Page 1

查询LP3931供应商

LP3931

Dual RGB LED Driver with High Current Boost DC-DC

Converter

LP3931 Dual RGB LED Driver with High Current Boost DC-DC Converter

August 2004

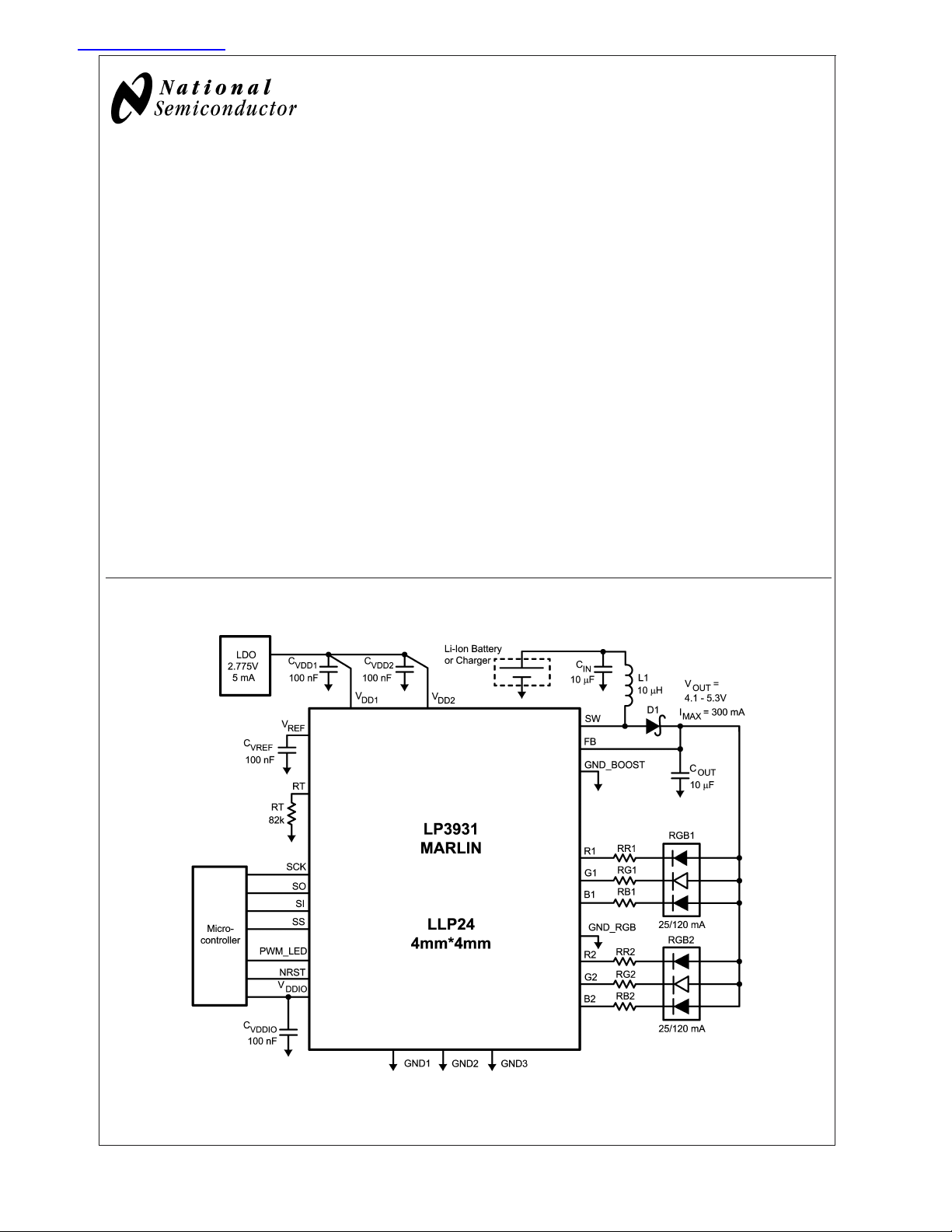

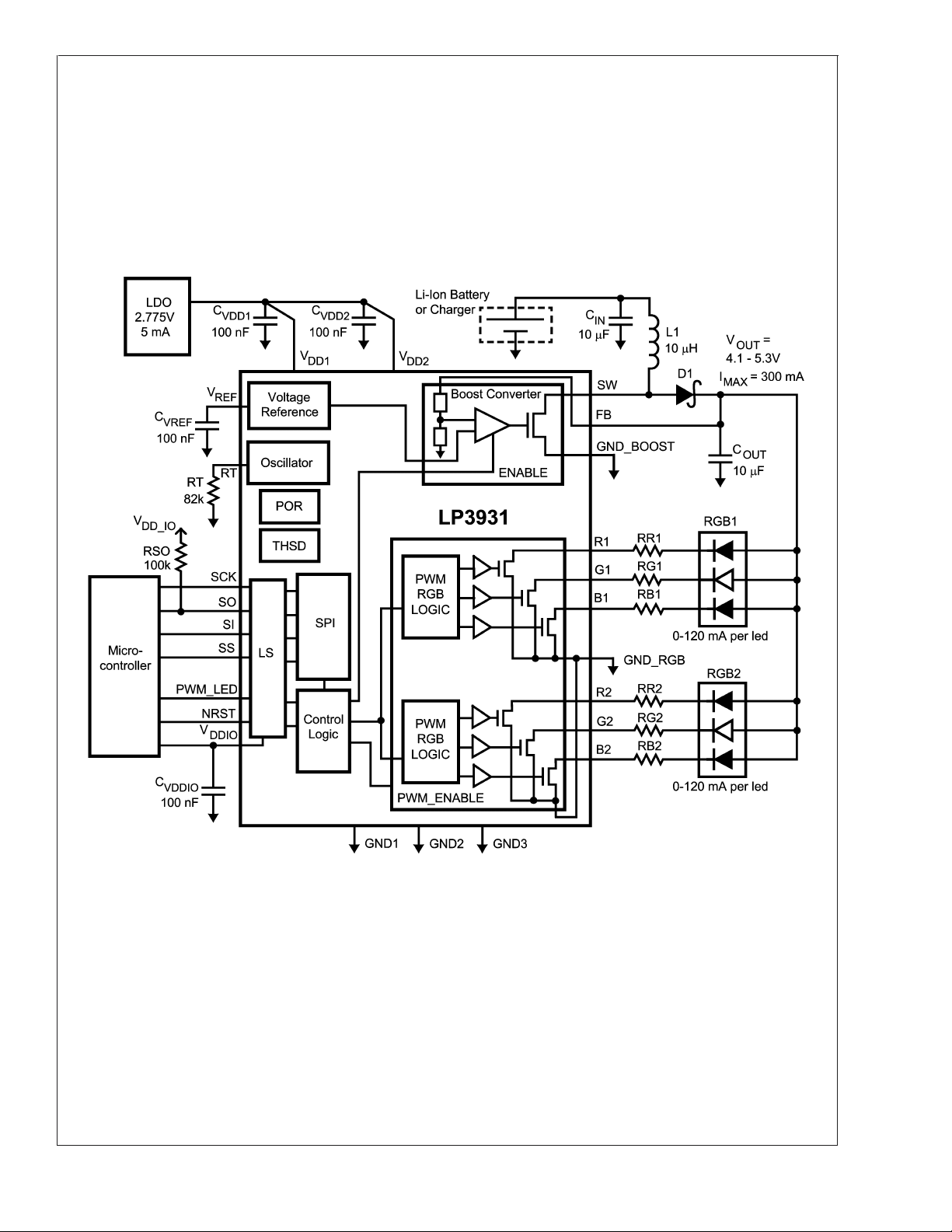

General Description

The LP3931 is a RGB LED driver with high current boost

DC-DC converter designed for portable wireless applications. It contains 2 sets of RGB LED drivers that are PWMdriven with programmable color, intensity and blinking patterns. They additionally feature a FLASH function to support

picture taking with camera-enabled cellular phones.

An efficient magnetic boost DC/DC converter provides the

required bias, operating from a single Li-Ion battery. The

DC/DC converter output voltage is user programmable for

adapting to different LED types and for efficiency optimization.

All functions are software controllable through the SPI interface and internal registers.

