Page 1

LP3927

Cellular/PCS System Power Management IC

LP3927 Cellular/PCS System Power Management IC

August 2002

General Description

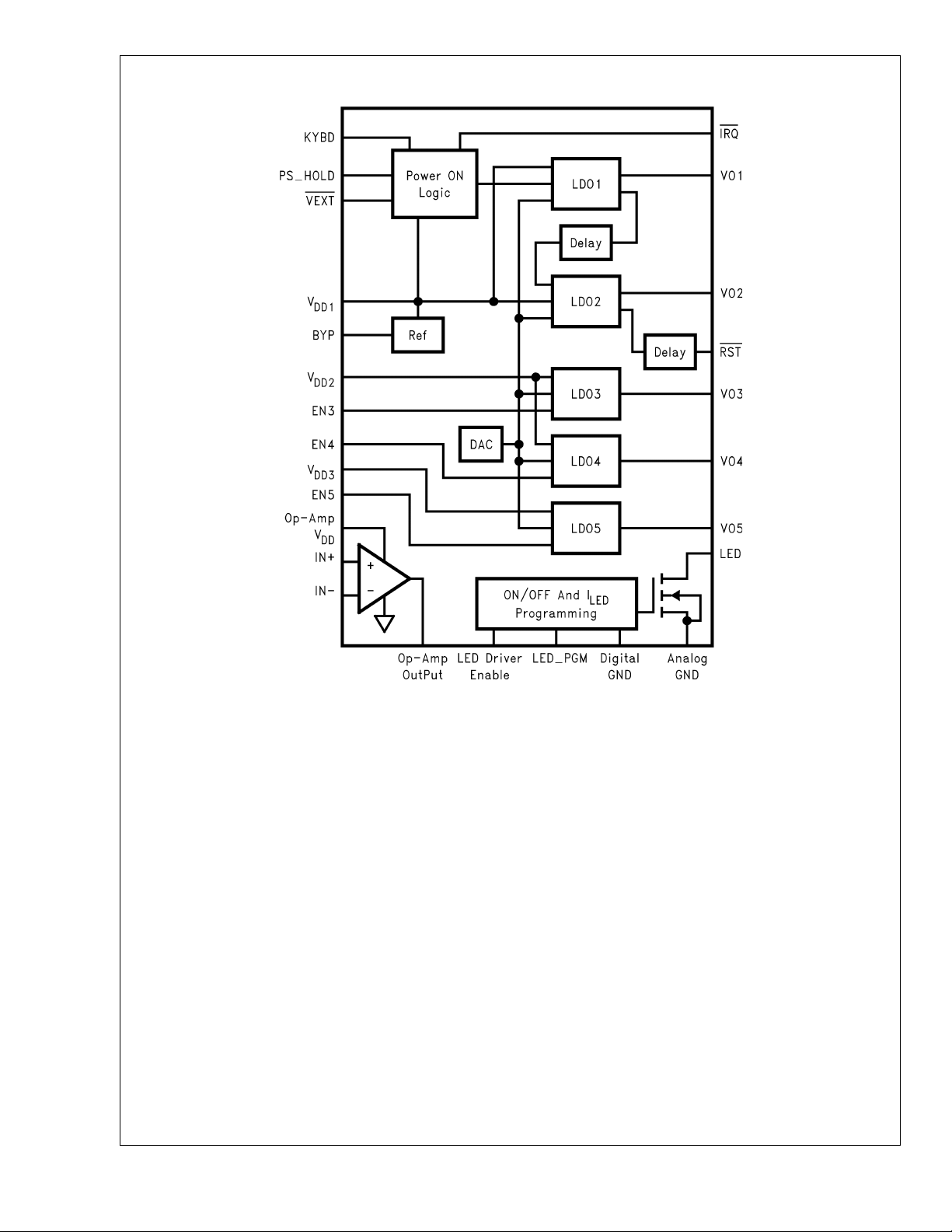

The LP3927 system power management IC is designed for

cellular/PCS handsets as well as other portable systems that

require intelligent power management. Each device contains

five low-dropout linear regulators (LDO’s), a reset timer, a

power-up control logic, a general-purpose open drain output

that can be used to light LEDs, and a CMOS rail-to-rail

input/output operational amplifier.

Each linear regulator features an extremely low dropout

voltage of 100 mV (typ) at maximum output current. LDO1

and LDO2 are powered on and off by either the KYBD or the

VEXT pin. LDO3, LDO4 and LDO5 each have its independent enable pin. LDO1 and LDO4 are rated at 150 mA each,

LDO2 and LDO5 are rated at 200 mA each and LDO3 is

rated at 100 mA. All LDO’s are optimized for low noise and

high isolation.

The open drain output current sink can be programmed up to

150 mA by using an external low cost resistor.

A single supply, low voltage operational amplifier has rail to

rail input and output with 600 kHz of gain-bandwidth product.

