Page 1

LMP2021/LMP2022

Zero Drift, Low Noise, EMI Hardened Amplifiers

LMP2021/LMP2022 Zero Drift, Low Noise, EMI Hardened Amplifiers

November 6, 2008

General Description

The LMP2021/LMP2022 are single and dual precision operational amplifiers offering ultra low input offset voltage, near

zero input offset voltage drift, very low input voltage noise and

very high open loop gain. They are part of the LMP® precision

family and are ideal for instrumentation and sensor interfaces.

The LMP2021/LMP2022 have only 0.004 µV/°C of input offset

voltage drift, and 0.4 µV of input offset voltage. These attributes provide great precision in high accuracy applications.

The proprietary continuous correction circuitry guarantees

impressive CMRR and PSRR, removes the 1/f noise component, and eliminates the need for calibration in many circuits.

With only 260 nVPP (0.1 Hz to 10 Hz) of input voltage noise

and no 1/f noise component, the LMP2021/LMP2022 are suitable for low frequency applications such as industrial precision weigh scales. The low input bias current of 23 pA makes

these excellent choices for high source impedance circuits

such as non-invasive medical instrumentation as well as test

and measurement equipment. The extremely high open loop

gain of 160 dB drastically reduces gain error in high gain applications. With ultra precision DC specifications and very low

noise, the LMP2021/LMP2022 are ideal for position sensors,

bridge sensors, pressure sensors, medical equipment and

other high accuracy applications with very low error budgets.

The LMP2021 is offered in 5-Pin SOT-23 and 8-Pin SOIC

packages. The LMP2022 is offered in 8-Pin MSOP and 8-Pin

SOIC packages.

Features

(Typical Values, TA = 25°C, VS = 5V)

Input offset voltage (typical) −0.4 µV

■

Input offset voltage (max) ±5 µV

■

Input offset voltage drift (typical) -0.004 µV/°C

■

Input offset voltage drift (max) ±0.02 µV/°C

■

Input voltage noise, AV = 1000 11 nV/√Hz

■

Open loop gain 160 dB

■

CMRR 139 dB

■

PSRR 130 dB

■

Supply voltage range 2.2V to 5.5V

■

Supply current (per amplifier) 1.1 mA

■

Input bias current ±25 pA

■

GBW 5 MHz

■

Slew rate 2.6 V/µs

■

Operating temperature range −40°C to 125°C

■

5-Pin SOT-23, 8-Pin MSOP and 8-Pin SOIC Packages

■

Applications

Precision instrumentation amplifiers

■

Battery powered instrumentation

■

Thermocouple amplifiers

■

Bridge amplifiers

■

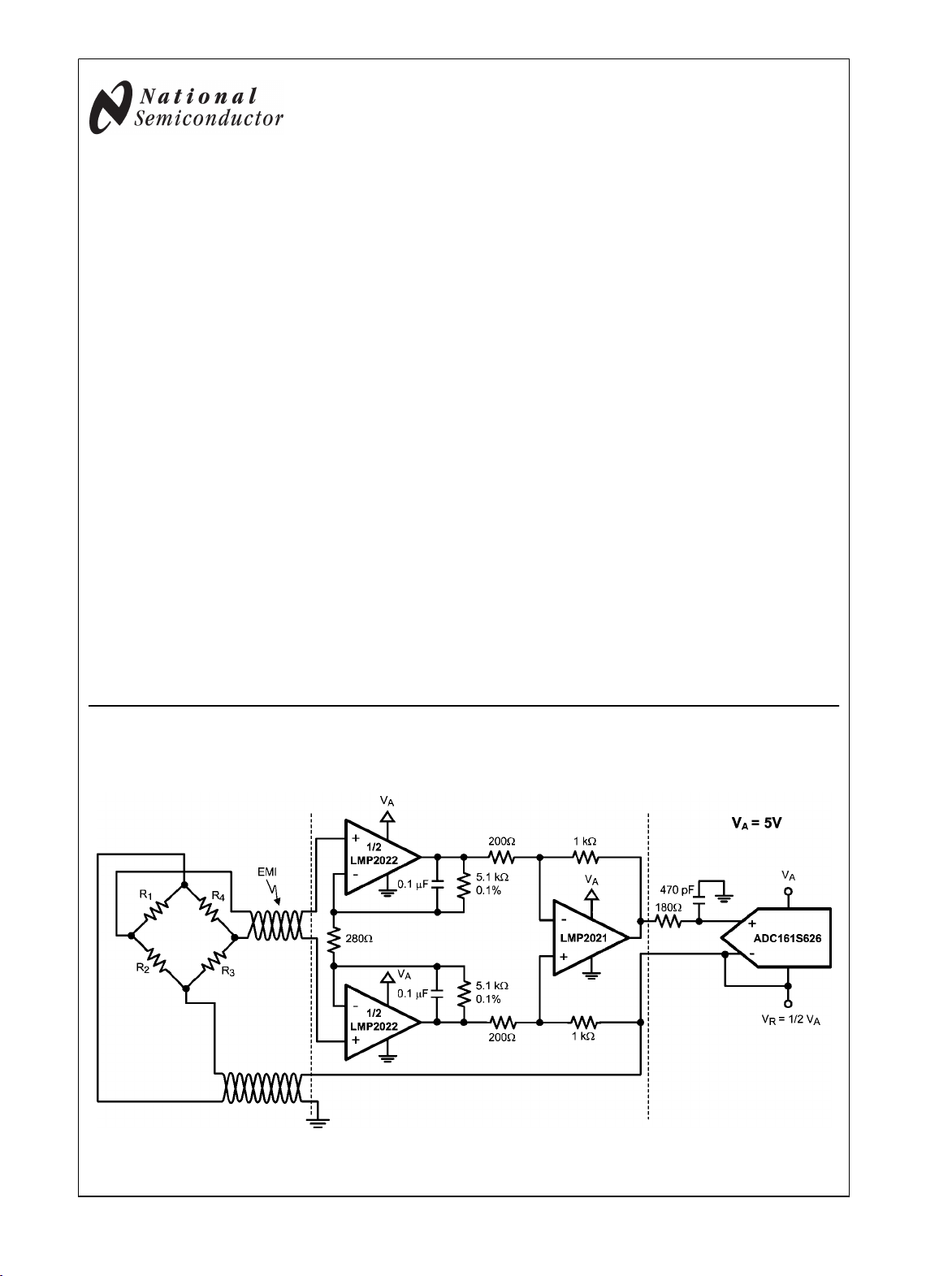

Typical Application

Bridge Amplifier

The LMP2021/LMP2022 support systems with up to 24 bits of accuracy.

LMP® is a registered trademark of National Semiconductor Corporation.

© 2008 National Semiconductor Corporation 300149 www.national.com

30014972

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

ESD Tolerance (Note 2)

Human Body Model 2000V

Machine Model 200V

LMP2021/LMP2022

Charge Device Model 1000V

VIN Differential ±V

Supply Voltage (VS = V+ – V−)

Output Short-Circuit Duration to V+ or V

(Note 3)

Storage Temperature Range −65°C to 150°C

−

6.0V

5s

Soldering Information

Infrared or Convection (20 sec) 235°C

Wave Soldering Lead Temperature

(10 sec) 260°C

Operating Ratings (Note 1)

Temperature Range −40°C to 125°C

Supply Voltage (VS = V+ – V–)

Package Thermal Resistance (θJA)

