Page 1

January 15, 2008

LMP2232 Dual

Micropower, 1.8V, Precision, Operational Amplifier with

CMOS Input

General Description

The LMP2232 is a dual micropower precision amplifier designed for battery powered applications. The 1.8V to 5.0V

guaranteed supply voltage range and quiescent power consumption of only 29 μW extend the battery life in portable

systems. The LMP2232 is part of the LMP® precision amplifier

family. The high impedance CMOS input makes it ideal for

instrumentation and other sensor interface applications.

The LMP2232 has a maximum offset voltage of 150 μV and

maximum offset voltage drift of only 0.5 μV/°C along with low

bias current of only ±20 fA. These precise specifications make

the LMP2232 a great choice for maintaining system accuracy

and long term stability.

The LMP2232 has a rail-to-rail output that swings 15 mV from

the supply voltage, which increases system dynamic range.

The common mode input voltage range extends 200 mV below the negative supply, thus the LMP2232 is ideal for ground

sensing in single supply applications.

The LMP2232 is offered in 8-pin SOIC and MSOP packages.

The LMP2231 is the single version of this product and the

LMP2234 is the quad version of this product. Both of these

products are available on National Semiconductor's website.

Features

(For VS = 5V, Typical unless otherwise noted)

■

Supply current (per channel) 10 µA

■

Operating voltage range 1.6V to 5.5V

■

Low TCV

OS

±0.5 µV/°C (max)

■

V

OS

±150 µV (max)

■

Input bias current 20 fA

■

PSRR 120 dB

■

CMRR 97 dB

■

Open loop gain 120 dB

■

Gain bandwidth product 130 kHz

■

Slew rate 58 V/ms

■

Input voltage noise, f = 1 kHz 60 nV/√Hz

■

Temperature range –40°C to 125°C

Applications

■

Precision instrumentation amplifiers

■

Battery powered medical instrumentation

■

High impedance sensors

■

Strain gauge bridge amplifier

■

Thermocouple amplifiers

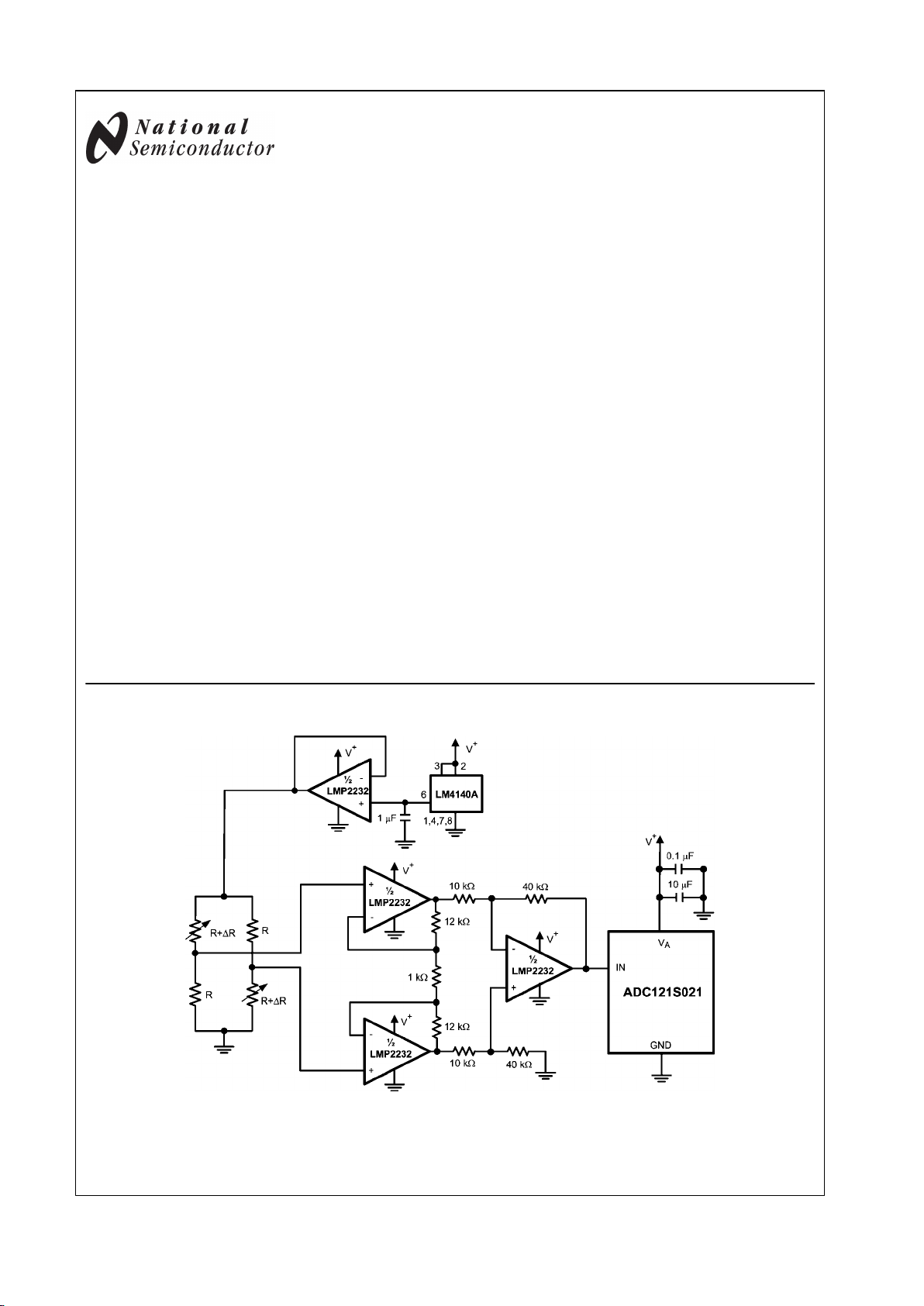

Typical Application

30033974

Strain Gauge Bridge Amplifier

LMP® is a registered trademark of National Semiconductor Corporation.

