Page 1

Data Sheet

LRS1338A-1

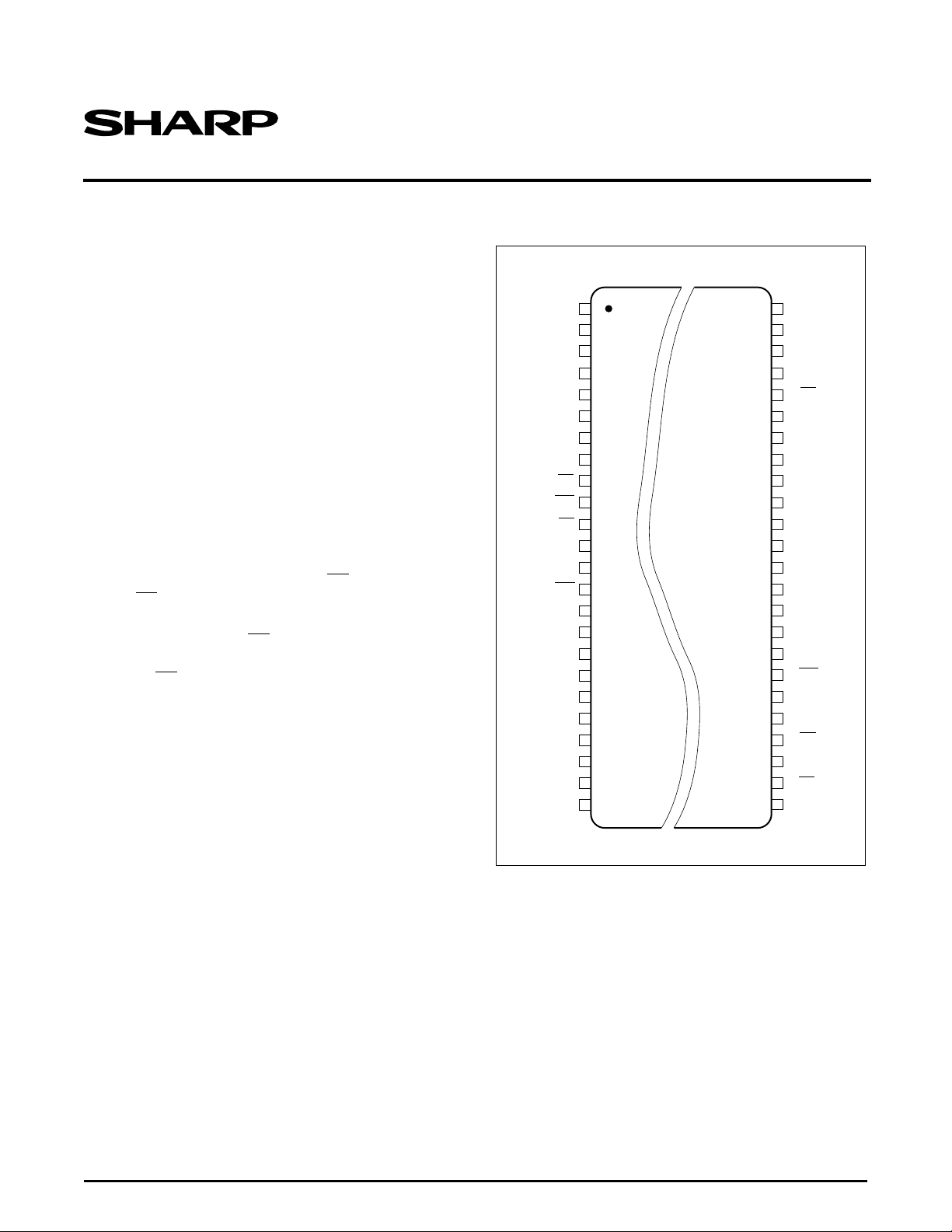

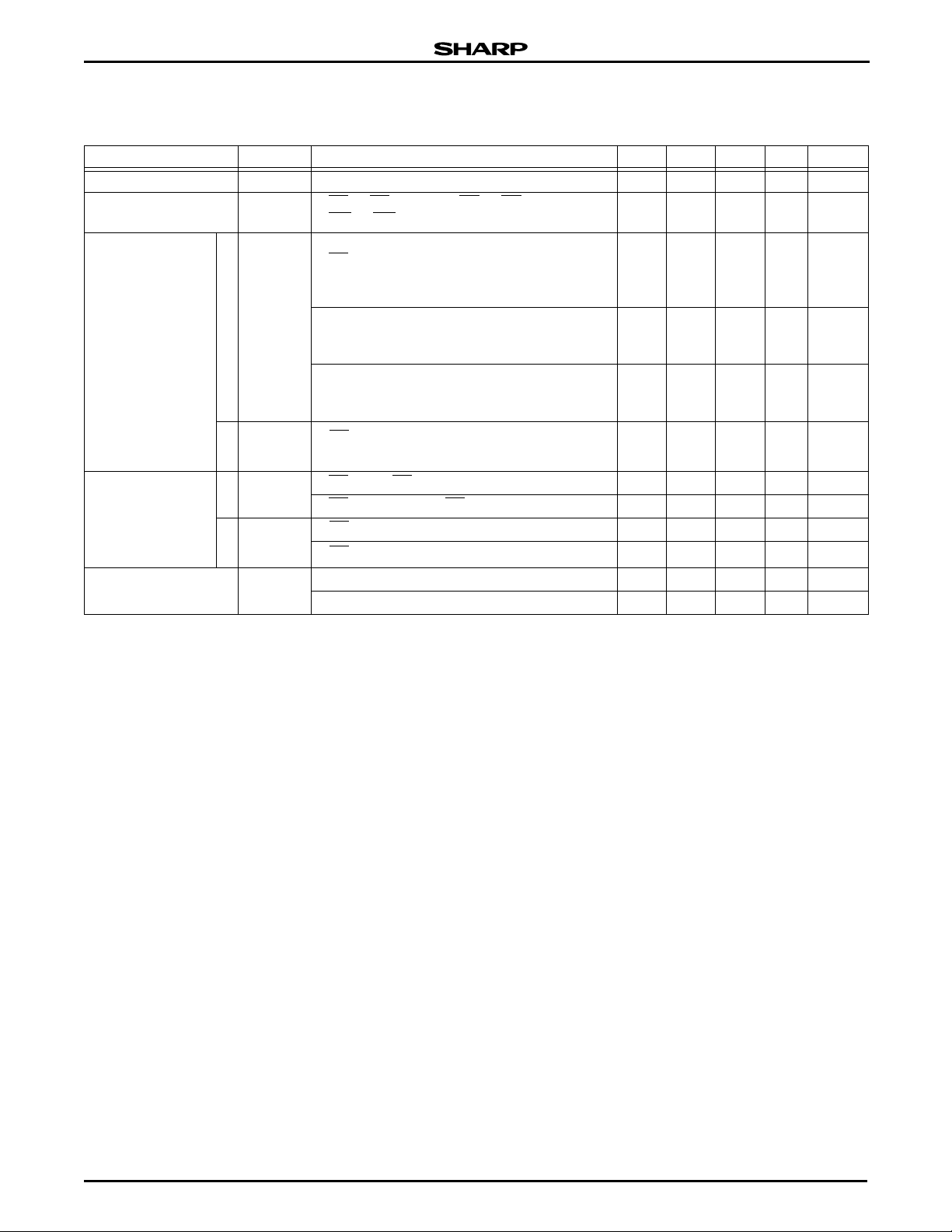

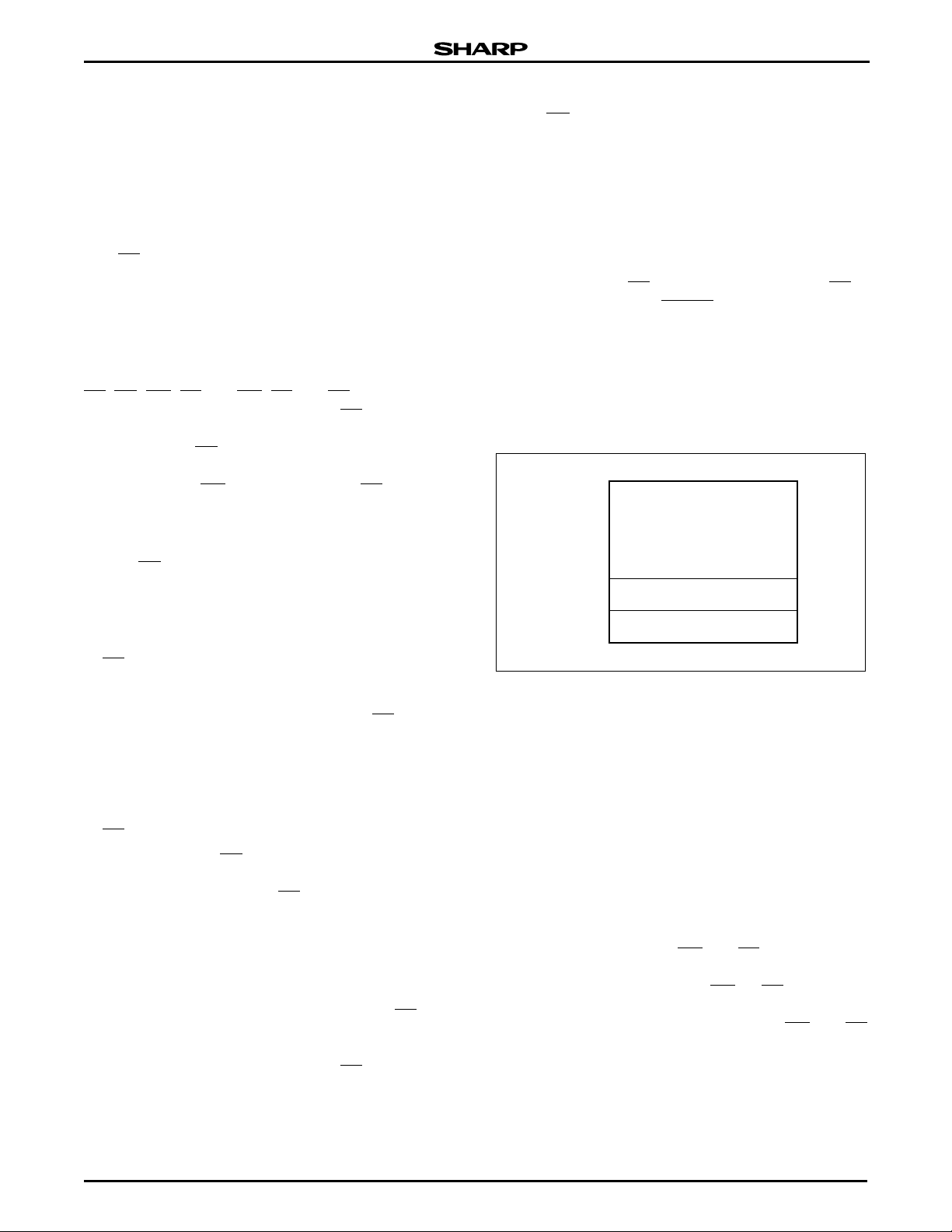

TOP VIEW48-PIN TSOP

2

3

4

5

8

9

S-A

9

/F-A

8

S-A12/F-A

11

S-A13/F-A

12

S-A14/F-A

13

48

45

42

6

7S-A

10

/F-A

9

S-A11/F-A

10

47

46

I/O

14

S-CE

I/O

15

I/O

13

10

11

12

I/O

7

13

44

I/O

3

43

I/O

10

I/O

6

14

15

16

17

18

19

20

39

36

41

40

38

37

I/O

1

S-WE

I/O

8

S-A7/F-A

6

S-A6/F-A

5

S-A8/F-A

7

F-A18

F-A17

F-WP

S-A

5

/F-A

4

I/O

0

F-OE

I/O

5

I/O

4

I/O

12

I/O

9

1

S-A

15

/F-A

14

S-A16/F-A

15

S-A17/F-A

16

21

22

23

24S-A

0

S-A2/F-A

1

S-A4/F-A

3

S-A3/F-A

2

34

F-CE

35

GND

31

33

32

30

29

S-A

1

/F-A

0

F-RP

F-WE

S-OE

F-V

PP

S-V

CC

F-V

CC

I/O

11

I/O

2

27

28

26

25

LRS1338A

Stacked Chip

8M Flash Memory and 2M SRAM

FEATURES

PIN CONFIGURATION

• Flash memory and SRAM

• Stacked die chip scale package

• 48-pin TSOP (TSOP48-P-1014) plastic package

• Power supply: 2.7 V to 3.6 V

• Operating temperature: -40°C to +85°C

• Access time (MAX.):

– Flash memory: 120 ns

– SRAM: 85 ns

• Operating current (MAX.):

–Flash memory

– Read: 25 mA (t

– Word write: 57 mA (F -V

– Block erase: 42 mA (F-V

– SRAM: 25 mA (t

• Standby current

2

CYCLE

CYCLE

= 200 ns)

≥ 3.0 V)

CC

≥ 3.0 V)

CC

= 200 ns)

– Flash memory: 20 µA MAX. (F-CE ≥ F-VCC - 0.2 V,

F-RP

≤ 0.2 V, F-VPP ≤ 0.2 V)

–SRAM:

– 40 µA MAX. (S-CE

• Fully static operation

• Three-state output

NOTES:

1. Block erase and word write operations of flash memory with

2. Total standby current is the summation of flash’s memory standby

DESCRIPTION

as 524,288 × 16-bit flash memory and 262,144 × 8-bit

static RAM in one package. It is fabricated using silicongate CMOS process technology.

