Datasheet LT1105IN8, LT1105IN, LT1105CN8, LT1105CN, LT1103CT7 Datasheet (Linear Technology)

Page 1

OBSOLETE:

FOR INFORMATION PURPOSES ONLY

Contact Linear Technology for Potential Replacement

FEATURES

■

±1% Line and Load Regulation with No Optocoupler

■

Switch Frequency Up to 200kHz

■

Internal 2A Switch and Current Sense (LT1103)

■

Internal 1A Totem-Pole Driver (LT1105)

■

Start-Up Mode Draws Only 200µA

■

Fully Protected Against Overloads

■

Overvoltage Lockout of Main Supply

■

Protected Against Underdrive or Overdrive to FET

■

Operates in Continuous or Discontinuous Mode

■

Ideal for Flyback and Forward Topologies

■

Isolated Flyback Mode Has Fully Floating Outputs

U

APPLICATIONS

■

Up to 250W Isolated Mains Converter

■

Up to 50W Isolated Telecom Converter

■

Fully Isolated Multiple Outputs

■

Distributed Power Conversion Networks

LT1103/LT1105

Offline Switching Regulator

U

DESCRIPTION

The LT®1103 Offline Switching Regulator is designed for

high input voltage applications using an external FET

switch whose source is driven by the open collector output

of the LT1103. The LT1103 is optimized for 15W to 100W

applications. For higher power applications or additional

switch current flexibility, the LT1105 is available and its

totem pole output drives the gate of an external FET.

Unique design of the LT1103/LT1105 eliminates the need

for an optocoupler while still providing ±1% load and line

regulation in a magnetic flux-sensed converter. This significantly simplifies the design of offline power supplies

and reduces the number of components which must cross

the isolation barrier to one, the transformer.

The LT1103/LT1105 current mode switching techniques

are well suited to transformer isolated flyback and forward

topologies while providing ease of frequency compensation with a minimum of external components. Low external part count for a typical application combines with a

, LTC and LT are registered trademarks of Linear Technology Corporation.

TYPICAL APPLICATION

Fully Isolated Flyback 100kHz 50W Converter with Load Regulation Compensation

85V

TO 270V

AC

AC

+

–

BRIDGE

RECTIFIER

+

LINE

FILTER

+

220µF

385V

BAV21

13k

1%

4.75k

1%

499Ω

1000pF

18.7k

0.047µF

100Ω

BAV21

1N4148

Danger!! Lethal Voltages Present – See Text

39µF

35V

+

220k

1W

0.047µF

V

FB

GND

IN

U

DANGER!!

HIGH VOLTA

1N4148

V

SW

LT1103

15V

V

OSC

C

330Ω

0.1µF

G

390pF

E!!

1.5KE300A

5W

MUR150

BUK426-800A

10Ω

+

1µF

25V

OPTIONAL OUTPUT FILTER

MBR2045

*OUTPUT CAPACITOR IS THREE 1200µF,

50V CAPACITORS IN PARALLEL TO

ACHIEVE REQUIRED RIPPLE CURRENT

RATING AND LOW ESR.

TRANSFORMER DATA:

COILTRONICS CTX110228-3

L

= 1.6mH

(PRI)

N

PRI:NSEC

N

BIAS:NSEC

LT1103 TA13

+

*50V

3600µF

WINDINGS FOR

OPTIONAL

OUTPUTS

±12V

DC

= 1:0.05

= 1:0.27

10µH

+

50V

470µF

5V

10A

Load Regulation

5.25

5.20

5.15

5.10

5.05

(V)

5.00

OUT

V

4.95

4.90

4.85

4.80

4.75

0

270V

2

3

1

220V

AC

110V

AC

AC

579

6

4

I

OUT

8

(A)

85V

AC

LT1103 TA02

10

1

Page 2

LT1103/LT1105

U

DESCRIPTION

200kHz maximum switching frequency to achieve high

power density. Performance at switching frequencies

above 100kHz may be degraded due to internal timing

constraints associated with fully isolated flyback mode.

Included are the oscillator, control, and protection circuitry such as current limit and overvoltage lockout.

Switch frequency and maximum duty cycle are adjustable.

Bootstrap circuitry draws 200µA for start-up of isolated

topologies. A 5V reference as well as a 15V gate bias are

available to power external primary-side circuitry. No

external current sense resistor is necessary with LT1103

because it is integrated with the high current switch. The

LT1105 brings out the input to the current limit amplifier

and requires the use of an external sense resistor.

The LT1103/LT1105 have unique features not found on

other offline switching regulators. Adaptive antisat switch

drive allows wide ranging load currents while maintaining

high efficiency. The external FET is protected from insufficient or excessive gate drive voltage with a drive detection circuit. An externally activated shutdown mode

reduces total supply current to less than 200µA, typical for

standby operation. Fully isolated and regulated outputs

can be generated in the optional isolated flyback mode

without the need for optocouplers or other isolated feedback paths.

U

U

WAR I G!

DANGEROUS AND LETHAL POTENTIALS ARE

PRESENT IN OFFLINE CIRCUITS!

BEFORE PROCEEDING ANY FURTHER, THE

READER IS WARNED THAT CAUTION MUST

BE USED IN THE CONSTRUCTION, TESTING

AND USE OF OFFLINE CIRCUITS. HIGH

VOLTAGE, AC LINE-CONNECTED POTENTIALS

ARE PRESENT IN THESE CIRCUITS. EXTREME

CAUTION MUST BE USED IN WORKING WITH

AND MAKING CONNECTIONS TO THESE

CIRCUITS. REPEAT: OFFLINE CIRCUITS

CONTAIN DANGEROUS, AC LINE-CONNECTED

HIGH VOLTAGE POTENTIALS. USE CAUTION.

ALL TESTING PERFORMED ON AN OFFLINE

CIRCUIT MUST BE DONE WITH AN ISOLATION

TRANSFORMER CONNECTED BETWEEN THE

OFFLINE CIRCUIT'S INPUT AND THE AC LINE.

USERS AND CONSTRUCTORS OF OFFLINE

CIRCUITS MUST OBSERVE THIS PRECAUTION

WHEN CONNECTING TEST EQUIPMENT TO

THE CIRCUIT TO AVOID ELECTRIC SHOCK.

REPEAT: AN ISOLATION TRANSFORMER

MUST BE CONNECTED BETWEEN THE CIRCUIT

INPUT AND THE AC LINE IF ANY TEST

EQUIPMENT IS TO BE CONNECTED.

WW

W

ABSOLUTE MAXIMUM RATINGS

VIN.......................................................................... 30V

V

Output Voltage (LT1103)................................. 50V

SW

VSW Output Current (200ns)(LT1105) ................. ±1.5A

VC, FB, OSC, SS ........................................................ 6V

I

(LT1105) ........................................................... 3V

LIM

0VLO Input Current ............................................... 1mA

Lead Temperature (Soldering, 10 sec.)................ 300°C

U

(Note 1)

2

Maximum Operating Ambient Temperature Range

LT1103C .............................................. 0°C to 70°C

LT1105C .............................................. 0°C to 70°C

Maximum Operating Junction Temperature Range

LT1103C ............................................. 0°C to 100°C

LT1105C ............................................ 0°C to 100°C

LT1105I ......................................... –40°C to 125°C

Storage Temperature Range ................. –65°C to 150°C

Page 3

LT1103/LT1105

U

W

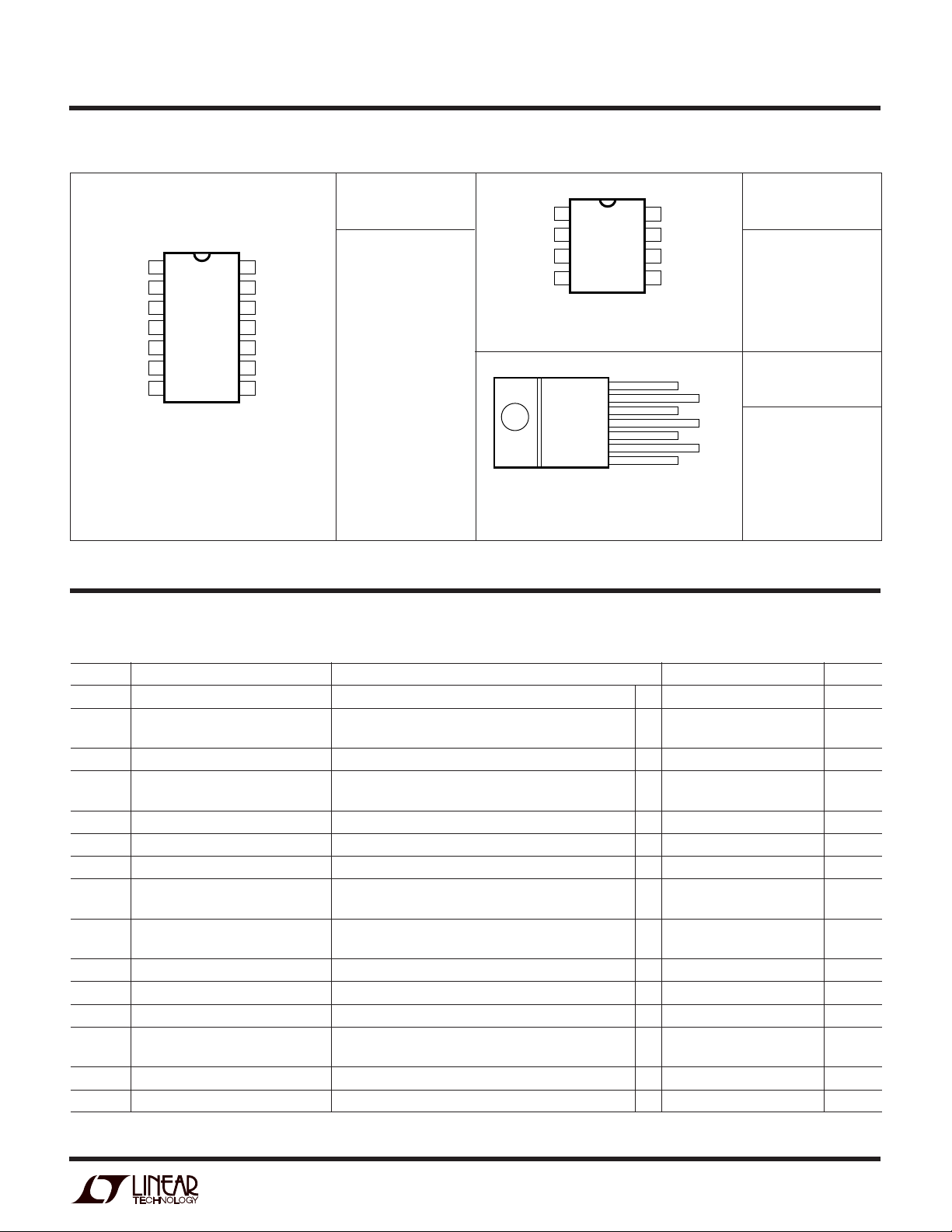

PACKAGE/ORDER INFORMATION

ORDER PART

NUMBER

TOP VIEW

PWRGND

1

2

OVLO

3

FB

4

V

C

5

5V

6

SS

7

GND

N PACKAGE

14-LEAD PDIP

PINS 1 AND 7 MUST BE TIED TOGETHER

T

= 100°C, θJA = 100°C/W

JMAX

V

14

SW

NC

13

NC

12

15V

11

V

10

IN

OSC

9

I

8

LIM

Consult factory for Military grade parts.

