Page 1

LT1111

0

LOAD CURRENT (mA)

0

1

OUTPUT VOLTAGE (V)

2

3

4

5

6

50 100 150 200

LT1111 • TA02

25 75 125 175

VIN = 2V 2.2 2.4 2.6 2.8 3V

Micropower

DC/DC Converter

Adjustable and Fixed 5V, 12V

EATU

F

■

Operates at Supply Voltages from 2V to 30V

■

72kHz Oscillator

■

Works with Surface Mount Inductors

■

Only Three External Components Required

■

Step-Up or Step-Down Mode

■

Low-Battery Detector Comparator On-Chip

■

User Adjustable Current Limit

■

Internal 1A Power Switch

■

Fixed or Adjustable Output Voltage Versions

■

Space Saving 8-Pin MiniDIP or SO-8 Package

PPLICATI

A

■

3V to 5V, 5V to 12V Converters

■

9V to 5V, 12V to 5V Converters

■

Remote Controls

■

Peripherals and Add-On Cards

■

Battery Backup Supplies

■

Uninterruptible Supplies

■

Laptop and Palmtop Computers

■

Cellular Telephones

■

Portable Instruments

■

Flash Memory VPP Generators

RE

S

O

U

S

DUESCRIPTIO

The LT1111 is a versatile micropower DC/DC converter.

The device requires only three external components to

deliver a fixed output of 5V or 12V. Supply voltage ranges

from 2V to 12V in step-up mode and to 30V in step-down

mode. The LT1111 functions equally well in step-up, stepdown, or inverting applications.

The LT1111 oscillator is set at 72kHz, optimizing the

device to work with off-the-shelf surface mount inductors.

The device can deliver 5V at 100mA from a 3V input in

step-up mode or 5V at 200mA from a 12V input in stepdown mode.

Switch current limit can be programmed with a single

resistor. An auxiliary open-collector gain block can be

configured as a low-battery detector, linear post regulator,

undervoltage lock-out circuit, or error amplifier.

For input sources of less than 2V use the LT1110.

3V INPUT

U

O

A

PPLICATITYPICAL

All Surface Mount 3V to 5V Step-Up Converter

SUMIDA

+

10 F*

*OPTIONAL

µ

I

GND SW2

V

LIM

LT1111CS8-5

IN

SENSE

CD54-220M

SW1

22µH

MBRS120T3

+

5V

100mA

33 F

µ

LT1111 • TA01

Typical Load Regulation

1

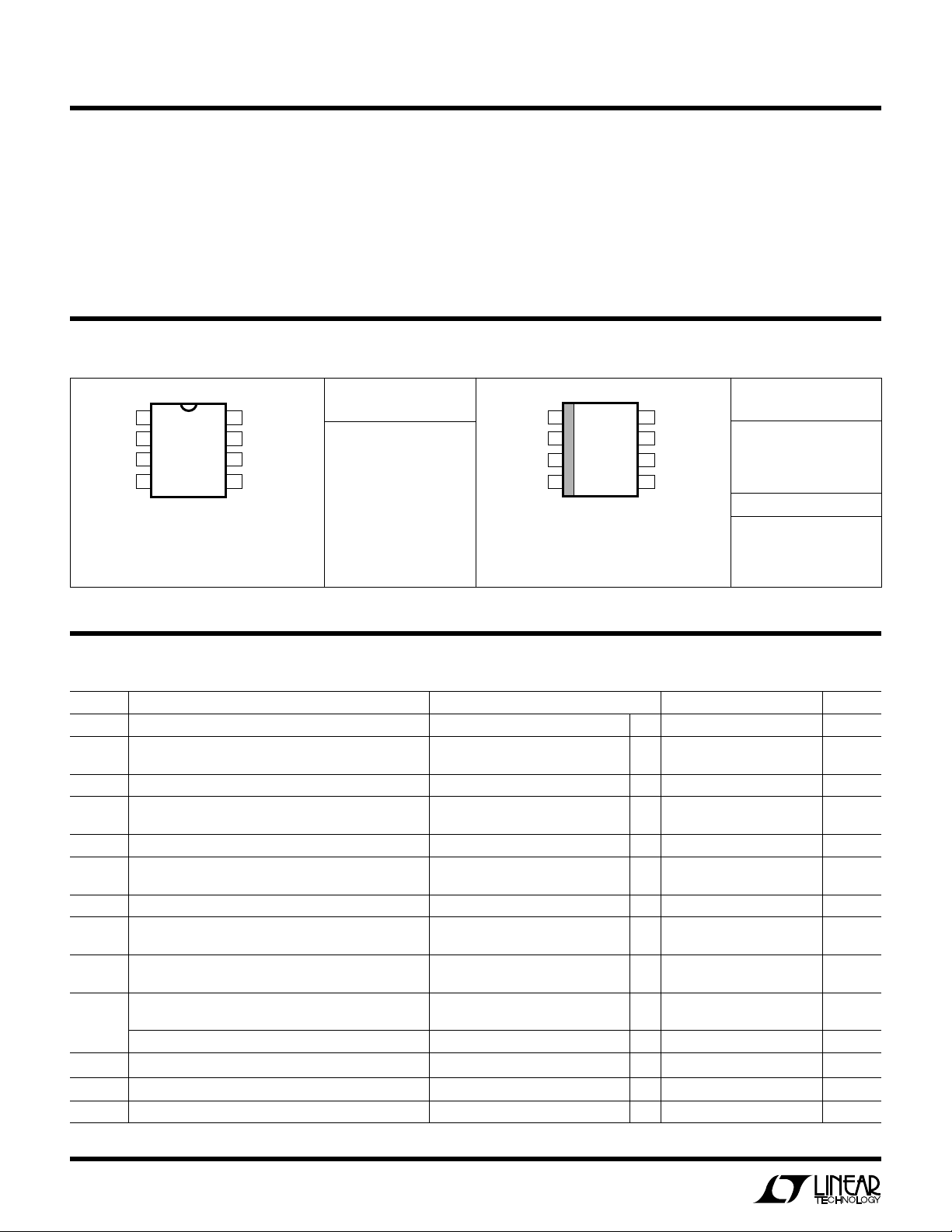

Page 2

L T 1111

A

W

O

LUTEXI T

S

A

WUW

ARB

U

G

I

S

Supply Voltage (VIN)............................................... 36V

SW1 Pin Voltage (V

SW2 Pin Voltage (V

) ......................................... 50V

SW1

) ............................ – 0.5V to V

SW2

Feedback Pin Voltage (LT1111) ............................. 5.5V

Switch Current....................................................... 1.5A

Maximum Power Dissipation ............................ 500mW

WU

/

PACKAGE

I

1

LIM

V

2

IN

SW1

3

SW2

4

J8 PACKAGE

8-LEAD CERAMIC DIP

T

JMAX

T

JMAX

O

RDER I FOR ATIO

TOP VIEW

FB (SENSE)*

8

SET

7

A0

6

GND

5

N8 PACKAGE

8-LEAD PLASTIC DIP

*FIXED VERSIONS

= 150°C, θJA = 120°C/W (J)

