Page 1

®

PRODUCT SPECIFICATIONS

Integrated Circuits Group

LRS1302

Stacked Chip

8M Flash and 1M SRAM

(Model No.: LRS13023)

Spec No.: EL116039

Issue Date: June 11, 1999

Page 2

SHARP

l

Handle this document carefully for it contains material protected by international

copyright law. Any reproduction, full or in part, of this material is prohibited

without the express written permission of the company.

l

When using the products covered herein, please observe the conditions written herein

and the precautions outlined in the following paragraphs. In no event shall the

company be liable for any damages resulting from failure to strictly adhere to these

conditions and precautions.

(1)

LRS13023

The products covered herein are designed and manufactured for the following

application areas. When using the products covered herein for the equipment

listed in Paragraph (2). even for the following application areas, be sure

to observe the precautions given in Paragraph (2). Never use the products

for the equipment listed in Paragraph (3).

- Office electronics

* Instrumentation and measuring equipment

- Machine tools

- Audiovisual equipment

- Home appliances

* Communication equipment other than for trunk lines

(2) Those contemplating using the products covered herein for the following

equipment which demands high reliability, should first contact a sales

representative of the company and then accept responsibility for incorporating

into the design fail-sale operation, redundancy, and other appropriate measures

for ensuring reliability and safety of the equipment and the overall system.

* Control and safety devices for airplanes, trains, automobiles, and other

transportation equipment

* Mainframe computers

- Traffic control systems

* Gas leak detectors and automatic cutoff devices

- Rescue and security equipment

* Other safety devices and safety equipment,etc.

(3) Do not use the products covered herein for the following equipment which

demands extremely high performance in terms of functionality, reliability, or

accuracy.

- Aerospace equipment

- Communications equipment for trunk lines

- Control equipment for the nuclear power industry

- Medical equipment related to life support, etc.

(4) Please direct all queries and comments regarding the interpretation of the

above three Paragraphs to a sales representative of the company.

l

Please direct all queries regarding the products covered herein to a sales

representative of the company.

Page 3

-

SHARP

LRS13023

Part 1 Overview

l.Description

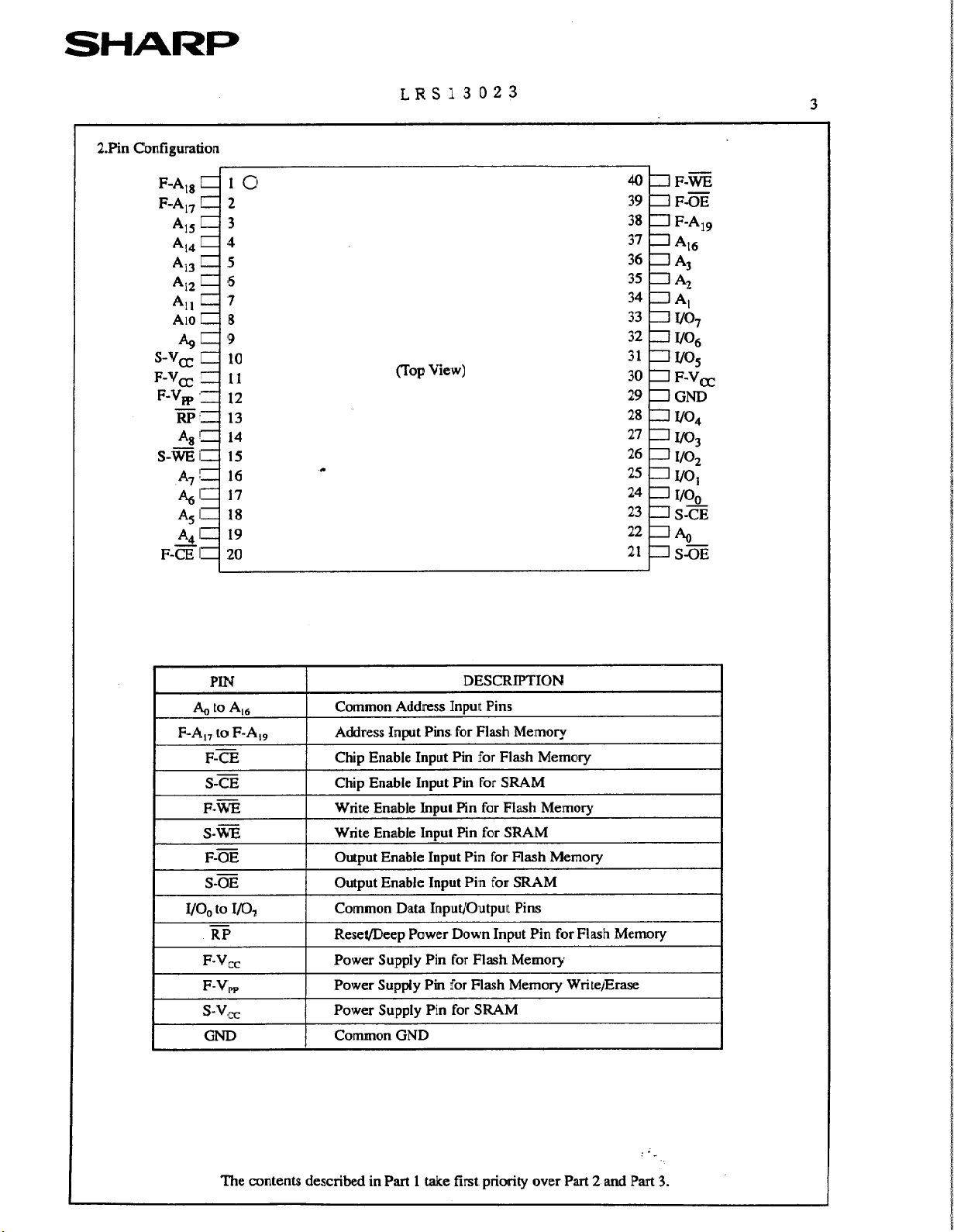

The LRS1302 is a combination memory organized as

memory and

It is fabricated using silicon-gate CMOS process technology.

Features

OAccess Time

Flashmemoryaccesstime

SRAM access time

OOpemtingcurrent

Flash memory Read

SRAM

131,072X8

Byte write

Block erase

operatin%

bit static RAM in one package.

- * * *

. . . .

. . . .

. . . .

. . . .

- - * *

1448,576 X 8

130 nsMax.

70 nsMax.

12 mAMax. (t&ti2OOns)

57 r&Max.

37 mAMax.

25 mA Max. hcxJz.=2=)

,

bit flash

2

ostandbycurrent

Flash memory

Sk4M

(Total standby curnat is the summation of Flash memory’s standby current and SRAM’s one.)

OPower supply

OSRAM data retention voltage

OOperating temperature

OFully static operation

oThree-state output

ONot designed or rated as radiation hardened

040 pin TSOP ( TSOP~O-p-0819 plastic package

OFlash memory has P-type bulk silicon, and SRAh4 has N-type bulk silicon.

. . . .

. . . .

. . . .

. . . .

. . . .

20 @ Max. (F-EZF-Vc,0.2V,

EbO.2V, F-V&O.2V)

30 pA Max. (S-EZS-Vc,0.2V)

0.7 @ Typ. (T,=25”c, S-V,-3V,

S-CErs-Vcc-0.2V)

2.7V to 3.6V @ead/SRAM write)

2.7~ to 3.6~ @LASH erase/write)(T,=O to 85c

2.0 V Min.

40°C to +85”c

The contents described in Part 1 take first priority over Part 2 and Part 3.

Page 4

-

SHARP

LRS13023

Part 1 Overview

l.Description

The LRS1302 is a combination memory organized as

memory and

It is fabricated using silicon-gate CMOS process technology.

OAccess Time

Flashmemoryaccesstime

SRAM access time

OOpemtingcment

Flash memory Read

SRAM Operating

131,072X8

Byte write

Block erase

bit static RAM in one package.

- * * *

. . . .

. . . .

. . . .

. . . .

- - * *

1,048,576X 8 bit flash

130 nsMax.

70 nsMax.

12 mAMax. (t&ti2Oons>

57 mAMax.

37 mAMax.

25 mAMax.

,

hcxJ&oons)

2

ostandbycurrent

Flash memory

Sk4M

(Total standby current is the summation of Flash memory’s standby current and SRAM’s one.)

3Power supply

3SRAM data retention voltage

3Operating temperature

IFully static operation

3Three-state output

JNot designed or rated as radiation hardened

240 Pin TSOP ( TSOP~O-p-0819 plastic package

IFlash memory has P-type bulk silicon, and SRAM has N-type bulk silicon.

. . . .

. . . .

. . . .

. . . .

. . . .

20 pA Max. (F-EZF-Vc,0.2V,

EbO.2V, F-V&O.2V)

30 @ Max. (S-=ZS-Vc,0.2V)

0.7 @ Typ. (T,=25”c, S-V,-3V,

s-CEZS-vcc-0.2v)

2.7V to 3.6V @ead/SPAM write)

2.7~ to 3.6~ (FLASH erase/write>Cr,=O to 85c

2.0 V Min.

40°C to +85”c

The contents described in Part 1 take first priority over Part 2 and Part 3.

Page 5

m

.

Page 6

SHARI=

LRS13023

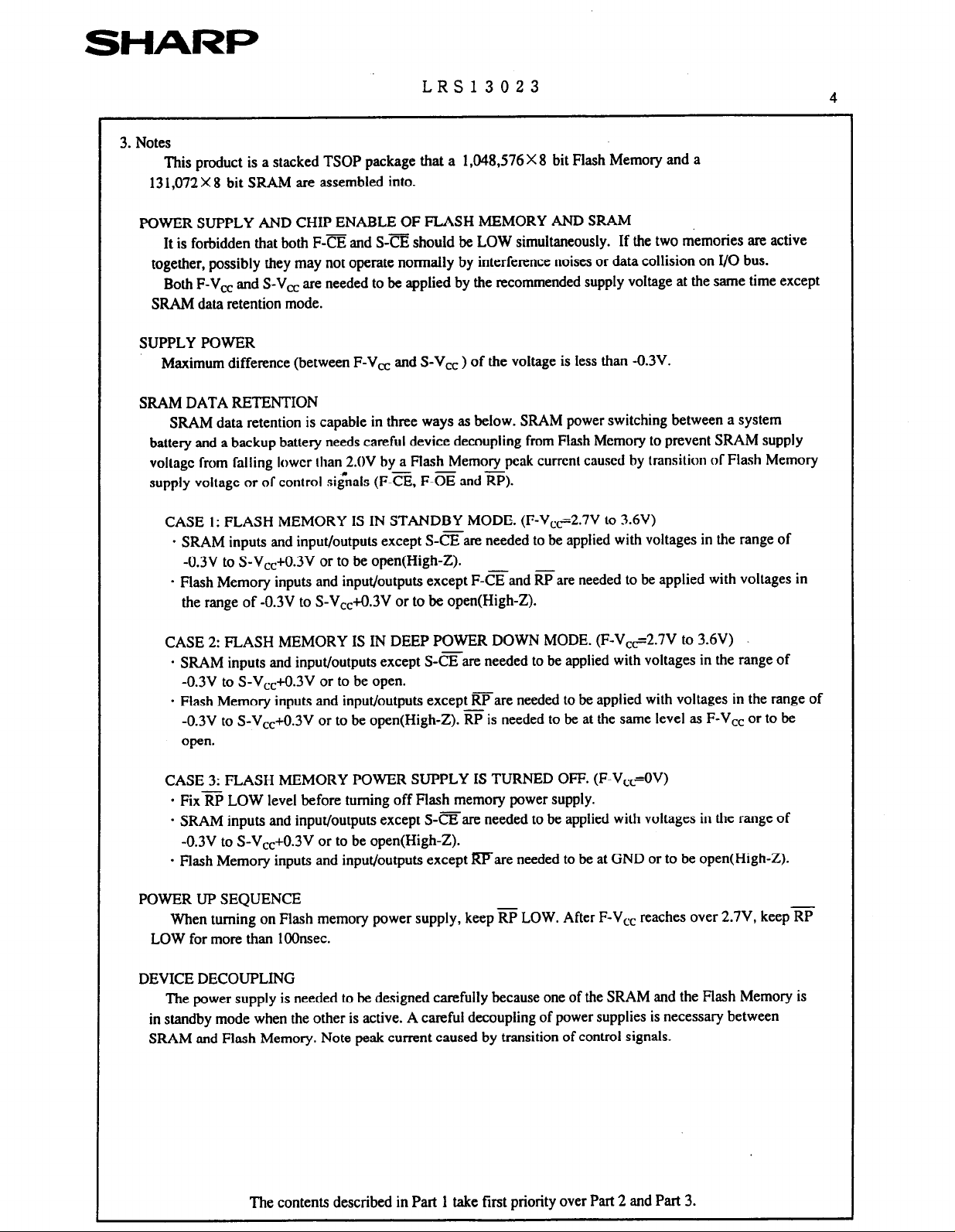

3. Notes

This product is a stacked TSOP package that a 1,048,576X 8 bit Flash Memory and a

13 1,072 X 8 bit SRAM are assembled into.

POWER SUPPLY AND CHIP ENABLE OF FLASH MEMORY AND SRAM

It is forbidden that both F-E and S-E should be LOW simultaneously. If the two memories are active

together, possibly they may not operate normally by interference noises or data collision on I/O bus.

Both F-V, and S-V, are needed to be applied by the recommended supply voltage at the same time except

SRAM data retention mode.

SUPPLY POWER

Maximum difference (between F-V,

SRAM DATA RETENTION

SRAM data retention is capable in three ways as below. SRAM power switching between a system

battery and a backup battery needs careful

voltage from

supply voltage or of control si{nals (F-B, F-?% and RP).

CASE I: FLASH MEMORY IS IN STANDBY MODE. (F-Vcc=2.7V to 3.6V)

* SRAM inputs and input/outputs except S-mare needed to be applied with voltages in the range of

-0.3V to S-Vcc+O.3V or to be open(High-Z).

