Page 1

February 7, 2008

LME49600

High Performance, High Fidelity, High Current Audio Buffer

General Description

The LME49600 is a high performance, low distortion high fidelity 250mA audio buffer. The LME49600 is designed for a

wide range of applications. It can be used inside the feedback

loop of op amps.

The LME49600 offers a pin-selectable bandwidth: a low current, 110MHz bandwidth mode that consumes 7.3mA and a

wide 180MHz bandwidth mode that consumes 13.2mA. In

both modes the LME49600 has a nominal 2000V/μs slew

rate. Bandwidth is easily adjusted by either leaving the BW

pin unconnected or connecting a resistor between the BW pin

and the VEE pin.

The LME49600 is fully protected through internal current limit

and thermal shutdown.

Key Specifications

■ Low THD+N

(V

OUT

= 3V

RMS

, f = 1kHz, Figure 2)

0.00003% (typ)

■ Slew Rate 2000V/μs (typ)

■ High Output Current 250mA (typ)

■ Bandwidth

BW pin floating 110MHz (typ)

BW connected to V

EE

180MHz (typ)

■ Supply Voltage Range ±2.25V ≤ V

S

≤ ±18V

Features

■

Pin-selectable bandwidth and quiescent current

■

Pure fidelity. Pure performance

■

Short circuit protection

■

Thermal shutdown

■

TO–263 surface-mount package

Applications

■

Headphone amplifier output drive stage

■

Line drivers

■

Low power audio amplifiers

■

High-current operational amplifier output stage

■

ATE Pin Driver Buffer

■

Power supply regulator

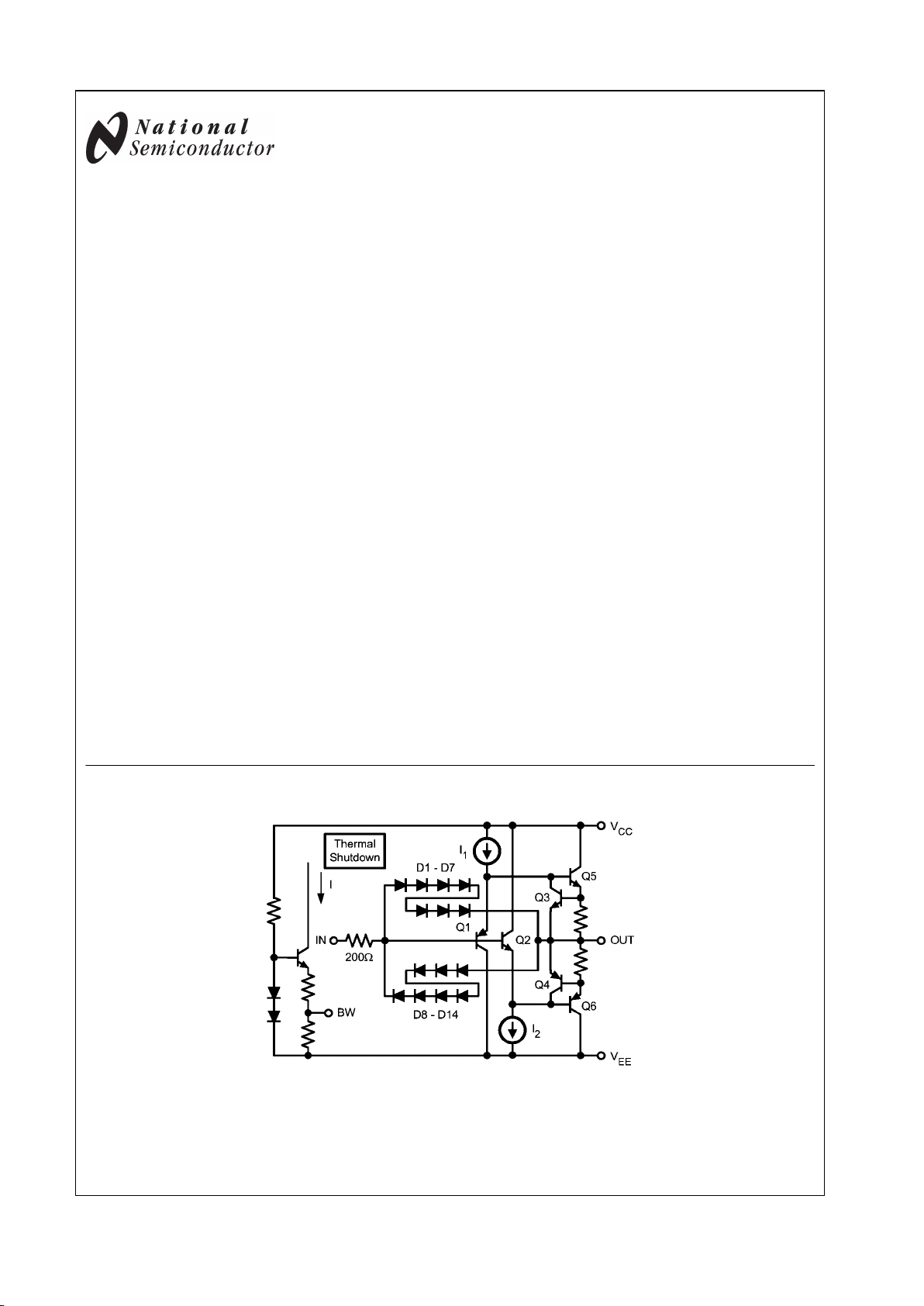

Functional Block Diagram

30029805

FIGURE 1. Simplified Circuit Diagram (Note: I1 and I2 are mirrored from I)

Boomer® is a registered trademark of National Semiconductor Corporation.

