Datasheet LM9617-5SENSORS, LM9617HEADBOARD, LM9617CEA, LM9617CCEA-2, LM9617CCEA Datasheet (NSC)

Page 1

2000 National Semiconductor Corporation Confidential www.national.com

March 2001

LM9617 Monochrome CMOS Image Sensor VGA 30 FPS

General Description

The LM9617 is a high performance, low power, third inch VGA

CMOS Active Pixel Sensor capable of capturing grey-scale digital still or motion images and converting them to a digital data

stream.

In addition to the active pixel array, an on-chip 12 bit A/D convertor, fixed pattern noise elimination circuits and a video gain is

provided. Furthermore, an integrated programmable smart timing and control circuit allows the user maximum flexibility in

adjusting integration time, active window size, gain and frame

rate. Various control, timing and power modes are also provided.

Features

• Supplied with micro lenses

• Video or snapshot operations

• Progressive scan and interlace read out modes.

• Programmable pixel clock, inter-frame and inter-line delays.

• Programmable partial or full frame integration

• Programmable gain

• Horizontal & vertical sub-sampling (2:1 & 4:2)

• Windowing

• External snapshot trigger & event synchronisation signals

• Auto black level compensation

• Flexible digital video read-out supporting programmable:

- polarity for synchronisation and pixel clock signals

- leading edge adjustment for horizontal synchronization

• Programmable via 2 wire I2C compatible serial interface

• Power on reset & power down mode

Applications

• Security Cameras

• Toys

• Machine Vision

• Biometrics

• Infrared Camera

• Barcode Scanner

Key Specifications

• Array Format

Total: 664H x 504V

Active: 648H x 488V

• Effective Image Area

Total: 4.98mm x 3.78 mm

Active: 4.86 mm x 3.66 mm

• Optical Format 1/3“

• Pixel Size 7.5µm x 7.5µm

• Video Outputs 8,10 & 12 Bit Digital

• Dynamic Range 57dB

• FPN 0.35%

Sensitivity 28.7 Kilo LSBs / lux.s

• Quantum Efficiency 27%

• Fill Factor 47% (no micro lens)

• Package 48 LCC

• Single Supply 3.3 V

• Power Consumption 90 mW

• Operating Temp 0 to 50oC

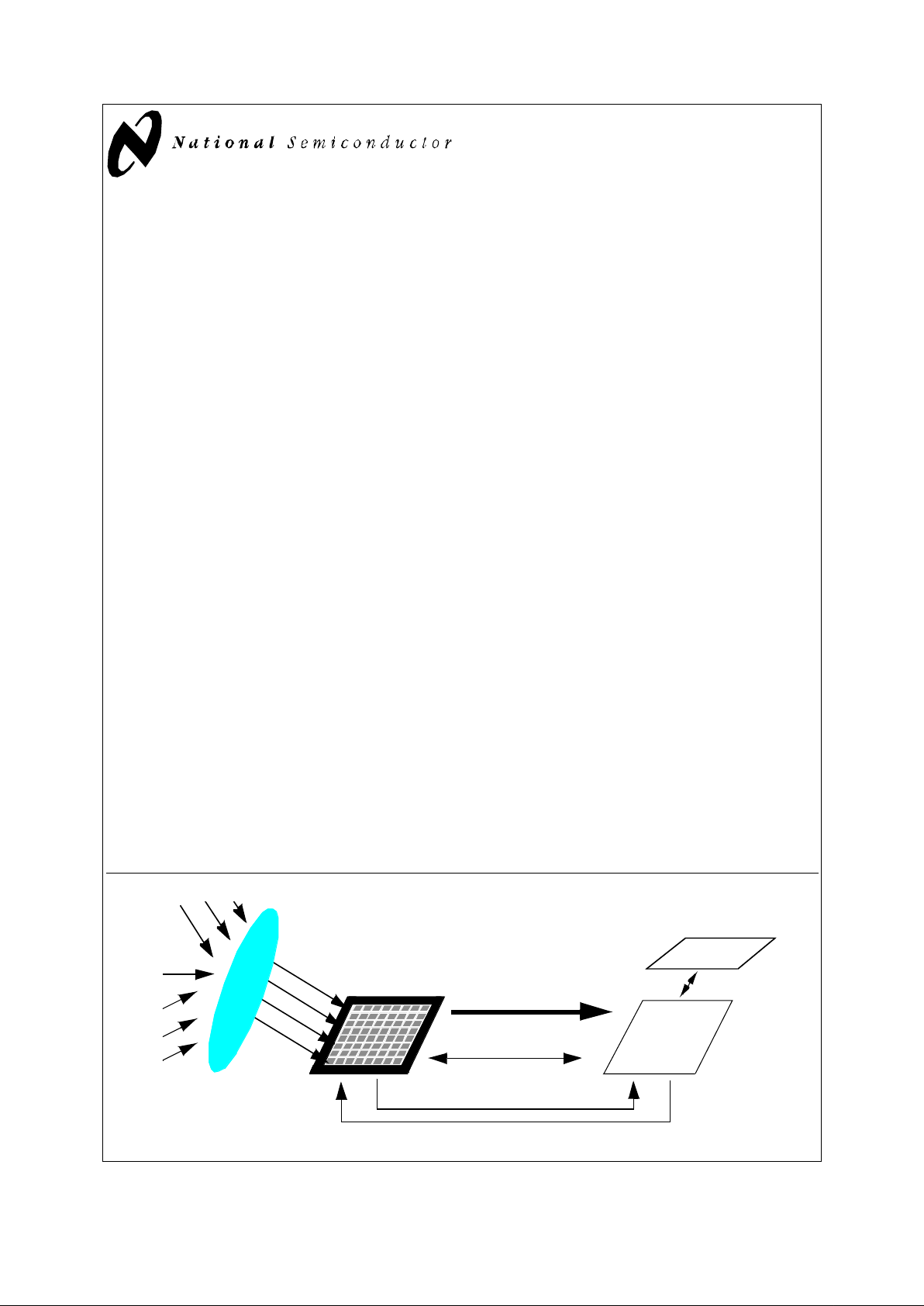

12bit digital image

lens

I2C compatible

Digital Image

Processor

Storage

snapshot

event trigger

LM9617

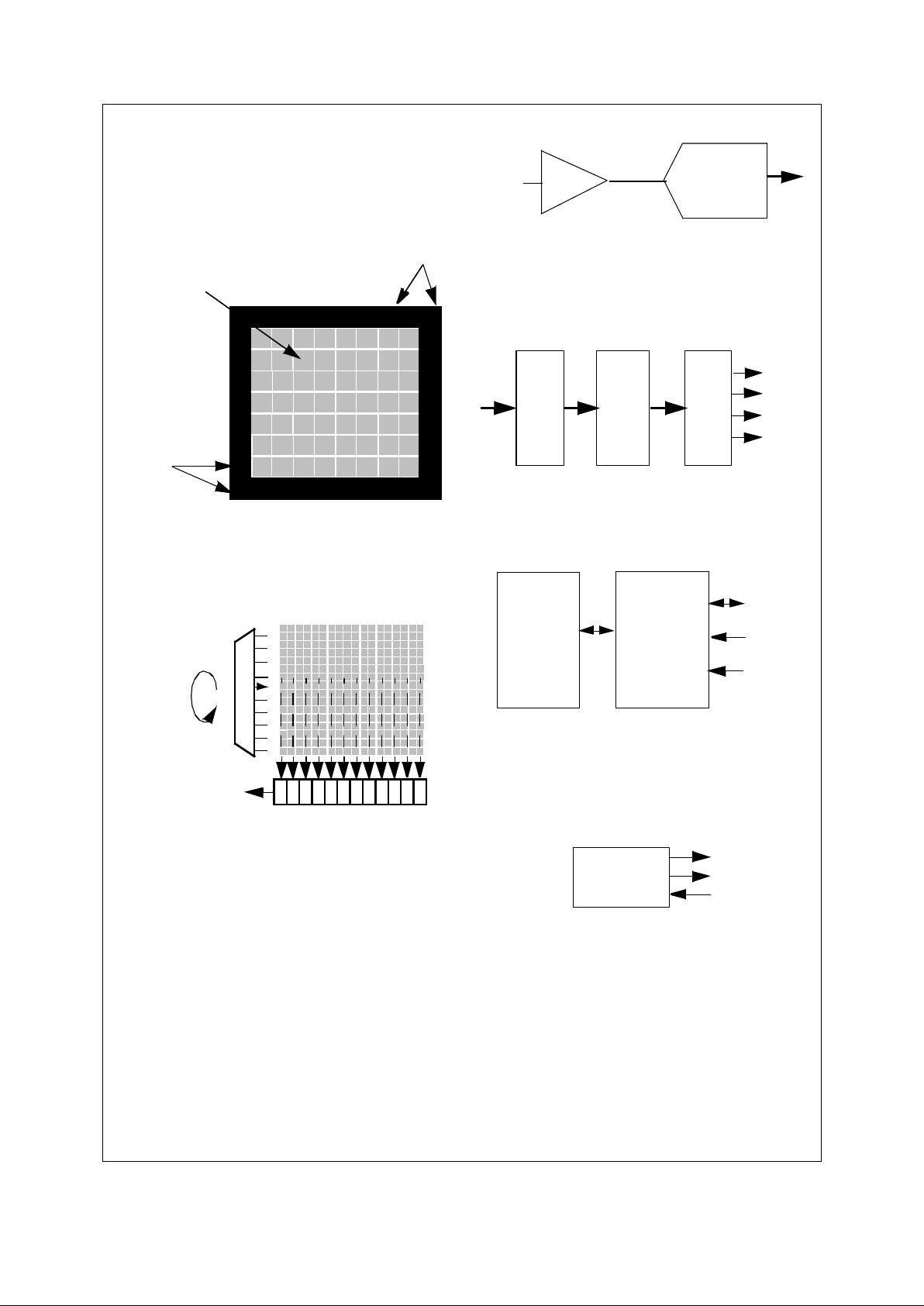

System Block Diagram

LM9617 Monochrome CMOS Image Sensor VGA 30 FPS

Page 2

Confidential 2 www.national.com

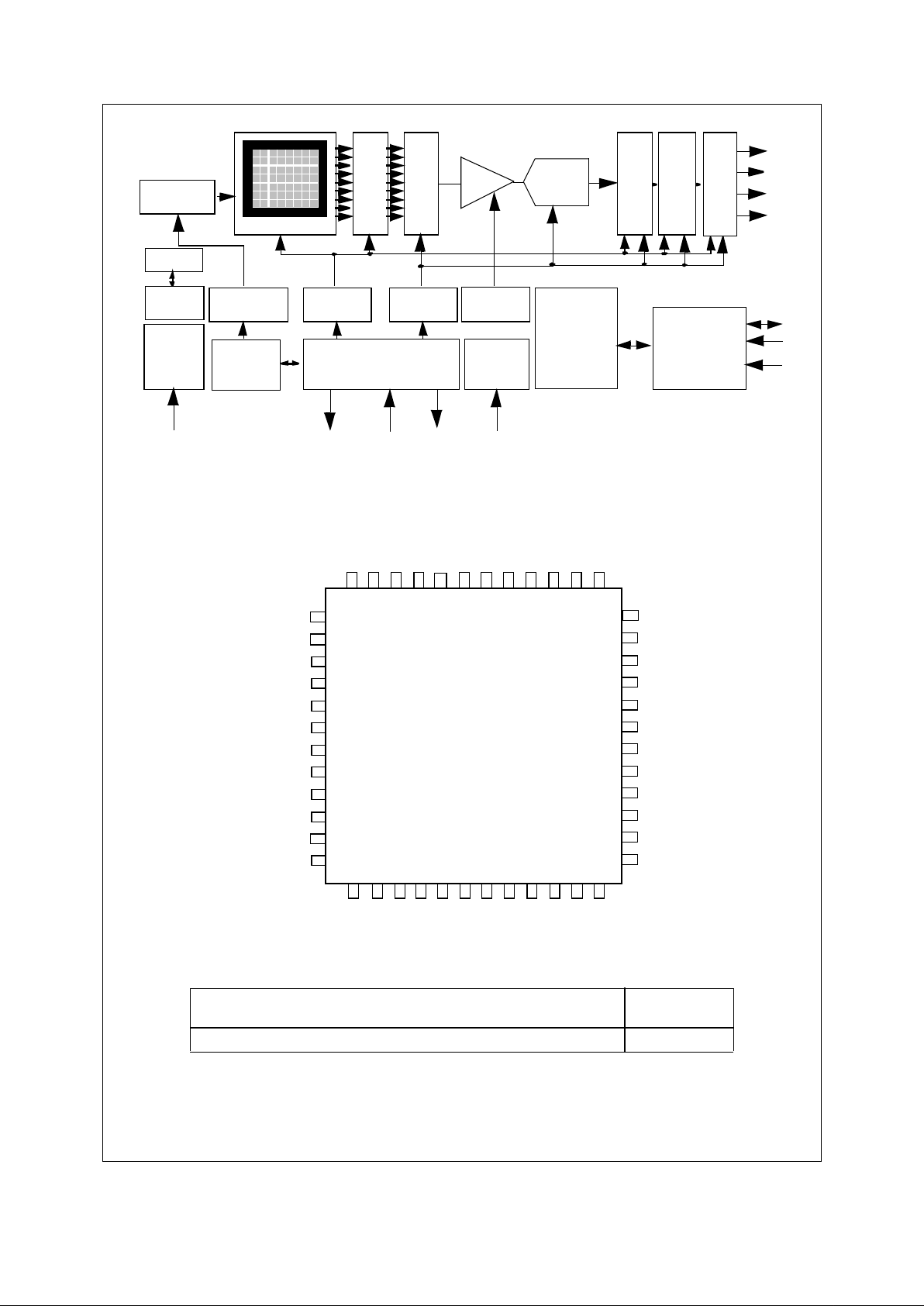

Column CDS

APS Array

Horizontal Shif t

Register

POR

1

2 Bit A/D

AMP

Bad P ixel

Detect & Correct

Digital Video

Frame r

Black Level

Compensation

d[11:0]

pclk

hsync

vsync

Row Address

Decoder

Vertical

Horizontal

Master Timer

Timing

Timing

Row Address

Gen

Clock Gen

I2C Compatible

Register Bank

Reset

Gen

Gain

Control

Serial I/F

sda

sclk

sadr

Power

Control

pdwnsnapshot

extsync

Controller

(sequencer)