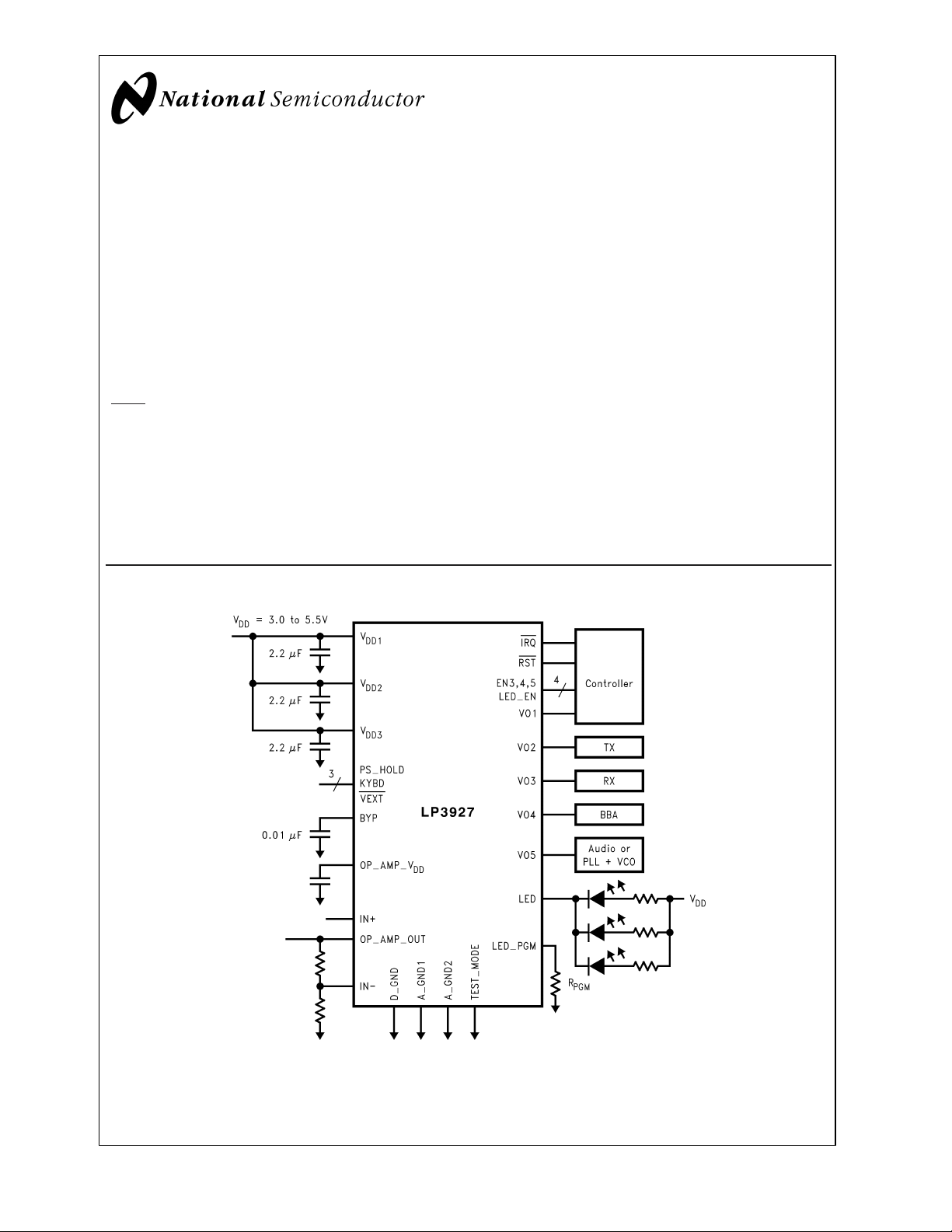

Typical Application Circuit

Key Specifications

n 3.0V to 5.5V Input Voltage Range

n Two 200 mA, Two 150 mA and One 100 mA LDO’s

n 100 mV typ Dropout Voltage

n 150 mA General-Purpose Open-drain programmable

current sink for back light LED

n Low Voltage Rail to Rail Input/Output Operational

Amplifier

n 28 pin LLP package

@

I

MAX

Applications

n Cellular/PCS handsets

n PDA’s, Palmtops, and portable terminals

n Single–Cell Li+ Systems

n 2- or 3- Cell NiMH, NiCd or Alkaline System

20037901

V

DD1,VDD2

© 2002 National Semiconductor Corporation DS200379 www.national.com

and V

must be tied together externally. Collectively called VDD.

