Page 1

1 www.national.com

General Description

The LM9 822 is a hig h performan ce Analog Front End (AFE) for

image sensor processing systems. It performs all the analog and

mixed signal functions (correlated double sampling, color specific gain and offset correction, and analog to digital conversion)

necessary to digitiz e the output of a w ide variety of CIS and

CCD sensors. The LM9822 has a 14 bit 6MHz ADC.

Features

• 6 million pixels/s conversion rate

• Digitally programmed gain and offset for red, green and blue

color balancing

• Correlated Double Sampling for lowest noise from CCD

sensors

• Compatible with CCD and CIS type image sensors

• Internal Voltage Reference Generation

• TTL/CMOS compatible inp ut/output

Key Specifications

• Output Data Resolution 14 Bits

• Pixel Conversion Rate 6MHz

• Analog Supply Voltage 5V±5%

• I/O Supply Voltage 3.3V±10% or 5V±5%

• Power Dissipation (typical) 375mW

Applications

• Color Flatbed Document Scanners

• Color Sheetfed Scanners

• Multifunction Imaging Products

• Digital Copiers

• General Purpose Linear Array Imaging

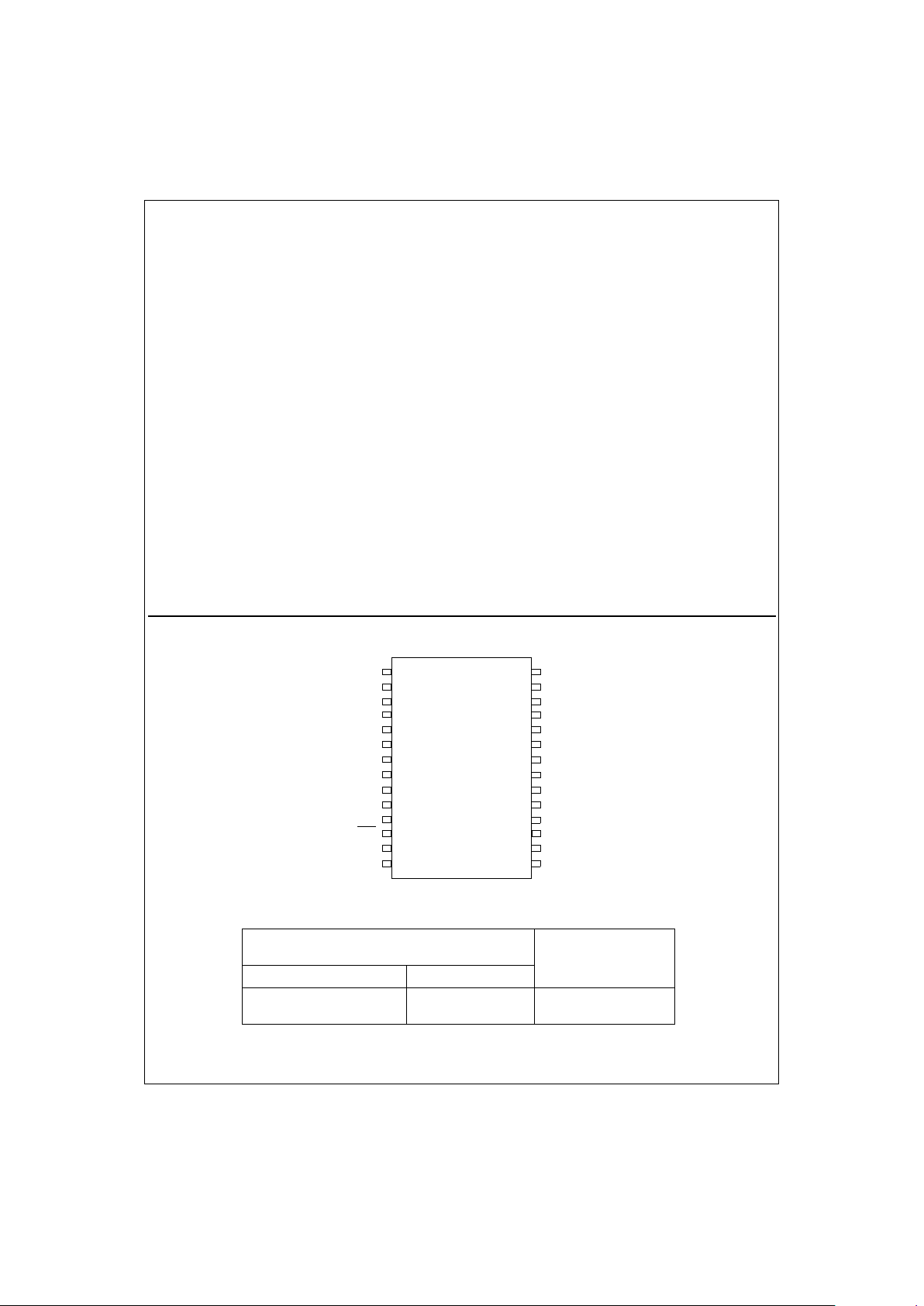

LM9822 3 Channel 42-Bit Color Scanner Analog Front End

Connection Diagram

LM9822

28 pin

SOIC

SCLK

SDI

SEN

D2

D0

V

D

DGND

D4

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

23

22

21

24

25

26

27

28

D7

D6

D5

MCLK

V

A

V

A

V

REF-

OS

B

OS

G

CLMP

OS

R

V

REF+

AGND

AGND

VSMP

SDO

V

REFMID

V

BANDGAP

D3

D1

May 1999

LM9822 3 Channel 42-Bit Color Scanner Analog Front End

N

©1999 National Semiconductor Corporation

TRI-STATE® is a registered trademark of National Semiconductor Corporation.

Ordering Information

Notes: 1 - Rail tran spo r t med i a, 2 6 pa rt s per rail, 2 - Tape and reel transport media, 1000 parts per reel

