Page 1

LM9811

10-Bit Greyscale/30-Bit Color

Linear CCD Sensor Processor

LM9811 10-Bit Greyscale/30-Bit Color Linear CCD Sensor Processor

April 1998

General Description

The LM9811 is a high performance integrated signal

processor/digitizer for linear CCD image scanners. The

LM9811 performs all the analog processing (correlated

double sampling for black level and offset compensation,

pixel-by-pixel gain (shading) correction, and 10-bit

analog-to-digital conversion) necessary to maximize the performance of a wide range of linear CCD sensors.

The LM9811 can be digitally programmed to work with a

wide variety of CCDs from different manufacturers. An internal configuration register sets CCD and sampling timing to

maximize performance, simplifying the design and manufacturing processes.

The LM9811 can be used with parallel output color CCDs. A

signal inversion mode eases use with CIS sensors. For

complementary voltage reference see the LM4041.

Applications

n Color and Greyscale Flatbed and Sheetfed Scanners

n Fax and Multifunction Peripherals

n Digital Copiers

n General Purpose Linear CCD Imaging

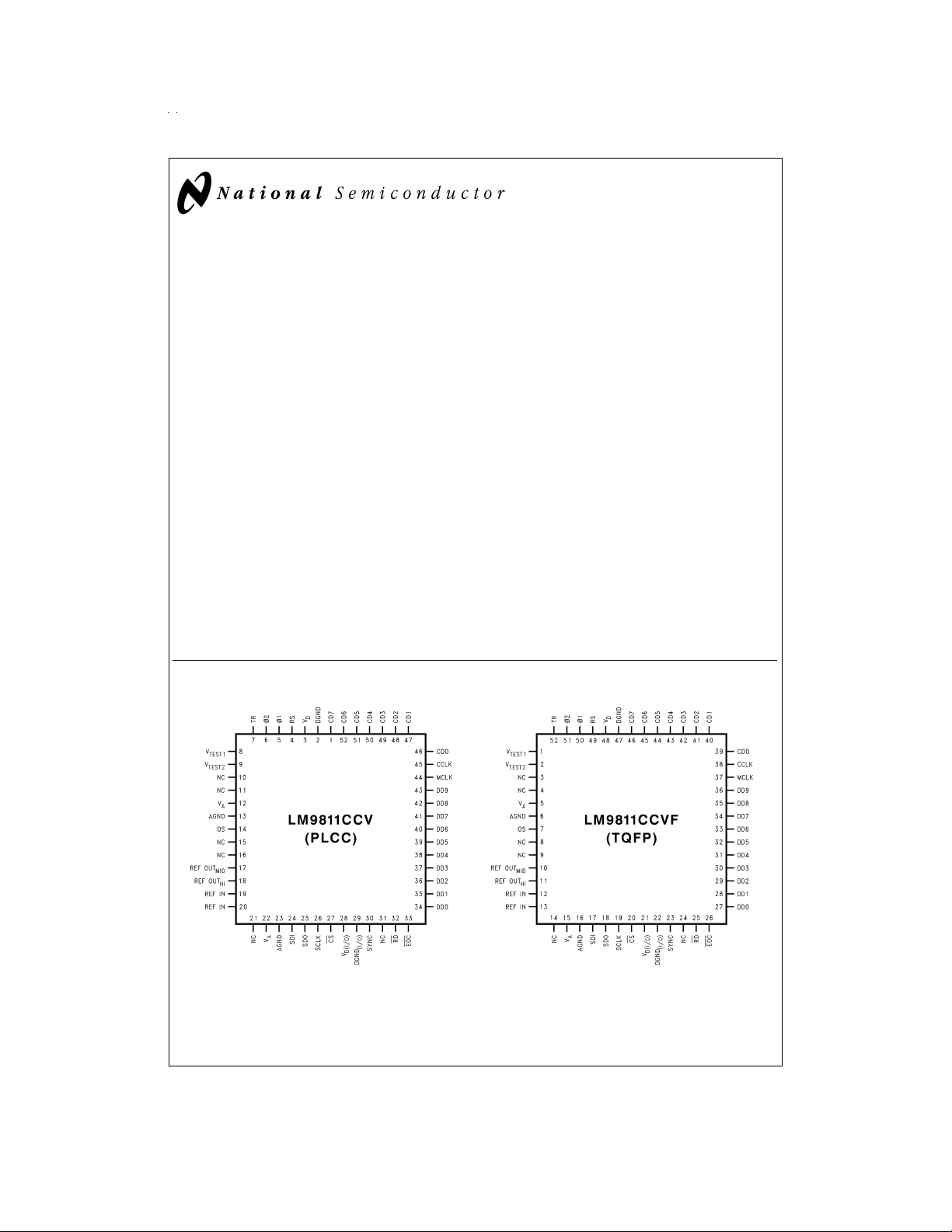

Connection Diagrams

Features

n 1.5 Million pixels/s conversion rate

n Pixel-rate shading correction for individual pixels

maximizes dynamic range and resolution, even on

“weak” pixels

n Implements Correlated Double Sampling for minimum

noise and offset error

n Reference and signal sampling points digitally controlled

in 40ns increments for maximum performance

n Generates all necessary CCD clock signals

n Compatible with a wide range of linear CCDs

n Supports some Contact Image Sensors (CIS)

n TTL/CMOS input/output compatible

Key Specifications

n Resolution: 10 Bits

n Pixel Conversion Rate: 1.5MHz

n Supply Voltage: +5V

n Supply Voltage

(Digital I/O): +3.3V

n Power Dissipation: 260mW (max)

±

10%or +5V±5

±

5

%

%

DS012813-1 DS012813-2

TRI-STATE®is a registeredtrademark of National Semiconductor Corporation.

™

MICROWIRE

SPI

© 1999 National Semiconductor Corporation DS012813 www.national.com

is a trademark of National Semiconductor Corporation.

™

is a trademark of Motorola, Inc.

Page 2

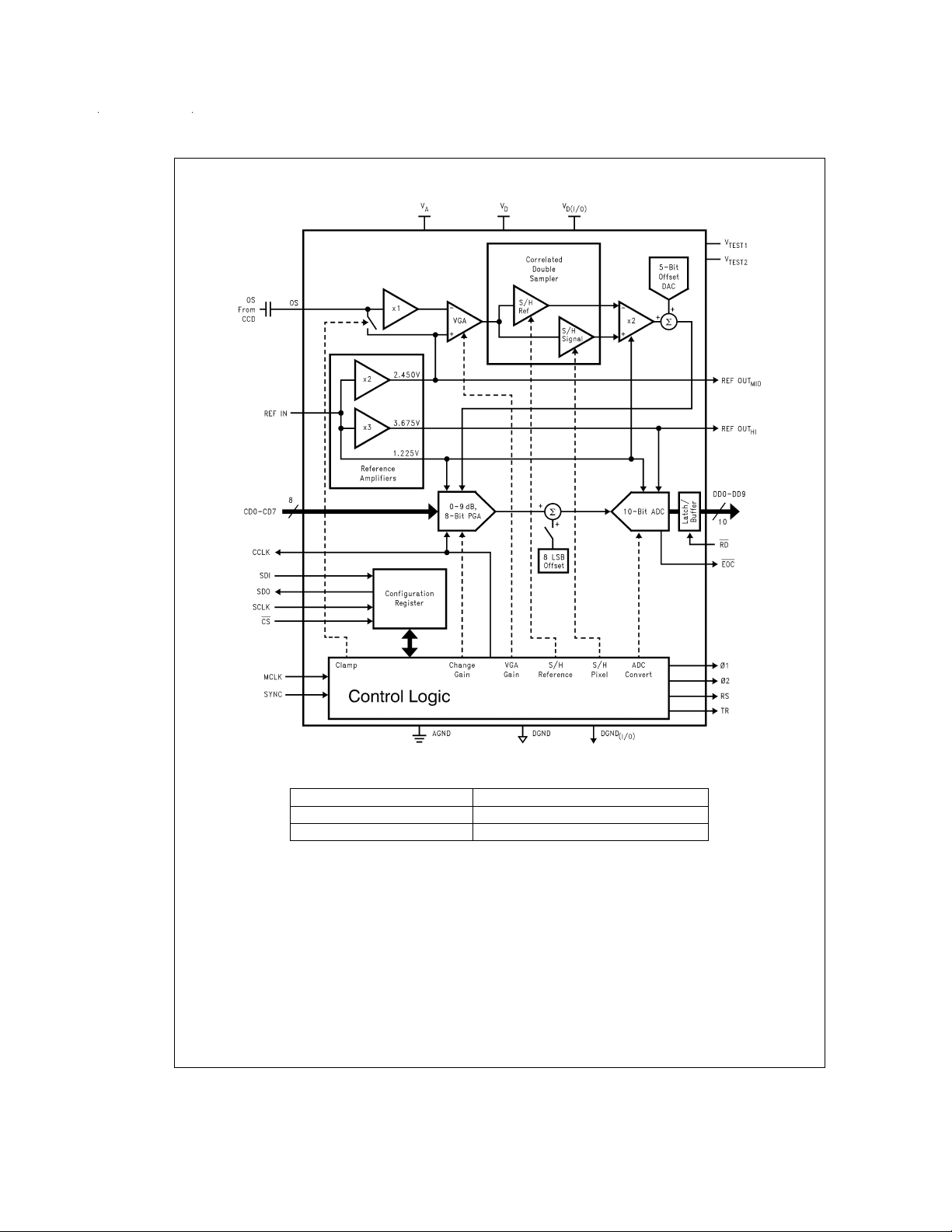

Block Diagram

Ordering Information

Commercial (0˚C ≤ TA≤ +70˚C) Package

LM9811CCV V52A 52-Pin Plastic Leaded Chip Carrier

LM9811CCVF VEG52A 52-Pin Thin Quad Flatpack

www.national.com 2

DS012813-3

Page 3

Absolute Maximum Ratings (Notes 1, 2)

+

=

=

=

Positive Supply Voltage (V

V

V

A

D

with Respect to

GND=AGND=DGND=DGND

(I/O)

Voltage on any Input or Output Pin 0.3V to V

Input Current at any Pin (Note 3)

Package Input Current (Note 3)

=

Package Dissipation at T

25˚C (Note 4)

A

ESD Susceptibility (Note 5)

Human Body Model 2000V

Soldering Information (Note 6)

Infrared, 10 seconds

LM9811CCV 300˚C

)

V

D(I/O

6.5V

+

+0.3V

±

25 mA

±

50 mA

Operating Ratings (Notes 1, 2)

Operating Temperature

Range T

LM9811CCV, LM9811CCVF 0˚C ≤ TA≤ +70˚C

Supply Voltage +4.75V to +5.25V

V

A

Supply Voltage +4.75V to +5.25V

V

D

Supply Voltage +2.7V to +5.25V

V

D(I/O)

| ≤ 100 mV

|V

A–VD

V

A–VD(I/O)

OS, REF IN Voltage Range −0.05V to V

CD0–CD7, MCLK, SYNC,

SDI, SCLK, CS, RD,

Voltage Range −0.05V to V

MIN

D(I/O)

