Page 1

查询LMH6505供应商

LMH6505

Wideband, Low Power, Linear-in-dB, Variable Gain

Amplifier

LMH6505 Wideband, Low Power, Linear-in-dB, Variable Gain Amplifier

January 2006

General Description

The LMH6505 is a wideband DC coupled voltage controlled

gain stage followed by a high-speed current feedback op

amp which can directly drive a low impedance load. The gain

adjustment range is 80 dB for up to 10 MHz which is accomplished by varying the gain control input voltage, V

Maximum gain is set by external components, and the gain

can be reduced all the way to cut-off. Power consumption is

110 mW with a speed of 150 MHz and a gain control bandwidth (BW) of 100 MHz. Output referred DC offset voltage is

less than 55 mV over the entire gain control voltage range.

Device-to-device gain matching is within

mum gain. Furthermore, gain is tested and guaranteed over

a wide range. The output current feedback op amp allows

high frequency large signals (Slew Rate = 1500 V/µs) and

can also drive a heavy load current (60 mA) guaranteed.

Near ideal input characteristics (i.e. low input bias current,

low offset, low pin 3 resistance) enable the device to be

easily configured as an inverting amplifier as well.

To provide ease of use when working with a single supply,

the V

ground pin potential (pin 4). V

order to ease drive requirement. In single supply operation,

the ground pin is tied to a "virtual" half supply.

The LMH6505’s gain control is linear in dB for a large portion

of the total gain control range from 0 dB down to −85 dB

25˚C, as shown below. This makes the device suitable for

AGC applications. For linear gain control applications, see

the LMH6503 datasheet.

The LMH6505 is available in either the SOIC-8 or the

MSOP-8 package. The combination of minimal external

components and small outline packages allows the

LMH6505 to be used in space-constrained applications.

range is set to be from 0V to +2V relative to the

G

input impedance is high in

G

±

0.5 dB at maxi-

.

G

Features

VS=±5V, TA= 25˚C, RF=1kΩ,RG= 100Ω,RL= 100Ω,A

=A

n −3 dB BW 150 MHz

n Gain control BW 100 MHz

n Adjustment range (

n Gain matching (limit)

n Supply voltage range 7V to 12V

n Slew rate (inverting) 1500 V/µs

n Supply current (no load) 11 mA

n Linear output current

n Output voltage swing

n Input noise voltage 4.4 nV/

n Input noise current 2.6 pA/

n THD (20 MHz, RL= 100Ω,VO=2VPP) −45 dBc

= 9.4 V/V, Typical values unless specified.

VMAX

<

10 MHz) 80 dB

Applications

n Variable attenuator

n AGC

n Voltage controlled filter

n Video imaging processing

@

±

0.50 dB

±

60 mA

±

V

2.4V

Typical Application

A

= 9.4 V/V

VMAX

Gain vs. V

© 2006 National Semiconductor Corporation DS201710 www.national.com

G

20171011

20171002

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

LMH6505

Distributors for availability and specifications.

Junction Temperature 150˚C

Soldering Information:

Infrared or Convection (20 sec) 235˚C

Wave Soldering (10 sec) 260˚C

ESD Tolerance (Note 4)

Human Body Model 2000V

Machine Model 200V

±

Input Current

10 mA

Output Current 120 mA (Note 3)

Supply Voltages (V

Voltage at Input/ Output pins V

+-V−

) 12.6V

+

+0.8V, V−−0.8V

Storage Temperature Range −65˚C to 150˚C

Operating Ratings (Note 1)

Supply Voltages (V

Operating Temperature Range −40˚C to +85˚C

Thermal Resistance: (θ

8 -Pin SOIC 60 165

8-Pin MSOP 65 235

+-V−

) 7Vto12V

)(θJA)

JC

Electrical Characteristics(Note 2)

Unless otherwise specified, all limits are guaranteed for TJ= 25˚C, VS=±5V, A

±

0.1V, RL= 100Ω,VG= +2V. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions

Frequency Domain Response

BW −3 dB Bandwidth V

GF Gain Flatness V

<

1V

OUT

V

OUT

OUT

<

4VPP,A

<

1V

PP

= 100 38

VMAX

PP

0.9V ≤ VG≤ 2V,±0.2 dB

Att Range Flat Band (Relative to Max Gain)

Attenuation Range (Note 13)

BW

Gain control Bandwidth V

±

0.2 dB Flatness, f<30 MHz 26

±

0.1 dB Flatness, f<30 MHz 9.5

= 1V (Note 12) 100 MHz

G

Control

CT (dB) Feed-through V

= 0V, 30 MHz

G

(Output/Input)