S

5-Pin SOT-23 164 °C/W

8-Pin SOIC (LMP2021) 106 °C/W

8-Pin SOIC (LMP2022) 106 °C/W

8-Pin MSOP 217 °C/W

Junction Temperature (Note 4) 150°C max

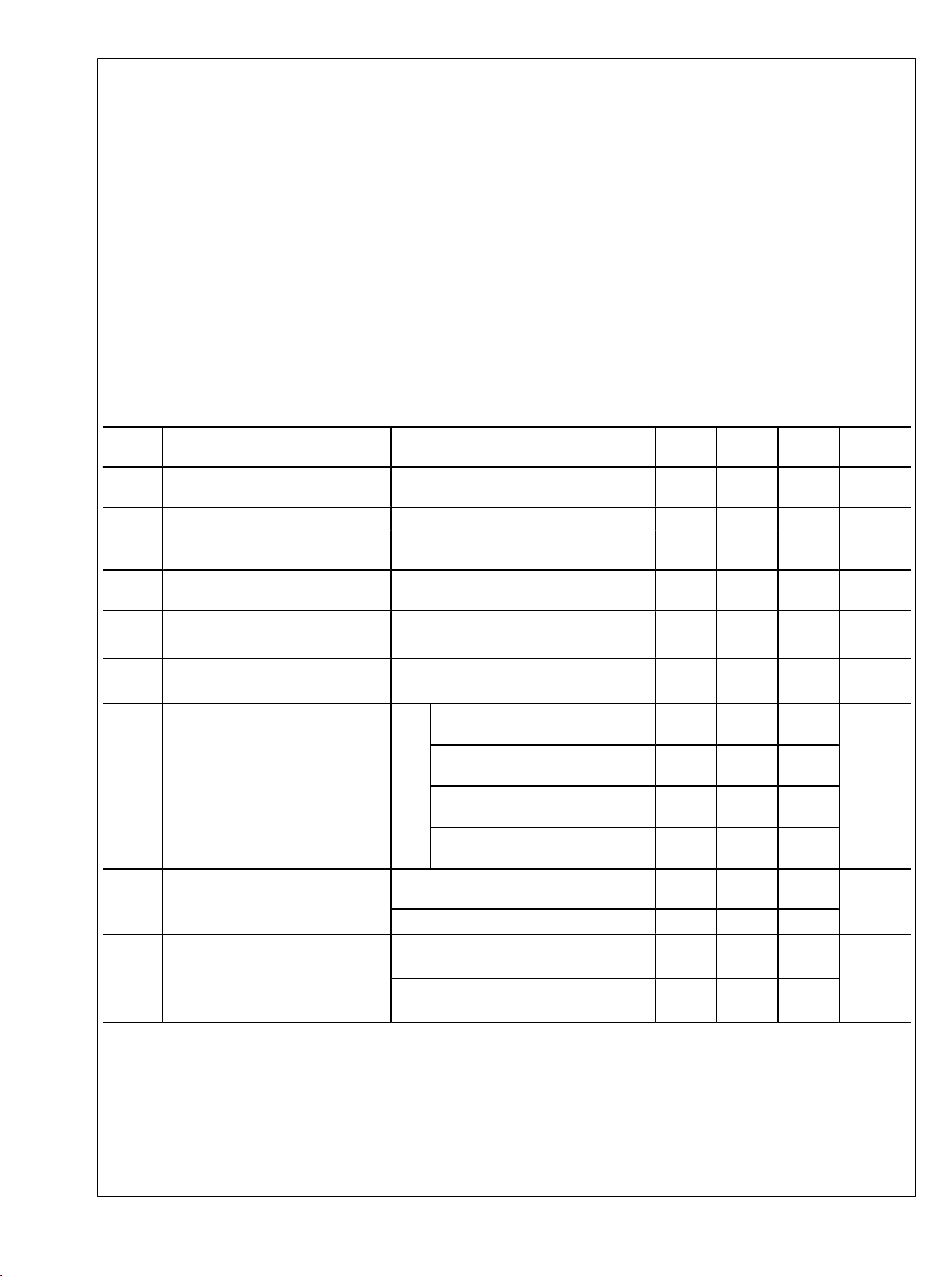

2.5V Electrical Characteristics (Note 5)

Unless otherwise specified, all limits are guaranteed for TA = 25°C, V+ = 2.5V, V− = 0V, VCM = V+/2, RL >10 kΩ to V+/2. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 7)

V

OS

TCV

I

B

I

OS

CMRR Common Mode Rejection Ratio

CMVR Input Common-Mode Voltage Range

Input Offset Voltage –0.9 ±5

Input Offset Voltage Drift (Note 8) 0.001 ±0.02

OS

Input Bias Current ±23 ±100

Input Offset Current ±57 ±200

−0.2V ≤ VCM ≤ 1.7V

0V ≤ VCM ≤ 1.5V

Large Signal CMRR ≥ 105 dB

105

102

−0.2

Large Signal CMRR ≥ 102 dB

EMIRR Electro-Magnetic Interference

Rejection Ratio

(Note 9)

IN+

and

IN−

V

= 100 mVP (−20 dBVP)

RF-PEAK

f = 400 MHz

V

= 100 mVP (−20 dBVP)

RF-PEAK

f = 900 MHz

V

= 100 mVP (−20 dBVP)

RF-PEAK

f = 1800 MHz

V

= 100 mVP (−20 dBVP)

RF-PEAK

f = 2400 MHz

PSRR Power Supply Rejection Ratio

2.5V ≤ V+ ≤ 5.5V, VCM = 0

115

112

2.2V ≤ V+ ≤ 5.5V, VCM = 0

A

VOL

Large Signal Voltage Gain

RL = 10 kΩ to V+/2

V

= 0.5V to 2V

OUT

RL = 2 kΩ to V+/2

V

= 0.5V to 2V

OUT

110 130

124

119

120

115

0

40

48

67

79

Typ

(Note 6)

141

130

150

150

(Note 7)