= 90°C, θJA = 130°C/W (N)

ORDER PART

NUMBER

LT1111CN8

LT1111CN8-5

LT1111CN8-12

LT1111MJ8

LT1111MJ8-5

LT1111MJ8-12

Operating Temperature Range

LT1111C............................................... 0°C to 70°C

IN

LT1111I ......................................... –40°C to 105°C

LT1111M ....................................... –55°C to 125°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

U

I

1

LIM

V

2

IN

SW1

3

SW2

4

8-LEAD PLASTIC SO

*FIXED VERSION

T

JMAX

TOP VIEW

8

7

6

5

S8 PACKAGE

= 90°C, θJA = 150°C/W

FB (SENSE)*

SET

A0

GND

ORDER PART

NUMBER

LT1111CS8

LT1111CS8-5

LT1111CS8-12

S8 PART MARKING

1111

11115

11111

Consult factory for Industrial grade parts

LECTRICAL C CHARA TERIST

E

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

Q

V

IN

V

OUT

f

OSC

DC Duty Cycle: Step-Up Mode Full Load 43 50 59 %

t

ON

V

SAT

I

FB

I

SET

V

OL

Quiescent Current Switch OFF 300 400 µA

Input Voltage Step-Up Mode ● 2.0 12.6 V

Comparator Trip Point Voltage LT1111 (Note 1) ● 1.20 1.25 1.30 V

Output Sense Voltage LT1111-5 (Note 2) ● 4.75 5.00 5.25 V

Comparator Hysteresis LT1111 ● 8 12.5 mV

Output Hysteresis LT1111-5 ● 32 50 mV

Oscillator Frequency 54 72 88 kHz

Step-Down Mode 24 34 50 %

Switch ON Time: Step-Up Mode I

Step-Down Mode V

SW Saturation Voltage, Step-Up Mode VIN = 3.0V, ISW = 650mA 0.5 0.65 V

SW Saturation Voltage, Step-Down Mode VIN = 12V, ISW = 650mA 1.1 1.5 V

Feedback Pin Bias Current LT1111, VFB = 0V ● 70 120 nA

Set Pin Bias Current V

Gain Block Output Low I

ICS

VIN = 3V, Military or Commercial Version

Step-Down Mode

LT1111-12 (Note 2) ● 11.40 12.00 12.60 V

LT1111-12 ● 75 120 mV

Tied to V

LIM

OUT

VIN = 5.0V, ISW = 1A 0.8 1.0 V

SET

SINK

IN

, = 5V, VIN = 12V 3.3 5 7.8 µs

= V

REF

= 300µA, V

= 1.00V ● 0.15 0.4 V

SET

● 30.0 V

579 µs

● 70 300 nA

2

Page 3

LT1111

LECTRICAL C CHARA TERIST

E

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Reference Line Regulation 5V ≤ VIN ≤ 30V ● 0.02 0.075 %/V

A

V

I

LIM

VIN = 3V, –55°C ≤ TA ≤ 125°C unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

Q

f

OSC

DC Duty Cycle: Step-Up Mode Full Load ● 40 50 62 %

t

ON

V

SAT

Gain Block Gain RL = 100k (Note 3) ● 1000 6000 V/V

Current Limit 220Ω from I

Current Limit Temperature Coefficient ● –0.3 %/°C

Switch OFF Leakage Current Measured at SW1 Pin, V

Maximum Excursion Below GND I

Quiescent Current Switch OFF ● 300 500 µA

Oscillator Frequency ● 45 72 100 kHz

Step-Down Mode

Switch ON Time: Step-Up Mode I

Step-Down Mode V

Reference Line Regulation 2V ≤ VIN ≤ 5V, 25°C ≤ TA ≤ 125°C 0.2 0.4 %/V

SW Saturation Voltage, Step-Up Mode 0°C ≤ TA ≤ 125°C, ISW = 500mA, 0.5 0.65 V

SW Saturation Voltage, Step-Down Mode VIN = 12V, 0°C ≤ TA ≤ 125°C 1.5 V

ICS

VIN = 3V, Military or Commercial Version

2V ≤ VIN ≤ 5V 0.20 0.400 %/V

to V

LIM

IN

= 12V 1 10 µA

SW1

≤ 10µA, Switch OFF –400 –350 mV

SW1

● 20 55 %

Tied to V

LIM

OUT

2.4V ≤ VIN ≤ 5V, TA = –55°C 0.8 %/V

= –55°C, ISW = 400mA

T

A

ISW = 500mA TA = –55°C 2.0 V

IN

= 5V, VIN = 12V ● 39µs

● 5711 µs

400 mA

LT1111M

VIN = 3V, 0°C ≤ TA ≤ 70°C unless otherwise noted.

LT1111C

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

Q

f

OSC

DC Duty Cycle: Step-Up Mode Full Load ● 43 50 59 %

t

ON

V

SAT

The ● denotes specifications which apply over the full operating

temperature range.

Note 1: This specification guarantees that both the high and low trip points

of the comparator fall within the 1.20V to 1.30V range.

Quiescent Current Switch OFF ● 300 450 µA

Oscillator Frequency ● 54 72 95 kH

Step-Down Mode

Switch ON Time: Step-Up Mode I

Step-Down Mode V

Reference Line Regulation 2V ≤ VIN ≤ 5V ● 0.2 0.7 %/V

SW Saturation Voltage, Step-Up Mode VIN = 3V, ISW = 650mA ● 0.5 0.65 V

SW Saturation Voltage, Step-Down Mode VIN = 12V, ISW = 650mA ● 1.1 1.50 V

Tied to V

LIM

OUT

IN

= 5V, VIN = 12V ● 3.3 5 7.8 µs

Note 2: The output voltage waveform will exhibit a sawtooth shape due to

the comparator hysteresis. The output voltage on the fixed output versions

will always be within the specified range.

Note 3: 100k resistor connected between a 5V source and the A0 pin.