irq

mclk

Overall Chip Block Diagram

Figure 1. Chip Block Diagram

7

9

10

11

12

13

14

15

16

18

17

42

40

39

38

37

36

35

34

33

31

32

sclk

resetb

pdwn

vss_dig

vdd_dig

vsync

pclk

mclk

d1

d0

fine_i

vss_od1

vss_od3

gnd

fine_ctrl

offset

vdd_ana1

vdd_ana2

vss_ana2

sda

sadr

irq

vdd_pix

vrl

vsrvdd

extsync

vdd_od 1

6 5 4 3 2

1

48 47 46 45

NC

d4

d5

d6d8d7

d9

vdd_od2

vss_od2

19 20 21 2322 24 25 26 27 28 30

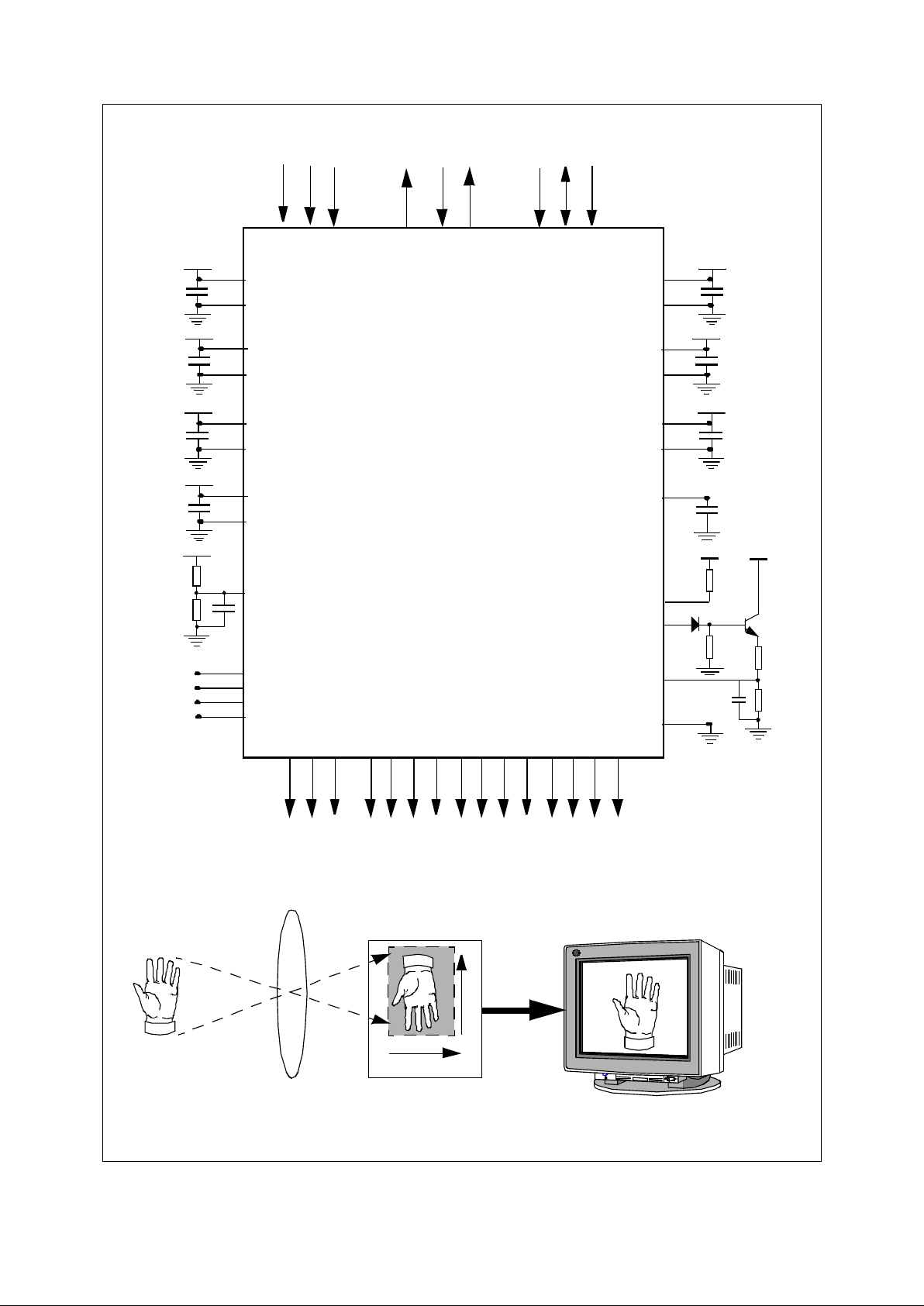

48 PIN LCC

43

d11

d10

8

snapshot

41

NC

44

vref_adc

29

d3

d2

LM9617

hsync

vss_ana1

vdd_o d3

NC

NC

Connection Diagram

Ordering Information

Temperature

(0°C ≤ TA ≤ +50°C)

NS Package

LM9617 CCEA LCC

LM9617

Page 3

Confidential 3 www.national.com

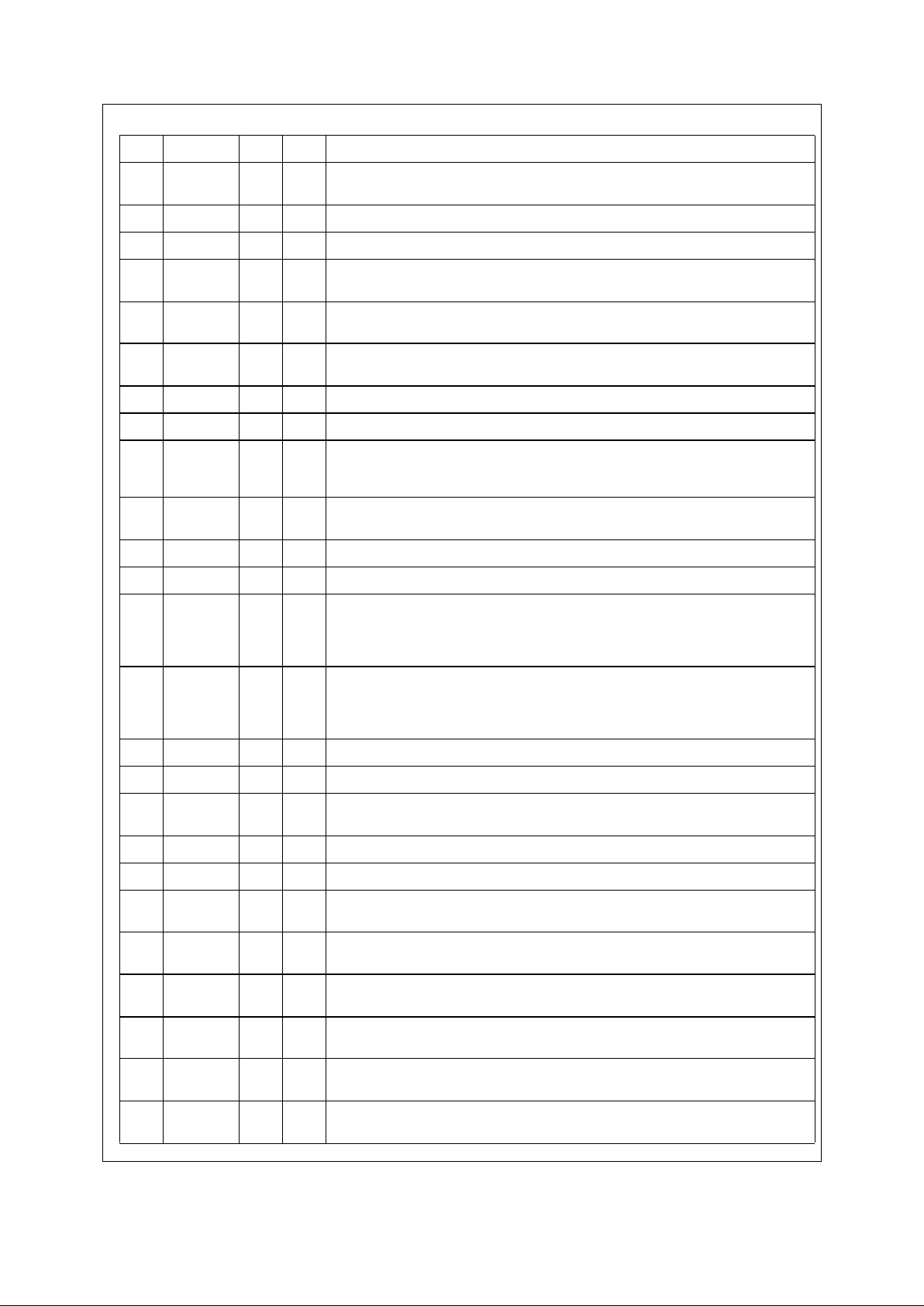

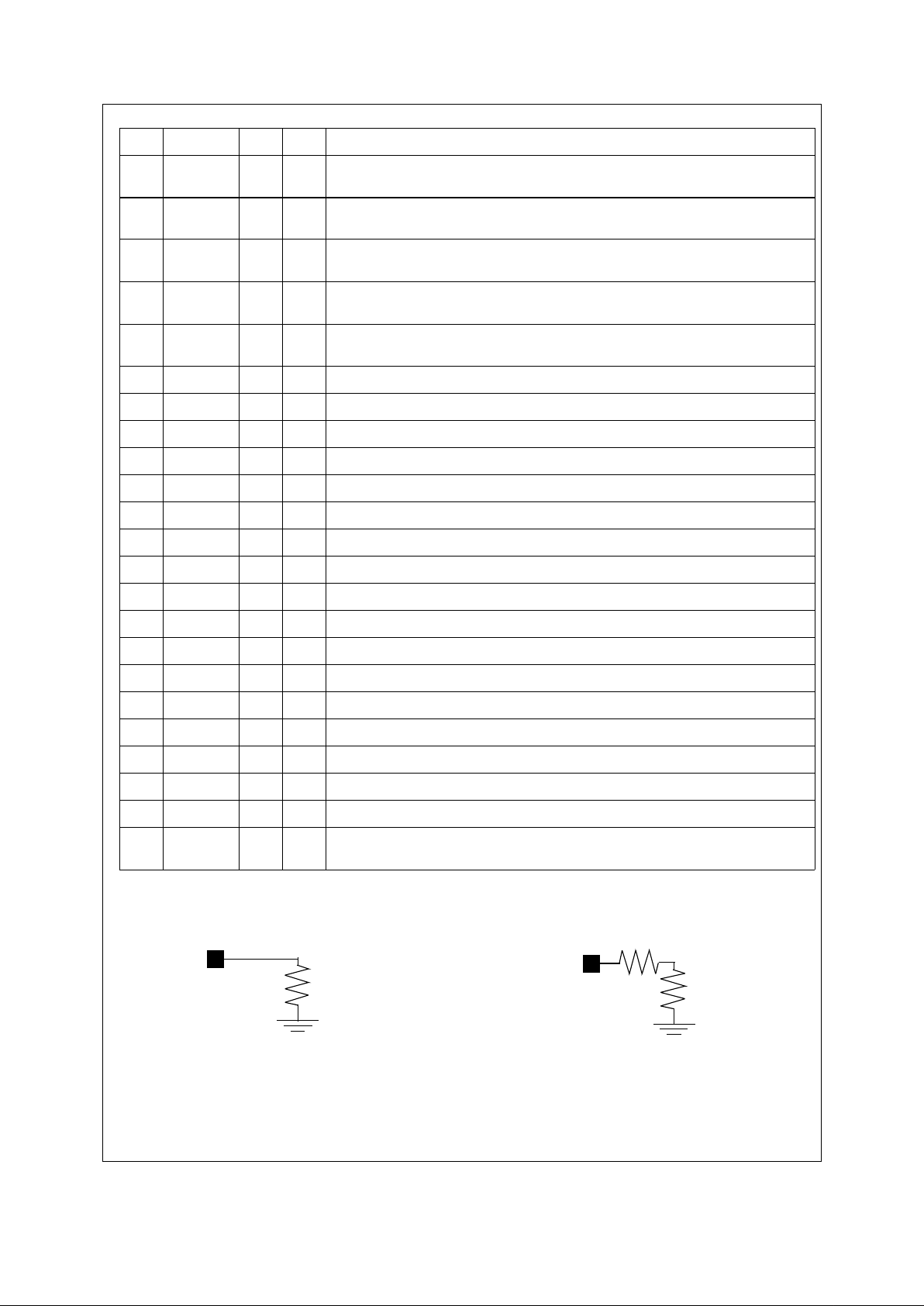

Typical Application Circuit

0.1µF

1.5k

Ω

820

Ω

3.3V analog

0.1µF

3.3V digital

12

9

37

36

35

7 6810

vss_dig

resetb

vdd_ana1

vss_ana1

vref_adc

vdd_od1

vss_od1

sadr

extsyn c

sclk

sda

d9

d8

d7d5d6

d4

d1

d0

snapshot

30 29 28 2627 25 24 23 22 21 17

d2

d3

11

vdd_dig

48 5

20

d10

d11

0.1µF

3.3V analog

31

32

vdd_od2

vss_od2

0.1µF

3.3V digital

0.1µF

3.3V digital

47

46

vdd_pix

vrl

0.1µF

3

2

1

vsrvdd

1.0µF

13 14 15

hsyn c

vsync

pclk

LM9617

pdwn

Serial Control Bus

System Control

Digital Video Bus

Camera Control

irq

4

33

34

vdd_ana2

vss_ana2

0.1µF

3.3V analog

16

mclk

vdd_od3

vss_od3

0.1µF

44

45

fine_i

41

gnd

40

3.3V analog

3.3V digital

offset

fine_ctrl

39

NC

18

NC

19

NC

42

NC

43

10kΩ

1.2kΩ

470Ω

2N3904

1N4148

4.7µF

vdd_ana

22kΩ

vdd_ana

38

1%

1%

1%

1%

Figure 2. Typical Application Diagram

Scan Read Out Direction

Figure 3. Scan directions and position of origin in imaging system

(0,0)

pin 1

CMOS Image Sensor

(0,0)

digital

out

lens

(0,0)

horizontal scan

vertical scan

LM9617

Page 4

Confidential 4 www.national.com

Pin Descriptions

Pin Name I/O Typ Description

1 vsrvdd I0 P

Analog bidirectional, it should be connect to ground via a 1.0µf capacitor. This pin is the

internal charge pump voltage source.