DD3

Page 2

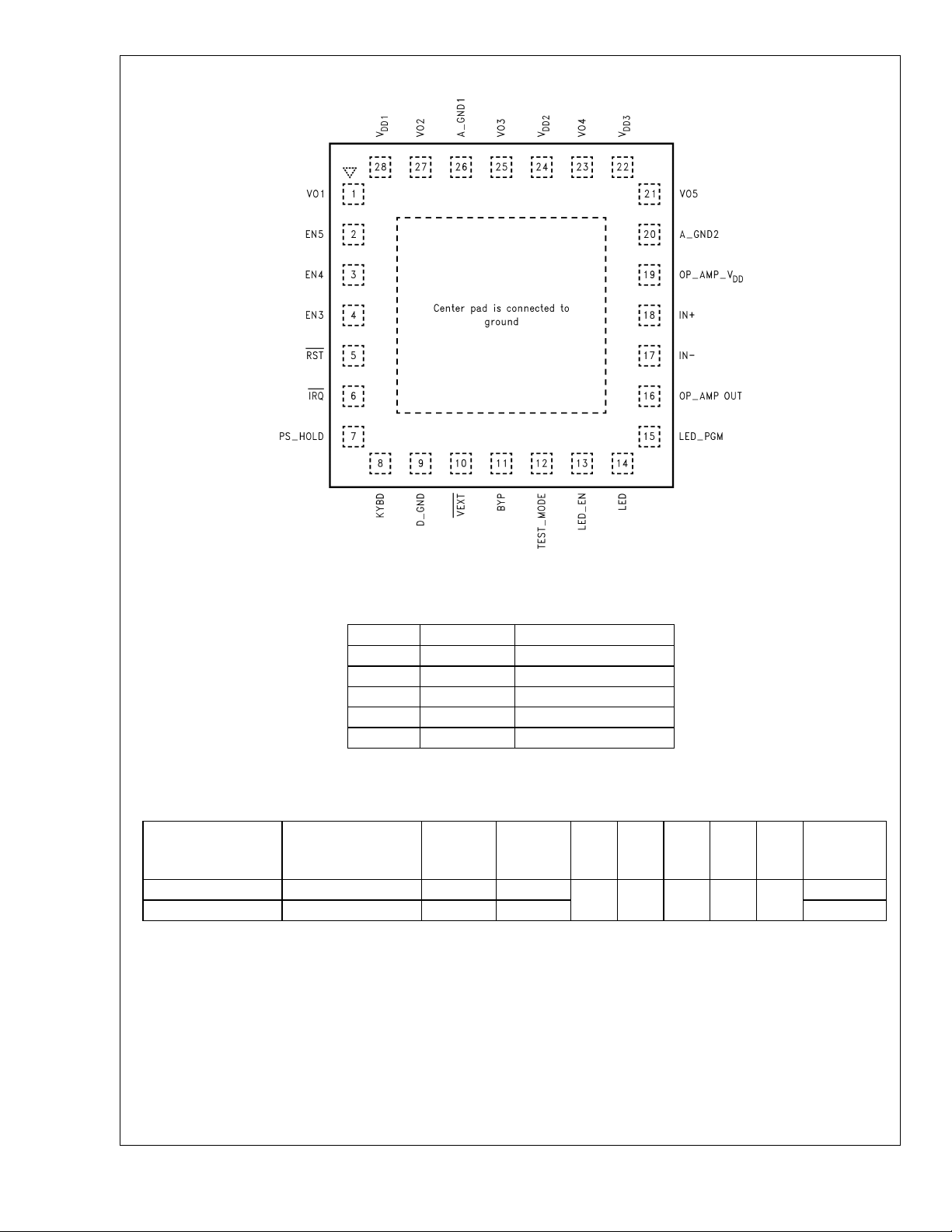

LP3927 Pin Out Diagram (Top View)

LP3927

20037902

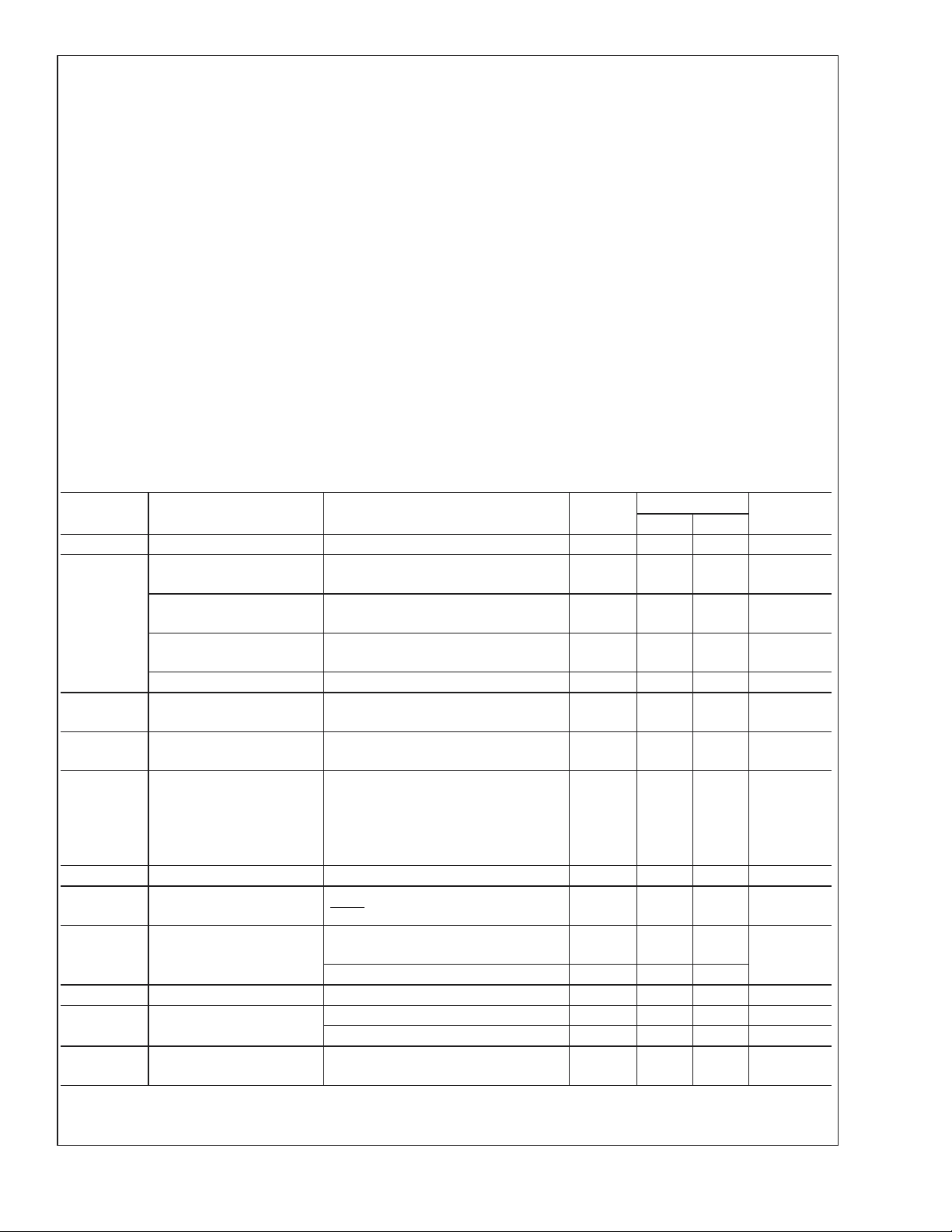

Output Current Rating and Voltage Options

I

(mA) Voltage Options (V)

MAX

LDO1 150 1.8, 1.9, 2.5, 2.6*, 2.7

LDO2 200 1.8, 2.85*, 2.9, 3.0

LDO3 100 2.7, 2.8, 2.9

LDO4 150 2.7, 2.8, 2.9

LDO5 200 2.7, 2.8, 2.9, 3.0

*

denotes the voltage options that are available currently. For other options, please contact the

National Semiconductor factory sales office/distributors for availability and specifications.

*

, 3.0

*

, 3.0

*

Ordering Information

LP3927 Supplied as

1000 Units, tape and

reel

LP3927ILQ-AH LP3927ILQX-AH X

LP3927ILQ-AJ LP3927ILQX-AJ X 3927AJ

For LDO delay options, please refer to Electrical Characteristics Table.