● 24 34 50 %

● 5.0 7 9.0 µs

3

Page 4

L T 1111

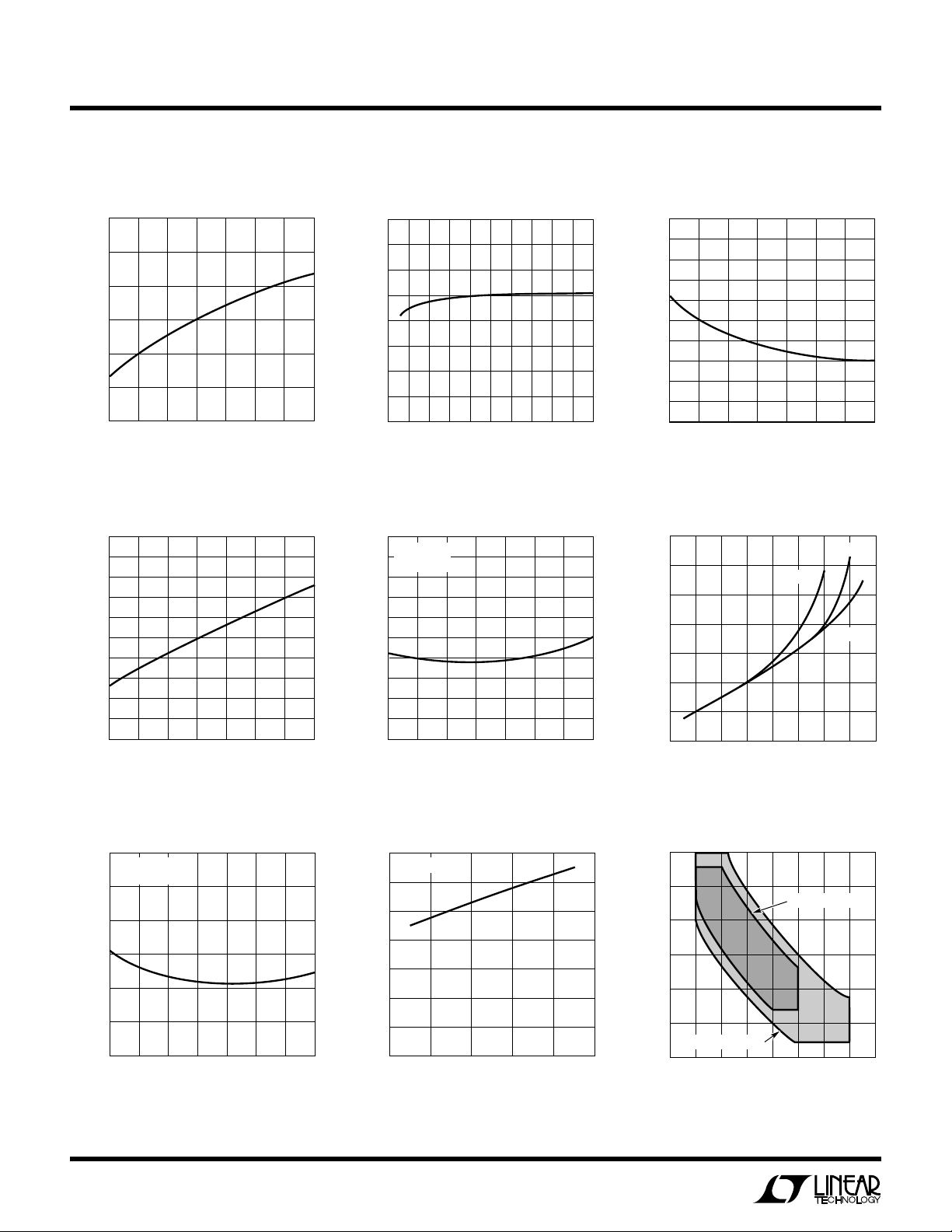

TEMPERATURE (°C)

ON TIME (µs)

–50 –25 0 25

LT111 • TPC03

50 75 100

125

10

9.5

9.0

8.5

8.0

7.5

7.0

6.5

6.0

5.5

5.0

SWITCH CURRENT (A)

SATURATION VOLTAGE (V)

0 0.2

0.4 0.6

LT1111 • TPC06

0.8

1.0

1.2

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

1.4

VIN = 3V

V

IN

= 2V

V

IN

= 5V

SWITCH ON TIME (µs)

OSCILLATOR FREQUENCY (KHz)

4

567

LT1111 • TPC09

89

100

90

80

70

60

50

40

10 11 12

–55°C ≤ TA ≤ 125°C

0°C ≤ TA ≤ 70°C

UW

Y

PICA

100

90

80

70

60

OSCILLATOR FREQUENCY (KHz)

50

40

60

58

56

54

52

50

48

DUTY CYCLE (%)

46

44

42

40

–50 –25 0 25

LPER

F

O

R

AT

CCHARA TERIST

E

C

ICS

Oscillator Frequency Oscillator Frequency Switch ON Time

75

74

73

72

71

70

FREQUENCY (KHz)

69

68

–50

–25 0

TEMPERATURE (°C)

25

50

75

100

LT1111 • TPC01

125

67

0

36

15 18 21

912

INPUT VOLTAGE (V)

242730

LT1111 • TPC02

Saturation Voltage Saturation Voltage

Duty Cycle Step-Up Mode Step-Up Mode

1.0

VIN = 3V

0.9

I

650mA

=

SW

0.8

0.7

0.6

0.5

0.4

0.3

SATURATION VOLTAGE (V)

0.2

0.1

50 75 100

TEMPERATURE (°C)

125

LT1111 • TPC04

0

–50 – 25 0 25

TEMPERATURE (°C)

50 75 100

LT1111 • TPC05

125

Switch ON Voltage Switch ON Voltage Minimum/Maximum Frequency

Step-Down Mode Step-Down Mode vs ON Time

2.00

VIN = 12V

I

SW

1.75

1.50

1.25

ON VOLTAGE (V)

1.00

0.75

0.50

–50 –25 0 25

4

650mA

=

TEMPERATURE (°C)

50 75 100

LT1111 • TPC07

125

1.4

VIN = 12V

1.2

1.0

0.8

0.6

ON VOLTAGE (V)

0.4

0.2

0

0 0.2 0.4 0.6

SWITCH CURRENT (A)