© 2008 National Semiconductor Corporation 300339 www.national.com

LMP2232 Dual 1.8V, Micropower, Precision, Operational Amplifier with CMOS Input

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

ESD Tolerance (Note 2)

Human Body Model 2000V

Machine Model 100V

Differential Input Voltage ±300 mV

Supply Voltage (VS = V+ - V–)

6V

Voltage on Input/Output Pins V+ + 0.3V, V– – 0.3V

Storage Temperature Range −65°C to 150°C

Junction Temperature (Note 3) 150°C

Mounting Temperature

Infrared or Convection (20 sec.) +235°C

Wave Soldering Lead

Temperature (10 sec.) +260°C

Operating Ratings (Note 1)

Operating Temperature Range (Note 3) −40°C to 125°C

Supply Voltage (VS = V+ - V–)

1.6V to 5.5V

Package Thermal Resistance (θJA)(Note 3)

8-Pin SOIC 111.2 °C/W

8-Pin MSOP 147.4 °C/W

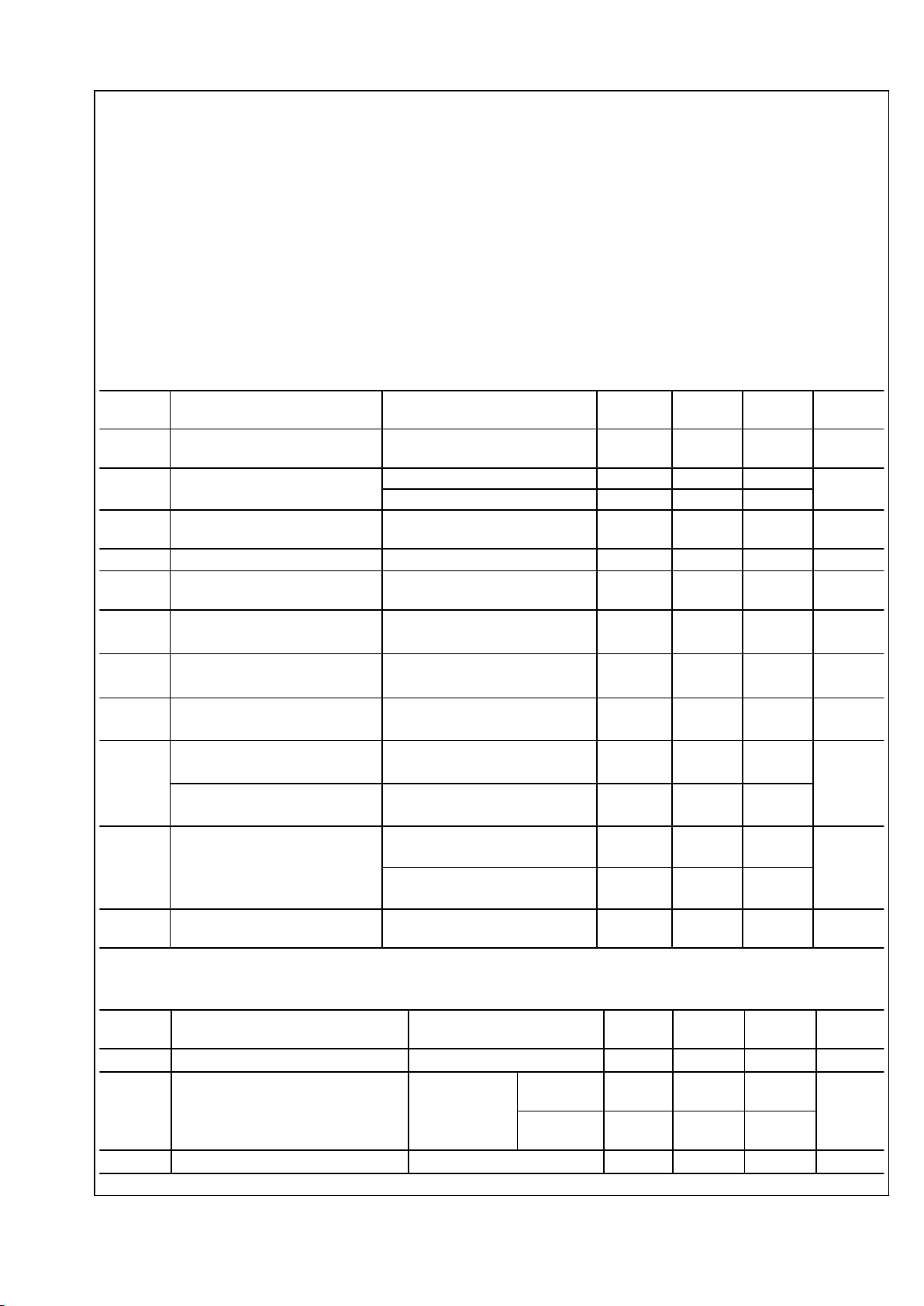

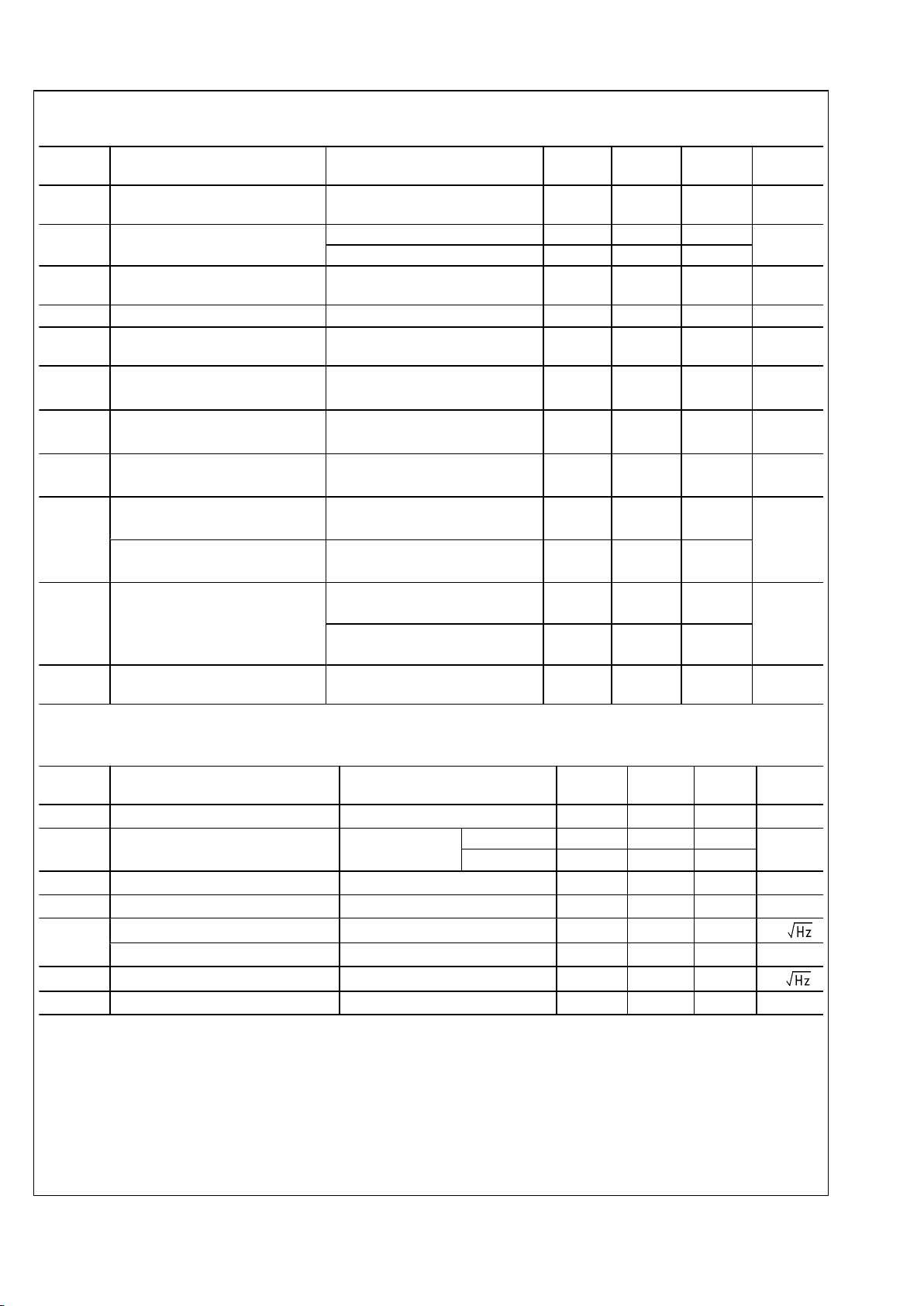

5V DC Electrical Characteristics (Note 4) Unless otherwise specified, all limits guaranteed for T

A

= 25°C,

V+ = 5V, V− = 0V, VCM = VO = V+/2, and RL > 1 MΩ. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

V