GR Gain Adjustment Range f<10 MHz 80

<

f

30 MHz 71

Time Domain Response

t

r,tf

Rise and Fall Time 0.5V Step 2.1 ns

OS % Overshoot 10 %

SR Slew Rate (Note 5) Non Inverting 900

Inverting 1500

Distortion & Noise Performance

HD2 2

nd

Harmonic Distortion 2VPP, 20 MHz −47

rd

Harmonic Distortion –61

THD Total Harmonic Distortion −45

En tot Total Equivalent Input Noise f

I

N

Input Noise Current f>1 MHz 2.6 pA/

>

1 MHz, R

SOURCE

=50Ω 4.4 nV/

DG Differential Gain f = 4.43 MHz, RL= 100Ω 0.30 %

DP Differential Phase 0.15 deg

DC & Miscellaneous Performance

GACCU Gain Accuracy

(See Application Information)

G Match Gain Matching

(See Application Information)

V

= 2.0V 0

G

<

0.8V

V

G

0.8V

<

V

2V +0.1/−0.53 +4.3/−3.9

G

= 2.0V —

<

<

V

2V — +4.2/−4.0

G

K Gain Multiplier

(See Application Information)

= 9.4 V/V, RF=1kΩ,RG= 100Ω,VIN=

VMAX

Min

(Note 6)

Typ

(Note 6)

Max

(Note 6) Units

150

40 MHz

−51 dB

±

0.50

±

0.50

0.890

0.830

0.940 0.990

1.04

MHz

dB

dB

V/µs

dBcHD3 3

dB

dB

V/V

www.national.com 2

Page 3

Electrical Characteristics(Note 2) (Continued)

Unless otherwise specified, all limits are guaranteed for TJ= 25˚C, VS=±5V, A

±

0.1V, RL= 100Ω,VG= +2V. Boldface limits apply at the temperature extremes.

Symbol Parameter Conditions

NL Input Voltage Range RGOpen

V

IN

V

LR

IN

I

RG_MAX

I

BIAS

TC I

R

IN

C

IN

I

VG

TC I

R

VG

C

VG

V

OUT

V

OUT

R

OUT

I

OUT

V

O

OFFSET

RGCurrent Pin 3

Bias Current Pin 2 (Note 7) −0.6 −2.5

Bias Current Drift Pin 2 (Note 8) –190 pA/˚C

BIAS

Input Resistance Pin 2 7 MΩ

Input Capacitance Pin 2 2.8 pF

VGBias Current Pin 1, VG= 2V (Note 7) 0.9 µA

VGBias Drift Pin 1 (Note 8) 10 pA/˚C

VG

VGInput Resistance Pin 1 25 MΩ

VGInput Capacitance Pin 1 2.8 pF

L Output Voltage Range RL= 100Ω

NL RL= Open

Output Impedance DC 0.12 Ω

Output Current V

Output Offset Voltage 0V<V

+PSRR +Power Supply Rejection Ratio

(Note 9)

−PSRR −Power Supply Rejection Ratio

(Note 9)

I

S

Supply Current No Load 9.5

= 100Ω

G

=±4V from Rails

OUT

<

2V

G

Input Referred, 1V change,

= 2.2V

V

G

Input Referred, 1V change,

= 2.2V

V

G

VMAX

Min

(Note 6)

±

±

±

±

±

±

±

±

–65 –72 dB

–65 –75

= 9.4 V/V, RF=1kΩ,RG= 100Ω,VIN=

0.60

Typ

(Note 6)

±

3

±

0.74

Max

(Note 6) Units

0.50

6.0

±

7.4 mA

5.0

−2.6

2.1

±

2.4

1.9

±

3.1

60

±

80 mA

40

±

10

±

55

±

70

11 14

7.5

16

LMH6505

V

µA

V

mV

dB

mA

www.national.com3

Page 4

Electrical Characteristics(Note 2) (Continued)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

intended to be functional, but specific performance is not guaranteed. For guaranteed specifications, see the Electrical Characteristics.

LMH6505

Note 2: Electrical Table values apply only for factory testing conditions at the temperature indicated. Factory testing conditions result in very limited self-heating of

the device such that T

Note 3: The maximum output current (I

Note 4: Human Body Model is 1.5 kΩ in series with 100 pF. Machine Model is 0Ω in series with 200 pF

Note 5: Slew rate is the average of the rising and falling slew rates.

Note 6: Typical values represent the most likely parametric norm. Bold numbers refer to over temperature limits.

Note 7: Positive current corresponds to current flowing into the device.

Note 8: Drift is determined by dividing the change in parameter distribution at temperature extremes by the total temperature change.

Note 9: +PSRR definition: [|∆V

subtracted out.

Note 10: Gain/Phase normalized to low frequency value at 25˚C.

Note 11: Gain/Phase normalized to low frequency value at each setting.

Note 12: Gain control frequency response schematic:

. No guarantee of parametric performance is indicated in the Electrical Tables under conditions of internal self-heating where T

J=TA

OUT

) is determined by device power dissipation limitations or value specified, whichever is lower.

