Q2’s collector base junction

from influencing A1’s operation.

Q1 should contribute negligible timing error to minimize

overall delay. Figure 16’s photo verifies Q1’s wideband

operation. Trace B, Q1’s source, lags the input (Trace A) by

only 300ps. Input, FET buffer output and C1 output appear

as Traces A, B and C, respectively in Figure 17. As before,

the FET buffer is seen to contribute small timing error, and

C1’s output is about 8ns delayed from the input.

A = 1V/DIV

B = 1V/DIV

200ps/DIV 1394 F16

V

TRIG

±3V

–

LT1394

C1

OUTPUT

INPUT

±3V

5V

Q1

2N5486

+

10M

10M

0.1µF

1394 F15

Q2

2N3904

100Ω

–5V

1.5k

330pF

0.01µF

A1

LT1097

10k

–

+

0.1µF

Figure 15. Buffer Provides 2pF, 50pA Input Characteristics for

Fast Trigger. Amplifier-Stabilized Biasing Eliminates FET Offset

Figure 16. Trigger Buffer’s 300ps Delay Minimizes

Timing Error. 4GHz Sampling Oscilloscope’s Output Is

a Series of Dots

C = 2V/DIV

A = 1V/DIV

B = 1V/DIV

10ns/DIV 1394 F17

Figure 17. Input (Trace A), FET Source (Trace B)

and Output (Trace C) Waveforms for the Trigger.

Total Delay Is 8ns

13

Page 14

LT1394

U

WUU

APPLICATIONS INFORMATION

High Speed Adaptive Trigger Circuit

Line and fibre-optic receivers often require an adaptive

trigger to compensate for variations in signal amplitude

and DC offsets. The circuit in Figure 18 triggers on 2mV to

175mV signals from 100Hz to 45MHz while operating from

a single 5V rail. A1, operating at a gain of 15, provides

wideband AC gain. The output of this stage biases a 2-way

peak detector (Q1 through Q4). The maximum peak is

stored in Q2’s emitter capacitor, while the minimum excursion is retained in Q4’s emitter capacitor. The DC value of

the midpoint of A1’s output signal appears at the junction

of the 500pF capacitor and the 3MΩ units. This point

always sits midway between the signal’s excursions,

egardless of absolute amplitude. This signal-adaptive voltage is buffered by A2 to set the trigger voltage at the

LT1394’s positive input. The LT1394’s negative input is

biased directly from A1’s output. The LT1394’s output, the

circuit’s output, is unaffected by >85:1 signal amplitude

variations. Bandwidth limiting in A1 does not affect triggering because the adaptive trigger threshold varies

ratiometrically to maintain circuit output.

Figure 19 shows operating waveforms at 45MHz. Trace A’s

input produces Trace B’s amplified output at A1. The

comparator’s output is Trace C.

Split supply versions of this circuit can achieve bandwidths to 50MHz with wider input operating range.

A = 0.1V/DIV

B = 0.1V/DIV

C = 5V/DIV

AN72 F64

50ns/DIV

Figure 19. Adaptive Trigger Responding to a 40MHz,

5mV Input. Input Amplitude Variations from 2mV to

175mV Are Accommodated

10µF

5V

2k

1

0.005µF

14

2k

6

5

3M

4

500pF

0.005µF

10

12

11

3M

Q4

+

LT1006

–

5V

A2

Q1, Q2, Q3, Q4 = CA3096 ARRAY:

TIE SUBSTRATE (PIN 16) TO GROUND

= 1N4148

470Ω

+

470Ω

0.1µF

LT1394

–

TRIGGER

OUT

1394 F18

3

Q1 Q2

+

LT1227

5V

A1

2

–

750Ω

2k

5V

+

+

0.1µF

INPUT

36Ω

100µF

510Ω

0.1µF

13

Q3

15

Figure 18. 45MHz Single Supply Adaptive Trigger. Output Comparator’s

Threshold Varies Ratiometrically with Input Amplitude, Maintaining Data

Integrity over >85:1 Input Amplitude Range

14

Page 15

PACKAGE DESCRIPTION

(

U

Dimensions in inches (millimeters) unless otherwise noted.

