Page 1

December 2006

LMV221

50 MHz to 3.5 GHz 40 dB Logarithmic Power Detector for

CDMA and WCDMA

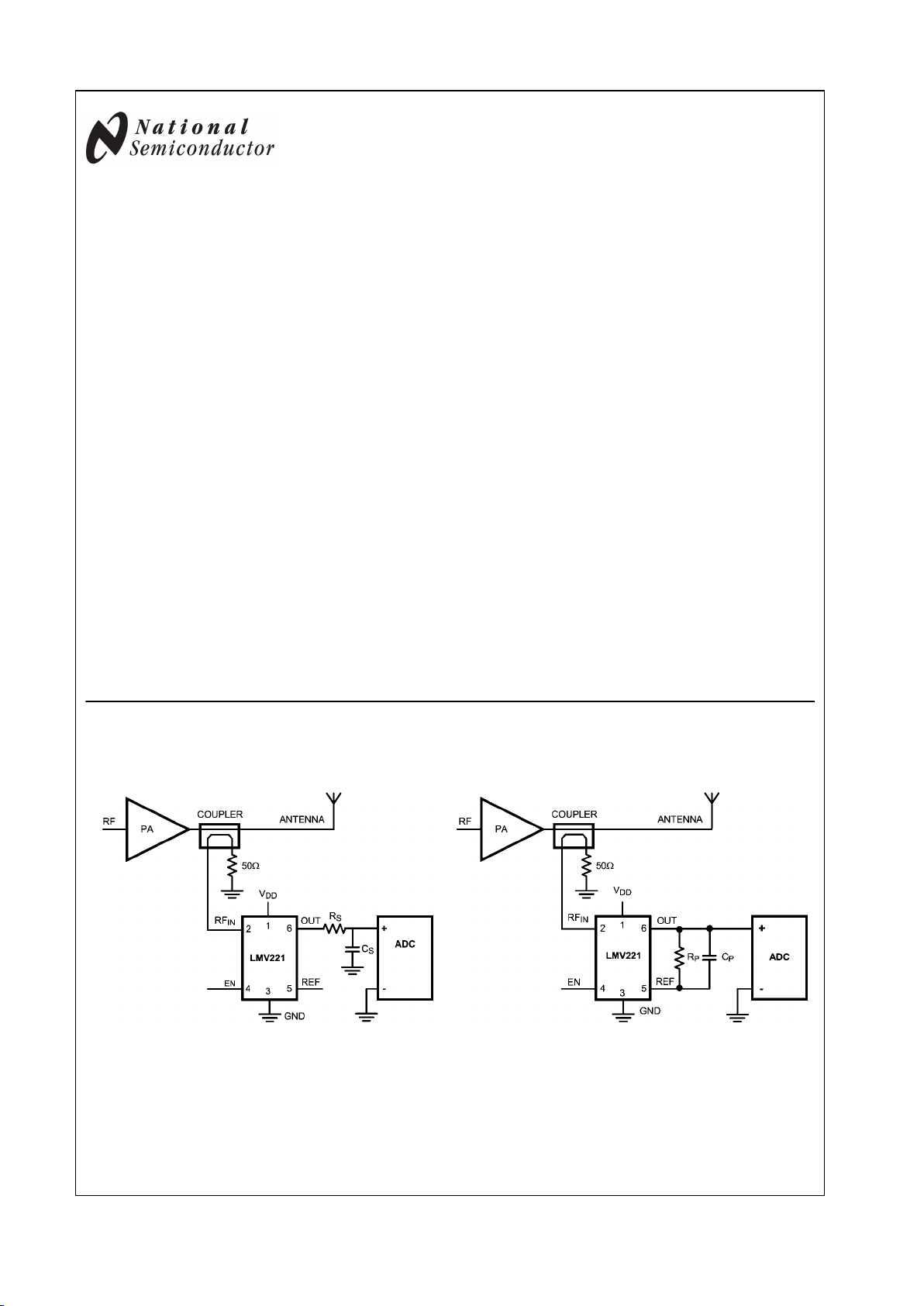

General Description

The LMV221 is a 40 dB RF power detector intended for use

in CDMA and WCDMA applications. The device has an RF

frequency range from 50 MHz to 3.5 GHz. It provides an accurate temperature and supply compensated output voltage

that relates linearly to the RF input power in dBm. The circuit

operates with a single supply from 2.7V to 3.3V.

The LMV221 has an RF power detection range from −45 dBm

to −5 dBm and is ideally suited for direct use in combination

with a 30 dB directional coupler. Additional low-pass filtering

of the output signal can be realized by means of an external

resistor and capacitor. Figure (a) shows a detector with an

additional output low pass filter. The filter frequency is set with

RS and CS.

Figure (b) shows a detector with an additional feedback low

pass filter. Resistor RP is optional and will lower the Trans

impedance gain (R

TRANS

). The filter frequency is set with

CP//C

TRANS

and RP//R

TRANS

.

The device is active for Enable = High, otherwise it is in a low

power consumption shutdown mode. To save power and prevent discharge of an external filter capacitance, the output

(OUT) is high-impedance during shutdown.

The LMV221 power detector is offered in the small 2.2 mm x

2.5 mm x 0.8 mm LLP package.

Features

■

40 dB linear in dB power detection range

■

Output voltage range 0.3 to 2V

■

Shutdown

■

Multi-band operation from 50 MHz to 3.5 GHz

■

0.5 dB accurate temperature compensation

■

External configurable output filter bandwidth

■

2.2 mm x 2.5 mm x 0.8 mm LLP 6 package

Applications

■

UMTS/CDMA/WCDMA RF power control

■

GSM/GPRS RF power control

■

PA modules

■

IEEE 802.11b, g (WLAN)

Typical Application

(a) LMV221 with output RC Low Pass Filter

20173771

(b) LMV221 with feedback (R)C Low Pass Filter

20173704

© 2007 National Semiconductor Corporation 201737 www.national.com

LMV221 50 MHz to 3.5 GHz 40 dB Logarithmic Power Detector for CDMA and WCDMA

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage

VDD - GND

3.6V

RF Input

Input power 10 dBm

DC Voltage 400 mV

Enable Input Voltage VSS - 0.4V < V

EN

< VDD + 0.4V

ESD Tolerance (Note 2)

Human Body Model 2000V

Machine Model 200V

Charge Device Model 2000V

Storage Temperature

Range −65°C to 150°C

Junction Temperature

(Note 3) 150°C

Maximum Lead Temperature

(Soldering,10 sec) 260°C

Operating Ratings (Note 1)

