Page 1

FEATURES

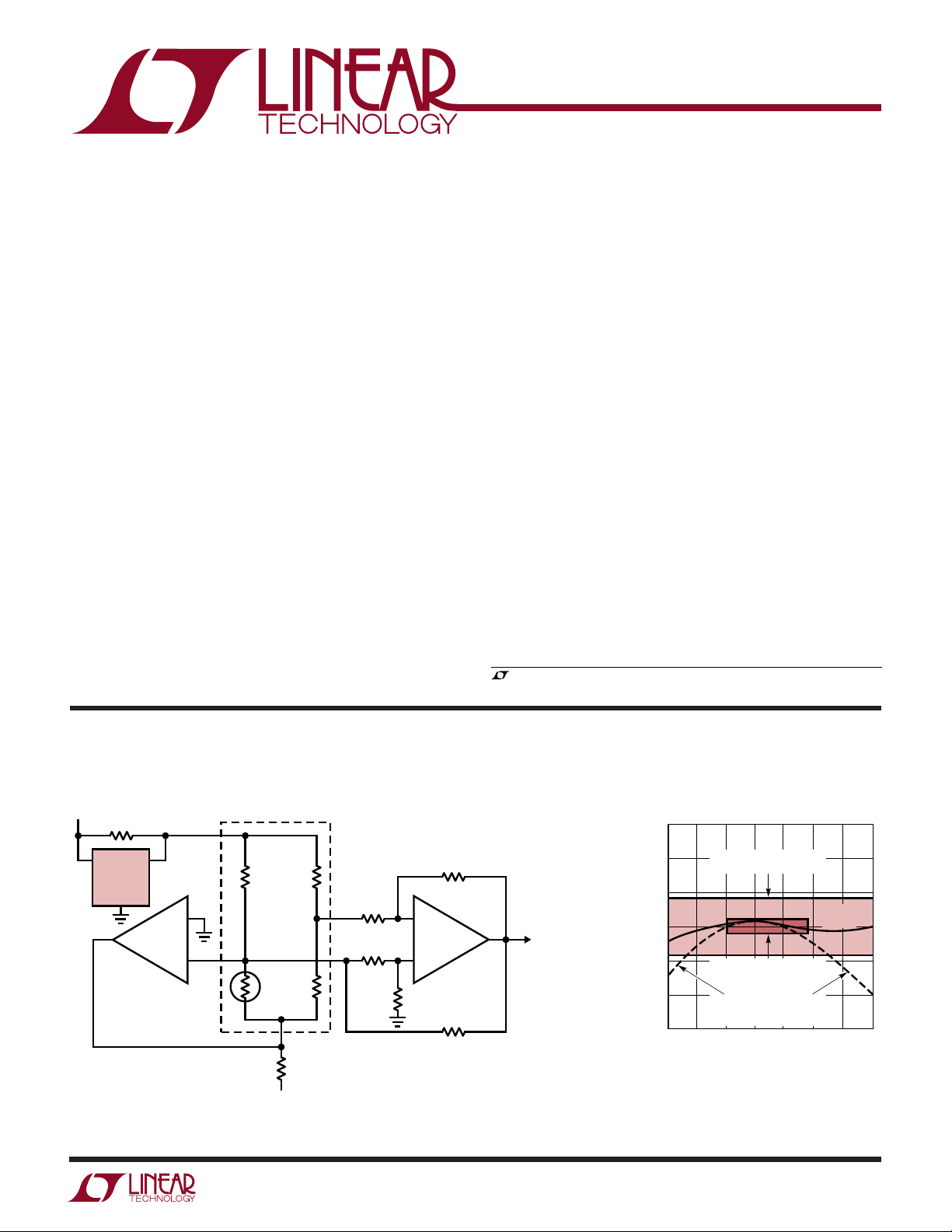

TEMPERATURE (˚C)

–50

OUTPUT VOLTAGE (NORMALIZED) (V)

1.001

1.002

1.003

25 75

1019 TA02

1.000

0.999

–25 0

50 100 125

0.998

0.997

5ppm/°C

0°C TO 70°C “BOX”

LT1019

CURVE

UNCOMPENSATED

“STANDARD” BANDGAP

DRIFT CURVE

10ppm/°C

FULL TEMP RANGE “BOX”

LT1019

Precision Reference

U

DESCRIPTIO

■

Tight Initial Output Voltage: <0.05%

■

Ultralow Drift: 3ppm/°C Typical

■

Series or Shunt Operation

■

Curvature Corrected

■

Ultrahigh Line Rejection: ≈0.5ppm/V

■

Low Output Impedance: ≈0.02Ω

■

Plug-In Replacement for Present References

■

Available at 2.5V, 4.5V, 5V, and 10V

■

100% Noise Tested

■

Temperature Output

■

Industrial Temperature Range in SO-8

U

APPLICATIO S

■

Negative Shunt References

■

A/D and D/A Converters

■

Precision Regulators

■

Constant Current Sources

■

V/F Converters

■

Bridge Excitation

The LT®1019 is a third generation bandgap voltage reference utilizing thin film technology and a greatly improved

curvature correction technique. Wafer level trimming of

both reference and output voltage combines to produce

units with high yields to very low TC and tight initial

tolerance of output voltage.

The LT1019 can both sink and source up to 10mA and can

be used in either the series or shunt mode. This allows the

reference to be used for both positive and negative output

voltages without external components. Minimum input/

output voltage is less than 1V in the series mode, providing

improved tolerance of low line conditions.

The LT1019 is available in four voltages: 2.5V, 4.5V, 5V

and 10V. It is a direct replacement for most bandgap

references presently available including AD580, AD581,

REF-01, REF-02, MC1400, MC1404 and LM168.

, LTC and LT are registered trademarks of Linear Technology Corporation.

TYPICAL APPLICATION

15V

357Ω*

0.5W

IN

LT1019-5

GND

5V

OUT

†

A1

LT1637

Ultralinear Strain Guage

350Ω

BRIDGE

+

–

ACTIVE

ELEMENT

–15V

–5V

357Ω*

0.5W

U

R3

2M

R2

20k

R4

20k

*

REDUCES REFERENCE AND AMPLIFIER

LOADING TO ≈0.

**

IF R6 = R3, BRIDGE IS NOT LOADED BY R2 AND R4.

