Page 1

N

LM9810/20 10/12-Bit Image Sensor Processor Analog Front End

General Description

The LM9810 and LM 9820 are high performance Ana log Front

Ends (AFEs) for image sensor processing systems. The

LM9810/20 perform s all the analog and mixed signal func tions

(correlated double s ampling, color s pecific gain and offset correction, and analog to digital conversion) necessar y to digitize

the output of a wide variety of CIS and CCD sensors. The

LM9810 has a 10 bit 6M Hz ADC, and the LM982 0 has a 12 bit

6MHz ADC. The LM98 10 and L M9820 a re pin-for-pin and functionally compatible.

Applications

•

Color Flatbed Document Scanners

•

Color Sheetfed Scanners

•

Multifunction Imaging Product s

•

Digital Copiers

•

General Purpose Linear CCD Imaging

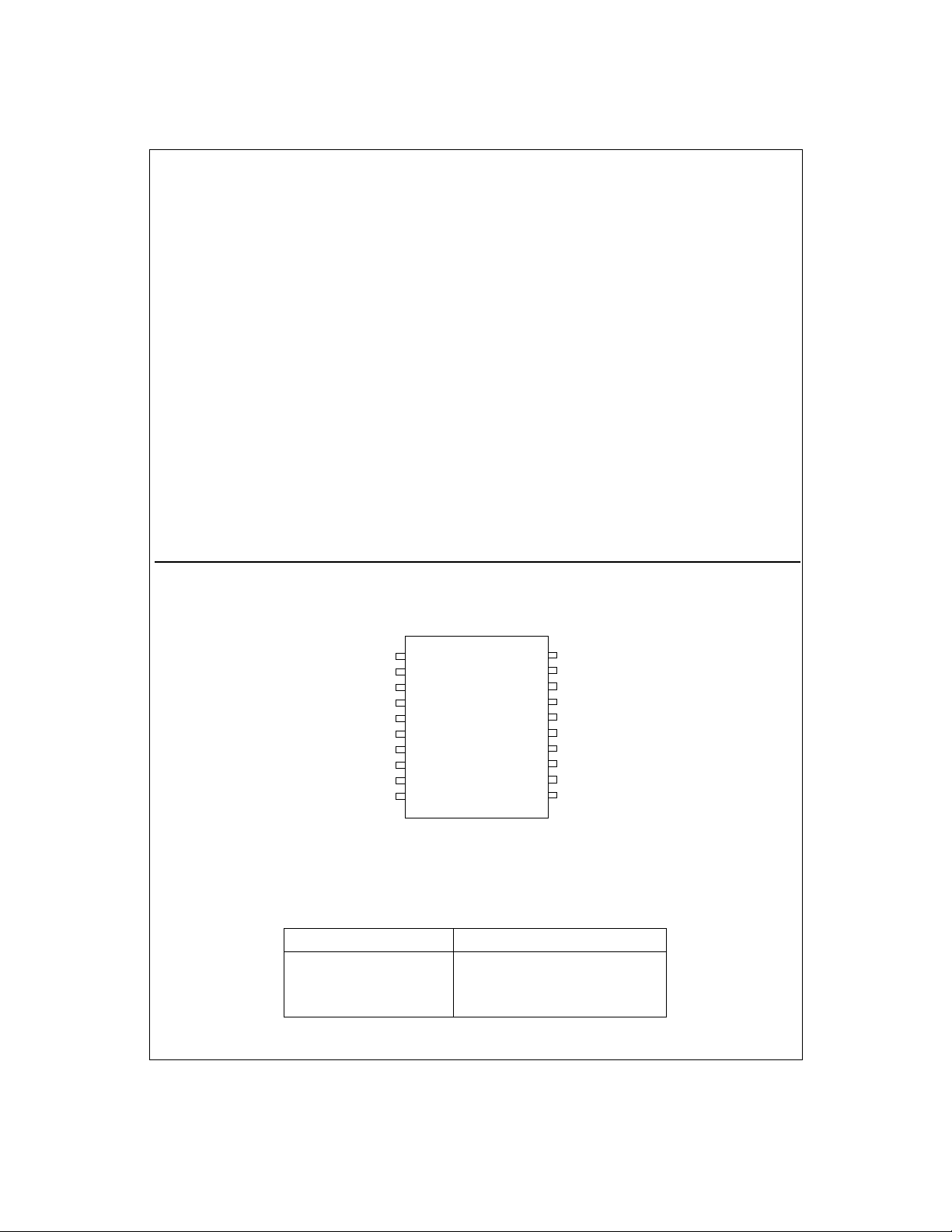

Connection Diagrams

Features

•

6 million pixels/s conversion rate

•

Digitally programm ed gain and offset for red, green and blue

pixels

•

Correlated Double Sampling for lowest noise

•

TTL/CMOS input/output compatible

Key Specifications

•

Output Data Resolution 10/12 Bits

•

Pixel Conversion Rate 6MHz

•

Supply Voltage 5V±5%

•

Power Dissi pation 300mW

LM9810/20 10/12-Bit Image Sensor Processor Analog Front End

July 1998

V

1

REF-

V

REFMID

RefBypass

SampCLK

V

REF+

OS

OS

OS

AGND

2

3

LM9810

4

5

R

6

G

7

B

VA

8

9

10

LM9820

Ordering Information

Commercial (0°C ≤ TA ≤ +70°C) Package

LM9810CCWM

LM9810CCWMX

LM9820CCWM

LM9820CCWMX

TRI-STATE® is a registered trademark of National Semiconductor Corporation.

©1997,1998 National Semiconductor Corporation

DGND

20

VD

19

MCLK

18

D5

17

D4

&

20 Pin Wide SOIC

20 Pin Wide SOIC, Tape & Reel

20 Pin Wide SOIC

20 Pin Wide SOIC, Tape & Reel

16

15

14

13

12

11

D3

D2 (SCLK)

D1 (Latch)

D0 (SDI)

NewLine

1

http://www.national.com

Page 2

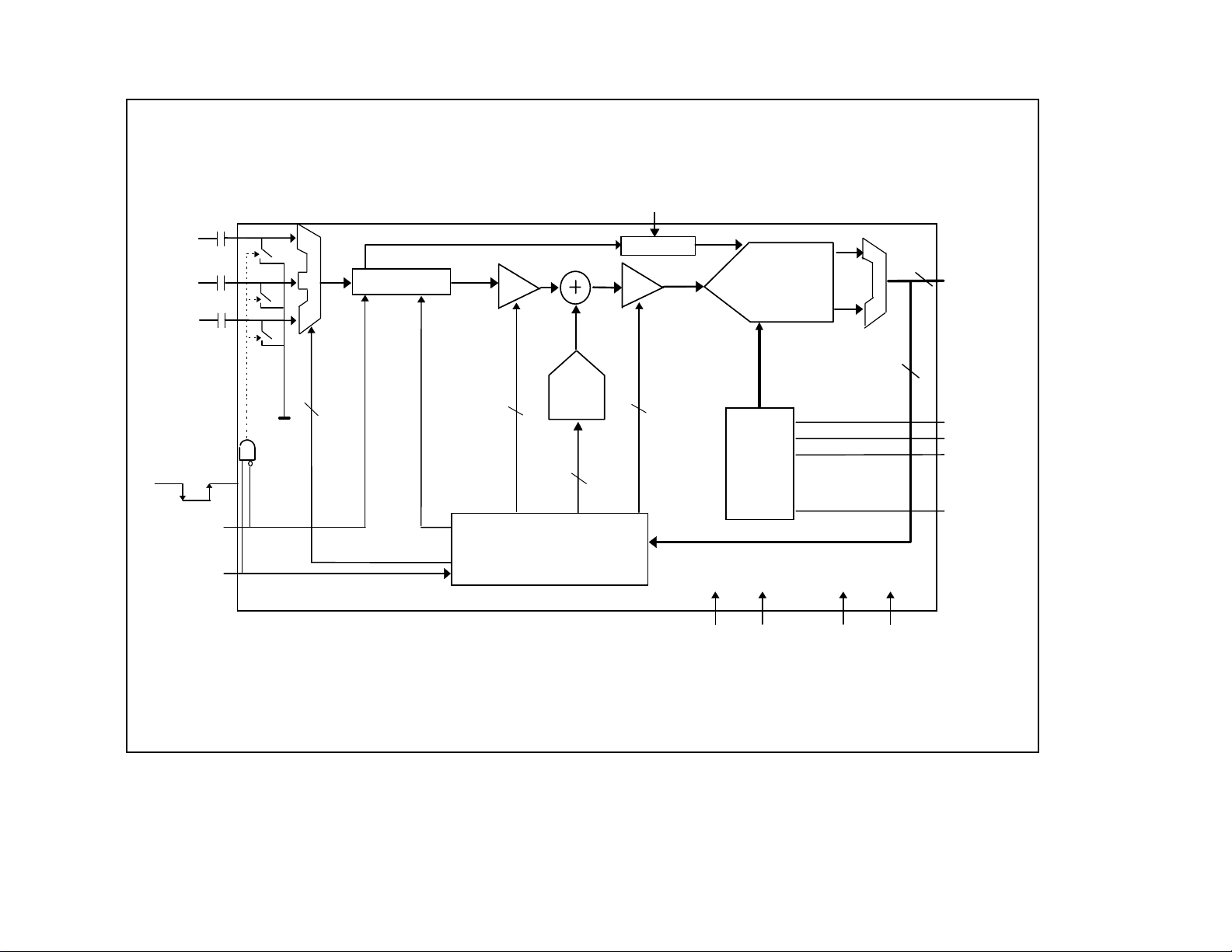

Block Diagram

MCLK

OS

R

OS

G

OS

B

V

signal

V

SampCLK

NewLine

SampCLK

M

U

X

2

V

REF+

or

V

Mux

Select

-

Sampler

0 to 2V

V

Sampling

Mode

SIG

x3 Boost

Gain of

1 or 3

x3

Offset

1

DAC

Offset

6

ADC Clock

PGA

.93 to 3

PGA Gain

5

10/12 bit

6MH z

ADC

Bandgap

Voltage

Reference

M

U

D2,D1,D0

programming

interface

6

D5-D0

3

V

REF+

V

REFMID

V

REF-

RefBypass

Configuration Register

Sampling Mode,

Offset & Gain for R,G,B

VA

AGNDDGND

VD

http://www.national.com

Page 3

(

)

