Page 1

LMC6024

Low Power CMOS Quad Operational Amplifier

LMC6024 Low Power CMOS Quad Operational Amplifier

August 2000

General Description

The LMC6024 is a CMOS quad operational amplifier which

can operate from either a single supply or dual supplies. Its

performance features include an input common-mode range

that reaches V

100 kΩ and5kΩloads) that is equal to or better than widely

accepted bipolar equivalents, while the power supply requirement is less than 1 mW.

This chip is built with National’s advanced Double-Poly

Silicon-Gate CMOS process.

See the LMC6022 datasheet for a CMOS dual operational

amplifier with these same features.

−

, low input bias current and voltage gain (into

Features

n Specified for 100 kΩ and5kΩloads

n High voltage gain 120 dB

n Low offset voltage drift 2.5 µV/˚C

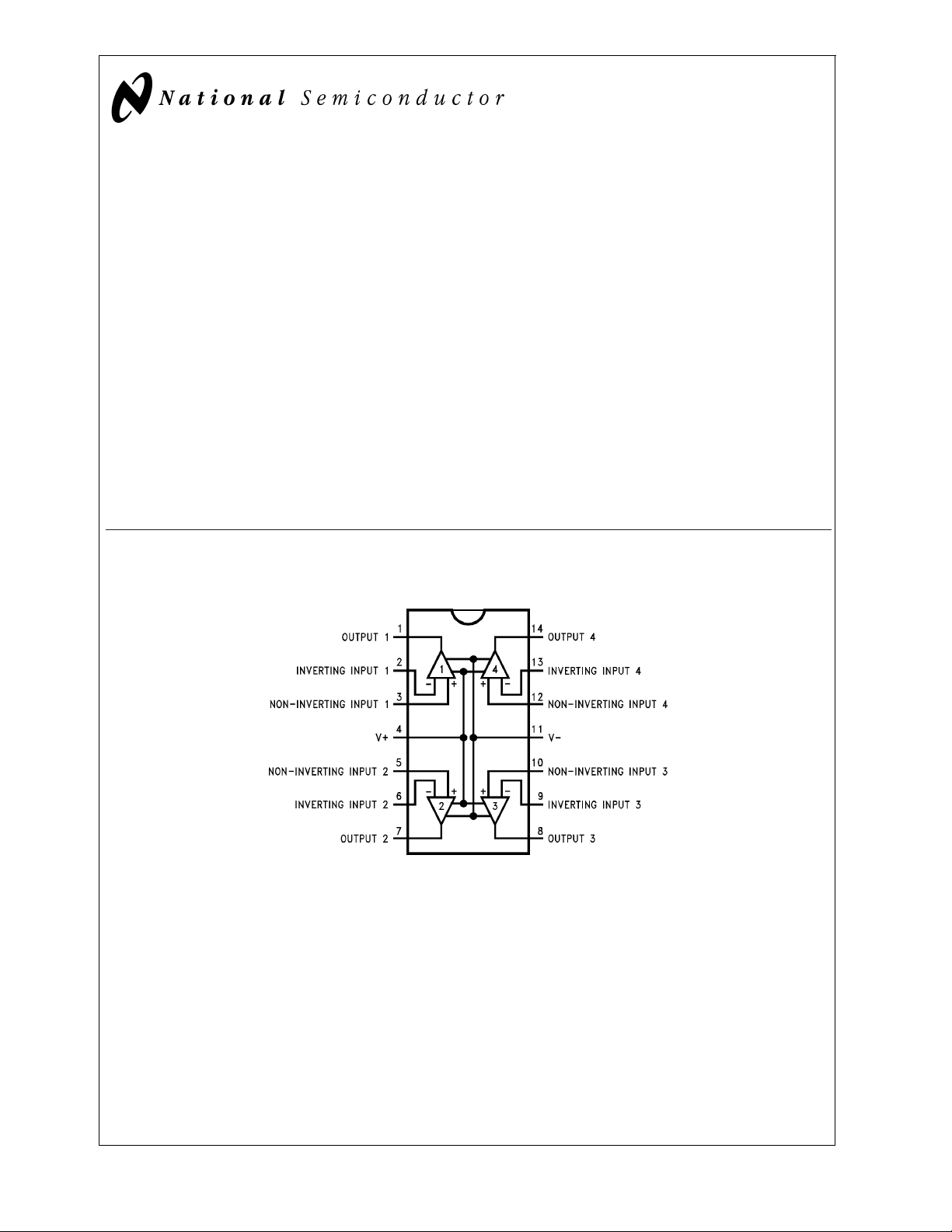

Connection Diagram

14-Pin DIP/SO

n Ultra low input bias current 40 fA

n Input common-mode range includes V

n Operating range from +5V to +15V supply

n Low distortion 0.01% at 1 kHz

n Slew rate 0.11 V/µs

n Micropower operation 1 mW

−

Applications

n High-impedance buffer or preamplifier

n Current-to-voltage converter

n Long-term integrator

n Sample-and-hold circuit

n Peak detector

n Medical instrumentation

n Industrial controls

DS011235-1

Top View

© 2000 National Semiconductor Corporation DS011235 www.national.com

Page 2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

LMC6024

Distributors for availability and specifications.

