Page 1

LT1312

Single PCMCIA

OBSOLETE:

FOR INFORMATION PURPOSES ONLY

Contact Linear Technology for Potential Replacement

FEATURES

■

Digital Selection of 0V, VCC, 12V or Hi-Z

■

120mA Output Current Capability

■

Internal Current Limiting and Thermal Shutdown

■

Automatic Switching from 3.3V to 5V

■

Powered from Unregulated 13V to 20V Supply

■

Logic Compatible with Standard PCMCIA Controllers

■

1µF Output Capacitor

■

30µA Quiescent Current in Hi-Z or 0V Mode

■

VPP Valid Status Feedback Signal

■

No VPP Overshoot

■

8-Pin SO Packaging

U

APPLICATIONS

■

Notebook Computers

■

Palmtop Computers

■

Pen-Based Computers

■

Handi-Terminals

■

Bar-Code Readers

■

Flash Memory Programming

VPP Driver/Regulator

U

DESCRIPTION

The LT®1312 is a member of Linear Technology

Corporation’s family of PCMCIA drivers/regulators. The

LT1312 provides 0V, 3.3V, 5V, 12V and Hi-Z regulated

power to the VPP pin of a PCMCIA card slot from a single

unregulated 13V to 20V supply. When used in conjunction

with a PC card interface controller, the LT1312 forms a

complete minimum component-count interface for palmtop, pen-based and notebook computers. The VPP output

voltage is selected by two logic compatible digital inputs

which interface directly with industry standard PC card

interface controllers.

Automatic 3.3V to 5V switching is provided by an internal

comparator which continuously monitors the PC card V

supply and automatically adjusts the regulated VPP output to match VCC when the VPP = VCC mode is selected.

An open-collector VPP VALID output is driven low when

VPP is in regulation at 12V.

The LT1312 is available in an 8-pin SO package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

