Page 1

LP3982

Micropower, Ultra Low-Dropout, Low-Noise, 300mA

CMOS Regulator

LP3982 Micropower, Ultra Low-Dropout, Low-Noise, 300mA CMOS Regulator

March 2006

General Description

The LP3982 low-dropout (LDO) CMOS linear regulator is

available in 1.8V, 2.5V, 2.77V, 2.82V, 3.0V, 3.3V, and adjustable versions. They deliver 300mA of output current. Packaged in an 8-Pin MSOP, the LP3982 is pin and package

compatible with Maxim’s MAX8860. The LM3982 is also

available in the small footprint LLP package.

The LP3982 suits battery powered applications because of

its shutdown mode (1nA typ), low quiescent current (90µA

typ), and LDO voltage (120mV typ). The low dropout voltage

allows for more utilization of a battery’s available energy by

operating closer to its end-of-life voltage. The LP3982’s

PMOS output transistor consumes relatively no drive current

compared to PNP LDO regulators.

This PMOS regulator is stable with small ceramic capacitive

loads (2.2µF typ).

These devices also include regulation fault detection, a

bandgap voltage reference, constant current limiting and

thermal overload protection.

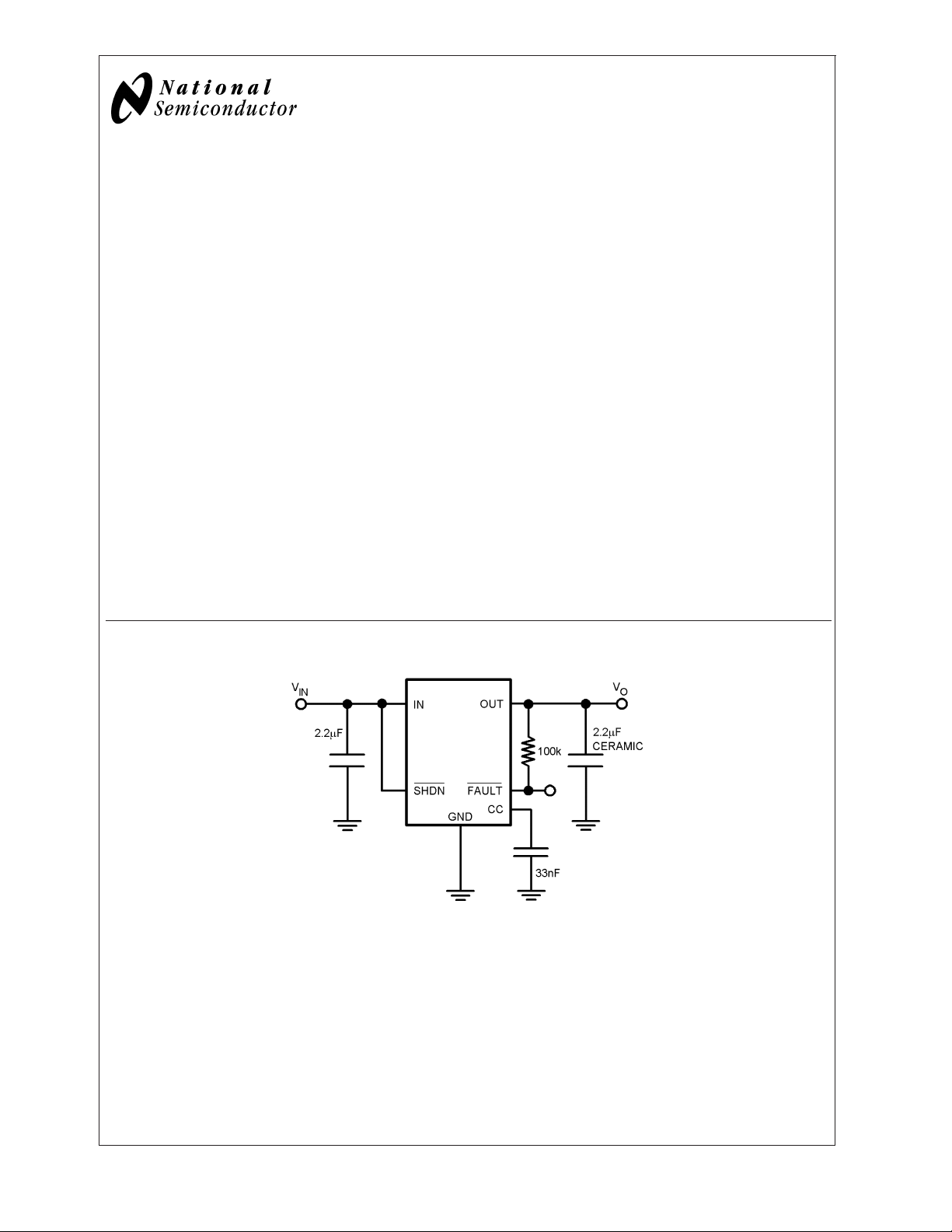

Application Circuit

Features

n MAX8860 pin, package and spec. compatible

n LLP space saving package

n 300mA guaranteed output current

n 120mV typical dropout

n 90µA typical quiescent current

n 1nA typical shutdown mode

n 60dB typical PSRR

n 2.5V to 6V input range

n 120µs typical turn-on time

n Stable with small ceramic output capacitors

n 37µV RMS output voltage noise (10Hz to 100kHz)

n Over temperature/over current protection

±

n

2% output voltage tolerance

@

300mA

Applications

n Wireless handsets

n DSP core power

n Battery powered electronics

n Portable information appliances

20036931

© 2006 National Semiconductor Corporation DS200369 www.national.com

Page 2

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

LP3982

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V

IN,VOUT,VSHDN,VSET,VCC

V

FAULT

,

−0.3V to 6.5V

ESD Rating

Human Body Model (Note 6) 2kV

Machine Model 200V

