Page 1

LP2995

DDR Termination Regulator

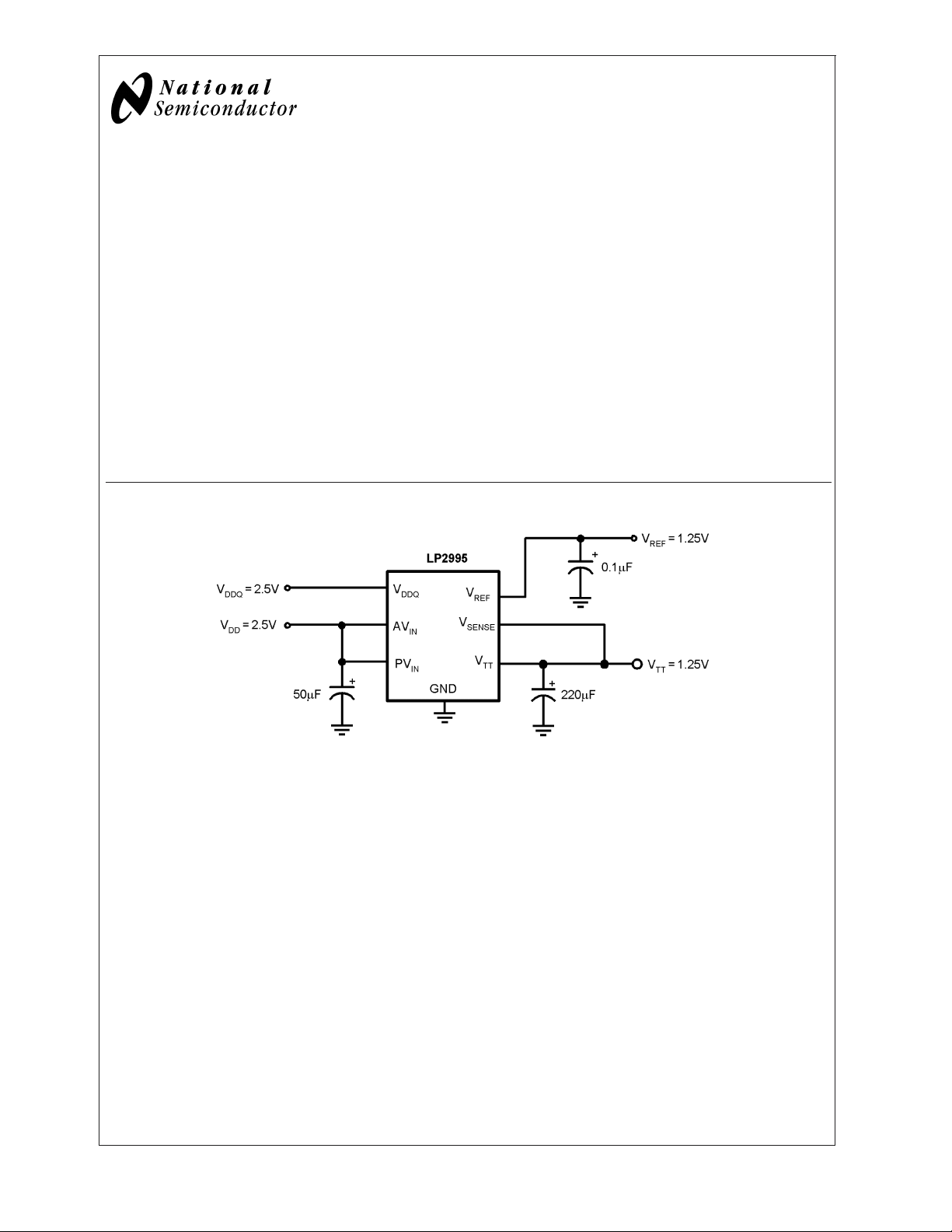

LP2995 DDR Termination Regulator

July 2003

General Description

The LP2995 linear regulator is designed to meet the JEDEC

SSTL-2 and SSTL-3 specifications for termination of DDRSDRAM. The device contains a high-speed operational amplifier to provide excellent response to load transients. The

output stage prevents shoot through while delivering 1.5A

continuous current and transient peaks up to 3A in the

application as required for DDR-SDRAM termination. The

LP2995 also incorporates a V

load regulation and a V

chipset and DDR DIMMS.