Typical Application

Features

n High Efficiency Programmable 300 mA Magnetic Boost

DC-DC converter

n 2 separately controlled PWM RGB LED drivers with

programmable color, brightness, turn on/off slopes and

blinking patterns

n FLASH function with up to 6 outputs, each up to

120 mA

n Functions software controlled through SPI interface

n Additional LED on/off and dimming hardware control

n Programmable low current Standby mode

n Low voltage digital interface down to 1.8V

n Space efficient 24-pin LLP package

Applications

n GSM Cellular Phones

n WCDMA, CDMA and CDMA2000 Phones

n PHS and PDC Cellular Phone

20117301

© 2004 National Semiconductor Corporation DS201173 www.national.com

Page 2

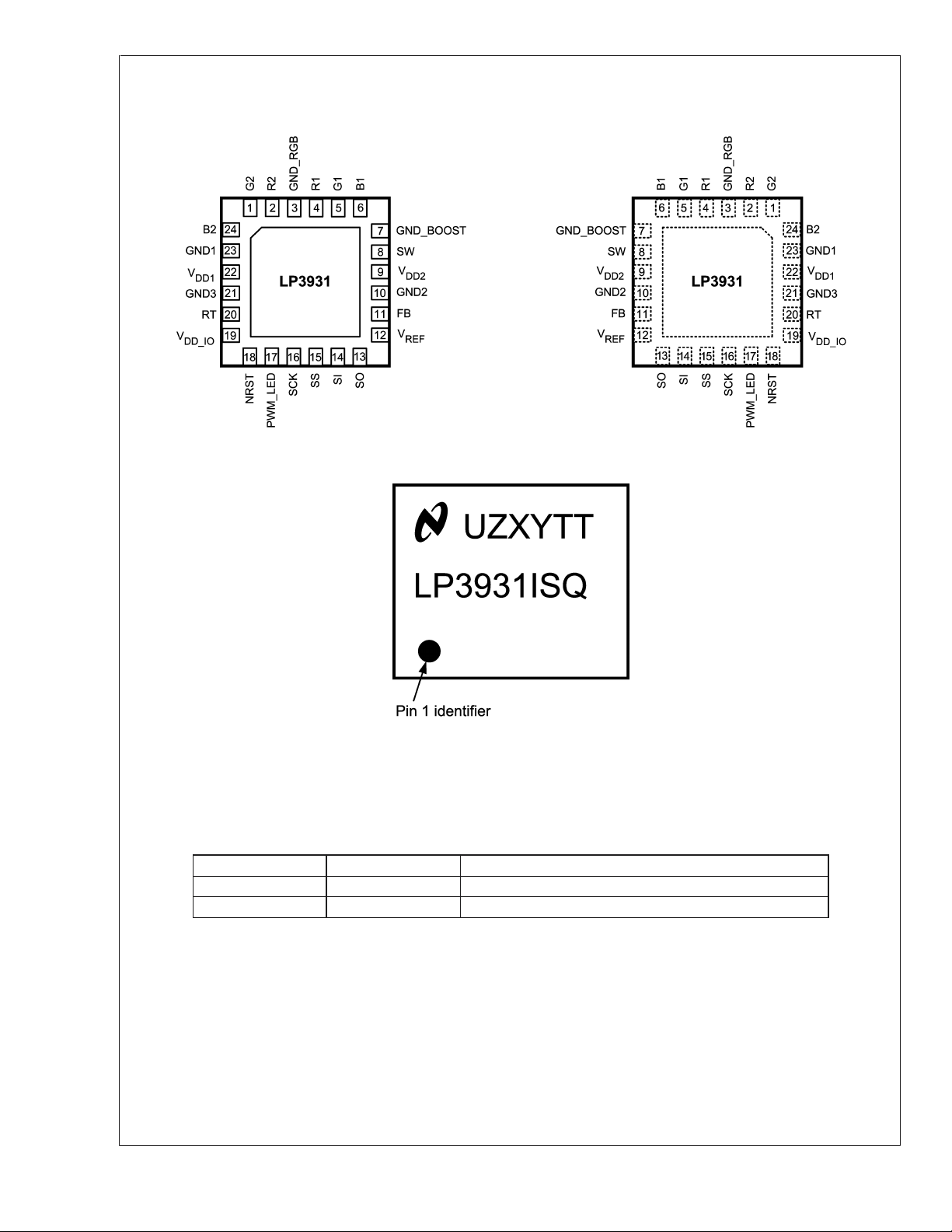

Connection Diagrams and Package Mark Information

LP3931

24-Lead LLP Package,4x4x0.8mm

NS Package Number NSQAL024

Bottom View

20117303

Top View

20117304

20117302

Package Mark — Top View

Note: The actual physical placement of the package marking will vary from part to part. The package marking “XY” designates

the date code. “UZ” and “TT” are NSC internal codes for die manufacturing and assembly traceability. Both will vary considerably.

Ordering Information

Order Number Package Marking Supplied As

LP3931ISQ LP3931ISQ 1000 units, Tape-and-Reel

LP3931ISQX LP3931ISQ 2500 units, Tape-and-Reel

www.national.com 2

Page 3

Pin Description

Pin # Name Type Description

1 G2 Output Open Drain, Green LED2

2 R2 Output Open Drain, Red LED2

3 GND_RGB Ground RGB Driver Ground

4 R1 Output Open Drain, Red LED1

5 G1 Output Open Drain, Green LED1

6 B1 Output Open Drain, Blue LED1

7 GND_BOOST Ground Power Switch Ground

8 SW Output Open Drain, Boost Converter Power Switch

9V

DD2

10 GND2 Ground Ground

11 FB Input Boost Converter Feedback

12 V

REF

13 SO Logic Output SPI Serial Data Out

14 SI Logic Input SPI Serial Data Input

15 SS Logic Input SPI Slave Select

16 SCK Logic Input SPI Clock

17 PWM_LED Input LED Control for On/Off or PWM Dimming

18 NRST Logic Input Low Active Reset Input

19 V

DDIO

20 RT Input Oscillator Resistor

21 GND3 Ground Ground

22 V

DD1

23 GND1 Ground Ground

24 B2 Output Open Drain, Blue LED2

Power Supply Voltage for Internal Digital Circuits

Output Internal Reference Bypass Capacitor

Power Supply Voltage for Logic IO Signals