Thermal Resistance (θ

)

JA

8-Pin MSOP 223˚C/W

8-Pin LLP (Note 3)

Fault Sink Current 20mA

Power Dissipation (Note 3)

Storage Temperature Range −65˚C to 160˚C

Junction Temperature (T

) 150˚C

J

Lead Temperature (10 sec.) 260˚C

Operating Ratings(Note 1), (Note 2)

Temperature Range −40˚C to 85˚C

Supply Voltage 2.5V to 6.0V

Electrical Characteristics

Unless otherwise specified, all limits guaranteed for VIN=VO+0.5V (Note 7), V

TJ= 25˚C. Boldface limits apply for the operating temperature extremes: −40˚C and 85˚C.

Symbol Parameter Conditions Min

V

∆V

IN

O

Input Voltage 2.5 6.0 V

Output Voltage Tolerance 100µA ≤ I

V

IN=VO

≤ 300mA

OUT

+0.5V, (Note 7)

SET = OUT for the Adjust

Versions

V

I

O

I

LIMIT

I

Q

V

∆V

O

DO

O

Output Adjust Range Adjust Version Only 1.25 6 V

Maximum Output Current Average DC Current Rating 300 mA

Output Current Limit 330 770 mA

Supply Current I

Shutdown Supply Current V

Dropout Voltage

(Note 7), (Note 8)

Line Regulation I

= 0mA 90 270

OUT

I

= 300mA 225

OUT

= 0V, SHDN = GND 0.001 1 µA

O

I

= 1mA 0.4

OUT

= 200mA 80 220

OUT

I

= 300mA 120

OUT

= 1mA, (VO+ 0.5V) ≤ VI≤ 6V

OUT

(Note 7)

e

V

n

SHDN

Load Regulation 100µA ≤ I

Output Voltage Noise I

= 10mA, 10Hz ≤ f ≤ 100kHz 37 µV

OUT

Output Voltage Noise Density 10Hz ≤ f ≤ 100kHz, C

SHDN Input Threshold VIH,(VO+ 0.5V) ≤ VI≤ 6V

≤ 300mA 0.002 %/mA

OUT

= 10µF 190 nV/

OUT

(Note 7)

,(VO+ 0.5V) ≤ VI≤ 6V

V

IL

(Note 7)

I

SHDN

I

SET

SHDN Input Bias Current SHDN = GND or IN 0.1 100 nA

SET Input Leakage SET = 1.3V, Adjust Version Only

(Note 9)

V

FAULT

FAULTDetection Voltage VO≥ 2.5V, I

OUT

= 200mA

(Note 10)

I

= 2mA 0.115 0.25 V

SINK

I

FAULT

T

SD

FAULT Output Low Voltage

FAULT Off-Leakage Current FAULT = 3.6V, SHDN = 0V 0.1 100 nA

Thermal Shutdown

Temperature

Thermal Shutdown Hysteresis 10

T

ON

Start-Up Time C

= 10µF, VOat 90% of Final

OUT

Value

Note 1: Absolute Maximum ratings indicate limits beyond which damage may occur. Electrical specifications do not apply when operating the device outside of its

rated operating conditions.

