Page 1

July 2007

LMP8100

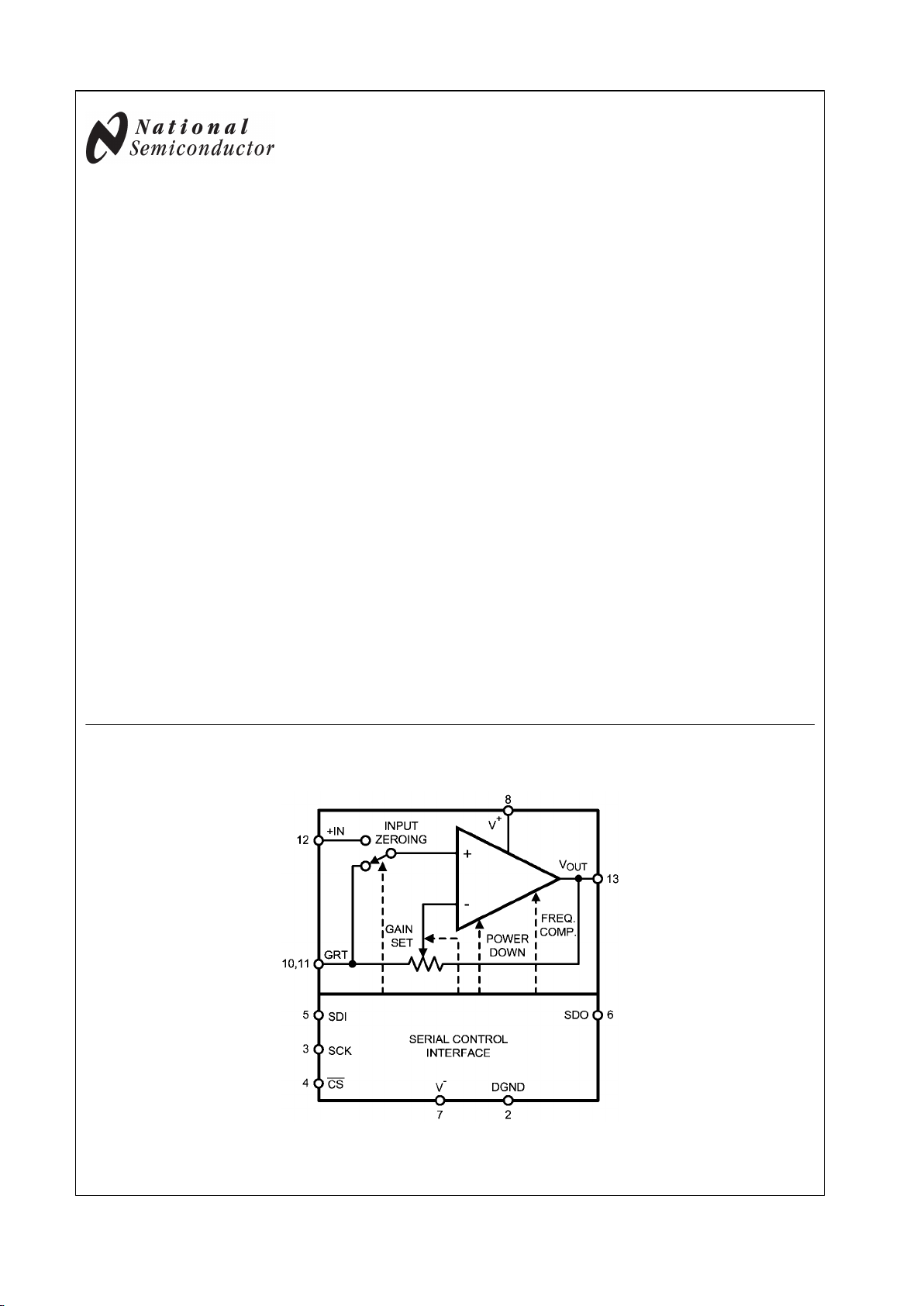

Programmable Gain Amplifier

General Description

The LMP8100 programmable gain amplifier features an adjustable gain from 1 to 16 V/V in 1 V/V increments. At the core

of the LMP8100 is a precision, 33 MHz, CMOS input, rail-torail input/output operational amplifier with a typical open-loop

gain of 110 dB. Amplifier closed-loop gain is set by an array

of precision thin-film resistors. Amplifier control modes are

programmed via a serial port that allows devices to be cascaded so that an array of LMP8100 amplifiers can be programmed by a single serial data stream. The control mode

registers are double buffered to insure glitch-free transitions

between programmed settings. The LMP8100 is part of the

LMP® precision amplifier family and is ideal for a variety of

applications.

The amplifier features several programmable controls including: gain; a power-conserving shutdown mode which can

reduce current consumption to only 20 μA; an input zeroing

switch which allows the output offset voltage to be measured

to facilitate system calibration; and four levels of internal frequency compensation which can be set to maximize bandwidth at the different gain settings.

The LMP8100 comes in a 14-Pin SOIC package.

Features

Typical Values, TA = 25°C

■

Gain error (over temperature range)

—

LMP8100A 0.03%

—

LMP8100 0.075%

■

Gain range 1 to 16 V/V in 1 V/V steps

■

Programmable frequency compensation

■

Input zero calibration switch

■

Input offset voltage (max, LMP8100A)

250 μV

■

Input bias current 0.1 pA

■

Input noise voltage 12 nV/√Hz

■

Unity gain bandwidth 33 MHz

■

Slew rate 12 V/μs

■

Output current 20 mA

■

Supply voltage range 2.7V to 5.5V

■

Supply current 5.3 mA

■

Rail-to-Rail output swing V+ −50 mV to V− +50 mV

Applications

■

Industrial instrumentation

■

Data acquisition systems

■

Test equipment

■

Scaling amplifier

■

Gain control

■

Sensor interface

Simplified Block Diagram

20147607

LMP® is a registered trademark of National Semiconductor Corporation.