Power Supply Voltage for Internal Analog Circuits

LP3931

www.national.com3

Page 4

Absolute Maximum Ratings (Notes 1,

2)

LP3931

If Military/Aerospace specified devices are required,

ESD Rating (Note 8)

Human Body Model: 2 kV

Machine Model: 200V

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

V (SW, FB, R1- 2, G1-2,

B1-2) pins:

Voltage to GND (Notes 3, 4) −0.3V to +7.2V

V

DD1,VDD2,VDD_IO

Voltage on Logic Pins –0.3V to V

−0.3V to +6.0V

DD_IO

+0.3V, with 6.0V max

I (R1, G1, B1, R2, G2, B2)

(Note 5) 150 mA

I(V

)10µA

REF

Continuous Power Dissipation

(Note 6) Internally Limited

Junction Temperature (T

) 125˚C

J-MAX

Operating Ratings (Notes 1, 2)

V (SW, FB, R1-2, G1-2, B1-2) 3.0V to 6.0V

V

DD1,VDD2

V

DD_IO

(Note 4) 2.65V to 2.9V

1.8V to V

Recommended Load Current 0 mA to 300 mA

Junction Temperature (T

Ambient Temperature (T

) Range −40˚C to +125˚C

J

) Range

A

(Note 9) −40˚C to +85˚C

Thermal Properties

Junction-to-Ambient Thermal Resistance (θJA),

SQA24A Package (Note 10) 39˚C/W

Storage Temperature Range −65˚C to +150˚C

Maximum Lead Temperature

(Reflow soldering, 3 times)

(Note 7) 240˚C

Electrical Characteristics (Notes 2, 11)

Limits in standard typeface are for TJ= 25˚C. Limits in boldface type apply over the operating ambient temperature range

(−40˚C ≤ T

=V

DD2=VDDIO

(Note 12).

Symbol Parameter Condition Min Typ Max Units

I

DD

I

DD_IO

V

REF

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under which operation of

the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the

Electrical Characteristics tables.

Note 2: All voltages are with respect to the potential at the GND pins (GND1-3, GND_BOOST, GND_RGB).

Note 3: Battery/Charger voltage should be above 6V no more than 10% of the operational lifetime.

Note 4: Voltage tolerance of LP3931 above 6.0V relies on fact that V

(ON) at all conditions, National Semiconductor does not guarantee any parameters or reliability for this device.

Note 5: The total load current of the boost converter should be limited to 300 mA.

Note 6: Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at T

140˚C (typ.).

Note 7: For detailed package and soldering specifications and information, please refer to National Semiconductor Application Note 1187: Leadless Leadframe

Package (LLP).