OS

Input Offset Voltage ±10 ±150

±230

μV

TCV

OS

Input Offset Voltage Drift LMP2232A ±0.3 ±0.5

μV/°C

LMP2232B ±0.3 ±2.5

I

BIAS

Input Bias Current 0.02 ±3

±125

pA

I

OS

Input Offset Current 5 fA

CMRR Common Mode Rejection Ratio

0V ≤ VCM ≤ 4V

81

80

97

dB

PSRR Power Supply Rejection Ratio

1.6V ≤ V+ ≤ 5.5V

V− = 0V, VCM = 0V

83

83

120

dB

CMVR Common Mode Voltage Range

CMRR ≥ 80 dB

CMRR ≥ 79 dB

−0.2

−0.2

4.2

4.2

V

A

VOL

Large Signal Voltage Gain VO = 0.3V to 4.7V

RL = 10 kΩ to V+/2

110

108

120

dB

V

O

Output Swing High

RL = 10 kΩ to V+/2

VIN(diff) = 100 mV

17 50

50

mV

from either

rail

Output Swing Low

RL = 10 kΩ to V+/2

VIN(diff) = −100 mV

17 50

50

I

O

Output Current (Note 7) Sourcing, VO to V

−

VIN(diff) = 100 mV

27

19

30

mA

Sinking, VO to V

+

VIN(diff) = −100 mV

17

12

22

I

S

Supply Current 19 27

28

μA

5V AC Electrical Characteristics (Note 4) Unless otherwise specified, all limits guaranteed for T

A

= 25°C,

V+ = 5V, V− = 0V, VCM = VO = V+/2, and RL > 1 MΩ. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