0.8 1.0

LT1111 • TPC08

Page 5

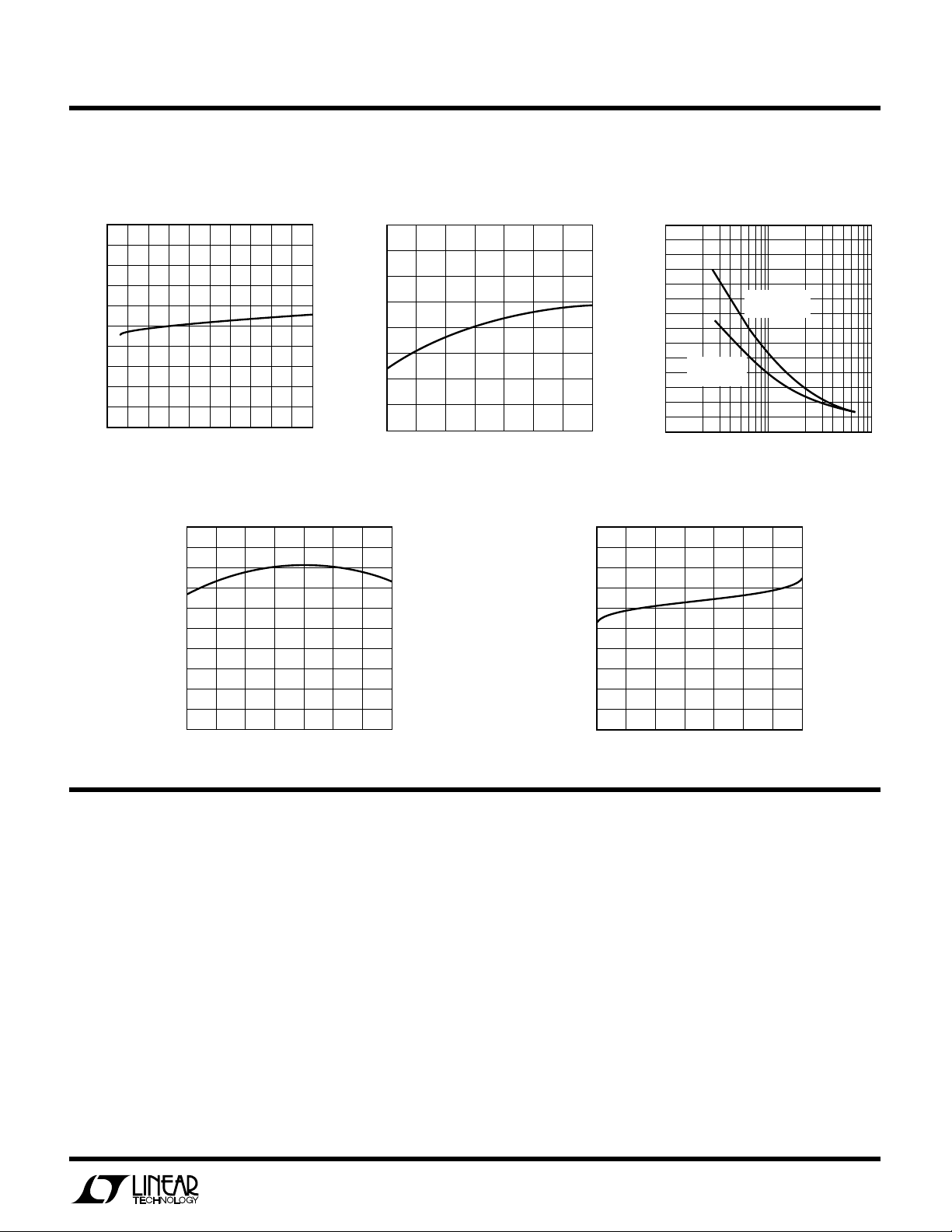

UW

Y

PICA

400

380

360

340

320

300

280

260

QUIESCENT CURRENT (µA)

240

220

200

LPER

F

O

R

AT

CCHARA TERIST

E

C

ICS

Quiescent Current Quiescent Current vs R

500

450

400

350

300

250

200

QUIESCENT CURRENT (µA)

150

6

3

0

912151821242730

INPUT VOLTAGE (V)

LT1111 • TPC10

100

–50

–25

0 25 50 75 100 125

TEMPERATURE (°C)

LT1111 • TPC11

Set Pin Bias Current Feedback Bias Current

100

90

80

70

60

50

40

30

BIAS CURRENT (nA)

20

10

0

–25

–50

0 25 50 75 100 125

TEMPERATURE (°C)

LT1111 • TPC13

100

90

80

70

60

50

40

30

BIAS CURRENT (nA)

20

10

0

–25

–50

Maximum Switch Current

LIM

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

STEP-DOWN

0.5

SWITCH CURRENT (A)

0.4

0.3

0.2

0.1

10

0 25 50 75 100 125

TEMPERATURE (°C)

V

IN

= 12V

STEP-UP

2V ≤ V

100

R

LIM

LT1111 • TPC14

(Ω)

IN

≤ 5V

LT1111

1000

LT1111 • TPC12

U

PI

I

FUUC

(Pin 1): Connect this pin to VIN for normal use. Where

LIM

TI

O

U

S

lower current limit is desired, connect a resistor between

I

and VIN. A 220Ω resistor will limit the switch current

LIM

to approximately 400mA.

V

(Pin 2): Input Supply Voltage.

IN

SW1 (Pin 3): Collector of Power Transistor. For step-up

mode connect to inductor/diode. For step-down mode

connect to VIN.

SW2 (Pin 4): Emitter of Power Transistor. For step-up

mode connect to ground. For step-down mode connect to

inductor/diode. This pin must never be allowed to go more

than a Schottky diode drop below ground.

GND (Pin 5): Ground.

A0 (Pin 6): Auxiliary Gain Block (GB) Output. Open collector,

can sink 300µA.

SET (Pin 7): GB Input. GB is an op amp with positive input

connected to SET pin and negative input connected to

1.25V reference.

FB/SENSE (Pin 8): On the LT1111 (adjustable) this pin

goes to the comparator input. On the LT1111-5 and

LT1111-12, this pin goes to the internal application resistor

that sets output voltage.

5

Page 6

L T 1111

LT1111 • BD02

IN

V

GND

SET

A0

A2

1.25V

REFERENCE

A1

OSCILLATOR

DRIVER

R1

SW1

SW2

LIM

I

R2

220k

SENSE

LT1111-5:

LT1111-12:

R1 = 73.5k

R1 = 25.5k

GAIN BLOCK/

ERROR AMP

COMPARATOR

+

–

+

–

BLOCK

IDAGRA

W

S

LT1111

+

A2

–

GAIN BLOCK/

ERROR AMP

+

A1

–

COMPARATOR

FB

I

AT

O

U

A0

OSCILLATOR

I

LIM

DRIVER

SW1

SW2

LT1111 • BD01

1.25V

REFERENCE

GND

LT11

SET

V

IN

11 OPER

The LT1111 is a gated oscillator switcher. This type

architecture has very low supply current because the

switch is cycled when the feedback pin voltage drops

below the reference voltage. Circuit operation can best be

understood by referring to the LT1111 block diagram.

Comparator A1 compares the feedback (FB) pin voltage

with the 1.25V reference signal. When FB drops below

1.25V, A1 switches on the 72kHz oscillator. The driver

amplifier boosts the signal level to drive the output NPN

power switch. The switch cycling action raises the output

voltage and FB pin voltage. When the FB voltage is sufficient to trip A1, the oscillator is gated off. A small amount

of hysteresis built into A1 ensures loop stability without

external frequency compensation. When the comparator

output is low, the oscillator and all high current circuitry is

turned off, lowering device quiescent current to just 300µA.

OUT

and V

IN

The oscillator is set internally for 7µs ON time and 7µs OFF

time, optimizing the device for circuits where V

differ by roughly a factor of 2. Examples include a 3V to 5V

step-up converter or a 9V to 5V step-down converter.

6

LT1111-5/LT1111-12

Gain block A2 can serve as a low-battery detector. The

negative input of A2 is the 1.25V reference. A resistor

divider from VIN to GND, with the mid-point connected to

the SET pin provides the trip voltage in a low-battery

detector application. AO can sink 300µA (use a 22k

resistor pull-up to 5V).

A resistor connected between the I

pin and VIN sets

LIM

maximum switch current. When the switch current exceeds the set value, the switch cycle is prematurely

terminated. If current limit is not used, I

should be tied

LIM

directly to VIN. Propagation delay through the current limit

circuitry is approximately 1µs.

In step-up mode the switch emitter (SW2) is connected to

ground and the switch collector (SW1) drives the inductor; in step-down mode the collector is connected to V

IN

and the emitter drives the inductor.