Note 8: The Human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. The machine model is a 200 pF capacitor discharged

directly into each pin. MIL-STD-883 3015.7.

≤ +85˚C). Unless otherwise noted, specifications apply to the LP3931 Typical Application Circuit (pg. 1) with: V

J

= 2.775V, C

VDD1=CVDD2=CVDDIO

Standby Supply Current

(V

DD1

and V

DD2

current)

No-Load Supply Current

(V

DD1

and V

current, boost off)

DD2

= 0.1 µF, C

OUT=CIN

NSTBY = L (register)

SCK, SS, SI, NRST = H

NSTBY = H (reg.)

EN_BOOST = L (reg.)

= 10 µF, C

= 0.1 µF, L1= 10 µH, RT= 82k

VREF

1 5 µA

170 250 µA

SCK, SS, SI, NRST = H

Full Load Supply Current

(V

DD1

and V

current, boost on)

DD2

NSTBY = H (reg.)

EN_BOOST = H (reg.)

SCK, SS, SI, NRST = H

1mA

All Outputs Active

V

Standby Supply Current NSTBY = L (reg.)

DD_IO

SCK, SS, SI, NRST = H

V

Supply Current 1 MHz SCK Frequency

DD_IO

=50pFatSOPin

C

L

Reference Voltage (Note 13) I (V

REF

Test Purposes Only

DD1

) ≤ 1 nA,

and V

(2.775V) are available (ON) at all conditions. If V

DD2

1.205

−2

1µA

20 µA

1.23 1.255

+2

and V

DD1

= 160˚C (typ.) and disengages at TJ=

J

are not available

DD2

DD1,2

DD1

V

%

www.national.com 4

Page 5

Electrical Characteristics (Notes 2, 11) (Continued)

Note 9: In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may have to be

derated. Maximum ambient temperature (T

dissipation of the device in the application (P

following equation: T

Note 10: Junction-to-ambient thermal resistance is highly application and board-layout dependent. In applications where high maximum power dissipation exists,

special care must be paid to thermal dissipation issues in board design.

Note 11: Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the most likely norm.

Note 12: Low-ESR Surface-Mount Ceramic Capacitors (MLCCs) are used in setting electrical characteristics.

Note 13: V

A-MAX=TJ-MAX-OP

pin (Bandgap reference output) is for internal use only. A capacitor should always be placed between V

REF

) is dependent on the maximum operating junction temperature (T

A-MAX

), and the junction-to ambient thermal resistance of the part/package in the application (θJA), as given by the

D-MAX

−(θJAxP

D-MAX

).

= 125˚C), the maximum power

J-MAX-OP

and GND1.

REF

Block Diagram

LP3931

LP3931 Block Diagram

20117305

www.national.com5

Page 6

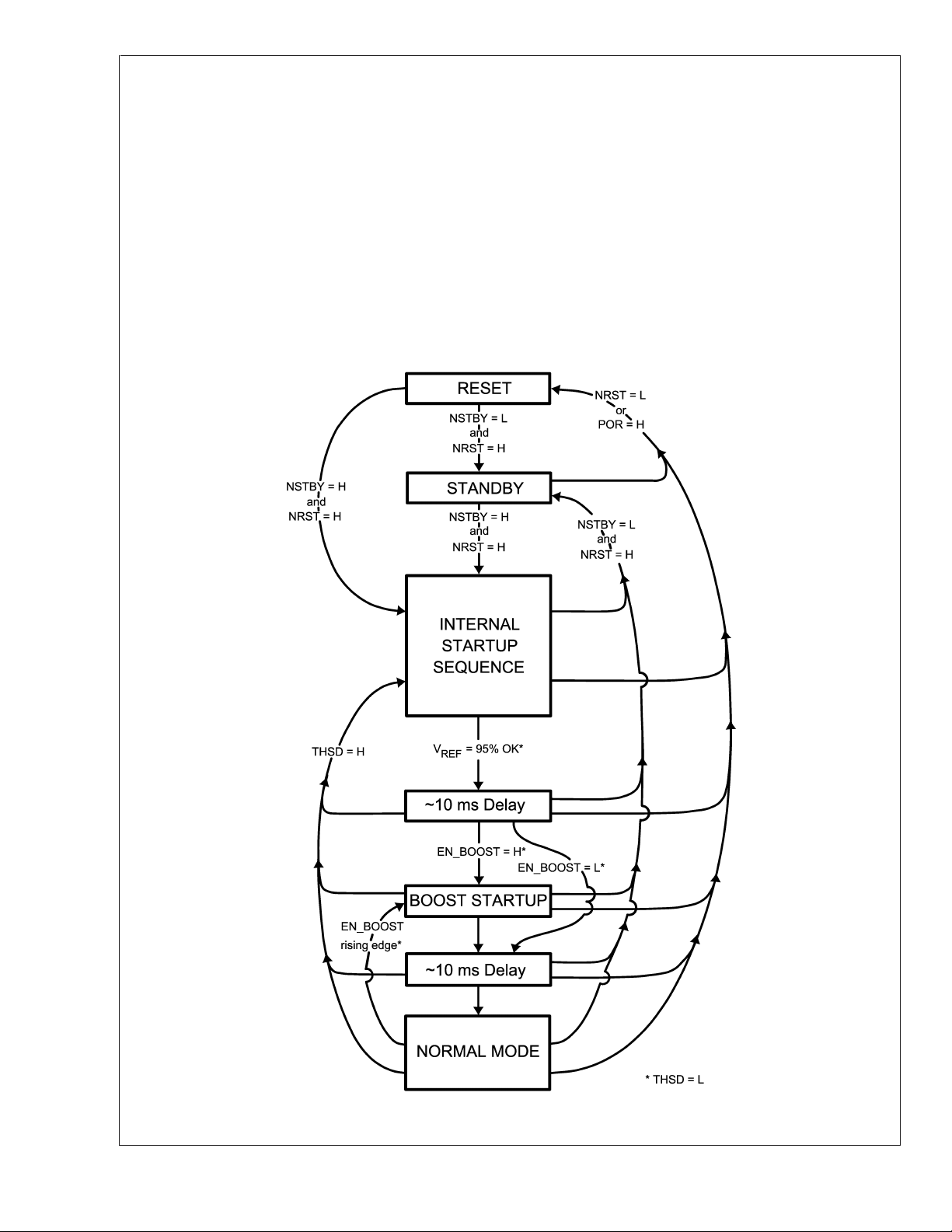

Modes of Operation

RESET: In the RESET mode all the internal registers are reset to the default values (Boost output register 3Fh

