Page 1

LP2994

DDR Termination Regulator

LP2994 DDR Termination Regulator

June 2005

General Description

The LP2994 regulator is designed to provide a linear solution

to meet the JEDEC SSTL-2 and SSTL-3 specifications (Series Stub Termination Logic) for active termination of DDRSDRAM. The device utilizes an internal operational amplifier

to provide linear regulation of V

expensive external components. The output stage prevents

shoot through while delivering 1.5A continuous current and

maintaining excellent load regulation. The LP2994 also incorporates an active low shutdown pin to tri-state the output

during Suspend To Ram (STR) states.

Patents Pending

without the need for

TT

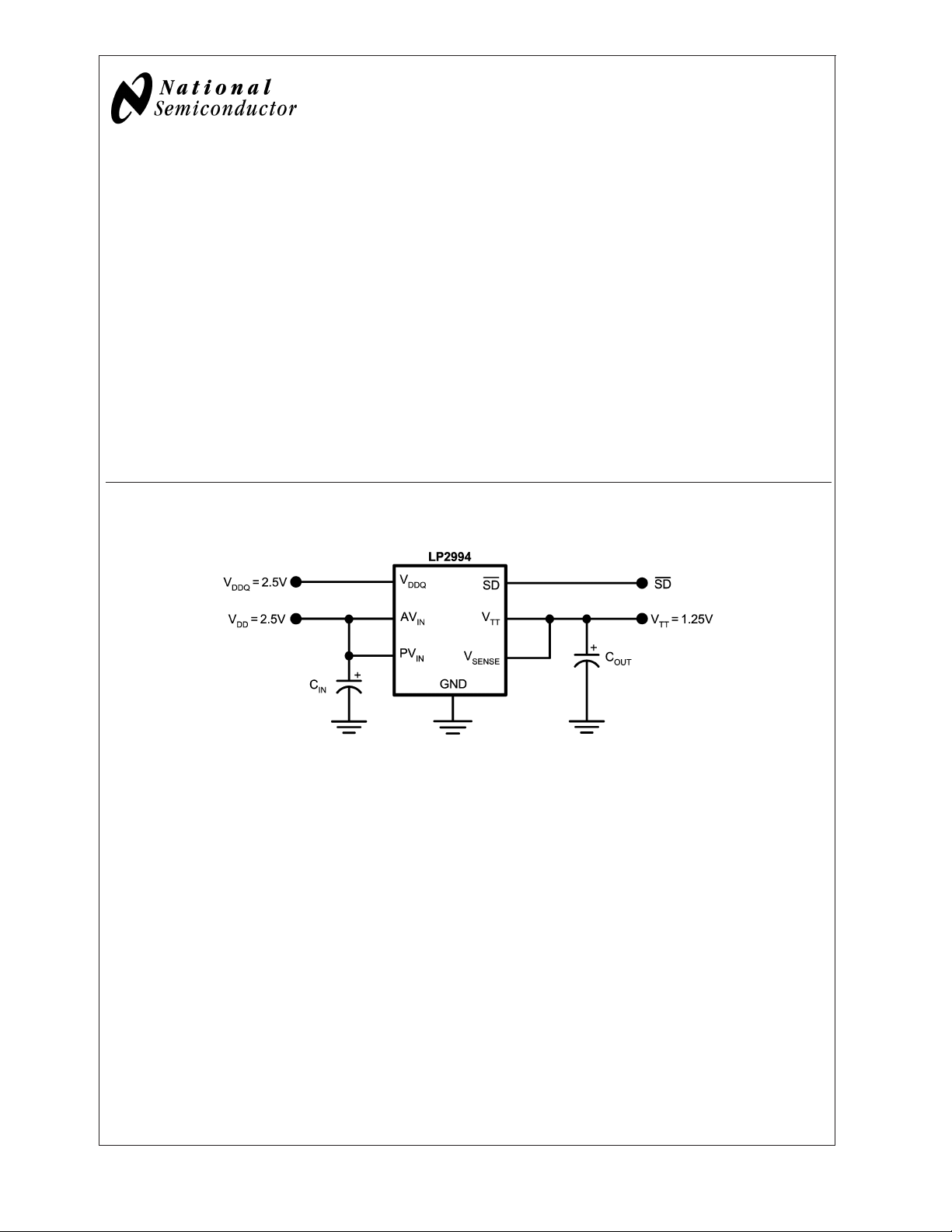

Typical Application Circuit

Features

n Source and sink current

n Low external component count

n Independent analog and power rails

n Linear topology

n Small package SO-8

n Low cost and easy to use

n Shutdown pin

Applications

n SSTL-2

n SSTL-3

n DDR-SDRAM Termination

n DDR-II Termination