© 2008 National Semiconductor Corporation 300298 www.national.com

LME49600 High Performance, High Fidelity, High Current Audio Buffer

Page 2

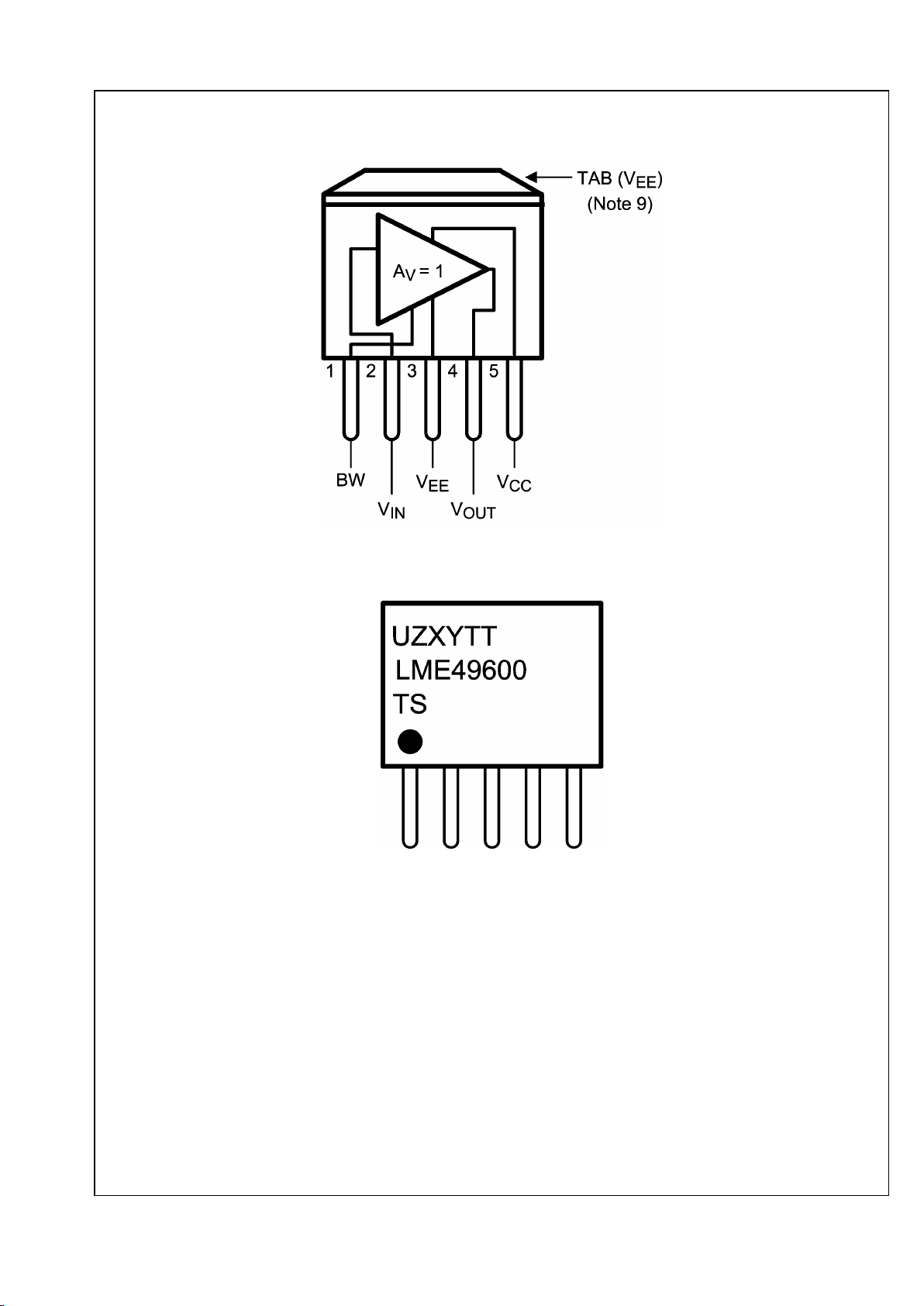

Connection Diagrams

300298a0

Top View

Order Number LME49600TS

See NS Package Number TS5B

30029832

Top View

U — Wafer fabrication code

Z — Assembly plant

XY — 2 Digit date code

TT — Lot traceability

www.national.com 2

LME49600

Page 3

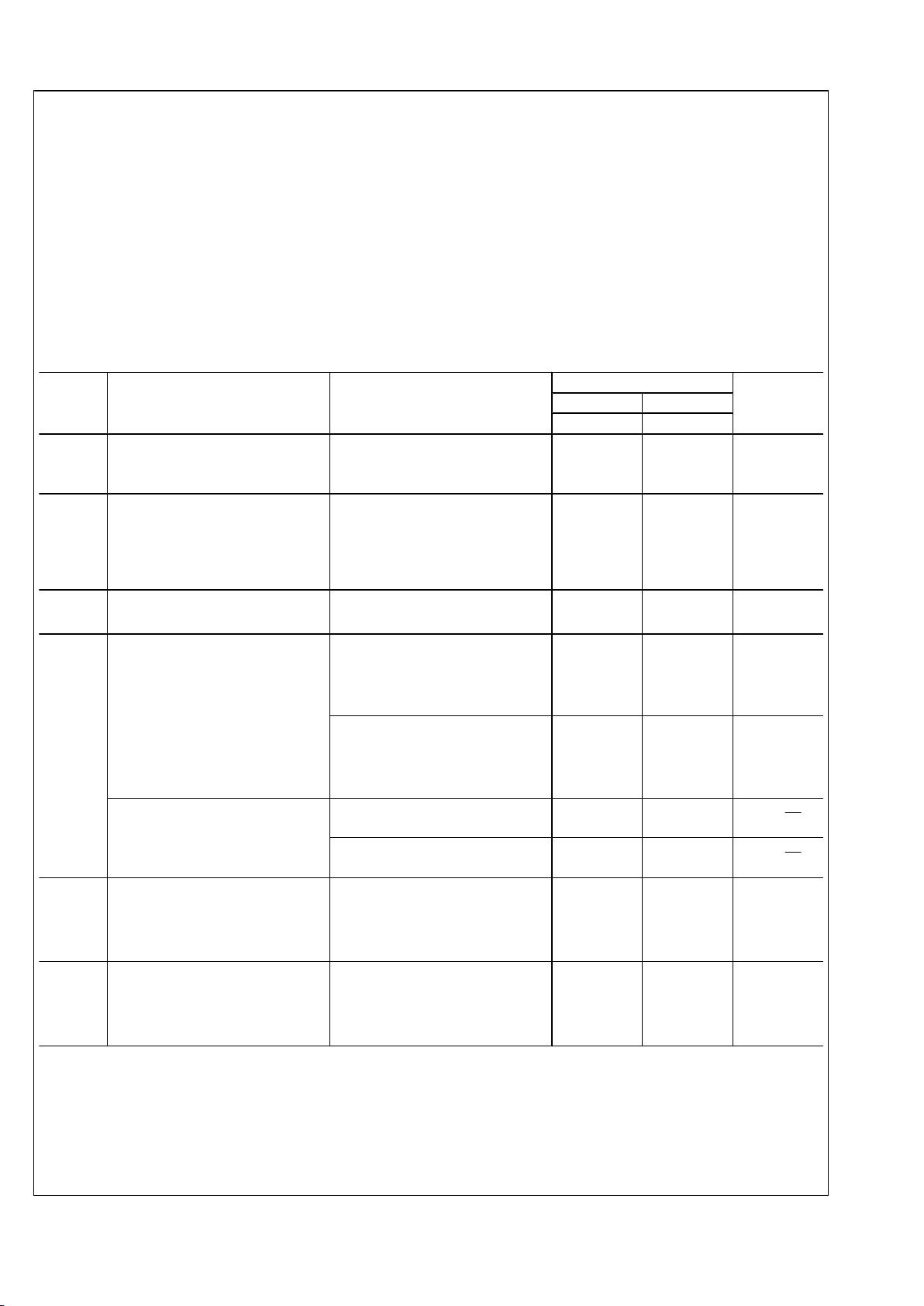

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage ±20V

ESD Ratings(Note 4) 2000V

ESD Ratings (Note 5) 200V

Storage Temperature −40°C to +150°C

Junction Temperature 150°C

Thermal Resistance

θ

JC

4°C/W

θ

JA

65°C/W

θJA (Note 3)