Differential Input Voltage

+−V−

Supply Voltage (V

) 16V

Lead Temperature

(Soldering, 10 sec.) 260˚C

Storage Temperature Range −65˚C to +150˚C

Voltage at Output/Input Pin (V

Current at Input Pin

Current at Output Pin

±

Supply Voltage

+

) + 0.3V, (V−) − 0.3V

±

±

18 mA

5mA

Output Short Circuit to V

Junction Temperature 150˚C

ESD Tolerance (Note 4) 1000V

Power Dissipation (Note 3)

Operating Ratings

Temperature Range −40˚C ≤ TJ≤ +85˚C

Supply Voltage Range 4.75V to 15.5V

Power Dissipation (Note 10)

Thermal Resistance (θ

14-Pin DIP 85˚C/W

14-Pin SO 115˚C/W

−

), (Note 11)

JA

Current at Power Supply Pin 35 mA

Output Short Circuit to V

+

(Note 12)

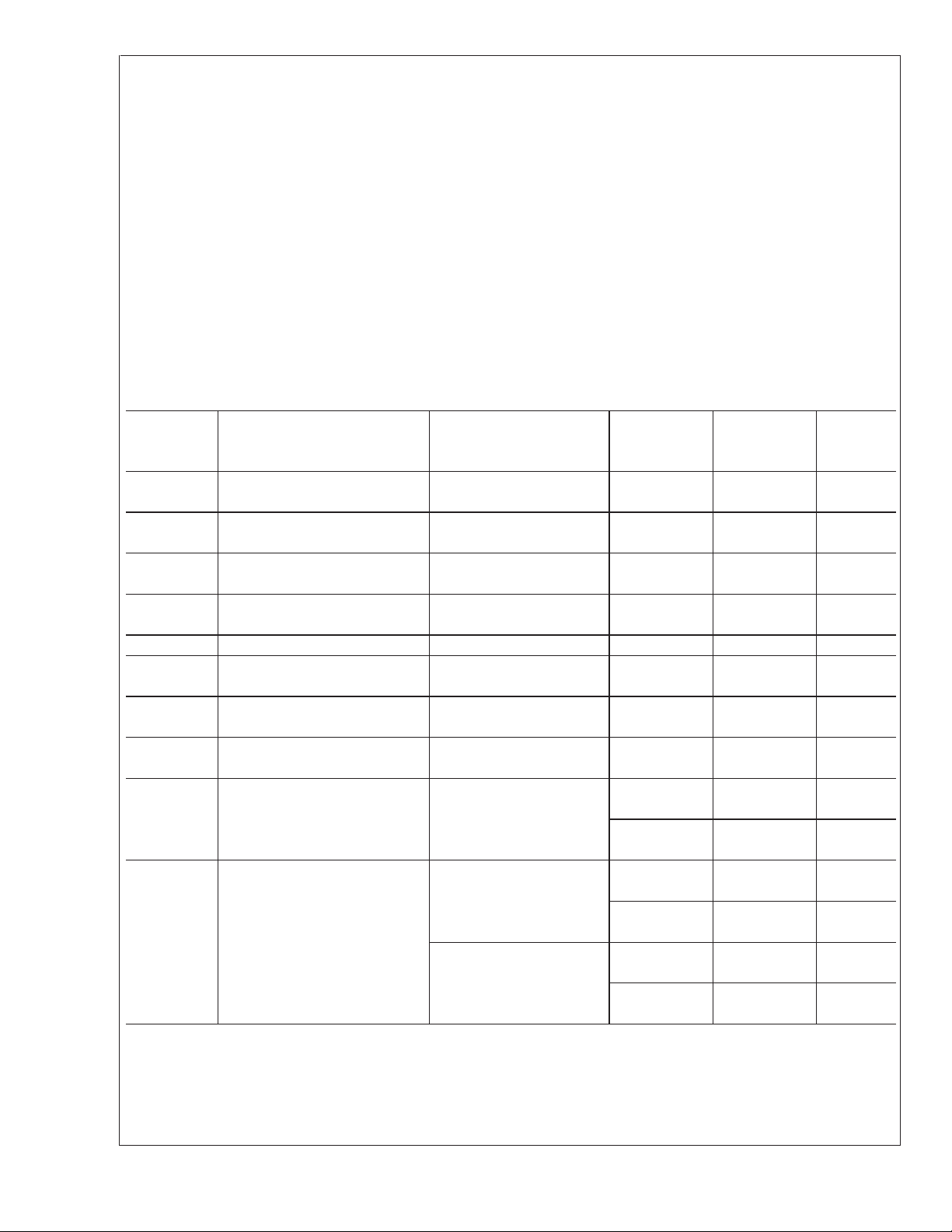

DC Electrical Characteristics

The following specifications apply for V+= 5V, V−= 0V, VCM= 1.5V, VO= 2.5V, and RL= 1M unless otherwise noted. Boldface limits apply at the temperature extremes; all other limits TJ= 25˚C.