≤ TA≤ T

≥ −100 mV

+ 0.05V

A

+ 0.05V

LM9811CCVF 220˚C

Storage Temperature −65˚C to +150˚C

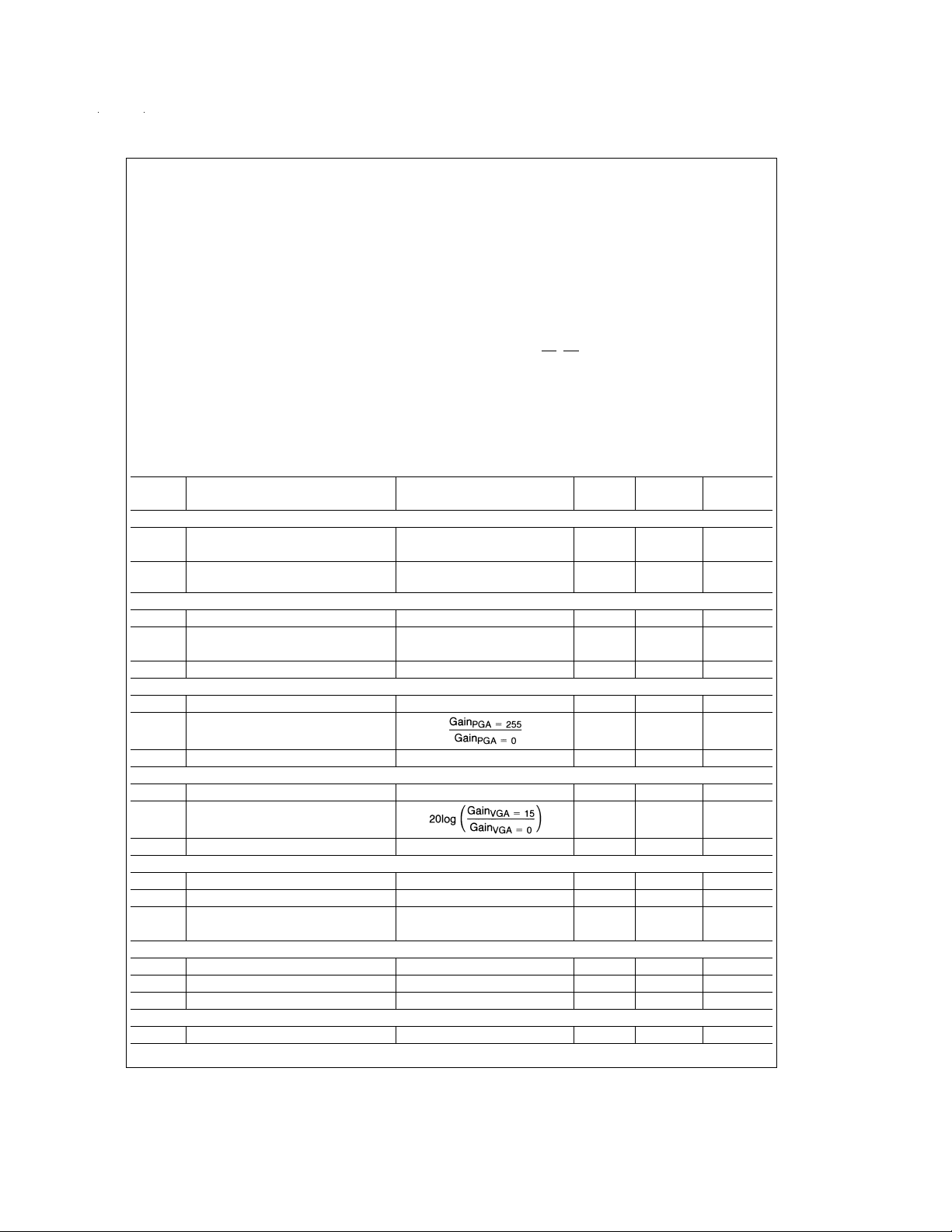

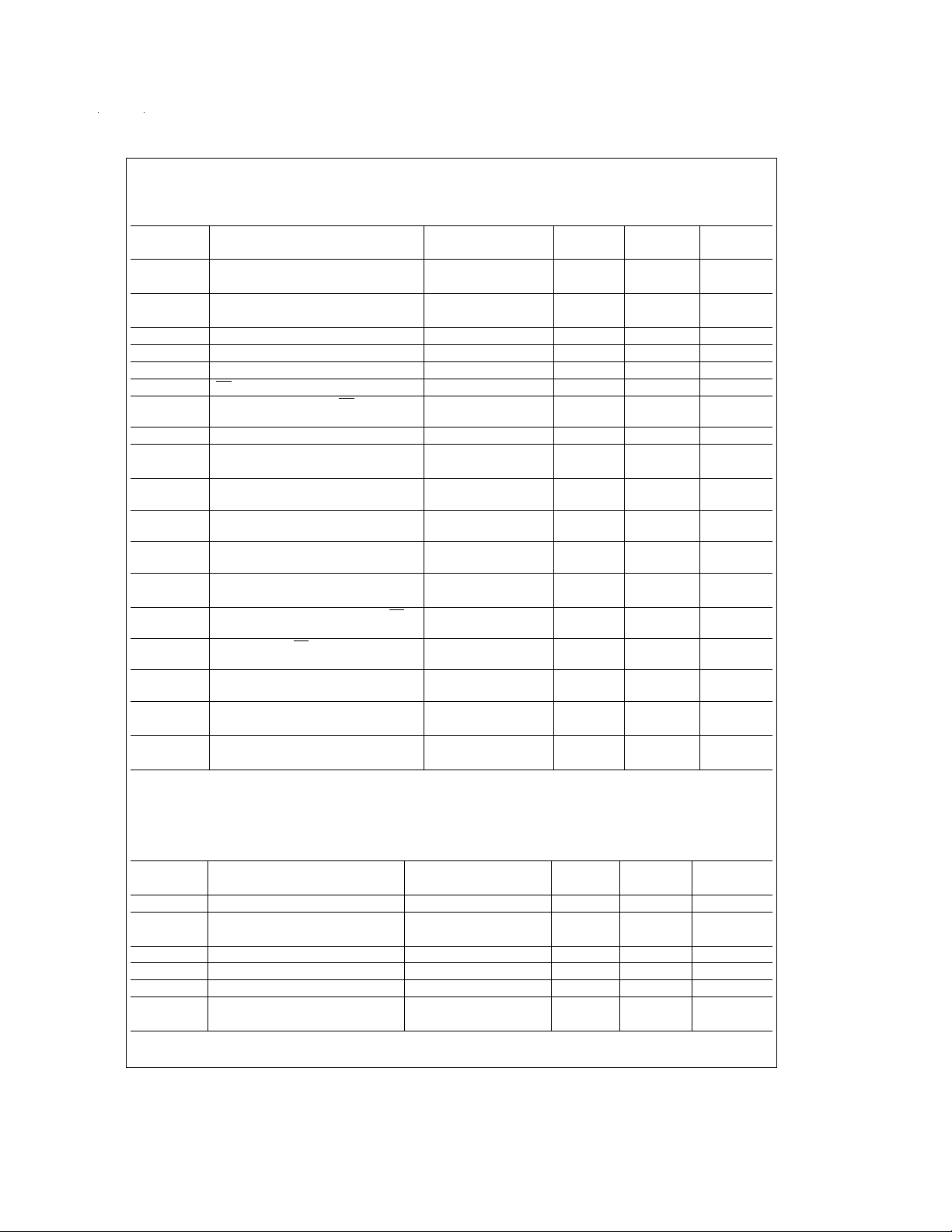

Electrical Characteristics

=

The following specifications apply for AGND=DGND=DGND(I/O)=0V, V

REF IN=+1.225V

apply for T

DC,fMCLK

=

=

T

A

J

=

20MHz, R

to T

T

MIN

MAX

=

25Ω. All LSB units are ADC LSBs unless otherwise specified. Boldface limits

S

; all other limits T

=

A

=

T

25˚C. (Note 8)

J

=

V

A

+5.0V

D

DC,VD(I/O)

Symbol Parameter Conditions Typical Limits Units

(Note 9) (Note 10) (Limits)

CCD SOURCE REQUIREMENTS FOR FULL SPECIFIED ACCURACY AND DYNAMIC RANGE (Note 11)

V

WHITE

Maximum Peak CCD Differential VGA Gain=0dB 1.1 V (min)

Signal Range VGA Gain=9dB 0.4 V (min)

V

RFT

Maximum CCD Reset FeedThrough

Amplitude

ADC CHARACTERISTICS (Note 16)

Resolution with No Missing Codes f

ILE Integral Linearity Error (Note 12) f

DNL Differential Non-Linearity f

=

12MHz 9 Bits (min)

MCLK

=

12MHz

MCLK

=

12MHz +2.0 LSB (max)

MCLK

PGA CHARACTERISTICS

Monotonicity 8 Bits (min)

=

+5.0 or +3.0V

,

DC

2 V (min)

+4.0 LSB (max)

−3.0 LSB (min)

MAX

PGA Adjustment Range

Gain Error at any Gain (Note 14) 1.4

VGA CHARACTERISTICS

Monotonicity 4 Bits (min)

VGA Adjustment Range

Gain Error at any Gain (Note 15)

OFFSET TRIM CHARACTERISTICS

Offset DAC LSB Size In Units of ADC LSBs 1.7 LSB

Offset DAC DNL In Units of Offset DAC LSBs

Offset Add Magnitude In Units of ADC LSBs 8

SYSTEM CHARACTERISTICS

Full Channel Gain Error VGA Gain=1, PGA Gain=1

Pre-PGA Offset Error (In ADC LSBs) VGA Gain=1, Offset DAC=0

Post-PGA Offset Error (In ADC LSBs) Offset Add=0

REFERENCE AND ANALOG INPUT CHARACTERSTICS (Note 7)

OS Input Capacitance 5 pF

2.95 2.8 V/V (min)

%

(max)

8.95 8.5 dB (min)

±

0.15 dB (max)

±

0.25

±

0.9 LSB

6.4 LSB (min)

10.0 LSB (max)

±

0.6

±

4 LSB

±

4 LSB

±

3.0

%

(max)

www.national.com3

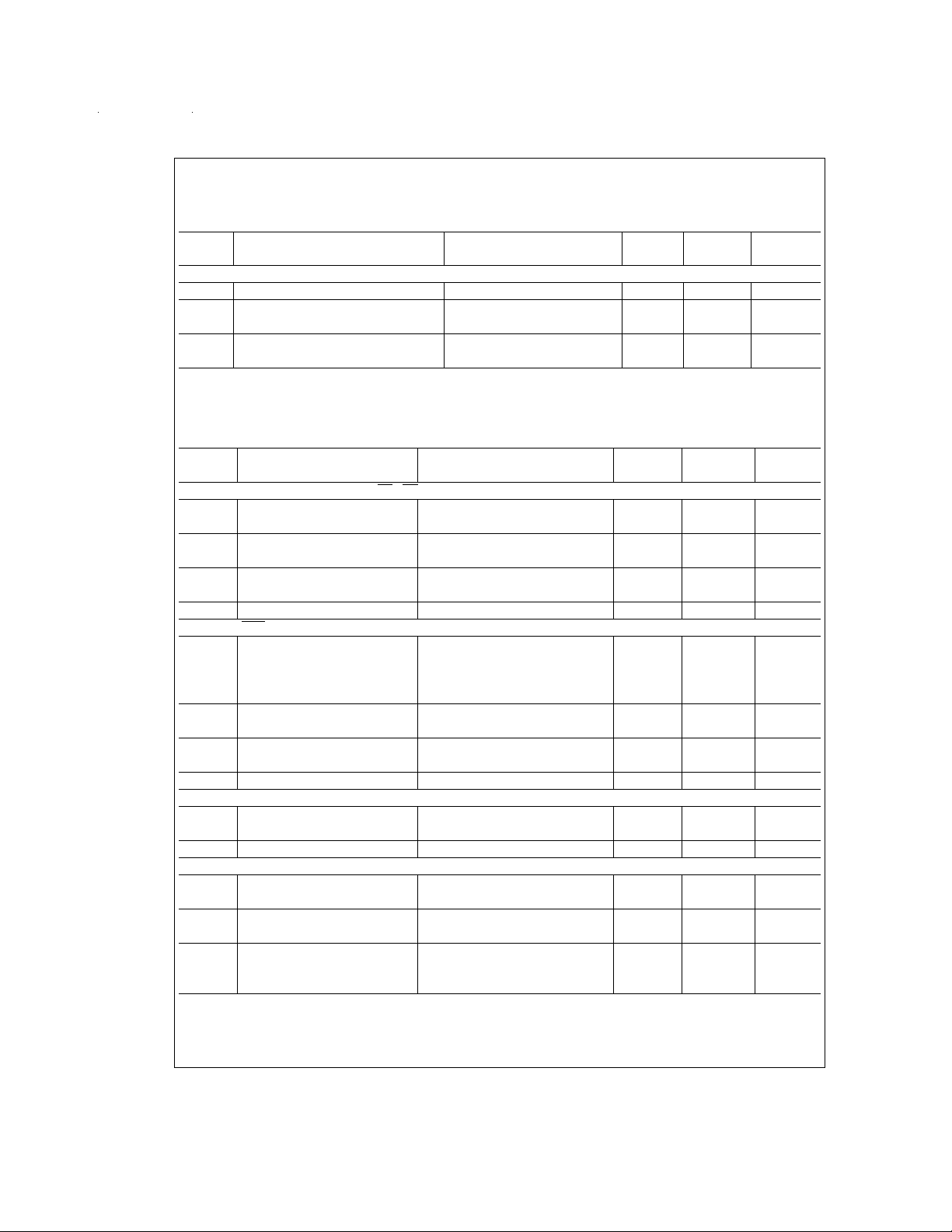

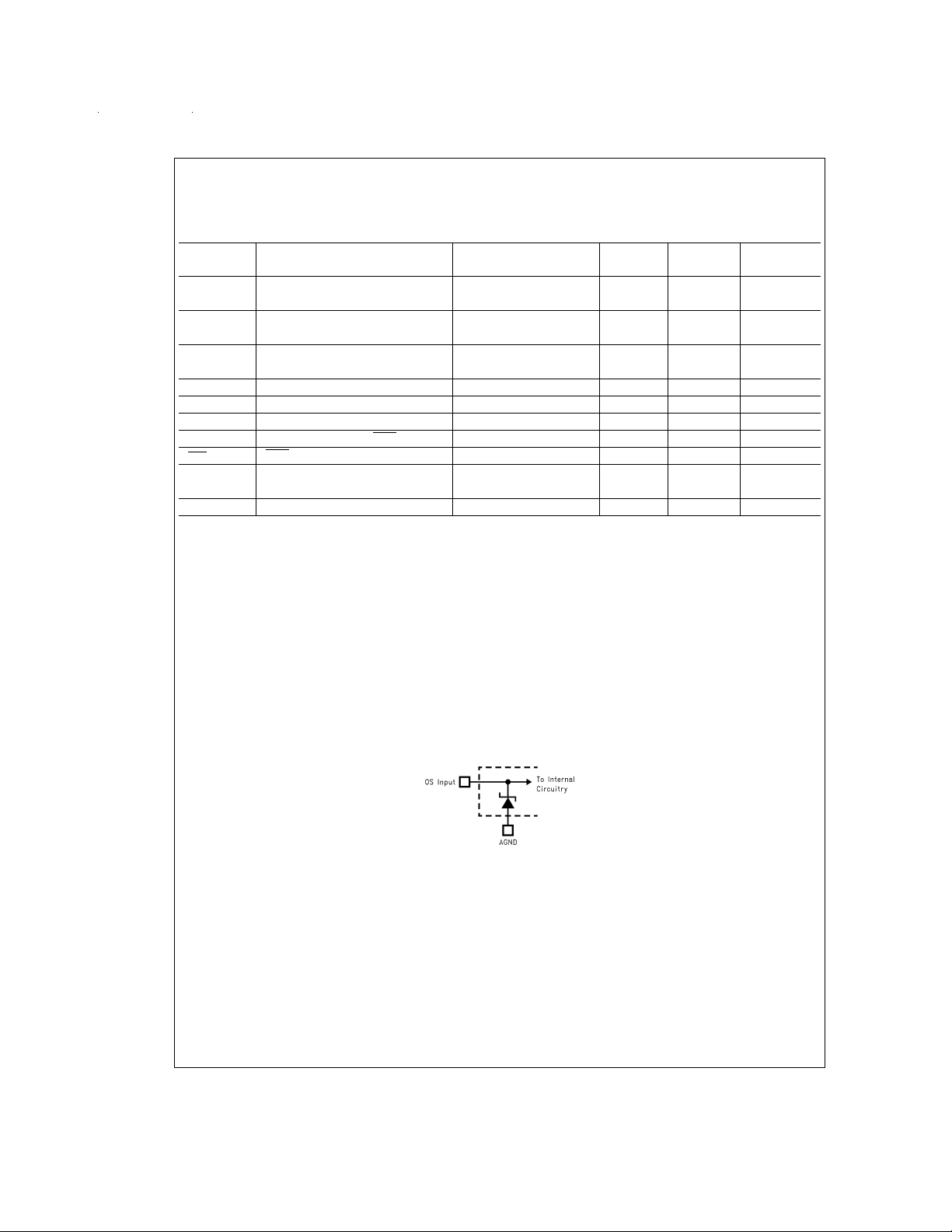

Page 4

Electrical Characteristics (Continued)

=

The following specifications apply for AGND=DGND=DGND(I/O)=0V, V

REF IN=+1.225VDC,f

apply for T

=

=

T

A

J

=

20MHz, R

MCLK

to T

T

MIN

MAX

=

25Ω. All LSB units are ADC LSBs unless otherwise specified. Boldface limits

S

; all other limits T

=

A

=

T

25˚C. (Note 8)

J

=

V

A

+5.0V

D

DC,VD(I/O)

Symbol Parameter Conditions Typical Limits Units

(Note 9) (Note 10) (Limits)

REFERENCE AND ANALOG INPUT CHARACTERSTICS (Note 7)

OS Input Leakage Current Measured with OS=2.45V

R

REF

ADC Reference Ladder (REF OUT

to REF IN) Impedance 2000 Ω (max)

HI

DC

950

REF IN Reference Voltage (Note 13) 1.225

=

+5.0 or +3.0V

,

DC

2 20 nA (max)

500 Ω (min)

1.19 V (min)

1.26 V (max)

DC and Logic Electrical Characteristics

The following specifications apply for AGND=DGND=DGND

IN=+1.225V

25˚C.