GBW Gain-Bandwidth Product

CL = 20 pF, RL = 10 kΩ

130 kHz

SR Slew Rate AV = +1 Falling Edge 33

32

58

V/ms

Rising Edge 33

32

48

θ

m

Phase Margin

CL = 20 pF, RL = 10 kΩ

68 deg

www.national.com 2

LMP2232

Page 3

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

G

m

Gain Margin

CL = 20 pF, RL = 10 kΩ

27

dB

e

n

Input-Referred Voltage Noise Density f = 1 kHz 60

nV/

Input Referred Voltage Noise 0.1 Hz to 10 Hz 2.3

μV

PP

i

n

Input-Referred Current Noise f = 1 kHz 10

fA/

THD+N Total Harmonic Distortion + Noise

f = 100 Hz, RL = 10 kΩ

0.002

%

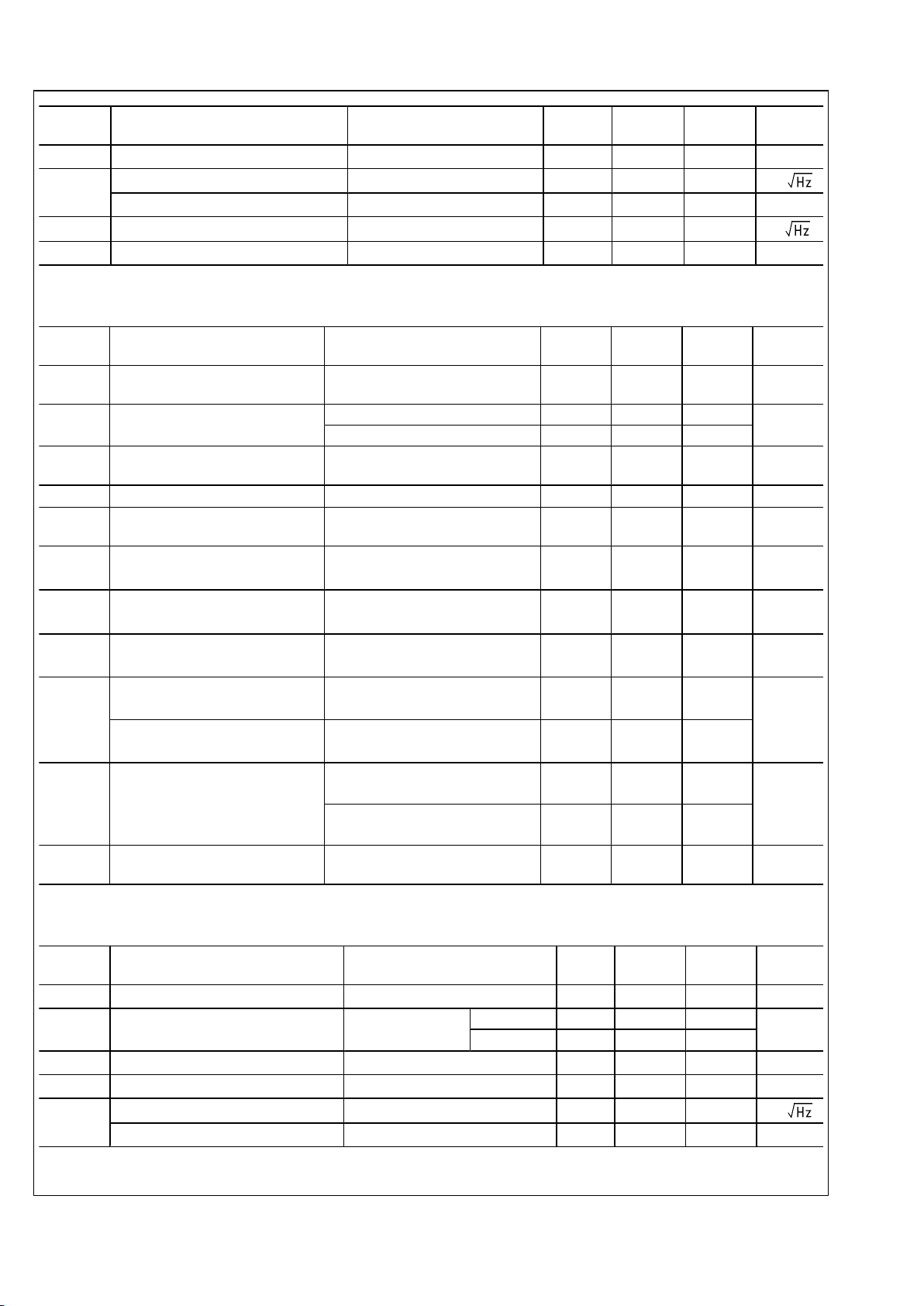

3.3V DC Electrical Characteristics (Note 4) Unless otherwise specified, all limits guaranteed for

T A = 25°C, V+ = 3.3V, V− = 0V, VCM = VO = V+/2, and RL > 1 MΩ. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

V

OS

Input Offset Voltage ±10 ±160

±250

μV

TCV

OS

Input Offset Voltage Drift LMP2232A ±0.3 ±0.5

μV/°C

LMP2232B ±0.3 ±2.5

I

BIAS

Input Bias Current 0.02 ±3

±125

pA

I

OS

Input Offset Current 5

fA

CMRR Common Mode Rejection Ratio

0V ≤ VCM ≤ 2.3V

79

77

92

dB

PSRR Power Supply Rejection Ratio

1.6V ≤ V+ ≤ 5.5V

V− = 0V, VCM = 0V

83

83

120

dB

CMVR Common Mode Voltage Range

CMRR ≥ 78 dB

CMRR ≥ 77 dB

−0.2

−0.2

2.5

2.5

V

A

VOL

Large Signal Voltage Gain VO = 0.3V to 3V

RL = 10 kΩ to V+/2

108

107

120

dB

V

O

Output Swing High

RL = 10 kΩ to V+/2

VIN(diff) = 100 mV

14 50

50

mV

from either

rail

Output Swing Low

RL = 10 kΩ to V+/2

VIN(diff) = −100 mV

14 50

50

I

O

Output Current (Note 7) Sourcing, VO to V

−

VIN(diff) = 100 mV

11

8

14

mA

Sinking, VO to V

+

VIN(diff) = −100 mV

8

5

11

I

S

Supply Current 17 25

26

μA

3.3V AC Electrical Characteristics (Note 4) Unless otherwise is specified, all limits guaranteed for

TA = 25°C, V+ = 3.3V, V− = 0V, VCM = VO = V+/2, and RL > 1 MΩ. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