20°C/W

Soldering Information

TO-263 Package (10 seconds) 260°C

Operating Ratings (Notes 1, 2)

Temperature Range

T

MIN

≤ TA ≤ T

MAX

−40°C ≤ TA ≤ 85°C

Supply Voltage ±2.25V to ±18V

System Electrical Characteristics for LME49600 The following specifications apply for V

S

= ±15V,

fIN = 1kHz, unless otherwise specified. Typicals and limits apply for TA = 25°C.

Symbol Parameter Conditions

LME49600

Units

(Limits)

Typical Limit

(Note 6) (Note 7)

I

Q

Total Quiescent Current

I

OUT

= 0

BW pin: No connect

BW pin: Connected to VEE pin

7.3

13.2

10.5

18

mA (max)

mA (max)

THD+N

Total Harmonic Distortion + Noise

(Note 8)

AV = 1, V

OUT

= 3V

RMS

, R

L

= 32Ω, BW = 80kHz,

closed loop see Figure 2.

f = 1kHz

f = 20kHz

0.000035

0.0005

%

%

SR Slew Rate

30 ≤ BW ≤ 180MHz

V

OUT

= 20V

P-P

, RL = 100Ω

2000

V/μs

BW

Bandwidth

AV = –3dB

BW pin: No Connect

RL = 100Ω

RL = 1kΩ

100

110

MHz

MHz

AV = –3dB

BW pin: Connected to VEE pin

RL = 100Ω

RL = 1kΩ

160

180

MHz

MHz

Voltage Noise Density

f = 10kHz

BW pin: No Connect

3.0

nV/√Hz

f = 10kHz

BW pin: Connected to V

EE

pin

2.6

nV/√Hz

t

s

Settling Time

ΔV = 10V, RL = 100Ω

1% Accuracy

BW pin: No connect

BW pin: Connected to VEE pin

200

60

ns

ns

A

V

Voltage Gain

V

OUT

= ±10V

RL = 67Ω

RL = 100Ω

RL = 1kΩ

0.93

0.95

0.99

0.90

0.92

0.98

V/V (min)

V/V (min)

V/V (min)

3 www.national.com

LME49600

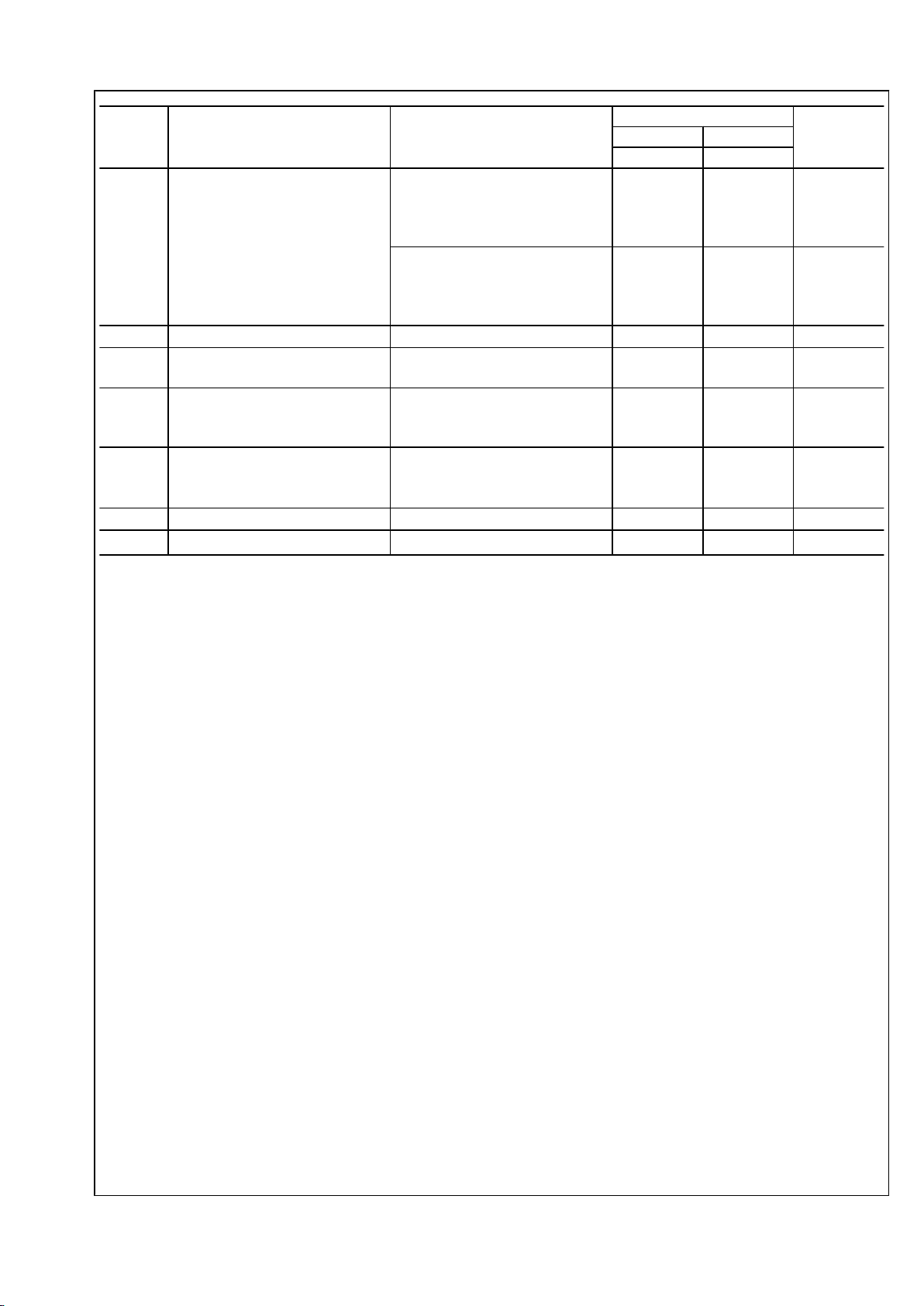

Page 4

Symbol Parameter Conditions

LME49600

Units

(Limits)