© 2007 National Semiconductor Corporation 201476 www.national.com

LMP8100 Programmable Gain Amplifier

Page 2

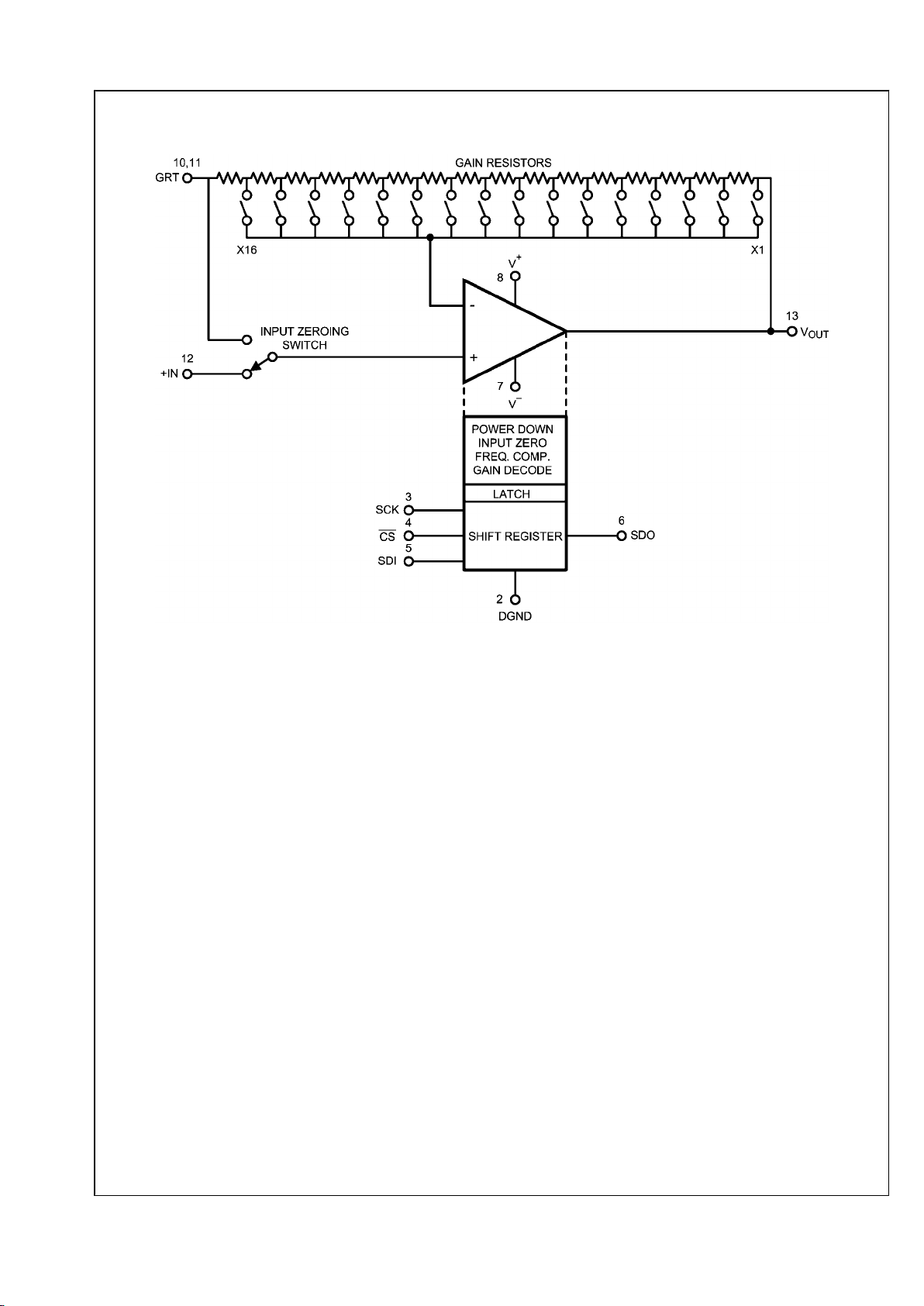

Block Diagram

20147602

www.national.com 2

LMP8100

Page 3

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

ESD Tolerance (Note 2)

Human Body Model 2 kV

Machine Model 200V

VIN Differential

2.5V

Output Short Circuit Duration (Note 3)

Supply Voltage (VS = V+ – V−)

6V

Voltage at Input and Output Pins V+ +0.3V, V− −0.3V

Input Current ±10 mA

Storage Temperature Range −65°C to +150°C

Junction Temperature (Note 4) +150°C

Soldering Information

Lead Temperature, Infrared or

Convection Reflow (20 sec) 235°C

Lead Temperature, Wave Solder (10

sec) 260°C

Operating Ratings (Note 1)

Supply Voltage (VS = V+ – V−)

2.7V to 5.5V

Junction Temperature Range (Note 4)

LMP8100A −40°C to +125°C

LMP8100 −40°C to +85°C

Package Thermal Resistance (θJA (Note 4)

