Page 1

N

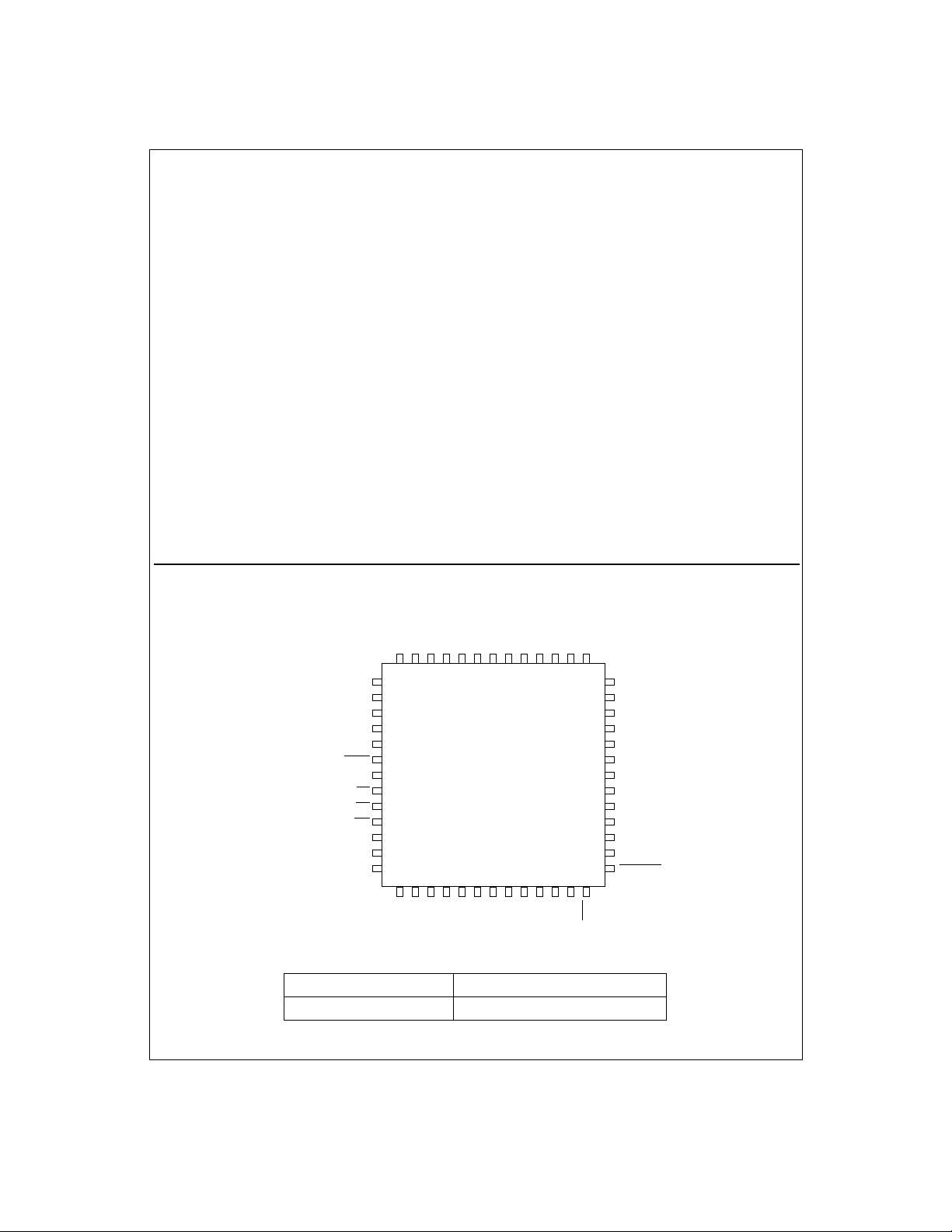

LM9812 30-Bit Color Linear CCD Sensor Processor

LM9812 30-Bit Color Linear CCD Sensor Processor

December 1997

General Description

The LM9812 is a high performance integrated signal processor/digitizer for color linear CCD image scanners. The LM9812

performs all the si gnal processing ( correlated double sa mpling,

pixel rate offset and shading correc tion, color balance control,

and 10-bit analog-to- digital conversion) necessary to maximize

the performance of a wide range of linear CCD sensors.

The LM9812 can be digitally programme d to work with a wi de

variety of CCDs from different manufacture rs, including both 3

output RGB and 2 output GRGB CCDs. An internal Configuration Register sets CCD and sampling timing to maximize performance, simplifying the design and manufacturing processes. For

complementary voltage reference see the LM4041-ADJ.

Applications

•

Color Flatbed Document Scanners

•

Color Sheetfed Scanners

•

Multifunction Imaging Products

•

Digital Copiers

•

General Purpose Linear CCD Imaging

Connection Diagrams

OSROSGOSBV

TR2

8

TR1

9

RS

10

ø2

11

ø1

SYNC

CS

RD

WR

MCLK

OCLK

GCLK

12

13

14

15

16

17

18

19

20

LM9812CCV

21 22 23 24 25 26 27 28 29 30 31 32 33

CD9

CD8

CD7

CD6

RUN/STOP

Features

•

6 million pixels/s conversion rate (2MHz/channel x 3)

•

Pixel rate shading (gain) correction for individual pixels

eliminates errors from PRNU, illumination, etc.

•

Digitally programmed color balance controls

•

Pixel rate offset correction for highest quality in dark regions

•

Correlated Double Sampling for lowest noise

•

Reference and signal sampling points digitally controlled in

20ns increments

•

2x and 4x analog fast preview/low resolution modes

•

Digital control of CCD integration time

•

Generates all necessary CCD clock signals

•

Compatible with a wide range of color linear CCDs and

Contact Image Sensors (CIS)

•

TTL/CMOS input/output compatible

Key Specifications

•

Output Data Resolution 10 Bits

•

Pixel Conversion Rate (total) 6MHz

•

Supply Voltage +5V±5%

•

Supply Voltage (Digital I/O) +3.3V±10% or +5V±5%

•

Power Dissipation (typical) 390mW

REF IN

A

AGND

V

V

1234567

D

V

CD5

DGND

REF MID OUTVREF MID INVREF HI OUT

REF HI IN

V

52 51 50 49 48 47

CD4

CD3

CD2

CD1

REF LO OUTVREF LO IN

V

CD0

TEST

EOC

46

45

44

43

42

41

40

39

38

37

36

35

34

D9

D8

D7

D6

D5

V

DI/O

D4

DGND

I/O

D3

D2

D1

D0

RD PIXEL

Ordering Information

Commercial (0°C ≤ TA ≤ +70°C) Package

LM9812CCV V52A 52 Pin Plastic Leaded Chip Carrier

TRI-STATE® is a registered trademark of National Semiconductor Corporation.