Typical Limit

(Note 6) (Note 7)

V

OUT

Voltage Output

Positive

I

OUT

= 10mA

I

OUT

= 100mA

I

OUT

= 150mA

VCC –1.4

VCC –2.0

VCC –2.3

VCC –1.6

VCC –2.1

VCC –2.7

V (min)

V (min)

V (min)

Negative

I

OUT

= –10mA

I

OUT

= –100mA

I

OUT

= –150mA

VEE +1.5

VEE +3.1

VEE +3.5

VEE +1.6

VEE +2.4

VEE +3.2

V (min)

V (min)

V (min)

I

OUT

Output Current

±250 mA

I

OUT-SC

Short Circuit Output Current

BW pin: No Connect

BW pin: Connected to VEE pin

±490

±490

±550

mA (max)

mA (max)

I

B

Input Bias Current

VIN = 0V

BW pin: No Connect

BW pin: Connected to VEE pin

±1.0

±3.0

±2.5

±5.0

μA (max)

μA (max)

Z

IN

Input Impedance

RL = 100Ω

BW pin: No Connect

BW pin: Connected to VEE pin

7.5

5.5

MΩ

MΩ

V

OS

Offset Voltage ±17 ±60 mV (max)

VOS/°C

Offset Voltage vs Temperature

40°C ≤ TA ≤ +125°C

±100

μV/°C

Note 1: All voltages are measured with respect to ground, unless otherwise specified.

Note 2: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical specifications under particular test conditions

which guarantee specific performance limits. This assumes that the device is within the Operating Ratings. Specifications are not guaranteed for parameters

where no limit is given, however, the typical value is a good indication of device performance.

Note 3: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

JMAX

, θJA, and the ambient temperature TA. The maximum

allowable power dissipation is P

DMAX

= (T

JMAX–TA

)/θJA or the number given in Absolute Maximum Ratings, whichever is lower. For the LME49600, typical

application (shown in Figure 2) with V

SUPPLY

= 30V, RL = 32Ω, the total power dissipation is 1.9W. θJA = 20°C/W for the TO–263 package mounted to 16in2 1oz

copper surface heat sink area.

Note 4: Human body model, 100pF discharged through a 1.5kΩ resistor.

Note 5: Machine Model, 220pF – 240pF discharged through all pins.

Note 6: Typical specifications are specified at 25°C and represent the parametric norm.

Note 7: Tested limits are guaranteed to National's AOQL (Average Outgoing Quality Level).

Note 8: This is the distortion of the LME49600 operating in a closed loop configuration with an LME49710. When operating in an operational amplifier's feedback

loop, the amplifier’s open loop gain dominates, linearizing the system and determining the overall system distortion.

Note 9: The TSB package is non-isolated package. The package's metal back and any heat sink to which it is mounted are connected to the same potential as

the -VEE pin.