LT1105CN

LT1105IN

U

TOP VIEW

GND

1

I

2

LIM

3

FB

45

V

C

N8 PACKAGE

8-LEAD PDIP

T

= 100°C, θJA = 130°C/W

JMAX

FRONT VIEW

7

6

5

4

3

2

1

T7 PACKAGE

CASE IS CONNECTED TO GROUND. LEADS ARE FORMED

7-LEAD TO-220

= 100°C, θJA = 50°C/W

T

JMAX

ORDER PART

8

V

SW

15V

7

6

V

IN

OSC

NUMBER

LT1105CN8

LT1105IN8

ORDER PART

15V

V

IN

OSC

GND

V

C

FB

V

SW

NUMBER

LT1103CT7

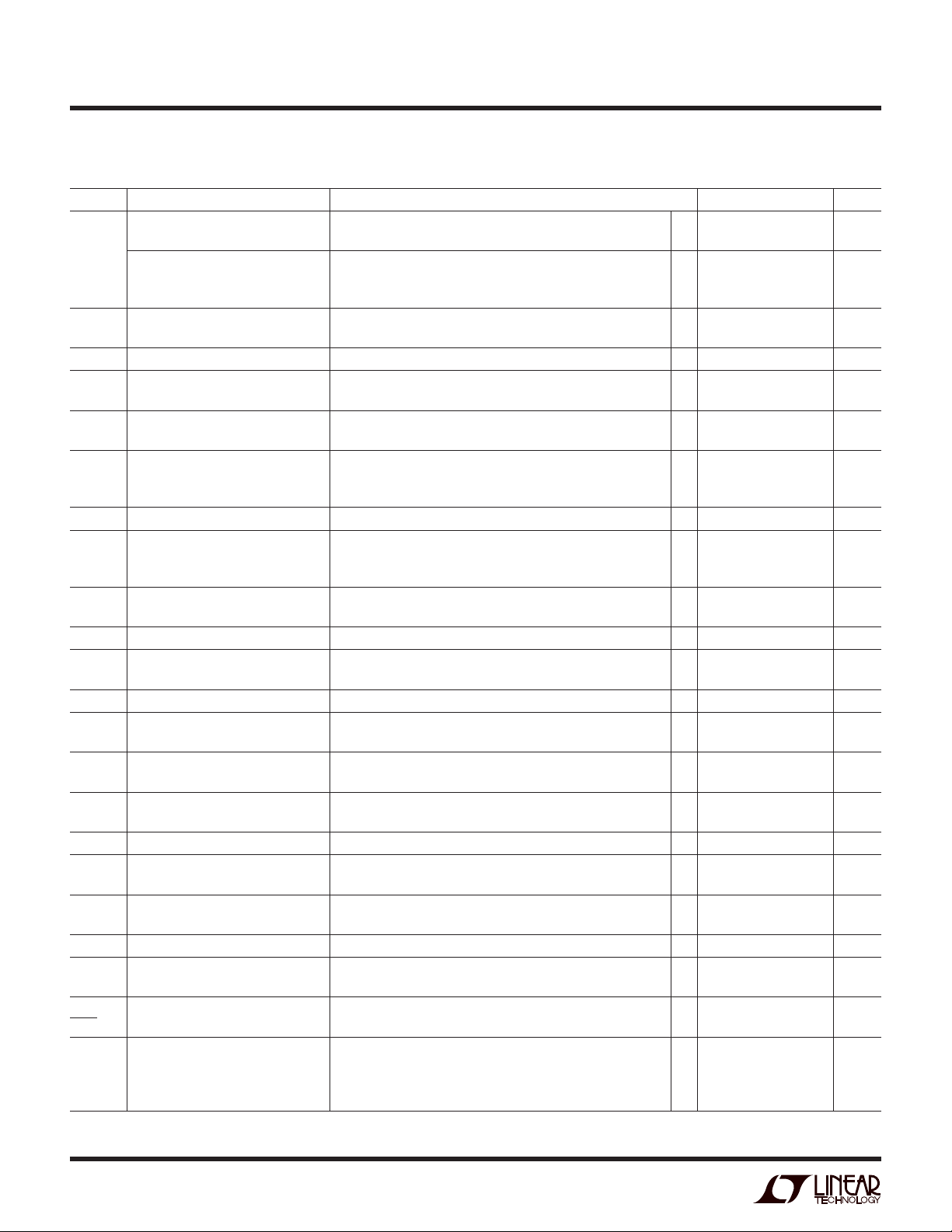

ELECTRICAL CHARACTERISTICS

VIN = 20V, VC = 0.85V, OVLO = 0V, VSW Open, TA = 25°C, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

Q

I

START

V

REF

V

GATE

SF Oscillator Scaling Factor FB = 4V, VC = Open, Measured at VSW, ISW = 25mA, 36 40 44 Hz • µF

Supply Current 8V < VIN < 30V, After Device Has Started ● 10 20 30 mA

Start-Up Current VIN < VIN Start Threshold ● 200 400 µA

Industrial Grade

● 450 µA

VIN Start Threshold ● 14.5 16.0 17.5 V

VIN Shutdown Threshold Note: Switching Stops When VSW < 10V (LT1103) ● 5.0 7.0 8.0 V

Note: Switching Stops When V

< 10V (LT1105)

GATE

5V Reference Voltage ● 4.80 4.95 5.20 V

V

Line Regulation 10V < VIN < 30V ● 0.025 0.1 %/ V

REF

V

Load Regulation 0mA < IL < 20mA ● 0.025 0.05 %/mA

REF

V

Short-Circuit Current Commercial Grade ● 25 60 110 mA

REF

Industrial Grade

● 20 120 mA

15V Short-Circuit Current Commercial Grade ● 30 130 mA

Industrial Grade

● 25 140 mA

15V Gate Bias Reference 17 < VIN < 30V, 0mA < IL < 30mA ● 13.8 15.0 16.2 V

15V Dropout Voltage VIN = 15V, IL = 30mA ● 2.0 2.5 V

15V Short-Circuit Current ● 30 70 130 mA

OVLO = 5V, f

OSC

= SF/C

OSC,

40kHz < f

< 200kHz ● 32 40 48 Hz • µF

OSC

Oscillator Valley Voltage 2.0 V

Oscillator Peak Voltage 4.5 V

3

Page 4

LT1103/LT1105

ELECTRICAL CHARACTERISTICS

VIN = 20V, VC = 0.85V, OVLO = 0V, VSW Open, TA = 25°C, unless otherwise noted.

SYMBOL PARAMETER CONDITONS MIN TYP MAX UNIT

DC Preset Max Switch Duty Cycle FB = 4V, VC = Open, f

(LT1103) Note: Maximum Duty Cycle Can Be Altered at OSC Pin

Preset Max Switch Duty Cycle FB = 4V, VC = Open, f

(LT1105) Note: Maximum Duty Cycle Can Be Altered at OSC Pin

Industrial Grade ● 55 75 %

OVLO Threshold Overvoltage Lockout Threshold at Which Switching is Inhibited ● 2.3 2.5 2.7 V

Industrial Grade

OVLO Input Bias Current OVLO = 2V, Measured Out of Pin (Note 2) ● 1.0 3.0 µA

V

FB

gm Error Amp Transconductance ∆I(VC) = ±50µA 9000 12000 17500 µmho

A

V

BV Switch Breakdown Voltage ISW = 5mA ● 50 70 V

∆I

IN

∆I

SW

FB Threshold Voltage I(VC) = 0mA 4.425 4.50 4.575 V

FB Input Bias Current FB = VFB (Note 3) ● 51020 µA

Industrial Grade

Change in FB Input FB = VFB, VC = 1V to 4V (Note 3) 8 11 13 µA/V

Bias Current with Change in V

FB Threshold Line Regulation 10V < VIN < 30V ● 0.025 0.10 %/V

Error Amp Voltage Gain 1V < VC < 3V ● 500 1250 V/V

VC Switching Threshold Switch Duty Cycle = 0% ● 0.85 1.25 1.4 V

Shutdown Threshold Voltage ● 50 150 250 mV

Error Amp Source Current ● 150 275 µA

Error Amp Sink Current ● 1.5 3 4.5 mA

Error Amp Clamp Voltage FB = 4.75V ● 0.3 0.7 0.9 V

Soft-Start Charging Current SS = 0V ● 25 40 60 µA

Soft-Start Reset Current VIN = 6V, SS = 0.3V ● 12 mA

Output Switch Leakage VSW = 45V ● 500 µA

(LT1103) V

(LT1103)

VSW Current Limit (LT1103) Duty Cycle = 25% (Note 4) ● 2.0 2.5 3.0 A

Output Switch On Resistance ● 0.4 0.75 Ω

(LT1103)

IQ Increase During Switch On Time ISW = 0.5A to 1.5A ● 30 50 mA/A

(LT1103)

Switch Output High Level ISW = 200mA, V

(LT1105) I

Switch Output High Level I

Industrial Grade I

C

Industrial Grade

Industrial Grade

Industrial Grade

Industrial Grade

Industrial Grade

FB = 4.0V

Industrial Grade

= 15V ● 200 µA

SW

= 750mA, V

SW

= 200mA, V

SW

= 750mA, V

SW

= 40kHz, ISW = 25mA, ● 58 65 72 %

OSC

= 40kHz, ISW = 25mA, ● 56 63 70 %

OSC

● 2.2 2.8 V

● 4.400 4.50 4.600 V

● 422µA

● 71114 µA/V

● 615µA/V

● 6000 12000 20000 µmho

● 5000 24000 µmho

● 450 V/V

● 50 300 mV

● 0.7 4.5 mA

● 4.2 4.4 4.6 V

● 20 75 µA

= 15V ● 13.00 13.5 V

GATE

= 15V ● 12.50 13.2 V

GATE

= 15V ● 12.75 V

GATE

= 15V ● 12.25 V

GATE

4

Page 5

LT1103/LT1105

ELECTRICAL CHARACTERISTICS

VIN = 20V, VC = 0.85V, OVLO = 0V, VSW Open, TA = 25°C, unless otherwise noted.

SYMBOL PARAMETER CONDITONS MIN TYP MAX UNIT

Switch Output Low Level ISW = 200mA ● 0.25 0.50 V

(LT1105) I

Rise Time (LT1105) CL = 1000pF 50 ns

Fall Time (LT1105) CL = 1000pF 20 ns

I

Threshold Voltage (LT1105) Duty Cycle = 25% (Note 5) ● 300 375 450 mV

LIM

Low Switch Drive Lockout Measured at VSW (LT1103) ● 9.0 9.5 10.5 V

Threshold Measured at 15V Gate Bias Reference (LT1105)

High Switch Drive Lockout Measured at VSW (LT1103) ● 17.0 18.5 20.0 V

Threshold Measured at 15V Gate Bias Reference (LT1105)

= 750mA ● 0.75 1.50 V

SW

The ● denotes specifications which apply over the full operating

temperature range.

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The OVLO pin is clamped with a 5.5V Zener and can sink a

maximum input current of 1mA.

Note 3: FB input bias current changes as a function of the V

Rate of change of FB input bias current is 11µA/V of change on V

pin voltage.

C

. By

C

Note 4: Current limit on VSW is constant for DC < 35% and decreases for

DC > 35% due to internal slope compensation circuity. The LT1103 switch

current limit is given by I

Note 5: The current limit threshold voltage is constant for DC < 35% and

decreases for DC > 35% due to internal slope compensation circuitry. The

LT1105 switch current limit threshold voltage is given by V

(1.7 – DC) above 35% duty cycle.

including a resistor in series with the FB pin, load regulation can be set

to zero.

