Page 1

LT1021

Precision Reference

EATU

F

■

Pin Compatible with Most Bandgap Reference

RE

S

Applications, Including Ref 01, Ref 02, LM368,

MC1400 and MC1404 with Greatly Improved

Stability, Noise and Drift

■

Ultralow Drift: 5ppm/°C Max Slope

■

Trimmed Output Voltage

■

Operates in Series or Shunt Mode

■

Output Sinks and Sources in Series Mode

■

Very Low Noise: <1ppm

■

>100dB Ripple Rejection

■

Minimum Input/Output Differential of 1V

■

100% Noise Tested

U

O

PPLICATI

A

■

A/D and D/A Converters

■

Precision Regulators

■

Digital Voltmeters

■

Inertial Navigation Systems

■

Precision Scales

■

Portable Reference Standard

S

(0.1Hz to 10Hz)

P-P

DUESCRIPTIO

The LT®1021 is a precision reference with ultralow drift

and noise, extremely good long term stability and almost

total immunity to input voltage variations. The reference

output will both source and sink up to 10mA. Three

voltages are available: 5V, 7V and 10V. The 7V and 10V

units can be used as shunt regulators (two-terminal zeners)

with the same precision characteristics as the threeterminal connection. Special care has been taken to minimize thermal regulation effects and temperature

induced hysteresis.

The LT1021 references are based on a buried zener diode

structure that eliminates noise and stability problems

associated with surface breakdown devices. Further, a

subsurface zener exhibits better temperature drift and

time stability than even the best bandgap references.

Unique circuit design makes the LT1021 the first IC

reference to offer ultralow drift without the use of high

power on-chip heaters.

The LT1021-7 uses no resistive divider to set output

voltage, and therefore exhibits the best long term stability

and temperature hysteresis. The LT1021-5 and LT102110 are intended for systems requiring a precise 5V or 10V

reference with an initial tolerance as low as ±0.05%.

, LTC and LT are registered trademarks of Linear Technology Corporation.

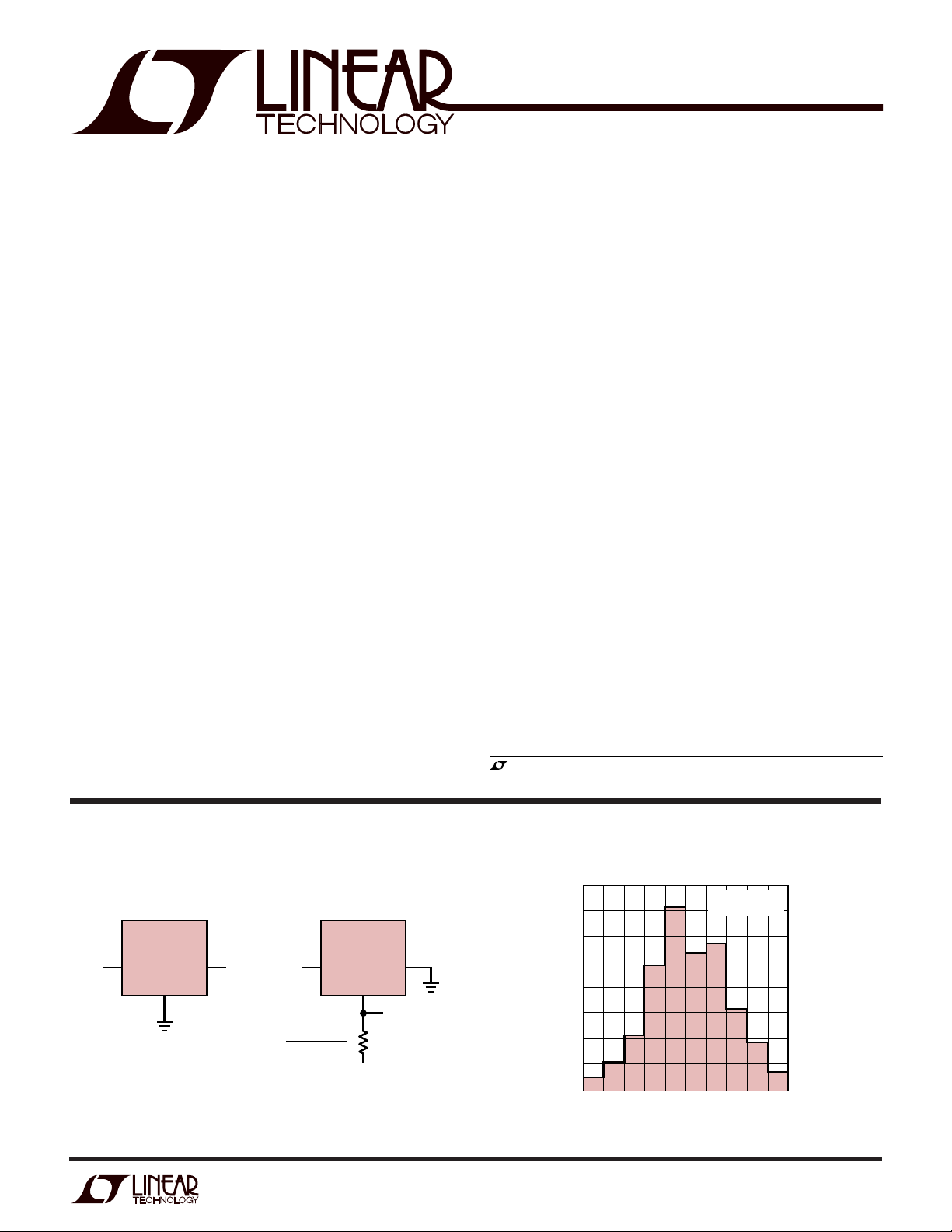

U

O

A

PPLICATITYPICAL

Typical Distribution of Temperature Drift

Basic Positive and Negative Connections

LT1021

IN

V

IN

OUT

GND

V

OUT

R1 =

NC

V

I

LOAD

OUT

LT1021

(7 AND 10 ONLY)

IN

GND

– (V–)

+ 1.5mA

–15V

(V

OUT

–V

OUT

R1

–

)

1021 TA01

24

21

18

15

12

UNITS (%)

9

6

3

– 0

–5

DISTRIBUTION

OF THREE RUNS

–3 –1 1 52–4 –2 0 4

OUTPUT DRIFT (ppm/°C)

3

1021 TA01

1

Page 2

LT1021

A

W

O

LUTEXI T

S

A

WUW

ARB

U

G

I

(Note 1)