=VIN,CIN=C

SHDN

(Note 5)

Typ

(Note 4)

= 2.2µF, CCC= 33nF,

OUT

Max

(Note 5)

−2 +2

−3 +3

−0.1 0.01 0.1 %/V

2

0.4

0.1 2.5 nA

120 280 mV

160

120 µs

Units

%of

V

OUT (NOM)

µA

mVI

RMS

V

˚C

www.national.com 2

Page 3

Electrical Characteristics (Continued)

Note 2: All voltages are with respect to the potential at the ground pin.

Note 3: Maximum Power dissipation for the device is calculated using the following equations:

LP3982

where T

package θ

thus below 25˚C the power dissipation figure can be increased by 4.5mW per degree, and similarity decreased by this factor for temperatures above 25˚C. The value

of the θ

resistance and power dissipation for the LLP package, refer to Application Note AN-1187.

Note 4: Typical Values represent the most likely parametric norm.

Note 5: All limits are guaranteed by testing or statistical analysis.

Note 6: Human body model: 1.5kΩ in series with 100pF.

Note 7: Condition does not apply to input voltages below 2.5V since this is the minimum input operating voltage.

Note 8: Dropout voltage is measured by reducing V

version.

Note 9: The SET pin is not externally connected for the fixed versions.

Note 10: The FAULT detection voltage is specified for the input to output voltage differential at which the FAULT pin goes active low.

is the maximum junction temperature, TAis the ambient temperature, and θJAis the junction-to-ambient thermal resistance. E.g. for the MSOP-8

J(MAX)

= 223˚C/W, T

JA

for the LLP package is specifically dependent on the PCB trace area, trace material, and the number of layers and thermal vias. For improved thermal

JA

= 150˚C and using TA= 25˚C, the maximum power dissipation is found to be 561mW. The derating factor (−1/θJA) = −4.5mW/˚C,

J(MAX)

until VOdrops 100mV from its nominal value at VIN-VO= 0.5V. Dropout Voltage does not apply to the 1.8