* Flash Memory inputs and input/outputs except F-eand Gare needed to be applied with voltages in

the range of -0.3V to S-V,,+O.3V or to be open(High-Z).

failing

lower han

2.OV by a Flash Memory peak current caused by transition of Flash Memory

and S-V, ) of the voltage is less than -0.3V.

device

decoupling from Flash Memory to prevent SRAM

4

supply

CASE 2: FLASH MEMORY IS IN DEEP POWER DOWN MODE. (F-Vcc=2.7V to 3.6V)

* SRAM inputs and input/outputs except S-mare needed to be applied wilh voltages in the range of

-0.3V to S-V,c+O.3V or to be open.

* Flash Memory inputs and input/outputs except mare needed to be applied with voltages in the range of

-0.3V to S-Vc,+O.3V or to be open(High-Z). RP is needed to be at the same level as F-V,, or to be

open.

CASE 3: FLASH MEMORY POWER SUPPLY IS TURNED OFF. (F-VcpOV)

* Fix- LOW level before turning off Flash memory power supply.

* SRAM inputs and input/outputs except S-mare needed to be applied with voltages in the range of

-0.3V to S-V,c+O.3V or to be open(High-Z).

- Flash Memory inputs and input/outputs except mare needed to be at GND or to be open(High-Z).

POWER UP SEQUENCE

When turning on Flash memory power supply, keep i@ LOW. After F-V,, reaches over 2.7V, keep RP

LOW for more than 1OOnsec.

DEVICE DECOUPLING

The power supply is needed to be designed carefully because one of the SRAM and the Flash Memory is

in standby mode when the other is active. A careful decoupling of power supplies is necessary between

SRAM and Flash Memory. Note peak current caused by transition of control signals.

The contents described in Part 1 take first priority over Part 2 and Part 3.

Page 7

SHARP

LRS13023

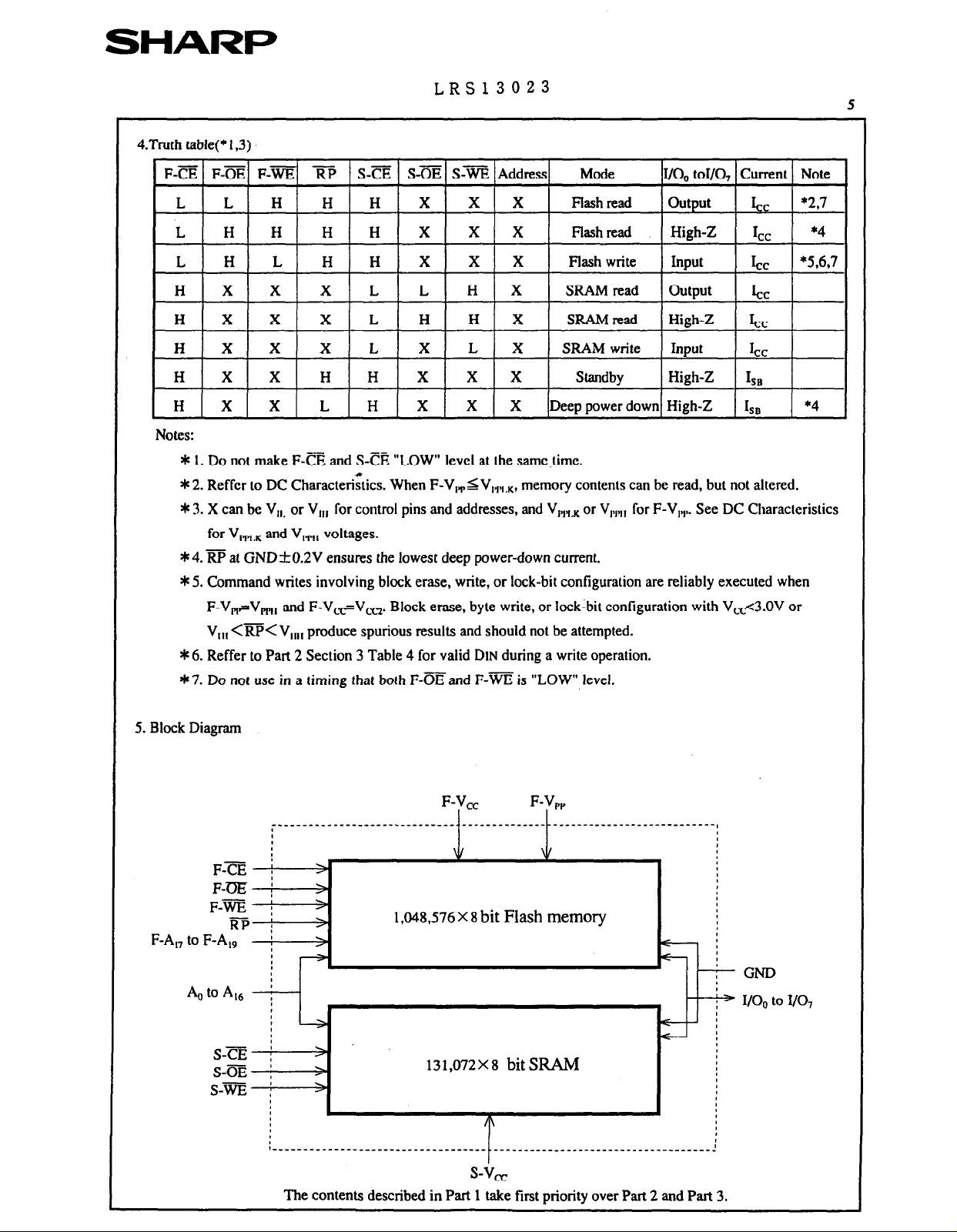

4.Truth table(* 1.3)

F-a F-m F-m RP S-a S-m S-m Address Mode I/O, toI/O, Current Note

LLHHHXXX Flash read output

LHHHHXXX Flash read High-Z I,, *4

LHLHHXXX Flash write Input

HXXXLLHX SRAM read output Ice

HXXXLHHX sR4M read High-Z I,,

HXXXLXLX SRAM write Input I

HXXHHXXX Standby High-Z Iss

HXXLHXXX Deep power down High-Z Isa *4

Notes:

* 1. Do not make F-C? and S-C8 “LOW” level at the samc,limc.

* 2. Reffcr to DC Character&tics. When F-V&V,,.,.,, memory contents can be read, but not altered.

* 3. X can be V,,, or V,,, for control pins and addresses, and V,,nx or VI,,,,, for F-V,,,,. See DC Characteristics

for V,,,k and V,,.,, voltages.

* 4. i@ at GND f0.2V ensures the lowest deep power-down current.

* 5. Command writes involving block erase, write, or lock-bit configuration are reliably executed when

F-V,,=V,, and F-V,@,. Block erase, byte write, or lock-bit conliguration with Vcc<3.0V or

V,,, <m< V,,,, produce spurious results and should not be attempted.

* 6. Reffer to Part 2 Section 3 Table 4 for valid DIN during a write operation.

$7. Do not

use in

a timing that both F-mand F-WE is “LOW” level.

EC

kc

cc

5

*2,7

*5,6,7

5. Block Diagram

F-n i

F-GE / >

F-m j

RP ;

F-A,, to F-A,, !

&to&, ;

S-TE /

S-FE

s-m ;

F-V, F-V,,

____________________----------.------------------------------------------

9

w v

3

>

>

>

4

I

>

>

>

1,048,576 X 8

131,072X8

bit Flash memory

bit SR4M

I

e- ;

e

0

>

The contents described in Part 1 take first priority over Part 2 and Part 3.

Page 8

SHARP

LRS13023

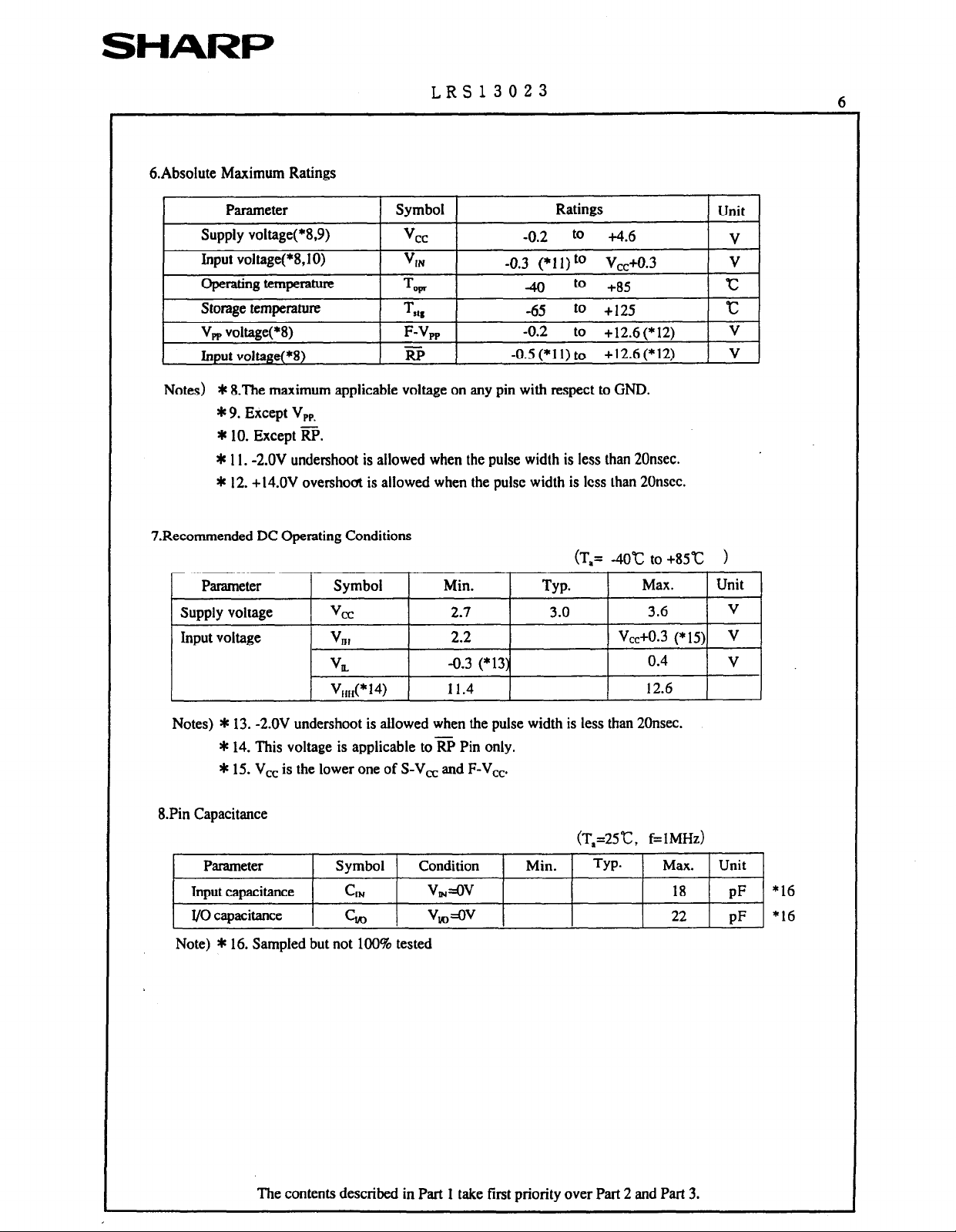

6.Absolute Maximum Ratings

Notes) * 8.The maximum applicable voltage on any pin with respect to GND.

* 9. Except Vrp,

* 10. Except @.

* 11. -2.OV undershoot is allowed when the pulse width is less than 20nsec.

* 12. +14.OV overshoot is allowed when the pulse width is less than 2Onscc.

7.Recommended DC Operating Conditions

CT,= -40°C to +85”c )

Parameter Symbol Min.

Supply voltage

Input voltage

vc-2

V”,

VU.

v,,,,(* 14)

2.7 3.0 3.6

2.2 V,,+O.3 (*15) V

-0.3 (*13:

11.4 12.6

TYP.

Max. Unit

V

0.4

V

6

Notes) * 13. -2.OV undershoot is allowed when the pulse width is less than 2Onsec.

* 14. This voltage is applicable toi@ Pin only.

* 15. V, is the lower one of S-V, and F-V,,.

8.Pin Capacitance

(T,=25”c, f=lMHz)

Parameter Symbol Condition

Input capacitance

I/O capacitance

Note) * 16. Sampled but not 100% tested

Gi

CIA3

v,=ov

v,=ov

Min. TYP.

Max. Unit

18

22

PF

PF

*16

*16

The contents described in Part 1 take first priority over Part 2 and Part 3.