(

)

(

)

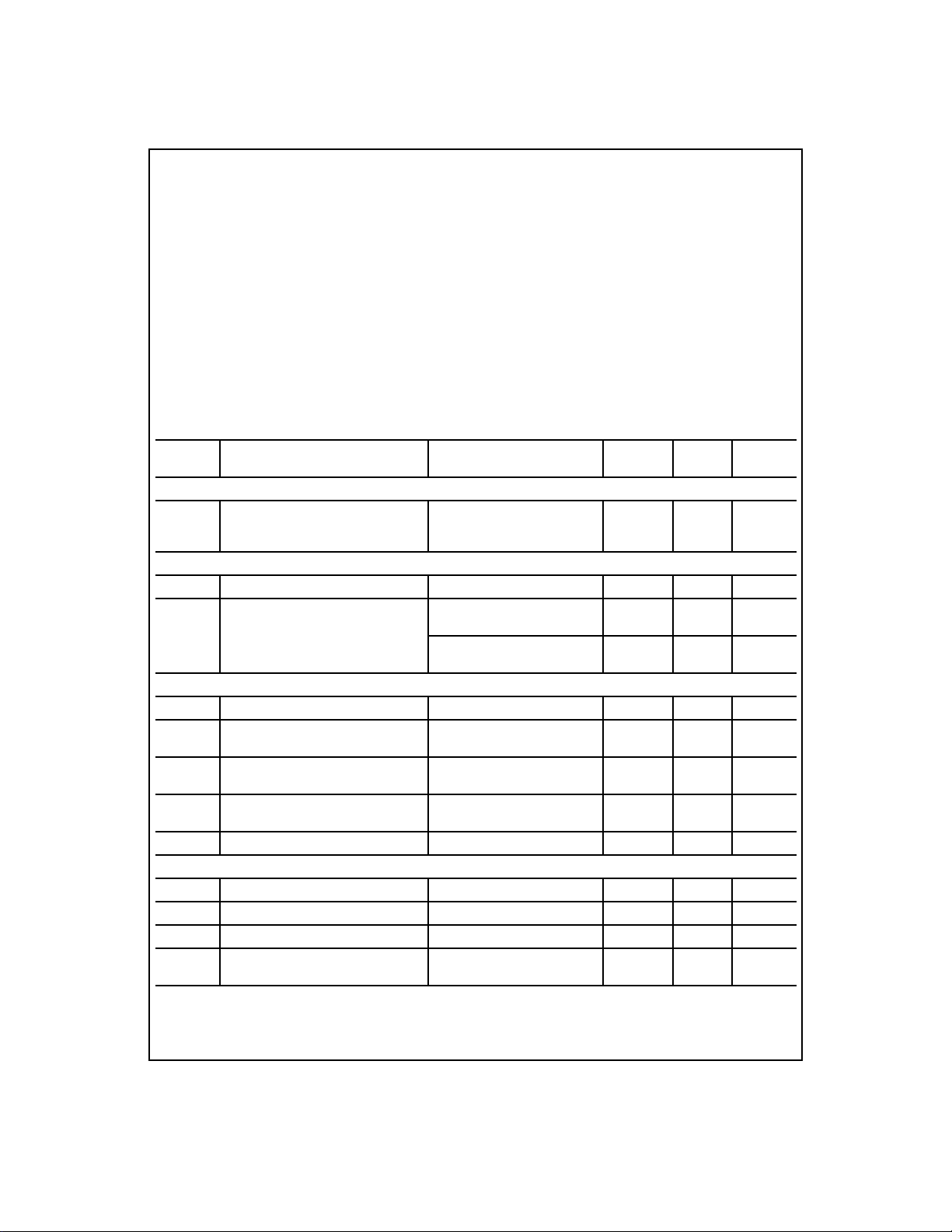

Absolute Maximum Ratings

(Notes 1 & 2)

Positive Supply Voltage (V+=VA=VD)

With Respect to GND=

Voltage On Any Input or Output Pin -0.3V to V

Input Current at any pin

Package Input Current

Package Dissipation at T

ESD Susceptibility

AGND=DGND

(Note 3)

(Note 3)

A

(Note 5)

= 25°C

+

±25mA

±50mA

(Note 4)

Human Body Model 2000V

+0.3V

Operating Ratings

Operating Temperature Range T

6.5V

VA

Supply Voltage +4.75V to +5.25V

VD

Supply Voltage +4.75V to +5.25V

VA-VD

|

|

OS

, OSG, OS

R

Input Voltage Range -0.05V to VA + 0.05V

NewLine, SampCLK, D0-D2, MCLK

Input Voltage Range -0.05V to

Soldering Information

Infrared, 10 second s

(Note 6)

300°C

Storage Temperature -65°C to +150°C

Electrical Characteristics

The following specifications apply for

T

A=TJ=TMIN

to T

; all other limits TA=TJ=25°C.

MAX

AGND=DGND

=0V, VA=VD=+5.0V

(Notes 7, 8, & 12)

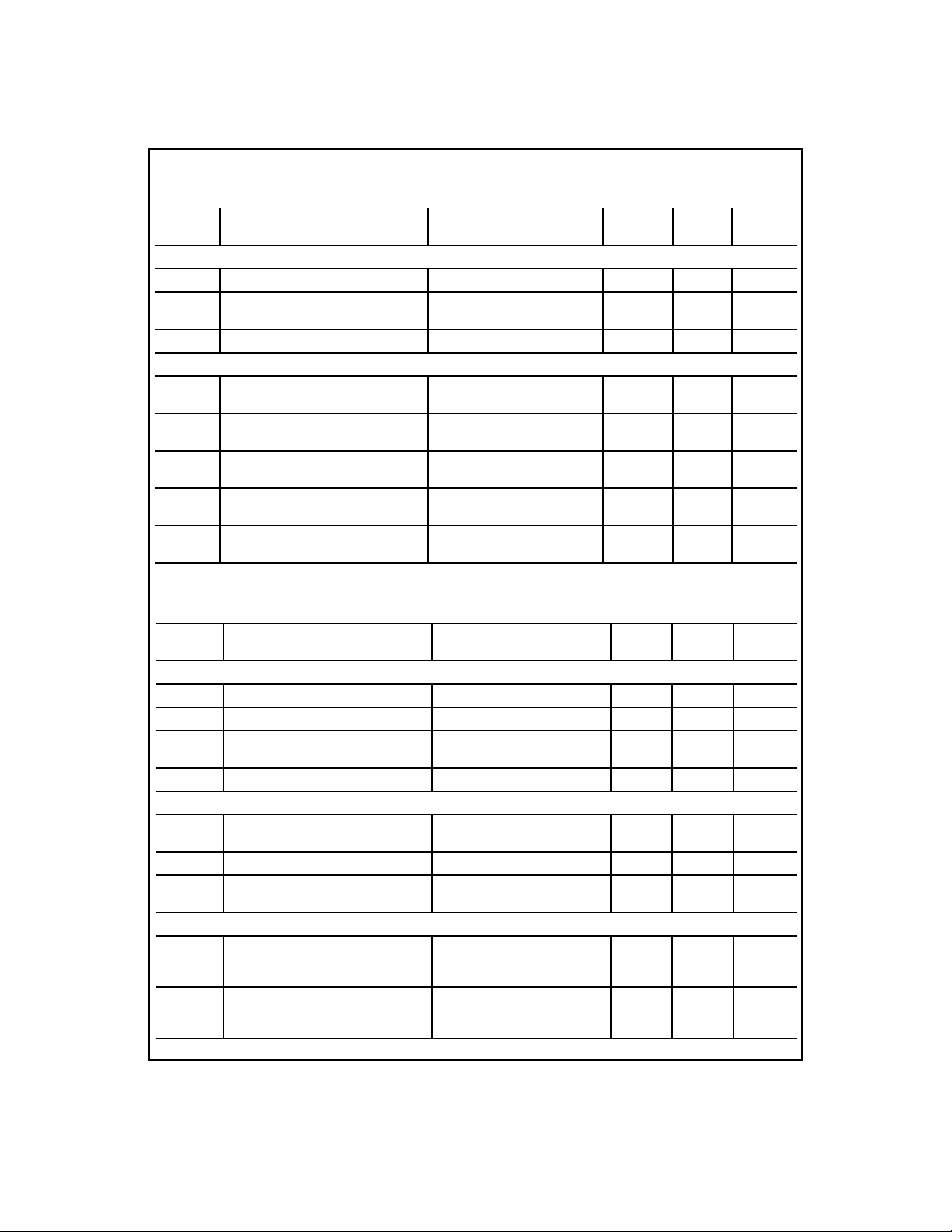

Symbol Parameter Conditions

CCD/CIS Source Requirements for Full Specified Accuracy and Dynamic Range

V

OS

Sensor’s Maximum Peak Differential

PEAK

Signal Range

Gain = 0.933

Gain = 3.0

Gain = 9.0

Analog Input Characteristics

OS

OS

OS

,

,

R

Input Capacitance 5 pF

G

B

Measured with OS = 3.5V

OS

OS

OS

,

,

R

Input Leakage Current

G

B

CDS disabled, selected OS input

CDS disabled, unselected OS

input

Coarse Color Balance PGA Characteristics

Monotonicity 5 bits (min)

G

(Minimum PGA Gain) PGA Setting = 0 0.93

0

(Maximum PGA Gain) PGA Setting = 31 3.0

G

31

x3 Boost Gain

Gain Error at any gain

(Note 13)

x3 Boost Setting On

(bit B5 of Gain Register is set)