LP3927 Supplied as

4500 Units, tape and

reel

Standard

LDO delay

Optional

LDO delay

VO1

VO2

VO3

VO4

VO5

(V)

(V)

(V)

2.6 2.85 2.9 2.9 3.0

(V)

(V)

TOP

MARKING

3927AH

www.national.com 2

Page 3

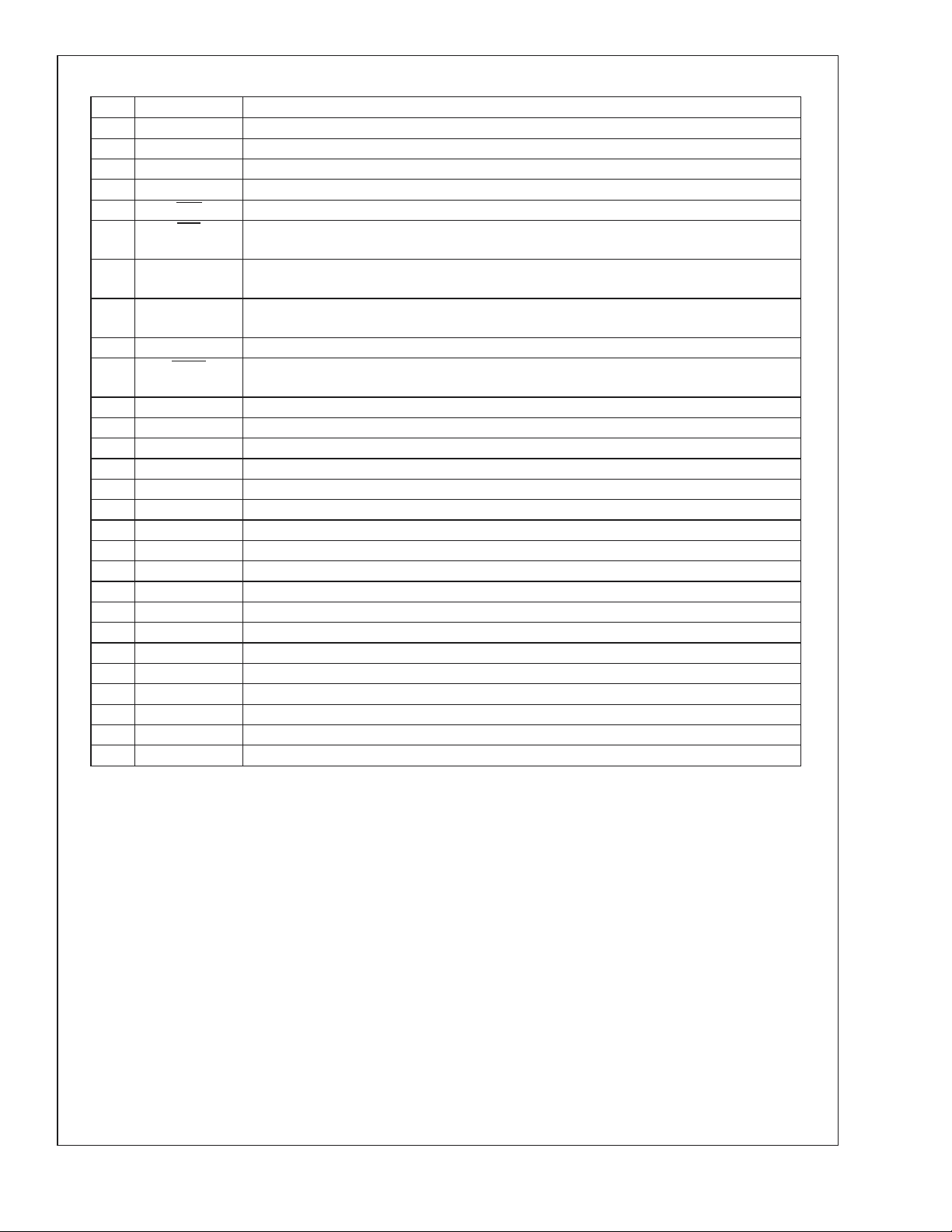

Pin Description

Pin Name Functional Description

1 VO1 150 mA, LDO1 output pin.

2 EN5 LDO5 enable input.

3 EN4 LDO4 enable input.

4 EN3 LDO3 enable input.

5 RST

6 IRQ

7 PS_HOLD Input from the processor to the LP3927. A HIGH indicates a steady supply of power is

8 KYBD An active high input signal indicating the keyboard “On/Off” button has been asserted. Refer

9 D_GND Digital ground, used primarily for the digital and DAC circuits.

10 VEXT

11 BYP Reference bypass pin.

12 TEST_MODE Pin used for production testing, factory use only. This pin should be grounded in applications.

13 LED_EN LED driver enable input.

14 LED LED driver, drain connection of the LED drive MOSFET.

15 LED_PGM LED drive current programming pin.

16 OP_AMP_OUT Operational amplifier output pin.

17 IN− − input of the Op-Amp.

18 IN+ + input of the Op-Amp.

19 OP_AMP_V

20 A_GND2 Ground for analog.

21 VO5 200 mA, LDO5 output pin.

22 V

DD3

23 VO4 150 mA, LDO4 output pin.

24 V

DD2

25 VO3 100 mA, LDO3 output pin.

26 A_GND1 Ground for analog.

27 VO2 200 mA, LDO2 output pin.

28 V

DD1

Externally pulled high, open drain output to processor/memory reset.

Externally pulled high, open drain output to processor interrupt indicating KYBD has gone

high.

granted. Refer to ’Application Hints’ section for more detail.

to ’Application Hints’ section for more detail.

Active low input indicating a battery charger insertion Refer to ’Application Hints’ section for

more detail.

Power supply pin for Op-Amp.