Temperature Range

0°C ≤ T

A

≤ +70°C

NS Package

Number

Order Number Device Marking

LM9822CCWM

1

LM9822CCWMX

2

LM9822CCWM

LM9822CCWM

M28B

M28B

Page 2

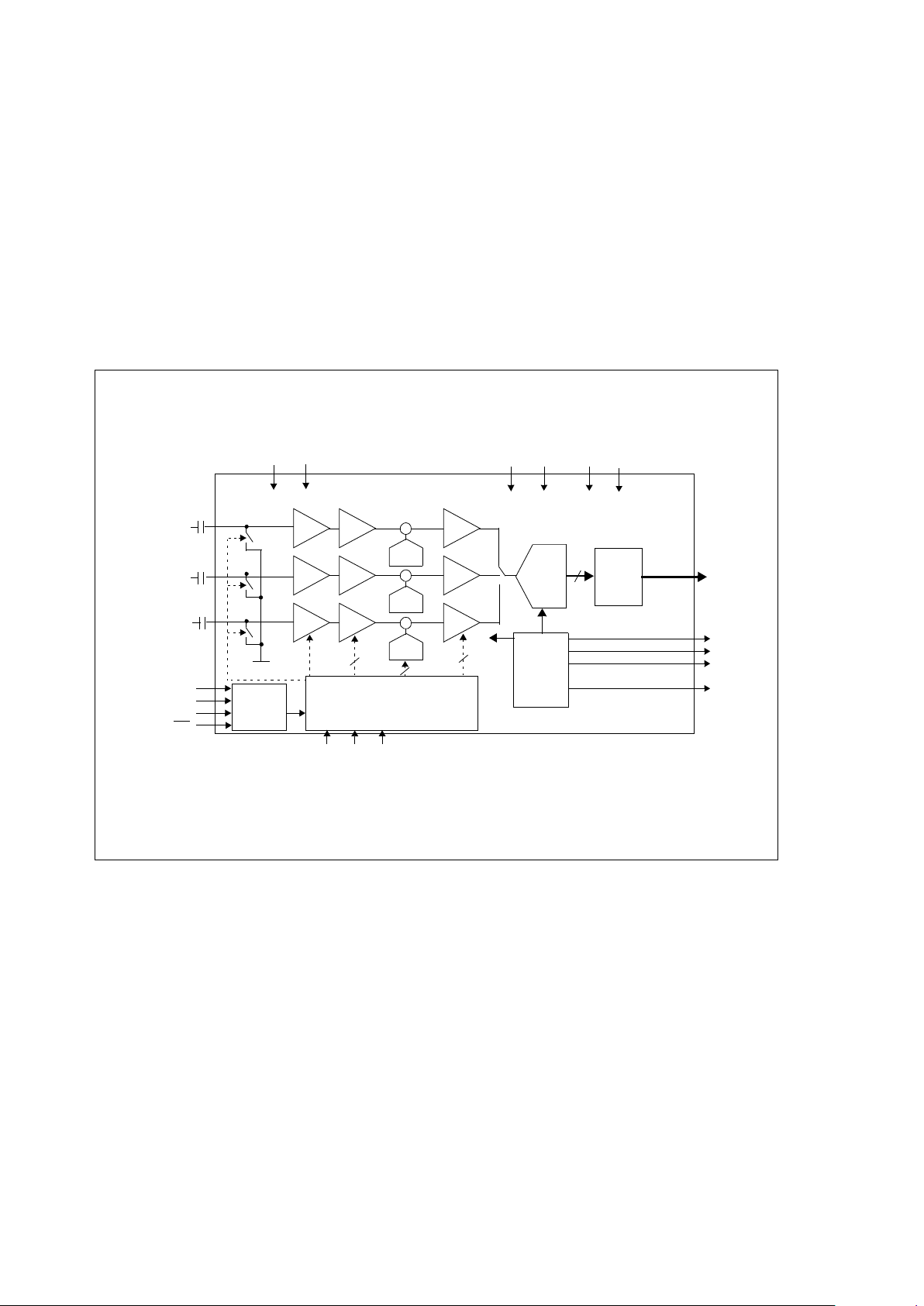

LM9822 Block Diagram

Serial

Interface

Coarse Color

Balance PGAs

DAC

R

Offset

+

+

OS

R

RED OS

from CCD

CDS

OS

G

GREEN OS

from CCD

CDS

OS

B

BLUE OS

from CCD

CDS

x0.93

to x3

DAC

G

Offset

+

+

DAC

B

Offset

+

+

VClamp

x1or x3

Static

Offset

DACs

V

BANDGAP

V

REF+

V

REFMID

V

REF-

Internal

Bandgap

Reference

x1or x3

x1or x3

Gain

Boost

x0.93

to x3

x0.93

to x3

Timing and Control

14

5

6

1

SCLK

SDI

SEN

V

A

V

D

AGND

DGNDVAAGND

MCLK

14 bits

to 8 bit

Bytes

D7 - D0

CLMP VSMP

14-Bit

ADC

SDO

2 www.national.com

Page 3

3 www.national.com

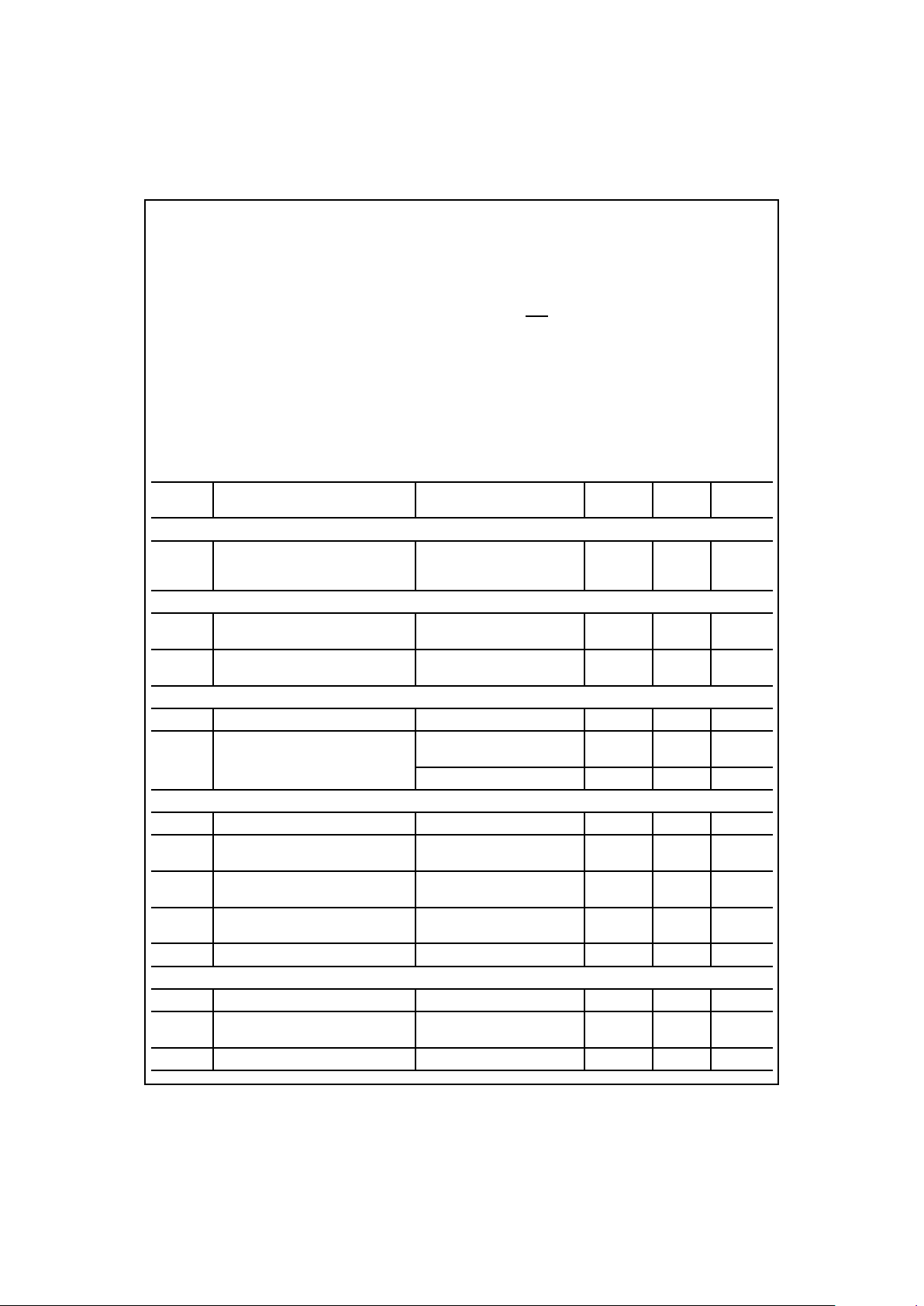

Electrical Characteristics

The following specifications apply for AGND=DGND=0V, VA=+5.0V

DC

,

V

D

=+3.0 or +5.0VDC, f

MCLK

=12MHz.

Boldface limits apply

for T

A=TJ=TMIN

to T

MAX

; all other limits TA=TJ=25°C. (Notes 7, 8, 12 & 16)

Symbol Parameter Conditions

Typical

(Note 9)

Limits

(Note 10)

Units

(Limits)

CCD/CIS Source Requirements for Full Specified Accuracy an d Dynamic Range

(Note 12)

V

OS PEAK

Sensor’s Maximum Peak Differential

Signal Range

Gain = 0.933

Gain = 3.0

Gain = 9.0

2.1

0.65

0.21

V

V

V

Full Channel Linearity (In un it s of 12 bit LSBs)

(Note 14)

DNL Differential Non-Linearity

+0.9

-0.4

+2

-0.9

LSB(max)

INL Integral Non-Linearity Error (Note 11) ±2.2

+5

-7

LSB(max)

Analog Input Characteristics

OS

R

,

OS

G

,

OS

B

Input Capacitance 5 pF

OS

R

,

OS

G

,

OS

B

Input Leakage Current

Measured with OS = 3.5V

DC

CDS disabled

20

25

µA (max)

CDS enabled 10 nA

Coarse Color Balance PGA Characteristics

Monotonicity

5

bits (min)

G

0

(Minimum PGA Ga in) PGA Setting = 0 0.93

.90

.96

V/V (min)

V/V (m ax)

G

31

(Maximum PGA Gain) PGA Setting = 31 3.0

2.95

3.07

V/V (min)

V/V (m ax)

x3 Boost Gain

x3 Boost Setting On

(Bit 5 of Gain Register is set)

3.0

2.86

3.08

V/V (min)

V/V (m ax)

Gain Error at any gain (Note 13) ±0.3

1.6

% (max)

Static Offset DAC Characteristics (In units of 12 bit LSBs)

Monotonicity

6

bits (min)

Offset DAC LSB size PGA gain = 1 18.9

13

24

LSB (min)

LSB (max)

Offset DAC Adjustment Range PGA gain = 1 ±585

±570

LSB (min)

Positive Supply Voltage (V+=VA=VD)

With Respect to

GND=AGND=DGND

6.5V

Voltage On Any Input or Output Pin -0.3V to V

+

+0.3V

Input Current at any pin (Note 3) ±25mA

Package Input Current (Note 3) ±50mA

Package Dissipation at T

A

= 25°C (Note 4)

ESD Susceptibility (Note 5)

Human Body Model 7000V

Machine Model 450V

Soldering Information

Infrared, 10 seconds (Note 6) 235°C

Storage Temperature -65°C to +150°C

Operating Temperature Range T

MIN

=0°C≤TA≤T

MAX

=+70°C

V

A

Supply Voltage +4.75V to +5.25V

V

D

Supp l y Voltage +3.0V to +5.25V

V

D-VA

≤ 100mV

OS

R

, OSG, OS

B

Input Voltage Range -0.05V to A + 0.05V

SCLK, SDI, SEN

, MCLK, VSMP, CLMP

Input Voltage Range -0.05V to V

D

+ 0.05V

Absolute Maximum Ratings

(Notes 1& 2)

Operating Ratings

(Notes 1& 2)

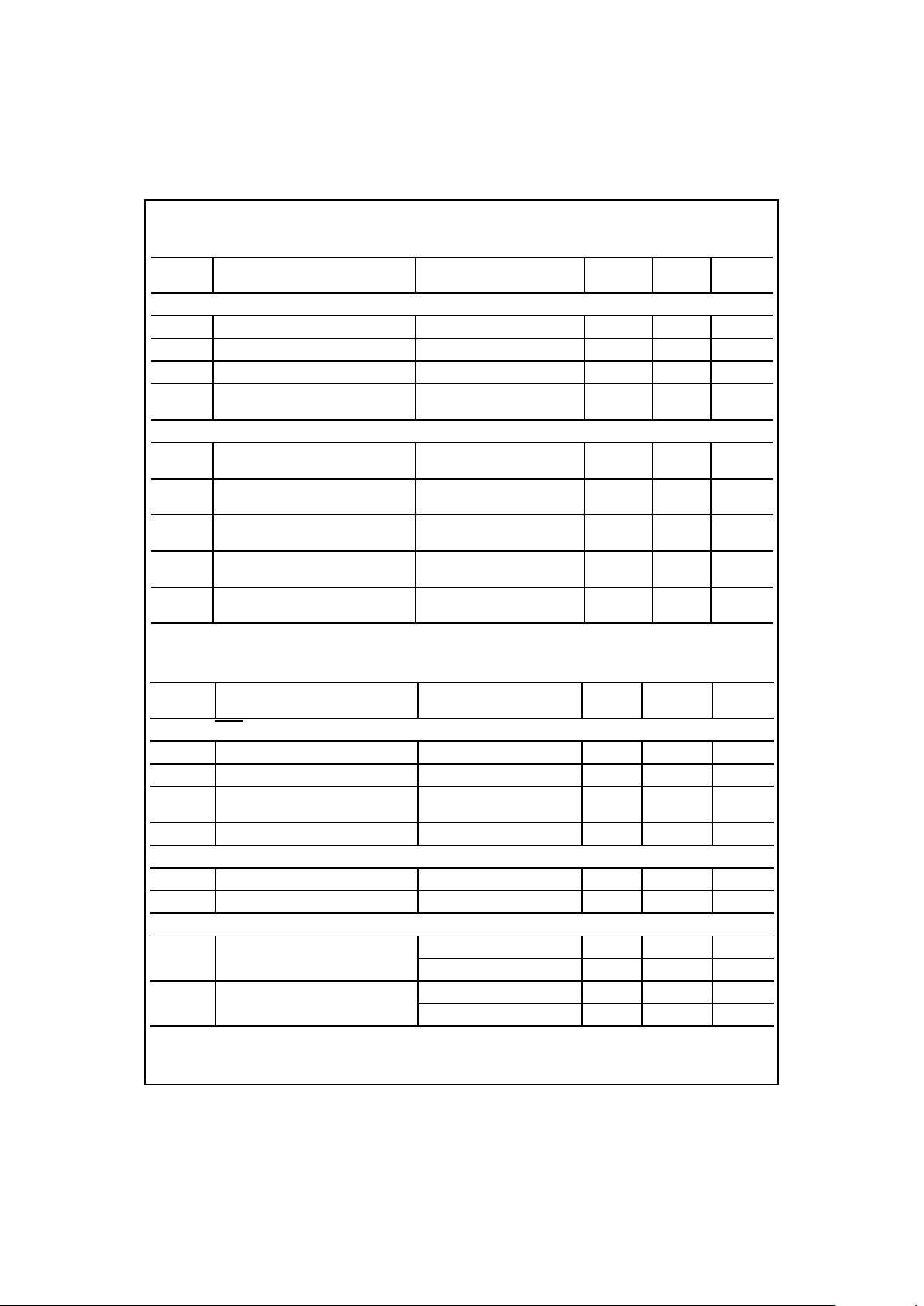

Page 4

4 www.national.com

Symbol Parameter Conditions

Typical

(Note 9)