The LT1111-5 and LT1111-12 are functionally identical to

the LT1111. The -5 and -12 versions have on-chip voltage

setting resistors for fixed 5V or 12V outputs. Pin 8 on the

fixed versions should be connected to the output. No

external resistors are needed.

Page 7

LT1111

P

f

L OSC

/()02

It

V

R

e

L

IN

Rt

L

() – ( )

–

=

′

′

103

It

V

L

t

L

IN

()

= ()04

ELI

L

PEAK

=

1

2

052()

P V V V mA mW

L

=+

()()

=12 0 5 4 5 60 480 06.–. ()

P

f

mW

kHz

J

L

OSC

==

480

72

67 07.()µ

U

O

PPLICATI

A

Inductor Selection — General

A DC/DC converter operates by storing energy as magnetic flux in an inductor core, and then switching this

energy into the load. Since it is flux, not charge, that is

stored, the output voltage can be higher, lower, or opposite in polarity to the input voltage by choosing an

appropriate switching topology. To operate as an efficient

energy transfer element, the inductor must fulfill three

requirements. First, the inductance must be low enough

for the inductor to store adequate energy under the worst

case condition of minimum input voltage and switch-on

time. The inductance must also be high enough so maximum current ratings of the LT1111 and inductor are not

exceeded at the other worst case condition of maximum

input voltage and ON time. Additionally, the inductor core

must be able to store the required flux; i.e., it must not

saturate. At power levels generally encountered with

LT1111 based designs, small surface mount ferrite core

units with saturation current ratings in the 300mA to 1A

range and DCR less than 0.4Ω (depending on application)

are adequate. Lastly, the inductor must have sufficiently

low DC resistance so excessive power is not lost as heat

in the windings. An additional consideration is ElectroMagnetic Interference (EMI). Toroid and pot core type

inductors are recommended in applications where EMI

must be kept to a minimum; for example, where there are

sensitive analog circuitry or transducers nearby. Rod core

types are a less expensive choice where EMI is not a

problem. Minimum and maximum input voltage, output

voltage and output current must be established before an

inductor can be selected.

Inductor Selection — Step-Up Converter

In a step-up, or boost converter (Figure 4), power generated by the inductor makes up the difference between

input and output. Power required from the inductor is

determined by:

S

I FOR ATIO

WU

U

in order for the converter to regulate the output.

When the switch is closed, current in the inductor builds

according to:

where R′ is the sum of the switch equivalent resistance

(0.8Ω typical at 25°C) and the inductor DC resistance.

When the drop across the switch is small compared to VIN,

the simple lossless equation:

can be used. These equations assume that at t = 0,

inductor current is zero. This situation is called “discontinuous mode operation” in switching regulator parlance.

Setting “t” to the switch-on time from the LT1111 specification table (typically 7µs) will yield I

“L” and VIN. Once I

at the end of the switch-on time can be calculated as:

EL must be greater than PL/f

the required power. For best efficiency I

kept to 1A or less. Higher switch currents will cause

excessive drop across the switch resulting in reduced

efficiency. In general, switch current should be held to as

low a value as possible in order to keep switch, diode and

inductor losses at a minimum.

As an example, suppose 12V at 60mA is to be generated

from a 4.5V to 8V input. Recalling equation (01),

is known, energy in the inductor

PEAK

for the converter to deliver

OSC

for a specific

PEAK

should be

PEAK

PV VV I

=+

()()

L OUT D IN

where VD is the diode drop (0.5V for a 1N5818 Schottky).

Energy required by the inductor per cycle must be equal or

greater than:

–()01

MIN

OUT

Energy required from the inductor is

7

Page 8

L T 1111

L

VVV

I

t

IN MIN SW OUT

PEAK

ON

=

−−

× ()11

I

mA

mA

PEAK

=

()

+

+

=

2 300

050

505

12 15 05

600 12

.

.

–. .

()

L

mA

sH==

12 1 5 5

600

764 13

–.–

.()µµ

U

O

PPLICATI

A

Picking an inductor value of 47µH with 0.2Ω DCR results

in a peak switch current of:

V

45

I

PEAK

Substituting I

EHAJ

L

Since 9.1µJ > 6.7µJ, the 47µH inductor will work. This

trial-and-error approach can be used to select the optimum inductor. Keep in mind the switch current maximum

rating of 1.5A. If the calculated peak current exceeds this,

consider using the LT1110. The 70% duty cycle of the

LT1110 allows more energy per cycle to be stored in the

inductor, resulting in more output power.

A resistor can be added in series with the I

switch current limit. The resistor should be picked so the

calculated I

Switch Current (from Typical Performance Characteristic

curves). Then, as VIN increases, switch current is held

constant, resulting in increasing efficiency.

Inductor Selection — Step-Down Converter

.

=

10

.

PEAK

1

=

47 0 623 9 1 09

µµ.. ()

()( )

2

PEAK

S

I FOR ATIO

s

×

10 7

–.ΩΩµ

emA

1 623 08

–.()

into Equation 04 results in:

at minimum VIN is equal to the Maximum

47

H

µ

2

=

WU

=

pin to invoke

LIM

U

I

= output current

OUT

V

= output voltage

OUT

VIN = minimum input voltage

VSW is actually a function of switch current which is in turn

a function of VIN, L, time, and V

be used for VSW as a very conservative value.

Once I

where tON = switch-on time (7µs).

Next, the current limit resistor R

I

PEAK

of this resistor keeps maximum switch current constant as

the input voltage is increased.

As an example, suppose 5V at 300mA is to be generated

from a 12V to 24V input. Recalling Equation (10),

Next, inductor value is calculated using Equation (11):

is known, inductor value can be derived from:

PEAK

from the R

Step-Down Mode curve. The addition

LIM

. To simplify, 1.5V can

OUT

is selected to give

LIM

The step-down case (Figure 5) differs from the step-up in

that the inductor current flows through the load during

both the charge and discharge periods of the inductor.

Current through the switch should be limited to ~650mA

in this mode. Higher current can be obtained by using an

external switch (see Figure 6). The I

successful operation over varying inputs.

After establishing output voltage, output current and input

voltage range, peak switch current can be calculated by the

formula:

I

PEAK

where DC = duty cycle (0.50)

8

2

=

VSW = switch drop in step-down mode

VD = diode drop (0.5V for a 1N5818)

I

OUT OUT D

DC

VV

+

VV V

IN SW D

+

pin is the key to

LIM

10–()

Use the next lowest standard value (56µH).

Then pick R

= 56Ω.

Inductor Selection — Positive-to-Negative Converter

Figure 7 shows hookup for positive-to-negative conversion. All of the output power must come from the inductor.

