Page 1

查询LMC6462供应商

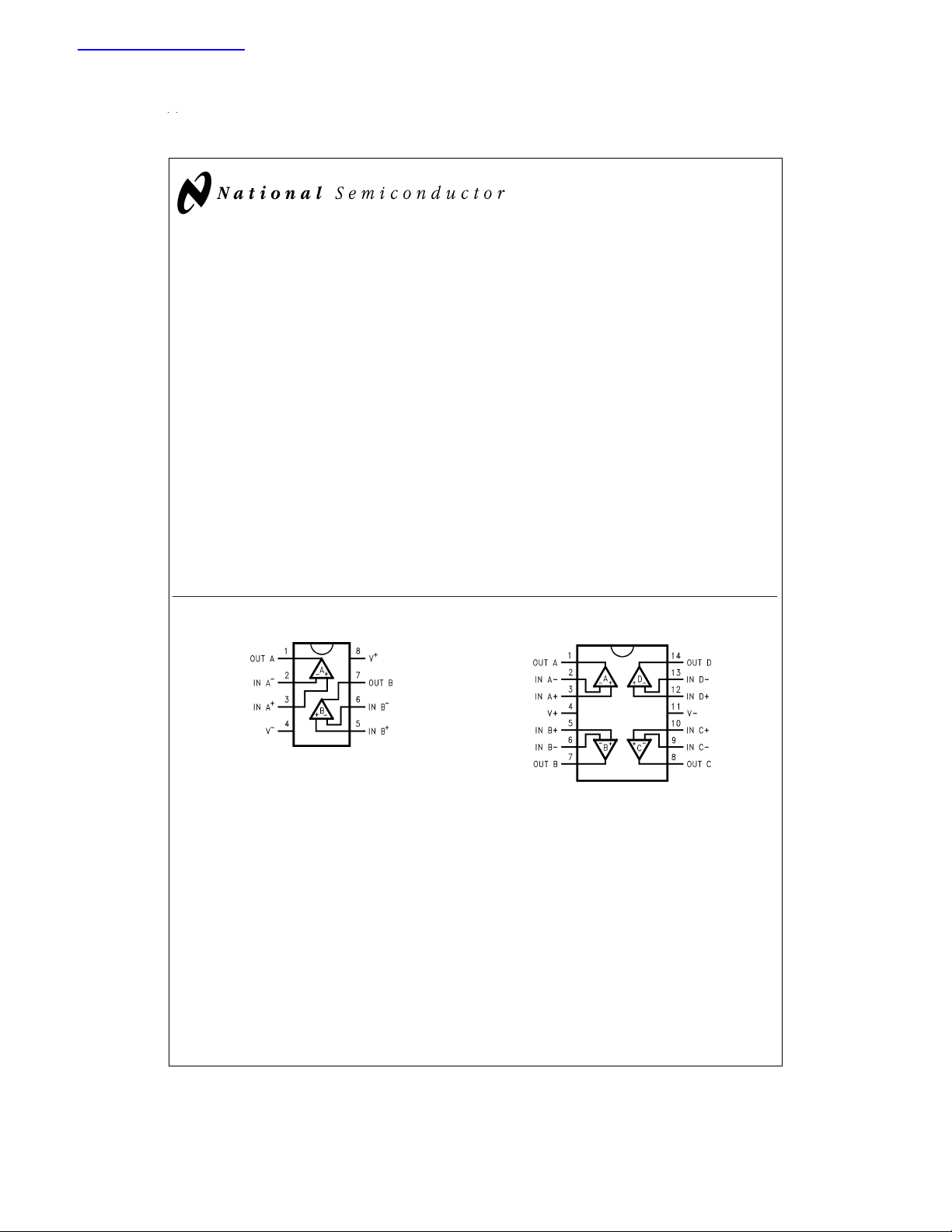

LMC6462 Dual/LMC6464 Quad

Micropower, Rail-to-Rail Input and Output CMOS

Operational Amplifier

May 1999

LMC6462 Dual/LMC6464 Quad Micropower, Rail-to-Rail Input and Output CMOS Operational

Amplifier

General Description

The LMC6462/4 is a micropower version of the popular

LMC6482/4, combining Rail-to-Rail Input and Output Range

with very low power consumption.

The LMC6462/4 provides an input common-mode voltage

range that exceeds both rails.The rail-to-rail output swing of

the amplifier, guaranteed for loads down to 25 kΩ, assures

maximum dynamic sigal range. This rail-to-rail performance

of the amplifier, combined with its high voltage gain makes it

unique among rail-to-rail amplifiers. The LMC6462/4 is an

excellent upgrade for circuits using limited common-mode

range amplifiers.

The LMC6462/4, with guaranteed specifications at 3V and

5V, is especially well-suited for low voltage applications. A

quiescent power consumption of 60 µW per amplifier (at V

=

3V) can extend the useful life of battery operated systems.

The amplifier’s 150 fA input current, low offset voltage of

0.25 mV, and 85 dB CMRR maintain accuracy in

battery-powered systems.

8-Pin DIP/SO

DS012051-1

Top View

Features

(Typical unless otherwise noted)

n Ultra Low Supply Current 20 µA/Amplifier

n Guaranteed Characteristics at 3V and 5V

n Rail-to-Rail Input Common-Mode Voltage Range

n Rail-to-Rail Output Swing

(within 10 mV of rail, V

n Low Input Current 150 fA

n Low Input Offset Voltage 0.25 mV

=

S

5V and R

Applications

n Battery Operated Circuits

n Transducer Interface Circuits

n Portable Communication Devices

S

n Medical Applications

n Battery Monitoring

14-Pin DIP/SO

Top View

=

25 kΩ)