2 vrl I A Anti blooming pin. This pin is normally tied to ground.

3 vdd_pix I P 3.3 volt supply for the pixel array.

4 irq O D

Digital output, the interrupt request pin. This pin generates interrupts during snapshot

mode.

5 sadr I D

Digital input with pull down resistor. This pin is used to program different slave addresses

for the sensor in an I2C compatible system.

6 sda IO D

I2C compatible serial interface data bus. The output stage of this pin has an open drain

driver.

7 sclk I D I2C compatible serial interface clock.

8 snapshot I D Digital input with pull down resistor used to activate (trigger) a snapshot sequence.

9 resetb I D

Digital input with pull up resistor. When forced to a logic 0 the sensor is reset to its default

power up state. The resetb signal is internally synchronized to mclk which must be run-

ning for a reset to occur.

10 pdwn I D

Digital input with pull down resistor. When forced to a logic 1 the sensor is put into power

down mode.

11 vss_dig I P 0 volt power supply for the digital circuits.

12 vdd_dig I P 3.3 volt power supply for the digital circuits.

13 hsync IO D

Digital Bidirectional. This is a dual mode pin. When the sensor’s digital video port is con-

figured to be a master, (the default), this pin is an output and is the horizontal synchroni-

zation pulse. When the sensor’s digital video port is configured to be a slave, this pin is

an input and is the row trigger.

14 vsync IO D

Digital Bidirectional. This is a dual mode pin. When the sensor’s digital video port is con-

figured to be a master, (the default), this pin is an output and is the vertical synchroniza-

tion pulse. When the sensor’s digital video port is configured to be a slave, this pin is an

input and is the frame trigger.

15 pclk O D Digital output. The pixel clock.

16 mclk I D Digital input. The sensor’s master clock input.

17 d0 O D

Digital output. Bit 0 of the digital video output bus. This output can be put into tri-state

mode.

18 NC Pin not used, do not connect.

19 NC Pin not used, do not connect.

20 d1 O D

Digital output. Bit 1 of the digital video output bus. This output can be put into tri-state

mode.

21 d2 O D

Digital output. Bit 2 of the digital video output bus. This output can be put into tri-state

mode.

22 d3 O D

Digital output. Bit 3 of the digital video output bus. This output can be put into tri-state

mode.

23 d4 O D

Digital output. Bit 4 of the digital video output bus. This output can be put into tri-state

mode.

24 d5 O D

Digital output. Bit 5 of the digital video output bus. This output can be put into tri-state

mode.

25 d6 O D

Digital output. Bit 6 of the digital video output bus. This output can be put into tri-state

mode.

LM9617

Page 5

Confidential 5 www.national.com

Pin Descriptions (Continued)

Legend: (I=Input), (O=Output), (IO=Bi-directional), (P=Power), (D=Digital), (A=Analog).

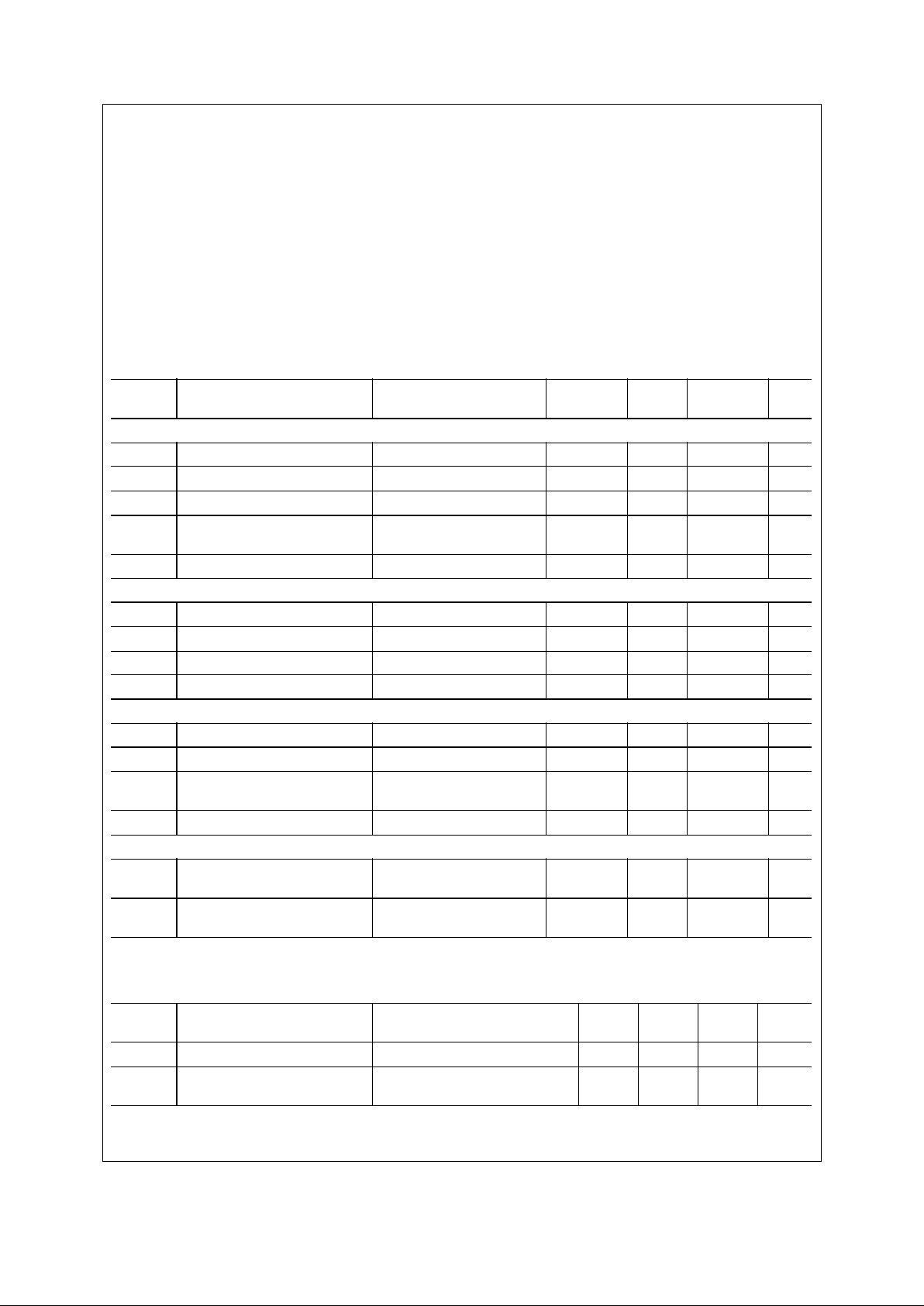

Figure 4. Equivalent Circuits For adc_ref and offset pins

Pin Name I/O Typ Description

26 d7 O D

Digital output. Bit 7 of the digital video output bus. This output can be put into tri-state

mode.

27 d8 O D

Digital output. Bit 8 of the digital video output bus. This output can be put into tri-state

mode.

28 d9 O D

Digital output. Bit 9 of the digital video output bus. This output can be put into tri-state

mode.

29 d10 O D

Digital output. Bit 10 of the digital video output bus. This output can be put into tri-state

mode.

30 d11 O D

Digital output. Bit 11 of the digital video output bus. This output can be put into tri-state

mode.

31 vdd_od2 I P 3.3 volt supply for the digital IO buffers.

32 vss_od2 I P 0 volt supply for the digital IO buffers

33 vdd_ana2 I P 3.3 volt supply for analog circuits.

34 vss_ana2 I P 0 volt supply for analog circuits.

35 vref_adc I A A/D reference resistor ladder voltage. See figure 4 for equivalent circuit.

36 vss_ana1 I P 0 volt supply for analog circuits.

37 vdd_ana1 I P 3.3 volt supply for analog circuits.

38 offset I A Analog input used to adjust the offset of the sensor. See figure 4 for equivalent circuit.

39 fine_ctrl O A Analog output used to drive the offset pin.

40 gnd This pin must be tied to ground.

41 fine_i I A Bias current for the fine offset adjust.

42 NC Pin not used, do not connect.

43 NC Pin not used, do not connect.

44 vdd_od3 I P 3.3 volt supply for the sensor.

45 vss_od3 I P 0 volt supply for the sensor.

46 vss_od1 I P 0 volt supply for the digital IO buffers

47 vdd_od1 I P 3.3 volt supply for the digital IO buffers.

48 extsync O D

Digital output. The external event synchronization signal is used to synchronize external

events in snapshot mode.

800Ω

adc_vref

1KΩ

200Ω

offset

LM9617

Page 6

Confidential 6 www.national.com

Absolute Maximum Ratings (Notes 1 & 2)

Any Positive Supply Voltage 6.5V

Voltage On Any Input or Output Pin -0.5V to 6.5V

Input Current at any pin (Note 3) ±25mA

ESD Susceptibility (Note 5)

Human Body Model 2000V

Machine Model 200V

Package Input Current (Note 3) ±50mA

Package Power Dissipation @ TA(Note 4) 2.5W

Soldering Temperature Infrared,

10 seconds (Note 6) 220°C

Storage Temperature -40°C to 125°C

Operating Ratings (Notes 1 & 2)

Operating Temperature Range 0°C≤T≤+50°C

All VDD Supply Voltages +3.15V to +3.6V

Voltage Range on vref_adc pin +0.6V to +1.0V

Voltage Range on offset pin +0.04V to +0.4V

DC and logic level specifications

The following specifications apply for all VDD pins= +3.3V. Boldface limits apply for TA = T

MIN

to T

MAX

: all other limits TA = 25oC

(Note 7)

Power Dissipation Specifications

The following specifications apply for All VDD pins = +3.3V. Boldface limits apply for TA = T

MIN

to T

MAX

: all other limits TA = 25oC.

Symbol Parameter Conditions

Min

note 9

Typical

note 8

Max

note 9

Units

sclk, sda, sadr, Digital Input/Output Characteristics

VIH Logical “1” Input Voltage 0.7*vdd_od vdd_od+0.5 V

VIL Logical “0” Input Voltage -0.5 0.3*vdd_od V

VOL Logical “0” Output Voltage vdd_od = +3.15V, Iout=3.0mA 0.5 V

V

hys

Hysteresis (SCLK pin only) vdd_od = +3.15V

0.05*vdd_o

d

V

I

leak

Input Leakage Current Vin=vss_od -1 mA

mclk, snapshot, pdwn, resetb, hsync, vsync Digital Input Characteristics

VIH Logical “1” Input Voltage vdd_dig = +3.6V 2.0 V

VIL Logical “0” Input Voltage vdd_dig = +3.15V 0.8 V

IIH Logical “1” Input Current VIH = vdd_dig 0.1 mA

IIL Logical “0” Input Current VIL = vss_dig -1 mA

d0 - d11, pclk, hsync, vsync, extsync, irq, Digital Output Characteristics

VOH Logical “1” Output Voltage vdd_od=3.15V, Iout=-1.6mA 2.2 V

VOL Logical “0” Output Voltage vdd_od=3.15V, Iout =-1.6mA 0.5 V

IOZ TRI-STATE Output Current

VOUT = vss_od

VOUT = vdd_od

-0.1

0.1

mA

mA

IOS Output Short Circuit Current +/-17 mA

Power Supply Characteristics

IA Analog Supply Current

Power down mode, no clock.

Operational mode in dark

700

19

mA

mA

ID Digital Supply Current

Power down mode, no clock.

Operational mode in dark

300

7

mA

mA

Symbol Parameter Conditions

Min

note 9

Typical

note 8

Max

note 9

Units

P

dwn

Power Down no clock running 5 mW

PWR Average Power Dissipation

mclk = 48Mhz & sensors default settings in dark.

90 mW

LM9617

Page 7

Confidential 7 www.national.com

Video Amplifier Specifications

The following specifications apply for all VDD pins= +3.3V. Boldface limits apply for TA = T

MIN

to T

MAX

: all other limits TA = 25oC.

AC Electrical Characteristics

The following specifications apply for All VDD pins = +3.3V. Boldface limits apply for TA = T

MIN

to T

MAX

: all other limits TA = 25oC.

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate con-

ditions for which the device is functional, but do not guarantee specific performance limits. For guaranteed specifications

and test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions

listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 2: All voltages are measured with respect to VSS = vss_ana = vss_od = vss_dig = 0V, unless otherwise specified.

Note 3: When the voltage at any pin exceeds the power supplies (VIN < VSS or VIN > VDD), the current at that pin should be lim-

ited to 25mA. The 50mA maximum package input current rating limits the number of pins that can safely exceed the power

supplies with an input current of 25mA.

Note 4: The absolute maximum junction temperature (TJmax) for this device is 125oC. The maximum allowable power dissipation

is dictated by TJmax, the junction-to-ambient thermal resistance (ΘJA), and the ambient temperature (TA), and can be cal-

culated using the formula PDMAX = (TJmax - TA)/ΘJA. In the 48-pin LCC, ΘJA is 38.5oC/W, so PDMAX = 2.5W at 25oC

and 1.94W at the maximum operating ambient temperature of 50oC. Note that the power dissipation of this device under

normal operation will be well under the PDMAX of the package.

Note 5: Human body model is 100pF capacitor discharged through a 1.5kΩ resistor. Machine model is 220pF discharged through

ZERO Ohms.

Note 6: See AN450, “Surface Mounting Methods and Their Effect on Product Reliability”, or the section entitled “Surface Mount”

found in any post 1986 National Semiconductor Linear Data Book, for other methods of soldering surface mount devices.

Note 7: The analog inputs are protected as shown below. Input voltage magnitude up to 500mV beyond the supply rails will not

damage this device. However, input errors will be generated If the input goes above AV+ and below AGND.

Note 8: Typical figures are at TJ = 25oC, and represent most likely parametric norms.

Note 9: Test limits are guaranteed to National's AOQL (Average Outgoing Quality Level).