W

U

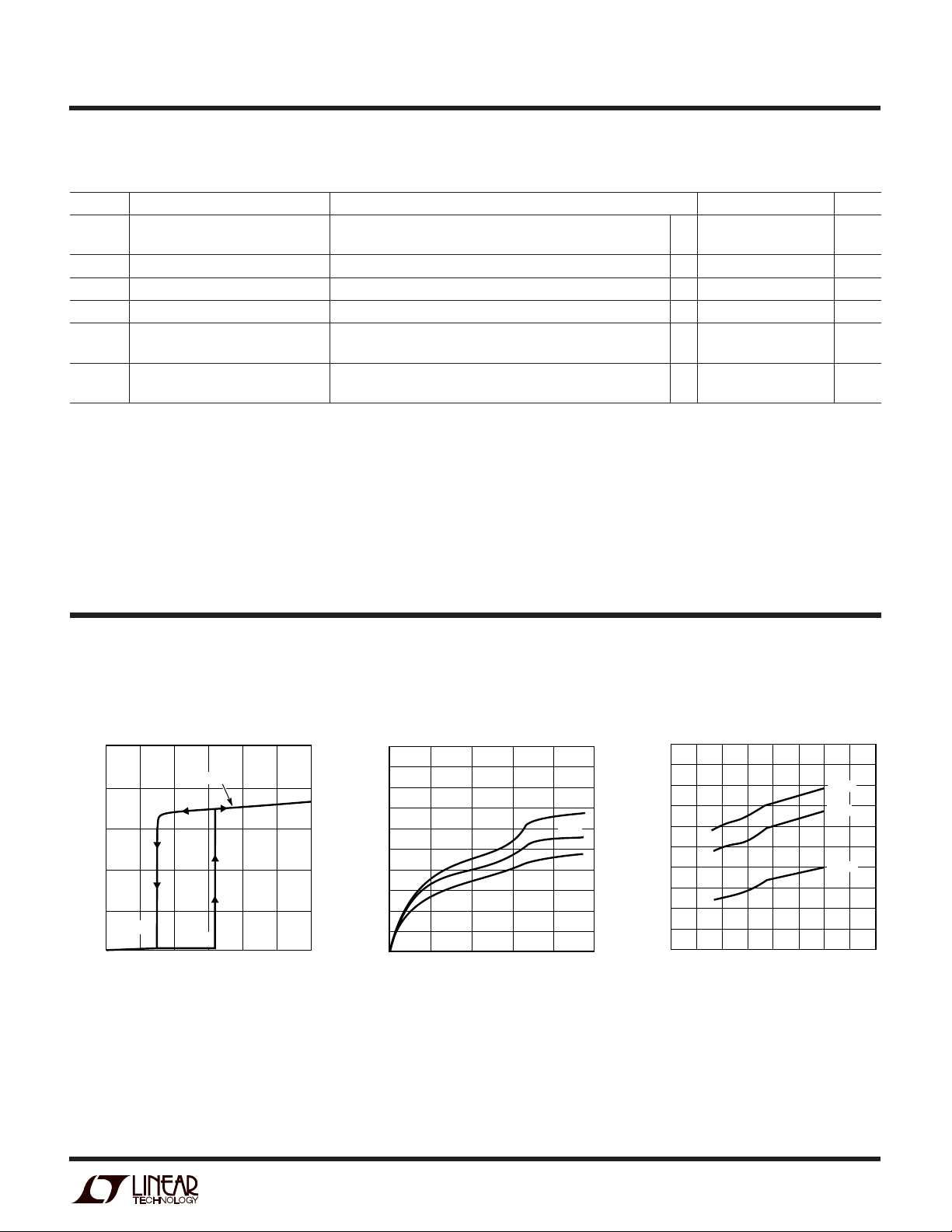

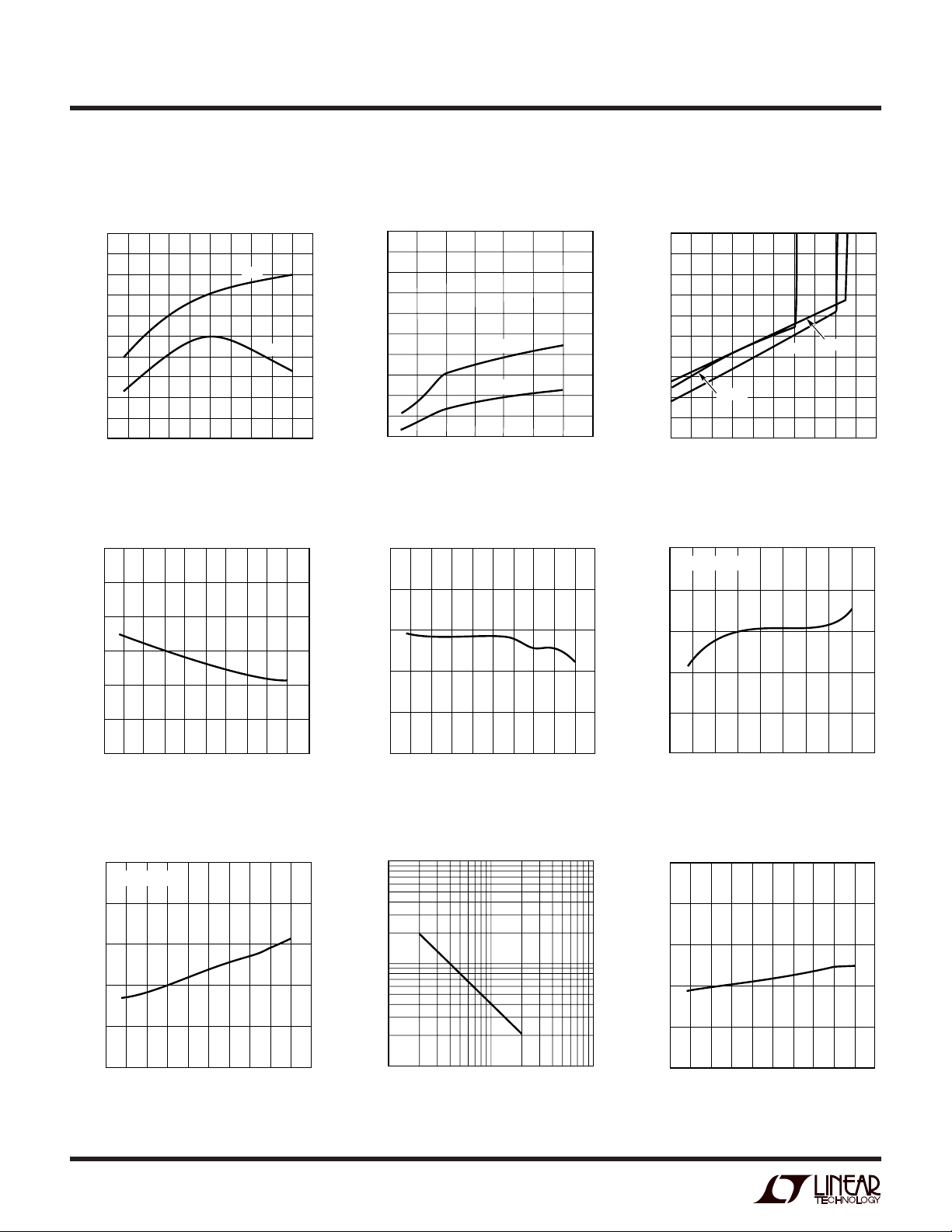

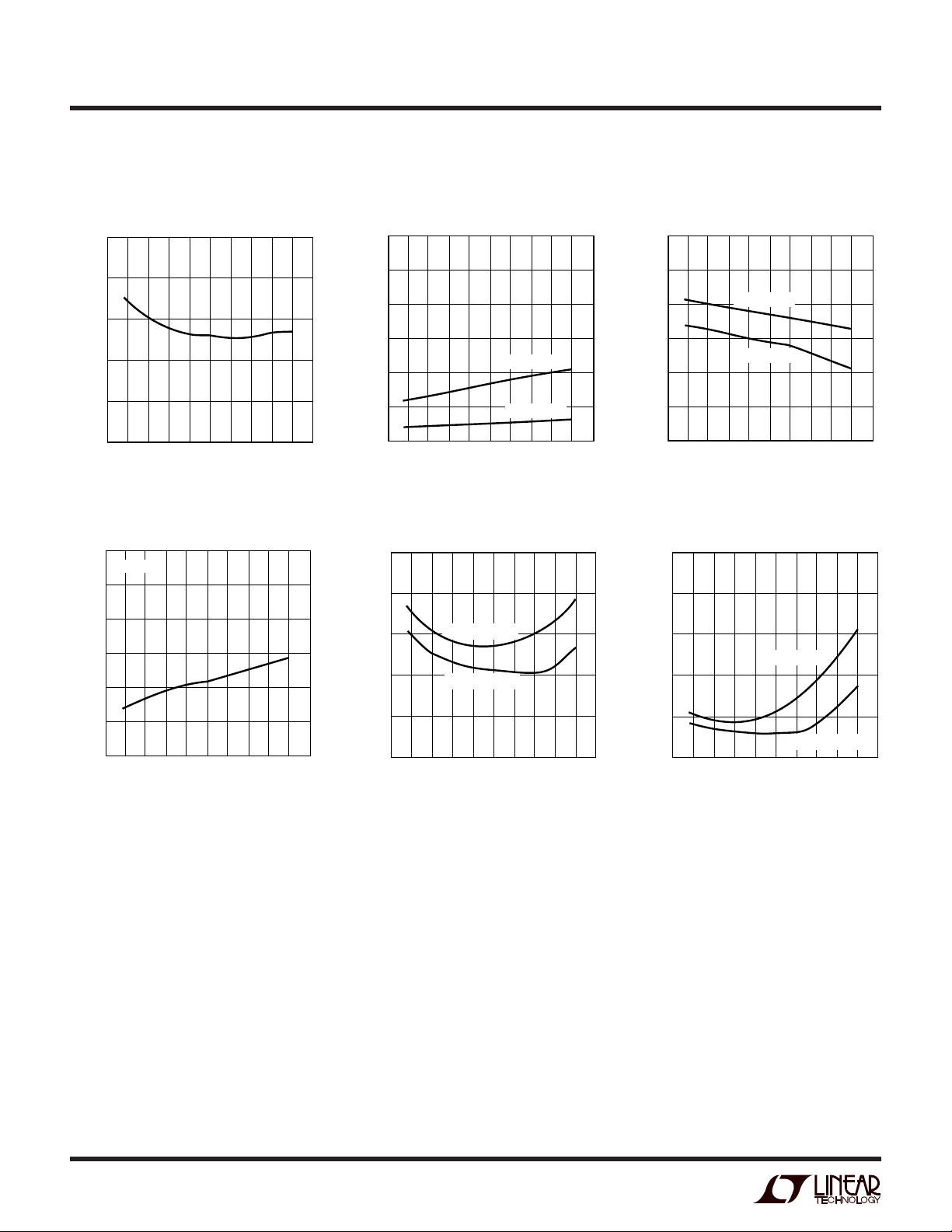

TYPICAL PERFORMANCE CHARACTERISTICS

Start-Up Supply Current vs

Supply Current vs Input Voltage

25

20

15

10

SUPPLY CURRENT (mA)

5

I

SHUT

0

0

5

25°C

I

START

10 15 20

INPUT VOLTAGE (V)

25 30

LT1103 G01

Input Voltage

500

450

400

350

300

250

200

150

100

START-UP SUPPLY CURRENT (µA)

50

0

0

125°C

–55°C

3

6

INPUT VOLTAGE (V)

9

12

25°C

LT1103 G02

1.76 (1.536 – DC) above 35% duty cycle.