Page 9

SHARP

LRS13023

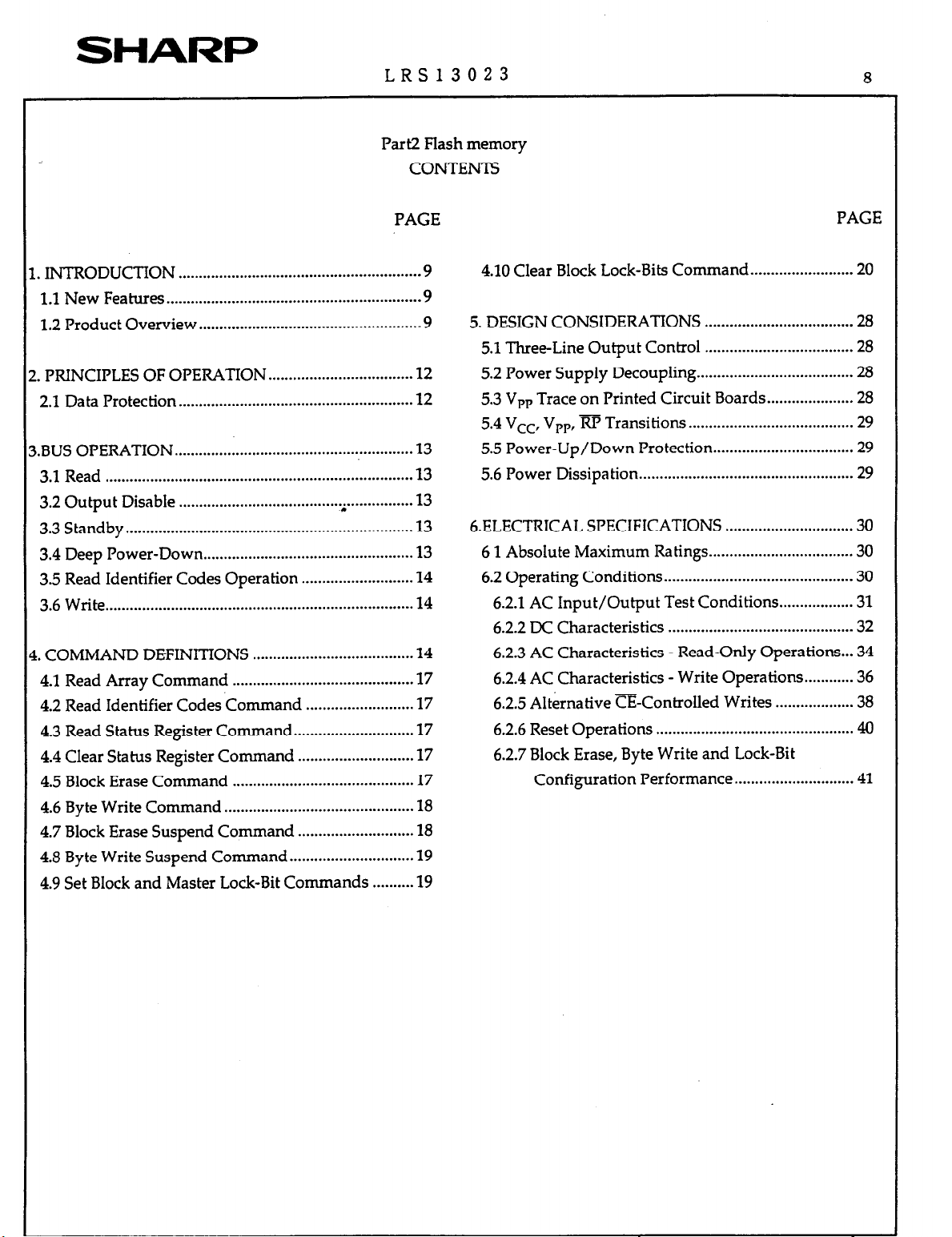

Part2 Flash memory

CONTENTS

8

PAGE

.. INTRODUCTION

1.1 New Features.. ...........................................................

1.2 Product Overview

!. PRINCIPLES OF OPERATION

2.1 Data Protection

I.BUS OPERATION.. ........................................... .

3.1 Read

3.2 Output Disable

3.3 Standby

3.4 Deep Power-Down

3.5 Read Identifier Codes Operation

3.6 Write ...........................................................................

I. COMMAND DEFINITIONS

4.1 Read Array Command

4.2 Read Identifier Codes Command .........................

4.3 Read Status Register Command..

4.4 Clear Status Register

4.5 Block Erase Command

4.6 Byte Write Command ..............................................

4.7 Block Erase Suspend Command

4.8 Byte Write Suspend Command.. ...........................

4.9 Set Block and Master Lock-Bit Commands

........................................................................... 13

...................................................................... 13

........................................................... 9

......................................................

...................................

.........................................................

............

........................................

...................................................

.......................................

............................................ 17

Command

............................................ 17

;............... 13

........................... 14

..........................

...........................

...........................

.........

-9

9

12

12

13

13

14

14

.17

.17

.17

18

.18

.19

-19

PAGE

4.10 Clear Block Lock-Bits

5. DESIGN CONSIDERATIONS .................................... 28

5.1 Three-Line Output Control .................................... 28

5.2 Power Supply

5.3 V,, Trace on Printed Circuit Boards.. ................... 28

5.4 V,,, V,,, i?is Transitions.. ......................................

5.5 Power-Up/Down Protection.. ................................ 29

5.6 Power Dissipation.. .................................................. 29

6.ELECTRICAL SPECIFICATIONS ............................... 30

6 1 Absolute Maximum

6.2 Operating Conditions..

6.2.1 AC Input/Output Test Conditions.. ................ 31

6.2.2 DC Characteristics .............................................

6.2.3 AC Characteristics - Read-Only Operations

6.2.4 AC Characteristics - Write Operations..

6.2.5 Alternative a-Controlled Writes ................... 38

6.2.6 Reset Operations ................................................ 40

6.2.7 Block Erase, Byte Write and Lock-Bit

Configuration Performance.. ...........................

Decoupling.. .................................... 28

Command.. ....................... 20

29

Ratings.. ................................. 30

............................................ 30

32

... 34

.36

.........

41

Page 10

SHARP

LRS13023

Part2 Flash memory

CONTENTS

8

PAGE

.. INTRODUCTION

1.1 New Features.. ...........................................................

1.2 Product Overview

!. PRINCIPLES OF OPERATION

2.1 Data Protection

I.BUS OPERATION.. ........................................... . ............ 13

3.1 Read

3.2 Output Disable

3.3 Standby

3.4 Deep Power-Down

3.5 Read Identifier Codes Operation

3.6 Write ...........................................................................

I. COMMAND DEFINITIONS

4.1 Read Array Command

4.2 Read Identifier

4.3 Read Status Register Command..

4.4 Clear Status Register Command

4.5 Block Erase Command

4.6 Byte Write Command

4.7 Block Erase Suspend

4.8 Byte Write Suspend

4.9 Set Block and Master Lock-Bit Commands

........................................................................... 13

...................................................................... 13

...........................................................

......................................................

...................................

.........................................................

........................................

...................................................

....................................... 14

............................................ 17

Codes Command

............................................ 17

.............................................. 18

Command

Command..

;............... 13

........................... 14

.........................

..........................

...........................

...........................

...........................

.........

9

-9

9

12

12

13

14

.17

.17

.17

.18

.19

-19

PAGE

4.10 Clear Block Lock-Bits Command.. ....................... 20

.........

28

.36

5. DESIGN CONSIDERATIONS ....................................

5.1 Three-Line Output Control .................................... 28

5.2 Power Supply

5.3 V,, Trace on Printed

5.4 V,,, V,,, i?is Transitions.. ...................................... 29

5.5 Power-Up/Down

5.6 Power Dissipation..

6.ELECTRICAL SPECIFICATIONS ............................... 30

6 1 Absolute Maximum

6.2 Operating Conditions..

6.2.1 AC Input/Output

6.2.2 DC Characteristics ............................................. 32

6.2.3 AC Characteristics - Read-Only Operations ... 34

6.2.4 AC Characteristics - Write Operations..

6.2.5 Alternative a-Controlled Writes ................... 38

6.2.6 Reset Operations ................................................ 40

6.2.7 Block Erase, Byte Write and Lock-Bit

Configuration Performance.. ........................... 41

Decoupling.. .................................... 28

Circuit Boards.. ................... 28

Protection.. ................................ 29

.................................................. 29

Ratings.. ................................. 30

............................................ 30

Test Conditions.. ................ 31

Page 11

SHARP

LRS13023

INTRODUCTION

his datasheet contains LRS1302 specifications.

iection 1 provides a flash memory overview. Sections

!, 3,4, and 5 describe the memory organization and

unctiordity. Section 6 covers electrical specifications.

..l New Features

The LRS1302 SmartVoltage Flash memory maintains

)ackwards-compatibility with SHARP’s 28F008SA.

Cey enhancements over the 28F008SA include:

SmartVoltage Technology

*Enhanced Suspend Capabilities

Jn-System Block Locking

30th devices share a compatible, status register, and

oftware command set. These similarities enable a

clean upgrade from the 28FOO8SA to LRS1302. When

upgrading, it is important to note the following

iifferences:

-Because of new feature support, the two devices

have different device codes. This allows for

software optimization.

.VPpLK has been lowered from 6SV to 1.5V to

support 2.7V-3.6V block erase, byte write, and

lock-bit configuration operations. Designs

switch VPP off during read operations should make

sure that the VP, voltage transitions to GND.

*To take advantage of SmartVoltage technology,

allow VP, connection to 2.7V-3.6V.

that

SmartVoltage technology provides a choice of Vcc and

VP, combinations, as shown in Table 1, to meet system

performance and power expectations. V, at 2.7V to

3.6V eliminates the need for a separate 12V converter.

In addition to flexible erase and program voltages, the

dedicated VPP pm gives complete data protection

when VP, I VP,,.

Table 1. V,, and VP, Voltage Combinations Offered

;_.

2,7V to 3.6V(‘l) 2.7V to 3.6V

NOTE’ ’

‘1. FLASH Erase/Write(T*=O”C to 85°C)

Internal Vcc and

automatically configures the device for optimized read

and write operations.

A Command User Interface (CUT) serves as the

interface between the system processor and internal

operation of the device. A valid command sequence

written to the CUT initiates device automation. An

internal Write State Machine (WSM) automatically

executes the algorithms and timings necessary for

block erase, byte write, and lock-bit configuration

operations.

A block erase operation erases one of the device’s

64Kbyte blocks typically within 1.8 second

independent of other blocks. Each block can be

independently erased 100,000 times (1.6 million block

erases per device). Block erase suspend mode allows

system software to suspend block erase to read or

write data from any other block.

by SmartVoltage Technology

Vcc Voltage VPP Voltage

VW

detection Circuitry

9

I

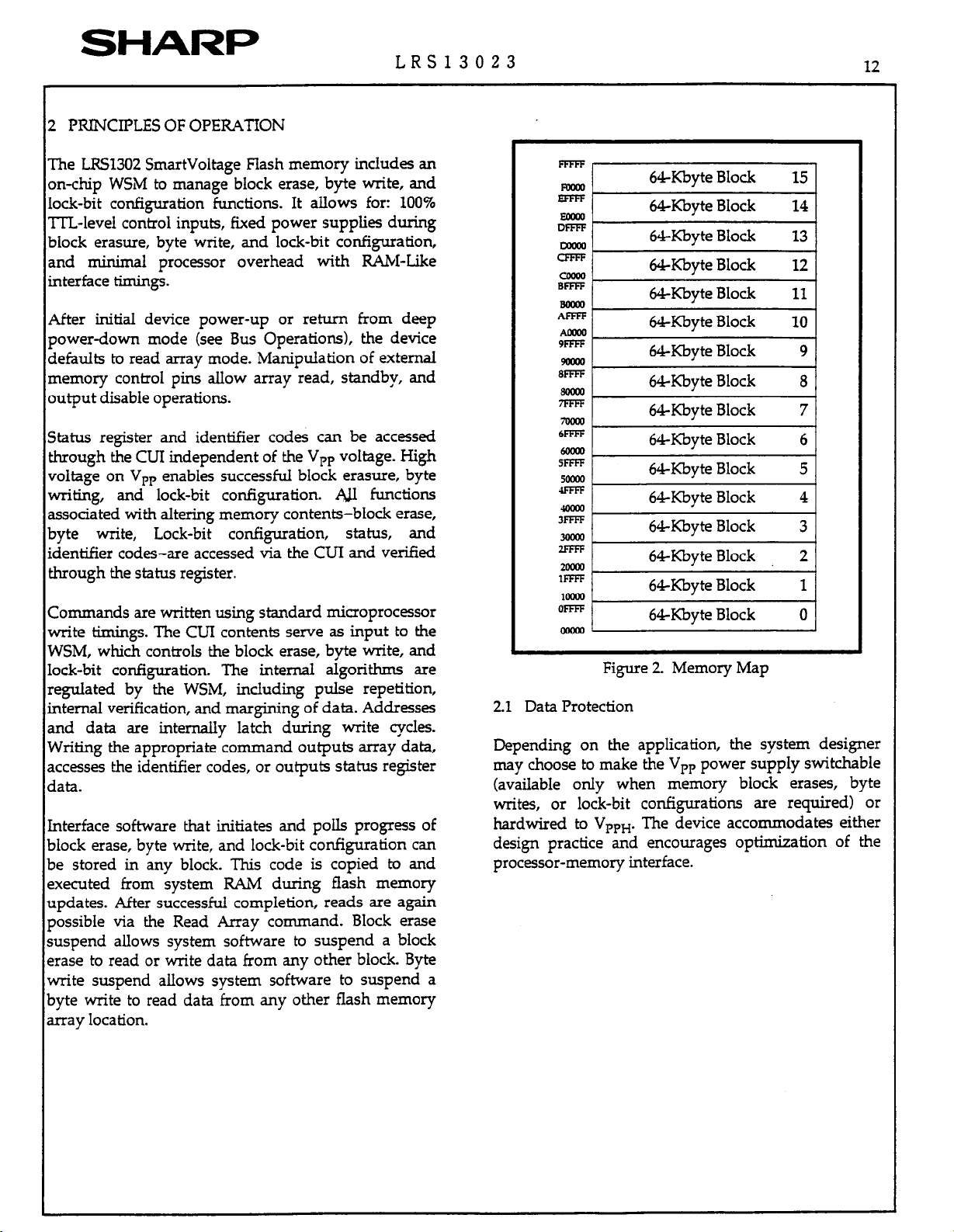

I.2 Product Overview

The LRS1302 is a high-performance &Mbit

;martVoltage Flash memory organized as 1 Mbyte of 8

>its. The 1 Mbyte of data is arranged in sixteen

&Kbyte blocks which are individually erasable,

o&able, and unlockable in-system. The memory map

s shown in Figure 2.

Writing memory data is performed in byte increments

typically within 17 us. Byte write suspend mode

enables the system to read data or execute code from

any other flash memory array location.