Limits

(Note 10)

Units

(Limits)

Internal Reference Characteristics

V

REFMID

Mid Reference Output Voltage 2.5 V

V

REF+ OUT

Positive Reference Output Voltage 3.5 V

V

REF- OUT

Negative Reference Output Voltage 1.5 V

∆V

REF

Differential Reference Voltage

V

REF+ OUT

- V

REF- OUT

2.0 V

System Characteristics (In units of 12 bit LSBs) (see section 5.1, Internal Offsets)

C

Analog Channel Gain Constant

(ADC Codes/V)

Includes voltage reference

variation, gain setting = 1

2107

1934

2281

LSB (min)

LSB (max)

V

OS1

Pre-Boost Analog Channel Offset Error,

CCD Mode

17.3

-61

+94

LSB (min)

LSB (max)

V

OS1

Pre-Boost Analog Channel Offset Error,

CIS Mode

27

-49

+103

LSB (min)

LSB (max)

V

OS2

Pre-PGA Analog Channel Offset Error -40

-124

+44

LSB (min)

LSB (max)

V

OS3

Post-PGA Analog Channel Offset Error -38

-130

+55

LSB (min)

LSB (max)

DC and Logic Electrical Characteristics

The following specifications apply for AGND=DGND=0V, VA=+5.0V

DC

,

V

D

=+3.0 or +5.0VDC, f

MCLK

=12MHz.

Boldface limits apply

for T

A=TJ=TMIN

to T

MAX

; all other limits A=TJ=25°C. (Notes 7& 8)

Symbol Parameter Conditions

Typical

(Note 9)

Limits

(Note 10)

Units

(Limits)

SCLK, SDI, SEN,

MCLK, VSMP, CLMP Digital Input Characteristics

V

IN(1)

Logical “1” Input Voltage VA=5.25V

2.0

V (max)

V

IN(0)

Logical “0” Input Voltage VA=4.75V

0.8

V (min)

I

IN

Input Leakage Current

V

IN

=V

A

VIN=DGND

0.1

-0.1

µA(max)

µA(max)

C

IN

Input Capacitance 5 pF

D0-D7 Digital Output Characteristics

V

OUT(1)

Logical “1” Output Voltage I

OUT

=-360µA

0.8*V

D

V (min)

V

OUT(0)

Logical “0” Output Voltage I

OUT

=1.6mA

0.2*V

D

V (max)

Power Supply Characteristics

I

A

Analog Supply Current

Operating 75

108

mA (max)

Power Down 675

900

µA (max)

I

D

Digital Supply Current (Note 15)

Operating 210

475

µA (max)

Power Down 2

25

µA (max)

Electrical Characteristics

(Continued)

The following specifications apply for AGND=DGND=0V, V

A

=+5.0V

DC

,

V

D

=+3.0 or +5.0VDC, f

MCLK

=12MHz.

Boldface limits apply

for T

A=TJ=TMIN

to T

MAX

; all other limits TA=TJ=25°C. (Notes 7, 8, 12 & 16)

Page 5

5 www.national.com

AC Electrical Characteristics

The following specifications apply for AGND=DGND=0V, VA=+5.0V

DC

,

V

D

=+3.0 or +5.0VDC, f

MCLK

=12MHz, except where noted

otherwise.

Boldface li mit s apply for

A=TJ=TMIN

to T

MAX

; all other limits TA=TJ=25°C. (Notes 7& 8)

Note 1:

Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is functional,

but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characte ristics. The guaranteed specifications apply

only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the list ed te st con di tions.

Note 2:

All voltages are measured with respect to GND=AGND=DGND=0V, unless otherwise specified.

Note 3:

When the input voltage (V

IN

) at any pin exceeds the power supplies (VIN<GND or VIN>VA or

V

D

), the current at that pin should be limited to 25mA. The 50m

maximum pac kage input c urre nt ra tin g limits the nu mb er of pin s that can simultaneously safely exceed the power supplies with an input current of 25mA to two.

Note 4:

The maximum power dissipation must be derated at elevated temperatures and is dictated by T

J

max,

Θ

JA

and the ambient temperature, TA. Th e maximum allow-

able power dissipation at any temperature is P

D

= (TJmax - TA) /

Θ

JA

. TJmax = 150°C for this device. The typ ica l t he rmal resi stance (

Θ

JA

) of this p a rt when board mounted

is 69°C /W for the M28 B SOIC package

.

Note 5:

Human body model, 100pF capacitor discharged through a 1.5kΩ resistor. Machine model, 200 pF capacitor discharged through a 0Ω resistor.

Note 6:

See AN450 “Surface Mounting Methods and Their Effect on Product Reliability” or the section titled “Surface Mount” found in any National S e miconductor Linear

Data Book for other methods of so l de r i ng sur f a ce m ount devices.

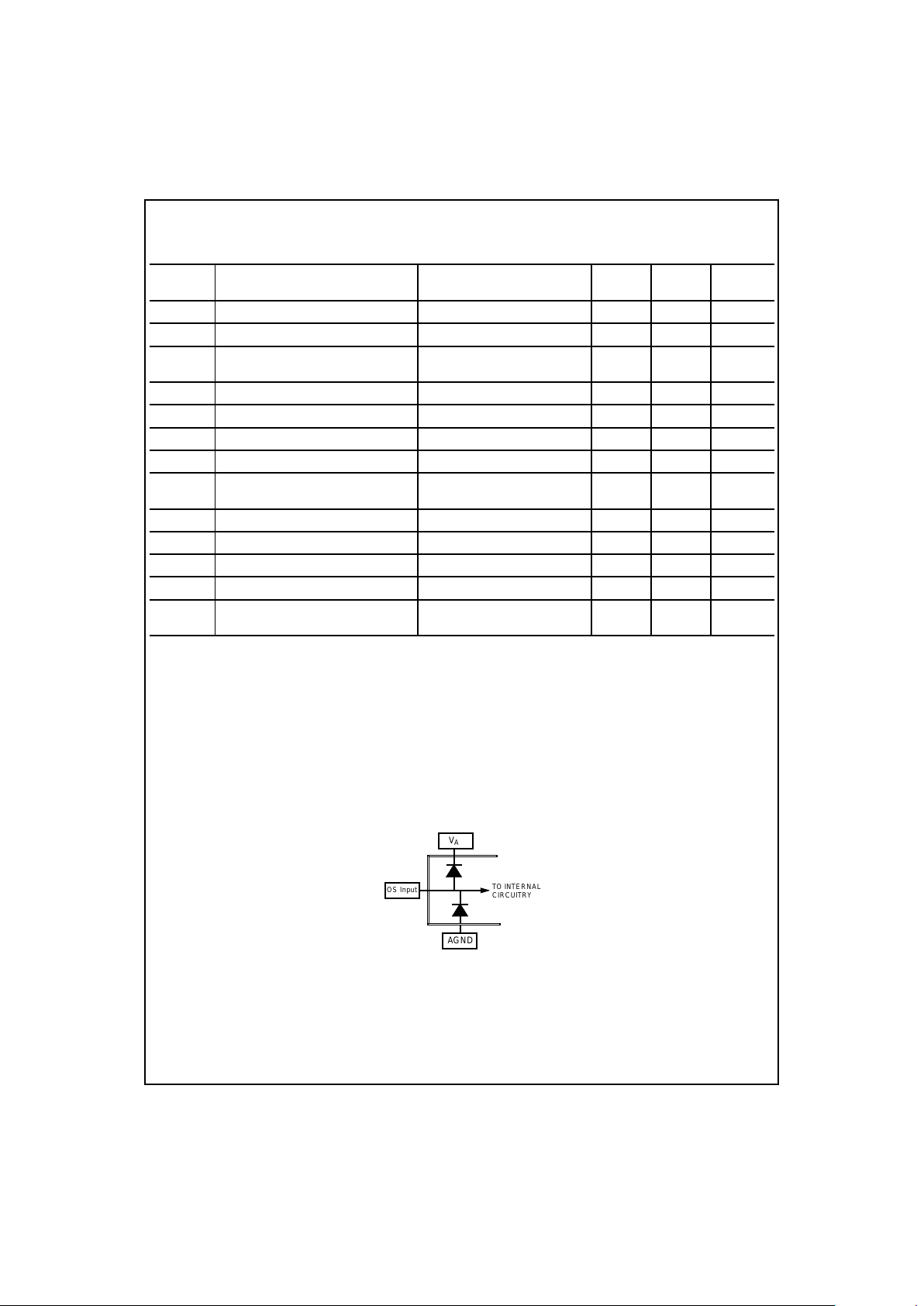

Note 7:

Two diodes clamp the OS analog inputs to

AGND

and

V

A

as shown below. This input protection, in combination with the external clamp capacitor and the output

impedance of the sensor, prevents damage to the LM9822 from transients during power-up.

Note 8:

To guarantee accuracy, it is required that V

A

and VD be connected to clean, low noise power supplies, with separate bypass capacitors at each supply pin. When

both V

A

and VD are operated at 5.0V, they must be powered by the same regulator, with separate power planes or traces and separate bypass capaci to rs at each suppl y pin.

Sym b ol Paramete r Condi tions

Typi cal

(Note 9)

Limits

(Note 10)

Units

(Limits)

f

MCLK

Maximum MCLK frequency

12

MHz (min)

t

MCLK

MCLK period 83 ns (min)

MCLK duty cycle

40

60

%(min)

%(max)

t

SCLK

Serial Clock Period

1

t

MCLK

(min)

t

SEN

Serial Enable high time

3

t

MCLK

(min)

t

SSU

SDI setup time

1

ns (min)

t

SH

SDI hold time

3

ns (min)

t

SDDO

SCLK

edge to new valid data

V

D

= 5.0V

V

D

= 3.3V

8.5

19

20

ns (max)

t

VSU

VSMP setup time

1

ns (min)

t

VH

VSMP hold time

3

ns (min)

t

CSU

CLMP setup time

1

ns (min)

t

CH

CLMP hold time

3

ns (min)

t

DDO

MCLK

edge to new valid data

V

D

= 5.0V

V

D

= 3.3V

16

25

25

ns (max)

ns (max)

OS Input

AGND

V

A

TO INTERN AL

CIRCUITRY

Page 6

6 www.national.com

Electrical Characteristics

(Continued)

Note 9:

Typicals are at T

J=TA

=25°C, f

MCLK

= 12MHz, and represent most likely parametric norm.