CC

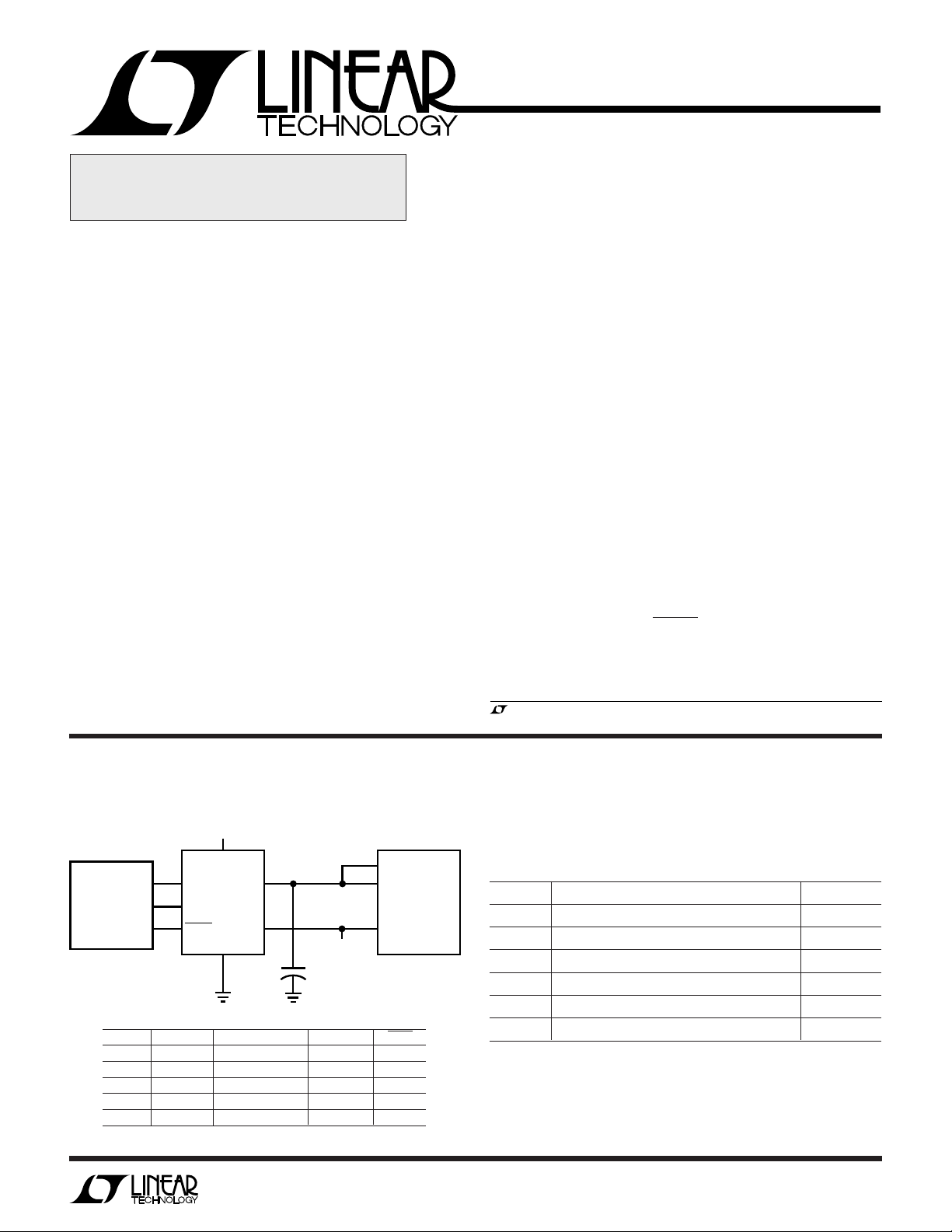

TYPICAL APPLICATION

Typical PCMCIA Single Slot VPP Driver

13V TO 20V

V

S

VPP

PCMCIA

CARD SLOT

CONTROLLER

LT1312 TRUTH TABLE

EN0 EN1 SENSE VPP

00 X 0V 1

1 0 X 12V 0

0 1 3.0V TO 3.6V 3.3V 1

0 1 4.5V TO 5.5V 5V 1

1 1 X Hi-Z 1

X = DON’T CARE

EN0

VALID SENSE

LT1312EN1

GND

OUT

+

C

1µF

TANTALUM

U

3.3V OR 5V

OUT

OUT

VPP1

VPP2

PCMCIA

CARD SLOT

V

CC

VALID

LT1312 TA1

Linear Technology PCMCIA Product Family

DEVICE DESCRIPTION PACKAGE

LT1312 SINGLE PCMCIA VPP DRIVER/REGULATOR 8-PIN SO

LT1313 DUAL PCMCIA VPP DRIVER/REGULATOR 16-PIN SO*

LTC®1314 SINGLE PCMCIA SWITCH MATRIX 14-PIN SO

LTC1315 DUAL PCMCIA SWITCH MATRIX 24-PIN SSOP

LTC1470 PROTECTED VCC 5V/3.3V SWITCH MATRIX 8-PIN SO

LTC1472 PROTECTED VCC AND VPP SWITCH MATRIX 16-PIN SO*

*NARROW BODY

1

Page 2

LT1312

1

2

3

4

8

7

6

5

TOP VIEW

S8 PACKAGE

8-LEAD PLASTIC SO

GND

ENO

EN1

VALID

VPP

OUT

N.C.

V

S

SENSE

WW

W

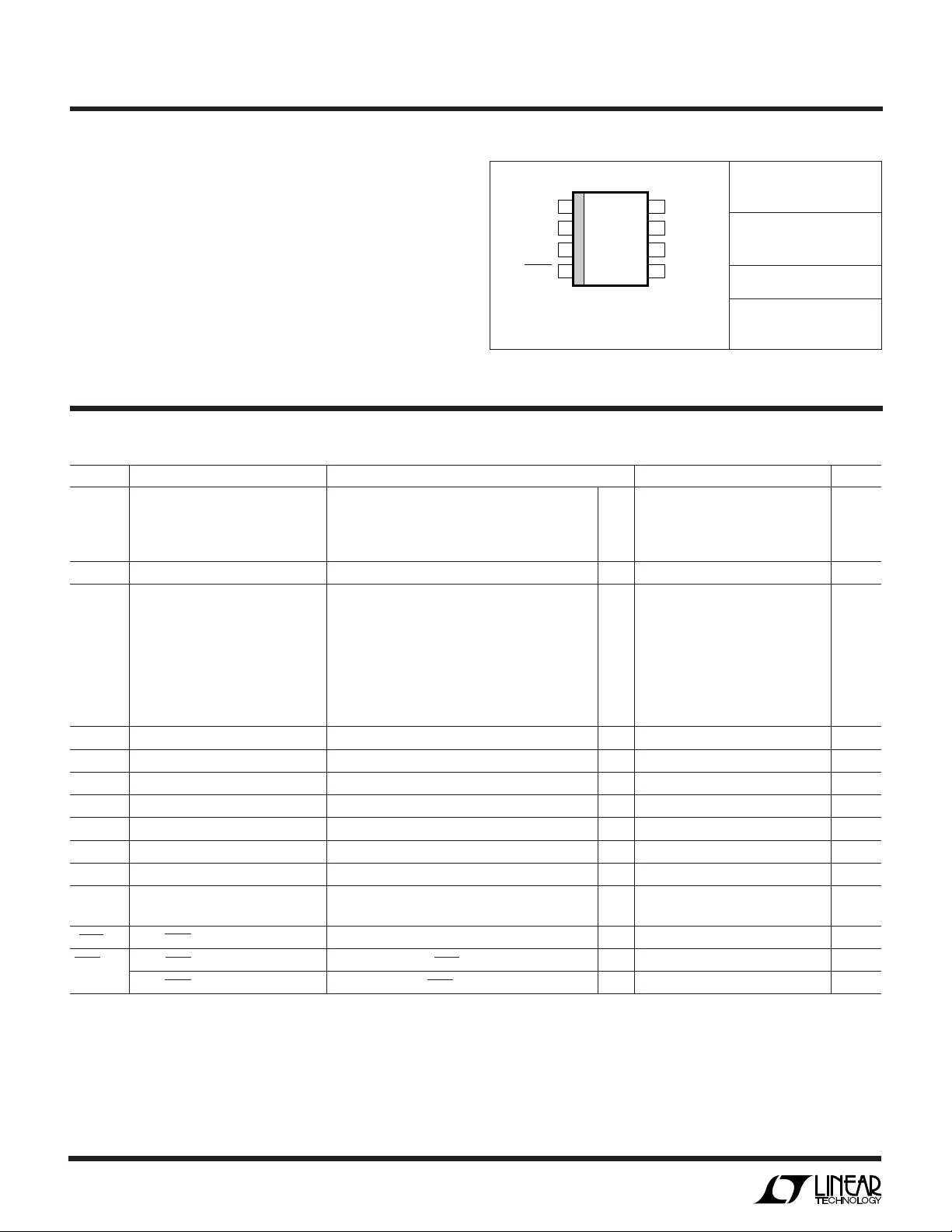

ABSOLUTE MAXIMUM RATINGS

Supply Voltage ........................................................ 22V

Digital Input Voltage ........................ 7V to (GND – 0.3V)

U

U

W

PACKAGE/ORDER INFORMATION

ORDER PART

NUMBER

U

Sense Input Voltage......................... 7V to (GND – 0.3V)

Valid Output Voltage ...................... 15V to (GND – 0.3V)

LT1312CS8

Output Short-Circuit Duration.......................... Indefinite

Operating Temperature ................................ 0°C to 70°C

S8 PART MARKING

Junction Temperature................................ 0°C to 125°C

Storage Temperature Range ..................–65°C to 150°C

T

= 125°C, θJA = 150°C/W

JMAX

1312

Lead Temperature (Soldering, 10 sec).................. 300°C

Consult factory for Industrial and Military grade parts.