1

Page 12

SHARP

LRS13023

10

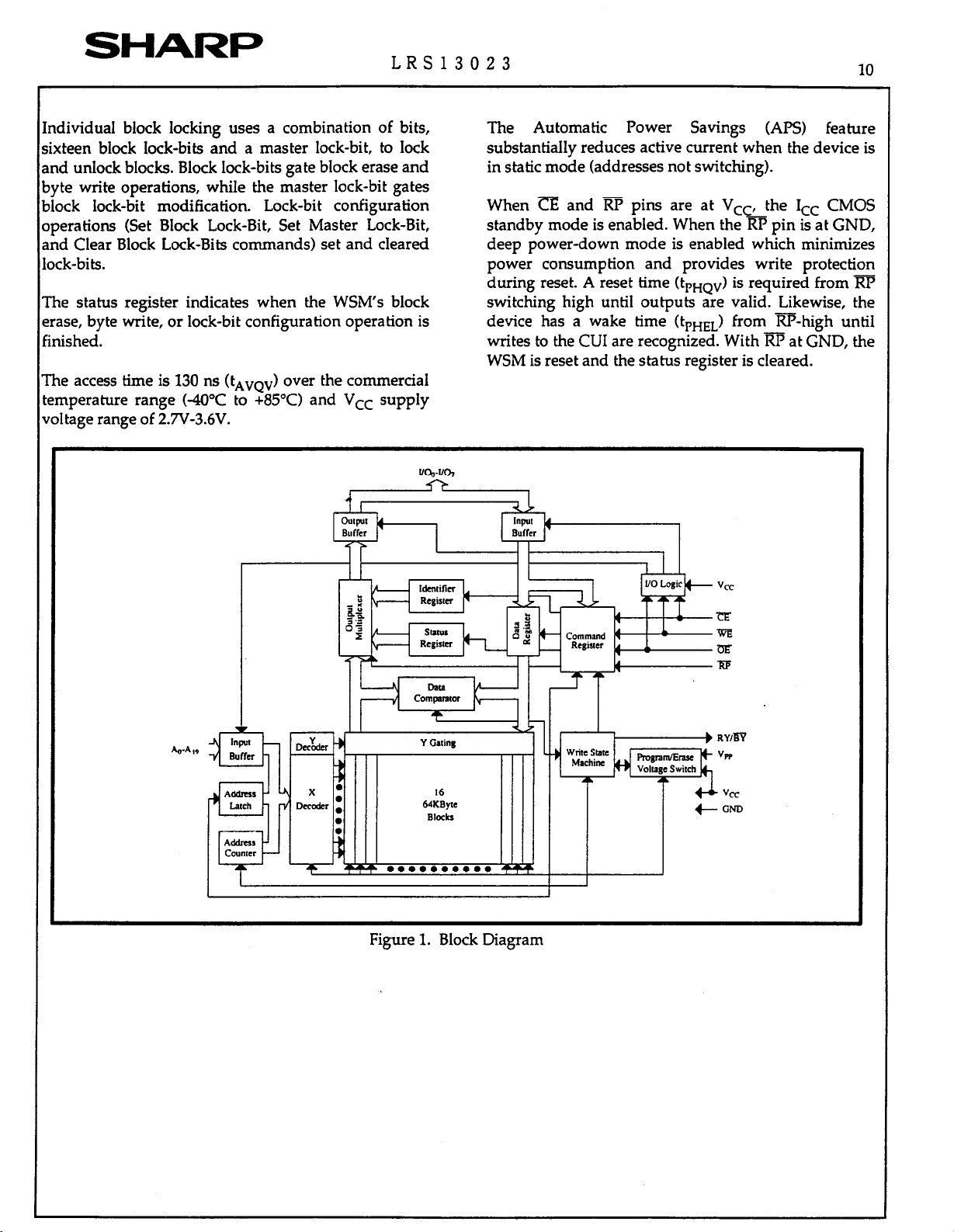

~Individual block locking uses a combination of bits,

‘sixteen block lock-bits and a master lock-bit, to lock

land unlock blocks. Block lock-bits gate block erase and

‘byte write operations, while the master lock-bit gates

~block lock-bit modification. Lock-bit configuration

loperations (Set Block Lock-Bit, Set Master Lock-Bit,

and Clear Block Lock-Bits commands) set and cleared

lock-bits.

The status register indicates when the WSM’s block

erase, byte write, or lock-bit configuration operation is

finished.

The access time is 130 ns (tAvQv) over the commercial

temperature range (-40°C to +BS’C) and V,, supply

voltage range of 2.7V-3.6V.

The Automatic Power Savings (AI%) feature

substantially reduces active current when the device is

in static mode (addresses not switching).

When a and RF pins are at V,,, the I,, CMOS

standby mode is enabled. When the RP pin is at GND,

deep power-down mode is enabled which minimizes

power consumption and provides write protection

during reset. A reset time (tPHqv) is required from RP

switching high until outputs are valid. Likewise, the

device has a wake time (tpHEL) from m-high until

writes to the CUI are recognized. With RP at GND, the

WSM is reset and the status register is cleared.

4 x :

occcdc.r .

16

64KByle

.

BlOCb

Figure 1. Block Diagram

Page 13

SHARP

Svm

f40-419

I/O&O~

CE

Rp

OE

_. _-

WE

bP

Vcc

GND

rote: V,-,

LRS13023

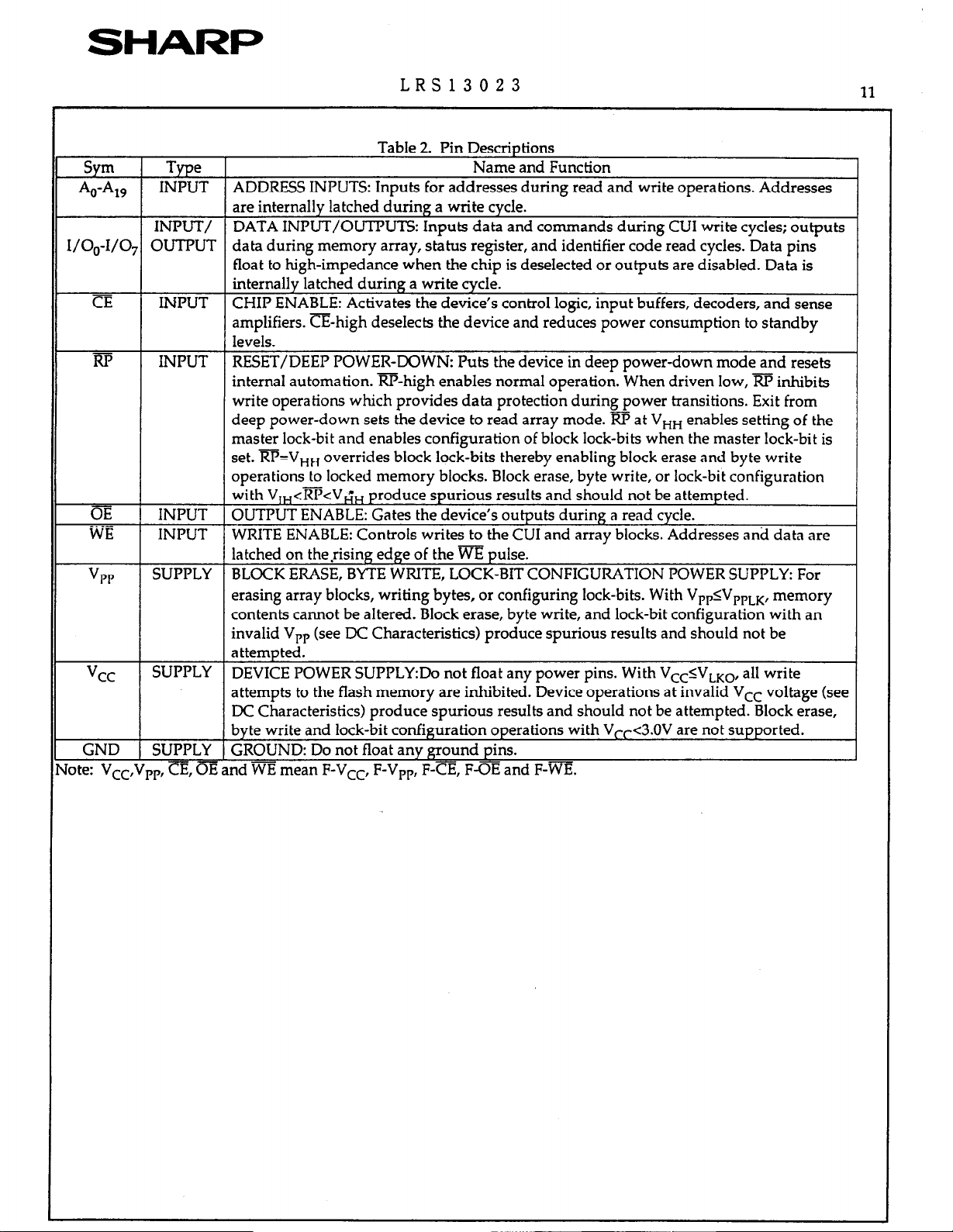

Table 2. Pin Descriptions

Type

INPUT

INPUT/

OUTPUT

INPUT

INPUT

INPUT

INPUT

SUPPLY

SUPPLY

SUPPLY GROUND: Do not float any ground pins.

,P, n, m and WE mean F-V,,, F-V,,, F-a, Fa and F-WE.

ADDRESS INPUTS: Inputs for addresses during read and write operations. Addresses

are internally latched during a write cycle.

DATA INPUT/OUTPUTS: Inputs data and commands during CUI write cycles; outputs

data during memory array, status register, and identifier code read cycles. Data pins

float to high-impedance when the chip is deselected or outputs are disabled. Data is

internally latched during a write cycle.

CHIP ENABLE: Activates the device’s control logic, input buffers, decoders, and sense

amplifiers. a-high deselects the device and reduces power consumption to standby

levels.

RESET/DEEP POWER-DOWN: Puts the device in deep power-down mode and resets

internal automation. m-high enables normal operation. When driven low, p inhibits

write operations which provides data protection during power transitions. Exit from

deep power-down sets the device to read array mode. Ris at V,, enables setting of the

master lock-bit and enables configuration of block lock-bits when the master lock-bit is

-

set. RP=V,,, overrides block lock-bits thereby enabling block erase and byte write

operations to locked memory blocks. Block erase, byte write, or lock-bit configuration

with V,,<RI’cV& produce spurious results and should not be attempted.

OUTPUT ENABLE: Gates the device’s outputs during a read cycle.

WRITE ENABLE: Controls writes to the CUI and array blocks. Addresses

latched

BLOCK ERASE, BYTE WRITE, LOCK-BIT CONFIGURATION POWER SUPPLY: For

erasing array blocks, writing bytes, or configuring lock-bits. With VPP5VPPLK, memory

contents cannot

invalid VP, (see DC Characteristics) produce spurious results and should not be

attempted.

DEVICE POWER SUPPLYDo not float any power pins. With VCCIVLKO, all write

attempts to the flash memory are inhibited. Device operations at invalid Vcc voltage (see

DC Characteristics) produce spurious results and should not be attempted. Block erase,

byte write and lock-bit configuration operations with V,,<3.OV are not supported.

on

the rising edge of the WE pulse.

be altered. Block erase, byte write, and lock-bit configuration with an

Name and Function

and

11

data are

Page 14

SHARI=

2 PRINCIPLES OF OPERATION

LRS13023

12

The LRS1302 SmartVoltage Flash memory includes an

on-chip WSM to manage block erase, byte write, and

lock-bit configuration functions. It allows for: 100%

TTL-level control inputs, fixed power supplies during

block erasure, byte write, and lock-bit configuration,

and minimal processor overhead with RAM-Like

interface timings.

After initial device power-up or return from deep

power-down mode (see Bus Operations), the device

defaults to read array mode. Manipulation of external

memory control pins allow array read, standby, and

output disable operations.

Status register and identifier codes can be accessed

through the CUI independent of the VP, voltage. High

voltage on V,, enables successful block erasure, byte

writing, and lock-bit configuration. All functions

associated with altering memory contents-block erase,

byte write, Lock-bit configuration, status, and

identifier codes-are accessed via the CUI and verified

through the status register.

Commands are written using standard microprocessor

write timings. The CUI contents serve as input to the

WSM, which controls the block erase, byte write, and

lock-bit configuration. The internal algorithms are

regulated by the WSM, including pulse repetition,

internal verification, and margining of data. Addresses

and data are internally latch during write cycles.

Writing the appropriate command outputs array data,

accesses the identifier codes, or outputs status register

data.

Interface software that initiates and polls progress of

block erase, byte write, and lock-bit configuration can

be stored in any block. This code is copied to and

executed from system RAM during flash memory

updates. After successful completion, reads are again

possible via the Read Array command. Block erase

suspend allows system software to suspend a block

erase to read or write data from any other block. Byte

write suspend allows system software to suspend a

byte write to read data from any other flash memory

array location.

I

I

Aoooo

9FFFF

9oMw)

SFFFF

8oooO

7FFFF

7owo

6FFFF

t5wlo

SFFFF

2Izzz

I

I

mm

OFFFF

ooom

2.1 Data Protection

Depending on the application, the system designer

may choose to make the V,, power supply switchable

(available only when memory block erases, byte

writes, or lock-bit configurations are required) or

hardwired to V,,,.

design practice and encourages optimization of the

processor-memory interface.

64Kbyte Block

64-Kbyte Block

64Kbyte Block 4 1

64Kbyte Block

64Kbyte Block 0

Figure 2. Memory Map

The device accommodates either

15 I

10 I

l/

Page 15

SHARI=

LRS13023

When VPPIVPPLK, memory contents cannot be altered.

The CUI, with two-step block erase, byte write, or

lock-bit configuration command sequences, provides

protection from unwanted operations even when high

voltage is applied to VP+. All write functions are

disabled when V,,

VLKO or when RP is at Vl,. The device’s block locking

capability provides additional protection from

inadvertent code or data alteration by gating erase and

byte write operations.

3 BUS OPERATION

The local CPU reads and writes flash memory

in-system. All bus cycles to or from the flash memory

:onform to standard microprocessor bus cycles.

3.1 Read

Information can be read from any block, identifier

:odes, or status register independent of the VP,

voltage. RP can be at either Vl, or V,,.

The first task is to write the appropriate read mode

:ommand (Read Array, Read Identifier Codes, or Read

status Register) to the CUI. Upon initial device

Tower-up or after exit from deep power-down mode,

:he device automatically resets to read array mode.