S-CE

< -30°C are not supported.

T

A

current and SRAM’s one.

The LRS1338A is a combination memory organized

≥ S-VCC - 0.2 V)

– 0.6 µA TYP. (T

A

≥ S-VCC - 0.2 V)

= 25°C, S-VCC = 3 V,

Figure 1. LRS1338A Pin Configuration

Data Sheet 1

Page 2

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

CC

SRAM

S-V

F-V

CC

F-CE

F-OE

F-WE

F-RP

F-WP

, F-A

F-A

17

S-A1 to S-A

F-A

to F-A

0

S-A

S-CE

S-OE

S-WE

F-V

524,288 x 16 BIT

FLASH MEMORY

18

17

,

16

0

262,144 x 8 BIT

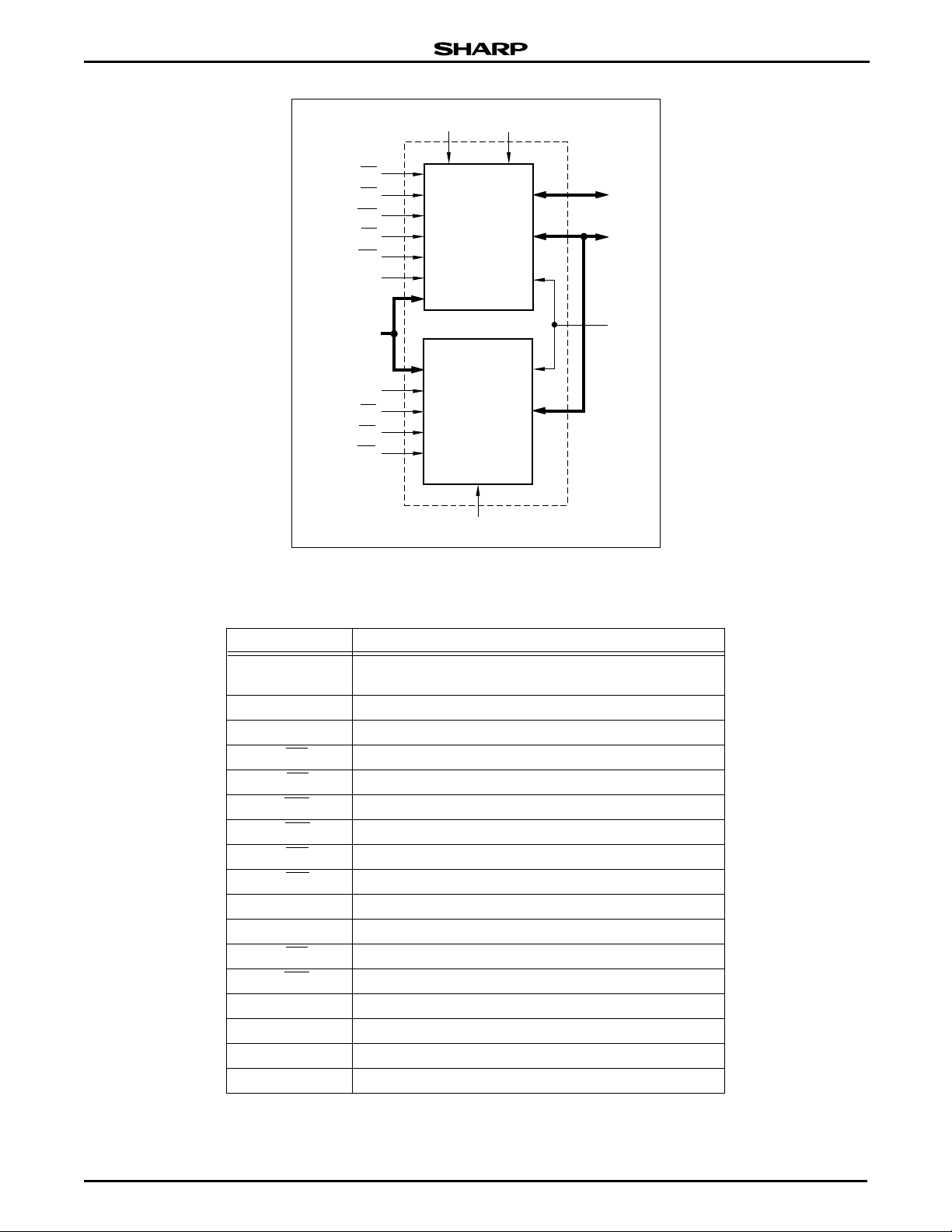

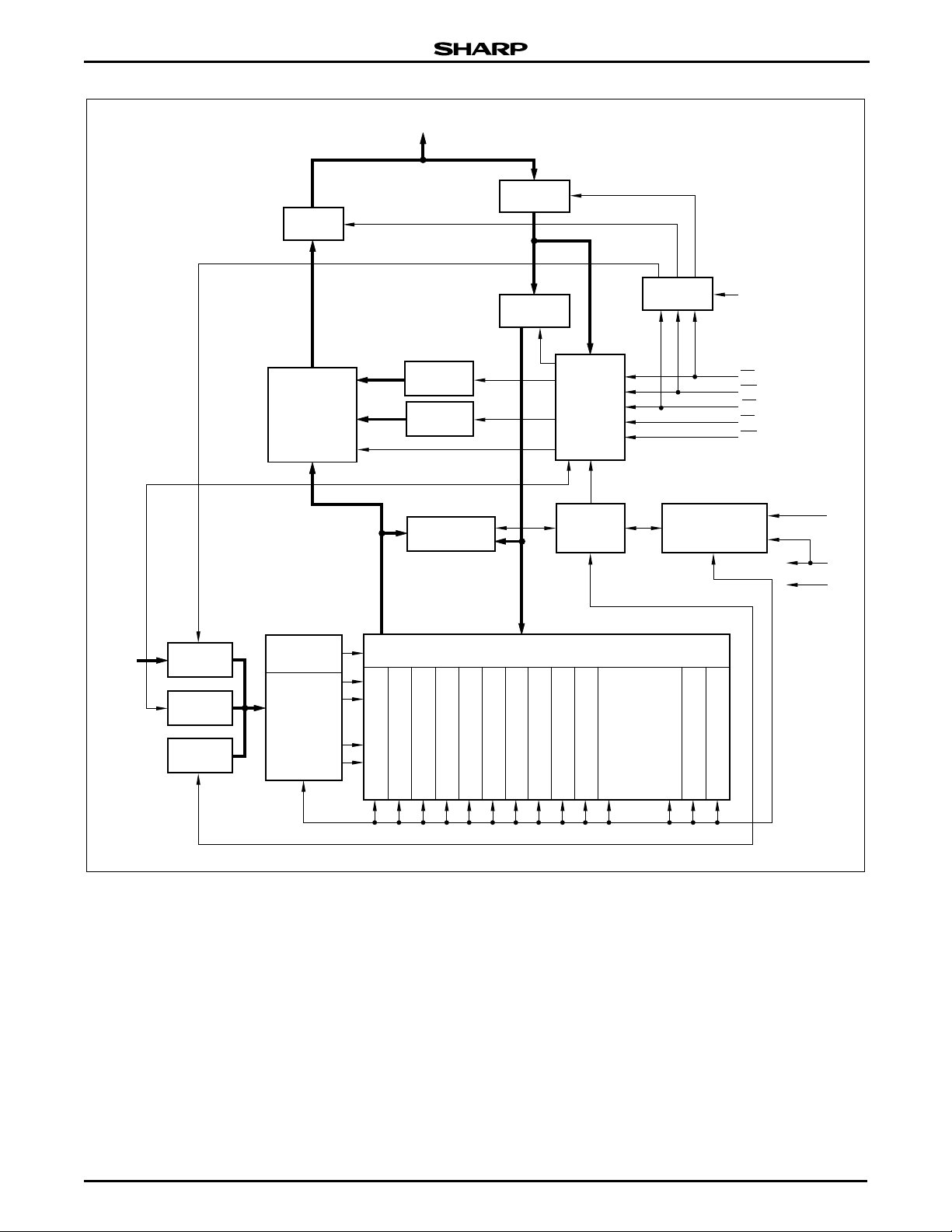

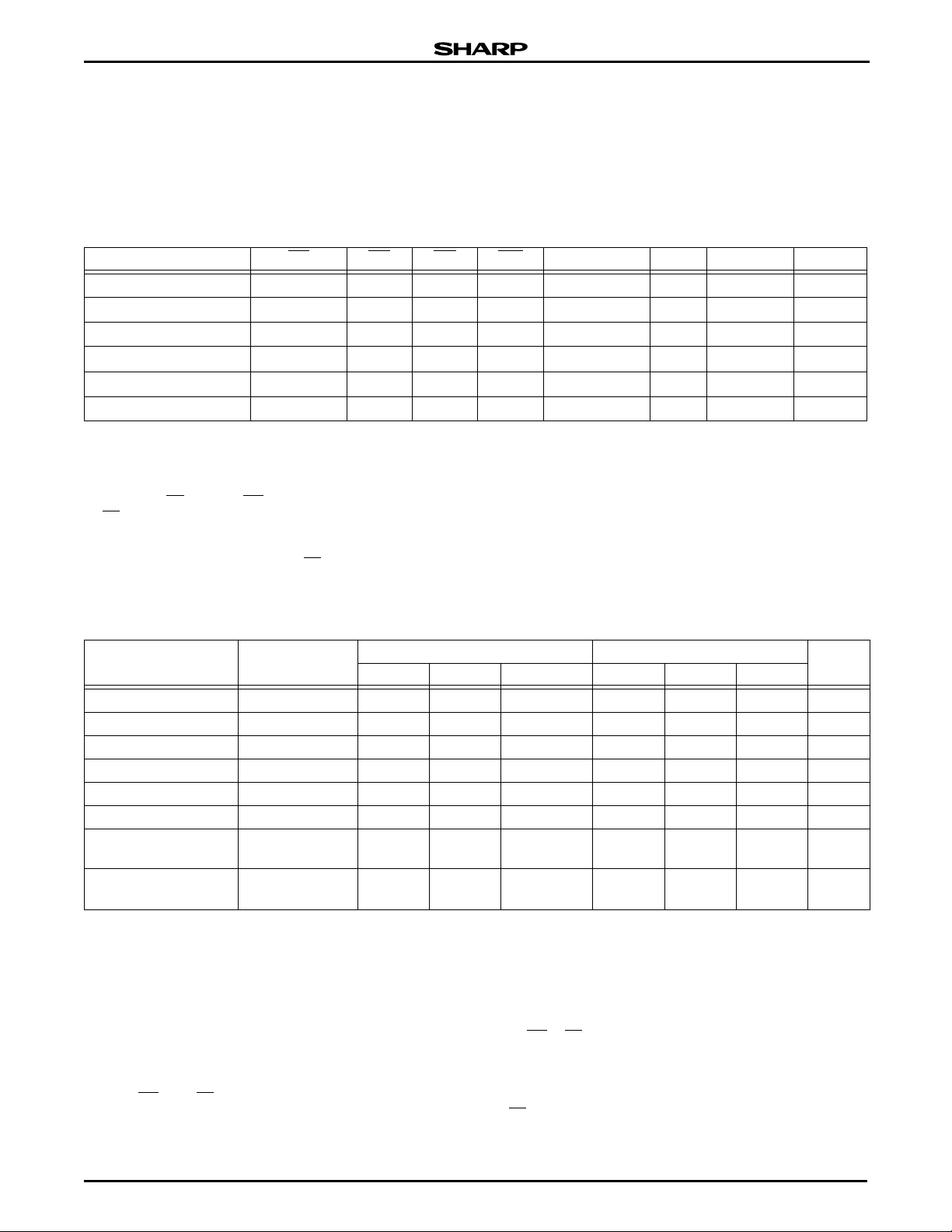

Figure 2. LRS1338A Block Diagram

PP

I/O8 to

I/O

15

I/O0 to

I/O

7

GND

LRS1338A-2

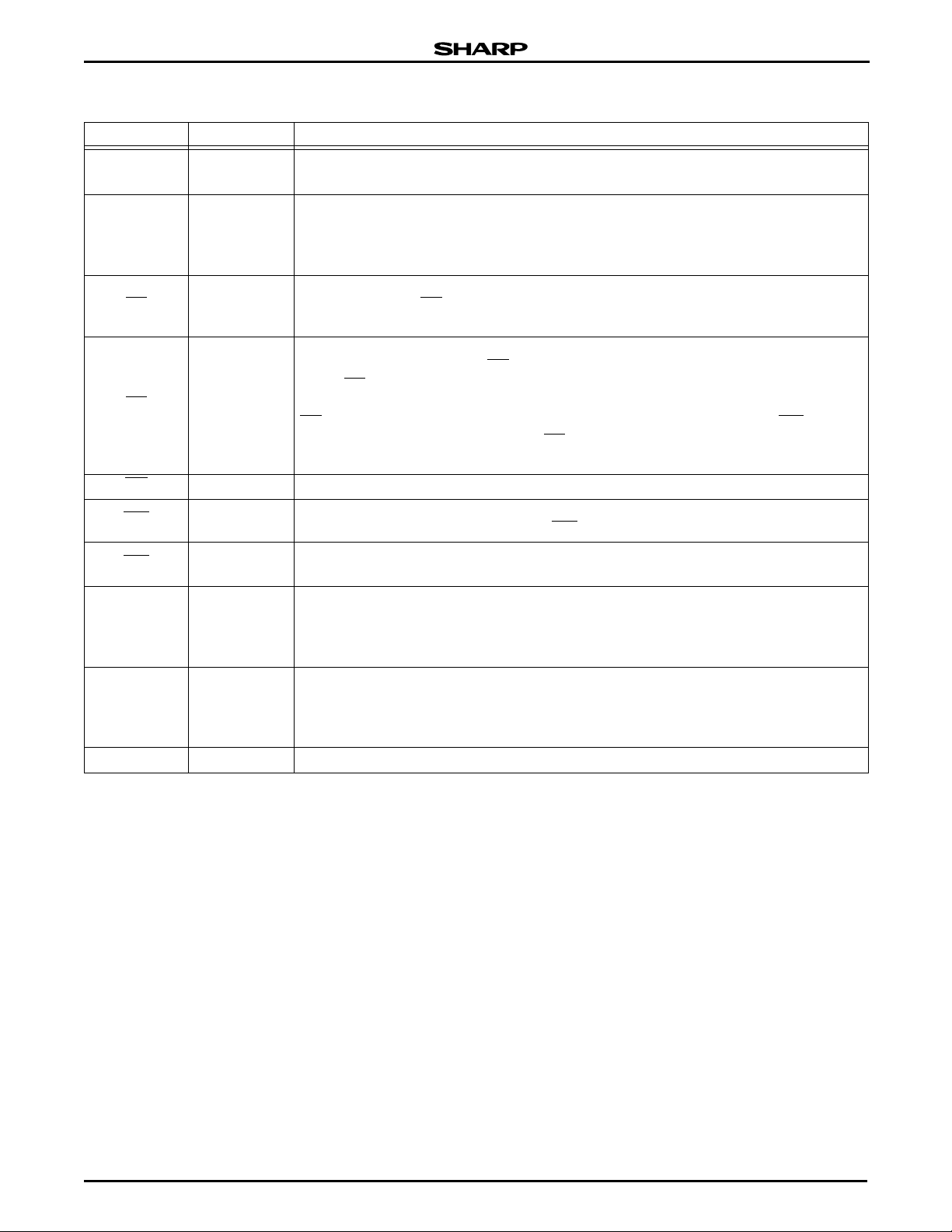

Table 1. Pin Descriptions

PIN DESCRIPTION

S-A

to S-A

1

F-A0 to F-A

S-A

F-A

17

F-CE

S-CE

F-WE

S-WE

F-OE

S-OE

I/O

0

I/O

to I/O

8

F-RP

F-WP

F-V

F-V

S-V

0

to F-A

to I/0

CC

PP

CC

17

Common Address Input Pins

16

Address Input Pin for SRAM

Address Input Pin for Flash Memory

18

Chip Enable Input Pin for Flash Memory

Chip Enable Input Pin for SRAM

Write Enable Input Pin for Flash Memory

Write Enable Input Pin for SRAM

Output Enable Input Pin for Flash Memory

Output Enable Input Pin for SRAM

Common Data Input/Output Pins

7

Data Input/Output Pins for Flash Memory

15

Reset/Deep Power Down Input Pin for Flash Memory

Write Protect Pin for Flash Memory’s Boot Block

Power Supply Pin for Flash Memory

Power Supply Pin for Flash Memory Write/Erase

Power Supply Pin for SRAM

GND Common Ground

2 Data Sheet

Page 3

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

GENERAL DESIGN GUIDELINES

Supply Po wer

Maximum difference (between F-VCC and S-VCC) of

the voltage is less than 0.3 V.

Power Supply and Chip Enable of Flash

Memory and SRAM

It is forbidden that both F-CE and S-CE should be

LOW simultaneously. If the two memories are active

together, they many not op erate nor mally du e to inter ference noi ses or dat a collis ion on I/O bus. Bot h F-V

CC

and S-VCC need to be applied by the recommende d

supply voltage at the same time except SRAM data

retention mode.

SRAM Data Retention

SRAM data retention is capable in three ways.

SRAM power switching betwee n a system bat tery an d

a backup battery needs careful device decoupling from

Flash Memory to prevent SRAM supply voltage from

falling lower than 2.0 V by a Flash Mem ory peak current caused by transitio n of F la sh Mem or y supp ly vol tage or of control signals (F-CE

CASE 1: FLASH MEMORY IS IN STANDBY MODE

(F-V

= 2.7 V TO 3.6 V)

CC

• SRAM inputs and input/outputs except S-CE

be applied with voltages in the range of -0.3 V to

S-V