Patents Pending

REF

pin to provide superior

SENSE

output as a reference for the

Typical Application Circuit

Features

n Low output voltage offset

n Works with +5v, +3.3v and 2.5v rails

n Source and sink current

n Low external component count

n No external resistors required

n Linear topology

n Available in SO-8, PSOP-8 or LLP-16 packages

n Low cost and easy to use

Applications

n DDR Termination Voltage

n SSTL-2

n SSTL-3

20039302

© 2003 National Semiconductor Corporation DS200393 www.national.com

Page 2

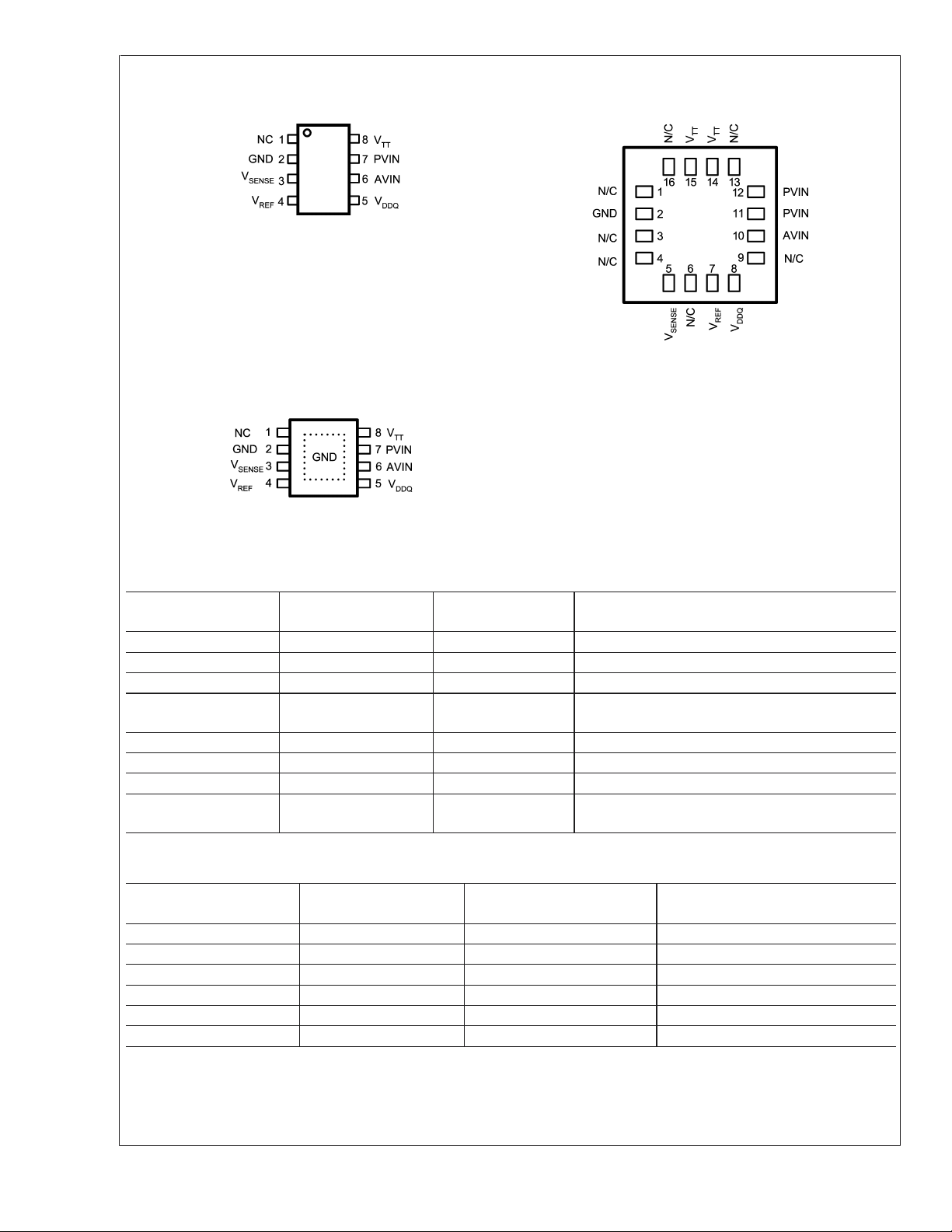

Connection Diagrams

LP2995

SO-8 (M08A) Package LQA- 16 Package

PSOP-8 (MRA08A) Package

Pin Description

SO-8 Pin or

PSOP-8 Pin

1 1,3,4,6,9, 13,16 NC No internal connection. Can be used for vias.

2 2 GND Ground.

3 5 VSENSE Feedback pin for regulating VTT.

4 7 VREF Buffered internal reference voltage of

5 8 VDDQ Input for internal reference equal to VDDQ/2.

6 10 AVIN Analog input pin.

7 11, 12 PVIN Power input pin.

8 14, 15 VTT Output voltage for connection to termination

Top View

20039320

20039304

Top View

20039350

Top View

LLP Pin Name Function

VDDQ/2.

resistors.