Four control pins dictate the data flow in and out of

:he component: CE, OE, WE, and m. CE and m must

>e driven active to obtain data at the outputs. m is the

device selection control, and when active enables the

ielected memory device. m is the data output

I/O&O,) control and when active drives the

ielected memory data onto the I/O bus. WE must be

it VI, and m must be at V,, or V,,. Figure 12

llustrates a read cycle.

1.2 Output Disable

Mith 0lY at a logic-high level (Vt,), the device outputs

Ire disabled. Output pins I/0,-1/0, are placed in a

high-impedance state.

is below the write lockout voltage

.c

---

13

3.3 Standby

n at a logic-high level (V,,) places the device in

standby mode which substantially reduces device

power consumption. I/O&O, outputs are placed in

a high-impedance state independent of OE. If

deselected during block erase, byte write, or lock-bit

configuration, the device continues functioning, and

consuming active power until the operation completes.

3.4 Deep Power-Down

i?Ij at V,, initiates the deep power-down mode.

In read modes, m-low deselects the memory, places

output drivers in a high-impedance state and turns off

all internal circuits. RP must be held low for a

minimum of 100 ns. Time tPHQv is required after

return from power-down until initial memory access

outputs are valid. After this wake-up interval, normal

operation is restored. The CUI is reset to read array

mode and status register is set to 80H.

During block erase, byte write, or lock-bit

configuration modes, m-low will abort the operation.

Memory contents being altered are no longer valid; the

data may be partially erased or written. Time tpHWL is

required after Rp goes to logic-high (VI,) before

another command can be written.

As with any automated device, it is important to assert

Rp during system reset. When the system comes out of

reset, it expects to read from the flash memory.

Automated flash memories provide status information

when accessed during block erase, byte write, or

lock-bit configuration modes. If a CPU reset occurs

with no flash memory reset, proper CPU initialization

may not occur because the flash memory may be

providing status information instead of array data.

SHARP’s flash memories allow proper CPU

initialization following a system reset through the use

of the i?l? input. In this application, Rp is controlled by

the same m signal that resets the system CPU.

Page 16

SHARP

LRS13023

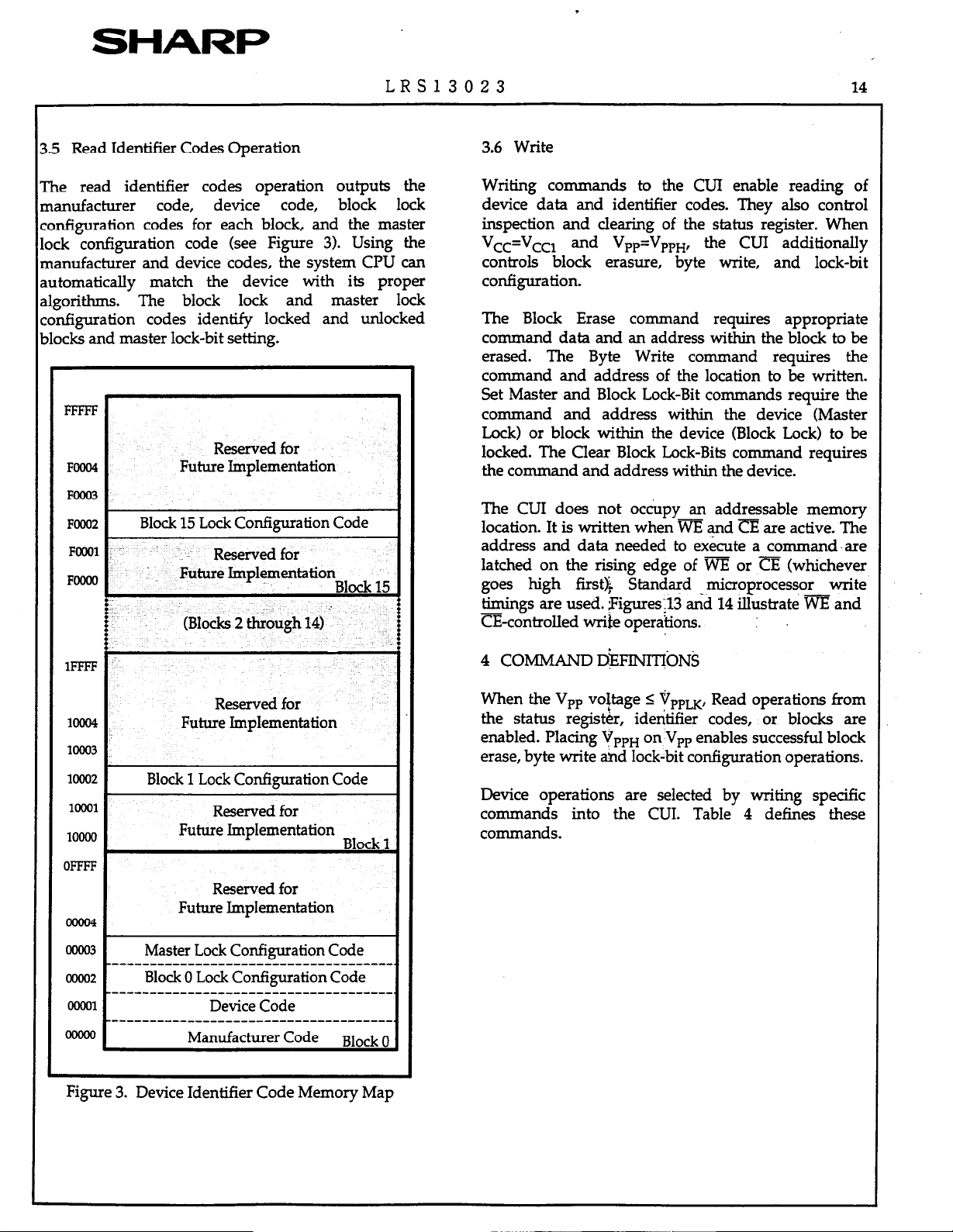

1.5 Read Identifier Codes Operation

The read identifier codes operation outputs the

nanufacturer code, device code, block lock

:onfiguration codes for each block, and the master

ock configuration code (see Figure 3). Using the

nanufacturer and device codes, the system CPU can

u,rtomatically match the device with its proper

algorithms. The block lock and master lock

:onfiguration codes identify locked and unlocked

~1ock.s and master lock-bit setting.

Reserved for

FOO04

FOOO3

FOOOZ 1

FOOOl

FOOOO

Future Implementation

Block 15 Lock Configuration Code

Reserved for

Future Implementation

Block 1

(Blocks 2 through 14) ’

14

3.6 Write

Writing commands to the CUI enable reading of

device data and identifier codes. They also control

inspection and clearing of the status register. When

V,--=Vccl and VPP=VPPH, the CUI additionally

controls block erasure, byte write, and lock-bit

configuration.

The Block Erase command requires appropriate

command data and an address within the block to be

erased. The Byte Write command requires the

command and address of the location to be written.

Set Master and Block Lock-Bit commands require the

command and address within the device (Master

Lock) or block within the device (Block Lock) to be

locked. The Clear Block Lock-Bits co

mmand requires

the command and address within the device.

The CUI does not occupy an addressable memory

location. It is written when WE and a are active. The

address and data needed to execute a command-are

latched on the rising edge of WE or CE (whichever

goes high first& Stand,ard microprocessor write

timings are used. jQures:13 and 14 illustrate WE and

m-controlled write operahons.

:

IFFFF

Reserved for

looo4

1ooo3

I

Future Implementation

Block 1 Lock Configuration Code

OFFFF

Reserved for

Future Implementation

oooo4

oooo3

moo2

ooml

Master Lock Configuration Code

------------------------------------.