14-Pin SOIC 145°C/W

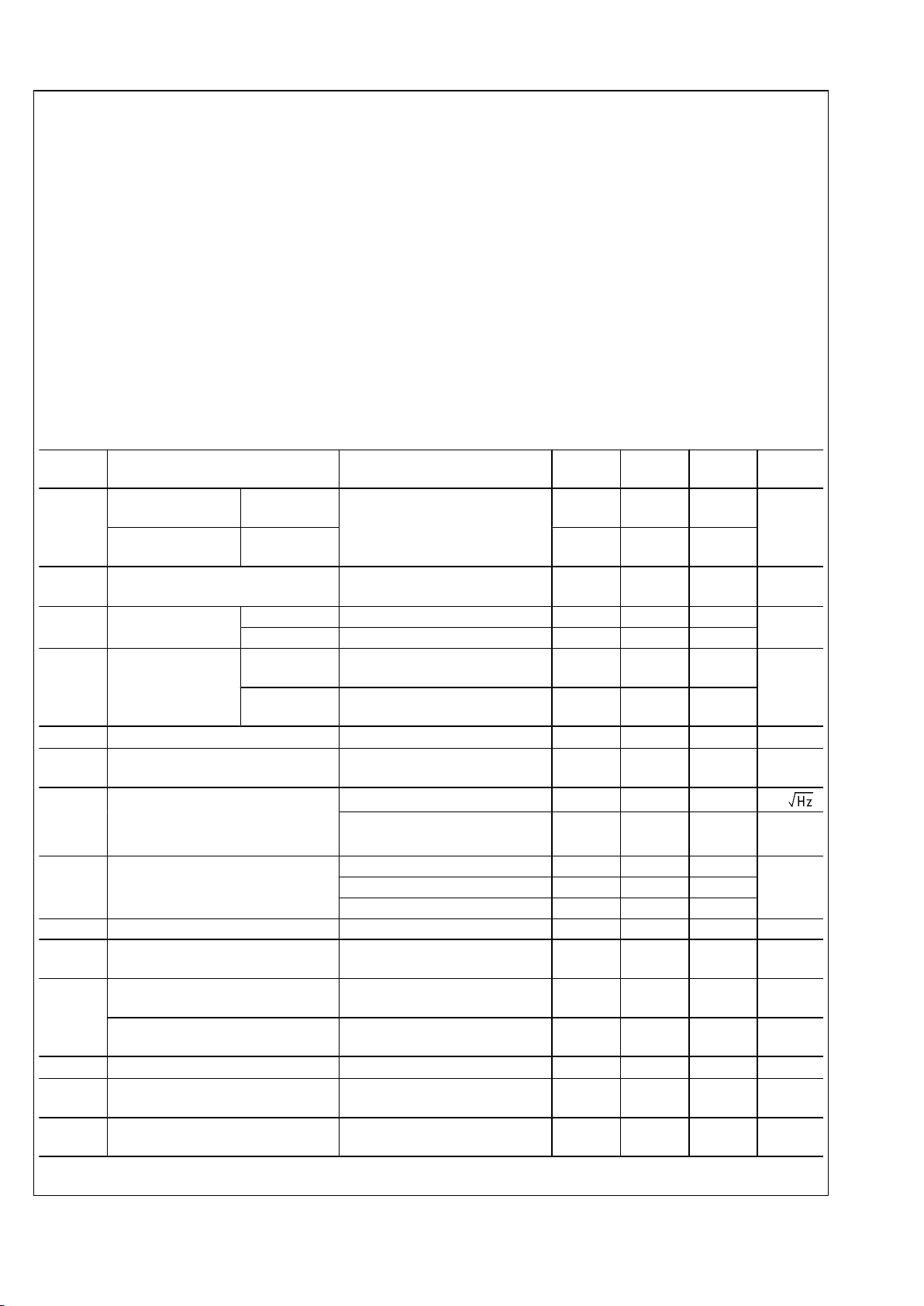

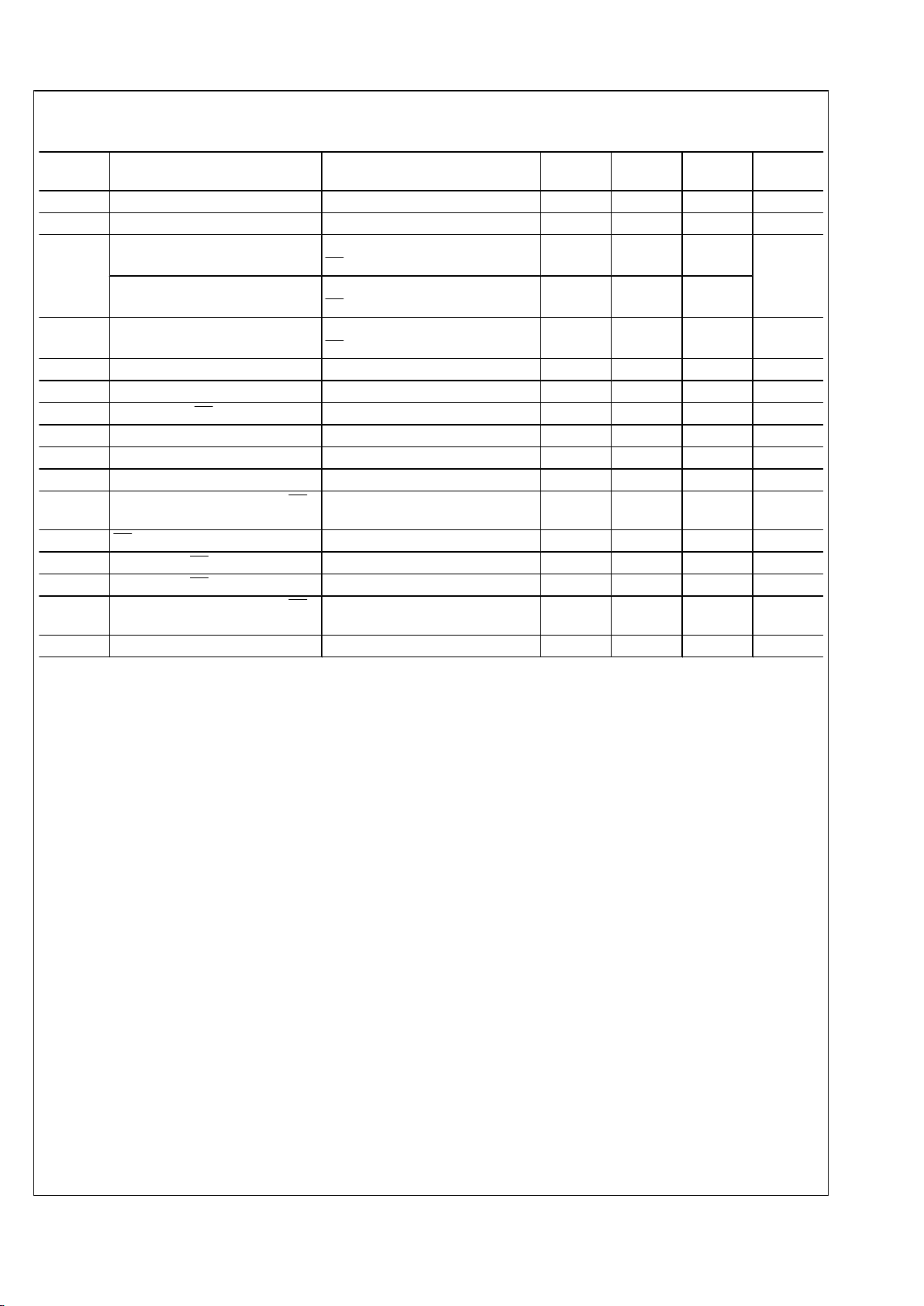

5V Electrical Characteristics

Unless otherwise specified, all limits are guaranteed for TA = 25°C. V+ = 5V , V– = 0V, DGND = 0V, +IN = GRT = V+/2, RL = 10

kΩ to V+/2; Gain = 1 V/V. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

Gain Error LMP8100A 0V < +IN (DC) < 3.5V,

1 V/V ≤ Gain ≤ 16 V/V,

0.5V < V

OUT

< 4.5V

0.015 0.03

0.03

%

Gain Error LMP8100 0.015 0.075

0.075

LMP8100 Gain Error (Gain = 1 V/V)