Internal Reference Characteristics

V

REFMID

V

V

∆

Mid Supply Output Voltage 2.5 V

Positive Reference Output Voltage 3.5 V

REF+

Negative Reference Output Voltage 1.5 V

REF-

Differential Reference Voltage

V

REF

V

- V

REF+

REF-

, f

=24MHz, Rs=25Ω. Boldface limits apply for

DC

MCLK

B

DC

Note 12

(Notes 1 & 2)

≤

Typical

Note 9

MIN

=0°C≤T

Limits

Note 10

T

=+70°C

A

MAX

≤

100mV

VD

+ 0.05V

Units

(Limits)

2.1

0.65

0.21

20 25 µA (max)

10 nA

3.0

.90

.96

2.96

3.15

2.93

3.05

V/V (min)

V/V (max)

V/V (min)

V/V (max)

V/V (min)

V/V (max)

±0.4 1.67 % (max)

2.0 V

V

V

V

3

http://www.national.com

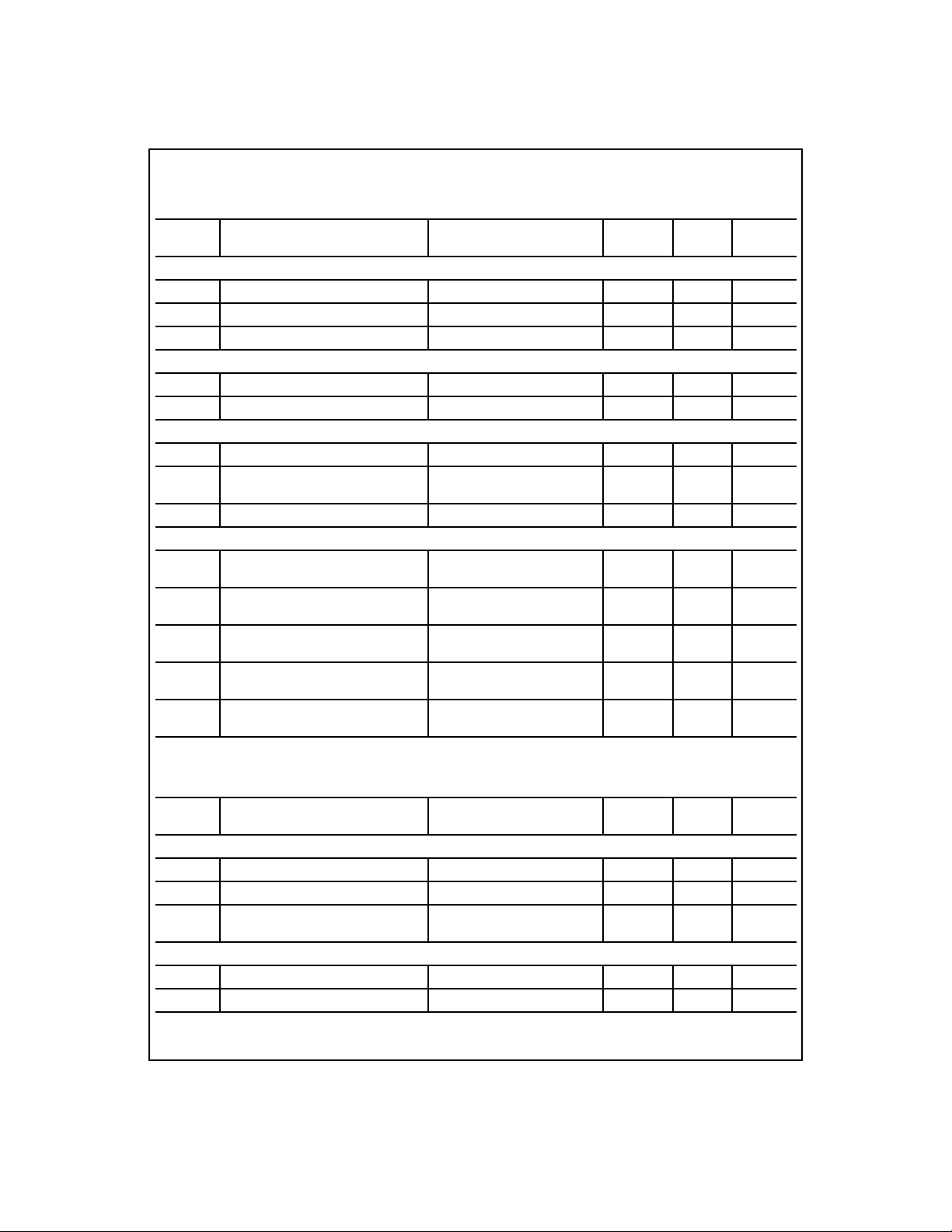

Page 4

LM9810 Electrical Characteristics

(

)

(

)

(

)

(

)

(

)

(

)

The following specifications apply for

T

A=TJ=TMIN

to T

; all other limits TA=TJ=25°C. All LSB limits are in units of the LM9810’s 10 bit ADC.

MAX

AGND=DGND

=0V, VA=VD=+5.0V

Symbol Parameter Conditions

ADC Characteristics

Resolution with No Missing Codes 10 bits (min)

INL Integral Non-Linearity Error

(Note 11)

DNL Differential Non-Linearity ±0.25 ±1.0 LSB (max)

Full Channel Linearity

INL Integral Non-Linearity Error

Note 14

(Note 11)

DNL Differential Non-Linearity ±0.40 LSB

Static Offset DAC Characteristics

Monotonicity 6 bits (min)

Offset DAC LSB size PGA gain = 1 5

Offset DAC Adjustment Range PGA gain = 1 ±150 ±140 LSB (min)

System Characteristics (see section 1.7.1, Internal Offsets)

Analog Channel Gain Constant

C

(ADC Codes/V)

V

V

V

V

Pre-Boost Analog Channel Offset Error,

OS1

CCD Mode

Pre-Boost Analog Channel Offset Error,

OS1

CIS Mode

Pre-PGA Analog Channel Offset Error -10

OS2

Post-PGA Analog Channel Offset Error -11

OS3

Includes voltage reference

variation, gain setting = 1

, f

=24MHz, Rs=25Ω. Boldface limits apply for

DC

MCLK

(Notes 7, 8, & 12)

Typical

Note 9

±0.35 ±1.5 LSB (max)

±0.9 LSB

502

4.4

4.5

Limits

Note 10

3.4

6.4

468

532

-7.2

+15.7

-6.5

+15.2

-28

+5.3

-30.6

+7.3

LSB (min)

LSB (max)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

Units

(Limits)

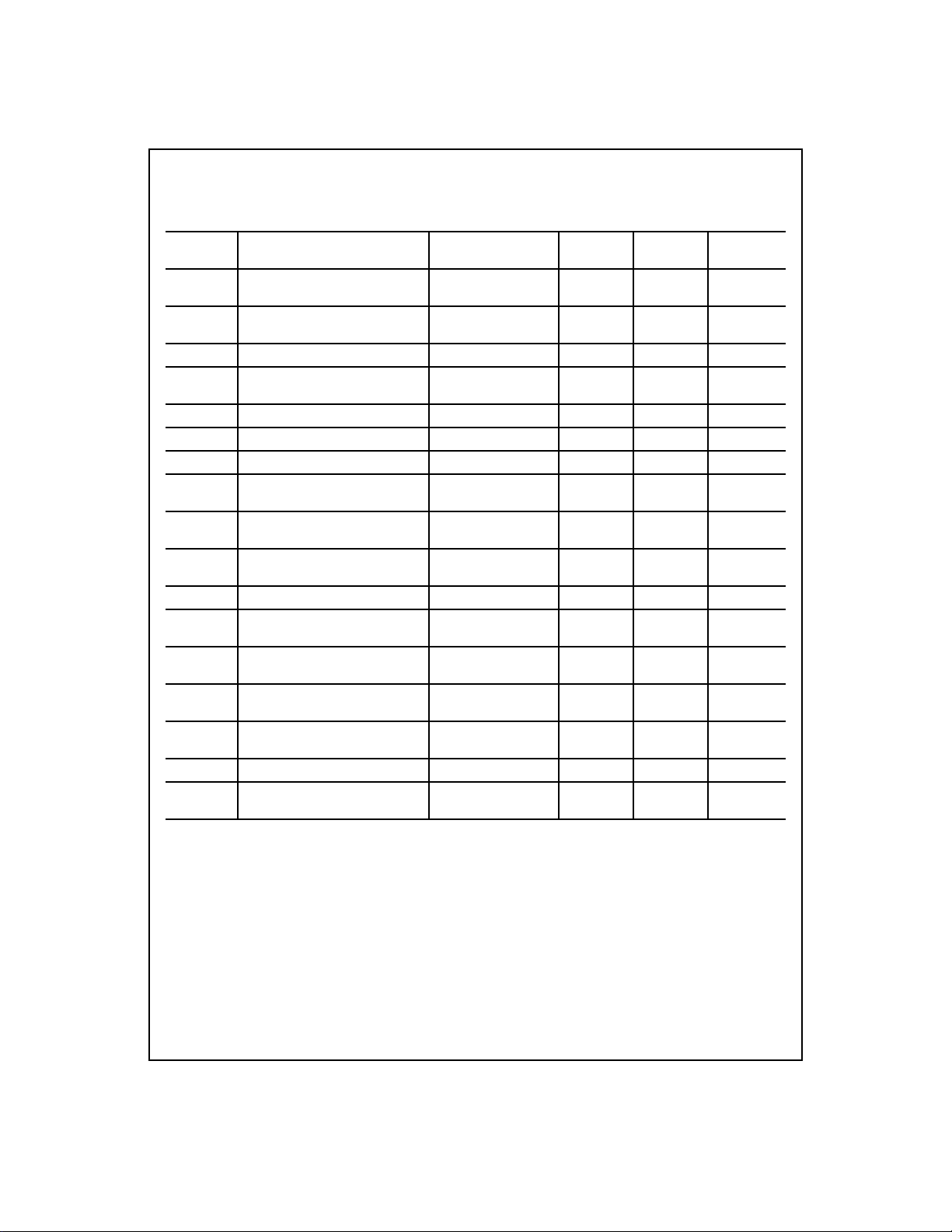

LM9820 Electrical Characteristics

The following specifications apply for

T

A=TJ=TMIN

to T

; all other limits TA=TJ=25°C. All LSB limits are in units of the LM9820’s 12 bit ADC.