20045904

FIGURE 1. SSTL-2 VTTTermination

© 2005 National Semiconductor Corporation DS200459 www.national.com

Page 2

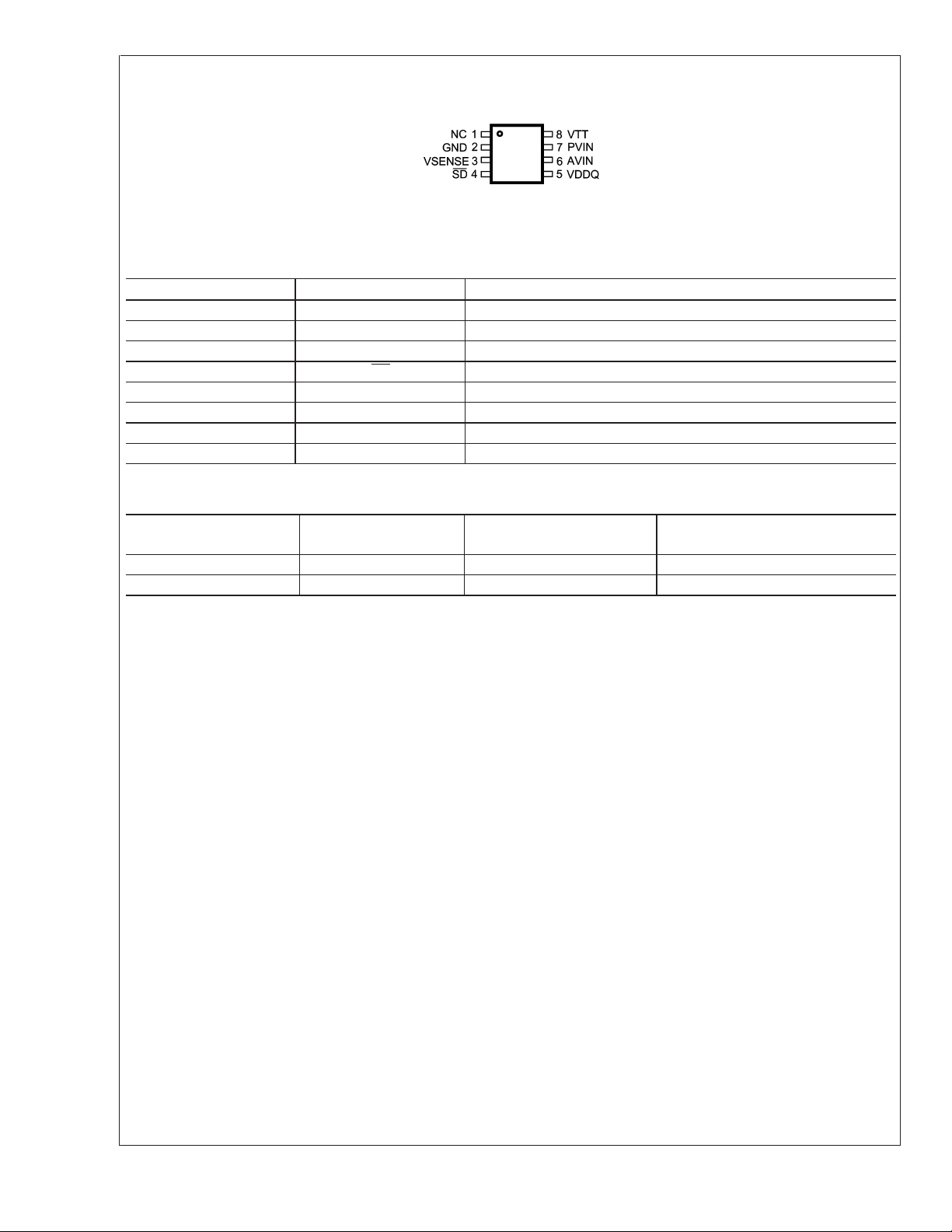

Connection Diagram

LP2994

SO-8 (M08A) Package

Top View

20045902

Pin Descriptions

SO-8 Pin Name Function

1 NC No internal connection

2 GND Ground

3 VSENSE Feedback pin for regulating VTT

4SD

5 VDDQ Input for internal reference equal to VDDQ/2

6 AVIN Analog input pin

7 PVIN Power input pin

8 VTT Output voltage for connection to termination resistors

Active low shutdown pin

Ordering Information

Order Number Package Type

LP2994M SO-8 M08A 95 Units per Rail

LP2994MX SO-8 M08A 2500 Units Tape and Reel

NSC Package

Drawing

Supplied As

www.national.com 2

Page 3

LP2994

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

PVIN, AVIN, VTT, VDDQ, SD to GND −0.3V to +6V

Storage Temp. Range −65˚C to +150˚C

Junction Temperature 150˚C

PVIN Supply Voltage -0.3V to (AVIN +

0.3V)

SD Input Voltage -0.3V to (AVIN +

0.3V)

VTT Output Voltage -0.3V to (PVIN +

0.3V)