Extended +IN Range

+IN > 3.5V,

0.3V < V

OUT

< 4.7V

0.1

0.2

%

TCGE Gain Drift LMP8100A Gain = 16 0.5 2.2

ppm/°C

LMP8100 Gain = 16 0.8 4.8

V

OS

Input Offset Voltage LMP8100A ±50 ±250

±450

µV

LMP8100 ±50 ±400

±600

TCV

OS

Input Offset Temp Coefficient (Note 8) 1.5 5 µV/°C

I

B

Input Bias Current 0.1 5

100

pA

e

n

Input-Referred Noise Voltage

f = 10 kHz, 1 V/V ≤ Gain ≤ 16 V/V

12

nV/

f = 0.1 Hz to 10 Hz, 1 V/V ≤ Gain

≤ 16 V/V

3.8 µV

PP

BW Bandwidth C1 = C0 = 0, Gain = 1 V/V 33

MHz

C1 = C0 = 0, Gain = 2 V/V 15.5

C1 = C0 = 1, Gain = 16 V/V 9.5

SR Slew Rate (Note 7) 12 V/µs

PSRR Power Supply Rejection Ratio 2.7V < V+ < 5.5V 90

85

100

dB

V

O

Output Swing

High

+IN = 5V 4.9

4.85

4.95

V

Output Swing

Low

+IN = 0V 50 100

150

mV

I

O

Output Current Sourcing and Sinking 15 20 mA

V

IN

Input Voltage Range –0.2

0

5.2

5.0

V

I

S

Supply Current 5.3 6.0

7.2

mA

3 www.national.com

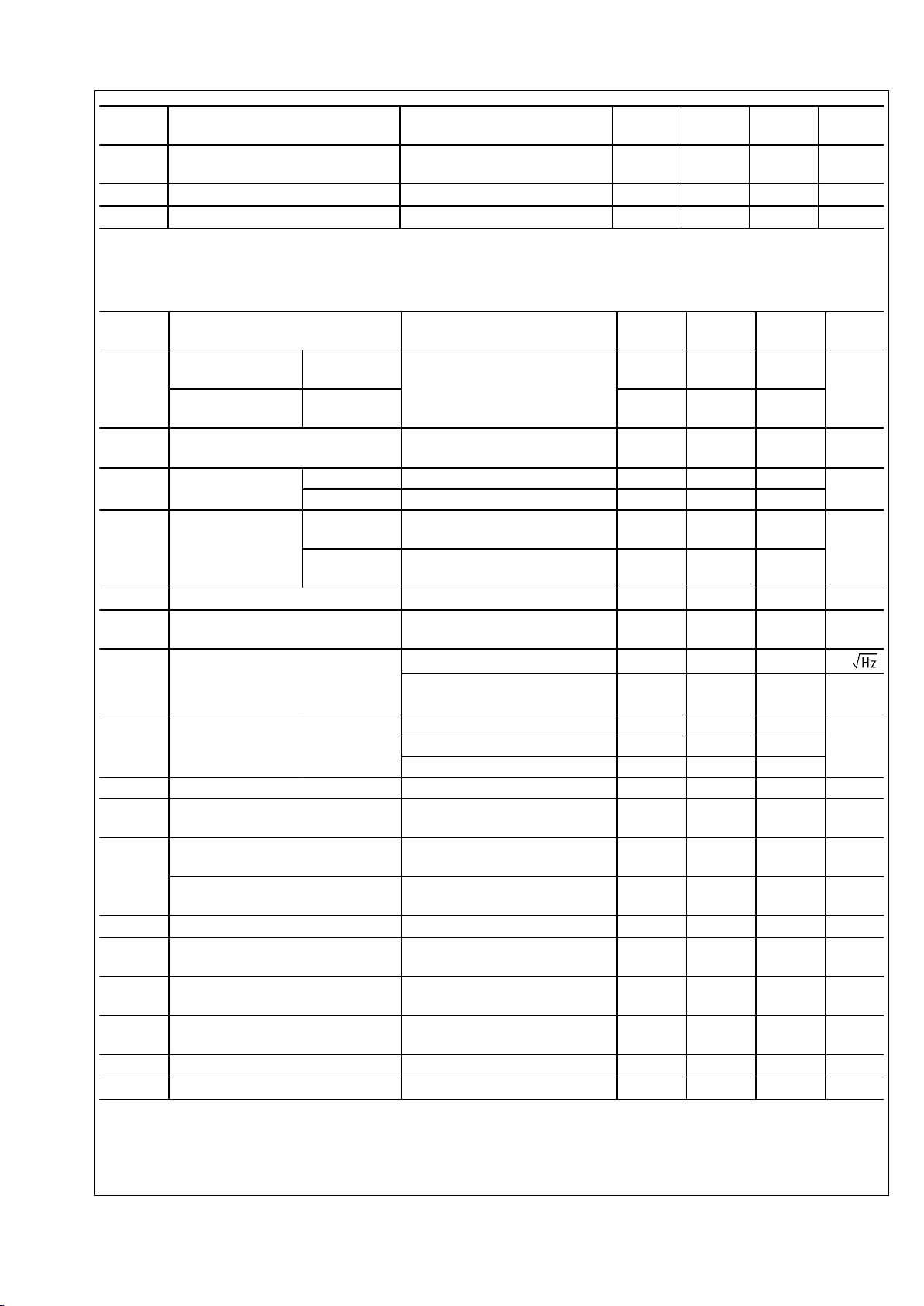

LMP8100

Page 4

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

I

PD

Supply Current, Power Down 3.5 20

40

µA

Feedback Resistance 5.6

kΩ

R

IN

Input Impedance f = 10 Hz >10

GΩ

3.3V Electrical Characteristics

Unless otherwise specified, all limits are guaranteed for TA = 25°C. V+ = 3.3V , V– = 0V, DGND = 0V, +IN = GRT = V+/2,

RL = 10 kΩ to V+/2; Gain = 1 V/V. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

Gain Error LMP8100A 0V < +IN < 1.8V,

1 V/V ≤ Gain ≤ 16 V/V,

0.3V < V

OUT

< 3.0V

0.015 0.03

0.03

%

Gain Error LMP8100 0.015 0.075

0.075

LMP8100 Gain Error (Gain = 1 V/V)

Extended +IN Range

+IN > 1.8V,

0.3V < V

OUT

< 3.0V

0.1

0.2

%

TCGE Gain Drift LMP8100A Gain = 16 0.5 2.2

ppm/°C

LMP8100 Gain = 16 0.8 4.8

V

OS

Input Offset Voltage LMP8100A ±50 ±250

±450

µV

LMP8100 ±50 ±400

±600

TCV

OS

Input Offset Temp Coefficient (Note 8) 1.5 5 µV/°C

I

B

Input Bias Current 0.1 5

100

pA

e

n

Input-referred Noise Voltage

f = 10 kHz, 1 V/V ≤ Gain ≤ 16 V/V

12

nV/

f = 0.1 Hz to 10 Hz, 1 V/V ≤ Gain ≤

16 V/V

3.8 µV

PP

BW Bandwidth C1 = C0 = 0, Gain = 1 V/V 33

MHzC1 = C0 = 0, Gain = 2 V/V 15.5

C1 = C0 = 1, Gain = 16 V/V 9.5

SR Slew Rate (Note 7) 12 V/µs

PSRR Power Supply Rejection Ratio 2.7V < V+ < 3.6V 90

80

100

dB

V

O

Output Swing

High

+IN = 3.3V 3.2

3.15

3.25

V

Output Swing

Low

+IN = 0V 50 100

150

mV

I

O

Output Current Sourcing and Sinking 15 20 mA

V

IN

Input Voltage Range −0.2

0

3.5

3.3

V

I

S

Supply Current 5.1 5.8

7.0

mA

I

PD

Supply Current, Power Down 1.8 20

40

µA

Feedback Resistance 5.6

kΩ

R

IN

Input Impedance >10

GΩ

www.national.com 4

LMP8100

Page 5

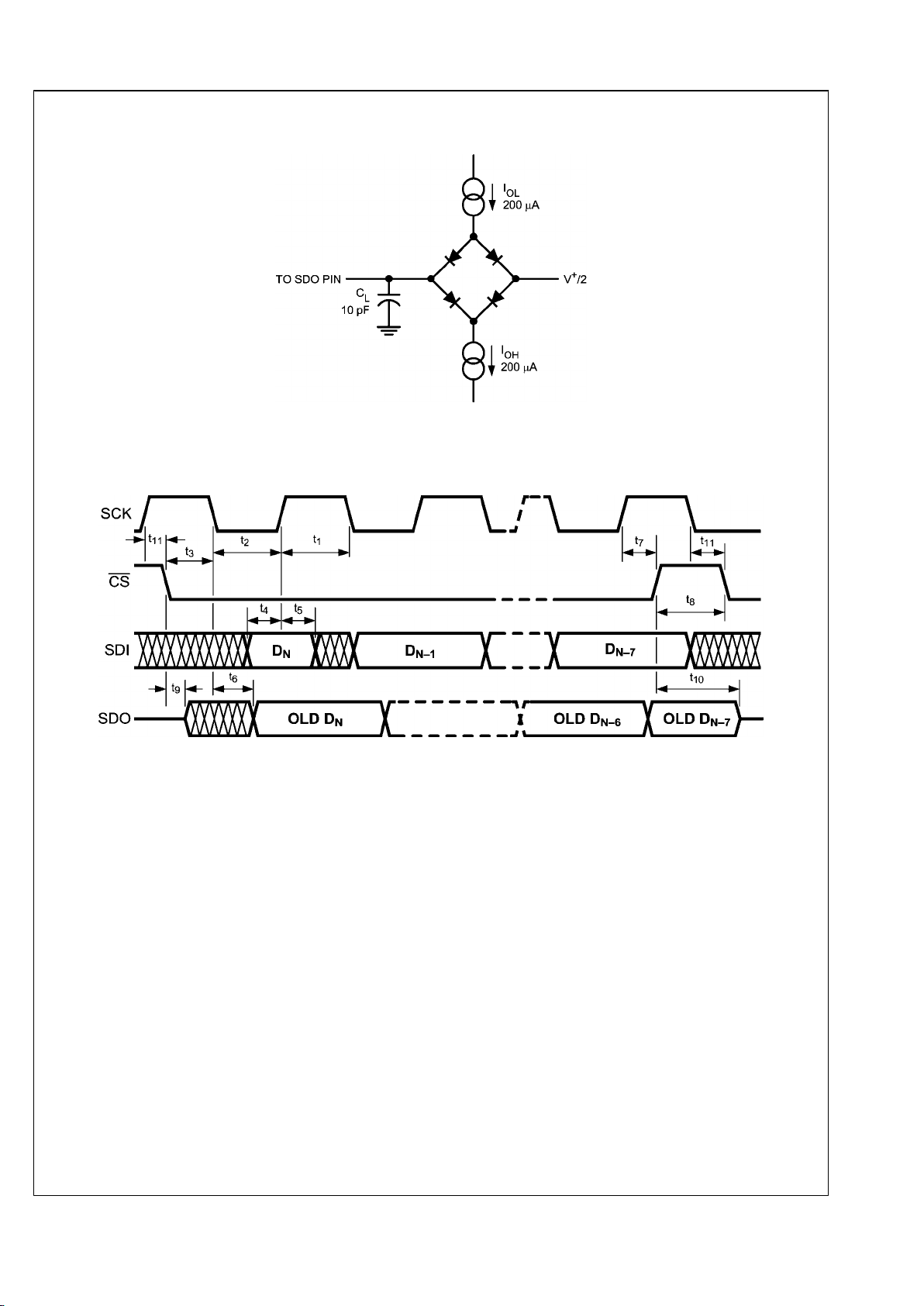

Electrical Characteristics (Serial Interface)

Unless otherwise specified, all limits guaranteed for TA = 25°C, V+ - V− ≥ 2.7V, VD = V+ - DGND ≥ 2.5V.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

V

IL

Logic Low Threshold

0.3 × V

D

V

V

IH

Logic High Threshold

0.7 × V

D

V

I

SDO

Output Source Current, SDO VD = 3.3V or 5.0V,

CS = 0V, VOH = V+ – 0.7V

−7

mA

Output Sink Current, SDO VD = 3.3V or 5.0V,

CS = 0V, VOL = 1.0V

10

I

OZ

Output Tri-state Leakage Current,

SDO

VD = 3.3V or 5.0V,

CS = VD = 3.3V or 5V

±1 µA

t

1

High Period, SCK (Note 9) 100

ns

t

2

Low Period, SCK (Note 9) 100

ns

t

3

Set Up Time, CS to SCK (Note 9) 50

ns

t

4

Set Up Time, SDI to SCK (Note 9) 30

ns

t

5

Hold Time, SCK to SDI (Note 9) 10

ns

t

6

Prop. Delay, SCK to SDO (Note 9)

60 ns

t

7

Hold Time, SCK Transition to CS

Rising Edge

(Note 9) 50

ns

t

8

CS Inactive (Note 9) 50

ns

t

9

Prop. Delay, CS to SDO Active (Note 9)

50 ns

t

10

Prop. Delay, CS to SDO Inactive (Note 9)

50 ns

t

11

Hold Time, SCK Transition to CS

Falling Edge

(Note 9) 10

ns

tR/t

F

Signal Rise and Fall Times (Note 9) 1.5

5 ns

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but for which specific performance is not guaranteed. For guaranteed specifications and the test conditions, see Electrical Characteristics.