Symbol Parameter Conditions

Min

note 9

Typical

note 8

Max

note 9

Units

Video Amplifier Nominal Gain 64 linear steps 0-15 dB

Symbol Parameter Conditions

Min

note 9

Typical

note 8

Max

note 9

Units

F

mclk

Input Clock Frequency 12 48 MHz

T

ch

Clock High Time @ CLK

max

10 45 ns

T

cl

Clock Low Time @ CLK

max

10 45 ns

Clock Duty Cycle @ CLK

max

45/55 55/45 min/max

Trc, TfcClock Input Rise and Fall Time 3 ns

F

hclk

Internal System Clock Frequency

1.0 14.0 MHz

T

reset

Reset pulse width 1.0 µs

FRM

rate

Frame Rate 1 30 fps

IOP

Pad

VDD

VSS

Internal Circuits

LM9617

Page 8

Confidential 8 www.national.com

CMOS Active Pixel Array Specifications

Image Sensor Specifications

The following specifications apply for All VDD pins = +3.3V, TA = 25oC, Illumination Color Temperature = 2850oK, IR cutoff filter at

700nm, mclk = 48MHz, frame rate = 30Hz, vref_adc = 0.6 volt, video gain 0dB.

Note 1: Typical figures are at TJ = 25oC, and represent most likely parametric norms.

Parameter Value Units

Number of pixels (column, row)

Total

Active

664 x 504

648 x 488

pixels

pixels

Array size (x,y Dimensions)

Total

Active

4.98 x 3.78

4.86 x 3.66

mm

mm

Pixel Pitch 7.5 µ

Fill Factor (without micro-lens) 47 %

Parameter Conditions

Min Typical

note 1

Max Units

Optical Sensitivity @ A/D output 28.7 kLSBs/(lux.s)

Optical Sensitivity @ A/D input

4.13

volt/(lux.s)

Dynamic Range 57 dB

Read Noise 5.3 LSBs

Offset Fixed Pattern Noise

RMS value of pixel FPN in dark

as a percentage of full scale.

0.35 %

Sensitivity Fixed Pattern Noise

RMS variation of pixel sensitivities as a percentage of the average sensitivity.

1 %

LM9617

Page 9

Confidential 9 www.national.com

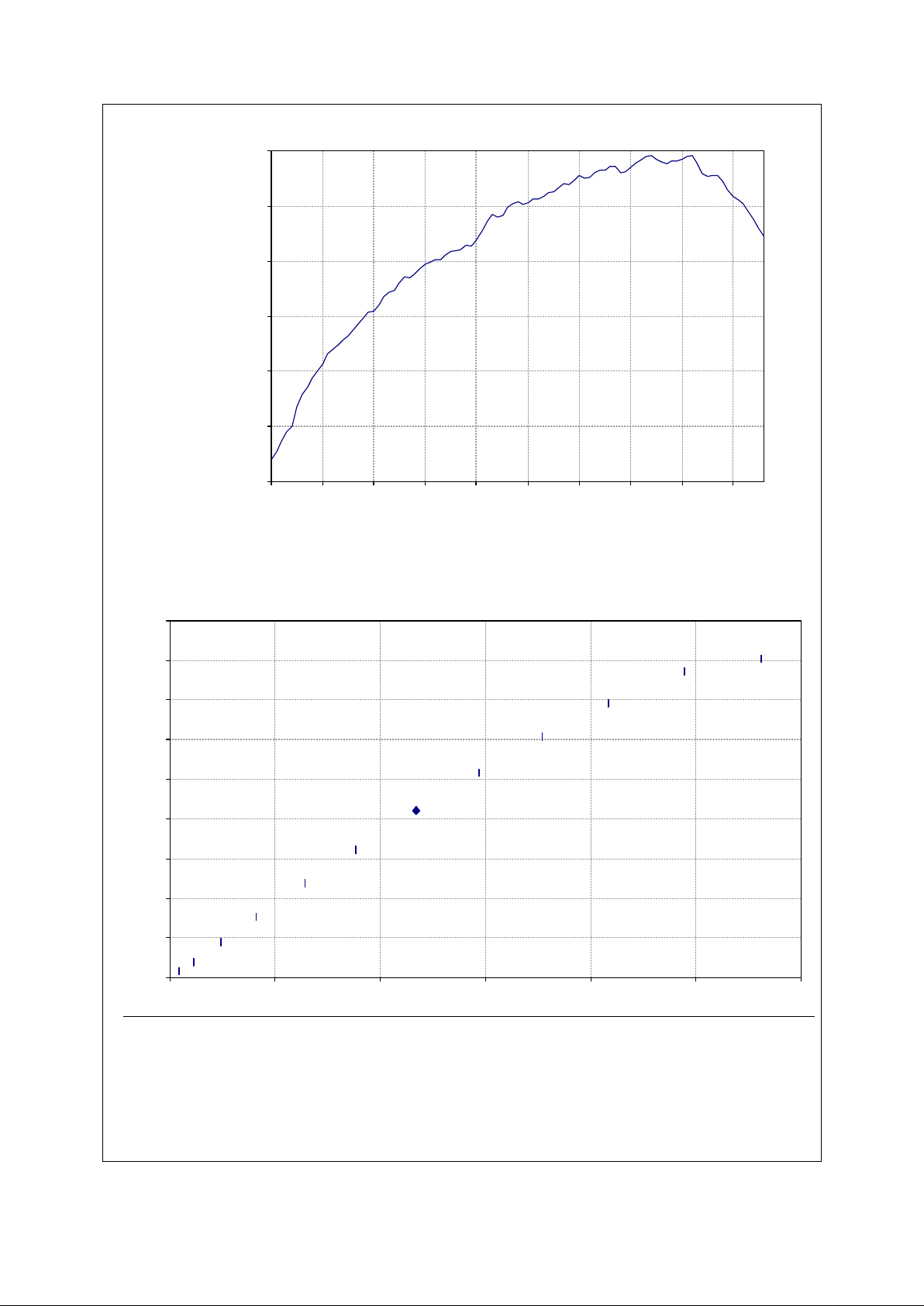

Sensor Response Curves

0.00E+00

2.00E+02

4.00E+02

6.00E+02

8.00E+02

1.00E+03

1.20E+03

370 420 470 520 570 620 670 720 770 820

wavelength [nm]

Spectral sensitivity [V/((W/m^2)*s)]

Figure 5. Spectral Response Curve

0

500

1000

1500

2000

2500

3000

3500

4000

4500

0 0.05 0.1 0.15 0.2 0.25 0.3

Exposure (lux.sec)

A/D output code

Figure 6. Linearity Response Curve

LM9617

Page 10

Confidential 10 www.national.com

Functional Description

1.0 OVERVIEW

1.1 Light Capture and Conversion

The LM9617 contains a CMOS active pixel array consisting of

648 rows by 488 columns. This active region is surrounded by 8

columns and 8 rows of optically shielded (black) pixels as shown

in Figure.

8 columns, 8 rows

black pixels

8 columns, 8 rows

black pixels

648 columns, 488 rows

mono-chrome active pixels

Figure 7: CMOS APS region of the LM9617

At the beginning of a given integration time the on-board timing

and control circuit will reset every pixel in the array one row at a

time as shown in Figure 8. Note that all pixels in the same row

are simultaneously reset, but not all pixels in the array.

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

9

10

11

12

14

13

15

CDS/Shift Register

Line Address

Analog Data Out

Figure 8: CMOS APS Row and Column addressing scheme

At the end of the integration time, the timing and control circuit

will address each row and simultaneously transfer the integrated

value of the pixel to a correlated double sampling circuit and

then to a shift register as shown in Figure 8.

Once the correlated double sampled data has been loaded into

the shift register, the timing and control circuit will shift them out

one pixel at a time starting with column “a”.

The pixel data is then fed into an analog video amplifier, where a

user programmed gain is applied .

After gain adjustment the analog value of each pixel is converted to a 12 bit digital data as shown in Figure 9.

12 Bit A/D

Video

AMP

Analog pixel values Digital pixel data

0-15dB

Figure 9: Analog Signals In, Digital Data Out.

The digital pixel data is further processed to:

• remove defects due to bad pixels,

• compensate black level, before being framed and presented

on the digital output port. (see Figure 10).

Figure 10. Digital Pixel Processing.

1.2 Program and Control Interfaces

The programming, control and status monitoring of the LM9617

is achieved through a two wire I2C compatible serial bus. In

addition, a slave address pin is provided (see Figure 11).

Figure 11. Control Interface to the LM9617.

Additional control and status pins: snapshot and external event

synchronization are provided allowing the latency of the serial

control port to be bypassed during single frame capture. An

interrupt request pin is also available allowing complex snapshot

operations to be controlled via an external micro-processor (see

Figure 12).

Figure 12. Snapshot & External Event Trigger Signals

Bad Pixel

Correction

Digital Video

Framer

Black Level

Compensation

do[11:0]

pclk

hsync

vsync

I2C Compatible

Register Bank

Serial I/F

sda

sclk

sadr

Timing

Generator

irq

snapshot

extsyn

LM9617

Page 11

Confidential 11 www.national.com

Functional Description (continued)

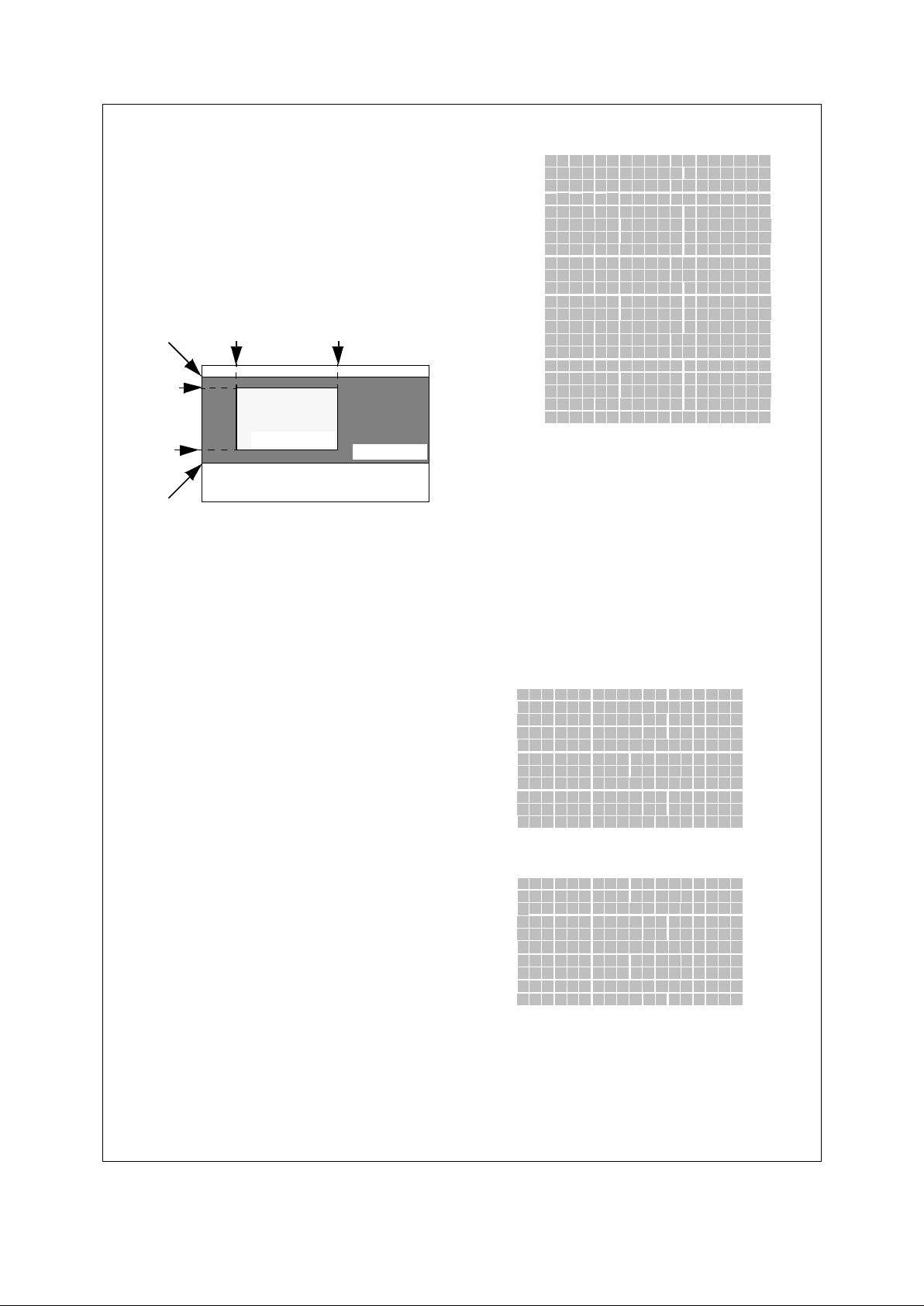

2.0 WINDOWING

The integrated timing and control circuit allows any size window

in any position within the active region of the array to be read out

with a 1x1 pixel resolution. The window read out is called the

“Display Window”.

A “Scan Window” must be defined first, by programing the start

and end row addresses as shown in Figure 13. Four coordinates

(start row address, start column address, end row address &

end column address) are programmed to define the size and

location of the “Display Window” to be read out (see Figure 13).

Figure 13. Windowing

Notes:

• The “Display Window” must always be defined within the

“Scan Window”.

• A “Display Window” can only be read out in the progressive

scan mode.

• By default the “Display Window” is the complete array.

2.1 Programming the scan window

Two registers (SROWS & SROWE) are provided to program the

size of the scan window. The start and end row address of the

scan window is given by:

Where:

SwStartRow

is the contents of the Scan Window start row

register (SROWS)

SwEndROW

is the contents of the Scan Window end row register (SROWE)

SwLsb

is bit 6 of the Display Window LSB register

(DWLSB)

2.2 Programming the display window

Five register (DROWS, DROWE, DCOLS, DCOLE and DWLSB)

are provided to program the display window as described in the

register section of this datasheet.

3.0 READ OUT MODES

3.1 Progressive Scan Readout Mode

In progressive scan readout mode, every pixel in every row in

the display window is consecutively read out, one pixel at a time,

starting with the left most pixel in the top most row. Hence, for

the example shown in Figure 13, the read out order will be

a0,b0,...,r0 then a1,b1,...,r1 and so on until pixel r20 is read out.

a b c d e f g h i j k l mn o p q r

1

2

3

4

5

6

7

8

9

10

11

12

13

15

14

16

17

18

19

20

Row/Vertical

0

Column/Horizontal

Figure 14: Progressive Scan Read Out Mode

3.2 Interlaced Readout Mode

In interlaced readout mode, pixels are read out in two fields, an

Odd Field followed by an Even Field.