SO-8 Thermal Resistance (θ

) 151˚C/W

JA

Lead Temperature (Soldering, 10 sec) 260˚C

ESD Rating (Note 2) 2kV

Operating Range

Junction Temp. Range (Note 3) 0˚C to +125˚C

AVIN Supply Voltage 2.2V to 5.5V

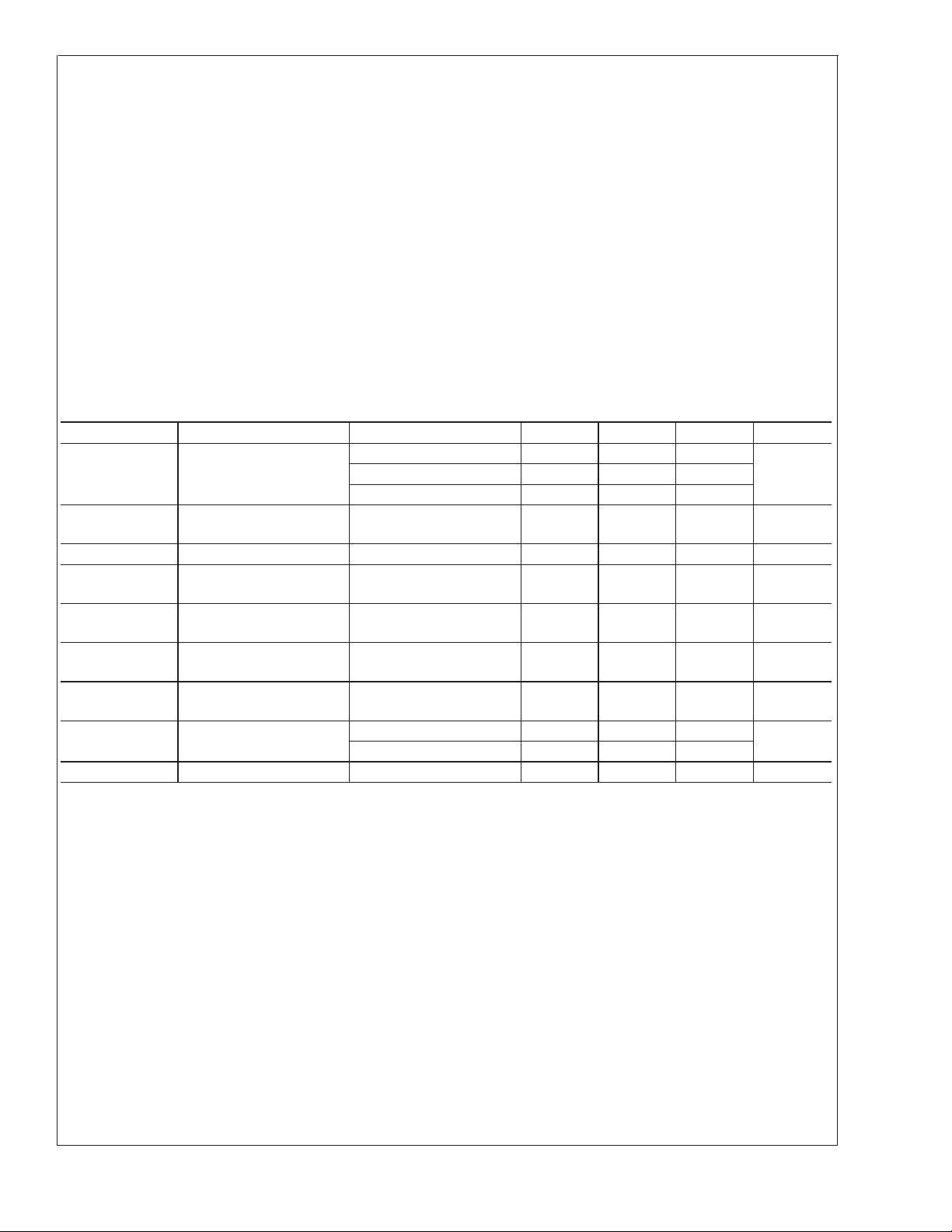

Electrical Characteristics Specifications with standard typeface are for T

type apply over the full Operating Temperature Range (T

AVIN = PVIN = 2.5V, VDDQ = 2.5V (Note 4).

Symbol Parameter Conditions Min Typ Max Units

V

TT

VTTOutput Voltage

= 0A (Note 5)

I

OUT

VIN=VDDQ = 2.3V 1.108 1.138 1.168

VIN=VDDQ = 2.7V 1.305 1.334 1.360

I

q

Quiescent Current I

OUT

(Note 6)

Z

I

QSD

VDDQ

VDDQ Input Impedance 86 100 kΩ

Quiescent current in

shutdown

I

SD

V

IH

Shutdown Leakage

Current

Minimum Shutdown High

SD=0V

SD = 2.5V

Level

V

IL

Maximum Shutdown Low

Level

∆V

TT/VTT

Load Regulation

(Note 7)

I

SENSE

Note 1: Absolute maximum ratings indicate limits beyond which damage to the device may occur. Operating range indicates conditions for which the device is

intended to be functional, but does not guarantee specific performance limits. For guaranteed specifications and test conditions see Electrical Characteristics. The

guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed

test conditions.

Note 2: The human body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin.

Note 3: At elevated temperatures, devices must be derated based on thermal resistance. The device in the SO-8 package must be derated at θ

junction to ambient with no heat sink.

Note 4: Limits are 100% production tested at 25˚C. Limits over the operating temperature range are guaranteed through correlation using Statistical Quality Control

(SQC) methods. The limits are used to calculate National’s Average Outgoing Quality Level (AOQL).

Note 5: VIN is defined as the VIN = AVIN = PVIN

Note 6: Quiescent current defined as the current flow into AVIN.

Note 7: Load regulation is tested by using a 10ms current pulse and measuring V

SENSE Input Current 100 pA

I

I

OUT

OUT

= 0˚C to +125˚C). Unless otherwise specified,

J

=0A

1.9 V

= 0 to 1.5A -0.4 %

= 0 to −1.5A +0.4

.