S

Input Voltage .......................................................... 40V

Input/Output Voltage Differential ............................ 35V

Output-to-Ground Voltage (Shunt Mode Current Limit)

LT1021-5............................................................. 10V

LT1021-7............................................................. 10V

LT1021-10........................................................... 16V

Trim Pin-to-Ground Voltage

Positive ............................................... Equal to V

OUT

Negative ........................................................... – 20V

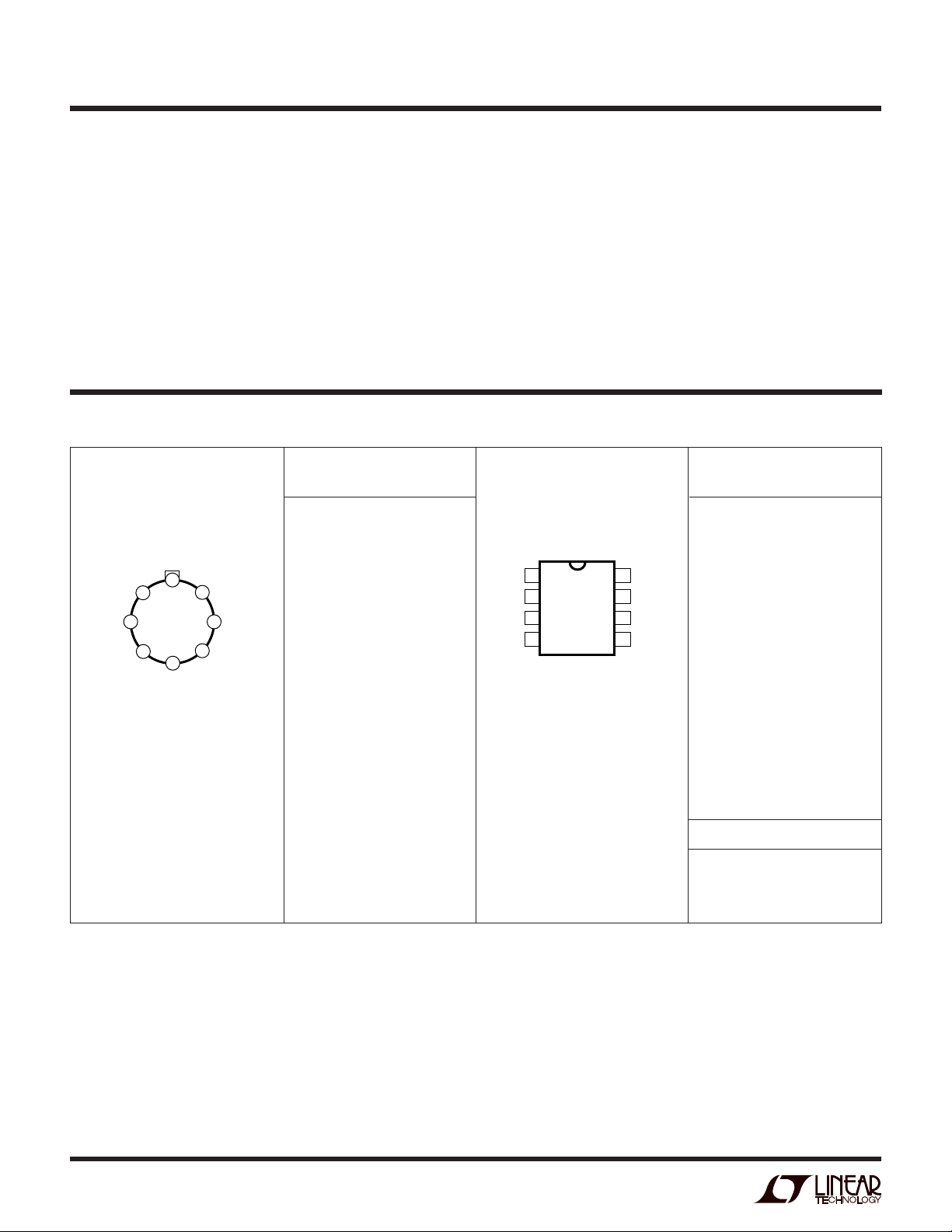

PACKAGE

/

O

RDER I FOR ATIO

WU

U

ORDER PART

NUMBER

LT1021BCH-5

TOP VIEW

NC*

8

1

NC*

2

V

IN

3

NC*

H PACKAGE

8-LEAD TO-5 METAL CAN

CONNECTED INTERNALLY.

*

D0 NOT CONNECT EXTERNAL

CIRCUITRY TO THESE PINS

NO TRIM PIN ON LT1021-7.

**

DO NOT CONNECT EXTERNAL

CIRCUITRY TO PIN 5 ON LT1021-7

T

= 150°C, θJA = 150°C/W,θJC = 45°C/W

JMAX

7

5

4

GND

NC*

6

TRIM

V

OUT

**

LT1021BMH-5

LT1021CCH-5

LT1021CMH-5

LT1021DCH-5

LT1021DMH-5

LT1021BCH-7

LT1021BMH-7

LT1021DCH-7

LT1021DMH-7

LT1021BCH-10

LT1021BMH-10

LT1021CCH-10

LT1021CMH-10

LT1021DCH-10

LT1021DMH-10

Output Short-Circuit Duration

VIN = 35V......................................................... 10 sec

VIN ≤ 20V ................................................... Indefinite

Operating Temperature Range

Commercial ............................................ 0°C to 70°C

Industrial ........................................... –40°C to 85°C

Military ............................................ –55°C to 125°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................ 300°C

ORDER PART

NUMBER

LT1021BCN8-5

TOP VIEW

DNC*

1

V

2

IN

DNC*

3

GND

4

N8 PACKAGE

8-LEAD PDIP

CONNECTED INTERNALLY.

*

D0 NOT CONNECT EXTERNAL

CIRCUITRY TO THESE PINS

NO TRIM PIN ON LT1021-7.