Note 2: Human Body Model, applicable std. MIL-STD-883, Method 3015.7. Machine Model, applicable std. JESD22–A115–A (ESD MM std. of JEDEC). FieldInduced Charge-Device Model, applicable std. JESD22–C101–C (ESD FICDM std. of JEDEC).

Note 3: The short circuit test is a momentary test which applies to both single-supply and split-supply operation. Continuous short circuit operation at elevated

ambient temperature can exceed the maximum allowable junction temperature of 150°C.

Note 4: The maximum power dissipation is a function of T

J(MAX)

, θJA. The maximum allowable power dissipation at any ambient temperature is PD = (T

J(MAX)

–

TA)/ θJA. All numbers apply for packages soldered directly onto a PC Board.

Note 5: Typical Values indicate the most likely parametric norm as determined at the time of characterization. Actual typical values may vary over time and will

also depend on the application and configuration. The typical values are not tested and are not guaranteed on shipped production material.

Note 6: All limits are guaranteed by testing or statistical analysis.

Note 7: Slew rate is the average of the rising and falling slew rates.

Note 8: The offset voltage average drift is determined by dividing the value of VOS at the temperature extremes by the total temperature change.

Note 9: Load for these tests is shown in the Timing Diagram Test Circuit.

5 www.national.com

LMP8100

Page 6

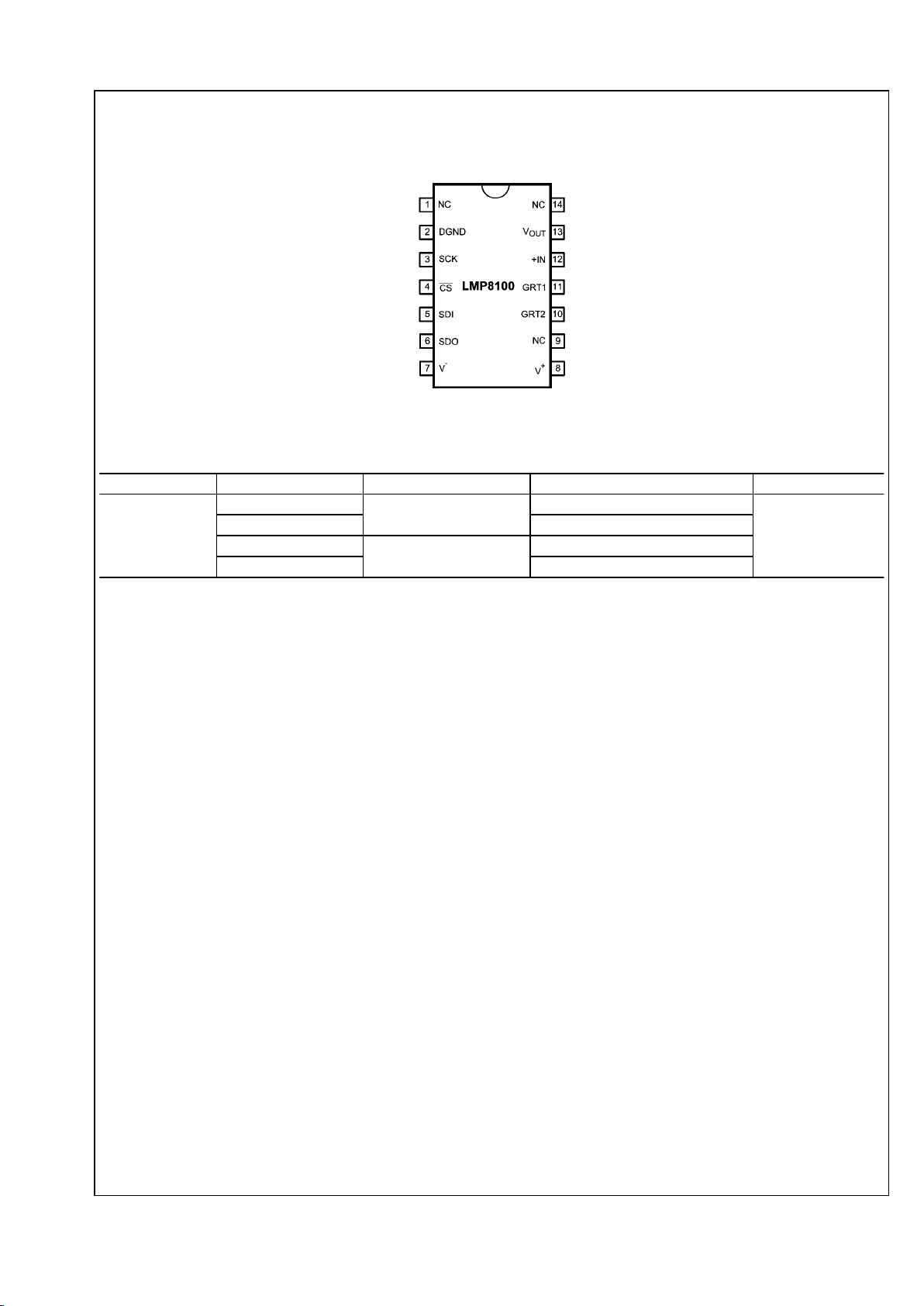

Connection Diagram

14-Pin SOIC