In this case,

P

= (V

L

In this mode the switch is arranged in common collector

or step-down mode. The switch drop can be modeled as

a 0.75V source in series with a 0.65Ω resistor. When the

from the curve. For I

LIM

+ V

)(I

OUT

D

) (14)

OUT

= 600mA, R

PEAK

LIM

Page 9

LT1111

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

switch closes, current in the inductor builds according to

Rt

–

e

′

L

L

V

=

L

115–()

R

′

It

()

L

where R′ = 0.65Ω + DCR

VL = VIN – 0.75V

As an example, suppose –5V at 50mA is to be generated

from a 4.5V to 5.5V input. Recalling Equation (14),

P

= (-5V+0.5V)(50mA) = 275mW (16)

L

Energy required from the inductor is:

P

f

OSC

275

L

mW

==

72

kHz

38 17.. ()µ

J

Picking an inductor value of 56µH with 0.2Ω DCR results

in a peak switch current of:

capacitors provide still better performance at more expense. We recommend OS-CON capacitors from Sanyo

Corporation (San Diego, CA). These units are physically

quite small and have extremely low ESR. To illustrate,

Figures 1, 2, and 3 show the output voltage of an LT1111

based converter with three 100µF capacitors. The peak

switch current is 500mA in all cases. Figure 1 shows a

Sprague 501D, 25V aluminum capacitor. V

jumps by

OUT

over 120mV when the switch turns off, followed by a drop

in voltage as the inductor dumps into the capacitor. This

works out to be an ESR of over 0.24Ω.

Figure 2 shows the

same circuit, but with a Sprague 150D, 20V tantalum

capacitor replacing the aluminum unit. Output jump is

now about 35mV, corresponding to an ESR of 0.07Ω.

Figure 3 shows the circuit with a 16V OS-CON unit. ESR

is now only 0.02Ω.

s

×

085 7

–.

45 075

.–.

VV

I

PEAK

Substituting I

()

=

065 02

..

+

ΩΩ

()

PEAK

1

EHAJ

=

56 0 445 5 54 19

µµ...()

()( )

L

2

1 445 18

–.()

into Equation (04) results in:

Ωµ

emA

56

µ

2

=

=

H

Since 5.54µJ > 3.82µJ, the 56µH inductor will work.

With this relatively small input range, R

necessary and the I

pin can be tied directly to VIN. As in

LIM

is not usually

LIM

the step-down case, peak switch current should be limited

to ~650mA.

Capacitor Selection

Selecting the right output capacitor is almost as important

as selecting the right inductor. A poor choice for a filter

capacitor can result in poor efficiency and/or high output

ripple. Ordinary aluminum electrolytics, while inexpensive

and readily available, may have unacceptably poor Equivalent Series Resistance (ESR) and ESL (inductance). There

are low ESR aluminum capacitors on the market specifically designed for switch mode DC/DC converters which

work much better than general-purpose units. Tantalum

50mV/DIV

50mV/DIV

50mV/DIV

5µs/DIV

Figure 1. Aluminum

5µs/DIV

Figure 2. Tantalum

5µs/DIV

Figure 3. OS-CON

LT1111 • F01

LT1111 • F02

LT1111 • F01

9

Page 10

L T 1111

I

V

L

t

PEA K

IN

ON

= ()20

V

R

R

V

OUT

=+

()

1

2

1

125 21.()

I

V

VV

L

t

PEAK

IN

SW OUT

ON

=

−−

()22

LT1111 • F05

GND

SW2

SW1

LIM

I

IN

V

R3

100

FB

V

OUT

+

C2

+

C1

D1

1N5818

V

IN

R2

R1

L1

Ω

LT1111

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

Diode Selection

Speed, forward drop, and leakage current are the three

main considerations in selecting a catch diode for LT1111

converters. General purpose rectifiers such as the 1N4001

are

unsuitable

for use in

any

switching regulator applica-

tion. Although they are rated at 1A, the switching time of

a 1N4001 is in the 10µs to 50µs range. At best, efficiency

will be severely compromised when these diodes are

used; at worst, the circuit may not work at all. Most

LT1111 circuits will be well served by a 1N5818 Schottky

diode, or its surface mount equivalent, the MBRS130T3.

The combination of 500mV forward drop at 1A current,

fast turn ON and turn OFF time, and 4µA to 10µA leakage

current fit nicely with LT1111 requirements. At peak

switch currents of 100mA or less, a 1N4148 signal diode

may be used. This diode has leakage current in the 1nA to

5nA range at 25°C and lower cost than a 1N5818. (You can

also use them to get your circuit up and running, but

beware of destroying the diode at 1A switch currents.)

Step-Up (Boost Mode) Operation

At the end of the switch ON time the current in L1 is1:

Immediately after switch turn-off, the SW1 voltage pin

starts to rise because current cannot instantaneously stop

flowing in L1. When the voltage reaches V

+ VD, the

OUT

inductor current flows through D1 into C1, increasing

V

. This action is repeated as needed by the LT1111 to

OUT

keep VFB at the internal reference voltage of 1.25V. R1 and

R2 set the output voltage according to the formula

Step-Down (Buck Mode) Operation

A step-down DC/DC converter converts a higher voltage

to a lower voltage. The usual hookup for an LT1111 based

step-down converter is shown in Figure 5.

A step-up DC/DC converter delivers an output voltage

higher than the input voltage. Step-up converters are not

short-circuit protected since there is a DC path from input

to output.

The usual step-up configuration for the LT1111 is shown

in Figure 4. The LT1111 first pulls SW1 low causing VIN –

V

10

to appear across L1. A current then builds up in L1.

CESAT

L1

V

IN

R3*

V

*OPTIONAL

I

LIM

GND SW2

Figure 4. Step-Up Mode Hookup.

Refer to Table 1 for Component Values.

LT1111

IN

SW1

FB

D1

V

OUT

R2

+

C1

When the switch turns on, SW2 pulls up to V

puts a voltage across L1 equal to VIN – VSW – V

R1

causing a current to build up in L1. At the end of the switch

Figure 5. Step-Down Mode Hookup

– VSW. This

IN

OUT

,

ON time, the current in L1 is equal to:

LT1111 • F04

Note 1: This simple expression neglects the effect of switch and coil

resistance. This is taken into account in the “Inductor Selection” section.

Page 11

LT1111

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

When the switch turns off, the SW2 pin falls rapidly and

actually goes below ground. D1 turns on when SW2

reaches 0.4V below ground.

DIODE

. The voltage at SW2 must never be allowed to go

D1 MUST BE A SCHOTTKY

below –0.5V. A silicon diode such as the 1N4933 will allow

SW2 to go to –0.8V, causing potentially destructive power

dissipation inside the LT1111. Output voltage is determined by:

V

OUT

=+

1

R

2

R

1

V

125 23.()

()

R3 programs switch current limit. This is especially important in applications where the input varies over a wide

range. Without R3, the switch stays on for a fixed time each

cycle. Under certain conditions the current in L1 can build

up to excessive levels, exceeding the switch rating and/or

saturating the inductor. The 100Ω resistor programs the

switch to turn off when the current reaches approximately

700mA. When using the LT1111 in step-down mode,

output voltage should be limited to 6.2V or less. Higher

output voltages can be accommodated by inserting a

1N5818 diode in series with the SW2 pin (anode connected to SW2).

R1

V

GND

0.3Ω

IN

LT1111

I

SW2

L

SW1

FB

V

IN

30V

MAX

+

C2

Figure 6. Q1 Permits Higher Current Switching.