2.2V to 5.5V

Max

±10

±300

±250

1.7

1.5

Units

μV

μV/°C

pA

pA

dB

V

dB

dB

dB

www.national.com 2

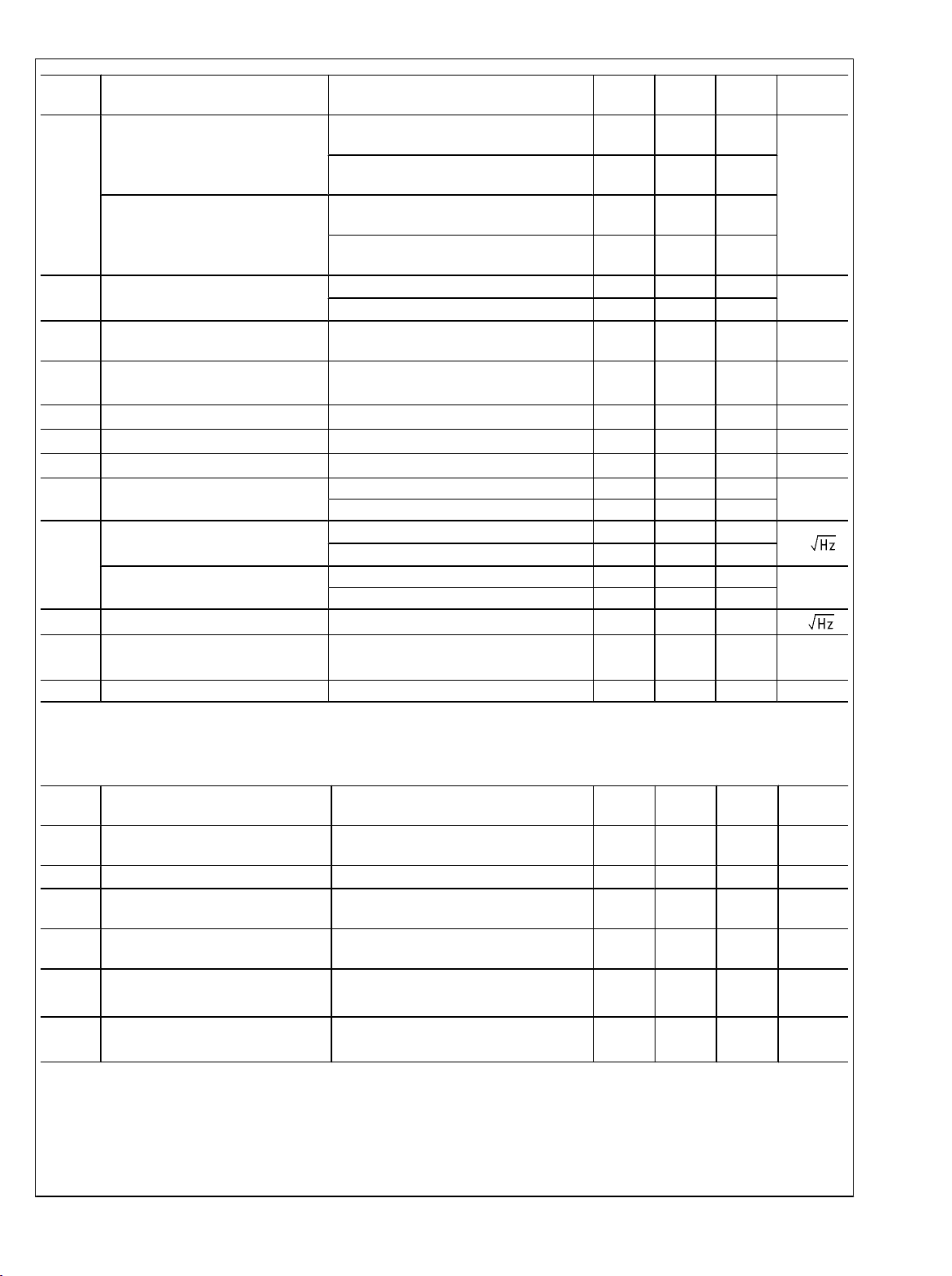

Page 3

LMP2021/LMP2022

Symbol Parameter Conditions Min

(Note 7)

V

OUT

Output Swing High

RL = 10 kΩ to V+/2

38 50

Typ

(Note 6)

Max

(Note 7)

Units

70

62 85

115

30 45

55

58 75

mV

from either

rail

Output Swing Low

RL = 2 kΩ to V+/2

RL = 10 kΩ to V+/2

RL = 2 kΩ to V+/2

95

I

OUT

I

S

SR Slew Rate (Note 10)

GBW Gain Bandwidth Product

G

M

Φ

M

C

IN

e

n

i

n

t

r

Linear Output Current Sourcing, V

Sinking, V

= 2V 30 50

OUT

= 0.5V 30 50

OUT

Supply Current Per Amplifier 0.95 1.10

1.37

2.5

5 MHz

10 dB

60 deg

Gain Margin

Phase Margin

AV = +1, CL = 20 pF, RL = 10 kΩ

VO = 2 V

PP

CL = 20 pF, RL = 10 kΩ

CL = 20 pF, RL = 10 kΩ

CL = 20 pF, RL = 10 kΩ

Input Capacitance Common Mode 12

Differential Mode 12

Input-Referred Voltage Noise

Density

f = 0.1 kHz or 10 kHz, AV = 1000 11

f = 0.1 kHz or 10 kHz, AV = 100 15

Input-Referred Voltage Noise 0.1 Hz to 10 Hz 260

0.01 Hz to 10 Hz 330

Input-Referred Current Noise f = 1 kHz 350

Recovery time

to 0.1%, RL = 10 kΩ, AV = −50,

V

= 1.25 VPP Step, Duration = 50 μs

OUT

50 µs

mA

mA

V/μs

pF

nV/

nV

fA/

CT Cross Talk LMP2022, f = 1 kHz 150 dB

PP

5V Electrical Characteristics (Note 5)

Unless otherwise specified, all limits are guaranteed for TA = 25°C, V+ = 5V, V− = 0V, VCM = V+/2, RL > 10 kΩ to V+/2. Boldface

limits apply at the temperature extremes.

Symbol Parameter Conditions Min

(Note 7)

V

OS

TCV

I

B

I

OS

CMRR Common Mode Rejection Ratio

CMVR Input Common-Mode Voltage Range

Input Offset Voltage −0.4 ±5

Input Offset Voltage Drift (Note 8) −0.004 ±0.02

OS

Input Bias Current ±25 ±100

Input Offset Current ±48 ±200

−0.2V ≤ VCM ≤ 4.2V

0V ≤ VCM ≤ 4.0V

Large Signal CMRR ≥ 120 dB

120

115

–0.2

Large Signal CMRR ≥ 115 dB

0

Typ

(Note 6)

139

4.2

Max

(Note 7)

±10

±300

±250

4.0

Units

μV

μV/°C

pA

pA

dB

V

3 www.national.com

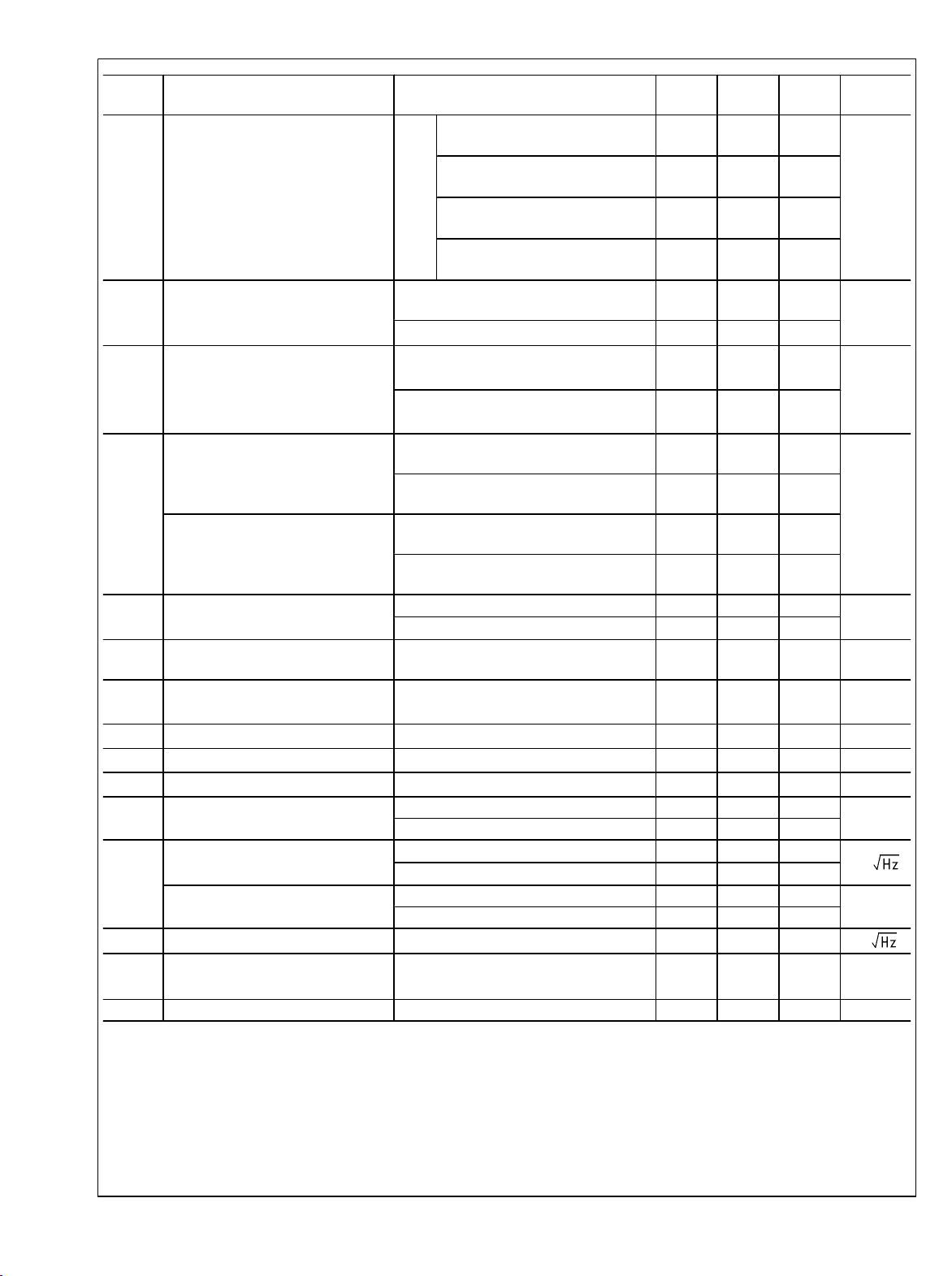

Page 4

Symbol Parameter Conditions Min

EMIRR Electro-Magnetic Interference

Rejection Ratio

(Note 9)