20147601

Top View

Ordering Information

Package Part Number Package Marking Transport Media NSC Drawing

14-Pin SOIC

LMP8100AMA

LMP8100AMA

55 Units/Rail

M14A

LMP8100AMAX 2.5k units Tape and Reel

LMP8100MA

LMP8100MA

55 Units/Rail

LMP8100MAX 2.5k units Tape and Reel

www.national.com 6

LMP8100

Page 7

Timing Diagram Test Circuit

20147653

Timing Diagram

20147603

7 www.national.com

LMP8100

Page 8

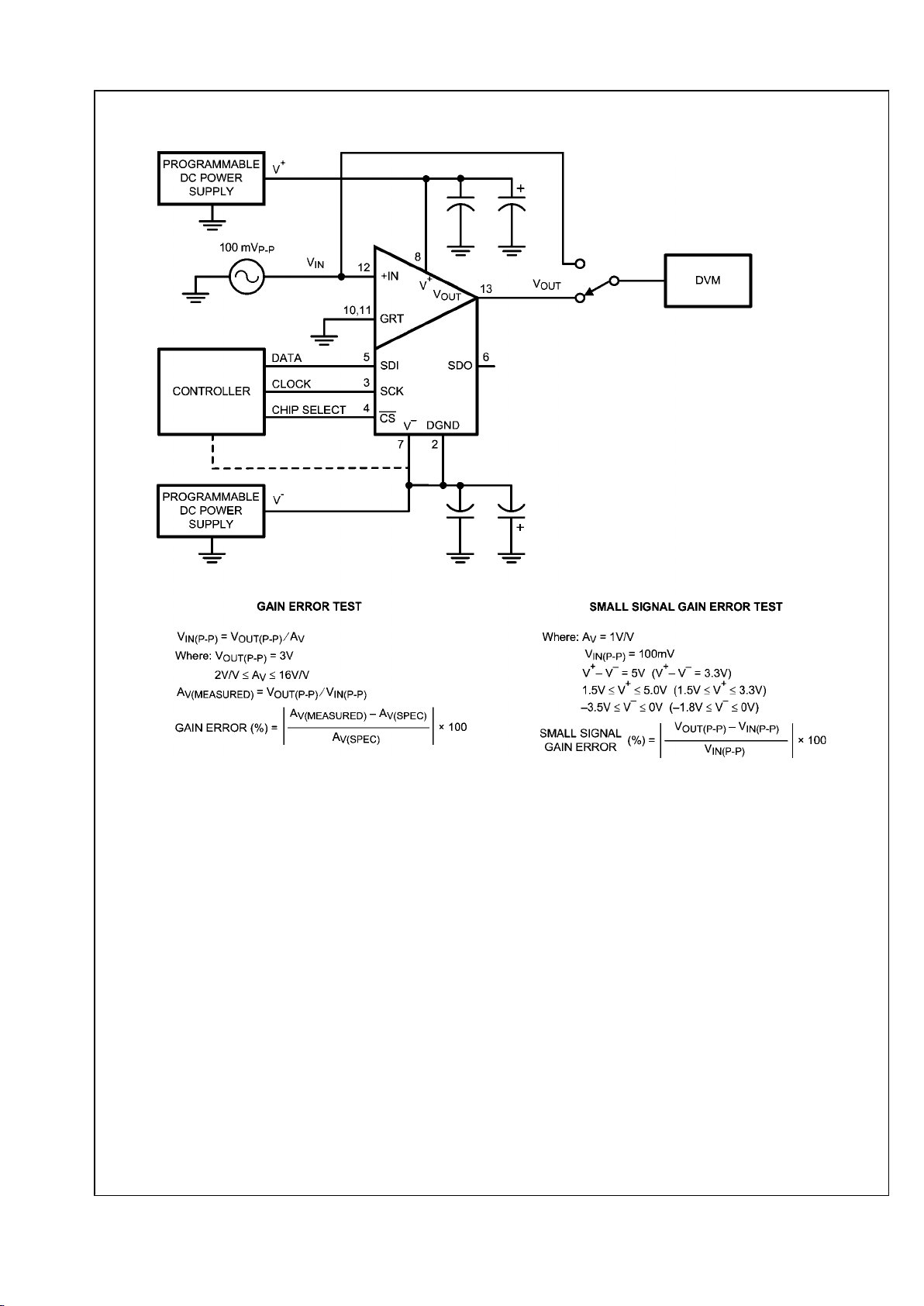

Test Circuit Diagram

20147609

Test Circuit

www.national.com 8

LMP8100

Page 9

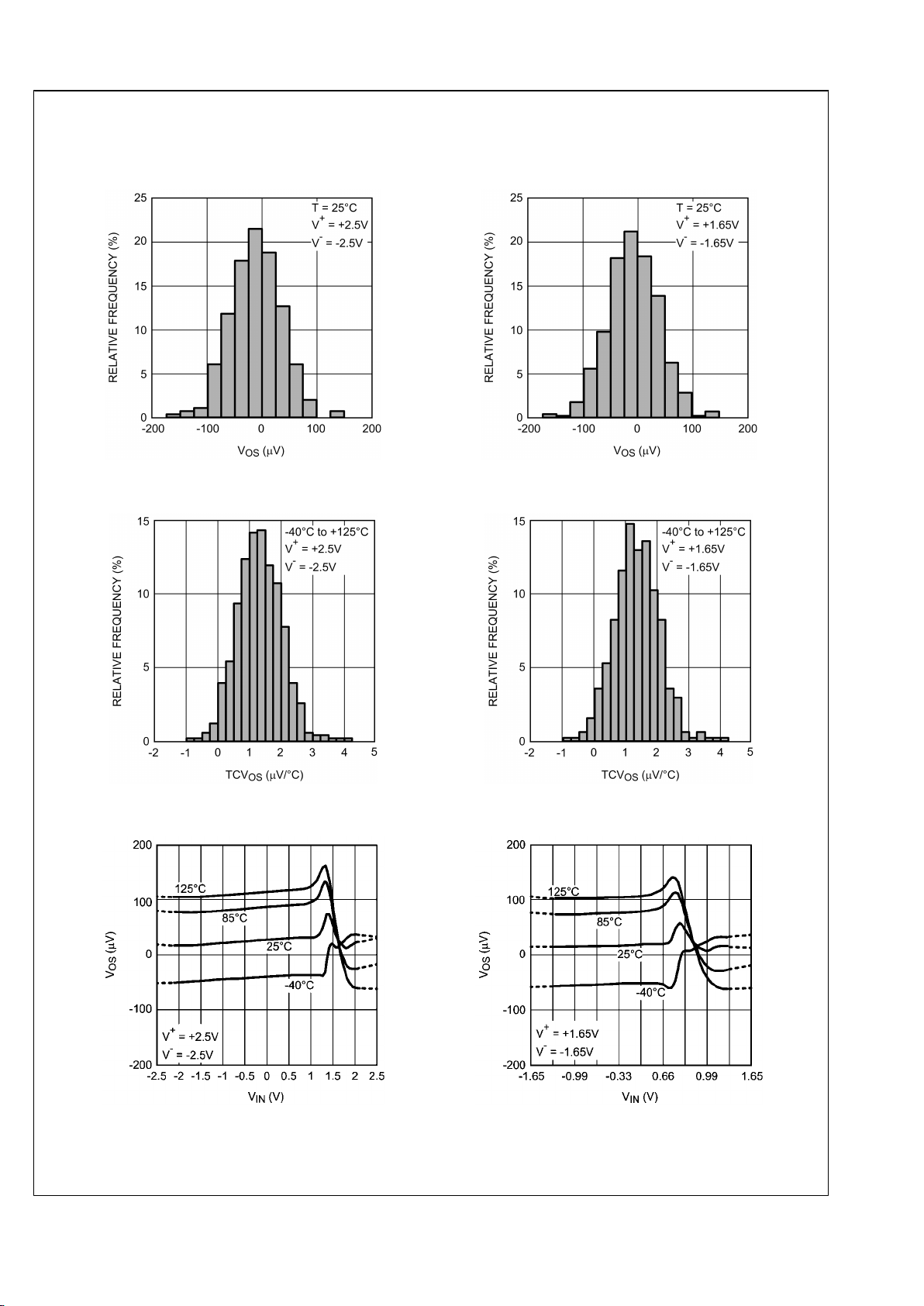

Typical Performance Characteristics

Offset Voltage Distribution

20147685

Offset Voltage Distribution

20147686

TCVOS Distribution

20147683

TCVOS Distribution

20147684

VOS vs. V

IN

20147666

VOS vs. V

IN

20147667

9 www.national.com

LMP8100

Page 10

VOS vs. V

S

20147665

VOS vs. V

S

20147664

IB vs. V

IN

20147662

IB vs. V

IN

20147663

IS vs. V

S

20147660

IS vs. V

S

20147661

www.national.com 10

LMP8100

Page 11

DC Gain Error A = 1

20147689

DC Gain Error A = 1

20147687

DC Gain Error A = 2

20147690

DC Gain Error A = 2

20147688

Small Signal Gain Error vs. +IN DC Level

20147633

Small Signal Gain Error vs. +IN DC Level

20147651

11 www.national.com

LMP8100

Page 12

PSRR vs. Frequency

20147610

PSRR vs. Frequency

20147611

I

OUT

vs. V

OUT

(Source)

20147669

I

OUT

vs. V

OUT

(Sink)

20147668

I

OUT

vs. V

OUT

(Source)

20147671

I

OUT

vs. V

OUT

(Sink)