L

DS012051-2

© 1999 National Semiconductor Corporation DS012051 www.national.com

Page 2

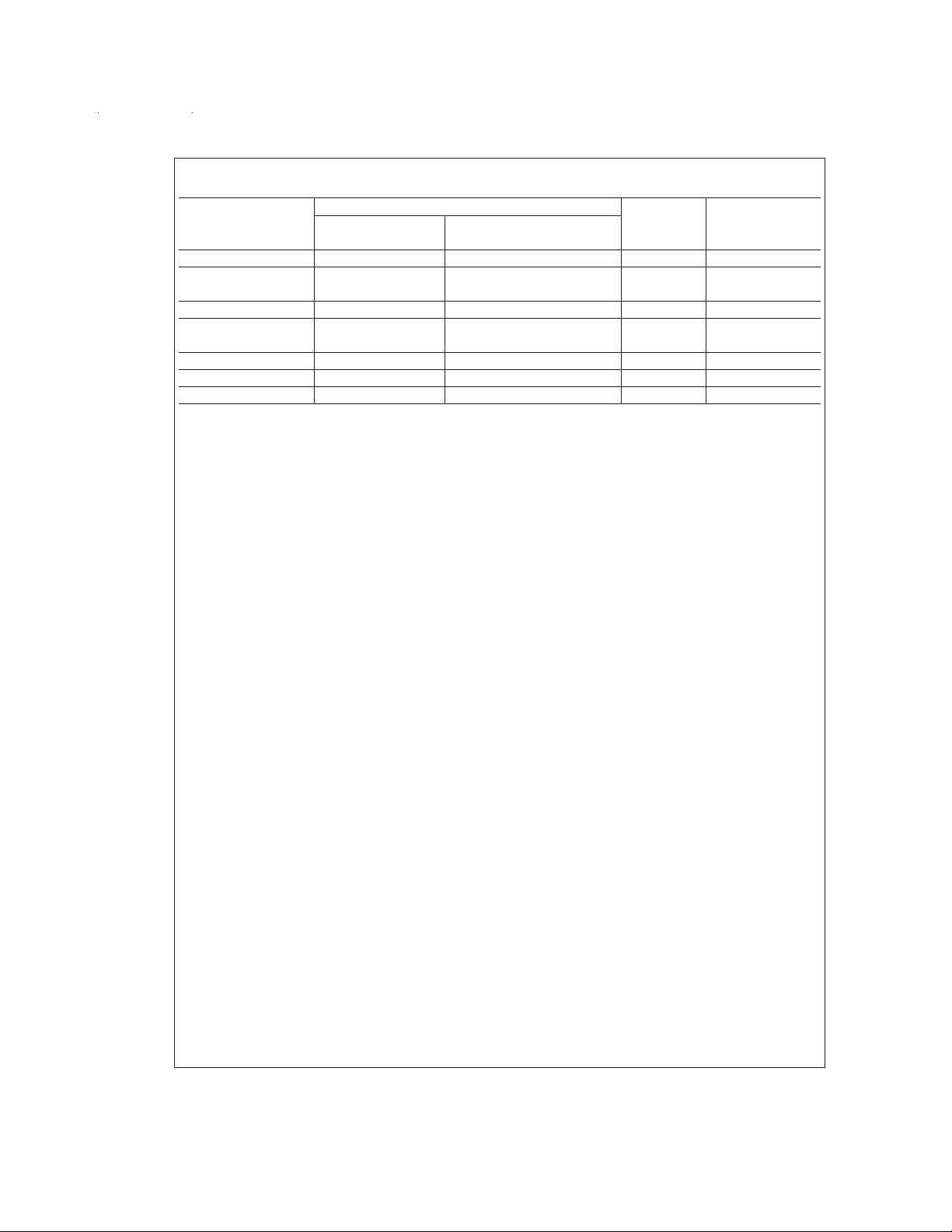

Ordering Information

Package Temperature Range NSC Transport

Military Industrial Drawing Media

−55˚C to +125˚C −40˚C to +85˚C

8-Pin Molded DIP LMC6462AMN LMC6462AIN, LMC6462BIN N08E Rails

8-Pin SO-8 LMC6462AIM, LMC6462BIM M08A Rails

LMC6462AIMX, LMC6462BIMX M08A Tape and Reel

14-Pin Molded DIP LMC6464AMN LMC6464AIN, LMC6464BIN N14A Rails

14-Pin SO-14 LMC6464AIM, LMC6464BIM M14A Rails

LMC6464AIMX, LMC6464BIMX M14A Tape and Reel

8-Pin Ceramic DIP LMC6462AMJ-QML J08A Rails

14-Pin Ceramic DIP LMC6464AMJ-QML J14A Rails

14-Pin Ceramic SOIC LMC6464AMWG-QML WG14A Trays

www.national.com 2

Page 3

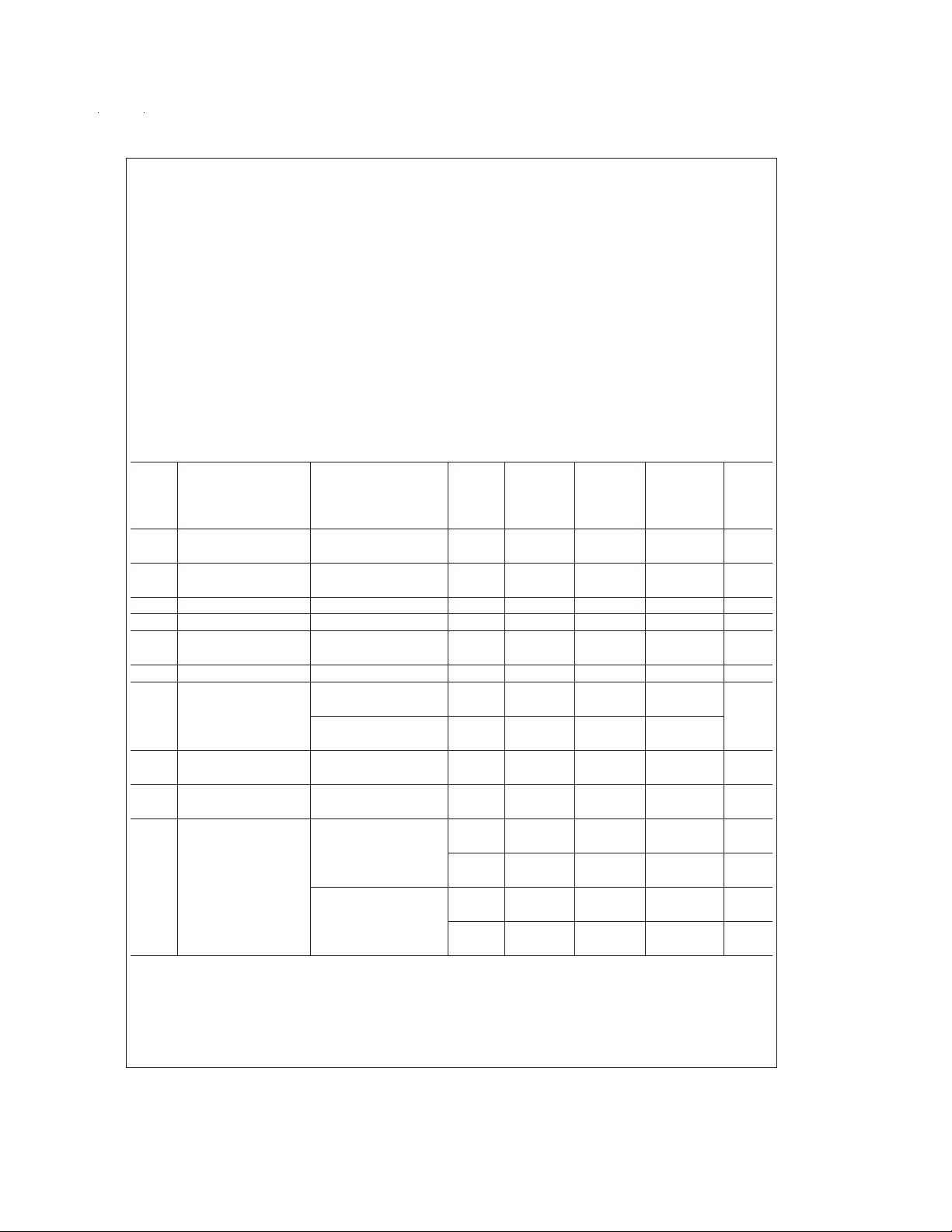

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

ESD Tolerance (Note 2) 2.0 kV

Differential Input Voltage

Voltage at Input/Output Pin (V