TT

= 25˚C and limits in boldface

J

272 400 µA

21 45 µA

2

5 µA

2

0.8 V

= 151.2˚ C/W

JA

nA

VVIN=VDDQ = 2.5V 1.210 1.236 1.260

www.national.com3

Page 4

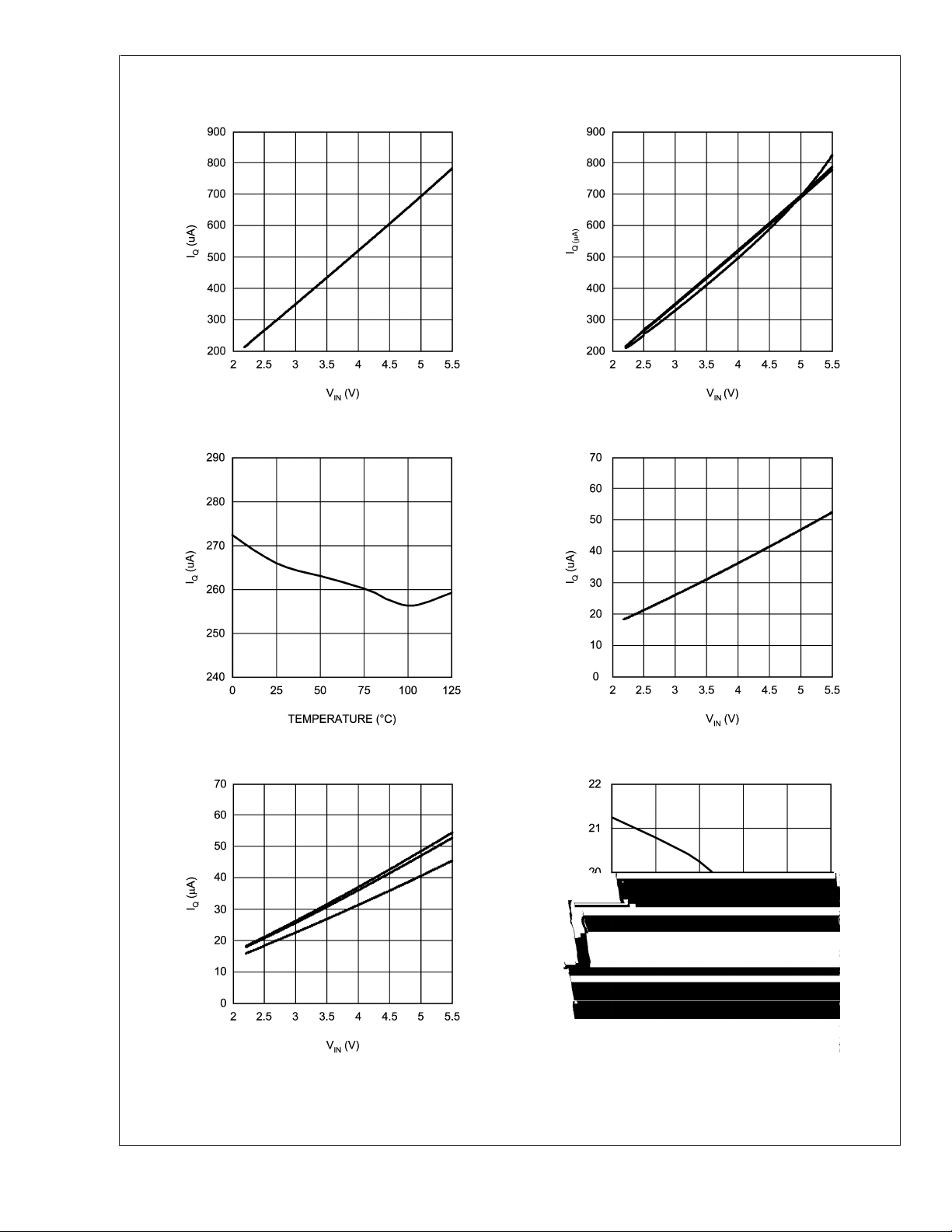

Typical Performance Characteristics

LP2994

Iq vs Temperature ( VIN= 2.5V) ISDvs VIN(25˚C)

Iq vs VIN(25˚C) Iq vs VIN(0, 25, and 125˚C)

20045914 20045915

20045916

ISDvs VIN(0, 25, and 125˚C) ISDvs Temperature ( VIN= 2.5V)