OUT

/∆V+|/AV], −PSRR definition: [|∆V

/∆V−|/AV] with 0.1V input voltage. ∆V

OUT

is the change in output voltage with offset shift

OUT

>

TA.

J

20171016

Note 13: Flat Band Attenuation (Relative To Max Gain) Range Definition: Specified as the attenuation range from maximum which allows gain flatness specified

±

(either

0.2dB or±0.1dB), relative to A

±

0.2 dB: 19.7 dB down to -6.3 dB = 26 dB range

±

0.1 dB: 19.7 dB down to 10.2 dB = 9.5 dB range

gain. For example, for f<30 MHz, here are the Flat Band Attenuation ranges:

VMAX

Connection Diagram

8-Pin SOIC

Top View

20171001

Ordering Information

Package Part Number Package Marking Transport Media NSC Drawing

8-Pin SOIC

8-Pin MSOP

LMH6505MA

LMH6505MAX 2.5k Units Tape and Reel

LMH6505MM

LMH6505MMX 3.5k Units Tape and Reel

LMH6505MA

A93A

95 Units/Rail

1k Units Tape and Reel

M08A

MUA08A

www.national.com 4

Page 5

LMH6505

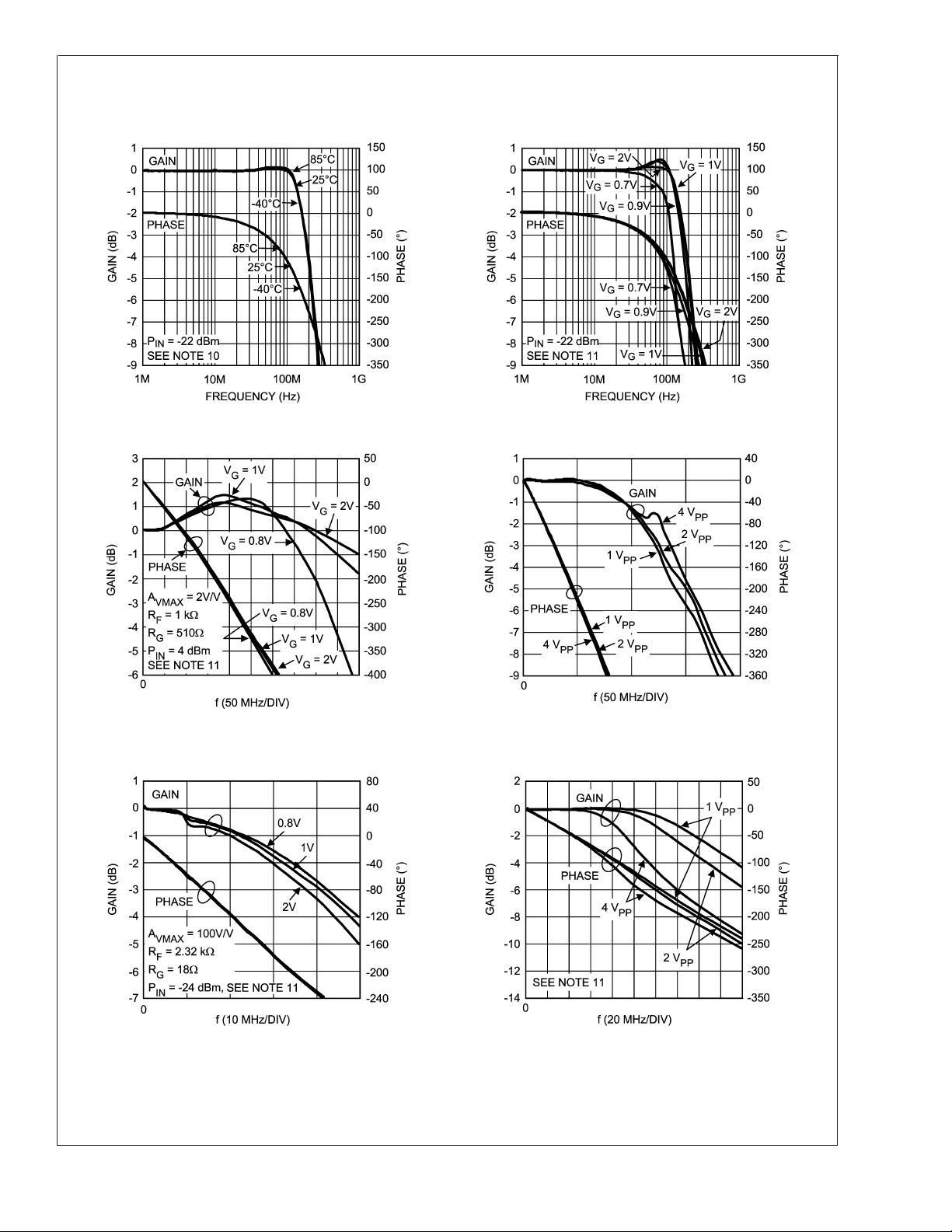

Typical Performance Characteristics Unless otherwise specified: V

V

G=VGMAX,RF

=1kΩ,RG= 100Ω,VIN= 0.1V, input terminated in 50Ω.RL= 100Ω, Typical values.