Ordering Information

Order Number Package Type

LP2995M SO-8 M08A 95 Units per Rail

LP2995MX SO-8 M08A 2500 Units Tape and Reel

LP2995MR PSOP-8 MRA08A 95 Units per Rail

LP2995MRX PSOP-8 MRA08A 2500 Units Tape and Reel

LP2995LQ LLP-16 LQA16A 1000 Units Tape and Reel

LP2995LQX LLP-16 LQA16A 4500 Units Tape and Reel

www.national.com 2

NSC Package

Drawing

Supplied As

Page 3

LP2995

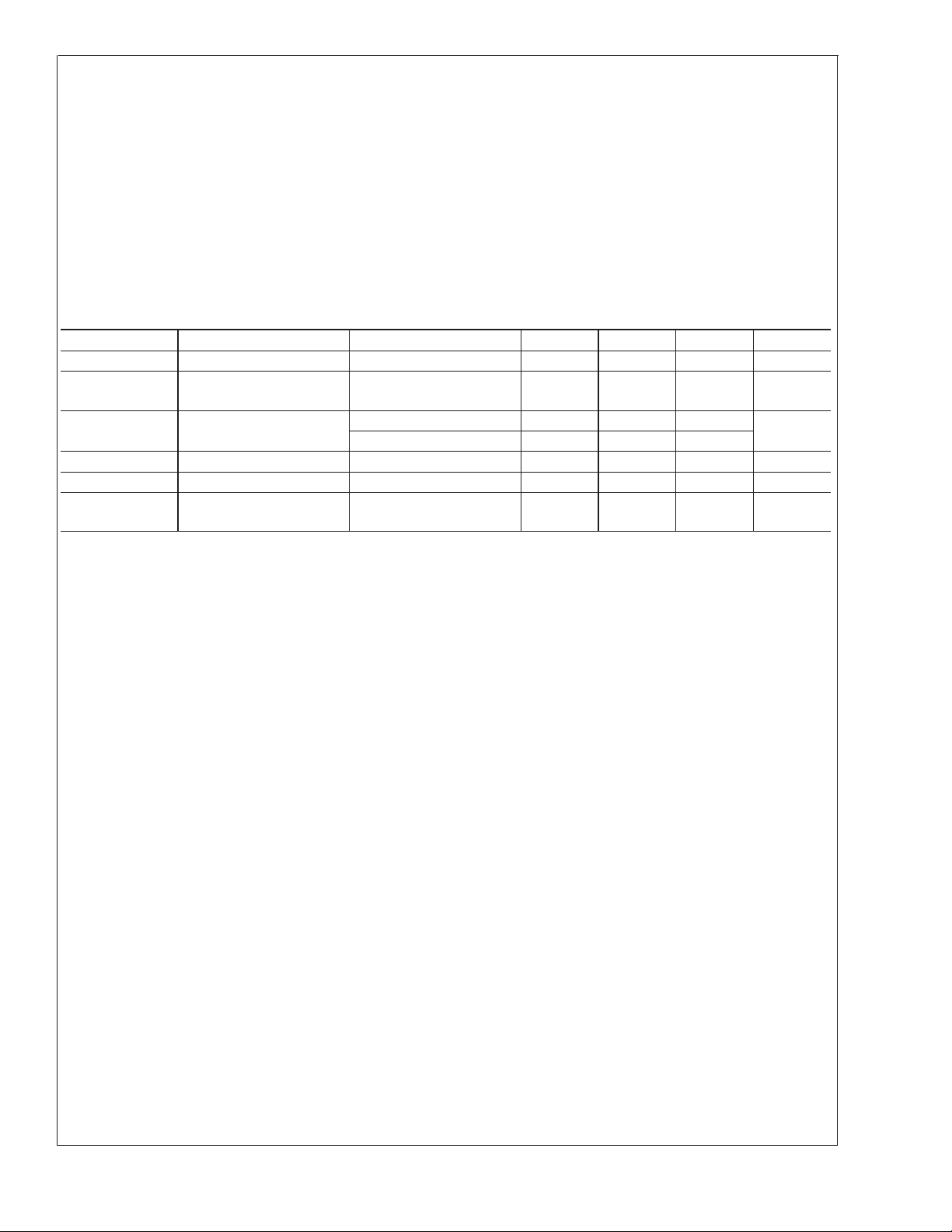

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

Lead Temperature (Soldering, 10 sec) 260˚C

ESD Rating (Note 7) 1kV

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Operating Range

PVIN, AVIN, VDDQ to GND −0.3V to +6V

Storage Temp. Range −65˚C to +150˚C

Junction Temperature 150˚C

SO-8 Thermal Resistance (θ

LLP-16 Thermal Resistance (θ

) 151˚C/W

JA

) 51˚C/W

JA

Electrical Characteristics Specifications with standard typeface are for T

type apply over the full Operating Temperature Range (T

AVIN = PVIN = 2.5V, VDDQ = 2.5V (Note 6).

Symbol Parameter Conditions Min Typ Max Units

V

REF

VOS

VTT

V

Voltage I

REF

VTTOutput Voltage Offset I

REF_OUT

OUT

(Note 2)

∆V

Z

Z

I

q

TT/VTT

VREF

VDDQ

Load Regulation

(Note 3)

V

Output Impedance I

REF

VDDQ Input Impedance 100 kΩ

Quiescent Current I

I

I

OUT

OUT

REF

OUT

(Note 4)

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating range indicates conditions for which the device is