GBW Gain-Bandwidth Product

CL = 20 pF, RL = 10 kΩ

128 kHz

SR Slew Rate AV = +1, CL = 20 pF

RL = 10 kΩ

Falling Edge 58

V/ms

Rising Edge 48

θ

m

Phase Margin

CL = 20 pF, RL = 10 kΩ

66 deg

G

m

Gain Margin

CL = 20 pF, RL = 10 kΩ

26 dB

e

n

Input-Referred Voltage Noise Density f = 1 kHz 60

nV/

Input-Referred Voltage Noise 0.1 Hz to 10 Hz 2.4

μV

PP

3 www.national.com

LMP2232

Page 4

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

i

n

Input-Referred Current Noise f = 1 kHz 10

fA/

THD+N Total Harmonic Distortion + Noise

f = 100 Hz, RL = 10 kΩ

0.003

%

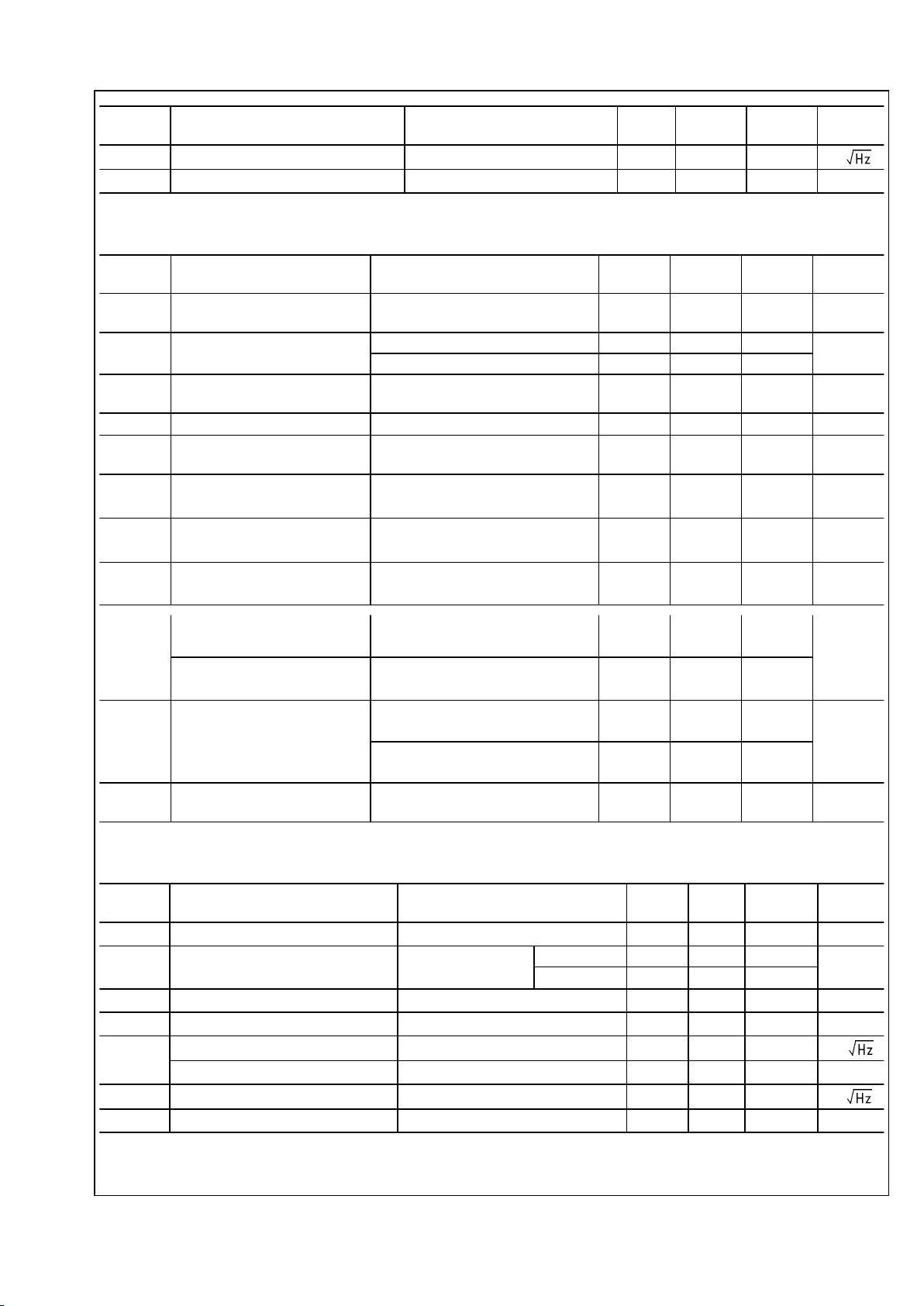

2.5V DC Electrical Characteristics (Note 4) Unless otherwise specified, all limits guaranteed for

TA = 25°C, V+ = 2.5V, V− = 0V, VCM = VO = V+/2, and RL > 1MΩ. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

V

OS

Input Offset Voltage ±10 ±190

±275

μV

TCV

OS

Input Offset Voltage Drift LMP2232A ±0.3 ±0.5

μV/°C

LMP2232B ±0.3 ±2.5

I

Bias

Input Bias Current 0.02 ±3

±125

pA

I

OS

Input Offset Current 5

fA

CMRR Common Mode Rejection Ratio

0V ≤ VCM ≤ 1.5V

77

76

91

dB

PSRR Power Supply Rejection Ratio

1.6V ≤ V+ ≤ 5.5V

V– = 0V, VCM = 0V

83

83

120

dB

CMVR Common Mode Voltage Range

CMRR ≥ 77 dB

CMRR ≥ 76 dB

−0.2

−0.2

1.7

1.7

V

A

VOL

Large Signal Voltage Gain VO = 0.3V to 2.2V

RL = 10 kΩ to V+/2

104

104

120

dB

V

O

Output Swing High

RL = 10 kΩ to V+/2

VIN(diff) = 100 mV

12 50

50

mV

from either

rail

Output Swing Low

RL = 10 kΩ to V+/2

VIN(diff) = –100 mV

13 50

50

I

O

Output Current (Note 7) Sourcing, VO to V

–

VIN(diff) = 100 mV

5

4

8

mA

Sinking, VO to V

+

VIN(diff) = –100 mV

3.5

2.5

7

I

S

Supply Current 16 24

25

µA

2.5V AC Electrical Characteristics (Note 4) Unless otherwise specified, all limits guaranteed for

TA = 25°C, V+ = 2.5V, V− = 0V, VCM = VO = V+/2, and RL > 1MΩ. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

GBW Gain-Bandwidth Product

CL = 20 pF, RL = 10 kΩ

128 kHz

SR Slew Rate AV = +1, CL = 20 pF

RL = 10 kΩ

Falling Edge 58

V/ms

Rising Edge 48

θ

m

Phase Margin

CL = 20 pF, RL = 10 kΩ

64 deg

G

m

Gain Margin

CL = 20 pF, RL = 10 kΩ

26

dB

e

n

Input-Referred Voltage Noise Density f = 1 kHz 60

nV/

Input-Referred Voltage Noise 0.1 Hz to 10 Hz 2.5

μV

PP

i

n

Input-Referred Current Noise f = 1 kHz 10

fA/

THD+N Total Harmonic Distortion + Noise

f = 100 Hz, RL = 10 kΩ

0.005 %

www.national.com 4

LMP2232

Page 5

1.8V DC Electrical Characteristics (Note 4) Unless otherwise specified, all limits guaranteed for

T A = 25°C, V+ = 1.8V, V− = 0V, VCM = VO = V+/2, and RL > 1 MΩ. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

V

OS

Input Offset Voltage ±10 ±230

±325

μV

TCV

OS

Input Offset Voltage Drift LMP2232A ±0.3 ±0.5

μV/°C

LMP2232B ±0.3 ±2.5

I

BIAS

Input Bias Current 0.02 ±3

±125

pA

I

OS

Input Offset Current 5 fA

CMRR Common Mode Rejection Ratio

0V ≤ VCM ≤ 0.8V

76

75

92

dB

PSRR Power Supply Rejection Ratio

1.6V ≤ V+ ≤ 5.5V

V− = 0V, VCM = 0V

83

83

120

dB

CMVR Common Mode Voltage Range

CMRR ≥ 76 dB

CMRR ≥ 75 dB

−0.2

0

1.0

1.0

V

A

VOL

Large Signal Voltage Gain VO = 0.3V to 1.5V

RL = 10 kΩ to V+/2

103

103

120

dB

V

O

Output Swing High

RL = 10 kΩ to V+/2

VIN(diff) = 100 mV

12 50

50

mV

from either

rail

Output Swing Low

RL = 10 kΩ to V+/2

VIN(diff) = −100 mV

13 50

50

I

O

Output Current (Note 7) Sourcing, VO to V

–

VIN(diff) = 100 mV

2.5

2

5

mA

Sinking, VO to V

+

VIN(diff) = −100 mV

2

1.5

5

I

S

Supply Current 16 24

25

µA

1.8V AC Electrical Characteristics (Note 4) Unless otherwise is specified, all limits guaranteed for

TA = 25°C, V+ = 1.8V, V− = 0V, VCM = VO = V+/2, and RL > 1 MΩ. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 6)

Typ

(Note 5)

Max

(Note 6)

Units

GBW Gain-Bandwidth Product

CL = 20 pF, RL = 10 kΩ

127 kHz

SR Slew Rate AV = +1, CL = 20 pF

RL = 10 kΩ

Falling Edge 58

V/ms

Rising Edge 48

θ

m

Phase Margin

CL = 20 pF, RL = 10 kΩ

60 deg

G

m

Gain Margin

CL = 20 pF, RL = 10 kΩ

25

dB

e

n

Input-Referred Voltage Noise Density f = 1 kHz 60

nV/

Input-Referred Voltage Noise 0.1 Hz to 10 Hz 2.4

μV

PP

i

n

Input-Referred Current Noise f = 1 kHz 10

fA/

THD+N Total Harmonic Distortion + Noise

f = 100 Hz, RL = 10 kΩ

0.005 %

5 www.national.com

LMP2232

Page 6

Note 1: Absolute Maximum Ratings indicate limits beyond which damage may occur. Operating Ratings indicate conditions for which the device is intended to

be functional, but specific performance is not guaranteed. For guaranteed specifications and test conditions, see the Electrical Characteristics.