DD

Input power pin for LDO5. V

DD1,VDD2

Input power pin for LDO3 and LDO4. V

Input power pin for LDO1 and LDO2. V

and V

DD3

DD1,VDD2

DD1,VDD2

must be tied together externally.

and V

and V

must be tied together externally.

DD3

must be tied together externally.

DD3

LP3927

www.national.com3

Page 4

Functional Block Diagram

LP3927

20037903

www.national.com 4

Page 5

LP3927

Absolute Maximum Ratings (Notes 1,

All other pins 2 kV

2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

All pins except LED_PGM,

BYP, op amp’s inputs & output −0.3V to 6.0V

OP_AMP_OUT, IN-, IN+ -0.3V to 5.5V

GND to GND SLUG

±

0.3V

Junction Temperature 150˚C

Storage Information −65˚C to 150˚C

Soldering Temperature

Pad Temperature 235˚C

Maximum Power Dissipation (Note 3) 2.6W

Operating Ratings (Notes 1, 2)

V

DD1,VDD2,VDD3

EN3, EN4, EN5 −0.3V to (V

C

:

OUT

Capacitance 1.0 µF to 20.0 µF

ESR 0.005Ω to 0.5Ω

Junction Temperature −40˚C to 125˚C

Operating Temperature −40˚C to 85˚C

Thermal Resistance (Note 5)

θ

(LLP28) 30.8˚C/W

JA

Maximum Power Dissipation (Note 6) 1.78W

, KYBD, OP_AMP_V

ESD (Note 4):

KYBD 4 kV

Electrical Characteristics, LDO’s

Unless otherwise noted, VDD=V

OUT(target)

0.1 µF. Typical values and limits appearing in normal type apply for T

the entire junction temperature range for operation, −40˚C to +85˚C. (Notes 7, 8)

Symbol Parameter Conditions Typical

V

∆V

DD

OUT

Input Voltage Range V

Output Voltage Tolerance I

Load Regulation I

Line Regulation V

Total Accuracy Error −3.5 +3.5 %

V

IN-VOUT

e

N

Dropout Voltage I

Output Noise Voltage I

PSRR Power Supply Ripple

Rejection Ratio

Cross Talk (Note 10) 30 dB

I

I

I

C

R

Q

GND

SC

OUT

SHUNT

Quiescent Current I

Ground Current I

Short Circuit Current Limit V

Output Capacitor Capacitance 120 µF

VO2-VO5Output Shunt

Resistor

+ 0.7V, CIN(V

DD1,VDD2,VDD3

OUT=IMAX

V

DD

OUT

V

DD

DD=VOUT(target)

I

OUT=IMAX

OUT=IMAX

OUT

/2,

= 3.7V

= 100 µA to I

= 3.7V

/2

= 100 µA,

DD1,VDD2,VDD3

,KYBD 3.7 3 5.5 V

,

MAX

+0.7V to 5.5V

(Note 9) 100 170

) = 4.7 µF, C

= 25˚C. Limits appearing in boldface type apply over

J

OUT

10 Hz ≤ f ≤ 100 kHz 27 µV

CIN= 2.2µF, I

OUT=IMAX

,

f = 100 Hz

f=1kHz

f=10kHz

f = 100 kHz

= 0, PS_HOLD = KYBD = 0

OUT

VEXT = V

OUT1=IOUT2

DD

= 1 mA,

LDO3, LDO4, LDO5 OFF

I

OUT1,IOUT2,IOUT3,IOUT4,IOUT5=IMAX

=0V 400 %ofI

OUT

ESR 5 500 mΩ

3.0V to 5.5V

DD

+ 0.3V)

DD

(VO1 to VO5) = 2.2 µF, C

Limit

Min Max

byp

Units

−2 +2 %

−2 +2 %

−40 +40 mV

mV

200

45

45

dB

30

10

5

µA

8

100 200 µA

400 950

70 200 Ω

=

rms

MAX

www.national.com5

Page 6

Electrical Characteristics, Digital Interface

LP3927

Symbol Parameter Conditions Typical

V

OL

V

IH

V

IL

I

LEAKAGE

Logic Low Output RST and IRQ

I

= 250 µA

LOAD

Logic High Input KYBD and VEXT 0.7 V

EN3–5, PS_HOLD 1.4

LED_EN 0.85V

Logic Low Input KYBD and VEXT 0.2 V

EN3–5, PS_HOLD 0.4

LED_EN 0.2 V

Input Leakage Current VEXT, PS_HOLD, IRQ,

KYBD, EN3– 5, 0V ≤ VDD≤ 5.5V

Electrical Characteristics, Error Flag

Symbol Parameter Conditions Typical

V

Th-H

V

Th-L

t

DELAY-H

t

DELAY-L

R

DELAY

t

DELAY

t

Hold-UP

Error Flag High Vo1and Vo2Outputs (Note 11) 95 92 98 % V

Error Flag Low 90 89 92

(Note 12) 6 0 10 µs

Keyboard Debounce Delay (Note 13) 32 16 64 ms

VEXT Debounce Delay

(Note 13) 32 16 64 ms

RST Reset Delay (Note 14) 20 10 40 ms

LDO Delay, standard (Note 15) 125 0 250 µs

LDO Delay, optional 10 5 20 ms

PS_HOLD Input (Note 16) 500 250 1000 ms

Limit

Min Max

Units

150 mV

DD

DD

DD

DD

−10 +10 µA

Limit

Min Max

Units

6 0 10 µs

V

V

OUT

Electrical Characteristics, Backlight LED Driver

Symbol Parameter Conditions Typical

I

LED

Drive Current V

LED

= 1V, R

= 130kΩ 150 125 175 mA

PGM

Electrical Characteristics, Operational Amplifier

Unless otherwise noted, V

OP_AMP_VDD

appearing in normal type apply for T

= 3.3V, VCM=V

= 25˚C. Limits appearing in boldface type apply over the entire junction temperature

J

OUT=VOP_AMP_VDD

/2 and R

range for operation, −40˚C to +85˚C. (Note 7)