Block 0 Lock Configuration Code

~~~~~~~~----__-__---________________(

--------_-__________----------------.

Device Code

Manufacturer Code

Block

Figure 3. Device Identifier Code Memory Map

4 COMMAND D&INITlON~

When the VP, voftage I VPPLK, Read operations from

the status register, identifier codes, or blocks are

enabled. Placing VP,, on.Vpp enables successful block

erase, byte write and lock-bit configuration operations.

Device operations are selected by writing specific

commands into the CUI. Table 4 defines these

commands.

Page 17

SHARP

LRS13023 15

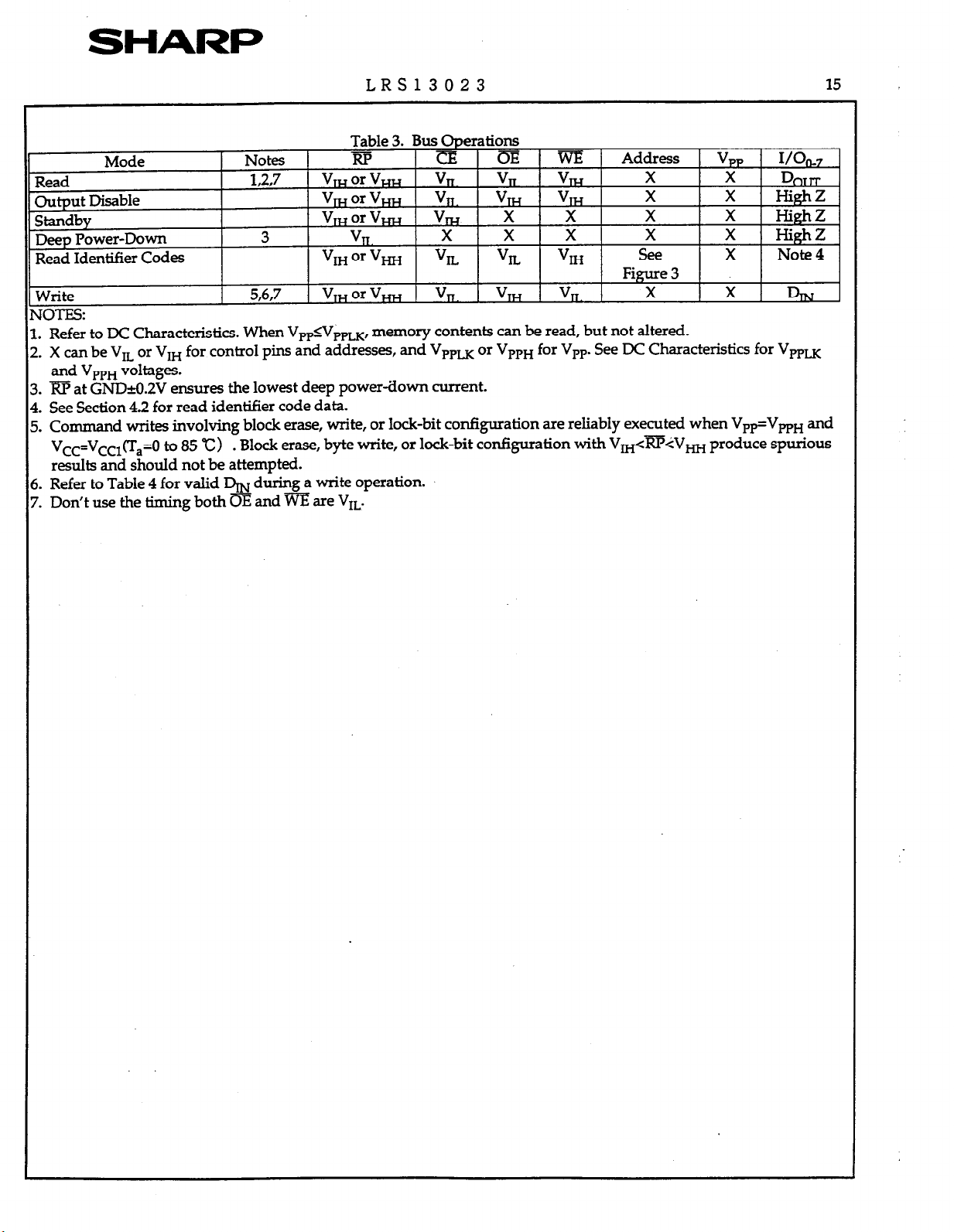

NOTES:

1. Refer to DC Characteristics. When VPPIVPP,,

2. X can be VI, or V,, for control pins and addresses, and VP,, or VP,, for VP,. See DC Characteristics for VW,

and V,,, voltages.

3. i@ at GND&.2V ensures the lowest deep power-down current.

4. See Section 4.2 for read identifier code data.

5. Command writes involving block erase, write, or lock-bit configuration are reliably executed when VPp=VppH and

Vcc=VccIU~=O to 85 “c)

results and should not be attempted.

6. Refer to Table 4 for valid h during a write operation.

7. Don’t use the timing both m and m are VIM

. Block erase, byte write, or lock-bit configuration with V,<mkV, produce spurious

memory contents can be read, but not altered.

Page 18

SHARI=

LRS13023

16

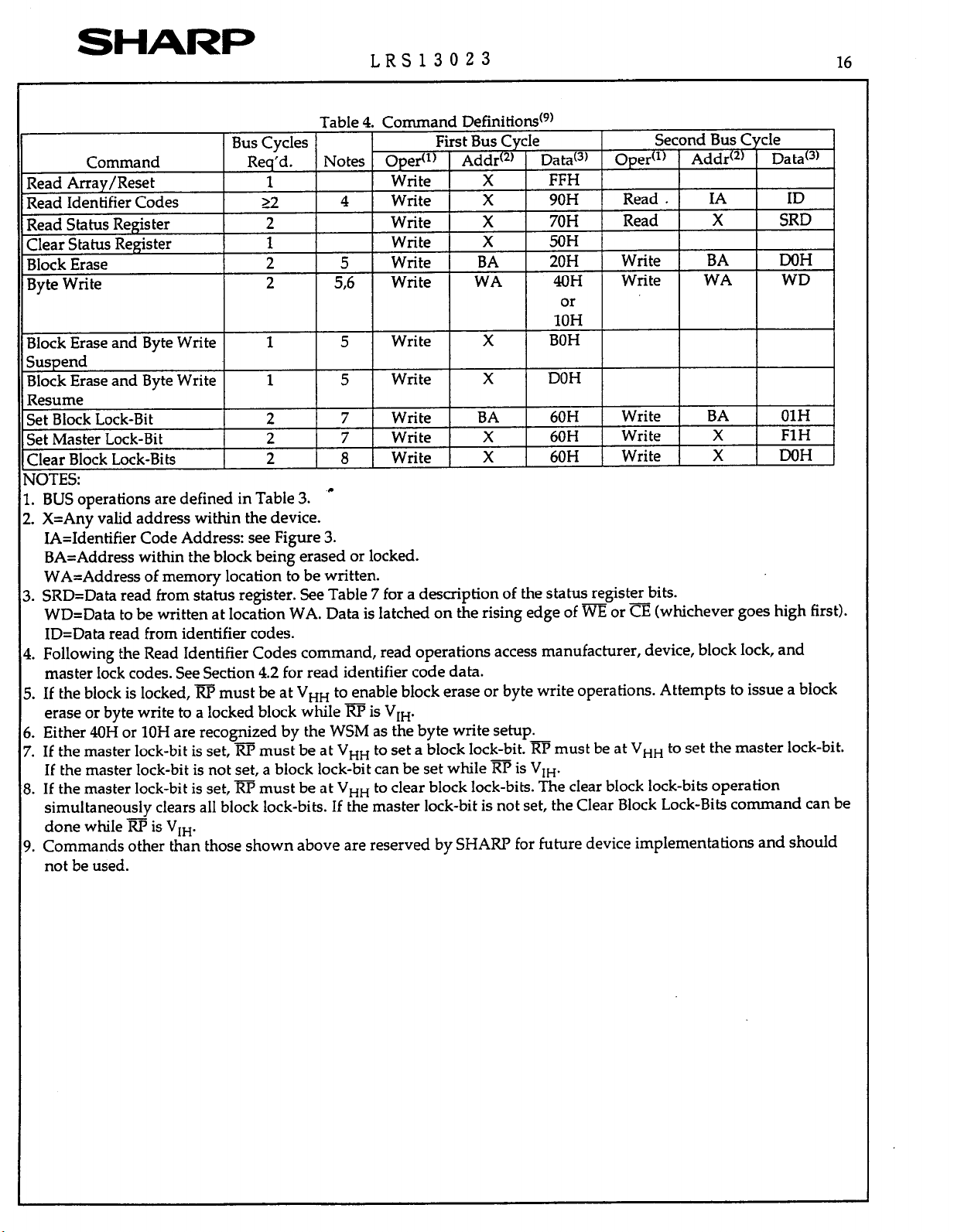

Table 4. Commanc - - ___._. ~_ _

RIW f-vr1c.c

Command

Read Array/Reset

Read Identifier Codes

Read Status Register

Clear Status Register 1

Block Erase 2 5

Byte Write

Req’d . Notes

1

22

2

2

56

Ope# ) Addrc2) 1 DataQ) Oper(l) 1 Addrt2) 1 Datac3)

Write X

4 Write X 90H

Write X 70H

Write X 5UH

Write BA 20H

Write WA 40H

I I I I

Block Erase and Byte Write

Suspend

Block Erase and Byte Write

Resume

Set Block Lock-Bit 2 7 Write BA 60H

Set Master Lock-Bit 2

Clear Block Lock-Bits 2 8 Write

NOTES:

1. BUS operations are defined in Table 3. ”

2. X=Any valid address within the device.

IA=Identifier Code Address: see Figure 3.

BA=Address within the block being erased or locked.

WA=Address of memory location to be written.

3. SRD=Data read from status register. See Table 7 for a description of the status register bits.

WD=Data to be written at location WA. Data is latched on the rising edge of WE or CE (whichever goes high first).

ID=Data read from identifier codes.

4. Following the Read Identifier Codes command, read operations access manufacturer, device, block lock, and

master lock codes. See Section 4.2 for read identifier code data.

5. If the block is locked, i?i? must be at V,,

erase or byte write to a locked block while m is VII+

6. Either 40H or 10H are recognized by the WSM as the byte write setup.

7. If the master lock-bit is set, m must be at V,,

If the master lock-bit is not set, a biock lock-bit can be set while i?is is V,,.

8. If the master lock-bit is set, RP must be at V,, to clear block lock-bits. The clear block lock-bits operation

simultaneously clears all block lock-bits. If the master lock-bit is not set, the Clear Block Lock-Bits command can be

done while RR 1s Vl,.

9. Commands other than those shown above are reserved by SHARP for future device implementa lions and should

not be used.

-.

1

1

5 Write

5 Write

7 Write X 60H

to enable block erase or byte write operations. Attempts to issue a block

to set a block lock-bit. RP must be at V,, to set the master lock-bit.

1 Definitions(9)

Fist Bus Cycle Second Bus Cycle

---- I

FFH

Read. IA ID

_. ----

or I

10H

X BOH

X

X 60H Write X DOH

DOH

Read X

Write BA

Write WA WD

I I

Write BA OlH

Write X FlH

I

SRD

DOH

I

Page 19

SHARP

.

LRS13023

:.l Read Array Command

Jpon initial device power-up and after exit from deep

jowerdown mode, the device defaults to read array

node. This operation is also initiated by writing the

lead Array command. The device remains enabled for

eads until another command is written. Once the

nternal WSM has started a block erase, byte write or

sck-bit configuration, the device will not recognize

he Read Array command until the WSM completes its

lperation unless the WSM is suspended via an Erase

luspend or Byte Write Suspend command. The Read

bray command functions independently of the VP,

poltage and m can be V,, or V,,.

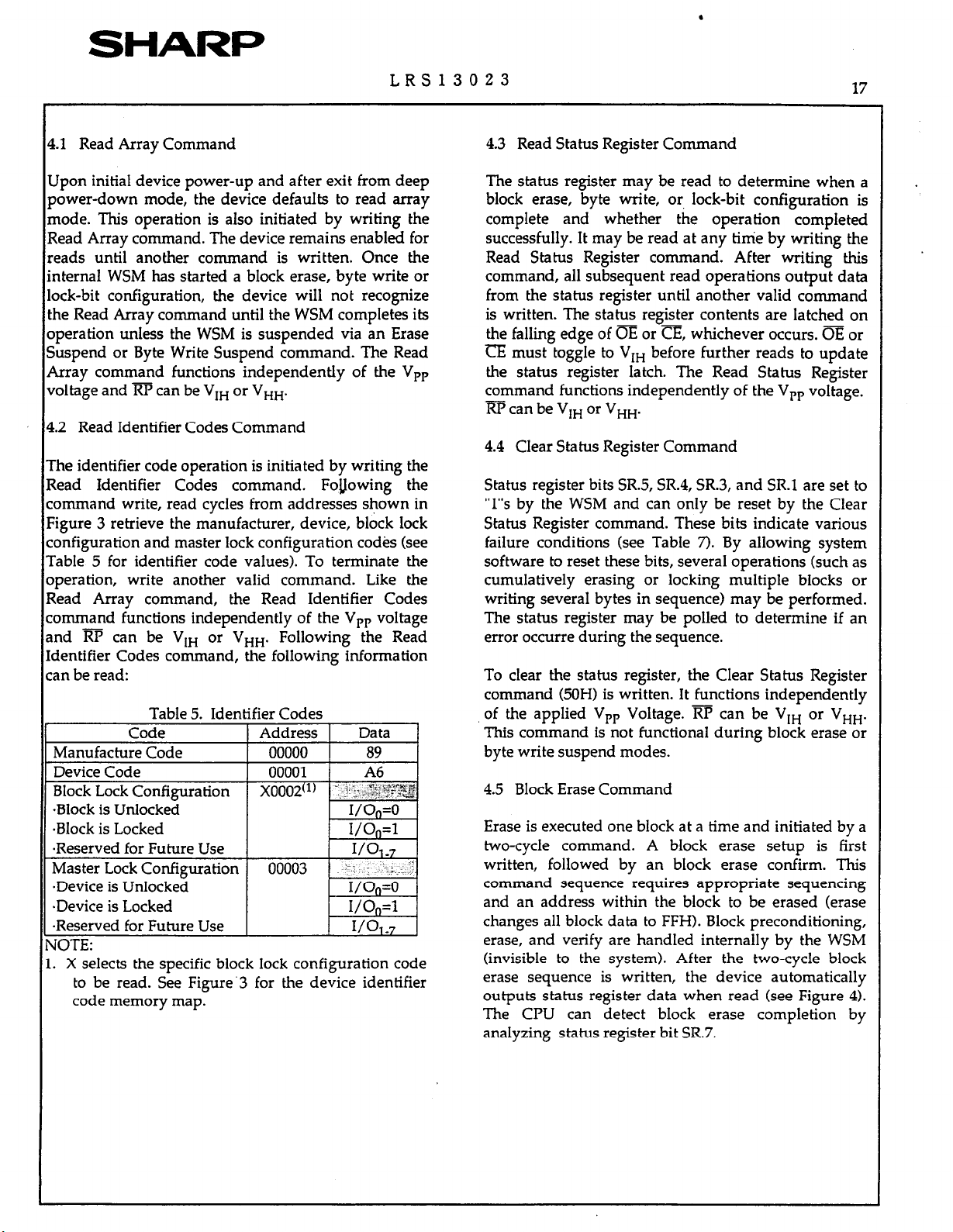

,.2 Read Identifier Codes Command

‘he identifier code operation is initiated by writing the

Lead Identifier Codes command. Following the

ommand write, read cycles from addresses shown in

‘igure 3 retrieve the manufacturer, device, block lock

onfigura tion and master lock configuration codes (see

‘able 5 for identifier code values). To terminate the

Nperation, write another valid command. Like the

Lead Array command, the Read Identifier Codes

ommand functions independently of the VP, voltage

-

nd RP can be V,, or V,,. Following the Read

dentifier Codes command, the following information

an be read:

Table 5. Identifier Codes

17

4.3 Read Status Register Command

The status register may be read to determine when a

block erase, byte write, or, lock-bit configuration is

complete and whether the operation completed

successfully. It may be read at any time by writing the

Read Status Register command. After writing this

command, all subsequent read operations output data

from the status register until another valid command

is written. The status register contents are latched on

the falling edge of OE or CE, whichever occurs. OE or

iZ must toggle to V,,

the status register latch. The Read Status Register

command functions independently of the VP, voltage.

Rp can be V,, or V,,.

4.4 Clear Status Register Command

Status register bits SR.5, SR.4, SR.3, and SR.1 are set to

“1”s by the WSM and can only be reset by the Clear

Status Register command. These bits indicate various

failure conditions (see Table 7). By allowing system

software to reset these bits, several operations (such as

cumulatively erasing or locking multiple blocks or

writing several bytes in sequence) may be performed.

The status register may be polled to determine if an

error occurre during the sequence.

To clear the status register, the Clear Status Register

command (50H) is written. It functions independently

of the applied VP, Voltage. RP can be V,, or V,,.

This command is not functional during block erase or

byte write suspend modes.

before further reads to update

Block Lock Configuration

.Block is Unlocked

*Block is Locked

-Reserved for Future Use

Master Lock Configuration

SDevice is Unlocked

,Device is Locked

,Reserved for Future Use

IOTE:

. X selects the specific block lock configuration code

to be read. See Figure’3 for the device identifier

code memory map.

4.5 Block Erase Command

Erase is executed one block at a time and initiated by a

two-cycle command. A block erase setup is first

written, followed by an block erase confirm. This

command sequence requires appropriate sequencing

and an address within the block to be erased (erase

changes all block data to FFH). Block preconditioning,

erase, and verify are handled internally by the WSM

(invisible to the system). After the two-cycle block

erase sequence is written, the device automatically

outputs status register data when read (see Figure 4).

The CPU can detect block erase completion by

analyzing status register bit SR.7.

Page 20

SHARP

LRS13023

When the block erase is complete, status register bit

SR.5 should be checked. If a block erase error is

detected, the status register should be cleared before

system software attempts corrective actions. The CLJI

remains in read status register mode until a new

command is issued.

This two-step command sequence of set-up followed

by execution ensures that block contents are not

accidentally erased. An invalid Block Erase command

sequence will result in both status register bits SR.4

and SR.5 being set to “1”. Also, reliable block erasure

can only occur when Vcc=VccI and V,=V,,,. In the

absence of this high voltage, block contents are

protected against erasure. If block erase is attempted

while Vppflppm,

Successful block erase requires that the corresponding

block lock-bit be cleared or, if set, that m=V,. If

block erase is attempted when the corresponding

block lock-bit is set and m=V,,, SR.1 and SR5 wi.lI be

set to “1”. Block erase operations with V,<pcV,

produce spurious results and should not be attempted.

SR.3 and SR5 will be set to “1”.

18

register bits SR3 and SR4 will be set to “1”. Successful

byte write requires that the corresponding block

lock-bit be cleared or, if set, that i@=V,. If byte write

is attempted when the corresponding block lock-bit is

set and RP=V,,,

write operations with VI,<m<V,, produce spurious

results and should not be attempted.

4.7 Block Erase Suspend Command

The Block Erase Suspend command allows block-erase

interruption to read or byte-write data in another

block of memory. Once the block-erase process starts,

writing the Block Erase Suspend command requests

that the WSM suspend the block erase sequence at a

predetermined point in the algorithm. The device

outputs status register data when read after the Block

Erase Suspend command is written. Polling status

register bits SR.7 and SR.6 can determine when the

block erase operation has been suspended (both will

be set to “1”). Specification tw- defines the block

erase suspend latency. I I .%

SR.l and SR4 will be set to “1”. Byte

4.6 Byte Write Command

Byte

write is executed by a two-cycle command

sequence. Byte write setup (standard 40H or alternate

10H) is written, followed by a second write that

specifies the address and data (latched on the rising

edge of WE). The WSM then takes over, controlling the

byte

write and write verify algorithms internally. After

the byte write sequence is written, the device

automatically outputs status register data when read

[see Figure 5). The CPU can detect the completion of

the byte write event by analyzing status register bit

3R.7.

When byte write is complete, status register bit SR.4

should be checked. If byte write error is detected, the

status register should be cleared. The internal WSM

verify only detects errors for “1% that do not

juccessfully write to “0”s. The GUI remains in read

jtatus register mode until it receives another

:ommand.

&liable byte writes can only occur when V,c=VccI

md Vpp=Vppw

nemory contents are protected against byte writes. If

>yte write is attempted while VpplVppm, status

In the absence of this high voltage,

At this point, a Read Arraycomman

read data from blocks other than that which is

suspended. A Byte:Write comman

be issued during erase suspend to program data. in

other blocks. Using the Byte Write Suspend command

(see Section 4.81,. a..byte write operation can also. be

suspended. During-a byte write operation with block

erase suspended, status registerbit SR7 will return to

“0” . However, SR.6 will remain “1” to indicate block

erase suspend status.

The only other valid commands while block erase is

suspended are Read Status Register and Block Erase

Resume. After a Block Erase Resume command is

written to the flash memory, the WSM will continue

the block erase process. Status register bits SR.6 and

SR7 will automatically clear . After the Erase Resume

command is written, the device automatically outputs

status register data when read (see Figure 6). VP, must

remain at VP,, (the

erase) while block erase is suspended. m must also

remain at VI, or V, (the same m level used for

block erase). Block erase cannot resume until byte

write operations initiated during block erase suspend

have completed.

same

Vpp level used for block

d can be written to

d sequence can also

Page 21

SHARP

LRS13023

4.8 Byte Write Suspend Command

The Byte Write Suspend command allows byte write

interruption to read data in other flash memory

locations. Once the byte write process starts, writing

the Byte Write Suspend command requests that the

WSM suspend

predetermined point in the algorithm. The device

continues to output status register data when read

after the Byte Write Suspend command is written.

Polling status register bits SR.7 and SR.2 can determine

when the byte write operation has been suspended

(both will be set to “1”). Specification twHRHl defines

the byte write suspend latency.

At this point, a Read Array command can be written to

read data from locations other than that which is

suspended. The only other valid commands while byte

write is suspended are Read Status Register and Byte

Write Resume. After Byte Write Resume command is

written to the flash memory, the WSM will continue

the byte write process. Status register bits SR.2 and

SR7 will automatically clear. After the Byte Write

Resume command is written, the device automatically

outputs status register data when read (see Figure 7).

VP, must remain at V,, (the same VP, level used for

byte write) while in byte write suspend mode. m

must also remain at VrH or V, (the same Rp level

used for byte write).

4.9 Set Block and Master Lock-Bit Commands

A flexible block locking and unlocking scheme is

enabled via a combination of block lock-bits and a

master lock-bit. The block lock-bits gate program and

erase operations while the master lock-bit gates

block-lock bit modification. With the master lock-bit

not set, individual block lock-bits can be set using the

Set Block Lock-Bit command. The Set Master Lock-Bit

zommand, in conjunction with i@=V,, sets the

master lock-bit. After the master lock-bit is set,

subsequent setting of block lock-bits requires both the

Set Block Lock-Bit command and V, on the m pin.

see Table 6 for a summary of hardware and software

write protection options.

the byte write sequence at a

19

Set block lock-bit and master lock-bit are executed by a

two-cycle command sequence. The set block or master

lock-bit setup along with appropriate block or device

address is written followed by either the set block

lock-bit confirm (and an address within the block to be

locked) or the set master lock-bit confirm (and any

device address). The WSM then controls the set

lock-bit algorithm. After the sequence is written, the

device automatically outputs status register data when

read (see Figure 8). The CPU can detect the completion

of the set lock-bit event by analyzing status register bit

SR.7.

When the set lock-bit operation is complete, status

register bit SR.4 should be checked. If an error is

detected, the status register should be cleared. The

CUT will remain in read status register mode until a

new comman d is issued.

This two-step sequence of set-up followed by

execution ensures that lock-bits are not accidentally

set. An invalid Set Block or Master Lock-Bit command

will result in z&us register bits SR.4 and SR.5 being

set to “1”. Also; reliable operations occur only when

vcc=vccl

voltage, lock-bit contents are .protected against

alteration.

A successful set block lock-bit .operation requires that

the master lo&bit be cleared or, if the master lock-bit

is set, that Rp=V&. Eit is attempted with the master

lock-bit set and; RP=VIH, SR.l and SR.4 will be set to

“1” and the operation will fail. Set block lock-bit

operations while ~V,,<RP<V, :produce spurious

results and should not be attempted. A successful set

master lock-bit operation requires that m=V,. If it is

attempted with Rp=V,,, SR.l and SR.4 will be set to

“1” and the operation will fail. Set master lock-bit

operations with VIHcRR<V, produce spurious

results and should not be attempted.

and ‘V+=VPPH. ln the absence of this high

:

-

-

I

Page 22

SHARP

LRS13023 20

JO Clear Block Lock-Bits Command

J set block lock-bits are cleared in parallel via the

Iear Block Lock-Bits command. With the master