Supply Voltage (V

+−V−

) 16V

Current at Input Pin (Note 12)

Current at Output Pin

(Notes 3, 8)

Current at Power Supply Pin 40 mA

Lead Temp. (Soldering, 10 sec.) 260˚C

±

Supply Voltage

+

) + 0.3V, (V−) − 0.3V

±

5mA

±

30 mA

Operating Ratings (Note 1)

Supply Voltage 3.0V ≤ V

Junction Temperature Range

LMC6462AM, LMC6464AM −55˚C ≤ T

LMC6462AI, LMC6464AI −40˚C ≤ T

LMC6462BI, LMC6464BI −40˚C ≤ T

Thermal Resistance (θ

)

JA

N Package, 8-Pin Molded DIP 115˚C/W

M Package, 8-Pin Surface Mount 193˚C/W

N Package, 14-Pin Molded DIP 81˚C/W

M Package, 14-Pin

Surface Mount 126˚C/W

+

≤ 15.5V

≤ +125˚C

J

≤ +85˚C

J

≤ +85˚C

J

Storage Temperature Range −65˚C to +150˚C

Junction Temperature (Note 4) 150˚C

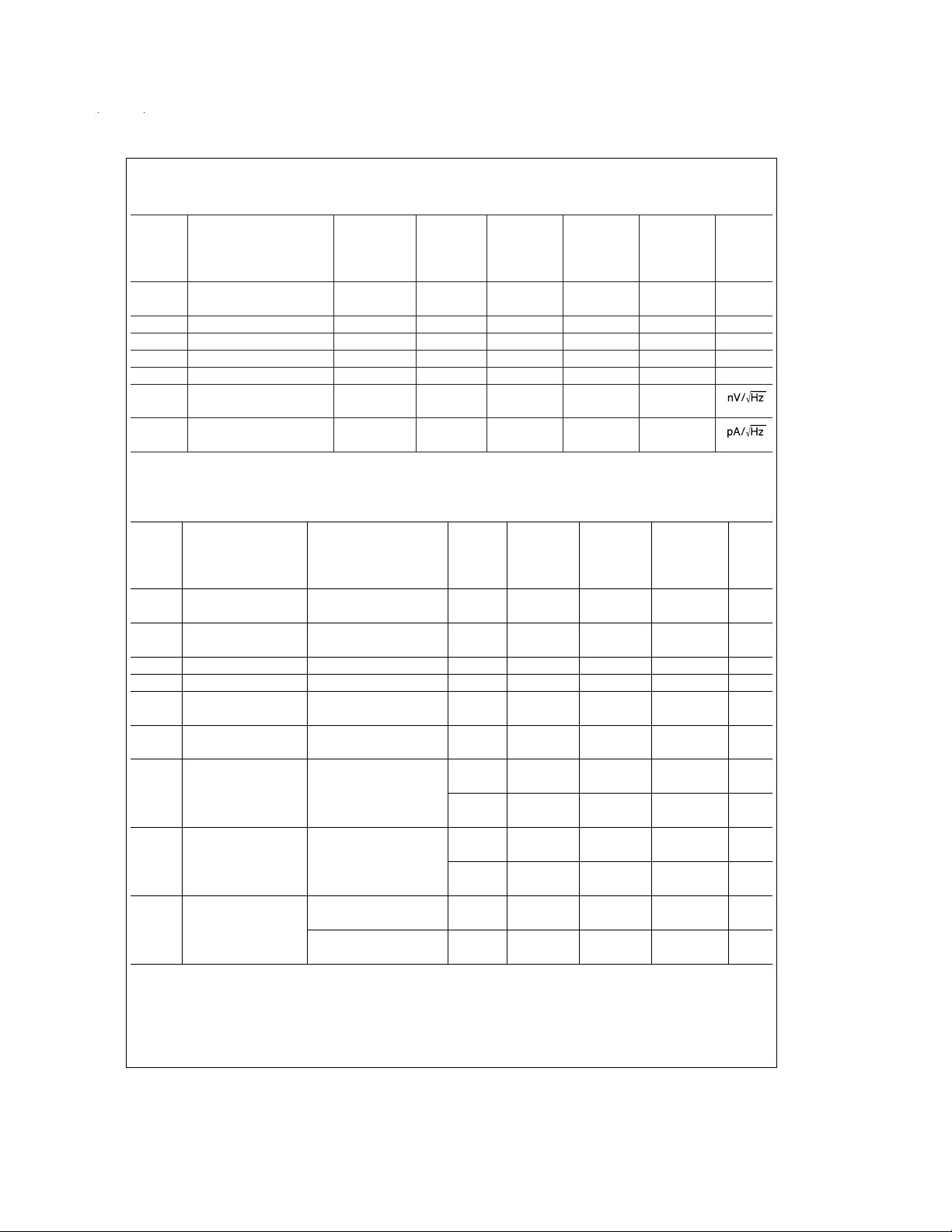

5V DC Electrical Characteristics

Unless otherwise specified, all limits guaranteed for T

limits apply at the temperature extremes.