MS8 Package

8-Lead Plastic MSOP

(LTC DWG # 05-08-1660)

0.118 ± 0.004*

(3.00 ± 0.102)

8

7

6

5

LT1394

0.192 ± 0.004

(4.88 ± 0.10)

12

0.040

± 0.006

SEATING

PLANE

(1.02 ± 0.15)

0.012

(0.30)

0.0256

REF

(0.65)

0.152mm) PER SIDE

TYP

0.007

(0.18)

0.021

± 0.006

(0.53 ± 0.015)

* DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006"

° – 6° TYP

0

0.118 ± 0.004**

4

3

(3.00 ± 0.102)

0.034 ± 0.004

(0.86 ± 0.102)

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.189 – 0.197*

(4.801 – 5.004)

7

8

6

0.006 ± 0.004

(0.15 ± 0.102)

MSOP (MS8) 1197

5

0.228 – 0.244

(5.791 – 6.197)

1

2

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

0.016 – 0.050

0.406 – 1.270

× 45°

0.053 – 0.069

(1.346 – 1.752)

0°– 8° TYP

0.014 – 0.019

(0.355 – 0.483)

0.150 – 0.157**

(3.810 – 3.988)

3

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

TYP

SO8 0996

15

Page 16

LT1394

U

TYPICAL APPLICATION

Voltage-Controlled Crystal Oscillator (VCXO)

Figure 20, a variant of the basic crystal oscillator, permits

voltage tuning the output frequency. Such voltage-controlled crystal oscillators (VCXO) are often employed

where slight variation of a stable carrier is required. This

example is specifically intended to provide a 4× NTSC

sub-carrier tunable oscillator suitable for phase locking.

The LT1394 is set up as a crystal oscillator, operating

similarly to Figure 3 (a). The varactor diode is biased from

the tuning input. The tuning network is arranged so a 0V

to 5V drive provides a reasonably symmetric, broad tuning

range around the 14.31818MHz center frequency. The

indicated selected capacitor sets tuning bandwidth. It

should be picked to complement loop response in phase

locking applications. Figure 21 is a plot of tuning input

voltage versus frequency deviation. Tuning deviation from

the 4× NTSC 14.31818MHz center frequency exceeds

±240ppm for a 0V to 5V input.

1N4148

1M

1M

5V

MV-209

C SELECT***

0.047µF

†

1M*

1M

9

8

7

6

5

14.31818MHz

4

3

2

FREQUENCY DEVIATION (kHz)

1

14.314.0MHz

0

0

13

INPUT VOLTAGE (V)

14.3217MHz

5

2

4

1394 F21

Figure 21. Control Voltage vs Output Frequency for Figure 15.

Tuning Deviation from Center Frequency Exceeds ±240ppm

5V

47k*

LT1004-2.5

1k*

3.9k*

V

IN

0V TO 5V

100pF

2k

390Ω

200pF

+

LT1394

–

Y1**

15pF

2k

100pF

* 1% FILM RESISTOR

** NORTHERN ENGINEERING LABS C-2350N-14.31818MHz

*** C SELECT SETS TUNING BANDWIDTH. SET TO COMPLEMENT

LOOP RESPONSE IN PHASE LOCKING APPLICATIONS

†

VARACTOR DIODE

FREQUENCY

OUTPUT

1394 F20

Figure 20. A 4× NTSC Sub-Carrier Voltage-Tunable Crystal Oscillator. Tuning Range

and Bandwidth Accommodate Variety of Phase Locked Loops

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1016 UltraFast Precision Comparator Industry Standard 10ns Comparator

LT1116 12ns Single Supply Ground-Sensing Comparator Single Supply Version of LT1016

LT1671 Fast Single Supply Comparator 60ns, 450µA Single Supply Comparator

LT1720 UltraFast Dual Single Supply Comparator Dual 4.5ns, 4mA Single Supply Comparator

1394f LT/TP 0499 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1998

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

Loading...

Loading...