Page 1

LM98501

10-Bit, 27 MSPS Camera Signal Processor

General Description

The LM98501 is a CCD signal processor for electronic cameras. The processor provides a common interface to a number of different image sensors including CCD, CMOS, and

CIS. Correlated double sampling reduces kTC noise from

the image signal. A fast, temperature stable, 8-bit digitally

programmable gain amplifier enables pixel-rate

white-balancing. An auxiliary input is provided, allowing for

the selection of anexternalsignal, useful for electronic titling

and video overlay. The 10-bit A/D converter preserves the

image quality with excellent noise performance. The

LM98501 also includes the supporting functions of digital

black level clamp and power down, ideally suited for portable

video applications. This low-power processor is a natural

choice for the most demanding imaging systems.

Applications

n Digital still camera

n Digital video camcorder

n Video conferencing

n Security camera

n Plain paper copier

n Flatbed or handheld color scanner

n Video processing for x-ray or infrared

n Barcode scanner

Features

n +3V single power supply

n Low power CMOS design

n 4-wire serial interface

n 2.5V data output voltage swing

n No missing codes

n AUX input with input clamp and programmable gain

n Four color gain and offset registers

n Digital black level clamp

n Small 48-lead LQFP package

Key Specifications

j

Maximum Input Level 1.0V peak-peak

j

CDS Sampling Rate 27 MSPS

j

PGA Gain Steps 256 Steps

j

PGA Gain Range 0.0 dB-32.0 dB

j

ADC Resolution 10-Bit

j

ADC Sampling Rate 27 MSPS

j

*Signal-to-Noise Ratio 60 dB 0 dB Gain, 1.0V Input

j

Power Dissipation

AV+ = DV+ = DV+ I/O = 3.0V 195 mW (typical)

j

Operating Temperature 0˚C to 70˚C

*

20 log10(VIN/RMS Output Noise)