LIM =

= 0.225

LIM

Quiescent Supply Current vs

Input Voltage

22

21

20

19

18

17

16

15

14

QUIESCENT SUPPLY CURRENT (mA)

13

12

0

515

15

10

20

INPUT VOLTAGE (V)

125°C

25°C

–55°C

35

30

25

40

LT1103 G03

5

Page 6

LT1103/LT1105

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

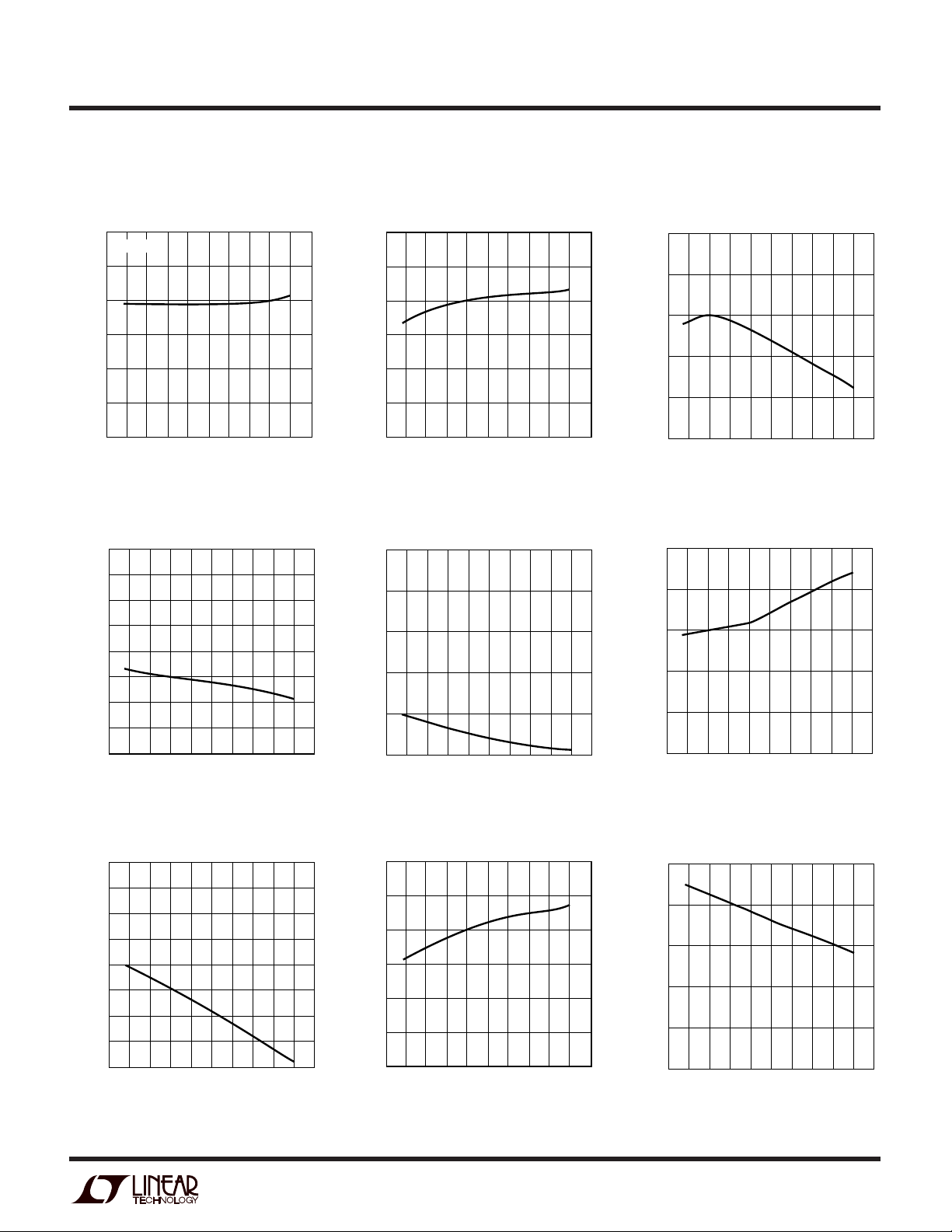

Quiescent Supply Current vs

Temperature

22

21

20

19

18

17

16

15

14

QUIESCENT SUPPLY CURRENT (mA)

13

12

–25

–50

–75

50 75 100 150

0

25

TEMPERATURE (°C)

VIN Start-Up Threshold vs

Temperature

17.5

17.0

16.5

16.0

15.5

START-UP THRESHOLD (V)

IN

V

15.0

30V

8V

125

LT1103 G04

175

Shutdown Supply Current vs

Input Voltage

500

450

A)

µ

400

350

300

250

200

150

100

SHUTDOWN SUPPLY CURRENT (

50

0

0

5

VC = 75mV

15

10

INPUT VOLTAGE (V)

VIN Shutdown Threshold vs

Temperature

8.0

7.7

7.4

7.1

SHUTDOWN THRESHOLD (V)

6.8

IN

V

VC = 0

20

Shutdown Supply Current vs

VC Voltage

500

450

400

350

300

250

200

150

SHUTDOWN CURRENT (µA)

100

50

30

LT1103 G05

35

25

0

0

–55°C

40

20

100 140 180

60

80

VC (mV)

25°C

120

125°C

160

200

LT1103 G06

Output Switch Frequency vs

Temperature

45

C

= 1000pF

OSC

43

41

39

37

OUTPUT SWITCH FREQUENCY (kHz)

14.5

–75

–50

0 50 100 150

–25 25 75 125

TEMPERATURE (°C)

Preset Switch Maximum Duty

Cycle vs Temperature

75

C

= 1000pF

OSC

72

69

66

63

PRESET SWITCH DUTY CYCLE (%)

60

–75

–25

25

0–50

TEMPERATURE (°C)

6

175

LT1103 G07

6.5

–75

–25

–50 0

75

25

50 100

TEMPERATURE (°C)

125

150

LT1103 G08

175

Switch Oscillator Frequency vs

Capacitance

1000

100

SWITCH FREQUENCY (kHz)

10

75

125

10050

150

LT1103 G10

175

100

1000 10000

CAPACITANCE (pF)

LT1103 G11

35

–50 0

–75

–25

TEMPERATURE (°C)

50 150

75

25

Overvoltage Lockout Threshold vs

Temperature

3.0

2.8

2.6

2.4

2.2

OVERVOLTAGE LOCKOUT THRESHOLD (V)

2.0

–75

–25

25

0–50

TEMPERATURE (°C)

75

10050

100

125

125

LT1103 G09

150

LT1103 G12

175

Page 7

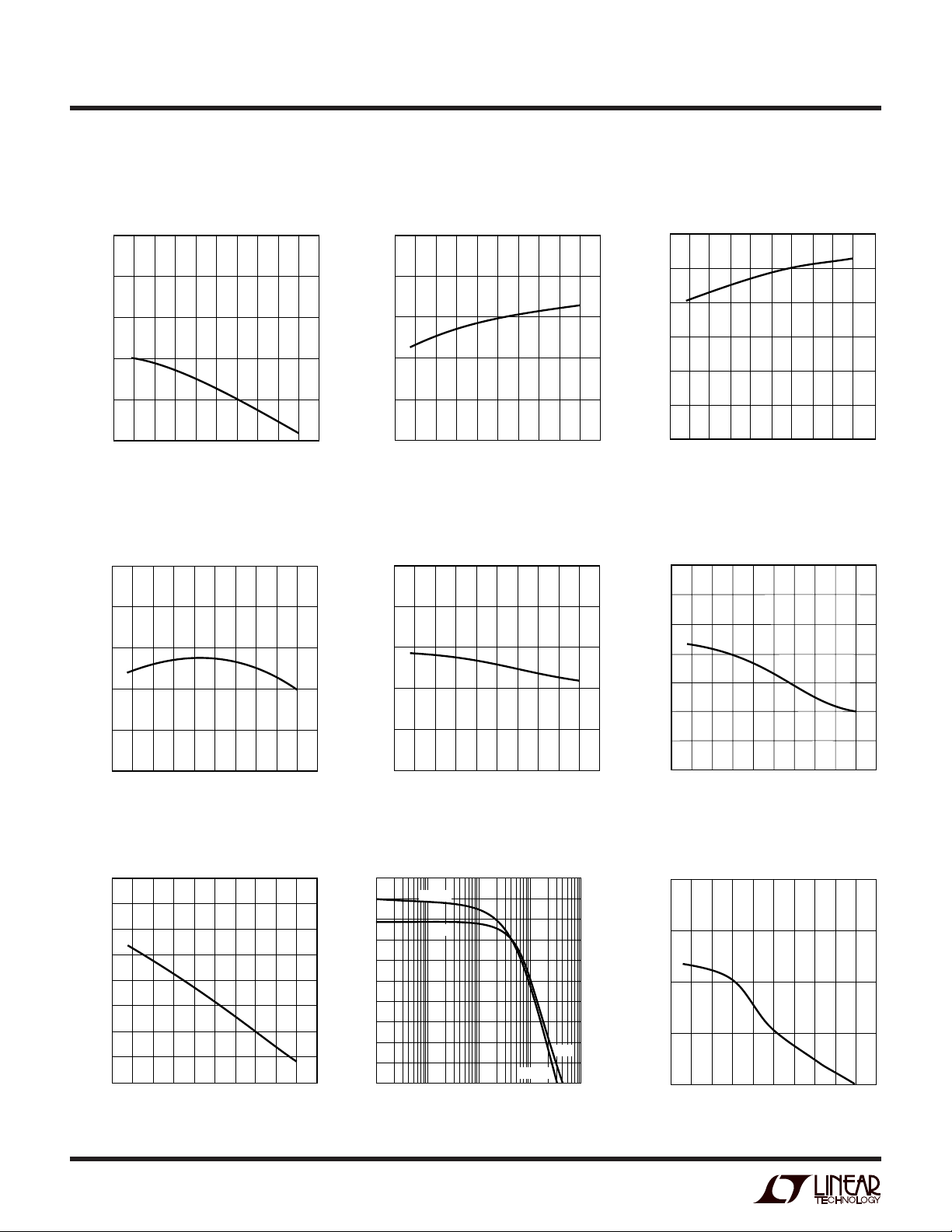

W

TEMPERATURE (°C)

–75

5V LINE REGULATION (%/V)

0.03

0.04

0.05

125

LT1103 G18

0.02

0.01

0

–25

25

75

175

150

10050

0–50

TEMPERATURE (°C)

–75

15V GATE BIAS DROPOUT VOLTAGE (V)

1.5

2.0

2.5

125

LT1103 G21

1.0

0.5

0

–25

25

75

175

150

10050

0–50

TEMPERATURE (°C)

–75

SOFT-START RESET CURRENT (mA)

3

4

5

125

LT1103 G15

2

1

0

–25

25

75

175

150

10050

0–50

U

TYPICAL PERFORMANCE CHARACTERISTICS

LT1103/LT1105

OVLO Input Bias Current vs

Temperature

0

OVLO = 2V

–0.5

–1.0

–1.5

–2.0

–2.5

OVLO INPUT BIAS CURRENT (µA)

–3.0

–75

–50

0 50 100 150

–25 25 75 125

TEMPERATURE (°C)

5V Reference Voltage vs

Temperature

5.20

5.15

5.10

5.05

5.00

4.95

4.90

5V REFERENCE VOLTAGE (V)

4.85

LT1103 G13

175

Soft-Start Charging Current vs

Temperature

60

50

40

30

20

10

SOFT-START CHARGING CURRENT (µA)

0

–75

–50

0 50 100 150

–25 25 75 125

TEMPERATURE (°C)

5V Load Regulation vs

Temperature

0.025

0.020

0.015

0.010

0.005

5V LOAD REGULATION (%/mA)

Soft-Start Reset Current vs

Temperature

175

LT1103 G14

5V Line Regulation vs

Temperature

4.80

–75

–50

–25

0

TEMPERATURE (°C)

5V Reference Short-Circuit

Current vs Temperature

110

100

90

80

70

60

50

40

5V REFERENCE SHORT-CIRCUIT CURRENT (mA)

30

–25

–50

0

TEMPERATURE (°C)

–75

100

50

75

25

50

75

25

100

125

125

150

LT1103 G16

150

LT1103 G19

175

175

0

–25

–75

25

0–50

TEMPERATURE (°C)

15V Gate Bias Reference vs

Temperature

16.2

15.8

15.4

15.0

14.6

15V GATE BIAS REFERENCE (V)

14.2

13.8

–75

–50

0 50 100 150

–25 25 75 125

TEMPERATURE (°C)

