Page 1

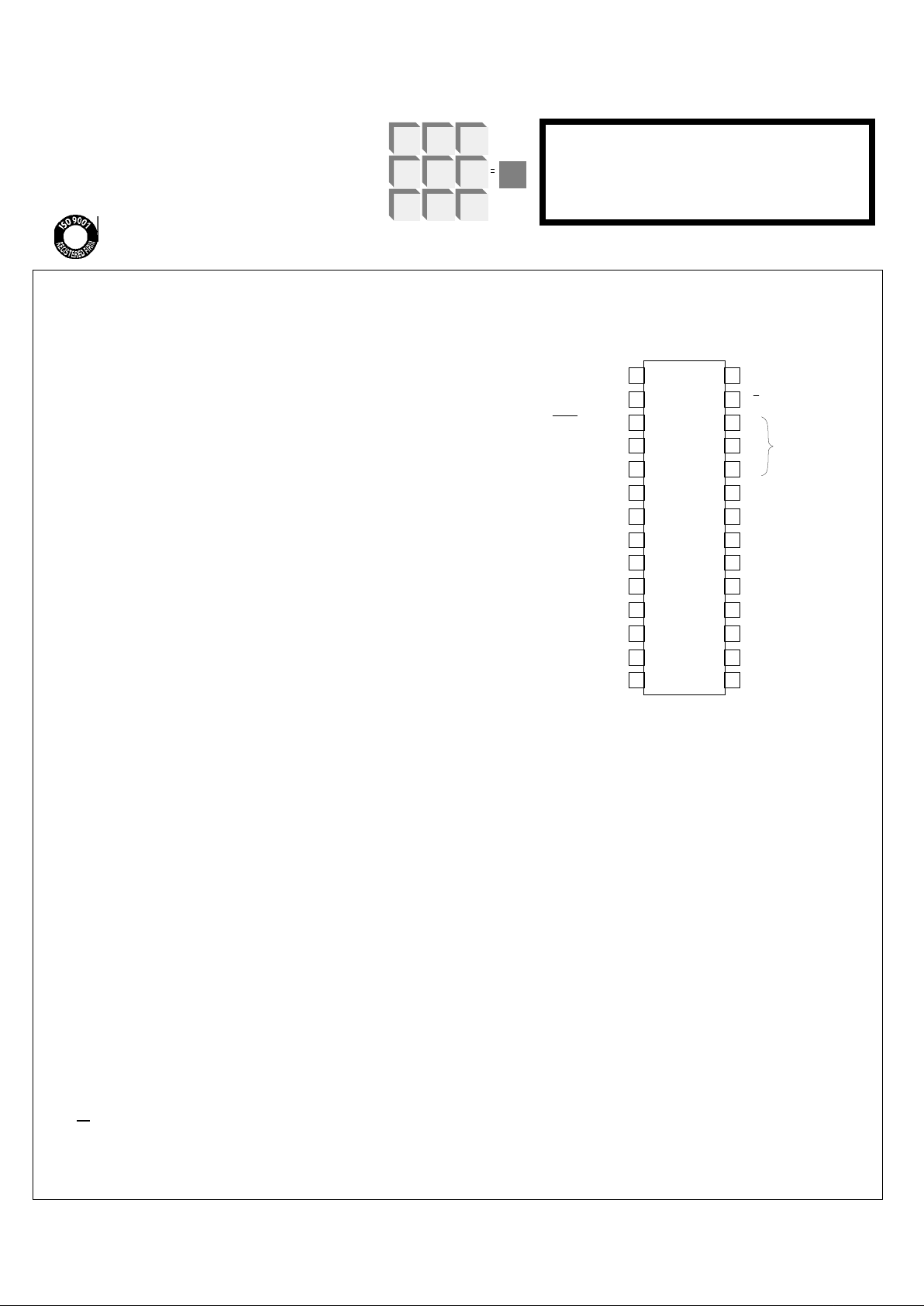

BRUSHLESS DC MOTOR CONTROLLER

GENERAL DESCRIPTION

The LS7560/LS7561 are CMOS integrated circuits designed to

control three or four phase brushless DC motors in a closed or

open loop configuration. The IC consists of a decoder which

provides proper commutation sequencing, a frequency-topulse width converter and error amplifier for closed loop motor