LM98501 10-Bit, 27 MSPS Camera Signal Processor

February 2000

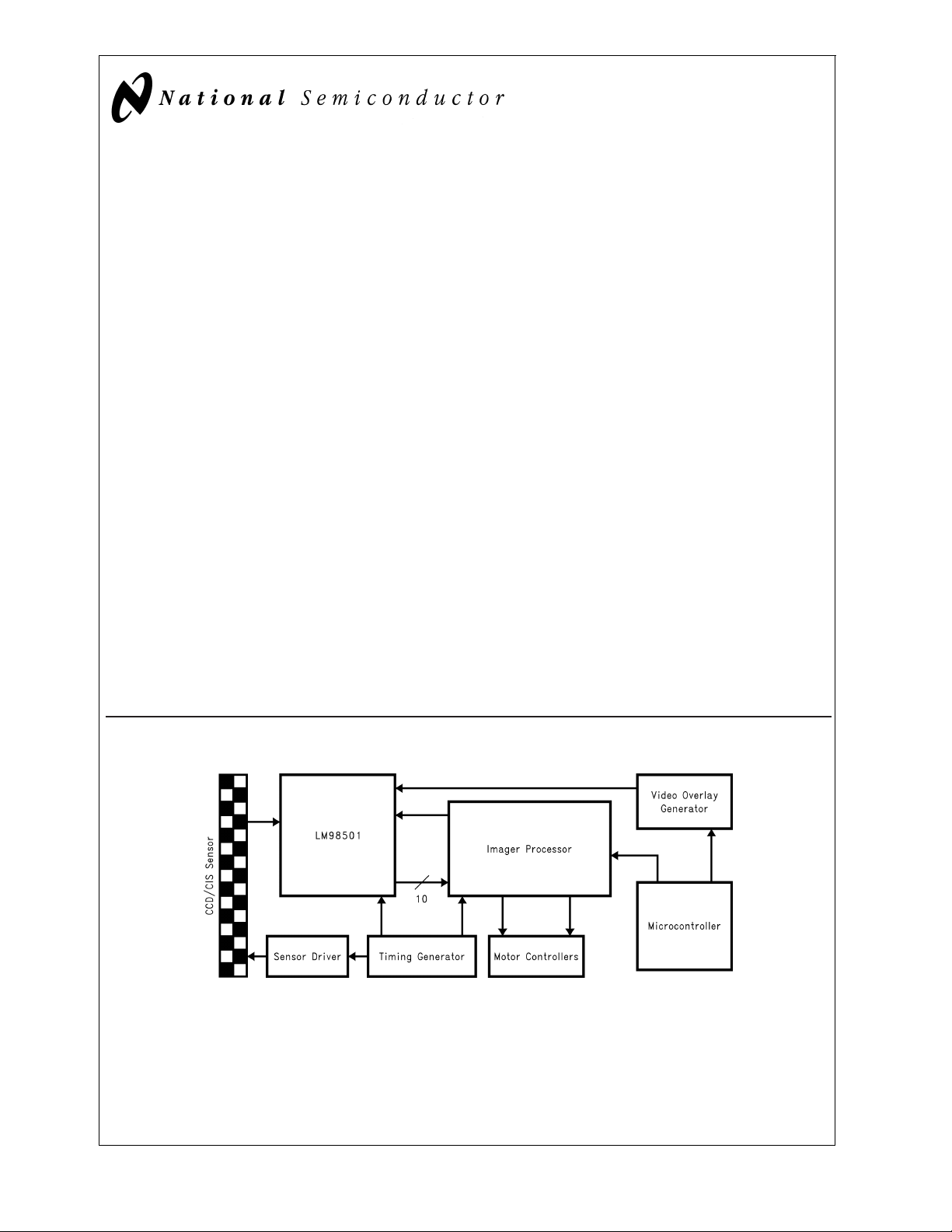

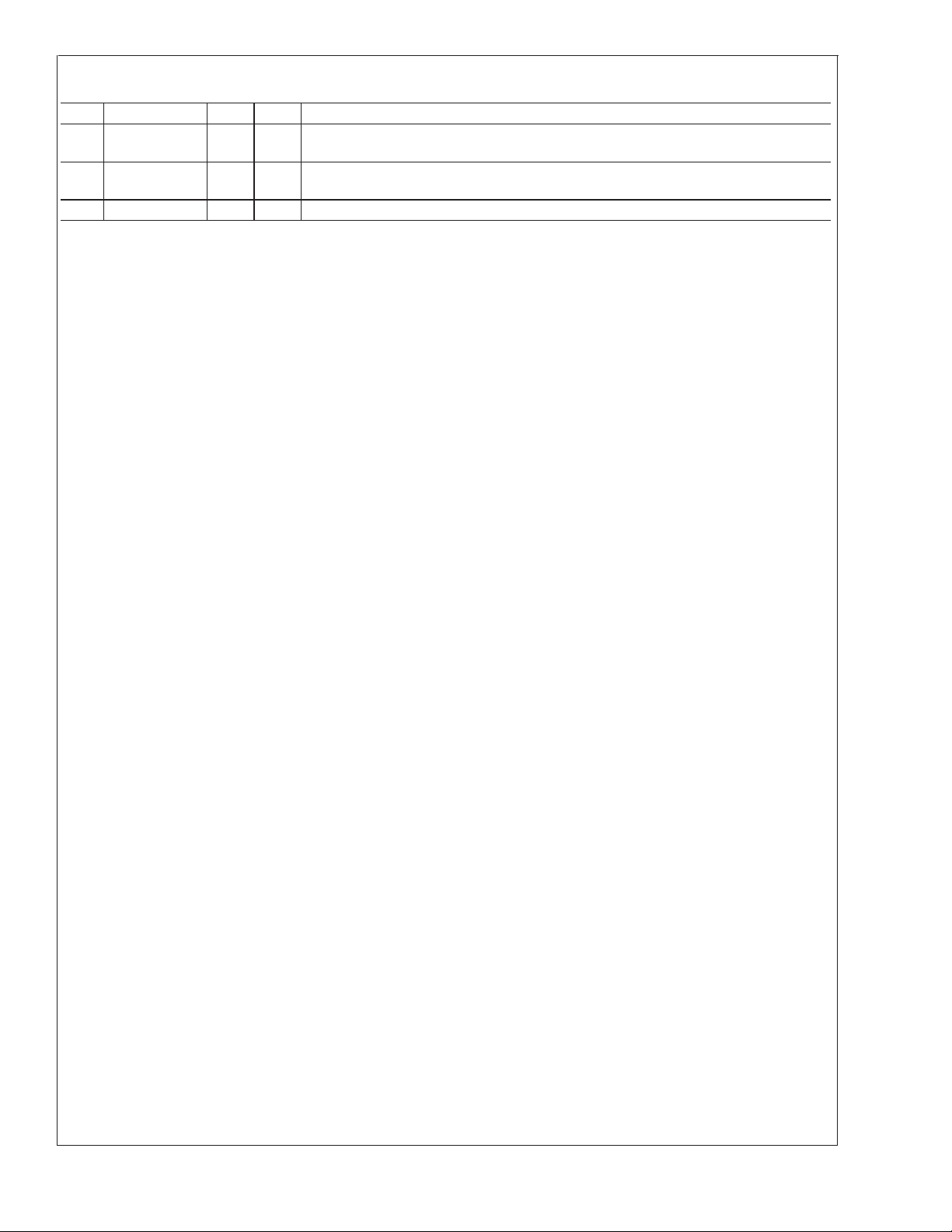

Typical Digital Camera Block Diagram

DS101292-1

© 2000 National Semiconductor Corporation DS101292 www.national.com

Page 2

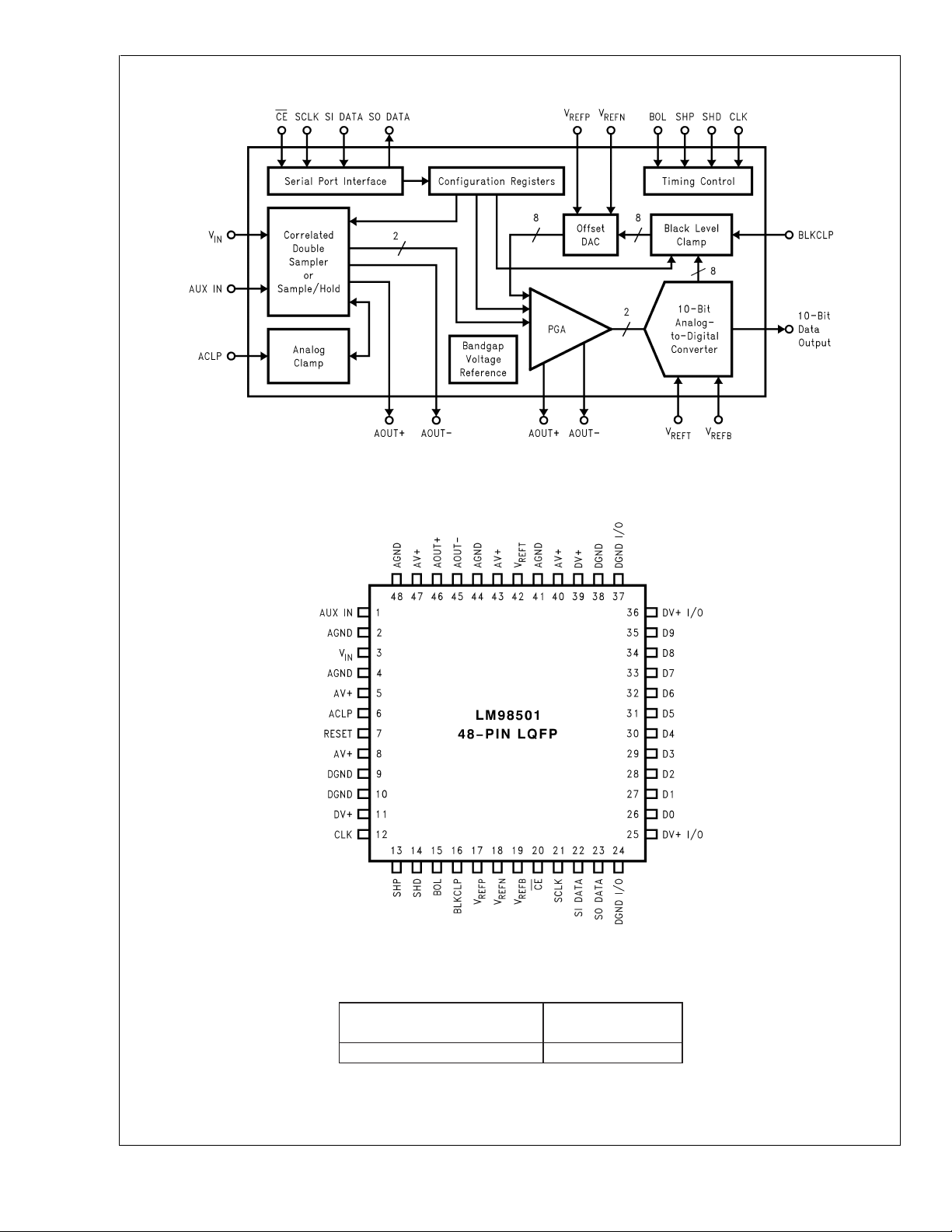

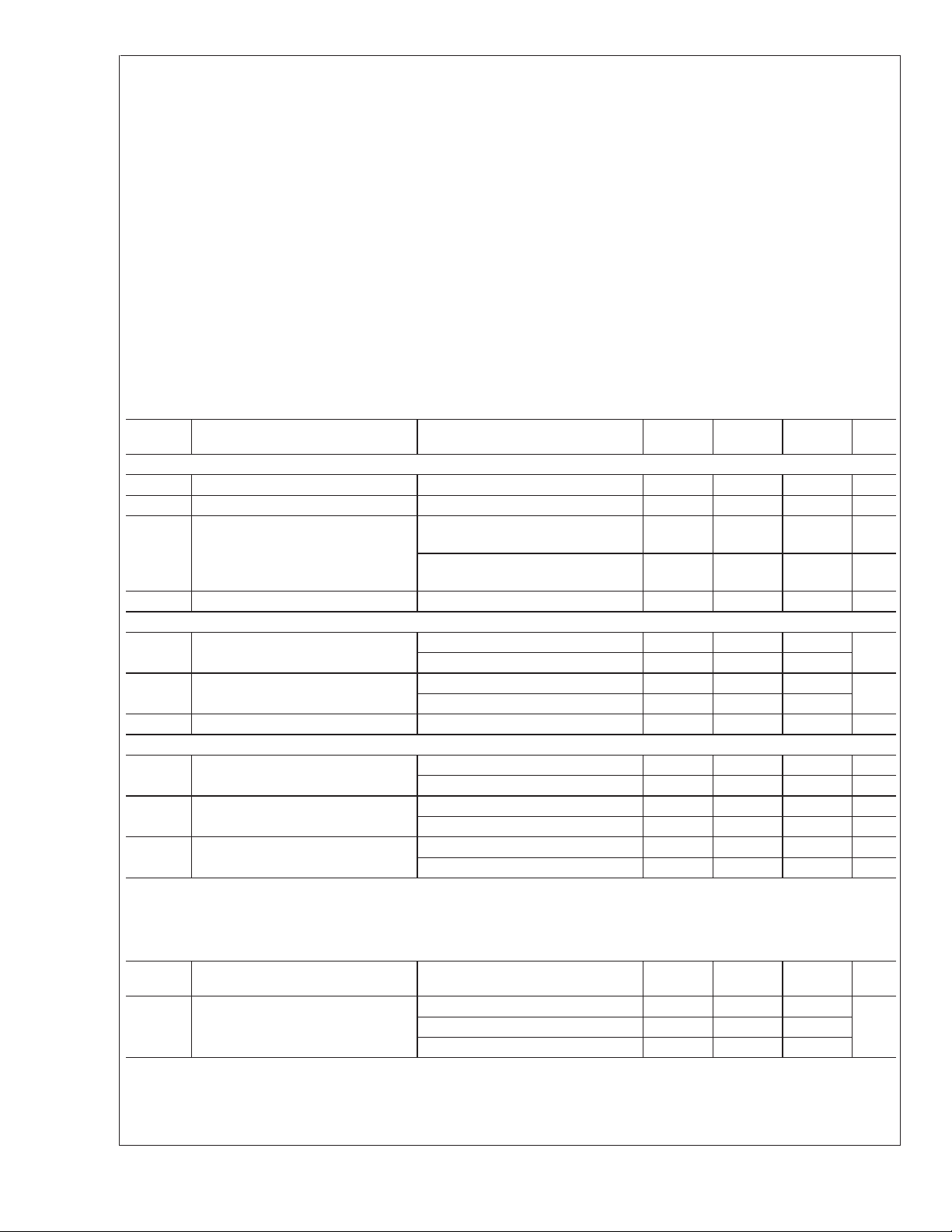

Overall Chip Block Diagram

LM98501

LM98501 Chip Pin Out

DS101292-2

FIGURE 1. Chip Block Diagram

FIGURE 2. Pin Out Diagram

Ordering Information

Commercial

(0˚C ≤ T

LM98501CCVBH LQFP

www.national.com 2

≤ +70˚C)