=

J

25˚C, V

+

=

5V, V

−

=

0V, V

CM

+

=

=

/2 and R

V

V

O

>

1M. Boldface

L

LMC6462AI LMC6462BI LMC6462AM

Symbol Parameter Conditions Typ LMC6464AI LMC6464BI LMC6464AM Units

(Note 5) Limit Limit Limit

(Note 6) (Note 6) (Note 6)

V

Input Offset Voltage 0.25 0.5 3.0 0.5 mV

OS

1.2 3.7 1.5 max

TCV

Input Offset Voltage 1.5 µV/˚C

OS

Average Drift

I

B

I

OS

C

Input Current (Note 13) 0.15 10 10 200 pA max

Input Offset Current (Note 13) 0.075 5 5 100 pA max

Common-Mode 3 pF

IN

Input Capacitance

R

IN

Input Resistance

CMRR Common Mode 0V ≤ V

+

=

Rejection Ratio V

15V 67 62 65

0V ≤ V

+

=

V

5V 67 62 65

+PSRR Positive Power Supply 5V ≤ V

−

Rejection Ratio V

=

0V, V

−PSRR Negative Power Supply −5V ≤ V

+

Rejection Ratio V

V

Input Common-Mode V

CM

=

0V, V

+

=

5V −0.2 −0.10 −0.10 −0.10 V

≤ 15.0V, 85 70 65 70 dB

CM

≤ 5.0V 85 70 65 70

CM

+

≤ 15V, 85 70 65 70 dB

=

2.5V 67 62 65 min

O

−

≤ −15V, 85 70 65 70 dB

=

−2.5V 67 62 65 min

O

>

10 Tera Ω

min

Voltage Range For CMRR ≥ 50 dB 0.00 0.00 0.00 max

5.30 5.25 5.25 5.25 V

5.00 5.00 5.00 min

+

=

V

15V −0.2 −0.15 −0.15 −0.15 V

For CMRR ≥ 50 dB 0.00 0.00 0.00 max

15.30 15.25 15.25 15.25 V

15.00 15.00 15.00 min

www.national.com3

Page 4

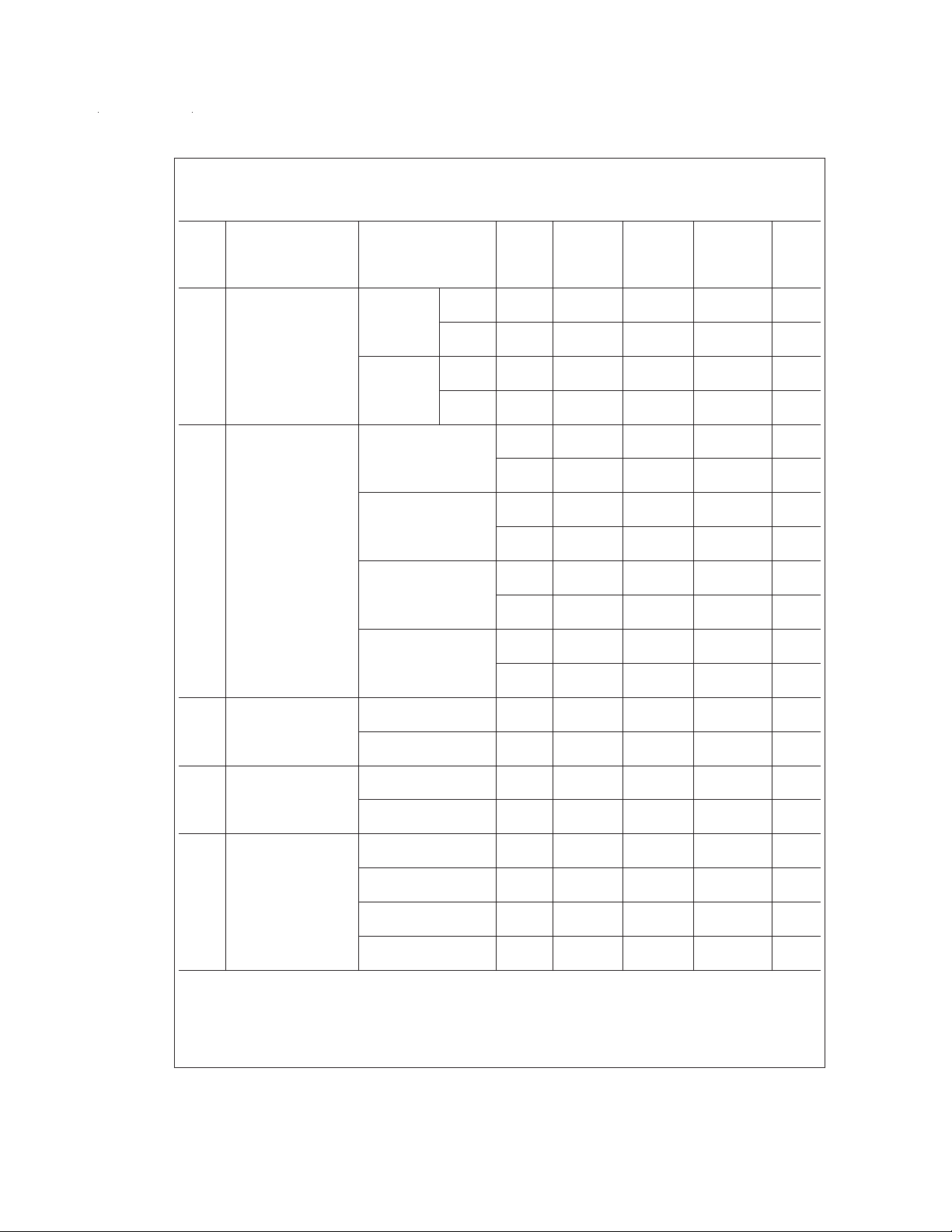

5V DC Electrical Characteristics (Continued)

Unless otherwise specified, all limits guaranteed for T

limits apply at the temperature extremes.