speed control, a PWM comparator and sawtooth oscillator for

external driver power control and a 5.5V reference generator

for supplying power to motor sensors. Also included is Fault

detection and indication, overcurrent sensing, dynamic motor

braking, forward/reverse input, sensor spacing selections and

an enable input control. The overcurrent sense condition will

disable all output drivers when using the LS7560 and only the

bottom drivers when using the LS7561.

The IC operates from 10V to 18V and provides CMOS compatible outputs for interfacing with external power devices.

Operating below 10V will activate a Fault Indication Output

and disable all Output Drivers.

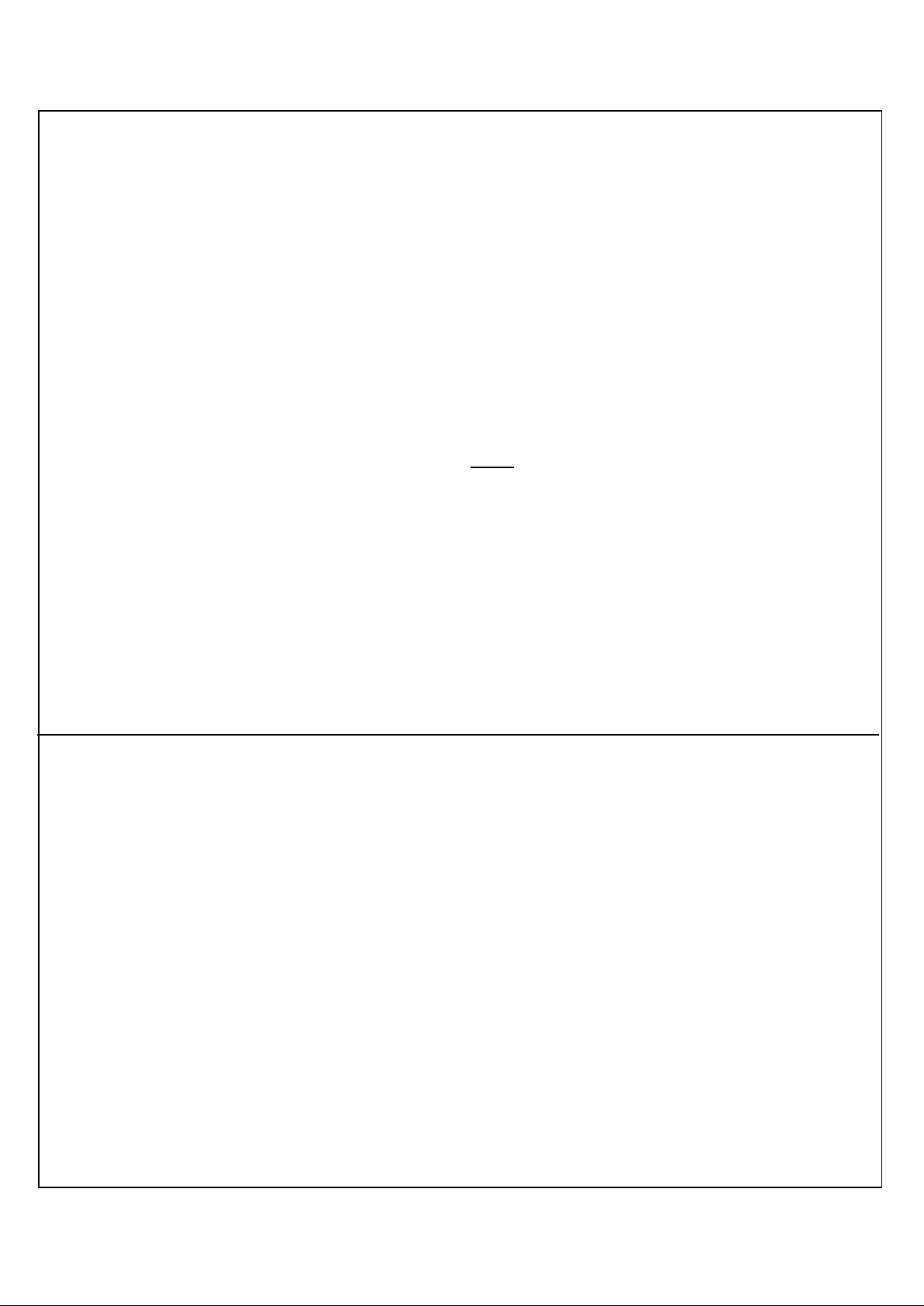

INPUT/OUTPUT DESCRIPTION: (See Figure 2)

SEQUENCE SELECT Input (Pin 1 )

A High on this input selects 60°/300° and a Low selects 120°/

240° electrical sensor separation. Use of a 300° or 240° motor

will cause opposite direction rotation as compared to a 60° or

120° motor.

F/R Input (Pin 27)

A High on this input selects Forward direction and a Low selects Reverse direction. The motor drive outputs are disabled

for 2 clock cycles at the onset of a direction change.

July 2002

7560-030599-1

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15

16

17

18

19

20

21

22

23

24

25

26

27

28

FIGURE 1. PIN CONNECTION DIAGRAM

LS7560

SEQUENCE SELECT

ENABLE

FAULT INDICATOR

RC

TACHOMETER OUT

ERROR AMP (+)

ERROR AMP (-)

OSCILLATOR

ERROR AMP OUT

CURRENT SENSE (+)

CURRENT SENSE (-)

OUT 6

OUT 5

OUT 4

OUT 3

OUT 2

OUT 1

VSS (-V)

VR

TOP DRIVER POLARITY SELECT

PWM CONTROL

BRAKE SELECT