A

DS101292-3

NS Package

Page 3

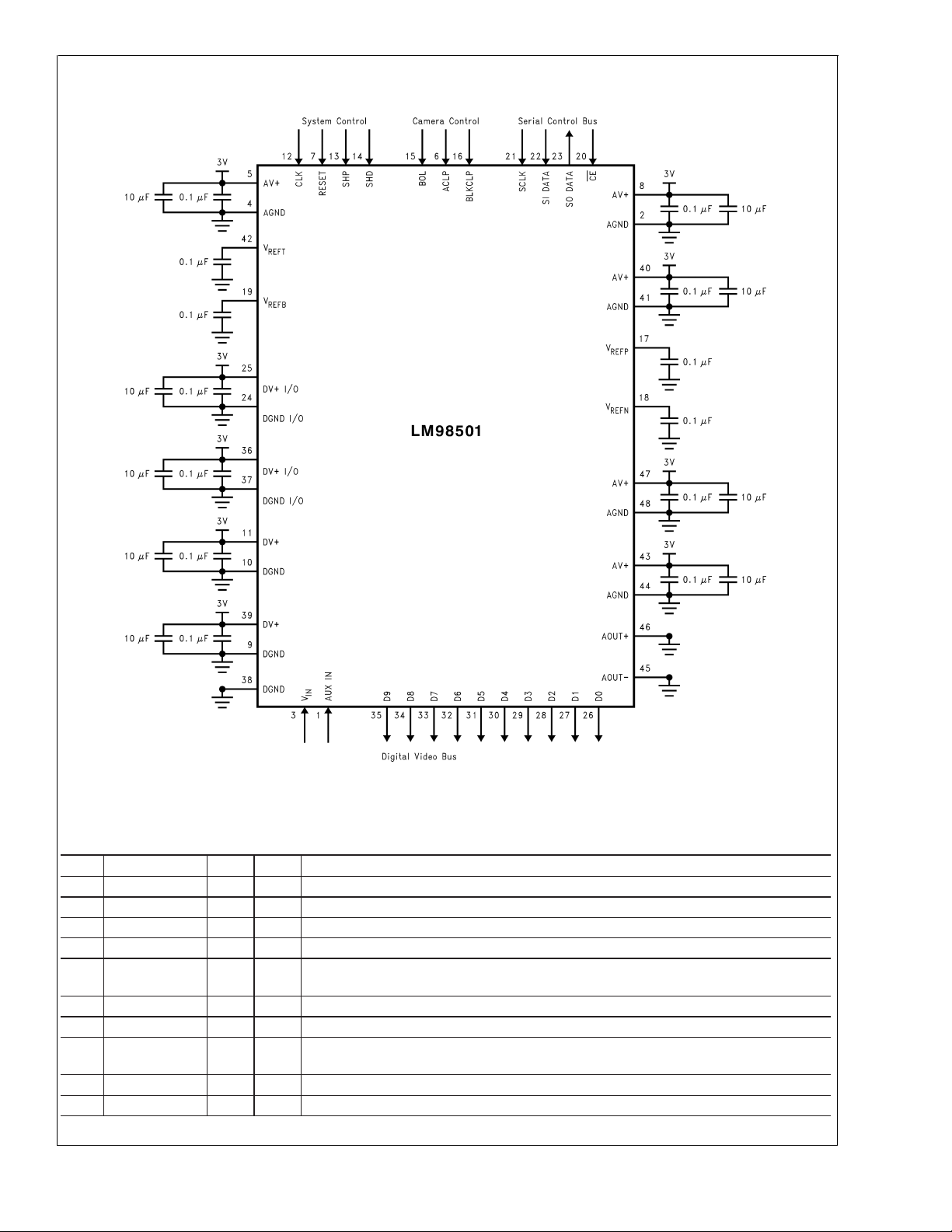

Typical Application Circuit

LM98501

DS101292-4

FIGURE 3. Typical Application Circuit Diagram

Pin Descriptions

Pin Name I/O Typ Description

1 AUX IN I A Auxiliary analog input.

2 AGND P Analog ground return.

3V

4 AGND P Analog ground return.

5 AV+ P +3V power supply for the analog circuits. Bypass each supply pin with 0.1 µF and

6 ACLP I D Analog clamp switch. Float pin when function not being used.

7 RESET I D Active-high master reset. Float pin when function not being used.

8 AV+ P +3V power supply for the analog circuits. Bypass each supply pin with 0.1 µF and

9 DGND P Digital ground return.

10 DGND P Digital ground return.

IN

I A Analog input. AC-couple input signal through a 0.1 µF capacitor

10 µF capacitors in parallel.

10 µF capacitors in parallel.

www.national.com3

Page 4

Pin Descriptions (Continued)

Pin Name I/O Typ Description

LM98501

11 DV+ P +3V power supply for the digital circuits. Bypass each supply pin with 0.1 µF and

10 µF capacitors in parallel.

12 CLK I D 27 MHz clock input.

13 SHP I D Correlated double sampler reset voltage clamp override. Programmable active-high or

active-low through serial interface. Connect to +3V digital supply when function not

being used (register values in default condition).

14 SHD I D Correlated double sampler video signal voltage sample override. Programmable

active-high or active-low through serial interface. Connect to +3V digital supply when

function not being used (register values in default condition).

15 BOL I D Active-high beginning of line switch input. Hold high during entire line of effective

pixels. Hold low during blanking period.

16 BLKCLP I D Active-high black level clamp switch input. Pulse high during black pixels to eliminate

black pixel offset from video signal.

17 V

18 V

19 V

REFP

REFN

REFB

20 CE

21 SCLK I D Serial interface clock used to decode the serial input data.

22 SI DATA I D Serial interface input port.

23 SO DATA O D Serial interface output port.

24 DGND I/O P Digital output driver ground return.

25 DV+ I/O P +3V power supply for the digital output driver circuits. Bypass each supply pin with

26 D0 O D Digital output. Bit 0 of 9 (LSB) of the digital video output bus.

27 D1 O D Digital output. Bit 1 of 9 of the digital video output bus.

28 D2 O D Digital output. Bit 2 of 9 of the digital video output bus.

29 D3 O D Digital output. Bit 3 of 9 of the digital video output bus.

30 D4 O D Digital output. Bit 4 of 9 of the digital video output bus.

31 D5 O D Digital output. Bit 5 of 9 of the digital video output bus.

32 D6 O D Digital output. Bit 6 of 9 of the digital video output bus.

33 D7 O D Digital output. Bit 7 of 9 of the digital video output bus.

34 D8 O D Digital output. Bit 8 of 9 of the digital video output bus.

35 D9 O D Digital output. Bit 9 of 9 (MSB) of the digital video output bus.

36 DV+ I/O P +3V power supply for the digital output driver circuits. Bypass each supply pin with

37 DGND I/O P Digital output driver ground return.

38 DGND P Digital ground return.

39 DV+ P +3V power supply for the digital circuits. Bypass each supply pin with 0.1 µF and 10

40 AV+ P +3V power supply for the analog circuits. Bypass each supply pin with 0.1 µF and 10

41 AGND P Analog ground return.

42 V

REFT

43 AV+ P +3V power supply for the analog circuits. Bypass each supply pin with 0.1 µF and 10

44 AGND P Analog ground return.

45 AOUT− O A Negative differential analog output from correlated double sampler or PGA (selectable

IO A Top of DAC reference ladder. Normally bypassed with a 0.1 µF capacitor. An external

DAC reference voltage may be applied to this pin.

IO A Bottom of DAC reference ladder. Normally bypassed with a 0.1 µF capacitor. An

external DAC reference voltage may be applied to this pin.

IO A Bottom of ADC reference ladder. Normally bypassed with a 0.1 µF capacitor. An

external ADC reference voltage may be applied to this pin.

I D Active-low chip enable for the serial interface.

0.1 µF and 10 µF capacitors in parallel.

0.1 µF and 10 µF capacitors in parallel.

µF capacitors in parallel.

µF capacitors in parallel.

IO A Top of ADC reference ladder. Normally bypassed with a 0.1 µF capacitor. An external

ADC reference voltage may be applied to this pin.

µF capacitors in parallel.

through the serial interface).

www.national.com 4

Page 5

Pin Descriptions (Continued)

Pin Name I/O Typ Description

46 AOUT+ O A Positive differential analog output from correlated double sampler or PGA (selectable

through the serial interface).

47 AV+ P +3V power supply for the analog circuits. Bypass each supply pin with 0.1 µF and 10

µF capacitors in parallel.

48 AGND P Analog ground return.

Legend: (I=Input), (O=Output), (IO=Bi-directional), (P=Power), (D=Digital), (A=Analog).

LM98501

www.national.com5

Page 6

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

LM98501

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Any Positive Supply Voltage 4.2V

Voltage on Any Input or Output Pin −0.3V to +4.2V

Input Current at Any Pin (Note 3)

Package Input Current (Note 3)

=

Package Dissipation at T

(Note 4)

25˚C

A

±

35 mA

±

50 mA

ESD Susceptibility (Note 5)

Human Body Model 2000V

Machine Model 200V

Soldering Temperature Infrared,

10 seconds (Note 6) 260˚C

DC and Logic Level Specifications

The following specifications apply for DV+=AV+=DV + I/O=+3.0V, C

noted. Boldface limits apply for T

Symbol Parameter Conditions

DIGITAL INPUT CHARACTERISTICS

V

IH

V

IL

I

IH

I

IL

Logical “1” Input Voltage 2.0 V

Logical “0” Input Voltage 1.0 V

Logical “1” Input Current VIH= DV+, Digital Inputs Except

Logical “0” Input Current VIL= DGND −100 nA

DIGITAL OUTPUT CHARACTERISTICS

V

OH

V

OL

I

OS

Logical “1” Output Voltage DV+ = 3.3V, I

Logical “0” Output Voltage DV+ = 3.3V, I

Output Short Circuit Current 30 mA

POWER SUPPLY CHARACTERISTICS

IA Analog Supply Current P

ID Digital Supply Current P

ID I/O Digital Output Driver Supply

Current

=

to T

T

A

MIN

: all other limits T

MAX

Reset

V

= DV+, Reset (internal

IH

pull-down resistor)

DV+ = 2.7V, I

DV+ = 2.7V, I

= LOW 56.8 mA

D

P

= HIGH 3.1 5.0 mA

D

= LOW 6.5 mA

D

P

= HIGH 0.1 1.0 mA

D

P

= LOW 2.3 mA

D

P

= HIGH 0.1 1.0 mA

D

Storage Temperature −65˚C to +150˚C

Operating Ratings (Notes 1, 2)

Operating Temperature Range 0˚C ≤ T

All Supply Voltages +2.7V to +3.3V

Voltage Range 0.0V to AV+

V

IN

Voltage Range 2.0V to 2.5V

V

REFT

Voltage Range 0.4V to 0.9V

V

REFB

Voltage Range 1.3V to 1.9V

V

REFP

Voltage Range 1.3V to 1.9V

V

REFN

All Digital Inputs Voltage Range −0.05V to +3.35V

=

10 pF, and f

L

=

25˚C (Note 7).

A

= −0.5 mA 2.5

OUT

= −0.5 mA 2.3

OUT

= 1.6 mA 0.4

OUT

= 1.6 mA 0.4

OUT

=

27 MHz unless otherwise

CLK

Min

(Note 9)

Typical

(Note 8)

100 nA

400 µA

Max

(Note 9)

≤ +70˚C

A

Units

V

V

Power Dissipation Specifications

The following specifications apply for DV+=AV+=DV + I/O=+3.0V, C

noted. Boldface limits apply for T

=

to T

T

A

MIN

: all other limits T

MAX

=

10 pF, and f

L

=

25˚C (Note 7).