Frequency Response Over Temperature Frequency Response for Various V

20171003 20171004

Frequency Response (A

= 2) Inverting Frequency Response

VMAX

=±5V, TA= 25˚C,

S

G

Frequency Response for Various VG(A

(Large Signal) Frequency Response for Various Amplitudes

20171046

= 100)

VMAX

20171045 20171064

20171044

www.national.com5

Page 6

Typical Performance Characteristics Unless otherwise specified: V

V

G=VGMAX,RF

LMH6505

=1kΩ,RG= 100Ω,VIN= 0.1V, input terminated in 50Ω.RL= 100Ω, Typical values. (Continued)

Gain Control Frequency Response I

=±5V, TA= 25˚C,

S

vs. V

S

S

20171033

ISvs. V

S

20171020

PSRR A

Input Bias Current vs. V

vs. Supply Voltage

VMAX

20171021

S

20171022

20171034

www.national.com 6

20171023

Page 7

LMH6505

Typical Performance Characteristics Unless otherwise specified: V

V

G=VGMAX,RF

=1kΩ,RG= 100Ω,VIN= 0.1V, input terminated in 50Ω.RL= 100Ω, Typical values. (Continued)

Feed through Isolation for Various A

IRGvs. V

IN

VMAX

20171041

Gain Variation Over entire Temp Range vs. V

=±5V, TA= 25˚C,

S

Gain vs. V

G

G

20171012

20171018

20171011

Output Offset Voltage vs. VG(Typical Unit #1) Output Offset Voltage vs. VG(Typical Unit #2)

20171025

20171030

www.national.com7

Page 8

Typical Performance Characteristics Unless otherwise specified: V

V

G=VGMAX,RF

LMH6505

Output Offset Voltage vs. V

=1kΩ,RG= 100Ω,VIN= 0.1V, input terminated in 50Ω.RL= 100Ω, Typical values. (Continued)

(Typical Unit #3) Distribution of Output Offset Voltage

G

=±5V, TA= 25˚C,

S

20171028

20171061

Output Noise Density vs. Frequency Output Noise Density vs. Frequency

20171008

20171038

Output Noise Density vs. Frequency Input Referred Noise Density vs. Frequency

20171037 20171036

www.national.com 8

Page 9

LMH6505

Typical Performance Characteristics Unless otherwise specified: V

V

G=VGMAX,RF

=1kΩ,RG= 100Ω,VIN= 0.1V, input terminated in 50Ω.RL= 100Ω, Typical values. (Continued)

=±5V, TA= 25˚C,

S

Output Voltage vs. Output Current (Sinking) Output Voltage vs. Output Current (Sourcing)

20171065 20171031

Distortion vs. Frequency HD vs. P

OUT

THD vs. P

OUT

20171042

20171009

THD vs. P

20171043

OUT

20171010

www.national.com9

Page 10

Typical Performance Characteristics Unless otherwise specified: V

V

G=VGMAX,RF

LMH6505

=1kΩ,RG= 100Ω,VIN= 0.1V, input terminated in 50Ω.RL= 100Ω, Typical values. (Continued)

THD vs. Gain THD vs. Gain

=±5V, TA= 25˚C,

S

20171039

Differential Gain & Phase VGBias Current vs. V

20171035

Output Impedance Step Response Plot

20171040

G

20171014

20171062

www.national.com 10

20171015

Page 11

LMH6505

Typical Performance Characteristics Unless otherwise specified: V

V

G=VGMAX,RF

=1kΩ,RG= 100Ω,VIN= 0.1V, input terminated in 50Ω.RL= 100Ω, Typical values. (Continued)

Step Response Plot Gain vs. V

20171017

=±5V, TA= 25˚C,

S

Step

G

20171032

www.national.com11

Page 12

Application Information

GENERAL DESCRIPTION

LMH6505

The key features of the LMH6505 are:

Low power

•

Broad voltage controlled gain and attenuation range

•

(From A

Bandwidth independent, resistor programmable gain

•

range (R

Broad signal and gain control bandwidths

•

Frequency response may be adjusted with R

•

High impedance signal and gain control inputs

•

The LMH6505 combines a closed loop input buffer (“X1”

Block in Figure 1), a voltage controlled variable gain cell

(“MULT” Block) and an output amplifier (“CFA” Block). The

input buffer is a transconductance stage whose gain is set by

the gain setting resistor, R

feedback op amp and is configured as a transimpedance

stage whose gain is set by, and is equal to, the feedback

resistor, R

defined by the ratio:K·R

with a nominal value of 0.940. As the gain control input (V

changes over its 0 to 2V range, the gain is adjusted over a

range of about 80 dB relative to the maximum set gain.