intended to be functional, but does not guarantee specific performance limits. For guaranteed specifications and test conditions see Electrical Characteristics. The

guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed

test conditions.

Note 2: V

Note 3: Load regulation is tested by using a 10ms current pulse and measuring V

Note 4: Quiescent current defined as the current flow into AVIN.

Note 5: At elevated temperatures, devices must be derated based on thermal resistance. The device in the SO-8 package must be derated at θ

junction to ambient with no heat sink. The device in the LLP-16 must be derated at θ

Note 6: Limits are 100% production tested at 25˚C. Limits over the operating temperature range are guaranteed through correlation using Statistical Quality Control

(SQC) methods. The limits are used to calculate National’s Average Outgoing Quality Level (AOQL).

Note 7: The human body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin.

offset is the voltage measurement defined as V

TT

subtracted from V

TT

J

= 0mA 1.21 1.235 1.26 V

=0A

= 0 to 1.5A 0.5 %

= 0 to −1.5A −0.5

= −5µA to +5µA 5 kΩ

=0A

Junction Temp. Range (Note 5) 0˚C to +125˚C

AVIN to GND 2.2V to 5.5V

PVIN to GND 2.2V to AVIN

= 25˚C and limits in boldface

J

= 0˚C to +125˚C). Unless otherwise specified,

−15

01520mV

−20

250 400 µA

.

REF

.

TT

= 51˚ C/W junction to ambient.