**

DO NOT CONNECT EXTERNAL

CIRCUITRY TO PIN 5 ON LT1021-7

T

= 130°C, θJA = 130°C/W (N)

JMAX

= 130°C, θJA = 150°C/W (S)

T

JMAX

S8 PACKAGE

8-LEAD PLASTIC SO

8

7

6

5

DNC*

DNC*

V

0UT

TRIM**

LT1021CCN8-5

LT1021CIN8-5

LT1021DCN8-5

LT1021DIN8-5

LT1021DCS8-5

LT1021BCN8-7

LT1021DCN8-7

LT1021DCS8-7

LT1021BCN8-10

LT1021CCN8-10

LT1021CIN8-10

LT1021DCN8-10

LT1021DCS8-10

LT1021DIN8-10

S8 PART MARKING

2

021DC5

021DC7

021DC1

Page 3

LT1021

LECTRICAL C CHARA TERIST

E

range, otherwise specifications are TA = 25°C. VIN = 10V, I

PARAMETER CONDITIONS MIN TYP MAX UNITS

Output Voltage (Note 2) LT1021C-5 4.9975 5.000 5.0025 V

Output Voltage Temperature Coefficient (Note 3) T

Line Regulation (Note 4) 7.2V ≤ VIN ≤ 10V 4 12 ppm/V

Load Regulation (Sourcing Current) 0 ≤ I

Load Regulation (Sinking Current) 0 ≤ I

Supply Current 0.8 1.2 mA

Output Voltage Noise (Note 6) 0.1Hz ≤ f ≤ 10Hz 3.0 µV

Long Term Stability of Output Voltage (Note 7) ∆t = 1000Hrs Noncumulative 15 ppm

Temperature Hysteresis of Output ∆T = ±25°C 10 ppm

ICS

LT1021B-5/LT1021D-5 4.9500 5.000 5.0500 V

≤ TJ ≤ T

MIN

LT1021B-5 ● 2 5 ppm/°C

LT1021C-5/LT1021D-5 ● 3 20 ppm/°C

10V ≤ V

OUT

(Note 4)

OUT

(Note 4)

10Hz ≤ f ≤ 1kHz 2.2 3.5 µV

The ● denotes specifications that apply over the full operating temperature

= 0, unless otherwise noted.

OUT

LT1021-5

MAX

● 20 ppm/V

≤ 40V 2 6 ppm/V

IN

≤ 10mA 10 20 ppm/mA

≤ 10mA 60 100 ppm/mA

● 10 ppm/V

● 35 ppm/mA

● 150 ppm/mA

● 1.5 mA

P-P

RMS

The ● denotes specifications that apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VIN = 12V, I

PARAMETER CONDITIONS MIN TYP MAX UNITS

Output Voltage (Note 2) 6.95 7.00 7.05 V

Output Voltage Temperature Coefficient (Note 3) T

Line Regulation (Note 4) 8.5V ≤ VIN ≤ 12V 1.0 4 ppm/V

Load Regulation (Sourcing Current) 0 ≤ I

Load Regulation (Shunt Mode) 1.2mA ≤ I

Supply Current (Series Mode) 0.75 1.2 mA

Minimum Current (Shunt Mode) VIN is Open 0.7 1.0 mA

Output Voltage Noise (Note 6) 0.1Hz ≤ f ≤ 10Hz 4.0 µV

Long Term Stability of Output Voltage (Note 7) ∆t = 1000Hrs Noncumulative 7 ppm

Temperature Hysteresis of Output ∆T = ±25°C 3 ppm

= 0, unless otherwise noted.

OUT

LT1021-7

≤ TJ ≤ T

MIN

LT1021B-7 ● 2 5 ppm/°C

LT1021D-7

12V ≤ V

(Note 4)

(Notes 4, 5)

10Hz ≤ f ≤ 1kHz 2.5 4.0 µV

MAX

● 3 20 ppm/°C

● 2.0 8 ppm/V

≤ 40V 0.5 2 ppm/V

IN

≤ 10mA 12 25 ppm/mA

OUT

≤ 10mA 50 100 ppm/mA

SHUNT

● 1.0 4 ppm/V

● 40 ppm/mA

● 150 ppm/mA

● 1.5 mA

● 1.2 mA

P-P

RMS

3

Page 4

LT1021

LECTRICAL C CHARA TERIST

E

range, otherwise specifications are TA = 25°C. VIN = 15V, I

PARAMETER CONDITIONS MIN TYP MAX UNITS

Output Voltage (Note 2) LT1021C-10 9.995 10.00 10.005 V

Output Voltage Temperature Coefficient (Note 3) T

Line Regulation (Note 4) 11.5V ≤ VIN ≤ 14.5V 1.0 4 ppm/V

Load Regulation (Sourcing Current) 0 ≤ I

Load Regulation (Shunt Mode) 1.7mA ≤ I

Supply Current (Series Mode) 1.2 1.7 mA

Minimum Current (Shunt Mode) VIN is Open 1.1 1.5 mA

Output Voltage Noise (Note 6) 0.1Hz ≤ f ≤ 10Hz 6.0 µV

Long Term Stability of Output Voltage (Note 7) ∆t = 1000Hrs Noncumulative 15 ppm

Temperature Hysteresis of Output ∆T = ±25°C 5 ppm

ICS

LT1021B-10/LT1021D-10 9.950 10.00 10.050 V

≤ TJ ≤ T

MIN

LT1021B-10 ● 2 5 ppm/°C

LT1021C-10/LT1021D-10 ● 5 20 ppm/°C

14.5V ≤ V

OUT

(Note 4)

(Notes 4, 5)

10Hz ≤ f ≤ 1kHz 3.5 6 µV

The ● denotes specifications that apply over the full operating temperature

= 0, unless otherwise noted.

OUT

LT1021-10

MAX

● 6 ppm/V

≤ 40V 0.5 2 ppm/V

IN

≤ 10mA 12 25 ppm/mA

≤ 10mA 50 100 ppm/mA

SHUNT

● 4 ppm/V

● 40 ppm/mA

● 150 ppm/mA

● 2.0 mA

● 1.7 mA

P-P

RMS

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Output voltage is measured immediately after turn-on. Changes

due to chip warm-up are typically less than 0.005%.

Note 3: Temperature coefficient is measured by dividing the change in

output voltage over the temperature range by the change in temperature.

Separate tests are done for hot and cold; T

Incremental slope is also measured at 25°C.

Note 4: Line and load regulation are measured on a pulse basis. Output

changes due to die temperature change must be taken into account

separately. Package thermal resistance is 150°C/W for TO-5 (H), 130°C/W

for N and 150°C/W for the SO-8.

to 25°C and 25°C to T

MIN

MAX

.

Note 5: Shunt mode regulation is measured with the input open. With the

input connected, shunt mode current can be reduced to 0mA. Load

regulation will remain the same.

Note 6: RMS noise is measured with a 2-pole highpass filter at 10Hz and a

2-pole lowpass filter at 1kHz. The resulting output is full-wave rectified and

then integrated for a fixed period, making the final reading an average as

opposed to RMS. Correction factors are used to convert from average to

RMS and correct for the non-ideal bandpass of the filters.