www.national.com 4

LME49600

Page 5

Typical Performance Characteristics

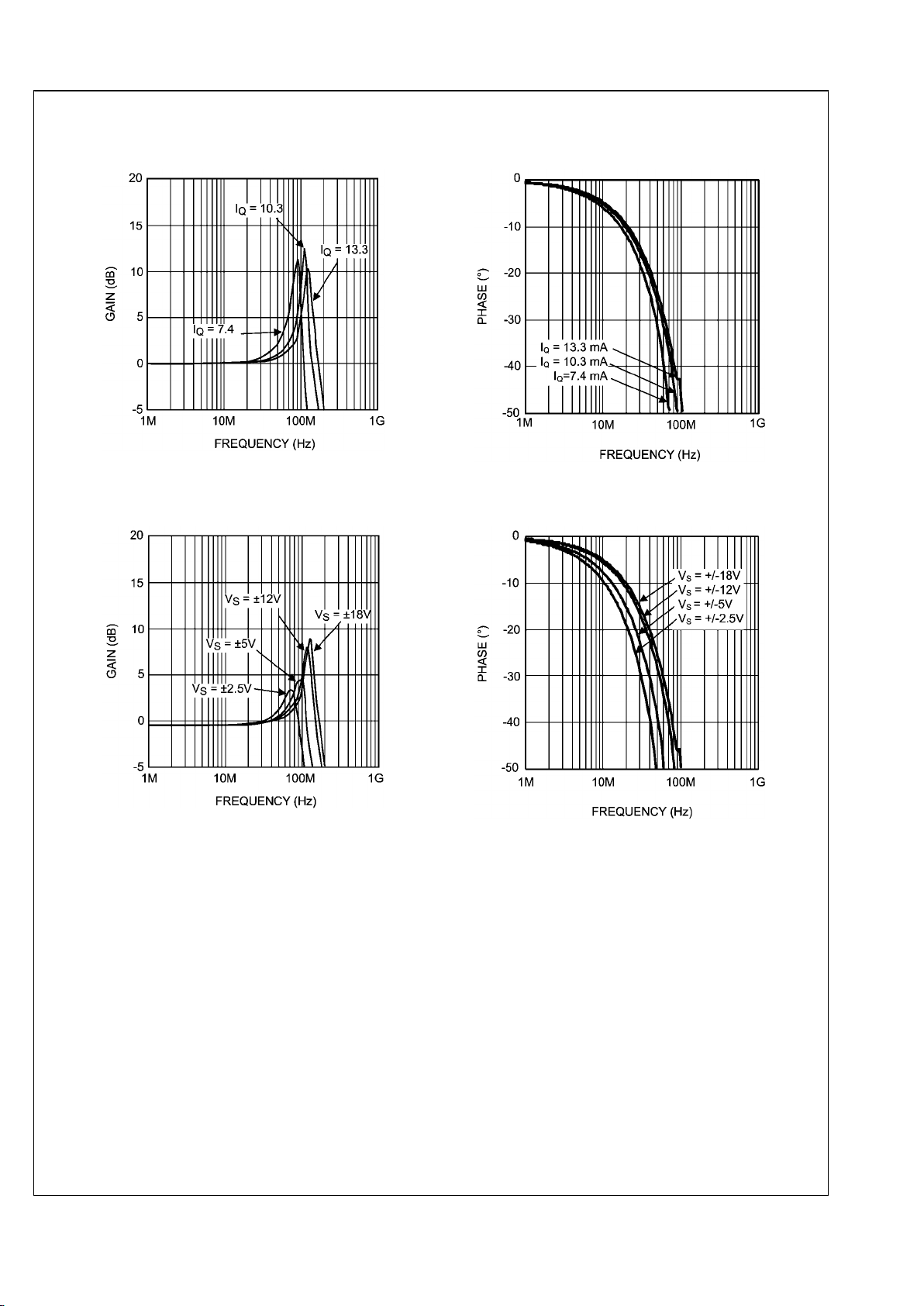

Gain vs Frequency vs Quiescent Current

30029899

Phase vs Frequency vs Quiescent Current

30029881

Gain vs Frequency vs Power Supply Voltage

Wide BW Mode

30029898

Phase vs Frequency vs Supply Voltage

Wide BW Mode

30029880

5 www.national.com

LME49600

Page 6

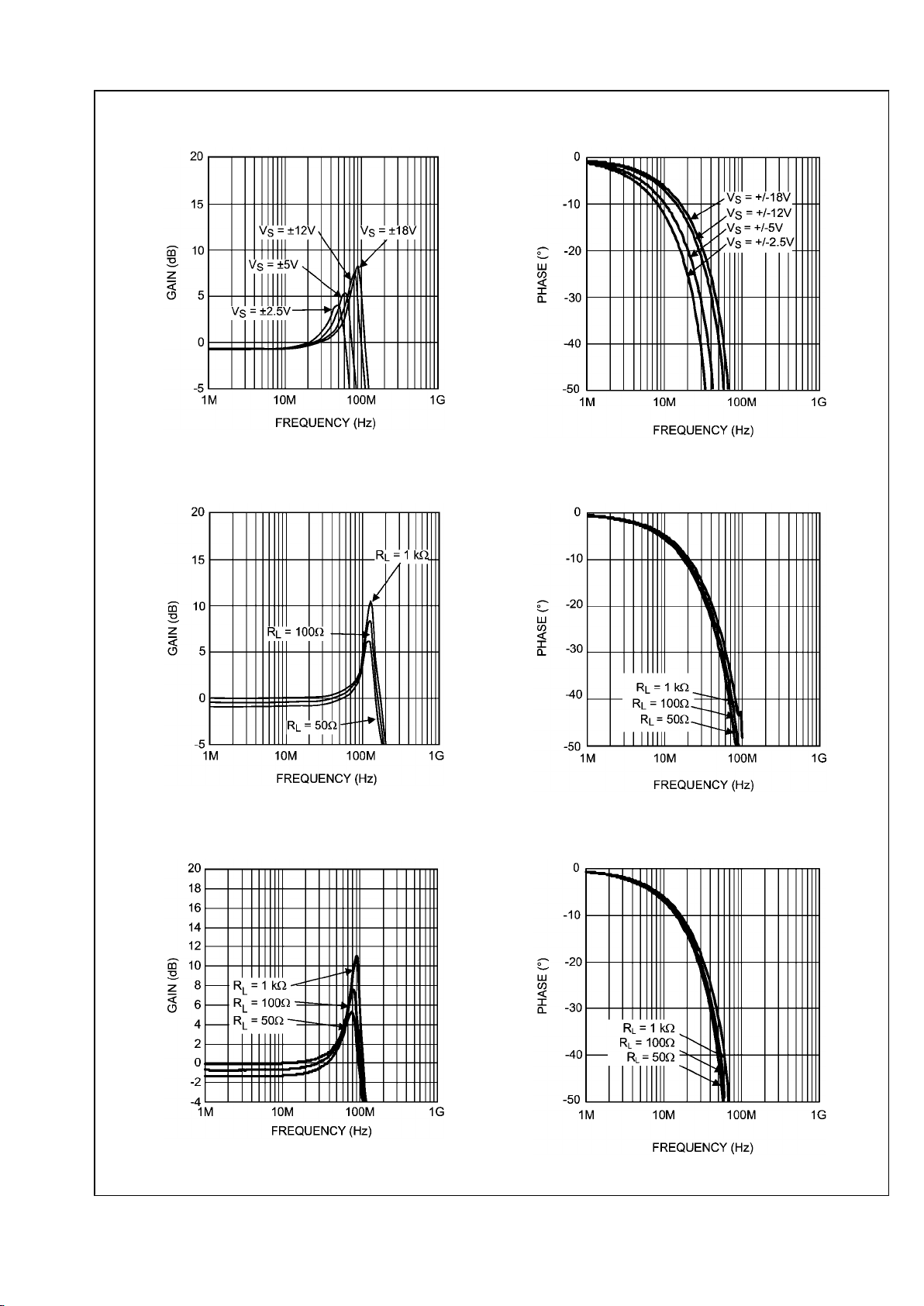

Gain vs Frequency vs Power Supply Voltage

Low IQ Mode

30029897

Phase vs Frequency vs Supply Voltage

Low IQ Mode

30029879

Gain vs Frequency vs R

LOAD

Wide BW Mode

30029896

Phase vs Frequency vs R

LOAD

Wide BW Mode

30029878

Gain vs Frequency vs R

LOAD

Low IQ Mode

30029895

Phase vs Frequency vs R

LOAD

Low IQ Mode

30029877

www.national.com 6

LME49600

Page 7

Gain vs Frequency vs C

LOAD

Wide BW Mode

30029894

Phase vs Frequency vs C

LOAD

Wide BW Mode

30029875

Gain vs Frequency vs C

LOAD

Low IQ Mode

30029893

Phase vs Frequency vs C

LOAD

Low IQ Mode

30029876

±PSRR vs Frequency

VS = ±15V, Wide BW Mode

30029890

±PSRR vs Frequency

VS = ±15V, Low IQ Mode

30029889

7 www.national.com

LME49600

Page 8

±PSRR vs Frequency

VS = ±15V, Wide BW Mode

30029892

±PSRR vs Frequency

VS = ±15V, Low IQ Mode

30029891

Quiescent Current vs Bandwidth Control Resistance

30029888

THD+N vs Output Voltage

VS = ±15V, RL = 32Ω, f = 1kHz

Both channels driven

300298j4

High BW Noise Curve

30029845

Low BW Noise Curve

30029846

www.national.com 8

LME49600

Page 9

Typical Application Diagram

300298j5

FIGURE 2. High Performance, High Fidelity LME49600 Audio Buffer Application

DISTORTION MEASUREMENTS

The vanishingly low residual distortion produced by

LME49710/LME49600 is below the capabilities of all commercially available equipment. This makes distortion measurements just slightly more difficult than simply connecting

a distortion meter to the amplifier’s inputs and outputs. The

solution, however, is quite simple: an additional resistor.