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

VPP

OUT

I

LKG

I

S

I

LIM

V

ENH

V

ENL

I

ENH

I

ENL

V

SEN5

V

SEN3

I

SEN

V

VALID TH

I

VALID

The ● denotes the specifications which apply over the full operating

temperature range.

Output Voltage Program to 12V, I

Program to 5V, I

Program to 3.3V, I

Program to 0V, I

Output Leakage Program to Hi-Z, 0V ≤ VPP

Supply Current Program to 0V ● 30 50 µA

Program to Hi-Z

Program to 12V, No Load

Program to 5V, No Load

Program to 3.3V, No Load

Program to 12V, I

Program to 5V, I

Program to 3.3V, I

Current Limit Program to 3.3V, 5V or 12V 330 500 mA

Enable Input High Voltage ● 2.4 V

Enable Input Low Voltage ● 0.4 V

Enable Input High Current 2.4V ≤ VIN ≤ 5.5V 20 50 µA

Enable Input Low Current 0V ≤ VIN ≤ 0.4V 0.01 1 µA

VCC Sense Threshold VPP

VCC Sense Threshold VPP

VCC Sense Input Current V

VPP

VPP

VPP

Threshold Voltage Program to 12V ● 10.5 11 11.5 V

VALID

Output Drive Current Program to 12V, V

VALID

Output Leakage Current Program to 0V, V

VALID

OUT

OUT

= 5V 38 60 µA

SENSE

V

= 3.3V 18 30 µA

SENSE

VS = 13V to 20V, TA = 25°C, unless otherwise noted.

≤ 120mA (Note 1) ● 11.52 12.00 12.48 V

OUT

≤ 30mA (Note 1) ● 4.75 5.00 5.25 V

OUT

≤ 30mA (Note 1) ● 3.135 3.30 3.465 V

OUT

= –300µA 0.42 0.60 V

OUT

≤ 12V ● –10 10 µA

OUT

● 30 50 µA

● 230 360 µA

● 75 120 µA

● 55 90 µA

= 120mA ● 126 132 mA

OUT

= 30mA ● 31 33 mA

OUT

= 30mA ● 31 33 mA

OUT

= 3.3V to 5V ● 3.60 4.05 4.50 V

= 5V to 3.3V ● 3.60 4.00 4.50 V

= 0.4V 1 3.3 mA

VALID

= 12V 0.1 10 µA

VALID

Note 1: For junction temperatures greater than 110°C, a minimum load

of 1mA is recommended.

2

Page 3

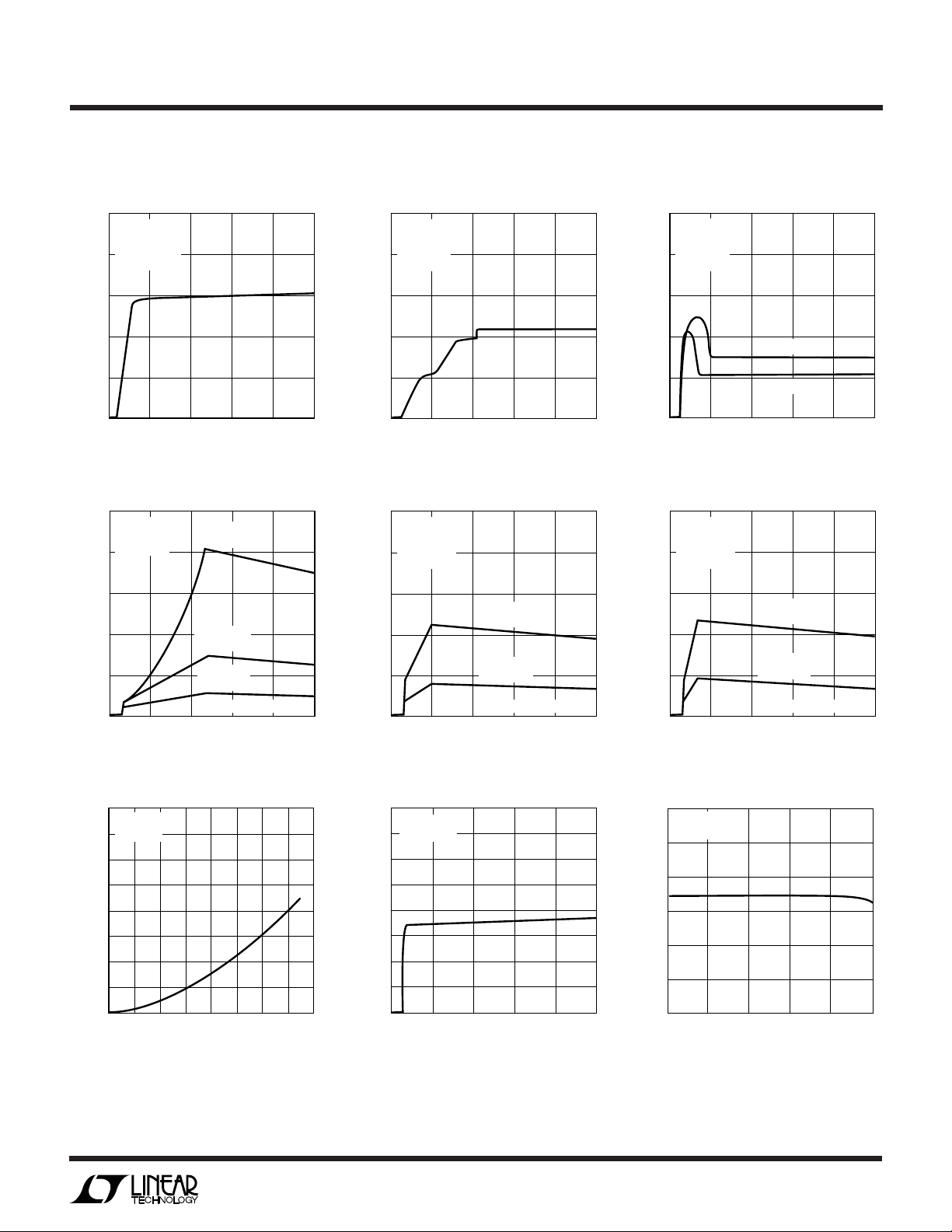

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

LT1312

Quiescent Current (12V Mode)Quiescent Current (0V or Hi-Z Mode)