FIGURE 1. LMH6505 Typical Application and Block

down to complete cutoff)

VMAX

)

G

. The output amplifier is a current

G

. The maximum gain, A

F

where “K” is the gain multiplier

F/RG

Diagram

, of the LMH6505 is

VMAX

R

: determines the input voltage range

G

: determines overall bandwidth

R

F

The amount of current which the input buffer can source/sink

into R

is limited and is given in the I

G

RG_MAX

specification.

This sets the maximum input voltage:

Eq. 2

As the I

RG_MAX

F

voltage or with the lowering of R

distortion will increase. Changes in R

limit is approached with increasing the input

, the device’s harmonic

G

will have a dramatic

F

effect on the small signal bandwidth. The output amplifier of

the LMH6505 is a current feedback amplifier (CFA) and its

bandwidth is determined by R

. As with any CFA, doubling

F

the feedback resistor will roughly cut the bandwidth of the

device in half. For more about CFA’s, see the basic tutorial,

OA-20, “Current Feedback Myths Debunked,” or a more

rigorous analysis, OA-13, “Current Feedback Amplifier Loop

Gain Analysis and Performance Enhancements.”

)

G

OTHER CONFIGURATIONS

1) Single Supply Operation

The LMH6505 can be configured for use in a single supply

environment. Doing so requires the following:

a) Bias pin 4 and R

close to the middle of V

is tied to pin 3. The “virtual half supply” needs to be

R

G

to a “virtual half supply” somewhere

G

+

and V−range. The other end of

capable of sinking and sourcing the expected current flow

through R

b) Ensure that V

.

G

can be adjusted from 0V to 2V above the

G

“virtual half supply”.

c) Bias the input (pin 2) to make sure that it stays within the

range of 2V above V

−

to 2V below V+. See the Input

Voltage Range specification in the Electrical Characteristics table. This can be accomplished by either DC biasing

the input and AC coupling the input signal, or alternatively, by direct coupling if the output of the driving stage

is also biased to half supply.

Arranged this way, the LMH6505 will respond to the current

20171047

flowing through R

similar to the split supply arrangement with V

. The gain control relationship will be

G

measured

G

with reference to pin 4. Keep in mind that the circuit described above will also center the output voltage to the

“virtual half supply voltage.”

SETTING THE LMH6505 MAXIMUM GAIN

Eq. 1

Although the LMH6505 is specified at A

recommended A

varies between 2 and 100. Higher

VMAX

= 9.4 V/V, the

VMAX

gains are possible but usually impractical due to output

offsets, noise and distortion. When varying A

VMAX

several

tradeoffs are made:

www.national.com 12

2) Arbitrarily Referenced Input Signal

Having a wide input voltage range on the input (pin 2)

±

3V typical), the LMH6505 can be configured to control the

(

gain on signals which are not referenced to ground (e.g. Half

Supply biased circuits, etc.). We will call this node the “reference node”. In such cases, the other end of R

which is

G

the side not tied to pin 3 can be tied to this reference node so

that R

will “look at” the difference between the signal and

G

this reference only. Keep in mind that the reference node

needs to source and sink the current flowing through R

.

G

Page 13

Application Information (Continued)

GAIN ACCURACY

Gain accuracy is defined as the actual gain compared

against the theoretical gain at a certain V

which are expressed in dB. (See Figure 2).

Theoretical gain is given by:

Eq. 3

Where K = 0.940 (nominal) N = 1.01V & VC=79mV@room

temperature

ForaV

range, the value specified in the tables represents

G

the worst case accuracy over the entire range. The "Typical"

value would be the difference between the "Typical gain" and

the "Theoretical gain." The "Max" value would be the worst

case difference between the actual gain and the "Theoretical

gain" for the entire population.

GAIN MATCHING

As Figure 2 shows, gain matching is the limit on gain variation at a certain V

±

Max" only. There is no "Typical." For a VGrange, the value

"

, expressed in dB, and is specified as

G

specified represents the worst case matching over the entire

range. The "Max" value would be the worst case difference

between the actual gain and the typical gain for the entire

population.

, the results of

G

GAIN PARTITIONING

If high levels of gain are needed, gain partitioning should be

considered:

20171052

FIGURE 3. Gain Partitioning

The maximum gain range for this circuit is given by the

following equation:

Eq. 4

The LMH6624 is a low noise wideband voltage feedback

amplifier. Setting R

gain of 20 dB. Setting R

at 909Ω and R1at 100Ω produces a

2

at 1000Ω as recommended and R

F

at 50Ω, produces a gain of about 26 dB in the LMH6505. The

total gain of this circuit is therefore approximately 46 dB. It is

important to understand that when partitioning to obtain high

levels of gain, very small signal levels will drive the amplifiers

to full scale output. For example, with 46 dB of gain, a 20 mV

signal at the input will drive the output of the LMH6624 to

200 mV and the output of the LMH6505 to 4V. Accordingly,

the designer must carefully consider the contributions of

each stage to the overall characteristics. Through gain partitioning the designer is provided with an opportunity to optimize the frequency response, noise, distortion, settling

time, and loading effects of each amplifier to achieve improved overall performance.