IN

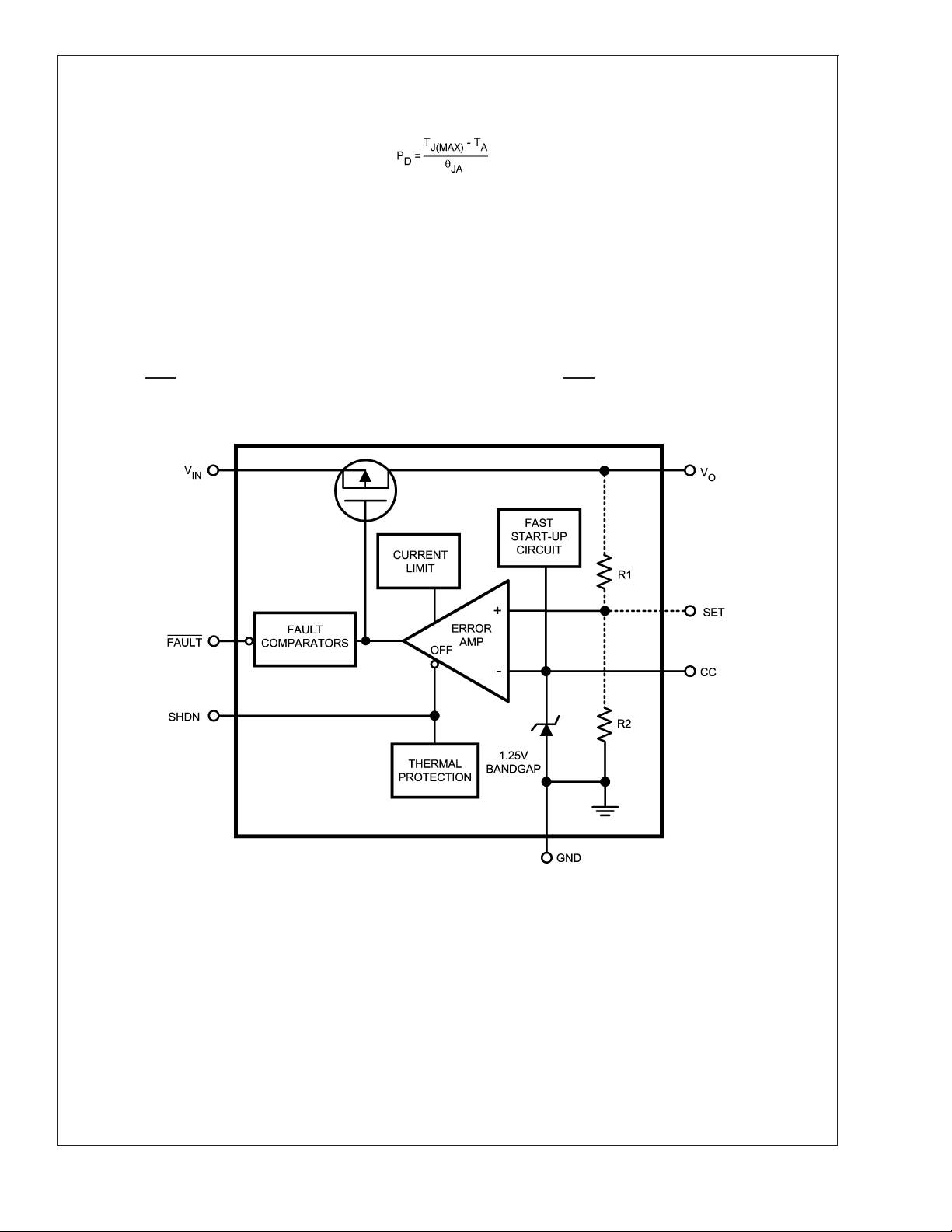

Functional Block Diagram

20036913

www.national.com3

Page 4

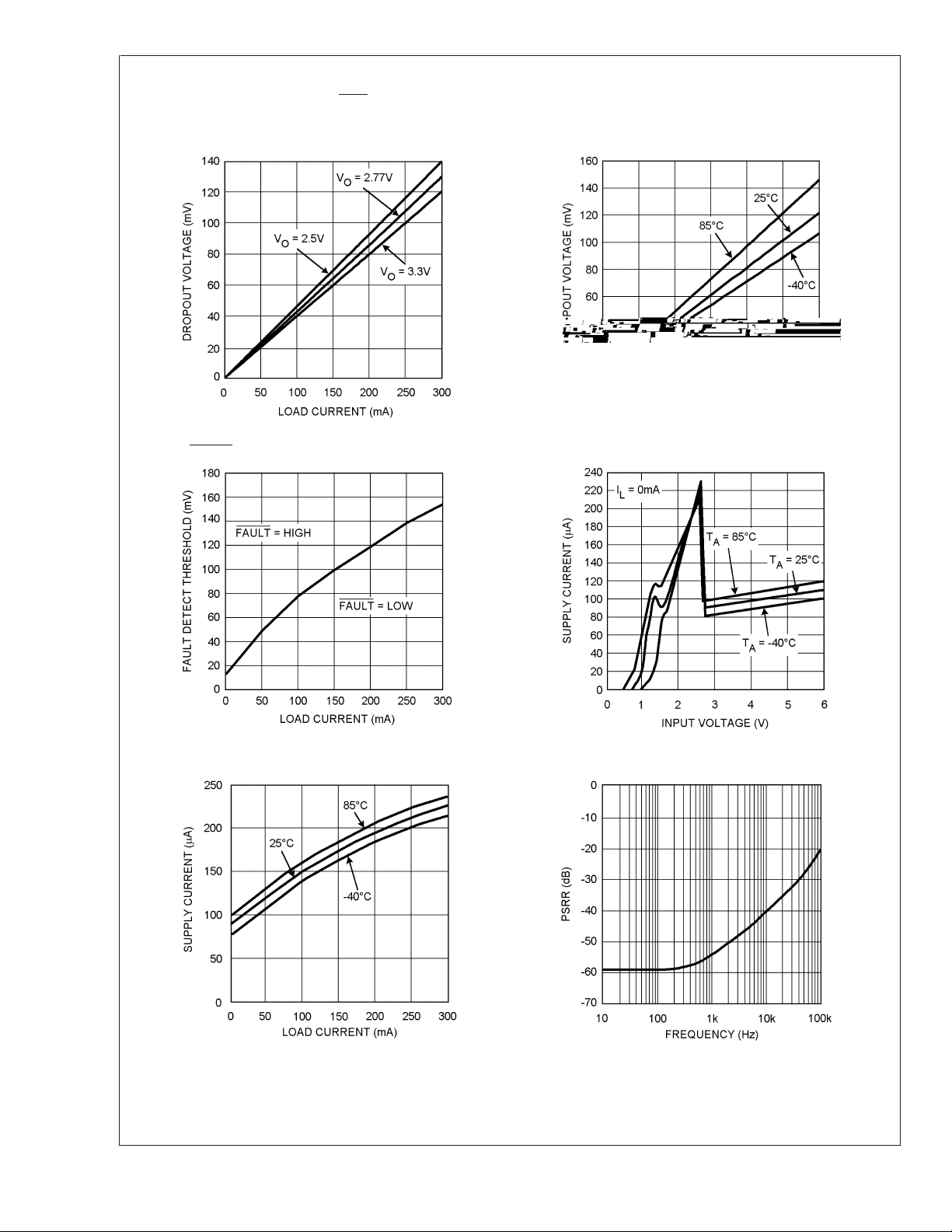

Typical Performance Characteristics Unless otherwise specified, V

2.2µF, C

LP3982

= 33nF, TJ= 25˚C, V

CC

SHDN=VIN

Dropout Voltage vs. Load Current

(For Different Output Voltages)

FAULT Detect Threshold vs. Load Current Supply Current vs. Input Voltage

.

Dropout Voltage vs. Load Current

(For Different Output Temperatures)

20036903 20036927

IN=VO

+ 0.5V, CIN=C

OUT

=

20036928

Supply Current vs. Load Current Power Supply Rejection Ratio vs. Frequency

20036930

www.national.com 4

20036929

20036904

Page 5

LP3982

Typical Performance Characteristics Unless otherwise specified, V

2.2µF, C

= 33nF, TJ= 25˚C, V

CC

Output Noise Spectral Density Output Noise (10Hz to 100kHz)

Output Impedance vs. Frequency Line Transient Response

=VIN. (Continued)

SHDN

20036905

IN=VO

+ 0.5V, CIN=C

20036906

OUT

=

20036907

Load Transient Shutdown Response

20036909

20036908

20036910

www.national.com5

Page 6

Typical Performance Characteristics Unless otherwise specified, V

2.2µF, C

LP3982

= 33nF, TJ= 25˚C, V

CC

Power-Up Response Power-Down Response

SHDN=VIN

. (Continued)

IN=VO

+ 0.5V, CIN=C

OUT

=

20036911

Application Information

GENERAL INFORMATION

LP3982 is package, pin and performance compatible with

Maxim’s MAX8860 excluding reverse battery protection and

Dual Mode

Figure 1 shows the functional block diagram for the LP3982.

A 1.25V bandgap reference, an error amplifier and a PMOS

pass transistor perform voltage regulation while being supported by shutdown, fault, and the usual Temperature and

current protection circuitry

The regulator’s topology is the classic type with negative

feedback from the output to one of the inputs of the error

amplifier. Feedback resistors R

external to the IC, depending on whether it is the fixed