Peak-to-peak noise is measured with a single highpass filter at 0.1Hz and a

2-pole lowpass filter at 10Hz. The unit is enclosed in a still-air environment

to eliminate thermocouple effects on the leads. Test time is 10 seconds.

Note 7: Consult factory for units with long term stability data.

4

Page 5

LPER

OUTPUT CURRENT (mA)

0

INPUT/OUTPUT VOLTAGE (V)

1.2

1.6

16

1021 G03

0.8

0.4

0

4

8

12

20

1.0

1.4

0.6

0.2

14

2

6

10

18

TJ = 125 °C

TJ = –55 °C

TJ = 25 °C

FREQUENCY (Hz)

100

NOISE VOLTAGE (nV/√Hz)

200

250

350

400

10 1k 10k

LT1021 G06

0

100

300

150

50

LT1021-10

LT1021-5

LT1021-7

Ripple Rejection

115

f = 150Hz

110

105

100

REJECTION (dB)

95

90

85

0

13

12

11

10

9

8

7

6

OUTPUT VOLTAGE (V)

5

4

3

10 20

515

INPUT VOLTAGE (V)

Start-Up (Series Mode)

VIN = 0V TO 12V

04

2

F

LT1021-10

LT1021-7

LT1021-5

6

TIME (µs)

R

O

LT1021-7

LT1021-10

LT1021-5

25

8

LT1021

UW

ATYPICA

30

10

35

LT1021 G01

12

LT1021 G04

40

14

CCHARA TERIST

E

C

Ripple Rejection

130

VIN = 15V

= 0

C

OUT

120

110

100

90

80

REJECTION (dB)

70

60

50

10

Start-Up (Shunt Mode)

LT1021-7, LT1021-10

11

10

9

8

7

OUTPUT VOLTAGE (V)

6

5

02

ICS

LT1021-7

LT1021-10

LT1021-5

100 1k 10k

FREQUENCY (Hz)

LT1021-10

+ 2V

V

OUT

0V

NC

LT1021-7

61012

48

TIME (µs)

LT1021 G02

1k

V

OUT

OUT

IN

GND

LT1021 G05

Minimum Input/Output Differential

LT1021-7, LT1021-10

Output Voltage Noise Spectrum

Output Voltage Noise

16

C

= 0

OUT

FILTER = 1 POLE

14

= 0.1Hz

f

LOW

12

10

8

6

RMS NOISE (µV)

4

2

0

10

LT1021-10

100 1k 10k

BANDWIDTH (Hz)

LT1021-7

LT1021-5

LT1021 G07

Output Voltage Temperature Drift

LT1021-5

5.006

5.004

5.002

5.000

4.998

OUTPUT VOLTAGE (V)

4.996

4.994

–50

0

–25

TEMPERATURE (°C)

50

25

Load Regulation LT1021-5

5

VIN = 8V

4

3

2

1

0

–1

–2

OUTPUT CHANGE (mV)

–3

–4

100

LT1021 G08

125

75

–5

–6–8 –4 0 4 8

–10

–2

SOURCING SINKING

OUTPUT CURRENT (mA)

2

6

10

LT1021 G09

5

Page 6

LT1021

TIME (MINUTES)

035

LT1021 G15

12

46

OUTPUT VOLTAGE NOISE (5µV/DIV)

5µV (1ppm)

FILTERING = 1 ZERO AT 0.1Hz

2 POLES AT 10Hz

LPER

Quiescent Current LT1021-5

1.8

1.6

1.4

1.2

1.0

0.8

0.6

INPUT CURRENT (mA)

0.4

0.2

= 0

I

OUT

TJ = –55°C

TJ = 25°C

TJ = 125°C

0

5 10152025 40

0

INPUT VOLTAGE (V)

F

O

R

ATYPICA

3530

LT1021 G10

UW

CCHARA TERIST

E

C

Sink Mode* Current Limit

LT1021-5

60

VIN = 8V

50

40

30

20

CURRENT INTO OUTPUT (mA)

10

0

26

4

0

*NOTE THAT AN INPUT VOLTAGE IS REQUIRED

FOR 5V UNITS.

ICS

10 18

12

8

OUTPUT VOLTAGE (V)

14

16

LT1021 G11

Thermal Regulation LT1021-5

VIN = 25V

∆POWER = 200mW

0

–0.5

–1.0

OUTPUT CHANGE (mV)

LOAD

REGULATION

I

LOAD

0

20

= 10mA

40

TIME (ms)

60

THERMAL

REGULATION

80

100

120

LT1021 G12

140

Load Transient Response

LT1021-5, C

I

SOURCE

I

SOURCE

I

SOURCE

OUTPUT CHANGE (50mV/DIV)

∆I

SOURCE

Output Voltage Temperature

Drift LT1021-7

7.003

7.002

7.001

7.000

6.999

OUTPUT VOLTAGE (V)

6.998

6.997

–50

–25

= 0

LOAD

= 0

50mV 50mV

= 0.5mA

= 2-10mA

= 100µA

102413

0

TEMPERATURE (°C)

P-P

3

TIME (µs)

25

I

SINK

I

SINK

∆I

SINK

0

50

= 0

I

SINK

= 2-10mA

= 100µA

75

= 0.2mA

2

LT1021 G13

100

LT1021 G16

P-P

4

125

Load Transient Response

LT1021-5, C

I

SOURCE

I

SOURCE

OUTPUT CHANGE (20mV/DIV)

∆I

SOURCE

LOAD

= 0

20mV 20mV

I

= 0.2mA

SOURCE

= 2-10mA

= 100µA

P-P

501020515

15

TIME (µs)

Load Regulation

LT1021-7, LT1021-10

5

VIN = 12V

4

3

2

1

0

–1

–2

OUTPUT CHANGE (mV)

–3

–4

–5

–6–8 –4 0 4 8

–10

SOURCING SINKING

–2

OUTPUT CURRENT (mA)

= 1000pF

I

= 0

SINK

I

SINK

I

SINK

∆I

SINK

0

2

= 0.2mA

= 2-10mA

= 100µA

10

LT1021 G14

6

LT1021 G17

P-P

Output Noise 0.1Hz to 10Hz

LT1021-5

20

Quiescent Current LT1021-7

1.8

1.6

1.4

1.2

1.0

0.8

0.6

INPUT CURRENT (mA)