20147670

www.national.com 12

LMP8100

Page 13

Small Signal Step Response

20147635

Small Signal Step Response

20147636

Small Signal Step Response

20147637

Small Signal Step Response

20147638

Small Signal Step Response

20147639

Small Signal Step Response

20147640

13 www.national.com

LMP8100

Page 14

Small Signal Step Response

20147641

Small Signal Step Response

20147642

Large Signal Step Response

20147643

Large Signal Step Response

20147644

Large Signal Step Response

20147645

Large Signal Step Response

20147646

www.national.com 14

LMP8100

Page 15

Large Signal Step Response

20147647

Large Signal Step Response

20147648

Large Signal Step Response

20147649

Large Signal Step Response

20147650

THD+N vs. Frequency

20147675

THD+N vs. Frequency

20147674

15 www.national.com

LMP8100

Page 16

THD+N vs. V

OUT

20147673

THD+N vs. V

OUT

20147672

Bandwidth vs. Capacitive Load

20147617

Bandwidth vs. Capacitive Load

20147618

Peaking vs. Capacitive Load

20147621

Peaking vs. Capacitive Load

20147622

www.national.com 16

LMP8100

Page 17

Peaking vs. Capacitive Load

20147623

Gain vs. Frequency

20147630

Gain vs. Frequency

20147629

Gain vs. Frequency

20147628

Gain vs. Frequency

20147627

AC Gain Error vs. Frequency

20147656

17 www.national.com

LMP8100

Page 18

AC Gain Error vs. Frequency

20147655

AC Gain Error vs. Frequency

20147657

AC Gain Error vs. Frequency

20147658

AC Gain Error vs. Frequency

20147659

Noise vs. Frequency

20147654

0.1 Hz to 10 Hz Noise

201476a2

www.national.com 18

LMP8100

Page 19

Closed Loop Output Impedance vs. Frequency

20147631

Input Impedance

201476a1

SDO V vs. I

20147634

SDO V vs. I

20147652

19 www.national.com

LMP8100

Page 20

Applications Information

LIFETIME DRIFT

Offset voltage (VOS) and gain are electrical parameters which

may drift over time. This drift, known as lifetime drift, is very

common in operational amplifiers; however, its effect is more

evident in precision amplifiers. This is due to the very low offset voltage specification and very precise gain specification

of the LMP8100. The LMP8100 has an option to zero out the

offset voltage. When the zero bit of the register is set high,

+IN is connected to GRT. Output offset voltage can be measured and adjusted out of the signal path. See the “Input

Zeroing” section, for more information. Numerous reliability

tests have been performed to characterize this drift for the

LMP8100. Prior to each long term reliability test the input offset voltage and gain at 2X and 16X of each LMP8100 was

measured at room temperature.

The long term reliability tests include Operating Life Time

(OPL) performed at 150°C for an extended period of time and

Temperature Humidity Bias Testing (THBT) at 85°C and 85%

humidity for an extended period of time. The offset voltage

and gain of 2X and 16X were measured again at room temperature after each reliability test.

The offset voltage drift is the difference between the initial

measurement and the later measurement, after the reliability

test.

The gain drift is the percentage difference between the initial

measurement and the later measurement, after the reliability

test. Figure 1 – Figure 4 show the offset voltage drift and gain

drift after 1000 hours of OPL.

Figure 5 – Figure 8 show the offset voltage drift and gain drift

after 1000 hours of THBT.

20147691

FIGURE 1. OPL VOS Drift

20147692

FIGURE 2. OPL VOS Drift

20147693

FIGURE 3. OPL Gain Drift, A = 2

20147694

FIGURE 4. OPL Gain Drift, A = 16

www.national.com 20

LMP8100

Page 21

20147695

FIGURE 5. THBT VOS Drift

20147696

FIGURE 6. THBT VOS Drift

20147697

FIGURE 7. THBT Gain Drift, A = 2

20147698

FIGURE 8. THBT Gain Drift, A = 16

POWER-ON RESET

The LMP8100 has a power-up reset feature that sets all the

register bits to 0 when the part is powered up. To implement

this feature the CS

and SCK pins must be held at or above

VIH when the LMP8100 is powered-up. Failure to power up in

this method can lead to an unpredictable state of the register

bits after power-up.

CONTROL REGISTER

The control register retains the information which controls the

amplifier gain, bandwidth compensation, input zeroing, and

power down. The register is loaded by way of the serial control

interface. The register is double buffered so that changes can

be made with minimum effect on amplifier performance. Table

1 shows the organization of the control register. Table 2 gives

the codes for gain setting, input zeroing and power down control. Table 3 shows the codes for the four gain-bandwidth

compensation levels.

TABLE 1. Control Register Format

C1 C0 Zero PD G3 G2 G1 G0

MSB LSB

C0, C1: Compensation setting

Zero: Zero Input

PD: Power Down

G0 to G3: Gain setting

21 www.national.com

LMP8100

Page 22

TABLE 2. Input Zero, Power-Down

and Gain Setting Codes

Zero PD G3 G2 G1 G0 Non-Inverting

Gain

0 0 0 0 0 1

0 0 0 0 1 2

0 0 0 1 0 3

0 0 0 1 1 4

0 0 1 0 0 5

0 0 1 0 1 6

0 0 1 1 0 7

0 0 1 1 1 8

0 1 0 0 0 9

0 1 0 0 1 10

0 1 0 1 0 11

0 1 0 1 1 12

0 1 1 0 0 13

0 1 1 0 1 14

0 1 1 1 0 15

0 1 1 1 1 16

X 1 X X X X Power Down

1 0 X X X X Zero Input

TABLE 3. Amplifier Gain Compensation Codes

C1 C0 Compensation

Level

Condition

0 0 0

Maximum

Compensation

0 1 1

1 0 2

1 1 3

Minimum

Compensation

AMPLIFIER GAIN SETTING AND BANDWIDTH

COMPENSATION CONTROL

The gain of the LMP8100 is set to one of 16 levels under program control by setting the appropriate bits G[3:0] of the

control register with a number from 00h to 15h. This sets the

gain to a level from 1 V/V to 16 V/V respectively.

The gain-bandwidth compensation is also selectable to one

of four levels under program control. The amount of compensation can be decreased to maximize the available bandwidth

as the gain of the amplifier is increased. The compensation

level is selected by setting bits C[1:0] of the control register

with a number from 00b to 11b with 00b being maximum compensation and 11b being minimum compensation. Table 4

shows the bandwidths achieved at several gain and compensation settings. It will be noted that for gains between X1 and

X5, the recommended compensation setting is 00b. For gain

settings between X6 and X10, compensation settings may be

00b and 01b. Gain settings between X11 and X15 may use

the three bandwidth compensation settings between 00b and

10b. At a gain of X16, all bandwidth compensation ranges

may be used. Note that, for lower gains, it is possible to undercompensate the amplifier into instability.

TABLE 4. Amplifier Gain and Compensation

vs. Bandwidth

Gain Compensation Bits 3 dB Bandwidth

(MHz)

V/V dB C1 C0

1 0 0 0 33.0

2 6.02 0 0 15.5

6 15.6 0 0 4.2

6 15.6 0 1 8.3

11 20.8 0 0 2.0

11 20.8 0 1 3.9

11 20.8 1 0 6.6

16 24.1 0 0 1.3

16 24.1 0 1 2.3

16 24.1 1 0 3.8

16 24.1 1 1 9.5

NON-INVERTING AMPLIFIER OPERATION

The principal application of the LMP8100 is as a non-inverting

amplifier as shown in the simplified schematic, Figure 9. The

amplifier supply voltage (V+ to V−) is specified as 5.5V maximum. The V– supply pin is connected to the system ground

for single supply operation. V− can be returned to a negative

voltage when required by the application. The digital supply

voltage for the serial interface is applied between the V+ supply pin and DGND.