voltage version or the adjustable version. The negative feedback and high open loop gain of the error amplifier cause the

two inputs of the error amplifier to be virtually equal in

voltage. If the output voltage changes due to load changes,

the error amplifier provides the appropriate drive to the pass

transistor to maintain the error amplifier’s inputs as virtually

equal. In short, the error amplifier keeps the output voltage

constant in order to keep its inputs equal.

™

function (fixed and adjustable combined).

and R2are either internal or

1

20036912

OUTPUT VOLTAGE SETTING (ADJ VERSION ONLY)

The output voltage is set according to the amount of negative feedback (Note that the pass transistor inverts the feedback signal.) Figure 2 simplifies the topology of the LP3982.

This type of regulator can be represented as an op amp

configured as non-inverting amplifier and a fixed DC Voltage

) for its input signal. The special characteristic of this

(V

REF

op amp is its extra-large output transistor that only sources

current. In terms of its non-inverting configuration, the output

voltage equals V

times the closed loop gain:

REF

Utilize the following equation for adjusting the output to a

particular voltage:

Choose R2= 100k to optimize accuracy, power supply rejection, noise and power consumption.

20036913

FIGURE 1. Functional Block Diagram for the LP3982

www.national.com 6

20036916

FIGURE 2. Regulator Topology Simplified

Page 7

Application Information (Continued)

Similarity in the output capabilities exists between op amps

and linear regulators. Just as rail-to-rail output op amps

allow their output voltage to approach the supply voltage,

low dropout regulators (LDOs) allow their output voltage to

operate close to the input voltage. Both achieve this by the

configuration of their output transistors. Standard op amps

and regulator outputs are at the source (or emitter) of the

output transistor. Rail-to-rail op amp and LDO regulator outputs are at the drain (or collector) of the output transistor.