=

J

25˚C, V

+

Symbol Parameter Conditions Typ LMC6464AI LMC6464BI LMC6464AM Units

(Note 5) Limit Limit Limit

A

Large Signal R

V

=

100 kΩ Sourcing 3000 V/mV

L

Voltage Gain (Note 7) min

Sinking 400 V/mV

=

R

25 kΩ Sourcing 2500 V/mV

L

(Note 7) min

Sinking 200 V/mV

+

V

I

SC

Output Swing V

O

Output Short Circuit Sourcing, V

=

5V 4.995 4.990 4.950 4.990 V

=

R

100 kΩ to V

L

+

=

V

5V 4.990 4.975 4.950 4.975 V

=

R

25 kΩ to V

L

+

=

V

15V 14.990 14.975 14.950 14.975 V

=

R

100 kΩ to V

L

+

=

V

15V 14.965 14.900 14.850 14.900 V

=

R

25 kΩ to V

L

+

/2 4.980 4.925 4.970 min

+

/2 4.965 4.850 4.955 min

+

/2 14.965 14.925 14.955 min

+

/2 14.850 14.800 14.800 min

=

0V 27 19 19 19 mA

O

Current 15 15 15 min

V+=5V Sinking, V

I

SC

Output Short Circuit Sourcing, V

=

5V 27 22 22 22 mA

O

=

0V 38 24 24 24 mA

O

Current 17 17 17 min

+

=

V

15V Sinking, V

=

12V 75 55 55 55 mA

O

(Note 8) 45 45 45 min

I

S

Supply Current Dual, LMC6462 40 55 55 55 µA

+

=

V

+5V, V

+

=

/2 70 70 75 max

V

O

Quad, LMC6464 80 110 110 110 µA

+

=

V

+5V, V

+

=

/2 140 140 150 max

V

O

Dual, LMC6462 50 60 60 60 µA

+

=

V

+15V, V

+

=

/2 70 70 75 max

V

O

Quad, LMC6464 90 120 120 120 µA

+

=

V

+15V, V

+

=

/2 140 140 150 max

V

O

=

5V, V

−

=

0V, V

CM

+

=

=

/2 and R

V

V

O

>

1M. Boldface

L

LMC6462AI LMC6462BI LMC6462AM

(Note 6) (Note 6) (Note 6)

0.005 0.010 0.050 0.010 V

0.020 0.075 0.030 max

0.010 0.020 0.050 0.020 V

0.035 0.150 0.045 max

0.010 0.025 0.050 0.025 V

0.035 0.075 0.050 max

0.025 0.050 0.100 0.050 V

0.150 0.200 0.200 max

17 17 17 min

min

min

www.national.com 4

Page 5

5V AC Electrical Characteristics

Unless otherwise specified, all limits guaranteed for T

limits apply at the temperature extremes.

=

J

25˚C, V

+

=

5V, V

−

=

0V, V

CM

+

=

=

/2 and R

V

V

O

>

1M. Boldface

L

LMC6462AI LMC6462BI LMC6462AM

Symbol Parameter Conditions Typ LMC6464AI LMC6464BI LMC6464AM Units

(Note 5) Limit Limit Limit

(Note 6) (Note 6) (Note 6)

SR Slew Rate (Note 9) 28 15 15 15 V/ms

888min

+

=

GBW Gain-Bandwidth Product V

φ

m

G

m

Phase Margin 50 Deg

Gain Margin 15 dB

15V 50 kHz

Amp-to-Amp Isolation (Note 10) 130 dB

e

n

i

n

Input-Referred f=1 kHz 80

Voltage Noise V

=

1V

CM

Input-Referred f=1 kHz 0.03

Current Noise

3V DC Electrical Characteristics

Unless otherwise specified, all limits guaranteed for T

limits apply at the temperature extremes.

=

J

25˚C, V

+

=

3V, V

−

=

0V, V

CM

+

=

=

/2 and R

V

V

O

>

1M. Boldface

L

LMC6462AI LMC6462BI LMC6462AM

Symbol Parameter Conditions Typ LMC6464AI LMC6464BI LMC6464AM Units

(Note 5) Limit Limit Limit

(Note 6) (Note 6) (Note 6)

V

OS

Input Offset Voltage 0.9 2.0 3.0 2.0 mV

2.7 3.7 3.0 max

TCV

Input Offset Voltage 2.0 µV/˚C

OS

Average Drift

I

B

I

OS

CMRR Common Mode 0V ≤ V

Input Current (Note 13) 0.15 10 10 200 pA

Input Offset Current (Note 13) 0.075 5 5 100 pA

≤ 3V 74 60 60 60 dB

CM

Rejection Ratio min

PSRR Power Supply 3V ≤ V

+

≤ 15V, V

−

=

0V 80 60 60 60 dB

Rejection Ratio min

V

CM

Input Common-Mode For CMRR ≥ 50 dB −0.10 0.0 0.0 0.0 V

Voltage Range max

3.0 3.0 3.0 3.0 V

min

V

O

Output Swing R

=

25 kΩ to V

L

+

/2 2.95 2.9 2.9 2.9 V

min

0.15 0.1 0.1 0.1 V

max

I

S

Supply Current Dual, LMC6462 40 55 55 55 µA

+

=

V

/2 70 70 70

V

O

Quad, LMC6464 80 110 110 110 µA

+

=

V

/2 140 140 140 max

V

O

www.national.com5

Page 6

3V AC Electrical Characteristics

Unless otherwise specified, V

tremes.

+

=

3V, V

−

=

0V, V

=

CM

+

=

/2 and R

V

V

O

>

1M. Boldface limits apply at the temperature ex-

L

LMC6462AI LMC6462BI LMC6462AM

Symbol Parameter Conditions Typ LMC6464AI LMC6464BI LMC6464AM Units

(Note 5) Limit Limit Limit

(Note 6) (Note 6) (Note 6)

SR Slew Rate (Note 11) 23 V/ms

GBW Gain-Bandwidth Product 50 kHz

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is intended to be functional, but specific performance is not guaranteed. For guaranteed specifications and the test conditions, see the Electrical Characteristics.

Note 2: Human body model, 1.5 kΩ in series with 100 pF. All pins rated per method 3015.6 of MIL-STD-883. This is a class 2 device rating.

Note 3: Applies to both single supply and split-supply operation. Continuous short circuit operationatelevatedambienttemperaturecanresultinexceedingthe maxi-

mum allowed junction temperature of 150˚C. Output currents in excess of

Note 4: The maximum power dissipation is a function of T

−TA)/θJA. All numbers apply for packages soldered directly into a PC board.

Note 5: Typical Values represent the most likely parametric norm.

Note 6: All limits are guaranteed by testing or statistical analysis.

+

Note 7: V

Note 8: Do not short circuit output to V

Note 9: V

Note 10: Input referred, V

Note 11: Connected as Voltage Follower with 2V step input. Number specified is the slower of either the positive or negative slew rates.

Note 12: Limiting input pin current is only necessary for input voltages that exceed absolute maximum input voltage ratings.