†

A1 V

ACTS AS A DIFFERENTIAL AMPLIFIER.

–

A2

LT1001

+

R5

2M

R6**

2M

LT1019 • TA01

AND DRIFT ARE NOT CRITICAL BECAUSE A2

OS

Output Voltage Drift

GAIN = 100

1

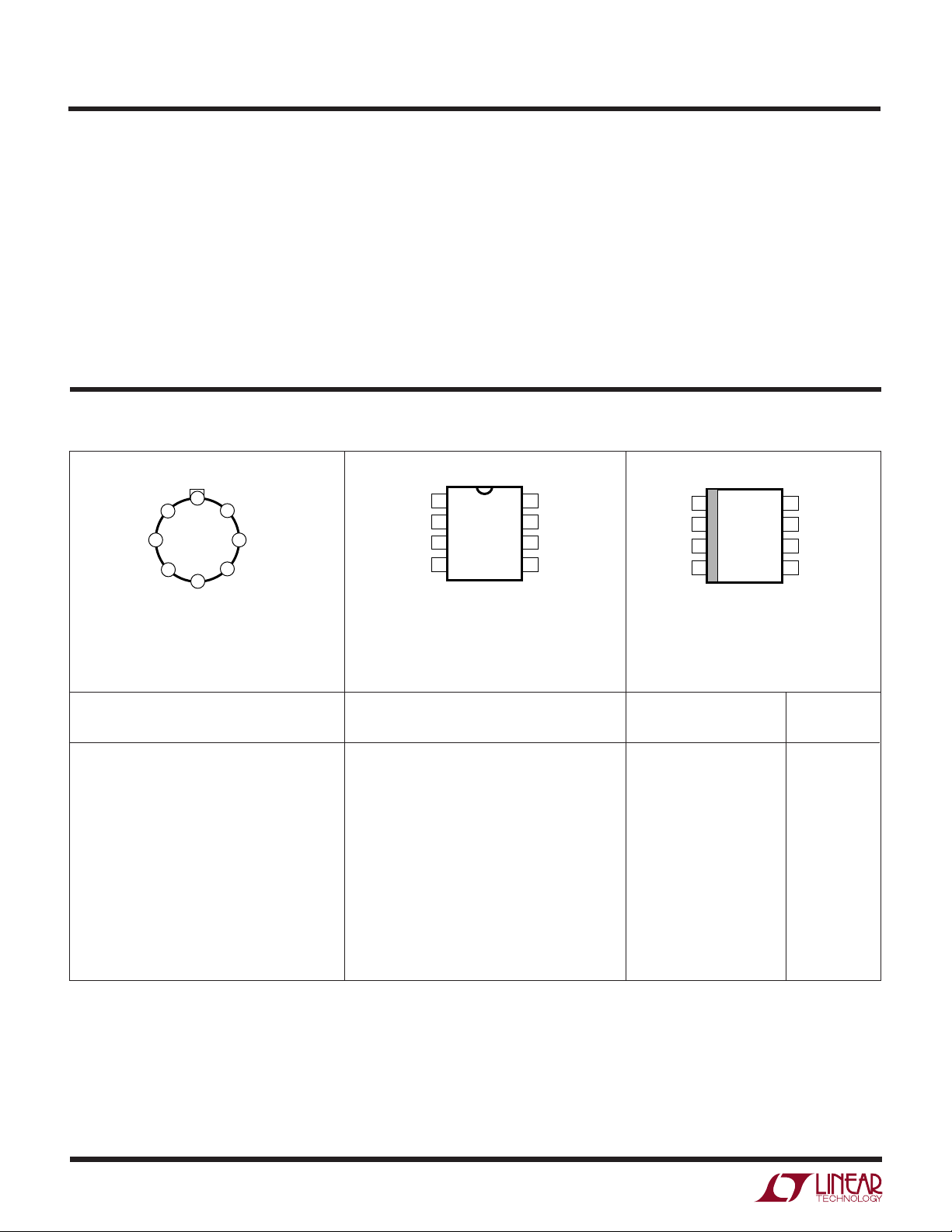

Page 2

LT1019

TOP VIEW

S8 PACKAGE

8-LEAD PLASTIC SO

1

2

3

4

8

7

6

5

DNC*

INPUT

TEMP

GND

DNC*

DNC*

OUTPUT

TRIM

*INTERNALLY CONNECTED. DO NOT

CONNECT EXTERNALLY.

A

W

O

LUTEXI TIS

S

A

WUW

U

ARB

G

(Note 1)

Input Voltage .......................................................... 40V

Output Voltage (Note 2)

LT1019-5, LT1019-10 ........................................ 16V

LT1019-2.5, LT1019-4.5 ...................................... 7V

Output Short-Circuit Duration (Note 2)

VIN < 20V.................................................... Indefinite

20V ≤ VIN ≤ 35V ............................................. 10 sec

WU

/

PACKAGE

DNC*

INPUT

TEMP

8-LEAD TO-5 METAL CAN

*INTERNALLY CONNECTED. DO NOT

CONNECT EXTERNALLY

T

= 150°C, θ

JMAX

O

RDER I FOR ATIO

TOP VIEW

DNC*

8

1

2

3

4

GND (CASE)

H PACKAGE

= 150°C/ W, θJC = 45°C/W

JA

DNC*

7

DNC*

6

OUTPUT

5

TRIM

1

INPUT

2

TEMP

3

GND

4

*INTERNALLY CONNECTED. DO NOT

CONNECT EXTERNALLY.