LP3931

STANDBY: The STANDBY mode is entered if the register bit NSTBY is LOW and Reset is not active. This is the low

STARTUP: INTERNAL STARTUP SEQUENCE powers up all the needed internal blocks (V

BOOST STARTUP: Soft start for boost output is generated in the BOOST STARTUP mode. In this mode the boost output is

NORMAL: During NORMAL mode the user controls the chip using the Control Registers. The registers can be written

(5.0V), all other registers 00h). Reset is entered always if input NRST is LOW or internal Power On Reset

is active.

power consumption mode, when all circuit functions are disabled. Registers can be written in this mode and

the control bits are effective immediately after power up.

, Bias, Oscillator etc.).

REF

To ensure the correct oscillator initialization, a 10 ms delay is generated by the internal state-machine.

Thermal shutdown (THSD) disables the chip operation and Startup mode is entered until no thermal

shutdown event is present.

raised in PFM mode during the 10 ms delay generated by the state-machine. The Boost startup is entered

from Internal Startup Sequence if EN_BOOST is HIGH or from Normal mode when EN_BOOST is written

HIGH.

in any sequence and any number of bits can be altered in a register in one write.

www.national.com 6

20117306

Page 7

Logic Interface Characteristics

(1.8V ≤ V

Symbol Parameter Conditions Min Typ Max Units

LOGIC INPUTS SS, SI, SCK, PWM_LED

V

IL

V

IH

I

I

f

SCK

LOGIC INPUT NRST

V

IL

V

IH

I

I

t

NRST

LOGIC OUTPUT SO

V

OL

V

OH

DD_IO

≤ V

DD1,2

)

Input Low Level 0.5 V

Input High Level V

− 0.5 V

DD_IO

Logic Input Current −1.0 1.0 µA

Clock Frequency V

= 2.775V 13 MHz

DD_IO

Input Low Level 0.5 V

Input High Level 1.5 V

Logic Input Current −1.0 1.0 µA

Reset Pulse Width 10 µs

Output Low Level ISO=3mA 0.3 0.5 V

Output High Level ISO=−3mA V

DD_IO

− 0.5 V

− 0.3 V

DD_IO

LP3931

SPI Interface

LP3931 is compatible with the SPI serial bus specification

and it operates as a slave. The transmission consists of

16-bit Write and Read Cycles. One cycle consists of 7 Address bits, 1 Read/Write (R/W) bit and 8 Data bits. R/W bit

high state defines a Write Cycle and low defines a Read

Cycle. SO output is normally in high-impedance state and it

is active only when Data is sent out during a Read Cycle. A

pull-up or pull-down resistor may be needed in SO line if a

SPI Write Cycle

floating logic signal can cause unintended current consumption in the input where SO is connected. The Address and

Data are transmitted MSB first. The Slave Select signal SS

must be low during the Cycle transmission. SS resets the

interface when high and it has to be taken high between

successive Cycles. Data is clocked in on the rising edge of

the SCK clock signal, while data is clocked out on the falling

edge of SCK.

20117307

SPI Read Cycle

20117308

www.national.com7

Page 8

SPI Interface (Continued)

LP3931

SPI Timing Diagram

20117309

SPI Timing Parameters

V

DD1,2=VDD_IO

= 2.775V

Symbol Parameter

1 Cycle Time 70 ns

2 Enable Lead Time 35 ns

3 Enable Lag Time 35 ns

4 Clock High Time 35 ns

5 Clock Low Time 35 ns

6 Data Setup Time 0 ns

7 Data Hold Time 20 ns

8 Data Access Time 0 20 ns

9 Disable Time 10 ns

10 Data Valid 20 ns

11 Data Hold Time 0 ns

12 SS Inactive Time 10 ns

Note: Data guaranteed by simulation.

Limit

Min Max

Units

Magnetic Boost DC/DC Converter

The LP3931 Boost DC/DC Converter generates a 4.1V–5.3V supply voltage for the LEDs from single Li-Ion battery (3V…4.5V).

The output voltage is controlled with an 8-bit register in 9 steps. The converter is a magnetic switching PWM mode DC/DC

converter with a current limit. The converter switching frequency is 1 MHz when timing resistor RT is 82 kΩ.

The topology of the magnetic boost converter is called CPM control, current programmed mode, where the inductor current is

measured and controlled with the feedback. The user can program the output voltage of the boost converter. The control changes

the resistor divider in the feedback loop.

The following figure shows the boost topology with the protection circuitry. Three different protection schemes are implemented:

1. Over voltage protection, limits the maximum output voltage

— Keeps the output below breakdown voltage.

— Prevents boost operation if battery voltage is much higher than desired output.

2. Over current protection, limits the maximum inductor current

— Voltage over switching NMOS is monitored; too high voltages turn the switch off.