)&bit not set, block lock-bits can be cleared using

nly the Clear Block Lock-Bits command. If the master

>ck-bit is set, clearing block lock-bits requires both the

Ilear Block Lock-Bits command and V, on the m

lin. See Table 6 for a summary of hardware and

oftware write protection options.

Ilear block lock-bits operation is executed by a

No-cycle command sequence. A clear block lock-bits

etup is first written. After the command is written,

le device automatically outputs status register data

fhen read (see Figure 9). The CPU can detect

ompletion of the clear block lock-bits event by

nalyzing status register bit SR7.

Vhen the operation is complete, status register bit

R5 should be checked. If a clear block lock-bit error is

.etected, the status register should be cleared. The

XJI will remain in read status register mode until

nother command is issued.

accidentally cleared. An invalid Clear Block Lock-Bits

command sequence will result in status register bits

SR.4 and SR5 being set to “1”. Also, a reliable clear

block lock-bits operation can only occur when

Vcc=VccI and VPP=VPP,. If a clear block lock-bits

operation is attempted while V+V,,, SR.3 and

SR.5 will be set to “1”. In the absence of this high

voltage, the block lock-bits content are protected

against alteration. A successful clear block lock-bits

operation requires that the master lock-bit is not set or,

if the master lock-bit is set, that m=V,. If it is

attempted with the master lock-bit set and i?is=VIH,

SR.1 and SR.5 will be set to “1” and the operation will

fail. A clear block lock-bits operation with VI&@

<V, produce spurious results and should not be

attempted.

If a clear block lock-bits operation is aborted due to

VP, or Vcc transitioning out of valid range or Rp

active transition, block lock-bit values are left in an

undetermined state. A repeat of clear block lock-bits is

required to initialize block lock-bit contents to known

values. Once the master lock-bit is set, it cannot be

cleared.

his two-step sequence of set-up followed by

xecution ensures that block lock-bits are not

Table 6. Write Protection Alternatives

Master Block

Operation

Block Erase or

Byte Write X

Set Block 0

Lock-Bit

Set Master

Lock-Bit

Clear Block

Lock-Bits

Lock-Bit Lock-Bit RF Effect

0

1 VTW Block is Locked. Block Erase and Byte Write Disabled

X V, or Set Block Lock-Bit Enabled

1 X VW

X

0

1 X

X

X V, or Clear Block Lock-Bits Enabled

V, or Block Erase and Byte Write Enabled

w.

VW

VHH

VW

.v, Master Lock-Bit Override. Set Block Lock-Bit Enabled

V,,

VW

-.

VW

V,,

VHH

Block Lock-Bit Override. Block Erase and Byte Write

Enabled

Master Lock-Bit is Set. Set Block Lock-Bit Disabled

Set Master Lock-Bit Disabled

Set Master Lock-Bit Enabled

Master Lock-Bit is Set. Clear Block Lock-Bits Disabled

Master Lock-Bit Override. Clear Block Lock-Bits

Page 23

SHARP

LRS13023

Table 7. Status Register Definition

WSMS 1 ESS 1 ECLBS ( BWSLBS ( VPRS BWSS DPS

7

SR.7 = WRITE STATE MACHINE STATUS Check SR.7 to determine block erase, byte write, or

1= Ready lock-bit configuration compIetion.

0 = Busy

SR.6 = ERASE SUSPEND STATUS If both SR.5 and SR.4 are “1”s after a block erase or

1= Block Erase Suspended lock-bit configuration attempt, an improper command

0 = Block Erase in Progress/Completed

SR.5 = ERASE AND CLEAR LOCK-BITS STATUS

1= Error in Block Erasure or Clear Lock-Bi is

0 = Successful Block Erase or Clear Lock-Bits

SR.4 = BYTE WRITE AND SET LOCK-BITeSTATUS

1 = Error in Byte Write or Set Master/Block Lock-Bit

0 = Successful Byte Write or Set Master/Block

Lock-Bit

SR.3 = V,, STATUS

1 = VP, Low Detect, Operation Abort

O=V,,OK

SR.2 = BYTE WRITE SUSPEND STATUS

1 = Byte Write Suspended

0 = Byte Write in Progress/Completed

SR.l = DEVICE PROTECT STATUS

1 = Master Lock-Bit, Block Lock-Bit and/or p Lock

Detected, Operation Abort

0 = Unlock

6

5 4 3 2 1 0

NOTES:

SR6-0 are invalid while SR.7=“0”.

sequence was entered.

SR.3 does not provide a continuous indication of VP,

level. The WSM interrogates and indicates the V,, level

only after Block Erase, Byte Write, Set Block/Master

Lock-Bit, or Clear Block Lock-Bits command sequences.

SR.3 is not guaranteed to reports accurate feedback only

when V,,=V,,,.

SR.1 does not provide a continuous indication of master

and block lock-bit values. The WSM interrogates the

master lock-bit, block lock-bit, and RP only after Block

Erase, Byte Write, or Lock-Bit configuration command

sequences. It informs the system, depending on the

attempted operation, if the block lock-bit is set, master

lock-bit is set, and/or RP is not V,,. Reading the block

lock and master lock configuration codes after writing

the Read Identifier Codes command indicates master

and block lock-bit status.

SR.0 is reserved for future use and should be masked

out when polling the status register.

I

21

R

SR.0 = RESERVED FOR FUTURE ENHANCEMENTS

Page 24

SHARP

LRS13023

22

Comment3

Check If Deeired

FULL STATUS CHECK PROCEDURE

Read Status Beg&r

IhtaCSee Above)

Suspmd Black

Read

I

Repeat for subsequent block erasores.

Full ,tailhls check can be done after each block erase or after a eequence of

bbck erasuree.

Write FFH after Ibe kut operation to phwe device in read array mode.

status Register Data

Check SR7

l.W!SM Ready

O=WSM Busy

Comments

Cheek SR3

l=Vpp Error Detect

Check SRI

Idkvice protect Detect

i?&Vt,,Block Lock-Bit is Set

Only required for systems

implementing lock-bit configuration

I

Block EmseSucceseful

Stmdby

I

SRS,SR4SR3 and SR.1 are only cleared by the Clear Status

Register Command in casea where multiple blocks are erased

before full etatoe b checked.

If error isdetected, clear the Status Register before attempting

retry or other error recovery.

Figure 4. Automated Block Erase Flowchart

Check SR4.5

Both I=Command Sequence Error

Check SRS

l=Block Erase Error

Page 25

SHARI=

LRS13023

Write 4OH or 10H

Add-

Wrih Byte

Data and Addrerr

FULLZTATIJS CHECK PROCEDURE

DataGee Above)

Bus

Opation

Write Byte write

Rnd

I

Repeat for subsequent byte writes..

SR full stahn check can be done after each byte write. or after a sequence of

byte write.

Write FFH after the last byte write operation to place device in

read array mate.

BUS

Opdi0n

Command Comment3

Data=Data to Be written

Addr=LocaMon to Be Writbn

status Register Data

I

Command Comments

I

Device Protect Error

Figure 5. Automated Byte Write Flowchart

1 Standby 1

Standby

Standby

SR45Rs3 and SRI are Only cleared by the Clear Stahm Register

command in cases when multiple locations are written before

If enur is detected, clear the Status Register before attempting

Check SR3

l=Vpp Error Detect

Check SRl

1=cevice Protect Detect

!@=V~~,Block Lock-Bit is Set

Only required for systems

implementing lock-bit configuration

Check SR4

l--Data Wrtte Ermr

Page 26

:.

.:.,.&“ARP

.:’

su.7.a

LRS13023

checksR7

1dvsMRcPdy

O=WSM Busy

0

24

w

I

Figure 6. Block Erase Suspend/Resume Flowchart

I

Wrik

Emm Dala=DoH

Resume

I

AddrrX

I

I

Page 27

Wrib?

I - I

*

Byte write

&Pd

Dah=BOH

AddrX

Sbhw Rrgister Dab

Add-X

I

I

Wrik

Rd

-AmY

I

Figure 7. Byte Write Suspend/Resume Flowchart

mta=FFH

Addr=X

I

Red Amy locatiom othrr

than that being wrhn.

Page 28

.

-

SHARP ’

Block/Devke Addraa

WriteOlHFtH.

Block/Device Add=

Check if Desired

. .,,,I

LRS13023

&pent for subsquent lack-bit aetoperattom.

Pull ,btus check an be don after ench kxk-blt set operation

or after P aqucm of lock-bit set opemtlons.

Write ITH after the last lock-bit set opentlan IO pl.m de+ In

read array made.

/

set

Bkck/Mrsta

Lack-Bit Setup

26

I

DZ?tP=6LJH

AddmBbxk AddrrsJ(BlaW,

Dcvia Address&laster)

FULLSTATlJSCHECKPROCEUJRE

Set Luck-Bit Emw

Check SR3

ld’pp Error Detect

I

CheckSRl

I=oevh Protect Detect

b-V,,

(Set Master lack-Bit Onentton)

i%V,“, Master Lock-Bit is Set

(Set Block Lack-Bit Operation)

CIwck~45

Both l-Command

scquencs Emx

Check SR4

l&t Lack-Bit Error

I

SR55R4,SR3andSRlareoniyclearedbythe

command In cases where multiple lack-bib am set before-

If aror is detected, dear the Stahu Register befoe attempting

aedtahra

Figure 8. Set Block and Master Lock-Bit Flowchart

Page 29

Write 60H

LRS13023

27

Wrttc WH

si

Sbtua RLghbr

sR.7.

3

FULL STATUS CHECK PROCEDURE

0

1

aear Bbck Dh=WH

Luck-Bib Confirm

Write FFH after tk Clear Block Lock-Bib opwatton to

ptw devke in mad array mode.

Add-X

Ckk 547.1

l=Ddce Protect Detect

i&V,“, Master lsck-Bit is Set

Commcnb

I I

SR.S5R4sR3andSR.1arem¶tycIearcdbythe

Regbbrcommand.

Figure 9. Clear Block Lock-Bits Flowchart

Check SR4.5

Both I=commad

SequmctErmr

CbeckSR5

l=Clear Blak Lack-Bib !&or

I

acershhu

Page 30

_____

SHARP

LRS13023

5 DESIGN CONSIDERATIONS

i.1 Three-Line Output Control

The device will often be used in large memory arrays.

SHARPprovides three control inputs to accommodate

nultiple memory connections. Three-line control

xovides for:

a. Lowest possible memory power dissipation.

b. Complete assurance that data bus contention wilI

not occur.

To use these control inputs efficiently, an address

iecoder should enable m while m should be

:onnected to all memory devices and the system’s

READ control line. This assures that only selected

nemory devices have active outputs while deselected

nemory devices are in standby mode. y should be

:onnected to the system POWERGOOD signal to

prevent unintended writes during system power

ran&ions. POWERGOOD should also toggle during

system reset.

outputs’ capacitive and inductive loading. Two-line

control and proper decoupling capacitor selection will

suppress transient voltage peaks. Each device shouId

have a 0.1 uF ceramic capacitor connected between its

V,, and GND and between its V,, and GND. These

high-frequency, low inductance capacitors should be

placed as close as possible to package leads.

Additionally, for every eight devices, a 4.7 pF

electrolytic capacitor should be placed at the array’s

power supply connection between Vc- and GND. The

bulk capacitor will overcome voltage slumps caused

by PC board &ace inductance.

5.3 V,, Trace on Printed Circuit Boards

Updating flash memories that reside in the target

system requires that the printed circuit board designer

pay attention to the V,, Power supply trace. The V,,

pin supplies the memory cell current for byte writing

and block erasing. Use similar trace widths and layout

considerations given to the V,, power bus. Adequate

V, supply traces and decoupling will decrease V,,

voltage spikes and overshoots.

i.2 Power Supply Decoupling

?ash memory power switching characteristics require

:areful device decoupling. System designers are

nterested in three supply current issues; standby

urrent levels, active current levels and transient peaks

rroduced by falling and rising edges of m and m.

Transient current magnitudes depend on the device

Page 31

LRS13023 29

5.4 V,,, V,,, i?is Transitions

3lock erase, byte write and lock-bit configuration are

lot guaranteed if Vpp

ange, V, falls outside of a valid Vccl range, or RP

N,, or V,,. If V,, error is detected, status register

)it SR3 is set to “1” along with SR4 or SR5, depending

m the attempted operation. If Rp transitions to V,

luring block erase, byte write, or lock-bit

:onfiguration, the operation will abort and the device

ti enter deep power-down. The aborted operation

nay leave data partially altered. Therefore, the

:ommand sequence must be repeated after normal

operation is restored. Device power-off or D

ransitions to V,, clear the status register.

The GUI latches co mmands issued by system software

md is not altered by V, or a transitions or WSM

~tions. Its state is read array mode upon power-up,

ifter exit from deep power-down or after Vcc

ransitions below Vu0

After block erase, byte write, or lock-bit configuration,

?ven after V,, transitions down to V,,,, the GUI

nust be placed in read array mode via the Read Array

:ommand if subsequent access to the memory array is

iesired.

5.5 Power-Up/Down Protection

The device is designed to offer protection against

t&dental block erasure, byte writing, or lock-bit

:onfiguration during power transitions. Upon

>ower-up, the device is indifferent as to which power

upply (V,, or V,,) powers-up first. Internal circuitry

‘esets the GUI to read array mode at power-up.

fails outside of a valid VP=

A system designer must guard against spurious writes

for V,eoltages above Vu0 when V,, is activ;.:;

both WE and m must be low for a comman * ,

driving either to VIH will inhibit writes. The GUI’s

two-step command sequence architecture provides

added level of protection against data alteration.

In-system block lock and unlock capability prevents

inadvertent data alteration. The device is disabled

while m=V,, regardless of its contro1 inputs state.

5.6 Power Dissipation

When designing portable systems, designers must

consider battery power consumption not only during

device operation, but also for data retention during

system idle time. Flash memory’s nonvolatility

increases usable battery life because data is retained

when system power is removed.

In addition, deep powerdown mode ensures

extremely low power consumption even when system

power is applied.. For example, portable computing

products and other power sensitive applications that

use an array of devices for solid-state storage can

consume negligible power by. lowering i?p to :VK

standby or sleep,modes. If access is again needed, the

devices can be read following the tpHQv and tpHwL

wake-up cycles required after Rp isfirst raised to V,,.

See AC Characteristics- Read Only and Write

Operations and Figures 12,13 .and 14 for more

information.

Page 32

SHARI=

LRS13023

ELECTRICAL SPECIFICATIONS

.1 Absolute Maximum Ratings*

:ommercial

During Read, Block Erase, Byte Write

and Lock-Bit Configuration . . . . . . . . . -40°C

Temperature under Bias . . . . . . . . . . . . . . . . . . -40°C to +85”C

torage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -65°C to

S

4

Toltage On Any Pin

(except Vcc, VP,, and m> . . . . . . . . . . . . -2.OV to +7.0Vt2)

rc- Supply

TPP Update Voltage during

Block Erase, Byte Write and

Lock-Bit

r Voltage with Respect to

T

GND during Lock-Bit

Configuration Operations . . . . . . . . . -2,OV to +14.0V(2J)

Output Short Circuit Current . . . . . . . . . . . . . . . . . . . . . . . . . . lOOmA(4)

C

Operating Temperature

to +85@)

+125”C

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -2.OV to +7.0Vt2)

Configuration . . . . . . . . . . . . . . -2.OV to +14.OV(23)

30

*WARNING: Stressing the device beyond the ‘Absolute

Maximum Ratings” may cause permanent damage.

These are stress ratings only. Operation beyond the

“Operating Conditions” is not recommended and

extended exposure beyond the “Operating Conditions”

may affect device reliability.

NOTES:

1. Operating temperature is for commercial product

defined by this specification.

2. All specified voltages are with respect to GND.

Minimum DC voltage is -0SV on input/output pins

and -0.2V on Vcthis level may undershoot to -2.OV for periods

~2011s. Maximum DC voltage on input/output pins

and V,, is V,,+O.5V which, during transitions,

may overshoot to V,,

3. Maximum DC voltage on VP, and Rp may overshoot

to +14.OV for periods c2Ons.

4. Output shorted for no more than one second. No

more than one output shorted at a time.

and V, pins. During transitions,

+2.OV for periods <2Ons.

6 .2 Operating Conditions

Symbol Parameter

T*

V,,,

JOTE:

. FLASH Erase/Write (TA=O to 85°C)

Operating Temperature

V,, Supply Voltage (2.7V-3.6V) 1 2.7

Temperature and V,, Operating Conditions

Notes Min Max unit Test Condition

-40 +85 “C Ambient Temperature

3.6

V

Page 33

SHARI=

.2.1 AC INPUT/OUTPUT TEST CONDITIONS