©1997 National Semiconductor Corporation

1

http://www.national.com

Page 2

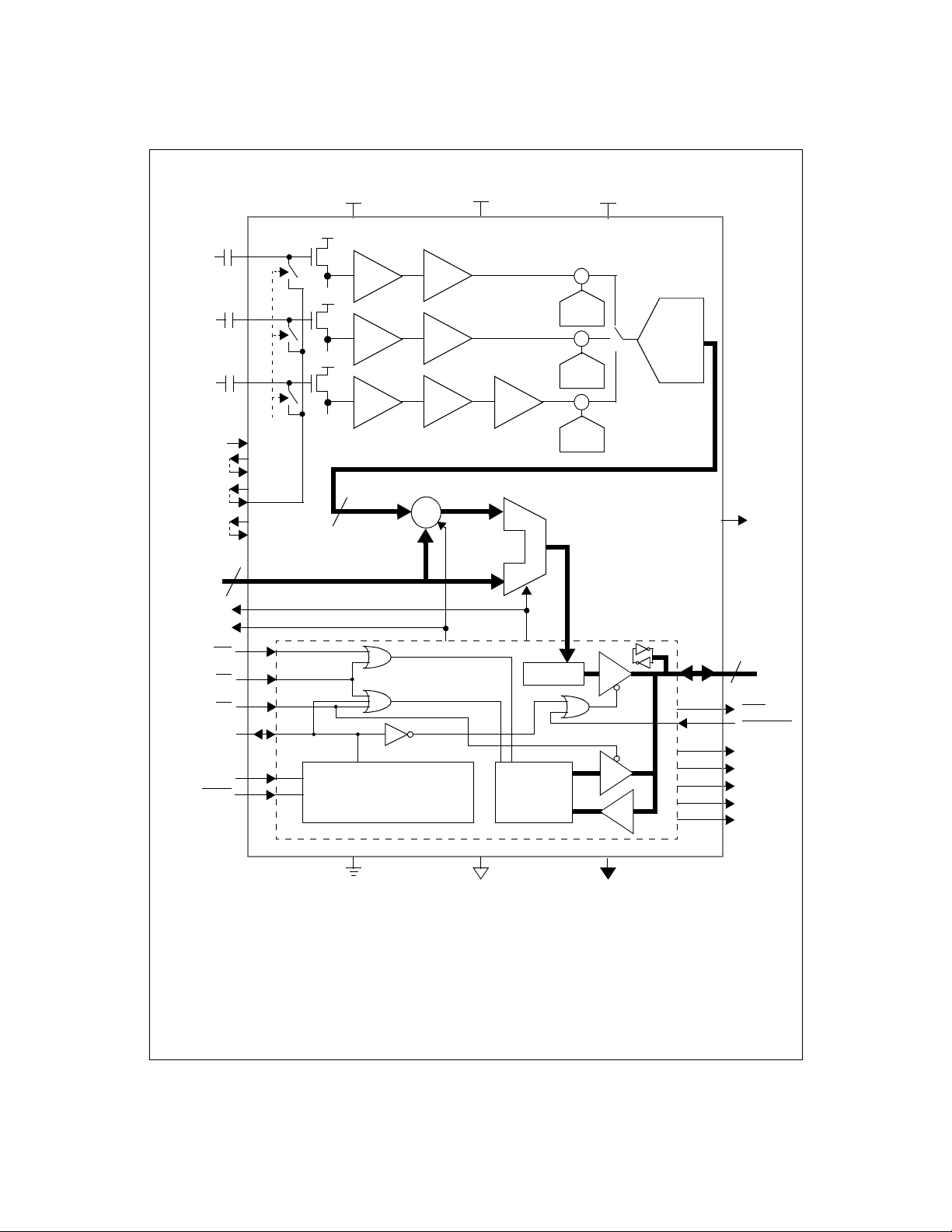

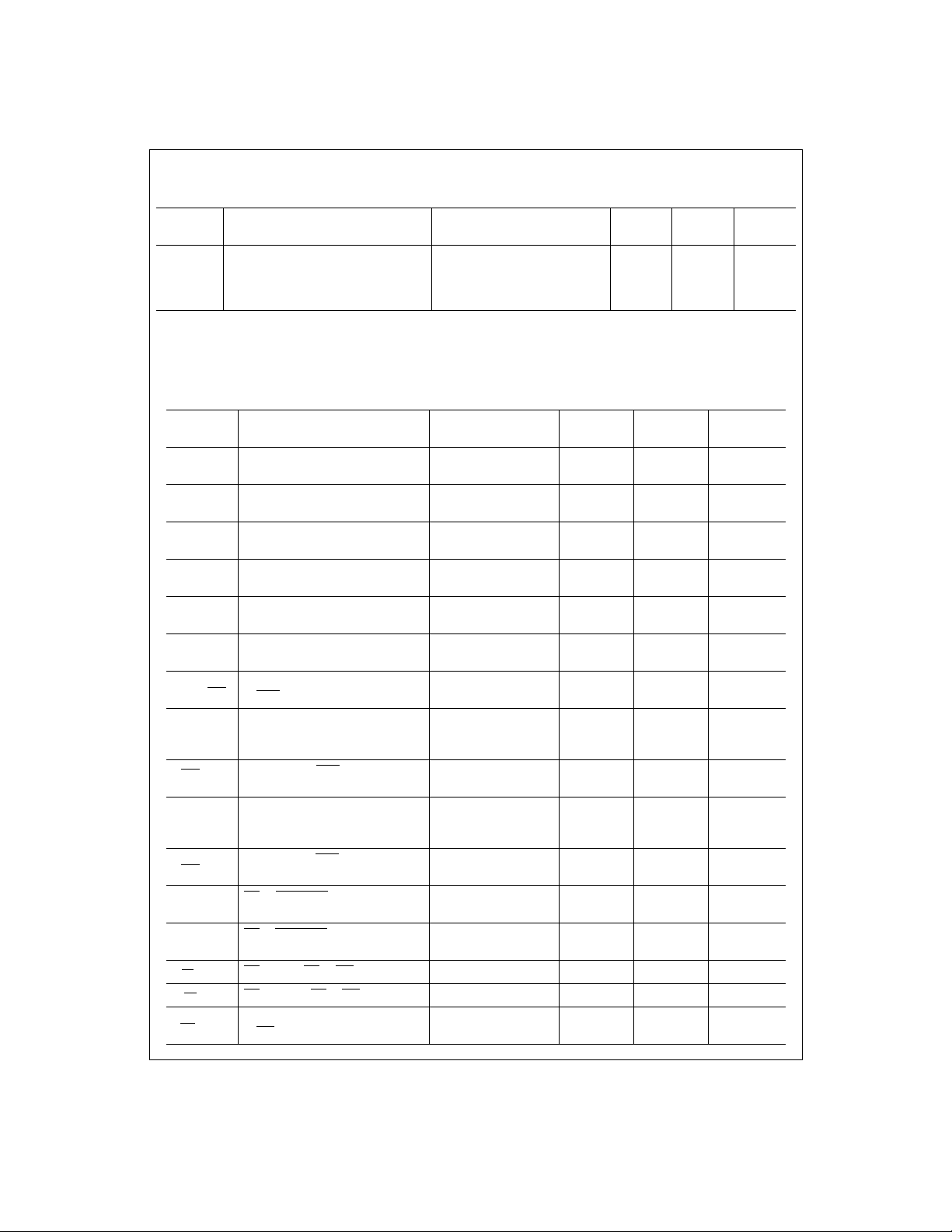

Block Diagram

RED OS

from Sensor

GREEN OS

from Sensor

BLUE OS

from Sensor

V

REF IN

V

REF LO OUT

V

REF LO IN

V

REF MID OUT

V

REF MID IN

V

REF HI OUT

V

REF HI IN

Gain/Offset

Coefficients

CD0-CD9

GCLK

SYNC

MCLK

RUN/STOP

OCLK

WR

CS

RD

OS

OS

OS

10

R

G

B

CLAMP

V

A

Coarse Color

Balance PGAs

CDS

CDS

CDS

x1-x3

x1-x3

x1-x3

Pixel-Rate Offset Subtractor

+

10 bits

+

-

Control

Logic

V

D

Blue Gain

x1or x3

Boost

Pixel-Rate

Shading Multiplier

Pixel Data

Latch

Configuration

Register

Static

Offset

DACs

+

²

+

Offset

DAC

+

²

+

Offset

DAC

+

²

+

Offset

DAC

V

DI/O

R

10-Bit,

6MHz

ADC

G

B

TEST

Pixel Data Output/

Control Data I/O

10

D0-D9

EOC

RD PIXEL

ø1

ø2

RS

TR1

TR2

AGND

DGND

2

DGND

I/O

http://www.national.com

Page 3

Absolute Maximum Ratings

Positive Supply Voltage (V+=VA=VD=V

With Respect to GND=AGND=DGND=DGND

Voltage On Any Input or Output Pin 0.3V to V

DI/O

(Notes 1 & 2)

)

I/O

+

+0.3V

Input Current at any pin (Note 3) ±25mA

Package Input Current (Note 3) ±50mA

Package Dissipation at T

ESD Susceptibility (Note 5)

= 25°C (Note 4)

A

Human Body Model 2000V

Soldering Information

Infrared, 10 seconds (Note 6) 300°C

Storage Temperature -65°C to +150°

Operating Ratings

Operating Temperature Range T

6.5V

LM9812CCV 0°C≤T

V

Supply Voltage +4.75V to +5.25V

A

V

Supply Voltage +4.75V to +5.25V

D

V

Supply Voltage +3.0V to +5.25V

DI/O

|V

|

A-VD

V

A-VDI/O

OS

, OSG, OSB, V

R

Input Voltage Range -0.05V to V

CD0-CD9, D0-D9, MCLK, SYNC,

RUN/STOP

REF IN

, CS, RD, WR, RD PIXEL

(Notes 1 & 2)

Input Voltage Range -0.05V to V

≤

MIN

≤

< -100mV

A

DI/O

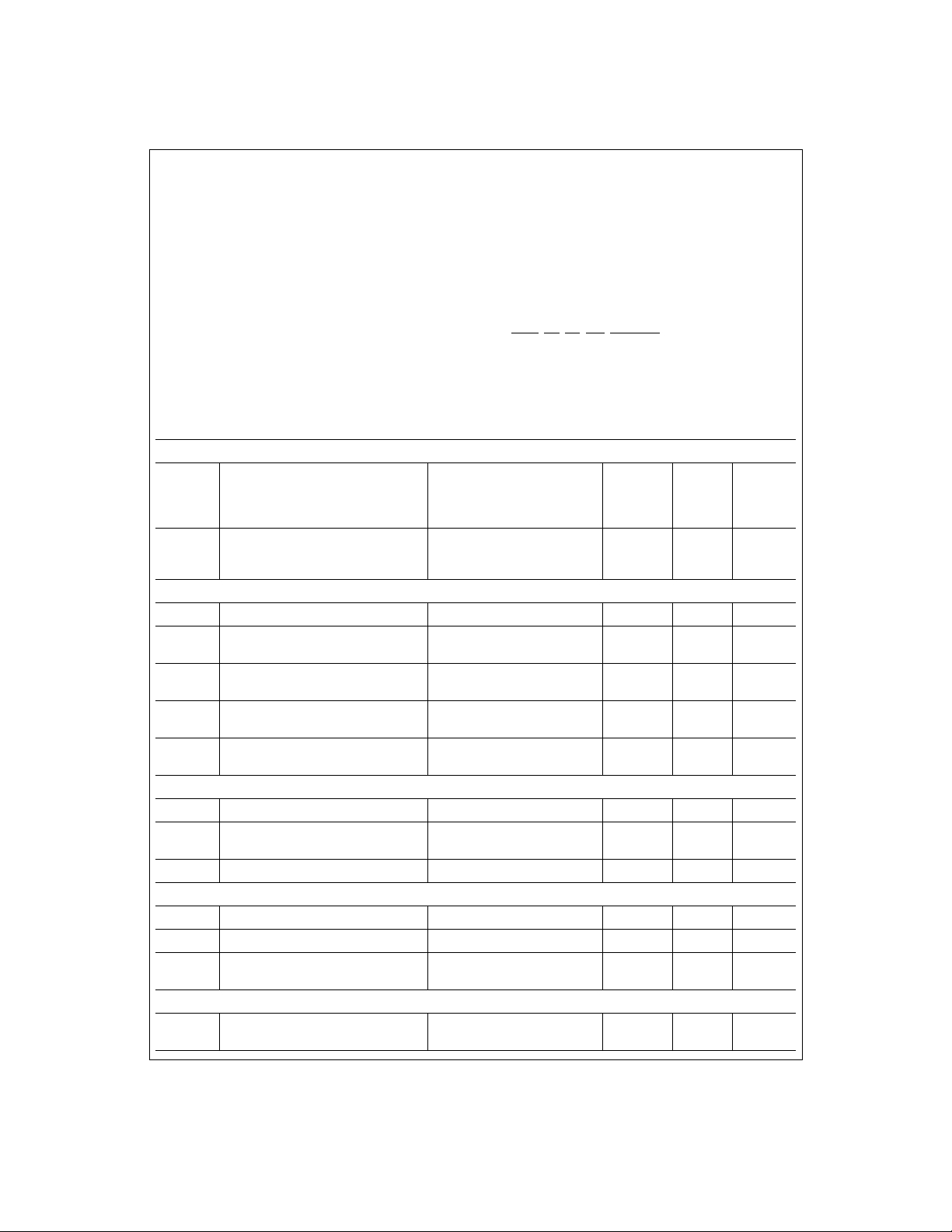

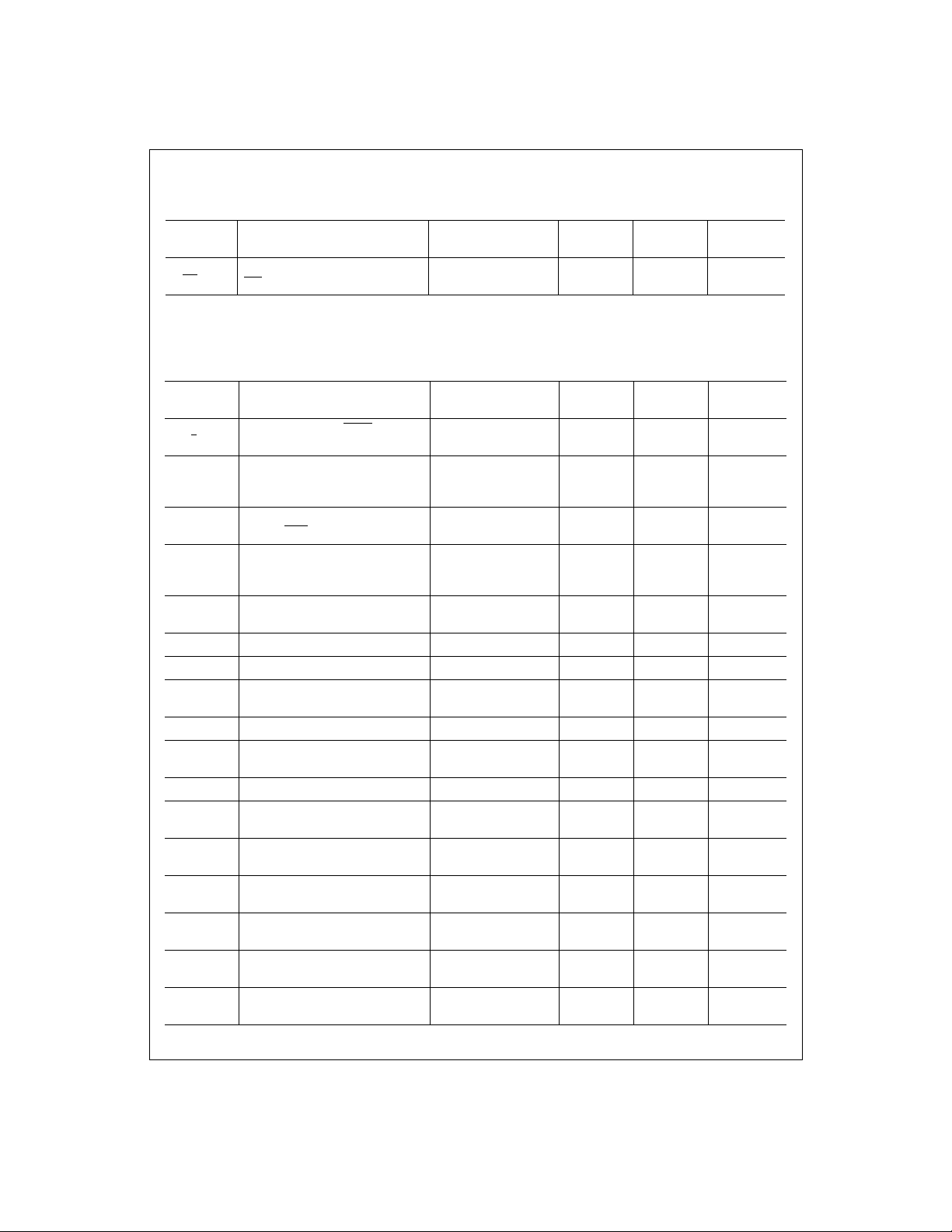

Electrical Characteristics

The following specifications apply for AGND=DGND=DGND

f

=24MHz, Rs=25Ω. Boldface limits apply for T

MCLK

=0V, VA=VD=+5.0V

I/O

A=TJ=TMIN

to T

; all other limits TA=TJ=25°C. (Notes 7, 8, & 12)

MAX

CCD/CIS Source Requirements for Full Specified Accuracy and Dynamic Range (Note 12)

Color Balance PGA gain = 0.933

V

OS PEAK

Sensor’s Maximum Peak Differential

Signal Range

Color Balance PGA gain = 3.0

Color Balance PGA gain = 9.0

(Blue Channel, BOOST on)

Sensor’s Maximum Correctable Range

of Pixel-to-Pixel V

Variation/Color

WHITE

Range 0

Range 1

Range 2

Coarse Color Balance PGA Characteristics

Monotonicity 5 bits (min)

G

(Minimum PGA Gain) PGA Setting = 0 0.93

0

G

(Maximum PGA Gain) PGA Setting = 31 3.00

31

G

BLUE BOOST

Blue PGA Boost Setting = x3 3.00

Gain Error at any gain (Note 14) ±1.0 ±4.0

Static Offset DAC Characteristics

Monotonicity 6 bits (min)

Offset DAC LSB size In units of ADC LSBs 4.2

Offset DAC Adjustment Range In units of ADC LSBs ±130 ±118 LSB (min)

ADC Characteristics

Resolution with No Missing Codes 10 Bits (min)

ILE Integral Linearity Error (Note 11) ±0.4 ±1.5 LSB (max)

DNL Differential Non-Linearity

System Characteristics

C Analog Channel Gain Constant 2.00

, V

=+5.0 or +3.3VDC, V

DC

DI/O

-0.14

+0.32

REF IN

1.0

0.33

0.11

67 (1:3)

50 (1:2)

33 (1:1.5)

0.90

0.97

2.85

3.20

2.72

3.27

1.3

7.2

-0.5

+1.0

1.83

2.17

= +2.0VDC,

≤

T

T

A

MAX

≤

+70°C

A

100mV

+ 0.05V

+ 0.05V

V (min)

V (min)

V (min)

%

%

%

V/V (max)

V/V (min)

V/V (max)

V/V (min)

V/V (max)

V/V (min)

% (min)

% (max)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

(min)

(max)