T

= 100°C, θ

JMAX

Specified Temperature Range

Commercial .............................................0°C to 70°C

Industrial ............................................ –40°C to 85°C

Military ............................................. –55°C to 125°C

Trim Pin Voltage................................................... ±30V

Temp Pin Voltage ..................................................... 5V

Storage Temperature Range (Note 11) –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

U

TOP VIEW

DNC*

8

DNC*

7

OUTPUT

6

TRIM

5

N8 PACKAGE

8-LEAD PDIP

T

= 130°C/ W

JA

JMAX

= 100°C, θ

= 130°C/ W

JA

LT1019ACH-2.5

LT1019ACH-4.5

LT1019ACH-5

LT1019ACH-10

LT1019AMH-2.5

LT1019AMH-4.5

LT1019AMH-5

LT1019AMH-10

ORDER PART

NUMBER

LT1019CH-2.5

LT1019CH-4.5

LT1019CH-5

LT1019CH-10

LT1019MH-2.5

LT1019MH-4.5

LT1019MH-5

LT1019MH-10

ORDER PART

NUMBER

LT1019ACN8-2.5

LT1019ACN8-4.5

LT1019ACN8-5

LT1019ACN8-10

LT1019CN8-2.5

LT1019CN8-4.5

LT1019CN8-5

LT1019CN8-10

LT1019IN8-2.5

LT1019IN8-4.5

LT1019IN8-5

LT1019IN8-10

ORDER PART

NUMBER

LT1019ACS8-2.5

LT1019ACS8-5

LT1019AIS8-2.5

LT1019AIS8-5

LT1019CS8-2.5

LT1019CS8-4.5

LT1019CS8-5

LT1019CS8-10

LT1019IS8-2.5

LT1019IS8-5

S8 PART

MARKING

19A25

19A05

19AI2

19AI5

1925

1945

1905

1910

19I25

19I05

2

Page 3

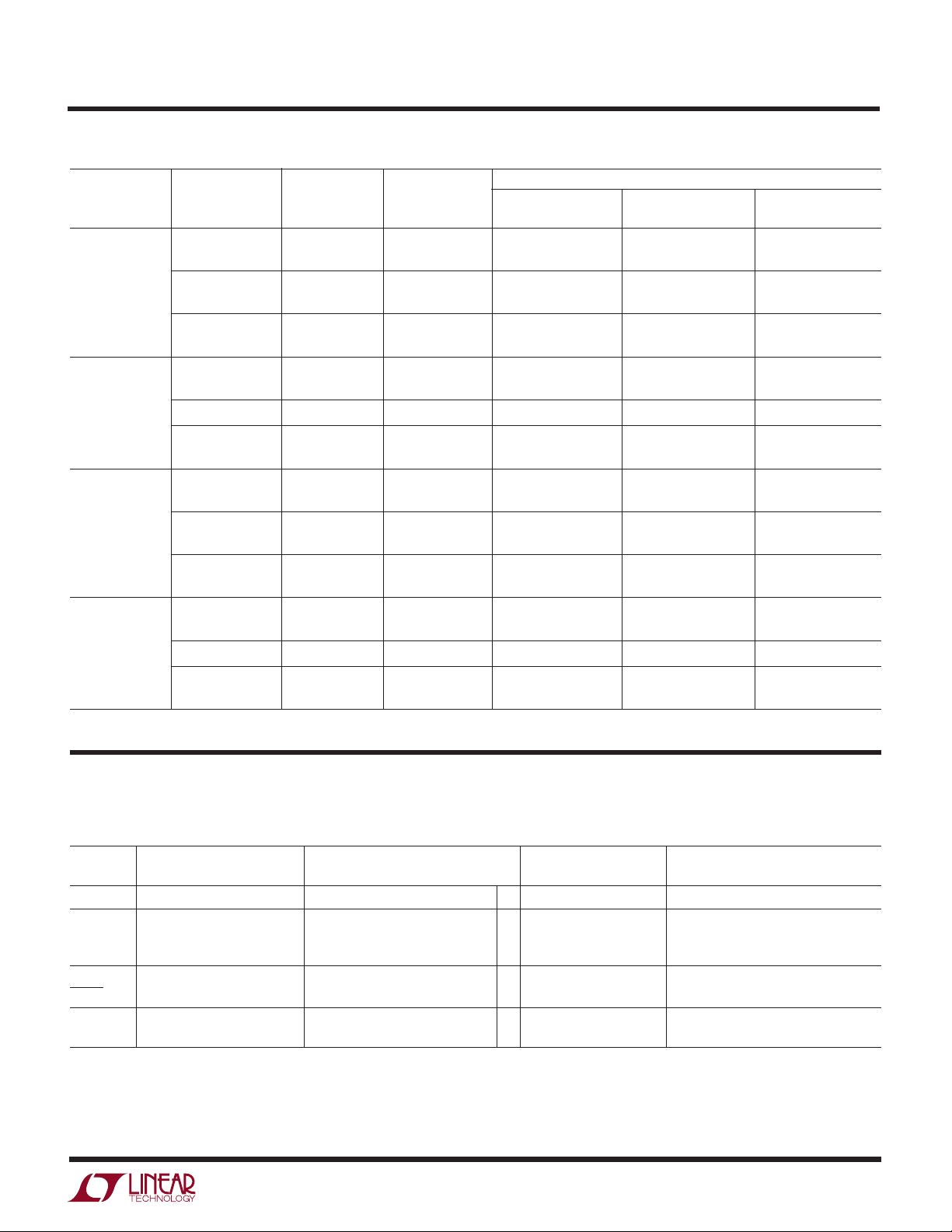

U

AVAILABLE OPTIO S

LT1019

OUTPUT TEMPERATURE

VOLTAGE TEMPERATURE ACCURACY COEFFICIENT TO-5 SO-8 PDIP-8

(V) (

2.5 0 to 70 0.05 5 LT1019ACH-2.5 LT1019ACS8-2.5 LT1019ACN8-2.5

4.5 0 to 70 0.05 5 LT1019ACH-4.5 LT1019ACN8-4.5