Supply Voltage 2.7V to 3.3V

Temperature Range −40°C to +85°C

RF Frequency Range 50 MHz to 3.5 GHz

RF Input Power Range (Note 5) −45 dBm to −5 dBm

−58 dBV to −18 dBV

Package Thermal Resistance θ

JA

(Note 3) 86.6°C/W

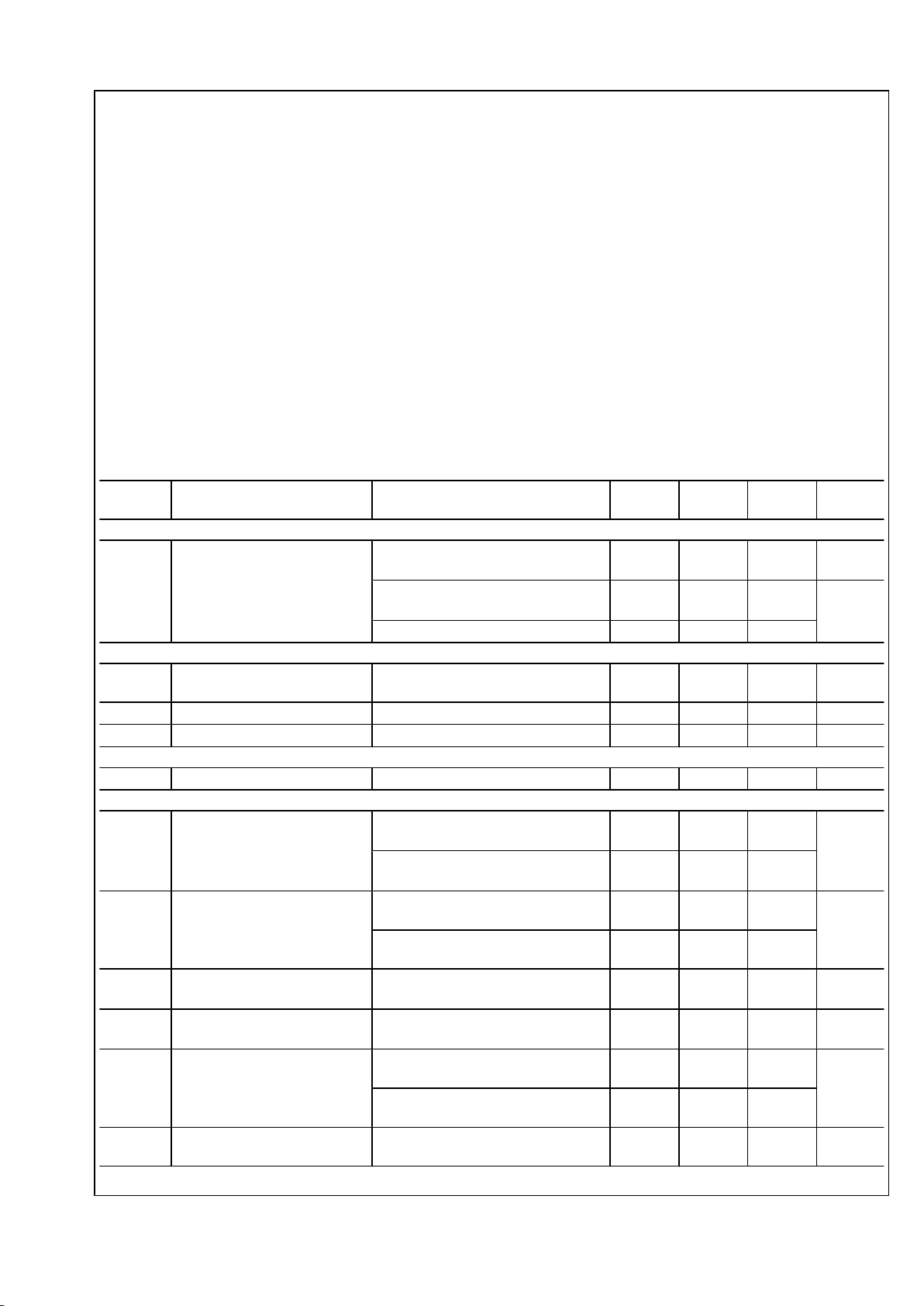

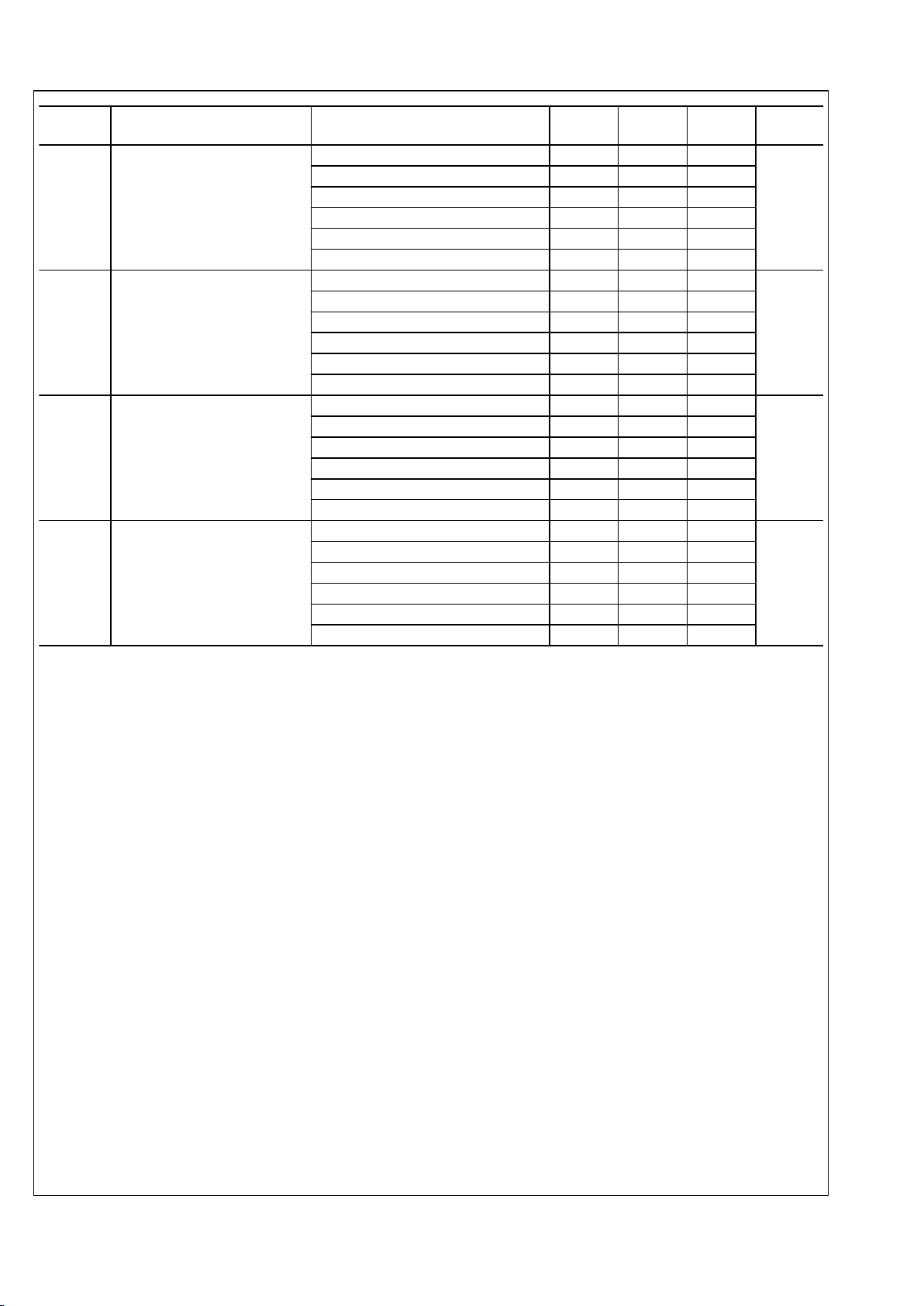

2.7 V DC and AC Electrical Characteristics

Unless otherwise specified, all limits are guaranteed to; TA = 25°C, VDD = 2.7V, RF input frequency f = 1855 MHz CW (Continuous

Wave, unmodulated). Boldface limits apply at the temperature extremes (Note 4).

Symbol Parameter Condition Min

(Note 6)

Typ

(Note 7)

Max

(Note 6)

Units

Supply Interface

I

DD

Supply Current Active mode: EN = High, no Signal

present at RFIN.

6.5

5

7.2 8.5

10

mA

Shutdown: EN = Low, no Signal present

at RFIN.

0.5 3

4

μA

EN = Low: PIN = 0 dBm (Note 8) 10

Logic Enable Interface

V

LOW

EN Logic Low Input Level

(Shutdown mode)

0.6 V

V

HIGH

EN Logic High Input Level 1.1 V

I

EN

Current into EN Pin 1

μA

RF Input Interface

R

IN

Input Resistance 40 47.1 60

Ω

Output Interface

V

OUT

Output Voltage Swing From Positive Rail, Sourcing,

V

REF

= 0V, I

OUT

= 1 mA

16 40

50

mV

From Negative Rail, Sinking,

V

REF

= 2.7V, I

OUT

= 1 mA

14 40

50

I

OUT

Output Short Circuit Current Sourcing, V

REF

= 0V, V

OUT

= 2.6V 3

2.7

5.4

mA

Sinking, V

REF

= 2.7V, V

OUT

= 0.1V 3

2.7

5.7

BW Small Signal Bandwidth No RF input signal. Measured from REF

input current to V

OUT

450 kHz

R

TRANS

Output Amp Transimpedance

Gain

No RF Input Signal, from I

REF

to V

OUT

,

DC

35 42.7 55

kΩ

SR Slew Rate Positive, V

REF

from 2.7V to 0V 3

2.7

4.1

V/µs

Negative, V

REF

from 0V to 2.7V 3

2.7

4.2

R

OUT

Output Impedance

(Note 8)

No RF Input Signal, EN = High. DC

measurement

0.6 5

6

Ω

www.national.com 2

LMV221

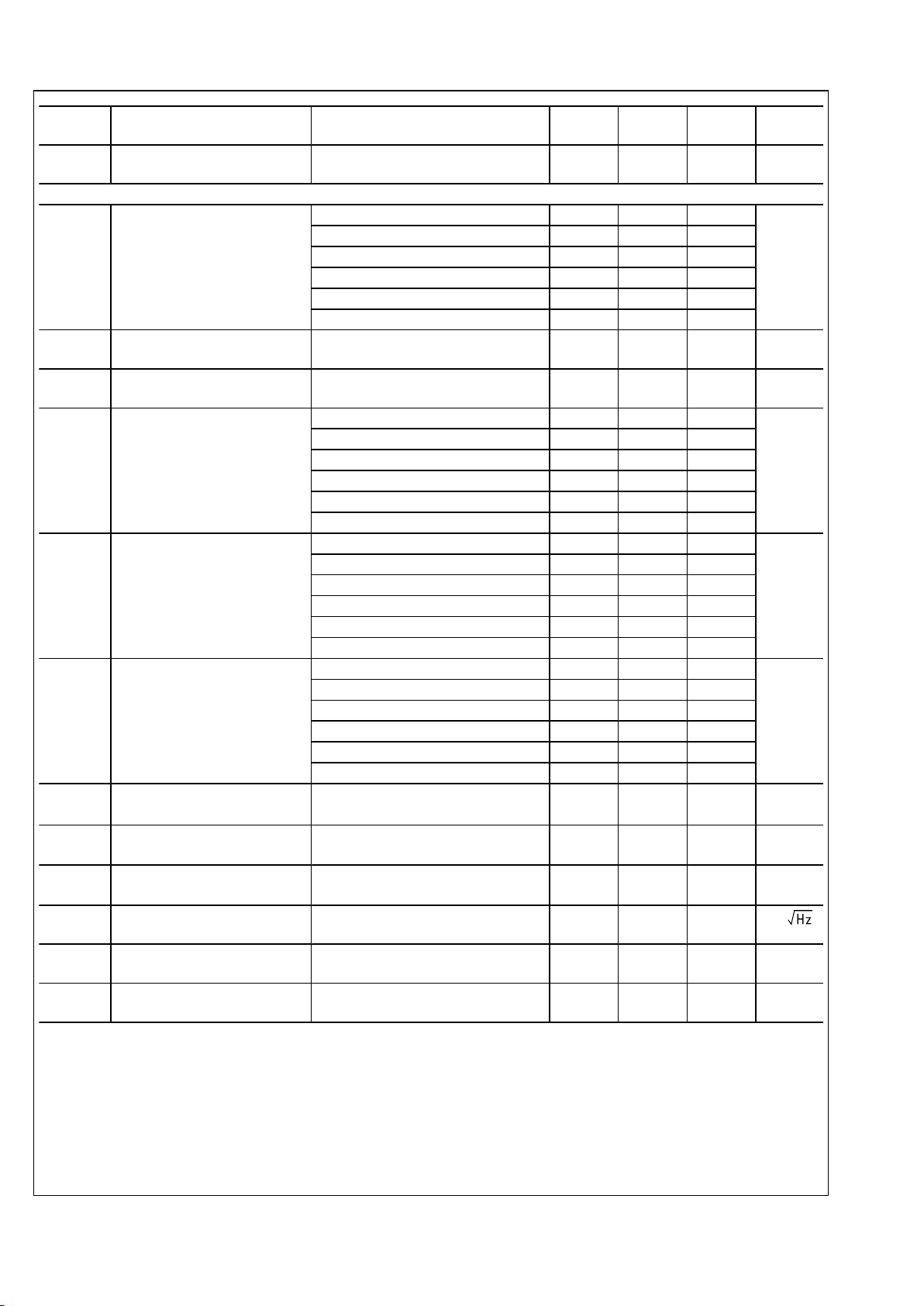

Page 3

Symbol Parameter Condition Min

(Note 6)

Typ

(Note 7)

Max

(Note 6)

Units

I

OUT,SD

Output Leakage Current in

Shutdown mode

EN = Low, V

OUT

= 2.0V 21 300

500

nA

RF Detector Transfer

V

OUT,MAX

Maximum Output Voltage

PIN= −5 dBm

(Note 8)

f = 50 MHz 1.67 1.76 1.83

V

f = 900 MHz 1.67 1.75 1.82

f = 1855 MHz 1.53 1.61 1.68

f = 2500 MHz 1.42 1.49 1.57

f = 3000 MHz 1.33 1.40 1.48

f = 3500 MHz 1.21 1.28 1.36

V

OUT,MIN

Minimum Output Voltage

(Pedestal)

No input Signal 175

142

250 350

388

mV

ΔV

OUT,MIN

Pedestal Variation over

temperature

No Input Signal, Relative to 25°C −20 20 mV

ΔV

OUT

Output Voltage Range

PIN from −45 dBm to −5 dBm

(Note 8)

f = 50 MHz 1.37 1.44 1.52

V

f = 900 MHz 1.34 1.40 1.47

f = 1855 MHz 1.24 1.30 1.37

f = 2500 MHz 1.14 1.20 1.30

f = 3000 MHz 1.07 1.12 1.20

f = 3500 MHz 0.96 1.01 1.09

K

SLOPE

Logarithmic Slope

(Note 8)

f = 50 MHz 39 40.5 42

mV/dB

f = 900 MHz 36.7 38.5 40

f = 1855 MHz 34.4 35.7 37.1

f = 2500 MHz 32.6 33.8 35.2

f = 3000 MHz 31 32.5 34

f = 3500 MHz 30 31.9 33.5

P

INT

Logarithmic Intercept

(Note 8)

f = 50 MHz −50.4 −49.4 −48.3

dBm

f = 900 MHz −54.1 −52.8 −51.6

f = 1855 MHz −53.2 −51.7 −50.2

f = 2500 MHz −51.8 −50 −48.3

f = 3000 MHz −51.1 −48.9 −46.6

f = 3500 MHz −49.6 −46.8 −44.1

t

ON

Turn-on Time

(Note 8)

No signal at PIN, Low-High transition

EN. V

OUT

to 90%

8 10

12

µs

t

R

Rise Time (Note 9) PIN = No signal to 0 dBm, V

OUT

from 10%

to 90%

2 12 µs

t

F

Fall Time (Note 9) PIN = 0 dBm to no signal, V

OUT

from 90%

to 10%

2 12 µs

e

n

Output Referred Noise

(Note 9)

PIN = −10 dBm, at 10 kHz 1.5

µV/

v

N

Output referred Noise

(Note 8)

Integrated over frequency band

1 kHz - 6.5 kHz

100 150

µV

RMS

PSRR Power Supply Rejection Ratio

(Note 9)