Adding this resistor extends the resolution of the distortion

measurement equipment.

The LME49710/LME49600’s low residual distortion is an input referred internal error. As shown in Figure 3, adding the

10Ω resistor connected between the amplifier’s inverting and

non-inverting inputs changes the amplifier’s noise gain. The

result is that the error signal (distortion) is amplified by a factor

of 101. Although the amplifier’s closed-loop gain is unaltered,

the feedback available to correct distortion errors is reduced

by 101, which means that measurement resolution increases

by 101. To ensure minimum effects on distortion measurements, keep the value of R1 low as shown in Figure 3.

This technique is verified by duplicating the measurements

with high closed loop gain and/or making the measurements

at high frequencies. Doing so produces distortion components that are within the measurement equipment’s capabilities. This datasheet’s THD+N and IMD values were generated using the above described circuit connected to an Audio

Precision System Two Cascade.

9 www.national.com

LME49600

Page 10

30029843

FIGURE 3. THD+N Distortion Test Circuit

Application Information

HIGH PERFORMANCE, HIGH FIDELITY HEADPHONE

AMPLIFIER

The LME49600 is the ideal solution for high output, high performance high fidelity head phone amplifiers. When placed in

the feedback loop of the LME49710, LME49720 or

LME49740 High Performance, High Fidelity audio operational

amplifier, the LME49600 is able to drive 32Ω headphones to

a dissipation of greater than 500mW at 0.00003% THD+N

while operating on ±15V power supply voltages. The circuit

schematic for a typical headphone amplifier is shown in Figure 4.

Operation

The following describes the circuit operation for the headphone amplifier’s Left Channel. The Right Channel operates

identically.

The audio input signal is applied to the input jack (HP31 or

J1/J2) and dc-coupled to the volume control, VR1. The output

signal from VR1’s wiper is applied to the non-inverting input

of U2-A, an LME49720 High Performance, High Fidelity audio

operational amplifier. U2-A’s AC signal gain is set by resistors

R2, R4, and R6. To allow for a DC-coupled signal path and to

ensure minimal output DC voltage regardless of the closedloop gain, the other half of the U2 is configured as a DC servo.

By constantly monitoring U2-A’s output, the servo creates a

voltage that compensates for any DC voltage that may be

present at the output. A correction voltage is generated and

applied to the feedback node at U2-A, pin 2. The servo ensures that the gain at DC is unity. Based on the values shown

in Figure 4, the RC combination formed by R11 and C7 sets

the servo’s high-pass cutoff at 0.16Hz. This is over two

decades below 20Hz, minimizing both amplitude and phase

perturbations in the audio frequency band’s lowest frequencies.

www.national.com 10

LME49600

Page 11

30029858

FIGURE 4. LME49600 delivers high output current for this high performance headphone amplifier

11 www.national.com

LME49600

Page 12

AUDIO BUFFERS

Audio buffers or unity-gain followers, have large current gain

and a voltage gain of one. Audio buffers serve many applications that require high input impedance, low output

impedance and high output current. They also offer constant

gain over a very wide bandwidth.

Buffers serve several useful functions, either in stand-alone

applications or in tandem with operational amplifiers. In standalone applications, their high input impedance and low output

impedance isolates a high impedance source from a low

impedance load.

SUPPLY BYPASSING

The LME49600 will place great demands on the power supply

voltage source when operating in applications that require

fast slewing and driving heavy loads. These conditions can

create high amplitude transient currents. A power supply’s

limited bandwidth can reduce the supply’s ability to supply the

needed current demands during these high slew rate conditions. This inability to supply the current demand is further

exacerbated by PCB trace or interconnecting wire inductance. The transient current flowing through the inductance

can produce voltage transients.

For example, the LME49600’s output voltage can slew at a

typical ±2000V/μs. When driving a 100Ω load, the di/dt current

demand is 20 A/μs. This current flowing through an inductance of 50nH (approximately 1.5” of 22 gage wire) will produce a 1V transient. In these and similar situations, place the

parallel combination of a solid 5μF to 10μF tantalum capacitor

and a ceramic 0.1μF capacitor as close as possible to the

device supply pins.

Ceramic capacitors with values in the range of 10μF to

100μF, ceramic capacitor have very lower ESR (typically less

than 10mΩ) and low ESL when compared to the same valued

tantalum capacitor. The ceramic capacitors, therefore, have

superior AC performance for bypassing high frequency noise.

In less demanding applications that have lighter loads or lower slew rates, the supply bypassing is not as critical. Capacitor

values in the range of 0.01μF to 0.1μF are adequate.

SIMPLIFIED LME49600 CIRCUIT DIAGRAM

The LME49600’s simplified circuit diagram is shown in Figures 1 and 5. The diagram shows the LME49600’s complementary emitter follower design, bias circuit and bandwidth

adjustment node.

30029805

FIGURE 5. Simplified Circuit Diagram

Figure 6 shows the LME49600 connected as an open-loop

buffer. The source impedance and optional input resistor,

RS, can alter the frequency response. As previously stated,

the power supplies should be bypassed with capacitors connected close to the LME49600’s power supply pins. Capacitor

values as low as 0.01μF to 0.1μF will ensure stable operation

in lightly loaded applications, but high output current and fast

output slewing can demand large current transients from the

power supplies. Place a recommended parallel combination

of a solid tantalum capacitor in the 5μF to 10μF range and a

ceramic 0.1μF capacitor as close as possible to the device

supply pins.

30029860

FIGURE 6. Buffer Connections

OUTPUT CURRENT

The LME49600 can continuously source or sink 250mA. Internal circuitry limits the short circuit output current to approximately ±450mA. For many applications that fully utilize the

LME49600’s current source and sink capabilities, thermal dissipation may be the factor that limits the continuous output

current.

The maximum output voltage swing magnitude varies with

junction temperature and output current. Using sufficient PCB

copper area as a heat sink when the metal tab of the

LME49600’s surface mount TO–263 package is soldered directly to the circuit board reduces thermal impedance. This in

turn reduces junction temperature. The PCB copper area

should be in the range of 3in2 (12.9cm2) to 6in2 (38.7cm2).

THERMAL PROTECTION

LME49600 power dissipated will cause the buffer’s junction

temperature to rise. A thermal protection circuit in the

LME49600 will disable the output when the junction temperature exceeds 150°C. When the thermal protection is activated, the output stage is disabled, allowing the device to cool.

The output circuitry is enabled when the junction temperature

drops below 150°C.

The TO–263 package has excellent thermal characteristics.