Typical LMC6024I

Symbol Parameter Conditions (Note 5) Limit Units

(Note 6)

V

OS

∆V

/∆T Input Offset Voltage 2.5 µV/˚C

OS

I

B

I

OS

R

IN

CMRR Common Mode 0V ≤ V

+PSRR Positive Power Supply 5V ≤ V

−PSRR Negative Power Supply 0V ≤ V

V

CM

A

V

Input Offset Voltage 1 9 mV

11 Max

Average Drift

Input Bias Current 0.04 pA

200 Max

Input Offset Current 0.01 pA

100 Max

Input Resistance

Rejection Ratio V

≤ 12V 83 63 dB

CM

+

= 15V 61 Min

+

≤ 15V 83 63 dB

>

1 TeraΩ

Rejection Ratio 61 Min

−

≤ −10V 94 74 dB

Rejection Ratio 73 Min

Input Common-Mode V+= 5V and 15V −0.4 −0.1 V

Voltage Range For CMRR ≥ 50 DB 0 Max

+

V

− 1.9 V+− 2.3 V

+

V

− 2.5 Min

Large Signal Voltage Gain RL= 100 kΩ (Note 7) 1000 200 V/mV

Sourcing 100 Min

Sinking 500 90 V/mV

40 Min

R

=5kΩ(Note 7) 1000 100 V/mV

L

Sourcing 75 Min

Sinking 250 50 V/mV

20 Min

(Note 2)