PIN = −10 dBm, f = 1800 MHz 55 60 dB

3 www.national.com

LMV221

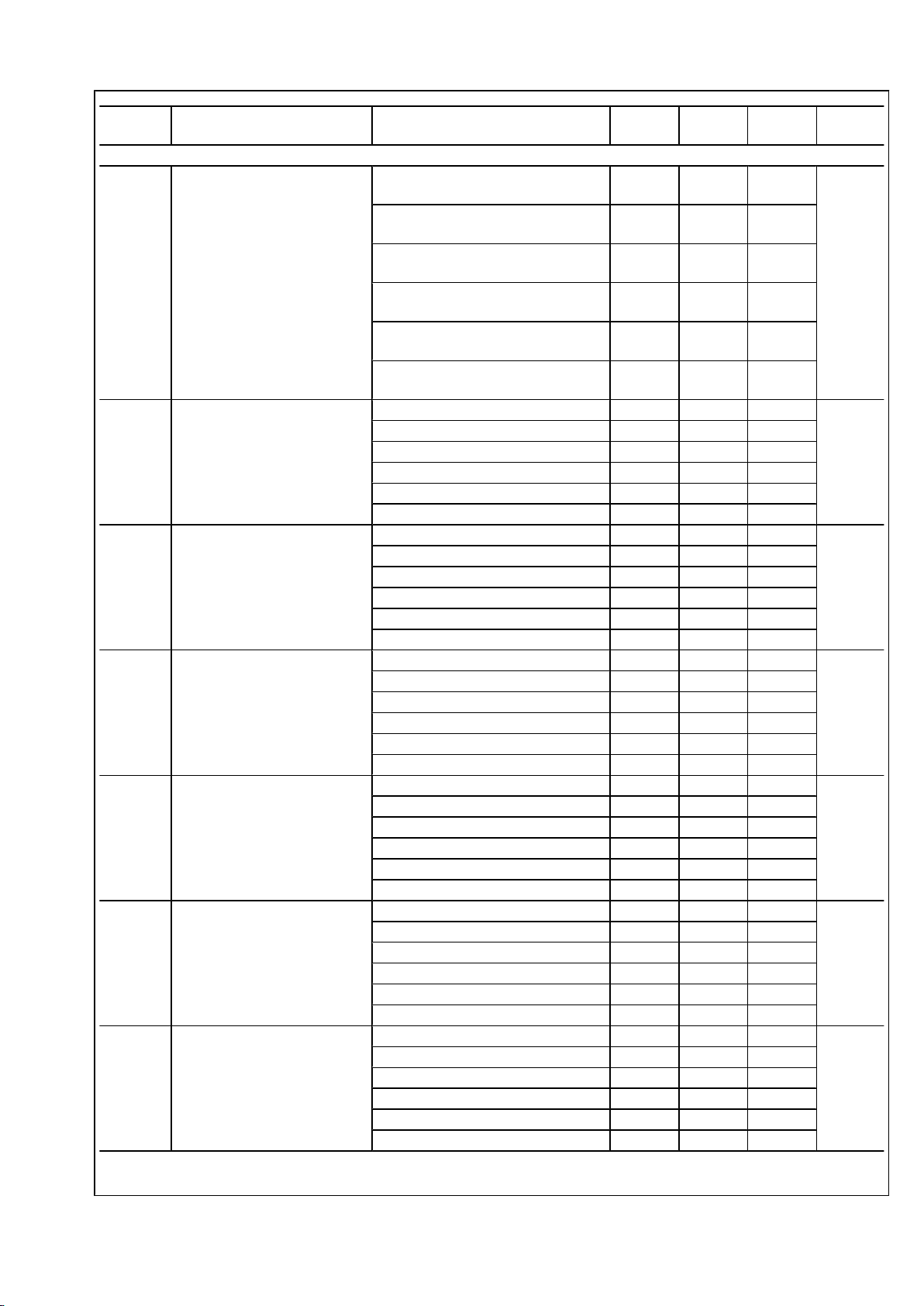

Page 4

Symbol Parameter Condition Min

(Note 6)

Typ

(Note 7)

Max

(Note 6)

Units

Power Measurement Performance

E

LC

Log Conformance Error

(Note 8)

−40 dBm ≤ PIN ≤ −10 dBm

f = 50 MHz −0.60

−1.10

0.53 0.56

1.3

dB

f = 900 MHz −0.70

−1.24

0.46 0.37

1.1

f = 1855 MHz −0.40

−1.1

0.48 0.24

1.1

f = 2500 MHz −0.43

−1.0

0.51 0.56

1.1

f = 3000 MHz −0.87

−1.2

0.56 1.34

1.6

f = 3500 MHz −1.73

−2.0

0.84 2.72

2.7

E

VOT

Variation over Temperature

(Note 8)

−40 dBm ≤ PIN ≤ −10 dBm

f = 50 MHz −1.1 0.4 1.4

dB

f = 900 MHz −1.0 0.38 1.27

f = 1855 MHz −1.1 0.44 1.31

f = 2500 MHz −1.1 0.48 1.15

f = 3000 MHz −1.2 0.5 0.98

f = 3500 MHz –1.2 0.62 0.85

E

1 dB

Measurement Error for a 1 dB

input power step (Note 8)

−40 dBm ≤ PIN ≤ −10 dBm

f = 50 MHz −0.06 0.069

dB

f = 900 MHz −0.056 0.056

f = 1855 MHz −0.069 0.069

f = 2500 MHz −0.084 0.084

f = 3000 MHz −0.092 0.092

f = 3500 MHz −0.10 0.10

E

10 dB

Measurement Error for a 10 dB

input power step (Note 8)

−40 dBm ≤ PIN ≤ −10 dBm

f = 50 MHz −0.65 0.57

dB

f = 900 MHz −0.75 0.58

f = 1855 MHz −0.88 0.72

f = 2500 MHz −0.86 0.75

f = 3000 MHz −0.85 0.77

f = 3500 MHz −0.76 0.74

S

T

Temperature Sensitivity

−40°C < TA < 25°C (Note 8)

−40 dBm ≤ PIN ≤ −10 dBm

f = 50 MHz −15 −7 1

mdB/°C

f = 900 MHz −13.4 −6 1.5

f = 1855 MHz −14.1 −5.9 2.3

f = 2500 MHz −13.4 −4.1 5.2

f = 3000 MHz −11.7 −1.8 8

f = 3500 MHz −10.5 0.5 1.2

S

T

Temperature Sensitivity

25°C < TA < 85°C (Note 8)

−40 dBm ≤ PIN ≤ −10 dBm

f = 50 MHz −12.3 −6.7 −1.1

mdB/°C

f = 900 MHz −13.1 −6.7 −0.2

f = 1855 MHz −14.7 −7.1 0.42

f = 2500 MHz −15.9 −7.6 0.63

f = 3000 MHz −18 −8.5 1

f = 3500 MHz −21.2 −9.5 2.5

S

T

Temperature Sensitivity

−40°C < TA < 25°C, (Note 8)

PIN = −10 dBm

f = 50 MHz −15.8 −8.3 −0.75

mdB/°C

f = 900 MHz −14.2 −6 2.2

f = 1855 MHz −14.9 −7.4 2

f = 2500 MHz −14.5 −6.6 1.3

f = 3000 MHz −13 −4.9 3.3

f = 3500 MHz −12 −3.4 5.3

www.national.com 4

LMV221

Page 5

Symbol Parameter Condition Min

(Note 6)

Typ

(Note 7)

Max

(Note 6)

Units

S

T

Temperature Sensitivity

25°C < TA < 85°C, (Note 8)

PIN = −10 dBm

f = 50 MHz −12.4 −8.9 −5.3

mdB/°C

f = 900 MHz −13.7 −9.4 −5

f = 1855 MHz −14.6 −10 −5.6

f = 2500 MHz −15.2 −10.8 −6.5

f = 3000 MHz −16.5 −12.2 −7.9

f = 3500 MHz −18.1 −13.5 −9

P

MAX

Maximum Input Power for

ELC = 1 dB(Note 8)

f = 50 MHz −8.85 −5.9

dBm

f = 900 MHz −9.3 −6.1

f = 1855 MHz −8.3 −5.5

f = 2500 MHz −6 −4.2

f = 3000 MHz −5.4 −3.7

f = 3500 MHz −7.2 −2.7

P

MIN

Minimum Input Power for

ELC = 1 dB (Note 8)

f = 50 MHz −40.3 −38.9

dBm

f = 900 MHz −44.2 −42.9

f = 1855 MHz −42.9 −41.2

f = 2500 MHz −40.4 −38.6

f = 3000 MHz −38.4 −35.8

f = 3500 MHz −35.3 −31.9

DR Dynamic Range for ELC = 1 dB

(Note 8)

f = 50 MHz 31.5 34.5

dB

f = 900 MHz 34.4 38.1

f = 1855 MHz 34 37.4

f = 2500 MHz 33.8 36.1

f = 3000 MHz 32.4 34.8

f = 3500 MHz 26.2 32.7

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see the Electrical Characteristics.

Note 2: Human body model, applicable std. MIL-STD-883, Method 3015.7. Machine model, applicable std. JESD22–A115–A (ESD MM std of JEDEC). FieldInduced Charge-Device Model, applicable std. JESD22–C101–C. (ESD FICDM std. of JEDEC)

Note 3: The maximum power dissipation is a function of T

J(MAX)

, θJA. The maximum allowable power dissipation at any ambient temperature is

PD = (T

J(MAX)

- TA)/θJA. All numbers apply for packages soldered directly into a PC board.

Note 4: Electrical Table values apply only for factory testing conditions at the temperature indicated. Factory testing conditions result in very limited self-heating

of the device such that TJ = TA. No guarantee of parametric performance is indicated in the electrical tables under conditions of internal self-heating where

TJ > TA.

Note 5: Power in dBV = dBm + 13 when the impedance is 50Ω.

Note 6: All limits are guaranteed by design or statistical analysis.

Note 7: Typical values represent the most likely parametric norm as determined at the time of characterization. Actual typical values may vary over time and will

also depend on the application and configuration. The typical values are not tested and are not guaranteed on shipped production material.

Note 8: All limits are guaranteed by design and measurements which are performed on a limited number of samples. Limits represent the mean ±3–sigma values.

The typical value represents the statistical mean value.

Note 9: This parameter is guaranteed by design and/or characterization and is not tested in production.

5 www.national.com

LMV221

Page 6

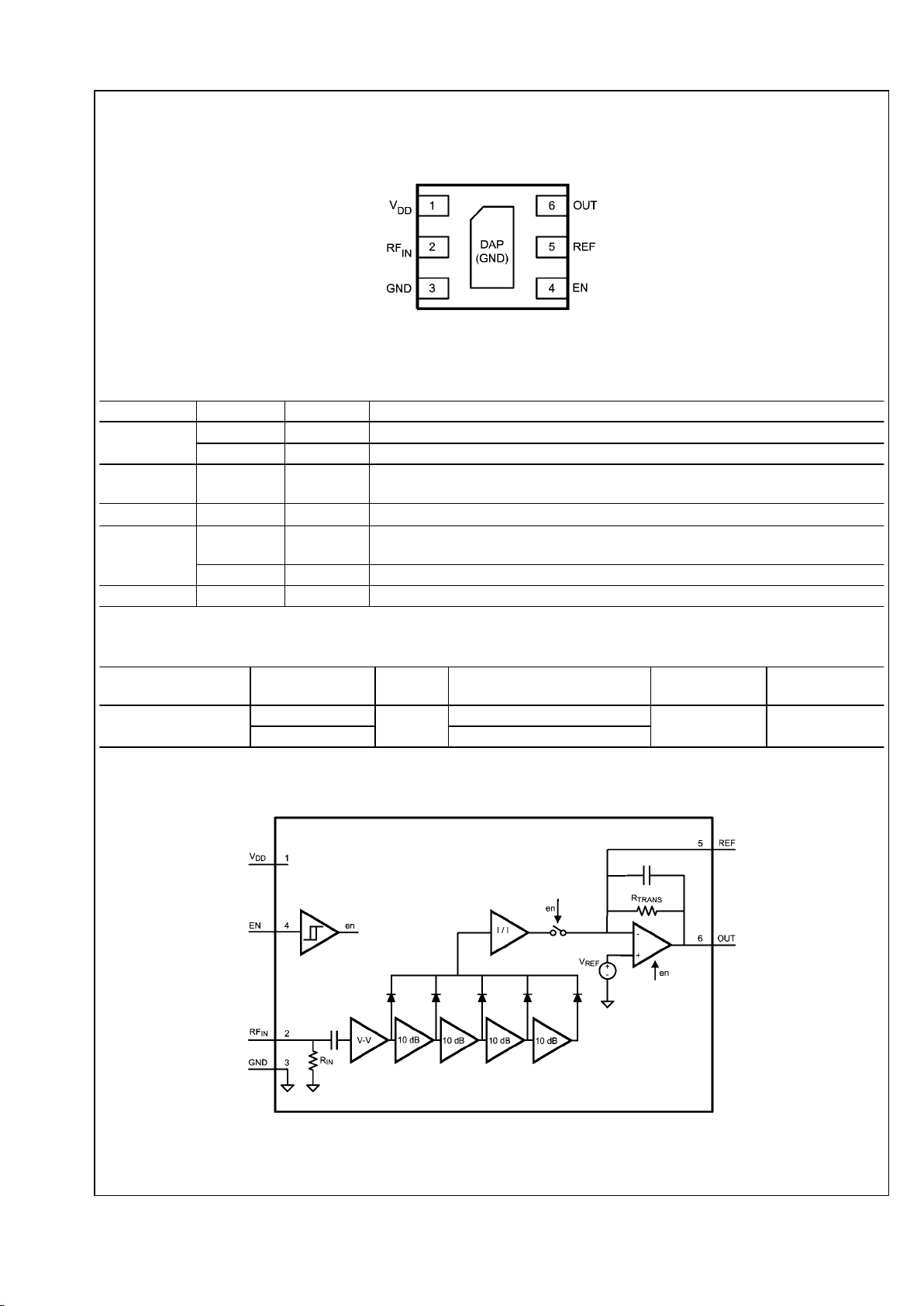

Connection Diagram

6-pin LLP

20173702

Top View

Pin Descriptions

LLP6 Name Description

Power Supply 1 V

DD

Positive Supply Voltage

3 GND Power Ground

Logic Input 4 EN The device is enabled for EN = High, and brought to a low-power shutdown mode for

EN = Low.