To minimize thermal impedance, its exposed die attach paddle should be soldered to a circuit board copper area for good

heat dissipation. Figure 7 shows typical thermal resistance

from junction to ambient as a function of the copper area. The

TO–263’s exposed die attach paddle is electrically connected

to the VEE power supply pin.

www.national.com 12

LME49600

Page 13

LOAD IMPEDANCE

The LME49600 is stable under any capacitive load when driven by a source that has an impedance of 50Ω or less. When

driving capacitive loads, any overshoot that is present on the

output signal can be reduced by shunting the load capacitance with a resistor.

OVERVOLTAGE PROTECTION

If the input-to-output differential voltage exceeds the

LME49600’s Absolute Maximum Rating of 3V, the internal

diode clamps shown in Figures 1 and 5 conduct, diverting

current around the compound emitter followers of Q1/Q5 (D1

– D7 for positive input), or around Q2/Q6 (D8 – D14 for negative inputs). Without this clamp, the input transistors Q1/Q2

and Q5/Q6 will zener and damage the buffer.

To ensure that the current flow through the diodes is held to

a save level, the internal 200Ω resistor in series with the input

limits the current through these clamps. If the additional current that flows during this situation can damage the source

that drives the LME49600’s input, add an external resistor in

series with the input (see Figure 6).

BANDWITH CONTROL PIN

The LME49600’s –3dB bandwidth is approximately 110MHz

in the low quiescent-current mode (7.3mA typical). Select this

mode by leaving the BW pin unconnected.

Connect the BW pin to the V

EE

pin to extend the LME49600’s

bandwidth to a nominal value of 180MHz. In this mode, the

quiescent current increases to approximately 13.2mA. Bandwidths between these two limits are easily selected by connecting a series resistor between the BW pin and V

EE

.

Regardless of the connection to the LME49600’s BW pin, the

rated output current and slew rate remain constant. With the

power supply voltage held constant, the wide-bandwidth

mode’s increased quiescent current causes a corresponding

increase in quiescent power dissipation. For all values of the

BW pin voltage, the quiescent power dissipation is equal to

the total supply voltage times the quiescent current (IQ *

(VCC + |V

EE

|)).

BOOSTING OP AMP OUTPUT CURRENT

When placed in the feedback loop, the LME49600 will increase an operational amplifier’s output current. The operational amplifier’s open loop gain will correct any LME49600

errors while operating inside the feedback loop.

To ensure that the operational amplifier and buffer system are

closed loop stable, the phase shift must be low. For a system

gain of one, the LME49600 must contribute less than 20° at

the operational amplifier’s unity-gain frequency. Various operating conditions may change or increase the total system

phase shift. These phase shift changes may affect the operational amplifier's stability.

Unity gain stability is preserved when the LME49600 is placed

in the feedback loop of most general-purpose or precision op

amps. When the LME46900 is driving high value capacitive

loads, the BW pin should be connected to the VEE pin for wide

bandwidth and stable operation. The wide bandwidth mode is

also suggested for high speed or fast-settling operational amplifiers. This preserves their stability and the ability to faithfully

amplify high frequency, fast-changing signals. Stability is ensured when pulsed signals exhibit no oscillations and ringing

is minimized while driving the intended load and operating in

the worst-case conditions that perturb the LME49600’s phase

response.

HIGH FREQUENCY APPLICATIONS

The LME49600’s wide bandwidth and very high slew rate

make it ideal for a variety of high-frequency open-loop applications such as an ADC input driver, 75Ω stepped volume

attenuator driver, and other low impedance loads. Circuit

board layout and bypassing techniques affect high frequency,

fast signal dynamic performance when the LME49600 operates open-loop.

A ground plane type circuit board layout is best for very high

frequency performance results. Bypass the power supply pins

(VCC and VEE) with 0.1μF ceramic chip capacitors in parallel

with solid tantalum 10μF capacitors placed as close as possible to the respective pins.

Source resistance can affect high-frequency peaking and

step response overshoot and ringing. Depending on the signal source, source impedance and layout, best nominal response may require an additional resistance of 25Ω to

200Ω in series with the input. Response with some loads (especially capacitive) can be improved with an output series

resistor in the range of 10Ω to 150Ω.

THERMAL MANAGEMENT

Heatsinking

For some applications, the LME49600 may require a heat

sink. The use of a heat sink is dependent on the maximum

LME49600 power dissipation and a given application’s maximum ambient temperature. In the TO-263 package, heat

sinking the LME49600 is easily accomplished by soldering

the package’s tab to a copper plane on the PCB. (Note: The

tab on the LME49600’s TO-263 package is electrically connected to VEE.)

Through the mechanisms of convection, heat conducts from

the LME49600 in all directions. A large percentage moves to

the surrounding air, some is absorbed by the circuit board

material and some is absorbed by the copper traces connected to the package’s pins. From the PCB material and the

copper, it then moves to the air. Natural convection depends

on the amount of surface area that contacts the air.

If a heat conductive copper plane has perfect thermal conduction (heat spreading) through the plane’s total area, the

temperature rise is inversely proportional to the total exposed

area. PCB copper planes are, in that sense, an aid to convection. These planes, however, are not thick enough to

ensure perfect heat conduction. Therefore, eventually a point

of diminishing returns is reached where increasing copper

area offers no additional heat conduction to the surrounding

air. This is apparent in Figure 7 as the thermal resistance

reaches an asymptote above a copper area of 8in2). As can

be seen, increasing the copper area produces decreasing

improvements in thermal resistance. This occurs, roughly, at

4in2 of 1 oz copper board. Some improvement continues until

about 16in2. Boards using 2 oz copper boards will have decrease thermal resistance providing a better heat sink compared to 1 oz. copper. Beyond 1oz or 2oz copper plane areas,

external heat sinks are required. Ultimately, the 1oz copper

area attains a nominal value of 20°C/W junction to ambient

thermal resistance (θJA) under zero air flow.

13 www.national.com

LME49600

Page 14

30029861

FIGURE 7. Thermal Resistance for 5 lead TO–263

Package Mounted on 1oz. Copper

A copper plane may be placed directly beneath the tab. Additionally, a matching plane can be placed on the opposite

side. If a plane is placed on the side opposite of the

LME49600, connect it to the plane to which the buffer’s metal

tab is soldered with a matrix of thermal vias per JEDEC Standard JESD51-5.

Determining Copper Area

Find the required copper heat sink area using the following

guidelines:

1. Determine the value of the circuit’s power dissipation, PD.

2. Specify a maximum operating ambient temperature, T

A

(MAX).