Note 10:

Tested limits are guaranteed to National's AOQL (Average O utgoing Quality Level).

Note 11:

Full channe l integral non-linea rity error is defined a s the d eviation of the analog v alue , expres sed in LSB s, from the straight line tha t best fits th e a ct u al transfer

function of th e AFE.

Note 12:

The sensor’s maximum peak differential signal range is defined as the peak sensor output voltage for a white (full scale) image, with respect to the dark reference

level.

Note 13:

PGA Gain Error is the maximum difference between the measured gain for any PGA code and the ideal gain calculated using:

where .

Note 14:

Full Channel IN L and DN L are te st e d w i th C DS disab le d, negative sign al pola rity , DOE = 0, and a si ngle OS inpu t with a gain register se ttin g of 1 (0 00 0 0 1b) and

an offset re gi st er s et ti ng o f 0 (0 00 000b).

Note 15:

The digital supply current (ID) does not include the load, data and switching frequency dependent current required to drive the digital output bus on pins (D7 - D0).

The curre nt requir ed to switch t he digita l d ata bus can be calc ulate d f rom : Isw = 2*N d*Psw* CL*V

D/tMCLK

where N d is total num ber of da ta pins, Psw is the pr obability of

each data bit switching, CL is the capacitive loading on each d ata pin, V

D

is the digital supply voltage and t

MCLK

is the period of the MCLK input. For most applications, Nd

is 8, Psw is ≈ 0.5, and V

D

is 5V, and the switching current can be calculated from: Isw = 40*CL/tMCLK. (With D at 3.3V, the equation bec omes : Isw = 2 6.4*CL/t

MCLK

.) For

example, if the capacitive load on each digital output pin (D7 - D0) is 20pF and the period of t

MCLK

is 1/12MHz or 83ns, then the digital switching current would be 9.6mA.

The calculated digital switching current will be drawn through the V

D

pin and should be c on s idere d a s part of th e total po wer bu d ge t for the LM9822.

Note 16:

All specifications quoted in LSBs are based on 12 bit resolution.

V

WHITE

V

REF

V

RFT

CCD Output Signal

CIS Output Signal

V

WHIT

Black Level

Gain

PGA

V

V

--- -

G0X

PGA code

32

-------------- -------------- -+=XG

31G0

–

()

32

31

----- -=

Page 7

7 www.national.com

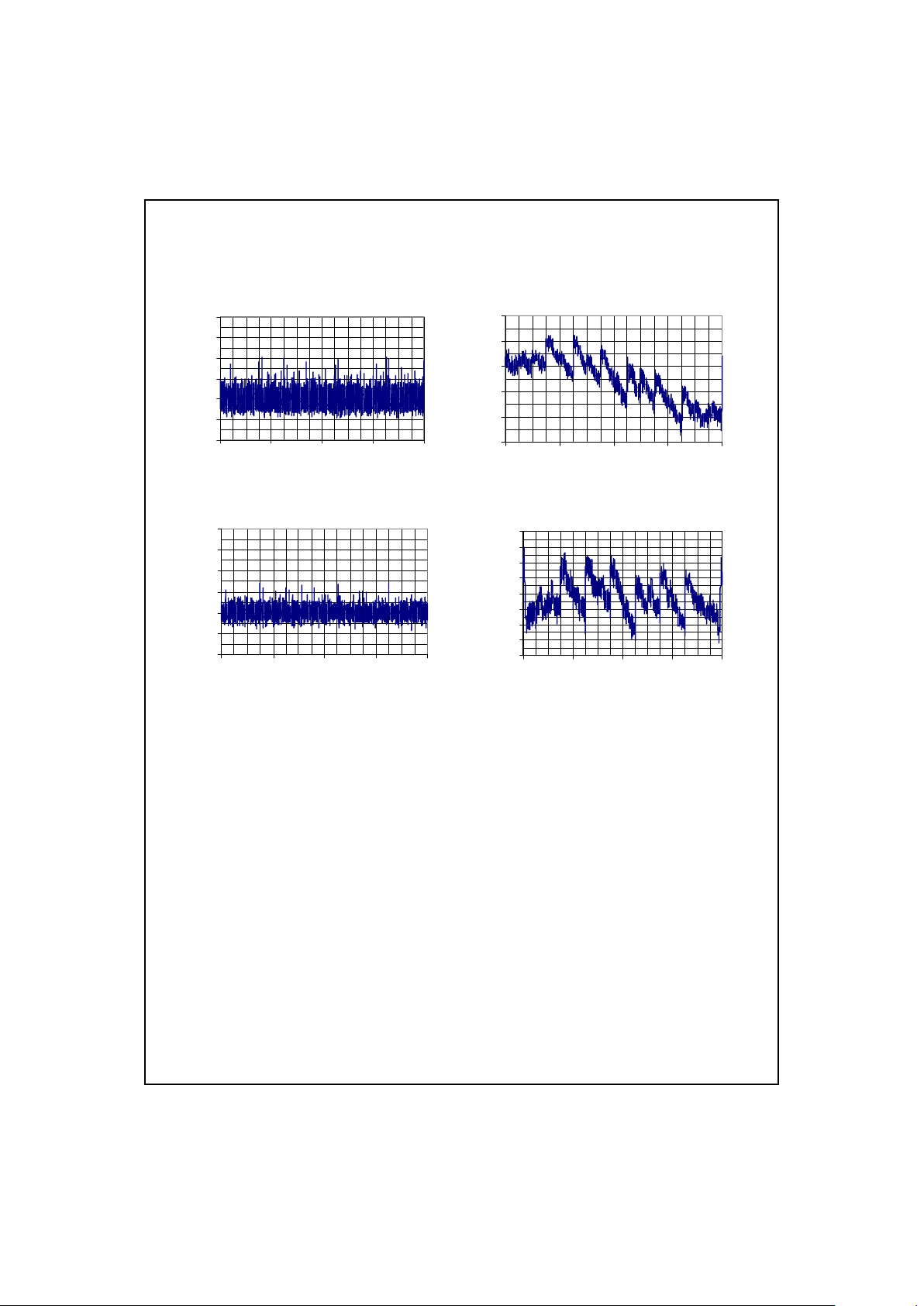

Typical Performance Characteristics

Full Channel DNL and INL

(Divide by 2, Monochrome Mode, 6 MHz Pixel Rate)

Note:

The LM9822 provides 14-bit data for high resolution imaging applications. The typical full channel device performance is shown

in the above graphs. In many applications, particularly those where high speed is important, or where lower cost CCD and CIS sensors

are used, the signal source is only accurate to 12 bits. In these applications, only 12-bit of data may be used. 12-bit DNL and INL pl ots

have also been provided to illustrate the performance of the LM9822 in these applications.

Typical 12 Bit DNL

-1

-0.5

0

0.5

1

1.5

2

0 1024 2048 3072 4096

Output Code

LSB

Typical 12 Bit INL

-2.5

-2

-1.5

-1

-0.5

0

0.5

1

1.5

0 1024 2048 3072 4096

Output Code

LSB

Typical 14 Bit DNL

-1

-0.5

0

0.5

1

1.5

2

0 4096 8192 12288 16384

Output Code

LSB

Typical 14 Bit INL

-15

-10

-5

0

5

10

0 4096 8192 12288 16384

Output Code

LSB

Page 8

8 www.national.com

Pin Descriptions

Connection Diagram

Analog Power

V

A

The two A pins are the analog supply pins.

They should be connected to a voltage

source of +5V and bypassed to

AGND

with a

0.1µF monolithic capacitor in parallel with a

10µF tantalum capacitor.

AGND

These two pins are the ground returns for

the analog supplies.

V

D

This is the positive supply pin for the digital

I/O pins. It should be connected to a voltage

source between +3.3V and +5.0V and be

bypassed to DGND with a 0.1µF monolithic

capacitor in parallel with a 10µF tantalum

capacitor.

DGND

This is the ground return for the digital supply.

Analog In put /O utpu t

OS

R

,

OS

G

,

OS

B

Analog Inputs. These inputs (for Red,

Green, and Blue) should be tied to the sensor’s OS (Output Signal) through DC blocking capacitors.

V

REF+

,

V

REFMID

,

V

REF-

Voltage reference bypass pins. V

REF+

,

V

REFMID

, and V

REF-

should each be

bypassed to

AGND

through a 0.1uF mono-

lithic ca pacitor.

Timing Control

MCLK

Master clock input. The ADC conversion

rate will be 1/2 of MCLK. 12MHz is the maximum frequency for MCLK.

VSMP

Sample timing input signal. If VSMP is high

on the rising edge of MCLK, the input is

sampled on the rising edge of the next

MCLK. The reference signal for the next

pixel will be sampled one to four MCLKs

later, depending on the value in the

CDSREF configuration bits. If CDS is not

enabled, the internal reference will be sampled during the reference sample time.

The number of MCLK cycles between

VSMP pulses determines the pixel rate.

Timing Diagrams 1 through 6 illustrate the

VSMP timings for all the valid pixel rates.

Note: See the applications section of the

datasheet for the proper timing relationships

between VSMP and MCLK.

CLMP

Clamp timing input. If CLMP and VSMP are

high on the ri sing edge of MCLK, all three

OS inputs will be internally connected to

V

CLAMP

during the next pixel.

V

CLAMP

is either

VREF+ or VREF- depending on the state of

the Signal Polarity bit in the Sample Mode

register (Reg. 0, Bit 4).

Data Output

D7-D0

Data Output pins. The 14 bit conversion

results of the ADC are multiplexed in 8 bit

bytes to

D7-D0

synchronous with MCLK.

The MSB consists of data bits d13-d6 on

pins D7-D0 and the LSB consists of d5-d0

on pins D7-D3 with D1 and D0 low.

Serial Input/Output

SCLK

Serial Shift Clock. Input data on SDI is valid

on the rising edge of SCLK. The minimum

SCLK period is 1 t

MCLK

.