0.4

0.2

10

= 0

I

OUT

TJ = –55°C

TJ = 25°C

TJ = 125°C

0

5 10152025 40

0

INPUT VOLTAGE (V)

3530

LT1021 G18

6

Page 7

LPER

TIME (MINUTES)

035

LT1021 G24

12

46

OUTPUT VOLTAGE NOISE (5µV/DIV)

5µV (0.7ppm)

FILTERING = 1 ZERO AT 0.1Hz

2 POLES AT 10Hz

F

O

Shunt Characteristics LT1021-7

1.2

INPUT PIN OPEN

1.0

0.8

0.6

0.4

CURRENT INTO OUTPUT (mA)

0.2

TJ = 25°C

TJ = –55°C

T

= 125°C

J

R

ATYPICA

UW

CCH ARA TERIST

E

C

Shunt Mode Current Limit

LT1021-7 Thermal Regulation LT1021-7

60

INPUT PIN OPEN

50

40

30

20

CURRENT INTO OUTPUT (mA)

10

ICS

VIN = 27V

∆POWER = 200mW

0

–0.5

–1.0

–1.5

OUTPUT CHANGE (mV)

LOAD

REGULATION

I

LOAD

= 10mA

LT1021

THERMAL

REGULATION*

0

13

0

OUTPUT TO GROUND VOLTAGE (V)

Load Transient Response

LT1021-7, C

I

SOURCE

5mV

I

SOURCE

OUTPUT VOLTAGE CHANGE

I

SOURCE

∆I

SOURCE

102413

NOTE VERTICAL SCALE CHANGE

BETWEEN SOURCING AND SINKING

Output Voltage Temperature

Drift LT1021-10

10.006

10.004

10.002

10.000

9.998

OUTPUT VOLTAGE (V)

9.996

9.994

–50

–25

2

LOAD

= 0

= 0.5mA

= 2-10mA

= 100µA

3

TIME (µs)

0

TEMPERATURE (°C)

7

59

6

4

8

1021 G19

= 0

I

= 0.8mA

SINK

I

= 1.2mA

SINK

50mV

I

= 1.4mA

SINK

I

= 2-10mA

SINK

= 100µA

∆I

P-P

SINK

0

50

25

P-P

2

4

LT1021 G22

100

LT1021 G25

125

75

0

26

4

0

8

OUTPUT VOLTAGE (V)

Load Transient Response

LT1021-7, C

I

SOURCE

OUTPUT VOLTAGE CHANGE

∆I

SOURCE

NOTE VERTICAL SCALE CHANGE

BETWEEN SOURCING AND SINKING

LOAD

= 0

5mV

I

= 0.5mA

SOURCE

I

= 2-10mA

SOURCE

= 100µA

P-P

501020515

15

5µs/DIV

Load Regulation

LT1021-7, LT1021-10

5

VIN = 12V

4

3

2

1

0

–1

–2

OUTPUT CHANGE (mV)

–3

–4

–5

–6–8 –4 0 4 8

–10

SOURCING SINKING

–2

OUTPUT CURRENT (mA)

14

10 18

16

12

LT1021 G20

= 1000pF

I

= 0.6mA

SINK

20mV

I

= 0.8mA

SINK

= 1mA

I

SINK

I

= 2-10mA

SINK

∆I

= 100µA

SINK

0

10

LT1021 G23

2

6

P-P

1021 G26

60

TIME (ms)

80

100

0

20

40

*INDEPENDENT OF TEMPERATURE COEFFICIENT

120

LT1021 G21

140

Output Noise 0.1Hz to 10Hz

LT1021-7

20

Input Supply Current LT1021-10

1.8

1.6

1.4

1.2

1.0

0.8

0.6

INPUT CURRENT (mA)

0.4

0.2

10

= 0

I

OUT

0

5 10152025 40

0

TJ = –55°C

TJ = 25°C

TJ = 125°C

INPUT VOLTAGE (V)

3530

1021 G27

7

Page 8

LT1021

LPER

Shunt Characteristics LT1021-10

1.8

INPUT PIN OPEN

1.6

1.4

1.2

1.0

0.8

0.6

0.4

CURRENT INTO OUTPUT (mA)

0.2

0

TJ = –55°C

0

OUTPUT TO GROUND VOLTAGE (V)

F

O

TJ = 125°C

42 6 10 12

8

R

ATYPICA

TJ = 25°C

1021 G28

UW

CCH ARA TERIST

E

C

Shunt Mode Current Limit

LT1021-10 Thermal Regulation LT1021-10

60

INPUT PIN OPEN

50

40

30

20

CURRENT INTO OUTPUT (mA)

10

0

26

4

0

ICS

10 18

12

8

OUTPUT VOLTAGE (V)

VIN = 30V

∆POWER = 200mW

0

–0.5

–1.0

–1.5

OUTPUT CHANGE (mV)

14

16

1021 G29

*INDEPENDENT OF TEMPERATURE COEFFICIENT

REGULATION

I

LOAD

0

20

LOAD

= 10mA

40

TIME (ms)

THERMAL

REGULATION*

60

80

100

120

1021 G30

140

Load Transient Response

LT1021-10, C

I

= 0

SOURCE

10mV

I

= 0.2mA

SOURCE

OUTPUT VOLTAGE CHANGE

I

SOURCE

∆I

= 100µA

SOURCE

102413

NOTE VERTICAL SCALE CHANGE

BETWEEN SOURCING AND SINKING

LOAD

= 2-10mA

P-P

3

TIME (µs)

= 0

I

SINK

I

SINK

∆I

SINK

0

= 0.6mA

50mV

I

SINK

I

= 1mA

SINK

= 2-10mA

= 100µA

= 0.8mA

2

1021 G31

P-P

4

Load Transient Response

LT1021-10, C

I

= 0

SOURCE

5mV

I

= 0.5mA

SOURCE

OUTPUT VOLTAGE CHANGE

I

SOURCE

∆I

= 100µA

SOURCE

102413

NOTE VERTICAL SCALE CHANGE

BETWEEN SOURCING AND SINKING

LOAD

I

SINK

= 2-10mA

P-P

3

TIME (µs)

= 1000pF

I

SINK

= 1.2mA

I

∆I

SINK

0

= 0.8mA

20mV

I

SINK

= 2-10mA

SINK

= 100µA

= 1.4mA

2

1021 G32

P-P

4

Output Noise 0.1Hz to 10Hz

LT1021-10

FILTERING = 1 ZERO AT 0.1Hz

OUTPUT VOLTAGE NOISE (10µV/DIV)

035

2 POLES AT 10Hz

10µV (1ppm)

12

TIME (MINUTES)

46

1021 G33

8

Page 9

LT1021

U

WUU

APPLICATIONS IN FORMA TION

Effect of Reference Drift on System Accuracy

A large portion of the temperature drift error budget in

many systems is the system reference voltage. This graph

indicates the maximum temperature coefficient allowable

if the reference is to contribute no more than 0.5LSB error

to the overall system performance. The example shown is

a 12-bit system designed to operate over a temperature

range from 25°C to 65°C. Assuming the system calibration is performed at 25°C, the temperature span is 40°C.