3

http://www.national.com

Page 4

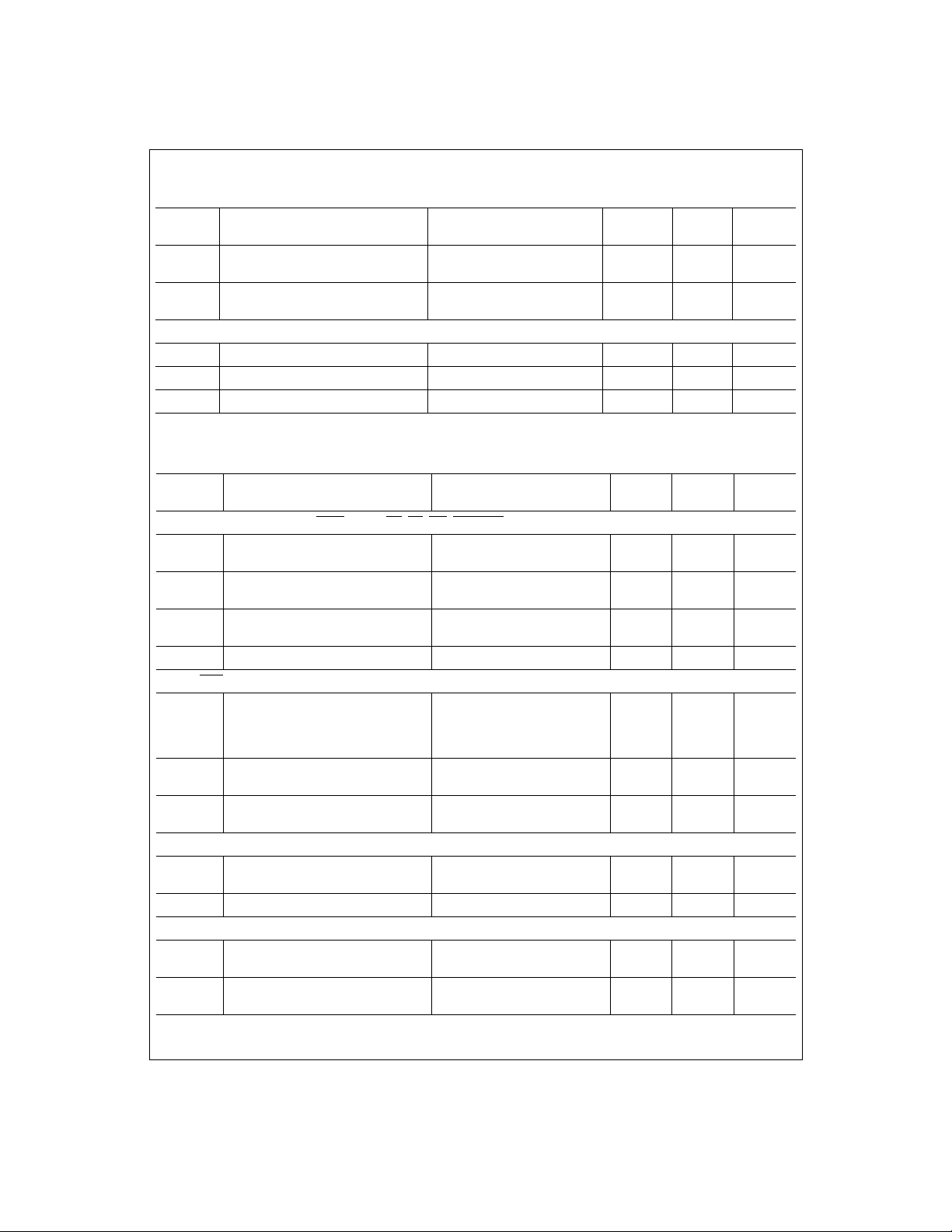

Electrical Characteristics

The following specifications apply for AGND=DGND=DGND

f

=24MHz, Rs=25Ω.

MCLK

V

V

V

Pre-PGA Analog Channel Offset Error

OS1

CCD Mode

Pre-PGA Analog Channel Offset Error

OS1

CIS Mode

Post-PGA Analog Channel Offset Error In units of ADC LSBs -5

OS2

Boldface limits apply for T

(Continued)

V

V

=0V,

=

I/O

A=TJ=TMIN

=

A

D

to T

; all other limits TA=TJ=25°C. (Notes 7, 8, & 12)

MAX

In units of ADC LSBs +5

In units of ADC LSBs +32

Reference and Analog Input Characteristics

OS

, OSG, OSB Input Capacitance 5 pF

R

OS

, OSG, OSB Input Leakage Current Measured with OS = 2.5V

R

V

Input Leakage Current Measured with V

REF IN

REF IN

DC and Logic Electrical Characteristics

V

The following specifications apply for AGND=DGND=DGND

f

=24MHz, Rs=25Ω.

MCLK

Boldface limits apply for T

I/O

A=TJ=TMIN

Symbol Parameter Conditions

D0-D9, CD0-CD9, MCLK, RUN/STOP

V

V

C

D0-D9, EOC

V

OUT(1)

V

OUT(0)

I

OUT

Logical “1” Input Voltage

IN(1)

Logical “0” Input Voltage

IN(0)

I

Input Leakage Current

IN

Input Capacitance 5 pF

IN

, GCLK, OCLK, SYNC Digital Output Characteristics

Logical “1” Output Voltage

Logical “0” Output Voltage

TRI-STATE® Output Current

(D0-D9 only)

, SYNC, CS, RD, WR, RD PIXEL Digital Input Characteristics

V

DI/O

V

DI/O

V

DI/O

V

DI/O

V

=V

IN

VIN=DGND

V

DI/O

V

DI/O

V

DI/O

V

DI/O

V

DI/O

V

DI/O

V

OUT

V

OUT

Ø1, Ø2, RS, TR1, TR2 Digital Output Characteristics

V

=4.75V, I

V

V

OUT(1)

OUT(0)

Logical “1” Output Voltage

Logical “0” Output Voltage VD=5.25V, I

D

V

=4.75V, I

D

Power Supply Characteristics

Analog Supply Current

I

A

I

Digital Supply Current

D

Operating

Standby

Operating

Standby

V

=0V,

=

=

A

D

to T

; all other limits TA=TJ=25°C. (Notes 7 & 8)

MAX

=5.25V

=3.6V

=4.75V

=3.0V

D

=4.75V, I

OUT

=4.75V, I

OUT

=3.0V, I

=3.0V, I

=5.25V, I

=3.6V, I

OUT

OUT

OUT

OUT

=-360µA

=-10µA

=1.6mA

=DGND

=V

D

=-360µA

OUT

=-10µA

OUT

=1.6mA

OUT

+5.0

V

= 2.0V

+5.0

V

=-360µA

=-10µA

=1.6mA

, V

=+5.0 or +3.3VDC, V

DC

DI/O

DC

DC

, V

=+5.0 or +3.3VDC, V

DC

DI/O

2

4

Typical

(Note 9)

0.1

-0.1

0.1

-0.1

60

7

4.7

0.1

REF IN

-40

+40

-65

+135

-40

+30

20

20

REF IN

Limits

(Note 10)

2.0

2.0

0.8

0.7

2.4

4.4

2.1

2.5

0.4

0.4

2.4

4.4

0.4

85

10

10

1.0

= +2.0VDC,

LSB (min)

LSB (max)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

nA (max)

nA (max)

= +2.0VDC,

Units

(Limits)

V (min)

V (min)

V (max)

V (max)

µA

µA

V (min)

V (min)

V (min)

V (min)

V (max)

V (max)

µA

µA

V (min)

V (min)

V (max)

mA (max)

mA (max)

mA (max)

mA (max)

4

http://www.national.com

Page 5

DC and Logic Electrical Characteristics

The following specifications apply for AGND=DGND=DGND

f

=24MHz, Rs=25Ω.

MCLK

Boldface limits apply for T

A=TJ=TMIN

I/O

(Continued)

V

V

=0V,

to T

+5.0

=

=

A

D

; all other limits TA=TJ=25°C. (Notes 7 & 8)

MAX

Symbol Parameter Conditions

I

DI/O

Digital I/O Supply Current

Operating, V

Standby, V

Operating, V

Standby, V

DI/O

DI/O

DI/O

= 5.0V

DI/O

= 3.3V

=5.0V

=3.3V

AC Electrical Characteristics, MCLK Independent

V

V

The following specifications apply for AGND=DGND=DGND

, tr=tf=5ns

=1/f

t

MCLK

MCLK

Boldface limits apply for T

, R

=25¾, CL (databus loading) = 50pF/pin.

s

A=TJ=TMIN

to T

; all other limits TA=TJ=25°C. (Notes 7 & 8)

MAX

I/O

=0V,

Symbol Parameter Conditions

f

MCLK

Maximum MCLK Frequency

Minimum MCLK Frequency

MCLK Duty Cycle

t

SETUP (OUT)

t

HOLD (OUT)

t

SETUP (IN)

t

HOLD (IN)

t

GCLK-EOC

Coefficient Data valid before latching

edge of OCLK or GCLK

Coefficient Data held after latching

edge of OCLK or GCLK

Coefficient Data Valid before latching

edge of OCLK or GCLK

Coefficient Data held after latching

edge of OCLK or GCLK

Rising edge of GLCK to falling edge

of EOC

(GCLK as output)

GCLK and OCLK as

outputs

GCLK and OCLK as

outputs

GCLK and OCLK as

inputs

GCLK and OCLK as

inputs

Rising edge of GLCK to falling edge

t

GCLK-OCLK

t

EOC-OCLK

t

OCLK-GCLK

of OCLK (GCLK and OCLK as

outputs)

Rising edge of EOC to rising edge of

OLCK (OCLK as output)

Rising edge of OLCK to falling edge

of GLCK (GCLK and OCLK as

2 bus / 2 clock mode 1 ns

2 clock mode 1 ns

2 clock mode 3 ns

outputs)

t

EOC-GCLK

t

DACC

t

D1H, D0H

t

CS SETUP

t

CS HOLD

t

WR SETUP

Rising edge of EOC to falling edge of

GLCK (GCLK as output)

RD or RD_PIXEL low to D0-D9 data

valid

RD or RD_PIXEL high to D0 - D 9 da ta

tri-state

CS setup of RD or WR

CS hold after RD or WR

D0-D9 data valid before rising edge

of WR

(setup time)

2 bus mode 2 ns

V

=

=

A

D

V

DI/O

, V

=+5.0 or +3.3VDC, V

DC

DI/O

=+5.0

V

DC

Typical

(Note 9)

12

-10

0

0

,

V

Typical

(Note 9)

12

5

2

0.3

REF IN

= +2.0VDC, f

Limits

(Note 10)

24

4

40

60

20

0

5

5

REF IN

Limits

(Note 10)

30

20

10

3

MCLK

= +2.0VDC,

Units

(Limits)

mA (max)

mA (max)

mA (max)

mA (max)

=24MHz

Units

(Limits)

MHz (min)

MHz (max)

% (min)

% (max)

ns (min)

ns (min)

ns (min)

ns (min)

,

2ns

15

13

41

20

0

0

5

ns (max)

ns (max)

ns (min)

ns (min)

ns (min)

5

http://www.national.com

Page 6

AC Electrical Characteristics, MCLK Independent

The following specifications apply for AGND=DGND=DGND

, tr=tf=5ns

=1/f

t

MCLK

MCLK

Boldface limits apply for T

, R

=25¾, CL (databus loading) = 50pF/pin.

s

A=TJ=TMIN

to T

; all other limits TA=TJ=25°C. (Notes 7 & 8)

MAX

I/O

=0V,

Symbol Parameter Conditions

t

WR HOLD

D0-D9 data valid after rising edge of

WR

(hold time)

V

=

A

=+5.0

V

V

=

D

DI/O

AC Electrical Characteristics, MCLK Dependent

The following specifications apply for AGND=DGND=DGND

=1/f

t

MCLK

MCLK

labeled C.R.

, tr=tf=5ns

Boldface limits apply for T

, R

=25Ω, CL (databus loading) = 50pF/pin. Refer to Table 2: Configuration Register Parameters for limits

s

A=TJ=TMIN

to T

=0V,

I/O

; all other limits TA=TJ=25°C. (Notes 7 & 8)

MAX

Symbol Parameter Conditions

t

R/S START

t

START

t

SYNC END

Rising edge of RUN/STOP to Rising

edge of SYNC

Rising edge of SYNC to rising edge

of TR1

Falling edge of SYNC to last rising

edge of EOC

SYNC OUT mode

SYNC IN mode

SYNC IN mode

SYNC OUT mode

SYNC IN mode

SYNC OUT mode

SYNC IN mode

t

SYNC LOW

t

TR1 WIDTH

t

TR2 WIDTH

t

GUARD

t

RS WIDTH

t

CLAMP ON

t

CLAMP OFF

t

t

RS

t

HOLD REF

t

HOLD SIG

t

OCLK LOW

t

OCLK HIGH

t

GCLK LOW

t

GCLK HIGH

SYNC low time

,

TR1, TR2 Transfer Pulse Width

TR1, TR2 Transfer Pulse Guardband

Reset Pulse Width

Start of Optical Black clamping

period

End of Optical Black clamping period

Ø1, Ø2 clock period

Ø

RS pulse position from Ø1 edge

Reference hold (sample) position

from RS edge

Signal hold (sample) position from

RS edge

OCLK low time (OCLK as Output)

OCLK high time (OCLK as Output)

GCLK low time (GCLK as Output)

GCLK high time (GCLK as Output)

SYNC OUT mode

Standard Mode

Even/Odd Mode

2 bus mode

1bus mode

2 bus mode

1 bus mode

2 bus mode

1 bus mode

2 bus mode

1 bus mode

V

=

A

=+5.0

V

V

=

D

DI/O

(Continued)

V

DC

Typical

(Note 9)

V

DC

Typical

(Note 9)

t

1+

GUARDBAND

t

13+

GUARDBAND

t

GUARDBAND

8

0

,

,

V

REF IN

V

REF IN

= +2.0VDC, f

Limits

(Note 10)

0

= +2.0VDC, f

Limits

(Note 10)

16

t

GUARDBAND

14+

t

GUARDBAND

t

GUARDBAND

9

0

8

# of EOL

PIxels - 4

C.R.