www.national.com 2

Page 3

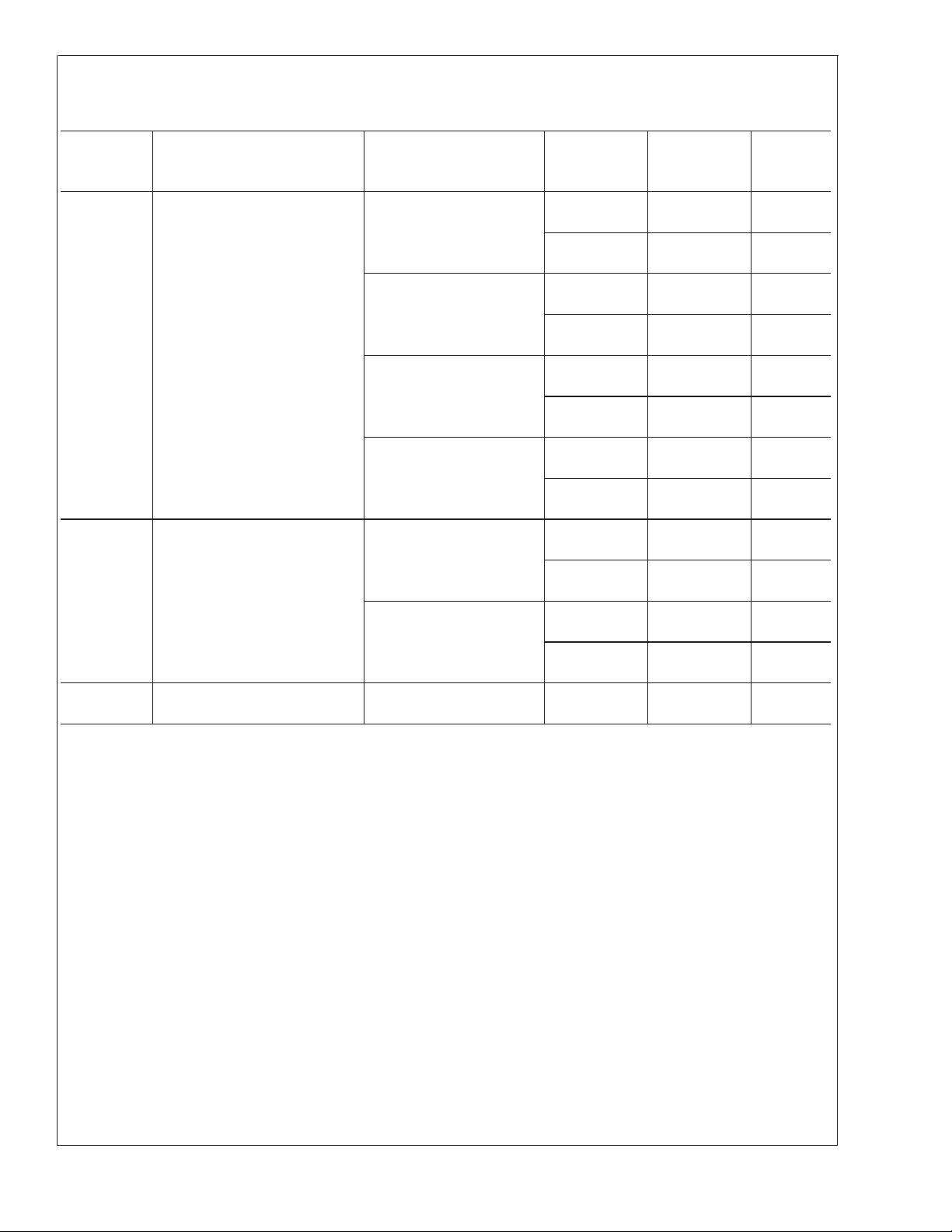

DC Electrical Characteristics (Continued)

The following specifications apply for V+= 5V, V−= 0V, VCM= 1.5V, VO= 2.5V, and RL= 1M unless otherwise noted. Boldface limits apply at the temperature extremes; all other limits TJ= 25˚C.

Typical LMC6024I

Symbol Parameter Conditions (Note 5) Limit Units

(Note 6)