MAX

AGND=DGND

=0V, VA=VD=+5.0V

Symbol Parameter Conditions

ADC Characteristics

Resolution with No Missing Codes 12 bits (min)

INL Integral Non-Linearity Error

(Note 11)

DNL Differential Non-Linearity ±0.6

Full Channel Linearity

INL Integral Non-Linearity Error

Note 14

(Note 11)

DNL Differential Non-Linearity ±0.65 LSB

, f

=24MHz, Rs=25Ω. Boldface limits apply for

DC

MCLK

(Notes 7, 8, & 12)

Typical

Note 9

Limits

Note 10

±1.1 ±4.0 LSB (max)

+1.75

-1.0

±3.4 LSB

4

http://www.national.com

Units

(Limits)

LSB (max)

Page 5

(

)

(

)

(

)

(

)

)

)

)

)

LM9820 Electrical Characteristics

The following specifications apply for

T

A=TJ=TMIN

to T

; all other limits TA=TJ=25°C. All LSB limits are in units of the LM9820’s 12 bit ADC.

MAX

AGND=DGND

(Continued)

=0V, VA=VD=+5.0V

,

f

DC

MCLK

Symbol Parameter Conditions

Static Offset DAC Characteristics

Monotonicity

Offset DAC LSB size PGA gain = 1 20

Offset DAC Adjustment Range PGA gain = 1 ±590

System Characteristics (see section 1.7.1, Internal Offsets)

Analog Channel Gain Constant

C

(ADC Codes/V)

V

V

V

V

Pre-Boost Analog Channel Offset Error,

OS1

CCD Mode

Pre-Boost Analog Channel Offset Error,

OS1

CIS Mode

Pre-PGA Analog Channel Offset Error -40

OS2

Post-PGA Analog Channel Offset Error -44

OS3

Includes voltage reference

variation, gain setting = 1

DC and Logic Electrical Characteristics

The following specifications apply for

T

A=TJ=TMIN

to T

; all other limits TA=TJ=25°C.

MAX

AGND=DGND

=0V, VA=VD=+5.0V

(Notes 7 & 8)

Symbol Parameter Conditions

D0-D2, MCLK, NewLine, SampCLK Digital Input Characteristics

V

V

C

Logical “1” Input Voltage

IN(1

Logical “0” Input Voltage

IN(0

I

Input Leakage Current

IN

Input Capacitance 5 pF

IN

VD

VD

V

IN

VIN=

=5.25V

=4.75V

=

D0-D5 Digital Output Characteristics

VD

V

V

OUT(1

OUT(0

I

OUT

Logical “1” Output Voltage

Logical “0” Output Voltage

TRI-STATE® Output Current

D0-D5

(

only)

=4.75V, I

VD

=4.75V, I

VD

=5.25V, I

V

OUT

V

OUT

Power Supply Characteristics

Operating

Analog Supply Current

I

A

Standby with input clocks stopped

Standby with input clocks running

Operating

Digital Supply Current

I

D

(Note 15)

Standby with input clocks stopped

Standby with input clocks running

VD

DGND

DGND

=

VD

=

DC

OUT

OUT

OUT

,

f

MCLK

=-360µA

=-10µA

=1.6mA

=24MHz, Rs=25Ω.

=24MHz, Rs=25Ω.

Boldface limits apply for

(Notes 7, 8, & 12)

Typical

Note 9

Limits

Note 10

6

14

26

±575

2008

17.6

18

1873

2129

-32.1

+68.9

-22.2

+57

-94.3

+16.4

-121

+28

Boldface limits apply for

Typical

Note 9

Limits

Note 10

2.0

0.8

0.1

-0.1

2.4

4.4

0.4

0.1

-0.1

45

0.8

57

0.9

3.0

220

110

320

200

220

Units

(Limits)

bits (min)

LSB (min)

LSB (max)

LSB (min)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

LSB (min)

LSB (max)

Units

(Limits)

V (max)

V (min)

µA(max)

µA(max)

V (min)

V (min)

V (max)

µA

µA

mA (max)

mA (max)

mA

µA (max)

µA (max)

µA

5

http://www.national.com

Page 6

AC Electrical Characteristics

The following specifications apply for

limits apply for T

A=TJ=TMIN

Symbol Parameter Conditions

AGND=DGND

to T

; all other limits TA=TJ=25°C.

MAX

=0V, VA=VD=+5.0V

(Notes 7 & 8)

=24MHz

,

t

MCLK

Typical

(Note 9)

=1/f

CLK

M

,

=5ns, Rs=25Ω.

t

r=tf

Limits

(Note 10)

,

f

DC

MCLK

Boldface

Units

(Limits)

f

MCLK

t

MCLK

t

SCNL

t

SampCLK

t

SampLo

t

SampHi

t

SampSU

t

DDO

t

HDO

t

SCLK

t

DSU

t

DH

t

SCLKLA

t

LASCLK

t

LA

t

LANL

Maximum

MCLK

MCLK

SampCLK

MCLK

Frequency

Duty Cycle

period 41 ns (min)

falling edge before

NewLine

falling edge

SampCLK

period

Low time for

High time for

SampCLK

edge of

falling edge of

SampCLK

SampCLK

falling edge before rising

MCLK

MCLK

before new valid

50 ns (min)

50 ns (min)

data

hold time of current data from falling

MCLK

edge of

D2

(SCLK) Serial Clock Period 1 t

Input data setup time before

D2

(SCLK) rising edge

Input data hold time after D2(SCLK)

rising edge

D2

(SCLK) rising edge after bit B0

D1

before

(Latch) rising edge

D1

(Latch) rising edge before next

D2

(SCLK) rising edge

High time for D1(Latch)

D1

(Latch) rising edge before

NewLine

falling edge

24

40

60

3

4

4

40

15

0

3

3

3

3

3

MHz (min)

% (min)

% (max)

t

(min)

MCLK

t

(min)

MCLK

ns (min)

ns (max)

ns (min)

(min)

MCLK

ns (min)

ns (min)

ns (min)

ns (min)

t

(min)

MCLK

t

SampCLK

(min)

Note 1: Absolute Max im um R atings indicate limits beyond wh ic h damage to the device may occur. Operating R atings indicate condit ions for which the device is functional,

but do not guarantee specific perfor m ance limits. For guaranteed specifications an d test conditions, see the Electrical C haracteristics. The guaranteed specifications apply

only for the test condition s lis te d. Some performance ch arac t eristics may degrade when th e devi ce is not operated under the listed te s t conditions.

Note 2: All voltages are measured with respect to GND=

Note 3: When the input voltage (V

maximum package inp ut c urrent rating limits the num ber of pins that can simultan eously safely exceed the power suppli es w it h an input current of 25mA t o two.

Note 4: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

able power dissipation at any temperature is P

is 84°C/W for the M20B SOI C package

Note 5: Human body m odel, 100pF capacit or discharged through a 1. 5kΩ resistor.

Note 6: See AN450 “Surface M ount ing M et hods and T heir Effect o n Prod uct Re liabilit y” o r the sect ion ti tled “ Surface M oun t” found in any N ation al Se mic ondu cto r Linea r

Data Book for other methods of soldering surface mount devices.

) at any pin exceed s the p ower su ppl ies (VIN<GND or VIN>VA or VD), the current at that pin sho uld be limite d to 25mA . The 50mA

IN

.

AGND=DGND

= (TJmax - TA) / ΘJA. TJmax = 150°C for this device. The typical thermal resistance (ΘJA) of this part when board moun te d

D

=0V, unless otherwise specified.