75

125

10050

150

LT1103 G17

175

15V Gate Bias Dropout Voltage vs

Temperature

175

LT1103 G20

7

Page 8

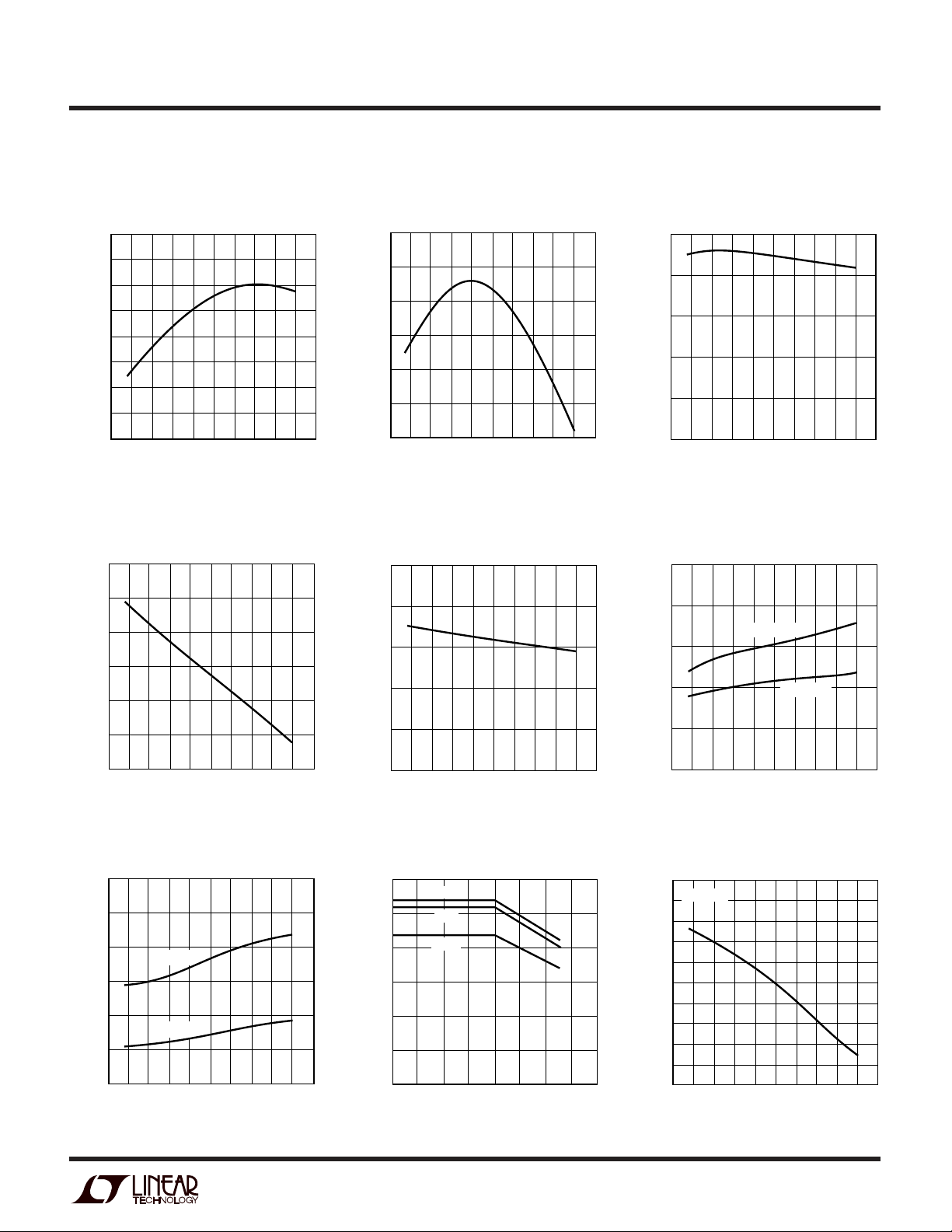

LT1103/LT1105

W

U

TYPICAL PERFORMANCE CHARACTERISTICS

15V Gate Bias Short-Circuit

Current vs Temperature

130

110

90

70

50

30

15V GATE BIAS SHORT-CIRCUIT CURRENT (mA)

–75

–25

25

0–50

TEMPERATURE (°C)

75

125

10050

Feedback Threshold vs

Temperature

4.60

4.56

4.52

150

LT1103 G22

175

Low Switch Drive Lockout

Threshold vs Temperature

10.5

10.2

9.9

9.6

9.3

LOW SWITCH DRIVE LOCKOUT THRESHOLD (V)

9.0

–75

–25

25

0–50

TEMPERATURE (°C)

75

10050

125

FB Input Bias Current vs

Temperature (VC = 1V)

20

16

12

150

LT1103 G23

175

High Switch Drive Lockout

Threshold vs Temperature

20.0

19.5

19.0

18.5

18.0

17.5

HIGH SWITCH DRIVE LOCKOUT THRESHOLD (V)

17.0

–75

–50

0 50 100 150

–25 25 75 125

TEMPERATURE (°C)

Change in FB Input Bias Current

with Change in VC vs Temperature

(VC = 1V to 4V)

14

13

12

(µA/V)

C

11

175

LT1103 G24

4.48

FEEDBACK THRESHOLD (V)

4.44

4.40

–75

–25

25

0–50

TEMPERATURE (°C)

75

Error Amplifier Transconductance

vs Temperature

25000

20000

15000

10000

5000

ERROR AMPLIFIER TRANSCONDUCTANCE (µmho)

–75

–50 0

–25

50

75

25

TEMPERATURE (°C)

10050

100

125

125

150

LT1103 G25

150

LT1103 G28

8

4

FB INPUT BIAS CURRENT (µA)

0

–25

175

–75

25

0–50

TEMPERATURE (°C)

Error Amplifier Transconductance

and Phase vs Frequency

0.020

0.018

0.016

0.014

0.012

0.010

0.008

0.006

0.004

0.002

0

ERROR AMPLIFIER TRANSCONDUCTANCE (mho)

175

0.1 10 100 1000

PHASE

gm

1

FREQUENCY (kHz)

75

PHASE

10

9

WITH CHANGE IN V

8

CHANGE IN FB INPUT BIAS CURRENT

7

10050

125

175

150

LT1103 G26

–75

–50

0

25

–25

TEMPERATURE (°C)

75 125

50

100

150

LT1103 G27

175

Error Amplifier Voltage Gain vs

Temperature

gm

LT1103 G29

200

180

160

140

120

100

80

60

40

20

0

2500

2000

1500

PHASE (DEGREES)

1000

ERROR AMPLIFIER VOLTAGE GAIN (V/V)

500

–75

–50

–25

0

25

TEMPERATURE (°C)

100

50

75

125

150

LT1103 G30

175

8

Page 9

LPER

F

O

Error Amplifier Source Current vs

Temperature

350

325

300

275

250

225

200

175

ERROR AMPLIFIER SOURCE CURRENT (µA)

150

–50 0

–75

–25

50

75

25

TEMPERATURE (°C)

Error Amplifier Low Clamp

Voltage vs Temperature

(FB = 4.75V)

0.9

R

100

125

ATYPICA

150

LT1103 G31

175

UW

CCHARA TERIST

E

C

Error Amplifier Sink Current vs

Temperature

4.5

4.0

3.5

3.0

2.5

2.0

ERROR AMPLIFIER SINK CURRENT (mA)

1.5

1.5

–25 25 75 125

–50

–75

VC Switching Threshold Voltage

vs Temperature

ICS

0 50 100 150

TEMPERATURE (°C)

LT1103 G32

175

LT1103/LT1105

Error Amplifier High Clamp

Voltage vs Temperature

(FB = 4V)

4.5

4.4

4.3

4.2

4.1

ERROR AMPLIFIER HIGH CLAMP VOLTAGE (V)

4.0

200

–75

–25

0–50

TEMPERATURE (°C)

75

125

25

10050

LT1103 Output Switch Leakage

Current vs Temperature

150

LT1103 G33

175

0.8

0.7

0.6

0.5

0.4

ERROR AMPLIFIER LOW CLAMP VOLTAGE (V)

0.3

–75

–50

0 50 100 150

–25 25 75 125

TEMPERATURE (°C)

LT1103 Switch Saturation Voltage

vs Temperature

1.2

1.0

0.8

0.6

0.4

0.2

LT1103 SWITCH SATURATION VOLTAGE (V)

0

–75

ISW = 1.5A

ISW = 0.5A

0 50 100 150

–25 25 75 125

–50

TEMPERATURE (°C)

LT1103 G34

LT1103 G38

175

175

1.3

1.1

0.9

SWITCHING THRESHOLD (V)

C

0.7

V

0.5

–75

–25

25

0–50

TEMPERATURE (°C)

LT1103 VSW Current Limit vs

Duty Cycle

3.0

2.5

2.0

1.5

CURRENT LIMIT (A)

SW

1.0

0.5

LT1103 V

0

0

–55°C

125°C

10

25°C

30 50 70

20 40

DUTY CYCLE (%)

160

VSW = 45V

120

80

40

0

75

10050

125

175

150

LT1103 G35

LT1103 OUTPUT SWITCH LEAKAGE CURRENT (µA)

–75

–25

0–50

TEMPERATURE (°C)

VSW = 15V

75

125

25

10050

150

LT1103 G36

175

LT1103 VSW Current Limit vs

Temperature

3.0

DC = 25%

2.9

2.8

2.7

2.6

2.5

CURRENT LIMIT (A)

2.4

SW

2.3

2.2

LT1103 V

2.1

60

80

LT1103 G39

2.0

–75

–50

–25

0

25

TEMPERATURE (°C)

50 100 150

75

125

LT1103 G40

175

9

Page 10

LT1103/LT1105

TEMPERATURE (°C)

–75

LT1105 V

SW

FALL TIME (ns)

60

80

100

125

LT1103 G45

40

20

0

–25

25

75

175

150

10050

0–50

C

LOAD

= 4700pF

C

LOAD

= 1000pF

LPER

F

O

R

ATYPICA

UW

CCHARA TERIST

E

C

ICS

LT1103 Driver Current vs

Temperature

50

40

30

20

10

LT1103 DRIVER CURRENT (mA/A)

0

–75

–25

0–50

TEMPERATURE (°C)

75

25

LT1105 Current Limit Threshold

Voltage vs Temperature

450

DC = 25°C

425

400

375

350

325

LT1105 VSW Low Saturation

Voltage vs Temperature

3.0

2.5

2.0

1.5

1.0

LOW SATURATION VOLTAGE (V)

SW

0.5

LT1105 V

0

–75

10050

125

175

150

LT1103 G41

–50

0 50 100 150

–25 25 75 125

TEMPERATURE (°C)

ISW = 750mA

ISW = 200mA

175

LT1103 G42

LT1105 VSW Rise Time vs

Temperature

100

80

C

= 4700pF

C

LOAD

LOAD

= 1000pF

60

RISE TIME (ns)

SW

40

LT1105 V

20

LT1105 VSW High Saturation

Voltage vs Temperature

3.0

2.5

2.0

1.5

1.0

HIGH SATURATION VOLTAGE (V)

SW

0.5

LT1105 V

0

–75

–50

ISW = 750mA

ISW = 200mA

0 50 100 150

–25 25 75 125

TEMPERATURE (°C)

LT1105 VSW Fall Time vs

Temperature

175

LT1103 G43

300

LT1105 CURRENT LIMIT THRESHOLD VOLTAGE (mV)

–75

–50

10

0 50 100 150

–25 25 75 125

TEMPERATURE (°C)

LT1103 G46

175

0

–75

–25

25

0–50

TEMPERATURE (°C)

75

10050

125

175

150

LT1103 G44

Page 11

UUU

PIN FUNCTIONS

LT1103/LT1105

LT1103

FB: The Feedback pin is the inverting input to the sampling

error amplifier. The noninverting input is tied to a 4.5V

reference. The FB pin is used for output voltage sensing.

The input bias current is a function of the control pin V

voltage and can be used for load regulation compensation

by including a resistor in series with the FB pin. The

sampling error amplifier has a typical gm of 0.012 mhos

and the output of the sampling error amplifier has asymmetrical slew rate to reduce overshoot during start-up

conditions or following the release of an output overload.

VC: The VC control pin is used for frequency compensa-

tion, current limiting and shutdown. It is the high impedance output of the sampling error amplifier and the input

of the current limit comparator.

GND: The Ground pin acts as both the negative sense

point for the internal sampling error amplifier feedback

signal and as the high current path for the 2A switch.

Also, the case of the 7-lead TO-220 is connected to

ground. Proper connections to ground for signal paths

and high current paths must be made in order to insure

good load regulation.

OSC: The Oscillator pin sets the operating frequency of the

regulator with one external capacitor to ground. Maximum

duty cycle can also be adjusted by using an external

resistor to alter the charge/discharge ratio.

VIN: The Input Supply pin is designed to operate with

voltages of 12V to 30V. The supply current is typically

200µA up to the start-up threshold of 16V. Normal operating supply current is fairly flat at 18mA down to the

shutdown threshold of 7V. Switching is inhibited for V

less than 12V due to the gate drive detection circuit.

15V: A 15V reference is used to bias the gate of an external

power FET. The voltage temperature coefficient is typically

3mV/°C and the output can source 30mA. Typical dropout

voltage is 1.5V for VIN less than 17V and 30mA of load

current.