LMH6505

G

20171051

FIGURE 2. LMH6505 Gain Accuracy & Gain Matching

Defined

LMH6505 GAIN CONTROL RANGE AND MINIMUM GAIN

Before discussing Gain Control Range, it is important to

understand the issues which limit it. The minimum gain of the

LMH6505 is theoretically zero, but in practical circuits it is

limited by the amount of feedthrough, here defined as the

gain when V

= 0V. Capacitive coupling through the board

G

and package, as well as coupling through the supplies, will

determine the amount of feedthrough. Even at DC, the input

signal will not be completely rejected. At high frequencies

feedthrough will get worse because of its capacitive nature.

At frequencies below 10 MHz, the feed through will be less

than −60 dB and therefore, it can be said that with

= 20 dB, the gain control range is 80 dB.

A

VMAX

www.national.com13

Page 14

Application Information (Continued)

LMH6505 GAIN CONTROL FUNCTION

LMH6505

In the plot, Gain vs. V

the control voltage. The “Gain (V/V)” plot, sometimes referred to as the S-curve, is the linear (V/V) gain. This is a

hyperbolic tangent relationship and is given by Equation 3.

The “Gain (dB)” plots the gain in dB and is linear over a wide

range of gains. Because of this, the LMH6505 gain control is

referred to as “linear-in-dB.”

For applications where the LMH6505 will be used at the

heart of a closed loop AGC circuit, the S-curve control characteristic provides a broad linear (in dB) control range with

soft limiting at the highest gains where large changes in

control voltage result in small changes in gain. For applications requiring a fully linear (in dB) control characteristic, use

the LMH6505 at half gain and below (V

GAIN STABILITY

The LMH6505 architecture allows complete attenuation of

the output signal from full gain to complete cut-off. This is

achieved by having the gain control signal V

signal which gets through to the final stage and which results

in the output signal. As a consequence, the R

average current (DC current) influences the operating point

of this “throttle” circuit and affects the LMH6505’s gain

slightly. Figure 4 below, shows this effect as a function of the

gain set by V

G

, we can see the gain as a function of

G

G

.

≤ 1V).

G

“throttle” the

pin’s (pin 3)

G

able limits, please refer to the LMH6502 (Differential Linear

in dB variable gain amplifier) datasheet instead at http://

www.national.com/ds/LM/LMH6502.pdf.

AVOIDING OVERDRIVE OF THE LMH6505 GAIN

CONTROL INPUT

There is an additional requirement for the LMH6505 Gain

Control Input (V

): VGmust not exceed +2.3V (with±5V

G

supplies). The gain control circuitry may saturate and the

gain may actually be reduced. In applications where V

G

being driven from a DAC, this can easily be addressed in the

software. If there is a linear loop driving V

, such as an AGC

G

loop, other methods of limiting the input voltage should be

implemented. One simple solution is to place a 2.2:1 resistive divider on the V

is operating off of

exceed 5V and through the divider V

input. If the device driving this divider

G

±

5V supplies as well, its output will not

can not exceed 2.3V.

G

IMPROVING THE LMH6505 LARGE SIGNAL

PERFORMANCE

Figure 5 illustrates an inverting gain scheme for the

LMH6505.

is

20171066

FIGURE 4. LMH6505 Gain Variation over RGDC

Current Capability vs. Gain

This plot shows the expected gain variation for the maximum

DC current capability (±4.5 mA). For example, with gain

R

G

) set to −60 dB, if the RGpin DC current is increased to

(A

V

4.5 mA sourcing, one would expect to see the gain increase

by about 3 dB (to −57 dB). Conversely, 4.5 mA DC sinking

current through R

would increase gain by 1.75 dB (to

G

−58.25 dB). As you can see from Figure 4 above, the effect

is most pronounced with reduced gain and is limited to less

than 3.75 dB variation maximum.

If the application is expected to experience R

DC current

G

variation and the LMH6505 gain variation is beyond accept-

20171054

FIGURE 5. Inverting Amplifier

The input signal is applied through the R

resistor. The V

G

pin should be grounded through a 25Ω resistor. The maximum gain range of this configuration is given in the following

equation:

Eq. 5

The inverting slew rate of the LMH6505 is much higher than

that of the non-inverting slew rate. This ≈ 2X performance

improvement comes about because in the non-inverting configuration the slew rate of the overall amplifier is limited by

the input buffer. In the inverting circuit, the input buffer remains at a fixed voltage and does not affect slew rate.

TRANSMISSION LINE MATCHING

One method for matching the characteristic impedance of a

transmission line is to place the appropriate resistor at the

input or output of the amplifier. Figure 6 shows a typical

circuit configuration for matching transmission lines.