Symbol Parameter Conditions Typical

V

DD

V

OS

TC V

I

B

I

OS

R

IN

CMRR Common-Mode Rejection Ratio 0V ≤ V

PSRR Power Supply Rejection Ratio V

OP_AMP_V

DD

Input Offset Voltage 1.2 10 mV

Offset Voltage Drift 10 µV/˚C

OS

Input Bias Current 0.2 nA

Input Offset Current 0.1 nA

Input Resistance

≤ 2.7V 70 dB

CM

OP_AMP_VDD

= 2.7V to

3.3V

=0

,V

CM

C

IN

Common-Mode Input Capacitor 3 pF

>

LOAD

1MΩ. Typical values and limits

3.3 3 5.5 V

>

60 dB

Limit

Min Max

Limit

Min Max

Units

Units

1GΩ

www.national.com 6

Page 7

Electrical Characteristics, Operational Amplifier (Continued)

Unless otherwise noted, V

OP_AMP_VDD

appearing in normal type apply for T

= 3.3V, VCM=V

= 25˚C. Limits appearing in boldface type apply over the entire junction temperature

J

OUT=VOP_AMP_VDD

/2 and R

range for operation, −40˚C to +85˚C. (Note 7)

Symbol Parameter Conditions Typical

V

OUT

I

S

Output Swing R

Supply Current V

=2kΩ 0.5 V

LOAD

OP_AMP_VDD

= 3.0V 0.5 1.4 mA

SR Slew Rate 0.7 V/µs

GBW Gain-Bandwidth Product 0.6 MHz

Note 1: Absolute Maximum Ratings are limits beyond which damage to the device may occur. Operating Ratings are conditions under which operation of the device

is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the Electrical

Characteristics tables.

Note 2: All voltages are with respect to the potential at the GND pin.

Note 3: The Absolute Maximum power dissipation depends on the ambient temperature and can be calculated using the formula

P=(TJ−TA)/θJA, (1)

where TJis the junction temperature, TAis the ambient temperature, and θJAis the junction-to-ambient thermal resistance. The 2.6W rating appearing under

Absolute Maximum Ratings results from substituting the Absolute Maximum junction temperature, 150˚C, for T

be dissipated safely at ambient temperatures below 70˚C. Less power can be dissipated safely at ambient temperatures above 70˚C. The Absolute Maximum power

dissipation can be increased by 32.5 mW for each degree below 70˚C, and it must be derated by 32.5 mW for each degree above 70˚C.

Note 4: The human-body model is used. The human-body model is 100 pF discharged through 1.5 kΩ.

Note 5: This figure is taken from a thermal modeling result. The test board is a 4 layer FR-4 board measuring 101mm x 101mm x 1.6mm with a3x3array of thermal

vias. The ground plane on the board is 50mm x 50mm. Ambient temperature in simulation is 22˚C, still air. Power dissipation is 1W.

Note 6: Like the Absolute Maximum power dissipation, the maximum power dissipation for operation depends on the ambient temperature. The 1.78W rating

appearing under Operating Ratings results from substituting the maximum junction temperature for operation, 125˚C, for T

(1) above. More power can be dissipated at ambient temperatures below 70˚C. Less power can be dissipated at ambient temperatures above 70˚C. The maximum

power dissipation for operation can be increased by 32.5 mW for each degree below 70˚C, and it must be derated by 32.5 mW for each degree above 70˚C.

Note 7: All limits guaranteed at room temperature (standard typeface) and at temperature extremes (bold typeface). All room temperature limits are 100%

production tested or guaranteed through statistical analysis. All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality

Control (SQC) methods.

Note 8: The target output voltage, which is labeled V

Note 9: Dropout voltage is the input-to-output voltage difference at which the output voltage is 100 mV below its nominal value. This specification does not apply

in cases it implies operation with an input voltage below the 2.5V minimum appearing under Operating Ratings. For example, this specification does not apply for

devices having 1.5V outputs because the specification would imply operation with an input voltage at or about 1.5V.

Note 10: Pulsing the load of LDO X from 100µA to Imax and measuring its effects at the output of LDO Y. LDO Y enabled but under no load.

Note 11: The error flags are internal to the chip. There is no external access to the signals. LDO1 error flag and the LDO2 error flag will go HIGH when the respective

LDO reaches its V

Note 12: The t

its error flag going LOW. Same delays apply to LDO2 and its error flag.

Note 13: Refer to Timing Diagram.

Note 14: The delay between LDO2 error flag HIGH and RST signal HIGH in the power up sequence. In the power down sequence, it is the delay between RST

signal LOW and LDO2 disabled.

Note 15: The delay between LDO1 error flag HIGH and LDO2 enable in power up sequence. In the power down sequence, it is the delay between LDO2 error flag

LOW and LDO1 disable. For the optional LDO delay, please contact the factory for availability.

Note 16: Time between RST high and PS_HOLD going high.

value. The error flags will go LOW when the respective LDO reaches its V

Th-H

is the delay between LDO1 reaching its V

DELAY-H

, is the desired or ideal output voltage.

OUT(target)

and its error flag going HIGH. The t

Th-H

Th-L

value.

DELAY-L

>

1MΩ. Typical values and limits

LOAD

Limit

Min Max

Units

3.1

, 70˚C for TA, and 30.8˚C/W for θJA. More power can

J

, 70˚C for TA, and 30.8˚C/W for θJAinto

J

is the delay between LDO1 reaching its V

Th-L

and

LP3927

www.national.com7

Page 8

Typical Performance Characteristics Unless otherwise specified, C

0.01 µF, V

LP3927

DD=VOUT

LDO4 Enable Response (Cout=2.2µF) LDO5 Enable Response (Cout=2.2µF)

+ 0.2V, TA= 25˚C, Enable pin is tied to VDD.