V

O

I

O

I

S

Output Voltage Swing V+= 5V 4.987 4.40 V

R

= 100 kΩ to 2.5V 4.43 Min

L

0.004 0.06 V

0.09 Max

+

V

= 5V 4.940 4.20 V

R

=5kΩto 2.5V 4.00 Min

L

0.040 0.25 V

0.35 Max

+

V

= 15V 14.970 14.00 V

R

= 100 kΩ to 7.5V 13.90 Min

L

0.007 0.06 V

0.09 Max

+

V

= 15V 14.840 13.70 V

R

=5kΩto 7.5V 13.50 Min

L

0.110 0.32 V

0.40 Max

Output Current V+=5V 22 13 mA

Sourcing, V

Sinking V

=0V 9 Min

O

=5V 21 13 mA

O

(Note 2) 9 Min

+

V

= 15V 40 23 mA

Sourcing, V

Sinking, V

=0V 15 Min

O

= 13V 39 23 mA

O

(Note 12) 15 Min

Supply Current All Four Amplifiers 160 240 µA

V

= 1.5V 280 Max

O

LMC6024

www.national.com3

Page 4

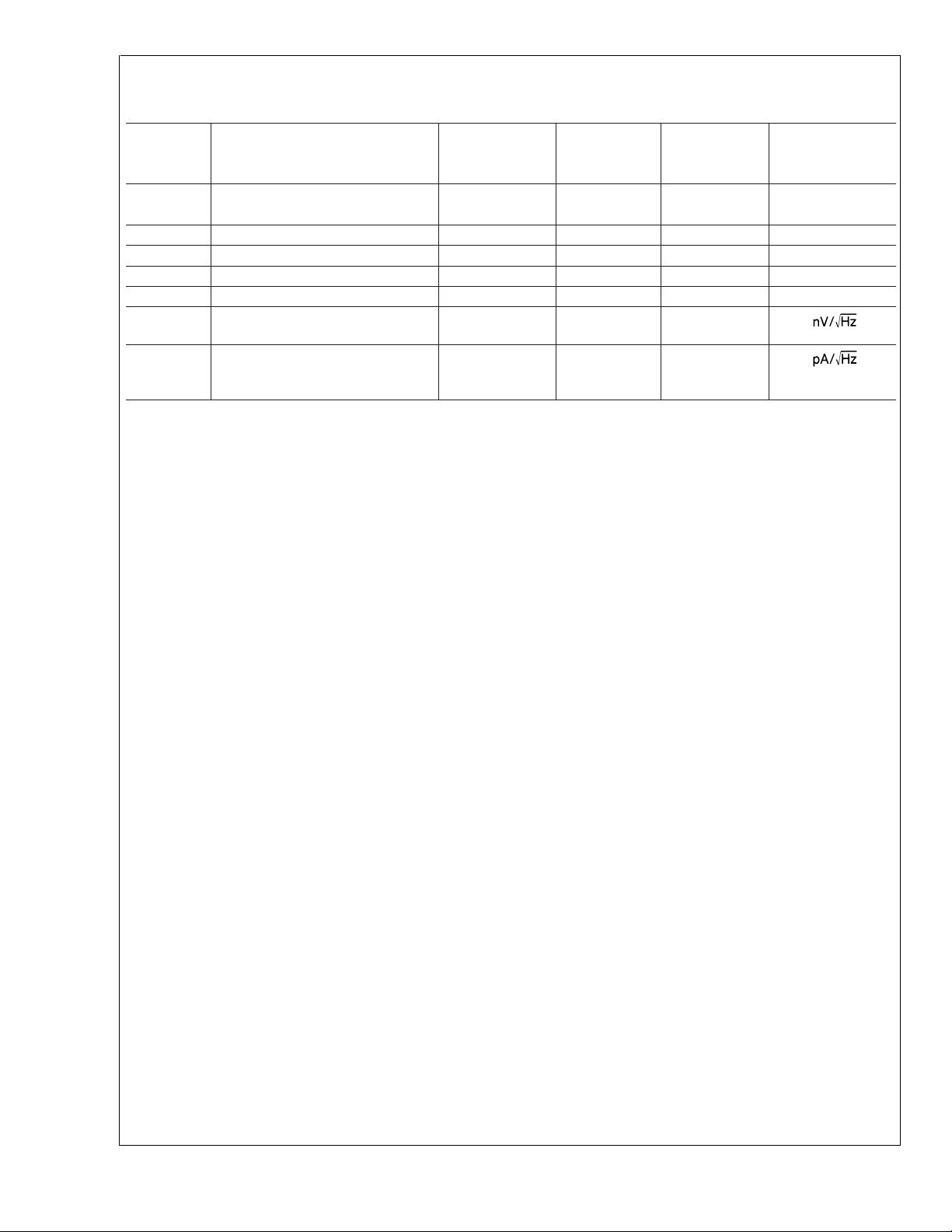

AC Electrical Characteristics

The following specifications apply for V+= 5V, V−= 0V, VCM= 1.5V, VO= 2.5V, and RL= 1M unless otherwise noted. Boldface limits apply at the temperature extremes; all other limits TJ= 25˚C.

LMC6024

Symbol Parameter Conditions (Note 5) Limit Units

SR Slew Rate (Note 8) 0.11 0.05 V/µs

GBW Gain-Bandwidth Product 0.35 MHz

θ

M

G

M

e

n

Phase Margin 50 Deg

Gain Margin 17 dB

Amp-to-Amp Isolation (Note 9) 130 dB

Input-Referred Voltage Noise F = 1 kHz 42

Typical LMC6024I

(Note 6)

0.03 Min

i

n

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings indicate conditions for which the device

is intended to be functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics.

The guaranteed specifications apply only for the test conditions listed.

Note 2: Applies to both single-supply and split-supply operation.Continuous short circuit operation at elevated ambient temperature and/or multiple Op Amp shorts

can result in exceeding the maximum allowed junction temperature of 150˚C. Output currents in excess of

Note 3: The maximum power dissipation is a function of T

−TA)/θJA.

Note 4: Human body model, 100 pF discharge through a 1.5 kΩ resistor.

Note 5: Typical values represent the most likely parametric norm.

Note 6: All limits are guaranteed by testing or correlation.

Note 7: V

Note 8: V

Note 9: Input referred, V

Note 10: For operating at elevated temperatures the device must be derated based on the thermal resistance θ

Note 11: All numbers apply for packages soldered directly into a PC board.

Note 12: Do not connect output to V

Input-Referred Current Noise F = 1 kHz 0.0002

±

30 mA over long term may adversly affect reliability.

, θJA, and TA. The maximum allowable power dissipation at any ambient temperature is PD=(T

J(max)

+

= 15V, VCM= 7.5V, and RLconnected to 7.5V. For Sourcing tests, 7.5V ≤ VO≤ 11.5V. For Sinking tests, 2.5V ≤ VO≤ 7.5V.

+

= 15V. Connected as Voltage Follower with 10V step input. Number specified is the slower of the positive and negative slew rates.

+

= 15V and RL= 100 kΩ connected to 7.5V. Each amp excited in turn with 1 kHz to produce VO=13VPP.

with PD=(TJ−TA)/θJA.

JA

+

when V+is greater than 13V or reliability may be adversely affected.