The Odd Field, consisting of all even rows contained within the

display window, is read out first. Each pixel in the “Odd Field” is

consecutively read out, one pixel at a time, starting with the left

most pixel in the top most even row.

The Even Field, consisting of all odd rows contained within the

display window, is then read out. Each pixel in the “Even Field”

is consecutively read out, one pixel at a time, starting with the

left most pixel in the top most odd row.

a b c d e f g h i j k l mn o p q r

2

4

6

8

10

12

14

16

18

20

0

Row/Vertical

Column/Horizontal

Odd Field

1

3

5

9

7

11

13

15

17

19

Row/Vertical

Column/Horizontal

Even Field

a b c d e f g h i j k l mn o p q r

Figure 15: Interlace Read Out Mode

Hence, for the example shown in Figure , the display window is

broken up into two fields, as shown in Figure . Pixels a0,b0,...,r0

followed by a2,b2,...,r2 and so on until pixels a20,b20,...r20 in

the even field are read out first. The even field read out is followed by pixels in the odd field, a1,b1,...,r1 then a3,b3,...,r3 until

pixels a19,b19,...,r19.

display row

Active Pixel Array

Display Window

Scan Window

display row

display col

display col

start address

end address

start address

end address

scan row

start address

scan row

end address

scan row start address = (2* SwStartRow) + SwLsb

scan row end address = (2* SwEndRow) + 1 + SwLsb

LM9617

Page 12

Confidential 12 www.national.com

Functional Description (continued)

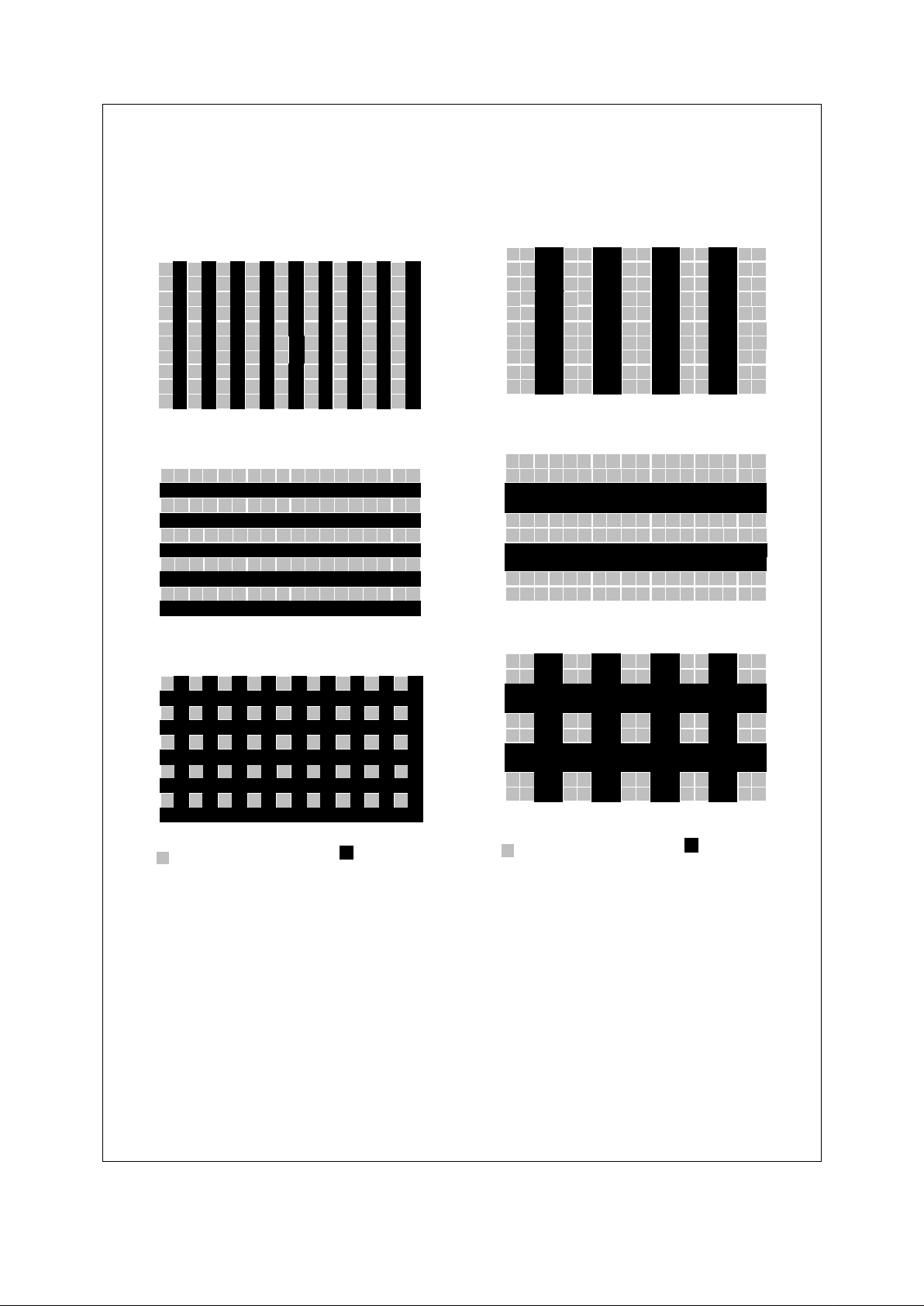

4.0 SUBSAMPLING MODES

4.1 2:1 Sub-Sampling

The timing and control circuit can be programmed to sub-sample pixels in the display window vertically, horizontally or both,

with an aspect ratio of 2:1 as illustrated in Figure16

0

1

2

3

4

5

6

7

8

9

Column/Horizontal

a b c d e f g h i j k l l n o p q r

a b c d e f g h i j k l m n o p

0

1

2

3

4

5

6

7

8

9

b) Vertical Sub-Sampling

Row/Vertical

Column/Horizontal

q

r

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

Column/Horizontal

Row/Vertical

9

a) Horizontal Sub-Sampling

c) Horizontal & Vertical Sub-Sampling

Read Out

Not Read Out

Row/Vertical

Figure 16: 2:1 Horizontal and Vertical Sub-Sampling

4.2 4:2 Sub-Sampling

The timing and control circuit can be programmed to sub-sample pixels in the display window vertically, horizontally or both,

with an aspect ratio of 4:2 as illustrated in Figure17.

Column/Horizontal

a) Horizontal Sub-sampling

Read Out

Not Read Out

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

9

Row/Vertical

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

9

Column/Horizontal

Row/Vertical

a b c d e f g h i j k l m n o p q r

0

1

2

3

4

5

6

7

8

9

Column/Horizontal

Row/ Vertica l

c) Horizontal & Vertical Sub-sampling

b) Vertical Sub-sampling

Figure 17: 4:2 Horizontal and Vertical Sub-Sampling

LM9617

Page 13

Confidential 13 www.national.com

Functional Description (continued)

5.0 SNAPSHOT MODE

The LM9617 is capable of capturing a single frame of an image

under hardware or software control, with or without the aid of an

external shutter. Two registers, SNAPSHOTMODE0 &

SNAPSHOTMODE1, are provided to program, monitor and control all snapshot sequences.

5.1 Software Controlled Snapshots

The snapshot mode events can be software controlled by writing

to and reading from the snapshot mode registers over the I2C

compatible interface.

5.2 Hardware Controlled Snapshots

Two dedicated pins are provided on the LM9617, snapshot &

extsync, allowing the snapshot mode events to be controlled by

hardware. The snapshot pin must be enabled by writing to the

SnapEnable bit of the MCFG0 register.

5.3 Auto Snapshot Mode

In auto snapshot mode (see figure 20), upon the receipt of a

snapshot or

FTriggerNow

trigger signal, the integrated timing and

control circuit will set the FTriggerEN bit and generate an internal TRIGGER signal (see figure 19), thus resetting the array one

row at a time. At end of the reset cycle the timing and control circuit will signal the shutter to open via extsync pin or

FtSync bit.

At the end of the programmed integration time the shutter will be

signalled to close, and the pixel read-out will commence as

shown in figure 18a. At the end of the read-out sequence the

FTriggerEN will be automatically reset and the sensor will return

to video capture mode as shown in figure 20.

If an external shutter is not available then at least two frames

need to be taken so that the pixels can be integrated over one

frame as shown in Figure 18b.

To use auto snapshot mode the SsEngage bit of the

SNAPSHOTMODE1 register must be set to zero.

Note 1: This wave form shows the snapshot pin programmed to the default pulse mode.

Note 2: The irq pulse is taken low when the snapshot trigger interrupt flag (SsTrigFlag) in the snapshot mode1 (SNAPMODE1) register is read.

Note 3: The irq pulse is taken low when the snapshot trigger interrupt flag (SsRdFlag) in the snapshot mode1 (SNAPMODE1) register is read.

Figure 18. Snapshot Mode

Start Snapshot Sequence

Start of Array Reset Frames

Open Shutter

Close shutter & start read-out

Read-out complete

FTriggerEn

snapshot or FTriggerNow

extsync or FtSync

FtBusy

Array reset,

irq

programmable 1 to 4 frames

Capture

Data

read-out

image

note 1

note 2

note 3

Start Snapshot sequence

Start of Array Reset Frames

Integration Start

Start Read-out

Read-out Complete

FTriggerEn

snapshot or FTriggerNow

extsync or FtSync

FtBusy

Bold external pins

italic register bits

Array reset,

irq

programmable 1 to 4 frames

Capture Data

read-out

image

note 1

note 2

note 3

a) With External Shutter

b) Without External Shutter

LM9617

Page 14

Confidential 14 www.national.com

Functional Description (continued)

Figure 19. Snapshot Trigger Generation Logic

Figure 20. Auto Snapshot Mode State Diagram

5.4 CPU Snapshot Mode

In CPU snapshot mode, the FTriggerEN is not set automatically

and an Interrupt generator can be enabled.

Hence, upon the receipt of a snapshot or

FTriggerNow

trigger

signal, the integrated timing and control circuit will generate an

internal TRIGGER signal as shown in figure 19 and then wait in

the IRQ state for the FTriggerEN bit to be manually set as shown

in figure 21.

Once the FtriggerEn bit is set the integrated timing and control

circuit will start resetting the array one row at a time. At end of

the reset cycle the timing and control circuit will signal the shutter to open via extsync pin or

FtSync bit. At the end of the programmed integration time the shutter will be signalled to close,

and the pixel read-out will commence as shown in figure 18a. At

the end of the read-out sequence the

FTriggerEN will be automatically disabled and the sensor will return to video capture

mode as shown in figure 20.

If an external shutter is not available then at least two frames

need to be taken so that the pixels can be integrated over one

frame as shown in Figure 18b.

To use CPU snapshot mode the SsEngage bit of the

SNAPSHOTMODE1 register must be set to one.

An interrupt generator can be enabled in CPU snapshot mode

by setting the SnapIntEn bit of SNAPSHOTMODE1 register. An

interrupt will be generated on the external interrupt pin, irq,

when a snapshot sequence is triggered (TRIGGER=1) or when

the array readout is complete at the end of the snapshot

sequence as shown figure 21.

Figure 21. CPU Snapshot Mode State Diagram

When an interrupt is generated by a TRIGGER event, the

SsTrigFlag bit in the SNAPSHOTMODE1 register is set. Similarly when an interrupt is generated at the completion of a readout the SsRdFlag in the SNAPSHOTMODE1 register is set.

The polarity of the irq pin can be programmed. The interrupt can

only be cleared by reading SsTrigFlag and the SsRdFlag as

shown in figure 22.

Figure 22. Interrupt Request Generation Logic

5.5 Pulse & Level Trigger Mode

The snapshot pin can be programmed to operate in pulse trigger mode where one snapshot sequence is executed per active

pulse or in level trigger mode where by snapshot sequences are

repeated as long as the level on the snapshot pin is held active.

(see figures 20 and 21).

Pulse and level trigger modes can be set by programming the

SnapshotMod bit in the SNAPSHOTMODE0 register.

snapshot

SnapShotPol

SnapEnable

FTriggerNow

TRIGGER

VIDEO

SNAP

PREVIEW

c:TRIGGER==1

c: SnapshotMod || (SnapshotMod && TRIGGER)

a:FTriggerEn=1

a:FTriggerEn=0

VIDEO

IRQ

a:SsTrigFlag=1

SNAP

c:FTriggerEn==1

PREVIEW

a: SsRdFlag = 1

a: FtTriggerEn = 0

c:TRIGGER==1

c: SsRdFlag && (SnapshotMod || (SnapshotMod && TRIGGER))

SsTrigFlag

SsRdFlag

SnapIntEn

IrqPol

irq

LM9617

Page 15

Confidential 15 www.national.com

Functional Description (continued)

6.0 CLOCK GENERATION MODULE

The LM9617 contains a clock generation module that will create

two clocks as follows:

Hclk, the horizontal clock. This is an internal system

clock and can be programmed to be the input

clock (mclk) or mclk divided by any number

between 1 and 255.

CLK

pixel

the pixel clock. This is the external pixel clock

that appears at the digital video port. It can be

Hclk or Hclk divided by 2. This clock cannot be

programed.

7.0 FRAME RATE PROGRAMING

A frame is defined as the time it takes to reset every pixel in the

array, integrate the incident light, convert it to digital data and

present it on the digital video port. This is not a concurrent process and is characterized in a series of events each needing a

certain amount of time as shown in Figure 23.

Figure 23. Frame Readout Flow Diagram

7.1 Full Frame Integration

Full frame integration is when each pixel in the array integrates

light incident on it for the duration of a frame (see Figure 24).

The number of Hclk clock cycles required to process & shift out

one row of pixels is given by:

Where:

R

opcycle

is a fixed integer value of 780 representing the

Row Operation Cycle Time in multiples of Hclk

clock cycles. It is the time required to carry out

all fixed row operations outlined in Figure 23.

R

delay

a programmable value between 0 & 2047 repre-

senting the Row Delay Time in multiples of Hclk.

This parameter allows the Row Operation Cycle

time to be extended. (See the Row Delay High

and Row Delay Low registers).

The number of rows in a scan window is given by:

Where:

RAD

end

is the end row address of the defined scan window. (See section 2.1)

RAD

start

is the start row address of the defined scan window. (Scan section 2.1).