C.R.

C.R.

C.R.

C.R.

12

24

C.R.

C.R.

C.R.

2*t

MCLK

1*t

MCLK

2*t

MCLK

3*t

MCLK

2*t

MCLK

1*t

MCLK

2*t

MCLK

3*t

MCLK

MCLK

MCLK

MCLKs (max)

MCLKs (min)

MCLKs (max)

MCLKs (max)

MCLKs (max)

MCLKs (min)

Pixel periods

=24MHz

Units

(Limits)

ns (min)

=24MHz

Units

(Limits)

MCLKs

MCLKs

MCLKs

MCLKs

MCLKs

MCLKs

MCLKs

MCLKs

MCLKs

MCLKs

MCLKs

ns

ns

ns

ns

,

,

6

http://www.national.com

Page 7

AC Electrical Characteristics, MCLK Dependent

V

V

=0V,

The following specifications apply for AGND=DGND=DGND

t

MCLK

labeled C.R.

, tr=tf=5ns

=1/f

MCLK

Boldface limits apply for T

, R

=25Ω, CL (databus loading) = 50pF/pin. Refer to Table 2: Configuration Register Parameters for limits

s

A=TJ=TMIN

I/O

to T

; all other limits TA=TJ=25°C. (Notes 7 & 8)

MAX

Symbol Parameter Conditions

t

EOC LOW

t

EOC HIGH

t

DATA VALID

EOC low time

EOC high time

D0-D9 data valid from falling

Read Phase = 0°)

Phase = 180°)

edge of EOC

or rising

(Data Read

(Data

=

A

D

V

=

(Continued)

=+5.0

DI/O

,

V

DC

Typical

(Note 9)

V

REF IN

= +2.0VDC, f

Limits

(Note 10)

2*t

MCLK

2*t

MCLK

4*t

-20ns

MCLK

MCLK

=24MHz

Units

(Limits)

ns

ns

ns (min)

,

OCLK rising edge to EOC falling edge

t

t

OCLK-EOC 1

(OCLK IN)

(Gain Coefficient Write Phase = 0°),

OCLK falling edge to EOC falling edge

(Gain Coefficient Write Phase = 180°)

1 bus mode w/ext OCLK

MCLK

4*t

+ 40ns

MCLK

ns (min)

ns (max)

OCLK rising edge to EOC rising edge

t

OCLK-EOC 2

(OCLK IN)

(Gain Coefficient Write Phase = 0°),

OCLK falling edge to EOC rising edge

(Gain Coefficient Write Phase = 180°)

2 bus mode w/ext OCLK

3*t

40ns

MCLK

ns (min)

ns (max)

GCLK rising edge to EOC falling edge

t

GCLK-EOC

(GCLK IN)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is functional,

but do not guaran te e specific performance limits. For guarante ed specifications and test conditio ns, s ee the Electrical Characteristics. Th e guaranteed spec if ic at ions apply

only for the test conditio ns lis t ed. Some performance c haracteristics may degrade w hen the device is not operated under the listed test conditions.

Note 2: All voltages are measured with respect to GND=AGND=DGND=DGND

Note 3: When the input voltage (V

imum package input cu rrent rating limits the numb er of pins that can simultaneously safely exceed the power supplies with an input current of 25mA to two.

Note 4: The maximum powe r dissipa tion must be de rated at elevated temp eratur es and is dicta ted by T

able power dissipatio n at any temperature is P

is 52°C/W for the V52A PLCC package

Note 5: Human body model, 100pF capacitor discharged through a 1.5kΩ resistor.

Note 6: See AN450 “Surface Mounting Methods and Their Effect on Product Reliability” or the section ti tl ed “Surface Mount” found in any post 1986 National Semiconduc-

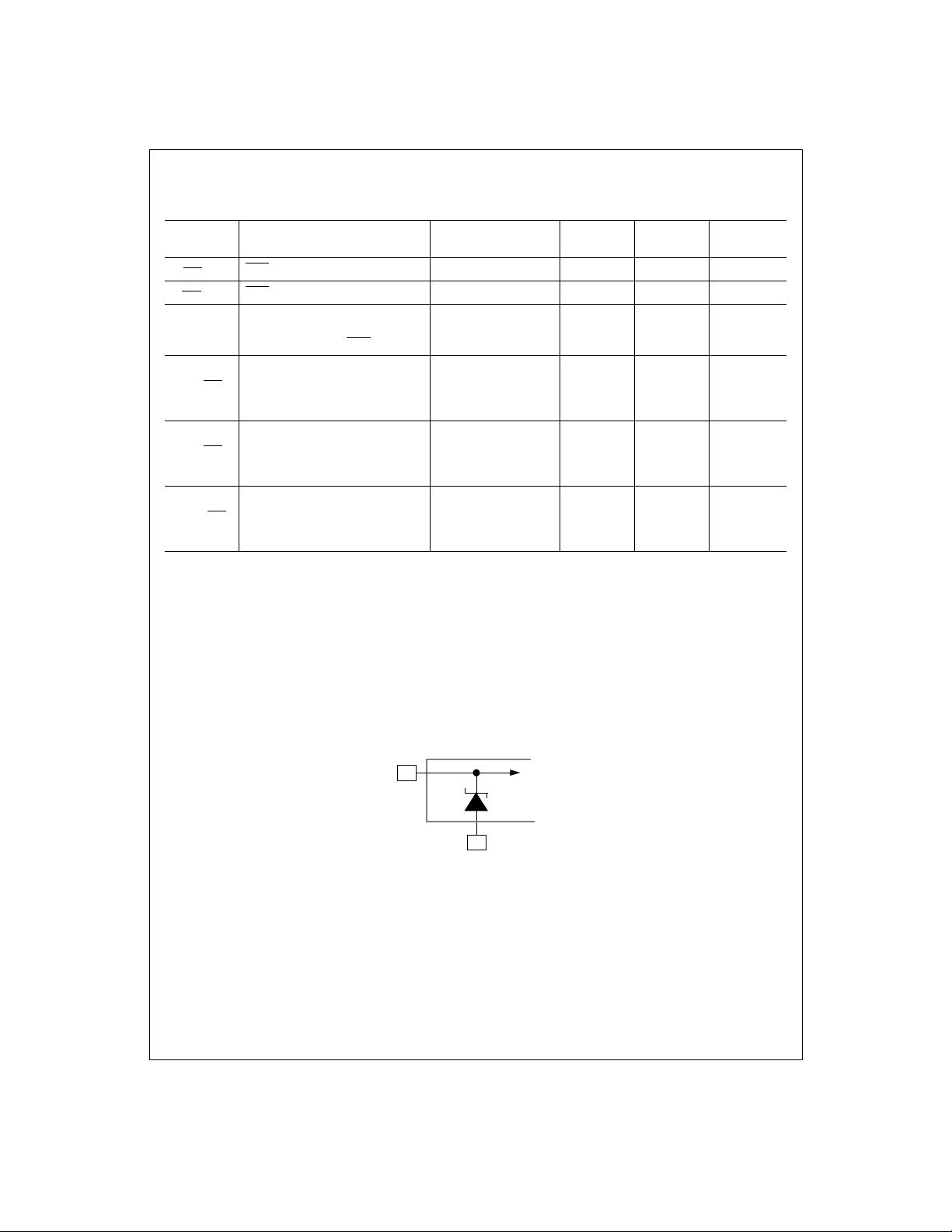

tor Linear Data Book for other methods of solder ing surface mount devices.

Note 7: A Zener diode c lamps the OS an alog inputs to AGND as shown below. This input prote ction, in combin ation with the exter nal clamp capaci tor and the outpu t

impedance of the se ns or, prevents dam age to the LM9812 fro m tran s ients during power-up.

(Gain Coefficient Write Phase = 0°),

GCLK falling edge to EOC falling edge

(Gain Coefficient Write Phase = 180°)

) at any pin exceeds the power supplies (VIN<GND or VIN>VA or VD), the current at that pin should be limited to 25mA. The 50mA max-

IN

= (TJmax - TA) / ΘJA. TJmax = 150°C for this device. The typical thermal resistance (ΘJA) of this part when board mounted

D

.

w/ext GCLK

=0V, unless otherwise specified.

I/O

max, ΘJA and the ambie nt temperature, TA. The maximum allow-

J

3*t

40ns

MCLK

ns (min)

ns (max)

OS Input

AGND

Note 8: To guarantee accuracy, it is required that V

Note 9: Typicals are at T

Note 10: Tested limits are guaranteed to Na t ional's AOQL (Average Outgoing Qualit y Level).

Note 11: Integral linearity error is defined as the deviation of the analog value, expressed in LSBs, from the straight line that best fits the actual transfer function of the ADC.

Note 12: V

a white (full scale) image with respect to the reference level, V

correctable range o f pixel-to-pixel V

is defined as the CCD OS voltage for the reference period f ollowing the reset feedthrough pulse. V

REF

J=TA

=25°C, f

MCLK

WHITE

and VD be connected together to the same power supply w it h s eparate bypass capacito rs at eac h supply pin.

A

= 24MHz, and represent most likely parametric norm.

is defined as the peak positive deviation above V

. V

REF

variation is defi ned as the maxim um variation in V

RFT

7

To Internal

Circuitry

is defined as the peak CCD pixel output voltage for

WHITE

of the reset feedthrough pulse. The maximum

(due to PRNU, light source intensity variation, optics, etc.) that the

WHITE

REF

http://www.national.com

Page 8

LM9812 can correc t for using its internal PGA.

CCD Output Signal

V

RFT

V

Note 13: Reference voltages below 1.80V may decreas e SNR. Reference voltages above 2.20V may cause linearity (headroom) errors inside the LM9812. The

LM4041DIM3-A D J (SOT-23 package) or the LM4041DIZ-ADJ (TO-92 package) bandgap voltage references are recommended for this application.

Note 14: PGA Gain Error is the maximum difference between the measured gain for any PGA code and the ideal gain calculated by using the formula

V

--- -

Gain

PGA

V

PGA code

G0X

---------------- ---------- -+=XG

where .

32

32

–()

------=

31G0

31

V

REF

WHITE

8

http://www.national.com

Page 9

Pin Descriptions

Sensor Driver Signals

ø1 Digital Output. Clock signal, phase 1.

ø2 Digital Output. Clock signal, phase 2.

RS Digital Output. Reset pulse.

TR1, TR2 Digital Output. Transfer pulses.

Analog I/O

OSR, OSG,

OS

,

B

V

REF IN

V

REF LO OUT,

V

REF LO IN

V

REF MID OUT,

V

REF MID IN

V

REF HI OUT,

V

REF HI IN

Analog Inputs. These inputs (for Red, Green,

and Blue) should be tied to the sensor’s OS

(Output Signal) through DC blocking capacitors.

Analog Input. This is the system reference voltage input and should be connected to a 2.0V

voltage source and bypassed to AGND wi th a

0.05µF monolithic capacit or.

Analog Output/Input. V

equal to 0.49V

=2V) developed by the LM9812. It should be

IN

tied to V

REF LO IN

a 0.05µF monolithic capacitor.

Analog Output/Input. V

equal to 0.49V

oped by the LM9812. It should be tied to V

and bypassed to AGND with a 0.05µF

MID IN

monolithic capacitor.

Analog Output/Input. V

equal to 0.49V

=2V) developed by the LM9812. It should be

IN

tied to V

REF HI IN

0.05µF monolithic capacit or.

REF LO OUT

- V

A

REF IN

and bypassed to AGND with

REF MID OUT

(2.45V for V

A

REF HI OUT

+ V

A

REF IN

and bypassed to AGND with a

is a voltage

/2 (1.45V for V

is a voltage

=2V) devel-

REF IN

is a voltage

/2 (3.45V for V

REF

REF

Configuration Register I/O

CS Digital Input. This is the Chip Select signal for

RD

WR

reading or writing to the Configuration Register

through the D0-D9 databus. This input must be

low in order to enable writing to or reading from

the Configuration Register.

Digital Input. A low signal on this input, when

SYNC and CS

the currently addressed Configuration Register on the D0-D9 databus. A RD

resets the internal address latching state

machine. NOTE: If this pin is taken low when

CS is high, the D0-D9 databus will come out of

tri-state and drive random data onto the bus.

Digital Input. This input, when simultaneously

asserted along with CS

the D0-D9 databus to the LM9812. If this is the

first write in the cycle, this data is the address

to be read or written to. If this is the second

write in the cycle, this data is the data to be

written to the Configuration Register at the currently latched address. Writing to the Configuration Register is independent of the state of

SYNC.

are also low, pl aces the data in

cycle also

, transfers the data on

REF

General Digital I/O

MCLK Digital Input. This is the 24MHz (typical) master

SYNC Digital Input (SYNC_IN mode) /

RUN/STOP

system clock.