20045918

www.national.com 4

20045917

20045919

Page 5

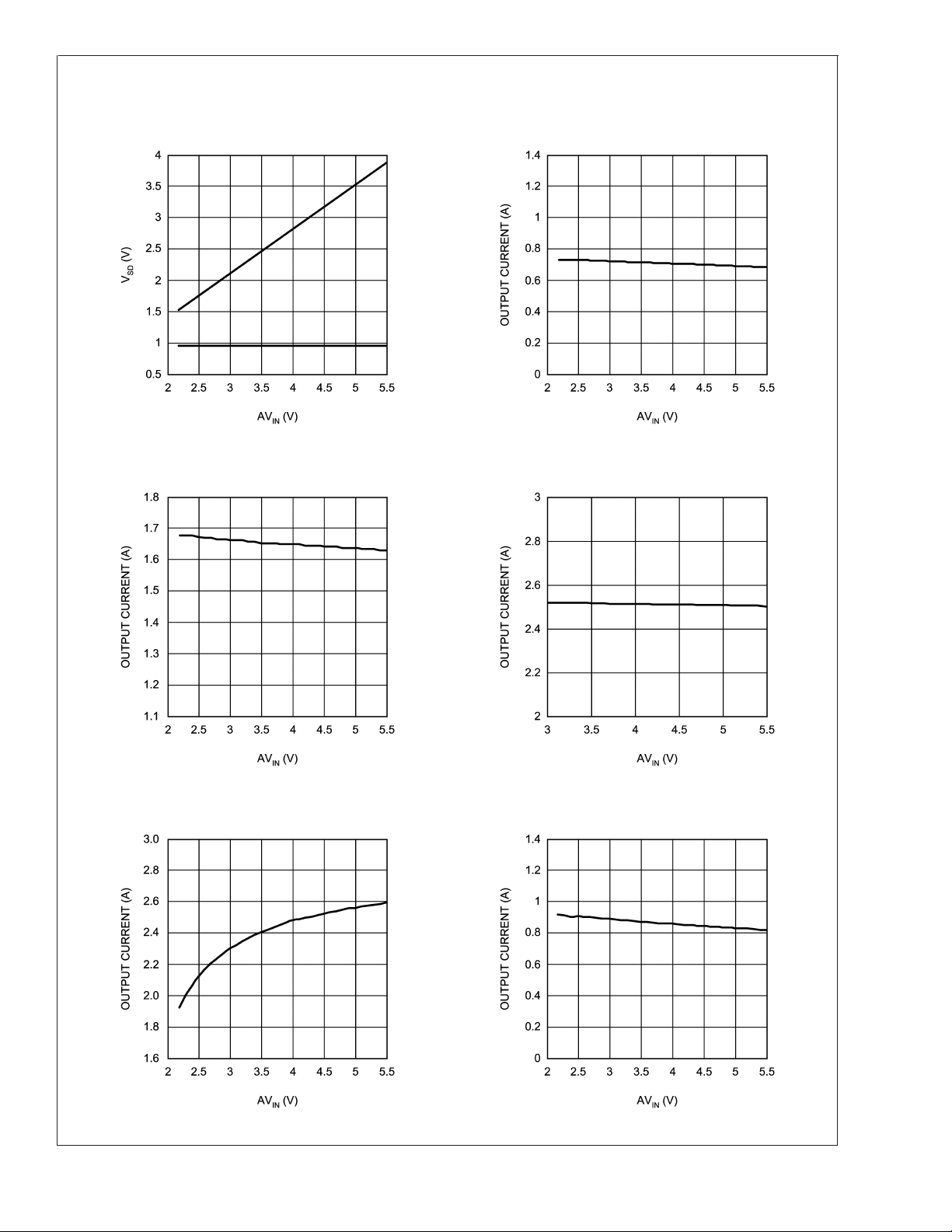

Typical Performance Characteristics (Continued)

LP2994

V

and VIHvs AVIN(25˚C)

IL

Maximum Sourcing Current vs AV

(V

= 2.5V, PVIN= 2.5V)

DDQ

Maximum Sourcing Current vs AV

(V

= 2.5V, PVIN= 1.8V)

DDQ

20045920 20045921

IN

Maximum Sourcing Current vs AV

(V

= 2.5V, PVIN= 3.3V)

DDQ

IN

IN

Maximum Sinking Current vs AV

(V

= 2.5V)

DDQ

20045922 20045923

IN

20045924 20045925

Maximum Sourcing Current vs AV

(V

= 1.8V, PVIN= 1.8V)

DDQ

IN

www.national.com5

Page 6

Typical Performance Characteristics (Continued)

LP2994

Maximum Sinking Current vs AV

(V

= 1.8V)

DDQ

VTTvs I

(0, 25, 85, and 125˚C) VTTvs I

OUT

IN

20045926 20045927

Maximum Sourcing Current vs AV

(V

= 1.8V, PVIN= 3.3V)

DDQ

OUT

IN

20045929 20045930

www.national.com 6

Page 7

Block Diagram

LP2994

20045903

Description

The LP2994 is a linear bus termination regulator designed to

meet the JEDEC requirements of SSTL-2 and SSTL-3. The

output, V

regulating the output voltage equal to V

stage has been designed to maintain excellent load regulation while preventing shoot through. The LP2994 also incorporates two distinct power rails which separates the analog

circuitry from the power output stage. This allows a split rail

approach to be utilized to decrease internal power dissipation. It also permits the LP2994 to provide a termination

solution for the next generation of DDR-SDRAM memory

(DDRII).

Series Stub Termination Logic (SSTL) was created to improve signal integrity of the data transmission across the

memory bus. This termination scheme is essential to prevent

data error from signal reflections while transmitting at high

frequencies encountered with DDR-SDRAM. The most common form of termination is Class II single parallel termination. This involves one R

is capable of sinking and sourcing current while

TT

series resistor from the chipset to

S

/ 2. The output

DDQ

the memory and one R

and RTare 25 Ohms, although these can be changed

for R

S

termination resistor. Typical values

T

to scale the current requirements from the LP2994. This

implementation can be seen below in Figure 2.

20045931

FIGURE 2. SSTL Termination Scheme

www.national.com7

Page 8

Pin Descriptions

LP2994

AVIN and PVIN

AVIN and PVIN are the input supply pins for the LP2994.

AVIN is used to supply all the internal control circuitry. PVIN,

however, is used exclusively to provide the rail voltage for

the output stage used to create V

capability to work off separate supplies depending on the

application. Higher voltages on PVIN will increase the maximum continuous output current because of output RDSON

limitations at voltages close to V

values of PVIN is that the internal power loss will also

increase, thermally limiting the design. For SSTL-2 applications, a good compromise would be to connect the AVIN and

PVIN directly together at 2.5V. This eliminates the need for

bypassing the two supply pins separately. The only limitation

on input voltage selection is that PVIN must be equal to or

lower than AVIN.