Note 13: Guaranteed limits are dictated by tester limitations and not device performance. Actual performance is reflected in the typical value.

Note 14: For guaranteed Military Temperature Range parameters see RETSMC6462/4X.

=

+

=

=

15V, V

15V. Connected as Voltage Follower with 10V step input. Number specified is the slower of either the positive or negative slew rates.

CM

7.5V and R

+

connected to 7.5V. For Sourcing tests, 7.5V ≤ VO≤ 11.5V. For Sinking tests, 3.5V ≤ VO≤ 7.5V.

L

+

, when V+is greater than 13V or reliability will be adversely affected.

=

15V and R

=

L

J(max)

100 kΩ connected to 7.5V. Each amp excited in turn with 1 kHz to produce V

±

, θJA, and TA. The maximum allowable power dissipation at any ambient temperature is P

30 mA over long term may adversely affect reliability.

=

O

12 V

.

PP

=

(T

D

J(max)

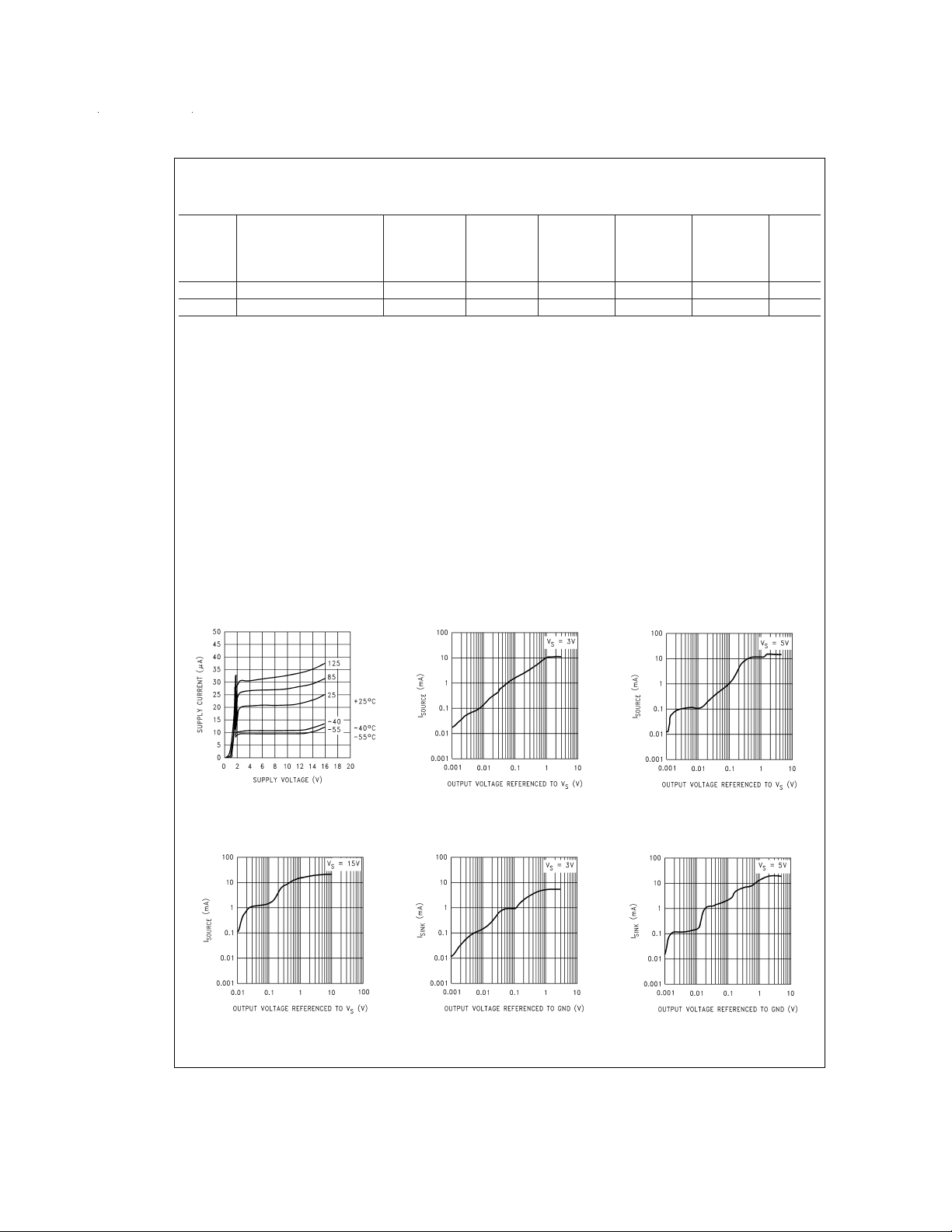

Typical Performance Characteristics V

Supply Current vs

Supply Voltage

DS012051-30

Sourcing Current vs

Output Voltage

DS012051-33

Sourcing Current vs

Output Voltage

Sinking Current vs

Output Voltage

=

+5V, Single Supply, T

S

DS012051-31

DS012051-34

=

25˚C unless otherwise specified

A

Sourcing Current vs

Output Voltage

Sinking Current vs

Output Voltage

DS012051-32

DS012051-35

www.national.com 6

Page 7

Typical Performance Characteristics V

specified (Continued)

=

+5V, Single Supply, T

S

=

25˚C unless otherwise

A

Sinking Current vs

Output Voltage

Input Voltage Noise

vs Input Voltage

Input Voltage vs

Output Voltage

DS012051-36

DS012051-39

Input Voltage

Noise vs Frequency

Input Voltage Noise

vs Input Voltage

Open Loop

Frequency Response

DS012051-37

DS012051-40

Input Voltage Noise

vs Input Voltage

DS012051-38

∆VOSvs CMR

DS012051-41

Open Loop Frequency

Response vs Temperature

DS012051-42

DS012051-43

DS012051-44

www.national.com7

Page 8

Typical Performance Characteristics V

specified (Continued)

=

+5V, Single Supply, T

S

=

25˚C unless otherwise

A

Gain and Phase vs

Capacitive Load

Non-Inverting Large

Signal Pulse Response

Non-Inverting Small

Signal Pulse Response

DS012051-45

DS012051-48

Slew Rate vs

Supply Voltage

Non-Inverting Large

Signal Pulse Response

Non-Inverting Small

Signal Pulse Response

DS012051-46

DS012051-49

Non-Inverting Large

Signal Pulse Response

DS012051-47

Non-Inverting Small

Signal Pulse Response

DS012051-50

Inverting Large

Signal Pulse Response

DS012051-51

www.national.com 8

DS012051-52

DS012051-53

Page 9

Typical Performance Characteristics V

specified (Continued)

=

+5V, Single Supply, T

S

=

25˚C unless otherwise

A

Inverting Large Signal

Pulse Response

DS012051-54

Inverting Large Signal

Pulse Response

Inverting Small Signal

Pulse Response

DS012051-57

Application Information

1.0 Input Common-Mode Voltage Range

The LMC6462/4 has a rail-to-rail input common-mode voltage range.

supplies with no resulting phase inversion on the output.