JA

= 151˚ C/W

JA

www.national.com3

Page 4

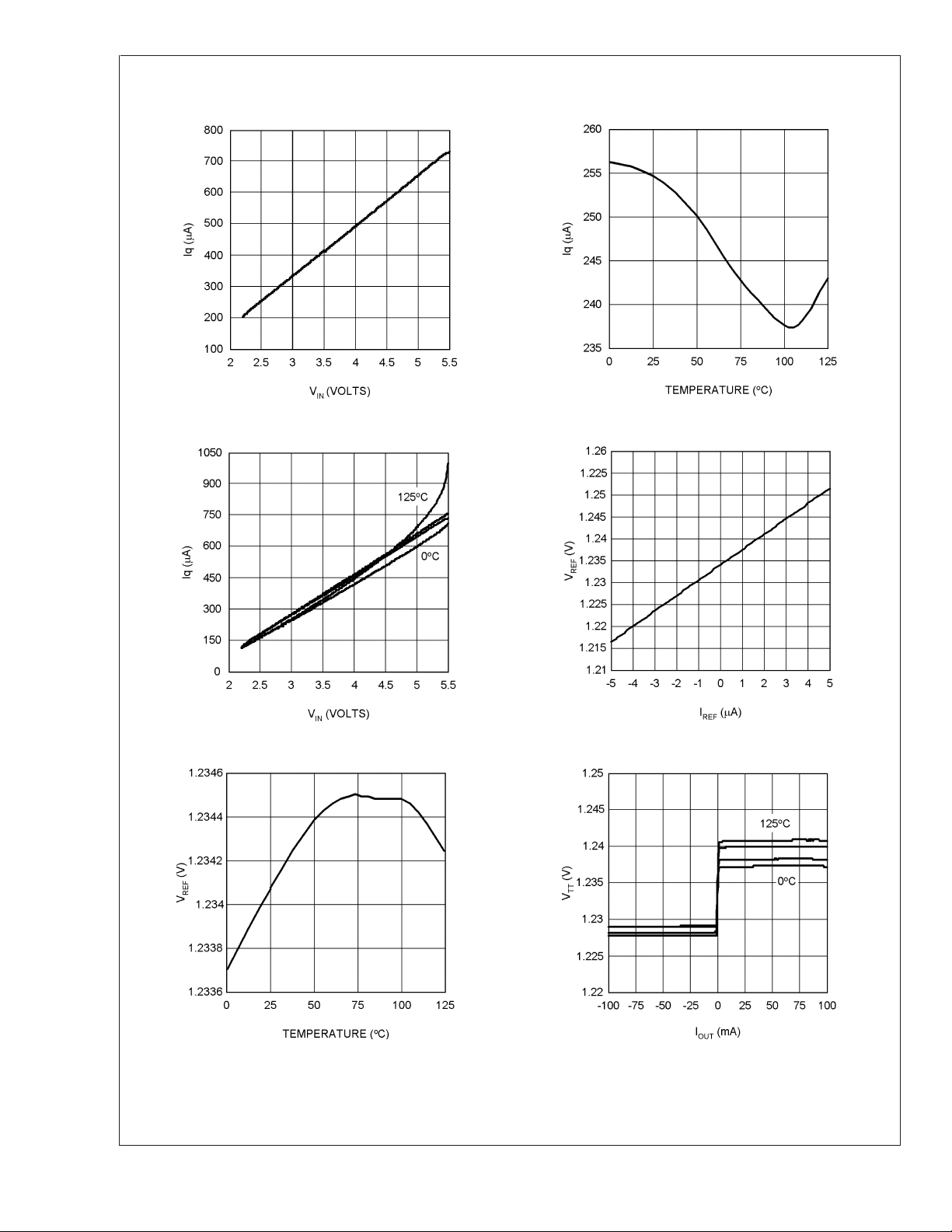

Typical Performance Characteristics

LP2995

Iq vs VIN(0, 25, 85, and 125˚C) V

Iq vs VIN(25˚C) Iq vs Temperature ( VIN= 2.5V)