Analog Input 2 RF

IN

RF input signal to the detector, internally terminated with 50 Ω.

Output 5 REF Reference output, for differential output measurement (without pedestal). Connected to

inverting input of output amplifier.

6 OUT Ground referenced detector output voltage (linear in dB)

DAP GND Ground (needs to be connected)

Ordering Information

Package Part Number Package

Marking

Transport Media NSC Drawing Status

LLP-6

LMV221SD

A96

1k Units Tape and Reel

SDB06A Released

LMV221SDX 4.5k Units Tape and Reel

Block Diagram

20173703

LMV221

www.national.com 6

LMV221

Page 7

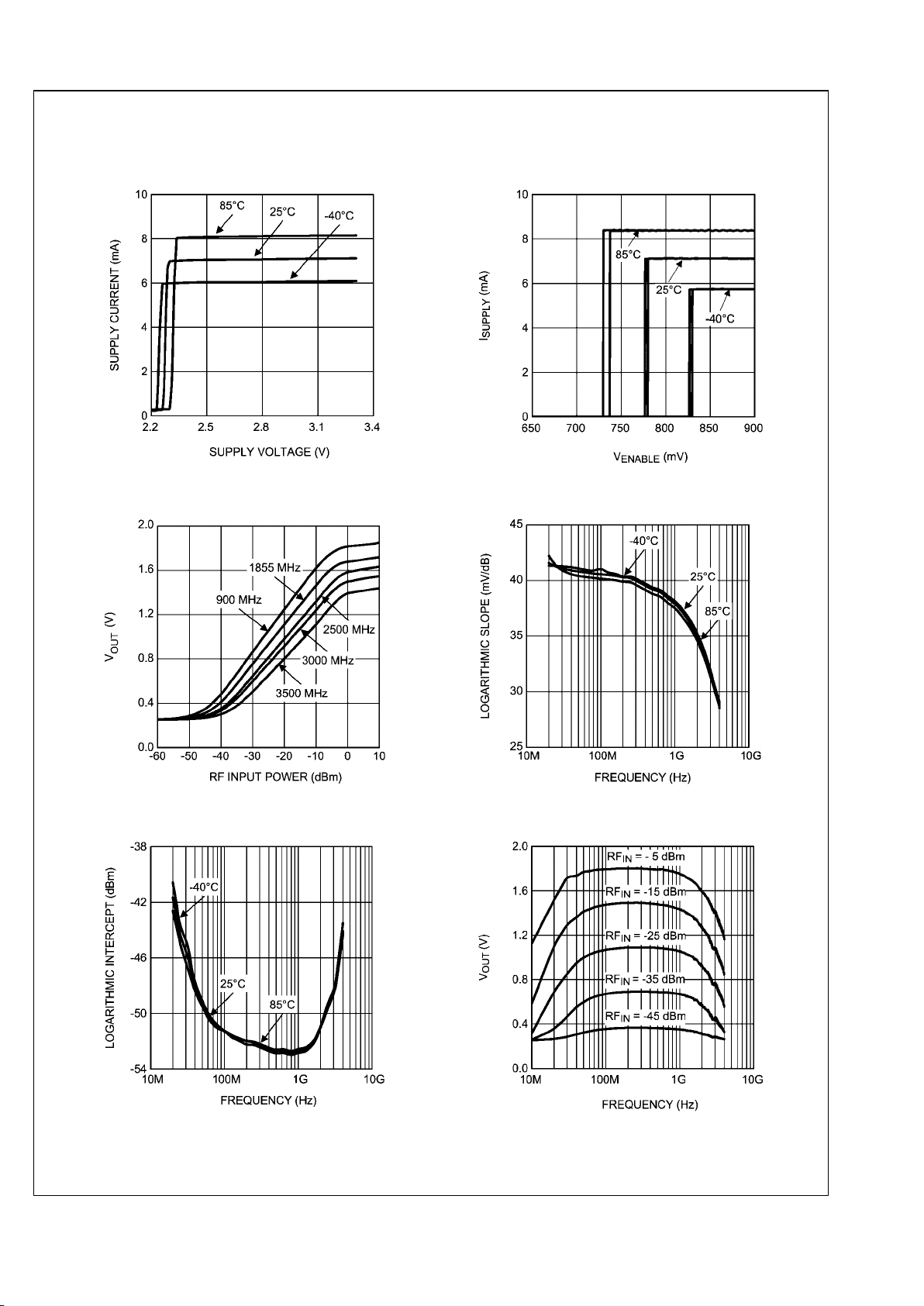

Typical Performance Characteristics Unless otherwise specified, V

DD

= 2.7V,

TA = 25°C, measured on a limited number of samples.

Supply Current vs. Supply Voltage

20173705

Supply Current vs. Enable Voltage

20173708

Output Voltage vs. RF input Power

20173712

Log Slope vs. Frequency

20173746

Log Intercept vs. Frequency

20173749

Output Voltage vs. Frequency

20173713

7 www.national.com

LMV221

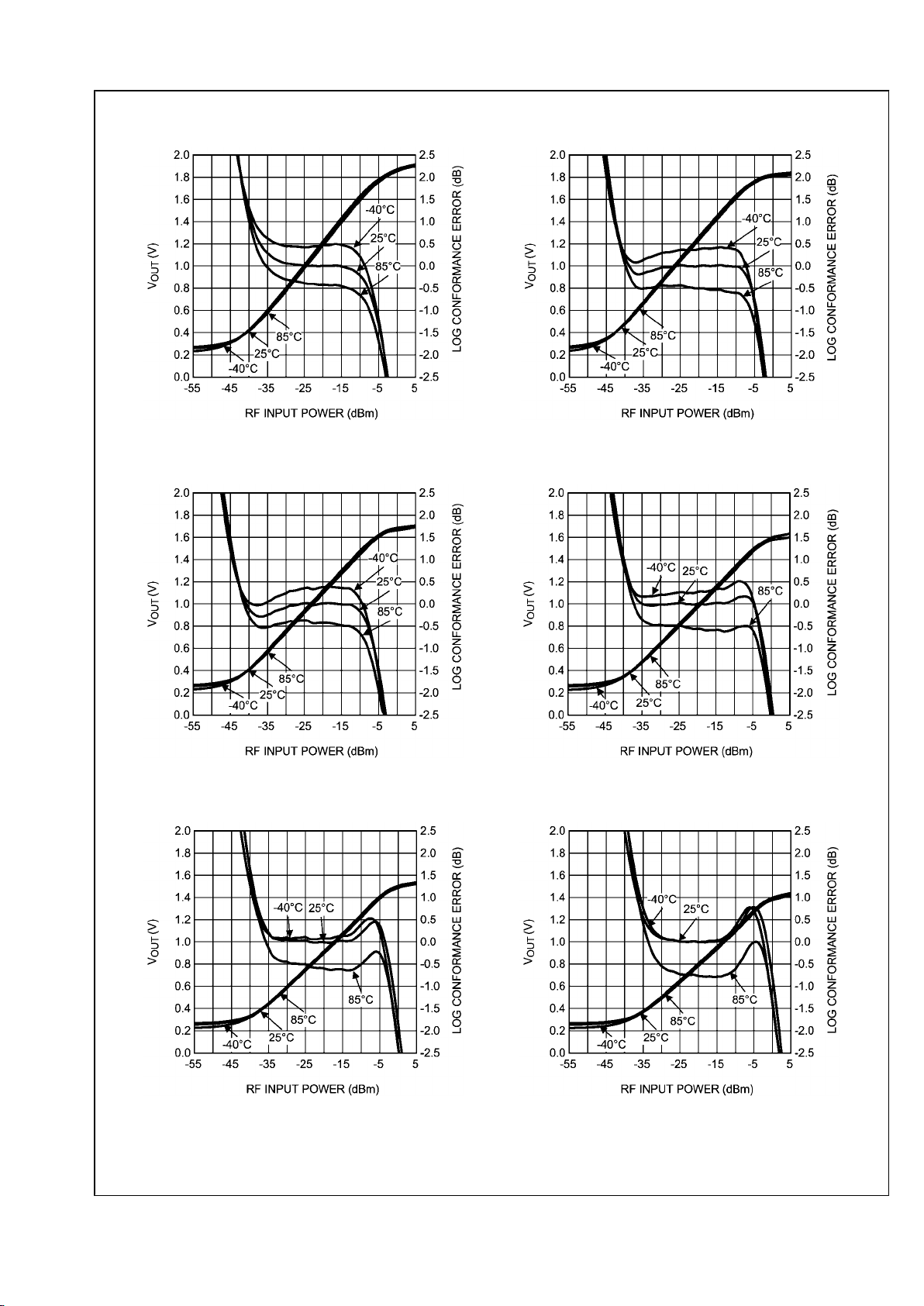

Page 8

Mean Output Voltage and Log Conformance Error vs.

RF Input Power at 50 MHz

20173714

Mean Output Voltage and Log Conformance Error vs.

RF Input Power at 900 MHz

20173716

Mean Output Voltage and Log Conformance Error vs.

RF Input Power at 1855 MHz

20173715

Mean Output Voltage and Log Conformance Error vs.

RF Input Power at 2500 MHz

20173717

Mean Output Voltage and Log Conformance Error vs.

RF Input Power at 3000 MHz

20173718

Mean Output Voltage and Log Conformance Error vs.