50

TJ = 25°C

EN0 = EN1= 0V

OR

40

EN0 = EN1= 5V

30

20

QUIESCENT CURRENT (µA)

10

0

5

0

10

SUPPLY VOLTAGE (V)

15

20

25

LT1312 G1

500

TJ = 25°C

EN0 = 5V

EN1 = 0V

400

=

∞

R

L

300

200

QUIESCENT CURRENT (µA)

100

0

5

0

SUPPLY VOLTAGE (V)

15

10

Ground Pin Current (12V Mode) Ground Pin Current (5V Mode)

10

TJ = 25°C

EN0 = 5V

EN1 = 0V

8

6

4

GROUND CURRENT (mA)

2

0

5

0

SUPPLY VOLTAGE (V)

R

L

I

= 60mA*

L

R

L

= 30mA*

I

L

*FOR VPP

10

= 100

R

L

= 120mA*

I

L

= 200

= 400

15

Ω

Ω

OUT

Ω

= 12V

20

25

LT1312 G4

2.5

TJ = 25°C

EN0 = 0V

EN1 = 5V

2.0

1.5

1.0

GROUND CURRENT (mA)

0.5

0

= 5V

V

SENSE

5

0

SUPPLY VOLTAGE (V)

R

L

I

L

R

= 500Ω

L

= 10mA*

I

L

*FOR VPP

10

= 167Ω

= 30mA*

15

OUT

= 5V

Quiescent Current (3.3V/5V Mode)

250

TJ = 25°C

EN0 = 0V

EN1 = 5V

200

=

∞

R

L

150

100

QUIESCENT CURRENT (µA)

50

20

25

LT1312 G2

0

5

0

V

= 5V

SENSE

V

= 3.3V

SENSE

15

10

SUPPLY VOLTAGE (V)

20

25

LT1312 G3

Ground Pin Current (3.3V Mode)

2.5

TJ = 25°C

EN0 = 0V

EN1 = 5V

2.0

1.5

1.0

GROUND CURRENT (mA)

0.5

20

25

LT1312 G5

0

= 3.3V

V

SENSE

= 110

Ω

R

L

I

= 30mA*

L

R

= 330

Ω

L

= 10mA*

I

L

*FOR VPP

5

0

10

SUPPLY VOLTAGE (V)

= 3.3V

OUT

15

20

25

LT1312 G6

Ground Pin Current

16

TJ = 25°C

= 15V

V

14

S

12

10

8

6

4

GROUND PIN CURRENT (mA)

2

0

0

20

60

40

OUTPUT CURRENT (mA)

Current Limit

800

TJ = 25°C

= 0V

VPP

700

600

500

400

300

200

SHORT-CIRCUIT CURRENT (mA)

100

100

80

120

140

LT1312 G7

160

OUT

0

510 20

0

INPUT VOLTAGE (V)

15

25

LT1312 G8

Current Limit

600

VS = 15V

= 0V

VPP

OUT

500

400

300

200

SHORT-CIRCUIT CURRENT (mA)

100

0

25 50 75 100

0

JUNCTION TEMPERATURE (°C)

125

LT1312 G9

3

Page 4

LT1312

TIME (ms)

–0.1 0 0.1 0.2 0.3 0.4 0.5 0.6

OUTPUT VOLTAGE

CHANGE (V)

LOAD

CURRENT (mA)