LT1111 Functions as Controller.

Q1

MJE210 OR

ZETEX ZTX749

R2

220

R3

330

R4

R5

L1

D1

1N5821

= 1.25V (1 + )

V

OUT

V

OUT

+

C1

R4

R5

LT1111 • TA08

Inverting Configurations

The LT1111 can be configured as a positive-to-negative

converter (Figure 7), or a negative-to-positive converter

(Figure 8). In Figure 7, the arrangement is very similar to

a step-down, except that the high side of the feedback is

referred to ground. This level shifts the output negative. As

in the step-down mode, D1 must be a Schottky diode,

and V

should be less than 6.2V. More negative out-

OUT

put voltages can be accommodated as in the prior section.

Higher Current Step-Down Operation

Output current can be increased by using a discrete PNP

pass transistor as shown in Figure 6. R1 serves as a

current limit sense. When the voltage drop across R1

equals a VBE, the switch turns off. For temperature compensation a Schottky diode can be inserted in series with

the I

pin. This also lowers the maximum drop across R1

LIM

to VBE – VD, increasing efficiency. As shown, switch

current is limited to 2A. Inductor value can be calculated

based on formulas in the “Inductor Selection — StepDown Converter” section with the following conservative

expression for VSW:

VVV V

=+ ≈

SW R Q SAT

11

10 24.()

R2 provides a current path to turn off Q1. R3 provides base

drive to Q1. R4 and R5 set output voltage. A PMOS FET can

be used in place of Q1 when VIN is between 10V and 20V.

V

IN

R3

V

I

LIM

+

C2

Figure 7. Positive-to-Negative Converter

IN

LT1111

GND

SW1

SW2

FB

L1

D1

1N5818

+

R1

C1

R2

–V

OUT

LT1111 • F07

In Figure 8, the input is negative while the output is

positive. In this configuration, the magnitude of the input

voltage can be higher or lower than the output voltage. A

level shift, provided by the PNP transistor, supplies proper

polarity feedback information to the regulator.

11

Page 12

L T 1111

LT1111 • F09

I

OFF

L

ON

SWITCH

LT1111 • F10

I

ON

L

OFF

SWITCH

PROGRAMMED CURRENT LIMIT

PPLICATI

A

+

C2

–V

IN

Using the I

U

O

S

I FOR ATIO

L1

LIM

LT1111

Pin

V

IN

SW1

FB

R2

I

A0

GND SW2

Figure 8. Negative-to-Positive Converter

LIM

WU

D1

+

LT1111 • F08

R1

V

= 1.25V + 0.6V

( )

OUT

R2

C1

U

R1

2N3906

V

OUT

The LT1111 switch can be programmed to turn off at a set

switch current, a feature not found on competing devices.

This enables the input to vary over a wide range without

exceeding the maximum switch rating or saturating the

inductor. Consider the case wh ere analysis shows the

LT1111 must operate at an 800mA peak switch current

with a 2V input. If VIN rises to 4V, the peak switch current

will rise to 1.6A, exceeding the maximum switch current

rating. With the proper resistor selected (see the “Maximum Switch Current vs I

” characteristic), the switch

LIM

current will be limited to 800mA, even if the input voltage

increases.

Another situation where the I

feature is useful occurs

LIM

when the device goes into continuous mode operation.

This occurs in step-up mode when:

V

+

OUT DIODE

V

<

VV DC

−

IN SW

−11

25()

When the input and output voltages satisfy this relationship, inductor current does not go to zero during the

switch OFF time. When the switch turns on again, the

current ramp starts from the non-zero current level in the

inductor just prior to switch turn-on. As shown in Figure

9, the inductor current increases to a high level before the

comparator turns off the oscillator. This high current can

cause excessive output ripple and requires oversizing the

output capacitor and inductor. With the I

feature,

LIM

however, the switch current turns off at a programmed

level as shown in Figure 10, keeping output ripple to a

minimum.

Figure 9. No Current Limit Causes Large Inductor

Current Build-Up

Figure 10. Current Limit Keeps Inductor Current Under Control

Figure 11 details current limit circuitry. Sense transistor

Q1, whose base and emitter are paralleled with power

switch Q2, is ratioed such that approximately 0.5% of

Q2’s collector current flows in Q1’s collector. This current

is passed through internal 80Ω resistor R1 and out

through the I

connected between I

When sufficient switch current flows to develop a V

across R1 + R

pin. The value of the external resistor

LIM

and VIN sets the current limit.

LIM

, Q3 turns on and injects current into the

LIM

BE

oscillator, turning off the switch. Delay through this circuitry is approximately 1µs. The current trip point becomes less accurate for switch ON times less than 3µs.

Resistor values programming switch ON time for 1µs or

less will cause spurious response in the switch circuitry

although the device will still maintain output regulation.

R

V

IN

Q3

OSCILLATOR

Figure 11. LT1111 Current Limit Circuitry

(EXTERNAL)

DRIVER

LIM

I

LIM

R1

80Ω

(INTERNAL)

Q1

SW1

Q2

SW2

LT1111 • F11

12

Page 13

LT1111

LT1111 • F12

V

BAT

R1

R2

1.25V

REF

SET

GND

IN

V

LT1111

47k

5V

TO

PROCESSOR

+

–

A0

R3

R1 =

V

LB

– 1.25V

35.1µA

V

LB

= BATTERY TRIP POINT

R2 = 33k

R3 = 1.6M

U

O

PPLICATI

A

S

I FOR ATIO

Using the Gain Block

The gain block (GB) on the LT1111 can be used as an error

amplifier, low-battery detector or linear post regulator.

WU

U

when the trip point is reached. Values in the 1M to 10M

range are optimal. However, the addition of R3 will

change the trip point.

The gain block itself is a very simple PNP input op amp with

an open collector NPN output. The negative input of the

gain block is tied internally to the 1.25V reference. The

positive input comes out on the SET pin.

Arrangement of the gain block as a low-battery detector

is straightforward. Figure 12 shows hookup. R1 and R2

need only be low enough in value so that the bias current

of the SET input does not cause large errors. 33k for R2

is adequate. R3 can be added to introduce a small amount

of hysteresis. This will cause the gain block to “snap”