IN

www.national.com 14

Page 15

Application Information (Continued)

FIGURE 6. Transmission Line Matching

LMH6505

20171056

The resistors R

S,RI,RO

istic impedance, Z

to match the output transmission line over a greater

C

O

, and RTare equal to the character-

, of the transmission line or cable. Use

O

frequency range. It compensates for the increase of the op

amp’s output impedance with frequency.

MINIMIZING PARASITIC EFFECTS ON SMALL SIGNAL

BANDWIDTH

The best way to minimize parasitic effects is to use surface

mount components and to minimize lead lengths and component distance from the LMH6505. For designs utilizing

through-hole components, specifically axial resistors, resistor self-capacitance should be considered. For example, the

average magnitude of parasitic capacitance of RN55D 1%

metal film resistors is about 0.15 pF with variations of as

much as 0.1 pF between lots. Given the LMH6505’s extended bandwidth, these small parasitic reactance variations

can cause measurable frequency response variations in the

highest octave. We therefore recommend the use of surface

mount resistors to minimize these parasitic reactance effects.

RECOMMENDATIONS

Here are some recommendations to avoid problems and to

get the best performance:

Do not place a capacitor across RF. However, an appro-

•

priately chosen series RC combination can be used to

shape the frequency response.

Keep traces connecting RFseparated and as short as

•

possible.

Place a small resistor (20-50Ω) between the output and

•

.

C

L

Cut away the ground plane, if any, under RG.

•

Keep decoupling capacitors as close as possible to the

•

LMH6505.

Connect pin 2 through a minimum resistance of 25Ω.

•

ADJUSTING OFFSETS AND DC LEVEL SHIFTING

Offsets can be broken into two parts: an input-referred term

and an output-referred term. These errors can be trimmed

using the circuit in Figure 7. First set V

trim pot R

to null the offset voltage at the output. This will

4

eliminate the output stage offsets. Next set V

adjust the trim pot R

to null the offset voltage at the output.

1

to 0V and adjust the

G

to 2V and

G

This will eliminate the input stage offsets.

20171057

FIGURE 7. Offset Adjust Circuit

DIGITAL GAIN CONTROL

Digitally variable gain control can be easily realized by driving the LMH6505 gain control input with a digital-to-analog

converter (DAC). Figure 8 illustrates such an application.

This circuit employs National Semiconductor’s eight-bit

DAC0830, the LMC8101 MOS input op amp (Rail-to-Rail

Input/Output), and the LMH6505 VGA. With V

REF

set to 2V,

the circuit provides up to 80 dB of gain control in 256 steps

with up to 0.05% full scale resolution. The maximum gain of

this circuit is 20 dB.

www.national.com15

Page 16

Application Information (Continued)

LMH6505

FIGURE 8. Digital Gain Control

20171058

0.25 V

= 100Ω. When the gain is adjusted to −15 dB (i.e. 35 dB

R

G

down from A

in the specified configuration, RF=1kΩ,

PP

), the input amplitude would be 1.41 V

VMAX

PP

and we can see the distortion is at its worst at this gain. If the

output amplitude of the AGC were to be raised above 0.25

, the input amplitudes for gains 40 dB down from A

V

PP

VMAX

would be even higher and the distortion would degrade

further. It is for this reason that we recommend lower output

amplitudes if wide gain ranges are desired. Using a postamp like the LMH6714/LMH6720/LMH6722 family or the

LMH6702 would be the best way to preserve dynamic range

and yield output amplitudes much higher than 100 mV

PP

Another way of addressing distortion performance and its

limitations on dynamic range, would be to raise the value of

. Just like any other high-speed amplifier, by increasing

R

G

the load resistance, and therefore decreasing the demanded

load current, the distortion performance will be improved in

most cases. With an increased R

increased to keep the same A

VMAX

will also have to be

G,RF

and this will decrease the

overall bandwidth. It may be possible to insert a series RC

combination across R

effect on BW when a large R

in order to counteract the negative

F

is used.

F

AUTOMATIC GAIN CONTROL (AGC) #1

.

USING THE LMH6505 IN AGC APPLICATIONS

In AGC applications, the control loop forces the LMH6505 to

have a fixed output amplitude. The input amplitude will vary

over a wide range and this can be the issue that limits

dynamic range. At high input amplitudes, the distortion due

to the input buffer driving R

may exceed that which is

G

produced by the output amplifier driving the load. In the plot,

THD vs. Gain, total harmonic distortion (THD) is plotted over

a gain range of nearly 35 dB for a fixed output amplitude of

Fast Response AGC Loop

The AGC circuit shown in Figure 9 will correcta6dBinput

amplitude step in 100 ns. The circuit includes a two op amp

precision rectifier amplitude detector (U1 and U2), and an

integrator (U3) to provide high loop gain at low frequencies.