DC,fMCLK

=

20MHz, R

=

25Ω. Boldface limits apply for T

s

(I/O)

=

Symbol Parameter Conditions Typical Limits Units

CD0–CD7, MCLK, SYNC, SDI, SCLK, CS , RD DIGITAL INPUT CHARACTERISTICS

=

V

5.25V 2.0 V (min)

V

IN(1)

V

IN(0)

I

IN

C

IN

Logical “1” Input Voltage

Logical “0” Input Voltage

Input Leakage Current

Input Capacitance 5 pF

D(I/O)

=

V

3.6V 2.0 V (min)

D(I/O)

=

V

4.75V 0.8 V (max)

D(I/O)

=

V

2.7V 0.7 V (max)

D(I/O)

=

V

V

IN

D

=

V

DGND −0.1 µA

IN

DD0–DD9, EOC , CCLK, SDO DIGITAL OUTPUT CHARACTERISTICS

=

V

4.75V, I

V

V

I

C

OUT

OUT(1)

OUT(0)

OUT

D(I/O)

=

V

Logical “1” Output Voltage

Logical “0” Output Voltage

TRI-STATE®Output Current V

(DD0–DD9 only) V

D(I/O)

=

V

D(I/O)

=

V

D(I/O)

=

V

D(I/O)

=

V

D(I/O)

=

OUT

=

OUT

TRI-STATE Output Capacitance 5 pF

OUT

4.75V, I

OUT

2.7V, I

OUT

2.7V, I

OUT

5.25V, I

OUT

3.6V, I

OUT

DGND 0.1 µA

V

D

φ1, φ2, RS, TR DIGITAL OUTPUT CHARACTERISTICS

V

V

OUT(1)

OUT(0)

Logical “1” Output Voltage

Logical “0” Output Voltage V

=

V

4.75V, I

D

=

V

4.75V, I

D

=

5.25V, I

D

OUT

OUT

OUT

=

=

=

POWER SUPPLY CHARACTERISTICS

I

A

I

D

I

D(I/O)

Analog Supply Current

Digital Supply Current

Digital I/O Supply Current

Operating 25 38 mA (max)

Standby 50 µA

Operating 6 8 mA (max)

Standby 65 µA

Operating, V

Operating, V

Standby, V

=

D(I/O)

=

D(I/O)

=

5.0V or 3.0V 1.7 mA

D(I/O)

=

0V, V

=

V

A

A

+5.0V

D

=

=

T

J

DC,VD(I/O)

to T

T

MIN

=

; all other limits T

MAX

+5.0 or +3.0V

A

, REF

DC

=

=

T

J

(Note 9) (Note 10) (Limits)

0.1 µA

=

−360 µA 2.4 V (min)

=

−10 µA 4.4 V (min)

=

−360 µA 2.1 V (min)

=

−10 µA 2.5 V (min)

=

1.6 mA 0.4 V (max)

=

1.6 mA 0.4 V (max)

−0.1 µA

−360 µA 2.4 V (min)

−10 µA 4.4 V (min)

1.6 mA 0.4 V (max)

5.0V 3.1 6 mA (max)

3.0V 1.6 4 mA (max)

www.national.com 4

Page 5

AC Electrical Characteristics, MCLK Independent

The following specifications apply for AGND=DGND=DGND

f

MCLK

=

T

MIN

=

20MHz, t

to T

MAX

=

1/f

MCLK

; all other limits T

MCLK,tr

=

=

t

f

=

=

T

A

J

5ns, R

25˚C.

s

=

25Ω,C

=

(I/O)

(databus loading)=50 pF/pin. Boldface limits apply for T

L

Symbol Parameter Conditions Typical Limits Units

f

MCLK

Maximum MCLK Frequency (Note 16) 20 MHz (min)

Minimum MCLK Frequency 1 MHz (max)

MCLK Duty Cycle

t

A

t

CDSETUP

t

CDHOLD

t

D1H,tD0H

t

DACC

f

SCLK

SYNC Setup of MCLK 5 10 ns (min)

Correction Data Valid to CLK Setup 14 20 ns (min)

Correction Data Valid to CLK Hold −12 0 ns (min)

RD High to DD0–DD9 TRI-STATE 5 15 ns (max)

Access Time Delay from RD Low to

DD0–DD9 Data Valid

Maximum SCLK Frequency 8 MHz (min)

SCLK Duty Cycle

t

SDI

t

HDI

t

DDO

t

HDO

t

DELAY

t

SETUP

t

S1H,tS0H

t

RDO

t

FDO

SDI Set-Up Time from SCLK

Rising Edge

SDI Hold Time from SCLK

Rising Edge

Delay from SCLK Falling Edge to

SDO Data Valid

SDO Hold Time from SCLK

Falling Edge

=

3k, C

R

L

DELAY from SCLK Falling Edge to CS

Rising or Falling Edge

Set-Up Time of CS Rising or Falling

Edge to SCLK Rising Edge

Delay from CS Rising Edge to SDO

TRI-STATE

SDO Rise Time, TRI-STATE to High

SDO Rise Time, Low to High 20 ns

SDO Fall Time, TRI-STATE to Low

SDO Fall Time, High to Low 20 ns

=

R

3k, C

L

=

3k, C

R

L

=

3k, C

R

L

=

=

0V, V

V

A

D

=

V

D(I/O)

, REF IN=+1.225VDC,

+5.0V

DC

(Note 9) (Note 10) (Limits)

30 40

70 60

15 30 ns (max)

40

60

3 10 ns (min)

2 15 ns (min)

25 55 ns (max)

=

25pF 30

L

55 ns (max)

5 ns (min)

5 10 ns (min)

0 10 ns (min)

=

50pF 25 50 ns (max)

L

=

50pF

L

=

50pF

L

20 ns

20 ns

%

%

%

%

=

A

(min)

(max)

(min)

(max)

T

J

AC Electrical Characteristics, MCLK Dependent

The following specifications apply for AGND=DGND=DGND

=

f

20MHz, t

MCLK

Register Parameters for limits labelled C.R. Boldface limits apply for T

25˚C.

MCLK

=

1/f

MCLK,tr

=

=

t

f

5ns, R

s

=

25Ω,C

=

(I/O)

(databus loading)=50 pF/pin. Refer to

L

Symbol Parameter Conditions Typical Limits Units

t

START

t

φ

t

TRWIDTH

t

GUARD

t

RSWIDTH

t

RS

MCLK to first φ1 High 50ns 1 t

φ1, φ2 Clock Period

Standard CCD Mode 400ns 8 t

Even/Odd CCD Mode 800ns 16 t

Transfer Pulse (TR) Width C.R. µs

φ1 to TR, TR to φ1 Guardband C.R. ns

Reset Pulse (RS) Width C.R. ns

Falling Edge of φ1 to RS Standard CCD Mode

Either Edge of φ1 to RS Even/Odd CCD Mode

0V, V

=

=

V

A

D

=

=

T

A

J

=

V

D(I/O)

to T

T

MIN

MAX

, REF IN=+1.225VDC,

+5.0V

DC

Table 2

; all other limits T

. Configuration

=

A

(Note 9) (Note 10) (Limits)

C.R. ns

www.national.com5

T

J

MCLK

MCLK

MCLK

=

Page 6

AC Electrical Characteristics, MCLK Dependent (Continued)

The following specifications apply for AGND=DGND=DGND

=

f

20MHz, t

MCLK

Register Parameters for limits labelled C.R. Boldface limits apply for T

25˚C.

MCLK

=

1/f

MCLK,tr

=

=

t

f

5ns, R

=

s

25Ω,C

=

(I/O)

(databus loading)=50 pF/pin. Refer to

L

Symbol Parameter Conditions Typical Limits Units

t

S/HREF

t

S/HSIG

t

S/HWIDTH

t

SYNCLOW

t

B

t

CCLKWIDTH

t

DATAVALID

t

EOCWIDTH

Falling Edge of φ1 to Ref. Sample Standard CCD Mode

Either Edge of φ1 to Ref. Sample Even/Odd CCD Mode

Falling Edge of φ1 to Sig. Sample Standard CCD Mode

Either Edge of φ1 to Sig. Sample Even/Odd CCD Mode

Sample Pulse Width

(Acquisition Time)

SYNC Low Between Lines 100ns 2 t

SYNC Setup of φ1 to End Line 2 t

CCLK Pulse Width 250ns 5 t

Data Valid Time from EOC Low 300 ns (min)

EOC Pulse Width 250ns 5 t

φ1 and φ2 Frequency

Standard CCD Mode 2.5MHz f

Even/Odd CCD Mode 1.25MHz f

φ1 and φ2 Duty Cycle 50

0V, V

=

=

V

A

D

=

=

T

A

J

=

V

D(I/O)

to T

T

MIN

MAX

, REF IN=+1.225VDC,

+5.0V

DC

Table 2

; all other limits T

. Configuration

=

T

A

J

(Note 9) (Note 10) (Limits)

C.R. ns

C.R. ns

50ns 1 t

/8 Hz

MCLK

/16 Hz

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

%

Electrical Characteristics (Notes)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 2: All voltages are measured with respect to GND=AGND=DGND=DGND

Note 3: When the input voltage (V

The 50 mA maximum package input current rating limits the number of pins that can simultaneously safely exceed the power supplies with an input current of 25

mA to two.

Note 4: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

allowable power dissipation at any temperature is P

mounted is 52˚C/W for the V52A PLCC package, and 70˚C/W for the VEG52A TQFP package.

Note 5: Human body model, 100pF capacitor discharged through a 1.5 kΩ resistor.

Note 6: See AN450 “Surface Mounting Methods and Their Effect on Product Reliability” or the section titled “Surface Mount” found in any National Semiconductor

Linear Data Book for other methods of soldering surface mount devices.

Note 7: AZener diode clamps the OS analog input to AGND as shown below. This input protection, in combination with the external clamp capacitor and the output

impedance of the CCD, prevents damage to the LM9811 from transients during power-up.

) at any pin exceeds the power supplies (V

IN

=

D

(T

Jmax–TA

)/θJA.T

Jmax

=

0V, unless otherwise specified.

(I/O)

<

GND or V

IN

=

150˚C for this device. The typical thermal resistance (θ

>

VAor VD), the current at that pin should be limited to 25 mA.

IN

, θJAand the ambient temperature, TA. The maximum

Jmax

) of this part when board

JA

=

(min)

(max)

Note 8: Toguarantee accuracy, it is required that V

Note 9: Typicals are at T

Note 10: Tested limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

=

=

T

25˚C, f

J

A

and VDbe connected together to the same power supply with separate bypass capacitors at each supply pin.

A

=

20MHz, and represent most likely parametric norm.