J(max)

www.national.com 4

Page 5

LMC6024

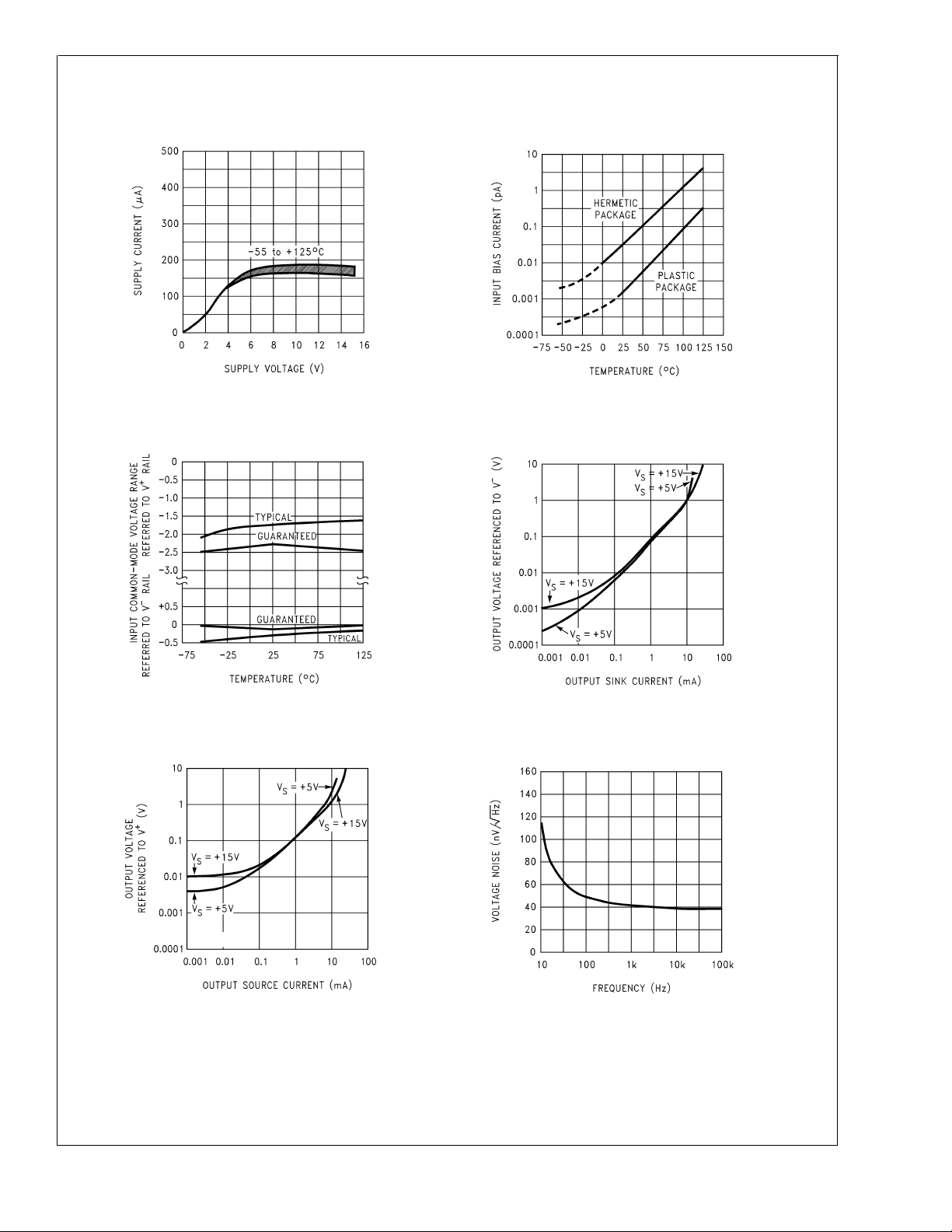

Typical Performance Characteristics V

Supply Current

vs Supply Voltage

DS011235-27

Common-Mode Voltage

Range vs Temperature

=±7.5V, TA= 25˚C unless otherwise specified

S

Input Bias Current

vs Temperature

DS011235-28

Output Characteristics

Current Sinking

Output Characteristics

Current Sourcing

DS011235-29

DS011235-31

DS011235-30

Input Voltage Noise

vs Frequency

DS011235-32

www.national.com5

Page 6

Typical Performance Characteristics V

LMC6024

Crosstalk Rejection

vs Frequency

=±7.5V, TA= 25˚C unless otherwise specified (Continued)

S

CMRR vs Frequency

CMRR vs Temperature

Open-Loop Voltage

Gain vs Temperature

DS011235-33

DS011235-34

Power Supply Rejection

Ratio vs Frequency

DS011235-35

DS011235-36

Open-Loop

Frequency Response

DS011235-37

www.national.com 6

DS011235-38

Page 7

LMC6024

Typical Performance Characteristics V

Gain and Phase Responses

vs Load Capacitance

DS011235-39

Gain Error

(V

vs V

OS

OUT

)

=±7.5V, TA= 25˚C unless otherwise specified (Continued)

S

Gain and Phase

Responses vs Temperature

DS011235-40

Non-Inverting Slew Rate

vs Temperature

Inverting Slew Rate

vs Temperature

DS011235-41

DS011235-43

Large-Signal Pulse

Non-Inverting Response

(A

= +1)

V

DS011235-42

DS011235-44

www.national.com7

Page 8

Typical Performance Characteristics V

LMC6024

Non-Inverting Small

Signal Pulse Response

(A

= +1)

V

=±7.5V, TA= 25˚C unless otherwise specified (Continued)

S

Inverting Large-Signal

Pulse Response

Inverting Small-Signal

Pulse Response

DS011235-45

DS011235-46

DS011235-47

www.national.com 8

Page 9

LMC6024

Typical Performance Characteristics V

Stability vs Capacitive Load

DS011235-4

Note 13: Avoid resistive loads of less than 500Ω, as they may cause instability.