+ 0.3 V or to be open (HIGH-Z).

CC

• Flash Memory inputs and input/outputs except F-CE

and RP need to be applied with voltages in the range

of -0.3 V to S-V

+ 0.3 V or to be open (HIGH-Z).

CC

, F-OE, and RP).

need to

CASE 2: FLASH MEMORY IS IN DEEP POWER

DOWN MODE (F-V

• SRAM inputs and input/outputs except S-CE

= 2.7 V TO 3.6 V)

CC

need to

be applied with voltages in the range of -0.3 V to

S-V

+ 0.3 V or to be open.

CC

• Flash Memory inputs and input/outputs except RP

need to be applied with voltages in the range of -0.3 V

to S-V

be at the same level as F-V

+ 0.3 V or to be open (HIGH-Z). RP needs to

CC

or to be open.

CC

CASE 3: FLASH MEMORY POWER SUPPLY IS

TURNED OFF (F-V

• Fix RP

LOW level before tu rning off Flash memo ry

CC

= 0 V)

power supply.

• SRAM inputs and input/outputs except S-CE

need to

be applied with voltages in the range of -0.3 V to

S-V

+ 0.3 V or to be open (HIGH-Z).

CC

• Flash Memory inputs and input/outputs except RP

need to be applied with voltages in the range of

-0.3 V to S-V

+ 0.3 V or to be open (HIGH-Z).

CC

Power Up Sequence

When turning on Flash memory power supply, keep

RP

LOW. After F-VCC reaches ove r 2.7 V, keep RP

LOW for more than 100 ns.

Device Decoupling

The power supply needs to be designed c arefully

because one of the SRAM and the F lash Me mor y is in

standby mode when the other is active. A careful

decoupling of power supplies is necessary between

SRAM and Flash Memory. Note peak current caused

by transition of control signals (F-CE

, S-CE).

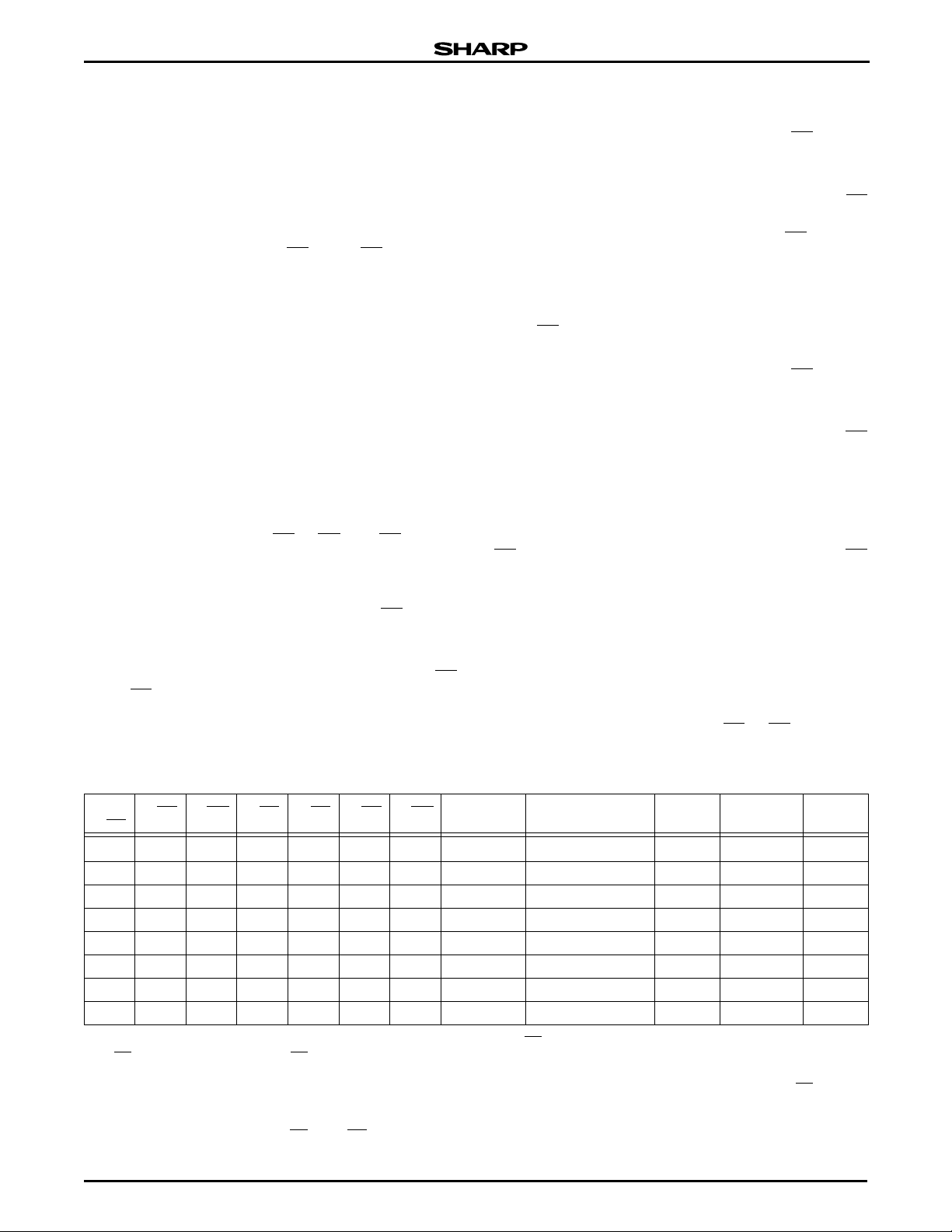

Table 2. Truth Table

F-CE F-OE F-WE F-RP S-CE S-OE S-WE ADDRESS MODE

L L H H H X X X Flas h read Output I

L H H H H X X X Flash read HIGH-Z I

LHLHHXX XFlash write Input I

H X X X L L H X SRAM read Output I

H X X X L H H X SRAM read HIGH-Z I

H X X X L X L X SRAM write Input I

H X X H H X X X Standby HIGH-Z I

X X X L H X X X Deep power down HIGH-Z I

NOTES:

1. F-CE

2. X can be V

3. Refer to DC Characteristics. When F-V

4. Do not use in a timing that both F-OE

should not be LOW when S-CE is LOW simultaneously.

or VIH for control pins and addresses, and V

for F-VPP. See DC Characteristics for V

tents can be read, but not altered.

IL

or V

and V

PPLK

≤ V

PP

and F-WE is LOW level.

PPLK

voltages.

PPH

, memory con-

PPLK

PPH

5. F-RP

6. Command writes involving block erase, write, or lock-bit configura-

7. Refer to Table 6 for valid D

1,2

to

I/O

0

I/O

at GND ± 0.2 V ensures the lowest deep power down current.

tion are reliably executed whe n F-V

block erase or word w rite operations wit h VIH < F-RP < VHH or

T

<-30°C produce spurious results and should not be attempted.

A

during a write operation.