The number of Hclk clocks required to process a full frame is

given by:

Where:

M

factor

is a Mode Factor which must be applied. It is

dependent on the selected mode of operation as

shown in the table below:

SWN

rows

is the Number of Rows in Selected Scan Win-

dow.

F

delay

a programmable value between 0 & 4097 repre-

senting the Inter Frame Delay in multiples of

RN

Hclk

. This parameter allows the frame time to

be extended. (See the Frame Delay High and

Frame Delay Low registers).

The frame rate is given by:

7.2 Partial Frame Integration

In some cases it is desirable to reduce the time during which the

pixels in the array are allowed to integrate incident light without

changing the frame rate.

This is known as Partial Fame Integration and can be achieved

by resetting pixels in a given row ahead of the row being

selected for readout as shown in Figure 24. The number of Hclk

clocks required to process a partial frame is given by:

Where:

RN

Hclk

is the number of Hclk clock cycles required to

process & shift out one row of pixels.

I

time

is the number of rows ahead of the current row

to be reset. (See the Integration Time High and

Low registers).

The Integration time is subject to the following limits:

Start

Row address = 0

Row delay time

Transfer all pixels to CDS

Shift all pixels out of row

Row address + 1

Last row?

Reset all pixels in row

Yes

No

Row Time

RN

Hclk

= R

opcycle

+ R

delay

Progressive Scan 1

Sub-sampling or Interlace/

Interlace

0.5

Mode Limit

Progressive Scan I

time <=

SWN

rows + Fdelay

Interlace I

time <=

SWN

rows + 2*Fdelay

Sub-Sampled I

time <=

SWN

rows +

0.5*F

delay

SWN

rows

= (RAD

end

- RAD

start

) + 1

FN

Hclk

= [(M

factor *

SWN

rows

) + F

delay] *

RN

Hclk

Hclk

FN

Hclk

Frame Rate =

FP

Hclk

= RN

Hclk * Itime

LM9617

Page 16

Confidential 16 www.national.com

Functional Description (continued)

Figure 24. Partial and Full Frame Integration

7.3 Frame Rate Programming Guide

The table bellow can be used as a guide for programming the sensor. Note that it is assumed that the sensor is being driven with a

48MHz clock. All programmed values are given in decimal.

register vclkgen rdelayh rdelayl fdelayh fdelayl srows srowe dwlsb

address 05hex 15hex 16hex 17hex 18hex 0Bhex 0Chex 12hex

fps [10:8] [7:0] [11:8] [7:0] [8:1] [8:1]

30 4 0 0 0 9 0 251 50

15 4 0 0 2 40 0 251 50

7.5 4 0 0 6 12 0 251 50

3.75 4 3 12 6 12 0 251 50

25 4 0 172 0 0 0 251 50

12.5 5 0 0 1 226 0 251 50

6.25 5 0 0 5 188 0 251 50

3.125 4 0 156 14 14 0 251 50

5 4 2 255 4 23 0 251 50

4 5 0 0 10 12 0 251 50

3 5 0 0 14 14 0 251 50

2 6 0 200 13 248 0 251 50

1 6 3 241 15 126 0 251 50

Row x

Programmable Row Delay Row CDS, Reset Row x & Shift

Programmable Row Delay Row CDS, Reset Row x+∆ & Shift

Partial Frame Integration

Full Frame integration

Row n

Row 0 Row 1

Frame

Row x+∆Row n

Frame

Row 0

Full Integration Time

Row 2

Frame N

Delay Delay

Partial Integration

Time

LM9617

Page 17

Confidential 17 www.national.com

Functional Description (continued)

8.0 SIGNAL PROCESSING

8.1 Bad Pixel Detection & Correction

The LM9617 has a built-in bad pixel detection and correction

block that operates on the fly. This block can be switched off by

the user.

8.2 Black Level Compensation

In addition to the programmable gain the LM9617 has a built in

black level compensation block as illustrated in Figure 25. This

block can be switched off.

Figure 25. Digital Black Level Compensation.

The black level compensation block will subtract the average

signal level of the black pixels around the array from the digital

video output to compensate for the temperature and integration

time dependent dark signal level of the pixels. The exponential

averaging circuit shown in figure 25 only operates on the least

significant 8 bits of the video data.

9.0 POWER MANAGMENT

9.1 Power Up and Down

The LM9617 is equipped with an on-board power management

system allowing the analog and digital circuitry to be switched

off (power down) and on (power up) at any time.

The sensor can be put into power down mode by asserting a

logic one on the “pdwn” pin or by writing to the power down bit in

the main configuration register via the I2C compatible serial

interface.

To power up the sensor a logic zero can be asserted on the

“pdwn” pin or write to the power down bit in the main configura-

tion register via the I2C compatible serial interface.

It will take a few milli seconds for all the circuits to power up. The

power management register contains a bit indicating when the

sensor is ready for use. During this time the sensor cannot be

used for capturing images. A status bit in the power management register will indicate when the sensor is ready for use.

9.2 Advanced Power Features

In addition to the power up/power down features of the sensor,

sections of the analog video processing chain can be powered

down and re-routed during normal operation. This flexibility

allows power dissipation to be traded of with signal gain as

shown in the table below:

Figure 26. Power Control

10.0 ANALOG GAIN ADJUSTMENT

The integrated analog programmable gain amplifier is capable

of applying a linear gain 1X to 5.6X in 64 linear steps. This can

be programmed using the VGAIN register as shown in the table

below:

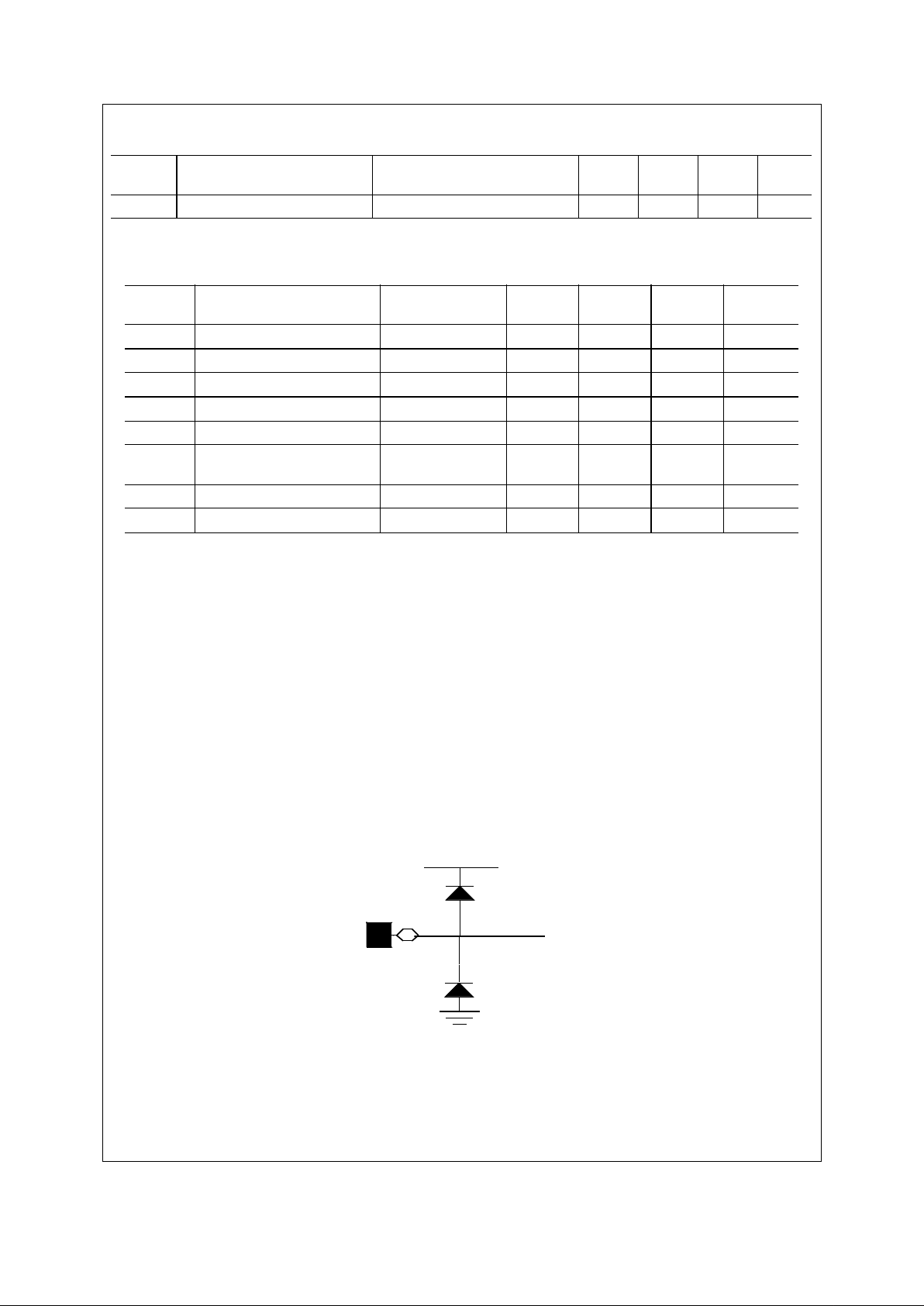

PGA Amp Power Saving

on 0mW

off 10mW

*

a

*

(1-a)

+

-

+

+

Σ

z

-1

only enabled for black pixels

input signal

com pensated output

Σ

VidGain

Dec

Code

VidGain

Hex

Code

Gain

Amp

Value

VidGain

Dec

Code

VidGain

Hex

Code

Gain

Amp

Value

0 00 1 32 20 3.34

1 01 1.07 33 21 3.41

2 02 1.15 34 22 3.48

3 03 1.22 35 23 3.56

4 04 1.29 36 24 3.63

5 05 1.37 37 25 3.7

6 06 1.44 38 26 3.77

7 07 1.51 39 27 3.85

8 08 1.58 40 28 3.92

9 09 1.66 41 29 3.99

10 0A 1.73 42 2A 4.07

11 0B 1.8 43 2B 4.14

12 0C 1.88 44 2C 4.21

13 0D 1.95 45 2D 4.29

14 0E 2.02 46 2E 4.36

15 0F 2.1 47 2F 4.43

16 10 2.17 48 30 4.5

17 11 2.24 49 31 4.58

18 12 2.31 50 32 4.65

19 13 2.39 51 33 4.72

20 14 2.46 52 34 4.8

21 15 2.53 53 35 4.87

22 16 2.61 54 36 4.94

23 17 2.68 55 37 5.02

24 18 2.75 56 38 5.09

25 19 2.83 57 39 5.16

26 1A 2.9 58 3A 5.23

27 1B 2.97 59 3B 5.31

28 1C 3.04 60 3C 5.38

29 1D 3.12 61 3D 5.45

30 1E 3.19 62 3E 5.53

31 1F 3.26 63 3F 5.6

LM9617

Page 18

Confidential 18 www.national.com

Functional Description (continued)

11.0 OFFSET ADJUSTMENT

For maximum image quality over a wide range of light conditions

it is necessary to set an appropriate offset voltage before using

the sensor to capture images. This offset voltage must be

applied to the offset pin (38) of the sensor, and is used to adjust

the analogue video signal being fed to the internal A/D.

The level of the offset voltage determines the black level of the

image and has a direct impact on the image quality. Too high an

offset results in a white washed or hazy looking image, while too

low of an offset results in a dark image with low contrast even

though the light conditions are good.

A fine offset adjustment should be applied to each part by programming the offset voltage via the I2C compatible serial inter-

face. To program an offset voltage the following procedure

should be followed:

The sensor’s offset, fine_i & fine_ctrl pins should be connected

as shown in figure 2.

The following procedure should be followed to calibrate the offset

• Disable the black level compensation block by writing a logic

1 to bit 4 of the Main Configuration Register 0 (MCFG0:

address 02Hex).

• The offset can be adjusted by writing to the Offset Compen-

sation Registers (OCR: addresses 1F, 22 & 25 hex). Writing

00hex will give the largest voltage, while writing FF hex will

give the smallest value.

• Run the following binary search algorithm

• For n=7 to 0 step -1

• {

Set bit n in the OCR registers (addresses 1F, 22 & 25

Hex) to a logic one by writing over the I2C compatible

interface.

Read a full frame and calculate the average black level

(BL

average

) of the first and last 5 black pixels in the every

row of the array

If (BL

average

< 100) then

Reset bit n in the OCR registers (addresses 1F, 22 &

25 Hex) to 0

else

Keep bit n set to one.

}

• Enable the black level compensation block (if desired) by writing a logic 0 to bit 4 of the Main Configuration Register 0

(MCFG0: address 02Hex).

12.0 OFFSET & GAIN

The fine offset adjustment and calibration method described in

section 11.0 will ensure that the sensor’s black level is optimized

for a fixed analog gain setting. However, when the analog gain is

changed substantially, the black level of the sensor will shift

resulting in a white washed image.

To stop this effect from occurring, the black level needs to be recalibrated. This can be done as part of the contrast adjustment

which is carried out by most digital image processors. If this is

not possible then the following method can be used.

The relationship between the gain and the offset can be

described with the following equation.

where:

Offset(G) is the offset that needs to be programmed in

the OCR1, OCR2 & OCR3 registers to ensure

the correct black level setting for an analog

gain setting of G.

Offset(0) is the offset that needs to be programmed in

the OCR1, OCR2 & OCR3 registers to ensure

the correct black level setting for unity analog

gain, (G=0).

C is a constant and will vary from sensor to sen-

sor

G is the value programmed in the VGAIN regis-

ter of the sensor which determines the sen-

sor’s analog gain.

The following procedure should be used to calculate the value of

C:

Use the calibration procedure described in section 11.0 to determine the offset at unity gain, offset(0). Note the VGAIN register

should be set to 0.

Set the sensor’s analog gain register (VGAIN) to its max setting,

31, and repeat the calibration procedure described in section

11.0. This will allow the offset at full gain, 31, that needs to be

programmed in the OCR1, OCR2 & OCR3 registers to ensure

the correct black level setting to be determined.

The value of C for a particular sensor can be calculated using

the following formula:

Once the value of C has been calculated, offset values for different gain settings can be calculated using equation 1. It is recommended that a two decimal point accuracy for C is maintained.