Note 2: Human Body Model, applicable std. MIL-STD-883, Method 3015.7. Machine Model, applicable std. JESD22-A115-A (ESD MM std. of JEDEC)

Field-Induced Charge-Device Model, applicable std. JESD22-C101-C (ESD FICDM std. of JEDEC).

Note 3: The maximum power dissipation is a function of T

J(MAX)

, θJA, and TA. The maximum allowable power dissipation at any ambient temperature is

PD = (T

J(MAX)

– TA)/ θJA. All numbers apply for packages soldered directly onto a PC board.

Note 4: Electrical Table values apply only for factory testing conditions at the temperature indicated. Factory testing conditions result in very limited self-heating

of the device such that TJ = TA. No guarantee of parametric performance is indicated in the electrical tables under conditions of internal self-heating where TJ >

TA. Absolute Maximum Ratings indicate junction temperature limits beyond which the device may be permanently degraded, either mechanically or electrically.

Note 5: Typical values represent the most likely parametric norm at the time of characterization. Actual typical values may vary over time and will also depend

on the application and configuration. The typical values are not tested and are not guaranteed on shipped production material.

Note 6: All limits are guaranteed by testing, statistical analysis or design.

Note 7: The short circuit test is a momentary open loop test.

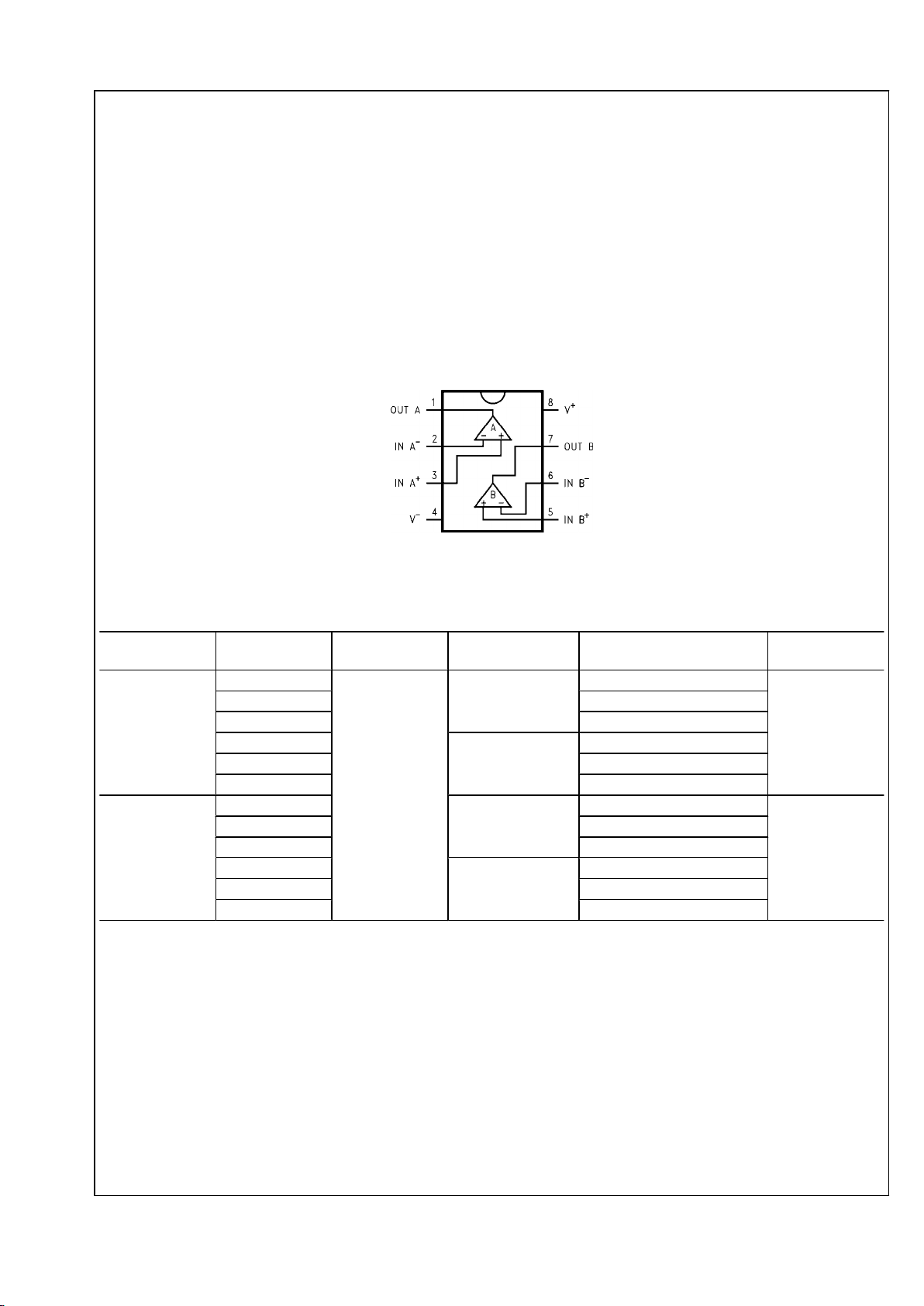

Connection Diagram

8-Pin MSOP/SOIC

30033938

Top View

Ordering Information

Package Part Number Temperature

Range

Package Marking Transport Media NSC Drawing

8-Pin SOIC

LMP2232AMA

–40°C to 125°C

LMP2232AMA

95 Units/Rail

M08A

LMP2232AMAE 250 Units Tape and Reel

LMP2232AMAX 2.5k Units Tape and Reel

LMP2232BMA

LMP2232BMA

95 Units/Rail

LMP2232BMAE 250 Units Tape and Reel

LMP2232BMAX 2.5k Units Tape and Reel

8-Pin MSOP

LMP2232AMM

AK5A

1k Units Tape and Reel

MUA08A

LMP2232AMME 250 Units Tape and Reel

LMP2232AMMX 3.5k Units Tape and Reel

LMP2232BMM

AK5B

1k Units Tape and Reel

LMP2232BMME 250 Units Tape and Reel

LMP2232BMMX 3.5k Units Tape and Reel

www.national.com 6

LMP2232

Page 7

Typical Performance Characteristics Unless otherwise Specified: T

A

= 25°C, VS = 5V, VCM = VS/2, where

VS = V+ - V

−

Offset Voltage Distribution

30033907

TCVOS Distribution

30033911

Offset Voltage Distribution

30033906

TCVOS Distribution

30033910

Offset Voltage Distribution

30033905

TCVOS Distribution

30033909

7 www.national.com

LMP2232

Page 8

Offset Voltage Distribution

30033973

TCVOS Distribution

30033969

Offset Voltage vs. V

CM

30033918

Offset Voltage vs. V

CM

30033965

Offset Voltage vs. V

CM

30033964

Offset Voltage vs. V

CM

30033972

www.national.com 8

LMP2232

Page 9

Offset Voltage vs. Temperature

30033971

Offset Voltage vs. Supply Voltage

30033970

0.1 Hz to 10 Hz Voltage Noise

30033933

0.1 Hz to 10 Hz Voltage Noise

30033934

0.1 Hz to 10 Hz Voltage Noise

30033932

0.1 Hz to 10 Hz Voltage Noise

30033931

9 www.national.com

LMP2232

Page 10

Input Bias Current vs. V

CM

30033955

Input Bias Current vs. V

CM

30033956

Input Bias Current vs. V

CM

30033957

Input Bias Current vs. V

CM

30033958

Input Bias Current vs. V

CM

30033959

Input Bias Current vs. V

CM

30033960

www.national.com 10

LMP2232

Page 11

Input Bias Current vs. V

CM

30033961

Input Bias Current vs. V

CM

30033962

PSRR vs. Frequency

30033966

Supply Current vs. Supply Voltage (per channel)

30033912

Sinking Current vs. Supply Voltage

30033913

Sourcing Current vs. Supply Voltage

30033914

11 www.national.com

LMP2232

Page 12

Output Swing High vs. Supply Voltage

30033915

Output Swing Low vs. Supply Voltage

30033916

Open Loop Frequency Response

30033921

Open Loop Frequency Response

30033922

Phase Margin vs. Capacitive Load

30033963

Slew Rate vs. Supply Voltage

30033930

www.national.com 12

LMP2232

Page 13

THD+N vs. Amplitude

30033928

THD+N vs. Frequency

30033929

Large Signal Step Response

30033924

Small Signal Step Response

30033923

Large Signal Step Response

30033926

Small Signal Step Response

30033925

13 www.national.com

LMP2232

Page 14

CMRR vs. Frequency

30033967

Input Voltage Noise vs. Frequency

30033919

www.national.com 14

LMP2232

Page 15