LMP2021/LMP2022

IN+

and

IN−

V

= 100 mVP (−20 dBVP)

RF-PEAK

f = 400 MHz

V

= 100 mVP (−20 dBVP)

RF-PEAK

f = 900 MHz

V

= 100 mVP (−20 dBVP)

RF-PEAK

f = 1800 MHz

V

= 100 mVP (−20 dBVP)

RF-PEAK

(Note 7)

58

64

72

82

Typ

(Note 6)

Max

(Note 7)

f = 2400 MHz

PSRR Power Supply Rejection Ratio

2.5V ≤ V+ ≤ 5.5V, VCM = 0

115

130

112

2.2V ≤ V+ ≤ 5.5V, VCM = 0

A

VOL

Large Signal Voltage Gain

RL = 10 kΩ to V+/2

V

= 0.5V to 4.5V

OUT

RL = 2 kΩ to V+/2

V

= 0.5V to 4.5V

OUT

V

OUT

Output Swing High

RL = 10 kΩ to V+/2

110 130

125

160

120

123

160

118

83 135

170

RL = 2 kΩ to V+/2

120 160

204

Output Swing Low

RL = 10 kΩ to V+/2

65 80

105

RL = 2 kΩ to V+/2

103 125

158

I

OUT

I

S

Linear Output Current Sourcing, V

Sinking, V

= 4.5V 30 50

OUT

= 0.5V 30 50

OUT

Supply Current Per Amplifier 1.1 1.25

1.57

SR Slew Rate (Note 10)

GBW Gain Bandwidth Product

G

M

Φ

M

C

IN

Gain Margin

Phase Margin

Input Capacitance Common Mode 12

AV = +1, CL = 20 pF, RL = 10 kΩ

VO = 2 V

PP

CL = 20 pF, RL = 10 kΩ

CL = 20 pF, RL = 10 kΩ

CL = 20 pF, RL = 10 kΩ

2.6

5 MHz

10 dB

60 deg

Differential Mode 12

e

n

Input-Referred Voltage Noise Density f = 0.1 kHz or 10 kHz, AV= 1000 11

f = 0.1 kHz or 10 kHz, AV= 100 15

Input-Referred Voltage Noise 0.1 Hz to 10 Hz Noise 260

0.01 Hz to 10 Hz Noise 330

i

n

t

r

Input-Referred Current Noise f = 1 kHz 350

Input Overload Recovery time

to 0.1%, RL = 10 kΩ, AV = −50,

V

= 2.5 VPP Step, Duration = 50 μs

OUT

50

CT Cross Talk LMP2022, f = 1 kHz 150 dB

Units

dB

dB

dB

mV

from

either rail

mA

mA

V/μs

pF

nV/

nV

PP

fA/

μs

www.national.com 4

Page 5

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see the Electrical Characteristics

Tables.

Note 2: Human Body Model per MIL-STD-883, Method 3015.7. Machine Model, per JESD22-A115-A. Field-Induced Charge-Device Model, per JESD22-C101C.

Note 3: Package power dissipation should be observed.

Note 4: The maximum power dissipation is a function of T

PD = (T

Note 5: Electrical Table values apply only for factory testing conditions at the temperature indicated. Factory testing conditions result in very limited self-heating

of the device such that TJ = TA. No guarantee of parametric performance is indicated in the electrical tables under conditions of internal self-heating where

TJ > TA.

Note 6: Typical values represent the most likely parametric norm at the time of characterization. Actual typical values may vary over time and will also depend

on the application and configuration. The typical values are not tested and are not guaranteed on shipped production material.

Note 7: All limits are guaranteed by testing, statistical analysis or design.

Note 8: Offset voltage temperature drift is determined by dividing the change in VOS at the temperature extremes by the total temperature change.

Note 9: The EMI Rejection Ratio is defined as EMIRR = 20Log ( V

Note 10: The number specified is the average of rising and falling slew rates and is measured at 90% to 10%.

- TA)/ θJA. All numbers apply for packages soldered directly onto a PC board.

J(MAX)

, θJA, and TA. The maximum allowable power dissipation at any ambient temperature is

J(MAX)

/ΔVOS).

R

F-PEAK

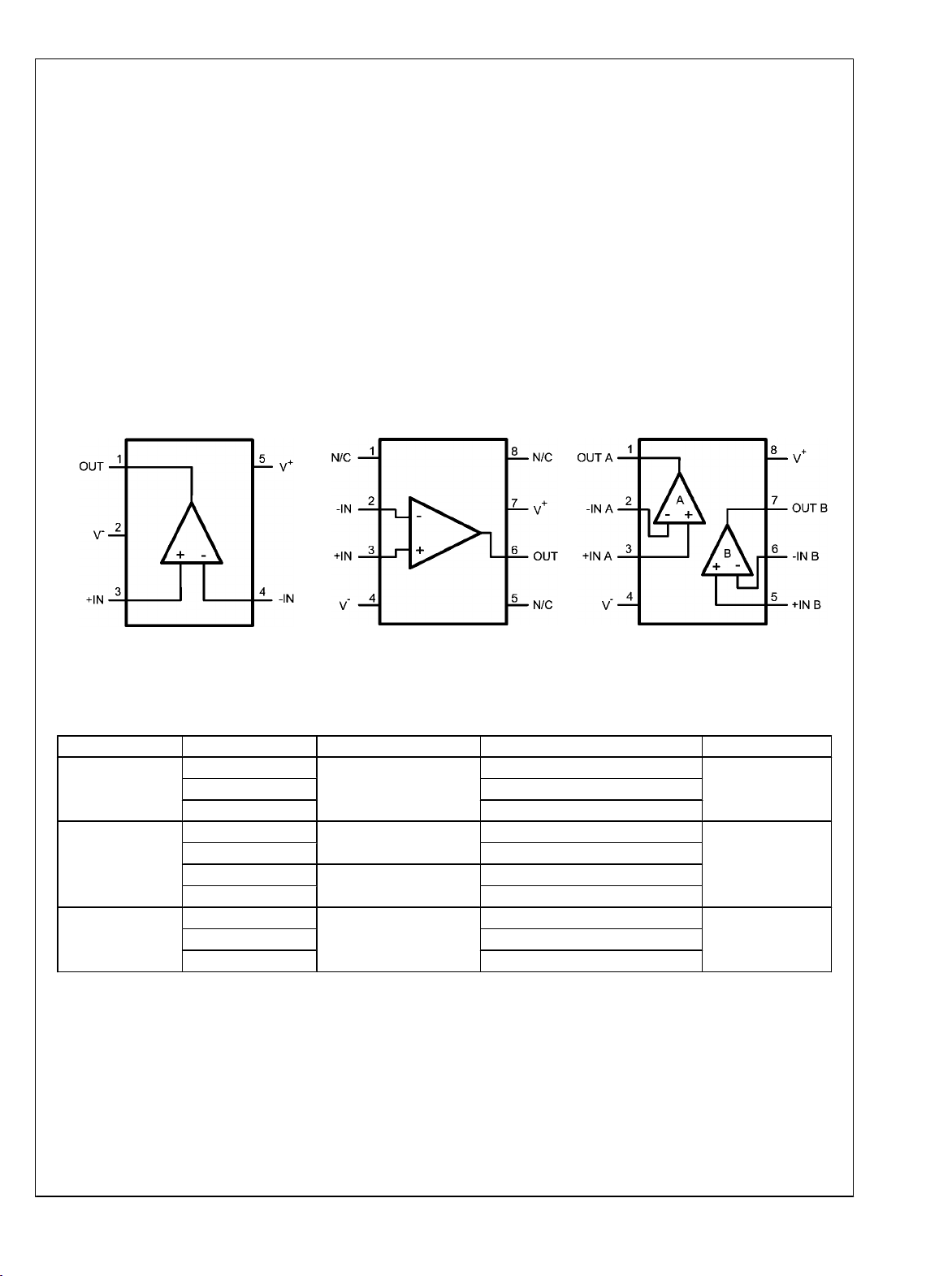

Connection Diagrams

LMP2021/LMP2022

5-Pin SOT-23

Top View

30014902

8-Pin SOIC (LMP2021)