Figure 12. Setting Low-Battery Detector Trip Point

Table 1. Component Selection for Common Converters

INPUT OUTPUT OUTPUT CIRCUIT INDUCTOR INDUCTOR CAPACITOR

VOLTAGE VOLTAGE CURRENT (MIN) FIGURE VALUE PART NUMBER VALUE NOTES

2 to 3.1 5 90mA 4 15µH S CD75-750K 33µF*

2 to 3.1 5 10mA 4 47µH S CD54-470K, C CTX50-1 10µF

2 to 3.1 12 30mA 4 15µH S CD75-150K 22µF

2 to 3.1 12 10mA 4 47µH S CD54-470K, C CTX50-1 10µF

5 12 90mA 4 33µH S CD75-330K 22µF

5 12 30mA 4 47µH S CD75-470K, C CTX50-1 15µF

6.5 to 11 5 50mA 5 15µH S CD54-150K 47µF**

12 to 20 5 300mA 5 56µH S CD105-560K, C CTX50-4 47µF**

20 to 30 5 300mA 5 120µH S CD105-121K, C CTX100-4 47µF**

5 –5 75mA 6 56µH S CD75-560K, C CTX50-4 47µF

12 –5 250mA 6 120µH S CD105-121K, C CTX100-4 100µF**

S = Sumida

C = Coiltronics

* Add 47Ω from I

** Add 220Ω from I

LIM

to V

LIM

IN

to V

IN

Table 2. Inductor Manufacturers

MANUFACTURER PART NUMBERS

Coiltronics Incorporated CTX100-4 Series

6000 Park of Commerce Blvd. Surface Mount

Boca Raton, FL 33487

407-241-7876

Toko America Incorporated Type 8RBS

1250 Feehanville Drive

Mount Prospect, IL 60056

312-297-0070

Sumida Electric Co. USA CD54

708-956-0666 CDR74

CDR105

Surface Mount

Table 3. Capacitor Manufacturers

MANUFACTURER PART NUMBERS

Sanyo Video Components OS-CON Series

1201 Sanyo Avenue

San Diego, CA 92073

619-661-6322

Nichicon America Corporation PL Series

927 East State Parkway

Schaumberg, IL 60173

708-843-7500

Sprague Electric Company 150D Solid Tantalums

Lower Main Street 550D Tantalex

Sanford, ME 04073

207-324-4140

Matsuo 267 Series

714-969-2491 Surface Mount

13

Page 14

L T 1111

U

O

PPLICATITYPICAL

SA

3V to –22V LCD Bias Generator

R1

100Ω

LT1111

V

IN

SW1

FB

SW2

MBRS130T3

I

LIM

2 × 1.5V

CELLS

* L1 = SUMIDA CD54-270K

FOR 5V INPUT CHANGE R1 TO 47Ω.

CONVERTER WILL DELIVER –22V AT 40mA.

3V

GND

L1*

27µH

1N4148

732k

1%

0.1µF

+

4.7µF

MBRS130T3

39.2k

1%

22µF+220k

–22V OUTPUT

7mA AT 2V INPUT

LT1111 • TA03

9V to 5V Step-Down Converter

I

LIM

9V

BATTERY

GND

* L1 = SUMIDA CD54-150K

100

Ω

LT1111-5

V

IN

SW1

SENSE

SW2

L1*

15µH

MBRS130T3

20V to 5V Step-Down Converter

VIN

12V TO 28V

100

Ω

LIM

LT1111-5

V

IN

SW1

SENSE

SW2

L1*

68µH

MBRS130T3

5V OUTPUT

300mA

+

47µF

LT1111 • TA06

I

5V OUTPUT

150mA AT 9V INPUT

22µF

50mA AT 6.5V INPUT

LT1111 • TA04

* L1 = SUMIDA CD74-680M

+

GND

14

Page 15

LT1111

U

O

PPLICATITYPICAL

SA

V

5V TO 12V

VIN

5V INPUT

100

Ω

LIM

LT1111-5

V

IN

SW1

SENSE

SW2

MBRS130T3

L1*

33µH

+

33µF

–5V OUTPUT

75mA

LT1111 • TA05

I

+

22µF

GND

* L1 = SUMIDA CD54-330K

Voltage Controlled Positive-to-Negative Converter

5V to –5V Converter

ZETEX†

ZTX788A

220Ω

V

IN

LT1006

–

+

V

GND

IN

LT1111

0.22Ω

I

LIM

SW2

SW1

FB

BAT54

220Ω

IN

20µH, 3A

MBRD320

200k

L1*

39k

+

47µF

–V

2W MAXIMUM OUTPUT

V

C

= –5.13 × VC

OUT

(0V TO 5V)

VIN

8V TO 18V

* L1 = COILTRONICS CTX20-4

†

ZETEX INC. 516-543-7100

High Power, Low Quiescent Current Step-Down Converter

L1*

0.22Ω

BAT54

V

GND

OPERATE STANDBY

I

LIM

IN

SW1

LT1111

FB

SW2

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

MTM20P08

51Ω2k

2N3904

1N4148

40.2k

* L1 = SUMIDA CDR105-100M

10µH, 3A

MBRD320

121k

+

220µF

LT1111 • TA07

LT1111 • TA20

5V

500mA

15

Page 16

L T 1111

PACKAGEDESCRIPTI

U

Dimensions in inches (millimeters) unless otherwise noted.

O

J8 Package

8-Lead Ceramic DIP

CORNER LEADS OPTION

0.290 – 0.320

(7.366 – 8.128)

0.008 – 0.018

(0.203 – 0.457)

0.385 ± 0.025

(9.779 ± 0.635)

0.300 – 0.320

(7.620 – 8.128)

0.009 – 0.015

(0.229 – 0.381)

0.325

8.255

()

+0.025

–0.015

+0.635

–0.381

0° – 15°

(4 PLCS)

0.023 – 0.045

(0.584 – 1.143)

HALF LEAD

OPTION

0.045 – 0.068

(1.143 – 1.727)

FULL LEAD

OPTION

0.065

(1.651)

TYP

0.045 ± 0.015

(1.143 ± 0.381)

0.045 – 0.068

(1.143 – 1.727)

0.014 – 0.026

(0.360 – 0.660)

NOTE: LEAD DIMENSIONS APPLY TO SOLDER DIP OR TIN PLATE LEADS.

0.045 – 0.065

(1.143 – 1.651)

0.100 ± 0.010

(2.540 ± 0.254)

N8 Package

8-Lead Plastic DIP

0.130 ± 0.005

(3.302 ± 0.127)

0.125

(3.175)

MIN

0.018 ± 0.003

(0.457 ± 0.076)

0.015 – 0.060

(0.381 – 1.524)

0.100 ± 0.010

(2.540 ± 0.254)

0.020

(0.508)

MIN

0.200

(5.080)

MAX

0.125

3.175

MIN

0.005

(0.127)

MIN

0.025

(0.635)

RAD TYP

0.400

(10.160)

876

12

87

12

MAX

3

0.405

(10.287)

MAX

5

4

65

3

4

0.250 ± 0.010

(6.350 ± 0.254)

0.220 – 0.310

(5.588 – 7.874)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006 INCH (0.15mm).

× 45°

0.016 – 0.050

0.406 – 1.270

0.053 – 0.069

(1.346 – 1.752)

0°– 8° TYP

0.014 – 0.019

(0.355 – 0.483)

Linear Technology Corporation

16

1630 McCarthy Blvd., Milpitas, CA 95035-7487

(408) 432-1900

●

FAX

: (408) 434-0507

●

TELEX

: 499-3977

S8 Package

8-Lead Plastic SOIC

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

0.228 – 0.244

(5.791 – 6.197)

0.189 – 0.197

(4.801 – 5.004)

7

8

1

2

LT/GP 0594 5K REV C • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1994

5

6

0.150 – 0.157

(3.810 – 3.988)

3

4

SO8 0294

Loading...

Loading...