MCLK

www.national.com 6

DS012813-4

Page 7

Electrical Characteristics (Notes) (Continued)

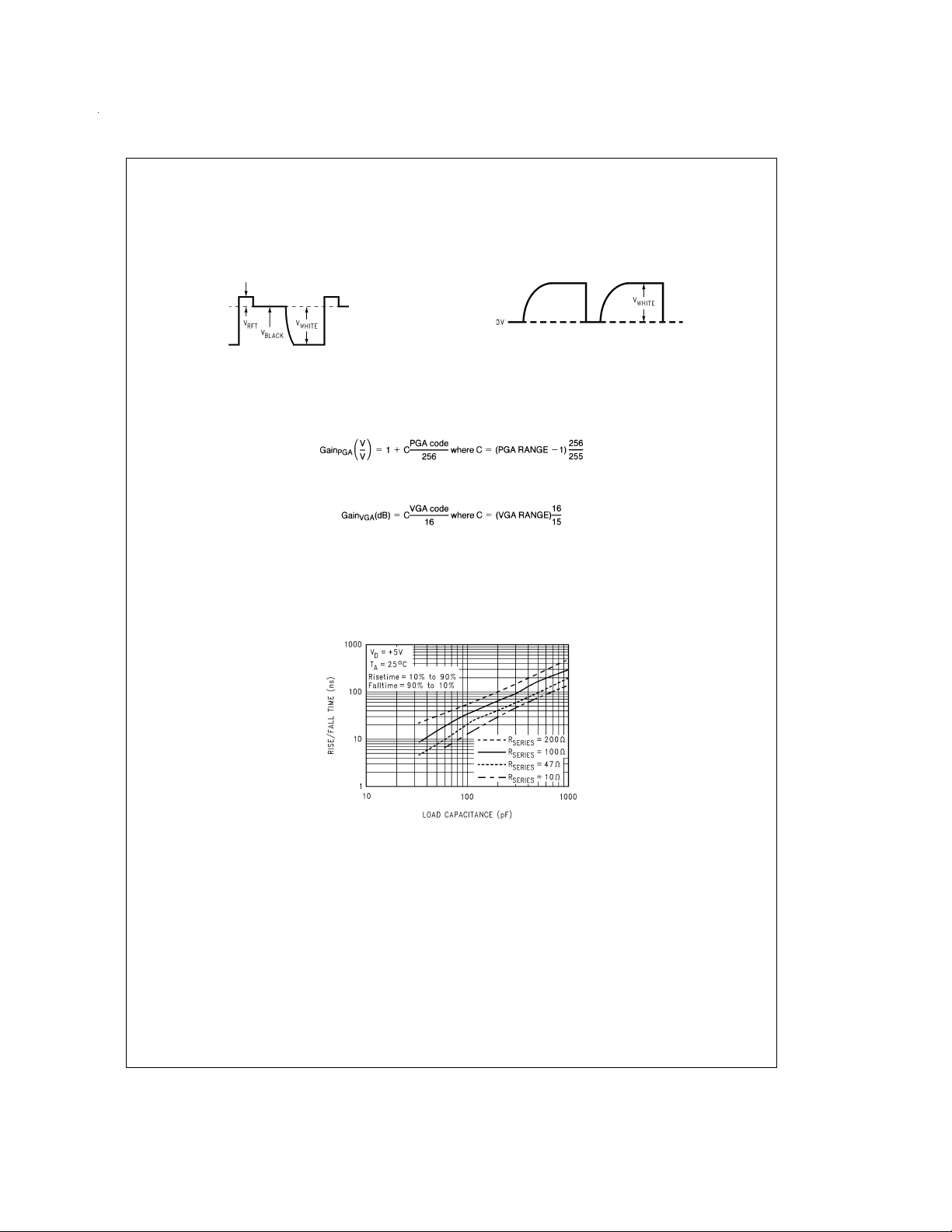

Note 11: For CCDs, V

pixel output voltage for a white (full scale) image with respect to the reference level, V

reset feedthrough pulse. For CIS, V

correctable range of pixel-to-pixel V

the LM9811 can correct for using its internal PGA.

is defined as the CCD OS voltage for the reference period following the reset feedthrough pulse. V

BLACK

is defined as the peak CCD pixel output voltage for a white (full scale) image with respect to GND (0V). The maximum

WHITE

variation is defined as the maximum variation in V

WHITE

BLACK-VRFT

WHITE

is defined as the peak CCD

is defined as the peak positive deviation above V

(due to PRNU, light source intensity variation, optics, etc.) that

WHITE

BLACK

of the

CCD Output Signal

DS012813-5

Note 12: Integral linearity error is defined as the deviation of the analog value, expressed in LSBs, from the straight line that best fits the actual transfer function

of the ADC.

Note 13: Reference voltages below 1.19V may decrease SNR. Reference voltages above 1.26V may cause clipping errors inside the LM9811. The

LM4041EIM3-1.2 (SOT-23 package) or the LM4041EIZ-1.2 (TO-92 package) bandgap voltage references are recommended for this application.

Note 14: PGA Gain Error is the maximum difference between the measured gain for any PGA code and the ideal gain calculated by using the formula

Note 15: VGA Gain Error is the maximum difference between the measured gain for any VGA code and the ideal gain calculated by using the formula

Note 16: ADC Characteristics (Resolution, INL and DNL) are guaranteed for f

except ADC Characteristics, which will be approximately 8 bits.

and PGA RANGE=the PGA adjustment range (in V/V) of the LM9811 under test.

and VGA RANGE=the VGA adjustment range (in dB) of the LM9811 under test.

up to 12MHz. For 12MHz<f

MCLK

CIS Output Signal

≤ 20 MHz, all specifications are guaranteed

MCLK

DS012813-6

Typical Performance Characteristics

φ1, φ2, RS, and TR Rise and Fall Times

Through a Series Resistance vs Load Capacitance

DS012813-8

www.national.com7

Page 8

Pin Descriptions

CCD Driver Signals

φ1 Digital Output. CCD clock signal, phase

φ2 Digital Output. CCD clock signal, phase

RS Digital Output. Reset pulse for the CCD.

TR Digital Output. Transfer pulse for the

OS Analog Input. This is the OS (Output

REF IN Analog Inputs. These two pins are the

REF OUT

REF OUT

,

V

TEST1

V

TEST2

SDI Digital Input. Serial Data Input pin.

SDO Digital Output. Serial Data Output pin.

SCLK Digital Input. This is the serial data

CS

CD0 (LSB)–

CD7 (MSB)

1.

2.

CCD.

Analog I/O

Signal) from the CCD. The maximum

peak signal that can be accurately

digitized is equal to the voltage at REF

IN, typically 1.225V.

system reference voltage inputs and

should be tied together to a 1.225V

voltage source and bypassed to AGND

with a 0.1 µF monolithic capacitor.

Analog Output. This reference voltage is

HI

developed internally by the LM9811,

and is equal to 3 times REF IN. It

should be bypassed to AGND with a

0.1 µF monolithic capacitor.

Analog Output. This reference voltage is

MID

developed internally by the LM9811,

and is equal to 2 times REF IN. It

should be bypassed to AGND using a

0.1 µF monolithic capacitor.

Analog Inputs/Outputs. These pins are

used for testing the device during

manufacture and should be left

unconnected.

Configuration Register I/O

clock, used to clock data in through SDI

and out through SDO. SCLK is

asynchronous to MCLK. Input data is

latched and output data is changed on

the rising edge of SCLK.

Digital Input. This is the Chip Select

signal for writing to the Configuration

Register through the serial interface.

This input must be low in order to

communicate with the Configuration

Register. This pin is used for serial I/O

only–it has no effect on any other

section of the chip.

Digital Coefficient I/O

Digital Inputs. Correction Coefficient

Databus. This is the 8-bit data path for

the gain adjust PGA, used during line

scan.

CCLK Digital Output. This is the signal that is

used to clock the Gain coefficients into

the LM9811. Data is latched on the

rising edge of CCLK.

Digital Output I/O

DD0 (LSB)–

DD9 (MSB)

Digital Outputs. Pixel Output Databus.

This data bus outputs the 10-bit digital

output data during line scan.

EOC

Digital Output. This is the End of

Conversion signal from the ADC

indicating that new pixel data is

available.

RD

Digital Input. Taking this input low

places the data stored in the output

latch on the bus. When this input is high

the DD0–DD9 bus is in TRI-STATE.

General Digital I/O

MCLK Digital Input. This is the 12MHz (typical)

master system clock.

SYNC Digital Input. A low-to-high transition on

this input begins a line scan operation.

The line scan operation terminates

when this input is taken low.

Analog Power

V

A

This is the positive supply pin for the

analog supply. It should be connected

to a voltage source of +5V and

bypassed to AGND with a 0.1 µF

monolithic capacitor in parallel with a

10 µF tantalum capacitor.

AGND This is the ground return for the analog

supply.

Digital Power

V

D

This is the positive supply pin for the

digital supply. It should be connected to

a voltage source of +5V and bypassed

to DGND with a 0.1 µF monolithic

capacitor.

DGND This is the ground return for the digital

supply.

V

D(I/O)

This is the positive supply pin for the

digital supply for the LM9811’s I/O. It

should be connected to a voltage

source of +3V to +5V and bypassed to

DGND

capacitor. If the supply for this pin is

different than the supply for V

it should also be bypassed with a 10 µF

with a 0.1 µF monolithic

(I/O)

and VD,

A

tantalum capacitor.

DGND

(I/O)

This is the ground return for the digital

supply for the LM9811’s I/O.

NC

NC All pins marked NC (no connect) should

be left floating. Do not tie NC pins to

ground., power supplies, or any other

potential or signal.

www.national.com 8

Page 9

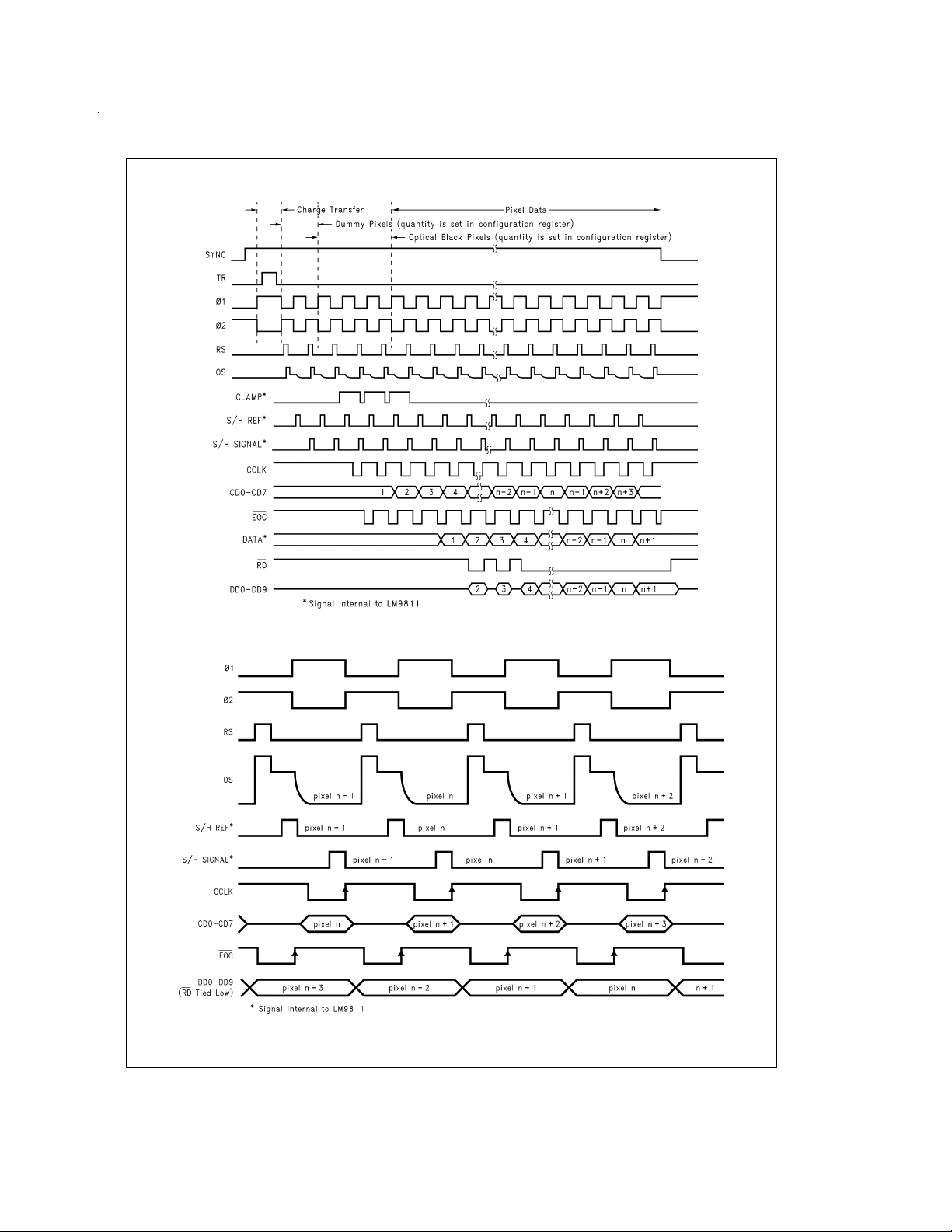

Timing Diagrams

DS012813-9

FIGURE 1. Line Scan Timing Overview

FIGURE 2. Pixel Pipeline Timing Overview

DS012813-10

www.national.com9

Page 10

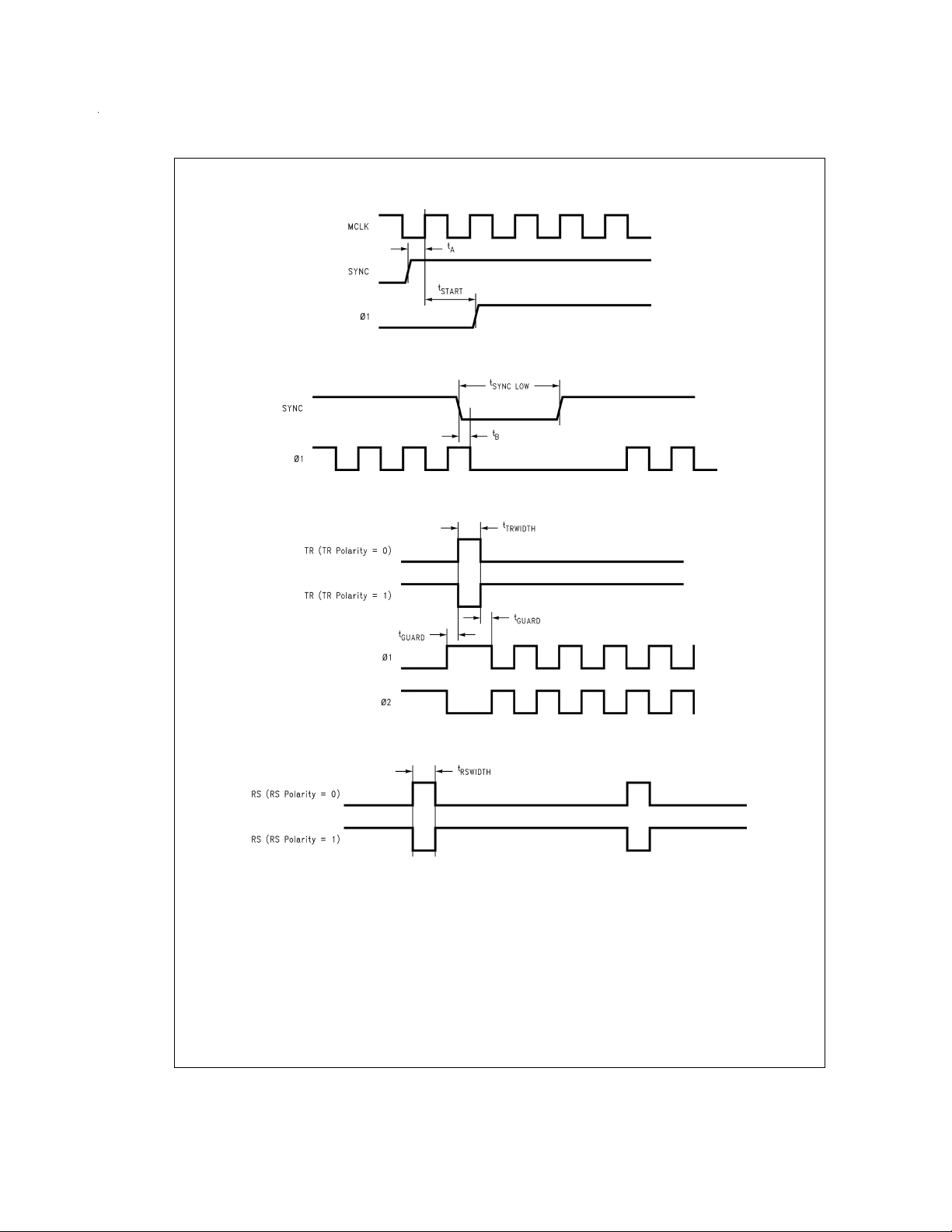

Timing Diagrams (Continued)