IN

CURRENT NOTE

15

CC

CC

CC

CC

CC

CC

SB

SB

= V

PP

and F-VCC=V

PPH

3, 4

5

4, 6, 7

5

CC1

Data Sheet 3

Page 4

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

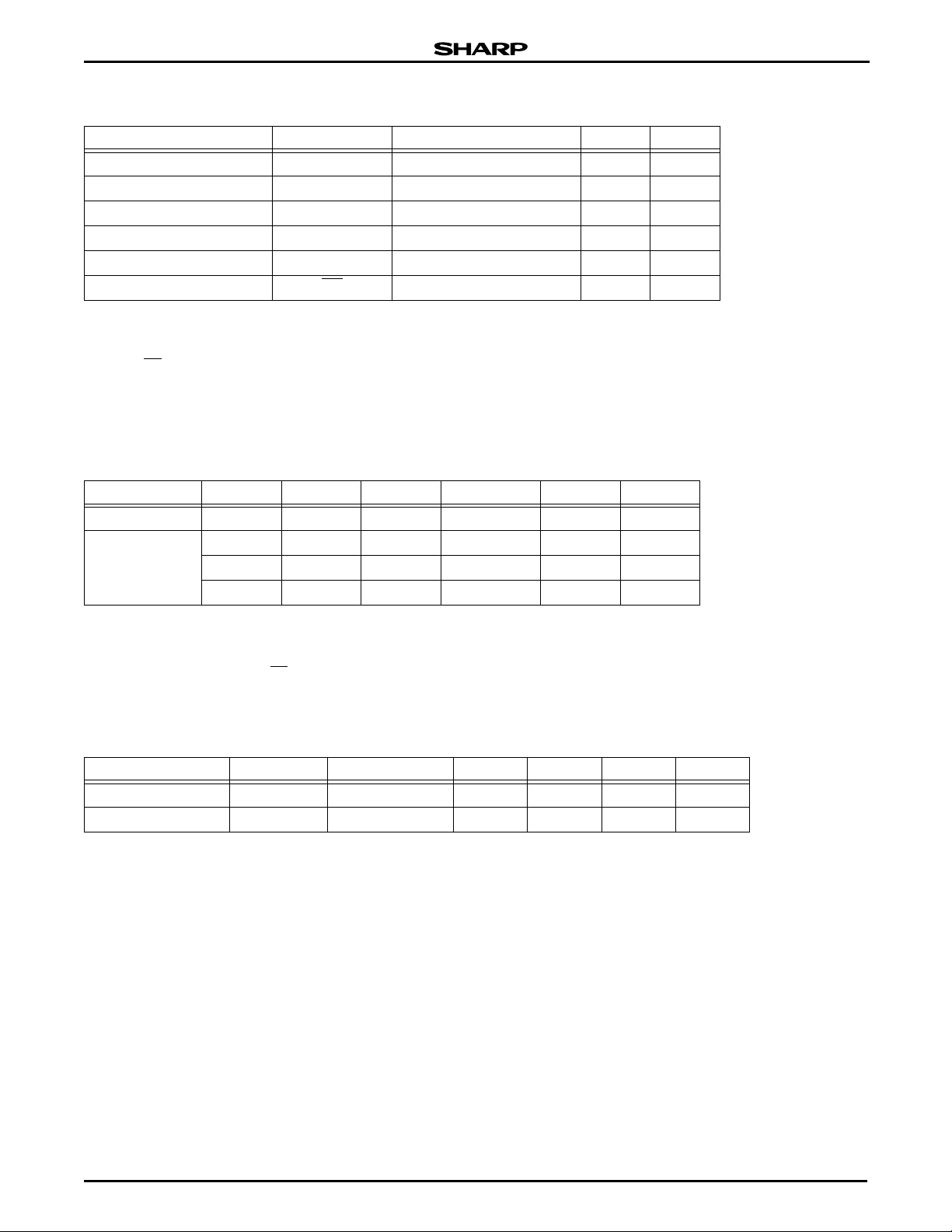

ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL RATINGS UNIT NOTES

Supply voltage V

Input voltage V

Operating temperature T

Storage temperature T

voltage V

V

PP

CC

IN

OPR

STG

PP

Input voltage RP

NOTES:

1. The maximum applicable voltage on any pins with respect to GND.

2. Except V

3. Except RP

4. -2.0 V undershoot is allowed when the pulse width is less than 20 ns.

5. +14.0 V overshoot is allowed when the pulse width is less than 20 ns.

PP

.

.

-0.2 to +4.6 V 1, 2

-0.3 to VCC +0.3 V 1, 3, 4

-40 to +85 °C

-65 to +125 °C

-0.2 to +12.6 V 1, 5

-0.5 to +12.6 V 1, 4, 5

RECOMMENDED DC OPERATING CONDITIONS

TA = -40°C to +85°C

PARAMETER SYMBOL MIN. TYP. MAX. UNIT NOTES

Supply voltage V

Input voltage

CC

V

IH

V

IL

V

HH

2.7 3.0 3.6 V

2.0 VCC + 0.3 V 1

-0.3 0.8 V 2

11.4 12.6 3

NOTES:

1. V

is the lower one of S-VCC and F-VCC.

CC

2. -2.0 V undershoot is allowed when the pulse width is less than 20 ns.

3. This voltage is applicable to F-RP

pin only.

PIN CAPACITANCE

TA = 25°C, f = 1 MHz

PARAMETER SYMBOL CONDITION MIN. TYP. MAX. UNIT

Input capacitance* C

I/O capacitance* C

NOTE: *

Sampled by not 100% tested.

IN

I/O

VIN = 0 V 20 pF

V

= 0 V 22 pF

I/O

4 Data Sheet

Page 5

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

DC ELECTRICAL CHARACTERISTICS

TA = -40°C to + 85°C, VCC = 2.7 V to 3.6 V

PARAMETER SYMBOL CONDITION MIN. TYP. MAX. UNIT NOTES

Input leakage current I

Output leakage current I

Operating supply

current

I

Flash

I

SRAM

I

Standby current

Flash

I

SRAM

Output voltage

NOTES:

1. This value is read current (I

2. Sampled but not 100% tested.

3. This value is operation current (I

4. This value is operation current (I

5. This value is operation current (I

VOL,

V

CCR

CC

CC

VIN = 0V to V

LI

F-CE, S-CE = VIH or F-OE, S-OE = VIH or

LO

, S-WE = VIH, V

F-WE

CC

= 0 V to V

I/O

CC

-1.5 1.5 µA

-1.5 1.5 µA

Read current, F-VPP ≤ F-VCC,

≤ 0.2 V, VIN ≥ VCC – 0.2 V or

F-CE

V

≤ 0.2 V

IN

= 200 ns, I

t

CYCLE

Summation of V

rent, and V

F-V

≥ 3.0 V

CC

PP

Summation of V

lock-bits current, and V

Block lock-bits current. F-V

= 0 mA

I/O

Byte Write or set l ock-bi t c ur-

CC

Byte Write or set lock-bit current.

Block Erase or Clear Block

CC

Block Erase or Clear

PP

≥ 3.0 V

CC

S-CE = 0.2 V, VIN ≥ VCC – 0.2 V or VIN ≥ 0.2 V

t

CYCLE

F-CE = VIH, RP = V

SB

F-CE

S-CE = V

SB

S-CE

= 200 ns, I

≥ VCC – 0.2 V, RP ≤ 0.2 V 20 µA 7

IH

≥ VCC – 0.2 V 0.6 40 µA 9, 10

= 0 mA

I/O

IH

IOL = 2.0 mA 0.4 V

I

OH

+ I

CCW

CCE

CC1

= 1.0 mA 2.4 V

OH

) of flash memory.

PPR

+ I

) of flash memory.

PPW

+ I

) of flash memory.

PPE

) of SRAM.

6. This value is standby current (I

7. This value is deep power down current (I

flash memory.

8. This value is standby current (I

9. This value is standby current (I

10.Reference values at V

CCS

SB1

SB

= 3.0 V and TA = +25°C

CC

25 mA 1

57 mA 2, 3

42 mA 2, 4

25 mA 5

2.0 mA 6

3.0 mA 8

+ I

) of flash memory.

PPS

CCD

) of SRAM

) of SRAM.

+ I

PPD

) of

Data Sheet 5

Page 6

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

FLASH MEMORY*

New Features

The LRS1388A flash memory ma intain s backw ards

compatibility with SHARP’s LH28F 800B G- L.

• SmartVoltage technolog y

• Enhanced suspend capabilities

• Boot block architecture

Please note the following important differences:

• V

has been lowered to 1.5 V to support 3.0 V

PPLK

block erase and word write operations. Designs that

switch V

sure that the V

• Allow V

off during read ope rations should ma ke

PP

connection to 3.0 V.

PP

voltage transitions to GND.

PP

Product Overview

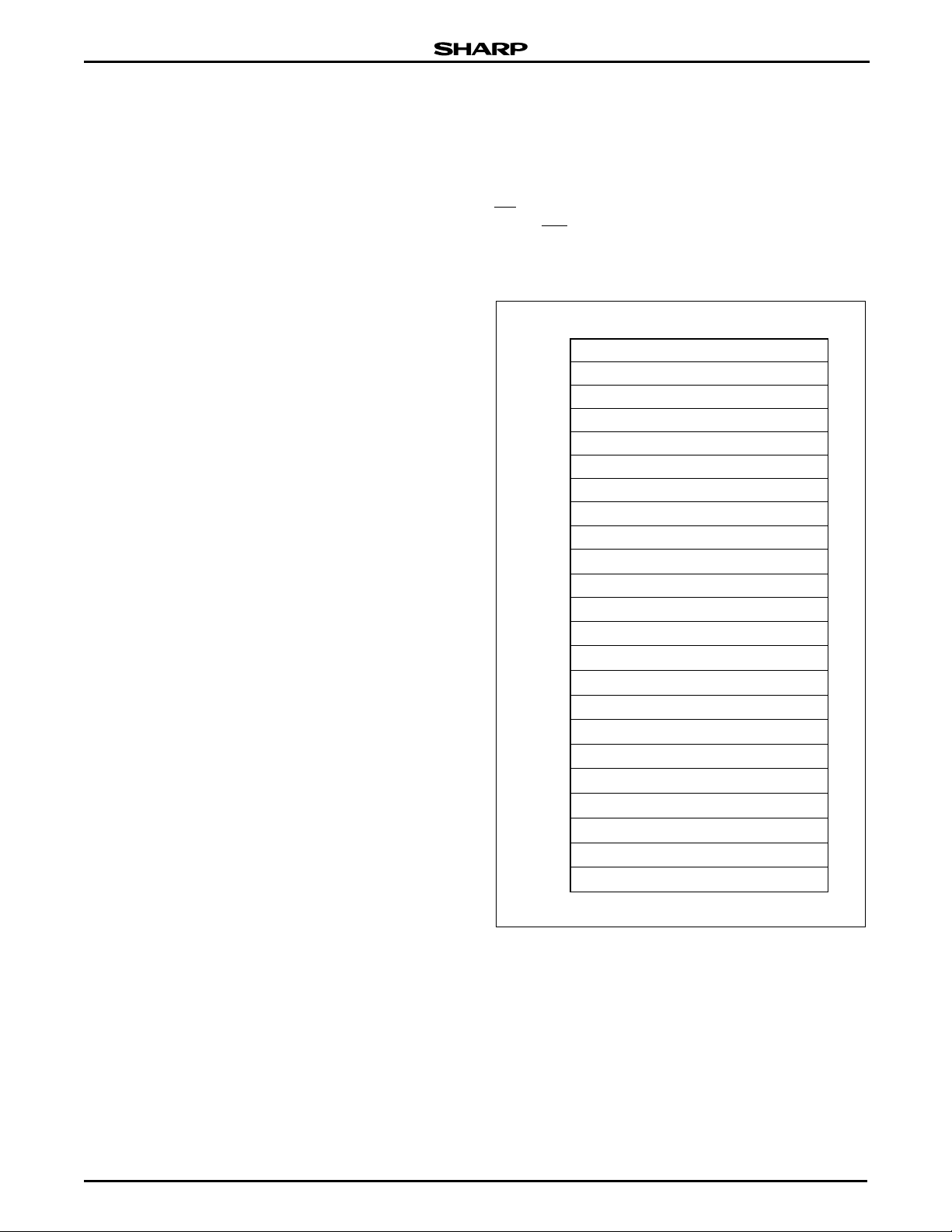

The LRS1338A is a high-performance 8M SmartVoltage flash memory organized as 512K-word of 16

bits. The 512K-word of data is arranged in two 4K-word

boot blocks, six 4K-word paramete r blocks and fifteen

32K-word main blocks wh ich are individuall y erasable

in-system. The memory map is shown in Figure 4.

SmartVoltage technolog y provides a choice of V

and VPP combinations, as shown in Table 3, to meet

system performance and power expectatio ns. In add ition to flexible erase and program voltages, the dedicated V

V

PP

≤ V

pin gives complete data protection when

PP

.

PPLK

Table 3. VCC and VPP Voltage Combinations

V

Voltage VPP Voltage

CC

2.7 V to 3.6 V 2.7 V to 3.6 V

Internal V

and VPP detection circuitry automati-

CC

cally configures the device for optimized read and write

operations.

CC

A Command User Interface (CUI) serves as the

interface between the system processor and internal

operation of the devi ce. A valid command seque nce

written to the CUI initiates device automation. An internal Write State Machine (WSM) automatically executes

the algorithms and timings necessary for block erase

and word write operations.

A block erase o perati on erases on e of the de vi ce’s

32K-word blocks typically within 1.14 se conds, 4Kword blocks typically with in 0 .38 s ec on ds ind epe nden t

of other blocks. Each block can be independently

erased 100,000 times. Block erase suspend mode

allows system software to suspend block erase to read

or write data from any other block.

Writing memory data is performed in word increments

of the device’s 32K-word blocks typically within 44.6 µs,

4K-word blocks typically within 45.9 µs. Word write suspend mode enables the system to read data or execute

code from any other fl as h me mor y array location.

The boot blocks can be locked for the WP

pin. Block

erase or word write fo r boot b lock mus t not be car ried

out by WP

to LOW and RP to VIH.

The status register indicates when the WSM’s block

erase or word write operation is finished.

The access time is 120 ns (t

cial temperature range (-40°C to +85°C) and V

) over the commer-

AVQV

CC

sup-

ply voltage range of 2.7 V to 3.6 V.