6

max, ΘJA and the ambient temperatu re, TA. The maximum a llow -

J

http://www.national.com

Page 7

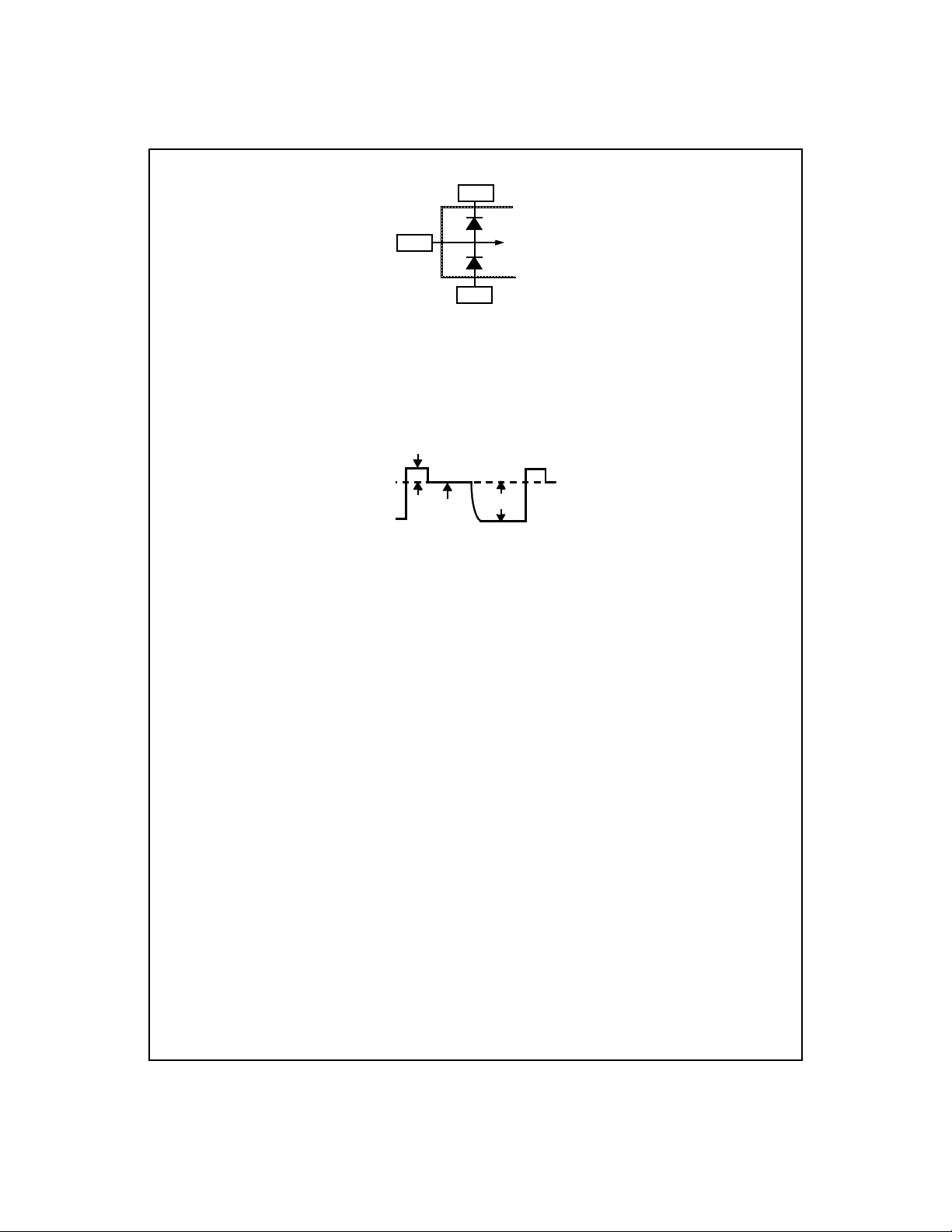

Note 7: Two diodes clamp the OS analo g inputs to

impedance of the sens or, prevents damage to the LM9810/2 0 f rom t ransients during power-u p.

AGND

and VA as shown below. This input protection, in co m bination with the external clamp capa c it or and the output

VA

OS Input

TO INTERNAL

CIRCUITRY

AGND

Note 8: To guarantee accuracy, it is required that VA and VD be connected together to the same power supply with separate bypass capacitors at each supply pin.

Note 9: Typicals are at T

J=TA

=25°C, f

= 24MHz, and repre s ent most likely parametric norm.

MCLK

Note 10: Tested limits are guaranteed to Nat ional's AOQL (Average Outgoing Quali ty Level).

Note 11: Integral non-linearity error is defined as the deviation of the analog value, expressed in LSBs, from the straight line th at best fits the actual transfer function of the

ADC.

Note 12: V

a white (full scale) image with respect to the reference level, V

correctable range of pixel-to-pixel V

LM9810/20 can corr ec t for using its internal PGA .

Note 13: PGA Gain Error is the maximum difference between the measured gain for any PGA code and the ideal gain calculated by using the formula

Gain

is defined as the CCD OS voltage for the reference period f ollowing the reset feedthrough pulse. V

PGA

REF

V

--- -

V

variation is define d as the maximu m variation in V

WHITE

PGA code

G0X

where .

-------------- ------------ -+=XG

32

31G0

.

REF

32

–()

------=

31

V

is defined as the peak positive deviation above V

RFT

CCD Output Signal

V

RFT

V

V

REF

WHITE

(due to PRNU, light source intensity variation, optics, etc.) that the

WHITE

is defined as the peak CCD pixel output voltage for

WHITE

of the reset feedthrough pulse. The maximum

REF

Note 14: Full C hannel INL and DNL are tested with CDS disabled, negative signal polarity, and a single OS input with a gain register setting of 1 (000001b) and an offset

register setting of 0 (000000b).

Note 15: The digital supply current (I

The current required to switch the digital data bus can be calculated from: Isw = 2*Nd*Psw*CL*

of each data bit switchin g, C L is t he capacitive loading on each data pin,

6, Psw should be .5, and

ital output pin (

will be drawn through the

VD

D5

- D0) is 20pF and the period of tSampCLK is 1/6MHz or 167ns , then the digital switching current would be 7.2mA. The calculated digital switching current

VD

) does not include the load, data and switching frequency dependent current required to drive the digital output bus on pins (D5 - D0).

D

VD

is the digital suppl y volta ge and tSampCLK i s the period of the

VD

/tSampCLK where N d is total number of data pins, Psw is the probability

SampCLK

signal. Since Nd is

is nominally 5V, the switching current can usually be calculated from: Isw = 30*CL/tSampCLK. For example, if the capacitive load on each dig-

pin and should be con s idered as part of the total power budget for he LM9810/20.

7

http://www.national.com

Page 8

Pin Descriptions

Analog Power

VA

AGND

OS

OS

,

R

RefBypass

V

REF+

,

V

REF-

MCLK

SampCLK

NewLine

G

V

REFMID

This is th e po si t ive supply p i n f o r t h e an al og

supply. It should be connected to a voltage

source of +5V and bypassed to

0.1µF monolithic capacitor in parallel with a

10µF tantalum capacitor.

This is the ground return for the analog supply.

OS

,

, Analog Inputs. These inputs (for Red,

B

Green, and Blue) should be tied to the sensor’s OS (Output Signal) through DC blocking capacitors.

Internally generated reference voltage

bypass pin. It should be bypassed to

through a .05uF monolithic capacitor.

Voltage reference bypass pins. They should

,

each be bypassed to

monolithic capacitor.

Input & Timing Control

Master Clock. The ADC conversion rate will

be a maximum of ¼ of

24MHz.

Sample Clock.

version rate of the ADC (up to ¼ of the

MCLK

rate) and sample timing. The signal

level is sampled while

held on the rising edge of

CDS is enabled, the falling edge of

causes the CCD reference level to be held.

If CDS is not enabled,

on the falling edge of

on the programmed signal polarity.

is also used with

nal coupling capacitors.

New Line signal. Used to indicate the start

of active pixels on a new line, to allow

clamping of the AC coupling caps, and to

allow programming of the configuration register. When

low, the OS inputs will be connected to

either

MCLK

of

mux and the offset and gain settings will be

set to the appropriate values for the first

color of the next line set in the color mode

setting in the Sampler and Color Mode Register. When

the pixel conversion data from the ADC.

When

STATE and

interface for programming the configuration

registers.

Analog I/O

SampCLK

NewLine

NewLine

is high and

V

V

or

REF+

after

NewLine

. On the first rising edge

REF-

NewLine

goes low, the internal

NewLine

is low, D[5-0] transmit

is high, D[5-0] enter TRI-

D2, D1

and D0 act as a serial

AGND

AGND

through a .05uF

MCLK

. Nominally

controls the con-

SampCLK

is low and

SampCLK

SampCLK

V

V

or

REF+

SampCLK

REF-

, depending

SampCLK

to clamp the exter-

SampCLK

with a

AGND

. When

is held

is

Digital Power

VD

This is the positive supply pin for the digital

supply. It should be connected to a voltage

source of +5V and bypassed to

DGND

0.1µF monolithic capacitor.

DGND

This is the ground return for the digital supply.

Digital I/O

D5-D0

Data Input/Output pins. When

NewLine

low, the 10 or 12 bit conversion results of

the ADC are multiplexed to

NewLine

is high, the output drivers enter TRI-

STATE and

D2, D1

D5-D0

. When

& D0 act as a serial interface for writing to the configuration registers.

LM9810

MCLK0, MCLK1, MCLK2, MCLK3

Output Mode

NewLine

(

Low)

D5

D4

D3

D2

D1

D0

LM9820

b9, b9, b3, b3

b8, b8, b2, b2

b7, b7, b1, b1

b6, b6, b0, b0

b5, b5, 0, 0

b4, b4, 0, 0

MCLK0, MCLK1, MCLK2, MCLK3

Output Mode

NewLine

(

Low)

D5

D4

D3

D2

D1

D0

b11, b11, b5, b5

b10, b10, b4, b4

b9, b9, b3, b3

b8, b8, b2, b2

b7, b7, b1, b1

b6, b6, b0, b0

Input Mode

NewLine

(

High)

D5-D3

D2

(SCLK) Serial Data Clock.

D1

(Latch) Latch and shift enable signal. When

Don’t Care

D1

(Latch) is low, da ta is shifted into D0(SDI).

D1

When

(Latch) go es hi gh , the la st n ine bit s

shifted into

D0

(SDI) will be used to program

the addres sed configuration register. To

avoid erroneous writes to the configuration

D1

registers,

when

D0

(SDI) Serial input data. Data is valid on D2(SCLK)

(Latch) should be pulled low

NewLine

is high.

rising edge. Three address bits followed by

six data bits (MSB first) should be shifted

D0

into

before D1(Latch) goes high.

with a

is

8

http://www.national.com

Page 9

Timing Diagrams

g

Diagram 2:

ram 3:

Dia

Diagram 1:

Pixel Conversion Timing and Latency

and Output Data Timing (

SampCLK

Timing for Programming the Con figuration Registers

NewLine

low)

9

http://www.national.com

Page 10

Timing Diagrams

g

NewLine

RS

OS

Clamp Signal

(Internal)

SampCLK

Ø1

(Even/Odd Mode)

Ø2

(Even/Odd Mode)

Ø1

(Standard Mode)

Ø2

(Standard Mode)

CCD Reset

signal

OS

Optical Black Pixel

Clamp On

Dia

CLAMP OFF

CCD Clamping Timing

ram 4:

Optical Black Pixel

First Active Pixel

SampCLK

Diagram 5:

CDS Timing

10

http://www.national.com

Page 11

Table 1: Configuration Register Address Table

Address

(Decimal)

0000

1001

2010

3011

4100

5101

6110

7111

Address

(Binary)