Application Information

LMP2232

The LMP2232 is a quad CMOS precision amplifier that offers

low offset voltage, low offset voltage drift, and high gain while

consuming less than 10 μA of supply current per channel.

The LMP2232 is a micropower op amp, consuming only

36 μA of current. Micropower op amps extend the run time of

battery powered systems and reduce energy consumption in

energy limited systems. The guaranteed supply voltage range

of 1.8V to 5.0V along with the ultra-low supply current extend

the battery run time in two ways. The extended guaranteed

power supply voltage range of 1.8V to 5.0V enables the op

amp to function when the battery voltage has depleted from

its nominal value down to 1.8V. In addition, the lower power

consumption increases the life of the battery.

The LMP2232 has input referred offset voltage of only

±150 μV maximum at room temperature. This offset is guaranteed to be less than ±230 μV over temperature. This minimal offset voltage along with very low TCVOS of only 0.3 µV/

°C typical allows more accurate signal detection and amplification in precision applications.

The low input bias current of only ±20 fA gives the LMP2232

superiority for use in high impedance sensor applications.

Bias current of an amplifier flows through source resistance

of the sensor and the voltage resulting from this current flow

appears as a noise voltage on the input of the amplifier. The

low input bias current enables the LMP2232 to interface with

high impedance sensors while generating negligible voltage

noise. Thus the LMP2232 provides better signal fidelity and

a higher signal-to-noise ratio when interfacing with high

impedance sensors.

National Semiconductor is heavily committed to precision

amplifiers and the market segments they serve. Technical

support and extensive characterization data is available for

sensitive applications or applications with a constrained error

budget.

The operating voltage range of 1.6V to 5.5V over the extensive temperature range of −40°C to 125°C makes the

LMP2232 an excellent choice for low voltage precision applications with extensive temperature requirements.

The LMP2232 is offered in the 8-pin MSOP and 8-pin SOIC

packages. These small packages are ideal solutions for area

constrained PC boards and portable electronics.

TOTAL NOISE CONTRIBUTION

The LMP2232 has very low input bias current, very low input

current noise, and low input voltage noise for micropower

amplifiers. As a result, these amplifiers make great choices

for circuits with high impedance sensor applications.

Figure 1 shows the typical input noise of the LMP2232 as a

function of source resistance where:

en denotes the input referred voltage noise

ei is the voltage drop across source resistance due to input

referred current noise or ei = RS * i

n

et shows the thermal noise of the source resistance

eni shows the total noise on the input.

Where:

The input current noise of the LMP2232 is so low that it will

not become the dominant factor in the total noise unless

source resistance exceeds 300 MΩ, which is an unrealistically high value. As is evident in Figure 1, at lower RS values,

total noise is dominated by the amplifier’s input voltage noise.

Once RS is larger than a 100 kΩ, then the dominant noise

factor becomes the thermal noise of RS. As mentioned before,

the current noise will not be the dominant noise factor for any

practical application.

30033948

FIGURE 1. Total Input Noise

VOLTAGE NOISE REDUCTION

The LMP2232 has an input voltage noise of 60nV/

. While

this value is very low for micropower amplifiers, this input

voltage noise can be further reduced by placing N amplifiers

in parallel as shown in Figure 2. The total voltage noise on the

output of this circuit is divided by the square root of the number of amplifiers used in this parallel combination. This is

because each individual amplifier acts as an independent

noise source, and the average noise of independent sources

is the quadrature sum of the independent sources divided by

the number of sources. For N identical amplifiers, this means:

15 www.national.com

LMP2232

Page 16

Figure 2 shows a schematic of this input voltage noise reduction circuit. Typical resistor values are: RG = 10Ω, RF = 1 kΩ,

and RO = 1 kΩ.