Digital Output (SYNC_OUT mode).

In the SYNC_IN mode, a low-to-high transition

on this input begins a line scan operation. The

line scan operation terminates when SYNC is

taken low. In the SYNC_OUT mode, the rising

edge of this output indicates the start of a line

of data and the falling edge indicates the end of

a line of data.

Digital Input. In the SYNC_OUT mode, this

input should be taken high to begin converting

a series of lines, and taken low to stop converting a series of lines. In the SYNC_IN mode this

input is ignored.

Digital Coefficient I/O

CD0 (LSB) CD9 (MSB)

OCLK Digital Input/Output. This is the signal that is

GCLK Digital Input/Output. This is the signal that is

Digital Inputs. This is the 10 bit data path for

the pixel-rate gain coefficient and offset data.

used to clock the Offset coefficients into the

LM9812 through the CD0-CD9 databus. This

can be either an output or an input depending

on the state of bit 7 of Register 9. D ata is

latched on the rising edge of OCLK.

used to clock the Shading (gain) coefficients

into the LM9812 through the CD0-CD9 databus. Th is can be either an outpu t or an input

depending on the state of bit 7 of Register 9.

Data is latched on the rising edge of GCLK.

Digital Output I/O

D0 (LSB)D9 (MSB)

EOC

RD PIXEL

Digital Inputs/Outputs. When SYNC is high and

RD PIXEL

bit digital output data during line scan. This

databus is also used for reading or writing to

the Configuration Register using the RD

and CS

Register can occur at any time. Reading from

the Configuration Register can only occur

when SYNC is low.

Digital Output. This is the End Of Conversion

signal from the LM9812 indicating that new

pixel data is available on the D0-D9 databus.

Digital Input. When SYNC is high, taking this

input low places the digital pixel data stored in

the output latch onto the D0-D9 bus. This input

is ignored when SYNC is low.

is low, this data bus outputs the 10

, WR

signals. Writing to the Configuration

Test

TEST Analog Output. This pin can be used to view

the CDS and Clamp signals. See Register 27,

bits 6 and 7.

9

http://www.national.com

Page 10

Analog Power

V

A

AGND This is the ground return for the analog supply.

This is the positive supply pin for the analog

supply. It should be connected to a voltage

source of +5V and bypassed to AGND with a

0.1µF monolithic capacitor in parallel with a

10µF tantalum capacitor.

Digital Power

V

D

DGND This is the ground return for the digital supply.

V

DI/O

DGND

This is the positive supply pin for the digital

supply. It should be connected to a voltage

source of +5V and bypassed to DGND with a

0.1µF monolithic capa citor.

This is the positive supply pin for the digital

supply for the LM9812’s I/O. It should be connected to a voltage source of +3V to +5V and

bypassed to DGND

capacitor. If the supply for this pin is different

than the supply for V

bypassed with a 10µF tantalum capacitor.

This is the ground return for the digital supply

I/O

for the LM9812’s I/O.

with a 0.1µF monolithic

I/O

and VD, it should also be

A

10

http://www.national.com

Page 11

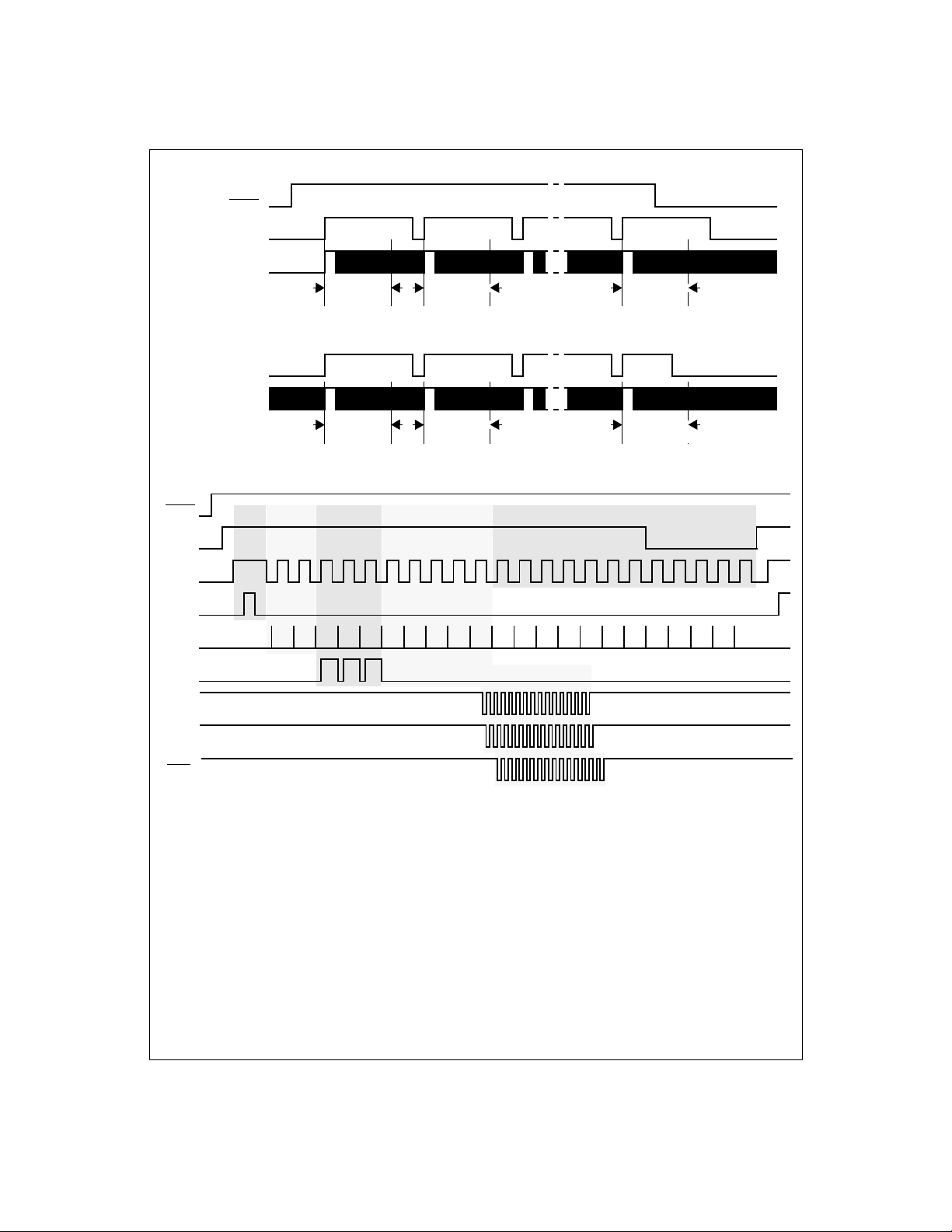

Timing Diagrams

RUN/STOP

SYNC (OUTPUT)

Ø1

SYNC (INPUT)

Ø1

RUN/

STOP

SYNC

(OUTPUT)

Ø1

TR1

Transfer

Dummy Black Valid Pix els

Line 1

Diagram 1: SYNC OUT Mode Timing, Multiple Lines

Line 1

Diagram 2: SYNC IN Mode Timing, Multiple Lines

Line 2 Line n

Line 2 Line n

Additional Integration Time

(truncated)

RS

CLAMP

OCLK

GLCK

EOC

123

Diagram 3: SYNC OUT Mode Timing, One Line

11

http://www.national.com

Page 12

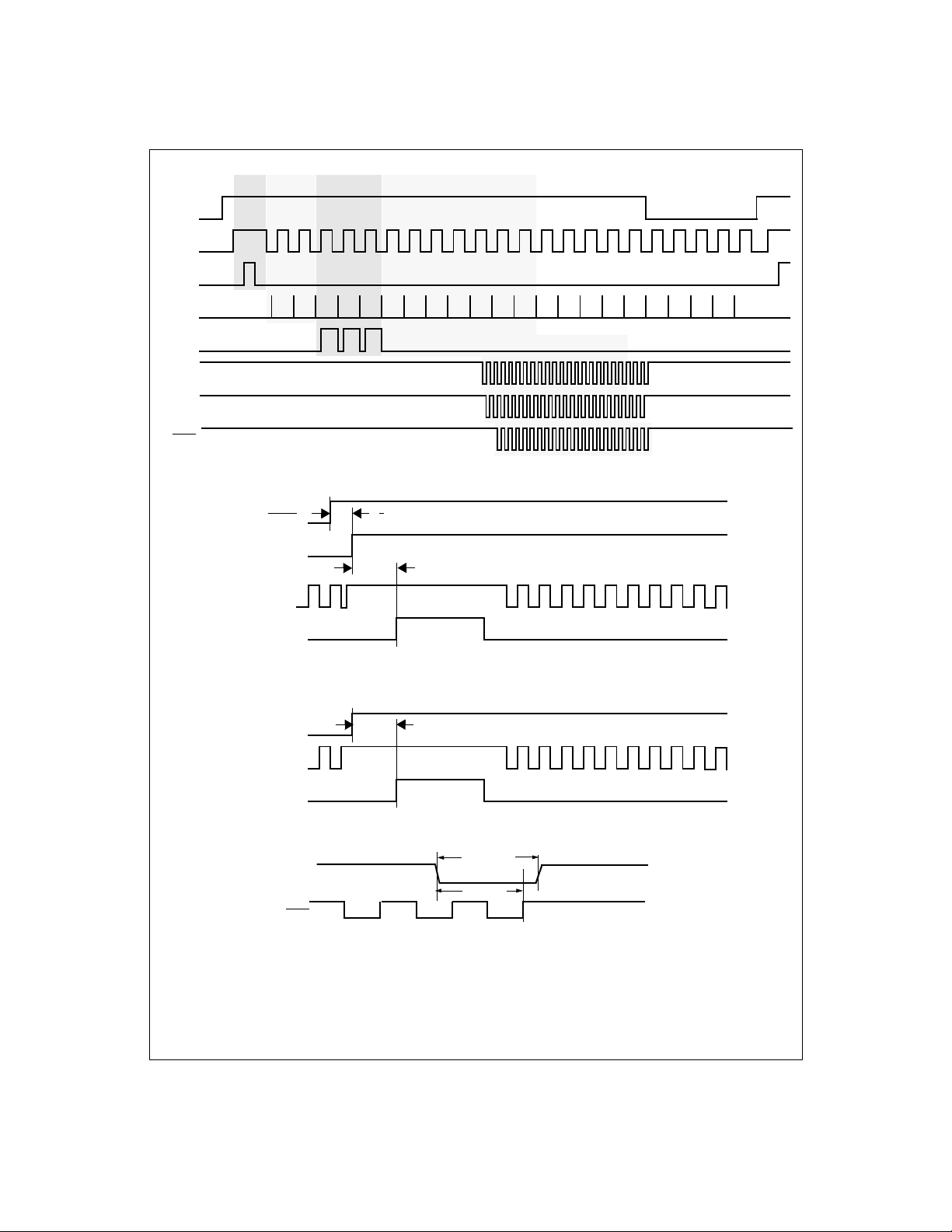

SYNC

(INPUT)

Ø1

TR1

RS

Transfer

Dummy Black Valid Pix els

CLAMP

OCLK

GLCK

EOC

RUN/STOP

SYNC (OUTPUT)

Ø1

TR1

SYNC (INPUT)

Ø1

TR1

123

Diagram 4: SYNC In Mode Timing, One Line

t

R/S START

t

START

Diagram 5: Start of Line Scan, SYNC OUT Mode, One TR Pulse

t

START

Diagram 6: Start of Line Scan, SYNC IN Mode, One TR Pulse

t

SYNC LOW

SYNC

t

SYNC END

8MCLK max

EOC

Diagram 7: Timing for End of Line/Start of Next Line

12

8MCLK min

http://www.national.com

Page 13

TR1 (TR1 Polarity = 0)

TR1 (TR1 Polarity = 1)

TR1 (TR1 Polarity = 0)

t

TR1 WIDTH

t

t

GUARD

GUARD

Ø1

Ø2

Diagram 8: TR Pulse Timing, One TR Pulse

t

TR1 WIDTH

RS

OS

Clamp Signal

(Internal)

TR1 (TR1 Polarity = 1)

TR1 (TR2 Polarity = 0)

TR2 (TR2 Polarity = 1)

RS (RS Polarity = 0)

RS (RS Polarity = 1)

t

GUARD

t

GUARD

t

GUARD

t

TR2 WIDTH

t

GUARD

Ø1

Ø2

Diagram 9: TR Pulse Timing, Two TR Pulses

t

RS WIDTH

Diagram 10: RS Pulse Polarity

nn+1n-1

nn+1n-1

t

CLAMP ON

nn-1

t

CLAMP OFF

Diagram 11: CCD Clamping Timing

13

http://www.national.com

Page 14

Ø1

(Even/Odd Mode)

Ø2

(Even/Odd Mode)

Ø1

(Standard Mode)

Ø2

(Standard Mode)

RS

t

RS WIDTH

t

Ø

t

Ø

t

RS

nn+1n-1

OS

CDS

(Internal)

Hold Ref

(n-1)

Ø1(Std Mode)

Ø2 (Std Mode)

Ø1(Even/Odd)

Ø2 (Even/Odd)