A2 A1 A0 B5 B4 B3 B3 B2 B1

Data Bits

Sampler and Color Mode

CDS Polarity N/A Mode2 Mode1 Mode0

Red DAC Offset Setting

Polarity MSB LSB

Green DAC Offset Setting

Polarity MSB LSB

Blue DAC Offset Setting

Polarity MSB LSB

Red Gain Setting

x3 MSB LSB

Green Gain Setting

x3 MSB LSB

Blue Gain Setting

x3 MSB LSB

Production Test and Pow er Down

Test Test T est Test Test PD

11

http://www.national.com

Page 12

Table 2: Configuration Register Parameters

Parameter

(Address)

CDS Enable

(0)

Signal Polarity

(0)

Color Mode

(0)

Control Bits Result

Sampler and Color Mode (0)

B5

0

1

B4

0

1

B2 B1 B0

Line Rate Color -

000

* state of the first line after a write to this register

001

010

011

100

101

110

Single Input Color - Mux selects

pixel rate:

RESERVED

Monochrome Mux selects

Monochrome Mux selects

Monochrome Mux selects

Bayer - Mux selects

* state of the first line after a write to this register

CDS Enabled

Single Ended (CDS disabled)

Negative Polarity

Positive Polarity

Mux, Gain & Offset change at the line rate:

*1st line: Mux =

2nd line: Mux =

3rd line: Mux =

OS

, Gain & Offset = R

R

OS

Gain & Offset = G

G

OS

Gain & Offset = B

B

repeat…

OS

input. Gain & Offs e t change at the

B

Gain & Offset = R,G,B,R,G,B…

OS

input. Gain & Offset = R

R

OS

input. Gain & Offset = G

G

OS

input. Gain & O ffset = B

B

OS

input. Gain & Offset change at the pixel rate:

B

*1st line: Gain & Offset = G,R,G,R,...

2nd line: Gain & Offset = B,G,B,G,…

repeat…

Green Stripe - Mux selects

rate:

111

* state of the first line after a write to this register

OS

input. Gain & Offset change at the pixel

B

*1st line: Gain & Offset = R,G,B,G,R,G,B,...

2nd line: Gain & Offset = B,G,R,G,B,G,R,…

repeat…

12

http://www.national.com

Page 13

(

)B4(

)

(

)

yp

)

(

yp

Table 2: Configuration Register Parameters

(Continued)

Parameter

(Address)

Offset Polarity

(1,2 & 3)

Offset Value

1,2 & 3

Typical Offset

Values

1,2 & 3

Boost Gain

Enable

(4,5 & 6)

Control Bits Result

Red, Green and Blue Offset DAC Settings (1, 2 & 3)

B5

0

1

MSB)B3 B2 B1 B0(LSB

B5

(SIGN)

0

0

0

• • •

0

0

1

1

1

• • •

1

1

B4

(MSB)

0

0

0

• • •

1

1

0

0

0

• • •

1

1

B3

0

0

0

• • •

1

1

0

0

0

• • •

1

1

B2

0

0

0

• • •

1

1

0

0

0

• • •

1

1

Positive Offset

Negative Offset

LM9810: Offset = 5LSBs * Offset Value * PGA Gain

LM9820: Offset = 20LSBs * Offset Value * PGA Gain

B1

0

0

1

• • •

1

1

0

0

1

• • •

1

1

B0

(LSB)

0

1

0

• • •

0

1

0

1

0

• • •

0

1

Red, Green and Blue Gain Settings (4,5 & 6)

B5

0

1

Boost Gain = 1V/V

Boost Gain = 3V/V

ical Offset (with PGA Gain = 1

T

LM9810 LSBs

0.00

+5

+10

• • •

+150

+155

0

-5

-10

• • •

-150

-155

LM9820 LSBs

0.00

+20

+40

• • •

+600

+620

0

-20

-40

• • •

-600

-620

PGA Gain Value

(4,5 & 6)

Gain

(4,5 & 6)

Typical Gain

Values

(4, 5 & 6)

B4

B5

x3)

• • •

• • •

• • •

B3

B4

(MSB)

0

0

0

0

0

0

1

1

1

1

1

1

0

0

0

• • •

1

1

1

• • •

0

0

0

• • •

1

1

1

B2 B1 B0

B3

0

0

0

• • •

1

1

1

• • •

0

0

0

• • •

1

1

1

Gain = Boost Gain * PGA Gain

B2

0

0

0

• • •

1

1

1

• • •

0

0

0

• • •

1

1

1

13

PGA Gain (V/V) =.933 + 0.0667 * (PGA Gain Value)

B1

0

0

1

• • •

0

1

1

• • •

0

0

1

• • •

0

1

1

B0

(LSB)

0

1

0

• • •

1

0

1

• • •

0

1

0

• • •

1

0

1

T

ical Gain

(V/V)

0.93

1.00

1.13

• • •

2.87

2.93

3.00

• • •

2.79

3.00

3.20

• • •

8.60

8.80

9.00

http://www.national.com

Page 14

p

Table 2: Configuration Register Parameters

(Continued)

Parameter

(Address)

Production Te st

(7)

Power Down

Enable

(7)

B5

B0

Control Bits Result

Production Test and Power Down (7)

B4

0

1

B3 B2 B1 Should all be set to zero for normal o

Normal Operation

Power Down

eration

14

http://www.national.com

Page 15

Applications Informati on

g

g

p

g

1.0 Programming the LM9810/20

1.1 Writing to the Configuration Register

NewLine

When

ing to the configuration registers.

(SCLK),

shift enable signal (Latc h). When

shifted into

D2

(SCLK). Three reg ister address bits followed by six data bits

should be shifted into

tions from low to high, the last 6 data bits will be stored into the

configuration registe r addressed by the previous 3 address bits

(as shown in Diagram 3).

3 cycles of the serial clock on

tion register.

1.2 CDS Mode

The LM9810/20 uses a high-p erforman ce CDS (Corr elated D ouble Sampling) circuit to re move many sources of noise a nd error

from the CCD signal. It also suppor ts CIS image sensors wit h a

single sampling mode.

Figure 1 shows the output stage of a typical CCD and the resulting output waveform:

RS (RESET)

SampCLK

Capacitor C1 converts the electrons coming from the CCD’s shift

register to an analog voltage. Th e source follower output stage

(Q2) buffers this voltage before it le aves the CCD. Q1 resets the

voltage across capacitor C1 betwee n pixels at intervals 2 and 5 .

When Q1 is on, th e out put sign al (OS) i s a t its most positive voltage. After Q1 tur ns off (period 3), the O S level represents the

residual voltage across C1 (V

charge injection from Q1 , thermal no ise from the ON r esistance

of Q1, and other sources of erro r. When the shift register clock

(Ø1) makes a low to high transition (period 4), the electrons from

the next pixel flow into C1. The charge across C1 now contains

the voltage proporti onal to the number of ele ctrons plus V

, an error term. If OS is sa mpled at the end of peri od 3 and

UAL

that voltage is subtracted from the OS at the end of per iod 4, the

V

RESIDUAL

is high, D2, D1 & D0 act as a serial interface for writ-

D2

D0

is the input data pin (SDI), and D1 is the latch and

D0

(SDI), and must be valid on each rising edge o f

D0

(SDI),

D1

(Latch) must remain h igh for at leas t

is the input serial clock

D1

(Latch) is low, serial data is

MSB first. When D1(Latch) transi-

D2

(SCLK) to write to the confi g ura-

V

DD

Q1

C1

e-

(from shift register)

Q2

OS

V

SS

Ø1

RS

OS

123 4 5

ure 1: CDS

Fi

RESIDUAL

). V

RESIDUAL

includes

RESID-

term is canceled and the noise on the signal is

reduced ([V

principal of Correlated Double Sampling.

SIGNAL+VRESIDUAL

]-V

RESIDUAL

= V

SIGNAL

). This is the

If the LM9810/20 is programmed for corr elated double samp ling

(bit B5 of register 0 is cleared), then the falling edge of

SampCLK

should occur toward the end of per iod 3 and the rising edge of

SampCLK

should occur towards the e nd of per iod 4. While

CLK

is high, the Reference level (V

held at the falling edge of

nal level (V

ing edge of

+ V

SIGNAL

RESIDUAL

SampCLK

. The output from the sampler is the potential

RESIDUAL

SampCLK

. While

) is sampled and it is held at the ris-

difference between the two samples, or V

) is sampled, and it is

SampCLK

.

SIGNAL

Samp-

is low, the sig-

1.3 CIS Mode

The LM9810/20 supports CIS (Contact Image Sensor) devices by

offering a sampling mode for capturing positive going signals, as

opposed to the CCD’s negative going signal. The output signal of

a CIS sensor (Figure 2) differs from a CCD signal in two primary

ways: its output increases with increasing si gnal strength, and it

does not usually have a reference level as an integral par t of the

output waveform of every pixel.

OS (CIS)

OS (CCD)

123 4 5

SampCLK

CIS

ure 2:

Fi

When the LM9810/ 20 is in CIS mode (Regist er 0, B5 =1), it u ses

V

V

or

either

REF+

of the Sampling and Color Mode register) as the reference (or

depending on th e signal p olari ty setting (B4

REF-

black) voltage for each pixel. If the signal polarity is set to one,

V

then

signal will be held on the rising edge of

zero, then

the OS signal will be held on the rising edge of

ing edge of

will be held on the falling edge of

REF-

V

will be held on the falling edge of

REF+

SampCLK

should occur near the e nd of per iod 4, and

at least 50ns after the falling edge of

1.4 Multi

lexer/Channel Switchin

SampCLK

SampCLK

SampCLK

SampCLK

.

and the OS

. If it is set to

SampCLK

and

. The ris-

The offset and gain sett ings auto matical ly switch after each ADC

conversion according to the color mode setting in th e Sampler

and Color Mod e register (register 0). For example, if the color

mode (bits B2,B1 & B0) is set to 001, the offset and gain will alternately switch between the R, G and B settings after each conversion. The input multiplexer never changes durin g a line, but if the

color mode is set to Line Rate Color (000), the mux will automatically switch after each new line.

The offset and gain settings will always start with the first channel

of the programmed mode after a falling edge on

NewLine

. For

15

http://www.national.com

Page 16

example, the R offset and gain settings will be used for the first

g

g

q

q

q

q

q

conversion following a falling edge on

NewLine

if the color mode is

set to Single Input Color (001).