It can be seen from the graph that the temperature coefficient of the reference must be no worse than 3ppm/°C if

it is to contribute less than 0.5LSB error. For this reason,

the LT1021 family has been optimized for low drift.

Maximum Allowable Reference Drift

100

8-BIT

The LT1021-10 “C” version is pre-trimmed to ±5mV and

therefore can utilize a restricted trim range. A 75k resistor

in series with a 20kΩ potentiometer will give ±10mV trim

range. Effect on the output TC will be only 1ppm/°C for the

±5mV trim needed to set the “C” device to 10.000V.

LT1021-5

The LT1021-5 does have an output voltage trim pin, but

the TC of the nominal 4V open-circuit voltage at this pin is

about –1.7mV/°C. For the voltage trimming not to affect

reference output TC, the external trim voltage must track

the voltage on the trim pin. Input impedance of the trim pin

is about 100kΩ and attenuation to the output is 13:1. The

technique shown below is suggested for trimming the

output of the LT1021-5 while maintaining minimum shift

in output temperature coefficient. The R1/R2 ratio is

chosen to minimize interaction of trimming and TC shifts,

so the exact values shown should be used.

10-BIT

10

0.5LSB ERROR (ppm/°C)

MAXIMUM TEMPERATURE COEFFICIENT FOR

1.0

100

12-BIT

14-BIT

20 100

40

50

30

TEMPERATURE SPAN (°C)

807060

90

LT1021 AI01

Trimming Output Voltage

LT1021-10

The LT1021-10 has a trim pin for adjusting output voltage.

The impedance of the trim pin is about 12kΩ with a

nominal open-circuit voltage of 5V. It is designed to be

driven from a source impedance of 3kΩ or less to minimize changes in the LT1021 TC with output trimming.

Attenuation between the trim pin and the output is 70:1.

This allows ±70mV trim range when the trim pin is tied to

the wiper of a potentiometer connected between the

output and ground. A 10kΩ potentiometer is recommended, preferably a 20 turn cermet type with stable

characteristics over time and temperature.

LT1021-5

IN

GND

OUT

TRIM

R1

27k

1N4148

V

R2

50k

1021 AI02

OUT

LT1021-7

The 7V version of the LT1021 has no trim pin because the

internal architecture does not have a point which could be

driven conveniently from the output. Trimming must

therefore be done externally, as is the case with ordinary

reference diodes. Unlike these diodes, however, the output of the LT1021 can be loaded with a trim potentiometer.

The following trim techniques are suggested; one for

voltage output and one for current output. The voltage

output is trimmed for 6.95V. Current output is 1mA, as

shown, into a summing junction, but all resistors may be

scaled for currents up to 10mA.

Both of these circuits use the trimmers in a true potentiometric mode to reduce the effects of trimmer TC. The

voltage output has a 200Ω impedance, so loading must be

9

Page 10

LT1021

U

WUU

APPLICATIONS IN FORMA TION

minimized. In the current output circuit, R1 determines

output current. It should have a TC commensurate with the

LT1021 or track closely with the feedback resistor around

the op amp.

LT1021-7

IN

LT1021-7

IN

GND

OUT

GND

50k

OUT

R3

R3

10k

TC TRACKING TO 50ppm/°C

R2**

182k

R2*

14k

1%

R1*

7.15k

1.000mA

R1*

200Ω

1%

V

OUT

6.950V

1021 AI03

Kelvin Connections

Although the LT1021 does not have true force/sense

capability at its outputs, significant improvements in ground

loop and line loss problems can be achieved with proper

hook-up. In series mode operation, the ground pin of the

LT1021 carries only ≈1mA and can be used as a sense

line, greatly reducing ground loop and loss problems on

the low side of the reference. The high side supplies load

current so line resistance must be kept low. Twelve feet of

#22 gauge hook-up wire or 1 foot of 0.025 inch printed

circuit trace will create 2mV loss at 10mA output current.

This is equivalent to 1LSB in a 10V, 12-bit system.

The following circuits show proper hook-up to minimize

errors due to ground loops and line losses. Losses in the

output lead can be greatly reduced by adding a PNP boost

transistor if load currents are 5mA or higher. R2 can be

added to further reduce current in the output sense lead.

Standard Series Mode

–

OP AMP

+

1021 AI04

RESISTOR TC DETERMINES I

*

TC ≤ (10 • R1) TC. R2 AND R3 SCALE

**

WITH R1 FOR DIFFERENT OUTPUT CURRENTS

OUT

TC

Capacitive Loading and Transient Response

The LT1021 is stable with all capacitive loads, but for

optimum settling with load transients, output capacitance

should be under 1000pF. The output stage of the reference

is class AB with a fairly low idling current. This makes

transient response worst-case at light load currents. Because of internal current drain on the output, actual worstcase occurs at I

–0.8mA (sinking) on LT1021-7 and I

= 0 on LT1021-5, I

LOAD

LOAD

=

LOAD

= 1.4mA (sinking) on LT1021-10. Significantly better load transient

response is obtained by moving slightly away from these

points. See Load Transient Response curves for details. In

general, best transient response is obtained when the

output is sourcing current. In critical applications, a 10µ F

solid tantalum capacitor with several ohms in series

provides optimum output bypass.