Application Hints

AMPLIFIER TOPOLOGY

The topology chosen for the LMC6024 is unconventional

(compared to general-purpose op amps) in that the traditional unity-gain buffer output stage is not used; instead, the

output is taken directly from the output of the integrator, to allow rail-to-rail output swing. Since the buffer traditionally delivers the power to the load, while maintaining high op amp

gain and stability, and must withstand shorts to either rail,

these tasks now fall to the integrator.

As a result of these demands, the integrator is a compound

affair with an embedded gain stage that is doubly fed forward

(via C

driver. In addition, the output portion of the integrator is a

push-pull configuration for delivering heavy loads. While

sinking current the whole amplifier path consists of three

gain stages with one stage fed forward, whereas while

sourcing the path contains four gain stages with two fed

forward.

and Cff) by a dedicated unity-gain compensation

f

=±7.5V, TA= 25˚C unless otherwise specified (Continued)

S

Stability vs Capacitive Load

DS011235-5

ing load resistance of 5 kΩ or less, the gain will be reduced

as indicated in the Electrical Characterisitics. The op amp

can drive load resistance as low as 500Ω without instability.

COMPENSATING INPUT CAPACITANCE

Refer to the LMC660 or LMC662 datasheets to determine

whether or not a feedback capacitor will be necessary for

compensation and what the value of that capacitor would be.

CAPACITIVE LOAD TOLERANCE

Like many other op amps, the LMC6024 may oscillate when

its applied load appears capacitive. The threshold of oscillation varies both with load and circuit gain. The configuration

most sensitive to oscillation is a unity-gain follower. See the

Typical Performance Characteristics.

The load capacitance interacts with the op amp’s output resistance to create an additional pole. If this pole frequency is

sufficiently low,it will degrade the op amp’s phase margin so

that the amplifier is no longer stable at low gains. The addition of a small resistor (50Ω to 100Ω) in series with the op

amp’s output, and a capacitor (5 pF to 10 pF) from inverting

input to output pins, returns the phase margin to a safe value

without interfering with lower-frequency circuit operation.

Thus, larger values of capacitance can be tolerated without

oscillation. Note that in all cases, the output will ring heavily

when the load capcitance is near the threshold for

oscillation.

DS011235-6

FIGURE 1. LMC6024 Circuit Topology (Each Amplifier)

The large signal voltage gain while sourcing is comparable

to traditional bipolar op amps, for load resistance of at least

5kΩ. The gain while sinking is higher than most CMOS op

amps, due to the additional gain stage; however, when driv-

www.national.com9

Page 10

Application Hints (Continued)

LMC6024

DS011235-26

FIGURE 3. Compensating for Large

Capacitive Loads with a Pull Up Resistor

DS011235-7

FIGURE 2. Rx, Cx Improve Capacitive Load Tolerance

Capacitive load driving capability is enhanced by using a pull

up resistor to V

+

Figure 3

. Typically a pull up resistor conducting 50 µA or more will significantly improve capacitive

load responses. The value of the pull up resistor must be determined based on the current sinking capability of the amplifier with respect to the desired output swing. Open loop gain

of the amplifier can also be affected by the pull up resistor

(see Electrical Characteristics).

PRINTED-CIRCUIT-BOARD LAYOUT

FOR HIGH-IMPEDANCE WORK

It is generally recognized that any circuit which must operate

with less than 1000 pA of leakage current requires special

layout of the PC board. When one wishes to take advantage

of the ultra-low bias current of the LMC6024, typically less

than 0.04 pA, it is essential to have an excellent layout. Fortunately, the techniques for obtaining low leakages are quite

simple. First, the user must not ignore the surface leakage of

the PC board, even though it may sometimes appear acceptably low, because under conditions of high humidity or dust

or contamination, the surface leakage will be appreciable.

To minimize the effect of any surface leakage, lay out a ring

of foil completely surrounding the LMC6024’s inputs and the

terminals of capacitors, diodes, conductors, resistors, relay

terminals, etc. connected to the op-amp’s inputs. See

4

. To have a significant effect, guard rings should be placed

Figure

on both the top and bottom of the PC board. This PC foil

must then be connected to a voltage which is at the same

voltage as the amplifier inputs, since no leakage current can

flow between two points at the same potential. For example,

a PC board trace-to-pad resistance of 10

12

ohms, which is

normally considered a very large resistance, could leak 5 pA

if the trace were a 5V bus adjacent to the pad of an input.