FIGURE 4. Timing for End of Line/Start of Next Line

DS012813-11

FIGURE 3. Timing for Start of Line Scan

DS012813-12

FIGURE 5. TR Pulse Timing

FIGURE 6. RS Pulse Polarity

www.national.com 10

DS012813-13

DS012813-14

Page 11

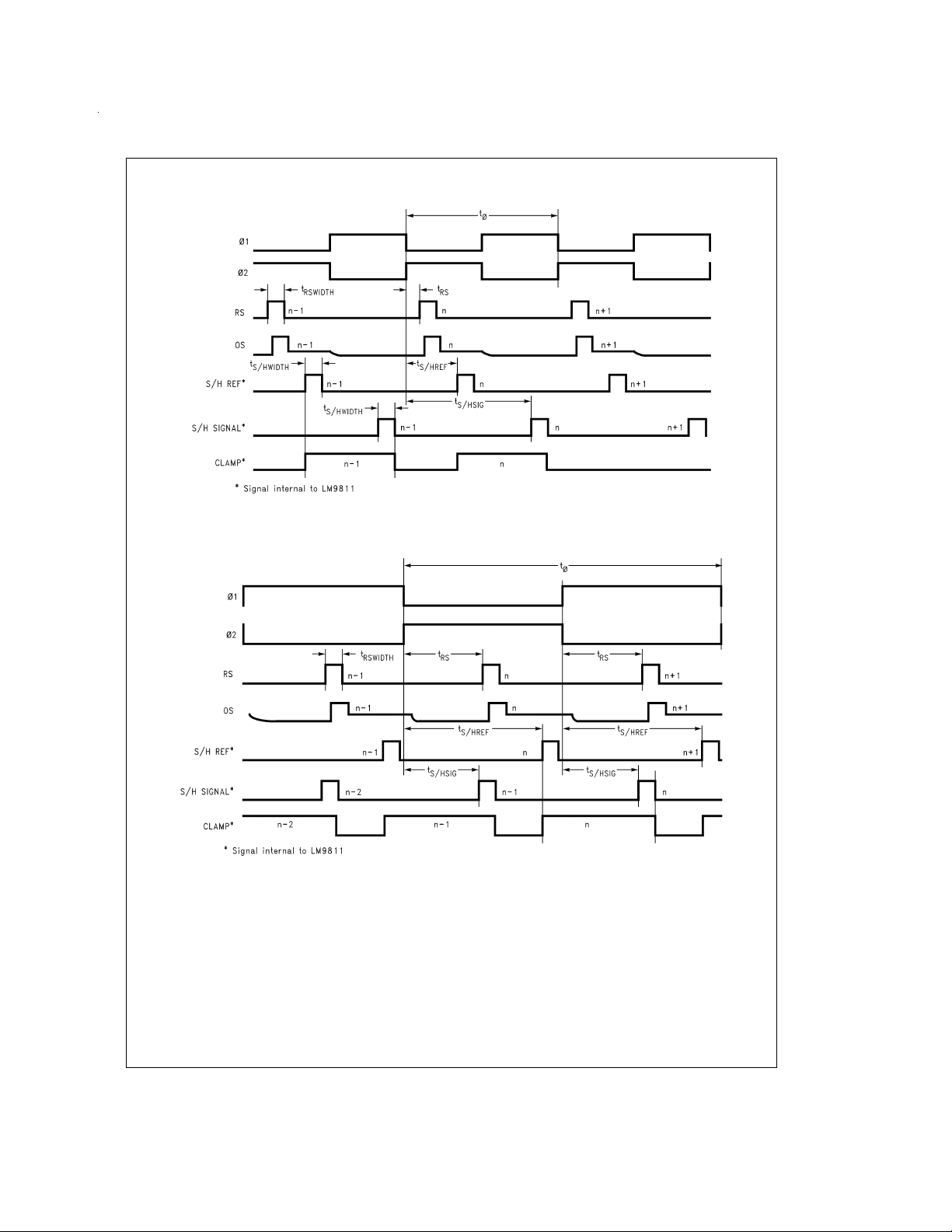

Timing Diagrams (Continued)

Note: Clamp signal only active during optical black pixels at beginning of line.

FIGURE 7. CCD Timing

Note: Clamp signal only active during optical black pixels at beginning of line.

FIGURE 8. CCD Timing (Even/Odd CCDs)

DS012813-15

DS012813-16

www.national.com11

Page 12

Timing Diagrams (Continued)

i=value programmed in Dummy Pixel Register - 1 (for example: Dummy Pixel Register=17→i=16→16 Dummy Pixel).

j=value programmed in Optical Black Register.

FIGURE 9. Dummy Pixel and Optical Black Pixel Timing

FIGURE 10. Coefficient Data Timing

DS012813-17

DS012813-18

FIGURE 11. Output Data Timing

www.national.com 12

DS012813-19

Page 13

Timing Diagrams (Continued)

FIGURE 12. Data Timing (Output and Coefficient Data Sharing Same Bus)

Serial Configuration Register Timing Diagrams

DS012813-20

FIGURE 13. Configuration Register Write Timing using CS, Continuous SCLK (16-Bit Word)

FIGURE 14. Configuration Register Read Timing using CS, Continuous SCLK (16-Bit Word)

DS012813-21

DS012813-22

www.national.com13

Page 14

Serial Configuration Register Timing Diagrams (Continued)

FIGURE 15. SDO Timing

FIGURE 16. Configuration Register Write Timing with CS Continuously Low (16-Bit Word)

FIGURE 17. Configuration Register Write Timing with CS Continuously Low (Two 8-Bit Bytes)

DS012813-23

DS012813-24

DS012813-25

FIGURE 18. Configuration Register Read Timing with CS Continuously Low (16-Bit Word)

FIGURE 19. Configuration Register Read Timing with CS Continuously Low (Two 8-Bit Bytes)

www.national.com 14

DS012813-26

DS012813-27

Page 15

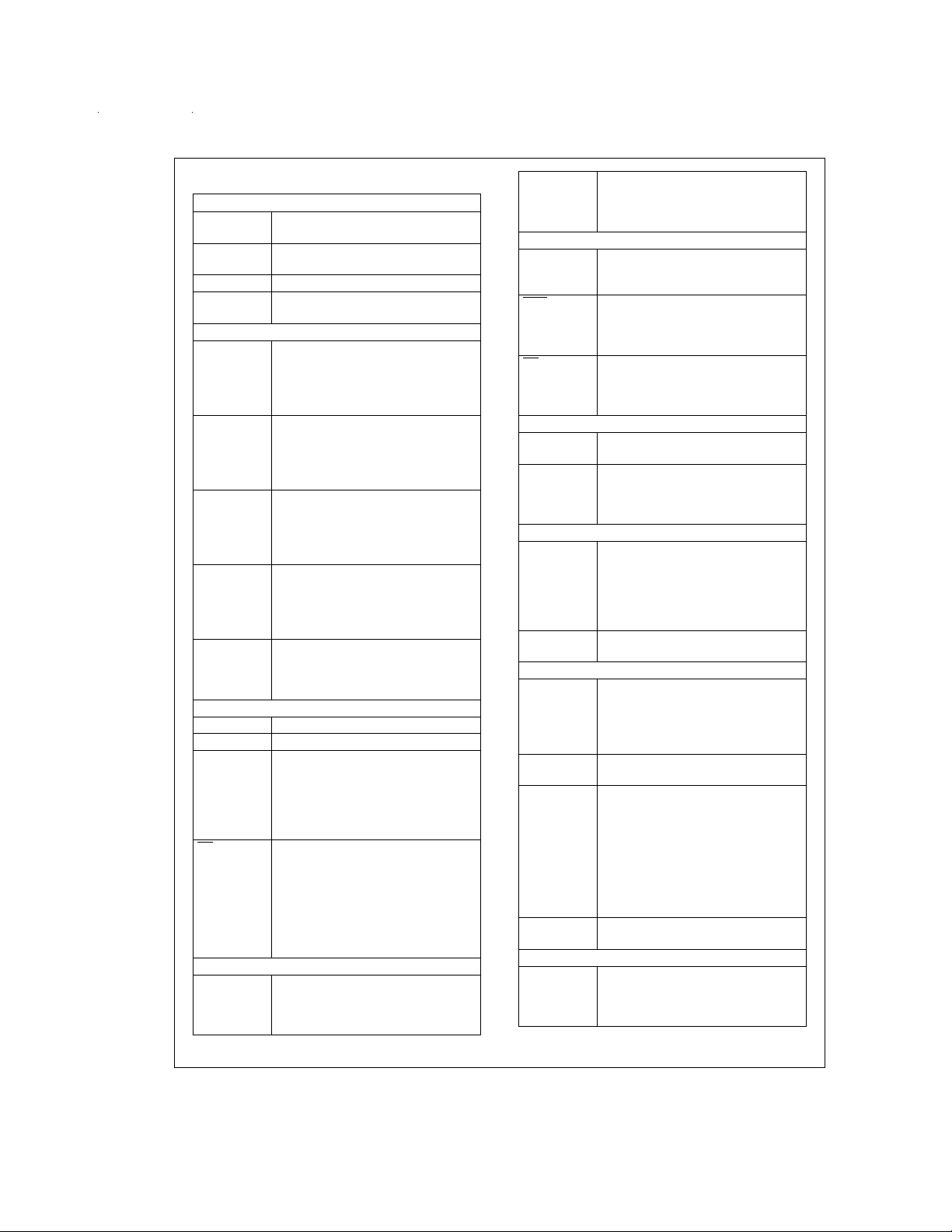

Configuration Register t

20MHz (t

=

50ns). Times for 12MHz MCLK can be calculated by multiplying by

MCLK

MCLK

=

=

1/f

1 MCLK period. Examples given in parenthesis are for f

MCLK

MCLK

=

TABLE 1. Configuration Register Address Table

A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0

000

Standard

Mode or

Even/Odd

Mode

RS

Pulse

Width

RS

Pulse

Polarity

RS Pulse Position

MODE RSW1 RSW0 RSPOL RSPOS3 RSPOS2 RSPOS1 RSPOS0

001

Sample Reference Position

(Maximum Register Value is 14)

Sample Signal Position

SR3 SR2 SR1 SR0 SS3 SS2 SS1 SS0

010

φ1 φ2RSTR

Enable Enable Enable Enable Guardband Polarity

TR Pulse Width

TR–φ1TR

φ1EN φ2EN RSEN TREN TRW1 TRW0 TRGRD TRPOL

0 1 1 Signal

Polarity

Dummy Pixels (Minimum Register Value is 2)

SIGPOL BLS6 BLS5 BLS4 BLS3 BLS2 BLS1 BLS0

100

101

110

BLL7 BLL6 BLL5 BLL4 BLL3 BLL2 BLL1 BLL0

GAIN7 GAIN6 GAIN5 GAIN4 GAIN3 GAIN2 GAIN1 GAIN0

PGA Gain

Source

Offset

DAC

Sign

Optical Black Pixels (Minimum Register Value is 1)

PGA Gain Coefficient

Power-

down

Offset

Add

VGA Gain

MSB

VGA

Gain

VGA

Gain

VGA Gain

LSB

PGASRC ODSIGN PD OFFADD VGA3 VGA2 VGA1 VGA0

111

Offset

MSB LSB

Offset

DAC

Offset

DAC

Offset

Test ModesDAC DAC

VOS3 VOS2 VOS1 VOS0 0000

TABLE 2. Configuration Register Parameters

Parameter Control Bits Result

MODE

MODE

0 Standard CCD (φ frequency=f

1 Even/Odd CCD (φ frequency=f

RS Pulse Width

)

(t

RSWIDTH

RS1 RS0

00 1t

01 2t

10 3t

11 4t

RS Pulse Polarity RSPOL

0 RS

1 RS

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

www.national.com15

/8)

/16)

(50ns)

(100ns)

(150ns)

(200ns)