The output amplitude is set by R

. The following are some

9

suggestions for building fast AGC loops: Precision rectifiers

work best with large output signals. Accuracy is improved by

blocking DC offsets, as shown in Figure 9.

www.national.com 16

Page 17

Application Information (Continued)

LMH6505

FIGURE 9. Automatic Gain Control Circuit #1

Signal frequencies must not reach the gain control port of the

LMH6505, or the output signal will be distorted (modulated

by itself). A fast settling AGC needs additional filtering beyond the integrator stage to block signal frequencies. This is

provided in Figure 9 by a simple R-C filter (R

and C3);

10

better distortion performance can be achieved with a more

complex filter. These filters should be scaled with the input

signal frequency. Loops with slower response time, which

means longer integration time constants, may not need the

R

10–C3

filter.

Checking the loop stability can be done by monitoring the V

voltage while applying a step change in input signal amplitude. Changing the input signal amplitude can be easily

done with an arbitrary waveform generator.

20171059

AUTOMATIC GAIN CONTROL (AGC) #2

Figure 10 illustrates an automatic gain control circuit that

employs two LMH6505. In this circuit, U1 receives the input

signal and produces an output signal of constant amplitude.

U2 is configured to provide negative feedback. U2 generates

a rectified gain control signal that works against an adjustable bias level which may be set by the potentiometer and

integrates the bias and negative feedback. The result-

R

B.CI

ant gain control signal is applied to the U1 gain control input

. The bias adjustment allows the U1 output to be set at an

V

G

G

arbitrary level less than the maximum output specification of

the amplifier. Rectification is accomplished in U2 by driving

both the amplifier input and the gain control input with the U1

output signal. The voltage divider that is formed by R

, sets the rectifier gain.

R

2

and

1

www.national.com17

Page 18

Application Information (Continued)

LMH6505

FIGURE 10. Automatic Gain Control Circuit #2

20171060

CIRCUIT LAYOUT CONSIDERATIONS & EVALUATION

BOARDS

A good high frequency PCB layout including ground plane

construction and power supply bypassing close to the package are critical to achieving full performance. The amplifier is

sensitive to stray capacitance to ground at the I

-

input (pin 7)

so it is best to keep the node trace area small. Shunt

capacitance across the feedback resistor should not be used

to compensate for this effect. Capacitance to ground should

be minimized by removing the ground plane from under the

body of R

. Parasitic or load capacitance directly on the

G

output (pin 6) degrades phase margin leading to frequency

response peaking.

The LMH6505 is fully stable when driving a 100Ω load. With

reduced load (e.g. 1k.) there is a possibility of instability at

very high frequencies beyond 400 MHz especially with a

capacitive load. When the LMH6505 is connected to a light

load as such, it is recommended to add a snubber network to

the output (e.g. 100Ω and 39 pF in series tied between the

LMH6505 output and ground). C

can also be isolated from

L

the output by placing a small resistor in series with the output

(pin 6).

Component parasitics also influence high frequency results.

Therefore it is recommended to use metal film resistors such

as RN55D or leadless components such as surface mount

devices. High profile sockets are not recommended.

National Semiconductor suggests the following evaluation

board as a guide for high frequency layout and as an aid in

device testing and characterization:

Device Package Evaluation Board

Part Number

LMH6505 SOIC CLC730066

The evaluation board can be shipped when a device sample

request is placed with National Semiconductor. Evaluation

board documentation can be found in the LMH6505 product

folder at www.National.com.

www.national.com 18

Page 19

Physical Dimensions inches (millimeters) unless otherwise noted

8-Pin SOIC

NS Package Number M08A

LMH6505

8-Pin MSOP

NS Package Number MUA08A

www.national.com19

Page 20

Notes

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves

the right at any time without notice to change said circuitry and specifications.

For the most current product information visit us at www.national.com.

LIFE SUPPORT POLICY

LMH6505 Wideband, Low Power, Linear-in-dB, Variable Gain Amplifier

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL COUNSEL OF NATIONAL SEMICONDUCTOR

CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the body, or

(b) support or sustain life, and whose failure to perform when

properly used in accordance with instructions for use

2. A critical component is any component of a life support

device or system whose failure to perform can be reasonably

expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

provided in the labeling, can be reasonably expected to result

in a significant injury to the user.

BANNED SUBSTANCE COMPLIANCE

National Semiconductor manufactures products and uses packing materials that meet the provisions of the Customer Products

Stewardship Specification (CSP-9-111C2) and the Banned Substances and Materials of Interest Specification (CSP-9-111S2) and contain

no ‘‘Banned Substances’’ as defined in CSP-9-111S2.

Leadfree products are RoHS compliant.

National Semiconductor

Americas Customer

Support Center

Email: new.feedback@nsc.com

Tel: 1-800-272-9959

www.national.com

National Semiconductor

Europe Customer Support Center

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Support Center

Email: ap.support@nsc.com

National Semiconductor

Japan Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

Loading...

Loading...