For the Single Input Co lor, Bayer and Green Stripe mod es, the

mux will always connect the

and gain settings will alternate values every pixel according to the

OS

input to the sampler. The offset

B

order indicated by the Sampler and Color Mode register (see

Table 2). T he first falling edge of

NewLine

following a write to the

Sampler and Color Mode register will ready the offset and gain to

cycle through the colors o f the first lin e of the p rogrammed color

mode. Each subsequent falling edge of

NewLine

will switch the offset and gain settings to the first color of the next line. The

LM9810/20’s unused OS inputs should not be left uncon nected.

All three OS inputs should be tied together on the LM9810/20

side of the clamp capacitor (see Figure 3).

C

SENSOR

DOS

CLAMP

OS

NC

OS

OS

OS

B

G

R

1.7 Offset DAC

The Offset DAC removes the DC offsets generated by the sensor

and the LM9810/20’s analog signal chain (see section 1.7.1,

Internal Offsets). The DAC value for each color (registers 1,2 and

3) should be set during calibration to the lowest value that still

results in an ADC output code greater than zero for all the pixels

when scanning a black line. With a PGA gain of 1V/V, each LSB

of the offset DAC typically adds the equivalent of 5 LM9810 LSBs

or 20 LM9820 LSBs, providing a total offset adjustment range of

±150 LM9810 LSBs or ±590 LM9820 LSBs. The Offset DAC’s

output voltage is given by:

V

DAC

E

uation 2:

⋅=

9.75mV (value in B4 - B0)

Offset DAC Output Voltage

In terms of output codes, the offset is given by:

Offset 5LSBs (value in B4 - B0) PGA Gain

E

uation 3:

Offset 20LSBs (value in B4 - B0) PGA Gain

E

uation 4:

⋅⋅=

LM9810 Offset Equation

⋅⋅=

LM9820 Offset Equation

LM9810/20

Figure 3:

For the Line Rate Color mode, the mux will cycle through the

OS

and

G

and B offset & gain settings will be used when the mux is set to

OS

the

gain settings will always be used on the first line following a write

OS Connections for single output sensors

OS

inputs after each falling edge of

B

OS

and

G

OS

input, respectively.

B

,

R

NewLine

. The R, G

OS

and the R offset &

R

OS

register 0.

1.5 Data Latency

SampCLK

The latency through the LM9 810/20 is 8

MCLK

one

period. The data o utput on D5 - D0 (MSBs b11 - b6 or

periods plus

b9 - b4) represents data whose reference sig nal was sampled 8

SampCLK

t

1.6 Pro

MCLK

+ t

SampSU

+ t

rammable Gain

earlier (see Diagram 1).

The output of the Sampler drives the input of the x3 Boost gain

stage. The gain of the x3 Boost g ain is 3V/V if bit B 5 of the current color’s gain register (registers 4,5, and 6) is set, or 1V/V if bit

B5 is cleared. The output o f the x3 gain stage is the i nput to the

offset DAC and the output of the offset DAC is the input to the

PGA (Programmable Gain Am pli fie r). The PGA provides 5 b its o f

gain correction over a 0.93V/V to 3V/V (-0.6 to 9.5dB) range. The

x3 Boost gain stage and the P GA can be co mbin ed for an overall

gain range of .93V/V t o 9.0V/V (-.6 to 19dB ). The ga in set ting for

each color (registers 4 , 5 and 6) should be se t during calibration

to bring the maximum amp litude of the strongest pi xel to a level

just below the desired maximum output from the ADC. The PGA

gain is determined by the following equation:

V

--- -

PGA Gain

V

0.933 + .0667 (value in bits B4-B0)=

uation 1:

E

PGA Gain

If the x3 Boost gain is enabled then the overall signal gain will be

three times the PGA gain.

The offset is positive if bit B5 is clear ed and n egati ve if B5 is set.

Since the analog offs et is added before the PGA gain, the value

of the PGA gain must be consider ed when selecting the offset

DAC values.

,

R

1.7.1 Internal Offsets

Figure 4 is a model of the LM9 810/2 0’s internal of fsets. Equati on

5 shows how to calculate the expected output code given the

input voltage (V

OS3

V

), the programmed offset DAC voltage (V

grammed gains (G

IN

), the LM9810/20 inter nal offsets ( V

B

PGA

, G

) and the analog channel gain con-

DAC

stant C.

C is a constant that combines the gain error through the AFE, reference voltage variance, and ana log voltage to digital co de conversion into one constant. Ideally, C = 2048 codes/V (4096

codes/2V) for the LM98 20 and 512 code s/V (1024 codes/2V) for

the LM9810. Manufacturing tolerances widen the range of C (see

Electrical Specifications).

x3 Boost

1V/V or

3V/V

+

V

Σ

IN

+

V

OS1

=

D

OUT

E

uation 5: Output code calculation with internal offsets

+

G

B

Σ

+

V

OS2

ure 4:

Fi

+()

VINV

OS1

PGA

0.93V/V to

3V/V

DAC

+

G

PGA

ADC

Σ

+

V

OS3

+

Σ

+

Offset

DAC

V

Internal Offset Model

++()

G

BVDACVOS2

G

PGAVOS1

Equation 6 is a simplification of the output code calculation,

neglecting the LM9810/20’s internal offsets.

16

http://www.national.com

OS1

OS2

, V

,

), the pro-

D

OUT

+()

C

Page 17

=

g

D

OUTVINGBVDAC

+()

G

PGA

C

Equation 6: Simplified output code calculation

the LM9810/20 is operating in CDS mode. In CDS mode, the

LM9810/20 leakag e current s hould be no more t han 20nA. With

CDS disabled, which will likely be the case when CIS sensors are

used, the LM9810 /20 lea kage cu rrent can be as hi gh as 25uA at

the maximum conversion rate.

1.8 Power Down Mode

Setting the Power Down (bit B0 of register 7) puts the device in a

low power standby mode. The analog sections are turned off to

conserve power. The digital logic will continue to operate if

continues, so for minimum power dissipation

MCLK

MCLK

should be

stopped when the LM9810/20 enters the Power Down mode.

Recovery from Power Down typically takes 50µs (the time

required for the reference voltages to settle to 0.5 LSB accuracy).

2.0 Clamping

To perform a DC restore across the AC coupling capacitors at the

beginning of every line, the LM9810/20 implements a clam ping

NewLine

function. When

is high and

inputs will be connected to either

of the Sampling and Color Mode register. If B4 is set to one (positive signal polarity), then the OS inputs will be connected to

. If B4 is set to zero (negative signal polarity), then they will be

connected to

V

REF+

.

SampCLK

V

REF+

is low, all three OS

V

or

, depending on B4

REF-

V

REF-

2.1 Clamp Capacitor Selection

This section explains how to sel ect appropriate clamp c apacitor

values.

C

CLAMP

OS

OS

SENSOR

DOS

NC

V

REF+

or

V

REF-

LM9810/20

Figure 5:

OS Clamp Capacitor and Internal Clamp

The output signal of many sensors ri des on a DC offset (greater

than 5V for many CCDs) which is incompatible with the

LM9810/20’s 5V operation. To eliminate this offset without resorting to additional higher voltage components, the output of the

sensor is AC coupled to the LM 9810/20 through a DC blocking

capacitor, C

used. The value of this capaci tor is determined by the lea kage

. The sensor’s DOS output, if available, is not

CLAMP

current of the LM9810/20’s OS input and the output impedance of

the sensor. The leakage t hrough the OS input de termines how

quickly the capacitor value will drift from the clamp value of

V

or

, which then deter mines how many pixels can be pro-

REF-

cessed before the droop causes errors in the conversion (±0.1V

V

REF+

is the recommended limit for CDS ope ration). The output impedance of the sensor deter mines how quickly the ca pacitor can be

charged to the clamp value d uring the black reference per iod at

the beginning of every line.

The minimum clamp capacitor value is de termined by th e maximum droop the LM9810/20 can tolerate while converting one

sensor line. The minimum clamp capacitor value is much small er

for CDS mode applications t han it is for CIS mode applicat ions.

The LM9810/20 input lea kage current is conside rably less when

2.1.1 CDS mode Minimum Clamp Capacitor Calculation:

The following equation takes the maximum leakage current into

the OS input, the maximum allowable droop, the number of pixels

on the sensor, and the pixel conversion rate, f

vides the minimum clamp capacitor value:

i

C

CLAMP MIN

Equation 7:

-------- -dt=

dV

leaka

e current (A)

-------------------- ------------------------------ max droop(V)

CDS mode C

CLAMP MIN

number of pixels

----------------- -------------------------- -=

Calculation

SampCLK

f

SampCLK

, and pro-

For example, if the OS input leakage curren t is 20nA wors t-case,

the sensor has 2700 act ive pixels, the conversion rate is 2MHz

(t

mum clamp capacitor value is:

= 500ns), and the max droop desi red is 0.1V, the mini-

SampCLK

2700

20nA

-------------- -=

270pF=

------------- 2MHz

0.1V

CLAMP MIN

C

Equation 8:

CLAMP MIN

CDS mode C

Example

2.1.2 CIS mode Minimum Clamp Capacitor Calculation:

If CDS is disabled, th en the m aximum L M9 810 /20 OS inpu t l e akage current can be calculated from:

=

I

leakageVSATfSampCLKCSAMP

Equation 9:

where V

and C

CIS mode Input Leakage Current Calculation

SAT

is the peak pixel signal swing of the CIS OS output

SAMP

is the capacitance o f the LM9810/ 20’s internal sam-

pling capacitor (2pF). Inserting this into Equation 7 results in:

C

CLAMP MIN

with C

Equation 10:

SAMP

equal to 2pF and V

i

-------- -dt=

dV

V

SAT

------------------ --------- C

t

SampCLK

CIS mode C

t

SampCLK

------------------ ----------------- -num pixels=

SAMP

max droop(V)