Page 16

Configuration Register t

20MHz (t

=

50ns). Times for 12MHz MCLK can be calculated by multiplying by

MCLK

MCLK

=

=

1/f

1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

TABLE 2. Configuration Register Parameters (Continued)

Parameter Control Bits Result

RSPOS3 RSPOS2 RSPOS1 RSPOS0

0 0 0 0 0.0t

0 0 0 1 0.5t

0 0 1 0 1.0t

0 0 1 1 1.5t

0 1 0 0 2.0t

0 1 0 1 2.5t

RS Pulse Position

)

(t

RS

0 1 1 0 3.0t

0 1 1 1 3.5t

1 0 0 0 4.0t

1 0 0 1 4.5t

1 0 1 0 5.0t

1 0 1 1 5.5t

1 1 0 0 6.0t

1 1 0 1 6.5t

1 1 1 0 7.0t

1 1 1 1 7.5t

SR3 SR2 SR1 SR0

0 0 0 0 0.0t

0 0 0 1 0.5t

0 0 1 0 1.0t

0 0 1 1 1.5t

0 1 0 0 2.0t

0 1 0 1 2.5t

Sample Reference

Position (t

S/HREF

)

0 1 1 0 3.0t

0 1 1 1 3.5t

1 0 0 0 4.0t

1 0 0 1 4.5t

1 0 1 0 5.0t

1 0 1 1 5.5t

1 1 0 0 6.0t

1 1 0 1 6.5t

1 1 1 0 7.0t

1 1 1 1 Not Valid

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

=

(0ns)

(25ns)

(50ns)

(75ns)

(100ns)

(125ns)

(150ns)

(175ns)

(200ns)

(225ns)

(250ns)

(275ns)

(300ns)

(325ns)

(350ns)

(375ns)

(0ns)

(25ns)

(50ns)

(75ns)

(100ns)

(125ns)

(150ns)

(175ns)

(200ns)

(225ns)

(250ns)

(275ns)

(300ns)

(325ns)

(350ns)

www.national.com 16

Page 17

Configuration Register t

20MHz (t

=

50ns). Times for 12MHz MCLK can be calculated by multiplying by

MCLK

MCLK

=

=

1/f

1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

TABLE 2. Configuration Register Parameters (Continued)

Parameter Control Bits Result

SS3 SS2 SS1 SS0

0 0 0 0 0.0t

0 0 0 1 0.5t

0 0 1 0 1.0t

0 0 1 1 1.5t

0 1 0 0 2.0t

0 1 0 1 2.5t

Sample Signal

Position (t

S/HSIG

)

0 1 1 0 3.0t

0 1 1 1 3.5t

1 0 0 0 4.0t

1 0 0 1 4.5t

1 0 1 0 5.0t

1 0 1 1 5.5t

1 1 0 0 6.0t

1 1 0 1 6.5t

1 1 1 0 7.0t

1 1 1 1 7.5t

φ1EN

φ1 Enable

0 φ1 Output Off

1 φ1 Output On

φ2EN

φ2 Enable

0 φ2 Output Off

1 φ2 Output On

RSEN

RS Enable

0 RS Output Off

1 RS Output On

TREN

TR Enable

0 TR Output Off

1 TR Output On

TRW1 TRW0

TR Pulse Width

)

(t

TRWIDTH

0 0 20 t

0 1 30 t

1 0 40 t

1 1 50 t

TR-φ1 TRGRD

Guardband 0 1t

(t

)1 2t

GUARD

TRPOL

TR Polarity

0 TR

1 TR

SIGPOL

Single Polarity

0 Positive (CIS)

1 Negative (CCD)

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

MCLK

=

(0ns)

(25ns)

(50ns)

(75ns)

(100ns)

(125ns)

(150ns)

(175ns)

(200ns)

(225ns)

(250ns)

(275ns)

(300ns)

(325ns)

(350ns)

(375ns)

(1.0 µs)

(1.5 µs)

(2.0 µs)

(2.5 µs)

(50ns)

(100ns)

www.national.com17

Page 18

Configuration Register t

20MHz (t

=

50ns). Times for 12MHz MCLK can be calculated by multiplying by

MCLK

MCLK

=

=

1/f

1 MCLK period. Examples given in parenthesis are for f

MCLK

MCLK

=

(Continued)

TABLE 2. Configuration Register Parameters (Continued)

Parameter Control Bits Result

BLS6 BLS5 BLS4 BLS3 BLS2 BLS1 BLS0 Dummy Pixels

Dummy Pixels

Note: Minimum

Register Value is 2.

Actual number of

dummy pixels in CCD

should be one less

than number in this

register.

0 000000 NotValid

0 000001 NotValid

0 000010 1

0 000011 2

••••••• •

1 111101 124

1 111110 125

1 111111 126

BLL7 BLL6 BLL5 BLL4 BLL3 BLL2 BLL1 BLL0 Optical Black Pixels

0 0000000 NotValid

0 0000001 1

Optical Black Pixels

Note: Minimum

Register Value is 1.

0 0000010 2

0 0000011 3

•••••••• •

1 1111101 253

1 1111110 254

1 1111111 255

GAIN7 GAIN6 GAIN5 GAIN4 GAIN3 GAIN2 GAIN1 GAIN0 dB [V/V]

0 0000000 0.00 1.000

0 0000001 0.07 1.008

Internal PGA

Gain Coefficient

0 0000010 0.13 1.015

•••••••• •

1 1111101 9.35 2.935

1 1111110 9.37 2.942

1 1111111 9.40 2.950

PGA Gain PGASRC

Coefficient 0 Internal

Source 1 External

ODSIGN

Offset DAC Sign

0 Negative

1 Positive

PD

Power Down

0 Operating

1 Powered Down

OFF ADD

Offset Add

0 Offset

1 Offset

z

z

+8 LSB

0 LSB

www.national.com 18

Page 19

Configuration Register t

20MHz (t

=

50ns). Times for 12MHz MCLK can be calculated by multiplying by

MCLK

MCLK

=

=

1/f

1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

TABLE 2. Configuration Register Parameters (Continued)

Parameter Control Bits Result

VGA3 VGA2 VGA1 VGA0 dB [V/V]

0 0 0 0 0.00 1.00

0 0 0 1 0.60 1.07

0 0 1 0 1.20 1.15

0 0 1 1 1.79 1.23

0 1 0 0 2.39 1.32

0 1 0 1 2.99 1.41

0 1 1 0 3.59 1.51

VGA Gain

0 1 1 1 4.19 1.62

1 0 0 0 4.79 1.74

1 0 0 1 5.38 1.86

1 0 1 0 5.98 1.99

1 0 1 1 6.58 2.13

1 1 0 0 7.18 2.29

1 1 0 1 7.78 2.45

1 1 1 0 8.38 2.62

1 1 1 1 8.97 2.81

MCLK

=

www.national.com19

Page 20

Configuration Register t

20MHz (t

=

50ns). Times for 12MHz MCLK can be calculated by multiplying by

MCLK

MCLK

=

=

1/f

1 MCLK period. Examples given in parenthesis are for f

MCLK

(Continued)

TABLE 2. Configuration Register Parameters (Continued)

Parameter Control Bits Result

ODSIGN VOS3 VOS2 VOS1 VOS0 Offset (LSB)

0 0000 0

0 0001 −1.68

0 0010 −3.36

0 0011 −5.04

0 0100 −6.72

0 0101 −8.40

0 0110 −10.08

0 0111 −11.76

0 1000 −13.44

0 1001 −15.12

0 1010 −16.80

0 1011 −18.48

0 1100 −20.16

0 1101 −21.84

0 1110 −23.52

Offset DAC

0 1111 −25.20

1 0000 0

1 0001 +1.68

1 0010 +3.36

1 0011 +5.04

1 0100 +6.72

1 0101 +8.40

1 0110 +10.08

1 0111 +11.76

1 1000 +13.44

1 1001 +15.12

1 1010 +16.80

1 1011 +18.48

1 1100 +20.16

1 1101 +21.84

1 1110 +23.52

1 1111 +25.20

MCLK

=

www.national.com 20

Page 21

Block Diagram of LM9811-Based System

Power supplies and bypass capacitors not shown for clarity.

FIGURE 20. LM9811 System Block Diagram

Applications Information

1.0 THEORY OF OPERATION

The LM9811 removes errors fromand digitizes alinear CCD

pixel stream, while providing all the necessary clock signals

to drive the CCD. Offset and gain errors for individual pixels

are removed at the pixel rate. Offset errors are removed

through correlated double sampling (CDS). Gain errors

(which may come from any combination of PRNU, uneven illumination, cos

moved through the use of a 8-bit programmable gain amplifier (PGA) in front of the ADC.

1.1 The Analog Signal Path

(See Block Diagram)

The analog output signal from the CCD is connected to the

OS Input of the LM9811 through a 0.01 µF (typical, seeSection 4.2,

During the CCD’s optical black pixel segment at the beginning of every line, this input is clamped to the REF OUT

voltage (approximately 2.45V). This DC restore operation

fixes the reference level of the CCD pixel stream at REF

OUT

MID

The signal is then buffered and fed to a digitally-programmed

4-bit VGA (variable gain amplifier). The gain of the VGA is

digitally programmable in 16 steps from 1V/V to 3V/V. The

VGAis used to compensate for peak white CCD outputs less

than the 1.225V full-scale required by the LM9811 for maximum dynamic range. When used with parallel output CCDs,

the VGA can fine-tune the amplitude of the red, green, and

blue signals. For a detailed explanation of the VGA, see Section 4.3.

The output of the VGA goes into the CDS (Correlated Double

Sampling) stage, consisting of two sample/hold amplifiers:

S/H Ref (Reference) and S/H Signal. The reference level of

the signal is sampled and held by the S/H Refcircuit and the

active pixel data is sampled and held by the S/H Signal circuit. The output of S/H Ref is subtractedfrom the S/HSignal

4

effect, RGB filter mismatch, etc.) are re-

Clamp Capacitor Selection

) DC blocking capacitor.

.

MID

DS012813-28

output and amplified by 2. The full-scale signal range at this

point is approximately 2.45Vp-p. CDS reduces or eliminates

many sources of noise, including reset noise, flicker noise,

and both high and low frequency pixel-to-pixel offset variation. For more information on the CDS stage, see Section

4.4.

At this point an offset voltage can be injected by the 5-bit (4

bits + sign) Offset DAC. This voltage is designed to compensate for any small fixed DC offset introduced by the CDS

S/Hs and the x2 amplifier. The LSB size of the DAC is approximately 1.7 ADC LSBs (4 mV). The adjustment range is

±

25 ADC LSBs. For a detailed explanation of the Offset

DAC, see Section 4.6.

The next stage is the PGA. This is a programmable gain am-

plifier that changes the gain

at the pixel rate

to correct for

gain errors due to PRNU, uneven illumination (such as cos

effect), RGB filter mismatch, etc.The gain adjustment range

is 0 dB to 9 dB (1V/V to 3V/V) with 8 bits of resolution. The

gain data (correction coefficients) is provided on the

CD0–CD7 bus. The gain may also be fixed at any value between 0 dB and 9 dB with the PGA Gain Coefficient configuration register. For additional information on the PGA,

see Section 4.7.

An approximately 8 LSB (19 mV) offset can be added at the

output of the PGA stage if necessary to ensure that the offset

is greater than zero. This eliminates the possibility of a negative offset clipping the darkest output pixels. For more information on the Offset Add Bit, see Section 4.8.

Finally, the output of the PGA is digitized by the ADC and

made available on the DD0–DD9 bus (Section 4.9).

Three reference voltages are used throughout the signal

path: the externally supplied REF IN (1.225V), and the internally generated REF OUT

(3.675V).

(2.45V) and REF OUT

MID

4

HI

www.national.com21

Page 22

Applications Information (Continued)

1.2 The CCD Clocking Signals

To maximize the flexibility of the LM9811, the CCD’s φ1, φ2,

RS, and TR pulses are internally generated, with a wide

range of options, making these signals compatible with most

commercial linear CCDs. In many cases, these output signals can drive the CCD clock inputs directly,with only series

resistors (for slew rate control) between the LM9811’s outputs and the CCD clock inputs.

1.3 The Digital Interface

There are three main sections to the digital interface of the

LM9811: a serial interface to the Configuration Register,

where all device programming is done, an 8 bit-wide input

databus for gain correction coefficients with a synchronous

clock output (CCLK), and a 10-bit output databus for the final

pixel output data with a synchronous end of conversion output signal (EOC) and an output enable input (RD). Please

note that the CS input affects only the serial I/O–it has no effect on the output databus, input coefficient bus, or any other

section of the LM9811.

2.0 DIGITAL INTERFACE

2.1 Reading and Writing to the Configuration Register

Communication with the Configuration Register is done

through a standard MICROWIRE

terface is also compatible with the Motorola SPI

and is simple enough to easily be implemented in custom

hardware if needed.

The serial interface timing is shown in

Figures 16, 17, 18, 19

(Please note that some microcontrollers output data MSB

first. When using these microcontrollers the bits in the configuration register are effectively reversed.) Input data is

latched on the rising edge of SCLK, and output data changes

on the falling edge of SCLK. CS must be low to enable serial

I/O.

If SCLK is only clocked whensending or receiving data from

the LM9811, and held low at all other times, then CS can be

tied low permanently as shown in

SCLK is continuous, then CS must be usedto determine the

beginning and the end of a serial byte or word (see

13, 14

). Note that CS must make its high-to-low and

low-to-high transitions when SCLK is low, otherwise the internal bit counter may receive an erroneous pulse, causing

an error in the write or read operation.

Data may be transmitted and received in two 8-bit bytes

(typical with microcontroller interfaces) or one 16-bit word

(for custom serial controllers).