5 0 to 70 0.05 5 LT1019ACH-5 LT1019ACS8-5 LT1019ACN8-5

10 0 to 70 0.05 5 LT1019ACH-10 LT1019ACN8-10

°

C) (%) (ppm/°C) H8 S8 N8

0.2 20 LT1019CH-2.5 LT1019CS8-2.5 LT1019CN8-2.5

–40 to 85 0.05 10 LT1019AIS8-2.5

0.2 20 LT1019IS8-2.5 LT1019IN8-2.5

–55 to 125 0.05 10 LT1019AMH-2.5

0.2 25 LT1019MH-2.5

0.2 20 LT1019CH-4.5 LT1019CS8-4.5 LT1019CN8-4.5

–40 to 85 0.2 20 LT1019IN8-4.5

–55 to 125 0.05 10 LT1019AMH-4.5

0.2 25 LT1019MH-4.5

0.2 20 LT1019CH-5 LT1019CS8-5 LT1019CN8-5

–40 to 85 0.05 10 LT1019AIS8-5

0.2 20 LT1019IS8-5 LT1019IN8-5

–55 to 125 0.05 10 LT1019AMH-5

0.2 25 LT1019MH-5

0.2 20 LT1019CH-10 LT1019CS8-10 LT1019CN8-10

–40 to 85 0.2 20 LT1019IN8-10

–55 to 125 0.05 10 LT1019AMH-10

0.2 25 LT1019MH-10

PACKAGE TYPE

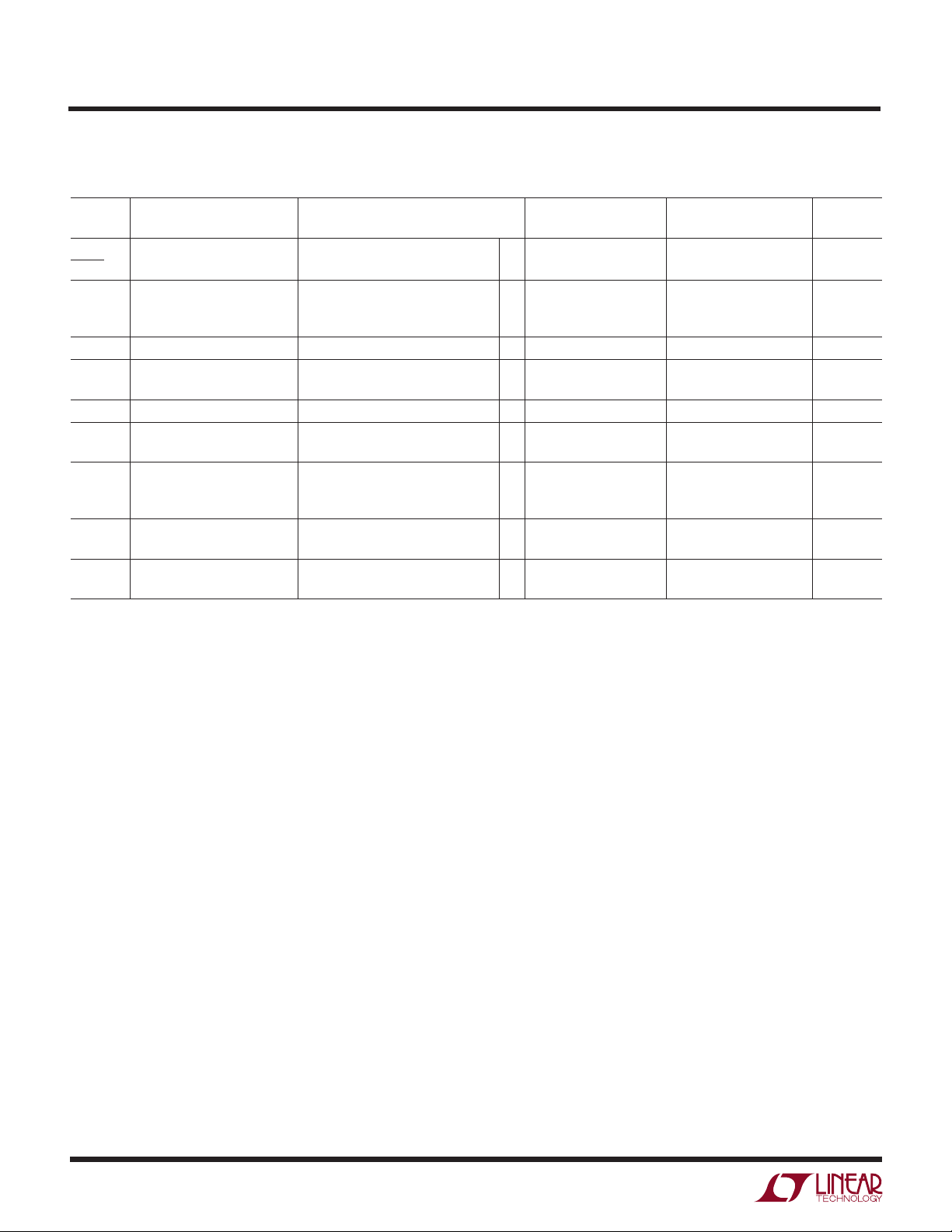

LECTRICAL C CHARA TERIST

E

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VIN = 15V, I

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

TC Output Voltage LT1019C (0°C to 70°C) ● 3 5 5 20 ppm/°C

∆V

OUT

∆V

IN

RR Ripple Rejection 50Hz ≤ f ≤ 400Hz 90 110 90 110 dB

= 0 unless otherwise noted.

OUT

Output Voltage Tolerance 0.02 0.05 0.02 0.2 %

Temperature Coefficient LT1019I (–40°C to 85°C)

(Note 3) LT1019M (–55°C to 125°C)

Line Regulation (Note 4) (V

OUT

ICS

LT1019A LT1019

● 3 10 5 20 ppm/°C

● 5 10 8 25 ppm/°C

+ 1.5V) ≤ VIN ≤ 40V 0.5 3 0.5 3 ppm/V

● 1.0 5 1.0 5 ppm/V

● 84 84 dB

3

Page 4

LT1019

LECTRICAL C CHARA TERIST

E

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VIN = 15V, I

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

∆V

OUT

∆I

OUT

I

Q

I

SC

e

n

= 0 unless otherwise noted.