3. Duty cycle limiting, done with digital control.

www.national.com 8

Page 9

Magnetic Boost DC/DC Converter (Continued)

Boost Converter Topology

20117310

Magnetic Boost DC/DC Converter Electrical Characteristics

Symbol Parameter Conditions Min Typ Max Units

I

LOAD

V

FB

RDS

f

PWF

t

STARTUP

I

CL_OUT

ON

Load Current

Voltage Accuracy at FB Pin

(Boost Converter Output

Voltage Accuracy)

Voltage at FB Pin

(Boost Converter Output

Voltage)

3.0V ≤ V

V

OUT

1mA≤ I

3.0V ≤ V

V(FB)=5V

1mA≤ I

3.0V

V

(SCHOTTKY)

1mA≤ I

V

IN

Switch ON Resistance V

DD1,2

0.5A

PWM Mode Switching

RT=82kΩ

Frequency

Frequency Accuracy 2.65 ≤ V

RT=82kΩ −9 +9

Startup Time From NSTBY and

EN_BOOST

>

0-

SW Pin Current Limit 670 800 915

≤ 4.5V

IN

(FB) = 5V

≤ 300 mA

SW

≤ V (FB) – 0.5

IN

≤ 300 mA

SW

<

<

V

5V +

IN

≤ 300 mA

SW

>

5V+V

(SCHOTTKY)

= 2.775V, ISW=

≤ 2.9 −6

DD1,2

1 transition

0 300 mA

−5 +5 %

5V

VIN–V

(SCHOTTKY)

0.4 0.7 Ω

1 MHz

±

3+6

25 ms

530 995

LP3931

V

%

mA

Boost Standby Mode

User can set the Boost Converter to STANDBY mode by writing the register bit EN_BOOST low. When EN_BOOST is written

high, the converter waits for 10 ms for the internal voltages and currents to stabilize and then starts for 10 ms in PFM mode and

then goes to PWM mode.

www.national.com9

Page 10

Boost Output Voltage Control

User can control the boost output voltage by 8-bit boost

LP3931

output register as follows:

Register 0DH

Boost Output [7:0]

0000 0000 4.15

0000 0001 4.30

0000 0011 4.40

0000 0111 4.55

0000 1111 4.70

0001 1111 4.85

0011 1111 5.00 Default

0111 1111 5.15

1111 1111 5.30

BOOST Output Voltage

(typical)

Boost Output Voltage Control

20117311

Boost Converter Typical Performance Characteristics V

otherwise stated.

Boost Converter Efficiency

20117312

Boost Frequency vs RT Resistor

= 3.6V, V

IN

= 5.0V if not

OUT

20117313

Battery Current vs Voltage

20117314

www.national.com 10

Battery Current vs Voltage

20117320

Page 11

LP3931

Boost Converter Typical Performance Characteristics V

otherwise stated. (Continued)

Boost Typical Waveforms at 100 mA Load

20117321

Boost Startup with No Load

= 3.6V, V

IN

= 5.0V if not

OUT

20117317

Boost Line Regulation

20117318

Boost Load Regulation, 50 mA-100 mA

20117319

www.national.com11

Page 12

Multiple RGB LED Drivers

The RGB driver has six outputs that can independently drive

LP3931

2 separate RGB LEDs or six LEDs of any kind. User has

control over the following parameters separately for each

LED:

ON and OFF (start and stop time in blinking cycle)

•

DUTY (PWM brightness control)

•

SLOPE (dimming slope)

•

ENABLE (output enable control)

•

The main blinking cycle is controlled with 2-bit CYCLE control (0.25 / 0.5 / 1.0 / 2.0s).

In the FLASH mode all the outputs are controlled in one

phase and the PWM period is 50 µs. The time averaged

FLASH mode current is three times the normal mode current

at the same DUTY value.

Blinking can be controlled separately for each output.

ON and OFF times define, when a LED turns on and off

within the blinking cycle. When both ON and OFF are 0, the

LED is on and doesn’t blink. If ON equals OFF but is not 0,

the LED is turned off.

RGB PWM Operating Principle

20117322

RGB_START is the master enable control for the whole RGB

function. The internal PWM and blinking control can be

disabled by setting the RGB_PWM control LOW. In this case

the individual enable controls can be used to switch outputs

on and off. PWM_LED input can be used for external hardware PWM control.

In the normal PWM mode the R, G and B switches are

controlled in 3 phases (one phase per driver). During each

phase the peak current set by the external ballast resistor is

driven through the LED for the time defined by DUTY setting

(0 µs–50 µs). As a time averaged current this means

0%–33% of the peak current. The PWM period is 150 µs and

the pulse frequency is 6.67 kHz in normal mode.

Example Blinking Waveforms

20117324

Application Note AN1291 describes in detail the RGB driver

functionality of LP3933. The RGB driver in LP3931 is identical with LP3933.

Normal Mode PWM Waveforms

20117323

at Different Duty Settings

www.national.com 12

Page 13

RGB Driver Electrical Characteristics

(R1, G1, B1, R2, G2, B2 outputs)

Symbol Parameter Conditions Min Typ Max Units

R

DS-ON

I

LEAKAGE

I

MAX

T

SMAX

T

SMIN

T

SRES

T

START/STOP

ON Resistance 3.5 6 Ω

Off State Leakage Current VFB= 5V, LED driver off 0.03 1 µA

Maximum Sink Current (Note 5) 120 mA

Maximum Slope Period At Maximum Duty Setting 0.93 s

Minimum Slope Period At Maximum Duty Setting 31 ms

Slope Resolution At Maximum Duty Setting 62 ms

Start/Stop Resolution Cycle 1s 1/16 s

Duty Duty Step Size 1/16

T

D

D

D

D

F

F

BLINK

CYCF

CYC

RESF

RES

PWMF

PWM

Blinking Cycle Accuracy −6

Duty Cycle Range EN_FLASH = 1 0 99.6 %

Duty Cycle Range EN_FLASH = 0 0 33.2 %

Duty Resolution EN_FLASH = 1 (4-bit) 6.64 %

Duty Resolution EN_FLASH = 0 (4-bit) 2.21 %

PWM Frequency EN_FLASH = 1 20 kHz

PWM Frequency EN_FLASH = 0 6.67 kHz

±

3+6 %

RGB LED PWM Control (Note 14)