Figure 1

shows an input voltage exceeding both

Inverting Small Signal

Pulse Response

DS012051-55

Inverting Small Signal

Pulse Response

DS012051-58

pins, possibly affecting reliability. The input current can be

externally limited to

in

Figure 3

±

5 mA, with an input resistor, as shown

.

DS012051-56

DS012051-5

FIGURE 1. An Input Voltage Signal Exceeds

the LMC6462/4 Power Supply Voltage

with No Output Phase Inversion

+

=

The absolute maximum input voltage at V

3V is 300 mV

beyond either supply rail at room temperature. Voltages

greatly exceeding this absolute maximum rating, as in

2

, can cause excessive current to flow in or out of the input

Figure

DS012051-6

FIGURE 2. A±7.5V Input Signal Greatly Exceeds

the 3V Supply in

No Phase Inversion Due to R

Figure 3

Causing

I

www.national.com9

Page 10

Application Information (Continued)

DS012051-7

FIGURE 3. Input Current Protection for Voltages

2.0 Rail-to-Rail Output

The approximated output resistance of the LMC6462/4 is

180Ω sourcing, and 130Ω sinking at V

sourcing and 83Ω sinking at V

swing can be estimated as a function of load using the calculated output resistance.

3.0 Capacitive Load Tolerance

The LMC6462/4 can typically drive a 200 pF load with V

5V at unity gain without oscillating. The unity gain follower is

the most sensitive configuration to capacitive load. Direct capacitive loading reduces the phase margin of op-amps. The

combination of the op-amp’s output impedance and the capacitive load induces phase lag. This results in either an underdamped pulse response or oscillation.

Capacitive load compensation can be accomplished using

resistive isolation as shown in

component of the load in parallel to the capacitive component, the isolation resistor and the resistive load create a

voltage divider at the output. This introduces a DC error at

the output.

Exceeding the Supply Voltage

=

S

=

5V.The maximum output

S

Figure 4

. If there is a resistive

3V, and 110Ω

S

Another circuit, shown in

Figure 6

, is also used to indirectly

drive capacitive loads. This circuit is an improvement to the

circuit shown in

Figure 4

because it provides DC accuracy as

well as AC stability. R1 and C1 serve to counteract the loss

of phase margin by feeding the high frequency component of

the output signal back to the amplifiers inverting input,

thereby preserving phase margin in the overall feedback

loop. The values of R1 and C1 should be experimentally determined by the system designer for the desired pulse response. Increased capacitive drive is possible by increasing

the value of the capacitor in the feedback loop.

=

FIGURE 6. LMC6462 Non-Inverting Amplifier,

Compensated to Handle a 300 pF Capacitive

and 100 kΩ Resistive Load

DS012051-10

DS012051-8

FIGURE 4. Resistive Isolation of

a 300 pF Capacitive Load

DS012051-9

FIGURE 5. Pulse Response of the LMC6462

Circuit Shown in

Figure 5

displays the pulse response of the LMC6462/4 cir-

cuit in

Figure 4

.

www.national.com 10

Figure 4

DS012051-11

FIGURE 7. Pulse Response of

LMC6462 Circuit in

The pulse response of the circuit shown in

in

Figure 7

.

Figure 6

Figure 6

is shown

4.0 Compensating for Input Capacitance

It is quite common to use large values of feedback resistance with amplifiers that have ultra-low input current, like

the LMC6462/4. Large feedback resistors can react with

small values of input capacitance due to transducers, photodiodes, and circuits board parasitics to reduce phase

margins.

Page 11

Application Information (Continued)

DS012051-12

FIGURE 8. Canceling the Effect of Input Capacitance

The effect of input capacitance can be compensated for by

adding a feedback capacitor. The feedback capacitor (as in

Figure 8

), CF, is first estimated by:

or

≤ R2C

R

which typically provides significant overcompensation.

1CIN

Printed circuit board stray capacitance may be larger or

smaller than that of a breadboard, so the actual optimum

value for C

checked on the actual circuit. (Refer to the LMC660 quad

may be different. The values of CFshould be

F

CMOS amplifier data sheet for a more detailed discussion.)

5.0 Offset Voltage Adjustment

Offset voltage adjustment circuits are illustrated in

and

Figure 10

. Large value resistances and potentiometers

are used to reduce power consumption while providing typi-

±

cally

2.5 mV of adjustment range, referred to the input, for

both configurations with V

S

FIGURE 9. Inverting Configuration

Offset Voltage Adjustment

F

Figure 9

=

±

5V.

DS012051-13

DS012051-14

FIGURE 10. Non-Inverting Configuration

Offset Voltage Adjustment

6.0 Spice Macromodel

A Spice macromodel is available for the LMC6462/4. This

model includes a simulation of:

Input common-mode voltage range

•

Frequency and transient response

•

GBW dependence on loading conditions

•

Quiescent and dynamic supply current

•

Output swing dependence on loading conditions

•

and many more characteristics as listed on the macromodel

disk.

Contact the National Semiconductor Customer Response

Center to obtain an operational amplifier Spice model library

disk.

7.0 Printed-Circuit-Board Layout

for High-Impedance Work

It is generally recognized that any circuit which must operate

with less than 1000 pA of leakage current requires special

layout of the PC board. When one wishes to take advantage

of the ultra-low input current of the LMC6462/4, typically 150

fA, it is essential to have an excellent layout. Fortunately, the

techniques of obtaining low leakages are quite simple. First,

the user must not ignore the surface leakage of the PC

board, even though it may sometimes appear acceptably

low, because under conditions of high humidity or dust or

contamination, the surface leakage will be appreciable.