SDO

Serial Data Output. Data bits are shifted out

of SDO on falling edges of SCLK. The first

eight falling edges of SCLK after SEN goes

low will shift out eight data bits (MSB first)

from the configuration register addressed

during the previous SEN

low time.

SDI

Serial Data Input. A read/write bit, followed

by a four address bits and eight data bits is

shifted into SDI, MSB first. Data should be

valid on the rising edge of SCLK. If the

read/write bit is a “0” (a write), then the

shifted data bits will be stored. If the

read/write bit is a “1” (a read), then the data

bits will be ignored , and SDO will shift out

the addressed register’s contents during the

next SEN

low time.

SEN

Shift enable and load signal. When SEN is

low, data is shifted into SDI. When SEN

goes high, the last thirteen bits (one

read/write, four address and eight data)

shifted into SDI will be used to program the

addressed configuration register. SEN

must

be high for at least 3 MCLK cycles between

SEN

low times.

LM9822

28 pin

SOIC

SCLK

SDI

SEN

D2

D0

V

D

DGND

D4

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

23

22

21

24

25

26

27

28

D7

D6

D5

MCLK

V

A

V

A

V

REF-

OS

B

OS

G

CLMP

OS

R

V

REF+

AGND

AGND

VSMP

SDO

V

REFMID

V

BANDGAP

D3

D1

Page 9

9 www.national.com

Timing Diagrams

OSR,

Diagram 1:

Divide by 6 Color Mode Sample and Data Output Timing

VSMP

OSG,

OS

B

D7 -D0

Sample Signal

Sample Reference

MCLK

Level

Level

GH GL BLBH RH RL GH GL BH BL

H = d13-d6

L = d5-d0

ADC Clock

(internal)

N+1N

N

N-1

RH

N-4N-5N-5 N-4 N-4

DOE (Register 0, Bit 4) = 0

Diagram 2:

Divide by 6 Monochrome Mode Sample and Data Output Timing (Green Input shown)

VSMP

OS

G

D7 -D0

Sample Signal

Sample Reference

MCLK

Level

Level

XX XX XXXX GH GL XX XX XX XX

H = d13-d6

L = d5-d0

ADC Clock

(internal)

NN-1

N+1

N

GH

N-4

DOE (Register 0, Bit 4) = 0

OSR,

Diagram 3:

Divide by 8 Color Mode Sample and Data Output Timing

VSMP

OSG,

OS

B

D7 -D0

Sample Signal

Sample Reference

MCLK

Level

Level

RH RL GLGH BH BL XX XX RH RLXX

H = d13-d6

L = d5-d0

ADC Clock

(internal)

N-1

N

N

N+1

GH

N-4 N-4 N-4

N-3

DOE (Register 0, Bit 4) = 0

Page 10

10 www.national.com

Timing Diagrams

(Continued)

Diagram 4:

Divide by 8 Monochrome Mode Sample and Data Output T im in g (Gre en Input Shown)

VSMP

OS

G

D7 -D0

Sample Signal

Sample Reference

MCLK

Level

Level

GH GL XXXX XX XX XX XX GH GLXX

H = d13-d6

L = d5-d0

ADC Clock

(internal)

N-1

N

N

N+1

N-4 N-3

XX XX

DOE (Register 0, Bit 4) = 0

Diagram 5:

Divide by 3 Monochrome Mode Sample and Data Output Timing (Green Input shown)

VSMP

D7 -D0

Sample Signal

Sample Reference

MCLK

Level

Level

GH GL GH GL GH GL GH

H = d13-d6

L = d5-d0

ADC Clock

(internal)

OS

G

CDSREF = 00

N

N

N-1

N+1

N+1

N+2

N+2

N-11 N-10 N-9

GL

DOE (Register 0, Bit 4) = 0

Diagram 6:

Divide by 2 Monochrome Mode Sample and Data Output Timing (Green Input shown)

VSMP

D7 -D0

Sample Signal

Sample Reference

MCLK

Level

Level

GH GL GLGH GH GL GH GL GH GL

H = d13-d6

L = d5-d0

ADC Clock

(internal)

OS

G

CDSREF = 00

N

N

N+1

N+1

N+2

N+2

N+3

N+3N-1

N-1

N+4

N-11 N-10 N-9 N-8 N-7

DOE (Register 0, Bit 4) = 0

Page 11

11 www.national.com

Timing Diagrams

(Continued)

Diagram 7:

Programmable Reference Sample Timing

VSMP

D3 -D0

Sample Signal

Sample Reference

MCLK

OSR,OSG,

OS

B

CDSREF=00 CDSREF=01 CDSREF=10 CDSREF=11

Diagram 8:

Clamp Timing With SMPCL = 0

VSMP

Sample Signal

Sample Reference

MCLK

OS

CDSREF = 00

N

N

N-1

N+1

N+1

N+2

N+2

CLMP

Clamp On

(internal signal)

Diagram 9:

Clamp Timing With SMPCL = 1

VSMP

Sample Signal

Sample Reference

MCLK

OS

CDSREF = 00

N

N

N-1

N+1

N+1

N+2

N+2

CLMP

Clamp On

(internal signal)

Diagram 10:

Configuration Register Serial Write Timing

SEN

SDI

SCLK

0 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0 XXXX

R/W bit

Diagram 11:

Configuration Register Serial Read Timing

SEN

SDI

SCLK

1

A3 - A0

XX XX

SDO

XX

b7 - b0

1

A3 - A0

R/W bit

Page 12

12 www.national.com

Timing Diagrams

(Continued)

Diagram 12:

Serial Input and Output Timing

SEN

SDI

SCLK

D0

SDO

D1D2

D5D6D7

A2A3R/W D7A1 A0XX

XX D2D3D4

t

SDDO

t

SH

t

SSU

t

SH

t

SSU

t

SEN

t

SCLK

1/2 t

SCLK

1/2 t

SCLK

Diagram 13:

MCLK, VSMP and CLMP Input Timing and Data Output Timing

VSMP

MCLK

D7 - D0

DOE = 0

CLMP

t

VSUtVH

t

CH

t

CSU

t

MCLK

t

DDO

D7 - D0

DOE = 1

t

DDO

Page 13

13 www.national.com

Table 1: Configuration Register Address Table

Address

(Binary)

Register Name and Bit Definitions

A3 A2 A1 A0 B7 B6 B5 B4 B3 B2 B1 B0

0000

Sample Mode (Power Up Default = 62h)

I/O Mode DOE CDS Polarity SMPCL CDSREF1 CDSREF0 PD

0001

Red Offset Setting (Power Up Default = 00h)

N/A N/A

Polarity MSB LSB

0010

Green Offset Setting (Power Up Default = 00h)

N/A N/A

Polarity MSB LSB

0011

Blue Offset Setting (Power Up Default = 00h)

N/A N/A

Polarity MSB LSB

0100

Red Gain Setting (Power Up Default = 00h)

N/A N/A

x3 MSB LSB

0101

Green Gain Setting (Power Up Default = 00h)

N/A N/A

x3 MSB LSB

0110

Blue Gai n Set ting (Powe r Up D efaul t = 0 0 h )

N/A N/A

x3 MSB LSB

0111

Color Mode (Power Up Default = 00h)

N/A N/A N/A N/A N/A N/A

CM1 CM0

1000

Test Register 0 (Power Up Default = 00h)

00000000

1001

Test Register 1 (Power Up Default = 10h)

00010000

1010

Test Register 2 (Power Up Default = 00h)

00000000

Page 14

14 www.national.com

Table 2: Configuration Register Parameters

Power-Up Default Register Settings are shown in

Bold Italic s

Parameter

(Address)

Control Bits Result

Sample Mode (0)

I/O Mode

(0)

B7

0

1

Normal Output Driver Operation

Reduced Slew Rate Output Driver Operation

DOE

(Data Output Edge)

(0)

B6

0

1

D7-D0 are clocked out (change) on the falling edge of MCLK - Recommended setting for

lowest noise and best overall performance.

D7-D0 are clocked out (change) on the rising edge of MCLK

CDS (Enable)

(0)

B5

0

1

CDS disabled (CIS)

CDS Enabled (CCD)

Signal Pol arit y

(0)

B4

0

1

Negative Polarity (CCD) Clamping to V

REF+

Positive Polarity (CIS) Clamping to V

REF-

SMPCL

(0)

B3

0

1

Clamp is on for 1 MCLK before reference sampled

Clamp is on between the reference and the signal sample points

CDSREF

(0)

B2

0

0

1

1

B1

0

1

0

1

Reference (for pixel N+1) sampled 1 MCLK cycle after signal (for pixel N) sampled

Reference (for pixel N+1) sampled 2 MCLK cycle after signal (for pixel N) sampled

Reference (for pixel N+1) sampled 3 MCLK cycle after signal (for pixel N) sampled

Reference (for pixel N+1) sampled 4 MCLK cycle after signal (for pixel N) sampled

PD

(Powe r Down)

(0)

B0

0

1

Operating

Low Power Standby

Page 15

15 www.national.com

Red, Green and Blue Offset DAC Settings ( 1, 2 & 3)

Offset Polarity

B5

0

1

Positive Offset

Negative Offset

Offset Value

B4(M

SB)

B3 B2 B1 B0(LSB) Typical Offset = 20LSBs * Offset Value * PGA Gain

Typical Offset

Values

B5

(SIGN

)

0

0

0

• • •

0

0

1

1

1

• • •

1

1

B4

(MSB)

0

0

0

• • •

1

1

0

0

0

• • •

1

1

B3

0

0

0

• • •

1

1

0

0

0

• • •

1

1

B2

0

0

0

• • •

1

1

0

0

0

• • •

1

1

B1

0

0

1

• • •

1

1

0

0

1

• • •

1

1

B0

(LSB)

0

1

0

• • •

0

1

0

1

0

• • •

0

1

Typical Offset (with PGA Gain = 1)

12 bit LSBs

0.00

+20

+40

• • •

+600

+620

0

-20

-40

• • •

-600

-620

Red, Green and Blue Gain Settings (4, 5 & 6)

Boost Gain Enable

B5

0

1

Boost Gain = 1V/V

Boost Gain = 3V/V

PGA Gain Value

B4(M

SB)

B3

B2 B1 B0(LSB)

PGA Gain (V/V) =.933 + 0.0667 * (PGA Gain Value)

Gain

Gain = Boost Gain * PGA Gain

Table 2: Configuration Register Parameters

(Continued)

Power-Up Default Register Settings are shown in

Bold Italics

Parameter

(Address)

Control Bits Result

Page 16

16 www.national.com

Typical Gain Values

B5

(

x3)

0

0

0

• • •

0

0

0

• • •

1

1

1

• • •

1

1

1

B4

(MSB)

0

0

0

• • •

1

1

1

• • •

0

0

0

• • •

1

1

1

B3

0

0

0

• • •

1

1

1

• • •

0

0

0

• • •

1

1

1

B2

0

0

0

• • •

1

1

1

• • •

0

0

0

• • •

1

1

1

B1

0

0

1

• • •

0

1

1

• • •

0

0

1

• • •

0

1

1

B0

(LSB)

0

1

0

• • •

1

0

1

• • •

0

1

0

• • •

1

0

1

Typical Gain

(V/V)

0.93

1.00

1.07

• • •

2.87

2.93

3.00

• • •

2.79

3.00

3.20

• • •

8.60

8.80

9.00

Color Mode (7)

Color Mode

B1

0

0

1

1

B0

0

1

0

1

Color

Monochrome - Red

Monochrome - Green

Monochrome - Blue

Reserved Register 0 (8)

Reserved

Register 0

0 0 0 0 0 0 0 0

Reserved, always set to 00h.