R1DUTY[3:0]

G1DUTY[3:0]

B1DUTY[3:0]

R2DUTY[3:0]

G2DUTY[3:0]

B2DUTY[3:0]

R1SLOPE[3:0]

G1SLOPE[3:0]

B1SLOPE[3:0]

R2SLOPE[3:0]

G2SLOPE[3:0]

B2SLOPE[3:0]

R1ON[3:0]

G1ON[3:0]

B1ON[3:0]

R2ON[3:0]

G2ON[3:0]

B2ON[3:0]

R1OFF[3:0]

G1OFF[3:0]

B1OFF[3:0]

R2OFF[3:0]

G2OFF[3:0]

B2OFF[3:0]

CYCLE[1:0] CYCLE sets the blinking cycle: [00] for 0.25s, [01] for 0.5s, [10] for 1s and [11] for 2s. CYCLE effects to

DUTY sets the brightness of the LED by adjusting the duty cycle of the PWM driver. The minimum DUTY

cycle is 0% [0000] and the maximum in the Flash mode is ∼ 100% [1111] of peak pulse current. The

peak pulse current is determined by the external resistor, LED forward voltage drop and the boost

voltage. In normal mode the maximum duty cycle is 33%.

SLOPE sets the turn-on and turn-off slopes. Fastest slope is set by [0000] and slowest by [1111]. SLOPE

changes the duty cycle at constant, programmable rate. For each slope setting the maximum slope time

appears at maximum DUTY setting. When DUTY is reduced, the slope time decreases proportionally. For

example, in case of maximum DUTY, the sloping time can be adjusted from 31 ms [0000] to 930 ms

[1111]. For 50% DUTY [0111] the sloping time is 14 ms [0000] to 434 ms [1111]. The blinking cycle has

no effect on SLOPE.

ON sets the beginning time of the turn-on slope. The on-time is relative to the selected blinking cycle

length. On-setting N (N = 0 – 15) sets the on-time to N/16 * cycle length.

OFF sets the beginning time of the turn-off slope. Off-time is relative to the blinking cycle length in the

same way as the on-time.

If ON=0,OFF=0and RGB_PWM = 1, then the RGB outputs are continuously on (no blinking), the

DUTY setting controls the brightness and the SLOPE control is ignored.

If ON and OFF are the same, but not 0, the RGB outputs are turned off.

all RGB LEDs.

LP3931

www.national.com13

Page 14

RGB LED PWM Control (Note 14) (Continued)

LP3931

RSW1

GSW1

BSW1

RSW2

GSW2

BSW2

RGB_START Master Switch:

RGB_PWM RGB_PWM = 0→RSW, GWS and BSW control directly the RGB outputs (on/off control only)

EN_FLASH1

EN_FLASH2

R1_PWM

G1_PWM

B1_PWM

R2_PWM

G2_PWM

B2_PWM

PWM_LED input can be used as a direct on/off or PWM brightness control for selected White LED or RGB outputs. For example it can trigger the Flash using a Flash

signal from the camera. If PWM_LED input is not used, it must be tied to V

Note 14: Application Note 1291, “Driving RGB LEDs Using LP3933 Lighting Management System” contains a thorough description of the RGB driver functionality

including programming examples. It applies to LP3931, too.

Enable for R1 switch

Enable for G1 switch

Enable for B1 switch

Enable for R2 switch

Enable for G2 switch

Enable for B2 switch

RGB_START = 0→RGB OFF

RGB_START = 1→RGB ON, starts the new cycle fromt=0

RGB_PWM = 1→Normal PWM RGB functionality (duty, slope, on/off times, cycle)

Flash Mode enable controls for RGB1 and RGB2. In Flash mode (EN_FLASH = 1) RGB outputs are

PWM controlled simultaneously, not in 3-phase system as in the Normal Mode.

XX_PWM = 0→External PWM control from PWM_LED pin is disabled

XX_PWM = 1→External PWM control from PWM_LED pin is enabled

Internal PWM control (DUTY) can be used independently of external PWM control. External PWM has

the same effect on all enabled outputs.

.

DD_IO

Recommended External

Components

OUTPUT CAPACITOR, C

The output capacitor C

the output ripple voltage so C

lected. In general, the higher the value of C

output ripple magnitude. Multilayer ceramic capacitors with

low ESR are the best choice. At the lighter loads, the low

ESR ceramics offer a much lower V

higher ESR tantalums of the same value. At the higher loads,

the ceramics offer a slightly lower V

than the tantalums of the same value. However, the dv/dt of

the V

ripple with the ceramics is much lower than the

OUT

tantalums under all load conditions. Capacitor voltage rating

must be sufficient, 10V or greater is recommended.

INPUT CAPACITOR, C

The input capacitor CINdirectly affects the magnitude of the

input ripple voltage and to a lesser degree the V

higher value C

will give a lower VINripple. Capacitor volt-

IN

age rating must be sufficient, 10V or greater is recommended.

OUTPUT DIODE, D

A Schottky diode should be used for the output diode. To

maintain high efficiency the average current rating of the

schottky diode should be larger than the peak inductor cur-

OUT

directly affects the magnitude of

OUT

IN

OUT

should be carefully se-

OUT

OUT

OUT

ripple magnitude

OUT

, the lower the

ripple than the

ripple. A

OUT

rent (1A). Schottky diodes with a low forward drop and fast

switching speeds are ideal for increasing efficiency in portable applications. Choose a reverse breakdown of the

schottky diode larger than the output voltage. Do not use

ordinary rectifier diodes, since slow switching speeds and

long recovery times cause the efficiency and the load regulation to suffer.