(Note that the die temperature, TJ, will be higher than

TA by an amount that is dependent on the thermal resistance

from junction to ambient, θJA). Therefore, TA must be specified such that TJ does not exceed the absolute maximum die

temperature of 150°C.

3. Specify a maximum allowable junction temperature, T

J

(MAX)

, This is the LME49600’s die temperature when the buffer

is drawing maximum current (quiescent and load). It is prudent to design for a maximum continuous junction temperature of 100°C to 130°C. Ensure, however, that the junction

temperature never exceeds the 150°C absolute maximum

rating for the part.

4. Calculate the value of junction to ambient thermal resistance, θ

JA

5. θJA as a function of copper area in square inches is shown

in Figure 7. Choose a copper area that will guarantee the

specified T

J(MAX)

for the calculated θJA. The maximum value

of junction to ambient thermal resistance, θJA, is defined as:

θJA= (T

J(MAX)

- T

A(MAX)

)/ P

D(MAX)

(°C/W) (1)

where:

T

J(MAX)

= the maximum recommended junction temperature

T

A(MAX)

= the maximum ambient temperature in the

LME49600’s environment

P

D(MAX)

= the maximum recommended power dissipation

Note: The allowable thermal resistance is determined by the

maximum allowable temperature increase:

T

RISE

= T

J(MAX)

- T

A(MAX)

Thus, if ambient temperature extremes force T

RISE

to exceed

the design maximum, the part must be de-rated by either decreasing PD to a safe level, reducing θJA further or, if available,

using a larger copper area.

Procedure

1. First determine the maximum power dissipated by the

LME49600, P

D(MAX)

. For the simple case of the buffer driving

a resistive load, and assuming equal supplies, P

D(MAX)

is giv-

en by:

P

DMAX(AC)

= (IS x VS) + (VS)2 / (2π2RL) (Watts) (2)

P

DMAX(DC)

= (IS x VS) + (VS)2 / RL (Watts) (3)

where:

VS = |VEE| + V

CC

(V)

IS =quiescent supply current (A)

Equation (2) is for sinusoidal output voltages and (3) is for DC

output voltages

2. Determine the maximum allowable die temperature rise,

T

RISE(MAX)

= T

J(MAX)

- T

A(MAX)

(°C)

3. Using the calculated value of T

RISE(MAX)

and P

D(MAX)

, find

the required value of junction to ambient thermal resistance

combining equation 1 and equation 4 to derive equation 5:

θJA = T

RISE(MAX)

/ P

D(MAX)

(4)

4. Finally, choose the minimum value of copper area from

Figure 7 based on the value for θJA.

Example

Assume the following conditions: VS = |VEE| + VCC = 30V, R

L

= 32Ω, IS = 15mA, sinusoidal output voltage, T

J(MAX)

= 125°

C, T

A(MAX)

= 85°C.

Applying Equation (2):

P

DMAX

= (IS x VS) + (VS)2 / 2π2R

L

= (15mA)(30V) + 900V2 / 142Ω

= 1.86W

Applying Equation (4):

T

RISE(MAX)

= 125°C – 85°C

= 40°C

Applying Equation (5):

θJA = 40°C/1.86W

= 21.5°C/W

www.national.com 14

LME49600

Page 15

Examining the Copper Area vs. θJA plot indicates that a thermal resistance of 50°C/W is possible with a 12in2 plane of one

layer of 1oz copper. Other solutions include using two layers

of 1oz copper or the use of 2oz copper. Higher dissipation

may require forced air flow. As a safety margin, an extra 15%

heat sinking capability is recommended.

When amplifying AC signals, wave shapes and the nature of

the load (reactive, non-reactive) also influence dissipation.

Peak dissipation can be several times the average with reactive loads. It is particularly important to determine dissipation

when driving large load capacitance.

The LME49600’s dissipation in DC circuit applications is easily computed using Equation (3). After the value of dissipation

is determined, the heat sink copper area calculation is the

same as for AC signals.

SLEW RATE

A buffer’s voltage slew rate is its output signal’s rate of change

with respect to an input signal’s step changes. For resistive

loads, slew rate is limited by internal circuit capacitance and

operating current (in general, the higher the operating current

for a given internal capacitance, the faster the slew rate).

However, when driving capacitive loads, the slew rate may be

limited by the available peak output current according to the

following expression.

dv/dt = IPK / C

L

(5)

Output voltages with high slew rates will require large output

load currents. For example if the part is required to slew at

1000V/μs with a load capacitance of 1nF, the current demanded from the LME49600 is 1A. Therefore, fast slew rate

is incompatible with a capacitive load of this value. Also, if

CL is in parallel with the load, the peak current available to the

load decreases as CL increases.

15 www.national.com

LME49600

Page 16

30029844

FIGURE 8. High Speed Positive and Negative Regulator

www.national.com 16

LME49600

Page 17

Revision History

Rev Date Description

1.0 01/15/08 Initial release.

1.01 01/16/08 Edited specification table.

1.02 02/07/08 Edited applications information.

17 www.national.com

LME49600

Page 18

Physical Dimensions inches (millimeters) unless otherwise noted

Order Number LME49600TS

See NS Package TS5B

www.national.com 18

LME49600

Page 19

Notes

19 www.national.com

LME49600

Page 20

Notes

LME49600 High Performance, High Fidelity, High Current Audio Buffer

For more National Semiconductor product information and proven design tools, visit the following Web sites at:

Products Design Support

Amplifiers www.national.com/amplifiers WEBENCH www.national.com/webench

Audio www.national.com/audio Analog University www.national.com/AU

Clock Conditioners www.national.com/timing App Notes www.national.com/appnotes

Data Converters www.national.com/adc Distributors www.national.com/contacts

Displays www.national.com/displays Green Compliance www.national.com/quality/green

Ethernet www.national.com/ethernet Packaging www.national.com/packaging

Interface www.national.com/interface Quality and Reliability www.national.com/quality

LVDS www.national.com/lvds Reference Designs www.national.com/refdesigns

Power Management www.national.com/power Feedback www.national.com/feedback

Switching Regulators www.national.com/switchers

LDOs www.national.com/ldo

LED Lighting www.national.com/led

PowerWise www.national.com/powerwise

Serial Digital Interface (SDI) www.national.com/sdi

Temperature Sensors www.national.com/tempsensors

Wireless (PLL/VCO) www.national.com/wireless

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2008 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Technical

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Technical Support Center

Email: europe.support@nsc.com

German Tel: +49 (0) 180 5010 771

English Tel: +44 (0) 870 850 4288

National Semiconductor Asia

Pacific Technical Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Technical Support Center

Email: jpn.feedback@nsc.com

www.national.com

Loading...

Loading...