BRAKE

S1

S2

S3

F/R

VDD (+V)

HALL

SENSORS

TOP VIEW

S1, S2, S3 Inputs (Pins 24, 25, 26)

Hall Sensor inputs which are decoded to determine the Motor

Commutation Sequence. An invalid input code disables all motor

outputs. Inputs have Schmitt Trigger buffers for noise immunity.

BRAKE Input (Pin 23)

With the BRAKE SELECT input Low, a High on the BRAKE input

forces the Top Drivers to an OFF condition and the Bottom Drivers

to a PWM ON condition. If the Motor is under Closed Loop control,

the Loop is automatically opened and the error amplifier output is

connected to the Error Amp (-) input. By controlling the voltage at

teh Error Amp (+) input, the PWM duty cycle is controlled during

braking. This manner of braking prevents the Bottom Motor Drivers

from drawing excessive current, a condition which can occur during

normal braking, when the Bottom Drivers are turned ON unconditionally. With the BRAKE SELECT input High, a High on the

BRAKE input unconditionally causes the Top Drivers to turn OFF

and the Bottom Drivers to turn ON. The BRAKE function has priority over all other functions.

BRAKE SELECT Input (Pin 22)

A Low on this input selects PWM control of braking and a High selects unconditional braking.

ENABLE Input (Pin 2)

When the ENABLE input is above VR/2, all Output Drivers are enabled and when it is below VR/2.2, all Output Drivers are disabled.

This input has a nominal hysteresis of .05VR, where VR is the internally generated Reference Voltage available on Pin 19. Because

the ENABLE input is level sensitive, it can easily be used to control

operation of the IC based on an Analog Fault Condition.