This replaces the threshold (or diode drop) limitations on the

output with the less restrictive source-to-drain (or V

tations. There is a trade-off, of course. The output impedance become significantly higher, thus providing a critically

lower pole when combined with the capacitive load. That’s

why rail-to-rail op amps are usually poor at driving capacitive

loads and recommend a series output resistor when doing

so. LDOs require the same series resistance except that the

internal resistance of the output capacitor will usually suffice.

Refer to the output capacitance section for more information.

SAT

) limi-

LP3982

20036917

FIGURE 3. Simplified Model of Regulator

Loop Gain Components

OUTPUT CAPACITANCE

The LP3982 is specifically designed to employ ceramic output capacitors as low as 2.2µF. Ceramic capacitors below

10µF offer significant cost and space savings, along with

high frequency noise filtering. Higher values and other types

and of capacitor may be used, but their equivalent series

resistance (ESR) should be maintained below 0.5Ω

Ceramic capacitor of the value required by the LP3982 are

available in the following dielectric types: Z5U, Y5V, X5R and

X7R. The Z5U and Y5V types exhibit a 50% or more drop in

capacitance value as their temperature increases from 25˚C,

an important consideration. The X5R generally maintain their

±

capacitance value within

20%. The X7R type are desirable

for their tighter tolerance of 10% over temperature.

Ceramic capacitors pose a challenge because of their rela-

tively low ESR. Like most other LDOs, the LP3982 relies on

a zero in the frequency response to compensate against

excessive phase shift in the regulator’s feedback loop. If the

phase shift reaches 360˚ (i.e.; becomes positive), the regulator will oscillate. This compensation usually resides in the

zero generated by the combination of the output capacitor

with its equivalent series resistance (ESR). The zero is

intended to cancel the effects of the pole generated by the

load capacitance (C

tion of the load resistance (R

) of the regulator. The challenge posed by low ESR

(R

O

) combined with the parallel combina-

L

) and the output resistance

L

capacitors is that the zero it generates can be too high in

frequency for the pole that it’s intended to compensate. The

LP3982 overcomes this challenge by internally generating a

strategically placed zero.

Figure 3 shows a basic model for the linear regulator that

helps describe what happens to the output signal as it is

processed through its feedback loop; that is, describe its

loop gain (LG). The LG includes two main transfer functions:

the error amplifier and the load. The error amplifier provides

voltage gain and a dominant pole, while the load provides a

zero and a pole. The LG of the model in Figure 3 is described

by the following equation:

The first term of the above equation expresses the voltage

gain (numerator) and a single pole role-off (denominator) of

the error amplifier. The second term expresses the zero

(numerator) and pole (denominator) of the load in combination with the R

of the regulator.

O

Figure 4 shows a Bode plot that represents a case where the

zero contributed by the load is too high to cancel the effect of

the pole contributed by the load and R

. The solid line

O

illustrates the loop gain while the dashed line illustrates the

corresponding phase shift. Notice that the phase shift at

unity gain is a total 360˚ -the criteria for oscillation.

www.national.com7

Page 8

Application Information (Continued)

LP3982

FIGURE 4. Loop Gain Bode Plot Illustrating

Inadequately High Zero for Stability Compensation

The LP3982 generates an internal zero that makes up for the

inadequately high zero of the low ESR ceramic output capacitor. This internally generated zero is strategically placed

to provide positive phase shift near unity gain, thus providing

a stable phase margin.

NO-LOAD STABILITY

The LP3982 remains stable during no-load conditions, a

necessary feature for CMOS RAM keep-alive applications.

INPUT CAPACITOR

The LP3982 requires a minimum input capacitance of about

1µF. The value may be increased indefinitely. The type is not

critical to stability. However, instability may occur with bench

set-ups where long supply leads are used, particularly at

near dropout and high current conditions. This is attributed to

the lead inductance coupling to the output through the gate

oxide of the pass transistor; thus, forming a pseudo LCR

network within the Loop-gain. A 10µF tantalum input capacitor remedies this non-situ condition; its larger ESR acts to

dampen the pseudo LCR network. This may only be necessary for some bench setups. 1µF ceramic input capacitor are

fine for most end-use applications.