INPUT

GROUND

RETURN

LT1021

IN

GND

KEEP THIS LINE RESISTANCE LOW

OUT

Series Mode with Boost Transistor

INPUT

R1

220Ω

2N3906

IN

LT1021

OUT

GND

GROUND

RETURN

*OPTIONAL—REDUCES CURRENT IN OUTPUT SENSE LEAD

R2 = 2.4k (LT1021-5), 3k (LT1021-7), 5.6k (LT1021-10)

R2*

1021 AI06

+

LOAD

1021 AI05

LOAD

10

Page 11

LT1021

U

WUU

APPLICATIONS IN FORMA TION

Effects of Air Movement on Low Frequency Noise

The LT1021 has very low noise because of the buried zener

used in its design. In the 0.1Hz to 10Hz band, peak-to-peak

noise is about 0.5ppm of the DC output. To achieve this

low noise, however, care must be taken to shield the

reference from ambient air turbulence. Air movement can

create noise because of thermoelectric differences

between IC package leads (especially kovar lead TO-5) and

printed circuit board materials and/or sockets. Power

dissipation in the reference, even though it rarely exceeds

20mW, is enough to cause small temperature gradients in

the package leads. Variations in thermal resistance, caused

by uneven air flow, create differential lead temperatures,

thereby causing thermoelectric voltage noise at the output

of the reference. The following XY plotter trace dramatically illustrates this effect. The first half of the plot was

done with the LT1021 shielded from ambient air with a

small foam cup. The cup was then removed for the second

half of the trace. Ambient in both cases was a lab environment with no excessive air turbulence from air conditioners, opening/closing doors, etc. Removing the foam cup

increases the output noise by almost an order of magnitude in the 0.01Hz to 1Hz band! The kovar leads of the

TO-5 (H) package are the primary culprit. Alloy 42 and

copper lead frames used on dual-in-line packages are not

nearly as sensitive to thermally generated noise because

they are intrinsically matched.

There is nothing magical about foam cups—any enclosure which blocks air flow from the reference will do.

Smaller enclosures are better since they do not allow the

build-up of internally generated air movement. Naturally,

heat generating components external to the reference

itself should not be included inside the enclosure.

Noise Induced By Air Turbulence (TO-5 Package)

LT1021-7 (TO-5 PACKAGE)

f = 0.01Hz TO 10Hz

20µV

OUTPUT VOLTAGE NOISE (20µV/DIV)

0610

24

TIME (MINUTES)

FOAM CUP

REMOVED

812

1021 AI07

U

TYPICAL APPLICATIONS

Restricted Trim Range for Improved

Resolution, 10V, “C” Version Only

LT1021C-10

IN 10.000V

IN

OUT V

GND TRIM

TRIM RANGE ≈ ±10mV

R1

75k

R2

50k

1021 TA11

LT1021-10

V

IN

GND

OUT

TRIM

IN

*CAN BE RAISED TO 20k FOR

LESS CRITICAL APPLICATIONS

R1*

10k

1021 TA03

Negative Series ReferenceLT1021-10 Full Trim Range (±0.7%)

15V

V

OUT

4.7k

–15V

R1

4.7k

R2

Q1

2N2905

D1

15V

LT1021-10

IN

GND

LT1021 TA04

OUT

–10V AT 50mA

11

Page 12

LT1021

LT1021-10

OUT

IN

TRIM

GND

4.32k

V

OUT

= 10.24V

V

IN

5k

V

–

= –15V*

*MUST BE WELL REGULATED

dV

OUT

dV

–

=

15mV

V

1021 TA12

TYPICAL APPLICATIONS

U

Boosted Output Current

with No Current Limit

+

≥ (V

OUT

+ 1.8V)

LT1021

V

2-Pole Lowpass Filtered Reference

LT1021

IN

V

IN

OUT

GND

IN

GND

R1

220Ω

OUT

R1

36k

+

f = 10Hz

2N2905

10V AT

100mA

2µF

SOLID

TANT

1021 TA05

1µF

MYLAR

R2

36k

+

V

–

LT1001

+

0.5µF

MYLAR

Boosted Output Current

with Current Limit

≥ V

+ 2.8V

OUT

*GLOWS IN CURRENT LIMIT,

DO NOT OMIT

V

IN

TOTAL NOISE

≤2µV

RMS

1Hz ≤ f ≤ 10kHz

D1*

LED

V

LT1021

REF

IN

GND

Ultraprecise Current Source

R1

220Ω

OUT

+

8.2Ω

15V

2N2905

10V AT

100mA

2µF

SOLID

TANT

1021 TA06

LT1021-7

IN

OUT

GND

6

Operating 5V Reference from 5V Supply

C1*

5µF

+

1N914

1N914

+

CMOS LOGIC GATE**

≥ 2kHz*

f

IN

FOR HIGHER FREQUENCIES C1 AND C2 MAY BE DECREASED

*

PARALLEL GATES FOR HIGHER REFERENCE CURRENT LOADING

**

TRIM

100Ω

≈8.5V

C2*

5µF

17.4k

1%

15V

7

–

2

LT1001

–15V

3

+

4

I

REGULATION < 1ppm/V

COMPLIANCE = –13V TO 7V

LT1021-5

IN

OUT

GND

OUT

6.98k*

0.1%

*LOW TC

= 1mA

5V LOGIC

SUPPLY

5V

REFERENCE

1021 TA07

1021 TA16

LT1021-10

12

OUT

GND

–15V

TRIM

1.2k

–V

REF

1021 TA13

CMOS DAC with Low Drift Full-Scale Trimming**

4.02K

R1

4.99k

1%

R2

40.2Ω

1%

*

TC LESS THAN 200ppm/°C

**

NO ZERO ADJUST REQUIRED

WITH LT1007 (V

REF

7520, ETC

CMOS

DAC

0S

FB

≤ 60µV)

I

OUT

30pF

–

LT1007C

+

R3

1%

R4*

100Ω

FULL-SCALE

ADJUST

10V

F.S.

LT1236 TA15

Trimming 10V Units to 10.24V

Page 13

U

LT1021-10

OUT

GND

IN

1021 TA08

R

L

30mA

15V

R1*

169Ω

V

OUT

10V

TYPICAL LOAD

CURRENT = 30mA

SELECT R1 TO DELIVER TYPICAL LOAD CURRENT.