The Configuration Register is programmed by sending a

control byte to the serial port. This byte indicates whether

this is a read or a write operation, and gives the 3-bit address

of the register bank to be read from or written to. If this is a

read operation, the next 8 SCLKs will output the data at the

requested location on the SDO pin. If this is a write operation, the data to be sent to the specified location should be

clocked in on the SDI input duringthe next 8 SCLKs. Data is

sent and received using the LSB (Least Significant Bit) first

format.

For maximum system reliability, each configuration register

location can be read back and verified after a write.

™

serial interface. This in-

. Data is sent serially, LSB first.

™

standard

Figures 13, 14

and

Figures 16, 17, 18, 19

Figures

.If

If the serial I/O to the configuration register falls out of sync

for any reason, it can be reset by sending 8 or more SCLKs

with CS held high.

2.2 Writing Correction Coefficient Data on the

CD0–CD7 Bus

Correction coefficient data for each pixel is latched on the

rising edge of the CCLK output signal (see

that there is a 3 pixel latency between when the coefficient

data is latched and when the output data is available. As

ure 2

,

Pixel Pipeline Timing Overview

for pixel n is latched shortly before the output data for pixel

n-2 becomes available on the output databus (DD0–DD9).

Note that there is no way to provide a correction coefficient

for pixel 1, the first pixelin the CCD array. This is usually not

a problem since the first several pixels of a CCD are usually

optical black pixels, and used for clamping.

2.3 Reading Output Data on the DD0–DD9 Bus

The corrected digital output data representing each pixel is

available on the DD0–DD9 databus. The data is valid after

the falling edge of the EOC output. The RD input takes the

databus in and out of TRI-STATE. RD can be held low at all

times if there are noother devicesneeding the bus, or it can

be used to TRI-STATE the bus between pixels, allowing

other devices access to the bus.

(Output and Coefficient Data Sharing Same Bus)

how EOC can be tied to RD to automatically multiplex between coefficient data and conversion data.

2.4 MCLK

This is the master clock input that controls the LM9811. The

pixel conversion rate is fixed at 1/8 of this frequency.Many of

the timing parameters are also relative to the frequency of

this clock.

2.5 SYNC

This input signals the beginning of a line. When SYNC goes

high, the LM9811 generates a TR pulse, then begins converting pixels until the SYNC line is brought low again. Since

there is no pixel counter in the LM9811, it will work with

CCDs of any length.

3.0 DIGITAL CCD INTERFACE

3.1 Buffering φ1, φ2, RS, and TR

The LM9811can drive the φ1, φ2, RS, and TR inputs of many

CCDs directly, without the need for external buffersbetween

the LM9811 and the CCD. Most linear CCDs designed for

scanner applications require 0V to 5V signal swings into

20pF to 500pF input loading. Series resistors are typically inserted between the driver and the CCD to control slew rate

and isolate the driver from the large load capacitances. The

values of these resistors are usually given in the CCD’s

datasheet.

4.0 ANALOG INTERFACE

4.1 Voltage Reference

The two REF IN pinsshould beconnected to a 1.225V

reference voltage capable of sinking between 2 mA and

5 mA of current coming from the 500Ω–1400Ω resistor string

between REF OUT

bandgap reference is recommended for this application as

shown in

Figure 21

and REF IN. The LM4041-1.2 1.225V

HI

. The inexpensive “E” grade meets all the

Figure 10

). Note

Fig-

shows, coefficientdata

Figure 12,Data Timing

, shows

±

2

%

www.national.com 22

Page 23

Applications Information (Continued)

requirements of the application and is available in a TO-92

(LM4041EIZ-1.2) package as well as a SOT-23 package

(LM4041EIM3-1.2) to minimize board space.

Due to the transient currents generated by the LM9811’s

ADC, PGA, and CDS circuitry, the REF IN pins, the REF

OUT

pin and the REF OUTHIpin should all be bypassed

MID

to AGND with 0.1 µF monolithic capacitors.

DS012813-29

FIGURE 21. Voltage Reference Generation

4.2 Clamp Capacitor Section

This section is very long because it is relatively complicated

to explain, but the answer is short and simple: A clamp capacitor value of 0.01 µF should work in almost all applications. The rest of this section describes exactly how this

value is selected.

droop (100 mV), the number of pixels on the CCD, and the

pixel conversion rate (f

clamp capacitor value:

/8) and provides the minimum

MCLK

For example, if the OS input leakage current is 20 nA worstcase, the CCD has 2700 active pixels, theconversion rate is

1.5MHz (f

0.1V, the minimum clamp capacitor value is:

=

12MHz), and the max droop desired is

MCLK

The maximum size of the clamp capacitor is determined by

the amount of time available to charge it to the desiredvalue

during the optical black portion of theCCD output. The internal clamp is on for each pixel from therising edge of the S/H

ref pulse to the falling edge of the S/H signal pulse (see

ures 7, 8

). This time can be calculated using the values

Fig-

stored in the Sample Signal and Sample Reference configuration registers and the MCLK frequency. For normal CCDs:

And for even/odd CCDs:

DS012813-30

FIGURE 22. OS Clamp Capacitor and Internal Clamp

The output signal of many CCDs rides on a large DC offset

(typically 8V to 10V) which is incompatible with the LM9811’s

5V operation. To eliminate this offset without resorting to additional higher voltage components, the output of the CCDis

AC coupled to the LM9811 through a DC blocking capacitor,

(the CCD’s DOS output is not used). The value of

C

CLAMP

this capacitor is determined by the leakage current of the

LM9811’s OS input and the output impedance of the CCD.

The leakage through the OS input determines how quickly

the capacitor value will drift from the clamp value of REF

OUT

, which then determines how many pixels can be

MID

processed before the droop causes errors in the conversion

±

(

0.1V is the recommended limit). The output impedance of

the CCD determines how quickly the capacitor can be

charged to the clamp value during the black reference period

at the beginning of every line.

The minimum clamp capacitor value is determined by the

maximum droop the LM9811 can tolerate while converting

one CCD line. The following equation takes the maximum

leakage current into the OS input, the maximum allowable

Where SS is the value in the Sample Signal Position register

(0–15), SR is the value in the Sample Reference Position

register (0–14), f

the amount of time (per pixel) that the clamp is on.

is the MCLK frequency, and t

MCLK

DARK

The following equation takes the number of optical black pixels, the amount of time (per pixel) that the clamp is closed,

the CCD’s output impedance, and the desired accuracy of

the final clamp voltage and provides the maximum clamp capacitor value that allows the clamp capacitor to settle to the

desired accuracy within a single line:

Where n=the number of optical black pixels, t

amount of time (per pixel) that the clamp is on, R

output impedance of the CCD, and accuracy is the ratio of

DARK

OUT

is the

is the

the worst-case initial capacitor voltage to the desired final

capacitor voltage. For example, if a CCD has 18 black reference pixels, the output impedance ofthe CCDis 1500Ω, the

LM9811is configured to clamp for 500ns, theworst caseinitial voltage across the capacitoris 10V, and the desired voltage after clamping is 0.1V (accuracy=10/0.1=100), then:

www.national.com23

is

Page 24

Applications Information (Continued)

The final value for C

C

will work in this example.

CLAMP MAX

, but no less than C

In some cases, depending on primarily on the choice of

CCD, C

CLAMP MAX

meaning that the capacitor cannot be charged to its final voltage during the black pixels at the beginning of a line and hold

its voltage without drooping for the duration of that line. This

is usually not a problem because in most applications the

CCD is clocked continuously as soon as poweris applied. In

this case, a larger capacitor can be used (guaranteeing that

the C

CLAMP MIN

age is forced across the capacitor overmultiple lines. This is

requirement is met), and the final clamp volt-

the equation to calculate how many lines are required before

the capacitor settles to the desired accuracy:

should be less than or equal to

CLAMP

CLAMP MIN

may actually be

less

. A value of 470 pF

than the C

CLAMP MIN

,

Using the values shown before and a clamp capacitor value

of 0.01 µF, this works out to be:

At a 2.5MHz conversion rate, this is about 14ms.

In this example a 0.01 µF capacitor takes 14ms after

power-up to charge to its final value, but its droop across all

subsequent lines is now less than 2 mV (using the previous

example’s values). This wide margin is the reasona C

value of 0.01 µF will work in most applications.

CLAMP

4.3 VGA

The LM9811has a VGA (Variable GainAmplifier) that can be

used to increase the amplitude of the CCD signal prior to

sampling, correction, and digitization. The gain of the VGA is

0 dB to 9 dB and is determined by the codes in the 4-bit VGA

Gain register, as given by the equation:

This gain may be changed at theline rate (not the pixel rate)

by writing to the configuration register. You can write to the

configuration register to change the gain at any time, but if

you write during a line, the remaining pixels of that line may

be corrupted. It is best to change the gain afterall active pixels have been read out or while SYNC is low.

4.4 Correlated Double Sampler (CDS)

Figure 23

shows the output stage of a typical CCD and the

resulting output waveform:

DS012813-31

FIGURE 23. CDS

Capacitor C1 converts the electrons coming from the CCD’s

shift register to an analog voltage. The source follower output stage (Q2) buffersthis voltage before it leaves the CCD.

Q1 resets the voltage across capacitor C1 in between every

pixel at intervals 2 and 5. When Q1 is on, the output signal

(OS) is at its maximum. After Q1 turns off (period 3), the OS

level represents the residual voltage acrossC1 (V

V

RESIDUAL

from the ON resistance of Q1, and other sources of error.

includes charge injection from Q1, thermal noise

RESIDUAL

When the shift register clock (φ1) makes a low to high transition (period 4), the electrons from the next pixel flow into

C1. The charge across C1 now contains the voltage proportional to the number of electrons plus V

term. If OS is sampled at the end of period 3 and that voltage

RESIDUAL

, an error

is subtracted from the OS at the end of period 4, the

V

RESIDUAL

duced. ([V

is the principal of Correlated Double Sampling.

term is canceled and the noise on the signal is re-

SIGNAL+VRESIDUAL

]−V

RESIDUAL

=

V

SIGNAL

). This

The LM9811 implements CDS with two switched-capacitor

S/H amplifiers. With a 12MHz MCLK input, the LM9811’s

S/Hs acquire a signal within an 83ns window which can be

placed anywhere in the pixel period with 42ns precision. See

Figures 7, 8

for more detailed timing information.

4.5 CIS Mode

The LM9811 provides some support for CIS (Contact Image

Sensor) devices by offering a sampling mode for capturing

positive going signals, as opposed to the CCD’s negative going signal.

).

www.national.com 24

Page 25

Applications Information (Continued)

DS012813-32

FIGURE 24. CIS vs CCD Output Signals

While CIS devices do not usually have a reference level with

which to perform correlated double sampling, many have a

very repeatable reset level which can be used as a black reference allowing the LM9811 to perform pseudo CDS on the

signal. For more information on CIS applications, see Section 9.0. When the Signal Polarity bit is set to a zero, the

LM9811expects a positive going signal, typically from a CIS

device. When the Signal Polarity bit is set to a one, the

LM9811 expects a negative going signal, typically from a

CCD sensor.

4.6 Offset DAC

The 4 bit plus sign offset DAC isused to compensate for DC

offsets due to the correlated double samplingstage. The offset can be corrected in 31 steps of 1.7 ADC LSB size between −25.2 LSB and +25.2 LSB. Note that the DAC comes

before the PGA, so any offset errors at this stage are multiplied by the gain of the PGA. The calibration procedure described in Section 5.0 demonstrates how to use the DAC to

eliminate offset errors before scanning begins.

Note that this DAC is programmed during LM9811

calibration/configuration and is not meant to compensate for

pixel-to-pixel CCD offset errors. CDS cancels the pixel-rate

offset errors.

4.7 Programmable Gain Amplifier (PGA)

The PGAprovides 8 bits of pixel-to-pixel gain correction over

a 0 dB to 9 dB (x1 to x3) range. After the input signal is

sampled and held by the CDS stage, it is amplified by the

gain indicated by the data (“PGA Code”) on the CD0–CD7

databus using the formula:

4.8 Offset Add Bit

In addition to the Offset DAC, there is a bit in the configuration register which, when set, adds apositive 8 LSBoffset at

the output of the PGA. This offsetensures that any offset between the output of the PGA and the ADC is positive, so that

no dark level information is lost due to negative offsets. The

calibration procedure described in Section 5.0 demonstrates

how to set this bit.

4.9 ADC

The ADC converts the normalized analog output signal to a

10-bit digital code. The EOC output goes from high to low to

indicate that a new conversion is ready. ADC data can be

latched by external memory on the rising edge of EOC. The

RD input takes the ADC’s output buffer in and out of

TRI-STATE. RD may be tied to EOC in many applications,

putting the data on the bus only when EOC is low, and allowing other data on the bus (such as CD0–CD7 correction

data) at other times. In this way the output data and correction coefficient data can share the same databus (see

12

).

5.0 CALIBRATION

Calibration of a CCD scanner is done to normalize the pixels

of a linear CCD so that each pixel produces the same digital

output code at the output of the scanner when presented

with the same image light intensity. This intensity ranges

from black (no light) to white (maximum light intensity). The

CCD’s analog output may have large pixel-to-pixel DC offsets (corresponding to errors on black signals) and

pixel-to-pixel variations in their output voltage given the

same white image (corresponding to errors on brighter signals). If these offsets are subtracted from each pixel, and

each pixel is given its own gain setting tocorrect for different

efficiencies, then these errors can be eliminated.

Ideally the digital output code for any pixel would be zero for

a black image, and some code near fullscale for an image

with maximum brightness. For a 10-bit system like the

LM9811, that code might be 1000. This code will be called

the Target Code.

The LM9811 eliminates these global and pixel-to-pixel offset

and gain errors with its Correlated Double Sampling (CDS),

Offset DACs, Variable Gain Amplifier, and pixel-rate Programmable Gain Amplifier. This section describes how to

program the LM9811 and the coefficient RAM being used

with it to eliminate these errors.

Calibration of a LM9811-based system requires3 steps. The

first, described in Section 5.1,

black image and normalizes the digital output code for each

pixel to a code at or near 0.