PSRR vs Frequency LDO3 Enable Response (Cout=2.2µF)

20037908

= 1 µF ceramic, C

IN

20037909

BYP

=

20037910 20037911

LDO2 (1.8V Option) Load Transient LDO2 (2.85V Option) Load Transient

20037929 20037930

www.national.com 8

Page 9

LP3927

Typical Performance Characteristics Unless otherwise specified, C

0.01 µF, V

DD=VOUT

LDO4 (2.8V Option) Load Transient LDO5 (3.0V Option) Load Transient

LDO2 (1.8V Option) Line Transient LDO2 (2.85V Option) Line Transient

+ 0.2V, TA= 25˚C, Enable pin is tied to VDD. (Continued)

20037931 20037932

= 1 µF ceramic, C

IN

BYP

=

20037933 20037934

LDO4 (2.8V Option) Line Transient LDO5 (3.0V Option) Line Transient

20037935 20037936

www.national.com9

Page 10

LP3927

Keyboard Start-Up/Shut-Down

Note: Diagram indicates Open Drain IRQ tied to VDD.

***

= Internal signal

1. Keyboard de-bounce delay, 32 msec typ.

2. Delay between LDO1 reaching 95% of its output voltage and LDO2 enable, 125 µsec typical.

3. Both LDO1 and LDO2 outputs reach 95% of respective output voltage, start RST timer.

4. RST delay, 20 msec typical.

5. IRQ is active low.

6. Keyboard press must be greater than 32 msec.

7. PS_HOLD timer begins upon RST going high.

8. Maximum of 500 msec period from RST going high to PS_HOLD going high.

9. Response time from PS_HOLD going low to RST going low.

10. Delay between RST high-low transition to LDO2 disable.

11. Delay between LDO2 disable and LDO1 disable.

20037925

www.national.com 10

Page 11

Keyboard Held at Start-Up/Shut-Down

LP3927

Note: Diagram indicates Open Drain IRQ tied to VDD.

***

= Internal signal

1. Keyboard de-bounce delay, 32msec typ.

2. Delay between LDO1 reaching 95% of its output voltage and LDO2 enable.

3. Both LDO1 and LDO2 outputs reach 95% of the respective output voltage, start RST timer.

4. Reset delay.

5. IRQ is active low.

6. Keyboard press must be greater than 32 msec.

7. PS_HOLD timer begins upon RST going high.

8. Maximum of 500 msec period from RST going high to PS_HOLD going high.

9. Response time from PS_HOLD going low to RST going low.

10. Delay between RST high-low transition to LDO2 disable.

11. Delay between LDO2 disable and LDO1 disable.

20037926

www.national.com11

Page 12

LP3927

VEXT Detect Start-Up/Shut Down

Note: Diagram indicates Open Drain IRQ tied to VDD.

***

= Internal signal

1. VEXT goes active low.

2. VEXT 32 msec de-bounce period.

3. Delay between LDO1 and LDO2 enables.

4. Both LDO1 and LDO2 outputs reach 95% of respective output voltage, start Reset timer.

5. Reset delay.

6. Period between Reset and PS_HOLD going high is not relevant since VEXT is low

7. PS_HOLD goes low but LDOs continue to run since VEXT is low.

8. PS_HOLD is low and VEXT goes high, RST pin goes low.

9. Delay between RST going low and LDO2 disabled.

10. Delay between LDO2 and LDO1 disabled.

20037927

www.national.com 12

Page 13

VEXT Detect W/Keyboard Interrupts

LP3927

Note: Diagram indicates Open Drain IRQ tied to VDD.

***

= Internal signal

1. VEXT goes active low.

2. VEXT 32 msec de-bounce period.

3. Delay between LDO1 and LDO2 enable.

4. Both LDO1 and LDO2 outputs reach 95% of respective output voltage, start Reset timer.

5. Reset delay.

6. Keyboard de-bounce delay.

7. Keyboard pulse must be a minimum of 32 msec.

8. PS_HOLD may go low after Key press, but LDOs stay on since VEXT is low.

9. VEXT goes high, begin shutdown since PS_HOLD is low.

10. Delay between RST going low and LDO2 disabled.

11. Delay between LDO2 disable and LDO1 disabled.

20037928

www.national.com13

Page 14

Application Hints

LP3927

LP3927 Function Description

The LP3927 is designed for cellular/PCS handsets. The

LDOs power the microprocessor, RF and digital sections of

the phone. When a KYBD debounce of longer than 32 ms is

detected by the LP3927, the IRQ signal is asserted and sent

to the microprocessor. In addition, the KYBD signal turns on

LDO1. When LDO1 reaches 95% of its output voltage option, a 125 µs delay (standard LDO delay. The optional LDO

delay has a 10msec delay) takes place, and LDO2 turns on.

When LDO2 reaches 95% of its output voltage option, RST

goes high after a 20 ms delay. At this point, the microprocessor comes out of reset and the LP3927 starts the PS_HOLD timer. If PS_HOLD goes high before 500 ms, IRQ is

de-asserted. If PS_HOLD stays low for longer than 500 ms,

IRQ will still de-assert, but RST will also be asserted, and the

part will power down.

The power down sequence is the exact reverse of the power

up sequence. PS_HOLD from the microprocessor goes low,

indicating a request to turn the part off. This causes RST to

go low. LDO2 will be turned off after a 20 ms delay. When

LDO2 drops to 90% of its output voltage option, LDO1 will

start to turn off after a 125 µs (or a 10msec) delay. Another

KYBD debounce after power up does not necessary mean

power down.

Whenever LDO1 or LDO2 falls under 90% of the output

voltage option, RST immediately goes low to bring

PS_HOLD low in order to turn the part off.

Plugging the charger into the cell phone will cause an external signal VEXT to toggle from high to low. The LP3927 will

respond differently to this signal depending on the scenario:

Case 1: If a charger is plugged into the cell phone after the

phone is already on, the VEXT signal go from high to low.

The LP3927 will acknowledge this signal but all other signals

remain unchanged.