OUT

Load Regulation Series 0 ≤ I

Mode (Notes 4, 5) ● 0.08 0.08 mV/mA (Ω)

Load Regulation, 1mA ≤ I

Shunt Mode 2.5V, 4.5V, 5V

Thermal Regulation (Note 7) ∆P = 200mW, t = 50ms 0.1 0.5 0.1 0.5 ppm/mW

Quiescent Current 0.65 1.0 0.65 1.2 mA

Series Mode

Minimum Shunt Current (Note 8) ● 0.5 0.8 0.5 0.8 mA

Minimum Input/Output I

Voltage Differential I

Trim Range LT1019-2.5 ±3.5 ±6 ±3.5 ±6%

Short-Circuit Current 2V ≤ VIN ≤ 35V 15 25 50 15 25 50 mA

Output Connected to GND

Output Voltage Noise 10Hz ≤ f ≤ 1kHz 2.5 4 2.5 4 ppm (RMS)

(Note 10) 0.1Hz ≤ f ≤ 10Hz 2.5 2.5 ppm (P-P)

OUT

10V

≤ 1mA ● 0.9 1.1 0.9 1.1 V

OUT

= 10mA ● 1.3 1.3 V

OUT

LT1019-5 ±3.5 5, –13 ±3.5 5, –13 %

LT1019-10 ±3.5 5, –27 ±3.5 5, –27 %

ICS

LTC1019A LTC1019

≤ 10mA (Note 5) 0.02 0.05 0.02 0.05 mV/mA (Ω)

≤ 10mA (Notes 5, 6)

SHUNT

● 0.1 0.4 0.1 0.4 mV/mA (Ω)

● 0.8 0.8 mV/mA (Ω)

● 1.3 1.5 mA

● 10 10 mA

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: These are high power conditions and are therefore guaranteed

only at temperatures equal to or below 70°C. Input is either floating, tied to

output or held higher than output.

Note 3: Output voltage drift is measured using the box method. Output

voltage is recorded at T

readings is subtracted from the highest and the resultant difference is

divided by (T

Note 4: Line regulation and load regulation are measured on a pulse basis

with low duty cycle. Effects due to die heating must be taken into account

separately. See thermal regulation and application section.

Note 5: Load regulation is measured at a point 1/8" below the base of the

package with Kelvin contacts.

Note 6: Shunt regulation is measured with the input floating. This

parameter is also guaranteed with the input connected (V

0mA ≤ I

– T

MAX

≤ 10mA. Shunt and sink current flow into the output.

SINK

MIN

MIN

).

, 25°C and T

. The lowest of these three

MAX

– V

IN

OUT

) > 1V,

Note 7: Thermal regulation is caused by die temperature gradients created

by load current or input voltage changes. This effect must be added to

normal line or load regulation.

Note 8: Minimum shunt current is measured with shunt voltage held

20mV below the value measured at 1mA shunt current.

Note 9: Minimum input/output voltage is measured by holding input

voltage 0.5V above the nominal output voltage, while measuring

– V

OUT

.

V

IN

Note 10: RMS noise is measured with a single pole highpass filter at 10Hz

and a 2-pole lowpass filter at 1kHz. The resulting output is full-wave

rectified and then integrated for a fixed period, making the final reading an

average as opposed to RMS. A correction factor of 1.1 is used to convert

from average to RMS, and a second correction of 0.88 is used to correct

the nonideal bandpass of the filters.

Note 11: If the part is stored outside of the specified temperature range,

the output may shift due to hysteresis.

4

Page 5

LPER

INPUT VOLTAGE (V)

0

CURRENT (mA)

0.8

1.0

1.2

40

LT1019 • TPC03

0.6

0.4

0

10

20

30

0.2

1.6

1.4

35

5

15

25

45

125°C

25°C

–55°C

F

O

Quiescent Current (LT1019-2.5)

1.6

1.4

1.2

1.0

0.8

0.6

CURRENT (mA)

0.4

0.2

0

0

5

10

15

20

25

INPUT VOLTAGE (V)

Minimum Input/Output Voltage

Differential

10

7.5

5.0

OUTPUT CURRENT (mA)

2.5

0

0.2 0.6

0.4

0

INPUT/OUTPUT VOLTAGE (V)

TJ = –55°CTJ = 125°C

1.0 1.8

1.2

0.8

R

125°C

25°C

–55°C

35

30

LT1019 • TPC01

TJ = 25°C

1.4

LT1019 • TPC04

ATYPICA

40

1.6

UW

CCHARA TERIST

E

C

Quiescent Current

(LT1019-4.5/LT1019-5)

1.6

1.4

1.2

1.0

0.8

0.6

CURRENT (mA)

0.4

0.2

45

0

0

5

Load Regulation

2.0

TJ = 25°C

1.5

1.0

0.5

LT1019-2.5

0

–0.5

OUTPUT CHANGE (mV)

–1.0

–1.5

–2.0

–8

–10

ICS

125°C

25°C

–55°C

15

20

10

INPUT VOLTAGE (V)

LT1019-10

LT1019-4.5/LT1019-5

–6

SINKING SOURCING

OUTPUT CURENT (mA)

–4

–2

0

35

25

30

LT1019 • TPC02

2

6

4

LT1019 • TPC05

LT1019

Quiescent Current (LT1019-10)

45

40

Ripple Rejection

120

110

100

90

80

70

60

50

INPUT VOLTAGE/OUTPUT VOLTAGE (dB)

10

8

40

10 1k 10k 1M

LT1019-2.5

100

LT1019-10

FREQUENCY (Hz)

TJ = 25°C

LT1019-4.5

LT1019-5

100k

LT1019 • TPC06

Shunt Mode Characteristics

(LT1019-2.5)

1.0

INPUT OPEN

0.9

0.8

0.7

0.6

0.5

0.4

CURRENT (mA)

0.3

TJ = 125°C

0.2

0.1

0

0

0.5 1.5

1.0

OUTPUT-TO-GROUND VOLTAGE (V)

TJ = 25°C

TJ = –55°C

2.0

2.5

3.0

3.5

LT1019 • TPC07

4.0

Shunt Mode Characteristics

(LT1019-5)

1.0

INPUT OPEN

0.9

0.8

0.7

0.6

0.5

0.4

CURRENT (mA)

0.3

TJ = 125°C

0.2

0.1

0

0

TJ = 25°C

TJ = –55°C

13

2

OUTPUT-TO-GROUND VOLTAGE (V)

4

Shunt Mode Characteristics

(LT1019-10)

1.0

INPUT OPEN

0.9

0.8

0.7

0.6

0.5

0.4

CURRENT (mA)

TJ = 125°C

0.3

0.2

0.1

7

6

5

8

LT1019 • TPC08

0

TJ = 25°C

TJ = –55°C

0

26

4

OUTPUT-TO-GROUND VOLTAGE (V)

8

14

12

10

16

LT1019 • TPC09

5

Page 6

LT1019

Temp Pin Voltage

0.90

0.85

0.80

0.75

0.70

0.65

0.60

VOLTAGE (V)

0.55

0.50

0.45

0.40

–50

–25

LPER

25

0

JUNCTION TEMPERATURE (°C)

R

F

O

50

75

ATYPICA

100

LT1019 • TPC10

UW

E

C

125

CCHARA TERIST

Line Regulation

140

I

OUT

120

TJ = 25°C

100

80

60

40

20

LT1019-2.5

0

–10

OUTPUT VOLTAGE CHANGE (µV)

–20

–30

0

515

10

20

INPUT VOLTAGE (V)

ICS

LT1019-10

LT1019-5

30

25

35

LT1019 • TPC11

LT1019-2.5* Stability with

Output Capacitance

10

1

REGION OF POSSIBLE

0.1

0.01

OUTPUT CAPACITOR (µF)

0.001

40

0.0001

20 0 10

*LT1019-4.5/LT1019-5/LT1019-10 ARE STABLE

10

15 5 5 15

SINK CURRENT SOURCE CURRENT

OUTPUT CURRENT (mA)

WITH ALL LOAD CAPACITANCE.