The second step, Section 5.2,

tion

, finds the optimum gain setting that places the output

voltage of all the pixels within the 9 dB adjustment range of

the PGA.

The final step, described in Section 5.3,

efficients (Shading Calibration)

the gain required to normalize theoutput of each pixel tothe

desired output code (the Target code).

5.1 Offset Calibration

This procedure corrects for static offsets generated by the

CCD and the LM9811. Because the LM9811 uses CDS to

eliminate the pixel-to-pixel offset errors of the CCD, no

pixel-rate offset correction is required.

Offset Calibration

Coarse Gain (VGA) Calibra-

PGA Correction Co-

, describes how to calculate

Figure

, takes a

www.national.com25

Page 26

Applications Information (Continued)

DS012813-33

FIGURE 25. Offset Calibration

To use the Offset DAC and Offset Add bit for offset correction, the offset errors (V

mined, as shown in

voltage at the PGAoutput, using the ADC with a black image

on the CCD (a black image can usually be createdsimply by

turning off the scanner’s illumination). If this voltage is known

with a PGA gain of 1.00V/V (0 dB) and 2.95V/V (9 dB), then

the offset errors (V

the following two equations:

=

V

ADC1

1(V

OS1+VDAC1

(PGA gain=1)

=

V

ADC2

2.95(V

OS1+VDAC1

(PGA gain=2.95)

Solving for V

V

OS1

V

OS2

=

(V

ADC2–VADC1

=

(2.95V

and V

OS1

ADC1–VADC2

These equations were used to produce this procedure for

cancelling the LM9811’s offset errors. Please note that all

voltages and measurements are in units of ADC LSBs to

simplify calibration.

1. Set the VGA Gain to 1V/V (VGA code=0).

2. Set the Offset DAC (V

LSBs) to ensure the total offset is positive and therefore

measurable by the ADC.

3. Set the Offset Add bit (V

4. Set the PGA Gain to 1V/V (PGA code=0).

5. Digitize a black line.

6. Calculate the average (in ADC LSBs) ofall the valid pixels in the black line and store that number as V

7. Set the PGA Gain to 2.95V/V (PGA code=255).

8. Digitize a black line.

9. Calculate the average (in ADC LSBs) ofall the valid pixels in the black line and store that number as V

10. Calculate V

V

OS1

OS1

=

(V

ADC2

11. Program the Offset DAC register using the formula:

and V

OS1

Figure 25

and V

OS1

OS2

)/1.95–V

OS2

. This is done be measuring the

) can be determined from

OS2

)+V

OS2+VDAC2

)+V

OS2+VDAC2

:

DAC1

)/1.95–V

DAC2

) to its maximum value (+25.2

DAC1

)to0.

DAC2

:

)–V

)/1.95–25.2

ADC1

) must first be deter-

.

ADC1

.

ADC2

Offset DAC code=-(V

=

(25.2 + (V

=

15 + 0.3(V

ADC1–VADC2

ADC1–VADC2

)(15/25.2)

OS1

)/1.95)(15/25.2)

)

(Note: This calculation can be approximated as

15 + 10(V

ADC1–VADC2

)/32

for ease of programming in 8-bit microcontrollers)

>

V

12. If 3V

If 3V

ADC1

ADC1

, then set the Offset Add bit to 0.

ADC2

<

V

, set the Offset Add bit to 1.

ADC2

13. The final value of the offset present at theADC input can

be used for the shading calibration calculations. Calculate the final value of the ADC input offset (V

ing:

A. (3V

ADC1–VADC2

)/2

OFFSET

) us-

(if the Offset Add bit is 0), or

B. (3V

ADC1–VADC2

)/2+8

(if the Offset Add bit is 1)

5.2 Coarse Gain Calibration

The LM9811’s PGA corrects for upto 9dB of variation in the

CCD output signal’s white level intensity. That 9 dB range

has to be centered inside the 9 dB window of correction as

shown in

Figure 26

. The window’s upper limit is determined

by the Target code, and the lower limit by theTargetcode divided by 2.8 (this corresponds to the minimum gain range of

the PGA). To allow proper calibration, the amplitude of all the

pixels in the CCD should be inside this range when those

pixels are scanning an image corresponding to the Target

code. The placement of the pixels inside the 9 dB window

can be controlled by any ofthree ways: changing the gainof

the VGA, changing the integration time of the CCD, or

changing the intensity of the light source.

In most designs, the output waveform of the CCD can be

brought into the 9 dB correction range of the PGAby adjusting the gain of the VGA. This is the next step in system

calibration.

DS012813-34

FIGURE 26. CCD Input Signal In Range

Figure 27

is a flowchart of one technique to find the optimum

VGAgain setting during calibration. Calibration begins with a

VGA gain setting of 1V/V and increments the VGAgain until

one of the four possible results occur. Result 1 is the desired

outcome, where the signal falls into the range shown in

ure 26

and the VGA calibration has been successful.

Fig-

www.national.com 26

Page 27

Applications Information (Continued)

FIGURE 27. VGA Calibration Flowchart

There are several conditions that can cause the VGA gain

calibration routine to fail. Result 2, “Signal is too strong: Decrease light intensity or integration time” is shown in

28

. This condition indicates that the amplitude of one or

more of the white pixels coming from the CCD is greater than

the maximum input voltage that the LM9811 is capable of accepting (about 1.2Vp-p). In this case the amplitude of the

analog CCD output must be reduced before it enters the

LM9811’s OS input to prevent clipping. This can be done by

reducing the intensity of the light source or shortening the integration time of the CCD.

Figure

DS012813-35

has more uniform illumination, higher quality lenses, or other

opto-mechanical techniques to reduce variation across all

the active pixels.

DS012813-36

FIGURE 28. CCD Input Signal Too Strong

The second possible failure mode of the VGA calibration

(Result 3) occurs if there is “Toomuch variation” in the amplitude of the pixels coming from the CCD (

Figure 29

). The

LM9811can correct for up to a 2.8to 1variation in pixel amplitude. If the variation is greaterthan thisthan it must be reduced before it can perform shading correction on all the pixels. Typically this is done by using a better light source that

DS012813-37

FIGURE 29. CCD Input Signal Range Too Wide

DS012813-38

FIGURE 30. CCD Input Signal Too Weak

The final problem that can occur during VGA calibration (Result 4) is the “Signal too weak: increase light intensity or integration time” condition, shown in

Figure 30

. In this case,

www.national.com27

Page 28

Applications Information (Continued)

even with the VGA gain set to a maximum of 2.8, the amplitude of one or more pixels is less than the minimum required

for shading correction. The solution is to increase the intensity of the light source or lengthen the integration time of the

CCD to increase the CCD’s output amplitude.

To ensure that a scanner system is manufacturable, the result of the VGA calibration must always be State1. States2,

3, and 4 must be eliminated either by ensuring that the total

variation in light intensity (from all sources) from system to

system to a maximum of9 dB,or by being able to adjust the

light source’s intensity and/or the CCD’s light integration

time.

5.3 PGA Correction Coefficients (Shading Calibration)

Once the input signal has been centered inside the range the

LM9811 can correct for, correction coefficients must be generated for each pixel to compensatefor the gain error ofthat

pixel.

1. Set Offset DAC and Add Bit as determined in Section

5.1.

2. Set the VGAgain to the value determined in Section 5.2.

3. Set the PGA gain to 0 dB.

4. Scan a reference line corresponding to all white or light

grey and store it in memory.

5. Calculate the required gain correction coefficients for

each pixel using the formula:

Where Uncorrected Codenis the ADC output code for pixel

n with the PGA gain=0 dB, Target Code is the number that

corresponds to the desired output from the ADC with the

given reference line input, and Correction Coefficient

the gain correction number that is sent to theCD0–CD7 correction databus to provide gain correction for pixel n when

digitizing a line with the LM9811’s PGA gain correction operating.

If it is difficult or undesirable to do the division, subtraction,

and multiplication operations shown above for every pixel,

then a lookup table can be generated in advance that willreturn the Correction Coefficient for any Uncorrected Code.

This table can be stored in ROM or RAM and can speed up

the calibration process. The disadvantage of this technique

is that the Target Code must be fixed when the table is generated, so only one Target Code can be used (unless multiple tables are generated).

All the Correction Coefficients must be stored and sent to the

LM9811 through the CD0–CD7 databus for every line

scanned.

6.0 POWER SUPPLY CONSIDERATIONS

6.1 General

The LM9811should be powered by a single+5V source (unless 3V-compatible digital I/O is required— see Section 6.2).

The analog supplies (V

V

) are brought out individually to allow separate by-

D(I/O)

passing for each supply input. They should

) and the digital supplies (VDand

A

not

by two or more different supplies.

n

be powered

In systems with separate analog and digital +5V supplies, all

the supply pins of the LM9811 should be powered by the

analog +5V supply. Each supply input should be bypassed to

its respective ground with a 0.1 µF capacitor located as close

as possible to the supply input pin. A single 10 µF tantalum

should be placed near the V

quency bypassing.

supply pin to provide low fre-

A

To minimize noise, keep the LM9811 and all analog components as far as possible from noise generators, such as

switching power supplies and high frequency digital busses.

If possible, isolate all the analog components and signals

(OS, reference inputs and outputs, V

ground plane, separate from the digital ground plane. The

, AGND) on an analog

A

two ground planes should be tied together at a single point,

preferably the point where the power supply enters the PCB.

6.2 3V Compatible Digital I/O

If 3V digital I/O operation is desired, the V

powered by a separate 3V

±

10%or 3.3V±10%supply. In

this case, all the digital I/O pins (CD0–CD7, CCLK, MCLK,

DD0–DD9, EOC, RD,SYNC, CS, SCLK, SDO,and SDI) will

be 3V compatible. The CCD clock signals (φ1, φ2, RS, and

TR) remain 5V outputs, powered by V

V

input should be bypassed to DGND

D(I/O)

combination of a 0.1 µF capacitor and a 10 µF tantalum capacitor.

6.3 Power Down Mode

Setting the Power Down bit to a “1” puts the device in a low

power standby mode. The CCD outputs (φ1, φ2, RS, andTR)

are pulled low and the analog sections are turned off to conserve power. The digital logic will continue to operate if

MCLK continues and SYNC is held high, so for minimum

power dissipation MCLK should be stopped when the

LM9811 enters the Power Down mode. Recovery from

Power Down typically takes 50 µs (the time required for the

is

reference voltages to settle to 0.5 LSB accuracy).

7.0 COLOR

There are two primary ways to use the LM9811 in a color

system with a triple output (RGB) CCD. The first is to use

one LM9801 with an external multiplexer.This is the simplest

solution. The second technique is to use one LM9811 per

RGB color.

7.1 Parallel Output CCD, One LM9811

Figure 31

is an example of how to use a single LM9811 with

a triple-output RGB CCD. In this case an entire line of red is

digitized, followed by an entire line of green, then blue. This

solution provides a 1.5 Mpixels/sec (for an effective 500k

RGB pixels/sec after de-interleaving) pixel rate using a high

performance triple output color CCD.

The Mux 1 multiplexer, located between the CCD’s OS outputs and the LM9811’s OS input, selects the color to bedigitized according to the states of theA and B inputs (described

below). The multiplexer’s speed requirements are minimal

because the mux switches atthe linerate, not the pixel rate.

Also, since the output of the mux goes into a high impedance, low-capacitance input, the ON resistance of the mux is

not critical. The 74HC4052 is a good choice for this

application.

pin may be

D(I/O)

. In this case the

D

with a parallel

(I/O)

www.national.com 28

Page 29

Applications Information (Continued)

FIGURE 31. Parallel Output CCD Application Circuit

DS012813-39

FIGURE 32. Parallel Output CCD Timing

To maximize the integration time for the Red, Green, and

Blue photodiodes, the transfer (TR) pulses should be stag-

Figure 32

gered as shown in

. This is done by a demultiplexer

(Mux 2) between the TR output of the LM9811and the transfer gate inputs of the CCD. If the CCD’s transfer gate input

capacitance is relatively low (see theCCD datasheet for this

specification and the requirements for TR pulse rise and fall

time), then the other half of the 74HC4052 may be used to

switch the TR pulses as shown. If the TR gate input capacitance is so large that the minimum TR rise and fall times can

not be met because of the 200Ω max on resistance of the

74HC4052’s switches, then the 74HC4052 can not be used

to multiplex the TR output and should be replaced with an

active demultiplexer such as the 74HC155 dual 2-to-4 demultiplexer.

Two signals (A and B) must be generated to choose which

color is going to be digitized and receives the TR pulse.

These signals can be as simple as the output of a two bit

counter that counts from 0 to 2 (0, 1, 2, 0, 1, 2, etc.). This

counter should be incremented after the end of the previous

line and before the first transfer pulse of the next line. Also,

DS012813-40

since each color will need a different VGAgain, the appropriate VGA gain value for each color should be sent to the

LM9811 during this time.

7.2 Parallel Output CCD, Three LM9811s

Figure 33

uses three LM9811s to achieve a 4.5 Mpixel/sec

(1.5M RGB pixels/sec) pixel rate. The three LM9811s are

synchronized by applying the same MCLK and SYNC signals to all three devices. One LM9811 provides the clock signals required for the CCD. Since the coefficient data for all

three LM9811s will be latched simultaneously on the rising

edge of CCLK, the correction coefficient bus must either be

at least 24 bits wide (8 correction coefficient bits by 3

LM9811s) or run at a 4.5MHz rate and be latched into a

buffer between the correction coefficient databus and each

LM9811. Similarly, the output data for all three LM9811s will

be available simultaneously at the 3 output databusses.

Since each LM9811 is dedicated to one color, the VGA gain

does not change during line scan.

www.national.com29

Page 30

Applications Information (Continued)

DS012813-41

FIGURE 33. Parallel Output CCD, Three LM9811

8.0 TYPICAL GREYSCALE APPLICATION

Figure 34