To minimize the effect of any surface leakage, lay out a ring

of foil completely surrounding the LMC6462’s inputs and the

terminals of capacitors, diodes, conductors, resistors, relay

terminals, etc. connected to the op-amp’s inputs, as in

ure 11

. To have a significant effect, guard rings should be

Fig-

placed in both the top and bottom of the PC board. This PC

foil must then be connected to a voltage which is at the same

voltage as the amplifier inputs, since no leakage current can

flow between two points at the same potential. For example,

a PC board trace-to-pad resistance of 10

12

Ω, which is normally considered a very large resistance, could leak 5 pA if

the trace were a 5V bus adjacent to the pad of the input. This

would cause a 30 times degradation from the LMC6462/4’s

actual performance. However, if a guard ring is held within 5

mV of the inputs, then even a resistance of 10

cause only 0.05 pA of leakage current. See

11

Ω would

Figure 12

for

typical connections of guard rings for standard op-amp

configurations.

www.national.com11

Page 12

Application Information (Continued)

board at all, but bend it up in the air and use only air as an insulator. Air is an excellent insulator. In this case you may

have to forego some of the advantages of PC board construction, but the advantages are sometimes well worth the

effort of using point-to-point up-in-the-air wiring. See

13

.

Figure

DS012051-15

FIGURE 11. Example of Guard Ring in P.C. Board

Layout

DS012051-16

Inverting Amplifier

DS012051-17

Non-Inverting Amplifier

(Input pins are lifted out of PC board and soldered directly to components.

All other pins connected to PC board.)

DS012051-19

FIGURE 13. Air Wiring

DS012051-18

Follower

FIGURE 12. Typical Connections of Guard Rings

The designer should be aware that when it is inappropriate

to lay out a PC board for the sake of just a few circuits, there

is another technique which is even better than a guard ring

on a PC board: Don’t insert the amplifier’s input pin into the

www.national.com 12

Page 13

Application Information (Continued)

8.0 Instrumentation Circuits

The LMC6464 has the high input impedance, large

common-mode range and high CMRR needed for designing

instrumentation circuits. Instrumentation circuits designed

with the LMC6464 can reject a larger range of

common-mode signals than most in-amps. This makes instrumentation circuits designed with the LMC6464 an excellent choice for noisy or industrial environments. Other appli-

FIGURE 14. Low Power Three Op-Amp Instrumentation Amplifier

cations that benefit from these features include analytic

medical instruments, magnetic field detectors, gas detectors,

and silicon-based transducers.

A small valued potentiometer is used in series with Rg to set

the differential gain of the three op-amp instrumentation circuit in

Figure 14

. This combination is used instead of one

large valued potentiometer to increase gain trim accuracy

and reduce error due to vibration.

DS012051-20

A two op-amp instrumentation amplifier designed for a gain

of 100 is shown in

Figure 15

. Low sensitivity trimming is

made for offset voltage, CMRR and gain. Low cost and low

power consumption are the main advantages of this two

op-amp circuit.

FIGURE 15. Low-Power Two-Op-Amp Instrumentation Amplifier

Higher frequency and larger common-mode range applications are best facilitated by a three op-amp instrumentation

amplifier.

DS012051-21

www.national.com13

Page 14

Typical Single-Supply Applications

TRANSDUCER INTERFACE CIRCUITS

DS012051-22

FIGURE 16. Photo Detector Circuit

Photocells can be used in portable light measuring instruments. The LMC6462, which can be operated off a battery, is

an excellent choice for this circuit because of its very low input current and offset voltage.

LMC6462 AS A COMPARATOR

DS012051-23

FIGURE 17. Comparator with Hysteresis

Figure 17

shows the application of the LMC6462 as a comparator. The hysteresis is determined by the ratio of the two

resistors. The LMC6462 can thus be used as a micropower

comparator,in applications where the quiescent current is an

important parameter.

HALF-WAVE AND FULL-WAVE RECTIFIERS

DS012051-25

FIGURE 19. Full-Wave Rectifier

with Input Current Protection (R

In

Figure 18 Figure 19

,RIlimits current into the amplifier

)

I

since excess current can be caused by the input voltage exceeding the supply voltage.

PRECISION CURRENT SOURCE

DS012051-26

FIGURE 20. Precision Current Source

The output current I

OUT

is given by:

OSCILLATORS

DS012051-24

FIGURE 18. Half-Wave Rectifier with

Input Current Protection (R

www.national.com 14

)

I

DS012051-27

FIGURE 21. 1 Hz Square-Wave Oscillator

For single supply 5V operation, the output of the circuit will

swing from 0V to 5V. The voltage divider set up R

R

will cause the non-inverting input of the LMC6462 to

4

move from 1.67V (

1

⁄3of 5V) to 3.33V (2⁄3of 5V). This voltage

2,R3

and

behaves as the threshold voltage.

R

and C1determine the time constant of the circuit. The fre-

1

quency of oscillation, f

OSC

is

Page 15

Typical Single-Supply Applications

(Continued)

where ∆t is the time the amplifier input takes to move from

1.67V to 3.33V. The calculations are shown below.

where τ=RC=0.68 seconds

=

→

t

0.27 seconds.

1

and

=

→

0.75 seconds

t

2

Then,

=

1Hz

LOW FREQUENCY NULL

DS012051-28

FIGURE 22. High Gain Amplifier

with Low Frequency Null

Output offset voltage is the error introduced in the output

voltage due to the inherent input offset voltage V

amplifier.

,ofan

OS

Output Offset Voltage=(Input Offset Voltage) (Gain)

In the above configuration, the resistors R

mine the nominal voltage around which the input signal, V

and R6deter-

5

should be symmetrical. The high frequency component of

the input signal V

quency component will be nulled since the DC level of the

will be unaffected while the low fre-

IN

output will be the input offset voltage of the LMC6462 plus

the bias voltage. This implies that the output offset voltage

due to the top amplifier will be eliminated.

IN

www.national.com15

Page 16

Physical Dimensions inches (millimeters) unless otherwise noted

8-Pin Small Outline Package

Order Number LMC6462AIM or LMC6462BIM

NS Package Number M08A

14-Pin Small Outline Package

Order Number LMC6464AIM or LMC6464BIM

NS Package Number M14A

www.national.com 16

Page 17

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

8-Pin Molded Dual-In-Line Package

Order Number LMC6462AIN or LMC6462BIN

NS Package Number N08E

14-Pin Molded Dual-In-Line Pacakge

Order Number LMC6462AIN or LMC6464BIN

NS Package Number N14A

www.national.com17

Page 18

Amplifier

Notes

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

LMC6462 Dual/LMC6464 Quad Micropower, Rail-to-Rail Input and Output CMOS Operational

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...