RF Input Power at 3500 MHz

20173719

www.national.com 8

LMV221

Page 9

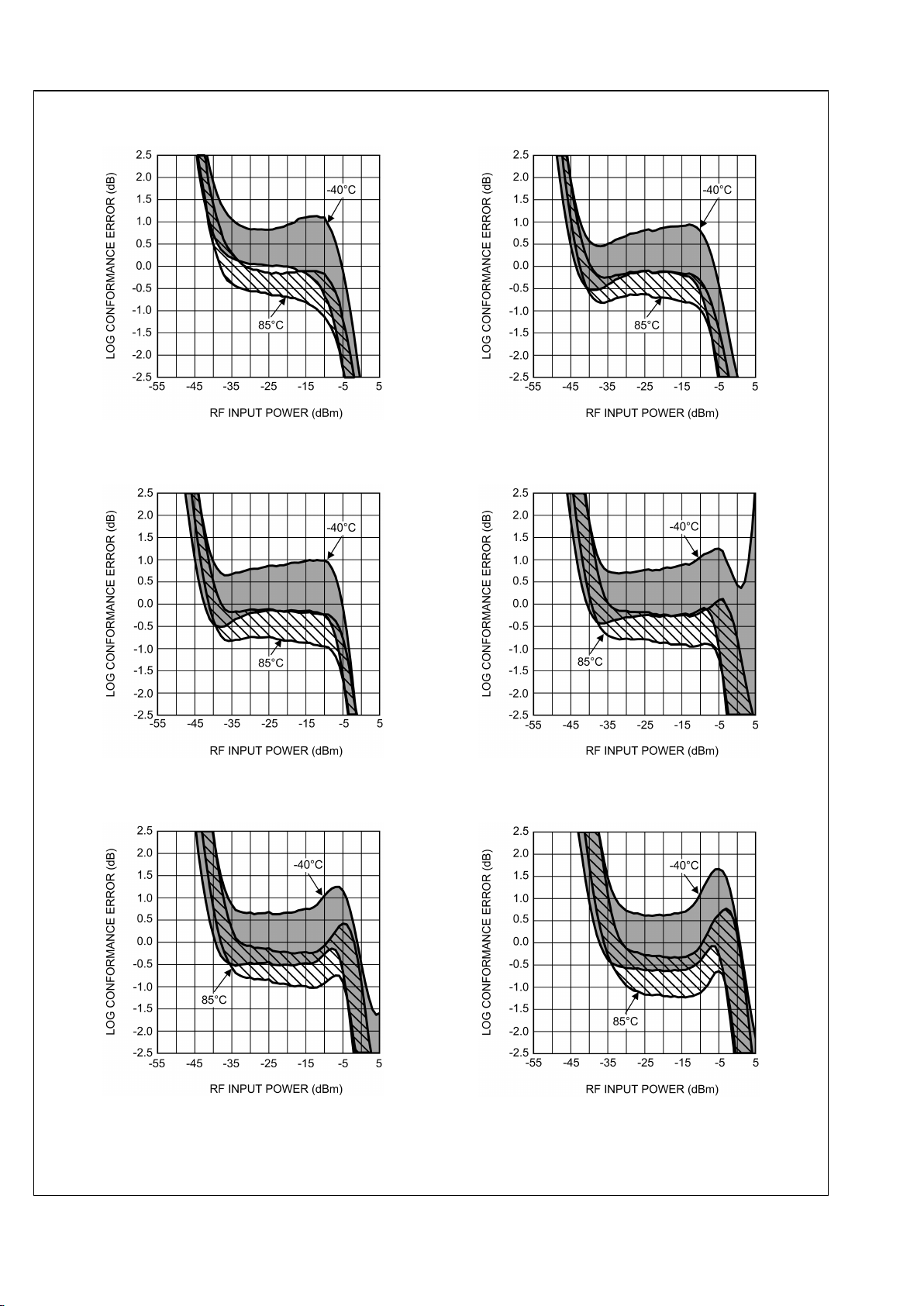

Log Conformance Error (Mean ±3 sigma) vs.

RF Input Power at 50 MHz

20173762

Log Conformance Error (Mean ±3 sigma) vs.

RF Input Power at 900 MHz

20173763

Log Conformance Error (Mean ±3 sigma) vs.

RF Input Power at 1855 MHz

20173764

Log Conformance Error (Mean ±3 sigma) vs.

RF Input Power at 2500 MHz

20173768

Log Conformance Error (Mean ±3 sigma) vs.

RF Input Power at 3000 MHz

20173769

Log Conformance Error (Mean ±3 sigma) vs.

RF Input Power at 3500 MHz

20173767

9 www.national.com

LMV221

Page 10

Mean Temperature Drift Error vs.

RF Input Power at 50 MHz

20173720

Mean Temperature Drift Error vs.

RF Input Power at 900 MHz

20173721

Mean Temperature Drift Error vs.

RF Input Power at 1855 MHz

20173722

Mean Temperature Drift Error vs.

RF Input Power at 2500 MHz

20173723

Mean Temperature Drift Error vs.

RF Input Power at 3000 MHz

20173724

Mean Temperature Drift Error vs.

RF Input Power at 3500 MHz

20173725

www.national.com 10

LMV221

Page 11

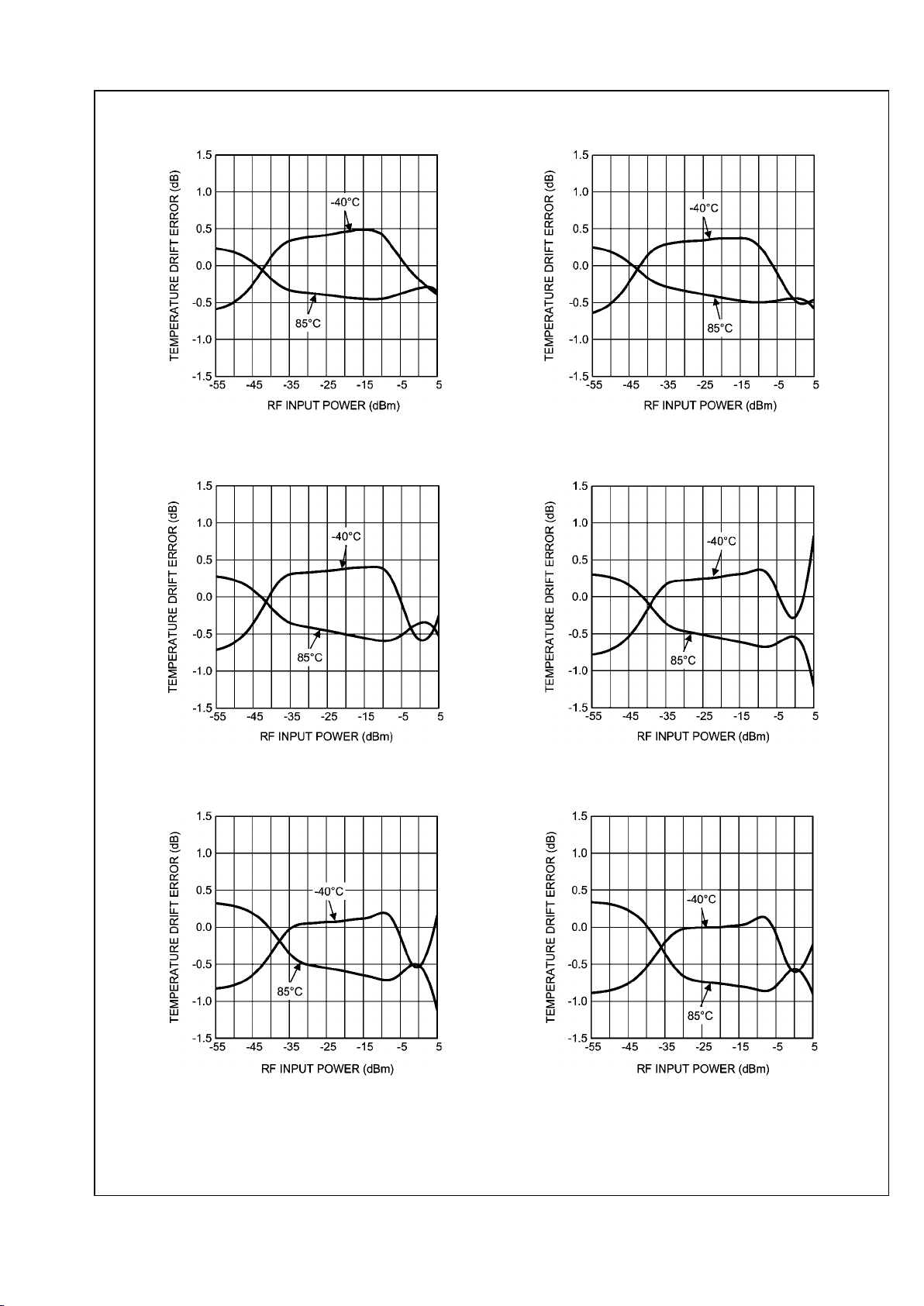

Temperature Drift Error (Mean ±3 sigma) vs.

RF Input Power at 50 MHz

20173750

Temperature Drift Error (Mean ±3 sigma) vs.

RF Input Power at 900 MHz

20173751

Temperature Drift Error (Mean ±3 sigma) vs.

RF Input Power at 1855 MHz

20173752

Temperature Drift Error (Mean ±3 sigma) vs.

RF Input Power at 2500 MHz

20173753

Temperature Drift Error (Mean ±3 sigma) vs.

RF Input Power at 3000 MHz

20173754

Temperature Drift Error (Mean ±3 sigma) vs.

RF Input Power at 3500 MHz

20173755

11 www.national.com

LMV221

Page 12

Error for 1 dB Input Power Step vs.

RF Input Power at 50 MHz

20173726

Error for 1 dB Input Power Step vs.

RF Input Power at 900 MHz

20173727

Error for 1 dB Input Power Step vs.

RF Input Power at 1855 MHz

20173728

Error for 1 dB Input Power Step vs.

RF Input Power at 2500 MHz

20173729

Error for 1 dB Input Power Step vs.

RF Input Power at 3000 MHz

20173730

Error for 1 dB Input Power Step vs.

RF Input Power at 3500 MHz

20173731

www.national.com 12

LMV221

Page 13

Error for 10 dB Input Power Step vs.

RF Input Power at 50 MHz

20173732

Error for 10 dB Input Power Step vs.

RF Input Power at 900 MHz

20173733

Error for 10 dB Input Power Step vs.

RF Input Power at 1855 MHz

20173734

Error for 10 dB Input Power Step vs.

RF Input Power at 2500 MHz

20173735

Error for 10 dB Input Power Step vs.

RF Input Power at 3000 MHz

20173736

Error for 10 dB Input Power Step vs.

RF Input Power at 3500 MHz

20173737

13 www.national.com

LMV221

Page 14

Mean Temperature Sensitivity vs.

RF Input Power at 50 MHz

20173738

Mean Temperature Sensitivity vs.

RF Input Power at 900 MHz

20173739

Mean Temperature Sensitivity vs.

RF Input Power at 1855 MHz

20173740

Mean Temperature Sensitivity vs.

RF Input Power at 2500 MHz

20173741

Mean Temperature Sensitivity vs.

RF Input Power at 3000 MHz

20173742

Mean Temperature Sensitivity vs.

RF Input Power at 3500 MHz

20173743

www.national.com 14

LMV221

Page 15

Temperature Sensitivity (Mean ±3 sigma) vs.

RF Input Power at 50 MHz

20173756

Temperature Sensitivity (Mean ±3 sigma) vs.

RF Input Power at 900 MHz

20173757

Temperature Sensitivity (Mean ±3 sigma) vs.

RF Input Power at 1855 MHz

20173758

Temperature Sensitivity (Mean ±3 sigma) vs.

RF Input Power at 2500 MHz

20173759

Temperature Sensitivity (Mean ±3 sigma) vs.

RF Input Power at 3000 MHz

20173760

Temperature Sensitivity (Mean ±3 sigma) vs.

RF Input Power at 3500 MHz

20173761

15 www.national.com

LMV221

Page 16

Output Voltage and Log Conformance Error vs.

RF Input Power for various modulation types at 900 MHz

20173772

Output Voltage and Log Conformance Error vs.

RF Input Power for various modulation types at 1855 MHz

20173773

RF Input Impedance vs. Frequency

(Resistance & Reactance)

20173748

Output Noise Spectrum vs. Frequency

20173745

Power Supply Rejection Ratio vs. Frequency

20173747

Output Amplifier Gain & Phase vs. Frequency

20173707

www.national.com 16

LMV221

Page 17

Sourcing Output Current vs. Output Voltage

20173709

Sinking Output Current vs. Output Voltage

20173710

Output Voltage vs. Sourcing Current

20173711

Output Voltage vs. Sinking Current

20173706

17 www.national.com

LMV221

Page 18

Application Notes

The LMV221 is a versatile logarithmic RF power detector

suitable for use in power measurement systems. The

LMV221 is particularly well suited for CDMA and UMTS applications. It produces a DC voltage that is a measure for the

applied RF power.

This application section describes the behavior of the

LMV221 and explains how accurate measurements can be

performed. Besides this an overview is given of the interfacing

options with the connected circuitry as well as the recommended layout for the LMV221.

1. FUNCTIONALITY AND APPLICATION OF RF POWER

DETECTORS

This first section describes the functional behavior of RF power detectors and their typical application. Based on a number

of key electrical characteristics of RF power detectors, section

1.1 discusses the functionality of RF power detectors in general and of the LMV221 LOG detector in particular. Subsequently, section 1.2 describes two important applications of

the LMV221 detector.

1.1 Functionality of RF Power Detectors

An RF power detector is a device that produces a DC output

voltage in response to the RF power level of the signal applied

to its input. A wide variety of power detectors can be distinguished, each having certain properties that suit a particular

application. This section provides an overview of the key

characteristics of power detectors, and discusses the most

important types of power detectors. The functional behavior

of the LMV221 is discussed in detail.

1.1.1 Key Characteristics of RF Power Detectors.

Power detectors are used to accurately measure the power

of a signal inside the application. The attainable accuracy of

the measurement is therefore dependent upon the accuracy

and predictability of the detector transfer function from the RF

input power to the DC output voltage.