~~~z2~~~~

AC test inputs are driven at 2.7V for a Logic’l” and O.OV for a Logic “0.” Input timing begins, and output timing ends, at 1.35V.

Input rise and fall times (10% to 90%) cl0 ns.

Figure 10. Transient InputjOutput Reference Waveform for V,-=2.7V-3.6V

13

lN914

-c

LRS13023

Test Configuration Capacitance Loading Value

Test Configuration

Vo=2.7V-3.6V so

C,

,(pF)

31

CL Includes Jig

Capacitance

Figure 11. Transient Equivalent Testing Load

Circuit

Page 34

SHARP

i.2.2 DC CHAR4CTERISTICS

Spl

IL1

IL0

kcs

kCD

Input Load Current 1

Output Leakage Current 1 20.5

V,, Standby Current

V,, Deep Power-Down

Current

kCR

kcw

V,-- Read Current

V,, Byte Write orSet

Lock-Bit Current

kCE

V,, Block Erase or Clear

Block Lock-Bits Current

kcws

V,- Byte Write or Block

I(-(.FS Erase Suspend Current

bPs

Ipp*

IlTD

VP, Standby or Read 1 22 215

Current 10 200 pA

VPP

Current

4TW

VP, Byte Write or

SetLock-Bit Current

IPPE

VP, Block Erase orClear

Lock-Bit Current

IPPWS

PPFS

VP, Byte Write or Block 1 10 200

Erase Suspend Current

Parameter Notes Typ

Deep Power-Down 1 0.1 5

1,5

1

1,45

c

L6

1,6

12

L6

L6

LRS13023

DC Characteristics

Vcc=2.7V-3.6V Test

Max unit Conditions

20.5

PA

PA

20 100

PA

0.2 2 mA TTL Inputs

20

PA

7 12 mA CMOS Inputs

8 18 mA

17 mA

17 mA

1 6 mA a=&,

PA

PA

40

mA

20 mA

@

VCC=VCCMax

V,,,,=VTC or GND

VCC=VCCMax

Vnr

TT=Vcc or GND

CMOS Inputs

kc=V,,Max

CE=RF=Vc-c-~0.2V

VCC=VC-Max

CEaEV,~

i@=GND+-0.2V

I,, ,T=OmA

VCC=VCCMax, ~=GND

f=5MHz(3.3V, 2.7V)101 ,=OmA

-I-rL Inputs

VCC=VCCMax, CE=GND

-

f=5MHz(3.3V, 2.7V)I,, ,=OmA

VPP=VlTH

VPP=VlTH

V,,IV~~

V,p>V(-r

m=GND+0.2V

VlT=VPPH

VPP=VPPH

vPP=vPPH

32

Page 35

SHARI=

LRS13023 33

DC Characteristics (Continued)

VoH2 Output High Voltage

cMos)

VP,, V,, Lockout during

Normal Operations

V,, VP, during Byte Write,

Block Erase or Lock-Bit

Operations

V, .KO V,, Lockout Voltage

VI-II-I

NOTES:

1. All currents are in RMS unless otherwise noted.

2. kcws~dhEs

3. Block erases, byte writes, and lock-bit configurations are inhibited when VPPIvPPx, and not guaranteed in the

4. Automatic Power Savings @F’S) reduces typical ~C-J to 3mA at 3.3V V,- in static operation.

5. CMOS inputs are either V,-c- +0.2V or GNDk0.2V. TTL inputs are either V, or V,.

6. Sampled, not 100% tested.

7. Master lock-bit set operations are inhibited when D=V,,. Block lock-bit configuration operations are inhibited

8. m connection to a V, supp 1 y is allowed for a Maximum cumulative period of 80 hours.

Rp Unlock Voltage

are specified with the device de-selected. If read or byte written while in erase suspend mode,

the device’s current draw is the sum of kms or kcEs and &-- or &--JJ, respectively.

range between VPPx(Max> and VP&&n) and above VP&Max).

when the master lock-bit is set and Rp=V,. Block erases and byte writes are inhibited when the corresponding

block-lock bit is set and P=VIH.

6

3,6

7,;

0.85

V,,

Vcc

-0.4

2.7

2.0

11.4

1.5

3.6

12.6

V v,-=v,,Min

&=-2.5uA

V

V

V

V

V Set master lock-bit

TA=O to 85°C

Override master and block lock-bit

. .

Page 36

SHARI=

LRS13023

6.2.3 AC CHARACTERISTICS - READ-ONLY OPERATIONS(‘)

Vo=2.7V-3.6V, TA=-400C to +8S”C

Sym 1 Parameter

tA”*V 1 Read Cycle Time

rddress to Output Delay

rt Delay

RR Hieh to Outout Delav

)I2 to Output Delay

I, -

CE to Outp

a High to

/

OE to Outo;

Cm-Ii] gh to ( Output in High Z

bH

NOTES:

1. See AC Input/Output Reference Waveform for maximum allowable input slew rate.

2. m may be delayed up to tELQV-kLQV

3. Sampled, not 100% tested.

Output Hold from Address, a or OE Change,

Whichever Occurs First

1

It in Low 2

7

atput in High 2

1tinLowz

affer the falling edge of a without impact on

1 Notes 1 Min

130

! I !

2

2 ii0

3 0 ns

3 55

3 0 ns

3 20 ns

3 0

Max 1 unit ]

I

! !

130

I

tELQv.

130 ns

600

!

34

ns

ns

Ix.3 I

ns

ns

ns

1

1

Page 37

SHARI=

LRS13023

.DDRESS~A)

VOL

HIGH Z

Device

Address Selection

,

Data Valid

Address Stable

, -__----__-_

tAVEL-

c

4

Valid Output

I, tavnv

-----------

::::::::::y:::y%{

HIGH z

vcc

-E(P)

VIH I

VIL

-----------7

4

tPHOV

c

Figure 12. AC Waveform for Read

------------

Operations

Page 38

SHARP

LRS13023

AC CHARACTERISTICS - WRITE OPERATION(‘)

Vo=27V-3.6V, T,=O’C to +85”C

Parameter

Write Cycle *

Rp High Recovery to WE Going Low

a Setup to WE Going Lqw

rime

Width

LD

--

to m Goi

ing High

ng High

Notes Min

130

2

I

2 100 ns

2

3 50 ns

1

10

50 ns

100

Max unit

ns

P

ns

ns

-1

I

1

NOTES:

1. Read timing characteristics during block erase, byte write and lock-bit configuration operations are the same as

during read-onry operations. Refer to AC Characteristics for read-only operations.