50

–0.4

0.4

LT1312 G18

100

–0.2

0

0.2

C

OUT

= 1µF

C

OUT

= 10µF

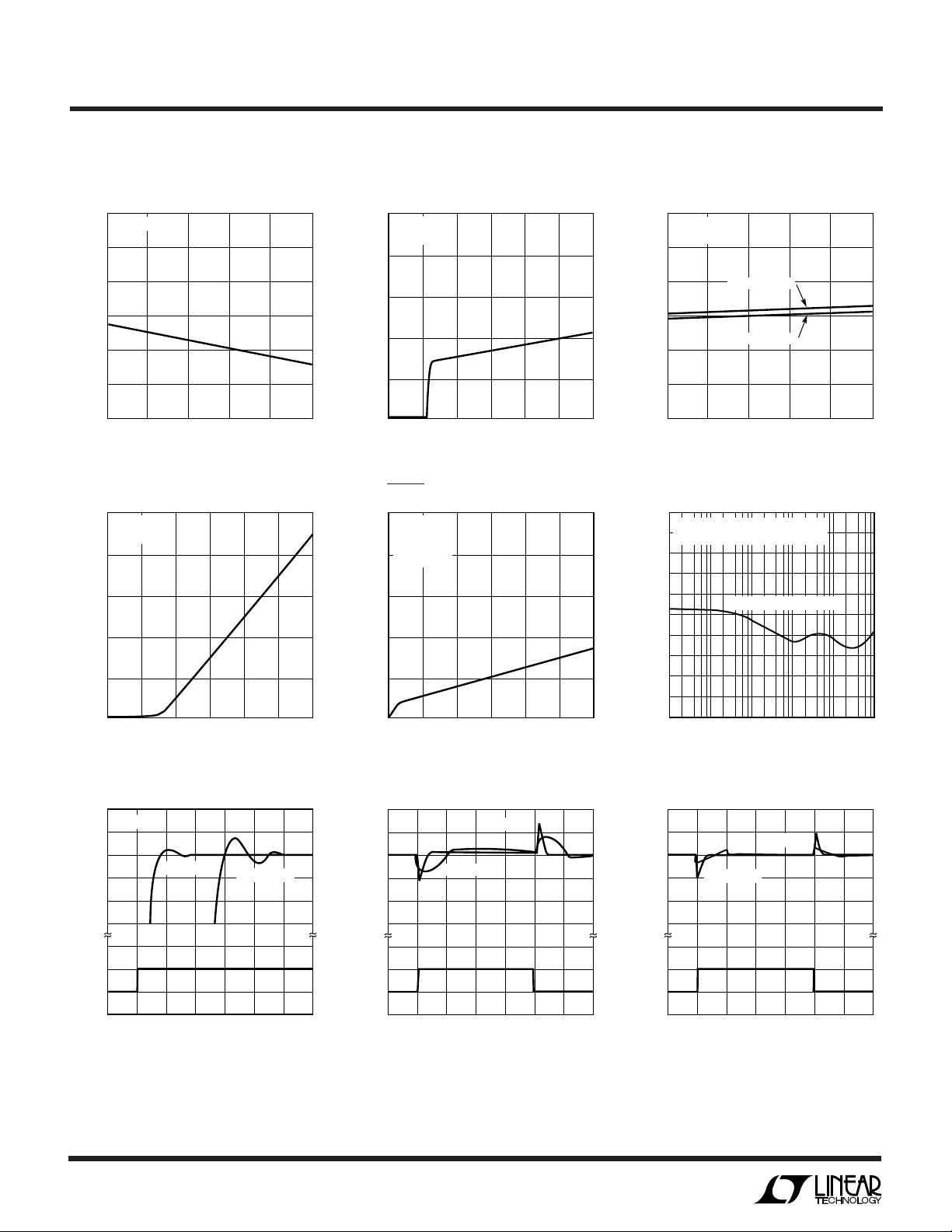

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

3.0

VS = 15V

2.5

2.0

1.5

1.0

0.5

INPUT THRESHOLD VOLTAGE (V)

0

25 50 75 100

0

JUNCTION TEMPERATURE (°C)

VCC Sense Input Current

50

TJ = 25°C

V

= 15V

S

40

30

20

LT1312 G10

125

Enable Input CurrentEnable Input Threshold Voltage

50

TJ = 25°C

V

= 15V

S

40

30

20

ENABLE INPUT CURRENT (µA)

10

0

0

234

1

ENABLE INPUT VOLTAGE (V)

VALID Output Voltage

1.0

TJ = 25°C

V

= 15V

S

EN0 = 5V

0.8

EN1 = 0V

0.6

0.4

56

LT1312 G11

VCC Sense Threshold Voltage

5.5

TJ = 25°C

= 15V

V

S

5.0

4.5

4.0

3.5

SENSE THRESHOLD VOLTAGES (V)

3.0

CC

V

2.5

0

SWITCH TO 5V

SWITCH TO 3.3V

25 50 75 100

JUNCTION TEMPERATURE (°C)

Ripple Rejection (12V)

100

TJ = 25°C, 12V MODE

80

60

40

= 15V + 100mV

V

S

RIPPLE

RMS

C

= 1µF TANTALUM

OUT

125

LT1312 G12

SENSE INPUT CURRENT (µA)

CC

V

12.4

12.2

12.0

11.8

OUTPUT VOLTAGE (V)EN0 INPUT (V)

11.6

10

0

0

234

1

ENABLE INPUT VOLTAGE (V)

56

LT1312 G13

12V Turn-On Waveform

VS = 15V

C

= 1µF

OUT

5

0

–0.2 0 0.2 0.4 0.6 0.8 1.0 1.2

TIME (ms)

C

= 10µF

OUT

LT1312 G16

VALID OUTPUT VOLTAGE (V)

0.2

0

0

1.0 1.5 2.0

0.5

VALID OUTPUT CURRENT (mA)

Line Transient Response (12V)

40

20

0

–20

CHANGE (mV)

OUTPUT VOLTAGE

–40

15

SUPPLY

13

VOLTAGE (V)

–0.1 0 0.1 0.2 0.3 0.4 0.5 0.6

C

OUT

C

OUT

= 10µF

TIME (ms)

= 1µF

2.5 3.0

LT1312 G14

LT1312 G17

20

RIPPLE REJECTION RATIO (dB)

0

100 1k 10k 100k 1M

10

FREQUENCY (Hz)

Load Transient Response (12V)

LT1312 G15

4

Page 5

UUU

PIN FUNCTIONS

LT1312

Supply Pin: Power is supplied to the device through the

supply pin. The supply pin should be bypassed to ground

if the device is more than 6 inches away from the main

supply capacitor. A bypass capacitor in the range of 0.1µF

to 1µF is sufficient. The supply voltage to the LT1312 can

be loosely regulated between 13V and 20V. See Applications Information section for more detail.

VPP

Pin: This regulated output supplies power to the

OUT

PCMCIA card VPP pins which are typically tied together

at the card socket. The VPP

output is current limited

OUT

to approximately 330mA. Thermal shutdown provides a

second level of protection. A 1µF to 10µF tantalum output

capacitor is recommended. See Applications Information section for more detail on output capacitor considerations.

Input Enable Pins: The two digital input pins are high

impedance inputs with approximately 20µA input current

W

BLOCK DIAGRAM

at 2.4V. The input thresholds are compatible with CMOS

controllers and can be driven from either 5V or 3.3V

CMOS logic. ESD protection diodes limit input excursions

to 0.6V below ground.

VALID Output Pin: This pin is an open-collector NPN

output which is driven low when the VPP

pin is in

OUT

regulation, i.e., when it is above 11V. An external 51k pullup resistor is connected between this output and the same

5V or 3.3V logic supply powering the PCMCIA compatible

control logic.