20039309 20039310

vs I

REF

REF

20039311 20039312

V

vs Temperature (No Load) VTTvs I

REF

20039313 20039314

www.national.com 4

(0, 25, 85, and 125˚C)

OUT

Page 5

Typical Performance Characteristics (Continued)

LP2995

V

vs I

TT

OUT

20039315

Maximum Output Current (Sinking) vs V

(VDDQ = 2.5)

Maximum Output Current (Sourcing) vs V

IN

(VDDQ = 2.5)

20039316

IN

20039317

www.national.com5

Page 6

Block Diagram

LP2995

20039301

Description

The LP2995 is a linear bus termination regulator designed to

meet the JEDEC requirements of SSTL-2 and SSTL-3. The

LP2995 is capable of sinking and sourcing current at the

output V

buffered reference voltage that also tracks VDDQ/2is

generated on the V

the DDR-SDRAM and Northbridge Chipset. V

to track the V

entire current range while preventing shoot through on the

output stage.

Series Stub Termination Logic (SSTL) was created to improve signal integrity of the data transmission across the

memory bus. This termination scheme is essential to prevent

data error from signal reflections while transmitting at high

frequencies encountered with DDR RAM. The most common

form of termination is Class II single parallel termination. This

involves using one Rs series resistor from the chipset to the

memory and one Rt termination resistor. This implementation can be seen below in Figure 1.

, regulating the voltage to equal VDDQ / 2. A

TT

pin for providing a global reference to

REF

voltage with a tight tolerance over the

REF

is designed

TT

Typical values for R

and RTare 25 Ohms although these

S

can be changed to scale the current requirements from the

LP2995. For determination of the current requirements of

DDR-SDRAM termination please refer to the accompanying

application notes.

20039308

FIGURE 1.

www.national.com 6

Page 7

Pin Descriptions

AVIN AND PVIN

AVIN and PVIN are the input supply pins for the LP2995.

AVIN is used to supply all the internal control circuitry for the

two op-amps and the output stage of V

exclusively to provide the rail voltage for the output stage on

the power operational amplifier used to create V

SSTL-2 applications AVIN and PVIN pins should be connected directly and tied to the 2.5V rail for optimal performance. This eliminates the need for bypassing the two supply pins separately.

VDDQ

VDDQ is the input that is used to create the internal reference voltage for regulating V

TT

and V

generated by two internal 50kΩ resistors. This guarantees

that V

TT

and V

will track VDDQ / 2 precisely. The optimal

REF

implementation of VDDQ is as a remote sense for the reference input. This can be achieved by connecting VDDQ

directly to the 2.5V rail at the DIMM. This ensures that the

reference voltage tracks the DDR memory rails precisely

without a large voltage drop from the power lines. For

SSTL-2 applications VDDQ will be a 2.5V signal, which will

create a 1.25V reference voltage on V

termination voltage at V

. For SSTL-3 applications it may

TT

be desirable to have a different scaling factor for creating the

internal reference voltage besides 0.5. For instance a typical

value that is commonly used is to have the reference voltage

*

equal VDDQ

0.45. This can be achieved by placing a resistor in series with the VDDQ pin to effectively change the

resistor divider.

V

SENSE

The purpose of the sense pin is to provide improved remote

load regulation. In most motherboard applications the termination resistors will connect to V

TT

output voltage was regulated only at the output of the

LP2995, then the long trace will cause a significant IR drop,

resulting in a termination voltage lower at one end of the bus

than the other. The V

pin can be used to improve this

SENSE

performance, by connecting it to the middle of the bus. This

will provide a better distribution across the entire termination

bus.

Note: If remote load regulation is not used, then the V

connected to V

V

REF

V

provides the buffered output of the internal reference

REF

.

TT

voltage VDDQ / 2. This output should be used to provide the

reference voltage for the Northbridge chipset and memory.

Since these inputs are typically an extremely high impedance, there should be little current drawn from V

improved performance, an output bypass capacitor can be

used, located close to the pin, to help with noise. A ceramic

capacitor in the range of 0.1 µF to 0.01 µF is recommended.