Offset(G) = Offset(0) + C * G

0.4

Offset(31) - Offset(0)

3.95

C =

LM9617

Page 19

Confidential 19 www.national.com

Functional Description (continued)

13.0 SERIAL BUS

The serial bus interface consists of the sda (serial data), sclk

(serial clock) and sadr (device address select) pins. The

LM9617 can operate only as a slave.

The sclk pin is an input, it only and controls the serial interface,

all other clock functions within LM9617 use the master clock pin,

mclk.

13.1 Start/Stop Conditions

The serial bus will recognize a logic 1 to logic 0 transition on the

sda pin while the sclk pin is at logic 1 as the start condition. A

logic 0 to logic 1 transition on the sda pin while the sclk pin is at

logic 1 is interrupted as the stop condition as shown in Figure

27.

Figure 27. Start/Stop Conditions

13.2 Device Address

The serial bus Device Address of the LM9617 is set to 1010101

when sadr is tied low and 0110011 when sadr is tied high. The

value for sadr is set at power up.

13.3 Acknowledgment

The LM9617 will hold the value of the sda pin to a logic 0 during

the logic 1 state of the Acknowledge clock pulse on sclk as

shown in Figure 28.

Figure 28. Acknowledge

13.4 Data Valid

The master must ensure that data is stable during the logic 1

state of the sclk pin. All transitions on the sda pin can only occur

when the logic level on the sclk pin is “0” as shown in Figure 29.

Figure 29. Data Validity

13.5 Byte Format

Every byte consists of 8 bits. Each byte transferred on the bus

must be followed by an Acknowledge. The most significant bit of

the byte is should always be transmitted first. See Figure 30.

13.6 Write Operation

A write operation is initiated by the master with a Start Condition

followed by the sensor’s Device Address and Write bit. When

the master receives an Acknowledge from the sensor it can

transmit 8 bit internal register address. The sensor will respond

with a second Acknowledge signaling the master to transmit 8

write data bits. A third Acknowledge is issued by the sensor

when the data has been successfully received.

The write operation is completed when the master asserts a

Stop Condition or a second Start Condition. See Figure 31.

13.7 Read Operation

A read operation is initiated by the master with a Start Condition

followed by the sensor’s Device Address and Write bit. When

the master receives an Acknowledge from the sensor it can

transmit the internal Register Address byte. The sensor will

respond with a second Acknowledge. The master must then

issue a new Start Condition followed by the sensor’s Device

Address and read bit. The sensor will respond with an Acknowledged followed by the Read Data byte.

The read operation is completed when the master asserts a Not

Acknowledge followed by Stop Condition or a second Start Condition. See Figure 32.

sda

sclk

S P

start condition stop condition

1 2

7 8

9

sda

from master

sda

from sensor

sclk

MSB

ACK

ACK

START

S

Clock pulse

for ACK

sda

sclk

data line

stable;

data valid

change

of data

allowed

data line

stable;

data valid

Figure 30. Serial Bus Byte Format

Figure 31. Serial Bus Write Operation

Figure 32. Serial Bus Read Operation

sclk

sda

1 2

7

8

9 1

8

2

MSB

ACK

S

P

ack signal

from receiver

byte complete

clock line

held low

9

ack signal

from receiver

ACK

Address

WS A

Register

A

Data

A P

Device

Address Byte

bold sensor action

Device

S A

Register Data Device

A S AR P

_

A

ByteAddressAddress

W

Address

bold sensor action

LM9617

Page 20

Confidential 20 www.national.com

Functional Description (continued)

14.0 DIGITAL VIDEO PORT

The captured image is placed onto a flexible 12-bit digital port as

shown in Figure 10. The digital video port consists of a programmable 12-bit digital Data Out Bus (d[11:0]) and three program-

mable synchronisation signals (hsync, vsync, pclk).

By default the synchronisation signals are configured to operate

in “master” mode. They can be programed to operate in “slave”

mode.

The following sections are a detailed description of the timing

and programming modes of digital video port.

Pixel data is output on a 12-bit digital video bus. This bus can be

tri-stated by asserting the TriState bit in the VIDEOMODE1 register.

14.1 Digital Video Data Out Bus (d[11:0])

A programmable matrix switch is provided to map the output of

the internal pixel framer to the pins of the digital video bus as

illustrated in Figure 33.

Figure 33. Digital Video Bus Switching Modes

This feature allows a programmable digital gain to be implemented when connecting the sensor to 8 or 10 bit digital video

processing systems as illustrated in Figure 34. The unused bits

on the digital video bus can be optionally tri-stated.

Figure 34. Example of connection to 10/8 bit systems

Synchronisation Signals in Master Mode

By default the sensor’s digital video port’s synchronisation signals are configured to operate in master mode. In master mode

the integrated timing and control block controls the flow of data

onto the 12-bit digital port, three synchronisation outputs are

provided:

pclk is the pixel clock output pin.

hsync is the horizontal synchronisation output signal.

vsync is the vertical synchronisation output signal.

14.2 Pixel Clock Output Pin (pclk) (Master Mode)

The pixel clock output pin, pclk, is provided to act as a synchronisation reference for the pixel data appearing at the digital

video out bus pins d[11:0]. This pin can be programmed to operate in two modes:

• In free running mode the pixel clock output pin, pclk, is always

running with a fixed period. Pixel data appearing on the digital

video bus d[11:0] are synchronized to a specified active edge

of the clock as shown in Figure 35.

Figure 35. pclk in Free Running Mode

• In data ready mode, the pixel clock output pin (pclk) will pro-

duce a pulse with a specified level every time valid pixel data

appears on the digital video bus d[11:0] as shown in Figure

36.

d11

9

Internal Pixel Framer Output Register

d10 8d9 7d86d7 5d6 4d5 3d4 2d3 1d2

010

d1 d0

11

a) MSB Bit 11, Switch Mode (default)

b) MSB Bit 10, Switch Mode

d) MSB bit 8, Switch Mode

Internal Pixel Framer Output Register

d11 d10 d9 d8 d7 d6 d5 d4 d3 d2 d1 d0

9 8 7 6 5 4 3 2 1 0

1011

c) MSB bit 9, Switch Mode

d0

Internal Pixel Framer Output Register

d11 d10 d9 d8 d7 d6 d5 d4 d3 d2 d1

9 8 7 6 5 4 3 2 1 0

1011

Internal Pixel Framer Output Register

d11 d10 d9 d8 d7 d6 d5 d4 d3 d2 d1

9 8 7 6 5 4 3 2 1 01011

d0

10 bit

Digital

Image

Processor

d9d11

d8d10

d7d9

d6d8

d5d7

d4d6

d3d5

d2d4

d1d3

d0d2

d1

d0

LM9617

8 bit

Digital

Image

Processor

d7d11

d6d10

d5d9

d4d8

d3d7

d2d6

d1d5

d0d4

d3

d2

d1

d0

LM9617

a) LM9617 Connected to a 10 bit Digital Image Processors

b) LM9617 Connected to a 8 bit Digital Image Processors

pclk

d[11:0]

pclk

d[11:0]

a) pclk active edge negative

b) pclk active edge positive (default)

invalid pixel data

LM9617

Page 21

Confidential 21 www.national.com

Functional Description (continued)

,

Figure 36. pclk in Data Ready Mode

By default the pixel clock is a free running active low (pixel data

changes on the positive edge of the clock) with a period equal to

the internal hclk. The active edge of the clock can be pro-

grammed such that pixel data changes on the positive or negative edge of the clock.

14.3 Horizontal Synchronisation Output Pin (hsync)

The horizontal synchronisation output pin, hsync, is used as an

indicator for row data. The hsync output pin can be programmed

to operate in two modes as follows:

• Level mode should be used when the pixel clock, pclk, is programmed to operate in free running mode. In level mode the

hsync output pin will go to the specified level (high or low) at

the start of each row and remain at that level until the last

pixel of that row is read out on d[11:0] as shown in Figure 37.

The hsync level is always synchronized to the active edge of

pclk.

Figure 37. hsync in Level Mode

• Pulse mode should be used when the pixel clock, pclk, is programmed to operate in data ready mode. In pulse mode the

hsync output pin will produce a pulse at the end of each row.

The width of the pulse will be a minimum of four pclk cycles

and its polarity can be programmed as shown in Figure 38.

The hsync level is always synchronized to the active edge of

pclk

Figure 38. hsync in Pulse Mode

By default the first pixel data at the beginning of each row is

placed on the digital video bus as soon as hsync is activated. It

is possible to program up to 15 dummy pixels to be readout at

the beginning of each row before the real pixel data is readout.

This feature is supported for both level and pulse mode.

14.4 Vertical/Horizontal Synchronisation Pin (vsync)

The vertical synchronisation output pin, vsync, is used as an

indicator for pixel data within a frame. The vsync output pin can

be programmed to operate in two modes as follows:

• Level mode should be used when the pixel clock, pclk, is programmed to operate in free running mode. In level mode the

vsync output pin will go to the specified level (high or low) at

the start of each frame and remain at that level until the last

pixel of that row in the frame is placed on d[11:0] as shown in

Figure 39. The hsync level is always synchronized to the

active edge of pclk.

Figure 39. vsync in Level Mode

• Pulse mode should be used when the pixel clock, pclk, is pro-

grammed to operate in data ready mode. In pulse mode the

vsync output pin will produce a pulse at the end of each

frame. The width of the pulse will be a minimum of four hclk

cycles and its polarity can be programmed as shown in Figure

40. The vsync level is always synchronized to the active edge

of pclk.

Figure 40. vsync in pulse mode

14.5 Odd/Even Mode

In odd/even mode the vsync signal is used to indicate when

pixel data from an odd and even field is being placed on the digital video bus d[11:0]. The polarity of vsync can still be programmed in this mode as shown in Figure 41

Figure 41. vsync in odd/even Mode

pclk

d[11:0]

pclk

d[11:0]

a) pclk active edge negative

b) pclk active edge positive

invalid pixel data

pclk

d[11:0]

invalid pixel data

b) hsync programmed to be active low

hsync

Row n

Row n+1

pclk

d[11:0]

a) hsync programmed to be active high (default)

hsync

Row n

Row n+1

pclk

d[11:0]

hsync

Row n

Row n+1

a) hsync programmed to be active high

pclk

d[11:0]

hsync

Row n Row n+1

b) hsync programmed to be active low

invalid pixel data

pclk

d[11:0]

invalid pixel data

b) vsync programmed to be active low

vsync

Frame n

Frame n+1

pclk

d[11:0]

a) vsync programmed to be active high

vsync

Frame n

Frame n+1

pclk

d[11:0]

vsync

Frame n

Frame n+1

a) vsync programmed to be active high

pclk

d[11:0]

vsync

Frame n

Frame n+1

b) vsync programmed to be active low (default)

invalid pixel data

pclk

d[11:0]

invalid pixel data

b) vsync programmed to be active low

vsync

Odd Field

Even Field

pclk

d[11:0]

a) vsync programmed to be active high (default)

vsync

Odd Field

Even Field

LM9617

Page 22

Confidential 22 www.national.com

Functional Description (continued)

Figure 42. Example of Digital Video Port Timing in Progressive Scan Mode

Figure 43. Example of Digital Video Port Timing in Interlaced Mode

Figure 44. Example of Digital Video Port Timing in 2:1 Sub-sampling Mode

Figure 45. Example of Digital Video Port Timing in 4:2 Sub-sampling Mode

c0 c1 c2 c3 c4 c5 c6 c7 c8 c9

c0 c1 c2 c3 c4 c5 c6 c7 c8 c9

pclk

vsync

hsync

d[11:0]

c0 c1 c2 c3 c4 c5 c6 c7 c8 c9 c0 c1 c2 c3 c4 c5 c6 c7 c8 c9

frame 1

row1

row 2

row 1

row 2

frame 2

Programmable hsync to 1st valid pixel delay

Programmable inter-frame delay

Programmable row delay

c0 c1 c2 c3 c4 c5 c6 c7 c8 c9 c0 c1 c2 c3 c4 c5 c6 c7 c8 c9

pclk

vsync

hsync

d[11:0]

c0 c1 c2 c3 c4 c5 c6 c7 c8 c9 c0 c1 c2 c3 c4 c5 c6 c7 c8 c9

Odd Field

row1 row 3 row 2 row 4

Even Field

Programmable hsync to 1st valid pixel delay

Programmable inter-frame delay

Programmable row delay

c0 c2 c 4 c6 c8 c0 c2 c4 c6 c8

pclk

vsync

hysync

d[11:0]

c0 c2 c4 c6 c8 c0 c2 c4 c6 c8

row 3

frame 1 frame 2

row 1row 3row 1

Programmable hsync to 1st valid pixel delay

Programmable inter-frame delay

Programmable inter-row delay

c0 c2 c4 c6 c8 c0 c2 c4 c5 c8

pclk

vsync

hsync

d[11:0]

c0 c2 c4 c6 c8 c0 c2 c4 c6 c8

row 2

frame 1 frame 2

row 1row 2row 1

Programmable hsync to 1st valid pixel delay

Programmable inter-frame delay

Programmable inter-row delay

LM9617

Page 23

Confidential 23 www.national.com

Functional Description (continued)

14.6 Synchronisation Signals in Slave Mode

The sensor’s digital video port’s synchronisation signals can be

programmed to operate in slave mode. In slave mode the integrated timing and control block will only start frame and row processing upon the receipt of triggers from an external source.

Only two synchronization signals are used in slave mode as follows:

hsync is the row trigger input signal.

vsync is the frame trigger input signal.

Figure 46 shows the LM9617’s digital video port in slave mode

connected to a digital video processor master DVP.

Figure 46. LM9617 in slave mode

14.7 Row Trigger Input Pin (hsync)

The row trigger input pin, hsync, is used to trigger the processing of a given row. It must be activated for at least two “mclk”

cycle. The first pixel data will appear at d[11:0] “X

mclk

“periods

after the assertion of the row trigger, were X

mclk

is given by:

Where:

DW

StAd

is the value of the display window column start

address.

The polarity of the active level of the row trigger is programmable. By default it is active high.

14.8 Frame Trigger Input Pin (vsync)

The frame trigger input pin, vsync, is used to reset the row

address counter and prepare the array for row processing. It

must be activated for at least one “mclk” cycle and no more than

96 mclk cycles after the activation of hsync as illustrated in Figure 48.