A

Symbol Parameter Conditions

PWR Average Power Dissipation AV+=DV+=DV+ I/O=2.7V 150

AV+=DV+=DV+ I/O=3.3V 240

www.national.com 6

=

27 MHz unless otherwise

CLK

Min

(Note 9)

(Note 8)

Typical

Max

(Note 9)

Units

mWAV+=DV+=DV+ I/O=3.0V 195

Page 7

Correlated Double Sampler Specifications

The following specifications apply for DV+=AV+=DV + I/O=+3.0V, C

noted. Boldface limits apply for T

Symbol Parameter Conditions

V

IN

I

IN

C

IN

R

IN

t

AD

t

SHP

Input Voltage Level 1.0 V

Input Leakage Current 010nA

Input Capacitance 5pF

Input Resistance 10 kΩ

Aperture Delay 2ns

CLK Falling Edge to SHP Falling

Edge

t

SHD

CLK Rising Edge to SHD Falling

Edge

=

to T

T

A

MIN

: all other limits T

MAX

PGA Specifications

The following specifications apply for DV+=AV+=DV + I/O=+3.0V, C

noted. Boldface limits apply for T

Symbol Parameter Conditions

Gain Resolution 8 Bits

Step Size (Gain / Resolution) 0 0.125 dB

Maximum Gain 32.0 dB

Minimum Gain 0.0 dB

Gain Error

Gain Error

@

20 MHz Deviation from Best-Fit Line after

@

27 MHz Deviation from Best-Fit Line after

=

to T

T

A

MIN

: all other limits T

MAX

End-Point Correction

End-Point Correction

=

10 pF, and f

L

=

25˚C (Note 7).

A

=

10 pF, and f

L

=

25˚C (Note 7).

A

=

27 MHz unless otherwise

CLK

Min

(Note 9)

Typical

(Note 8)

10

14

=

27 MHz unless otherwise

CLK

Min

(Note 9)

Typical

(Note 8)

±

±

LM98501

Max

(Note 9)

Max

(Note 9)

5

5

Units

p-p

Units

%

%

Offset DAC and Black Level Clamp Specifications

The following specifications apply for DV+=AV+=DV + I/O=+3.0V, C

noted. Boldface limits apply for T

=

to T

T

A

MIN

: all other limits T

MAX

Symbol Parameter Conditions

R

REF

Reference Ladder Resistance 50 kΩ

Resolution

Offset Adjustment Range PGA Gain=1.0 dB

Black Level Clamp Accuracy PGA Gain=0.0 dB

PGA Gain=32.0 dB

t

BLKCLP

Black Clamp Switch Pulse Width 20 T

=

10 pF, and f

L

=

25˚C (Note 7).

A

Analog to Digital Converter Specifications

The following specifications apply for DV+=AV+=DV + I/O=+3.0V, C

noted. Boldface limits apply for T

=

to T

T

A

MIN

: all other limits T

MAX

Symbol Parameter Conditions

R

V

V

V

V

REF

REFT

REFB

REFT

REFB

Reference Ladder Resistance 850 1000 1150 kΩ

Top of Reference Ladder V

Bottom of Reference Ladder V

–

Differential Reference Voltage V

not driven externally 2.25 2.4 V

REFT

not driven externally 0.6 0.75 V

REFB

and V

REFT

REFB

externally

Overrange Output Code V

Underrange Output Code V

>

V

IN

REFT

<

V

IN

REFB

Guaranteed No Missing Codes 10 Bits

=

L

=

25˚C (Note 7).

A

not driven

10 pF, and f

=

27 MHz unless otherwise

CLK

Min

(Note 9)

Typical

(Note 8)

±

±

93 mV

±

0.5 LSB

±

0.5 LSB

=

27 MHz unless otherwise

CLK

Min

(Note 9)

Typical

(Note 8)

1.5 V

1023

0

Max

(Note 9)

Units

7 Bits

CLK

Max

(Note 9)

Units

www.national.com7

Page 8

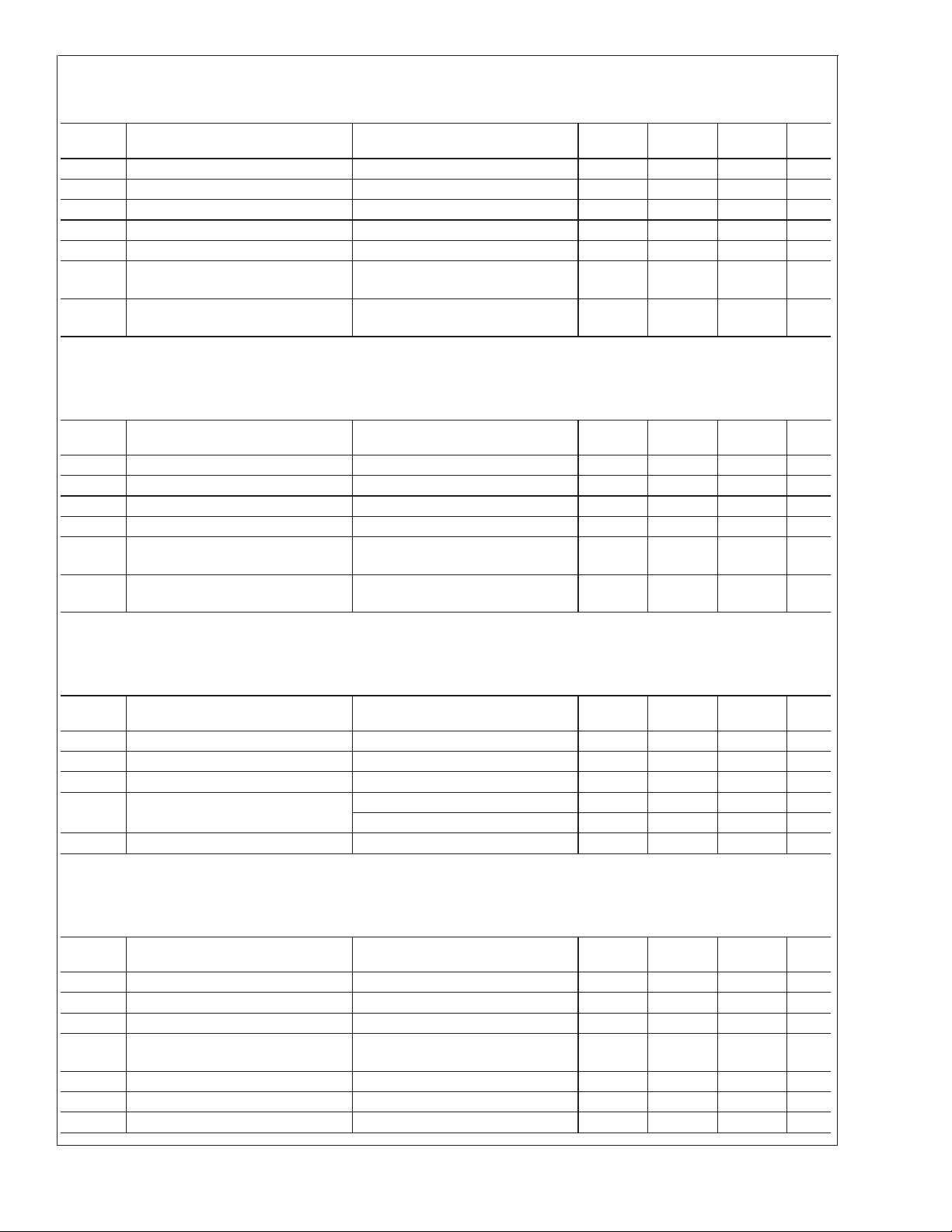

AC Electrical Characteristics

The following specifications apply for DV+=AV+=DV + I/O=+3.0V, C

Boldface limits apply for T

LM98501

=

to T

T

A

MIN

: all other limits T

MAX

Symbol Parameter Conditions

f

CLK

T

CLK

t

ch

t

cl

t

rc,tfc

Input Clock Frequency 1 27 30 MHz

Input Clock Period 33 37 1000 ns

Clock High Time

Clock Low Time

Clock Duty Cycle

@

CLK

max

@

CLK

max

@

CLK

max

Clock Input Rise and Fall Time 5 ns

Pipeline Delay (Latency) 7 T

t

VALID

t

OH

t

OD

Data Valid Time 27 ns

Output Data Hold Time 9 13 19 ns

Output Delay Time 14 20 26 ns

=

25˚C (Note 7).

A

=

10 pF, and f

L

(Note 9)

=

27 MHz unless otherwise noted.

CLK

Min

Typical

(Note 8)

Max

(Note 9)

15 ns

15 ns

45/55 min/max

Full Channel Performance Specifications

The following specifications apply for DV+=AV+=DV + I/O=+3.0V, C

noted. Boldface limits apply for T

=

to T

T

A

MIN

: all other limits T

MAX

=

10 pF, and f

L

=

25˚C (Note 7).

A

Symbol Parameter Conditions

DNL Differential Non-Linearity −1.0

INL Integral Non-Linearity +3.0/−1.5 LSB

=

*

SNR 0 dB Gain, 1.0V Input

ENOB Effective Number of Bits

THD Total Harmonic Distortion

*

20 log10(VIN/RMS Output Noise)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 2: All voltages are measured with respect to GND=AGND=DGND=0V, unless otherwise specified.

Note 3: When the voltage at any pin exceeds the power supplies (V

maximum package input current rating limits the number of pins that can safely exceed the power supplies with in input current of 25 mA to two.

Note 4: The absolute maximum junction temperature (T

junction-to-ambient thermal resistance (

*

JAis 69˚C/W, so P

LQFP,

device under normal operation will typically be about 180 mW. The values for maximum power dissipation listed above will be reached only when the LM98501 is

operated in a severe fault condition.

Note 5: Human body model is 100 pF capacitor discharged through a 1.5 kΩ resistor. Machine model is 220 pF discharged through 0Ω.

Note 6: See AN450, “Surface Mounting Methods and Their Effect on Product Reliability”, or the section entitled “Surface Mount” found in any post 1986 National

Semiconductor Linear Data Book, for other methods of soldering surface mount devices.