LSI/CSI

LSI Computer Systems, Inc. 1235 Walt Whitman Road, Melville, NY 11747 (631) 271-0400 FAX (631) 271-0405

U

L

®

A3800

FEATURES

• Open loop motor control

• Tachometer output for closed loop motor control

• Error Amplifier and PWM Speed Comparator with full accessibility

• High noise immunity Schmitt Triggers on Sensor inputs

• 5.5V Reference Supply for external sensors

• Cycle-by-cycle current sensing

• Static, or current limited dynamic, motor braking

• Output enable delay on speed direction reversal

• Enable input with fault sensing capability

• Fault Indicator output

• 60°/300° or 120°/240° electrical sensor spacing selection

• Selectable PWM of top and bottom drivers or bottom drivers only

• CMOS compatible motor outputs with drive capability

• Selectable top driver polarity

• Low power dissipation

• +10V to +18V operation (VDD-Vss)

• LS7560, LS7561 (DIP); LS7560-SD, LS7561-SD (Skinny DIP);

LS7560-S, LS7561-S (SOIC); LS7560-TS, LS7561-TS (TSSOP)

See Figure 1

LS7560

LS7561

Page 2

ERROR AMPLIFIER Inputs (Pins 6, 7 ) Output (Pin 8)

For closed loop control, the TACHOMETER Output is applied

through a resistor to the negative input of the Error Amplifier on

Pin 7. A speed control potentiometer is connected to the positive

input of the Error Amplifier on Pin 6. A parallel RC Network is connected between the Output of the Error Amplifier on Pin 8 and Pin

7. The Amplifier, configured this way, enables the variable pulse

width to be converted to a DC voltage which is used to control the

motor speed. The potentiometer is used to set the desired motor

speed. For open loop control, configure the Error Amplifier as a

voltage follower by connecting Pin 7 directly to Pin 8 and do not

connect the TACHOMETER Output signal to the Error Amplifier.

TOP DRIVER POLARITY SELECT Input (Pin 20)

A High on this input selects a High Polarity for the Top Output

Drivers Motor ON condition and a Low selects a Low Polarity.

OUTPUT DRIVERS (Pins 12, 13, 14, 15, 16, 17)

Each Driver Output provides a CMOS compatible signal for driving Buffers/Power Transistors. The Outputs are capable of sinking/sourcing 25mA with a 1.5V drop across the IC, at VDD = 12V.

FAULT INDICATOR Output (Pin 3)

Open drain output to provide sinking current for driving an external device such as an LED to indicate a malfunction condition.

The output occurs under any of the following conditions:

1) Overcurrent Sense condition

2) ENABLE Input below VR/2.2

3) Invalid Sensor code

4) Chip power supply less than 9V

5) VR Output less than 4.1V

VR Output (Pin 19)

5.5V Reference Voltage Output that can supply 20mA of current

at VDD =12V for powering input Sensors.

VDD (Pin 28)

VDD is Supply Voltage positive terminal.

OSCILLATOR (Pin 9)

An external RC network is connected to this input to set the frequency of the Sawtooth Schmitt Trigger Oscillator. The Sawtooth

is applied to the PWM Comparator along with the output of the Error Amplifier. The output of the PWM Comparator is a Pulse

Width Modulated Signal which is used to vary the effective drive

to the motor and, hence, the motor speed.

OVERCURRENT SENSE (Pins 10, 11)

The input to Pin 10 comes from the high side of a fractional ohm

current sensing resistor. The voltage at this input is compared to

an internal 100mV Reference. When the voltage exceeds the

100mV Reference, an Overcurrent Condition exists and the Output Drivers are switched OFF until the end of the sawtooth oscillator ramp-up. When the sawtooth switches low, the Overcurrent Condition is sampled, and if it no longer exists, the Output

Drivers are switched ON again. Otherwise, the Output Drivers remain OFF until the end of the next sawtooth. The input to Pin 11

comes from the low side (Gnd) of the current sensing resistor and

connects to the low side of the internal 100mV Reference.

PWM CONTROL Input (Pin 21)

A High on this input causes only the Bottom Drivers to be Pulse

Width Modulated. A Low on this input causes both Top and Bottom Drivers to have PWM.

TACHOMETER Output (Pin 5)

The output of the Frequency To Pulse Width Converter is tied to

this pin. The Converter uses the three SENSOR Inputs and external RC Network to generate a variable frequency output with a

fixed positive pulse width.