Top View

8-Pin SOIC/MSOP (LMP2022)

30014953

Ordering Information

Package Part Number Package Marking Transport Media NSC Drawing

5-Pin SOT-23

8-Pin SOIC

8-Pin MSOP

LMP2021MF

AF5A

LMP2021MFX 3k Units Tape and Reel

LMP2021MA

LMP2021MAX 2.5k Units Tape and Reel

LMP2022MA

LMP2022MAX 2.5k Units Tape and Reel

LMP2021MA

LMP2022MA

LMP2022MM

AV5A

LMP2022MMX 3.5k Units Tape and Reel

1k Units Tape and Reel

95 Units/Rail

95 Units/Rail

1k Units Tape and Reel

30014903

MF05ALMP2021MFE 250 Units Tape and Reel

M08A

MUA08ALMP2022MME 250 Units Tape and Reel

5 www.national.com

Page 6

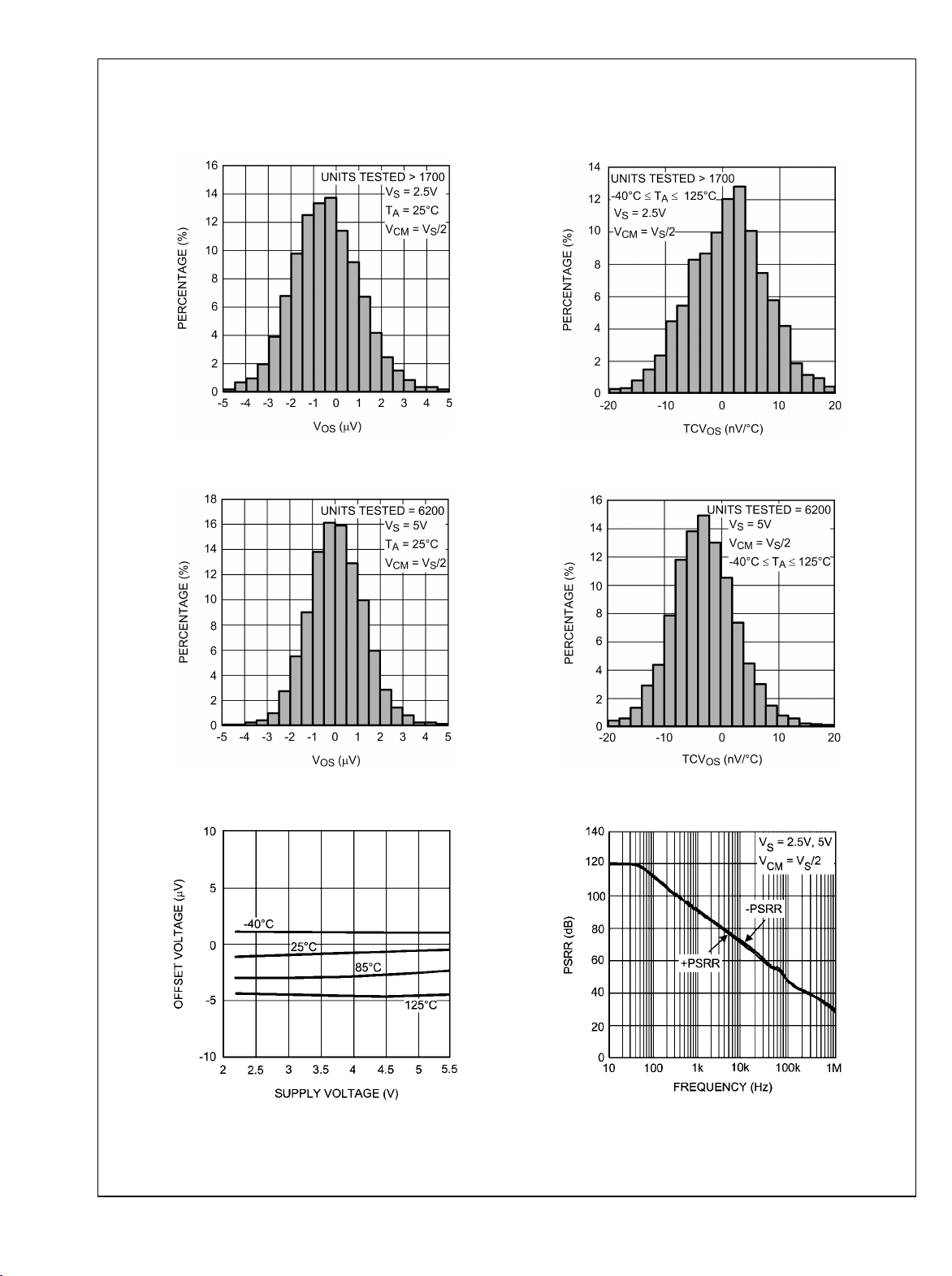

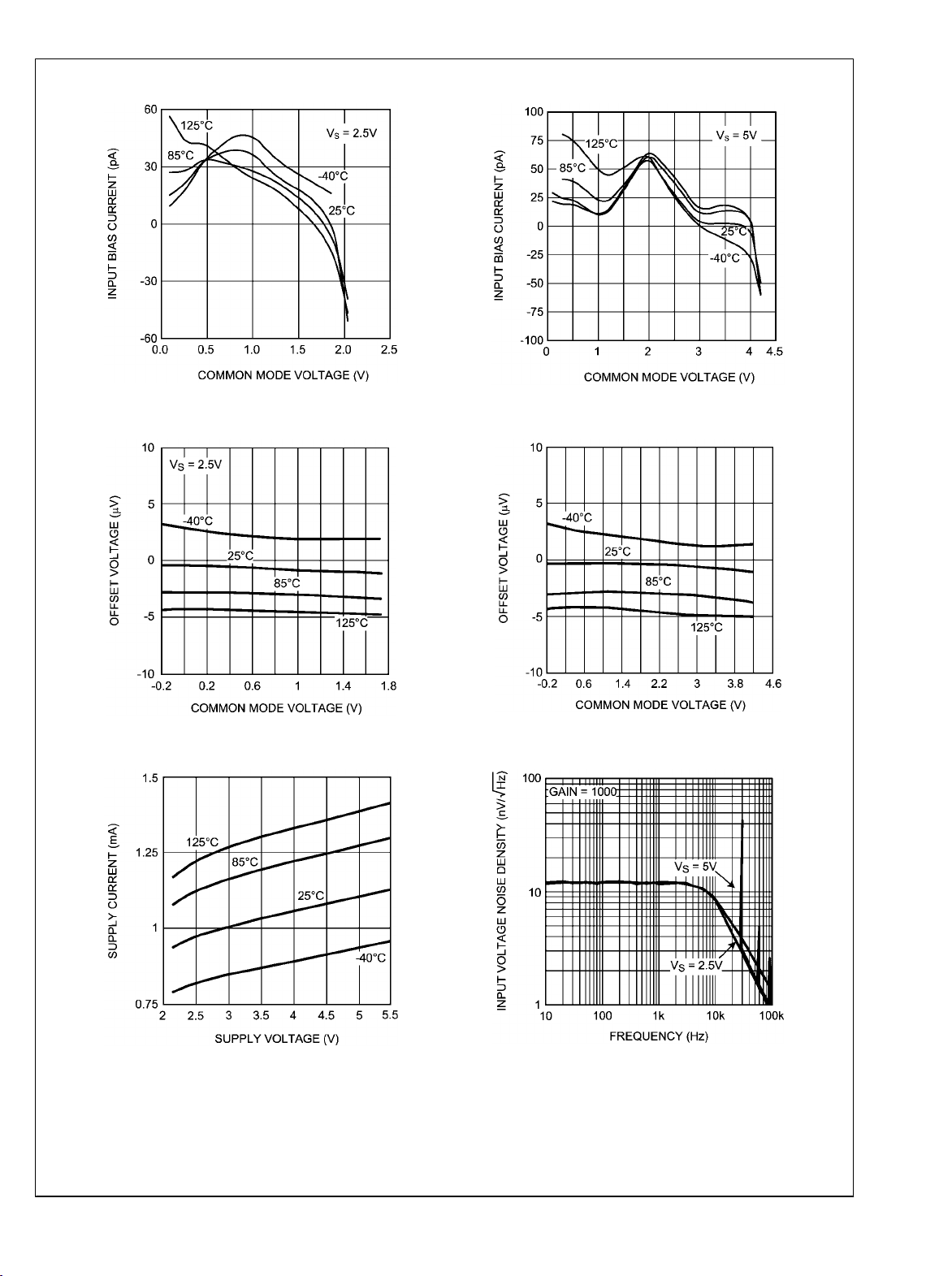

Typical Performance Characteristics Unless otherwise noted: T

VS= 5V, VCM = VS/2.

= 25°C, RL > 10 kΩ, VS= V+ – V–,

A

Offset Voltage Distribution

LMP2021/LMP2022

Offset Voltage Distribution

30014912

TCVOS Distribution

30014914

TCVOS Distribution

30014913

Offset Voltage vs. Supply Voltage

30014905

www.national.com 6

30014915

PSRR vs. Frequency

30014930

Page 7

LMP2021/LMP2022

Input Bias Current vs. V

Offset Voltage vs. V

CM

CM

30014962

Input Bias Current vs. V

Offset Voltage vs. V

CM

30014961

CM

30014906

Supply Current vs. Supply Voltage (Per Amplifier)

30014904

30014907

Input Voltage Noise vs. Frequency

30014926

7 www.national.com

Page 8

Open Loop Frequency Response

LMP2021/LMP2022

Open Loop Frequency Response

30014922

Open Loop Frequency Response Over Temperature

30014923

EMIRR vs. Input Power

30014921

EMIRR vs. Frequency

30014934

EMIRR vs. Input Power

30014932

www.national.com 8

30014933

Page 9

LMP2021/LMP2022

Time Domain Input Voltage Noise

CMRR vs. Frequency

30014928

Time Domain Input Voltage Noise

30014929

Slew Rate vs. Supply Voltage

Output Swing High vs. Supply Voltage

30014931

30014909

30014916

Output Swing Low vs. Supply Voltage

30014911

9 www.national.com

Page 10

Output Swing High vs. Supply Voltage

LMP2021/LMP2022

Output Swing Low vs. Supply Voltage

Overload Recovery Time

Large Signal Step Response

30014908

30014942

30014910

Overload Recovery Time

30014943

Small Signal Step Response

30014920

www.national.com 10

30014918

Page 11

LMP2021/LMP2022

Large Signal Step Response

30014919

Output Voltage vs. Output Current

Small Signal Step Response

30014917

Cross Talk Rejection Ratio vs. Frequency (LMP2022)

30014924

30014973

11 www.national.com

Page 12

Application Information

LMP2021/LMP2022

The LMP2021/LMP2022 are single and dual precision operational amplifiers with ultra low offset voltage, ultra low offset

voltage drift, and very low input voltage noise with no 1/f and

extended supply voltage range. The LMP2021/LMP2022 offer on chip EMI suppression circuitry which greatly enhances

LMP2021/LMP2022

the performance of these precision amplifiers in the presence

of radio frequency signals and other disturbances.

The LMP2021/LMP2022 utilize proprietary techniques to

measure and continuously correct the input offset error voltage. The LMP2021/LMP2022 have a DC input offset voltage

with a maximum value of ±5 μV and an input offset voltage

drift maximum value of 0.02 µV/°C. The input voltage noise of

the LMP2021/LMP2022 is less than 11 nV/

gain of 1000 V/V and has no flicker noise component. This

makes the LMP2021/LMP2022 ideal for high accuracy, low

frequency applications where lots of amplification is needed

and the input signal has a very small amplitude.

The proprietary input offset correction circuitry enables the

LMP2021/LMP2022 to have superior CMRR and PSRR performances. The combination of an open loop voltage gain of

160 dB, CMRR of 142 dB, PSRR of 130 dB, along with the