V

DDQ

V

is the input used to create the internal reference

DDQ

voltage for regulating V

. The reference voltage is gener-

TT

ated from a resistor divider of two internal 50kΩ resistors.

This guarantees that V

optimal implementation of V

will track V

TT

DDQ

can be achieved by connecting V

at the DIMM instead of AVIN and PVIN. This ensures that the

reference voltage tracks the DDR memory rails precisely

without a large voltage drop from the power lines. For

SSTL-2 applications V

will be a 2.5V signal, which will

DDQ

create a 1.25V termination voltage at V

Characteristics Table for exact values of V

ture).

V

SENSE

The purpose of the sense pin is to provide improved remote

load regulation. In most motherboard applications the termination resistors will connect to V

output voltage was regulated only at the output of the

LP2994 then the long trace will cause a significant IR drop

resulting in a termination voltage lower at one end of the bus

than the other. The V

pin can be used to improve this

SENSE

performance, by connecting it to the middle of the bus. This

will provide a better distribution across the entire termination

bus. If remote load regulation is not used then the V

pin must still be connected to VTT. Care should be taken

when a long V

trace is implemented in close proximity

SENSE

to the memory. Noise pickup in the V

problems with precise regulation of V

ramic capacitor placed next to the V

any high frequency signals and preventing errors.

Shutdown

The LP2994 contains an active low shutdown pin that can be

used to tri-state VTT. During shutdown V

exposed to voltages that exceed PVIN. With the shutdown

pin asserted low the quiescent current of the LP2994 will

drop, however, V

will always maintain its constant im-

DDQ

pedance of 100kΩ for generating the internal reference.

Therefore to calculate the total power loss in shutdown both

currents need to be considered. For more information refer

to the Thermal Dissipation section. The shutdown pin also

has an internal pull-up current, therefore to turn the part on

the shutdown pin can either be connected to AVIN or left

open.

. These pins have the

TT

. The disadvantage of high

TT

/ 2 precisely. The

DDQ

is as a remote sense. This

directly to the 2.5V rail

DDQ

(See Electrical

TT

TT

in a long plane. If the

TT

trace can cause

SENSE

. A small 0.1uF ce-

TT

pin can help filter

SENSE

TT

over tempera-

SENSE

should not be

V

TT

VTTis the regulated output that is used to terminate the bus

resistors. It is capable of sinking and sourcing current while

regulating the output precisely to V

/ 2. The LP2994 is

DDQ

designed to handle peak transient currents of up to +/- 3A

with excellent load regulation. The maximum continuous

current is a function of AVIN and PVIN and several curves

can be seen in the Typical Performance Characteristics section. If a transient is expected to last above the maximum

continuous current rating for a significant amount of time,

then the bulk output capacitor should be sized large enough

to prevent an excessive voltage drop. Despite the fact that

the LP2994 is designed to handle large transient output

currents it is not capable of handling these for long durations

under all conditions. The reason for this is that the SO-8

package is not able to thermally dissipate an infinite amount

of heat as a result of internal power loss. If large currents are

required for longer durations, then care should be taken to

ensure that the maximum junction temperature is not exceeded. Proper thermal de-rating should always be used

(Please refer to the Thermal Dissipation section).

Component Selections

INPUT CAPACITOR

The LP2994 does not require a capacitor for input stability,

but it is recommended for improved performance during

large load transients to prevent the input rail from dropping.

The input capacitor should be located as close as possible to

the PVIN pin. Several recommendations exist dependent on

the application required. Atypical value recommended for AL

electrolytic capacitors is 47uF. Ceramic capacitors can also

be used, a value in the range of 10uF with X5R dielectric or

better would be an ideal choice. The input capacitance can

be reduced if the LP2994 is placed close to the bulk capacitance from the output of the 2.5V DC-DC converter. If the two

supply rails (AVIN and PVIN) are separated then the 47uF

capacitor should be placed as close to possible to the PVIN

rail. An additional 0.1uF ceramic capacitor can be placed on

the AVIN rail to prevent excessive noise from coupling into

the device.

OUTPUT CAPACITOR

The LP2994 has been designed to be insensitive of output

capacitor size or ESR (Equivalent Series Resistance). This

allows the flexibility to use any capacitor desired. The choice

for output capacitor will be determined solely on the application and the requirements for load transient response of VTT.

As a general recommendation, the output capacitor should

be sized above 100uF with a low ESR for SSTL applications

with DDR-SDRAM. The value of ESR should be determined

by the maximum current spikes expected and the extent at

which the output voltage is allowed to droop. Several capacitor options are available on the market and a few of these

are highlighted below:

AL - It should be noted that many aluminum electrolytics only

specify impedance at a frequency of 120Hz, which indicates

they have poor high frequency performance. Only aluminum

electrolytics that have an impedance specified at a higher

frequency (approximately 100kHz) should be used for the

LP2994. To improve the ESR several AL electrolytics can be

combined in parallel for an overall reduction. An important

note to be aware of is the extent at which the ESR will

change over temperature. Aluminum electrolytic capacitors

can have their ESR rapidly increase at cold temperatures.

www.national.com 8

Page 9

LP2994

Component Selections (Continued)

Ceramic - Ceramic capacitors typically have a low capacitance, in the range of 10 to 100uF range, but they have

excellent AC performance for bypassing noise because of

very low ESR (typically less than 10mOhm). However, some

dielectric types have poor capacitance characteristics as a

function of voltage and temperature. Because of the typically

low value of capacitance it is recommended to use ceramic

capacitors in parallel with another capacitor such as an

aluminum electrolytic. A dielectric of X5R or better is recommended for all ceramic capacitors.