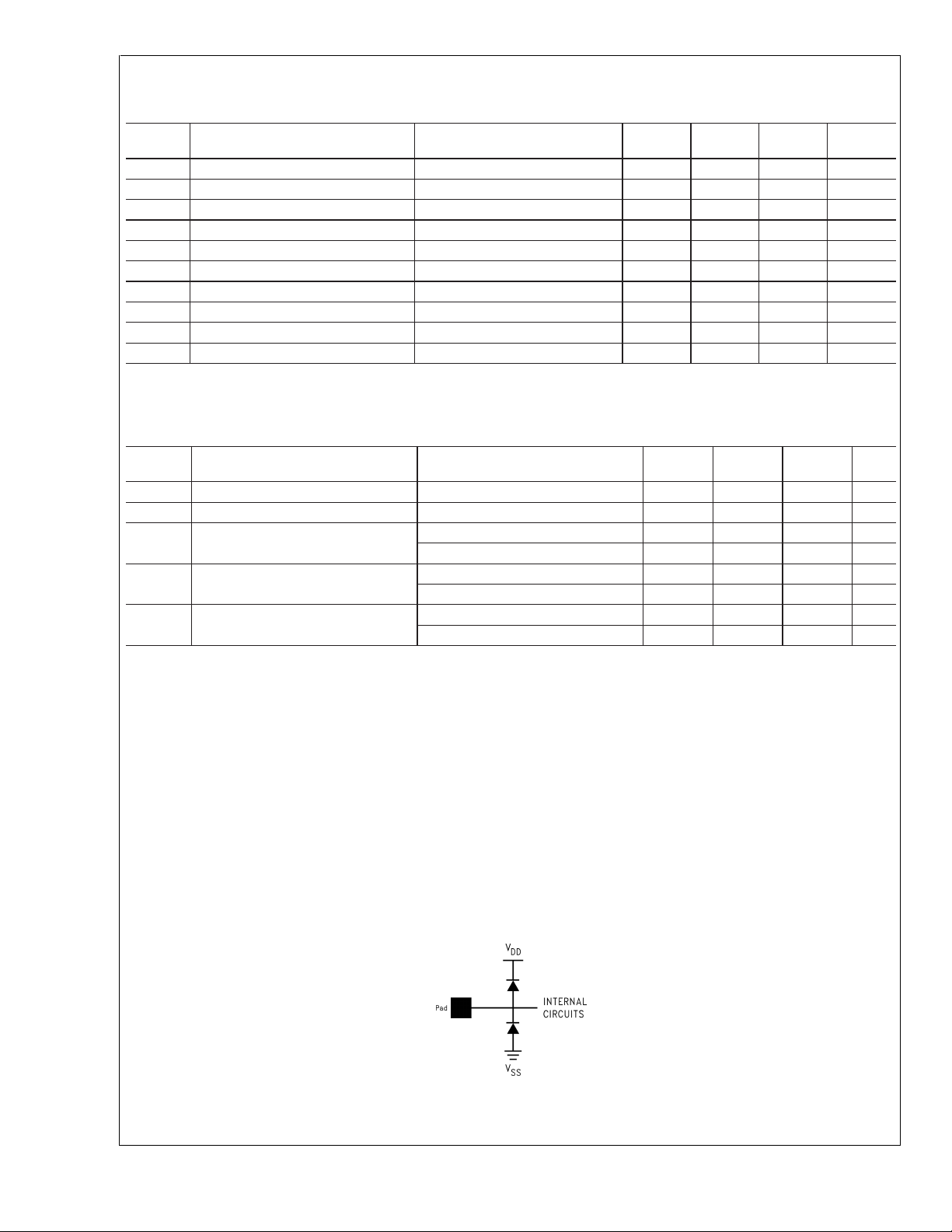

Note 7: The analog inputs are protected as shown below. Input voltage magnitude up to 500 mV beyond the supply rails will not damage this device. However, input

errors will be generated if the input goes above AV+ and below AGND.

DMAX

*

JA), and the ambient temperature (TA), and can be calculated using the formula P

=

1,811mW at 25˚C and 1,159 mW at the maximum operating ambient temperature of 70˚C. Note that the power dissipation of this

@

f

27 MHz 60 dB

CLK

=

@

f

20 MHz 61 dB

CLK

=

@

f

27 MHz 7.5 Bits

CLK

=

@

f

20 MHz 7.6 Bits

CLK

=

@

f

27 MHz −51 dB

CLK

=

@

f

20 MHz −60 dB

CLK

<

GND or V

IN

) for this device is 150˚C. The maximum allowable power dissipation is dictated by T

JMAX

>

AV+ or DV+), the current at that pin should be limited to 25 mA. The 50 mA

IN

=

27 MHz unless otherwise

CLK

Min

(Note 9)

Typical

(Note 8)

±

0.5 1.5 LSB

=

(T

DMAX

JMAX–TA

Max

(Note 9)

)/*JA. In the 48-pin

JMAX

Units

CLK

Units

, the

Note 8: Typical figures are at T

Note 9: Test limits are guaranteed to National’s AOQL (Averaging Outgoing Quality Level).

www.national.com 8

=

25˚C, and represent most likely parametric norms.

J

DS101292-18

Page 9

Typical Performance Characteristics

LM98501

DNL vs. Temperature

DNL vs. Clock Frequency

DS101292-19

DNL vs. Supply Voltage

DS101292-20

DNL vs. Clock Duty Supply

INL vs. Temperature

DS101292-21

DS101292-23

DS101292-22

INL vs. Supply Voltage

DS101292-24

www.national.com9

Page 10

Typical Performance Characteristics (Continued)

LM98501

INL vs. Clock Frequency

INL vs. Clock Duty Cycle

DS101292-25

Power Dissipation vs. Temperature

DS101292-27

Actual vs. Ideal PGA Gain and Clock Frequency

DS101292-26

Power Dissipation vs. Clock Frequency

DS101292-28

PGA Gain vs. Supply Voltage and Clock Frequency

DS101292-29

www.national.com 10

DS101292-30

Page 11

Typical Performance Characteristics (Continued)

LM98501

Grounded Input Noise

@

20 MHz Clock Frequency

DS101292-31

Spectral Response@20 MHz Clock Frequency

Grounded Input Noise@27 MHz Clock Frequency

DS101292-32

Spectral Response@27 MHz Clock Frequency

DS101292-33

DNL vs. Power Setting@27 MHz Clock Frequency

DS101292-35

DS101292-34

Power Dissipation vs. Power Setting

DS101292-36

www.national.com11

Page 12

CDS Sampling Timing

LM98501

1

SHP overrides the CLAMP signal’s falling edge for sampling the reset voltage (SHP is active-low by default).

2

The CLAMP signal is an internal signal derived from the CLK input whose falling edge samples the CCD reset voltage by default.

FIGURE 4. Pixel Rate Reset Voltage Sampling

1

SHP overrides the CLAMP signal’s falling edge for sampling the reset voltage (SHD is active-low by default).

2

The SAMPLE signal is an internal signal derived from the CLK input whose falling edge samples the CCD video signal by default.

FIGURE 5. Pixel Rate Video Signal Sampling

Horizontal Interval Timing

DS101292-5

DS101292-6

FIGURE 6. Typical Horizontal Interval Timing

www.national.com 12

DS101292-7

Page 13

Digital Output Timing

System Timing

LM98501

DS101292-8

FIGURE 7. Digital Output Data Timing

FIGURE 8. System Timing

System Overview

INTRODUCTION

The LM98501 is a 10-bit, complete analog-to-digital camera

signal processor for use with CCD imager systems operating

from a single +3V supply. The internal processing is carefully

optimized to maintain the signal-to-noise ratio and excellent

dynamic performance of most popular CCD imagers. The

system block diagram of the LM98501, shown on the cover

page of the datasheet, highlights the main features of the device: correlated double sampling (CDS), 0 dB–32 dB digitally

programmable gain amplifier (PGA), digital black level correction feedback loop, 8-bit DAC, analog clamp, bandgap

voltage reference, and a 10-bit, 27 MHz analog-to-digital

converter.

DS101292-9

CORRELATED DOUBLE SAMPLING

Correlated double sampling (CDS) is a key feature in CCD

image processors. The sampling process consists of two

samples being taken for each pixel. The first stores the reset

voltage of the input pixel, and the second stores the video

signal amplitude. The two samples are subtracted from one

another, effectively removing the reset error offset of each

pixel. This sampling system operates at 27 MHz, allowing

the use of imagers that have resolution at high speeds. Operation at these higher clock rates generates electronic images similar to a high-speed camera, preventing blearing of

the image caused by motion during the exposure.

www.national.com13

Page 14

System Overview (Continued)

LM98501

FIGURE 9. Correlated Double Sampling

PROGRAMMABLE GAIN AMPLIFIER

In a CCD imager, there may be millions of photo diodes that

normally have some gain variation from pixel to pixel. Other

gain errors are generated by the amount of light transmission and the quality of the color filters on the front of each

pixel of the imager. These filters make it possible for camera

to recognize color; therefore, each filter has to have correct

gain in order to generate the electronic voltages that would

be equal to white. Luminosity of a scene may have a colorcast, and the gain of a pixel must be changed in order to

compensate for the colorcast. These three sources of gain

error associated with each pixel are compensated for with a

wide bandwidth programmable gain amplifier that operates

at a pixel rate. The amplifier has a gain ranging from

0 dB–32 dB, and is “linear in dB” as shown in

linear in dB amplifier contains more gain steps in the lower

portion of the gain range so that color balance may be maintained during low light levels.

AUXILIARY INPUT

The LM98501 includes a high-level video switch that allows

a recorder playback video signal to be selected instead of

the camera image. This feature is especially useful when

adding electronic titles to images in the digital domain. In addition, the PGA gain and DAC offset are set to register 0 in

DS101292-10

Figure 16

.A

each case; therefore, appropriate gain and offset values

should be written to PGA gain and DAC offset register 0 prior

AUX IN usage.

BLACK LEVEL CLAMP

CCD signal processors require a reference level for the

proper handling of input signals; this reference level is commonly referred to as the black level. The LM98501 is designed to determine a signal’s black level during the CCD imager’s optical black pixels.