VCC Sense Pin: A built-in comparator and 4V reference

automatically switches the VPP

from 5V to 3.3V de-

OUT

pending upon the voltage sensed at the PCMCIA card

socket VCC pin. The input current for this pin is approximately 30µA. For 5V only operation, connect the Sense pin

directly to ground. An ESD protection diode limits the

input voltage to 0.6V below ground.

V

S

V

CC

SENSE

EN0

EN1

+

–

4V

LOW DROPOUT

LINEAR

REGULATOR

VOLTAGE

LOGIC CONTROL

11V

VPP

OUT

VALID

+

–

LT1312 BD

5

Page 6

LT1312

U

OPERATION

The LT1312 is a programmable output voltage, lowdropout linear regulator designed specifically for PCMCIA

VPP drive applications. Input power is typically obtained

from a loosely regulated input supply between 13V and

20V (see Applications Information section for more detail

on the input power supply). The LT1312 consists of the

following blocks:

Low Dropout Voltage Linear Regulator: The heart of the

LT1312 is a PNP-based low-dropout voltage regulator

which drops the unregulated supply voltage from 13V to

20V down to 12V, 5V, 3.3V, 0V or Hi-Z depending upon the

state of the two Enable inputs and the VCC Sense input. The

regulator has built-in current limiting and thermal shutdown to protect the device, the load, and the socket

against inadvertent short circuiting to ground.

U

WUU

APPLICATIONS INFORMATION

The LT1312 is a voltage programmable linear regulator

designed specifically for PCMCIA VPP driver applications.

The device operates with very low quiescent current

(30µA) in the 0V and Hi-Z modes of operation. In the Hi-Z

mode, the output leakage current falls to 1µA. Unloaded

quiescent current rises to only 55µA and 75µA when

programmed to 3.3V and 5V respectively. In addition to

the low quiescent currents, the LT1312 incorporates several protection features which make it ideal for PCMCIA

applications. The LT1312 has built-in current limiting

(330mA) and thermal shutdown to protect the device and

the socket VPP pins against inadvertent short-circuit

conditions.

Voltage Control Logic: The LT1312 has five possible

output modes: 0V, 3.3V, 5V, 12V and Hi-Z. These five

modes are selected by the two Enable inputs and the V

Sense input as described by the Truth Table.

V

Sense Comparator: When the VCC mode is selected,

CC

the LT1312 automatically adjusts the regulated VPP output voltage to 3.3V or 5V depending upon the voltage

present at the PC card VCC supply pin. The threshold

voltage for the comparator is set at 4V and there is

approximately 50mV of hysteresis provided to ensure

clean switching between 3.3V and 5V.

VPP VALID Comparator: A voltage comparator monitors

the output voltage when the 12V mode is selected and is

driven low when the output is in regulation above 11V.

an auxiliary winding to the 5V inductor in a split 3.3V/5V

LTC1142HV power supply system. A turns ratio of 1:1.8 is

used for transformer T1 to ensure that the input voltage to

the LT1312 falls between 13V and 20V under all load

conditions. The 9V output from this additional winding is

rectified by diode D2, added to the main 5V output and

applied to the input of the LT1312. (Note that the auxiliary

winding must be phased properly as shown in Figure 1.)

The auxiliary winding is referenced to the 5V output which

provides DC current feedback from the auxiliary supply to

the main 5V section. The AC transient response is improved by returning the negative lead of C5 to the 5V

output as shown.

CC

AUXILIARY WINDING POWER SUPPLIES

Because the LT1312 provides excellent output regulation,

the input power supply may be loosely regulated. One

convenient (and economic) source of power is an auxiliary

winding on the main 5V switching regulator inductor in the

main system power supply.

LTC®1142HV Auxiliary Winding Power Supply

Figure 1 is a schematic diagram which describes how a

loosely regulated 14V power supply is created by adding

6

When the 12V output is activated by a TTL high on the

Enable line, the 5V section of the LTC1142HV is forced into

continuous mode operation. A resistor divider composed

of R2, R3 and switch Q3 forces an offset which is subtracted from the internal offset at the Sense– input (pin 14)

of the LTC1142HV. When this external offset cancels the

built-in 25mV offset, Burst Mode

and the LTC1142HV is forced into continuous mode

operation. (See the LTC1142HV data sheet for further

detail). In this mode, the 14V auxiliary supply can be

Burst Mode is a trademark of Linear Technology Corporation.

TM

operation is inhibited

Page 7

LT1312

U

WUU

APPLICATIONS INFORMATION

V

1/2 LTC1142HV

5V REG

EN0

EN1

VALID

PDRIVE

NDRIVE

SENSE

SENSE

V

IN

+

–

6.5V TO 18V

10

9

20

15

14

IN

Q1

Q2

R3

18k

Q3

VN7002

+

D3

MBRS130T3

R1

100Ω

C2

1000pF

R2

100Ω

*LPE-6562-A026 DALE (605) 665-9301

+

C1

68µF

MBRS140

R5

0.033Ω

C3

220µF

D1

22Ω

T1

1.8T

30µH*

R4

D2

MBRS140

C4

1000pF

14V AUXILIARY SUPPLY

+

C5

22µF

5V

OUTPUT

V

S

VPP

EN0

VALID SENSE

OUT

LT1312EN1

GND

TO CARD VPP PIN

0V, 3.3V, 5V, 12V OR HI-Z

+

FROM

PIN

CARD V

CC

LT1312 F1

1µF

Figure 1. Deriving 14V Power from an Auxiliary Winding on the LTC1142HV 5V Regulator

loaded without regard to the loading on the 5V output of

the LTC1142HV.

Continuous mode operation is only invoked when the

LT1312 is programmed to 12V. If the LT1312 is programmed to 0V, 3.3V or 5V, power is obtained directly

from the main power source (battery pack) through diode

D1. Again, the LT1312 output can be loaded without

regard to the loading of the main 5V output.

R4 and C4 absorb transient voltage spikes associated with

the leakage inductance inherent in T1's secondary winding

and ensure that the auxiliary supply does not exceed 20V.