This would cause a 100 times degradation from the

LMC6024’s actual performance. However, if a guard ring is

held within 5 mV of the inputs, then even a resistance of 10

ohms would cause only 0.05 pA of leakage current, or perhaps a minor (2:1) degradation of the amplifier’s performance. See

Figure 5a,Figure 5b,Figure 5c

for typical connections of guard rings for standard op-amp configurations.

If both inputs are active and at high impedance, the guard

can be tied to ground and still provide some protection; see

Figure 5d

.

11

www.national.com 10

Page 11

Application Hints (Continued)

FIGURE 4. Example of Guard Ring in P.C. Board Layout (Using the LMC6024)

LMC6024

DS011235-8

DS011235-9

(a) Inverting Amplifier

DS011235-11

(c) Follower

FIGURE 5. Guard Ring Connections

The designer should be aware that when it is inappropriate

to lay out a PC board for the sake of just a few circuits, there

is another technique which is even better than a guard ring

on a PC board: Don’t insert the amplifier’s input pin into the

board at all, but bend it up in the air and use only air as an insulator. Air is an excellent insulator. In this case you may

have to forego some of the advantages of PC board con-

DS011235-10

(b) Non-Inverting Amplifier

DS011235-12

(d) Howland Current Pump

struction, but the advantages are sometimes well worth the

effort of using point-to-point up-in-the-air wiring. See

6

.

Figure

www.national.com11

Page 12

Application Hints (Continued)

LMC6024

(Input pins are lifted out of PC board and soldered directly to components.

All other pins connected to PC board.)

FIGURE 6. Air Wiring

BIAS CURRENT TESTING

The test method of

bias current with reasonable accuracy.To understand its operation, first close switch S2 momentarily. When S2 is

opened, then

Figure 7

is appropriate for bench-testing

DS011235-13

DS011235-14

FIGURE 7. Simple Input Bias Current Test Circuit

A suitable capacitor for C2 would bea5pFor10pFsilver

mica, NPO ceramic, or air-dielectric. When determining the

magnitude of I

−

, the leakage of the capacitor and socket

must be taken into account. Switch S2 should be left shorted

most of the time, or else the dielectric absorption of the capacitor C2 could cause errors.

Similarly, if S1 is shorted momentarily (while leaving S2

shorted)

Typical Single-Supply Applications (V

Photodiode Current-to-Voltage Converter

DS011235-15

Note 14: A 5V bias on the photodiode can cut its capacitance by a factor of

2 or 3, leading to improved response and lower noise. However, this bias on

the photodiode will cause photodiode leakage (also known as its dark current).

where Cxis the stray capacitance at the +input.

+

= 5.0 VDC)

Micropower Current Source

DS011235-16

(Upper limit of output range dictated by input common-mode range; lower

limit dictated by minimum current requirement of LM385.)

www.national.com 12

Page 13

Typical Single-Supply Applications (V

Low-Leakage Sample-and-Hold

Instrumentation Amplifier

+

= 5.0 VDC) (Continued)

DS011235-17

LMC6024

DS011235-18

If R1 = R5, R3 = R6, and R4 = R7;

Then

∴

AV≈ 100 for circuit shown.

For good CMRR over temperature, low drift resistors should be used. Matching of R3 to R6 and R4 to R7 affects CMRR. Gain may be adjusted through R2.

CMRR may be adjusted through R7.

fO=10Hz

Q = 2.1

Gain = −8.8

10 Hz Bandpass Filter

DS011235-19

fc=10Hz

d = 0.895

Gain = 1

10 Hz High-Pass Filter (2 dB Dip)

DS011235-20

www.national.com13

Page 14

Typical Single-Supply Applications (V

+

= 5.0 VDC) (Continued)

LMC6024

1 Hz Low-Pass Filter (Maximally Flat, Dual Supply

Only)

DS011235-21

High Gain Amplifier with Offset Voltage Reduction

DS011235-22

Gain = −46.8

Output offset voltage reduced to the

level of the input offset voltage of

the bottom amplifier (typically 1 mV),

referred to V

BIAS

.

Ordering Information

Temperature Range

Industrial

−40˚C ≤ T

LMC6024IM 14-Pin M14A Rail

LMC6024IMX Small Outline Tape and Reel

≤ +85˚C

J

Package

NSC

Drawing

Transport

Media

www.national.com 14

Page 15

Physical Dimensions inches (millimeters) unless otherwise noted

14-Pin Small Outline Molded Package (M)

Order Number LMC6024IM

NS Package Number M14A

LMC6024 Low Power CMOS Quad Operational Amplifier

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...