C

IN

VSW: The Switch Output pin is the collector of the internal

NPN power switch. This pin has a typical ON resistance of

0.4Ω and a minimum breakdown voltage of 50V. This pin

also ties to the FET gate drive detection circuit.

LT1105

All functions on the LT1105 are equivalent to the LT1103

with the exception of the VSW pin and the I

availability of the OVLO, 5V, and SS functions.

OVLO: The Overvoltage Lockout pin inhibits switching

when the pin is pulled above its threshold voltage of 2.5V.

OVLO is implemented with a resistor divider network from

the rectified DC line and is used to protect the external FET

from an overvoltage condition in the off state. This function is only available on the 14-lead PDIP.

5V: A 5V reference is available to power primary-side

circuitry. The temperature coefficient is typically

50ppm/°C and the output can source 25mA. This function is only available on the 14-lead PDIP.

SS: The Soft-Start pin is used to either program start-up

time with a capacitor to ground or to set external current

limit with a resistor divider. The SS pin has a 40µA pull-up

current and is reset to 0V by a 1mA pull-down current

during start-up and shutdown. This function is only available on the 14-lead PDIP.

VSW: The Switch Output pin is the output of a 1A NPN

totem-pole stage. The VSW pin turns the external FET on by

pulling its gate high. Break-Before-Make action of 200ns

on each switch edge is built in to eliminate cross conduction currents.

I

: The I

LIM

and requires the use of a noninductive, power sense

resistor from I

current limit threshold voltage is 350mV. The typical input

bias current is 100µA out of the pin.

pin is the input to the current limit amplifier

LIM

to ground to set current limit. The typical

LIM

pin and the

LIM

11

Page 12

LT1103/LT1105

W

BLOCK DIAGRA S

15V

15V

GATE

BIAS

OSC

LT1103

GATE

BIAS

DETECT

V

SW

V

0VLO

START-UP

16V

IN

7V

2.5V

5V

V

REF

5V

FB

OSCILLATOR

4.5V

OVERVOLTAGE

LOCKOUT

+

–

SAMPLING

ERROR AMP

= 0.012

g

m

LOGIC

COMP

0.15V

SHUT

DOWN

SPIKE

BLANK

DRIVER

ANTISAT

CURRENT

LIMIT

AMP

AV = 10

+

0.15Ω

–

6V

40µA

RESET

LT1103 BD

V

C

SS

GND

12

Page 13

W

BLOCK DIAGRA S

15V

15V

GATE

BIAS

OSC

LT1105

GATE

BIAS

DETECT

LT1103/LT1105

V

0VLO

START-UP

16V

IN

5V

FB

7V

5V

V

REF

2.5V

OSCILLATOR

4.5V

OVERVOLTAGE

LOCKOUT

+

–

SAMPLING

ERROR AMP

g

= 0.012

m

LOGIC

COMP

0.15V

SHUT

DOWN

SPIKE

BLANK

V

DRIVER

V

SW

DRIVER

ANTISAT

CURRENT

LIMIT

AMP

AV = 10

+

I

LIM

–

6V

40µA

RESET

LT1105 BD

C

SS

GND

13

Page 14

LT1103/LT1105

U

ATIOOPER

LT1103

The LT1103 is a current mode switcher. Switch duty cycle

is controlled by switch current rather than directly by the

output voltage. Referring to the block diagram, the switch

is turned on at the start of each oscillator cycle. It is turned

off when switch current reaches a predetermined level.

Control of output voltage is obtained by using the output

of a voltage sensing error amplifier to set current trip level.

This technique has several advantages. First, it has immediate response to input voltage variations, unlike ordinary

switchers which have notoriously poor line transient

response. Second, it reduces the 90° phase shift at mid

frequencies in the transformer. This greatly simplifies

closed-loop frequency compensation under widely varying input voltage or output load conditions. Finally, it

allows simple pulse-by-pulse current limiting to provide

maximum switch protection under output overload or

short-circuit conditions.

A start-up loop with hysteresis allows the IC supply

voltage to be bootstrapped from an extra primary side

winding on the power transformer. From 0V to 16V on VIN,

the LT1103 is in a prestart mode and total input current is

typically 200µA. Above 16V, up to 30V, the 6V regulator

that biases the internal circuitry and the externally available 15V regulator is turned on. The internal circuitry

remains biased on until VIN drops below 7V and the part

returns to the prestart mode. Output switching stops when

the VSW drive is less than 10V corresponding to VIN of

about 12V.

The oscillator provides the basic clock for all internal

timing. Frequency is adjustable to 200kHz with one external capacitor from OSC to ground. The oscillator turns on

the output switch via the logic and driver circuitry. Adaptive antisat circuitry detects the onset of saturation in the

power switch and adjusts driver current instantaneously

to limit switch saturation. This minimizes driver dissipation and provides very rapid turn-off of the switch.

The LT1103 is designed to drive the source of an external

power FET in common gate configuration. The 15V regulator biases the gate to guarantee the FET is on when the

switch is on. Special drive detection circuitry senses the

gate bias voltage and prevents the output switch from

turning on if the gate voltage is less than 10V or greater

than 20V, the industry standards for power MOSFET

operation.

The switch current is sensed internally and amplified to

trip the comparator and turn off the switch according to

the VC pin control voltage. A blanking circuit suppresses

the output of the current limit comparator for 500ns at the

beginning of each switch cycle. This prevents false tripping of the comparator due to current spikes caused by

external parasitic capacitance and diode stored charge.

The 4.5V Zener-based reference biases the positive input

of the sampling error amplifier. The negative input (FB) is

used for output voltage sensing. The sampling error

amplifier allows the LT1103 to operate in fully isolated

flyback mode by regulating from the flyback voltage of the

bootstrap winding. The leakage inductance spike at the

leading edge of the flyback waveform is ignored with a

blanking circuit. The flyback waveform is directly proportional to the output voltage in a transformer-coupled

flyback topology. Output voltages are fully floating up to

the breakdown voltage of the transformer windings. Multiple floating outputs are easily obtained with additional

windings.

The error signal developed at the comparator input is

brought out externally. This VC pin has three functions

including frequency compensation, current limit adjustment and total regulator shutdown. During normal operation, this pin sits at a voltage between 1.2V (low output

current) and 4.4V (high output current). The error amplifier is a current output (gm) type, so this voltage can be

externally clamped for adjusting current limit. Switch duty

cycle goes to zero if the VC pin is pulled to ground through

a diode, placing the LT1103 in an idle mode. Pulling the V

pin below 0.15V causes total regulator shutdown and

places the LT1103 in a prestart mode.

LT1105

The LT1105 is a current mode switcher. Switch duty cycle

is controlled by switch current rather than directly by

output voltage. Referring to the block diagram, the switch

is turned on at the start of each oscillator cycle. It is turned

off when switch current reaches a predetermined level.

C

14

Page 15

LT1103/LT1105

U

ATIOOPER

Control of output voltage is obtained by using the output

of a voltage sensing error amplifier to set current trip level.

This technique has several advantages. First, it has immediate response to input voltage variations, unlike ordinary

switchers which have notoriously poor line transient response. Second, it reduces the 90° phase shift at

midfrequencies in the transformer. This greatly simplifies

closed-loop frequency compensation under widely varying input voltage or output load conditions. Finally, it

allows simple pulse-by-pulse current limiting to provide

maximum switch protection under output overload or

short-circuit conditions.

A start-up loop with hysteresis allows the IC supply

voltage to be bootstrapped from an extra primary side

winding on the power transformer. From 0V to 16V on VIN,

the LT1105 is in prestart mode and total input current is

typically 200µA. Above 16V, up to 30V, the 6V regulator

that biases the internal circuitry and the externally available 5V and 15V regulators are turned on. The internal

circuitry remains biased on until VIN drops below 7V and

the part returns to prestart mode. Output switching stops

when the 15V gate bias reference is less than 10V corresponding to VIN of about 12V.

The oscillator provides the basic clock for all internal

timing. Frequency is adjustable to 200kHz with one external capacitor from OSC to ground. The oscillator turns on

the output switch via the logic and driver circuitry.

The LT1105 is designed to drive the gate of an external

power FET in common source configuration. The drivers

and the 1A maximum totem-pole output stage are biased

from the 15V gate bias reference. Special drive detection

circuity senses the gate bias reference voltage and prevents the output switch from turning on if this voltage is

less than 10V or greater than 20V. Break-Before-Make

action of 200ns is built into each switch edge to eliminate

cross conduction currents.

suppresses the output of the current limit comparator for

500ns at the beginning of each switch cycle. This prevents

false tripping of the comparator due to current spikes

caused by external parasitic capacitance and diode stored

charge.

A 4.5V Zener-based reference biases the positive input of

the sampling error amplifier. The negative input (FB) is

used for output voltage sensing. The sampling error

amplifier allows the LT1105 to operate in fully isolated

flyback mode by regulating the flyback voltage of the

bootstrap winding. The leakage inductance spike at the

leading edge of the flyback waveform is ignored with a

blanking circuit. The flyback waveform is directly proportional to the output voltage in the transformer coupled

flyback topology. Output voltages are fully floating up to

the breakdown voltage of the transformer windings. Multiple floating outputs are easily obtained with additional

windings.

The error signal developed at the comparator input is

brought out externally. The VC pin has three functions

including frequency compensation, current limit adjustment and total regulator shutdown. During normal operation, this pin sits at a voltage between 1.2V (low output

current) and 4.4V (high output current). The error amplifier is a current output (gm) type, so this voltage can be

externally clamped for adjusting current limit. Switch duty

cycle goes to zero if the VC pin is pulled to ground through

a diode, placing the LT1105 in an idle mode. Pulling the V

pin below 0.15V causes total regulator shutdown and

places the LT1105 in prestart mode.

The SS pin implements soft-start with one external capacitor to ground. The internal pull-up current and clamp

transistor limit the voltage at VC to one diode drop above

the voltage at the SS pin, thereby controlling the rate of rise

of switch current in the regulator. The SS pin is reset to 0V

when the LT1105 is in prestart mode.

C

Switch current is sensed externally through a precision,

power resistor. This allows for greater flexibility in switch

current and output power than allowed by the LT1103. The

voltage across the sense resistor is fed into the I

amplified to trip the comparator and turn off the switch

according to the VC pin control voltage. A blanking circuit

LIM

pin and

A final protection feature includes overvoltage lockout

monitoring of the main supply voltage on the OVLO pin. If

the OVLO pin is greater than 2.5V, the output switch is

prevented from turning on. This function can be disabled

by grounding the OVLO pin.

15

Page 16

LT1103/LT1105

U

WUU

APPLICATIONS INFORMATION

Bootstrap Start

It is inefficient as well as impractical to power a switching

regulator control IC from the rectified DC input as this

voltage is several hundred volts. Self-biased switching

regulator topologies take advantage of a lower voltage

auxiliary winding on the power transformer or inductor to

power the regulator, but require a start-up cycle to begin

regulation.

Start-up circuitry with hysteresis built into the LT1103/

LT1105 allows the input voltage to increase from 0V to

16V before the regulator tries to start. During this time the

start-up current of the switching regulator is typically

200µA and all internal voltage regulators are off. The low

quiescent current allows the input voltage to be trickled up

with only 500µA of current from the rectified DC line

voltage, thereby minimizing power dissipation in the startup resistor. At 16V, the internal voltage regulators are

turned on and switching begins. If enough power feeds

back through the auxiliary winding to keep the input

voltage to the switching regulator above 12V, then switching

continues and a bootstrap start is accomplished. If the

input voltage drops below 12V, then the FET drive detection

circuit locks out switching. The input voltage continues to

fall as the VIN bypass capacitor is discharged by the

normal quiescent current of the LT1103/LT1105. Once the

input voltage falls below 7V, the internal voltage regulators

are turned off and the switching regulator returns to the

low start-up current state. A continuous “burp start” mode

indicates a fault condition or an incomplete power loop.