Figure 2 is a graph of output voltage versus output current

for the auxiliary 14V supply shown in Figure 1. Note that

the auxiliary supply voltage is slightly higher when the 5V

output is heavily loaded. This is due to the increased

energy flowing through the main 5V inductor.

LTC1142 Auxiliary Power from the 3.3V Output

The circuit of Figure 1 can be modified for operation with

low-battery count applications (6 cell). As the input voltage falls, the 5V duty cycle increases to the point where

there is simply not enough time to transfer energy from the

5V primary to the auxiliary winding. For applications

where heavy 12V load currents exist in conjunction with

low input voltages (<6.5V), the auxiliary winding can be

derived from the 3.3V section instead of the 5V section of

the LTC1142. In this case, a transformer with a turns ratio

of 1:3.4 to 1:3.6 should be used in place of the 3.3V section

17

VIN = 8V

EN0 = HI

16

15

14

I

OUT5V

13

12

AUXILIARY OUTPUT VOLTAGE (V)

11

0.1

AUXILIARY OUTPUT CURRENT (mA)

Figure 2. LTC1142 Auxiliary Supply Voltage

= 0mA

I

= 1A

OUT5V

101 100 1000

LT1312 F2

7

Page 8

LT1312

U

WUU

APPLICATIONS INFORMATION

inductor as shown in Figure 3. MOSFET Q4 and diode D4

have been added and diode D1 is no longer used. In the

previous circuit, power is drawn directly from the batteries

through D1, when the LTC1142 is in Burst Mode operation

and the VPP pin requires 3.3V or 5V. For these lower input

voltages this technique is no longer valid as the input will

fall below the LT1312 regulator’s dropout voltage. To

correct for this situation, the additional switch Q4 forces

the switching regulator

whenever 3.3V, 5V or 12V

LINE POWERED SUPPLIES

In line operated products such as: desktop computers,

dedicated PC card readers/writers, medical equipment,

test and measurement equipment, etc., it is possible to

derive power from a relatively “raw” source such as a 5V

or 12V power supply. The 12V supply line in a desktop

computer however, is usually too “dirty” to apply directly

to the VPP pins of a PCMCIA card socket. Power supply

switching and load transients may create voltage spikes

into continuous mode operation

is selected.

on this line that may damage sensitive PCMCIA flash

memory cards if applied directly to the VPP pins.

Flash Memory Card VPP Power Considerations

PCMCIA compatible flash memory cards require tight

regulation of the 12V VPP programming supply to ensure

that the internal flash memory circuits are never subjected

to damaging conditions. Flash memory circuits are typically rated with an absolute maximum of 13.5V and VPP

must be maintained at 12V ±5% under all possible load

conditions during erase and program cycles. Undervoltage

can decrease specified flash memory reliability and overvoltage can damage the device1.

Generating 14V from 5V or 12V

It is important that the 12V VPP supply for the two VPP

lines to the card be free of voltage spikes. There should be

little or no overshoot during transitions to and from the

12V level.

1

See Application Note AP-357, “Power Supply Solutions for Flash Memory,”

Intel Corporation, 1992.

1/2 LTC1142

3.3V REG

EN0

EN1

VALID

V

PDRIVE

NDRIVE

SENSE

SENSE

Q4

VN7002

V

IN

5.4V TO 12V

24

IN

23

6

1

+

28

–

+

C1

68µF

Q1

D3

Q2

MBRS130T3

R1

100Ω

C2

1000pF

R3

18k

Q3

VN7002

R2

100Ω

+

*LPE-6582-A086 DALE (605) 665-9301

MBRS1100

T1

3.38T

22µH*

R4

0.033Ω

C3

220µF

R4

22Ω

D2

C4

1000pF

D4

18V

14V AUXILIARY SUPPLY

+

C5

22µF

3.3V

OUTPUT

Figure 3. Deriving Auxiliary 14V Power from an LTC1142 3.3V Regulator

V

S

EN0

VPP

OUT

LT1312EN1

VALID SENSE

GND

TO CARD VPP PIN

0V, 3.3V, 5V, 12V OR Hi-Z

+

1µF

FROM CARD

PIN

V

CC

LT1312 F3

8

Page 9

LT1312

V

S

EN0 VPP

OUT

LT1312

EN1

VALID SENSE

GND

+

>1µF TANTALUM

OR ALUMINUM

LT1312 F6

0.1µF

13V TO 20V

U

WUU

APPLICATIONS INFORMATION

1N5158

4

2

FB

1

1k

1µF

31

8

4

12V

5

V

IN

LT1172

3

100µH

V

SW

C

5V

+

22µF

GND V

+

Figure 4. Local 5V to 15V Boost Regulator for Line Operated Applications

100µH

+

22µF

100Ω

2

V

IN

LIM

LT1111CS8

SENSE

GND SW2

5

SW1I

1N5158

10k

1%

1k

1%

100k

1%

10k

1%

13.75V

+

100µF

V

S

EN0 VPP

VALID SENSE

13.75V

OUT

LT1312EN1

GND

+

LT1312 F4

TO CARD VPP PIN

0V, 5V, 12V OR HI-Z

1µF

+

100µF

V

S

EN0 VPP

EN1

VALID SENSE

OUT

LT1312

GND

+

LT1312 F5

TO CARD VPP PIN

0V, 5V, 12V OR HI-Z

1µF

Figure 5. Local 12V to 15V Boost Regulator for Line Operated Applications

This is easily accomplished by generating a local 14V

supply from a relatively “dirty” 5V or 12V supply as shown

in Figures 4 and 5. Precise voltage control (and further

filtering) is provided by the LT1312 driver/regulator. A

further advantage to this scheme is that it adds current

limit in series with the VPP pins to eliminate possible

damage to the card socket, the PC card, or the switching

power supply in the event of an accidental short circuit.