ultra low input offset voltage of only −0.4 µV, input offset voltage drift of only −0.004 µV/°C, and input voltage noise of only

260 nV

great choices for high gain transducer amplifiers, ADC buffer

amplifiers, DAC I-V conversion, and other applications requiring precision and long-term stability. Other features are

rail-to-rail output, low supply current of 1.1 mA per amplifier,

and a gain-bandwidth product of 5 MHz.

The LMP2021/LMP2022 have an extended supply voltage

range of 2.2V to 5.5V, making them ideal for battery operated

portable applications. The LMP2021 is offered in 5-pin

SOT-23 and 8-pin SOIC packages. The LMP2022 is offered

in 8-pin MSOP and 8-Pin SOIC packages.

EMI SUPPRESSION

The near-ubiquity of cellular, bluetooth, and Wi-Fi signals and

the rapid rise of sensing systems incorporating wireless radios make electromagnetic interference (EMI) an evermore

important design consideration for precision signal paths.

Though RF signals lie outside the op amp band, RF carrier

switching can modulate the DC offset of the op amp. Also

some common RF modulation schemes can induce downconverted components. The added DC offset and the induced

signals are amplified with the signal of interest and thus corrupt the measurement. The LMP2021/LMP2022 use on chip

filters to reject these unwanted RF signals at the inputs and

power supply pins; thereby preserving the integrity of the precision signal path.

Twisted pair cabling and the active front-end’s common-mode

rejection provide immunity against low frequency noise (i.e.

60 Hz or 50 Hz mains) but are ineffective against RF interference. Figure 12 displays this. Even a few centimeters of PCB

trace and wiring for sensors located close to the amplifier can

pick up significant 1 GHz RF. The integrated EMI filters of

LMP2021/LMP2022 reduce or eliminate external shielding

and filtering requirements, thereby increasing system robustness. A larger EMIRR means more rejection of the RF interference. For more information on EMIRR, please refer to

AN-1698.

at 0.1 Hz to 10 Hz make the LMP2021/LMP2022

PP

at a voltage

INPUT VOLTAGE NOISE

The input voltage noise density of the LMP2021/LMP2022

has no 1/f corner, and its value depends on the feedback network used. This feature of the LMP2021/LMP2022 differentiates this family from other products currently available from

other vendors. In particular, the input voltage noise density

decreases as the closed loop voltage gain of the LMP2021/

LMP2022 increases. The input voltage noise of the LMP2021/

LMP2022 is less than 11 nV/

when the closed loop voltage gain of the op amp is 1000. Higher voltage gains are

required for smaller input signals. When the input signal is

smaller, a lower input voltage noise is quite advantageous

and increases the signal to noise ratio.

Figure 1 shows the input voltage noise of the LMP2021/

LMP2022 as the closed loop gain increases.

30014959

FIGURE 1. Input Voltage Noise Density decreases with

Gain

Figure 2 shows the input voltage noise density does not have

the 1/f component.

30014951

FIGURE 2. Input Voltage Noise Density with no 1/f

With smaller and smaller input signals and high precision applications with lower error budget, the reduced input voltage

noise and no 1/f noise allow more flexibility in circuit design.

www.national.com 12

Page 13

ACHIEVING LOWER NOISE WITH FILTERING

The low input voltage noise of the LMP2021/LMP2022, and

no 1/f noise make these suitable for many applications with

noise sensitive designs. Simple filtering can be done on the

LMP2021/LMP2022 to remove high frequency noise. Figure

3 shows a simple circuit that achieves this.