The LM98501 provides both an analog clamp and a digital

black level correction loop. Pulsing the ACLP pin during optical black pixels causes the analog clamp circuitry to remove the offset associated with the input signal. During

dummy black pixels at the end of a horizontal line, setting the

BLKCLP pin for a minimum of 20 CLK cycles enables the

digital black level correction loop.

Actual black level correction may be performed through one

of two available methods— automatic or manual. In automatic mode, the black level is sampled from the ADC output

during black pixels by setting the BLKCLP input of the

LM98501. The ADC black level output value is then averaged over eight pixels and subtracted from the desired black

level stored in the black level configuration register. The result of the subtraction may then be integrated by a preset

scaling factor, effectively smoothing any sharp transitions

present in the black level signal, before the resulting error is

finally applied to the input of the PGA as an analog offset

generated by the DAC. The offset integration scaling factor is

stored in two bits of the software control register 0, and the

values available range from the full offset to offset

divided-by-16. In addition, an offset output enable bit is provided in the software control register 0, which when set,

routes the offset value to the digital output bus rather than

the DAC. Use of the automatic mode involves enabling the

black level offset auto-calibration bit in the software control

register 0 through the serial interface.

The manual method is intended for use with processing systems where the desired black level correction loop is external to the LM98501. In this mode, up to four available configuration registers may be used to store predetermined

offset values that will be applied on a pixel-rate basis. During

the vertical interval, new values may be stored in these registers for each horizontal line.

FIGURE 10. Digital Black Level Correction Loop

www.national.com 14

DS101292-11

Page 15

System Overview (Continued)

ANALOG CLAMP

During optical black pixels, an offset often appears on the

CCD generated input signal. This offset may be seen by the

CDS circuitry as a valid video signal rather than the actual

black level signal; therefore, the LM98501 provides an analog clamp designed to eliminate this offset during black pixels. Pulsing the analog input pin, ACLP, causes the output of

the CDS to be sampled by the analog clamp circuitry. Subsequently, an adjustment is made to the CDS reference voltages by the analog clamp to effectively eliminate any offset

present in the signal during black pixels.

10-BIT ANALOG-TO-DIGITAL CONVERTER

The selected imager’s analog signal is sampled by the CDS

and amplified to match the input requirements of the 10-bit

analog-to-digital converter by the PGA. The final step performed by the system is to convert the selected analog image to digital values with a 10 bits of resolution. The ADC

has differential inputs and outputs (internally) which aids in

the coping with headroom constraints common to +3V systems. Data is acquired at the falling edge of the clock and is

available at the digital output pins 7.0 clock cycles plus t

later.

INTERNAL VOLTAGE REFERENCE

An on-board, temperature stable voltage reference is employed based on a differential, continuous-time bandgap circuit. The employment of this on-chip reference eliminates

the need for external reference drive circuitry and components, minimizing cost and board space in a design. The use

of external bypass capacitors from the reference pins to

ground is recommended for reducing reference drive requirements, resulting in reduced power dissipation. A second

on-chip reference is used exclusively for the offset DAC and

follows the same procedures for bypassing with external capacitors.

INTERNAL TIMING GENERATION

All if the necessary clocks for the CDS and ADC operation

are generated internally from the LM98501’s master clock input. The CDS sampling clocks may be overridden by the

user via the SHP and SHD clock inputs. As depicted in

ure 4

and

Figure 5

, there are two signals generated internally

for CDS sampling referred to as CLAMP and SAMPLE.

These signals provide the rising edge reference for the sampling of the CCD input signal. The timing of CLAMP and

SAMPLE is derived from the clock; therefore, shifting the

clock phasing with respect to the CCD input signal would

also shift the rising (and falling) edges of CLAMP and

SAMPLE. The actual sampling of the CCD’s reset voltage

and video signal is performed on the falling edges of the

CLAMP and SAMPLE signals respectively. The user may

modify the position of the falling edges where the sampling

of the CCD input occurs by driving the SHP and SHD inputs

of the LM98501. The falling edges of SHP and SHD will supersede the falling edges of CLAMP and SAMPLE respectively and cause the duration of the sample pulse to shorten

accordingly. As evidenced in

Figure 4

and

Figure 5

ing edges of SHP and SHD should not occur earlier than

t

SHP

or t

after the respective falling [SHP] (or rising

SHD

[SHD]) edge of CLK.

OD

Fig-

, the fall-

SERIAL INTERFACE AND CONFIGURATION

REGISTERS

There are many options available to the user that may be

programmed via the LM98501’s serial interface. Configuration values are stored in registers for use by several functions such as programmable gain, offset, black level, and

color filter array.

The LM98501’s serial interface is used to store values into

16 8-bit configuration registers. Upon power-up or external

reset, the configuration registers will contain their respective

default values. Default values place the LM98501 in ‘single

channel’ mode, where only one PGA gain and offset are applied to the input signal.

The master CLK input is required to be running during serial

interface commands. Each command issued through the serial interface must have a minimum of 13 data bits (see

ures 13, 14

).

Fig-

PGA GAIN

The four PGA gain registers store four possible gain values

for the programmable gain amplifier (PGA). For example,

these four gain values may correspond to four possible colors in a color filter array.

ANALOG OFFSET

The analog offset registers store four possible values that

correspond to the four gain values. For example, the value

stored in the PGA gain register 0 (address 0h) is used in conjunction with the offset value stored in the analog offset register 0 (address 4h). This allows for four possible combinations of PGA gain and analog offset, one for each color filter.

These registers are read-only when offset auto-calibration is

enabled in the software control register 0. It should be noted

that each offset DAC step (1 LSB) corresponds to a 0.4 LSB

step at the ADC output. Therefore, if an offset of 20 digital

codes is desired at theADC output, a digital code value of 50

should be stored in the analog offset register(s). As a result,

the maximum offset seen at the ADC output as a result of

digital code values stored in the analog offset register(s) is

±

54 codes. It is possible to increase the digital output range

of the analog offset DAC, resulting in a increased maximum

ADC output code corresponding to a given DAC input. for

more information on increasing the DAC range, please see

ANALOG OFFSET DAC RANGE ADJUSTMENT

.

OUTPUT BLACK LEVEL

The output black level register is occupied by an 8-bit word

stored by the user that specifies the output level corresponding to optical black. For example, a user that wants an output

level of 16 for black pixels must write this value into the register during the horizontal interval. Once this has been accomplished, driving the BLKCLP high for 20 cycles of CLK

activates the digital black clamp loop and the black level is

forced to the value stored in the output black level register, in

the example case the code value of 16. As a result of the relationship between the DAC input and the ADC output (see

’Analog Offset’), the largest output black level code the

LM98501 is capable of clamping to is 54 codes.

LM98501

www.national.com15

Page 16

System Overview (Continued)

LM98501

DS101292-37

FIGURE 11. ADC Output vs. Black Level Register Value

COLOR FILTER ARRAY (CFA) CONFIGURATION

In order to utilize the LM98501’s programmable pixel-rate

gain, a color filter array (CFA)pattern must be defined. Some

commonly used CFApatterns are as follows:

Bayer Pattern

Line 0 Green Red Green Red

Line 1 Blue Green Blue Green

CMYG Pattern

Line 0 Cyan Magenta Yellow Green

Line 1 Cyan Green Yellow Magenta

Therefore, two 8-bit words must be written to the CFA line

registers to specify the CFA pattern being used. Also, two

2-bit numbers must be written to the CFA definition register

indicating the number of pixels per pattern in each line of the

defined CFA pattern. The information contained in the CFA

line registers indicates the registers where the respective

PGA gain and offset values are stored. For example, a system using the Bayer pattern defined above would first write

four PGA gains and their respective offsets into the four PGA

gain and four analog offset registers. Next, two 8-bit words

(one word/CFA line) would be written to the CFA configuration registers. The 8-bit CFA configuration words each consist of four 2-bit numbers, each of which is the address for

the gain and offset values of the color that appears in that location in the CFA line. Finally, two 2-bit numbers specifying

the number of elements in each CFAline must be written into

the CFAdefinition register. A CFAconfiguration will then contain four 2-bit numbers indicating the registers where the

gain and offset values are located for a maximum of four colors on each CFA line. In addition, the CFA definition register

will contain two 2-bit numbers that designate the number of

elements used in each CFA line for the particular CFA pattern being applied to the system.

Example A contains a CFA pattern that repeats the colors

cyan and magenta on the first line, and repeats the pattern

blue, green, green, blue on the second line. Each 2-bit number in the CFA line registers refers to a common set of PGA

gain and offset registers for each color. The first line indi-

cates that the color magenta uses the gain and offset values

stored in PGA gain register 1 (address 1h) and analog offset

register 1 (address 5h). Also, the first line indicates that the

color cyan uses the gain and offset values in PGA gain register 2 (address 2h) and analog offset register 2 (address

6h). The second line indicates gain and offset values for the

color blue and the color green in the same fashion as the first

line.

Example A

70

CFA Line 0 XX XX 01 10

CFA Line 1 11 00 00 11

CFA Definition 00 00 11 01

In addition to specifying the gain and offset for each line, it is

also necessary to specify the number of elements contained

in each CFAline’s pixel pattern. The CFAdefinition register is

used to store this value (number of elements per line). In example A, the user has stored the 2-bit binary number 01 into

the CFA definition register’s two LSB’s indicating that the

pattern in line 0 contains two repeating colors or elements.

Also, the 2-bit binary number 11 has been written into bit 2

and bit 3 of the CFAdefinition register indicating that the respective CFA pattern contains four repeating colors or elements, as the colors blue and green alternate position in the

example pattern.