The trickle current required to bootstrap the regulator

input voltage is typically generated with a resistor from the

rectified DC input voltage. When combined with the

regulator input bypass capacitor, the start-up resistor

creates a ramp whose slope governs the turn-on time of

the regulator as well as the period of the “burp start” mode.

The design trade-offs are power dissipated in the trickle

resistor, the turn-on time of the regulator, and the hold-up

time of the regulator input bypass capacitor. The value of

the start-up resistor is set by the minimum rectified DC

input voltage to guarantee sufficient start-up current. The

recommended minimum trickle current is 500µA. The

power rating of the start-up resistor is set by the maximum

rectified DC input voltage. A final consideration for the

start-up resistor is to insure that the maximum voltage

rating of the resistor is not exceeded. Typical carbon film

resistors have a voltage rating of 250V. The most reliable

and economical solution for the start-up resistor is generally

provided by placing several 0.25W resistors in series.

The LT1103/LT1105 is designed to operate with supply

pin voltages up to 30V. However, the auxiliary bias winding

should be designed for a typical output voltage of 17V to

minimize IC power dissipation and efficiency loss.

Allowances must also be made for cross regulation of the

bias voltage due to variations in the rectified DC line

voltage and output load current.

Soft-Start

Soft-start refers to the controlled increase of switch

current from a start-up or shutdown state. This allows the

power supply to come up to voltage in a controlled

manner and charge the output capacitor without activating

current limit. In general, soft-start is not required on the

LT1105 due to the design of the sampling error amplifier

gm stage which generates asymmetrical slew capability

on the VC pin.

This feature exhibits itself as a typical 3mA sink current

capability on the VC pin whereas source current is only

275µA. The low gm of the error amplifier allows smallvalued compensation capacitors to be used on VC. This

allows the sink current to slew the compensation capacitor

quickly. Therefore, overshoot of the output voltage on

start-up sequences and recovery from overload or shortcircuit conditions is prevented. However, if a longer startup period is required, the soft-start function can be used.

Soft-start is implemented with an internal 40µA pull-up

and a transistor clamp on the VC pin so that a single

external capacitor from SS ground can define the linear

ramp function. The voltage at VC is limited to one V

above the soft-start pin (SS). The time to maximum switch

current is defined as the capacitance on SS multiplied by

the active range in volts of the VC pin divided by the pullup current:

C •(3.2V)

T

40 A=µ

BE

16

Page 17

LT1103/LT1105

U

WUU

APPLICATIONS INFORMATION

SS is reset to 0V whenever VIN is less than 7V (prestart

mode) or when shutdown is activated by pulling VC below

0.15V. The SS pin has a guaranteed reset sink current of

1mA when either the regulator supply voltage VIN falls

below 7V or the regulator is placed in shutdown.

Shutdown

The LT1103/LT1105 can be put in a low quiescent current

shutdown mode by pulling VC below 150mV. In the

shutdown mode the internal voltage regulators are turned

off, SS is reset to 0V and the part draws less than 200µA.

To initiate shutdown, about 400µA must be pulled out of

VC until the internal voltage regulators turn off. Then, less

than 50µA pull-down current is required to maintain

shutdown. The shutdown function has about 60mV of

hysteresis on the VC pin before the part returns to normal

operation. Soft-start, if used, controls the recovery from

shutdown.

5V Reference

Ground (LT1103)

The ground pin of the LT1103 is important because it acts

as the negative sense point for the internal error amplifier

feedback signal, the negative sense point for the current

limit amplifier, and as the high current path for the 2A

switch. The tab of the 7-lead TO-220 is internally connected

to GND (Pin 4).

To avoid degradation of load regulation, the feedback

resistor divider string and the reference side of the bias

winding should be directly connected to the ground pin on

the package. These ground connections should not be

mixed with high current carrying ground return paths. The

length of the switch current ground path should be as

short as possible to the input supply bypass capacitor and

low resistance for best performance. The case of the

LT1103 package is desirable to use as the high current

ground return path as this is a lower resistive and inductive

path than that of the actual package pin and will help

minimize voltage spikes associated with the high dI/dt

switch current.

A 5V reference output is available for the user’s convenience

to power primary-side circuitry or to generate a clamp

voltage for switch current limiting. The output will source

25mA and the voltage temperature coefficient is typically

50ppm/°C. If bypassing of the 5V reference is required, a

0.1µF is recommended. Values of capacitance greater

than 1µF may be susceptible to ringing due to decreased

phase margin. In such cases, the capacitive load can be

isolated from the reference output with a small series

resistor at the expense of load regulation performance.

Overvoltage Lockout

The switching supply and primarily the external power

MOSFET can be protected from an extreme surge of the

input line voltage with the overvoltage lockout feature

implemented on the OVLO pin. If the voltage on OVLO rises

above its typical threshold voltage of 2.5V, output switching

is inhibited. This feature can be implemented with a

resistive divider off of the rectified DC input voltage. This

feature is only available on the LT1105 in the 14-lead PDIP

and must be tied to ground if left unused.

Avoiding long wire runs to the ground pin minimizes load

regulation effects and inductive voltages created by the

high dI/dt switch current. Ground plane techniques should

also be used and will help keep EMI to a minimum.

Grounding techniques are illustrated in the Typical

Applications section.

Ground (LT1105)

The ground pin of the LT1105 is important because it acts

as the negative sense point for the internal error amplifier

feedback signal and as the negative sense point for the

current limit amplifier. The LT1105 8-pin PDIP has Pin 1

as its ground. The LT1105 14-pin PDIP has Pin 1 and

Pin 7 as grounds and must be tied together for proper

operation.

To avoid degradation of load regulation, the feedback

resistor divider should be directly connected to the package

ground pin. These ground connections should not be

mixed with high current carrying ground return paths. The

length of the switch current ground path should be as

short as possible to the input supply bypass capacitor and

17

Page 18

LT1103/LT1105

U

WUU

APPLICATIONS INFORMATION

low resistance for best performance. This will help minimize

voltage spikes associated with the high dI/dt switch current.

Avoiding long wire runs to the ground pin minimizes load

regulation effects and inductive voltages created by the

high dI/dt switch current. Ground plane techniques should

also be used and will help keep EMI to a minimum.

Grounding techniques are illustrated in the Typical

Applications section.

Oscillator

The oscillator of the LT1103/LT1105 is a linear ramp type

powered from the internal 6V bias line. The charging

currents and voltage thresholds are generated internally

so that only one external capacitor is required to set the

frequency. The 150µA pull-up current, which is on all the

time, sets the preset maximum on-time of the switch and

the 450µA pull-down current which is turned on and off,

sets the dead time. The threshold voltages are typically 2V

and 4.5V, so for a 400pF capacitor the ramp-up time of the

voltage on the OSC pin is 6.67µs and the ramp-down time

is 3.3µs, resulting in an operating frequency of 100kHz.

Although the oscillator, as well as the rest of the switching

regulator, will function at higher frequencies, 200kHz is

the practical upper limit that will allow control range for

line and load regulation. The lowest operating frequency is

limited by the sampling error amplifier to about 10kHz.

The frequency temperature coefficient is typically – 80ppm/

°C with a good low T.C. capacitor. This means that with a

low temperature coefficient capacitor, the temperature

coefficient of the currents and the temperature coefficient

of the thresholds sum to –80ppm/°C over the commercial

temperature range. Bowing in the temperature coefficient

of the currents affects the frequency about ±3% at the

extremes of the military temperature range. The capacitor

type chosen will have a direct effect on the frequency

tempco.

Maximum duty cycle is set internally by the pull-up and

pull-down currents, independent of frequency. It can be

adjusted externally by modifying the fixed pull-up current

with an additional resistor. In practice, one resistor from

the OSC pin to the 5V reference or to ground does the job.

Note that the capacitor value must change to maintain the

same frequency. For example, a 24k resistor from 5V to

OSC and a 440pF capacitor from OSC to ground will yield

100kHz with 50% maximum duty cycle. A 56k resistor and

a 280pF capacitor from OSC to ground will yield 100 kHz

with 80% maximum duty cycle.

The oscillator can be synchronized to an external clock by

coupling a sync pulse into the OSC pin. The width of this

pulse should be a minimum of 500ns. The oscillator can

only be synchronized up in frequency and the synchronizing

frequency must be greater than the maximum possible

unsynchronized frequency (for the chosen oscillator

capacitor value). The amplitude of the sync pulse must be

chosen so that the sum of the oscillator voltage amplitude

plus the sync pulse amplitude does not exceed the 6V bias

reference. Otherwise, the oscillator pull-up current source

will saturate and erroneous operation will result. If the

LT1103/LT1105 is positioned on the primary side of the

transformer and the external clock on the isolated secondary

output side, the sync signal must be coupled into the OSC

pin using a pulse transformer. The pulse transformer must

meet all safety/isolation requirements as it also crosses

the isolation boundary. An example of externally

synchronizing the oscillator is shown in the Typical

Applications section.

Gate Biasing (LT1103)

The LT1103 is designed to drive an external power MOSFET

in the common gate or cascode connection with the V

pin. The advantage is that the switch current can be sensed

internally, eliminating a low value, power sense resistor.

The gate needs to be biased at a voltage high enough to

guarantee that the FET is saturated when the open-collector

source drive is on. This means 10V as specified in FET data

sheets, plus 1V for the typical switch saturation voltage,

plus a couple of volts for temperature variations and

processing tolerances. This leads to 15V for a practical

gate bias voltage.

Power MOSFETs are well suited to switching power supplies

because their high speed switching characteristics promote

high switching efficiency. To achieve high switching speed,

SW

18

Page 19

LT1103/LT1105

U

WUU

APPLICATIONS INFORMATION

A special circuit in the LT1103 senses the voltage at V

prior to turning on the switch. VSW is tied to the source of

the FET and should represent the bias voltage on the gate

when the switch is off. When the switch first turns off, the

drain flies back until it is clamped by a snubber network.

The source also flies high due to parasitic capacitive

coupling on the FET and parasitic inductance of the leads.

An extra diode from the source to the gate or VIN will

provide insurance against fault conditions that might

otherwise damage the FET. The diode clamps the source

to one diode drop above the gate or VIN, thereby limiting

the gate source reverse bias. Once the energy in the

leakage inductance spike is dissipated and the primary is

being regulated to its flyback voltage, the diode shuts off.

The source is then floating and its voltage will be close to

the gate voltage. If the sensed voltage on VSW is less than

10V or greater than 20V, the circuit prevents the switch

from turning on. This protects the FET from dissipating

high power in a nonsaturated state or from excessive gatesource voltage. The oscillator continues to run and the net

effect is to skip switching cycles until the gate bias voltage

is corrected. One consequence of the gate bias detection

circuit is that the start-up window is 6V if the gate is biased

from VIN and to 4V if the gate is biased from the 15V

output. This influences the size of the bypass capacitor on

VIN.

SW

keep the switch just at the edge of saturation. Very low

switch current results in nearly zero driver current and

high switch currents automatically increase driver current

as necessary. The ratio of switch current to driver current

is approximately 30:1. This ratio is determined by the

sizing of the extra emitter and the value of the current

source feeding the driver circuitry. The quasisaturation

state of the switch permits rapid turn-off without the need

for reverse base emitter voltage drive.

Gate Biasing (LT1105)

The LT1105 is designed to drive an external power MOSFET

in the common source configuration with the totem-pole

output VSW pin. The advantage is added switch current

flexibility (limited only by the choice of external power

FET) and higher output power applications than allowed by

LT1103. An external, noninductive, power sense resistor

must be used in series with the source of the FET to detect

switch current and must be tied to the input of the current

limit amplifier. The gate needs to be biased at a voltage

high enough to guarantee that the FET is saturated when

the totem-pole gate drive is on. This means 10V as

specified in FET data sheets, plus the totem-pole high side

saturation voltage plus a couple of volts for temperature

variations and processing tolerances. This leads to 15V for

a practical gate bias voltage.