In Figure 3 CF and the corner frequency of the filter resulting

from CF and RF will reduce the total noise.

30014936

FIGURE 3. Noise Reducing Filter for Lower Gains

In order to achieve lower noise floors for even more noise

stringent applications, a simple filter can be added to the op

amp’s output after the amplification stage. Figure 4 shows the

schematic of a simple circuit which achieves this objective.

Low noise amplifiers such as the LMV771 can be used to

create a single pole low pass filter on the output of the

LMP2021/LMP2022. The noise performance of the filtering

amplifier, LMV771 in this circuit, will not be dominant as the

input signal on LMP2021/LMP2022 has already been significantly gained up and as a result the effect of the input voltage

noise of the LMV771 is effectively not noticeable.

30014956

FIGURE 4. Enhanced Filter to Further Reduce Noise at

Higher Gains

Using the circuit in Figure 4 has the advantage of removing

the non-linear filter bandwidth dependency which is seen

when the circuit in Figure 3 is used. The difference in noise

performance of the circuits in Figures 3, 4 becomes apparent

only at higher gains. At voltage gains of 10 V/V or less, there

is no difference between the noise performance of the two

circuits.

30014974

FIGURE 5. RMS Input Referred Noise vs. Frequency

Figure 5 shows the total input referred noise vs. 3 dB corner

of both filters of Figure 3 and Figure 4 at gains of 100V/V and

1000V/V. For these measurements and using Figure 3's cir-

cuit, RF = 49.7 kΩ and RIN = 497Ω. Value of CF has been

changed to achieve the desired 3 dB filter corner frequency.

In the case of Figure 4's circuit, RF = 49.7 kΩ and RIN =

497Ω, R

achieve the desired 3 dB filter corner frequency. Figure 5

= 49.7 kΩ, and C

FILT

has been changed to

FILT

compares the RMS noise of these two circuits. As Figure 5

shows, the RMS noise measured the circuit in Figure 4 has

lower values and also depicts a more linear shape.

DIGITAL ACQUISITION SYSTEMS

High resolution ADC’s with 16-bits to 24-bits of resolution can

be limited by the noise of the amplifier driving them. The circuit

configuration, the value of the resistors used and the source

impedance seen by the amplifier can affect the noise of the

amplifier. The total noise at the output of the amplifier can be

dominated by one of several sources of noises such as: white

noise or broad band noise, 1/f noise, thermal noise, and current noise. In low frequency applications such as medical

instrumentation, the source impedance is generally low

enough that the current noise coupled into it does not impact

the total noise significantly. However, as the 1/f or flicker noise

is paramount to many application, the use of an auto correcting stabilized amplifier like the LMP2021/LMP2022 reduces

the total noise.

Table 1: RMS Input Noise Performance summarizes the input

and output referred RMS noise values for the LMP2021/

LMP2022 compared to that of Competitor A. As described in

previous sections, the outstanding noise performance of the

LMP2021/LMP2022 can be even further improved by adding

a simple low pass filter following the amplification stage.

The use of an additional filter, as shown in Figure 4 benefits

applications with higher gain. For this reason, at a gain of 10,

only the results of circuit in Figure 3 are shown. The RMS

input noise of the LMP2021/LMP2022 are compared with

Competitor A's input noise performance. Competitor A's RMS

input noise behaves the same with or without an additional

filter.

LMP2021/LMP2022

13 www.national.com

Page 14

Table 1: RMS Input Noise Performance

Amplifier

Gain

(V/V)

LMP2021/LMP2022

10

100

System

Bandwidth

Requirement

(Hz)

100 229 * 300

1000 763 * 1030

100 229 196 300

1000 763 621 1030

RMS Input Noise (nV)

LMP2021/LMP2022

Figure 3

Circuit

Figure 4

Circuit

10 71 46 95

1000

100 158 146 300

1000 608 462 1030

* No significant difference in Noise measurements at

AV = 10V/V

INPUT BIAS CURRENT

The bias current of the LMP2021/LMP2022 behaves differently than a conventional amplifier due to the dynamic tran-

Competitor

A

Figures 4, 3

Circuit

sient currents created on the input of an auto-zero circuit. The

input bias current is affected by the charge and discharge

current of the input auto-zero circuit. The amount of current

sunk or sourced from that stage is dependent on the combination of input impedance (resistance and capacitance), as

well as the balance and matching of these impedances across

the two inputs. This current, integrated in the auto-zero circuit,

causes a shift in the apparent "bias current". Because of this,

there is an apparent "bias current vs. input impedance" interaction. In the LMP2021/LMP2022 for an input resistive

impedance of 1 GΩ, the shift in input bias current can be up

to 40 pA. This input bias shift is caused by varying the input's

capacitive impedance. Since the input bias current is dependent on the input impedance, it is difficult to estimate what the

actual bias current is without knowing the end circuit and associated capacitive strays.

Figure 6 shows the input bias current of the LMP2021/

LMP2022 and that of another commercially available amplifier from a competitor. As it can be seen, the shift in LMP2021/

LMP2022 bias current is much lower than that of other chopper style or auto zero amplifiers available from other vendors.

FIGURE 6. Input Bias Current of LMP2021/LMP2022 is lower than Competitor A

LOWERING THE INPUT BIAS CURRENT

As mentioned in the INPUT BIAS CURRENT section, the input bias current of an auto zero amplifier such as the

LMP2021/LMP2022 varies with input impedance and feedback impedance. Once the value of a certain input resistance,

i.e. sensor resistance, is known, it is possible to optimize the

input bias current for this fixed input resistance by choosing

the capacitance value that minimizes that current. Figure 7

shows the input bias current vs. input impedance of the

LMP2021/LMP2022. The value of RG or input resistance in

this test is 1 GΩ. When this value of input resistance is used,

and when a parallel capacitance of 22 pF is placed on the

circuit, the resulting input bias current is nearly 0 pA.

Figure 7 can be used to extrapolate capacitor values for other

sensor resistances. For this purpose, the total impedance

seen by the input of the LMP2021/LMP2022 needs to be calculated based on Figure 7. By knowing the value of RG, one

can calculate the corresponding CG which minimizes the noninverting input bias current, positive bias current, value.

www.national.com 14

30014975

30014964

FIGURE 7. Input Bias Current vs. CG with RG = 1 GΩ

Page 15

LMP2021/LMP2022

In a typical I-V converter, the output voltage will be the sum

of DC offset plus bias current and the applied signal through

the feedback resistor. In a conventional input stage, the inverting input's capacitance has very little effect on the circuit.

This effect is generally on settling time and the dielectric

soakage time and can be ignored. In auto zero amplifiers, the

input capacitance effect will add another term to the output.

This additional term means that the baseline reading on the

output will be dependent on the input capacitance. The term

input capacitance for this purpose includes circuit strays and

any input cable capacitances. There is a slight variation in the

capacitive offset as the duty cycle and amplitude of the pulses

vary from part to part, depending on the correction at the time.

The lowest input current will be obtained when the

impedances, both resistive and capacitive, are matched between the inputs. By balancing the input capacitances, the

effect can be minimized. A simple way to balance the input

impedance is adding a capacitance in parallel to the feedback

resistance. The addition of this feedback capacitance reduces the bias current and increases the stability of the

operational amplifier. Figure 8 shows the input bias current of

the LMP2021/LMP2022 when RF is set to 1 GΩ. As it can be

seen from Figure 8, choosing the optimum value of CF will

help reducing the input bias current.

SENSOR IMPEDANCE

The sensor resistance, or the resistance connected to the inputs of the LMP2021/LMP2022, contributes to the total

impedance seen by the auto correcting input stage.

30014967

30014968

FIGURE 9. AUTO CORRECTING INPUT STAGE MODEL

As shown in Figure 9, the sum of RIN and R

a low pass filter with C

increases, the time constant of this filter increases, resulting

during correction cycles. As R

OUT

ON-SWITCH

will form

in a slower output signal which could have the effect of reducing the open loop gain, A

In order to prevent this reduction in A

impedance sensors or other high resistances connected to

, of the LMP2021/LMP2022.