INSTABILITY

20

1019 G12

W

BLOCK DIAGRA

LT1019-2.5 = 11k

LT1019-4.5 = 13.9k

LT1019-5 = 16k

LT1019-10 = 37.1k

R3

80k

TRIM

LT1019-4.5, LT1019-5,

LT1019-10 = 5k

LT1019-2.5 = 10k

R2

1.188V

UU W U

APPLICATIO S I FOR ATIO

Line and Load Regulation

Line regulation on the LT1019 is nearly perfect. A 10V

change in input voltage causes a typical output shift of less

than 5ppm. Load regulation (sourcing current) is nearly as

good. A 5mA change in load current shifts output voltage

by only 100µV. These are

low duty cycle pulses to eliminate heating effects. In real

world applications, the

changes must be considered.

electrical

thermal

effects, measured with

effects of load and line

R1

V

IN

–

V

+

OUT

GND

LT1019 • BD

Two separate thermal effects are evident in monolithic

circuits. One is a gradient effect, where power dissipation

on the die creates temperature gradients. These gradients

can cause output voltage shifts

ture coefficient of the reference is zero

even if the overall tempera-

. The LT1019, unlike

previous references, specifies thermal regulation caused

by die temperature gradients.The specification is

0.5ppm/mW. To calculate the effect on output voltage,

simply multiply the

change

in device power dissipation by

6

Page 7

UU W U

APPLICATIO S I FOR ATIO

LT1019

the thermal regulation specification. Example: a 10V

device with a nominal input voltage of 15V and load

current of 5mA. Find the effect of an input voltage change

of 1V and a load current change of 2mA.

∆P (line change) = (∆VIN)(I

∆V

∆P (load change)= (∆I

∆V

Even though these effects are small, they should be taken

into account in critical applications, especially where input

voltage or load current is high.

The second thermal effect is overall die temperature

change. The magnitude of this change is the product of

change in power dissipation times the thermal resistance

(θJA) of the IC package ≅ (100°C/ W to 150°C/ W). The

effect on the reference output is calculated by multiplying

die temperature change by the temperature drift specification of the reference. Example: same conditions as above

with θJA = 150°C/W and an LT1019 with 20ppm/°C drift

specification.

∆P (line change) = 5mW

∆V

∆P (load change)= 10mW

∆V

These calculations show that thermally induced output

voltage variations can easily exceed the electrical effects.

In critical applications where shifts in power dissipation

are expected, a small clip-on heat sink can significantly

improve these effects by reducing overall die temperature

change. Alternately, an LT1019A can be used with four

times lower TC. If warm-up drift is of concern, these

measures will also help. With warm-up drift,

power dissipation must be considered. In the example

given, warm-up drift (worst case) is equal to:

= (0.5ppm/mW)(5mW) = 2.5ppm

OUT

LOAD

= (2mA)(5V) = 10mW

= (0.5ppm/mW)(10mW) = 5ppm

OUT

= (5mW)(150°C/W)(20ppm/°C)

OUT

= 15ppm

= (10mW)(150°C/W)(20ppm/°C)

OUT

= 30ppm

) = (1V)(5mA) = 5mW

LOAD

)(VIN – V

OUT

)

total

device

Warm-up drift = [(VIN)(IQ) + (VIN – V

[(θJA)(TC)]

with IQ (quiescent current) = 0.6mA,

Warm-up drift = [(15V)(0.6mA) + (5V)(5mA)]

[(150°C/W)(25ppm/°C)]

= 127.5ppm

Note that 74% of the warm-up drift is due to load current

times input/output differential. This emphasizes the

importance of keeping both these numbers low in critical

applications.

Note that line regulation is now affected by reference

output impedance. R1 should have a wattage rating high

enough to withstand full input voltage if output shorts

must be tolerated. Even with load currents below 10mA,

R1 can be used to reduce power dissipation in the LT1019

for lower warm-up drift, etc.

Output Trimming

Output voltage trimming on the LT1019 is nominally

accomplished with a potentiometer connected from output to ground with the wiper tied to the trim pin. The

LT1019 was made compatible with existing references, so

the trim range is large: + 6%, –6% for the LT1019-2.5,

+5%, –13% for the LT1019-5, and +5%, –27% for the

LT1019-10. This large trim range makes precision trimming rather difficult. One solution is to insert resistors in

series with both ends of the potentiometer. This has the

disadvantage of potentially poor tracking between the

fixed resistors and the potentiometer. A second method of

reducing trim range is to insert a resistor in series with the

wiper of the potentiometer. This works well only for very

small trim range because of the mismatch in TCs between

the series resistor and the internal thin film resistors.

These film resistors can have a TC as high as 500ppm/°C.

That same TC is then transferred to the change in output

voltage: a 1% shift in output voltage causes a

(500ppm)(1%) = 5ppm/°C change in output voltage drift.

OUT

)(I

LOAD

)]

7

Page 8

LT1019

UU W U

APPLICATIO S I FOR ATIO

The worst-case error in initial output voltage for the

LT1019 is 0.2%, so a series resistor is satisfactory if the

output is simply trimmed to nominal value. The maximum

TC shift expected would be 1ppm/°C.

Using the Temp Pin

The LT1019 has a TEMP pin like several other bandgap

references. The voltage on this pin is directly proportional to absolute temperature (PTAT) with a slope of

approximately 2.1mV/°C. Room temperature voltage is

therefore approximately (295°K)(2.1mV/°C) = 620mV.