Certain key characteristics determine the accuracy of RF detectors and they are classified accordingly:

•

Temperature Stability

•

Dynamic Range

•

Waveform Dependency

•

Transfer Shape

Each of these aspects is discussed in further detail below.

Generally, the transfer function of RF power detectors is

slightly temperature dependent. This temperature drift re-

duces the accuracy of the power measurement, because

most applications are calibrated at room temperature. In such

systems, the temperature drift significantly contributes to the

overall system power measurement error. The temperature

stability of the transfer function differs for the various types of

power detectors. Generally, power detectors that contain only

one or few semiconductor devices (diodes, transistors) operating at RF frequencies attain the best temperature stability.

The dynamic range of a power detector is the input power

range for which it creates an accurately reproducible output

signal. What is considered accurate is determined by the applied criterion for the detector accuracy; the detector dynamic

range is thus always associated with certain power measurement accuracy. This accuracy is usually expressed as the

deviation of its transfer function from a certain predefined relationship, such as ”linear in dB" for LOG detectors and

”square-law" transfer (from input RF voltage to DC output

voltage) for Mean-Square detectors. For LOG-detectors, the

dynamic range is often specified as the power range for which

its transfer function follows the ideal linear-in-dB relationship

with an error smaller than or equal to ±1 dB. Again, the attainable dynamic range differs considerably for the various

types of power detectors.

According to its definition, the average power is a metric for

the average energy content of a signal and is not directly a

function of the shape of the signal in time. In other words, the

power contained in a 0 dBm sine wave is identical to the power contained in a 0 dBm square wave or a 0 dBm WCDMA

signal; all these signals have the same average power. Depending on the internal detection mechanism, though, power

detectors may produce a slightly different output signal in response to the aforementioned waveforms, even though their

average power level is the same. This is due to the fact that

not all power detectors strictly implement the definition formula for signal power, being the mean of the square of the

signal. Most types of detectors perform some mixture of peak

detection and average power detection. A waveform independent detector response is often desired in applications

that exhibit a large variety of waveforms, such that separate

calibration for each waveform becomes impractical.

The shape of the detector transfer function from the RF input

power to the DC output voltage determines the required resolution of the ADC connected to it. The overall power measurement error is the combination of the error introduced by

the detector, and the quantization error contributed by the

ADC. The impact of the quantization error on the overall

transfer's accuracy is highly dependent on the detector transfer shape, as illustrated in Figure 1.

www.national.com 18

LMV221

Page 19

20173770

(a)

20173766

(b)

FIGURE 1. Convex Detector Transfer Function (a) and Linear Transfer Function (b)

Figure 1 shows two different representations of the detector

transfer function. In both graphs the input power along the

horizontal axis is displayed in dBm, since most applications

specify power accuracy requirements in dBm (or dB). The

figure on the left shows a convex detector transfer function,

while the transfer function on the right hand side is linear (in

dB). The slope of the detector transfer function — i.e. the detector conversion gain – is of key importance for the impact

of the quantization error on the total measurement error. If the

detector transfer function slope is low, a change, ΔP, in the

input power results only in a small change of the detector output voltage, such that the quantization error will be relatively

large. On the other hand, if the detector transfer function slope

is high, the output voltage change for the same input power

change will be large, such that the quantization error is small.

The transfer function on the left has a very low slope at low

input power levels, resulting in a relatively large quantization

error. Therefore, to achieve accurate power measurement in

this region, a high-resolution ADC is required. On the other

hand, for high input power levels the quantization error will be

very small due to the steep slope of the curve in this region.

For accurate power measurement in this region, a much lower

ADC resolution is sufficient. The curve on the right has a constant slope over the power range of interest, such that the

required ADC resolution for a certain measurement accuracy

is constant. For this reason, the LOG-linear curve on the right

will generally lead to the lowest ADC resolution requirements

for certain power measurement accuracy.

1.1.2 Types of RF Power Detectors

Three different detector types are distinguished based on the

four characteristics previously discussed:

•

Diode Detector

•

(Root) Mean Square Detector

•

Logarithmic Detector

These three types of detectors are discussed in the following

sections. Advantages and disadvantages will be presented

for each type.

Diode Detector

A diode is one of the simplest types of RF detectors. As depicted in Figure 2, the diode converts the RF input voltage into

a rectified current. This unidirectional current charges the capacitor. The RC time constant of the resistor and the capacitor

determines the amount of filtering applied to the rectified (detected) signal.

20173774

FIGURE 2. Diode Detector

The advantages and disadvantages can be summarized as

follows:

•

The temperature stability of the diode detectors is

generally very good, since they contain only one

semiconductor device that operates at RF frequencies.

•

The dynamic range of diode detectors is poor. The

conversion gain from the RF input power to the output

voltage quickly drops to very low levels when the input

power decreases. Typically a dynamic range of 20 – 25 dB

can be realized with this type of detector.

•

The response of diode detectors is waveform dependent.

As a consequence of this dependency its output voltage

for e.g. a 0 dBm WCDMA signal is different than for a

0 dBm unmodulated carrier. This is due to the fact that the

diode measures peak power instead of average power.

The relation between peak power and average power is

dependent on the wave shape.

•

The transfer shape of diode detectors puts high

requirements on the resolution of the ADC that reads their

output voltage. Especially at low input power levels a very

high ADC resolution is required to achieve sufficient power

measurement accuracy (See Figure 1, left side).

(Root) Mean Square Detector

This type of detector is particularly suited for the power measurements of RF modulated signals that exhibits large peak

to average power ratio variations. This is because its opera-

19 www.national.com

LMV221

Page 20

tion is based on direct determination of the average power

and not – like the diode detector – of the peak power.

The advantages and disadvantages can be summarized as

follows:

•

The temperature stability of (R)MS detectors is almost as

good as the temperature stability of the diode detector;

only a small part of the circuit operates at RF frequencies,

while the rest of the circuit operates at low frequencies.

•

The dynamic range of (R)MS detectors is limited. The

lower end of the dynamic range is limited by internal device

offsets.

•

The response of (R)MS detectors is highly waveform

independent. This is a key advantage compared to other

types of detectors in applications that employ signals with

high peak-to-average power variations. For example, the

(R)MS detector response to a 0 dBm WCDMA signal and

a 0 dBm unmodulated carrier is essentially equal.

•

The transfer shape of R(MS) detectors has many

similarities with the diode detector and is therefore subject

to similar disadvantages with respect to the ADC

resolution requirements (See Figure 1, left side).

Logarithmic Detectors

The transfer function of a logarithmic detector has a linear in

dB response, which means that the output voltage changes

linearly with the RF power in dBm. This is convenient since

most communication standards specify transmit power levels

in dBm as well.

The advantages and disadvantages can be summarized as

follows:

•

The temperature stability of the LOG detector transfer

function is generally not as good as the stability of diode

and R(MS) detectors. This is because a significant part of

the circuit operates at RF frequencies.

•

The dynamic range of LOG detectors is usually much

larger than that of other types of detectors.

•

Since LOG detectors perform a kind of peak detection their

response is wave form dependent, similar to diode

detectors.

•

The transfer shape of LOG detectors puts the lowest

possible requirements on the ADC resolution (See Figure

1, right side).

1.1.3 Characteristics of the LMV221

The LMV221 is a Logarithmic RF power detector with approximately 40 dB dynamic range. This dynamic range plus

its logarithmic behavior make the LMV221 ideal for various

applications such as wireless transmit power control for CDMA and UMTS applications. The frequency range of the

LMV221 is from 50 MHz to 3.5 GHz, which makes it suitable

for various applications.

The LMV221 transfer function is accurately temperature compensated. This makes the measurement accurate for a wide

temperature range. Furthermore, the LMV221 can easily be

connected to a directional coupler because of its 50 ohm input

termination. The output range is adjustable to fit the ADC input

range. The detector can be switched into a power saving

shutdown mode for use in pulsed conditions.

1.2 Applications of RF Power Detectors

RF power detectors can be used in a wide variety of applications. This section discusses two application. The first example shows the LMV221 in a transmit power control loop, the

second application measures the voltage standing wave ratio

(VSWR).

1.2.1 Transmit Power Control Loop

The key benefit of a transmit power control loop circuit is that

it makes the transmit power insensitive to changes in the

Power Amplifier (PA) gain control function, such as changes

due to temperature drift. When a control loop is used, the

transfer function of the PA is eliminated from the overall transfer function. Instead, the overall transfer function is determined by the power detector. The overall transfer function

accuracy depends thus on the RF detector accuracy. The

LMV221 is especially suited for this application, due to the

accurate temperature stability of its transfer function.

Figure 3 shows a block diagram of a typical transmit power

control system. The output power of the PA is measured by

the LMV221 through a directional coupler. The measured

output voltage of the LMV221 is filtered and subsequently

digitized by the ADC inside the baseband chip. The baseband

adjusts the PA output power level by changing the gain control

signal of the RF VGA accordingly. With an input impedance

of 50Ω, the LMV221 can be directly connected to a 30 dB

directional coupler without the need for an additional external

attenuator. The setup can be adjusted to various PA output

ranges by selection of a directional coupler with the appropriate coupling factor.

20173797

FIGURE 3. Transmit Power Control System

1.2.2 Voltage Standing Wave Ratio Measurement

Transmission in RF systems requires matched termination by

the proper characteristic impedance at the transmitter and

receiver side of the link. In wireless transmission systems

though, matched termination of the antenna can rarely be

achieved. The part of the transmitted power that is reflected

at the antenna bounces back toward the PA and may cause

standing waves in the transmission line between the PA and

the antenna. These standing waves can attain unacceptable

levels that may damage the PA. A Voltage Standing Wave

Ratio (VSWR) measurement is used to detect such an occasion. It acts as an alarm function to prevent damage to the

transmitter.

VSWR is defined as the ratio of the maximum voltage divided

by the minimum voltage at a certain point on the transmission

line:

Where Γ = V

REFLECTED

/ V

FORWARD

denotes the reflection co-

efficient.

This means that to determine the VSWR, both the forward

(transmitted) and the reflected power levels have to be mea-

www.national.com 20

LMV221

Page 21

sured. This can be accomplished by using two LMV221 RF

power detectors according to Figure 4. A directional coupler

is used to separate the forward and reflected power waves on

the transmission line between the PA and the antenna. One

secondary output of the coupler provides a signal proportional

to the forward power wave, the other secondary output provides a signal proportional to the reflected power wave. The

outputs of both RF detectors that measure these signals are

connected to a micro-controller or baseband that calculates

the VSWR from the detector output signals.

20173794

FIGURE 4. VSWR Application

2. ACCURATE POWER MEASUREMENT

The power measurement accuracy achieved with a power

detector is not only determined by the accuracy of the detector

itself, but also by the way it is integrated into the application.

In many applications some form of calibration is employed to

improve the accuracy of the overall system beyond the intrinsic accuracy provided by the power detector. For example, for

LOG-detectors calibration can be used to eliminate part to

part spread of the LOG-slope and LOG-intercept from the

overall power measurement system, thereby improving its

power measurement accuracy.

This section shows how calibration techniques can be used

to improve the accuracy of a power measurement system beyond the intrinsic accuracy of the power detector itself. The

main focus of the section is on power measurement systems

using LOG-detectors, specifically the LMV221, but the more

generic concepts can also be applied to other power detectors. Other factors influencing the power measurement accuracy, such as the resolution of the ADC reading the detector

output signal will not be considered here since they are not

fundamentally due to the power detector.

2.1 Concept of Power Measurements

Power measurement systems generally consists of two clearly distinguishable parts with different functions:

1.

A power detector device, that generates a DC output

signal (voltage) in response to the power level of the (RF)

signal applied to its input.

2.

An “estimator” that converts the measured detector

output signal into a (digital) numeric value representing

the power level of the signal at the detector input.

A sketch of this conceptual configuration is depicted in Figure

5 .

20173779

FIGURE 5. Generic Concept of a Power Measurement

System

The core of the estimator is usually implemented as a software algorithm, receiving a digitized version of the detector

output voltage. Its transfer F

EST

from detector output voltage

to a numerical output should be equal to the inverse of the

detector transfer F

DET

from (RF) input power to DC output

voltage. If the power measurement system is ideal, i.e. if no

errors are introduced into the measurement result by the detector or the estimator, the measured power P

EST

- the output

of the estimator - and the actual input power PIN should be

identical. In that case, the measurement error E, the difference between the two, should be identically zero:

From the expression above it follows that one would design

the F

EST

transfer function to be the inverse of the F

DET

transfer

function.