Reserved Register 1 (9)

Reserved

Register 1

0 0 0 1 0 0 0 0

Reserved, always set to 10h.

Reserved Register 2 (A)

Reserved

Register 2

0 0 0 0 0 0 0 0

Reserved, always set to 00h.

Table 2: Configuration Register Parameters

(Continued)

Power-Up Default Register Settings are shown in

Bold Italics

Parameter

(Address)

Control Bits Result

Page 17

17 www.national.com

Applications Information

1.0 Introduction

The LM982 2 is a high performance scanner Analog Font End

(AFE) for image sensor processing systems. It is designed to

work with color CCD and CIS image sensors and provides a full 3

channel sampling, gain and offset correction system, coupled

with a 14 bit high speed analog to digital converter. A typical

application of the LM9822 is in a color flatbed document scanner.

The image sensing and processing portion of the system would

be configured similar to that shown in Figure 1.

Figure 1: LM9822 in Basic Color Scanner

2.0 CDS Correlated Double Sampler

The LM9822 uses a high-performance CDS (Correlated Double

Sampling) circuit to remove many sources of noise and error from

the image sensor output signal. It also supports CIS image sensors with a single ended sampling mode.

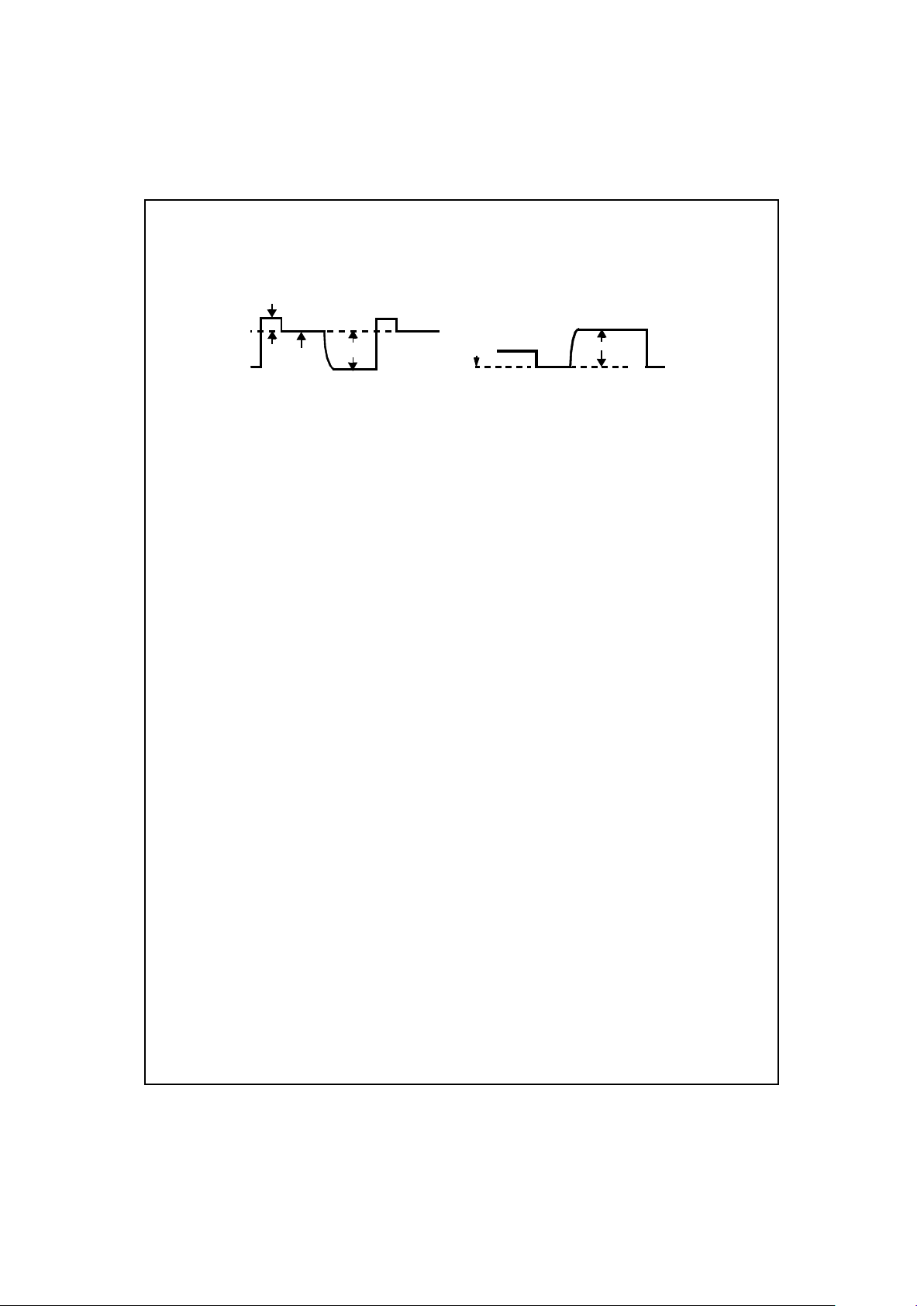

Figure 2 shows the output stage of a typical CCD and the resulting output waveform:

Figure 2: CDS

Capacitor C1 converts the electrons coming from the CCD’s shift

register to an analog voltage. The source follower output stage

(Q2) buffers this volta ge before it leaves the CCD. Q1 resets the

voltage across capacitor C1 between pixels at intervals 2 and 5.

When Q1 is on, the output signal (OS) is at its most positive voltage. After Q1 tu rns off (period 3), the OS level repre sents the

residual voltage across C1 (V

RESIDUAL

). V

RESIDUAL

includes

charge injection from Q1, therma l noise from the ON resistance

of Q1, and other sources of error. When the shift register clock

(Ø1) makes a low to high transition (period 4), the electrons from

the next pi xel flow into C 1. The ch arge across C1 now contains

the voltage proportional to the number of electrons plus V

RESID-

UAL

, an error term. If OS is sampled at the end of period 3 and

that voltage is subtracted from the OS at the end of period 4, the

V

RESIDUAL

term is canceled and the noise on the signal is

reduced ([V

SIGNAL+VRESIDUAL

]-V

RESIDUAL

= V

SIGNAL

). This is the

principal of Correlated Double Sampling.

3.0 CIS Mode (CDS Off, Selectable Signal Polarity)

The also LM9822 supports CIS (Contact Image Sensor) devices.

The output sig nal of a CIS sensor (Figure 3) differs from a CCD

signal in two primary ways: its output usually increases with

increasing signal strength, and it does not usually have a reference level as an integral part of th e output waveform of every

pixel.

Figure 3:

CIS

When the LM9822 is in CIS (CDS off) mode (Register 0, B5=1), it

uses either

V

REF+

or

V

REF-

as the reference (or black) voltage for

each pixel (depending on th e signal polarity setting (Register 0,

Bit 4)). If the s ignal polarity i s set to one, then

V

REF-

will be sam-

pled as the reference level. If it is set to zero, then

V

REF+

will be

sampled as the reference level.

4.0 Programmable Gain

The output of the Sampler drives the input of the x3 Boost gain

stage. The gain of each x3 Boost gain is 3V/V if bit B5 of that

color’s gain register (register 4,5, or 6) is set, or 1V/V if bit B5 is

cleared. The output of eac h x3 gain stage is the input an offset

DAC and the output of each offset DAC is the input to a PGA

(Programmable Gain Amplifier). Each PGA provides 5 bits of gain

correction over a 0.93V/V to 3V/V (-0.6 t o 9.5dB) range. The x3

Boost gain stage and t he PGA can be combined for an overall

gain range of 0.93V/V to 9.0V/V (-.6 to 19dB). The gain setting for

each color (registe rs 4, 5 and 6) shou ld b e s et during calibration

to bring th e maximum amplitude of the stron gest pixel to a level

just below the desired maximum output from the ADC. The PGA

gain is determined by the following equation:

If the x3 Boost gain is enabled then the overall s ignal gain will be

three times the PGA gain.

ASIC

LM9822

CCD

RAM

8 Output Data

8

OS

R

OS

G

OS

B

CCD Control

AFE Control

To H ost

Other scanner elements

omitted for simplicity.

RS (RESET)

e-

(from shift register)

OS

Q1

Q2

C1

V

DD

V

SS

Ø1

RS

OS

123 4 5

OS (CCD)

123 4 5

OS (CIS)

PGA Gain

V

V

--- -

0.933 + .0667 (value in bits B4-B0)=

Equation 1:

PGA Gain

Page 18

18 www.national.com

5.0 Offset DAC

The Offset DACs remove the DC offsets generated by the sensor

and the LM9822’s analog signal chain (see section 5.1, Inter nal

Offsets). The DAC value for each color (registers 1,2 and 3)

should be set during calibration to the lowest value that still

results in an ADC output code greater than zero for all the pixels

when scanning a black line. With a PGA gain of 1V/V, each LSB

of the offset DAC typically adds the equivalent of 20 ADC LSBs,

providing a total offset adjustment range of ±590 ADC LSBs. The

Offset DAC’s output voltage is given by:

In terms of 12 bit output codes, the offset is given by:

The offset is positive if bit B5 is cleared and negative if B5 is set.

Since the anal og of fset is added before the PGA gain, the value

of the PGA gain m ust be cons idered when selecting the offset

DAC values.