INDUCTOR, L

The LP3931’s high switching frequency enables the use of

the small surface mount inductor. A 10 µH shielded inductor

is suggested. The inductor should have a saturation current

rating higher than the peak current it will experience during

circuit operation (∼1A). Less than 100 mΩ ESR is suggested

for high efficiency. Open core inductors cause flux linkage

with circuit components and interfere with the normal operation of the circuit. This should be avoided. For high efficiency,

choose an inductor with a high frequency core material such

as ferrite to reduce the core losses. To minimize radiated

noise, use a toroid, pot core or shielded core inductor. The

inductor should be connected to the OUT pin as close to the

IC as possible. Examples of suitable inductors are TDK

types LLF4017T-100MR90C and VLF4012AT-100MR79 and

Coilcraft type DO3314T-103 (unshielded).

www.national.com 14

Page 15

Recommended External Components (Continued)

List of External Components

Symbol Symbol Explanation Value Unit Recommended Type

C

VDD1

C

VDD2

C

OUT

C

IN

C

VDDIO

RT Oscillator Frequency Bias Resistor 82 kΩ 1% (Note 15)

RSO SO Output Pull-up Resistor 100 kΩ

C

VREF

L

BOOST

D

OUT

RGB1 RGB LED1

RGB2 RGB LED2

R

R1,RG1,RB1

R

R2,RG2,RB2

LEDs White LEDs

Note 15: Resistor RT accuracy specification change from 1%→5% will be seen on timing accuracy of RGB block. Also the boost converter’s switching frequency

will be affected.

V

Bypass Capacitor 100 nF Ceramic, X7R

DD1

V

Bypass Capacitor 100 nF Ceramic, X7R

DD2

Output Capacitor from FB to GND 10 µF Ceramic, X7R/Y5V

Input Capacitor from Battery Voltage to GND 10 µF Ceramic, X7R/Y5V

V

Bypass Capacitor 100 nF Ceramic, X7R

DD_IO

Reference Voltage Capacitor, between V

and GND 100 nF Ceramic, X7R

REF

Boost Converter Inductor 10 µH Shielded, Low ESR, I

Rectifying Diode, V

Current Limit Resistor

Current Limit Resistor

@

Maxload 0.3 V Schottky Diode

F

User Defined

(See Application Note AN-1291 for resistor size calculation)

SAT

∼1A

LP3931

Control Registers

Control registers and register bits are shown in the following table.

ADDR REGISTER D7 D6 D5 D4 D3 D2 D1 D0

00H RGB Control register1 rgb pwm rgb start rsw1 gsw1 bsw1 rsw2 gsw2 bsw2

01H red1_on_off r1_on[3] r1_on[2] r1_on[1] r1_on[0] r1_off[3] r1_off[2] r1_off[1] r1_off[0]

02H green1_on_off g1_on[3] g1_on[2] g1_on[1] g1_on[0] g1_off[3] g1_off[2] g1_off[1] g1_off[0]

03H blue1_on_off b1_on[3] b1_on[2] b1_on[1] b1_on[0] b1_off[3] b1_off[2] b1_off[1] b1_off[0]

04H r1slope, r1duty r1slope[3] r1slope[2] r1slope[1] r1slope[0] r1duty[3] r1duty[2] r1duty[1] r1duty[0]

05H g1slope, g1duty g1slope[3] g1slope[2] g1slope[1] g1slope[0] g1duty[3] g1duty[2] g1duty[1] g1duty[0]

06H b1slope, b1duty b1slope[3] b1slope[2] b1slope[1] b1slope[0] b1duty[3] b1duty[2] b1duty[1] b1duty[0]

07H RGB Control register2 cycle[1] cycle[0] r1_pwm g1_pwm b1_pwm r2_pwm g2_pwm b2_pwm

0BH enables nstby en_boost en_flash1 en_flash2

0DH boost output boost[7] boost[6] boost[5] boost[4] boost[3] boost[2] boost[1] boost[0]

2AH red2_on_off r2_on[3] r2_on[2] r2_on[1] r2_on[0] r2_off[3] r2_off[2] r2_off[1] r2_off[0]

2BH green2_on_off g2_on[3] g2_on[2] g2_on[1] g2_on[0] g2_off[3] g2_off[2] g2_off[1] g2_off[0]

2CH blue2_on_off b2_on[3] b2_on[2] b2_on[1] b2_on[0] b2_off[3] b2_off[2] b2_off[1] b2_off[0]

2DH r2slope, r2duty r2slope[3] r2slope[2] r2slope[1] r2slope[0] r2duty[3] r2duty[2] r2duty[1] r2duty[0]

2EH g2slope, g2duty g2slope[3] g2slope[2] g2slope[1] g2slope[0] g2duty[3] g2duty[2] g2duty[1] g2duty[0]

2FH b2slope, b2duty b2slope[3] b2slope[2] b2slope[1] b2slope[0] b2duty[3] b2duty[2] b2duty[1] b2duty[0]

Default value of each register is 0000 0000 except boost output which is 0011 1111 (5V).

www.national.com15

Page 16

Application Examples

LP3931

LP3931 with One RGB and One FLASH LED

20117315

LP3931 with Two RGB and One FLASH LED

www.national.com 16

20117316

Page 17

Physical Dimensions inches (millimeters) unless otherwise noted

LP3931 Dual RGB LED Driver with High Current Boost DC-DC Converter

24-Lead LLP Package,4x4x0.8mm

NS Package Number NSQAL024

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor certifies that the products and packing materials meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification

(CSP-9-111S2) and contain no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Page 18

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...