Output Capacitance

The LT1312 is designed to be stable with a wide range of

output capacitors. The minimum recommended value is a

1µF with an ESR of 3Ω or less. The capacitor is connected

directly between the output pin and ground as shown in

Figure 6.

For applications where space is very limited, capacitors as

low as 0.33µF can be used. Extremely low ESR ceramic

capacitors with values less than 1µF must have a 2Ω

resistor added in series with the output capacitor as shown

in shown in Figure 7.

Figure 6. Recommended >1µF Tantalum Output Capacitor

13V TO 20V

0.1µF

V

S

EN0 VPP

EN1

VALID SENSE

OUT

LT1312

GND

2Ω

0.33µF

CERAMIC

LT1312 F7

Figure 7. Using a 0.33µF to 1µF Output Capacitor

9

Page 10

LT1312

U

WUU

APPLICATIONS INFORMATION

Transient and Switching Performance

The LT1312 is designed to produce minimal overshoot with

capacitors in the range of 1µF to 10µF. Larger capacitor

values can be used with a slowing of rise and fall times.

The positive output slew rate is determined by the 330mA

current limit and the output capacitor. The rise time for a

0V to 12V transition is approximately 40µs, the rise time

for a 10µF capacitor is roughly 400µs (see the Transient

Response curves in the Typical Performance Characteristics section).

The fall time from 12V to 0V is set by the output capacitor

and an internal pull-down current source which sinks

about 30mA. This source will fully discharge a 1µF capaci-

tor in less than 1ms.

Thermal Considerations

Power dissipated by the device is the sum of two components: output current multiplied by the input-output differential voltage I

multiplied by supply voltage I

The ground pin current can be found by examining the

Ground Pin Current curves in the Typical Performance

Characteristics section.

Heat sinking, for surface mounted devices, is accomplished by using the heat spreading capabilities of the PC

board and its copper traces.

The junction temperature of the LT1312 must be limited to

125°C to ensure proper operation. Use Table 1 in conjunction with the typical performance graphs, to calculate the

power dissipation and die temperature for a particular

application and ensure that the die temperature does not

exceed 125°C under any operating conditions.

OUT

× (V

IN

– V

), and ground pin current

OUT

× VIN.

GND

Table 1. S8 Package*

COPPER AREA THERMAL RESISTANCE

TOPSIDE BACKSIDE BOARD AREA (JUNCTION-TO-AMBIENT)

2500 sq mm 2500 sq mm 2500 sq mm 120°C/W

1000 sq mm 2500 sq mm 2500 sq mm 120°C/W

225 sq mm 2500 sq mm 2500 sq mm 125°C/W

1000 sq mm 1000 sq mm 1000 sq mm 131°C/W

*Device is mounted topside.

Calculating Junction Temperature

Example: given an output voltage of 12V, an input supply

voltage of 14V, an output current of 100mA, and a

maximum ambient temperature of 50°C, what will the

maximum junction temperature be?

Power dissipated by the device will be equal to:

I

× (VS – VPP

OUT

OUT

) + (I

GND

× VIN)

where:

I

= 100mA

OUT

VIN = 14V

I

GND

at (I

= 100mA, VIN = 14V) = 5mA

OUT

so,

PD = 100mA × (14V – 12V) + (5mA × 15V) = 0.275W

Using Table 1, the thermal resistance will be in the range

of 120°C/W to 131°C/W depending upon the copper area.

So the junction temperature rise above ambient will be

less than or equal to:

0.275W × 131°C/W = 36°C

The maximum junction temperature will then be equal to

the junction temperature rise above ambient plus the

maximum ambient temperature or:

10

T

= 50°C + 36°C = 86°C.

JMAX

Page 11

U

TYPICAL APPLICATIONS

V

LOGIC

LT1312

Single Slot Interface to CL-PD6710

13V TO 20V

V

CC

A_VPP_PGM

A_VPP_V

VPP_VALID

CIRRUS LOGIC

CL-PD6710

A_V

A_V

51K

CC

5V

_5

CC

_3

CC

Si9430DY OR

MMSF3P02HD

3.3V

V

S

EN0

VPP

LT1312

EN1

VALID

GND

Si9933DY OR

MMDF2P01HD

OUT

SENSE

Single Slot Interface to “365” Type Controller

+

3.3V OR 5V

1µF

VPP1

VPP2

PCMCIA

CARD SLOT

V

CC

+

10µF

LT1312 TA2

V

LOGIC

V

CC

A_VPP_EN0

A_VPP_EN1

“365” TYPE

CONTROLLER

A_V

CC

A_V

CC

A:GPI

_EN0

_EN1

51k

5V

IN1

LTC1157CS8

IN2

GND

13V TO 20V

V

S

EN0

VPP

OUT

EN1

LT1312

SENSE

VALID

GND

V

S

G1

Si9410DY OR

MMSF5N02HD

3.3V OR 5V

+

1µF

VPP1

VPP2

CARD SLOT

V

CC

PCMCIA

+

G2

Si9956DY OR

MMDF3N02HD

3.3V

10µF

LT1312 TA3

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

11

Page 12

LT1312

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

S8 Package

8-Lead Plastic SOIC

0.189 – 0.197*

(4.801 – 5.004)

7

8

5

6

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006 INCH (0.15mm).

× 45°

0.016 – 0.050

0.406 – 1.270

0.053 – 0.069

(1.346 – 1.752)

0°– 8° TYP

0.014 – 0.019

(0.355 – 0.483)

RELATED PARTS

See PCMCIA Product Family table on the first page of this data sheet.

0.150 – 0.157*

(3.810 – 3.988)

1

3

2

4

(0.101 – 0.254)

0.050

(1.270)

BSC

0.004 – 0.010

SO8 0294

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7487

(408) 432-1900

●

FAX

: (408) 434-0507

●

TELEX

: 499-3977

LT/GP 0894 10K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1994

Loading...

Loading...