If a tantalum input capacitor is intended for the final application, it is important to consider their tendency to fail in short

circuit mode, thus potentially damaging the part.

NOISE BYPASS CAPACITOR

The noise bypass capacitor (CC) significantly reduces output

noise of the LP3982. It connects between pin 6 and ground.

The optimum value for CC is 33nF.

Pin 6 directly connects to the high impedance output of the

bandgap. The DC leakage of the CC capacitor should be

considered; loading down the reference will reduce the output voltage. NPO and COG ceramic capacitors typically offer

very low leakage. Polypropylene and polycarbonate film carbonate capacitor offer even lower leakage currents.

CC does not affect the transient response; however, it does

affect turn-on time. The smaller the CC value, the quicker the

turn-on time.

20036919

POWER DISSIPATION

Power dissipation refers to the part’s ability to radiate heat

away from the silicon, with packaging being a key factor. A

reasonable analogy is the packaging a human being might

wear, a jacket for example. A jacket keeps a person comfortable on a cold day, but not so comfortable on a hot day. It

would be even worse if the person was exerting power

(exercising). This is because the jacket has resistance to

heat flow to the outside ambient air, like the IC package has

a thermal resistance from its junctions to the ambient (θ

has a unit of temperature per power and can be used to

θ

JA

JA

calculate the IC’s junction temperature as follows:

= θJA(PD) + T

T

J

A

TJis the junction temperature of the IC. θJAis the thermal

resistance from the junction to the ambient air outside the

package. PD is the power exerted by the IC, and T

A

is the

ambient temperature.

PD is calculated as follows:

PD=I

OUT(VIN-VO

for the LP3982 package (MSOP-8) is 223˚C/W with no

θ

JA

)

forced air flow, 182˚C/W with 225 linear feet per minute

(LFPM) of air flow, 163˚C/W with 500 LFPM of air flow, and

149˚C/W with 900 LFPM of air flow.

can also be decreased (improved) by considering the

θ

JA

layout of the PC board: heavy traces (particularly at V

the two V

pins), large planes, through-holes, etc.

OUT

Improvements and absolute measurements of the θ

and

IN

can

JA

be estimated by utilizing the thermal shutdown circuitry that

is internal to the IC. The thermal shutdown turns off the pass

transistor of the device when its junction temperature

reaches 160˚C (Typical). The pass transistor doesn’t turn on

again until the junction temperature drops about 10˚C (hysteresis).

Using the thermal shutdown circuit to estimate , θ

JA

can be

done as follows: With a low input to output voltage differential, set the load current to 300mA. Increase the input voltage

until the thermal shutdown begins to cycle on and off. Then

slowly decrease V

on. Record the resulting voltage differential (V

(100mV increments) until the part stays

IN

) and use it in

D

the following equation:

FAULT DETECTION

The LP3982 provides a FAULT pin that goes low during out

of regulation conditions like current limit and thermal shutdown, or when it approaches dropout. The latter monitors

the input-to-output voltage differential and compares it

against a threshold that is slightly above the dropout voltage.

This threshold also tracks the dropout voltage as it varies

with load current. Refer to Fault Detect vs. Load Current

curve in the typical characteristics section.

The FAULT pin requires a pull-up resistor since it is an

open-drain output. This resistor should be large in value to

reduce energy drain. A 100kΩ pull-up resistor works well for

most applications.

Figure 5 shows the LP3985 with delay added to the FAULT

pin for the reset pin of a microprocessor. The output of the

comparator stays low for a preset amount of time after the

regulator comes out of a fault condition.

).

www.national.com 8

Page 9

Application Information (Continued)

age. The upper threshold (V

) is set for 4.6V in order to

UT

exceed the recovery voltage of the battery.

20036902

FIGURE 6. Minimum Battery Detector that Disconnects

the Load Via the SHDN Pin of the LP3982

LP3982

20036921

FIGURE 5. Power on Delayed Reset Application

The delay time for the application of Figure 5 is set as

follows:

The application is set for a reset delay time of 8.8ms. Note

that the comparator should have high impedance inputs so

as to not load down the V

at the CC pin of the LP3982.