The polarity of the active level of the row trigger is programmable. By default it is active high.

RowTrig

FrameTrig

MasterClock

din[11:0]d[11:0]

hsync

vsync

pclk

mclk

DVP

LM9617

X

mclk

= 124 + DW

StAd

Figure 47. hsync slave mode timing diagram for centred display window of 642 pixels

Figure 48. vsync slave mode timing diagram for scan window of 504 rows.

779778777776 0 1 32 134 135 136 136 137 779778777 0 1776775774... ...

hsync

pixel 11

pixel 12

pixel 652

d[11:0]

mclk

mclk

count

642 valid pixels

780 clock cycles per line

779778777776 0 1 32 779778777 0 1776775774...

hsync

mclk

mclk

count

780 clock cycles per line

internal row

counter

line502

line 502

No more than

96 clock cycles

vsync

...

779778777 0 1776775774

line503 line 0

LM9617

Page 24

Confidential 24 www.national.com

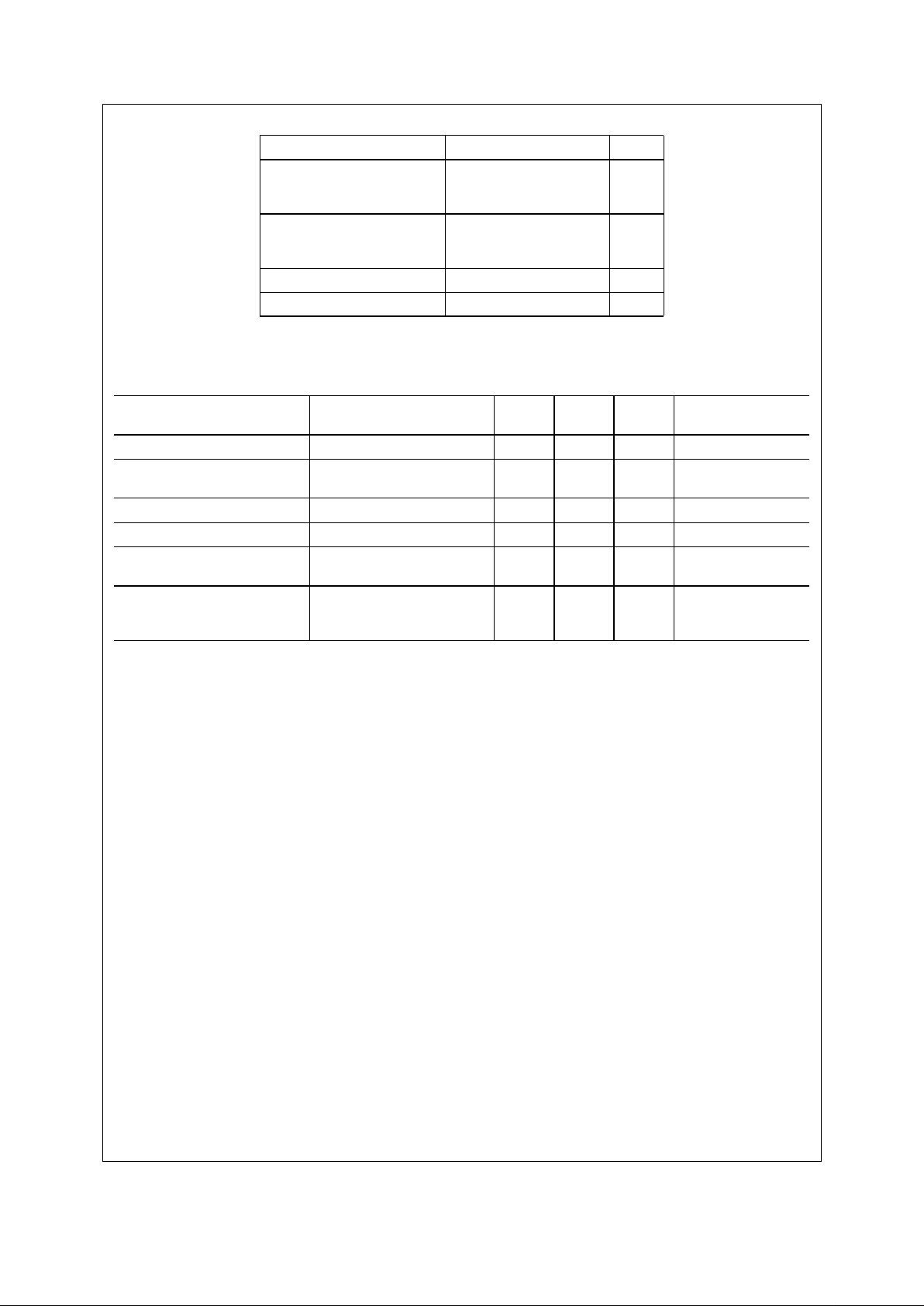

MEMORY MAP

ADDR Register Reset Value Description

00h Reserved for future use.

01h REV 02h Revision Register

02h MCFG0 00h Main Configuration Register 0

03h MCFG1 00h Main Configuration Register 1

04h PCR 00h Power Control Register.

05h VCLKGEN 04h Video Clock Generator

06h VMODE0 00h Video Mode 0 Register

07h VMODE1 00h Video Mode 1 Register

08h VMODE2 00h Video Mode 2 Register

09h SNAPMODE0 00h Snapshot Mode 0 Register

0Ah SNAPMODE1 00h Snapshot Mode 1 Register

0Bh SROWS 00h Scan Window Row Start Register

0Ch SROWE FBh Scan Window Row End Register

0Dh Reserved for future use.

0Eh DROWS 00h Display Window Row Start Register

0Fh DROWE FBh Display Window Row End Register

10h DCOLS 00h Display Window Column Start Register

11h DCOLE A5h Display Window Column End Register

12h DWLSB 32h Display Window LSB Register.

13h ITIMEH 00h Integration Time High Register

14h ITIMEL 00h Integration Time Low Register

15h RDELAYH 00h Row Delay High Register

16h RDELAYL 00h Row Delay Low Register

17h FDELAYH 00h Frame Delay High Register

18h FDELAYL 00h Frame Delay Low Register

19h VGAIN 00h Video Gain Register

1Fh OCR1 00h Offset Compensation Register 1

22h OCR1 00h Offset Compensation Register 1

25h OCR2 00h Offset Compensation Register 2

26h BLCOEFF 00h Black Level Compensation Coefficient Register

27h BPTH0H 00h Bad pixel Threshold 0 High Register

28h BPTH0L 00h Bad pixel Threshold 0 Low Register

29h BPTH1H 00h Bad pixel Threshold 1 High Register

2Ah BPTH1L 00h Bad pixel Threshold 1 Low Register

LM9617

Page 25

Confidential 25 www.national.com

Register Set

The following section describes all available registers in the

LM9617 register bank and their function.

Register Name Device Rev Register

Mnemonic REV

Address 01 Hex

Type Read Only.

Register Name Main Configuration 0

Address 02 Hex

Mnemonic MCFG0

Type: Read/Write

Reset Value 00 Hex

Register Name Main Configuration 1

Address 03 Hex

Mnemonic MCFG1

Type Read/Write

Reset Value 00 Hex

Register Name Power Control Register 1

Address 04 Hex

Mnemonic PCR

Type Read/Write

Reset Value 00 Hex

Bit Bit Symbol Description

7:0 SiRev The silicon revision register.

Bit Bit Symbol Description

7 PwrUpBusy (Read Only Bit)

Indicates that power on initialization is in progress. The sensor is

ready for use when this bit is at

logic 0.

6 PwrDown Assert to power down the sensor.

Writing a logic 1 to this register bit

has the same effect as taking the

pdwn pin high. Clear (the default)

this bit to power up the sensor.

5 BPCorrection Assert to enable the bad pixel

detection and correction circuit.

Clear (the default) to switch it off.

4 BlkLComp Assert to disable the black level

compensation circuit. Clear (the

default) to switch it on.

3 SnapEnable Assert to enable the external

snapshot pin. Clear (the default)

to disable the external snapshot

pin.

2:0 Reserved

Bit Bit Symbol Description

7 ColorMode Assert when using a mono-

chrome sensor. When this bit is

at a logic 1, Sub-Sampling is set

to 2:1 and every other row is

read out during interlace mode.

Clear (the default) when using a

color sensor. When this bit is at

logic 0, sub-sampling is set to

4:2 and every other row pair is

read out during interlace mode.

6 ScanMode Assert to set the sensor to inter-

lace readout mode. Clear (the

default) to set the sensor to progressive scan read out mode.

5 HSubSamEn Assert to enable horizontal sub-

sampling. Clear (the default) to

disable horizontal sub-sampling.

4 VSubSamEn Assert to enable vertical sub-

sampling. Clear (the default) to

disable vertical sub-sampling.

3 Reserved

2 SlaveMode Use to configure the digital

video port’s synchronisation sig-

nal to operate in slave mode. By

default the digital video’s port’s

synchronization signals are con-

figured to operate in master

mode.

1:0 Reserved

Bit Bit Symbol Description

7 ByPassGain Assert to route the analog video

signal from the output of the CDS

to the input of the 12 bit A/D. Clear

(the default) to route the signal to

the video gain amplifier.

6:4 Reserved

3 PwdnPGA Assert to power down the pro-

grammable video gain amplifier.

Clear (the default) to power up the

video gain amplifiers.

2:1 Reserved

0 PwDnADC Assert to power down the 12 bit

analog to digital convertor. Clear

(the default) to power up the 12 bit

analog to digital convertor.

LM9617

Page 26

Confidential 26 www.national.com

Register Set (continued)

Register Name Hclk Generator Register

Address 05 Hex

Mnemonic VCLKGEN

Type Read/Write

Reset Value 04 Hex.

Register Name Digital Video Mode 0

Address 06 Hex

Mnemonic VMODE0

Type Read/Write

Reset Value 00 Hex

Register Name Digital Video Mode 1

Address 07 Hex

Mnemonic VMODE1

Type Read/Write

Reset Value 00 Hext

Register Name Digital Video Mode 2

Address 08 Hex

Mnemonic VMODE2

Type Read/Write

Reset Value 00 Hex

Bit Bit Symbol Description

7:0 HclkGen Use to divide the frequency of

the sensors master clock input,

mclk to generate the internal

sensor clock, Hclk.

Program 00 Hex (the default) for

Hclk to equal mclk or divide

mclk by any number between 1

and FF Hex.

Bit Bit Symbol Description

7:6 PixDataSel Use to program the number of

active bits on the digital video bus

d[11:0], starting from the MSB

(d[11]). Inactive bits are tri-stated.:

5:4 PixDataMsb Use to program the routing of the

MSB output of the internal video

A/D to a bit on the digital video

bus.

3:0 Reserved

00 12 bit mode, bits

d[11:0] of the digital

video bus are active.

This is the default.

01 10 bit mode, bits

d[11:2] of the digital

video bus are active.

10 8 bit mode, bits

d[11:4] of the digital

video bus are active.

11 Reserved.

00 A/D [11:0] -> d[11:0].

01 A/D [10:0] -> d[11:1]

10 A/D [9:0] -> d[11:2]

11 A/D [8:0] -> d[11:3]

Bit Bit Symbol Description

7 PixClkMode Assert to set the pclk to “data

ready mode”. Clear, the default, to

set pclk to “free running mode”.

6 VsyncMode Assert to set the vsync pin to

“pulse mode”. Clear (the default)

to set the vsync signal to “level

mode”.

5 HsyncMode Assert to force the hsync signal to

pulse for a minimum of four pixel

clocks at the end of each row.

Clear (the default) to force the

hsync signal to a level indicating

valid data within a row.

4 PixClkPol Assert to set the active edge of

the pixel clock to negative. Clear

(the default) to set the active edge

of the clock to positive.

3 VsynPol Assert to force the vsync signal to

generate a logic 0 during a frame

readout (Level Mode), or a nega-

tive pulse at the end of a frame

readout (Pulse Mode). Clear (the

default) to force the vsync signal

to generate a logic 1 during a

frame readout (Level Mode), or a

negative pulse at the end of a

frame readout (Pulse Mode).

2 HsynPol Assert to force the hsync signal to

generate a logic 0 during a row

readout (Level Mode), or a nega-

tive pulse at the end of a row

readout (Pulse Mode). Clear (the

default) to force the hsync signal

to generate a logic 1 during a row

readout (Level Mode), or a nega-

tive pulse at the end of a readout

(Pulse Mode).

1 OddEvenEn Assert to force the vsync pin to act

as an odd/even field indicator.

Clear (the default) to force the

vsync pin to act as a vertical syn-

chronization signal.

0 TriState Assert to tri-state all output signals

(data and control) on the digital

video port. Clear (default) to

enable all signals (data and con-

trol) on the digital video port.

Bit Bit Symbol Description

7:4 HsyncAdjust Use to program the leading edge

of hsync to the first valid pixel at

the beginning of each row. This

can be 0-hex to F-hex corre-

sponding to 0 - 15 pixel clocks.

Default 0.

3:0 Reserved

LM9617

Page 27

Confidential 27 www.national.com

Register Set (continued)

Register Name Snapshot Mode Configuration Register 0

Address 09 Hex

Mnemonic SNAPMODE0

Type Read/Write

Reset Value 00 Hex

Register Name Snapshot Mode Configuration Register 1

Address 0A Hex

Mnemonic SNAPMODE1

Type Read/Write

Reset Value 00 Hex.

Bit Bit Symbol Description

7.6 SsFrames Program to set the number of

frames required before readout

during a snapshot with no external

shutter, (see Figure 18). By

default these two bits are set to 00

resulting in one frame before

readout:

5 ShutterEn Assert to indicate that an external

shutter will be used during snapshot mode. Clear (the default) to

indicate that snapshot mode will

be carried out without the aid of an

external shutter.

4 ExtSynPol Assert to set the active level of the

extsync signal to 0. Clear (the

default) to set the active level of

the extsync signal to 1.

3 Reserved

2 SnapshotMod Assert to set the snapshot pin to

level mode. In level mode the sensor will continually run snapshot

sequences as long as the snap-

shot pin is held to the active level.

Clear (the default) to set the snap-

shot signal to pulse mode. In

pulse mode the sensor will only

carry out one snapshot sequence

per pulse applied to the snapshot

pin.

1 SnapShotPol Assert to set the snapshot pin to