This voltage varies with process parameters and should

not be used to measure absolute temperature, but

rather relative temperature changes. Previous bandgap

references have been very sensitive to any loading on

the TEMP pin because it is an integral part of the

reference “core” itself. The LT1019 “taps” the core at a

special point which has much less effect on the reference. The relationship between TEMP pin loading and

a change in reference output voltage is less than

0.05%/µA, about ten times improvement over previous

references.

capacitance and load. The 2.5V device can oscillate when

sinking currents between 1mA and 6mA for load capacitance between 400pF and 2µF (see Figure 1).

If output bypassing is desired to reduce high frequency

output impedance, keep in mind that loop phase margin is

significantly reduced for output capacitors between 500pF

and 1µF if the capacitor has low ESR (Effective Series

Resistance). This can make the output “ring” with tran-

V

IN

LT1019

2Ω TO 5Ω

+

2µF

TANTALUM

(a) (b)

Figure 1. Output Bypassing

V

IN

LT1019

2Ω TO 5Ω

+

2µF TO 10µF

TANTALUM

1019 F01

sient loads. The best transient load response is obtained

by deliberately adding a resistor to increase ESR as shown

in Figure 1.

Output Bypassing

The LT1019 is designed to be stable with a wide range of

load currents and output capacitors. The 4.5V, 5V, and

10V devices do not oscillate under any combination of

U

TYPICAL APPLICATIO S

Wide Range Trim ≥ ±5%

R1

25k

V

OUT

1019 TA03

OUT

IN

V

IN

LT1019

TRIM

GND

Use configuration (a) if DC voltage error cannot be compromised as load current changes. Use (b) if absolute

minimum peak perturbation at the load is needed. For best

transient response, the output can be loaded with ≥1mA

DC current.

Narrow Trim Range (±0.2%)

R1

100k

1019 TA05

V

OUT

OUT

V

IN

IN

LT1019

TRIM

GND

*INCREASE TO 4.7M FOR LT1019A (±0.05%)

R2*

1.5M

8

Page 9

U

TYPICAL APPLICATIO S

LT1019

Trimming LT1019-5 Output to 5.120V

OUT

IN

V

IN

LT1019-5

TRIM

GND

*LOW TC CERMET

Precision 1µA Current Source

15V

11.5k

1%

5k*

8.25k

1%

OUT

IN

LT1019-2.5

TRIM

GND

V

OUT

41.2k

1%

5k*

±1% TRIM

4.02k

1%

1019 TA04

Trimming LT1019-10 Output to 10.240V

V

OUT

V

IN

OUT

IN

LT1019-10

TRIM

GND

*LOW TC CERMET

90.9k

1%

5k*

±1% TRIM

4.02k

1%

1019 TA06

Negative Series Reference

+

V

LT1019

R1*

IN

OUT

D1*

R2*

GND

I

Z

OUT

= 1µA

OUT

≥ 1011Ω

2.49M

1%

–

LT1012

+

*LOW TC CERMET, TRIM RANGE = ±1.5%

Output Current Boost with Current Limit

V+ ≥ (V

OUT

+ 2.8V)

LED

V

OUT

±11V COMPLIANCE

1019 TA07

GLOWS IN

CURRENT LIMIT

(DO NOT OMIT)