The Automatic Power Savi ngs (APS) feature substantially reduces activ e current when the devic e is in

static mode (addresses not switching). In APS mode,

the typical I

When CE

standby mode is enabled. When the RP

current is 1 mA at 3.3 V VCC.

CCR

and RP pins are at VCC, the ICC CMOS

pin is at GND,

deep power-down mode is enabled which minimi zes

power consumption a nd provide s write pr otection during reset. A reset time (t

) is required from RP

PHQV

switching HIGH until output s are valid. Likewise, the

device has a wake time (t

writes to the CUI are recognized. With RP

) from RP HIGH until

PHEL

at GND, the

WSM is reset and the status register is cleared.

NOTE: *

mands, voltage, etc. refer only to the Flash portion of this chip.

In the Flash Me mory sectio n all referenc e to pins, com -

6 Data Sheet

Page 7

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

- I/O

I/O

0

15

INPUT

BUFFER

OUTPUT

BUFFER

A0 - A

I/O

15

BLOCKS

LOGIC

PROGRAM/ERASE

VOLTAGE

SWITCH

DATA

REGISTER

IDENTIFIER

REGISTER

OUTPUT

MULTIPLEXER

18

INPUT

BUFFER

ADDRESS

LATCH

ADDRESS

COUNTER

Y

DECODER

X

DECODER

. . .

STATUS

REGISTER

DATA

COMPARATOR

BOOT BLOCK 0

BOOT BLOCK 1

PARAMETER BLOCK 0

PARAMETER BLOCK 1

PARAMETER BLOCK 2

PARAMETER BLOCK 3

COMMAND

USER

REGISTER

WRITE

STATE

MACHINE

Y GATING

32K-WORD

MAIN BLOCK 0

MAIN BLOCK 1

PARAMETER BLOCK 4

PARAMETER BLOCK 5

V

CC

CE

WE

OE

RP

WP

MAIN BLOCK 13

MAIN BLOCK 14

V

PP

V

CC

GND

. . .

LRS1338A-3

Figure 3. Flash Memory Block Diagram

Data Sheet 7

Page 8

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

Table 4. Flash Pin Descriptions

SYMBOL TYPE NAME AND FUNCTION

A

0

- A

18

Input

ADDRESS INPUTS: Inputs for addresses during read and write operations.

Addresses are internally latched during the write cycle.

DATA INPUT/OUTPUTS: Inputs da ta an d co mman ds du ring C UI wr ite cycl es ; ou t-

I/O

- I/O

0

15

Input/Output

puts data during memory array, status register, and identifier code read cycles. Data

pins float to HIG H- imp edan ce wh en the chi p is dese le ct ed or ou tp uts a r e di sabl e d.

Data is internally la tc he d dur in g a writ e cycle .

CHIP ENABLE: Activates the device’s control logic, input buffers, decoders, and

CE

Input

sense amplifiers. CE-HIGH deselects the device and reduces power consumption

to standby levels.

RESET/DEEP POWER-DOWN: Puts the device in deep power-down mode and

RP

Input

resets internal automation. RP

LOW, RP

inhibits write operations which provides data protection during power

transitions. Exit from deep power-down sets the device to read array mode. With

RP

= VHH, block erase or word write can operate to all blocks without WP state.

Block erase or word write with V

-HIGH enables normal operation. When driven

IH

not be attempted.

OE

WE

WP

Input OUTPUT ENABLE: Gates the device’s outputs during a read cycle.

Input

Input

WRITE ENABLE: Controls writes to the CIU and array blocks. Addresses and data

are latched on the rising edge of the WE

WRITE PROTECT: Master control for boot blocks locking. When V

blocks cannot be erased and programmed.

BLOCK ERASE an d WORD WRITE P OWER SUPPLY: For erasin g array bloc ks or

V

PP

Supply

writing words. With V

and word write with an invalid V

PP

≤ V

, memory contents cannot be altered. Block erase

PPLK

PP

results and should not be attempted.

DEVICE POWER SUPPLY: Do not float any power pins. With V

V

CC

Supply

write attempts to the flash memory are inhibited. Device operations at invalid

V

voltage (see ‘DC Characteristics’) produce spurious results and should not

CC

be attempted.

GND Supply GROUND: Do not float any ground pins.

< RP < VHH produce spurious results and should

pulse.

, locked boot

IL

(see ‘DC Characteristics’) produce spurious

CC

≤ V

LKO

, all

8 Data Sheet

Page 9

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

7

7F000

7FFFF

7EFFF

FE000

7DFFF

7D000

7CFFF

7C000

7BFFF

7B000

7AFFF

7A000

79FFF

79000

78FFF

78000

77FFF

70000

6FFFF

68000

67FFF

58000

57FFF

60000

5FFFF

50000

4FFFF

48000

47FFF

40000

3FFFF

38000

37FFF

30000

2FFFF

28000

27FFF

20000

1FFFF

18000

17FFF

10000

0FFFF

08000

07FFF

00000

8

9

10

11

12

13

14

32K-WORD MAIN BLOCK

632K-WORD MAIN BLOCK

532K-WORD MAIN BLOCK

4 32K-WORD MAIN BLOCK

332K-WORD MAIN BLOCK

232K-WORD MAIN BLOCK

132K-WORD MAIN BLOCK

032K-WORD MAIN BLOCK

54K-WORD PARAMETER BLOCK

44K-WORD PARAMETER BLOCK

34K-WORD PARAMETER BLOCK

24K-WORD PARAMETER BLOCK

14K-WORD PARAMETER BLOCK

04K-WORD PARAMETER BLOCK

14K-WORD BOOT BLOCK

0

4K-WORD BOOT BLOCK

TOP BOOT

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

32K-WORD MAIN BLOCK

LRS1338A-4

Principles of Operation

The LRS1388A SmartVoltage flash memory

includes an on-chip W SM to manage bloc k erase and

word write functions. It allows for: 100% TTL-level control inputs, fixed power supplies during block erasure,

word write, and minimal processor overhead with

RAM-like interface timings.

After initial device power-up or return from deep

power-down mode (see ‘Bus Operatio n’), the device

When V

altered. The CUI, with two-step bloc k erase or word

write command sequences, provides protec tion from

unwanted operations even when high voltage is

applied to V

V

is below the write lockout voltage V

CC

RP

is at VIL. The device’s boot blocks locking capability for WP

vertent code or data alteration by block erase and

word write operations.

≤ V

PP

. All write functions are d isabled when

PP

, memory contents cannot be

PPLK

provides additional protection from inad-

defaults to re ad array mode . Manipulation of external

memory control pins allow array read, standby, and

output disable operations.

Status register and identifier codes can be accessed

through the CUI indep endent of the F-V

High voltage on F-V

enables successful block era-

PP

voltage.

PP

sure and word writing. All functions associated with

altering m emory co ntents — block erase, word write,

status, and identifier codes — are accessed via the CUI

and verified through the status register.

Commands are written using standard microprocessor write timings. The CUI contents serve as input to

the WSM, which controls the block erase and word

write. The internal algorithms are regulated by the

WSM including pulse repetition , internal verif ication,

and margining of d ata. Addresses a nd data are internally latched during write cycles. Wr iting the appropriate command outputs array data, accesses the

identifier codes or outputs status register data.

Interface software that initiates and polls progress of

block erase and word write can be stored in any block.

This code is copied to and executed from system RAM

during flash memory updates. After successful completion, reads are again possible via the Read Array command. Block erase suspend allows system software to

suspend a block erase to read/write dat a from/to blocks

other than that which is suspended. Word writ e suspend allows system software to suspend a word write to

read data from any other flash memory array location.

DATA PROTECTION

Depending on the appl ication, the syst em designer

may choose to make the V

(available only when memor y block erases or word

writes are required) or hardwir ed to V

accommodates either design practice and encourages

optimization of the processor-memory interface.

Data Sheet 9

power supply switchable

PP

. The device

PPH

Figure 4. Memory Map

LKO

or when

Page 10

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

RESERVED FOR

FUTURE IMPLEMENTATION

DEVICE CODE

MANUFACTURER CODE

7FFFF

00001

00000

1338A-5

Bus Operation

The local CPU reads and writes f lash memory insystem. All bus cycles to or from the flash memory conform to standard microprocessor bus cycles.

READ

Information can be read from any block, identifier

codes or status register independent of the V

age. RP

can be either VIH or VHH.

The first task is to write the appropriate read mode

command (Read Array, Read Identifier Codes, or Read

Status Register) to the CUI. Upon initial device powerup or after exit from deep power-down mode, the device

automatically resets to read array mode. Five control

pins dictate the data flow in and out of the component:

CE

, OE, WE, RP and WP. CE and OE must be drive n

active to obtain data at the outputs. CE

is the device

selection control, and when active enables the selected

memory device. OE

is the data output (I/O0 - I/O15) control and when active drives the selected memory data

onto the I/O bus. WE

V

or VHH. Figure 12 illustrates a read cycle.

IH

must be at VIH and RP must be at

OUTPUT DISABLE

With OE

puts are disabled. Output pins (I/O

at a logic-HI GH le ve l ( VIH), the device out-

- I/O15) are placed

0

in a HIGH impedance state.

PP

volt-

As with any automated device, it is important to

assert RP

during system reset. When the system

comes out of reset, i t ex pec ts to re ad f ro m fl ash m emory. Automated flash memories provide status information when accessed during block erase or word write

modes. If a CPU reset occur s with no flash memory

reset, proper CPU initialization may not occur because

the flash memory may be provid ing status in formation

instead of arr ay data. SHARP ’s flash memories allow

proper CPU initialization following a system reset

through the use of RP

controlled by the same RESET

input. In this appl ication, RP is

signal that resets the

system CPU.

READ IDENTIFIER CODES OPERATION

The read identifier codes operation outputs the manufacturer code and devic e codes, the system CP U can

automatically match the device with its proper algorithms.

STANDBY

CE

at a logic HIGH level (VIH) places the device in

standby mode which substantially reduces device

power consumption. I/O

a HIGH-impedance st ate independent of OE

- I/O15 outputs are placed in

0

. If deselected during block erase or word write, the device continues functioning, and consuming active power until

the operation completes.

DEEP POWER-DOWN

RP

at VIL initiates the deep power down mode.

In read modes, RP

-LOW deselects the memory,

places output driver s in a HIGH-impedance s tate and

turns off all internal circuits. RP

a minimum of 1 00 ns. Time t

must be held LOW for

is required after

PHQV

return from power-down until initial memory access

outputs are valid. After this wake-up interval, normal

operation is restored. The CUI is reset to read array

mode and status register is set to 80H.

During block erase or word write modes, RP

-LOW

will abort the operation. Memory contents being altered

are no longer valid; the data may be partially erased or

written. Time t

HIGH (V

) before another command can be written.

IH

is required after RP goes to logic

PHWL

Figure 5. Device Identifier Code Memory Map

WRITE

Writing commands to the CUI enable reading of

device data and identifier codes. T hey also control

inspection and clearing of the status register.

When V

CC

= V

and VPP = V

CC1

, the CUI add i-

PPH

tionally controls block erasure and word write. The

Block Erase comman d requ ires ap propr iate com man d

data and an address within the block to be erased. The

Word Write command requires the command and

address of the location to be written.

The CUI does not occupy an addressable memory

location. It is wri tten wh en WE

and CE are active. The

address and data needed to execute a command ar e

latched on the rising edge of WE

or CE (whichever

goes HIGH first). Standard microprocessor write timings are used. F igure 13 a nd 14 illustrat e WE

and CE

controlled write operations.

10 Data Sheet

Page 11

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

COMMAND DEFINITIONS

When VPP ≤ V

, Read oper ation s from t he statu s

PPLK

Device operations are selected by writ ing specific com-

mands into the CUI. Tabl e 6 defines these comma nds.

register, identifier codes or blocks are enabled. Placing

V

on VPP enables successful block erase and word

PPH

write operations.

Table 5. Bus Operations

MODE RP

Read V

Output Disable V

Standby V

Deep Power-Down V

Read Identifier Codes V

Write V

NOTES:

1. Refer to ‘DC Characteristics’. When V

2. X can be V

See ‘DC Characteristics’ for V

3. Never hold OE

at GND ± 0.2 V ensures the lowest deep power-down current.

4. RP

5. See ‘Read Identifier Codes Command’ for read identifier code data.

6. Command writes involving block erase or word write are reliably executed when V

Block erase or word write with V

7. Refer to Table 6 for valid D

or VIH for control pins and addresses, and V

IL

LOW and WE LOW at the same time.

or V

IH

HH

or V

IH

HH

or V

IH

HH

IL

or V

IH

HH

or V

IH

HH

PP

and V

PPLK

< RP < VHH produce spurious results and should not be attempted.

IH

during a write operations.

IN

CE OE WE ADDRESS V

V

IL

V

IL

V

IH

V

IL

V

IH

V

IH

V

IH

XX X XHIGH Z

XXX X XHIGH Z4

≤ V

PPH

V

IL

V

IL

, memory contents can be read, but not altered.

PPLK

voltages.

V

V

PPLK

IL

IH

or V

PPH

V

IH

V

IL

for VPP.