RC Input (Pin 4)

The external RC network connected to this input programs the

positive pulse width of the Frequency to Pulse Width Converter.

VSS (Pin 18)

VSS is Supply Voltage negative terminal.

7560-040198-2

MAXIMUM RATINGS (Voltages referenced to Vss)

SYMBOL VALUE UNIT

Power Supply Voltage VDD 20 V

Voltage at any input VIN Vss - 0.3 to VR V

Operating Temperature TA -25 to +85 °C

Storage Temperature TSTG -65 to +150 °C

Output Drive Sink/Source Current Io 75 mA

VR Output Source Current IR 30 mA

ELECTRICAL CHARACTERISTICS

VDD = 12V, RT = 47kΩ, CT = 0.001µF, RS = 10kΩ, CS= 0.01µF (See Figure 3) TA = 25°C, unless otherwise specified

PARAMETER SYMBOL MIN TYP MAX UNIT

Reference Voltage VR 4.75 5.5 6.25 V

Line Regulation ∆VR - 100 200 mV

VDD = 10V to 18V, IREF =1.0mA

Temperature Stability

TA = 0°C to 70°C ∆VR - +/- 1.0 - %

TA = 0°C to 85°C ∆VR - +/- 1.3 - %

Error Amplifier:

Input Offset Voltage VIO - 5 15 mV

Input Current IIN - 0 10 nA

Input Common Mode Voltage Range VICR (0 to VR) V

Open Loop Voltage Gain (RL=15KΩ) AVOL 70 80 - dB

Common Mode Rejection Ratio CMRR 60 - - dB

Power Supply Rejection Ratio PSRR 60 - - dB

Page 3

PARAMETER SYMBOL MIN TYP MAX UNIT

Output High State (RL=15kΩ to Ground) VOH VR - - V

Output Low State (RL = 15kΩ to VR) VOL - - 1.0 V

Output Source or Sink Current Io - - 1.0 mA

Oscillator:

Oscillator Frequency FOSC 21 24 27 kHz

Percentage Frequency Change per Volt ∆F OSC ∆V - 0.4 1.0 %/V

(VDD = 10V to 18V) F

Sawtooth High Voltage VOSCP - 3.8 4.5 V

Sawtooth Low Voltage VOSCV 0.7 1.0 - V

Capacitor Discharge Current ID 0.6 1.0 2.5 mA

Logic Inputs:

Input Threshold Voltage VIH 3.0 2.3 - V

(Pins 1, 20, 21, 22, 23, 24, 25, 26, 27) VIL - 1.8 1.4 V

Brake and Sensor (Pins 23, 24, 25, 26)

High State Input Current (VIN = 4V) IIH -36 -27 -20 µA

Low State Input Current (VIL = 0V) IIL -50 -40 -30 µA

Sequence Select, Top Driver Polarity

Select, PWM Control, Brake Select,

and F/R Select (Pins 1, 20, 21, 22, 27)

High State Input Current (VIN = 4V) IIH -16 -12 -8 µA

Low State Input Current (VIL = 0V) IIL -25 -17 -10 µA

ENABLE Input Threshold Voltage (Pin 2) VIH 2.1 2.8 3.2 V

Hysteresis VH 0.2 0.3 0.4 V

ENABLE Input Current IIN - - 10 nA

Overcurrent Sense Comparator:

Input Threshold Voltage VIH 85 100 115 mV

Input Current IIN - - 10 nA

Outputs:

Closed Loop Control Section:

Tachometer Out

Output High Voltage (Isource = 1.5mA) VOH VR - 0.8 VR - 0.5 VR-.3 V

Output Low Voltage (ISINK = 5mA) VOL 0.18 0.27 0.40 V

Pulse Width TW 95 105 115 µs

Capacitor Discharge Current (RC Terminal) ID 1.8 3 7.5 mA

Output Drivers (Pins 12, 13, 14, 15, 16, 17)