Once both lines for the pattern have been stored, it is applied

when the beginning of line (BOL) signal is asserted by the

user. One line of the CFA pattern is applied repeatedly until

the BOL signal is reset (at the end of the current line). Once

the BOL signal is set again, the CFA line information is

changed from that defined by the CFAline 0 register to that

defined by the CFA line 1 register and the process starts

again. For more details of the timing of the BOL signal,

please refer to

SOFTWARE CONTROL

There are two software control registers accessible via the

serial interface. The software control registers are divided

into customer (register 0) and advanced (register 1) functions. Please refer to the register data descriptions for more

information on the software control registers.

POWER LEVEL CONTROL

The LM98501 is equipped with two power trim registers that

may be used to adjust power levels of various circuits internal to the device. In its default condition, the LM98501 is set

for optimum power and performance, and modifying the values stored in the power level control registers will affect performance as a result of the change in power level(s). In applications where maximum performance is desired, the

default values should be used. Otherwise, power levels may

be decreased at the slight expense of performance. Please

refer to the register data descriptions for more information

regarding the power level control registers.

TheADC coarse and fine bank power adjustment bits are located in the power level control 2 register, bits 7:4. Altering

these bits may significantly affect performance and power

dissipation. Please see “DNL vs. Power Control Setting

27 MHz Clock Frequency” and “Power Dissipation vs. Power

Control Setting” on page 11.

Figure 6

.

@

www.national.com 16

Page 17

Register Memory Map

Title Address Default Value

PGA Gain 0 0000 0000 0000 (0d)

PGA Gain 1 0001 0000 0000 (0d)

PGA Gain 2 0010 0000 0000 (0d)

PGA Gain 3 0011 0000 0000 (0d)

Analog Offset 0 0100 0000 0000 (0d)

Analog Offset 1 0101 0000 0000 (0d)

Analog Offset 2 0110 0000 0000 (0d)

Analog Offset 3 0111 0000 0000 (0d)

CFA Configuration 0 1000 0000 0000 (0d)

CFA Configuration 1 1001 0000 0000 (0d)

CFA Definition 1010 XXXX 0000 (0d)

Output Black Level 1011 0001 0000 (32d)

Software Control 0 1100 0100 1110 (78d)

Software Control 1 1101 XX00 0X00 (0d)

Power Level Control 0 1110 1010 1010 (170d)

Power Level Control 1 1111 0101 1010 (90d)

FIGURE 12. Register Memory Map

Register Data

The following section describes all available registers in the

LM98501 register bank and their functions.

PGA GAIN REGISTERS

Register Name PGA Gain 0

Address 0 Hex

Type Read/Write

Reset Value 0000 0000 Binary

Bit Bit Symbol Description

[7:0] PGA Gain 0.0 dB–32.0 dB in 0.125 dB

steps.

Register Name PGA Gain 1

Address 1 Hex

Type Read/Write

Reset Value 0000 0000 Binary

Bit Bit Symbol Description

[7:0] PGA Gain 0.0 dB–32.0 dB in 0.125 dB

steps.

Register Name PGA Gain 2

Address 2 Hex

Type Read/Write

Reset Value 0000 0000 Binary

Bit Bit Symbol Description

[7:0] PGA Gain 0.0 dB–32.0 dB in 0.125 dB

steps.

Reset Value 0000 0000 Binary

Bit Bit Symbol Description

[7:0] PGA Gain 0.0 dB–32.0 dB in 0.125 dB

steps.

ANALOG OFFSET REGISTERS

Register Name Analog Offset 0

Address 4 Hex

Type Read/Write

Reset Value 0000 0000 Binary

Bit Bit Symbol Description

[7:0] Signed Analog

Offset

Register Name Analog Offset 1

Address 5 Hex

Type Read/Write

Reset Value 0000 0000 Binary

Bit Bit Symbol Description

[7:0] Signed Analog

Offset

Register Name Analog Offset 2

Address 6 Hex

Type Read/Write

Reset Value 0000 0000 Binary

Digital representation of the

analog offset to be applied to

the input of the PGA. See

“Analog Offset” on page 15.

Digital representation of the

analog offset to be applied to

the input of the PGA. See

“Analog Offset” on page 15.

LM98501

Register Name PGA Gain 3

Address 3 Hex

Type Read/Write

www.national.com17

Page 18

Register Data (Continued)

LM98501

Bit Bit Symbol Description

[7:0] Signed Analog

Offset

Register Name Analog Offset 3

Address 7 Hex

Type Read/Write

Reset Value 0000 0000 Binary

Bit Bit Symbol Description

[7:0] Signed Analog

Offset

COLOR FILTER ARRAY REGISTERS

Register Name Color Filter Array Configuration 0

Address 8 Hex

Type Read/Write

Reset Value 0000 0000 Binary

Bit Bit Symbol Description

[7:6] Line0:Pixel3

Gain/Offset

[5:4] Line0:Pixel2

Gain/Offset

[3:2] Line0:Pixel1

Gain/Offset

[1:0] Line0:Pixel0

Gain/Offset

Register Name Color Filter Array Configuration 1

Address 9 Hex

Type Read/Write

Reset Value 0000 0000 Binary

Bit Bit Symbol Description

[7:6] Line1:Pixel3

Gain/Offset

[5:4] Line1:Pixel2

Gain/Offset

Digital representation of the

analog offset to be applied to

the input of the PGA. See

“Analog Offset” on page 15.

Digital representation of the

analog offset to be applied to

the input of the PGA. See

“Analog Offset” on page 15.

2 LSB’s of register

addresses where the gain

and offset for pixel 3 of the

CFA pattern are stored.

2 LSB’s of register

addresses where the gain

and offset for pixel 2 of the

CFA pattern are stored.

2 LSB’s of register

addresses where the gain

and offset for pixel 1 of the

CFA pattern are stored.

2 LSB’s of register

addresses where the gain

and offset for pixel 0 of the

CFA pattern are stored.

2 LSB’s of register

addresses where the gain

and offset for pixel 3 of the

CFA pattern are stored.

2 LSB’s of register

addresses where the gain

and offset for pixel 2 of the

CFA pattern are stored.

Bit Bit Symbol Description

[3:2] Line1:Pixel1

Gain/Offset

[1:0] Line1:Pixel0

Gain/Offset

Register Name Color Filter Array Definition

Address A Hex

Type Read/Write

Reset Value XXXX 0000 Binary

Bit Bit Symbol Description

[3:2] Line 1 Pixels Number of pixels in CFA

[2:1] Line 0 Pixels Number of pixels in CFA

OUTPUT BLACK LEVEL REGISTER

Register Name Output Black Level

Address B Hex

Type Read/Write

Reset Value 0001 0000 Binary

Bit Bit Symbol Description

[7:0] Black Level 0–256 output black level

SOFTWARE CONTROL REGISTERS

Register Name Software Control 0 (Customer)

Address C Hex

Type Read/Write

Reset Value 0100 1110 Binary

Bit Bit Symbol Description

[7] Offset Output

Enable

[6] Serial Output

Enable

[5:4] Offset

Integration

2 LSB’s of register

addresses where the gain

and offset for pixel 1 of the

CFA pattern are stored.

2 LSB’s of register

addresses where the gain

and offset for pixel 0 of the

CFA pattern are stored.

pattern defined in CFA line

1.

pattern defined in CFA line

0.

digital code value. (see

“Output Black Level” on

page 15)

Directs the offset error

calculated by the digital

black level correction loop to

the 10 digital output data

pins.

Enables the serial interface

output for reading register

values.

Offset integration factor

selection:

00 No Scaling

01 Divide-by-4

10 Divide-by-8

11 Divide-by-16

www.national.com 18

Page 19

Register Data (Continued)

Bit Bit Symbol Description

[3] Offset

Auto-Calibration

Enable

[2] SHP/SHD

Active-HIGH

Enable

[1] CDS Enable

(AUX-In

Disable)

[0] Analog Power

Down

Register Name Software Control 1 (Customer)

Address D Hex

Type Read/Write

Reset Value XX00 0X00 Binary

Bit Bit Symbol Description

[5:4] Analog Output

Select

[3] Analog Output

Enable

[1] ADC Reference

Select

[0] DAC Reference

Select

Enables the digital black

level correction loop.

offset registers are read-only

when offset auto-calibration

is enabled.

Inverts the SHP and SHD

inputs causing the CDS to

sample on the rising edges

of SHP and SHD.

Sampling

is performed on the falling

edges of SHP and SHD

when the signals are

Active-low.

Instructs the CDS to sample

the CCD input.

Otherwise,

the AUX In input is sampled

in sample-and-hold mode.

Cuts power to the on-chip

analog circuitry including the

CDS, PGA, ADC, and

bandgap references.

Routes the selected internal

analog signal to the

differential analog output

pins AOUT+ and AOUT−.

00 CDS

01 PGA Stage 1

10 PGA Stage 2

11 PGA Stage 3

Enables the differential

analog output pins AOUT+

and AOUT−. If the analog

outputs are disabled, the

pins should not be loaded.

Reference biasing selection

for the analog-to-digital

converter.

0 Passive Biasing

(Resistors)

1 Active Biasing

(Bandgap)

Reference biasing selection

for the digital-to-analog

converter.

0 Active Biasing

(Bandgap)

1 Passive Biasing

(Resistors)

Analog

Register Name Power Level Control 0

Address E Hex

Type Read/Write

Reset Value 1010 1010 Binary

Bit Bit Symbol Description

[7:6] PGA Stage 1

Amplifier Bias

[5:4] PGA

Common-Mode

Input Bias

[3:2] CDS Amplifier

Bias

[1:0] CDS

Common-Mode

Input Bias

Register Name Power Level Control 1

Address F Hex

Type Read/Write

Reset Value 0101 1010 Binary

Bit Bit Symbol Description

[7:6] ADC Coarse

Bank Bias

[5:4] ADC Fine Bank

Bias

[3:2] PGA Stage 3

Amplifier Bias

[1:0] PGA Stage 2

Amplifier Bias

Adjusts the power level of

the PGA stage 1 amplifier.