5.1 Internal Offsets

Figure 4 is a mod el o f the LM9822’s internal off sets. Equation 4

shows how to calculate the expected output code given the input

voltage (V

IN

), the L M98 22 in te rna l o ffsets (

OS1

, V

OS2

, V

OS3

),

the programmed offset DAC voltage (V

DAC

), the programmed

gains (G

B

, G

PGA

) and the analog channel gain constant C.

C is a constant that combines the gain error through the AFE, reference voltage variance, and analog voltage to digital code conversion into one constant. Ideally, C = 2048 codes/V (4096

codes/2V) in 12 bit LSBs. Manufactu ring tolerances widen the

range of C (see Electrical Specifications).

Figure 4:

Internal Offset Model

Equation 4: Output code calculation with in ternal offsets

Equation 5 is a simplification of the output code calculation,

neglecting the LM9822’s internal offsets.

Equation 5: Simplified output code calculation

6.0 Clamping

To perform a DC restore across the AC coupling capacitors at the

beginning of every line, the LM9822 implements a clamping function. The clamping function is initiated by asserting the CLMP

input. If CLMP and VSMP are both high on a rising edge of

MCLK, all three OS inputs will be internally connected to

V

REF+

or

V

REF-

during the next pixel, depending on bit 4 of register 0. If bit 4

is set to one (positive signal polarity), then the OS input will be

connected to

V

REF-

. If bit 4 is set to zero (negative signal polarity),

then it will be connected to

V

REF+

.

6.1 Clamp Capacitor Selection

The output signal of many sen sors rides on a DC offset (greater

than 5V for many CCDs) which is incompatible with the LM9822’s

5V operation. To eliminate this offset without resorting to additional higher voltage components, the output of the sensor is AC

coupled to the LM9822 through a DC blocking capacitor, C

CLAMP

.

The sensor’s DOS output, if a vailable, is not used. The value of

this capacitor is determined by the leakage current of the

LM9822’s OS input and the output impedance of the sensor. The

leakage through the OS input determines how quickly the capacitor value will drift from the clamp value of

V

REF+

or

V

REF-

, which

then determin es how many pixels can be process ed before the

droop causes errors in the conversion (±0.1V is the recommended limit for CDS operation). The outp ut impedance of the

sensor determines how quickly the capacitor can be charged to

the clamp value during the black referenc e period at the beginning of eve ry l ine.

The minimum clamp capacitor valu e is det ermined b y the maximum droop the LM9822 can tolerate while converting one sensor

line. The minimum clamp capacitor value is much smaller for CDS

mode applications than it is for CIS mode applications.

Figure 5:

Input Circuitry

The LM9822 input current is considerably less when the LM9822

is operat ing in CDS mode. In CDS mode, the LM9822 average

input current is no more than 25nA. With CDS disabled, which will

likely be the case when CIS sensors are used, the LM9822 input

impedance will be 1/(f

Sample*CS

). where f

Sample

is the sample

rate of the analog input and C

S

is 2pF.

V

DAC

9.75mV (value in B4 - B0)•=

Equation 2:

Offset DAC Out put Voltage

Offse t20L SBs(value in B4 - B0)• PGA Gain•=

Equation 3:

Offset in ADC Output Codes

V

DAC

DAC

Offset

G

PGA

Σ

+

+

ADC

+

+

+

+

V

OS3

V

OS2

Σ

Σ

G

B

+

+

V

OS1

V

IN

Σ

x3 Boost

1V/V or

3V/V

PGA

0.93V/V to

3V/V

D

OUT

D

OUT

VINV

OS1

+()GBV

DACVOS2

++()G

PGAVOS3

+()C=

D

OUTVINGBVDAC

+()G

PGA

C=

V

IN

+

CDS Mode Input Circuitry

Inside LM9822

C

CLAMP

OS

C

S

C

I

P1

P2

V

IN

+

CIS Mode Input Circuitry

Inside LM9822

C

CLAMP

OS

C

S

C

I

P1

P2

Vref

Applications Inf ormation (Continued)

Page 19

19 www.national.com

6.1.1 CDS mode Minimum Clamp Capacitor Calculation:

The following equation tak es the maximum leak age current into

the OS input, the maximum allowable droop, the number of pixels

on the sensor, and the pixel conversion rate, f

VSMP

, and provides

the minimum clamp capacitor value:

For example, if the OS input leakage current is 25nA worst-case,

the s ensor has 2700 active pixels, the conversion rate is 2MHz

(t

VSMP

= 500ns), and the max droop desired is 0.1V, the minimum

clamp capacitor value is:

6.1.2 CIS mode Minimum Clamp Capacitor Calculation:

If CDS is disabled, then the maximum LM9822 OS input leakage

current can be calculated from:

where V

SAT

is the peak pixel signal sw ing of the CIS OS output

and C

SAMP

is the capacitanc e of the LM9822 i nternal sampli ng

capacitor (2pF). Inserting this into Equation 6 results in:

with C

SAMP

equal to 2pF and V

SAT

equal to 2V (the LM9822

maximum input signal), then Equation 9 reduces to:

In CIS mode (CD S disabled), the max dro op limit must be much

more carefully chosen, since any change in the clamp capacitor’s

DC value will affect the LM9822 conversion results. If a droop of

one 10 bit LSB across a line is considered acceptable, then the

allowed droop voltage is calculated as: 2V/1024, or approximately

2mV. If there are 2700 active pixels on a line then:

6.1.3 Maximum Clamp Capacitor Calculation:

The maximum size of the clamp capacitor is determined by the

amount of time available t o charge i t to the de sired value during

the opt ical black port io n of the sensor output. The internal clamp

occurs when CLMP and VSMP are both high on a rising edge of

MCLK. If SMPCL=0, the clamps are on immediately before the

sample reference time, if SM PCL=1, the c lamps ar e on immediately after the sample reference time. If the LM9822 is operated

in Divide By 2 mode, then the clamp is on 50% of the time when

CLMP is high. In this case the available charge time per line can

be calculated using:

For example, if a senso r h as 18 black reference pixels and f

VSMP

is 2MHz with a 50% duty cycle, then t

CLAMP

is 4.5µs. Other

“Divide B y” modes will have lower or higher clamp duty cycles

accordingly, depending on the SMPCL setting. See

Diagram 8,

Clamp Timing With SMPCL = 0

and

Diagram 9, Clamp Timing

With SMPCL = 1

.

The following equat ion takes the numb er of optical black pixels,

the amount of time (per pixel) tha t the clamp is closed, the sensor’s output impedance, and the desired accuracy of the final

clamp voltage and provid es the maximum clamp capacitor value

that allows the clamp capacitor to set tle to th e desired accuracy

within a single line:

Where t

CLAMP

is the amou nt of time ( per line) that the clamp is

on, R

CLAMP

is the output impedance of the CCD plus 50Ω for the

LM9822 internal clamp switch, and accuracy is the ratio of the

worst-case initial capacitor voltage to th e desired final capacitor

voltage. If t

CLAMP

is 4.5µs, the output impedan ce of the sensor is

1500Ω, the worst case voltage change required across the capacitor (before the first lin e) is 5V, and the desired accuracy after

clamping is to within 0.1V (accuracy = 5/0.1 = 50), then:

The final value for C

CLAMP

should be less than or equal to

C

CLAMP MAX

, but no less than C

CLAMP MIN

.

In some cases, depending primarily on the choice of sensor,

C

CLAMP MAX

may actually be

less

than C

CLAMP MIN

, meaning that

the capacitor can n ot be charged t o its final voltage during the

black pixels at the beginning of a line and hold it’s voltage without

drooping for the duration of that line. This is usually not a problem

because in mos t applicat ions the sensor is clocked continuously

as soon as power is applied . In this cas e, a larger capacitor can

be used (guaranteeing that the C

CLAMP M I N

requirement is met),

and the final cla mp voltage is forced across the capacitor over

multiple lines. This equation calculates how many lines are

required before the capacitor settles to the desired accuracy:

Using the values shown b efore and a cla mp capacitor value of

0.01µF, this works out to be:

C

CLAMP MIN

i

dV

-------- -dt=

leakage current (A)

max droop(V)

--------------- ----------------------------------- -

number of pixel

f

VSMP

--------------- ---------------------------- -=

Equation 6:

CDS mode C

CLAMP MIN

Calculation

C

CLAMP MIN

25n

0.1V

------------- -

270

2MHz

-------------- -=

340p=

Equation 7:

CDS mode C

CLAMP MIN

Example

I

leakageVSATfSampC LKCSAMP

=

Equation 8:

CIS mode Input Leakage Current Calculation

C

CLAMP MIN

i

dV

-------- -dt=

V

SAT

t

SampCLK

---------------- ----------- C

SAMP

t

SampC LK

max droop(V)

--------------- -------------------- -num pixel=

Equation 9:

CIS mode C

CLAMP MIN

Calculation

C

CLAMP MIN

4p(F)(V)

max droop(V)

------------------ ------------------

num p ixels=

Equation 10:

CIS mode C

CLAMP MIN

Calculation

C

CLAMP MIN

4p(F)(V)

2mV

------------------- ---

270=

Equation 11:

CIS mode C

CLAMP MIN

Calculation Example

5.4uF=

t

CLAMP

Number of optical black pixels

2f

VSMP

------------------- --------------------------------- -------------------------- -=

Equation 12:

Clamp Time Per Line Calculation

C

CLAMP MAX

t

R

----- -

1

ln(accuracy)

-------------------- ------------=

t

CLAMP

R

CLAMP

------------------ --------

1

ln(accuracy)

------------------ --------------=

Equation 13:

C

CLAMP MAX

for a single line of charge time

C

CLAMP MAX

4.5 µs

155 Ω

-------------- ----

1

ln(50)

-------------- -=

728p=

Equation 14:

C

CLAMP MAX

Example

line sR

CLAMP

C

CLAMP

t

CLAMP

-------------- ---------- -

Initial Error Voltag

Final Error Voltag

--------------- --------------------------- ----------

ln=

Equation 15:

Number of Lines Required for Clamping

lines 155

0.01µF

4.5µs

----------------- --

5V

0.1V

----------- -

ln 13.5 lines==

Equation 16:

Clamping Lines Required Example

Applications Inf ormation (Continued)

Page 20

20 www.national.com

In this example, a 0.01µF capacitor takes 14 lines after power-up

to charge to its final value. On subsequent lines, the only error will

be the droop across a single line which should be significantly

less than the initial error.

If the LM9822 is operating in CDS

mode and multiple lines are used to charge up the clamping

capacitors after power-up, then a clam p capacitor value of

0.01µF should be significantly g reater than the calculated

C

CLAMP MIN

value and can virtually always be used.