Case 2: If a charger is plugged into the phone while the

phone is off, VEXT signal goes from high to low and the

LP3927 will proceed to turn LDO1 on after a 32 ms delay,

and the identical power-up sequence follows. This case

bypasses the power-up initiated by KYBD and IRQ. KYBD

remains low and IRQ remains high at all time during

power-up.

When the charger is plugged in, the phone cannot be turned

off unless both VEXT goes high and PS_HOLD goes low.

LDOs

The LP3927 contains five LDOs. LDO1 and 2 are powered

by the V

and LDO5 is powered by the V

must be tied together externally. All five LDOs accept an

input voltage from 3.0V to 5.5V. This accommodates the full

usable range of a single Li-On battery.

LDO1 and 4 each provide 150 mA of current. LDO2 and 5

each provide 200 mA of current. LDO3 provides 100 mA of

current. The output of each LDO can be programmed to

different voltage levels at the factory. Refer to “Output Current Rating and Voltage Options” Table for more details.

LDO Input Capacitor

An input capacitance of ≈ 2.2 µF is required between each

V

DD

may be increased without limit).

line; LDO3 and 4 are powered by the V

DD1

DD3

line. V

DD1,VDD2

input pins and ground. (The amount of the capacitance

DD2

and V

line;

DD3

This capacitor must be located a distance of not more than

1 cm from the input pin and returned to a clean analog

ground. Any good quality ceramic, tantalum, or film capacitor

may be used at the inputs.

Important: Tantalum capacitors can suffer catastrophic failures due to surge current when connected to a

low-impedance source of power (like a battery or a very

large capacitor). If a tantalum capacitor is used at the input,

it must be guaranteed by the manufacturer to have a surge

current rating sufficient for the application.

There are no requirements for the ESR on the input capacitor, but tolerance and termperature coefficient must be considered when selecting the capacitor to ensure the capacitance will be ≈ 1 µF over the entire operating temperature

range.

LDO Output Capacitor

The LDOs are designed specifically to work with very small

ceramic output capacitors. A ceramic capacitor (X7R, X5R,

Z5U, or Y5V) in 1 µF to 20 µF range with 5 mΩ to 500 mΩ

ESR range is suitable in the LP3927 application circuit.

It may also be possible to use tantalum or film capacitors at

the output, but these are not as attractive for reasons of size

and cost.

The output capacitor must meet the requirement for minimum amount of capacitance and also have an ESR (Equivalent Series Resistance) value which is within a stable range

(5 mΩ to 500 mΩ).

LED Current Driver

The LED pin on the LP3927 is an open-drain output that can

provide up to 150 mA to drive backlight LEDs. It is turned on

when the LED_EN pin is pulled high, and off when the

LED_EN pin is pulled low. The external resistor R

PGM

connected to the LED_PGM pin programs the output current of

LED. A 130 kΩ resistor sets the output current to 150 mA. An

approximated equation between R

PGM

and I

LED

is:

Operational Amplifier

The LP3927 has an internal op amp with rail-to-rail input and

output and a 600 kHz of gain-bandwidth product.

Leadless Leadframe Package (LLP)

The LP3927 is packaged in a 28-lead LLP package for

enhanced thermal performance. The 28-lead LLP measures

5mmx5mmx0.75 mm. Its small size and low profile is

ideal for handset applications and other portable applications

that require power management.

Thermal Performance

The LLP package is designed for enhanced thermal performance because of the exposed die attach pad at the bottom

center of the package. It brings advantage to thermal performance by creating a very direct path for thermal dissipation.

Compared to the traditional leaded packages where the die

attach pad is embedded inside the mold compound, the LLP

reduces a layer in the thermal path.

The thermal advantage of the LLP package is fully realized

only when the exposed die attach pad is soldered down to a

thermal land on the PCB board and thermal vias are planted

underneath the thermal land. Based on a LLP thermal mea-

www.national.com 14

Page 15

LP3927

Application Hints (Continued)

surement, junction to ambient thermal resistance (θ

be improved by as much as two times if a LLP is soldered on

the board with thermal land and thermal vias than if not.

Consider the following equation:

Where P is the power dissipated, TJis the maximum junction

temperature of the die, T

is the thermal resistance of the package. TJis specified

θ

JA

is the ambient temperature, and

A

at 150˚C.

According to the above equation, in the case where the

LP3927 is dissipating 3W of power, T

when T

of 125˚C and θJAof 30.8˚C/W are used in the

J

is limited to 32.6˚C

A

equation. In order to operate at a higher ambient temperature, power dissipation has to be reduced. A curve of maximum power dissipation vs ambient temperature is provided

below.

Power Dissipation vs Ambient Temperature

=30.8˚C/W)

(θ

JA

JA

) can

Layout Consideration

The LP3927 has an exposed die attach pad located at the

bottom center of the LLP package. It is imperative to create

a thermal land on the PCB board when designing a PCB

layout for the LLP package. The thermal land helps to conduct heat away from the die, and the land should be the

same dimension as the exposed pad on the bottom of the

LLP (1:1 ratio). The land should be on both the top and the

bottom layer of the PCB board. In addition, thermal vias

should be added inside the thermal land to conduct more

heat away from the surface of the PCB to the ground plane.

Typical pitch and outer diameter for these thermal vias are

1.27 mm and 0.33 mm respectively. Typical copper via barrel

plating is 1 oz. although thicker copper may be used to

improve thermal performance. The LP3927 bottom pad is

connected to ground. Therefore, the thermal land and vias

on the PCB board need to be connected to ground.

For more information on board layout techniques, refer to

Application Note 1187 “Leadless Leadframe Package

(LLP).” The application note also discusses package handling, solder stencil, and assembly process.

20037915

www.national.com15

Page 16

Physical Dimensions inches (millimeters)

unless otherwise noted

LP3927 Cellular/PCS System Power Management IC

28 Lead LLP Package

NS Package Number lqa28A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...