VSW Output (LT1103)

The VSW pin of the LT1103 is the collector of an internal

NPN power switch. This NPN has a typical on resistance of

0.4Ω and a typical breakdown voltage (BV

switching times and high efficiency are obtained by using

a special driver loop which automatically adapts base drive

current to the minimum required to keep the switch in a

quasisaturated state. The key element in the loop is an

extra emitter on the output power transistor as seen in the

block diagram. This emitter carries no current when the

NPN output transistor collector is high (unsaturated). In

this condition, the driver circuit can deliver very high base

drive to the switch for fast turn-on. When the switch

saturates, the extra emitter acts as a collector of an NPN

operating in inverted mode and pulls base current away

from the driver. This linear feedback loop serves itself to

) of 75V. Fast

CBO

Power MOSFETs are well suited to switching power supplies

because their high speed switching characteristics promote

high switching efficiency. To achieve high switching speed,

the gate capacitance must be charged and discharged

quickly with high peak currents. In particular, the turn-off

current can be as high as the peak switch current. The

switching speed is controlled by the impedance seen by

the gate capacitance. Practically speaking, zero impedance

is not desirable because of the high frequency noise spikes

introduced to the system. The gate bias supply which

drives the totem-pole output stage should be bypassed

with a 1µF low ESR capacitor to ground. This capacitor

supplies the energy to charge the gate capacitance during

gate drive turn-on. The power MOSFET should have a 5Ω

resistor or larger in series with its gate from the VSW pin

to define the source impedance.

19

Page 20

LT1103/LT1105

U

WUU

APPLICATIONS INFORMATION

The LT1105 provides a 15V regulated output intended for

driving the totem-pole output stage. It will source 30mA

into a capacitive load with no stability problems. The

output voltage temperature coefficient is 3mV/°C. If V

drops below 17V, the 15V output follows about 2.0V below

VIN until the part shuts down. If the 15V output is pulled

above 17.5V, it will sink 5mA.

A special circuit in the LT1105 senses the voltage at the

15V regulated output prior to turning on the switch. The

15V regulator drives the totem-pole output stage and the

VSW pin will pull the gate of the FET very close to the value

of the 15V output when VSW turns on. Therefore, the 15V

output represents what the gate bias voltage on the FET

will be when the FET is turned on. If the sensed voltage on

the 15V output is less than 10V or greater than 20V, the

circuit prevents the switch from turning on. This protects

the FET from dissipating high power in a nonsaturated

state or from excessive gate-source voltage. The oscillator

continues to run and the net effect is to skip switching

cycles until the gate bias voltage is corrected. One

consequence of the gate bias detection circuit is that the

start-up window is 4V. This influences the size of the

bypass capacitor on VIN.

VSW Output (LT1105)

The VSW pin of the LT1105 is the output of a 1A totem-pole

driver stage. This output stage turns an external power

MOSFET on by pulling its gate high. Break-Before-Make

action of 200ns is built into each switch edge to eliminate

cross-conduction currents. Fast switching times and high

efficiency are obtained by using a low loss output stage

and a special driver loop which automatically adapts base

drive current to the totem-pole low side drive. The key

element in the loop is an extra emitter on the output pulldown transistor as seen in the block diagram. This emitter

carries no current when the low side transistor collector

is high (unsaturated). In this condition, the driver can

deliver very high base drive to the output transistor for fast

turn-off. When the low side transistor saturates, the extra

emitter acts as a collector of an NPN operating in inverted

mode and pulls base current away from the driver. This

linear feedback loop serves itself to keep the switch just at

IN

the edge of saturation. This results in nearly zero driver

current. The quasisaturation state of the low side switch

permits rapid turn-on of the external FET when VSW pulls

high.

Fully Isolated Flyback Mode

A unique sampling error amplifier included in the control

loop of the LT1103/LT1105 eliminates the need for an

optoisolator while providing ±1% line and load regulation

in a magnetic flux-sensed flyback converter. In this mode,

the flyback voltage on the primary during “switch off” time

is sensed and regulated. It is difficult to derive a feedback

signal directly from the primary flyback voltage as this

voltage is typically several hundred volts. A dedicated

winding is not required because the bias winding for the

regulator lends itself to flux-sensing. Flux-sensing made

practical simplifies the design of off line power supplies by

minimizing the total number of external components and

reduces the components which must cross the isolation

barrier to one, the transformer. This inherently implies

greater safety and reliability. The transformer must be

optimized for coupling between the bias winding and the

secondary output winding(s) while maintaining the required

isolation and minimizing the parasitic leakage inductances.

Although magnetic flux-sensing has been used in the past,

the technique has exhibited poor output voltage regulation

due to the parasitics present in a transformer coupled

design. Transformers which provide the safety and isolation

as required by various international safety/regulatory

agencies also provide the poorest output voltage regulation.

Solutions to these parasitic elements have been achieved

with the novel sampling error amplifier of the LT1103/

LT1105. A brief review of flyback converter operation and

the problems which create a poorly regulated output will

provide insight on how the sampling error amplifier of the

LT1103/LT1105 addresses the regulation issue of magnetic

flux sensed converters.

The following figure shows a simplified diagram of a

flyback converter using magnetic flux sensing. The major

parasitic elements present in the transformer coupled

design are indicated. The relationships between the primary

20

Page 21

LT1103/LT1105

U

WUU

APPLICATIONS INFORMATION

voltage, the secondary voltage, the bias voltage and the

winding currents are indicated in the figures found on the

following page for both continuous and discontinuous

modes of operation.

Simplified Flyback Converter

V

IN

L(Ik

)

V

PRI

S1

BIAS

L(lk

)

SEC

1:N

N = TURNS RATIO FROM SECONDARY TO PRIMARY.

N1 = TURNS RATIO FROM SECONDARY TO BIAS.

N2 = N/N1

L(lk

PRI

L(lk

SEC

R = PARASITIC WINDING, DIODE AND OUTPUT

1:N1

CAPACITOR RESISTANCE.

When the switch “turns on,” the primary winding sees the

input voltage and the secondary and bias windings go to

negative voltages as a function of the turns ratio. Current

builds in the primary winding as the transformer stores

energy. When the switch “turns off,” the voltage across

the switch flies back to a clamp level as defined by a

snubber network until the energy in the leakage inductance of the primary dissipates. Leakage inductance is one

of the main parasitic elements in a flux-sensed converter

and is modeled as an inductor in series with the primary

and secondary of the transformer. These parasitic inductances contribute to changes in the bias winding voltage

and thus the output voltage with increasing load current.

The energy stored in the transformer transfers through the

secondary and bias windings during “switch off” time.

Ideally, the voltage across the bias winding is set by the DC

output voltage, the forward voltage of the output diode,

and the turns ratio of the transformer after the energy in

the leakage inductance spike of the primary is dissipated.

This relationship holds until the energy in the transformer

drops to zero (discontinuous mode) or the switch turns on

again (continuous mode). Either case results in the voltage across the secondary and bias windings decreasing

D1

R

) = PRIMARY LEAKAGE INDUCTANCE.

) = SECONDARY LEAKAGE INDUCTANCE.

V

OUT

C1

COMMON

LT1103 AI01

to zero or changing polarity. Therefore, the voltage on the

bias winding is only valid as a representation of the output

voltage while the secondary is delivering current.

Although the bias winding flyback voltage is a representation of the output voltage, its voltage is not constant. For

a brief period following the leakage inductance spike, the

bias winding flyback voltage decreases due to nonlinearities

and parasitics present in the transformer. Following this

nonlinear behavior is a period where the bias winding

flyback voltage decreases linearly. This behavior is easily

explained. Current flow in the secondary decreases linearly at a rate determined by the voltage across the

secondary and the inductance of the secondary. The

parasitic secondary leakage inductance appears as an

impedance in series with the secondary winding. In addition, parasitic resistances exist in the secondary winding,

the output diode and the output capacitor. These impedances can be combined to form a lumped sum equivalent

and which cause a voltage drop as secondary current

flows. This voltage drop is coupled from the secondary to

the bias winding flyback voltage and becomes more significant as the output is loaded more heavily. This voltage

drop is largest at the beginning of “switch off” time and

smallest just prior to either all transformer energy being

depleted or the switch turning on again.

The best representation of the output voltage is just prior

to either all transformer energy being used up and the bias

winding voltage collapsing to zero or just prior to the

switch turning on again and the bias winding going

negative. This point in time also represents the smallest

forward voltage for the output diode. It is possible to

redefine the relationship between the secondary winding

voltage and the bias winding voltage as:

VVfI•R

V

BIAS

()

=

++

OUT P

N1

where Vf is the forward voltage of the output diode, I is the

current flowing in the secondary, RP is the lumped sum

equivalent secondary parasitic impedance and N1 is the

transformer turns ratio from the secondary to the bias

winding. It is apparent that even though the above point in

21

Page 22

LT1103/LT1105

U

WUU

APPLICATIONS INFORMATION

Flyback Waveform for Continuous Mode Operation

V

ZENER

PRIMARY SWITCH VOLTAGE

+ Vf + (I

[V

a

b

c

d

e

f

∆I

OUT

V

IN

AREA “a” = AREA “b” TO MAINTAIN

ZERO VOLTS ACROSS PRIMARY

0V

SECONDARY WINDING VOLTAGE

[V

+ Vf + (I

OUT

0V

AREA “c” = AREA “d” TO MAINTAIN

ZERO VOLTS ACROSS SECONDARY

N • V

IN

BIAS WINDING VOLTAGE

[V

+ Vf + (I

OUT

0V

AREA “e” = AREA “f” TO MAINTAIN

ZERO VOLTS ACROSS BIAS WINDING

N2 • V

IN

I

PRI

SEC

SEC

SEC

• RP)]/N

• RP)]

• RP)]/N1

Flyback Waveform for Discontinuous Mode Operation

V

ZENER

PRIMARY SWITCH VOLTAGE

+ Vf + (I

[V

a

b

c

d

e

f

OUT

V

IN

AREA “a” = AREA “b” TO MAINTAIN

ZERO VOLTS ACROSS PRIMARY

0V

SECONDARY WINDING VOLTAGE

+ Vf + (I

[V

OUT

0V

AREA “c” = AREA “d” TO MAINTAIN

ZERO VOLTS ACROSS SECONDARY

N • V

IN

BIAS WINDING VOLTAGE

[V

+ Vf + (I

OUT

0V

AREA “e” = AREA “f” TO MAINTAIN

ZERO VOLTS ACROSS BIAS WINDING

N2 • V

IN

I

PRI

SEC

SEC

SEC

• RP)]/N

• RP)]

• RP)]/N1

∆t = (I

PRI

∆I

)[L(lk

PRI

PRIMARY CURRENT

0A

I

SEC = IPRI

SECONDARY CURRENT

0A

I

PRI

SWITCH CURRENT

0A

I

PRI

SNUBBER DIODE CURRENT

0A

)]/V

SNUB

∆I

/N

∆I

∆t = (I

)[L(lk

PRI

PRI

PRIMARY CURRENT

0A

I

SEC = IPRI

SECONDARY CURRENT

0A

I

PRI

SWITCH CURRENT

0A

I

PRI

SNUBBER DIODE CURRENT

0A

)]/V

SNUB

/N

LT1103 WF01

22

Page 23

LT1103/LT1105

U

WUU

APPLICATIONS INFORMATION

time is the most accurate representation of the output

voltage, the answer given by the bias winding voltage is

still off from the “true” answer by the amount I•RP/N1.

The sampling error amplifier of the LT1103/LT1105 provides solutions to the errors associated with the bias

winding flyback voltage. The error amplifier is comprised

of a leakage inductance spike blanking circuit, a slew rate

limited tracking amplifier, a level detector, a sample-andhold, an output gm stage and load regulation compensation circuitry. This all seems complicated at first glance,

but its operation is straightforward and transparent to the

user of the IC. When viewed from a system or block level,

the sampling error amplifier behaves like a simple transconductance amplifier. Here’s how it works.

The sampling error amplifier takes advantage of the fact

that the voltage across the bias winding during at least a

portion of switch off time is proportional to the DC output

voltage of the secondary winding. The feedback network

used to sense the bias winding voltage is no longer

comprised of a traditional peak detector in conjunction

with a resistor divider network. The feedback network

consists of a diode in series with the bias winding feeding

the resistor divider network directly. The resultant error

signal is then fed into the input of the error amplifier. The

purpose of the diode in series with the bias winding is now

not to peak detect, but to prevent the FB pin (input of the