Hybrid - Several hybrid capacitors such as OS-CON and SP

are available from several manufacturers. These offer a

large capacitance while maintaining a low ESR. These are

the best solution when size and performance are critical,

although their cost is typically higher than other capacitors.

Thermal Dissipation

Since the LP2994 is a linear regulator any current flow from

will result in internal power dissipation generating heat.

V

TT

To prevent damaging the part from exceeding the maximum

allowable junction temperature, care should be taken to

derate the part dependent on the maximum expected ambient temperature and power dissipation. The maximum allowable internal temperature rise (T

given the maximum ambient temperature (T

application and the maximum allowable junction temperature

).

(T

Jmax

T

Rmax=TJmax−TAmax

From this equation, the maximum power dissipation (PD)of

the part can be calculated:

P

Dmax=TRmax

The θJAof the LP2994 will be dependent on several variables: the package used; the thickness of copper; the number of vias and the airflow. For instance, the θ

is 163˚C/W with the package mounted to a standard 8x4

2-layer board with 1oz. copper, no airflow, and 0.5W dissipation at room temperature. This value can be reduced to

151.2˚C/W by changing to a 3x4 board with 2 oz. copper that

is the JEDEC standard. Figure 3 shows how the θ

with airflow for the two boards mentioned.

) can be calculated

Rmax

Amax

/ θ

JA

of the SO-8

JA

)ofthe

varies

JA

Additional improvements can be made by the judicious use

of vias to connect the part and dissipate heat to an internal

ground plane. Using larger traces and more copper on the

top side of the board can also help. With careful layout, it is

possible to reduce the θ

further than the nominal values

JA

shown in Figure 3.

Optimizing the θ

and placing the LP2994 in a section of a

JA

board exposed to lower ambient temperature allows the part

to operate with higher power dissipation. The internal power

dissipation can be calculated by summing the three main

sources of loss: output current at V

sourcing, and quiescent current at AVIN and V

, either sinking or

TT

DDQ

. During

the active state (when Shutdown is not held low) the total

internal power dissipation can be calculated from the following equations:

P

D=PAVIN+PVDDQ+PVTT

where,

P

AVIN=IAVINxVAVIN

P

VDDQ=VVDDQxIVDDQ=VVDDQ

2

xR

VDDQ

To calculate the maximum power dissipation at VTT, both

sinking and sourcing current conditions at V

need to be

TT

examined. Although only one equation will add into the total,

cannot source and sink current simultaneously.

V

TT

P

VTT=VVTTxILOAD

(Sinking)

or

P

VTT

=(V

PVIN-VVTT

)xI

LOAD

(Sourcing)

The power dissipation of the LP2994 can also be calculated

during the shutdown state. During this condition the output

will tri-state, therefore that term in the power equation

V

TT

will disappear as it cannot sink or source any current (leakage is negligible). The only losses during shutdown will be

the reduced quiescent current at AVIN and the constant

impedance that is seen at the V

P

D=PAVIN+PVDDQ

DDQ

pin.

Where,

P

AVIN=IAVINxVAVIN

P

VDDQ=VVDDQxIVDDQ=VVDDQ

2

xR

VDDQ

FIGURE 3. θJAvs Airflow

20045928

www.national.com9

Page 10

Typical Application Circuits

Several different application circuits have been shown in Figure 4 through Figure 13 to illustrate some of the options that are

LP2994

possible in configuring the LP2994. Graphs of the individual circuit performance can be found in the Typical Performance

Characteristics section in the beginning of the datasheet. These curves illustrate how the maximum output current is affected by

changes in AVIN and PVIN.

SSTL-2 APPLICATIONS

For the majority of applications that implement the SSTL-2 termination scheme, it is recommended to connect all the input rails

to the 2.5V rail. This provides an optimal trade-off between power dissipation and component count and selection. An example

of this circuit can be seen in Figure 4.

20045904

FIGURE 4. Recommended SSTL-2 Implementation

If power dissipation or efficiency is a major concern then the LP2994 has the ability to operate on split power rails. The output

stage (PVIN) can be operated on a lower rail such as 1.8V and the analog circuitry (AVIN) can be connected to a higher rail such

as 2.5V, 3.3V or 5V. This allows the internal power dissipation to be lowered when sourcing current from VTT. The disadvantage

of this circuit is that the maximum continuous current is reduced because of the lower rail voltage, although it is adequate for all

motherboard SSTL-2 applications. Increasing the output capacitance can also help if periods of large load transients will be

encountered.