In practice the power measurement error will not be zero, due

to the following effects:

•

The detector transfer function is subject to various kinds

of random errors that result in uncertainty in the detector

output voltage; the detector transfer function is not exactly

known.

•

The detector transfer function might be too complicated to

be implemented in a practical estimator.

The function of the estimator is then to estimate the input

power PIN, i.e. to produce an output P

EST

such that the power

measurement error is - on average - minimized, based on the

following information:

1.

Measurement of the not completely accurate detector

output voltage V

OUT

2.

Knowledge about the detector transfer function F

DET

, for

example the shape of the transfer function, the types of

errors present (part-to-part spread, temperature drift) etc.

Obviously the total measurement accuracy can be optimized

by minimizing the uncertainty in the detector output signal (i.e.

select an accurate power detector), and by incorporating as

much accurate information about the detector transfer function into the estimator as possible.

The knowledge about the detector transfer function is condensed into a mathematical model for the detector transfer

function, consisting of:

•

A formula for the detector transfer function.

21 www.national.com

LMV221

Page 22

•

Values for the parameters in this formula.

The values for the parameters in the model can be obtained

in various ways. They can be based on measurements of the

detector transfer function in a precisely controlled environment (parameter extraction). If the parameter values are separately determined for each individual device, errors like partto-part spread are eliminated from the measurement system.

Obviously, errors may occur when the operating conditions of

the detector (e.g. the temperature) become significantly different from the operating conditions during calibration (e.g.

room temperature). Subsequent sections will discuss examples of simple estimators for power measurements that result

in a number of commonly used metrics for the power measurement error: the LOG-conformance error, the temperature

drift error, the temperature sensitivity and differential power

error.

2.2 LOG-Conformance Error

Probably the simplest power measurement system that can

be realized is obtained when the LOG-detector transfer function is modelled as a perfect linear-in-dB relationship between

the input power and output voltage:

in which K

SLOPE

represents the LOG-slope and P

INTERCEPT

the

LOG-intercept. The estimator based on this model implements the inverse of the model equation, i.e.

The resulting power measurement error, the LOG-conformance error, is thus equal to:

The most important contributions to the LOG-conformance

error are generally:

•

The deviation of the actual detector transfer function from

an ideal Logarithm (the transfer function is nonlinear in

dB).

•

Drift of the detector transfer function over various

environmental conditions, most importantly temperature;

K

SLOPE

and P

INTERCEPT

are usually determined for room

temperature only.

•

Part-to-part spread of the (room temperature) transfer

function.

The latter component is conveniently removed by means of

calibration, i.e. if the LOG slope and LOG-intercept are determined for each individual detector device (at room temperature). This can be achieved by measurement of the detector

output voltage - at room temperature - for a series of different

power levels in the LOG-linear range of the detector transfer

function. The slope and intercept can then be determined by

means of linear regression.

An example of this type of error and its relationship to the

detector transfer function is depicted in Figure 6.

20173715

FIGURE 6. LOG-Conformance Error and LOG-Detector

Transfer Function

In the center of the detector's dynamic range, the LOG-conformance error is small, especially at room temperature; in

this region the transfer function closely follows the linear-indB relationship while K

SLOPE

and P

INTERCEPT

are determined

based on room temperature measurements. At the temperature extremes the error in the center of the range is slightly

larger due to the temperature drift of the detector transfer

function. The error rapidly increases toward the top and bottom end of the detector's dynamic range; here the detector

saturates and its transfer function starts to deviate significantly from the ideal LOG-linear model. The detector dynamic

range is usually defined as the power range for which the LOG

conformance error is smaller than a specified amount. Often

an error of ±1 dB is used as a criterion.

2.3 Temperature Drift Error

A more accurate power measurement system can be obtained if the first error contribution, due to the deviation from

the ideal LOG-linear model, is eliminated. This is achieved if

the actual measured detector transfer function at room temperature is used as a model for the detector, instead of the

ideal LOG-linear transfer function used in the previous section.

The formula used for such a detector is:

V

OUT,MOD

= F

DET(PIN,TO

)

where TO represents the temperature during calibration (room

temperature). The transfer function of the corresponding estimator is thus the inverse of this:

In this expression V

OUT

(T) represents the measured detector

output voltage at the operating temperature T.

The resulting measurement error is only due to drift of the

detector transfer function over temperature, and can be expressed as:

www.national.com 22

LMV221

Page 23

Unfortunately, the (numeric) inverse of the detector transfer

function at different temperatures makes this expression

rather impractical. However, since the drift error is usually

small V

OUT

(T) is only slightly different from V

OUT(TO

). This

means that we can apply the following approximation:

This expression is easily simplified by taking the following

considerations into account:

•

The drift error at the calibration temperature E(TO,TO)

equals zero (by definition).

•

The estimator transfer F

DET(VOUT,TO

) is not a function of

temperature; the estimator output changes over

temperature only due to the temperature dependence of

V

OUT

.

•

The actual detector input power PIN is not temperature

dependent (in the context of this expression).

•

The derivative of the estimator transfer function to V

OUT

equals approximately 1/K

SLOPE

in the LOG-linear region of

the detector transfer function (the region of interest).

Using this, we arrive at:

This expression is very similar to the expression of the LOGconformance error determined previously. The only difference is that instead of the output of the ideal LOG-linear

model, the actual detector output voltage at the calibration

temperature is now subtracted from the detector output voltage at the operating temperature.

Figure 7 depicts an example of the drift error.

20173722

FIGURE 7. Temperature Drift Error of the LMV221

at f = 1855 MHz

In agreement with the definition, the temperature drift error is

zero at the calibration temperature. Further, the main difference with the LOG-conformance error is observed at the top

and bottom end of the detection range; instead of a rapid increase the drift error settles to a small value at high and low

input power levels due to the fact that the detector saturation

levels are relatively temperature independent.

In a practical application it may not be possible to use the

exact inverse detector transfer function as the algorithm for

the estimator. For example it may require too much memory

and/or too much factory calibration time. However, using the

ideal LOG-linear model in combination with a few extra data

points at the top and bottom end of the detection range where the deviation is largest - can already significantly reduce the power measurement error.

2.4 Temperature Compensation

A further reduction of the power measurement error is possible if the operating temperature is measured in the application. For this purpose, the detector model used by the

estimator should be extended to cover the temperature dependency of the detector.

Since the detector transfer function is generally a smooth

function of temperature (the output voltage changes gradually

over temperature), the temperature is in most cases adequately modeled by a first-order or second-order polynomial,

i.e.

The required temperature dependence of the estimator, to

compensate for the detector temperature dependence can be

approximated similarly:

The last approximation results from the fact that a first-order

temperature compensation is usually sufficiently accurate.

The remainder of this section will therefore concentrate on

first-order compensation. For second and higher-order compensation a similar approach can be followed.

Ideally, the temperature drift could be completely eliminated

if the measurement system is calibrated at various temperatures and input power levels to determine the Temperature

Sensitivity S1. In a practical application, however that is usually not possible due to the associated high costs. The alternative is to use the average temperature drift in the estimator,

instead of the temperature sensitivity of each device individually. In this way it becomes possible to eliminate the systematic (reproducible) component of the temperature drift

without the need for calibration at different temperatures during manufacturing. What remains is the random temperature

drift, which differs from device to device. Figure 8 illustrates

the idea. The graph at the left schematically represents the

behavior of the drift error versus temperature at a certain input

power level for a large number of devices.

23 www.national.com

LMV221

Page 24

20173765

FIGURE 8. Elimination of the Systematic Component from the Temperature Drift

The mean drift error represents the reproducible - systematic

- part of the error, while the mean ± 3 sigma limits represent

the combined systematic plus random error component. Obviously the drift error must be zero at calibration temperature

T0. If the systematic component of the drift error is included

in the estimator, the total drift error becomes equal to only the

random component, as illustrated in the graph at the right of

Figure 8. A significant reduction of the temperature drift error

can be achieved in this way only if:

•

The systematic component is significantly larger than the

random error component (otherwise the difference is

negligible).

•

The operating temperature is measured with sufficient

accuracy.

It is essential for the effectiveness of the temperature compensation to assign the appropriate value to the temperature

sensitivity S1. Two different approaches can be followed to

determine this parameter:

•

Determination of a single value to be used over the entire

operating temperature range.

•

Division of the operating temperature range in segments

and use of separate values for each of the segments.

Also for the first method, the accuracy of the extracted temperature sensitivity increases when the number of measure-

ment temperatures increases. Linear regression to temperature can then be used to determine the two parameters of the

linear model for the temperature drift error: the first order temperature sensitivity S1 and the best-fit (room temperature)

value for the power estimate at T0 :F

DET[VOUT

(T),T0]. Note that

to achieve an overall - over all temperatures - minimum error,

the room temperature drift error in the model can be non-zero

at the calibration temperature (which is not in agreement with

the strict definition).

The second method does not have this drawback but is more

complex. In fact, segmentation of the temperature range is a

form of higher-order temperature compensation using only a

first-order model for the different segments: one for temperatures below 25°C, and one for temperatures above 25°C.

The mean (or typical) temperature sensitivity is the value to

be used for compensation of the systematic drift error component. Figure 9 shows the temperature drift error without and

with temperature compensation using two segments. With

compensation the systematic component is completely eliminated; the remaining random error component is centered

around zero. Note that the random component is slightly larger at −40°C than at 85°C.

20173752

20173795

FIGURE 9. Temperature Drift Error without and with Temperature Compensation

www.national.com 24

LMV221

Page 25

In a practical power measurement system, temperature compensation is usually only applied to a small power range

around the maximum power level for two reasons:

•

The various communication standards require the highest

accuracy in this range to limit interference.

•

The temperature sensitivity itself is a function of the power

level it becomes impractical to store a large number of

different temperature sensitivity values for different power

levels.

The table in the datasheet specifies the temperature sensitivity for the aforementioned two segments at an input power

level of -10 dBm (near the top-end of the detector dynamic

range). The typical value represents the mean which is to be

used for calibration.

2.5 Differential Power Errors

Many third generation communication systems contain a

power control loop through the base station and mobile unit

that requests both to frequently update the transmit power

level by a small amount (typically 1 dB). For such applications

it is important that the actual change of the transmit power is

sufficiently close to the requested power change.

The error metrics in the datasheet that describe the accuracy

of the detector for a change in the input power are E

1 dB

(for

a 1 dB change in the input power) and E

10 dB

(for a 10 dB step,

or ten consecutive steps of 1 dB). Since it can be assumed

that the temperature does not change during the power step

the differential error equals the difference of the drift error at

the two involved power levels:

It should be noted that the step error increases significantly

when one (or both) power levels in the above expression are

outside the detector dynamic range. For E

10 dB

this occurs

when PIN is less than 10 dB below the maximum input power

of the dynamic range, P

MAX

.

3. DETECTOR INTERFACING

For optimal performance of the LMV221, it is important that

all its pins are connected to the surrounding circuitry in the

appropriate way. This section discusses guidelines and requirements for the electrical connection of each pin of the

LMV221 to ensure proper operation of the device. Starting

from a block diagram, the function of each pin is elaborated.

Subsequently, the details of the electrical interfacing are separately discussed for each pin. Special attention will be paid

to the output filtering options and the differences between

single ended and differential interfacing with an ADC.

3.1 Block Diagram of the LMV221

The block diagram of the LMV221 is depicted in Figure 10.

20173703

FIGURE 10. Block Diagram of the LMV221

The core of the LMV221 is a progressive compression LOGdetector consisting of four gain stages. Each of these saturating stages has a gain of approximately 10 dB and therefore

realizes about 10 dB of the detector dynamic range. The five

diode cells perform the actual detection and convert the RF

signal to a DC current. This DC current is subsequently supplied to the transimpedance amplifier at the output, that converts it into an output voltage. In addition, the amplifier

provides buffering of and applies filtering to the detector output signal. To prevent discharge of filtering capacitors between OUT and GND in shutdown, a switch is inserted at the

amplifier input that opens in shutdown to realize a high

impedance output of the device.