LT1021 WILL THEN SOURCE OR SINK AS NECESSARY

TO MAINTAIN PROPER OUTPUT. DO NOT REMOVE LOAD

AS OUTPUT WILL BE DRIVEN UNREGULATED HIGH. LINE

REGULATION IS DEGRADED IN THIS APPLICATION

*

TYPICAL APPLICATIONS

LT1021

Strain Gauge Conditioner for 350Ω Bridge

R1

357Ω

1/2W

LM301A

1

100pF

OF AMPLIFIER

IN

28mA

+

†

–

8

28.5mA

3

2

LT1021-10

15V

THIS RESISTOR PROVIDES POSITIVE FEEDBACK TO

*

THE BRIDGE TO ELIMINATE LOADING EFFECT OF

THE AMPLIFIER. EFFECTIVE Z

STAGE IS ≥1MΩ. IF R2 TO R5 ARE CHANGED,

SET R6 = R3

IN

OUT

GND

6 6

5V

350Ω STRAIN

GAUGE BRIDGE**

R2

20k

R4

20k

R5

2M

–5V

357Ω

1/2W

–15V

BRIDGE IS ULTRALINEAR WHEN ALL LEGS ARE

**

ACTIVE, TWO IN COMPRESSION AND TWO IN TENSION,

OR WHEN ONE SIDE IS ACTIVE WITH ONE COMPRESSED

AND ONE TENSIONED LEG

†

OFFSET AND DRIFT OF LM301A ARE VIRTUALLY

ELIMINATED BY DIFFERENTIAL CONNECTION OF LT1012C

2

3

–

LT1012C

+

R6*

2M

R3

2M

1021 TA09

Negative Shunt Reference Driven

by Current Source

LT1021-10

OUT

GND

V

OUT

×100

LM334

–11V TO –40V

2.5mA

–10V (I

LOAD

27Ω

≤ 1mA)

1021 TA14

Precision DAC Reference with System TC Trim

LT1021-10

15V

IN

OUT

GND

TRIMS 1mA REFERENCE CURRENT

*

TC BY ±40ppm/°C. THIS TRIM SCHEME HAS

VERY LITTLE EFFECT ON ROOM TEMPERATURE

CURRENT TO MINIMIZE ITERATIVE TRIMMING

8.87k

1%

1.24k

1%

D1

1N457

50k

TC TRIM*

10k

1%

10k

1%

D2

1N457

50k

50k

ROOM TEMP

TRIM

200k

1%

10.36k

1%

1mA

Handling Higher Load Currents

8.45k

DAC

1021 TA17

13

Page 14

LT1021

TYPICAL APPLICATIONS

U

Ultralinear Platinum Temperature Sensor*

LT1021-10

IN

OUT

20V

100k

R2*

5k

R1**

253k

R8

R9

10M

–15V

R3**

5k

R7

392k

1%

†

R

S

100Ω AT

0°C

R10

182k

1%

R4

4.75k

1%

GND

R14

5k

R11

6.65M

1%

2

R5

200k

1%

3

R6

†

619k

STANDARD INDUSTRIAL 100Ω PLATINUM 4-WIRE SENSOR,

1%

ROSEMOUNT 78S OR EQUIVALENT. α = 0.00385

TRIM R9 FOR V

TRIM R12 FOR V

TRIM R14 FOR V

USE TRIM SEQUENCE AS SHOWN. TRIMS ARE NONINTERACTIVE

SO THAT ONLY ONE TRIM SEQUENCE IS NORMALLY REQUIRED.

*

FEEDBACK LINEARIZES OUTPUT TO ±0.005°C FROM

–50°C TO 150°C

**

WIREWOUND RESISTORS WITH LOW TC

–

LT1001

+

R

654k

20V

–15V

**

F

7

4

6

= 0V AT 0°C

OUT

= 10V AT 100°C

OUT

= 5V AT 50°C

OUT

R15

10k

R13

24.3k

R12

1k

=100mV/°C

V

OUT

–50°C ≤ T ≤ 150°C

1021 TA10

U

W

EQUIVALE T SCHE ATIC

D4

6.3V

INPUT

Q3

D1

D2

OUTPUT

D3

R1

Q1

+

–

A1

Q2

R2

LT1021 ES

GND

14

Page 15

PACKAGE DESCRIPTION

SEATING

PLANE

0.010 – 0.045*

(0.254 – 1.143)

45°TYP

U

Dimensions in inches (millimeters) unless otherwise noted.

H Package

8-Lead TO-5 Metal Can (0.200 PCD)

(LTC DWG # 05-08-1320)

0.335 – 0.370

(8.509 – 9.398)

DIA

0.305 – 0.335

(7.747 – 8.509)

0.016 – 0.021**

(0.406 – 0.533)

0.050

(1.270)

MAX

0.027 – 0.045

(0.686 – 1.143)

PIN 1

GAUGE

PLANE

0.200

(5.080)

TYP

0.165 – 0.185

(4.191 – 4.699)

0.500 – 0.750

(12.700 – 19.050)

REFERENCE

PLANE

0.028 – 0.034

(0.711 – 0.864)

0.040

(1.016)

MAX

LT1021

0.110 – 0.160

(2.794 – 4.064)

INSULATING

STANDOFF

*

**

N8 Package

8-Lead PDIP (Narrow 0.300)

(LTC DWG # 05-08-1510)

876

0.255 ± 0.015*

(6.477 ± 0.381)

12

0.300 – 0.325

(7.620 – 8.255)

0.065

(1.651)

0.009 – 0.015

(0.229 – 0.381)

+0.035

0.325

–0.015

+0.889

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

TYP

0.045 – 0.065

(1.143 – 1.651)

0.100

(2.54)

BSC

LEAD DIAMETER IS UNCONTROLLED BETWEEN THE REFERENCE PLANE

AND 0.045" BELOW THE REFERENCE PLANE

FOR SOLDER DIP LEAD FINISH, LEAD DIAMETER IS

0.400*

(10.160)

MAX

5

4

3

0.130 ± 0.005

(3.302 ± 0.127)

0.125

0.020

(3.175)

MIN

(0.508)

0.018 ± 0.003

(0.457 ± 0.076)

MIN

N8 1098

0.016 – 0.024

(0.406 – 0.610)

H8(TO-5) 0.200 PCD 1197

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

15

Page 16

LT1021

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.189 – 0.197*

(4.801 – 5.004)

7

8

5

6

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

(1.346 – 1.752)

0°– 8° TYP

0.016 – 0.050

0.406 – 1.270

0.053 – 0.069

0.014 – 0.019

(0.355 – 0.483)

0.150 – 0.157**

(3.810 – 3.988)

1

3

2

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

TYP

SO8 0996

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1019 Precision Bandgap Reference 0.05%, 5ppm/°C

LT1027 Precision 5V Reference 0.02%, 2ppm/°C

LT1236 Precision Reference SO-8, 5V and 10V, 0.05%, 5ppm/°C

LTC®1258 Micropower Reference 200mV Dropout, MSOP

LT1389 Nanopower Shunt Reference 800nA Operating Current

LT1460 Micropower Reference SOT-23, 2.5V, 5V, 10V

LT1634 Micropower Shunt Reference 0.05%, 10ppm/°C, MSOP

1021fa LT/GP 0399 2K REV A • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1995

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

Loading...

Loading...