VOL

in presence of high

VOL

the input of the LMP2021/LMP2022, a capacitor can be

placed in parallel to this input resistance. This is shown in

Figure 10

IN

30014965

FIGURE 8. Input Bias Current vs. CF with RF = 1 GΩ

The effect of bias current on a circuit can be estimated with

the following:

AV*I

Where AV is the closed loop gain of the system and I

I

denote the positive and negative bias current, respec-

BIAS−

tively. It is common to show the average of these bias currents

in product datasheets. If I

specified, use the I

tables for this calculation.

value provided in datasheet graphs or

BIAS

BIAS+*ZS

BIAS+

- I

BIAS−*ZF

and I

are not individually

BIAS−

BIAS+

and

For the application circuit shown in Figure 12, the LMP2022

amplifiers each have a gain of 18. With a sensor impedance

of 500Ω for the bridge, and using the above equation, the total

error due to the bias current on the outputs of the LMP2022

amplifier will be less than 200 nV.

30014969

30014970

FIGURE 10. Sensor Impedance with Parallel Capacitance

15 www.national.com

Page 16

CIN in Figure 10 adds a zero to the low pass filter and hence

eliminating the reduction in A

An alternative circuit to achieve this is shown in Figure 11.

of the LMP2021/LMP2022.

VOL

LMP2021/LMP2022

FIGURE 11. Alternative Sensor Impedance Circuit

TRANSIENT RESPONSE TO FAST INPUTS

On chip continuous auto zero correction circuitry eliminates

the 1/f noise and significantly reduces the offset voltage and

offset voltage drift; all of which are very low frequency events.

For slow changing sensor signals this correction is transparent. For excitations which may otherwise cause the output to

swing faster than 40 mV/µs, there are additional considerations which can be viewed two perspectives: for sine waves

and for steps.

For sinusoidal inputs, when the output is swinging rail-to-rail

on ±2.5V supplies, the auto zero circuitry will introduce distortions above 2.55 kHz. For smaller output swings, higher

frequencies can be amplified without the auto zero slew limitation as shown in table below. Signals above 20 kHz, are not

affected, though normally, closed loop bandwidth should be

kept below 20 kHz so as to avoid aliasing from the auto zero

circuit.

V

OUT-PEAK

For step-like inputs, such as those arising from disturbances

to a sensing system, the auto zero slew rate limitation manifests itself as an extended ramping and settling time, lasting

~100 µs.

DIFFERENTIAL BRIDGE SENSOR

Bridge sensors are used in a variety of applications such as

pressure sensors and weigh scales. Bridge sensors typically

have a very small differential output signal. This very small

signal needs to be accurately amplified before it can be fed

into an ADC. As discussed in the previous sections, the accuracy of the op amp used as the ADC driver is essential to

maintaining total system accuracy.

The high DC performance of the LMP2021/LMP2022 make

these amplifiers ideal choices for use with a bridge sensor.

The LMP2021/LMP2022 have very low input offset voltage

and very low input offset voltage drift. The open loop gain of

the LMP2021/LMP2022 is 160 dB.

(V) f

MAX-SINE WAVE

0.32 20

1 6.3

2.5 2.5

(kHz)

30014971

The on chip EMI rejection filters available on the LMP2021/

LMP2022 help remove the EMI interference introduced to the

signal and hence improve the overall system performance.

The circuit in Figure 12 shows a signal path solution for a typical bridge sensor using the LMP2021/LMP2022. Bridge sensors are created by replacing at least one, and up to all four,

of the resistors in a typical bridge with a sensor whose resistance varies in response to an external stimulus. Using four

sensors has the advantage of increasing output dynamic

range. Typical output voltage of one resistive pressure sensor

is 2 mV per 1V of bridge excitation voltage. Using four sensors, the output of the bridge is 8 mV per 1V. The bridge

voltage is this system is chosen to be 1/2 of the analog supply

voltage and equal to the reference voltage of the ADC161S626, 2.5V. This excitation voltage results in 2.5V * 8

mV = 20 mV of differential output signal on the bridge. This

20 mV signal must be accurately amplified by the amplifier to

best match the dynamic input range of the ADC. This is done

by using one LMP2022 and one LMP2021 in front of the ADC161S626. The gaining of this 20 mV signal is achieved in 2

stages and through an instrumentation amplifier. The

LMP2022 in Figure 12 amplifies each side of the differential

output of the bridge sensor by a gain 18. Bridge sensor measurements are usually done up to 10s of Hz. Placing a

300 Hz filter on the LMP2022 helps removing the higher frequency noise from this circuit. This filter is created by placing

two capacitors in the feedback path of the LMP2022 amplifiers. Using the LMP2022 with a gain of 18 reduces the input

referred voltage noise of the op amps and the system as a

result. Also, this gain allows direct filtering of the signal on the

LMP2022 without compromising noise performance. The differential output of the two amplifiers in the LMP2022 are then

fed into a LMP2021 configured as a difference amplifier. This

stage has a gain of 5, with a total system having a gain of

(18*2+1)*5 = 185. The LMP2021 has an outstanding CMRR

value of 139. This impressive CMRR improves system performance by removing the common mode signal introduced

by the bridge. With an overall gain of 185, the 20 mV differential input signal is gained up to 3.7V. This utilizes the

amplifiers output swing as well as the ADC's input dynamic

range.

This amplified signal is then fed into the ADC161S626. The

ADC161S626 is a 16-bit, 50 kSPS to 250 kSPS 5V ADC. In

order to utilize the maximum number of bits of the ADC161S626 in this configuration, a 2.5V reference voltage is

used. This 2.5V reference is also used to power the bridge

sensor and the inverting input of the ADC. Using the same

voltage source for these three points helps reducing the total

system error by eliminating error due to source variations.

With this system, the output signal of the bridge sensor which

can be up to 20 mV is accurately gained to the full scale of

the ADC and then digitized for further processing. The

LMP2021/LMP2022 introduced minimal error to the system

and improved the signal quality by removing common model

signals and high frequency noise.

www.national.com 16

Page 17

FIGURE 12. LMP2021/LMP2022 used with ADC161S626

LMP2021/LMP2022

30014972

17 www.national.com

Page 18

Physical Dimensions inches (millimeters) unless otherwise noted

LMP2021/LMP2022

5-Pin SOT-23

NS Package Number MF05A

NS Package Number M08A

www.national.com 18

8-Pin SOIC

Page 19

LMP2021/LMP2022

NS Package Number MUA08A

8-Pin MSOP

19 www.national.com

Page 20

Notes

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH® Tools www.national.com/webench

Audio www.national.com/audio App Notes www.national.com/appnotes

Clock and Timing www.national.com/timing Reference Designs www.national.com/refdesigns

Data Converters www.national.com/adc Samples www.national.com/samples

Interface www.national.com/interface Eval Boards www.national.com/evalboards

LVDS www.national.com/lvds Packaging www.national.com/packaging

Power Management www.national.com/power Green Compliance www.national.com/quality/green

Switching Regulators www.national.com/switchers Distributors www.national.com/contacts

LDOs www.national.com/ldo Quality and Reliability www.national.com/quality

LED Lighting www.national.com/led Feedback/Support www.national.com/feedback

Voltage Reference www.national.com/vref Design Made Easy www.national.com/easy

PowerWise® Solutions www.national.com/powerwise Solutions www.national.com/solutions

Serial Digital Interface (SDI) www.national.com/sdi Mil/Aero www.national.com/milaero

Temperature Sensors www.national.com/tempsensors Solar Magic® www.national.com/solarmagic

Wireless (PLL/VCO) www.national.com/wireless Analog University® www.national.com/AU

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

LMP2021/LMP2022 Zero Drift, Low Noise, EMI Hardened Amplifiers

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

www.national.com

National Semiconductor

Americas Technical

Support Center

Email: support@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

Page 21

Loading...

Loading...