3.2 RF Input

RF parts typically use a characteristic impedance of 50Ω. To

comply with this standard the LMV221 has an input

impedance of 50Ω. Using a characteristic impedance other

then 50Ω will cause a shift of the logarithmic intercept with

respect to the value given in the electrical characteristics table. This intercept shift can be calculated according to the

following formula: .

The intercept will shift to higher power levels for

R

SOURCE

> 50Ω, and will shift to lower power levels for

R

SOURCE

< 50Ω.

3.3 Shutdown

To save power, the LMV221 can be brought into a low-power

shutdown mode. The device is active for EN = HIGH

(VEN>1.1V) and in the low-power shutdown mode for EN =

LOW (VEN < 0.6V). In this state the output of the LMV221 is

switched to a high impedance mode. Using the shutdown

25 www.national.com

LMV221

Page 26

function, care must be taken not to exceed the absolute maximum ratings. Forcing a voltage to the enable input that is 400

mV higher than VDD or 400 mV lower than GND will damage

the device and further operations is not guaranteed. The absolute maximum ratings can also be exceeded when the

enable EN is switched to HIGH (from shutdown to active

mode) while the supply voltage is low (off). This should be

prevented at all times. A possible solution to protect the part

is to add a resistor of 100 kΩ in series with the enable input.

3.4 Output and Reference

This section describes the possible filtering techniques that

can be applied to reduce ripple in the detector output voltage.

In addition two different topologies to connect the LMV221 to

an ADC are elaborated.

3.4.1 Filtering

The output voltage of the LMV221 is a measure for the applied

RF signal on the RF input pin. Usually, the applied RF signal

contains AM modulation that causes low frequency ripple in

the detector output voltage. CDMA signals for instance contain a large amount of amplitude variations. Filtering of the

output signal can be used to eliminate this ripple. The filtering

can either be realized by a low pass output filter or a low pass

feedback filter. Those two techniques are depicted in Figure

11.

20173775 20173776

FIGURE 11. Low Pass Output Filter and Low Pass Feedback Filter

Depending on the system requirements one of the these filtering techniques can be selected. The low pass output filter

has the advantage that it preserves the output voltage when

the LMV221 is brought into shutdown. This is elaborated in

section 3.4.3. In the feedback filter, resistor RP discharges

capacitor CP in shutdown and therefore changes the output

voltage of the device.

A disadvantage of the low pass output filter is that the series

resistor RS limits the output drive capability. This may cause

inaccuracies in the voltage read by an ADC when the ADC

input impedance is not significantly larger than RS. In that

case, the current flowing through the ADC input induces an

error voltage across filter resistor RS. The low pass feedback

filter doesn’t have this disadvantage.

Note that adding an external resistor between OUT and REF

reduces the transfer gain (LOG-slope and LOG-intercept) of

the device. The internal feedback resistor sets the gain of the

transimpedance amplifier.

The filtering of the low pass output filter is realized by resistor

RS and capacitor CS. The −3 dB bandwidth of this filter can

then be calculated by: f

−3 dB

= 1 / 2πRSCS. The bandwidth of

the low pass feedback filter is determined by external resistor

RP in parallel with the internal resistor R

TRANS

, and external

capacitor CP in parallel with internal capacitor C

TRANS

(see

Figure 13). The −3 dB bandwidth of the feedback filter can be

calculated by f

−3 dB

= 1 / 2π (RP//R

TRANS

) (CP+C

TRANS

). The

bandwidth set by the internal resistor and capacitor (when no

external components are connected between OUT and REF)

equals f

−3 dB

= 1 / 2π R

TRANS CTRANS

= 450 kHz.

3.4.2 Interface to the ADC

The LMV221 can be connected to the ADC with a single ended or a differential topology. The single ended topology connects the output of the LMV221 to the input of the ADC and

the reference pin is not connected. In a differential topology,

both the output and the reference pins of the LMV221 are

connected to the ADC. The topologies are depicted in Figure

12.

20173776 20173777

FIGURE 12. Single Ended and Differential Application

www.national.com 26

LMV221

Page 27

The differential topology has the advantage that it is compensated for temperature drift of the internal reference voltage.

This can be explained by looking at the transimpedance amplifier of the LMV221 (Figure 13).

20173778

FIGURE 13. Output Stage of the LMV221

It can be seen that the output of the amplifier is set by the

detection current I

DET

multiplied by the resistor R

TRANS

plus

the reference voltage V

REF

:

V

OUT

= I

DET RTRANS

+ V

REF

I

DET

represents the detector current that is proportional to the

RF input power. The equation shows that temperature variations in V

REF

are also present in the output V

OUT

. In case of a

single ended topology the output is the only pin that is connected to the ADC. The ADC voltage for single ended is thus:

Single ended: V

ADC

= I

DET RTRANS

+ V

REF

A differential topology also connects the reference pin, which

is the value of reference voltage V

REF

. The ADC reads V

OUT

- V

REF

:

Differential: V

ADC

= V

OUT

- V

REF

= I

DET RTRANS

The resulting equation doesn’t contain the reference voltage

V

REF

anymore. Temperature variations in this reference volt-

age are therefore not measured by the ADC.

3.4.3 Output Behavior in Shutdown

In order to save power, the LMV221 can be used in pulsed

mode, such that it is active to perform the power measurement only during a fraction of the time. During the remaining

time the device is in low-power shutdown. Applications using

this approach usually require that the output value is available

at all times, also when the LMV221 is in shutdown. The settling time in active mode, however, should not become excessively large. This can be realized by the combination of

the LMV221 and a low pass output filter (see Figure 11, left

side), as discussed below.

In active mode, the filter capacitor CS is charged to the output

voltage of the LMV221 — which in this mode has a low output

impedance to enable fast settling. During shutdown-mode,

the capacitor should preserve this voltage. Discharge of C

S

through any current path should therefore be avoided in shutdown. The output impedance of the LMV221 becomes high

in shutdown, such that the discharge current cannot flow from

the capacitor top plate, through RS, and the LMV221's OUT

pin to GND. This is realized by the internal shutdown mechanism of the output amplifier and by the switch depicted in

Figure 13. Additionally, it should be ensured that the ADC input impedance is high as well, to prevent a possible discharge

path through the ADC.

4. BOARD LAYOUT RECOMMENDATIONS

As with any other RF device, careful attention must me paid

to the board layout. If the board layout isn’t properly designed,

unwanted signals can easily be detected or interference will

be picked up. This section gives guidelines for proper board

layout for the LMV221.

Electrical signals (voltages / currents) need a finite time to

travel through a trace or transmission line. RF voltage levels

at the generator side and at the detector side can therefore

be different. This is not only true for the RF strip line, but for

all traces on the PCB. Signals at different locations or traces

on the PCB will be in a different phase of the RF frequency

cycle. Phase differences in, e.g. the voltage across neighboring lines, may result in crosstalk between lines, due to parasitic capacitive or inductive coupling. This crosstalk is further

enhanced by the fact that all traces on the PCB are susceptible to resonance. The resonance frequency depends on the

trace geometry. Traces are particularly sensitive to interference when the length of the trace corresponds to a quarter of

the wavelength of the interfering signal or a multiple thereof.

4.1 Supply Lines

Since the PSRR of the LMV221 is finite, variations of the supply can result in some variation at the output. This can be

caused among others by RF injection from other parts of the

circuitry or the on/off switching of the PA.

4.1.1 Positive Supply (VDD)

In order to minimize the injection of RF interference into the

LMV221 through the supply lines, the phase difference between the PCB traces connecting to VDD and GND should be

minimized. A suitable way to achieve this is to short both connections for RF. This can be done by placing a small decoupling capacitor between the VDD and GND. It should be placed

as close as possible to the VDD and GND pins of the LMV221.

Due to the presence of the RF input, the best possible position

would be to extend the GND plane connecting to the DAP

slightly beyond the short edge of the package, such that the

capacitor can be placed directly to the VDD pin (Figure 14). Be

aware that the resonance frequency of the capacitor itself

should be above the highest RF frequency used in the application, since the capacitor acts as an inductor above its

resonance frequency.

27 www.national.com

LMV221

Page 28

20173701

FIGURE 14. Recommended Board Layout

Low frequency supply voltage variations due to PA switching

might result in a ripple at the output voltage. The LMV221 has

a Power Supply Rejection Ration of 60 dB for low frequencies.

4.1.2 Ground (GND)

The LMV221 needs a ground plane free of noise and other

disturbing signals. It is important to separate the RF ground

return path from the other grounds. This is due to the fact that

the RF input handles large voltage swings. A power level of

0 dBm will cause a voltage swing larger than 0.6 VPP, over the

internal 50Ω input resistor. This will result in a significant RF

return current toward the source. It is therefore recommended

that the RF ground return path not be used for other circuits

in the design. The RF path should be routed directly back to

the source without loops.

4.2 RF Input Interface

The LMV221 is designed to be used in RF applications, having a characteristic impedance of 50Ω. To achieve this

impedance, the input of the LMV221 needs to be connected

via a 50Ω transmission line. Transmission lines can be easily

created on PCBs using microstrip or (grounded) coplanar

waveguide (GCPW) configurations. This section will discuss

both configurations in a general way. For more details about

designing microstrip or GCPW transmission lines, a microwave designer handbook is recommended.

4.2.1 Microstrip Configuration

One way to create a transmission line is to use a microstrip

configuration. A cross section of the configuration is shown in

Figure 15, assuming a two layer PCB.

20173780

FIGURE 15. Microstrip Configuration

A conductor (trace) is placed on the topside of a PCB. The

bottom side of the PCB has a fully copper ground plane. The

characteristic impedance of the microstrip transmission line

is a function of the width W, height H, and the dielectric constant εr.

Characteristics such as height and the dielectric constant of

the board have significant impact on transmission line dimensions. A 50Ω transmission line may result in impractically wide

traces. A typical 1.6 mm thick FR4 board results in a trace

width of 2.9 mm, for instance. This is impractical for the

LMV221, since the pad width of the LLP-6 package is 0.25

mm. The transmission line has to be tapered from 2.9 mm to

0.25 mm. Significant reflections and resonances in the frequency transfer function of the board may occur due to this

tapering.

4.2.2 GCPW Configuration

A transmission line in a (grounded) coplanar waveguide

(GCPW) configuration will give more flexibility in terms of

trace width. The GCPW configuration is constructed with a

conductor surrounded by ground at a certain distance, S, on

the top side. Figure 16 shows a cross section of this configuration. The bottom side of the PCB is a ground plane. The

ground planes on both sides of the PCB should be firmly connected to each other by multiple vias. The characteristic

impedance of the transmission line is mainly determined by

www.national.com 28

LMV221

Page 29

the width W and the distance S. In order to minimize reflections, the width W of the center trace should match the size

of the package pad. The required value for the characteristic

impedance can subsequently be realized by selection of the

proper gap width S.

20173781

FIGURE 16. GCPW Configuration

4.3 Reference REF

The Reference pin can be used to compensate for temperature drift of the internal reference voltage as described in

Section 3.4.2. The REF pin is directly connected to the inverting input of the transimpedance amplifier. Thus, RF signals and other spurious signals couple directly through to the

output. Introduction of RF signals can be prevented by connecting a small capacitor between the REF pin and ground.

The capacitor should be placed close to the REF pin as depicted in Figure 14.

4.4 Output OUT

The OUT pin is sensitive to crosstalk from the RF input, especially at high power levels. The ESD diode between the

output and VDD may rectify the crosstalk, but may add an unwanted inaccurate DC component to the output voltage.

The board layout should minimize crosstalk between the detectors input RFIN and the detectors output. Using an additional capacitor connected between the output and the

positive supply voltage (VDD pin) or GND can prevent this. For

optimal performance this capacitor should be placed as close

as possible to the OUT pin of the LMV221; e.g. extend the

DAP GND plane and place the capacitor next to the OUT pin.

29 www.national.com

LMV221

Page 30

Physical Dimensions inches (millimeters) unless otherwise noted

6-Pin LLP

NS Package Number SDB06A

www.national.com 30

LMV221

Page 31

Notes

31 www.national.com

LMV221

Page 32

Notes

LMV221 50 MHz to 3.5 GHz 40 dB Logarithmic Power Detector for CDMA and WCDMA

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...