20147605

FIGURE 9. Basic Non-Inverting Amplifier

www.national.com 22

LMP8100

Page 23

GRT PINS

The GRT pins must have a low impedance connection to either ground or a reference voltage. Any parasitical impedance

on these pins will affect the gain accuracy of the LMP8100.

Figure 10 shows a simplified schematic of the LMP8100

showing the internal gain resistors and an external parasitical

resistance RP. The gain of the LMP8100 is determined by

RF and RG, the values of which are set by the internal register.

The gain of the amplifier is given by the equation

Any resistance between the GRT pins and either ground or a

reference voltage will change the gain to

20147679

FIGURE 10. LMP8100 with External Parasitical

Resistance

The connection between the GRT pins and ground or a reference voltage should be as short as possible using wide

traces to minimize the parasitical resistance. Figure 11 shows

two suggested methods of connecting the GRT pins to a

ground plane on the same layer or to a ground plane on a

different layer of the PCB.

20147676

FIGURE 11. GRT Connection Methods

The GRT pin can be connected to a reference voltage source

to provide an offset adjustment to the gain function. Any DC

resistance that may be present between the voltage source

and the GRT pin must be kept to an absolute minimum to

avoid introducing gain errors into the circuit.

INPUT ZEROING

Measurements made with the LMP8100 in the signal path

may be adjusted for the output offset voltage of the amplifier.

For example: The measurement of V

OUT

for offset correction

might be made using an ADC under microprocessor control.

Output offset is measured under program control by setting

the ZERO bit in the programming register. In this mode, +IN

is disconnected from the input pin and internally connected to

the GRT input. Figure 12 shows the LMP8100 in the input

zeroing mode.

23 www.national.com

LMP8100

Page 24

20147606

FIGURE 12. Non-Inverting Input Zeroing Function

SERIAL CONTROL INTERFACE OPERATION

The LMP8100 gain, bandwidth compensation, power down,

and input zeroing are controlled by data stored in a programming register. Data to be written into the control register is first

loaded into the LMP8100 via the serial interface. The serial

interface employs an 8-bit shift register. Data is loaded

through the serial data input, SDI. Data passing through the

shift register is output through the serial data output, SDO.

The serial clock, SCK controls the serial loading process. All

eight data bits are required to correctly program the amplifier.

The falling edge of CS enables the shift register to receive

data. The SCK signal must be high during the falling and rising

edge of CS. Each data bit is clocked into the shift register on

the rising edge of SCK. Data is transferred from the shift register to the holding register on the rising edge of CS. Operation

is shown in the timing diagram,Figure 13.

20147624

FIGURE 13. Serial Control Interface Timing

www.national.com 24

LMP8100

Page 25

The serial control pins can be connected in one of two ways

when two or more LMP8100s are used in an application.

Star Configuration

This configuration can be used if each LMP8100 will always

have the same value in each register. The connections are

shown in Figure 14. After the microcontroller writes a byte all

registers will have the same value.

20147680

FIGURE 14. Star Configuration

Daisy Chain Configuration

This configuration can be used to program the same or different values in the register of each LMP8100. The connections are shown in Figure 15. In this configuration the SDO

pin of each LMP8100 is connected to the SDI pin of the fol-

lowing LMP8100. The following two examples show how the

registers are written.

If all three LMP8100s need a gain of 11 with a compensation level of 10. (10001010)

Register of

LMP8100 #1

Register of

LMP8100 #2

Register of

LMP8100 #3

Notes

Power on 00000000 00000000 00000000 Default power on state (see above)

Byte one sent 10001010 00000000 00000000 The data in the register of LMP8100 #1 is

shifted into the register of LMP8100 #2, the

data in the register of LMP8100 #2 is shifted

into the register of LMP8100 #3.

Byte two sent 10001010 10001010 00000000

Byte three sent 10001010 10001010 10001010

If LMP8100 #1 needs a gain of 11 with a compensation level of 10 (10001010), LMP8100 #2 needs a gain of 6 with a compensation

of 00 (00000101), and LMP8100 #3 needs a gain of 2 with a compensation of 00 (00000001).

Register of

LMP8100 #1

Register of

LMP8100 #2

Register of

LMP8100 #3

Notes

Power on 00000000 00000000 00000000 Default power on state (see above)

Byte one sent 00000001 00000000 00000000 The data in the register of LMP8100 #1 is

shifted into the register of LMP8100 #2, the

data in the register of LMP8100 #2 is shifted

into the register of LMP8100 #3.

Byte two sent 00000101 00000001 00000000

Byte three sent 10001010 00000101 00000001

25 www.national.com

LMP8100

Page 26

20147681

FIGURE 15. Daisy Chain Configuration

POWER SUPPLY PURITY AND BYPASSING

Particular attention to power supply purity is needed in order

to preserve the LMP8100's gain accuracy and low noise. The

LMP8100 worst-case PSRR is 85 dB or 56.2 µV/V. Nevertheless, the usable dynamic range, gain accuracy and inherent low noise of the amplifier can be compromised through

the introduction and amplification of power supply noise.

To decouple the LMP8100 from supply line AC noise, a 0.1

µF capacitor should be located on each supply line, close to

the LMP8100. Adding a 10 µF capacitor in parallel with the

0.1 µF capacitor will reduce the noise introduced to the

LMP8100 even more by providing an AC path to ground for

most frequency ranges.

A power supply dropout (V+ -V− < 2.7V) can cause an unintended reset of the register. If a dropout occurs, the register

will need to be reprogrammed with the correct values.

SCALING AMPLIFIER

The LMP8100 is ideally suited for use as an amplifier between

a sensor that has a wide output range and an ADC. As the

signal from the sensor changes the gain of the LMP8100 can

be changed so that the entire input range of the ADC is being

used at all times. Figure 16 shows a data acquisition system

using the LMP8100 and the ADC121S101. The 100Ω resistor

and 390 pF capacitor form an antialiasing filter for the ADC121S101. The capacitor also stores and delivers charge to

the switched capacitor input of the ADC. The capacitive load

on the LMP8100 created by the 390pF capacitor is decreased

by the 100Ω resistor.

20147682

FIGURE 16. Data Acquisition System Using the LMP8100

www.national.com 26

LMP8100

Page 27

BRIDGE AMPLIFIER

In Figure 17 two LMP8100s are used with a LMP7711 to build

an amplifier for the signal from a GMR Magnetic Field Sensor.

The advantage of using the LMP8100 is that as the signal

strength from the Magnetic Field Sensor decreases, the gain

of the LMP8100 can be increased. An example is if the signal

from this composite amplifier is used to drive an ADC. When

the maximum magnetic field to be measured is applied, the

gain of the LMP7711 can be set to supply a full range signal

to the ADC input with the gain of the LMP8100 set to one. As

the magnetic field decreases, the gain of the LMP8100 can

be increased, so that the signal supplied to the ADC uses a

maximum amount of the ADC input range.

The following can be done to maximize performance:

•

Connect the GRT pins directly together and to GND with

a low impedance trace.

•

Make the traces between the Magnetic Field Sensor and

the LMP8100s short to minimize noise pickup.

•

Place 0.1 μF capacitors close to each of the LMP8100

supply pins.

The following can be done to simplify the design:

•

Connect the SCL, SCK, and CS lines in parallel and one

microcontroller can be used to drive both LMP8100s.

•

The SDO pin can be left floating.

The LM317 and LM6171 are used for the supply of the Magnetic Sensor. The 100Ω potentiometer is used to adjust the

supply voltage to the Magnetic Field Sensor. The 2 kΩ potentiometer is used to fine tune the negative supply to set the

Magnetic Field Sensor output to zero.

20147625

FIGURE 17. Bridge Amplifier

27 www.national.com

LMP8100

Page 28

Physical Dimensions inches (millimeters) unless otherwise noted

14-Pin SOIC

NS Package Number M14A

www.national.com 28

LMP8100

Page 29

Notes

29 www.national.com

LMP8100

Page 30

Notes

LMP8100 Programmable Gain Amplifier

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...