If the LM9822 is operating in CIS mo de, then significantly larger

clamp capacitors must be used. Fo rtunately, the output impedance of most CIS sensors is significantly smaller than the output

impedance of CCD sensors, and R

CLAMP

will be dominated by

the 50Ω from the LM9822 internal clamp switch. With a smaller

R

CLAMP

value, the clamp capacitors wi ll charge faster.

7.0 Power Supply Conside ra tions

The LM9822 analog supplies (

A

) should be powered by a single

+5V source. The two analog supplies are brought out individually

to allow separate bypassing for each supply input. They should

not

be powered by two or more different supplies.

Each sup ply input should be bypassed to its r espective ground

with a 0.1µF cap acito r locat ed as close a s poss ible t o the supply

input pin. A single 10µF tantalum capacitor should be placed near

the V

A

supply pins to provide low frequency bypassing.

The V

D

input can be powered at 3.3V or 5.0V. Power should be

supplied by a clean, low noise linear power supply, with a 0.1 µF

ceramic capacitor and a 10 µF tantalum capacitor placed near the

V

D

and DGND pins. If possible, a separate power and ground

plane should be provided to isolate the noisy digital output signals

from the sensitive analog supply pins. If the V

D

voltag e is lower

than V

A

, a separate linear regulator should be used. If VD and

A

are both at 5.0V, then they shou ld be supplied by a common linear regulator, with separate analog and digital power and ground

planes.

To minimi ze noise, keep the LM982 2 and a ll analog components

as far as possible from noise generators, such as switching power

supplies and high frequency digital busses. If possible, isolate all

the an alog components and signals (OS, reference inputs and

outputs,

A

, AGND) on an analog groun d plane, separate from

the digital ground plane. The two ground planes should be tied

together at a single point, preferably the point wher e the power

supply enters the PCB.

8.0 Serial Interface and Configuration Registers

The serial interface is used to program the configuration registers

which control the oper ation of the LM9822. The SEN

, SCLK, SDI

and SDO signals are used to set and verify c onfi guration register

settings. In addition, MCLK must be active during all serial interface activity. MCLK is used to register the level of the SE N

input

and drives the logic that process information input on the SDI line.

9.0 Sample Mode Register Se ttings

A brief overview of the sample mode register and the bit locations

is give in

Table 2: Configuration Register Parameters

on page

14. The function of each bit is summarized in the following sections.

9.1 Output Driver Mode

The Output Driver Mode bit is normal set to 0. This bit can be set

to 1 to reduce the slew rate of the output drivers.

9.2 DOE (Data Output Edge) Setting

The Data Output Edge bit selects which edge of MCLK is used to

clock output data onto the output pins. For lowest noise performance, this bit should be se t to 0. With this setting, new data is

placed on the D7-D0 p ins on every falling edge of MCLK. See

Diagrams 1 throu gh 6 and Diagram 13 for more information on

data output timing for the different Divide By modes, and detailed

timing of the output data signals.

The bit can be set to 1 to adjust t he data output timing for some

applications, but the noise performance of the LM9822 may be

somewhat degraded.

9.3 CDS Enable

The CDS Enable bit determines whether the sampling section of

the LM9822 operates in Correlated Double Sampling mode or in

Single Ended Sampling mode. CDS m ode is nor mally used with

CCD type sensors, while Sin gle Ended mode is normally used

with CIS type sensors.

9.4 Signal Polarity

Whether the LM9822 is operating in Correlated Double Sampling

Mode, or Single Ended Sampling mode, the basic sampling operation is the same. First a reference level is sampled, then a signal

level is sampled. For CDS mode o peration, i f t he signal level is

lower in voltage th an the reference level, the Signal Polarity bit

should be set to 0. This is the normal setting for CCD type sensors. If the signal level is more positive than the reference level,

the Signal Polarity bit would be set to 1 for Positive Polarity mode.

When Single Ended Mode is selected, the Signal Polarity bit

determines which internal reference voltage is used to compare

with the input signal. Most CIS type sensors have a positive polarity type output, and in this case the Signal Polarity Bit should be

set to 1. In this case, the internal V

REF-

is used a s the reference

level during the Reference Sampling period.

In addition, the Signal Polarity bit determines which internal reference voltage is used during the Clamping interval. If Signal Polarity = 0, V

REF+

is used for clamping, if Signal Polarity = 1, V

REF-

is

used.

9.5 SMPCL

The SMPCL setting controls when the clamping action occurs

during the acquisit ion cycle. If SMPCL is set to 0, the Clamp will

be on for 1 MCLK before the reference sampling point. If SMPCL

is set to 1, clamping will occur in the interval after the reference

sampling point, and before the signal sampling point. In this case,

the clamping time is dependent on the present “Divide By” mode,

and the settings of the CDSREF bits.

9.6 CDSREF

The CDSREF setting is provided to allow adjustable sampling

points for the reference sample at the higher “Divide By” modes.

This may be u seful to optimize the timing of the Reference Sam-

Applications Inf ormation (Continued)

Page 21

21 www.national.com

pling point for particular CCD sensors. Diagram 7 shows how the

various settings of CDSREF can be used to delay the Reference

Sampling point. Care must be taken to avoid setting CDSREF to

an inappropriate value w hen operating in the lower “Divide By”

modes.

Valid CDSREF settings are:

9.7 PD (Power Down) Mode

A Power Down bit is provided to configure the LM9822 in a lower

power “StandBy” mode. In this mode, typical power consumption

is reduced to less than 1% of normal operating power. The serial

interface is still act ive, but the majority of th e analog and digital

circuitry is powered down.

10.0 LM9822 Basic Operation

The normal operational sequence when using the LM9822 is as

follows:

Immediately afte r applying power, all configuration registers are

reset to default settings. MCLK should be applied, and the appropriate values written to the registers using the procedure discussed in section

8.0 Serial Interface and Configuration Registers

on page 20 and detailed in Diagrams 10, 11 and 12. Once the

configuration r egisters ar e loade d, the timing control signals can

be applied at the proper rates for the mode of conversion desired.

MCLK is applied initially with VSMP and CLMP low. After at least

3 MCLKS, VSMP and CLMP signal s can begin. The Divide By

mode is dete rmin ed by the ratio of MCLK to VSMP fr equency as

described in section 10.2.

14-Bit conversion results are placed on the data out put pins as

follows: The upper 8 bits are output first with bit 13 of the ADC on

D7 and the bit 6 of the ADC on D0. The lower 6 bits are then output with bit 5 of the ADC on D7 and b it 0 of the ADC on D2. D0

and D1 are always 0 when the lower 6 bits of data are being output. The exact timing and conversion latency of the output data is

affected by the settings of the DOE variable in the Sample Mode

register, and the Divide By mode of operation. If DOE = 0 (recommended setting for best performance), output data will change on

the falling edge of MCLK. If DOE = 1, output data is updated on

the rising edge of MCLK. See Diagrams 1 through 6 and Diagram

13 for more information on data output timing.

10.1 CLMP Operation

The CLMP si gnal is used to e ngage the LM 9822 in ternal clamp

circuits at the prop er t ime during the CCD or CIS data output

cycle. If both CLMP and VSMP are high on a rising edge of

MCLK, then CLMP will be applied during the next pixel. The exact

timing of the internal Clamp signal is determined by the Divide By

mode of operation a nd the setting of the SMPCL variable in the

Sample Mode register. If SMPCL = 0, then the Clamp is on for 1

MCLK before the reference is sampled. If SMPCL = 1 then the

clamp is on between the reference and the signal sample points.

Please see D iagram 8 and Diagram 9 for a graphic example of

this timing.

To c lamp acro ss multiple p ixels in a row, CLMP can be set high

and remain there for the entire number of pixels to be clamped,

then return ed to the low state fo r normal (sig nal) operat ion. This

may simplify the timing required to generate the CLMP signal.

10.2 MCLK and VSMP Timing

The relationship between VSMP and MCLK is used to determine

the 'Divide By' mode that is presentl y being used wit h the part.

Valid 'Divide By' settings are:

Color - /8, /6

Monochrome - /8, /6, /3, /2

When entering a n ew mode, it i s im port ant to provide consistent

MCLK/VSMP timing signals that meet the following condition.

When switching to a new 'Divide By' mode, VSMP should be held

low for a minimum of 3 MCLK cycles, then valid timing according

to the datasheet diagrams for the particular mode should be

started. This ensures that all internal circuitry is properly synchronized to the new conversion 'Divide By' mode being used. If the

timing relationship between VSMP and MCLK is disturbed for any

reason, the same procedure shou ld be u sed b efore restarting

operation in the chosen 'Divide By' mode.

For example: To chang e from monochrom e Divide By 3 mode to

monochrome Divide By 2 mode, VSMP should be held low for at

least 3 MCLK cycles, then VSMP can be brought high using

"Divide By 2" timing. If VSMP is not low for at least 3 MCLKs, the

LM9822 may enter an unknown mode.

Figure 6: Timing of Transitions between ‘Divide By’ Modes

“Divide By” Mode Valid CDSREF

/8 00,01,10,11

/6 00,01,10,11

/3 00,01

/2 00

MCLK

VSMP

Divide by 3 Transition Divide by 2

(≥ 3 MCLK)

Applications Inf ormation (Continued)

Page 22

LIFE SUPPORT POLICY

NATIONAL'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which,

(a) are intended f or surgical implant into the body, or (b) support

or sustain life, and whose failure to perform, when properly used

in accordance with instru ctions for use provided in the labeling,

can be reasonably expected to result in a significant injury to the

user.

2. A critical component is any component of a life support device

or system whose failure to perform can b e reasonably expected

to cause the failure of the life support device or system, or to

affect its safety or effectiveness.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

National Semiconductor Europe

Fax: +49 (0) 1 80-530 85 86

Email: eu r ope.suppor t @ nsc.com

Deutsch Tel: + 49 (0) 180-530 85 85

English Tel: + 49 (0) 180-532 78 32

Francais Tel: + 49 (0) 180-532 93 58

Italiano Tel: + 49 (0) 180-534 16 80

National Semicon du ctor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Se mi c on duc tor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7 507

N

Nation al does not assum e any responsibility for use of any circuitry described, no circuit patent licenses are implied and Nati nal reserves th e right at any tim e with out not ic e to ch ange said circuitr y and speci fi c ations.

Physical Dimension

inches (millimeters) unless otherwise noted

28-Lead (0.300" wide) Molded Small Outline Package (JEDEC)

Order Number LM9822CCWM

NS Package Number M28B

www.national.com

Loading...

Loading...