V

TT

VTTis the regulated output that is used to terminate the bus

resistors. It is capable of sinking and sourcing current while

regulating the output precisely to VDDQ / 2. The LP2995 is

designed to handle peak transient currents of up to

a fast transient response. The maximum continuous current

is a function of V

and can be viewed in the TYPICAL

IN

PERFORMANCE CHARACTERISTICS section. If a transient is expected to last above the maximum continuous

. PVIN is used

REF

. For

TT

. This voltage is

REF

and a 1.25V

REF

in a long plane. If the

pin must still be

SENSE

. For

REF

±

3A with

current rating for a significant amount of time then the output

capacitor should be sized large enough to prevent an excessive voltage drop. Despite the fact that the LP2995 is designed to handle large transient output currents it is not

capable of handling these for long durations, under all conditions. The reason for this is the standard packages are not

able to thermally dissipate the heat as a result of the internal

power loss. If large currents are required for longer durations, then care should be taken to ensure that the maximum

junction temperature is not exceeded. Proper thermal derating should always be used (please refer to the Thermal

Dissipation section).

Component Selection

INPUT CAPACITOR

The LP2995 does not require a capacitor for input stability,

but it is recommended for improved performance during

large load transients to prevent the input rail from dropping.

The input capacitor should be located as close as possible to

the PVIN pin. Several recommendations exist dependent on

the application required. A typical value recommended for AL

electrolytic capacitors is 50 µF. Ceramic capacitors can also

be used, a value in the range of 10 µF with X5R or better

would be an ideal choice. The input capacitance can be

reduced if the LP2995 is placed close to the bulk capacitance from the output of the 2.5V DC-DC converter.

OUTPUT CAPACITOr

The LP2995 has been designed to be insensitive of output

capacitor size or ESR (Equivalent Series Resistance). This

allows the flexibility to use any capacitor desired. The choice

for output capacitor will be determined solely on the application and the requirements for load transient response of V

As a general recommendation the output capacitor should

be sized above 100 µF with a low ESR for SSTL applications

with DDR-SDRAM. The value of ESR should be determined

by the maximum current spikes expected and the extent at

which the output voltage is allowed to droop. Several capacitor options are available on the market and a few of these

are highlighted below:

AL - It should be noted that many aluminum electrolytics only

specify impedance at a frequency of 120 Hz, which indicates

they have poor high frequency performance. Only aluminum

electrolytics that have an impedance specified at a higher

frequency (between 20 kHz and 100 kHz) should be used for

the LP2995. To improve the ESR several AL electrolytics can

be combined in parallel for an overall reduction. An important

note to be aware of is the extent at which the ESR will

change over temperature. Aluminum electrolytic capacitors

can have their ESR rapidly increase at cold temperatures.

Ceramic - Ceramic capacitors typically have a low capacitance, in the range of 10 to 100 µF range, but they have

excellent AC performance for bypassing noise because of

very low ESR (typically less than 10 mΩ). However, some

dielectric types do not have good capacitance characteristics as a function of voltage and temperature. Because of the

typically low value of capacitance it is recommended to use

ceramic capacitors in parallel with another capacitor such as

an aluminum electrolytic. A dielectric of X5R or better is

recommended for all ceramic capacitors.

Hybrid - Several hybrid capacitors such as OS-CON and SP

are available from several manufacturers. These offer a

large capacitance while maintaining a low ESR. These are

TT

LP2995

.

www.national.com7

Page 8

Component Selection (Continued)

LP2995

the best solution when size and performance are critical,

although their cost is typically higher than any other capacitor.

Capacitor recommendations for different application circuits

can be seen in the accompanying application notes with

supporting evaluation boards.

Thermal Dissipation

Since the LP2995 is a linear regulator any current flow from

will result in internal power dissipation generating heat.

V

TT

To prevent damaging the part from exceeding the maximum

allowable junction temperature, care should be taken to

derate the part dependent on the maximum expected ambient temperature and power dissipation. The maximum allowable internal temperature rise (T

given the maximum ambient temperature (T

application and the maximum allowable junction temperature

).