I/O0 - I/O15NOTES

PP

XXD

OUT

1, 2, 3

XXHIGH Z

See Figure 3 X 5

XXDIN3, 6, 7

= V

PP

and VCC = V

PPH

CC1

.

1

4

OPER.2ADDR.3DATA

4

NOTES

COMMAND

Read Array/Reset

Read Identifier Codes

Table 6. Command Definitions

BUS CYCLES

REQUIRED

FIRST BUS CYCLE SECOND BUS CYCLE

OPER.

2

ADDR.

3

DATA

1 Write X FFH

2 Write X 90H Read IA ID 5

≥

Read Status Register 2 Write X 70H Read X SRD

Clear Status Register 1 Write X 50H

Block Erase 2 Write BA 20H Write BA D0H 6

Word Write 2 Write WA 40H or 10H Write WA WD 6, 7

Block Erase and Word

Write Suspend

Block Erase and Word

Write Resume

NOTES:

1. Commands other than those shown in table are reserved by SHARP for

future device implementations and should not be used.

2. BUS operations are defined in Table 5.

3. X = Any valid address within the device; IA = Identifier Code Address, see Figure 5.

BA = Address within the block being erased; WA = Address of memory location to be written.

4. SRD = Data read from status register. See Table 9 for a description of the status register bits.

WD = Data to be written at location WA. Data is latched on the rising edge of WE

ID = Data read from identifier codes.

5. Following the Read Identifier Codes command, read operations access manufacturer and device codes.

See ‘Read Identifier Codes Command’ for read identifier code data.

6. When WP

Attempts to issue a block erase or word write to a locked boot block while RP

7. Either 40H or 10H are recognized by the WSM as the word write setup.

= VIL, RP must beat VHH to enable block erase or word write operations.

1WriteXB0H 6

1WriteXD0H 6

or CE (whichever goes HIGH first).

= VIH.

Data Sheet 11

Page 12

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

READ ARRAY COMMAND

Upon initial device power-up and after exit from

deep power-down mode, the device defaults to read

array mode. This operation is also initiated by writing

the Read Array command. The device remains

enabled for reads until another command is written.

Once the internal WSM has started a block erase or

word write, the device will not recognize the Read Array

command until the WSM completes its operatio n

unless the WSM is suspended via an Erase Sus pend

or Word Write Suspend command. The Read Array

command functions ind ependently of V

RP

can be VIH or VHH.

voltage and

PP

READ IDENTIFIER CODES COMMAND

The identifier code operation is initiated by writing the

Read Identifier Codes command. Following the command write, read cycles from addresses shown in Figure 5 retrieve the manufacturer and device codes (see

Table 7 for identifier code values). To terminate the

operation, write another valid command. Like the Read

Array command, the Read Id entifier Codes command

functions independently of the V

be V

or VHH. Following the Read Identifier Codes

IH

voltage and RP can

PP

command, the following information can be read.

Table 7. Identifier Codes

CODE ADDRESS DATA

Manufacture Code 00000H 00B0H

Device Code (Top Boot) 00001H 0060H

READ STATUS REGISTER COMMAND

The status register may be r ead to d eterm ine whe n

a block erase or word write is complete and whether

the operation completed successfully. It may be read at

any time by writi ng the Read Status Register command. After writing this command, all subsequent read

operations output data from the status register until

another valid com mand is written. T he status regi ster

contents are latche d on the falling edge of OE

whichever occurs. OE

or CE must toggle to VIH before

or CE,

further reads to update the status register latch. The

Read Status Register command func tions independently of the V

voltage. RP can be VIH or VHH.

PP

CLEAR STATUS REGISTER COMMAND

Status register bits SR.5, SR.4, SR.3 or SR.1 are set

to ‘1’s by the WSM a nd c an on ly be r es et by the Clear

Status Register comma nd. The se bits in dicate various

failure conditions (see Table x). By allowing system

software to re set these bits , several ope rations (suc h

as cumulativel y erasi ng multi ple bloc ks or w riting several words in sequence) may be performed. The status

register may be polled to determine if an error occurred

during the sequence.

To clear the status regis te r, the Cl ear S tatu s Regi ster command (50H) is written. It functio ns independently of the applied V

V

. This command is not functional during block

HH

voltage. RP can be VIH or

PP

erase or word write suspend modes.

BLOCK ERASE COMMAND

Erase is executed one block at a time an d initiated

by a two-cycle command. A block erase setup is first

written, followed by a block erase confirm. This command sequence requires appropriate sequencing an d

an address within the block to be erased (erase

changes all block data to FFFFH). Bloc k precondi tioning, erase, an d verify are handle d internally by th e

WSM (invisible to the system). After the two-cycle block

erase sequence is written, the device automatically

outputs status register data when read (see Figure 6) .

The CPU can detect block erase completion by analyzing the output data of the status register bit SR.7.

When the block erase is complete, status register bit

SR.5 should be checked. If a block erase error is

detected, the status regi ster should be cleare d before

system software attempts corrective action. The CUI

remains in read s tatus registe r mod e unti l a new command is issued.

This two-step command sequence of set-up followed by execution ensures that block contents are not

accidentally eras ed. An inva lid Block Er ase comman d

sequence will result in both status reg ister bits SR.4

and SR.5 being set to ‘1’. Also, rel iable block erasure

can only occur w hen V

CC

= V

and VPP = V

CC1

PPH

. In

the absence of this high voltage, block contents are

protected against erasure. If block erase is attempted

while V

PP

≤ V

, SR.3 and SR.5 will be set to ‘1’.

PPLK

Successful bloc k erase for b oot blocks requires th at if

set WP

to boot block w hen the corresp onding WP

RP

operations with V

= VIH or RP = VHH. If block erase is attem pte d

= VIL or

=VIH, SR.1 and SR.5 will be set to ‘1’. Block erase

< RP < VHH produce spurious

IH

results and should not be attempted.

12 Data Sheet

Page 13

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

Start

Write 20H

Block Address

Write D0H

Block Address

Read

Status Register

SR.7 =

0

Suspend

Block

Suspend Block

No

Erase Loop

Yes

Erase

1

Full Status

Check If Desired

Block Erase

Complete

FULL STATUS CHECK PROCEDURE

BUS

OPERATION

Write

Write

Read

COMMAND

Erase Setup

Erase

Confirm

COMMENTS

Data = 20H

Addr = Within Block to be Erased

Data = D0H

Addr = Within Block to be Erased

Status Register Data

Check SR.7

Standby

1 = WSM Ready

0 = WSM Busy

Repeat for subsequent block erasures.

Full status check can be done after each block erase

or after a sequence of block erasures.

Write FFH after the last operation to place device in read array mode.

Read Status Register

Data (See Above)

SR.3 =

SR.1 =

SR.4, 5 =

SR.5 =

Block Erase

Successful

1

0

1

0

1

0

1

0

V

PP

Range Error

Device

Protect Error

Command

Sequence Error

Block

Erase Error

BUS

OPERATION

Standby

Standby

Standby

Standby

SR.5, SR.4, SR.3, and SR.1 are only cleared by the Clear Status

Register Command in cases where multiple blocks are erased before

full status is checked.

If error is detected, clear the Status Register before attempting

retry or other error recovery.

COMMAND

COMMENTS

Check SR.3

1 = V

Error Detect

PP

Check SR.1

1 = Device Protect Detect

Check SR.4, 5

Both 1 = Command Sequence Error

Check SR.5

1 = Block Erase Error

LRS1338A-6

Figure 6. Automated Block Erase Flowchart

Data Sheet 13

Page 14

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

WORD WRITE COMMAND

Word write is executed by a two-cycle command

sequence. Word write setup (standard 40H or alternate

10H) is written, fol lowed by a sec ond write t hat specifies the address and data (latched on the rising edge of

WE

). The WSM th en takes over , controllin g the word

write and write verify algorithms internally. After the

word write sequence is written, the device automatically outputs st atus register data when read ( see Figure 7). The CPU can detect the completion of the word

write event by analyzing the status register bit SR.7.

When word write is complete, status register bit

SR.4 should be checked. If word write error is detected,

the status register should be cleared. The internal

WSM verify only detects errors for ‘1’s that do not successfully w rite to ‘0’s. The CUI remains in read status

register mode until it receives another command.

Reliable word writes can only occur when V

and VPP and V

. In the absence of this high voltage,

PPH

CC

= V

CC1

memory contents are protected against word writes. If

word write is att empt ed wh ile V

PP

≤ V

, status regis-

PPLK

ter bits SR.3 and SR.4 will be set to ‘1’.

Successful word write for boot blocks requires that if

set, that WP

attempted to boot block when the corresponding WP

V

or RP = VIH, SR.1 and SR.4 will be set to ‘1’. Word

IL

write operations with V

= VIH or RP = VHH. If word write is

=

< RP < VHH produce spurious

IH

results and should not be attempted.

BLOCK ERASE SUSPEND COMMAND

The Block Erase Suspend command allows blockerase interruption to read or word-write data in another

block of memory. Once the block-erase process starts,

writing the Block Erase Suspend command requests

that the WSM suspend the bloc k erase se quence at a

predetermined p oint in the algo rithm. The devi ce outputs status register data when rea d after the Block

Erase Suspend command is written. Polling status register bits SR.7 and SR.6 can determine when the block

erase operation has bee n suspen ded (both wil l be set

to ‘1’). Specification t

WHRH2

defines the block erase

suspend latency.

At this point, a Read Array command can be written

to read data from blocks other than that which is su spended. A Word Write command sequence can also be

issued during erase suspend t o program da ta in other

blocks. using the Wor d Wr ite Sus pend c ommand (see

‘Word Write Suspend Command’ section), a word write

operation can also be s uspended. During a word writ e

operation with block erase suspended, status register

bit SR.7 will return to ‘0’. However, SR.6 will remain ‘1’

to indicate block eras e suspend status.

The only other valid commands while block erase is

suspended are Read Statu s Re gis te r and Bl oc k Eras e

Resume. After a Block Erase Resum e command is

written to the flash memory, the WSM will continue the

block erase process. Status register bits SR.6 and

SR.7 will automatical ly clear. After the Erase Resum e

command is written, the device automatically outputs

status register data wh en read (see Figure 8). V

must remain at V

(the same VPP level used for

PPH

block erase) while block er ase is su spe nde d. RP

also remain at V

block erase). WP

same WP

level used for block erase). Block erase can-

or VHH (the same RP level used for

IH

must also remain at VIL or VIH (the

PP

must

not resume until wor d write operations initiated d uring

block erase suspend have completed.

14 Data Sheet

Page 15

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

Start

Write 40H or 10L

Address

Write Word

Data and Address

Read

Status Register

SR.7 =

0

Suspend

Word

Suspend Word

No

Write Loop

Yes

Write

1

Full Status

Check If Desired

Word Write

Complete

FULL STATUS CHECK PROCEDURE

BUS

OPERATION

Write

Write

Read

COMMAND

Setup

Word Write

Word

Write

COMMENTS

Data = 40H or 10H

Addr = Location to be Written

Data = Data to be Written

Addr = Location to be Written

Status Register Data

Check SR.7

Standby

1 = WSM Ready

0 = WSM Busy

Repeat for subsequent byte writes.

SR full status check can be done after each byte write

or after a sequence of byte writes.

Write FFH after the last byte write operation to place

device in read array mode.

Read Status Register

Data (See Above)

SR.3 =

SR.1 =

SR.4 =

Word Write

Successful

1

0

1

0

1

0

V

PP

Range Error

Device

Protect Error

Word Write

Error

Figure 7. Automated Word Write Flowchart

BUS

OPERATION

Standby

Standby

Standby

SR.4, SR.3, and SR.1 are only cleared by the Clear Status

Register Command in cases where multiple locations are written

before full status is checked.

If error is detected, clear the Status Register before attempting

retry or other error recovery.

COMMAND

COMMENTS

Check SR.3

1 = V

Error Detect

PP

Check SR.1

1 = Device Protect Detect

Check SR.4

1 = Data Write Error

LRS1338A-7

Data Sheet 15

Page 16

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

Read

Array Data

Start

Write B0H

Read

Status Register

SR.7 =

1

SR.6 =

1

Read or

Word

Write?

No

0

0

Word WriteRead

Write Loop

Block

Erase Completed

Word

BUS

OPERATION

Write

Read

Standby

Standby

Write

COMMAND

Erase

Suspend

Erase

Resume

COMMENTS

Data = B0H

Addr = X

Status Register Data

Addr = X

Check SR.7

1 = WSM Ready

0 = WSM Busy

Check SR.6

1 = Block Erase Suspended

0 = Block Erase Completed

Data = D0H

Addr = X

Done?

Yes

Write D0H

Block Erase

Resumed

Write FFH

Read Array Data

LRS1338A-8

Figure 8. Block Erase Suspend/Resume Flowchart

16 Data Sheet

Page 17

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

WORD WRITE SUSPEND COMMAND

The Word Write Suspend c ommand allows word

write interruption to read data in othe r flash memory

locations. Once the word write process sta rts, writing the

Word Write Suspend command requests that the WSM

suspend the word write sequ ence at a predetermined

point in the algorithm . The device continues to output

status register data when read after the Word Write Suspend command is written. Polling status register bits

SR.7 and SR.2 can determine when the word write operation has been suspended (both will be set to ‘1’). Specification t

defines the wor d write su spend late ncy.