RS

OS

CDS

Clamp

Note:

i = value programmed in Dummy Pixel Register

j = value programmed in Optical Black Register

Diagram 13: Dummy Pixel and Optical Black Pixel Timing

t

HOLD REF

Hold Signal

(n-1)

Diagram 12: CDS Ti ming

pixel 1

(dummy)

nn+1n-1

t

HOLD SIG

Hold Ref

(n)

pixel i pixel i +1

(dummy)

Hold Signal

(black)

(n)

Hold Ref

pixel i +j

(black)

(n-1)

(data)

14

http://www.national.com

Page 15

OCLK (from LM9812)

GCLK (from LM9812)

CD0-CD9

B Gain

n-1

t

GCLK-EOC

R Off

n

t

SETUP

t

HOLD

R Gain

t

GLCK-OCLK

t

SETUP

n

t

HOLD

G Off

n

t

OCLK-GCLK

G Gain

n

EOC

D0-D9

G Output Data

n-1

B Output Data

t

EOC-OCLK

n-1

Diagram 14: Digital Data Timing, Output Data and Coefficient Data on separate buses, two clocks

(OCLK and GCLK) for coefficient data, OCLK and GCLK generated by LM9812, RD PIXEL held low.

t

SETUP

t

HOLD

GCLK (from LM9812)

t

CD0-CD9

EOC

D0-D9

B Gain

t

GCLK-EOC

n-1

G Output Data

R Off

n

t

EOC-GCLK

n-1

R Gain

SETUP

n

B Output Data

t

HOLD

G Off

n

n-1

G Gain

Diagram 15: Digital Data Timing, output data and coefficient data on separate buses, one clock

(GCLK) for coefficient data, GCLK generated by LM9812, RD PIXEL

t

SETUP

t

HOLD

held low.

t

OCLK-GCLK

OCLK (from LM9812)

GCLK (from LM9812)

t

SETUP

t

HOLD

t

EOC-OCLK

CD0-CD9

B Gain

n-1

R Offset

n

R Gain

n

G Gain

n

G Offset

EOC = RD PIXEL

n

t

GCLK-EOC

n

R Gain

B Output Data

B Output Data

n

n-1

n-1

G Off

n

D0-D9

EXTERNAL DATABUS

G Output Data

G Output Data

n-1

n-1

R Off

n

Diagram 16: Digital Data Timing, output data and coefficient data on same buses, two clocks

(OCLK and GCLK) for coefficient data, OCLK and GCLK generated by LM9812.

15

R Out

B Gain

R Out

n

http://www.national.com

n

n

Page 16

GCLK (from LM9812)

CD0-CD9

EOC = RD PIXEL

D0-D9

EXTERNAL DATABUS

B Gain

t

GCLK-EOC

n-1

G Output Data

G Output Data

n-1

n-1

R Offset

R Off

n

t

SETUP

t

HOLD

R Gain

n

R Gain

n

B Output Data

B Output Data

n

n-1

n-1

G Offset

G Off

n

G Gain

n

G Gain

n

t

SETUP

t

n

R Out

R Out

HOLD

n

n

Diagram 17: Digital Data Timing, output data and coeffi cient data on same buses, one clock

(GCLK) for coefficient data, GCLK generated by LM9812.

t

SETUP

t

HOLD

OCLK (to LM9812)

GCLK (to LM9812)

t

R Gain

n

SETUP

t

HOLD

G Off

n

B Output Data

G Gain

t

OCLK-EOC 2 (OCLK IN)

n-1

n

t

GCLK-EOC (GCLK IN)

CD0-CD9

EOC

D0-D9

B Gain

n-1

R Off

n

G Output Data

n-1

Diagram 18: Digital Data Timing, output data and coefficient data on separate buses, two clocks (OCLK and

GCLK) for coefficient data, OCLK and GCLK input to LM9812, OCLK and GLCK phase = 0°, RD PIXEL

t

SETUP

t

HOLD

held low.

OCLK (to LM9812)

GCLK (to LM9812)

t

SETUP

t

HOLD

CD0-CD9

R Gain

n-1

G Off

n

G Gain

n

B Off

n

B Gain

n

EOC

t

GCLK-EOC (GCLK IN)

n-1

B Output Data

n-1

D0-D9

t

OCLK-EOC 2 (OCLK IN)

G Output Data

Diagram 19: Digital Data Timing, output data and coefficient data on separate buses, two clocks (OCLK and

GCLK) for coefficient data, OCLK and GCLK input to LM9812, OCLK and GLCK phase = 180°, RD PIXEL

16

http://www.national.com

held low.

Page 17

OCLK (to LM9812)

GCLK (to LM9812)

CD0-CD9

EOC

B Gain

t

SETUP

t

HOLD

t

SETUP

t

HOLD

n

R Gain

n

G Offset

G Gain

n

t

OCLK-EOC 1 (OCLK IN)

n

n-1

R Offset

t

GCLK-EOC (GCLK IN)

D0-D9

G Output Data

n-1

B Output Data

n-1

R Out

Diagram 20: Digital Data Timing, output data and coeffi cient data on same bus, two clocks (OCLK and

GCLK) for coefficient data, OCLK and GCLK input to LM9812, OCLK and GLCK phase = 0°.

t

SETUP

t

HOLD

OCLK (to LM9812)

GCLK (to LM9812)

t

SETUP

t

HOLD

CD0-CD9

R Gain

n-1

G Offset

G Gain

n

t

GCLK-EOC (GCLK IN)

n

B Offset

t

B Gain

n

OCLK-EOC 1 (OCLK IN)

n

EOC

D0-D9

G Output Data

n-1

B Output Data

n-1

R Out

Diagram 21: Digital Data Timing, output data and coeffi cient data on same bus, two clocks (OCLK and

GCLK) for coefficient data, OCLK and GCLK input to LM9812, OCLK and GLCK phase = 180°.

DATA (INTERNAL)

Green Internal Data

n-1

Blue Internal Data

n-1

EOC

t

RD PIXEL

D0-D9

DATAVALID

Green Output Data

n-1

t

DACC

B

n-1

B Output Data

t

D1H, tD0H

n-1

n

n

Diagram 22: RD PIXEL

Output Timing (Data Read Phase = 0°)

17

http://www.national.com

Page 18

DATA (INTERNAL)

EOC

RD PIXEL

D0-D9

Green Internal Data

t

DATAVALID

Green Output Data

n-1

n-1

Blue Internal Data

B

n-1

t

DACC

B Output Data

n-1

t

D1H, tD0H

n-1

Diagram 23: RD PIXEL

t

CS SETUP

Output Timing (Data Read Phase = 180°)

t

CS HOLD

t

CS SETUP

t

CS HOLD

CS

WR

t

WR SETUP

D0-D7

Note: To read from the Configuration Register, SYNC must be low, either by driving SYNC low (in SYN C IN mod e), or taking RUN/STOP low and waiting for SYNC to go low at the end of a line (in SYNC OUT mod e). T he Configuration Reg is t er c an be written to independent of the state of SYNC.

ADDRESS

t

WR HOLD

t

WR SETUP

DA TA

t

WR HOLD

Diagram 24: Writing to the Configuration Register, RD held high.

SYNC

t

CS SETUP

t

CS HOLD

t

CS SETUP

t

CS HOLD

CS

WR

RD

D0-D7

Note: To read from the Configuration Register, SYNC must be low, either by driving SYNC low (in SYNC IN mode), or taking RUN/STOP low and waiting for SYNC to go low at the end of a line (in SYNC OUT mode). The Configurat ion Register can be written to independe nt of th e stat e of SYNC.

t

WR SETUP

ADDRESS

t

WR HOLD

t

DACC

DATA

t

D1H, tD0H

Diagram 25: Reading the Configuration Register

18

http://www.national.com

Page 19

Table 1: Configuration Register Address Table

Address

(Decimal)

Address

(Binary)

A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0

0 00000

1 00001

2 00010

3 00011

4 00100

5 00101

6 00110

7 00111

8 01000

9 01001

10 01010

11 01011

12 01100

13 01101

14 01110

15 01111

16 10000

17 10001

18 10010

19 10011

20 10100

Data Bits

Static Offset (Red)

- - Sign MSB LSB

Static Offset (Green)

- - Sign MSB LSB

Static Offset (Blue)

- - Sign MSB LSB

Coarse Color Balance PGA (Red)

---MSB LSB

Coarse Color Balance PGA (Green)

---MSB LSB

Coarse Color Balance PGA (Blue)

x3 - - MSB LSB

Internal Offset Subtractor Coefficient

MSB LSB

Internal Gain Multiplier Coefficient

LSB

Internal Gain Multiplier Coefficient (LM9812 only)

------MSB

Misc Group 1

Internal

External

Coefficient

Clock

MSB LSB

MSB LSB

--MSB

--MSB

--MSB LSB

--MSB LSB

--MSB LSB

---MSB LSB

---MSB LSB

Number of

Coefficient

-

Number of End of Line Integration Pixels (LSB)

Number of End of Line Integration Pixels (MSB)

Number of

Databusses

Clocks

in System

Number of Dummy Pixels

Number of Optical Black Pixels

Number of Active Pixels (LSB)

Number of Active Pixels (MSB)

TR1 Pulse Duration

TR2 Pulse Duration

TR1/TR2 Guardbands

Optical Black Clamp Start

Optical Black Clamp End

Multiplier

Gain Range

1

Multiplier

Gain Range

0

Multiplier

Coefficient

Source

Offset

Coefficient

Source

LSB

LSB

19

http://www.national.com

Page 20

Address

(Decimal)

Address

(Binary)

A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0

21 10101

22 10110

23 10111

24 11000

25 11001

26 11010

27 11011

28 11100

Data Bits

Reset Pulse Width Reset Pulse Position

Bit 2 Bit 0 Bit 4 Bit 0

Reference Sample Position

- - - Bit 4 Bit 0

Signal Sample Position

- - - Bit 4 Bit 0

Misc Group 2

Signal

Polarity

Coefficient

Preview 1 Preview 2

8 or 10 bit

Power

Coefficient

Down

Gain

Write

Phase

TB7TB6000000

00000000

Bus

Offset

Coefficient

Write

Phase

Data Read

Phase

Internal/

External

- TR2 Enable TR1 Enable RS Enable Ø2 Enable Ø1 Enable

Ø1 Polarity

During TR1

SYNC

pulse

Misc Group 3

Misc Group 4

Test Mode 1

Test Mode 2

TR Pulse

Mode

(1 or 2

Pulses)

TR2 Pulse

Polarity

Red/Blue

Order for

2 Output

sensors

TR1 Pulse

Polarity

3 or 2

Output

sensor

RS Pulse

Polarity

Standard

or

Odd/Even

sensor

Ø1/Ø2

Polarity

Table 2: Configuration Register Parameters

t

Note:

MCLK

Parameter

(Address)

Red

Offset DAC (0)

Green

Offset DAC (1)

Blue

Offset DAC (2)

= 1/f

= 1 MCLK period. Examples given in parenthesis are for f

MCLK

Control Bits Result

D5

(SIGN)

0

0

0

• • •

0

0

1

1

1

• • •

1

1

D4

D3

D2

(MSB)

• • •

• • •

0

0

0

0

0

0

• • •

1

1

0

0

0

1

1

0

0

0

• • •

1

1

1

1

0

0

0

• • •

1

1

0

0

0

• • •

1

1

D1

• • •

• • •

20

= 24MHz (t

MCLK

D0

(LSB)

0

0

1

0

1

0

• • •

1

1

0

0

1

0

1

0

1

0

• • •

1

1

0

1

= 41.66ns).

MCLK

Typical Offset

(in ADC LSBs)

0.00

+4.2

+8.4

• • •

+126.0

+130.2

0.00

-4.2

-8.4

• • •

-126.0

-130.2

http://www.national.com

Page 21

Table 2: Configuration Register Parameters

t

Note:

MCLK

= 1/f

= 1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

MCLK

= 24MHz (t

= 41.66ns).

MCLK

Parameter

(Address)

Red PGA

(3)

Green PGA

(4)

Blue PGA

(5)

Coarse Color

Balance PGA

(Blue with x3

multiplier bit set)

(5)

Internal

Offset

Subtractor

Coefficient

(6)

D7

0

0

0

• • •

0

0

0

D7

1

1

1

• • •

1

1

1

D7

(MSB)

0

0

0

• • •

1

1

1

Control Bits Result

D4

(MSB)

0

0

0

• • •

1

1

1

D4

(MSB)

0

0

0

• • •

1

1

1

D6

0

0

0

• • •

1

1

1

D5

• • •

D4

0

0

0

1

1

1

0

0

0

• • •

1

1

1

D3

0

0

0

• • •

1

1

1

D3

0

0

0

• • •

1

1

1

D3

0

0

0

• • •

1

1

1

D2

• • •

D2

• • •

D2

• • •

D1

0

0

0

1

1

1

0

0

0

1

1

1

0

0

0

1

1

1

0

0

1

• • •

0

1

1

D1

0

0

1

• • •

0

1

1

D1

0

0

1

• • •

0

1

1

D0

(LSB)

0

1

0

• • •

1

0

1

D0

(LSB)

0

1

0

• • •

1

0

1

D0

(LSB)

0

1

0

• • •

1

0

1

Typical Gain

(V/V)

0.93

1.00

• • •

3.00

Typical Gain

(V/V)

2.79

3.00

• • •

9.00

Offset

(in ADC LSBs)

0

1

2

• • •

253

254

255

Internal

Multiplier

Gain

Coefficient

(7, 8)

Internal/External

Coefficient

Clocks (9)

Number of

Coefficient

Clocks (9)

Number of

Databuses in

System (9)

D9

(MSB)

0

0

0

• • •

1

1

1

D7

0

1

D5

0

1

D4

0

1

D8

• • •

D7

0

0

0

1

1

1

0

0

0

• • •

1

1

1

• • •

• • •

• • •

• • •

21

D2

• • •

D1

0

0

0

1

1

1

0

0

1

• • •

0

1

1

D0

(LSB)

0

1

0

• • •

1

0

1

External Coefficien t Clock Source

Internal Coefficient Clock Source

GCLK and OCLK

GCLK only

2 Databuses

1 Databus

Gain

(V/V)

See

Equation 5

http://www.national.com

Page 22

Table 2: Configuration Register Parameters

t

Note:

MCLK

= 1/f

= 1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

MCLK

= 24MHz (t

= 41.66ns).