20045905

FIGURE 5. Lower Power Dissipation SSTL-2 Implementation

The third option for SSTL-2 applications in the situation that a 1.8V rail is not available and it is not desirable to use 2.5V, is to

connect the LP2994 power rail to 3.3V. In this situation AVIN will be limited to operation on the 3.3V or 5V rail as PVIN can never

exceed AVIN. This configuration has the ability to provide the maximum continuous output current at the downside of higher

thermal dissipation. Care should be taken to prevent the LP2994 from experiencing large current levels which cause the junction

temperature to exceed the maximum. Because of this risk it is not recommended to supply the output stage with a voltage higher

than a nominal 3.3V rail.

www.national.com 10

Page 11

Typical Application Circuits (Continued)

20045906

FIGURE 6. SSTL-2 Implementation with higher voltage rails

DDR-II APPLICATIONS

With the separate V

memory. Figure 7 and Figure 8 show several implementations of recommended circuits with output curves displayed in the

Typical Performance Characteristics. Figure 7 shows the recommended circuit configuration for DDR-II applications. The output

stage is connected to the 1.8V rail and the AVIN pin can be connected to either a 3.3V or 5V rail.

pin and an internal resistor divider it is possible to use the LP2994 in applications utilizing DDR-II

DDQ

LP2994

20045907

FIGURE 7. Recommended DDR-II Termination

If it is not desirable to use the 1.8V rail it is possible to connect the output stage to a 3.3V rail. Care should be taken to not exceed

the maximum junction temperature as the thermal dissipation increases with lower V

output voltages. For this reason, it is not

TT

recommended to power PVIN off a rail higher than the nominal 3.3V. The advantage of this configuration is that it has the ability

to source and sink a higher maximum continuous current.

20045908

FIGURE 8. DDR-II Termination with higher voltage rails

If standards other than SSTL-2 are required, such as SSTL-3, it may be necessary to use a different scaling factor than 0.5 times

for regulating the output voltage. Several options are available to scale the output to any voltage required. One method is

V

DDQ

to level shift the output by using feedback resistors from V

10. Figure 9 shows how to use two resistors to level shift V

exact voltage at V

the following equation can be used.

TT

V

=(V

TT

to the V

TT

above the internal reference voltage of V

TT

/2)x(1+R1/R2)

DDQ

pin. This has been illustrated in Figure 9 and Figure

SENSE

/2. To calculate the

DDQ

www.national.com11

Page 12

Typical Application Circuits (Continued)

LP2994

FIGURE 9. Increasing VTTby Level Shifting

20045909

Conversely, the R2 resistor can be placed between V

voltage of V

=(V

V

TT

/2. The equations relating VTTand the resistors can be seen below:

DDQ

/2)x(1-R1/R2)

DDQ

SENSE

and V

to shift the VTToutput lower than the internal reference

DDQ

20045910

FIGURE 10. Decreasing VTTby Level Shifting

REFERENCE VOLTAGE

DDR-SDRAM and the motherboard chipsets usually require a reference voltage which tracks V

most applications it is advisable to use two equal resistors as a resistor divider. This prevents long V

. To implement this feature in

TT

traces from running

REF

across the motherboard picking up noise which can interfere with performance. However, in a few applications it may be desirable

to use the V

to create a V

of V

TT

output on the LP2994 to generate the V

TT

signal. Typically, the reference voltage required by chipsets and memory is well under 1µA combined,

REF

signal. The can be accomplished by using an RC filter on the output

REF

therefore, a fairly large resistor such as 1kΩ or larger can be used. A recommended capacitor would be a 1uF X7R ceramic

capacitor.

FIGURE 11. Creating a Reference Voltage for Memory and Chipsets

www.national.com 12

20045911

Page 13

Typical Application Circuits (Continued)

OUTPUT CAPACITOR SELECTION

For applications utilizing the LP2994 to terminate SSTL-2 I/O signals the typical application circuit shown in Figure 12 can be

implemented.

20045912

FIGURE 12. Typical SSTL-2 Application Circuit

This circuit permits termination in a minimum amount of board space and component count. Capacitor selection can be varied

depending on the number of lines terminated and the maximum load transient. However, with motherboards and other

applications where V

frequency decoupling. Figure 13 shown below depicts an example circuit where 2 bulk output capacitors could be situated at both

ends of the V

TT

is distributed across a long plane it is advisable to use multiple bulk capacitors and addition to high

TT

plane for optimal placement. Large aluminum electrolytic capacitors are used for their low ESR and low cost.

LP2994

20045913

FIGURE 13. Typical SSTL-2 Application Circuit for Motherboards

In most PC applications an extensive amount of decoupling is required because of the long interconnects encountered with the

DDR-SDRAM DIMMs mounted on modules. As a result bulk aluminum electrolytic capacitors in the range of 1000uF are typically

used.

PCB Layout Considerations

1. The input capacitor for the power rail should be placed

as close as possible to the PVIN pin.

2. V

at the point where regulation is required. For motherboard applications an ideal location would be at the

center of the termination bus.

3. V

at either the DIMM or the Chipset. This provides the

should be connected to the VTTtermination bus

SENSE

can be connected remotely to the V

DDQ

DDQ

rail input

age. Numerous vias from the ground connection to the

internal ground plane will help. Additionally these can be

located underneath the package if manufacturing standards permit.

5. Care should be taken when routing the V

SENSE

avoid noise pickup from switching I/O signals. A 0.1uF

ceramic capacitor located close to the V

SENSE

be used to filter any unwanted high frequency signal.

This can be an issue especially if long V

SENSE

used.

trace to

can also

traces are

most accurate point for creating the reference voltage.

4. For improved thermal performance excessive top side

copper should be used to dissipate heat from the pack-

www.national.com13

Page 14

Physical Dimensions inches (millimeters)

unless otherwise noted

LP2994 DDR Termination Regulator

8-Lead Small Outline Package (M8)

NS Package Number M08

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor manufactures products and uses packing materials that meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain

no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

Leadfree products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...