The power level is relative to

the value of the binary

number stored.

Adjusts the power level of

the PGA common-mode

input. The power level is

relative to the value of the

binary number stored.

Adjusts the power level of

the CDS amplifier. The

power level is relative to the

value of the binary number

stored.

Adjusts the power level of

the CDS common-mode

input. The power level is

relative to the value of the

binary number stored.

Adjusts the power level of

the ADC coarse bank. The

power level is relative to the

value of the binary number

stored.

Adjusts the power level of

the ADC fine bank. The

power level is relative to the

value of the binary number

stored.

Adjusts the power level of

the PGA stage 3 amplifier.

The power level is relative to

the value of the binary

number stored.

Adjusts the power level of

the PGA stage 2 amplifier.

The power level is relative to

the value of the binary

number stored.

LM98501

www.national.com19

Page 20

Serial Interface Timing Specifications

The following specifications apply AV+=DV+=DV + I/O=+3.0V, C

LM98501

Boldface limits apply for T

=

to T

T

A

MIN

: all other limits T

MAX

Symbol Parameter Conditions

t

MIN

SCLK Period 36 ns

SCLK Duty Cycle 40/60 50/50 60/40

SCLK Rise/Fall Time 4ns

t

IH

t

IS

t

CESC

t

SCCE

Input Hold Time 5 ns

Input Setup Time 6 ns

SCLK Start Time after CE Low 10 ns

CE Low after Last SCLK Rising

Edge

t

CEW

CE Pulse Width MCLK must be active during serial

interface commands.

t

t

DCE

OD

Input Data to CE Rising Edge 15 t

Output Delay Time 15 ns

Serial Interface Timing

L

=

25˚C (Note 7).

A

=

10 pF, and f

=

27 MHz unless otherwise noted.

CLK

Min

(Note 9)

Typical

(Note 8)

Max

(Note 9)

Units

%

5ns

2T

CLK

MIN

1

Serial output enable must be set in software control 0 for SO DATA output. Please see

FIGURE 13. Serial Interface Read Command Timing

1

Serial output enable must be set in software control 0 for SO DATA output. Please see

FIGURE 14. Serial Interface Write Command Timing

Register Data

Register Data

DS101292-12

section for more information.

DS101292-13

section for more information.

www.national.com 20

Page 21

PGA Gain Plots

LM98501

DS101292-14

FIGURE 15. PGA Gain (Linear Scale) vs. PGA Gain Code

FIGURE 16. PGA Gain (Logarithmic Scale) vs. PGA Gain Code

Applications Information

ANALOG-TO-DIGITAL CONVERTER REFERENCE

BYPASSING

Figure 17

minimal components. The V

each be bypassed to analog ground with 10 µF tantalum as

well as 0.1 µF ceramic capacitors. In a case where the internally generated reference voltages are not sufficient, the

user may supply external voltages to the reference pins.

However, the reference pin V

of 2.0V to 2.5V. Similarly, V

range of 0.4V to 0.9V.Any device used to drive the reference

pins should be able to source adequate current into the

V

REFT

the reference resistor ladder is at its minimum resistivity of

850Ω.

The reference voltage at the top of the resistor ladder

(V

tom of the resistor ladder (V

1.8V above. V

0.9V above ground. However, noise effects will be minimized

and accurate conversions insured when the total reference

voltage is approximately 2.25V and offset from ground by

0.75V.

shows a simple reference bypassing scheme with

and V

REFT

should be within the range

REFT

should be driven in the

REFB

and sink adequate current from the V

) may be as low as 1.2V above the voltage at the bot-

REFT

may be as low as 0.4V and as high as

REFB

) and may be as high as

REFB

REFB

REFB

pins should

pin when

DS101292-15

DS101292-16

FIGURE 17. Reference Bypassing

ANALOG OFFSET DAC REFERENCE BYPASSING

The analog offset DAC reference pins, VREFP and VREFN,

should be capacitively bypassed in the same fashion as the

ADC reference pins VREFT and VREFB (see

’Analog-to-Digital Converter Reference Bypassing’).

www.national.com21

Page 22

Applications Information (Continued)

ANALOG OFFSET DAC RANGE ADJUSTMENT

LM98501

The analog offset DAC has an input range of

Register Data

mately 0.4 LSB at the ADC output per DAC input code LSB

step. Therefore, the offset DAC is limited to providing offset

values less than or equal to

some applications, this range of output may not be sufficient.

It is possible to increase the range of the DAC by adjusting

the DAC reference range. The DAC reference range may be

adjusted by lowering the voltage at the DAC lower reference

pin, VREFN via use of a pull-down resistor from VREFN to

AGND. A resistor value of x.xx kΩ will increase the DAC

range by a factor of 1.25x, allowing offsets of

applied at the ADC output rather than the default maximum

and minimum offsets of

step to 1 LSB ADC output step relationship. Likewise, a resistor value of 750Ω will increase the DAC range by a factor

of 2.5x, allowing offsets of

ADC output, in this configuration, 1 LSB step of the DAC corresponds to 1 LSB step at the ADC output.

POWER SUPPLY CONSIDERATIONS

The LM98501 may draw a sufficient amount of current to

corrupt improperly bypassed power supplies. A 10 µF to

50 µF capacitor should be placed within 1 cm of the analog

power (AV+) pins of the device in parallel with a 0.1 µF ceramic chip capacitor placed as close to the device as layout

permits. Leadless chip capacitors are preferred because

they have a low lead inductance. As is the case with virtually

all high-speed semiconductors, the LM98501 should be assumed to have little power supply rejection; therefore, a

noise-free analog power source is required.

The analog and digital power supplies of the LM98501

should be sourced from the same supply voltage, but the

supply pins should be well isolated from one another. Isolating the supplies prevents digital noise from coupling back

into the analog supply pins. A choke (ferrite bead) is recommended to be placed between the analog and digital power

supply pins as well as a ceramic chip capacitor placed as

close as possible to the analog supply pin(s) of the device.

Additionally, it is not recommended that the LM98501’s digital supply be used for any other digital circuitry on the circuit

board. All other digital devices should be powered from a

separate digital supply well isolated from both the analog

and digital supplies of the LM98501.

THE LM98501 CLOCK

Although the LM98501 is tested and its performance guaranteed with a 27 MHz clock, it typically will function with clock

frequencies ranging from 1 MHz to 30 MHz. Performance is

best if the clock rise and fall times are less than 5 ns and the

clock trace is terminated near the clock input pin with a series RC network consisting of a 100Ω resistor and a 47 pF

capacitor.

LAYOUT AND GROUNDING TECHNIQUES

The proper routing of all signals and pertinent grounding

techniques are essential to insure the best signal-to-noise

ratio and dynamic performance possible. Separate analog

and digital ground planes ease meeting the datasheet limits.

). This analog offset corresponds to approxi-

±

54 LSB at the ADC output. In

±

54 LSB, resulting in a 2 LSB DAC

±

127 LSB to be applied at the

±

±

127 LSB (see

64 LSB to be

The analog ground plane should be low impedance and free

from noise of other components of the system.All bypass capacitors should be located as close to the pin as possible

and connected to the appropriate ground plane with short

<

traces (

noisy signal traces to avoid coupling of spurious signals into

the input.

Figure 18

power supply routing, ground plane separation, and bypass

capacitor placement. All input amplifiers, filters, and reference components should be placed on or over the analog

ground plane. All digital circuitry and I/O lines should be

placed over and grounded via the digital ground plane. Digital and analog signal lines should never run parallel to each

other in close proximity with each other. These signals

should only cross when absolutely necessary and then only

at 90˚ angles.

DYNAMIC PERFORMANCE

The LM98501 is AC tested and its dynamic performance is

guaranteed. The clock source driving the CLK input must be

free of jitter. For best AC performance, the clock source

should be isolated from other system digital circuitry with a

clock tree buffer(s). Meeting noise specifications depends

largely upon keeping digital noise out of the analog input of

the LM98501.

COMMON APPLICATION PITFALLS

Driving the inputs (analog or digital) beyond the power

supply potential. For proper operation, all input potentials

should not be greater than 300 mV above that of the power

supply. It is not uncommon for high speed digital circuits

(e.g. 74F and 74AC devices) to exhibit undershoot that falls

to a potential greater than 1.0V below the ground potential

and overshoot that rises to a potential greater than 1.0V

above the power supply potential. A resistor of 50Ω to 100Ω

in series with the offending digital input will, in most cases,

eliminate this problem.

Attempting to drive a high capacitance digital data bus.

The more capacitance the output drivers have to charge for

each conversion output, the more instantaneous digital current is required from the DV+ I/O and DGND I/O supply pins.

These large charging current spikes can couple into the analog section and subsequently may degrade dynamic performance of the system. Adequate bypassing and maintaining

separate analog and digital ground planes will reduce this

problem on the application system board. Buffering the digital data outputs may be necessary if the data bus being

driven by the LM98501 is heavily loaded. Dynamic performance may also be improved by adding series resistors of

47Ω at each digital output.

Driving the reference pins with devices that cannot

source or sink the current required by the reference resistor ladder. As mentioned previously, any devices driving

the reference resistor ladder must source sufficient current

into the top of the ladder. Additionally, the device connected

to the bottom of the ladder must be able to sink the necessary amount of current to keep the reference voltage(s)

stable. If the reference resistor ladder voltages are not stable

the converter output will not generate predictable output

codes.

1 cm). The analog input should be isolated from

provides an example of a suitable layout, including

www.national.com 22

Page 23

Applications Information (Continued)

LM98501

FIGURE 18. Recommended Layout Pattern

DS101292-17

www.national.com23

Page 24

Physical Dimensions inches (millimeters) unless otherwise noted

LM98501 10-Bit, 27 MSPS Camera Signal Processor

48-Lead LQFP Package

Order Number LM98501CCVBH

NS Package Number VBH48A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 180-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...