(T

Jmax

T

Rmax=TJmax−TAmax

From this equation, the maximum power dissipation (P

of the part can be calculated:

P

Dmax=TRmax

The θJAof the LP2995 will be dependent on several variables: the package used; the thickness of copper; the number of vias and the airflow. For instance, the θ

is 163˚C/W with the package mounted to a standard 8x4

2-layer board with 1oz. copper, no airflow, and 0.5W dissipation at room temperature. This value can be reduced to

151.2˚C/W by changing to a 3x4 board with 2 oz. copper that

is the JEDEC standard. Figure 2 shows how the θ

with airflow for the two boards mentioned.

) can be calculated

Rmax

/ θ

JA

)ofthe

Amax

of the SO-8

JA

JA

Dmax

varies

the DAP the θ

can be lowered significantly. Figure 3 shows

JA

the LLP thermal data when placed on a 4-layer JEDEC

board with copper thickness of 0.5/1/1/0.5 oz. The number of

vias, with a pitch of 1.27 mm, has been increased to the

maximum of 4 where a θ

of 50.41˚C/W can be obtained.

JA

Via wall thickness for this calculation is 0.036 mm for 1oz.

Copper.

)

LLP-16 θJAvs#of Vias (4 Layer JEDEC Board))

20039322

FIGURE 3.

Additional improvements in lowering the θ

can also be

JA

achieved with a constant airflow across the package. Maintaining the same conditions as above and utilizing the 2x2

via array, Figure 4 shows how the θ

varies with airflow.

JA

θJAvs Airflow (SO-8)

20039321

FIGURE 2.

Layout is also extremely critical to maximize the output

current with the LLP package. By simply placing vias under

www.national.com 8

θJAvs Airflow Speed (JEDEC Board with 4 Vias)

20039323

FIGURE 4.

Page 9

Typical Application Circuits

The typical application circuit used for SSTL-2 termination

schemes with DDR-SDRAM can be seen in Figure 5.

LP2995

SSTL-2 Implementation

For SSTL-3 and other applications it may be desirable to

*

change internal reference voltage scaling from VDDQ

0.5.

An external resistor in series with the VDDQ pin can be used

to lower the reference voltage. Internally two 50 kΩ resistors

SSTL-3 Implementation

FIGURE 5.

FIGURE 6.

20039306

set the output V

to be equal to VDDQ*0.5. The addition

TT

of a 11.1 kΩ external resistor will change the internal refer-

*

ence voltage causing the two outputs to track VDDQ

0.45.

An implementation of this circuit can be seen in Figure 6.

20039307

Another application that is sometimes required is to increase

output voltage from the scaling factor of VDDQ*0.5.

the V

TT

This can be accomplished independently of V

REF

by using a

FIGURE 7.

resistor divider network between V

TT,VSENSE

and Ground.

An example of this circuit can be seen in Figure 7.

20039303

www.national.com9

Page 10

PCB Layout Considerations

1. AVIN and PVIN should be tied together for optimal per-

LP2995

formance. A local bypass capacitor should be placed as

close as possible to the PVIN pin.

2. GND should be connected to a ground plane with multiple vias for improved thermal performance.

3. V

should be connected to the VTTtermination bus

SENSE

at the point where regulation is required. For motherboard applications an ideal location would be at the

center of the termination bus.

4. VDDQ can be connected remotely to the VDDQ rail

input at either the DIMM or the Chipset. This provides

the most accurate point for creating the reference voltage.

5. V

should be bypassed with a 0.01 µF or 0.1 µF

REF

ceramic capacitor for improved performance. This capacitor should be located as close as possible to the

pin.

V

REF

www.national.com 10

Page 11

Physical Dimensions inches (millimeters)

unless otherwise noted

LP2995

8-Lead Small Outline Package (M8)

NS Package Number M08A

www.national.com11

Page 12

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

LP2995

16-Lead LLP Package (LD)

NS Package Number LQA16A

8-Lead PSOP Package (PSOP-8)

NS Package Number MRA08A

www.national.com 12

Page 13

Notes

LP2995 DDR Termination Regulator

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...