IN

LT1019

GND

R1

220Ω

OUT

IN

V

*R1 =

8.2Ω

2N2905

≤ 100mA

I

LOAD

2µF SOLID TANTALUM

2N2905

+

– 5V

2mA

Q1

, R2 =

1019 TA08

AT 50mA–V

–V

REF

–

– V

V

REF

1mA

, D1 = V

REF

+ 5V

1019 TA10

9

Page 10

LT1019

WW

SCHE ATIC DIAGRA

IN

V

R21

20Ω

R32

Q32

Q31

Q33

R20

500Ω

750Ω

R23

Q27

100Ω

Q28

Q29

Q26

Q20

Q30

R33

R24

Q25

850Ω

OUT

V

1k

R17

R34

R27

R28

R26

R13

GND

24.5k

R19

15Ω

R31

22k

Q34

Q35

R16

3k

500Ω

4k

R15

3k

9k

9k

3k

Q23

Q19

Q18

Q6B

Q5 Q6A

Q24

Q21

C4

R35

C3

27k

Q16

Q15

Q17

Q14

Q22

Q13

Q11 Q12

2k

R18

Q10

1k

Q9

Q8

R12

R42

7.2k

4k

10

R25

Q7

Q37

R39

Q36

R36

82k

Q38

2.5

R5

R4

R14

R2

72k

R6

R29

Q2

780Ω

Q1

80k

TRIM

1k

R1

Q4

SHORT

FOR

Q3

R9

3k

1.6k

R8

2.5k

R7

R11A

R38

1.9k

3.75k

R11B

R37

5k

R3

1k

2k

Page 11

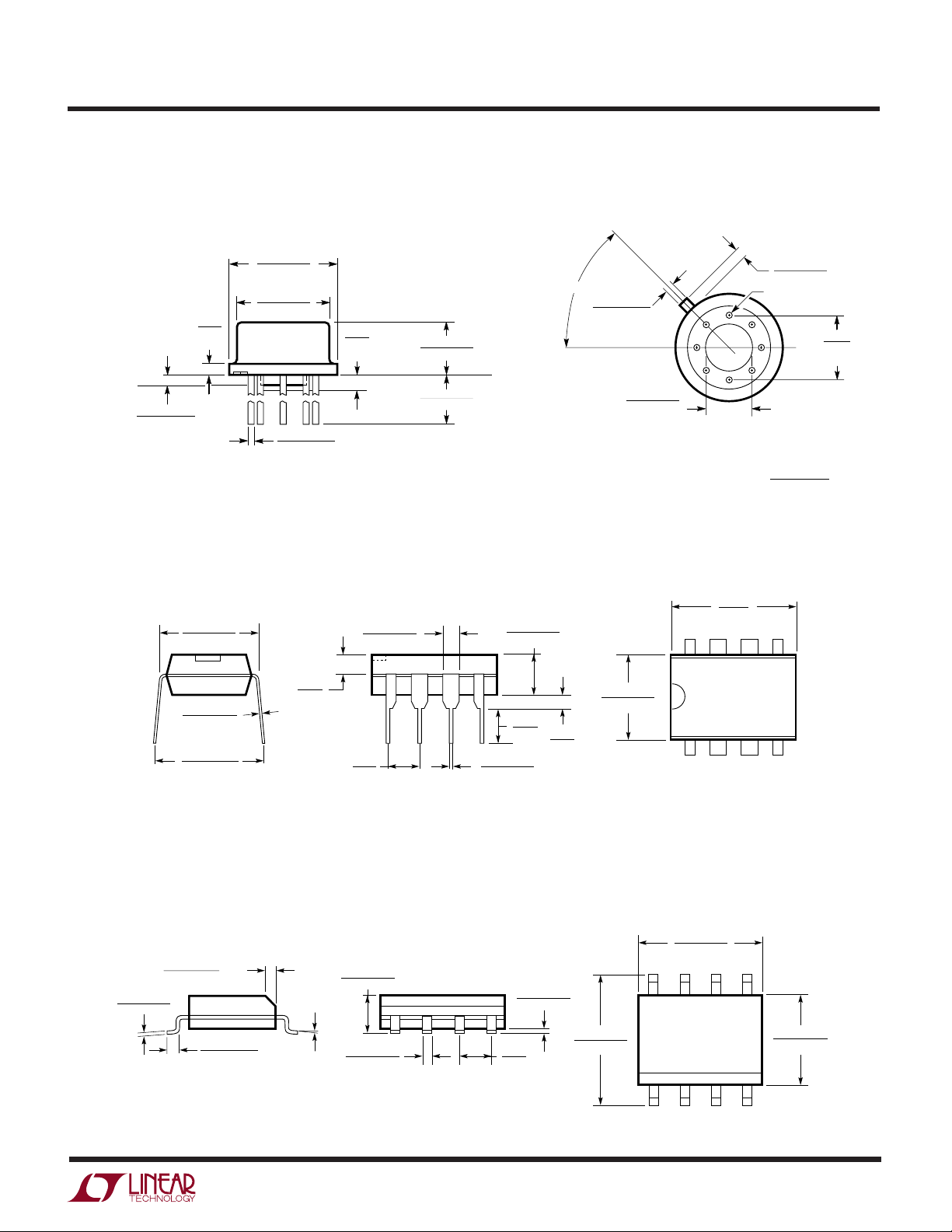

PACKAGE DESCRIPTIO

LT1019

U

Dimensions in inches (millimeters) unless otherwise noted.

H Package

8-Lead TO-5 Metal Can (0.200 PCD)

(LTC DWG # 05-08-1320)

SEATING

PLANE

0.335 – 0.370

(8.509 – 9.398)

DIA

0.305 – 0.335

(7.747 – 8.509)

0.016 – 0.021**

(0.406 – 0.533)

0.050

(1.270)

MAX

GAUGE

PLANE

(12.700 – 19.050)

0.010 – 0.045*

(0.254 – 1.143)

0.040

(1.016)

MAX

8-Lead PDIP (Narrow 0.300)

(LTC DWG # 05-08-1510)

0.300 – 0.325

(7.620 – 8.255)

0.065

(1.651)

0.009 – 0.015

(0.229 – 0.381)

+0.035

0.325

–0.015

+0.889

8.255

()

–0.381

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.010 INCH (0.254mm)

TYP

0.045 – 0.065

(1.143 – 1.651)

0.100

(2.54)

BSC

0.165 – 0.185

(4.191 – 4.699)

0.500 – 0.750

N8 Package

REFERENCE

PLANE

0.130 ± 0.005

(3.302 ± 0.127)

0.125

(3.175)

MIN

0.018 ± 0.003

(0.457 ± 0.076)

0.027 – 0.045

MAX

(0.686 – 1.143)

PIN 1

(0.406 – 0.610)

3

0.016 – 0.024

H8(TO-5) 0.200 PCD 1197

5

4

N8 1098

°TYP

45

0.028 – 0.034

(0.711 – 0.864)

0.110 – 0.160

(2.794 – 4.064)

INSULATING

STANDOFF

*

LEAD DIAMETER IS UNCONTROLLED BETWEEN THE REFERENCE PLANE

AND 0.045" BELOW THE REFERENCE PLANE

**

FOR SOLDER DIP LEAD FINISH, LEAD DIAMETER IS

0.400*

(10.160)

876

0.255 ± 0.015*

(6.477 ± 0.381)

0.020

(0.508)

MIN

12

0.200

(5.080)

TYP

8-Lead Plastic Small Outline (Narrow 0.150)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0.016 – 0.050

(0.406 – 1.270)

0.053 – 0.069

(1.346 – 1.752)

0°– 8° TYP

0.014 – 0.019

(0.355 – 0.483)

I

nformation furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

S8 Package

(LTC DWG # 05-08-1610)

TYP

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

0.228 – 0.244

(5.791 – 6.197)

0.189 – 0.197*

(4.801 – 5.004)

7

8

1

2

5

6

0.150 – 0.157**

(3.810 – 3.988)

3

4

SO8 1298

11

Page 12

LT1019

TYPICAL APPLICATION

U

Negative 10V Reference for CMOS DAC

OUT

LT1019-10

TRIM

GND

1.2k

–15V

59k

1%

5k*

5.76k

1%

*LOW TC CERMET, TRIM RANGE = ±1.5%

LTC1595

REF

FB

I

OUT

30pF

–

LT1007

+

V

1019 TA09

OUT

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1027 Precision 5V Reference Lowest TC, High Accuracy, Low Noise, Zener Based

LT1236 Precision Reference 5V and 10V Zener Based, 5ppm/°C, SO-8 Package

LT1460 Micropower Precision Series Reference Bandgap, 130µA Supply Current, 10ppm/°C, Available in SOT-23 Package

LT1634 Micropower Precision Shunt Reference Bandgap 0.05%, 10ppm/°C, 10µA Supply Current

LTC1798 Micropower Low Dropout Reference 0.15% Max, 6.5µA Supply Current

LT1461 Micropower Low Dropout Reference 3ppm/°C, 0.04%, 50µA Supply Current

1019fc LT/TP 1299 2K REV C • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1993

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

Loading...

Loading...