CLAMP MIN

SAT

Calculation

equal to 2V (the LM9810/20’s

maximum input signal), then Equation 10 reduces to:

4p(F)(V)

C

CLAMP MIN

Equation 11:

------------------ ----------------- max droop(V)

CIS mode C

num pixels=

CLAMP MIN

Calculation

In CIS mode (CDS disabled), the max droop limit must be much

more carefully chosen, since any change in the clamp capacitor’s

DC value will affect the LM9810/20’s conversion results. If a

droop of one 10 bit LSB a cross a line is considered acceptable,

then the allowed droop voltage is calculated as: 2V/1024, or

17

http://www.national.com

Page 18

approximately 2mV. If there are 2700 active pixels on a line then:

q

q

y

y

q

q

g

g

q

q

4p(F)(V)

------------------ ----

C

CLAMP MIN

2mV

2700=

5.4uF=

E

uation 12:

CIS mode C

CLAMP MIN

Calculation Example

2.1.3 Maximum Clamp Capacitor Calculation:

The maximum size of the clamp capacitor is determined by the

amount of time available to charge it to the desire d value during

the optical black por tion o f the s ensor output. The inte rnal clamp

is on wh en

SampCLK

NewLine

is high and

is low for half its cycle, then the available charge time

SampCLK

is low. If the applied

per line can be calculated using:

t

CLAMP

uation 13:

E

For example, if a sensor has 18 black reference pixels and f

CLK

is 2MHz with a 50% duty cycle, then t

Number of optical black pixels

------------------ --------------------------------- --------------------------- -=

2f

SampCLK

Clamp Time Per Line Calculation

CLAMP

is 4.5µs.

Samp-

The following equation takes the number of optical black pixels,

the amount of time (per pixel) that the cl amp is closed, the sensor’s output impedance, and the desired accuracy of the final

clamp voltage and provides the maximum cla mp capacitor value

that allows the clamp capa citor to settle to the desired accuracy

within a single line:

t

C

CLAMP MAX

C

uation 14:

E

Where t

CLAMP

on, R

CLAMP

LM9810/20’s internal clamp switch, and accuracy is the ratio o f

CLAMP MAX

is the amount of time (pe r line) that the clamp is

is the output impedance of the CCD plus 50Ω for t h e

1

----- -

------------------- -------------=

R

ln(accurac

t

CLAMP

----------------- -------- R

CLAMP

)

1

----------------- ---------------=

ln(accurac

)

for a single line of charge time

the worst-case initial capacitor voltage to the desired final capacitor voltage. If t

CLAMP

is 4.5µs, the output impedance of the sensor is 1500Ω, the worst case voltage chang e requ ired ac ross the

capacitor (before the first line ) is 5V, and the d esired accuracy

after clamping is to within 0.1V (accuracy = 5/0.1 = 50), then:

4.5µs

C

CLAMP MAX

----------------- 1550

Ω

1

-------------- -=

ln(50)

728pF=

CLAMP MIN

Example

.

uation 15:

E

The final value for C

C

CLAMP MAX

, but no less than C

C

CLAMP MAX

should be less than or equal to

CLAMP

In some cases, depending primarily on the choice of sensor,

C

CLAMP MAX

the capacitor can not b e charged to its final voltage du ring the

may actually be

less

than C

CLAMP MIN

, meaning that

black pixels at the beginning of a line and hold it’s voltage without

drooping for the duration of that line. This is usually not a problem

because in most appli cations the sen sor is clocked conti nuously

as soon as power is applied. In this case, a larger cap acitor can

be used (guaranteei ng that the C

and the final clamp voltage is forced across the capacitor over

CLAMP MIN

requirement is met) ,

multiple lines. This equation calculates how many lines are

required before the capacitor settles to the desired accuracy:

lines R

uation 16:

E

CLAMP

C

CLAMP

-------------------- ----t

CLAMP

Initial Error Volta

------------------ --------------------------------- -

ln=

Final Erro r Volta

Number of Lines Required for Clamping

e

e

Using the values shown before an d a clamp capacitor value of

0.01µF, this works out to be:

0.01µF

lines 1550

E

uation 17:

------------------ -

Clamping Lines Required Example

4.5µs

5V

----------- -

ln 13.5 lines==

0.1V

In this example, a 0.01µF capacitor takes 14 line s a fter p ower-up

to charge to its final value. On subsequent lines, the only error will

be the droop across a si ngle line which should be significantly

less than the initial error.

If the LM9810/20 is operatin g in CDS

mode and multiple lines are u sed to cha rge u p the clampin g

capacitors after p ower-up, then a clamp capacitor value of

0.01µF should be significantly greater than the calculated

C

CLAMP MIN

value and can virtually always be used.

If the LM9810/20 is operating in CIS mode, then significantly

larger clamp capacitors must be used. Fortunately, the output

impedance of most C IS sensors is signifi cantly smaller than the

output impedance of CCD sensors, and R

CLAMP

will be dominated by the 50Ω from the LM9810/20’s internal clamp switch.

With a smaller R

CLAMP

value, the clamp capacitors wi ll charge

faster.

3.0 Performance Considerations

3.1 Power Supply

The LM9810/20 should be powere d by a single +5V source. The

analog supplies (

VA

) and the digital supply (VD) are brought out

individually to allow separate bypassing for each supply input.

They should

not

be powered by two or more different supplies.

In systems with separate analog and digital +5V sup plies, all the

supply pins of the LM9810/2 0 should be powered by the analog

+5V supply. Each supply input should be bypassed to its r espective ground with a 0.1µF capacitor located as close as possible to

the supply input pin. A single 10µF tanta lum capa citor should be

placed near the

VA

supply pin to provi de low frequency bypass-

ing.

To minimize noise, keep t he LM9810/20 and a ll analog components as far as possible from noise generators, such as switching

power supplies and high frequency digital busses. If possible, isolate all the analo g co mp one nts an d si g nals (OS, reference inp uts

and output s ,

VA, AGND

) on an analog ground plane, separate from

the digital ground pl ane. The two ground planes should be tied

together at a single poin t, preferably the point where the power

supply enters the PCB.

3.2 SampCLK Timing

SampCLK

is used to time the stages o f the LM981 0/20’s sampler,

offset DAC and programmable gain amplifier. To allow for optimum input signal samplin g tim es,

chronously to

MCLK

. The LM9810/20’s ADC is synchroni zed with

SampCLK

may be applied asyn-

the its AFE (includi ng the sampl er, the offset DAC and the PGA)

MCLK

by

.

The LM9810/20’s internal ADC clock is cre ated throug h a combi -

18

http://www.national.com

Page 19

nation of the applied

synchronize the applied

SampCLK

SampCLK

will go low after the falling edge of

MCLK

of

. The ADC clock will stay low for two

then go high. It will stay high until the next fallin g edge of

is clocked by

MCLK

. Figure 6 illustrates this

and

MCLK

signals.

MCLK

is used to

signal. The internal ADC clock

SampCLK

is clocked by a rising

MCLK

cycles and

SampCLK, MCLK

SampCLK

, and

ADC clock timing relationship.

MCLK

SampCLK

ADC Clock

(internal)

D5 - D0 b11 - b6 b5 - b0

Figure 6: LM9810/20 Relative Event Timing

The LM9810/20 is a densely designed, mi xed-signal, monolithic

semiconductor. In creating the timing for the LM9810/20, it mus t

be considered that i nternal events, such as ADC sa mpling, and

output data bus switching can potentially a ffect coincident events

such as input signal sampling or o ffset DAC settling. One event

can interfere with another by co upl in g n ois e on sha red re sou rce s

such as the supply lines, internal voltage references, or the silicon

substrate.

SampCLK

To optimize the perfor mance o f the LM 9810/20,

should

be timed so that the input signal hold time s do not coinc ide with

output data switching and AD C clock transitions. In oth er words,

the rising and falling edges of

close to ADC clock edges or to output d ata transitio ns.

SampCLK

should not be placed

SampCLK

edges should be at least 20n s away from ADC clock edges to

avoid interference between the ADC and t he sampler.

SampCLK

edges should also be placed at l east 40n s after ou tput data transition times to avoid transition noise coupling.

Figure 6 is an example of

requirements at the maximum

SampCLK

gram 6,

transitions occur on

SampCLK

timing that will meet these

MCLK

frequency of 24MH z. In dia-

MCLK

falling edges which

will keep them more than 20ns away from ADC transitions, and

40ns after output data transitions.

19

http://www.national.com

Page 20

Physical Dimensions

inches (millimeters)

20 pin (.300” Wide) Molded Small Outline Package

20

http://www.national.com

Page 21

LIFE SUPPORT POLICY

NATIONAL'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which,

(a) are intended for surgical im plant into the body, or (b) support

or sustain life, and whose failure to perfor m, whe n prop erly use d

in accordance with instructions for use provided in the labeling,

can be reasonably expected to result i n a signifi cant inju r y to the

user.

2. A critical comp one nt is any component of a l ife support device

or system whose failure to perform can be reasonably expected

to cause the failure of the life suppor t device or system, or to

affect its safety or effectiveness.

National Semicond uc tor

N

Corporation

1111 West Bardin Road

Arlington, TX 76017

Tel: 1(800) 272-9959

Fax: 1(800) 737-7018

http://www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconduc tor Europe

Fax: a49 (0) 180-530 85 86

Email: europe.support @ nsc.com

Deutsch Tel: + 49 (0) 180-530 85 85

English Tel: + 49 (0) 180-532 78 32

Francais Tel: + 49 (0) 180-532 93 58

Italiano Tel: + 49 (0) 180-534 16 80

National Semiconductor Hong

Kong

13th Floor, Straight Block,

Ocean Centre, 5 Canton Rd.

Tsimshatsui, Kowloon

Hong Kong

Tel: (852) 2737-1600

Fax: (852) 2736-9960

National Semicondu c tor

Ltd. Japan Ltd.

Tel: 81-043-299-2308

Fax: 81-043-299-2408

Loading...

Loading...