Sourcing 25mA VOH 9.5 10.5 11 V

Sourcing 50mA VOH 8 8.8 9.5 V

Sinking 25mA VOL 1.0 1.30 2.0 V

Sinking 50mA VOL 2.75 3.40 4.2 V

Switching Times TR 30 45 60 ns

(CL = 250pF) TF 35 50 65 ns

Switching Times TR 100 150 200 ns

(CL = 1000pF) TF 130 180 230 ns

FAULT Output Voltage (ISINK = 16mA) VFO 47 - - kΩ

FAULT Off-State Leakage IF - 10 - nA

Under Voltage Lockout:

For VDD VUV 7.0 8.5 10 V

Hysteresis VH 0.45 0.65 0.85 V

For VR VUVR 3.5 4.1 4.8 V

Hysteresis VH 0.16 0.3 0.4 V

Power Supply Current

VDD = 10V IDD - 2.0 2.5 mA

VDD = 12V IDD - 3.0 4.0 mA

VDD = 18V IDD - 7.0 11.0 mA

7560-040298-3

Page 4

S

Q

S

R

Q

OSC.

SENSOR

Inputs

F/R

ENABLE

In

RC In

TACHOMETER

Out

VR

_

ERROR

AMP

_

PWM

GEN.

VR/2

FREQUENCY

TO

PULSE WIDTH

CONVERTER

DECODER

SEQUENCE

SELECT In

REFERENCE

GENERATOR

EDGE TRIGGERED

DELAY

FAULT INDICATOR Out

PWM CONTROL

In

BRAKE In

O1

O2

O3

O6

O5

O4

TOP DRIVER

POLARITY SELECT In

TOP

DRIVER

Outputs

BOTTOM

DRIVER

Outputs

+

_

+

+

+

_

BRAKE SELECT

FIGURE 2. LS7560/LS7561 MOTOR CONTROLLER BLOCK DIAGRAM

OVERCURRENT

SENSE In

17

16

15

14

13

12

22

23

8

6

7

5

4

2

27

VR

26

24

19

25

10

11

9

NC FOR LS7560

VDD FOR LS7561

20

21

3

1

7560/61-030599-4

R

VDD

VSS

28

18

INTERNAL BOND PAD

+

100mV

-

VR VR

VR

VR

VR

VR

VR

LOW VDD

DETECT

VDD

SWITCH

VDD

SWITCH

VDD

VR

CONTROL

CONTROL

VDD

VDD

VDD

VDD

VDD

VDD

LOW VR DETECT

ERROR AMP (-)

ERROR AMP (+)

ERROR AMP Out

OSCILLATOR

+V

-V

SWITCH

Page 5

7560-120497-5

7

8

6

19

9

VR

OSC

ERROR AMP(-)

ERROR AMP

OUT

ERROR AMP(+)

RT

CT

FIGURE 5. OPEN LOOP CONTROLLER

FIGURE 5. In this configuration, the PWM output

duty cycle to the motor drivers is directly proportional to the DC voltage applied to Pin 6, since

Pins 7 and 8 are tied together.

OUT6

OUT5

OUT4

12

13

14

10

11

VM

ENABLE

BRAKE

23

2

R

C

VR

FIGURE 4. THREE PHASE HALF WAVE MOTOR CONTROLLER

19

(+)

(-)

OVERCURRENT

SENSE

VR

24

25

26

27

21

20

22

15

16

17

14

13

12

10

11

5

7

8

6

9

4

3

28

18

19

2

1

23

ROTOR

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

S1

S2

S3

F/R

PWM CNTRL

TOP DRV

POL SEL

BRAKE SEL

BRAKE

OVERCURRENT

SENSE

SEQ SEL

TACH OUT

ENABLE

ERROR

AMP

OSC

RC

VR

VSS

VDD

FAULT

VM

VM

FIGURE 3. THREE PHASE CLOSED LOOP FULL WAVE MOTOR CONTROLLER

CS

VR

CT

RT

10K

R2

100K

C1

0.1µF

*

*

*

R1

TYPICAL

VALUES

*

1.0M

*

VR

S1

S2

S3

(-)

OUT

(+)

S1

S2

S3

Rs

(+)

(-)

R3

**

FIGURE 3. The closed loop mo-

tor control operation is achieved

by applying the Tachometer

Output at Pin 5 into the negative

terminal of the Error Amplifier

(Pin 7) through an R1-C1-R2 integrating network. The R1-C1

network is configured as a feedback circuit around the amplifier.