MCLK

Parameter

(Address)

Multiplier Gain

Range

(9)

Multiplier

Coefficient

Source

(9)

Offset Coefficient

Source

(9)

Dummy Pixels

(Minimum Value

is 0)

(10)

Optical Black

Pixels

(Minimum Value

is 1)

(11)

D3

D1

D0

D7

• • •

D7

• • •

Control Bits Result

0

0

1

1

0

1

0

1

0

0

0

1

1

1

0

0

0

1

1

1

D2

D6

• • •

D6

• • •

0

1

0

1

0

0

0

1

1

1

0

0

0

1

1

1

D5

0

0

0

• • •

1

1

1

D5

0

0

0

• • •

1

1

1

D4

0

0

0

• • •

1

1

1

D4

0

0

0

• • •

1

1

1

D3

• • •

D3

• • •

0

0

0

1

1

1

0

0

0

1

1

1

D2

0

0

0

• • •

1

1

1

D2

0

0

0

• • •

1

1

1

Range 0, 67% (1:3)

Range 1, 50% (1:2)

Range 2, 33% (1:1.5)

External CD0-CD9 Bus

Internal Register

External CD0-CD9 Bus

Internal Register

D1

0

0

1

• • •

0

1

1

D1

0

1

1

• • •

0

1

1

D0

0

1

0

• • •

1

0

1

D0

1

0

1

• • •

1

0

1

Not Used

0

1

2

• • •

253

254

255

1

2

3

• • •

253

254

255

Active Pixels

(Minimum Value

is 0)

(12, 13)

End of Line

Integration Pixels

(Minimum Value

is 5)

(14, 15)

D13

(MSB)

0

0

0

• • •

1

1

1

D13

(MSB)

0

0

0

• • •

1

1

1

D12

• • •

D12

• • •

D11

0

0

0

1

1

1

0

0

0

1

1

1

0

0

0

• • •

1

1

1

D11

0

0

0

• • •

1

1

1

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

22

D2

• • •

D2

• • •

D1

0

0

0

1

1

1

1

1

1

1

1

1

0

0

1

• • •

0

1

1

D1

0

1

1

• • •

0

1

1

D0

(LSB)

0

1

0

• • •

1

0

1

D0

(LSB)

1

0

1

• • •

1

0

1

Active Pixels

0

1

2

• • •

16381

16382

16383

End-of-Line Pixe ls

5

6

7

• • •

16381

16382

16383

http://www.national.com

Page 23

Table 2: Configuration Register Parameters

t

Note:

MCLK

= 1/f

= 1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

MCLK

= 24MHz (t

= 41.66ns).

MCLK

Parameter

(Address)

TR1

Pulse Duration

(16)

TR2

Pulse Duration

(17)

TR1/TR2 - Ø1

Guardband

(18)

Optical Black

Clamp Start

Position

(Must be Š

RS Pulse Width)

(19)

D

5

(MSB)

0

0

0

• • •

1

1

1

D

5

(MSB)

0

0

0

• • •

1

1

1

4

D

(MSB)

0

0

0

• • •

1

1

1

D4

• • •

D4

• • •

D3

• • •

Control Bits Result

D3

0

0

0

0

0

0

• • •

1

1

1

1

1

1

D3

0

0

0

0

0

0

• • •

1

1

1

1

1

1

D2

0

0

0

0

0

0

• • •

1

1

1

1

1

1

D2

0

0

0

• • •

1

1

1

D2

0

0

0

• • •

1

1

1

D1

0

0

1

• • •

0

1

1

D1

0

0

1

• • •

0

1

1

D1

0

0

1

• • •

0

1

1

D0

(LSB)

0

1

0

• • •

1

0

1

D0

(LSB)

0

1

0

• • •

1

0

1

D0

(LSB)

0

1

0

• • •

1

0

1

= (x/2)t

t

pixel

3 channel mode,

t

pixel

, where

pixel

= 12t

MCLK

= 8t

MCLK

channel mode

for

for 2

(except for x = 0:

duration for x = 0 is

0.5tpixel, same as

for x = 1)

= (x/2)t

t

pixel

3 channel mode,

t

pixel

, where

pixel

= 12t

MCLK

= 8t

MCLK

channel mode

for

for 2

(except for x = 0:

guardband for x = 0

is 0.5tpixel, same

as for x = 1)

TR Pulse Width

0.5 t

pixel

0.5 t

pixel

1.0 t

pixel

• • •

30.5 t

pixel

31.0 t

pixel

31.5 t

pixel

TR Guardband

0.5 t

pixel

0.5 t

pixel

1.0 t

pixel

• • •

30.5 t

pixel

31.0 t

pixel

31.5 t

pixel

Clamp Start

(1/(2*f

MCLK

0

))

1

2

• • •

29

30

31

Optical Black

Clamp Stop

Position

(20)

Reset Pulse

Width

(Minimum Value

Is 1)

(21)

D4

(MSB)

0

0

0

• • •

1

1

1

7

D

(MSB)

0

0

0

1

1

1

1

D3

• • •

D6

D2

0

0

0

0

0

0

• • •

1

1

1

1

1

1

D5

(LSB)

0

1

1

0

0

1

1

1

0

1

0

1

0

1

D1

0

0

1

• • •

0

1

1

23

D0

(LSB)

0

1

0

• • •

1

0

1

Clamp Stop

(1/(2*f

MCLK

0

))

1

2

• • •

29

30

31

RS Pulse Width

(1/(2*f

MCLK

1

))

2

3

4

5

6

7

http://www.national.com

Page 24

Table 2: Configuration Register Parameters

t

Note:

MCLK

= 1/f

= 1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

MCLK

= 24MHz (t

= 41.66ns).

MCLK

Parameter

(Address)

Reset Pulse

Position

(21)

Reference

Sample

Position

(22)

Signal

Sample

Position

(23)

D

4

(MSB)

0

0

0

• • •

1

1

1

D

4

(MSB)

0

0

0

• • •

1

1

1

D4

(MSB)

0

0

0

• • •

1

1

1

D3

• • •

D3

• • •

D3

• • •

Control Bits Result

D2

0

0

0

0

0

0

• • •

1

1

1

1

1

1

D2

0

0

0

0

0

0

• • •

1

1

1

1

1

1

D2

0

0

0

0

0

0

• • •

1

1

1

1

1

1

D1

0

0

1

• • •

0

1

1

D1

0

0

1

• • •

0

1

1

D1

0

0

1

• • •

0

1

1

D0

(LSB)

0

1

0

• • •

1

0

1

D0

(LSB)

0

1

0

• • •

1

0

1

D0

(LSB)

0

1

0

• • •

1

0

1

Reset Position

(1/(2*f

MCLK

0

))

1

2

• • •

29

30

31

Reference Position

(1/(2*f

MCLK

0

))

1

2

• • •

29

30

31

Signal Position

(1/(2*f

MCLK

0

))

1

2

• • •

29

30

31

Signal Polarity

(24)

Preview Mode

(24)

SYNC Pulse

(24)

TR Pulses

(24)

Red/Blue Order

for GRGB CCDs

(24)

Sensor Type

(24)

D7

D6

D4

D3

D2

D1

0

1

Negative, CDS On (CCD)

Positive, CDS Off (CIS)

D5

0

0

1

1

0

1

0

1

0

1

0

1

0

1

0

1

Normal Operation

Normal Operation

2x Speed

4x Speed

Externally Supplied (SYNC is Input)

Internally Generated (SYNC is Output)

1 TR Pulse (TR1)

2 TR Pulses (TR1 and TR2)

GR First

GB First

Dual Output (RG-BG)

Triple Output (R-G-B)

24

http://www.national.com

Page 25

Table 2: Configuration Register Parameters

t

Note:

MCLK

= 1/f

= 1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

MCLK

= 24MHz (t

= 41.66ns).

MCLK

Parameter

(Address)

Sensor Type

(24)

Power Down

(25)

Coefficient Bus

Width

(25)

TR2 Enabl e

(25)

TR1 Enabl e

(25)

RS Enable

(25)

Ø2 Enable

(25)

Ø1 Enable

(25)

D0

D7

D6

D4

D3

D2

D1

D0

Control Bits Result

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

In 8 bit mode, coefficient data is 8 bits wide,

input through CD0-CD7.

Standard

Even/Odd

Operating

Low Power Standby Mode

10 bit

8 bit

TR2 Enabled

TR2 Disabled

TR1 Enabled

TR1 Disabled

RS Enabled

RS Disabled

Ø2 Enabled

Ø2 Disabled

Ø1 Enabled

Ø1 Disabled

Gain Coefficient

Write Phase

(26)

Offset Coefficient

Write Phase

(26)

Data Read Phase

(26)

Ø1 Polarity

During TR1

(26)

TR2 Pulse

Polarity

(26)

TR1 Pulse

Polarity

(26)

D7

D6

D5

D4

D3

D2

0

1

0

1

0

1

0

1

0

1

0

1

25

0°

180°

0°

180°

0°

180°

High

Low

High

Low

High

Low

http://www.national.com

Page 26

Table 2: Configuration Register Parameters

t

Note:

MCLK

= 1/f

= 1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

MCLK

= 24MHz (t

= 41.66ns).

MCLK

Parameter

(Address)

RS Pulse Polarity

(26)

Ø1/Ø2 Polarity

(26)

Test Mode

(27)

Test Mode

(28)

Control Bits Result

D1

0

1

D0

0

1

TB7

TB6

0

0

1

0 0 0 0 0 0 0 0 Set all bits to 0

0

1

1

Set bits D0-D5 to 0

Test Output Is CDS Signal

Test Output is Clamp Signal

High

Low

Ø1 High/Ø2 Low

Ø1 Low/ Ø2 High

Test Output Low

26

http://www.national.com

Page 27

Applications Information

1.0 THEORY OF OPERATION

The LM9812 removes error s from and digitizes up t o 3 channe ls

of linear sensor pixel stream s, while providing all the necessar y

clock signals to drive the sensor. Offset and gain errors are

removed at the pixel rate, for individual pixels. Offset errors are

removed through corr elated double sampling (CDS), an analog

offset DAC for large DC offsets, and finally a pixel-rate digital offset subtractor for individual pixel offsets. Gain erro rs (which may

come from any combination of PRNU, uneven illumination, cos

effect, RGB filter mismatch, etc.) are re moved through th e use of

a 5 bit PGA in front of t he A DC ( for coarse ga i n cor re ction ) an d a

10x10bit pixel-rate digital multiplier for individual pixel gain errors.

1.1 ANALOG SIGNAL PATH (See Functional Block Diagram)

1.1.1 Clamping and Buffering

The Output Signals ( OS) fro m the ima ge sensor are capac itively

coupled to the three (OS

LM9812. Inside the LM9812, a DC restore operation is performed

by clamping the input signal to 2.5V when the input signal is

known to be black (during t he star t of a new line of image da ta).

To eliminate loading of the input signal, the signal is buffered

through a source follower before being sent to the CDS section.

1.1.2 CDS

The LM9812 uses a high performance C DS (Correlated Do uble

Sampling) circuit to remove many sources of noise and error from

the CCD signal. It also support s CIS image sensors with a single

sampling mode for positive-going signals.