WHRH1

Start

Write B0H

Read

Status Register

SR.7 =

SR.2 =

Write FFH

0

1

0

1

Word

Write Completed

At this point a Read Array comma nd can be written

to read data from locations other than that which is suspended. The only other valid commands while word

write is suspended are Read Status Register and Word

Write Resume. After W ord W ri te Re su me c om man d is

written to the flash memory, the WSM will continue the

word write process. Status register bits SR.2 and SR.7

will automatically clear . After the Word Write Resume

command is written, the device automatically outputs

status register data wh en read (see Figure 9). V

must remain at V

(the same VPP level used for word

PPH

write) while in word write suspend mode. RP

remain at V

write). WP

or VHH (the same RP level used for word

IH

must also remain VIL or VIH (the same WP

level used for word write).

BUS

OPERATION

Write

Read

Standby

Standby

Write

Read

Write

COMMAND

Word Write

Suspend

Read

Array

Word Write

Resume

COMMENTS

Data = B0H

Addr = X

Status Register Data

Addr = X

Check SR.7

1 = WSM Ready

0 = WSM Busy

Check SR.2

1 = Word Write Suspended

0 = Word Write Completed

Data = FFH

Addr = X

Read Array locations other

than that being written

Data = D0H

Addr = X

PP

must also

Read Array Data

Done

Reading?

Write D0H

Word Write

Resumed

No

Yes

Write FFH

Read Array Data

LRS1338A-9

Figure 9. Word Write Suspend/Resume Flowchart

Data Sheet 17

Page 18

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

Table 8. Write Protection Alternatives

OPERATION V

Word Write or

Block Erase

> V

PP

V

IL

PPLK

RP WP EFFECT

X X All blocks locked

V

IL

V

HH

V

IH

X All blocks locked

X All blocks unlocked

V

V

Two boot blocks locked

IL

All blocks unlocked

IH

Table 9. Status Register Definition

WSMS ESS ES WWS VPPS WWSS DPS R

76543210

SR.7 = Write State Machine Status (WSMS)

1 = Ready

0 = Busy

SR.6 = Erase Suspend Status (ESS)

1 = Block Erase Suspended

0 = Block Erase in Progress/Completed

SR.5 = Erase(s)

1 = Error in Block Erasure

0 = Successful Block Erase

SR.4 = Word Write (WWS)

NOTES:

1. Check SR.7 to determine block erase or word write c ompletion.

SR.6 - SR.0 are invalid while SR.7 = 0.

2. If both SR.5 and SR.4 are ‘1’s after a block erase attempt, an

improper command sequence was entered.

3. SR.3 does not provide a continuous indication of V

WSM interrogates and indicates the V

Erase or Word Write command sequences. SR.3 is not guaranteed to report accurate feedback only when V

4. The WSM interroga tes the WP

Word Write command sequences. It informs the system, depending

on the attempted operation, if the WP

5. SR.0 is reserved for future use and should be m asked out when

polling the status register.

and RP only after Block Eras e or

level only after Block

PP

is not VIH or RP is not VHH.

PP

≠ V

level. The

PP

PPH

1 = Error in Word Write

0 = Successful Word Write

.

SR.3 = V

1 = V

0 = V

Status (VPPS)

PP

LOW Detect, Operation Abort

PP

Okay

PP

SR.2 = Word Write Suspend Status (WWSS)

1 = Word Write Suspended

0 = Word Write in Progress/Completed

SR.1 = Device Protect Status (DPS)

1 = WP

and/or RP Lock Detected, Operation Abort

0 = Unlock

SR.0 = Reserved for future enhancements (R)

18 Data Sheet

Page 19

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

Design Considerations

THREE-LINE OUTPUT CONTROL

The device will often be used in large memory

arrays. SHARP provides three control inputs to accommodate multiple mem ory con nections . Three-l ine control provides for:

• Lowest possible memory power dissipation.

• Complete assurance that data bus contention will

not occur.

To use these control inputs efficiently, an address

decoder should enabl e CE

nected to all memory devices and the system’s READ

control line. This assures that only s elected memory

devices have active outputs whil e deselected memory

devices are in standby mode. RP

to the system POWERGOOD signal to prevent unintended writes during system power transitions. POWERGOOD should also toggle during system reset.

POWER SUPPLY DECOUPLING

Flash memor y power switching ch aracteristics

require careful device decoupling. System de signers

are interested i n three supply c urrent issues: st andby

current levels, active current levels and transient peaks

produced by falli ng and rising edges o f CE

Transient current magnitudes depend on the device

outputs’ capacitive and inductive loading. Two-line

control and proper decoupling capacitor selection will

suppress transi ent v oltage peak s. E ach d evice sho uld

have a 0.1 µF ceramic capacitor connected between its

V

and GND and between i ts VPP and GND. These

CC

high-frequency, low inductance capacitors should be

placed as close as possible to package leads. Additionally, for every eight devices, a 4.7 µF electrolytic capacitor should be placed at the array’s power supply

connection between V

will overcome voltage slumps caused by PC board

trace inductance.

V

TRACE ON PRINTED CIRCUIT BOARDS

PP

Updating flash memories that reside in the target

system requires tha t the pr inted circui t boar d design er

pay attention to the V

pin supplies the memory cell current for word writing

and block erasing. Use s imilar trace wid ths and layou t

considerations giv en to the V

V

supply traces and decoupling will decrease V

PP

voltage spikes and overshoots.

, VPP RP TRANSITIONS

V

CC

Block erase and word write are not guaranteed if

V

falls outside of a valid V

PP

side of a valid V

range, or RP ≠ VIH or VHH. If V

CC1

error is detected, status register bit SR.3 is set to ‘1’

while OE should be con-

should be connected

and OE.

and GND. The bulk capacitor

CC

power supply trace . The V

PP

power bus. Adeq uate

CC

range, VCC falls out-

PPH

PP

PP

PP

along with SR.4 or SR.5, d epending on the attempted

operation. If RP

transitions to VIL during blo ck erase or

word write, the operation wil l abort and the device will

enter deep power-down. The aborted op eration may

leave data partially altered. Therefore, the command

sequence must be repeated after normal operation is

restored. Device power-off or RP

transitions to VIL clear

the status register.

The CIU latches command s issued by syste m soft-

ware and is not altered by V

or CE transitions or

PP

WSM actions. Its state is read array mode upon powerup, after exit from dee p p ower -dow n o r afte r V

sitions below V

LKO

.

After block erase or word write, even after V

nation down to V

, the CUI must be placed in read

PPLK

CC

tran-

PP

tar-

array mode via the Read Array command if subsequent

access to the memory array is desired.

POWER-UP/DOWN PROTECTION

The device is designed to offer prote ction against

accidental block eras ure or word writing duri ng power

transitions. Upon power-up, the device is indifferent as

to which power supply (V

or VCC) powers-up first.

PP

Internal circuitry resets the CUI to read array mode a t

power-up.

A system designer must guard against spurious

writes for V

Since both WE

write, driving either to V

voltages above V

CC

when VPP is active.

LKO

and CE must be LOW for a com mand

will inhibit writes. The CUI’s

HH

two-step command sequence architectur e provides

added level of protection against data alteration.

provide additional pr otection from inadvertent

WP

code or data alteration.

The device is d isabl ed wh il e RP

= VIL regardless of

its control inputs state.

POWER DISSIPATION

When designing portable systems, designers must

consider bat tery power con sumption not on ly during

device operation, but also for data retention during system idle time. Flash memor y’s non-volatility increases

usable battery life because data is retain ed when system power is removed.

In addition, deep power-down mode ensures

extremely low power consumption e ven when syste m

power is applied. F or example, portable com puting

products and other power sen sitive applications that

use an array of devices for solid-state storage can consume negligible power by lowering RP

to VIL standby or

sleep modes. If access is again needed, the devices

can be read followi ng the t

cycles required after RP

is first raised to VIH. See ‘AC

PHQV

and t

PHWL

wake-up

Characteristics — Read Only and Write Operations’

and Figure 12, 13 and 14 for more information.

Data Sheet 19

Page 20

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

LRS1338A-10

INPUT

TEST POINTS

OUTPUT

2.7

0.0

1.35 1.35

NOTE: AC test inputs are driven at 2.7 V for a Logic '1' and 0.0 V

for a Logic '0'. Input timing begins and output timing ends

at 1.35 V. Input rise and fall times (10% to 90%) < 10 ns.

LRS1338A-11

DEVICE

UNDER

TEST

1N914

OUT

NOTE: C

L

Includes Jig Capacitance

R

L

= 3.3 kΩ

1.3 V

C

L

Electrical Specifications

ABSOLUTE MAXIMUM RATINGS

• Commercial Operating Temperature

– During Read, Block Erase and Word Write:

-40°C to +85°C (Note 1)

– Temperature under Bias: -40°C to +85°C (Note 1)

• Storage Temperature: -65°C to +125°C

• Voltage on any pin except V

-2.0 V to +7.0 V (Note 2)

Supply Voltage: -2.0 V to +7.0 V (Note 2)

• V

CC

• V

Update Voltage dur ing Block Erase and Word

PP

Write: -2.0 V to +14.0 V (Note 2 and 3)

Voltage: -2.0 V to +14.0 V (Note 2 and 3)

• RP

• Output Short Circuit Current: 100 mA (Note 4)

WARNING:

Ratings’ may cause permanent damage. These are stress ratings

only. Operation be yond the ‘Operatin g Conditions’ is not recommended and extended exposure beyond the ‘Operating Conditions’

may affect device reliability.

NOTES:

1. Operating temperature is for commercial product defined by this

specification.

2. All specified voltages are with respect to GND. Minimum DC voltage is -0.5 V on input /output pins and -0 .2 V on V

During transitions, this l e vel m a y un d ersh o ot to -2 .0 V fo r per iod s

< 20 ns. Maximum DC voltage on i nput/output pins and V

+ 0.5 V which, during transitions, may overshoot to VCC+ 2.0 V for

periods < 20 ns.

3. Maximum DC voltage on V

for periods <20 ns.

4. Output shorted for no more than one second. No more than one

output shorted at a time.

*Stressing the device beyond the ‘Absolute Maximum

and RP may overshoot to +14.0 V

PP

*

, VPP and RP:

CC

and VPP pins.

CC

CC

is V

CC

AC Test Conditions

Figure 10. Transient Input/Output Reference

Waveform for V

Figure 11. Transient Equivalent

Testin g Lo ad Circui t

Table 10. Test Configuration

Capacitance Loading Value

= 2.7 V to 3.6 V

CC

20 Data Sheet

TEST CONFIGURATION C

= 2.7 V to 3.6 V 50

V

CC

(pF)

L

Page 21

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

FLASH DC CHARACTERISTICS

V

= 2.7 V to 3.6 V

SYMBOL PARAMETER

I

I

LO

I

CCS

I

CCD

I

CCR

I

CCW

I

CCE

I

CCWS

I

CCES

I

PPS

I

PPR

I

PPD

I

PPW

I

PPE

I

PPWS

I

PPES

V

V

V

V

OH1

V

OH2

V

PPLK

V

PPH

V

LKO

V

Input Load Current ±0.5 µA VCC = VCC MAX., VIN = VCC or GND 1

LI

Output Leakage Current ±0.5 µA VCC = VCC MAX., V

VCC Standby Current

VCC Deep Power-Down Current 4 20 µA RP = GND ± 0.2 V 1

VCC Read Current

VCC Word Write Current 5 17 mA VPP = V

VCC Block Erase Current 4 17 mA VPP = V

VCC Word Write or Block

Erase Suspend Current

VPP Standby or Read Current

VPP Deep Power-Down Current 0.1 5 µA RP = GND ± 0.2 V 1

VPP Word Write C urrent 12 40 mA VPP = V

VPP Block Erase Current 8 25 mA VPP = V

VPP Word Write or Block Erase

Suspend Current

Input LOW Voltage -0.5 0.8 V 4

IL

Input HIGH Voltage 2.0 VCC + 0.5 V 4

IH

Output LOW Voltage 0.4 V VCC = VCC MIN., IOL = 2.0 mA 4

OL

Output HIGH Voltage (TTL) 2.4 V VCC = VCC MIN., IOH = 1.0 mA 4

Output HIGH Voltage (CMOS)

VPP Lockout during

Normal Operations

VPP during Word Write or Block

Erase Operations

VCC Lockout Voltage 2.0 V

RP Unlock Voltage 11.4 12.6 V Unable WP 7, 8

HH

CC

MIN. MAX.