30033946

FIGURE 2. Noise Reduction Circuit

PRECISION INSTRUMENTATION AMPLIFIER

Measurement of very small signals with an amplifier requires

close attention to the input impedance of the amplifier, gain

of the signal on the inputs, and the gain on each input of the

amplifier. This is because the difference of the input signal on

the two inputs is of the interest and the common signal is

considered noise. A classic circuit implementation is an instrumentation amplifier. Instrumentation amplifiers have a

finite, accurate, and stable gain. They also have extremely

high input impedances and very low output impedances. Finally they have an extremely high CMRR so that the amplifier

can only respond to the differential signal. A typical instrumentation amplifier is shown in Figure 3.

30033936

FIGURE 3. Instrumentation Amplifier

There are two stages in this amplifier. The last stage, output

stage, is a differential amplifier. In an ideal case the two amplifiers of the first stage, the input stage, would be set up as

buffers to isolate the inputs. However they cannot be connected as followers because of mismatch of amplifiers. That

is why there is a balancing resistor between the two. The

product of the two stages of gain will give the gain of the instrumentation amplifier. Ideally, the CMRR should be infinite.

However the output stage has a small non-zero common

mode gain which results from resistor mismatch.

In the input stage of the circuit, current is the same across all

resistors. This is due to the high input impedance and low

input bias current of the LMP2232.

(1)

By Ohm’s Law:

(2)

However:

(3)

So we have:

VO1–VO2 = (2a+1)(V1–V2) (4)

Now looking at the output of the instrumentation amplifier:

(5)

Substituting from Equation 4:

(6)

This shows the gain of the instrumentation amplifier to be:

−K(2a+1)

Typical values for this circuit can be obtained by setting:

a = 12 and K= 4. This results in an overall gain of −100.

www.national.com 16

LMP2232

Page 17

SINGLE SUPPLY STRAIN GAGE BRIDGE AMPLIFIER

Strain gauges are popular electrical elements used to measure force or pressure. Strain gauges are subjected to an

unknown force which is measured as the deflection on a previously calibrated scale. Pressure is often measured using the

same technique; however this pressure needs to be converted into force using an appropriate transducer. Strain gauges

are often resistors which are sensitive to pressure or to flexing. Sense resistor values range from tens of ohms to several

hundred kilo-ohms. The resistance change which is a result

of applied force across the strain gauge might be 1% of its

total value. An accurate and reliable system is needed to

measure this small resistance change. Bridge configurations

offer a reliable method for this measurement.

Bridge sensors are formed of four resistors, connected as a

quadrilateral. A voltage source or a current source is used

across one of the diagonals to excite the bridge while a voltage detector across the other diagonal measures the output

voltage.

Bridges are mainly used as null circuits or to measure differential voltages. Bridges will have no output voltage if the ratios

of two adjacent resistor values are equal. This fact is used in

null circuit measurements. These are particularly used in

feedback systems which involve electrochemical elements or

human interfaces. Null systems force an active resistor, such

as a strain gauge, to balance the bridge by influencing the

measured parameter.

Often in sensor applications at lease one of the resistors is a

variable resistor, or a sensor. The deviation of this active element from its initial value is measured as an indication of

change in the measured quantity. A change in output voltage

represents the sensor value change. Since the sensor value

change is often very small, the resulting output voltage is very

small in magnitude as well. This requires an extensive and

very precise amplification circuitry so that signal fidelity does

not change after amplification.

Sensitivity of a bridge is the ratio of its maximum expected

output change to the excitation voltage change.

Figure 4(a) shows a typical bridge sensor and Figure 4(b)

shows the bridge with four sensors. R in Figure 4(b) is the

nominal value of the sense resistor and the deviations from R

are proportional to the quantity being measured.

30033950

30033951

FIGURE 4. Bridge Sensor

Instrumentation amplifiers are great for interfacing with bridge

sensors. Bridge sensors often sense a very small differential

signal in the presence of a larger common mode voltage. Instrumentation amplifiers reject this common mode signal.

Figure 5 shows a strain gauge bridge amplifier. In this application one of the LMP2232 amplifiers is used to buffer the

LM4140A's precision output voltage. The LM4140A is a precision voltage reference. The other three amplifiers in the

LMP2232 are used to form an instrumentation amplifier. This

instrumentation amplifier uses the LMP2232's high CMRR

and low VOS and TCVOS to accurately amplify the small differential signal generated by the output of the bridge sensor.

This amplified signal is then fed into the ADC121S021 which

is a 12-bit analog to digital converter. This circuit works on a

single supply voltage of 5V.

17 www.national.com

LMP2232

Page 18

30033974

FIGURE 5. Strain Gage Bridge Amplifier

PORTABLE GAS DETECTION SENSOR

Gas sensors are used in many different industrial and medical

applications. They generate a current which is proportional to

the percentage of a particular gas sensed in an air sample.

This current goes through a load resistor and the resulting

voltage drop is measured. Depending on the sensed gas and

sensitivity of the sensor, the output current can be in the order

of tens of microamperes to a few milliamperes. Gas sensor

datasheets often specify a recommended load resistor value

or they suggest a range of load resistors to choose from.

Oxygen sensors are used when air quality or oxygen delivered to a patient needs to be monitored. Fresh air contains

20.9% oxygen. Air samples containing less than 18% oxygen

are considered dangerous. Oxygen sensors are also used in

industrial applications where the environment must lack oxygen. An example is when food is vacuum packed. There are

two main categories of oxygen sensors, those which sense

oxygen when it is abundantly present (i.e. in air or near an

oxygen tank) and those which detect very small traces of oxygen in ppm.

Figure 6 shows a typical circuit used to amplify the output

signal of an oxygen detector. The LMP2232 makes an excellent choice for this application as it draws only 36 µA of current

and operates on supply voltages down to 1.8V. This application detects oxygen in air. The oxygen sensor outputs a

known current through the load resistor. This value changes

with the amount of oxygen present in the air sample. Oxygen

sensors usually recommend a particular load resistor value

or specify a range of acceptable values for the load resistor.

Oxygen sensors typically have a life of one to two years. The

use of the micropower LMP2232 means minimal power usage

by the op amp and it enhances the battery life. Depending on

other components present in the circuit design, the battery

could last for the entire life of the oxygen sensor. The precision specifications of the LMP2232, such as its very low offset

voltage, low TCVOS, low input bias current, low CMRR, and

low PSRR are other factors which make the LMP2232 a great

choice for this application..

30033949

FIGURE 6. Precision Oxygen Sensor

www.national.com 18

LMP2232

Page 19

Physical Dimensions inches (millimeters) unless otherwise noted

8-Pin MSOP

NS Package Number MUA08A

8-Pin SOIC

NS Package Number M08A

19 www.national.com

LMP2232

Page 20

Notes

LMP2232 Dual 1.8V, Micropower, Precision, Operational Amplifier with CMOS Input

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Technical

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

www.national.com

Loading...

Loading...