Since the Tachometer Output

has a fixed positive pulse width,

the average value of the pulse

train is directly proportional to

the motor speed. The desired

speed is selected by applying a

voltage at the positive input

(Pin 6) of the Error Amplifier.

The resultant output voltage of

the Error Amplifier is applied to

an internal Comparator along

with a ramp waveform generated by the RC Network at Pin

9. The PWM signal at the Comparator output is used to drive

outputs 1 thru 6 and complete

the closed loop. For this configuration, Pin 20, the Top Driver

Polarity Select must be tied to

Ground.

FIGURE 4. This three phase half wave motor controller has no top power transistor to disconnect the windings from the power supply when the BRAKE is applied. Instead, a switching transistor is used which will permit braking for a time

determined by the RC time constant. When the capacitor discharges past the

ENABLE input switching point, the outputs will be turned off.

Page 6

7560-082197-6

17

15

14

12

10

11

ROTOR

3

1

2

4

24

25

26

S1

S2

S3

20

VM

OUT1

OUT3

OUT4

OUT6

FIGURE 6. FOUR PHASE FULL WAVE MOTOR CONTROLLER

23

BRAKE

TOP

DRIVER

POLARITY

SELECT

VM

S1

S2,S3

OVERCURRENT

SENSE

(+)

(+)

VM

S1

S2,S3

FIGURE 6. Four phase motor control requires only two Hall Sensor inputs spaced 90 electrical

degrees apart. S1 is connected to one sensor and S2 and S3 are tied together and connected to

the other sensor (Refer to Table 1). The BRAKE input (Pin 23) is used to control the Top Driver

Select (Pin 20) and the Top Motor Drivers. When the BRAKE input is applied, the Top Motor drivers are turned off and the Top Driver Polarity Select is forced low turning on the Outputs 1 and 3.

Since Outputs 4 and 6 are also turned on, the motor windings become shorted together.

The information included herein is believed to be

accurate and reliable. However, LSI Computer Systems,

Inc. assumes no responsibilities for inaccuracies, nor for

any infringements of patent rights of others which may

result from its use.

Page 7

11

14

10

17

15

12

VM

OUT1

OUT3

OUT4

OUT6

VR

FIGURE 7. FOUR PHASE HALFWAVE MOTOR CONTROLLER

19

2

20

23

ENABLE

TOP DRIVER

POLARITY

SELECT

BRAKE

(+)

(-)

OVERCURRENT

SENSE

22

23

5

7

6

8

BRAKE

SELECT

BRAKE

TACH OUT

OUT

VR

VR

(-)

(+)

ERROR

AMP

1M

100K

SPEED

CONTROL

PWM RATE

CONTROL

FIGURE 8. PWM BRAKING

0.1µF

VR

BRAKE

BRAKE

BRAKEBRAKE

BRAKEBRAKE

BRAKE

BRAKE

BRAKE

BRAKE

TYPICAL

VALUES

*

*

*

*

R2

R1

C1

FIGURE 7. This four phase half wave motor controller uses the same BRAKE circuit as in Figure 4 and switches

the Top Driver Select from a high to a low as in Figure 6.

FIGURE 8. Using an analog switch (such as the CD4066) PWM braking can be employed when the brake is

applied. At that time, the error amplifier is configured as a voltage follower and its input is switched from the

speed adjustment control to the PWM rate control. By adjusting the PWM rate control, the average motor

current during braking can be controlled.