REF

SHUTDOWN

The LP3982 goes into sleep mode when the SHDN pin is in

a logic low condition. During this condition, the pass transistor, error amplifier, and bandgap are turned off, reducing the

supply current to 1nA typical. The maximum guaranteed

voltage for a logic low at the SHDN pin is 0.4V. A minimum

guaranteed voltage of 2V at the SHDN pin will turn the

LP3982 back on. The SHDN pin may be directly tied to VINto

keep the part on. The SHDN pin may exceed VINbut not the

ABS MAX of 6.5V.

Figure 6 shows an application that uses the SHDN pin. It

detects when the battery is too low and disconnects the load

by turning off the regulator. A micropower comparator

(LMC7215) and reference (LM385) are combined with resistors to set the minimum battery voltage. At the minimum

battery voltage, the comparator output goes low and tuns off

the LP3982 and corresponding load. Hysteresis is added to

the minimum battery threshold to prevent the battery’s recovery voltage from falsely indicating an above minimum

condition. When the load is disconnected from the battery, it

automatically increases in terminal voltage because of the

reduced IR drop across its internal resistance. The Minimum

battery detector of figure 6 has a low detection threshold

) of 3.6V that corresponds to the minimum battery volt-

(V

LT

Resistor value for V

and VLTare determined as follows:

UT

(The application of figure 6 used a GTof 5µ mho)

The above procedure assumes a rail-to-rail output comparator. Essentially, R

lower threshold, then R

is in parallel with R1prior to reaching the

2

becomes parallel with R3for the

2

upper threshold. Note that the application requires rail-to-rail

input as well.

The resistor values shown in Figure 6 are the closest practical to calculated values.

FAST START-UP

The LP3982 provides fast start-up time for better system

efficiency. The start-up speed is maintained when using the

optional noise bypass capacitor. An internal 500µA current

source charges the capacitor until it reaches about 90% of its

final value.

www.national.com9

Page 10

Connection Diagrams

LP3982

8-Pin MSOP 8-Pin LLP Surface Mount

20036933

Top View

20036901

Note: The SET pin is internally disconnected for the fixed versions.

Top View

Ordering Information

Package Part Number Package Marking Transport Media NSC Drawing

8-Pin MSOP LP3982IMM-ADJ

LP3982IMMX-ADJ 3.5k Units Tape and Reel

LP3982IMM-1.8

LP3982IMMX-1.8 3.5k Units Tape and Reel

LP3982IMM-2.5

LP3982IMMX-2.5 3.5k Units Tape and Reel

LP3982IMM-2.77

LP3982IMMX-2.77 3.5k Units Tape and Reel

LP3982IMM-2.82

LP3982IMMX-2.82 3.5k Units Tape and Reel

LP3982IMM-3.0

LP3982IMMX-3.0 3.5k Units Tape and Reel

LP3982IMM-3.3

LP3982IMMX-3.3 3.5k Units Tape and Reel

8-Pin LLP LP3982ILD-1.8

LP3982ILDX-1.8 4.5k Units Tape and Reel

LP3982ILD-2.5

LP3982ILDX-2.5 4.5k Units Tape and Reel

LP3982ILD-2.77

LP3982ILDX-2.77 4.5k Units Tape and Reel

LP3982ILD-2.82

LP3982ILDX-2.82 4.5k Units Tape and Reel

LP3982ILD-3.0

LP3982ILDX-3.0 4.5k Units Tape and Reel

LP3982ILD-3.3

LP3982ILDX-3.3 4.5k Units Tape and Reel

LP3982ILD-ADJ

LP3982ILDX-ADJ 4.5k Units Tape and Reel

LEVB

LENB

LEPB

LERB

LESB

LETB

LEUB

LNB

LPB

LRB

LSB

LTB

LUB

LVB

1k Units Tape and Reel MUA08A

1k Units Tape and Reel

1k Units Tape and Reel

1k Units Tape and Reel

1k Units Tape and Reel

1k Units Tape and Reel

1k Units Tape and Reel

1k Units Tape and Reel LDA08C

1k Units Tape and Reel

1k Units Tape and Reel

1k Units Tape and Reel

1k Units Tape and Reel

1k Units Tape and Reel

1k Units Tape and Reel

www.national.com 10

Page 11

Physical Dimensions inches (millimeters) unless otherwise noted

LP3982

8-Pin MSOP

NS Package Number MUA08A

8-Lead LLP Surface Mount

NS Package Number LDA08C

www.national.com11

Page 12

Notes

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

LP3982 Micropower, Ultra Low-Dropout, Low-Noise, 300mA CMOS Regulator

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor manufactures products and uses packing materials that meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain

no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

Leadfree products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...