25 50 µA

0.2 2 mA

15 25 mA

30 mA

16mACE

±2 ±15 µA V

10 20.0 µA V

10 200 µA V

0.85 V

CC

-0.4 V VCC = VCC MIN., IOH = -100 µA 4

V

CC

UNIT

CMOS Inputs, V

CE

= RP = VCC ± 0.2 V

TTL Inputs, V

= RP = V

CE

CMOS Inputs, V

= GND, f = 5 MHz, I

CE

TTL Inputs, V

CE

= GND, f = 5 MHz, I

PPH

PPH

= V

IH

≤ V

PP

CC

> V

PP

CC

PPH

PPH

= V

PP

PPH

VVCC = VCC MIN., IOH = 2.5 mA 4

1.5 V 4, 6

2.7 3.6 V

TEST

CONDITIONS

= VCC or GND 1

OUT

= VCC MAX.,

CC

= VCC MAX.,

CC

IH

= VCC MAX.,

CC

OUT

= VCC MAX.,

CC

OUT

= 0 mA

= 0 mA

NOTES

1, 2

1, 2

1, 2, 3

1, 2, 3

1, 4

1, 4

1, 5

1

1

1, 4

1, 4

1

NOTES:

1. All currents are in RMS unless otherwise noted.

2. CMOS inputs are either V

are either V

3. Automatic Power Savings (APS) reduces typica l I

3.3 V V

4. Sampled, not 100% tested.

5. I

CCWS

or word written while in erase suspend mode, the device’s current

draw is the sum of I

or VIH.

IL

in static operation.

CC

and I

are specified with the device de-selected. If read

CCES

CCWS

± 0.2 V or GND ± 0.2 V. TTL inputs

CC

to 3 mA at

CCR

or I

CCES

and I

CCR

or I

CCW

, respectively.

6. Block erases and word writes are inhibited when V

and not guaranteed in the range between V

(MIN.).

V

PPH

7. Block erases and word writes are inhibited when the corresponding RP

= VIH or WP = VIL. Block erase and word write operations

are not guaranteed with V

should not be attempted.

8. RP

connection to a VHH supply is allowed for a maximum cumu-

lative period of 80 hours.

< 3.0 V or VIH < RP < VHH and

CC

PP

(MAX.) and

PPLK

≤ V

PPLK

Data Sheet 21

,

Page 22

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

FLASH AC CHARACTERISTICS — READ ONLY OPERATIONS

1

VCC = 2.7 V to 3.6 V, TA = 40°C to +85°C

SYMBOL PARAMETER MIN. MAX. UNIT NOTES

t

AVAV

t

AVQV

t

ELQV

t

PHQV

t

GLQV

t

ELQX

t

EHQZ

t

GLQX

t

GHQZ

t

OH

NOTES:

1. See ‘AC Input/Output Reference Waveform’ section for maximum allowable input slew rate.

may be delayed up to t

2. OE

3. Sampled, not 100% tested.

Read Cycle Time 120 ns

Address to Output Delay 120 ns

CE to Output Delay 120 ns 2

RP HIGH to Output Delay 600 ns

OE to Output Delay 50 ns 2

CE to Output in LOW Z 0 ns 3

CE HIGH to Output in HIGH Z 55 ns 3

OE to Output in LOW Z 0 ns 3

OE HIGH to Output in HIGH Z 20 ns 3

Output Hold from Address, CE or OE Change,

Whichever Occurs First

- t

ELQV

ADDRESSES (A)

after the falling edge of CE without impact on t

GLQV

DEVICE

ADDRESS SELECTION

V

IH

V

IL

0ns3

.

ELQV

DATA VALIDSTANDBY

ADDRESS STABLE

t

AVAV

CE (E)

OE (G)

WE (W)

DATA (D/Q)

- I/O15)

(I/O

0

V

CC

RP (P)

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

OH

V

OL

V

IH

V

IL

t

AVEL

t

PHQV

t

ELQX

t

AVQV

t

ELQV

t

GLQV

t

GLQX

VALID OUTPUT

t

EHQZ

t

GHQZ

t

OH

HIGH ZHIGH Z

LRS1338A-12

Figure 12. AC Waveforms for Read Operations

22 Data Sheet

Page 23

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

FLASH AC CHARACTERISTICS — WRITE OPERATIONS

1

VCC = 2.7 V to 3.6 V, TA = -40°C to +85°C

SYMBOL PARAMETER MIN. MAX. UNIT NOTES

t

AVAV

t

PHWL

t

ELWL

t

WLWH

t

PHHWH

t

SHWH

t

VPWH

t

AVWH

t

DVWH

t

WHDX

t

WHAX

t

WHEH

t

WHWL

t

WHGL

t

QVVL

t

QVPH

t

QVSL

Write Cycle Time 120 ns

RP HIGH Recovery to WE Going LOW 1 µs 2

CE Setup to WE Going LOW 10 ns

WE Pulse Width 50 ns

RP VHH to WE Going HIGH 100 ns 2

WP VIH Setup to WE Going HIGH 100 ns 2

VPP Setup to WE Going HIGH 100 ns 2

Address Setup to WE Going HIGH 50 ns 3

Data Setup to WE Going HIG H 50 ns 3

Data Hold from WE HIGH 5 ns

Address Hold from WE HIGH 5 ns

CE Hold from WE HIGH 10 ns

WE Pulse Width HIGH 30 ns

Write Recovery before Read 0 ns

VPP Hold from Valid SRD HIGH 0 ns 2, 4

RP VHH Hold from Valid SRD HIGH 0 ns 2, 4

WP VIH Hold from Valid SRD HIGH 0 ns 2, 4

NOTES:

1. Read timing characteristics during block erase and word write operations are the

same as during read-only operations. Refer to ‘AC Characteristics’ section for read-only operations.

2. Sampled, not 100% tested.

3. Refer to Table 6 for valid A

4. V

should be held at V

PP

determination of block erase or word write success (SR.1, SR.3, SR.4, SR.5 = 0).

and DIN for block erase or word write.

IN

(and if necessary RP should be held at VHH) until

PPH

Data Sheet 23

Page 24

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

2345 61

V

ADDRESSES (A)

CE (E)

OE (G)

WE (W)

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

t

WLWH

A

IN

t

AVAVtAVWH

t

ELWL

t

WHEH

t

WHWL

A

IN

t

WHAX

t

WHGL

t

WHOV1, 2, 3, 4

V

IH

V

V

V

V

V

V

V

V

PPH

PPLK

V

IL

IL

IH

IL

HH

IH

IL

HIGH Z

t

PHWL

DATA (I/O)

WP (S)

RP (P)

V

(V)

PP

NOTES:

1. V

power-up and standby.

CC

2. Write block erase or word write setup.

3. Write block erase confirm or valid address and data.

4. Automated erase or program delay.

5. Read status register data.

6. Write Read Array command.

Figure 13. AC Waveform for WE Controlled Write Operations

t

DVWH

t

WHDX

VALID

SRD

D

IN

t

SHWH

t

PHHWH

t

VPWH

D

IN

t

QVSL

t

QVPH

t

QVVL

D

IN

LRS1338A-13

24 Data Sheet

Page 25

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

ALTERNATIVE CE CONTROLLED WRITES

1

VCC = 2.7 V to 3.6 V, TA = 40°C to +85°C

SYMBOL PARAMETER MIN. MAX. UNIT NOTES

t

AVAV

t

PHEL

t

WLEL

t

ELEH

t

PHHEH

t

SHEH

t

VPEH

t

AVEH

t

DVEH

t

EHDX

t

EHAX

t

EHWH

t

EHEL

t

EHGL

t

QVVL

t

QVPH

t

QVSL

Write Cycle Time 120 ns

RP HIGH Recovery to CE Going LOW 1 µs 2

WE Setup to CE Going LOW 0 ns

CE Pulse Width 70 ns

RP VHH Setup to CE Going HIGH 100 ns 2

WP VIH Setup to CE Going HIGH 100 ns 2

VPP Setup to CE Going HIGH 100 ns 2

Address Setup to CE Going HIGH 50 ns 3

Data Setup to CE Going HIGH 50 ns 3

Data Hold from CE HIGH 5 ns

Address Hold from CE HIGH 5 ns

WE Hold from CE HIGH 0 ns

CE Pulse Width HIGH 25 ns

Write Recovery before Read 0 ns

VPP Hold from Valid SRD HIGH 0 ns 2, 4

RP VHH Hold from Valid SRD HIGH 0 ns 2, 4

WP VIH Hold from Valid SRD HIGH 0 ns 2, 4

NOTES:

1. In systems where CE

all setup, hold, and inactive WE

2. Sampled, not 100% tested.

3. Refer to Table 6 for valid A

4. V

should be held at V

PP

determination of block erase or word write success (SR.1, SR.3, SR.4, SR.5 = 0).

defines the write pulse width (within a longer WE timing waveform),

times should be measured relative to the CE waveform.

and DIN for block erase or word write.

IN

(and if necessary RP should be held at VHH) until

PPH

Data Sheet 25

Page 26

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

234561

V

ADDRESSES (A)

WE (W)

OE (G)

CE (E)

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

t

ELEH

t

A

IN

t

AVAVtAVEH

WLEL

t

EHWH

t

EHEL

A

IN

t

EHAX

t

EHGL

t

EHQV1, 2, 3, 4

V

IH

V

V

V

PPLK

V

V

V

V

V

V

PPH

IL

IL

IH

IL

HH

IH

IL

HIGH Z

t

PHEL

DATA (D/Q)

WP (S)

RP (P)

V

(V)

PP

NOTES:

1. V

power-up and standby.

CC

2. Write block erase or word write setup.

3. Write block erase confirm or valid address and data.

4. Automated erase or program delay.

5. Read status register data.

6. Write Read Array command.

t

DVEH

t

EHDX

VALID

SRD

D

IN

t

EHEH

t

PHHEH

t

VPEH

D

IN

t

QVSL

t

QVPH

t

QVVL

D

IN

LRS1338A-14

Figure 14. Alternate AC Waveform for CE Controlled Write Operations

26 Data Sheet

Page 27

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

RESET OPERATIONS

V

RP (P)

V

RP (P)

V

2.7 V - 3.6 V

CC

V

V

V

IH

IL

IL

IH

IL

t

PLPH

A. Reset during Block Erase or Word Write or Read Array Mode

t

VPH

B. RP rising Timing

LRS1338A-15

Figure 15. AC Waveform for Reset Operation

Table 11. Reset AC Specifications

SYMBOL PARAMETER

t

PLPH

t

VPH

NOTES:

1. If RP

the reset will complete within 100 ns.

2. When the device power-up holding RP

after V

RP Pulse LOW Time (if RP is tied to VCC,

this specification is not applicable)

VCC 2.7 V to RP HIGH 100 ns 2

is asserted while a block erase or word write operation is not executing,

has been in predefined range and also has been stable there.

CC

LOW minimum 100 ns is required

BLOCK ERASE AND WORD WRITE PERFORMANCE

VCC = 2.7 V to 3.6 V, TA = 40°C to +85°C

SYMBOL PARAMETER

t

t

t

WHRH1

t

WHRH2

WHQV1

t

EHQV1

WHQV2

t

EHQV2

, t

, t

EHRH1

EHRH2

Word Write Time 32K-word Block 44.6 µs 3

Word Write Time 4K-word Block 45.9 µs 3

Block Write Time 32K-word Block 1.46 sec 3

Block Write Time 4K-word Block 0.19 sec 3

Block Erase Time 32K-word Block 1.14 sec 3

Block Erase Time 4K-word Block 0.38 sec 3

Word Write Suspend Laten cy Time to Read 7 8 µs

Erase Suspend Latency Time to Read 18 22 µs

= 2.7 V to 3.6 V

V

CC

MIN. MAX.

100 ns 1

1

VPP = 2.7 V to 3.6 V

MIN. MAX. TYP.

UNIT NOTES

2

UNIT NOTES

NOTES:

1. Sampled, but not 100% tested.

2. Typical values measured at T

Subject to change based on device characterization.

3. Excludes system-level overhead.

= +25°C and nominal vo ltages.

A

Data Sheet 27

Page 28

LRS1338A Stacked Chip (8M Flash & 2M SRAM)

SRAM*

Description

The LRS1388A is a 2M bit static RAM organized as

262,144 × 8 bit which provides low-power standby

mode.

Features

• Access Time: 85 ns (MAX.)

• Operating Current:

– 40 mA (MAX.)

– 25 mA (MAX.)

Table 12. Truth Table

CE

H X X Standby HIGH Impedance Standby (I

L L X Write Data Inpu t Active (I

L H L Read Data Output Active (I

L H H Output Disable HIGH Impedance Active (I

NOTE:

WE OE MODE I/O0 - I/O

X = Don’t care, L= LOW, H = HIGH.

• Standby Current: 40 µA (MAX.)

• Data Retention Current: 0.6 µA (TYP. V

T

= 25°C)

A

CCDR

• Single Power Supply: 2.7 V to 3.6 V

• Operating Temperature: -40°C to +85°C

• Fully Static Operation

• Three-state Output

• Not Designed or Rated as Radiation Hardened

• P-Type Bulk Silicon

NOTE: *

age, etc. refer only to the SRAM portion of this chip.

In the SRAM section all reference to pins, commands, volt-

7

SUPPLY CURRENT

)

SB

)

CC

)

CC

)

CC

= 3 V,

28 Data Sheet

Page 29

Stacked Chip (8M Flash & 2M SRAM) LRS1338A

A

0

A

1

A

2

A

3

A

4

A

5

A

6

A

7

A

8

A

9

A

10

A

11

A

12

A

13

A

14

A

15

A

16

A

17

ADDRESS

BUFFER

10

ROW

DECODER

1024

MEMORY CELL ARRAY

(1024 x 256 x 8)

256 x 8

8

COLUMN

256

DECODER

COLUMN

GATE

V

CC