7560-040198-7

Page 8

TABLE 1. OUTPUT COMMUTATION SEQUENCE FOR THREE PHASE OPERATION

LS7560

SENSOR ELECTRICAL

SEPARATION TOP BOTTOM

60° 120° DRIVERS DRIVERS

S1, S2, S3 S1, S2, S3 F/R EN BRK OCS O1, O2, O3 O4, O5, O6 FAULT

0 0 0 0 0 1 1 1 0 0 0 1 1 0 1 0 1

1 0 0 1 0 1 1 1 0 0 1 1 0 0 1 0 1

1 1 0 1 0 0 1 1 0 0 1 1 0 1 0 0 1

1 1 1 1 1 0 1 1 0 0 1 0 1 1 0 0 1

0 1 1 0 1 0 1 1 0 0 1 0 1 0 0 1 1

0 0 1 0 1 1 1 1 0 0 0 1 1 0 0 1 1

0 1 0 0 0 0 X X 0 X 1 1 1 0 0 0 0

1 0 1 1 1 1 X X 0 X 1 1 1 0 0 0 0

0 0 0 0 0 1 0 1 0 0 1 0 1 1 0 0 1

1 0 0 1 0 1 0 1 0 0 1 0 1 0 0 1 1

1 1 0 1 0 0 0 1 0 0 0 1 1 0 0 1 1

1 1 1 1 1 0 0 1 0 0 0 1 1 0 1 0 1

0 1 1 0 1 0 0 1 0 0 1 1 0 0 1 0 1

0 0 1 0 1 1 0 1 0 0 1 1 0 1 0 0 1

0 1 0 0 0 0 X X 0 X 1 1 1 0 0 0 0

1 0 1 1 1 1 X X 0 X 1 1 1 0 0 0 0

X X X X X X X X 1 X 1 1 1 1 1 1 1

X X X X X X X X 0 1 1 1 1 0 0 0 0

X X X X X X X 0 0 X 1 1 1 0 0 0 0

NOTE 1: This Table assumes the TOP DRIVER POLARITY SELECT (Pin 20) = Logic 0. For Pin 20 = Logic 1,

invert the polarity of the top drivers.

NOTE 2: For the LS7561, the OVERCURRENT SENSE = Logic 1 only forces the bottom drivers to a Logic 0.

It has no effect on the top driver outputs which are determined by the other inputs as shown in the table.

EN = ENABLE

BRK = BRAKE

OCS = OVER

CURRENT

SENSE

TABLE 2. OUTPUT COMMUTATION SEQUENCE FOR FOUR PHASE OPERATION

LS7560

SENSOR ELECTRICAL

SEPARATION = 90° TOP BOTTOM

DRIVERS DRIVERS

S1 S2, S3 F/R EN BRK OCS O1, O3 O4, O6 FAULT

0 0 1 1 0 0 1 0 0 0 1

1 0 1 1 0 0 0 1 0 0 1

1 1 1 1 0 0 0 0 1 0 1

0 1 1 1 0 0 0 0 0 1 1

0 0 0 1 0 0 0 0 1 0 1

1 0 0 1 0 0 0 0 0 1 1

1 1 0 1 0 0 1 0 0 0 1

0 1 0 1 0 0 0 1 0 0 1

X X X X 1 X 0 0 1 1 1

X X X X 0 1 0 0 0 0 0

X X X 0 0 X 0 0 0 0 0

NOTE 1: SEQUENCE Input (Pin 1) set at a Logic 1.

NOTE 2: This Table assumes theTOP DRIVER POLARITY SELECT (Pin 20) = Logic 1. For Pin 20 = Logic 0, invert the

polarity of the top drivers.

NOTE 3: For the LS7561, the OVERCURRENT SENSE = Logic 1 only forces the bottom drivers to a Logic 0. It has no

effect on the Top Driver Outputs which are determined by the other inputs as shown on the table.

EN = ENABLE

BRK = BRAKE

OCS = OVER

CURRENT

SENSE

7560-102597-8

Loading...

Loading...