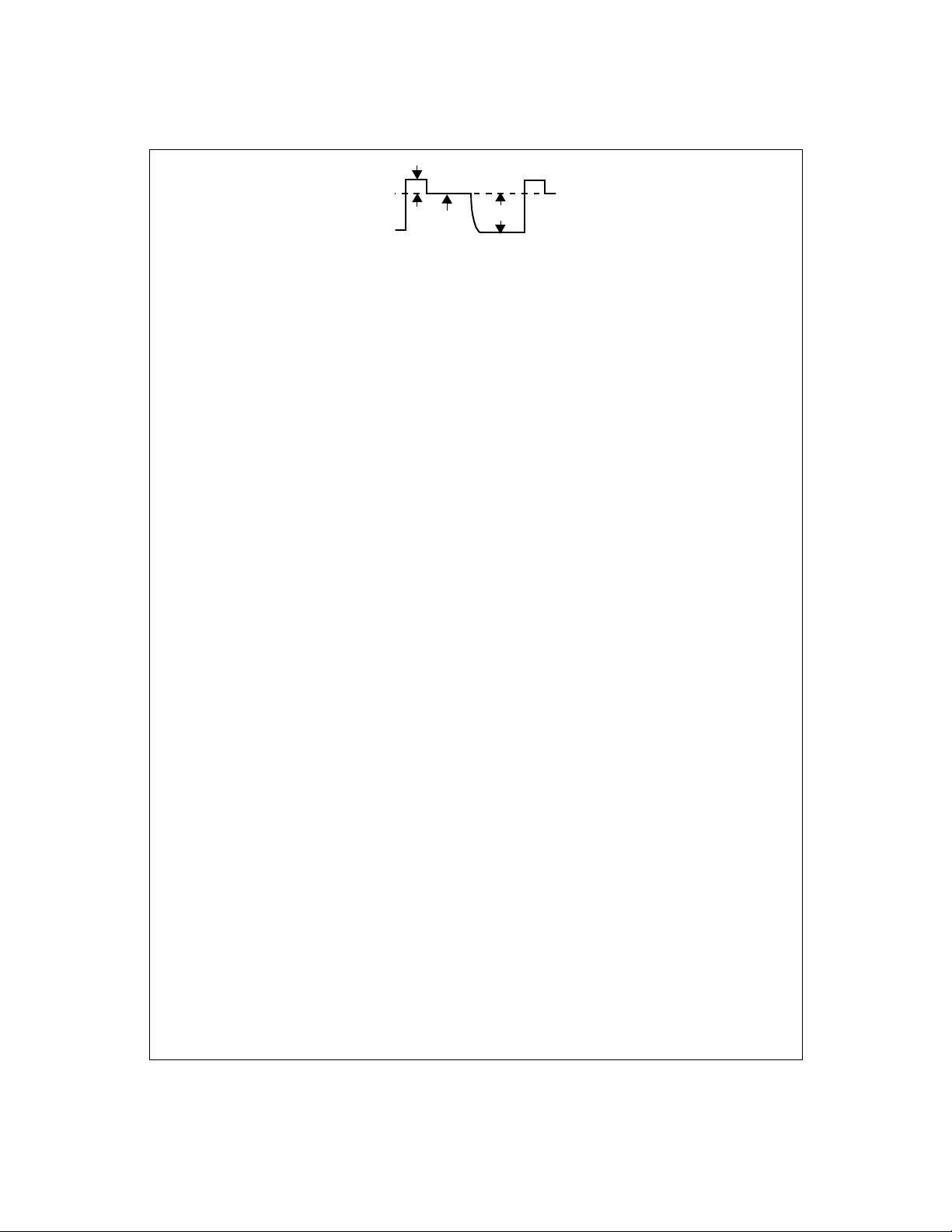

Figure 1 shows the output stage of a typ ical CCD and the resulting output waveform:

RS (RESET)

(from shift register)

Ø1

RS

OS

Capacitor C1 converts the electrons coming from the CCD’s shift

register to an analo g voltage. The source follower output stage

(Q2) buffers this voltage be fore it leaves the CCD. Q1 resets the

voltage across capacitor C1 in between every pixel at intervals 2

and 5. When Q1 is on, th e out put si gnal (OS) i s at its most p ositive voltage. After Q1 turns off (period 3), the OS level represents

the residual voltage across C1 ( V

charge injection f rom Q1, therma l noise from the ON resistance

of Q1, and other sources of error. When the shift register clock

, OSG, OSB) analog inputs of the

R

V

DD

Q1

C1

e-

Q2

OS

V

SS

123 4 5

Figure 1: CDS

). V

RESIDUAL

RESIDUAL

includes

(Ø1) makes a low to h i gh tran sition (period 4), the electrons from

the next pixel flow into C1. The charge across C1 now contains

the voltage propor tional to the number of electron s plus V

, an error term. If OS is sampled at the end of period 3 and

UAL

that voltage is subtracted from t he OS at the e nd of per i od 4, the

V

reduced ([V

principal of Correlated Double Sampling.

term is canceled and the noise on the signal is

RESIDUAL

SIGNAL+VRESIDUAL

]-V

RESIDUAL

= V

SIGNAL

). This is the

The LM9812’s CDS circuit acquires a signal within a 1 M C LK w in dow which can be placed anywhere in the pixel period with 0.5

4

MCLK precision. Se e Diagram 12 for more de tailed timing in formation.

1.2 CIS Mode

The LM9812 provides some support for CIS (Contact Image Sensor) devices by offering a sampling mode for capturing positive

going signals, as opposed to the CCD’s negative going signal.

The output signal of a CIS sensor ( Figure 2) dif fers from a CCD

signal in two primar y ways: its output increases with incr easing

signal strength, and it does no t usually have a reference level as

an integral part of the output waveform of every pixel.

OS (CIS)

OS (CCD)

123 4 5

Figure 2: CIS vs. CCD Output signals

When the LM9812 is in CIS mode (Re gister 24, bit 7 =1), it uses

the V

pixel. Since the LM9812 cla mps the input signal to V

level as the reference (or black) voltage for each

REF MID

the black portion at the beginning of every line, the output of the

sampler is an accurate and repea table repre sentation of t he that

pixel’s brightness.

1.2.1 Static PGAs

The output of the CD S stage drives the PGAs (Programmable

Gain Amplifiers). E ach PGA provide s 5 bits of fixed gain correction over a 0.93V/V to 3V/V (-0.6 to 9.5dB) range. The Blue channel has an optional x3 stage for a gain range of 2.8 V/V to 9.0 V/V

(8.9 to 19d B). Th e ga in o f ea ch P G A s h oul d be se t duri ng c al i br ation to bring the maximum amplitude of the strongest pixel to a

level just below the desired maximum outpu t from the ADC. The

gain is determined by the following equation:

Gain

V

--- -

V

0.93

PGA code

------------------- --------2.137+=

32

Equation 1: PGA Gain

The Blue Channel has an additional gain stage w ith a gain of

3V/V that may be switched on to compensate for the low amplitude blue output of some sensors. With the x3 bit set (Register 2,

bit 7=1), the blue gain is:

Gain

V

--- -

V

02.79

PGA code

-------------------- -------6.411+=

32

Equation 2: Blue Channel PGA Gain with x3 Bit Set

RESID-

REF MID

at

27

http://www.national.com

Page 28

This PGA is static - it does not change at the pixel rate. The PixelRate Shading Multiplier is used to eliminate pixel-to-pixel gain

errors (typically sensor PRNU and shading errors).

1.2.2 Static Offset DACs

The Static Offset DACs remove DC offsets generated by the sensor and the LM98 12’s analog signal chain. T he DACs should be

set during calibration to the lowest value that still resu lts in an

ADC output code > 0 for all the pixels. Each LSB of the offset

DAC is typically 4.2 ADC LSBs, providing a total offset adjustment range of ±130 ADC LSBs. The equation for the offset DAC

is:

()

Offset ADC LSBs

Equation 3: Offset DAC

Like the PGA, the Offse t DAC is static - it do es n ot change at the

pixel rate. The Pixel Rate Offset Subtrac tor is used to eliminate

pixel-to-pixel offset errors.

1.2.3 ADC

The 10 bit ADC quantizes the out put from the analog chai n and

passes the result to the digital section for pixel rate error correction. The ADC’s input range is equal to V

gain constant compensat ing for all sources of gain error throu ghout the entire analog signal path.

1.3 DIGITAL SIGNAL PATH

1.3.1 Pixel-Rate Offset Subtractor

The output of the ADC is fed to the Pixel-Rate Of fset Subtractor.

Each pixel of image data may have a different offset error. If bit 0

of Register 9 is set to a 0 a nd a byte rep re sent ing the offset error

code is fed to the Pixel-Rate Offset Subtractor through the CD0CD9 databus, the offset for each pixel can be subtracted from the

ADC output code at the pixel conversion rate. If this feature is not

desired, the Offset Su btrac tor can be set to a fixed value by wr iting the desired value to Regist er 6 and se tting bit 0 of Regi ster 9

to a 1.

Offset Subtractor Out ADC Output Offset Error Code

The offset subtractor input is 8 bits wide, input on CD0-CD7, for a

correction range of 0 to 255. Informat ion on bits CD 8 and CD9 i s

ignored.

1.3.2 Pixel-Rate Shading Multiplier

The Pixel Rate Shading Multiplier follows the Offset Subtractor.

This stage compensa tes for nonuniformities between individual

pixels (shading error). Each pixel of image data may have a different gain error. If bit 1 of Register 9 is set to a 0 and a word representing the gain correction coefficient is fed to the Pixel-Rate

Shading Multiplier through the CD0-CD9 databus, the gain for

each pixel is changed at the pixel rate to eliminate pixel-to- pixel

gain errors. If this feature is not desired, the Shading Multiplier

can be set to a fixed value by writing the desired gain value to

Registers 7 and 8 and setting bit 1 of Register 9 to a 1.

The equation for calc ulating the ga in of the multipli er is given in

Equation 5. The Pixel Rate Shading Mul tiplier ha s three different

gain ranges as shown i n

the strongest pixel to the weakest pixel is less than 1.5, the multi-

Equation 4: Offset Subtractor

Tabl e 1

4.2 DAC Code

=

()

/C, where C is the

REF IN

=

–

. For systems where the ratio of

Multiplier Gain(V/V) 1

Equation 5: Shading Multiplier Gain

plier gain range setting of 1:1.5 provides very accurate contro l of

the gain of each pixel. Systems with la rge r variat i on ca n use gain

ranges of 1:2 or 1:3.

Multiplier Gain Range

Minimum Gain

(V/V, Multiplier Input = 0)

Maximum Gain

(V/V, Multiplier Input = 1024)

N (used in Equation 5) 2048 1024 512

Bits D3, D2 of Register 9 1, 0 0, 1 0,0

Table 1:Shading Multiplier: 10 bit Coefficient Bus Width

When the 8 bit Coef fici en t Bus W id th is s elect ed ( R eg ister 25 , bi t

6=1), the coefficient da ta is only 8 bits wide, supplied on CD0CD7. This reduces the accuracy of the gain correction, but allows

the use of an 8 bit path to store coefficient data, instead of a 10 or

16 bit wide path.

Multiplier Gain Range

Minimum Gain

(V/V, Multiplier Input = 0)

Maximum Gain

(V/V, Multiplier Input = 256)

N (used in Equation 5) 512 256 128

Bits D3, D2 of Register 9 1, 0 0, 1 0,0

Table 2:Shading Multiplier: 8 bit Coefficient Bus Width

1.4 SENSOR CLOCK GENERATION

The LM9812 generates all of the clock signals required to directly

drive most commercial linear CCDs and some CIS - no external

clock buffers are necessary. Most linear CCDs designed for scanner applications require 0 to 5V signal swings into 20 to 500pF

input loading. Series r esistors are typically inser ted between the

driver and the CCD to control slew rate and isolate the driver from

the large load capacitances. The values of these resistors are

given in the CCD’s datasheet.

1.4.1 TR1 and TR2

The LM9812 supports one or two TR ( transfer, or shift) pulses as

shown in Diagrams 8 and 9. This pulse is used to transfer the

contents of each pixel’s photodiode to the CCD’s serial shift register for clocking out of the CCD. Configuration Re gisters 16, 17,

and 18 control th e TR1, TR2, and T R guardband pulse widths,

while Register 24, b it 3 determines whe ther the LM9812 gene rates TR1 only or bo th TR1 and TR2 at the begi nning of a line.

The polaritie s of the TR pulses are determined by Registe r 26,

bits 2 and 3. If not ne eded, one or both TR p ulses can be disabled by setting Register 25, bits 3 and 4 to the appropriate value.

28

Gain Correction Coefficient

----------------- --------------------------------- --------------------- -+=

N

1:1.5

1:2.0

(50%)

1:2.0

(50%)

1:3.0

(67%)

1:3.0

(67%)

(33%)

111

1.5 2.0 3.0

1:1.5

(33%)

111

1.5 2.0 3.0

http://www.national.com

Page 29

1.4.2 RS

The LM9812 also generates the RS (reset) pulse required to

clear the CCD’s output capacitor of the previous pixel’s charge.

The RS pulse’s width and position (relative to the edge of the ø1

pulse) is determ ined by the value in Configuration Register 21.

See Diagrams 10 and 12. The p olarity of the RS pul se is determined by Register 26, bit 1. If n ot needed, thi s pulse can be disabled by setting Register 25, bit 2 to a 1.

1.4.3 ø1 and ø2

ø1 and ø2 are the two phase clock for the CCD shift register. ø2

is always the inverse of ø1. For “standard” CCDs, the ø1 and ø2

frequency is equal to th e pixel rate, the same frequency as the

RS pulse. In Standard Mode, the RS pulse position and Sample

Reference/Sample Signal edges are set with respect to the falling

edge of ø1. For “even/odd” CCDs, the ø1 and ø2 frequency is

equal to one half the pixel rate, a pixels is sampled after both the

rising and falling edges of the ø clock. In Even/Odd Mode, the RS

pulse position and Sample Reference /Sample Signal edges are

set with respect to the either ed ge of ø1. Stand ard or Even/Odd

mode is selected by se tting bit 0 of Register 24. The absolute

polarity of the ø pulses is determined by Register 26, bits 0 and 4

(both bits perfor m the s ame f unc tion). If not need ed, one or b oth

ø pulses can be disabled by setting Register 25, bits 0 and 1 to

the appropriate value.

1.5 DIGITAL INTERFACE

There are three main sections to the digital interface of the